1. Introduction

In recent years, climate anomalies have become more common[

1]. The Paris Agreement called for limiting global warming efforts to 1.5°C by the end of the century. At present, more than 130 countries have committed to net zero, of which the Republic of Suriname and Bhutan are the countries that have achieved net zero emissions[

2]. China has issued a policy pledge to strive to peak carbon emissions by 2030 and achieve carbon neutrality by 2060. Furthermore, China has called for an 18% reduction in carbon emissions by 2025 compared with 2020 levels. Therefore, China's carbon emission reduction is urgent and difficult.

Lime is the primary component for the cement industry. It can be divided into quicklime, hard-burned lime, slaked lime and dolomite lime. In recent years, the global demand for lime has been increasing. In 2022, the world's total lime production was 430 million tons. China was the most influential country for lime production, accounting for 75.6% of the world's lime production, far more than the United States (4%), India (3.7%), Russia (2.6%) and other countries[

3]. Lime is produced by a process of crushing, screening and calcination of natural limestone. Carbon dioxide from the calcination process is the primary source of carbon emissions within this industry [

4]. The carbon emissions of the Chinese lime industry should not be overlooked. Reducing the carbon emissions of the Chinese lime industry will help achieve the national target.

This study examined the limestone mining enterprise in the Yangtze River Basin of China (referred to as "A Mine"). Using the IPCC emission factor method, a carbon emission life cycle accounting model for quicklime production was constructed and used to explore the carbon emission distribution in each production stage. Then, key carbon emission sources were identified, and effective low-carbon production measures for the largest carbon emission factors were proposed. This study provided the actual data of the lime enterprise in the Yangtze River basin, and determined the carbon emission factor of producing unit quicklime. More sustainable production strategies can be proposed based on the study.

Section 2 is literature review.

Section 3 summarizes the methodology.

Section 4 provides the analysis and results.

Section 5 proposes low-carbon transformation measures and recommendations.

Section 6 provides the conclusions.

2. Literature review

2.1. Carbon emission from the lime industry

Previous research has calculated carbon emissions from the lime industry in different countries. Augstin et al examined lime industry in EU. They considered mineral extraction, primary crushing, washing, screening, calcination as the system boundary. They calculated that producing 1 ton of lime on average produces 1.26 tons of carbon dioxide in the EU. Furthermore, they found that carbon emission associated to lime products can be accounted to two main causes. First, almost two third of the emissions were the decomposition of limestone at high temperature. The second factor was the industrial production of lime itself, including the combustion of fuels in the kiln, the electricity needed to operate the plant, and the transportation of different materials[

6].

Shan et al took the lime industry in China as an example, and took quarrying, crushing and screening, calcination as the system boundary. They found that 1 ton of lime potentially produced 0.98 tons of carbon dioxide, of which 69.92% came from emissions from industrial processes and 2.18 % from indirect emissions from electricity[

7]. The research on the carbon emission of the lime industry focused on the national level. However, the carbon emission factors of the lime industry process at the regional level, such as the Yangtze River basin, which is the largest economic belt in China, is unclear. It is necessary to explore the carbon emission from lime production in the economic belt.

2.2. Carbon emission reduction in the lime industry

Carbon reduction technologies in the lime industry mainly include carbon capture and storage (CCS) and fuel switching. CCS technologies include pre-combustion capture, post-combustion capture and oxygen-enriched combustion[

8]. Post-combustion capture, including physical/chemical absorption, membrane separation and physical/chemical adsorption, are considered to be more suitable for the lime industry[

9]. Physical/chemical absorption solvent, such as monoethanolamine, is usually taken as the benchmark solvent for carbon dioxide removal, and the carbon dioxide removal rate can reach 90% [

11]. Also, membrane separation has a good application potential in the cement industry. Hagg et al and Baker et al applied membrane separation to plant testing and demonstrated that it could remove 80% of carbon dioxide[

13]. In addition, physical/chemical adsorption has been applied in the lime industry. A typical physical/chemical adsorption device is the rotary adsorber device, which mainly uses vacuum-temperature-concentration pressure variation to adsorb carbon dioxide and has been used in cement plants in Canada[

15].

Fuel switching has been also taken as one of the solutions for carbon reduction in the cement industry. Traditional fuels in the industry cover coal, petroleum coke, petroleum and natural gas[

16]. Alternative fuels, such as waste tires, refuse derived fuel, and straws, have been used in the cement industry[

17], and can potentially be applied in the lime industry.

Overall, CCS and alternative fuel technologies are the most common carbon reduction technologies in the research, and it can provide an important basis for the study of carbon emission reduction measures.

3. Materials and Methods

3.1. Determination of Accounting Boundary

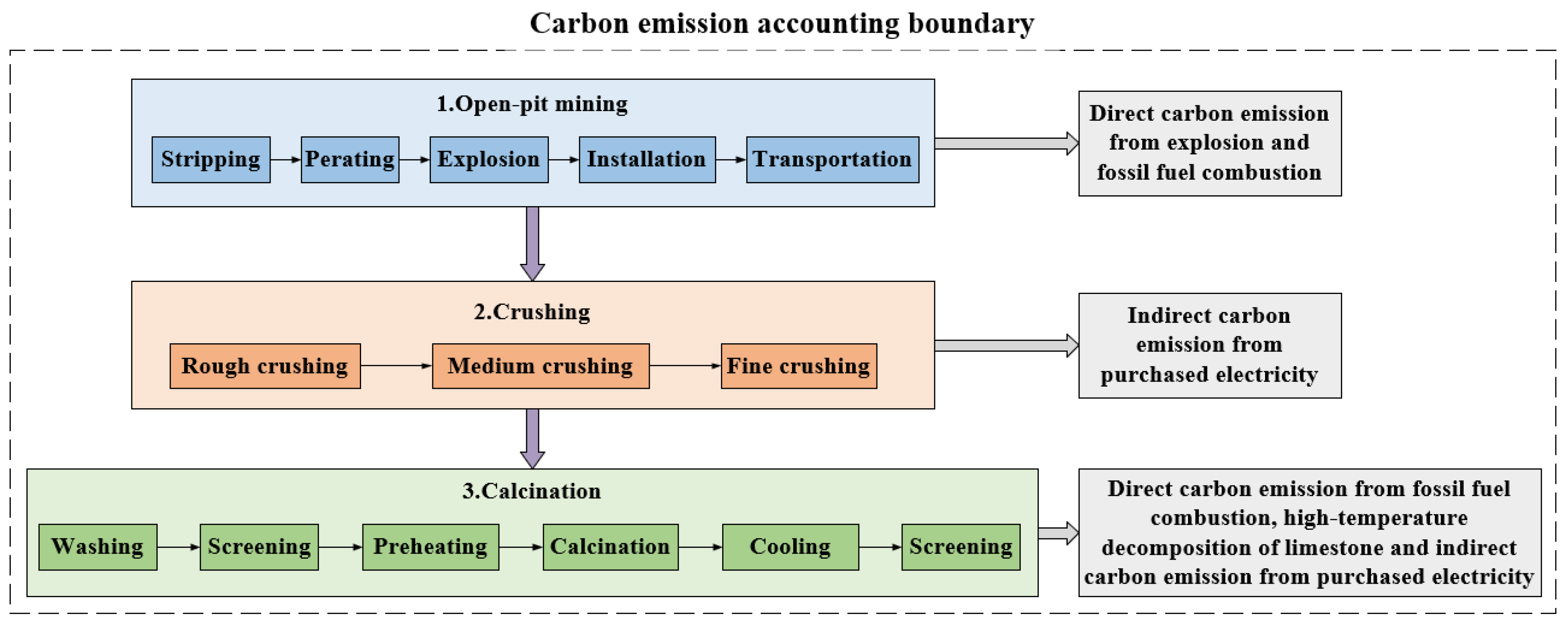

The determination of system boundaries is the basis of carbon emission accounting[

19]. In the study of the life cycle carbon emission characteristics of quicklime, based on the actual process flow distribution aggregation and other research[

20]. The life cycle of quicklime production is divided into three stages: open-pit mining, crushing and calcination. The carbon emission system boundaries include three stages of direct and indirect carbon emissions, excluding the office services in the mining area, as shown in

Figure 1.

3.2. Carbon Emission Source Composition

From the three stages of open-pit mining, crushing and calcination, the carbon emission sources of each stage were identified. Open-pit mining stage: explosion is prior to extraction. Ammonium nitrate explosives in explosion can produce a large amount of carbon dioxide. In addition, the power for mining equipment and transportation system mainly depends on the consumption of fossil fuels, especially diesel. Crushing stage: the jaw crusher reduces the limestone to the required particle size, which relies on electricity. Calcination stage: the calcination production line is composed of vertical preheater, rotary kiln, vertical cooler and other equipment. All this equipment relies on electricity to operate. Furthermore, limestone needs to be decomposed under high temperature conditions, and this heat generally comes from the combustion of coal.

3.3. Models

Greenhouse gas accounting methodologies can be divided into the IPCC emission factor method, the measured method and the mass balance of carbon method. The measured method has a high level of uncertainty and is not often used for carbon emission[

21]. The material balance algorithm is based on the analysis of carbon material flow balance without considering the specific process producing the emissions. The method is based on calculating the difference between the carbon input and carbon output of the industry[

22]. Compared with the previous two methodologies, the IPCC emission factor method is an internationally recognized used carbon emission assessment methodology, which can be used to estimate emission data for each category of emission[

23]. The IPCC emission factor method specifically provides the carbon emissions of the industrial process, which is helpful in identifying the key carbon emission sources and which makes it ideal for the carbon emission accounting in our study. Based on the IPCC emission factor method, the carbon emission accounting model of quicklime is as follows.

where E

t represents the total carbon dioxide emissions from quicklime life cycle, E

e is the carbon dioxide emissions generated by explosives, E

d is carbon dioxide emissions from diesel combustion, E

c is carbon dioxide emissions from coal combustion, E

p is carbon dioxide emissions indirectly generated by electricity consumption, and E

h is carbon dioxide emissions from high temperature decomposition of limestone.

(1) Explosion

Ammonium nitrate explosives release a large amount of carbon dioxide when detonated. The carbon emission calculation formula is:

Where ADe is the annual consumption of explosives, t/a. EFe (CO2) is the carbon emission factor, t/t.

(2) Diesel combustion

Greenhouse gas emission accounting methods and reporting guidelines for land transportation enterprises (Trial) ' (Development and Reform Office Climate [2015]1722) showed that the greenhouse gases of road transportation enterprises using diesel as fuel include CO

2, CH

4 and N

2O.

where AD

d is the annual consumption of diesel oil for mining equipment and transportation equipment, t/a ; NC

d represents diesel average low calorific value, GJ/t. EF

d (CO

2) is carbon emission factor for diesel, t/GJ. EF

d (CH

4) is CH

4 emission factor for diesel, t/GJ. EF

d (N

2O) is N

2O emission factor for diesel, t/GJ.

(3) Coal combustion

It is used as a fossil fuel of rotary kiln, and produce CO

2.

where AD

c is the annual consumption of rotary kiln bituminous coal, t/a. NC

c represents coal average low calorific value, GJ/t. EF

c (CO

2) is carbon emission factor for coal, t/GJ.

(4) Purchased electricity

China's power industry is dominated by thermal power generation. Therefore, the power industry is the key area of indirect carbon emission.

where AD

e is annual purchased power, MWh/a. EF

e (CO

2) is the annual average power supply emission factor of Central China Power Grid, t/MWh.

(5) High temperature decomposition of limestone

The decomposition of carbonate at high temperature is the main factor to produce carbon dioxide.

where EF

l (CO

2) is the CO

2 emission factor of limestone, t/t. M

l is quicklime annual production, t/a. M

d is the amount of Dust removal, t/a. M

l is the amount of limestone into the rotary kiln, t. M

c is coal for rotary kiln combustion, t/a. C

l is carbonate content in limestone, %.

The calculation of carbon emission factor of limestone is complicated. Jiao et al have studied the carbonate carbon emission factor of the cement industry[

24]. The calculation formula is as follows.

where R

C is the content of CaO in limestone, %. R

M is the content of MgO in limestone, %.

Other carbon emission factors data refer to 'General Principles of Comprehensive Energy Consumption Calculation GBT2589-2020' and 'Guidelines for Provincial Greenhouse Gas Inventories'. The specific values are shown in

Table 1.

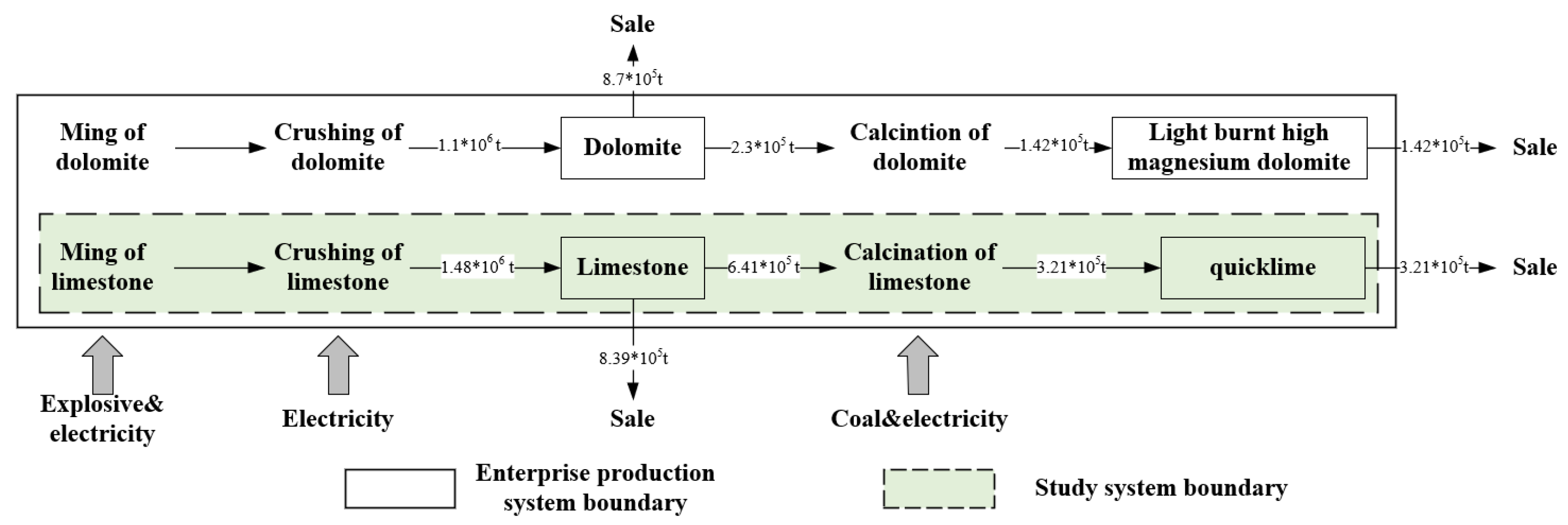

3.4. Data Sources

The life cycle of quicklime includes three stages. These three stages of carbon emission are divided into explosives, fuel combustion (diesel, coal), electricity consumption and limestone high temperature decomposition. The diesel consumption is mainly caused by mining loaders, excavators, bulldozers, explosive transporters and mining vehicles. The electricity consumption covers the crushing stage and the calcination stage. In July 2022, a 10-day investigation was carried out at Mine A in the Yangtze River basin to obtain the basic data for 2021. The total mining output of Mine A was 3.7*10

6t, including 1.48*10

6t of limestone, 1.1*10

6t of dolomite and 1.12*10

6t of gravel. The calcined products include quicklime and light-burned high-magnesium dolomite, and their yields are 3.21*10

5t and 1.42*10

5t. The consumption of materials and energy in the production process of all products is shown in

Table 2.

4. Results

Production at Mine A is divided into mining products and calcined products. The mining products include limestone and dolomite, which are calcined to generate quicklime and light burned high magnesium dolomite. The consumption of explosive, diesel, electricity and coal assessed for all production at Mine A (in

Table 2). The mostly highly processed product of Mine A is quicklime. Therefore, the production line of limestone calcination into quicklime is of particular concern. In 2021, 6.41*10

5t limestone was used as the raw material for the production of quicklime, and 3.21*10

5t of quicklime was resulted from calcination, as shown in

Figure 2.

Since only the production materials and energy consumption of quicklime were considered, the data in table 2 needs to be measured and distributed. In the mining output, the raw material (limestone) for the production of quicklime is 6.41*10

5t, accounting for 17% of the total mining output of 3.7*10

6t. According to the proportion of the production, the consumption of explosive, diesel and electricity used to produce limestone accounted for 17% of the data in

Table 2. Similarly, the output of quicklime was 3.21*10

5t, accounting for 69% of the total calcined product output of 4.63*10

5t, and the consumption of coal and electricity used to produce quicklime was calculated to be 69%. The calculation results are shown in

Table 3.

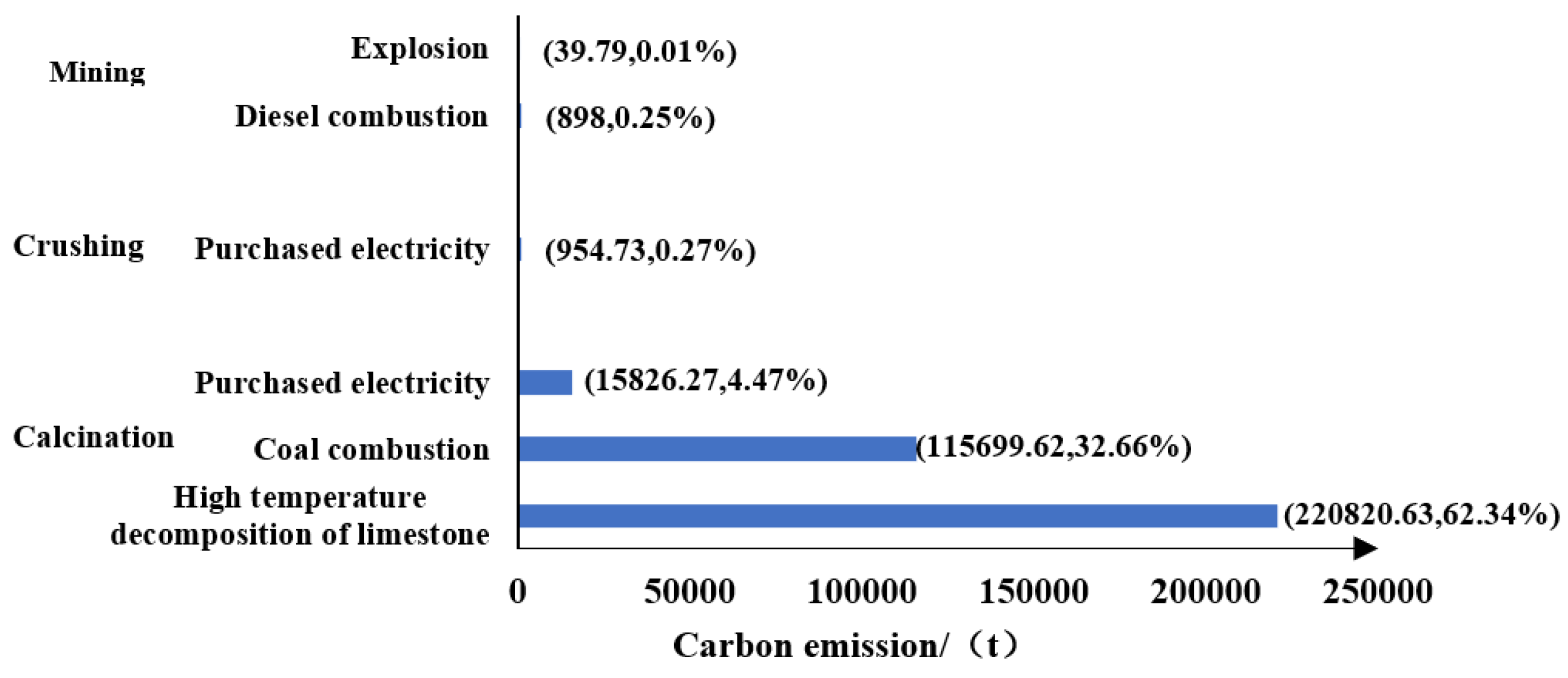

Table 3 shows the material and energy consumption for the production of quicklime. Based on Eq. (2)-(9), the carbon emissions of each stage were calculated respectively. The results are shown in

Figure 3.

In 2021, a total of 354,200 tons of carbon emissions were generated from producing 321,000 tons of quicklime. 0.26% of carbon emissions were generated in the open-pit mining stage, 0.27 % of carbon emissions were generated in the crushing stage, and 99.47% of carbon emissions were generated in the calcination stage. According to the unitized production of quicklime, the carbon emission of 1 ton quicklime was 1.46kg in the open-pit mining stage, 1.49kg in the crushing stage and 1100kg in the calcination stage, and the total carbon emission in the whole production process is 1102.95 kg. In the production process of quicklime, the high temperature decomposition of limestone was the largest carbon emission source, accounting for 62.34% of the total carbon emission, and the combustion of coal was also an important carbon emission source, accounting for 32.66% of the total carbon emission. These carbon emission sources were mainly concentrated in the calcination stage. Although the proportion of carbon emission from diesel combustion and electricity consumption in open-pit mining is less than 1%, it should not be ignored. Reasonable low carbon production measures should be put forward for Mine A.

5. Discussion

In this study, the carbon emission factor of quicklime of lime enterprise in the Yangtze River Basin was determined. Based on the IPCC emission factor method, the life cycle carbon emissions of quicklime were calculated. The results were that producing 1 ton of quicklime produced 1.1 tons of carbon dioxide, of which limestone high temperature decomposition accounted for 62.34% and fossil fuel combustion accounted for 32.66%, which was consistent with Augstin et al.[

6] and Shan et al. [

7]. Focusing on the key carbon emission sources of quicklime production, this study will start with the following carbon emission reduction technologies to promote low-carbon production of quicklime, and further analyze the emission reduction potential brought by the promotion of emission reduction technologies to the entire lime industry.

5.1. End decarbonization technology

In the calcination stage, the high temperature decomposition of limestone is the dominant factor of carbon emission. Post-combustion capture is a technology that can separate CO

2 from other components in the flue gas of the rotary kiln, thereby achieving CO

2 concentration. The post-combustion capture technology is characterized by the installation of CO

2 capture devices at the tail of the exhaust gas, which does not require large-scale transformation of existing equipment. It is the most effective CO

2 capture technology. The absorption method is the most mature technology for CO

2 capture after combustion. The methyldiethanolamine (MDEA) method is the most economical, and the CO2 recovery rate (up to 99 %) is the highest absorption method[

25]. This method has been successfully applied to the Puguang gas field in China, and the mechanism of the method is that the natural gas is in contact with MDEA solution from bottom to top to decarbonize[

26]. However, there is currently almost no application of the MDEA method within the mineral industry, so CO

2 capture technology has great development potential.

5.2. Fuel distribution optimization

In the calcination stage of quicklime production, coal combustion is a major source of carbon emission. Fuel optimization involves using clean energy to replace traditional fuels, thus reducing carbon emissions in the production process of mining areas. Dudin, et al. pointed out that natural gas is clean and energy efficiency[

27]. Handan Jinyu Taihang Cement Company replaced all traditional fuel coal with natural gas by 2020, which not only saved energy consumption, but also reduces CO2 emissions by 24 %[

28]. In this case study, traditional fuel coal was replaced with natural gas with the aim of reducing carbon emission in the calcination stage while main taining the same production process. According to the principle of equivalent substitution of fuel calorific value, referring to the general rule of comprehensive energy consumption calculation GBT2589-2020, the low calorific value of bituminous coal and natural gas is 19.57GJ/t and 0.0389GJ/m

3, respectively. Therefore, the calorific value of 1t coal is equivalent to 503m

3 natural gas. Based on the IPCC emission factor method, the carbon emission from 1t coal combustion is 1.74t, and the carbon emission from 503m

3 natural gas combustion is 1.09t. Replacing bituminous coal with natural gas, carbon emission can be reduced by 37 %, indicating that natural gas can bring significant carbon reduction effect. According to the lime production in 2022, the use of natural gas as calcined fuel in quicklime industry can reduce carbon emission by 120 million tons. In addition, straw is considered to be a promising green fuel because of its carbon neutrality. By co-processing bituminous coal, 50 % bituminous coal &50 % straw instead of 100% bituminous coal, the carbon emissions generated by fuel combustion can be reduced by 12%[

29]. Mining opperations may consider using clean fuels, or recycling straw, wood chips and other wastes to replace some traditional fuels in a synergistic manner, which will not only reduce carbon emissions from fuel combustion, but also make full use of the calorific value of waste to achieve energy recycling.

Diesel combustion is the main carbon emission source of open-pit mining. Some mining and transportation equipment at Mine A is nearing its end of life, and therefore consumes large amounts of fuel. The acquisition of new energy mining vehicles to replace diesel equipment, will achieve energy conservation and emission reduction.

5.3. Energy management and optimization

Along with targeted low-carbon production reforms for key carbon emission sources, targeting energy consumption in mining can also achieve the goal of energy saving and carbon reduction. According to the 'National Key Energy Saving and Low Carbon Technology Promotion Catalog (2017 edition, energy saving part) issued by the National Development and Reform Commission, digital power metering should be installed on operating equipment, and the data collected and analyzed in order to realize energy savings. Secondly, the mining equipment is in the starting state, but it has not been put into operation, resulting in a waste of diesel consumption. We suggest to strengthen control over the consumption of diesel, coal, electricity and other energy sources, so as to make room for energy saving and carbon reduction. Finally, the mining area should make good use of advances in technology means such as 5G, Internet of Things, and big data to bring greater efficiency. Through real-time analysis, intelligent decision-making, precise execution, instant feedback, and self-correction, it can not only save energy and reduce emissions in the mining field, but also help enterprises establish a good image[

30].

6. Conclusions

(1) The carbon emission accounting boundaries for the life cycle of quicklime was determined and its carbon emission sources were evaluated, including fuel (diesel, coal) combustion, explosion, electricity consumption and limestone high temperature decomposition. The IPCC emission factor method was used to construct the life cycle carbon emission accounting model of quicklime, and determined the carbon emission factor of producing unit quicklime of the lime enterprise in the Yangtze River basin.

(2) Through to the Yangtze River Basin Enterprise's analysis, a total of 354,200 tons of carbon emissions were generated from the production of 321,000 tons of quicklime. The carbon emissions in the open-pit mining stage, crushing stage and calcination stage account for 0.26%, 0.27% and 99.47%, respectively. According to the unitized production of quicklime, the carbon emission of 1t quicklime was 1.46 kg in the open-pit mining stage, 1.49 kg in the crushing stage and 1100 kg in the calcination stage. The total carbon emission of producing 1t quicklime was 1102.95 kg. In the three stages of quicklime production, the key carbon emission sources were concentrated in the calcination stage. The high temperature decomposition of limestone was the largest carbon emission source, accounting for 62.34% of the total carbon emission. Coal combustion was the second carbon emission source, accounting for 32.66% of the total carbon emission. The carbon emissions of diesel combustion in the open-pit mining stage and electricity consumption in the crushing stage account for a relatively small proportion, but the actual total carbon emissions are still large, and attention should also be paid to its carbon emission reduction.

(3) Low-carbon treatment suggestions are provided for the production of quicklime from three aspects. First, CO2 capture technology is used to realize decarburization of end flue gas. The second is to optimize the fuel. In the calcination stage, clean fuel or synergistic treatment of fuel can be used. In the open-pit mining stage, new energy equipment can be used instead of diesel equipment. Third, precise management of energy. It is suggested that the mining area can gradually promote carbon emission reduction measures according to its own operating conditions and move towards the road of green sustainable development.

Author Contributions

Erxi Wu: Methodology, formal analysis, investigation, data curation, writing original draft. Qiaozhi Wang: Conceptualization, methodology, writing reviewing and editing, supervision. Lihua Ke: Resources, writing reviewing and editing, supervision. Guangquan Zhang: Resources, supervision.

Funding

This work was supported by the National Natural Science Foundation of China (41701624) and the Innovation and Entrepreneurship Project for college students in Hubei Province(S201910488071).

Acknowledgments

We would like to express our gratitude to Simon Carter for his constructive commonents, which helped improved our work a lot. The authors would also appreciate for the anonymous reviewers for their contribution.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, Q.; Wang, Y.; Liu, L. Carbon Tax or Low-Carbon Subsidy? Carbon Reduction Policy Options under CCUS Investment. Sustainability. 2023, 15, 5301. [Google Scholar] [CrossRef]

- Soest, H.; Elzen, M.; Vuuren, D. Net-zero emission targets for major emitting countries consistent with the Paris Agreement. Nature Communications. 2021, 1, 2140. [Google Scholar] [CrossRef] [PubMed]

- Lime production by country in 2022. Global production of lime by country 2022 | Statista.

- Intergovernmental Panel on Climate Change (IPCC). Revised 1996 IPCC Guidelines for National Greenhouse Gas Inventories. Available online: https://www.ipcc-nggip.iges.or.jp/public/gl/invs1.html (accessed on 24 December 2018).

- Tong, Q.; Zhou, S. ; Guo Y, et al. Forecast and analysis on reducing China’s CO2 emissions from lime industrial process. International journal of environmental research and public health 2019, 16, 500. [Google Scholar] [CrossRef] [PubMed]

- Agustin Laveglia.; Luciano Sambataro.; Neven Ukrainczyk et al. Hydrated lime life-cycle assessment: Current and future scenarios in four EU countries. Journal of Cleaner Production 2022, 369, 133224. [CrossRef]

- Yuli Shan.; Zhu Liu. Dabo Guan. CO2 emissions from China’s lime industry. Applied Energy 2016, 166, 245–252. [CrossRef]

- Weber, C.; Mst, D.; Fichtner, W. Regulation: Grids and Environment. Springer Texts in Business and Economics. 2022. [Google Scholar]

- Plaza, MG.; Martinez, S.; Rubiera, F. CO2 capture, use, and Storage in the cement industry: State of the Art and expectations. Energies. 2020, 21, 5692. [Google Scholar] [CrossRef]

- Marco Simoni.; Mathew D. Wilkes.; Solomon Brown.; John L. Provis et al. Decarbonising the lime industry:

State-of-the-art. Renewable and Sustainable Energy Reviews 2022, 168, 112765. [CrossRef]

- Fine, NA.; Rochelle, GT. Absorption of nitrogen oxides in aqueous amines. Energy Proc. 2014, 63, 830–47. [Google Scholar] [CrossRef]

- Bui M, et al. Carbon capture and storage (CCS): the way forward. Energy Environ Sci. 2018, 5, 1062–176. [CrossRef]

- Hagg B, et al. Pilot demonstration-reporting on CO2 Capture from a cement plant using hollow fiber process. Energy Proc. 2017, 114, 6150–65. [CrossRef]

- Baker RW, et al. CO2 Capture from cement Plants and steel mills using membranes. Ind Eng Chem Res. 2018, 47, 15963–15970. [Google Scholar] [CrossRef]

- Svante. Inventys partners with total lafarge to bring carbon capture program to British Columbia. 2019.Vancouver, BC,Canada, https://svanteinc.com/wp-content/uploads/2019/05/NR_2019-05-28_Project-CO2MENT_FINAL.pdf.

- Georgiopoulou.; Martha.; Lyberatos, et al. Life cycle assessment of the use of alternative fuels in cement kilns: A case study. Journal of Environmental Management 2018.

- Bourtsalas A C, T.; Jiao, Z. ; Castaldi M J, et al. Use of non-recycled plastics and paper as alternative fuel in cement production. Journal of Cleaner Production 2018, 181, 8–16. [Google Scholar] [CrossRef]

- Gsk A.; Yhk A.; Ms B, et al. Life cycle assesment on tire derived fuel as alternative fuel in cement industry. 2021.

- Tao Gao.; Qing Liu.; Jianping Wang. A comparative study of carbon footprint and assessment standards, International Journal of Low-Carbon Technologies. 2014, 9, 237-243. [CrossRef]

- Ige O, E.; Olanrewaju O, A. ; Duffy K J, et al. A review of the effectiveness of Life Cycle Assessment for gauging environmental impacts from cement production. Journal of cleaner production, 2021; 15, 324. [Google Scholar]

- Li Peng.; Wu Wenhao.; Guo Wei. The challenges and recommendations of application of the measurement-based monitoring methodology in national carbon market. Environmental Economics Research, 2021; 6, 77–92.

- Junwen Chen.; Hua Zhang.; Gang Zhao.; Abdul Samad Qureshi. A novel method for estimating carbon emission based on industrial metabolism: Blast furnace iron-making with micro mechanism model. Energy Reports. 2022, 8, 10125-10133. [CrossRef]

- Shen, L.; Gao, T. ; Zhao J, et al. Factory-level measurements on CO2 emission factors of cement production in China. Renewable & Sustainable Energy Reviews, 2014; 34, 337–349. [Google Scholar]

- Penglin Jiao.; Zihe Zhang.; Ying Chen. Carbon emission calculation and economic analysis of self-produced lime in iron and steel enterprises. Resource conservation and environmental protection, 2018; 5, 57–58.

- Cavaignac R, S.; Ferreira N, L.; Guardani, R. Techno-economic and Environmental Process Evaluation of Biogas upgrading via amine scrubbing. Renewable Energy. 2021. [Google Scholar] [CrossRef]

- Zhenxia Nie. Puguang gas field MDEA desulfurization and decarbonization technology. Petrochemical technology. 2017, 24, 77. [Google Scholar]

- Dudin M, N.; Dudin M, N. ; Frolova E E, et al. Study of innovative technologies in the energy industry: nontraditional and renewable energy sources. Entrepreneurship and Sustainability Issues, 2019; 6. [Google Scholar]

- Guopeng Song. Comparison of application of semi-coke and natural gas in independent heat source ore powder enterprises. Cement engineering. 2021, 4, 80–82. [Google Scholar]

- Dan S, A.; Jin Y, A.; Bca B, et al. Life-cycle environmental impact analysis of a typical cement production chain. Applied Energy. 2016, 164, 916–923. [Google Scholar] [CrossRef]

- Weixing Lin.; Yuantao Zhang.; Qi Liu, et al. Thoughts on the layout of mineral resources development layout under the target of “Double carbon”. Mining Research and development. 2022; 42, 153–159.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).