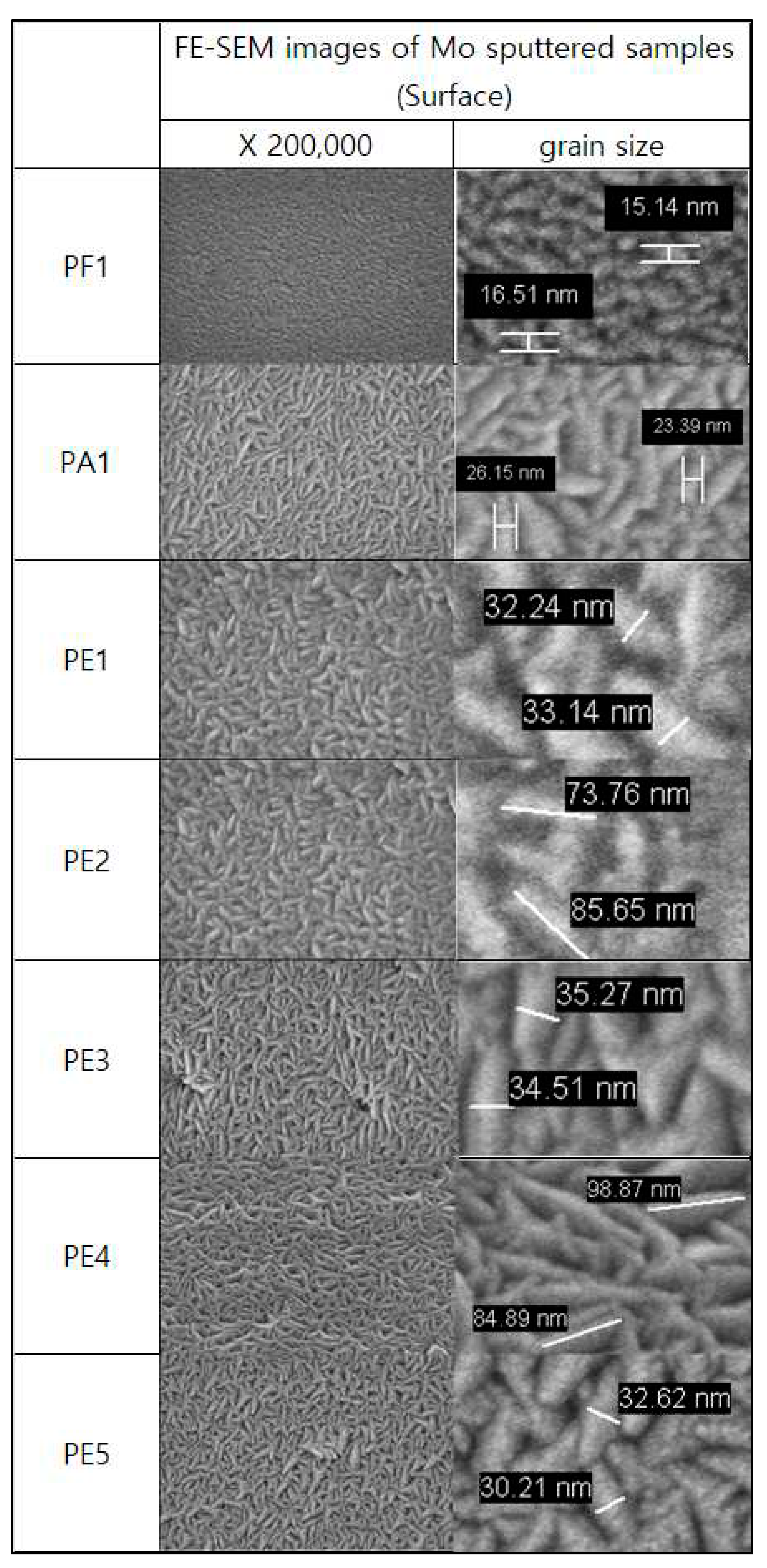

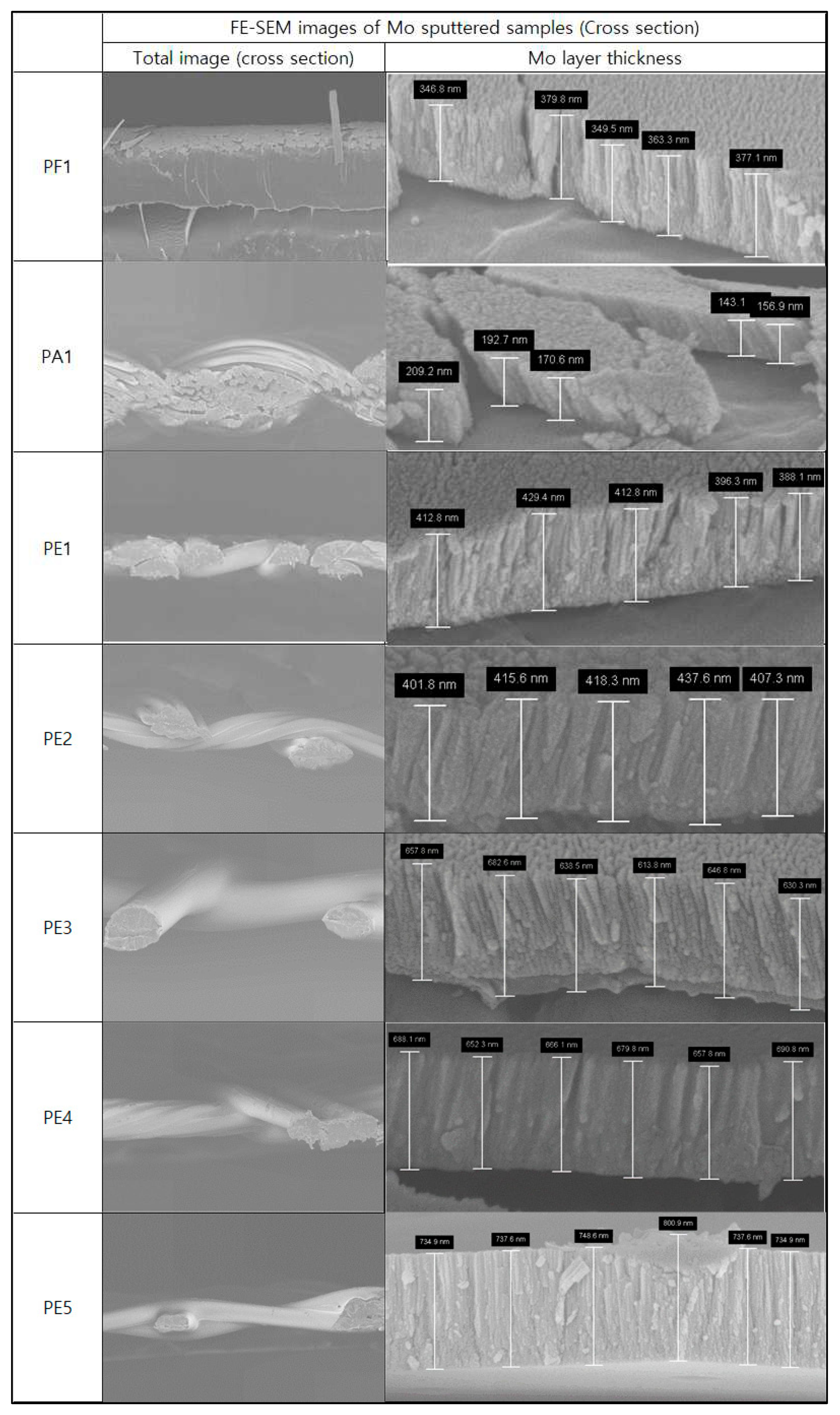

2.2. Characterization

As a result of examining the surface with FE-SEM after a molybdenum sputtering treatment, it was observed that molybdenum was well formed on the fiber surface in all sputtering treatment samples. EDS (energy dispersive spectroscopy, EDS Oxford Instruments, UK) and FE-SEM (field-emission scanning electron microscopy, Jeol, JSM 7401F, Japan) were used for surface characteristics.

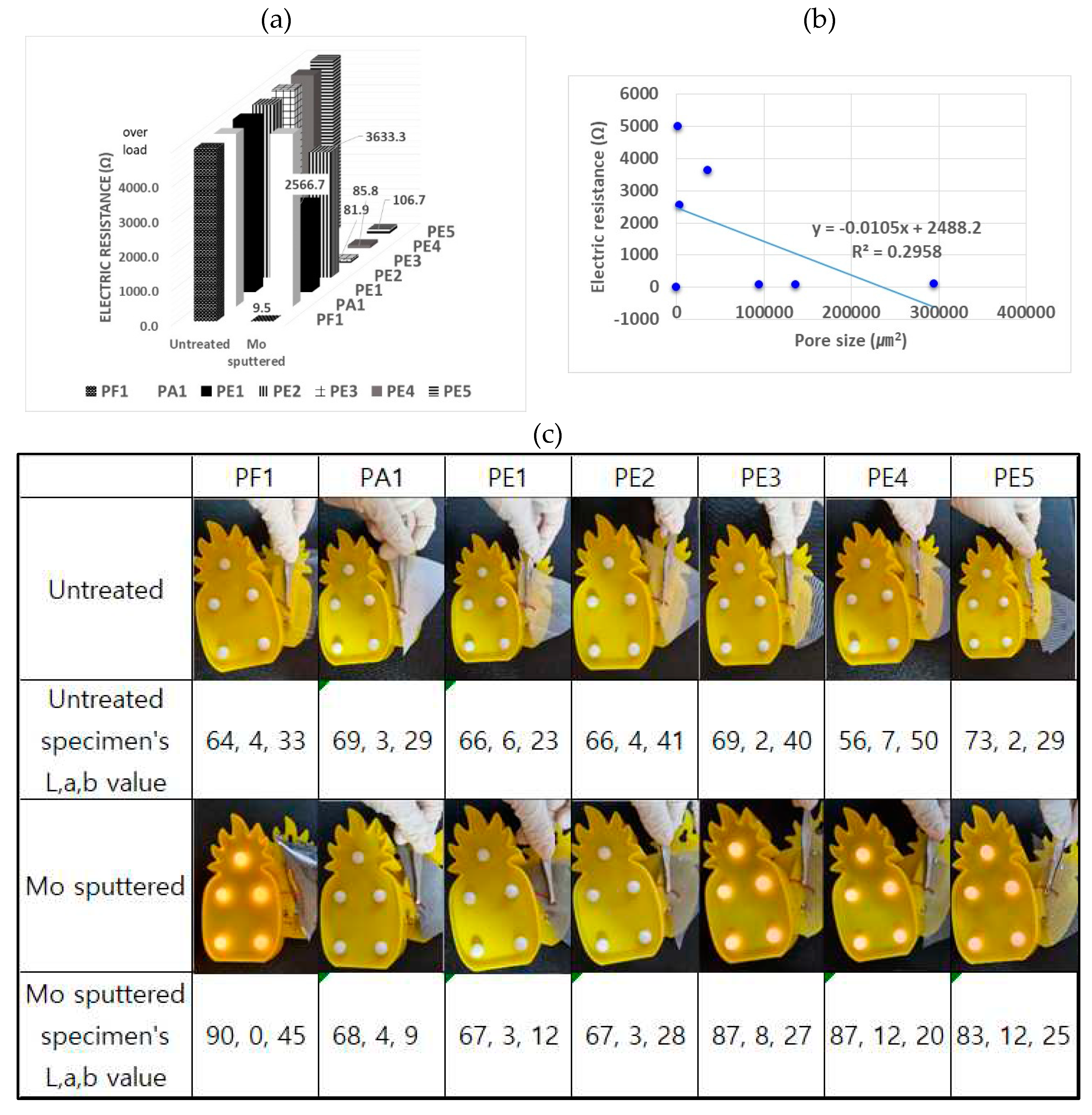

In the case of electrical resistance, a digital multimeter (Bluetooth Digital Multimeter, OWON D35T, Fujian Lilliput Optoelectronics Technology Co., Ltd. China) was used to study surface resistance before and after the molybdenum sputtering treatment. The independent variable is Mo treatment or not, and the dependent variable is electrical resistance.

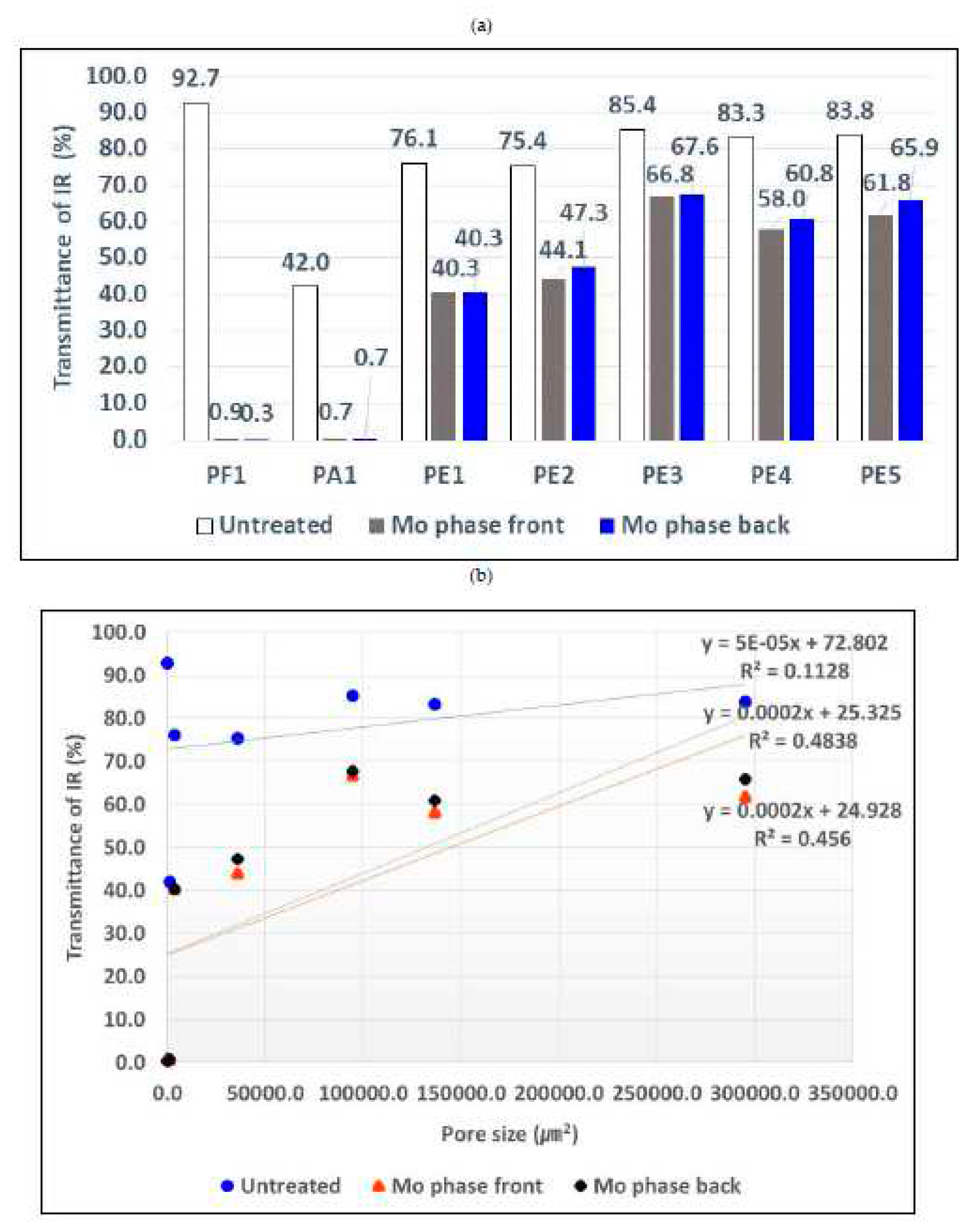

An infrared intensity tester (infrared emulating diodes, 5mm infrared LED, T-1 3/4 IR333-A, EVERLIGHT, Taiwan) was used for infrared transmittance. The infrared intensity irradiated to the sample was set to 200 W/m2. Additionally, the main infrared wavelength was 940 nm. The independent variable is Mo treatment and treatment surface direction, and the dependent variable is IR transmittance.

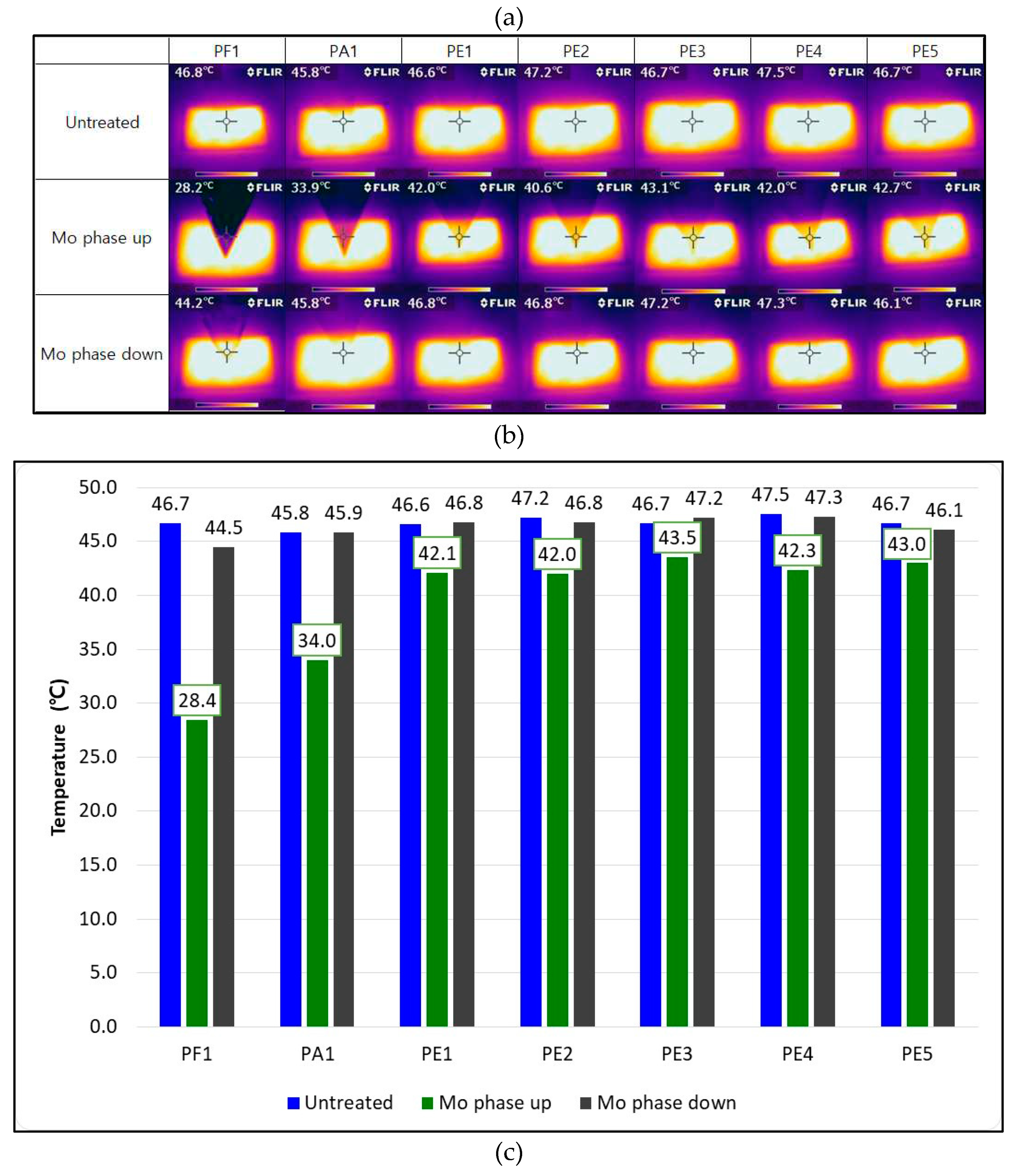

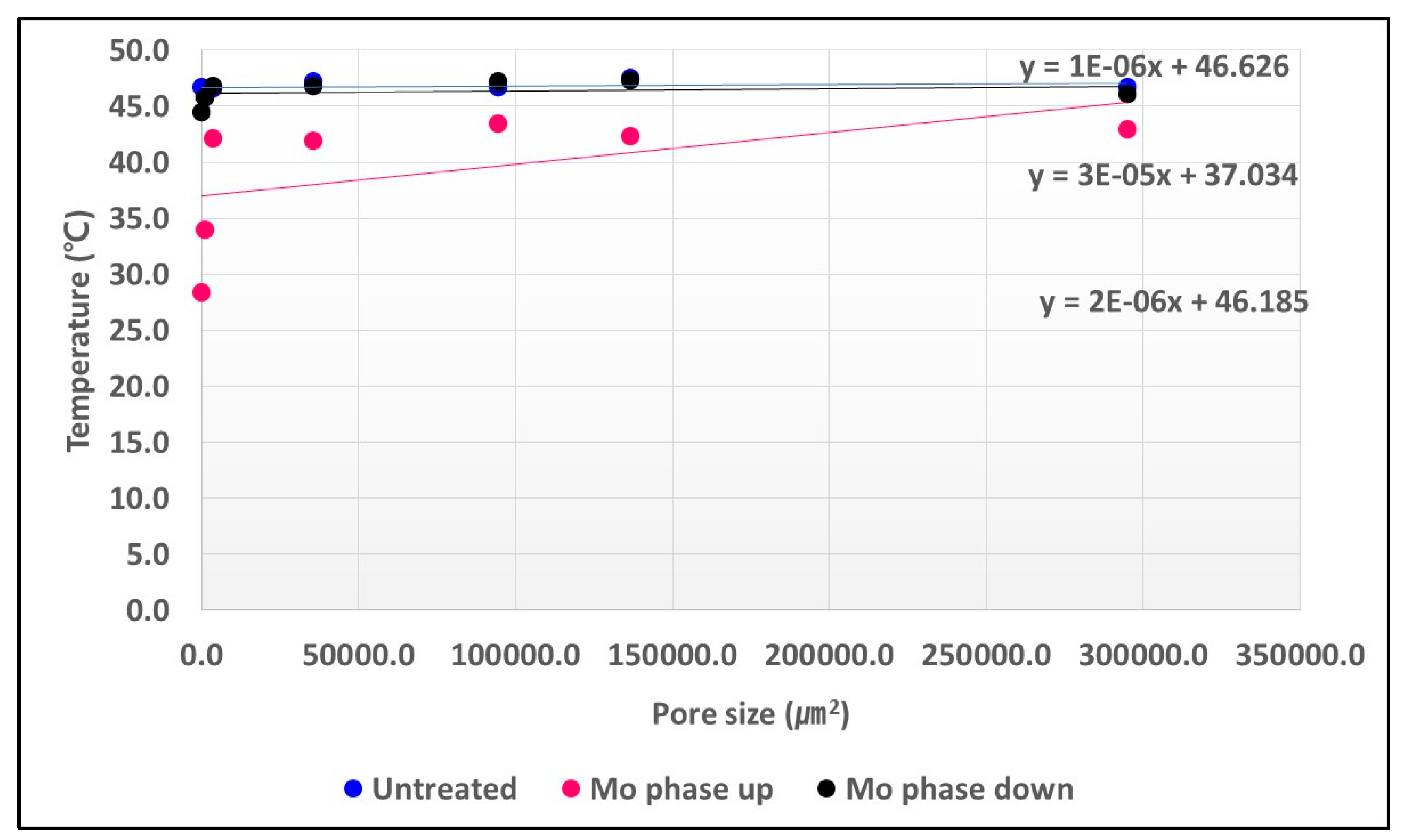

In the case of stealth characteristics, an infrared thermographic camera (Flir i7) was used. When taking a thermal image, a thermal image was acquired with an infrared thermal image camera while the sample was closely attached to the back of the hand while wearing latex gloves.

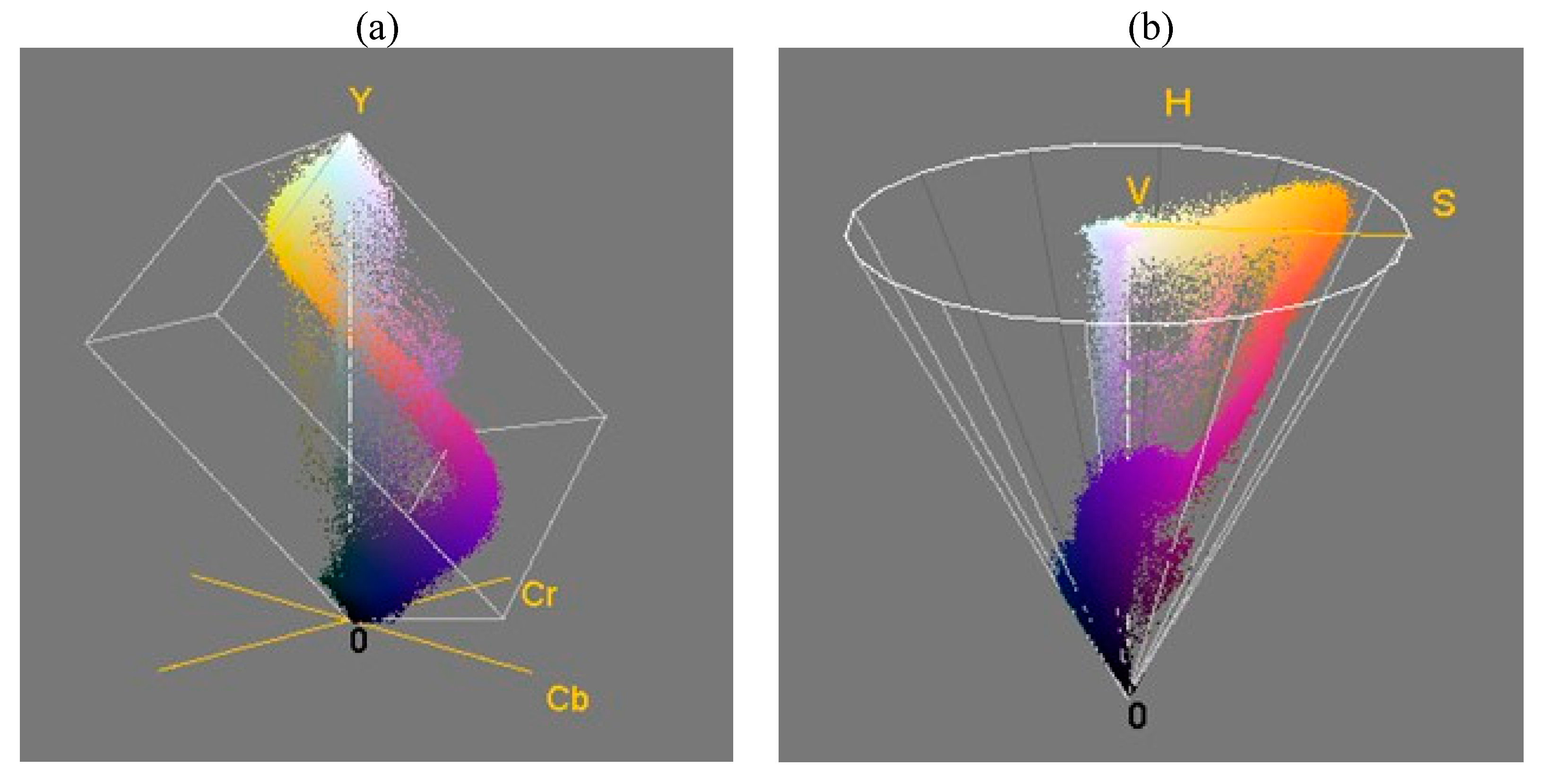

The Color Inspector 3D program was used to measure the hidden effect of infrared thermal imaging cameras and the values of H, S, V, Y, Cb, and Cr. In particular, H, S, V, and Y; Cb; and Cr values were studied using the Color Inspector 3D program. In addition, ΔH, ΔS, and ΔV; and ΔY, ΔCb, and ΔCr were calculated based on the data measured by the Color Inspector. The values of ΔH, ΔS, and ΔV are as follows (Eq. was calculated using 1~4) [

29,

30].

Each parameter in Eqs. (1)-(3) is defined below:

Huntreated: Value H of untreated specimens;

Htreated: Value H of sputtered specimens;

Suntreated: Value S of the untreated specimens;

Streated: Value S of the sputtered specimens;

Vuntreated: Value V of the untreated specimens;

Vuntreated: Value V of the sputtered specimens.

The HSV color space or HSV model is a method of expressing a color and a method of arranging a color according to the method. A specific color is designated by using coordinates of color (Hue), saturation, and brightness (Value). The color value H means the relative arrangement angle when the red with the longest wavelength is 0° in the color ring in which the visible light spectrum is arranged in an annular shape. Therefore, the H value ranges from 0° to 360°, and 360° and 0° refer to the same color red. The saturation value S represents the degree of darkness when the darkest state of a specific color is set to 100%. The saturation value of 0% represents an achromatic color of the same brightness. The brightness value V represents the degree of brightness when white, red, etc. are 100% and black is 0%.

<Eq.1> shows the degree of change in the “H” value due to the molybdenum sputtering treatment by subtracting the “H” value of the untreated sample from the “H” value of the molybdenum sputtering sample. The value of "H"’ in the concept of color space means a color angle (hue). In the case of <Eq. 2>, the change in the “S” value due to the molybdenum sputtering treatment is the value obtained by subtracting the “S” value of the “untreated sample” from the “S” value of the molybdenum sputtering sample. The "S" value in the color space represents the concentration and saturation of the color. Additionally, in Eq. 3, the value “V” of the “untreated sample” is subtracted from the value “V” of the molybdenum sputtering sample, indicating a change in color value by the molybdenum sputtering treatment. The "V" value in the color space represents the degree of brightness. Additionally, in Eq. 4 and the case of the "T" value, the color difference between the molybdenum sputtering-treated sample and the untreated sample in the color space is derived by combining them [

29,

30].

ΔY, ΔCb, and ΔCr were calculated using the following equation.

Each parameter in Eqs. (4)-(7) is defined below:

Yuntreated: Value Y of untreated specimen;

Ytreated: Value Y of sputtered specimen;

Cbuntreated: Value Cb of the untreated specimen;

Cbtreated: Value Cb of the sputtered specimen;

Cruntreated: Value Cr of the untreated specimen;

Crtreated: Value Cr of the sputtered specimen.

YCbCr is a type of color space used in imaging systems. Y is a luminance component, and Cb and Cr are color difference components. YCbCr is sometimes abbreviated as YCC. YCbCr is not an absolute color space and is a method of encoding RGB information, and the color of the actual image depends on the original RGB information used to display the signal. Therefore, the values expressed in YCbCr can only be predicted if standard RGB colors are used, or if an ICC profile is attached to be used to convert colors.

<Eq. 4> showed a change in the "Y" value due to molybdenum sputtering processing by subtracting the "Y" value of the untreated sample from the "Y" value of the molybdenum-sputtered sample. <Eq.5> shows the change in the value of “Cb” due to the treatment of molybdenum sputtering by subtracting the value of “Cb” of the “untreated sample” from the value of “Cb” of the molybdenum-sputtered sample. Eq. 6 shows the change in Cr value by the molybdenum sputtering treatment by subtracting the “Cr” value of the untreated sample from the “Cr” value of the molybdenum sputtering treatment sample.

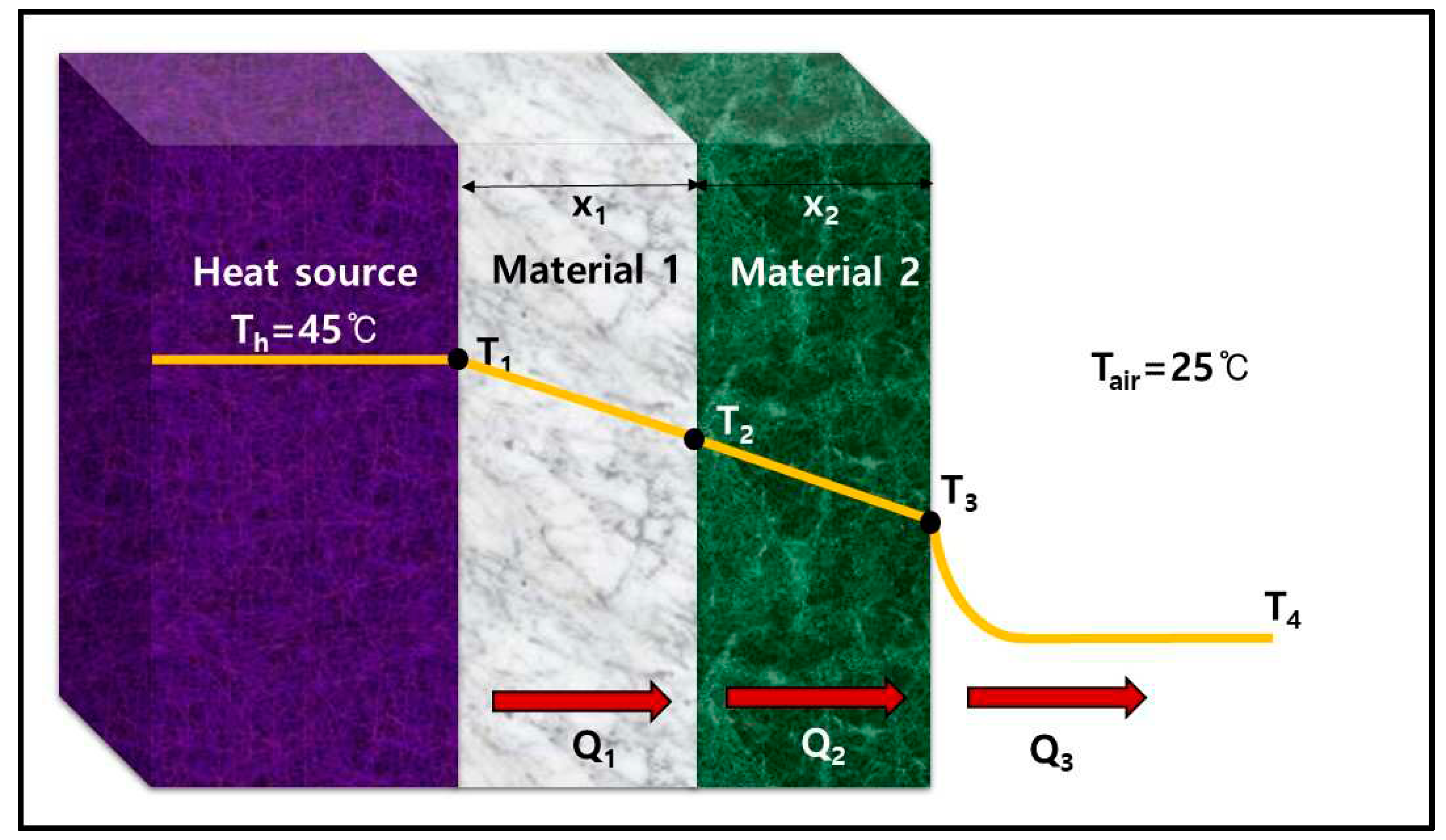

The heat transfer characteristic calculation is as follows.

Convection is the transfer of energy between the surfaces of liquids and solids. The movement of liquids plays an important role in increasing the speed of heat transfer rate. Convection can be expressed by the following equation (8). 'h' means the convective heat transfer coefficient. 'Tw' is the temperature of the solid surface (K), 'T∞' is the liquid temperature of the free flow (K), 'A' is the surface area (m

2), and 'Q' is the heat transfer rate (W)

Conduction is the mechanism by which thermal energy flows from high to low temperatures. Heat transfer within a solid can occur through conduction. Metals in particular are conductors with very high thermal conductivity. The conduction can be expressed according to Fourier's rule in the following equation (9). where 'Q' is the heat transfer rate, 'k' is the thermal conductivity, 'A' is the surface area (m

2), 'T' is the temperature (K), △T is the temperature difference (K), and 'x' is the thickness (m)

Radiation is the transfer of energy by electromagnetic waves. Energy can be transferred between a solid surface and a gas or between two or more surfaces. Radiation can be expressed in the following equation (10). where 'Q' is the heat transfer rate (W), 'A' is the surface area (m

2), ''' is the Stefan-Boltzmann constant (5.669 X 10

-8 W/m

2ᆞK

4), 'T

w' is the surface temperature of the material (K), and 'T∞' is the atmospheric temperature (K)

Various types of solids come into contact to form layers, and exposure to air or fluid results in a narrow difference in heat transfer through conduction, convection, or radiation.

The surface temperature was determined according to the above conduction, convection, and radiation theories, assuming a steady state with no time-induced temperature difference. The heat transfer rate calculated by this research model was derived through the above e equations (8)-(10), and presented again in equation (11).

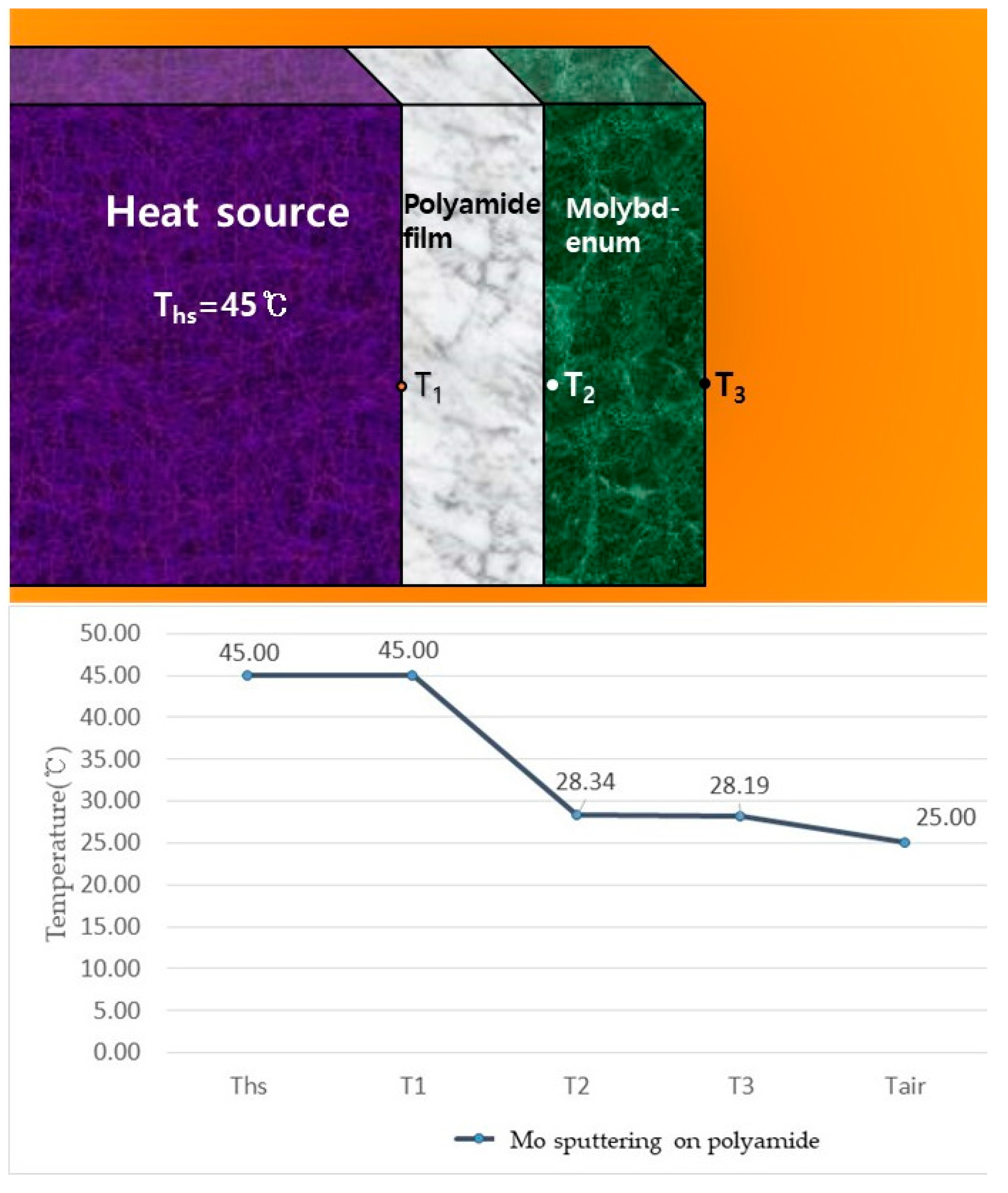

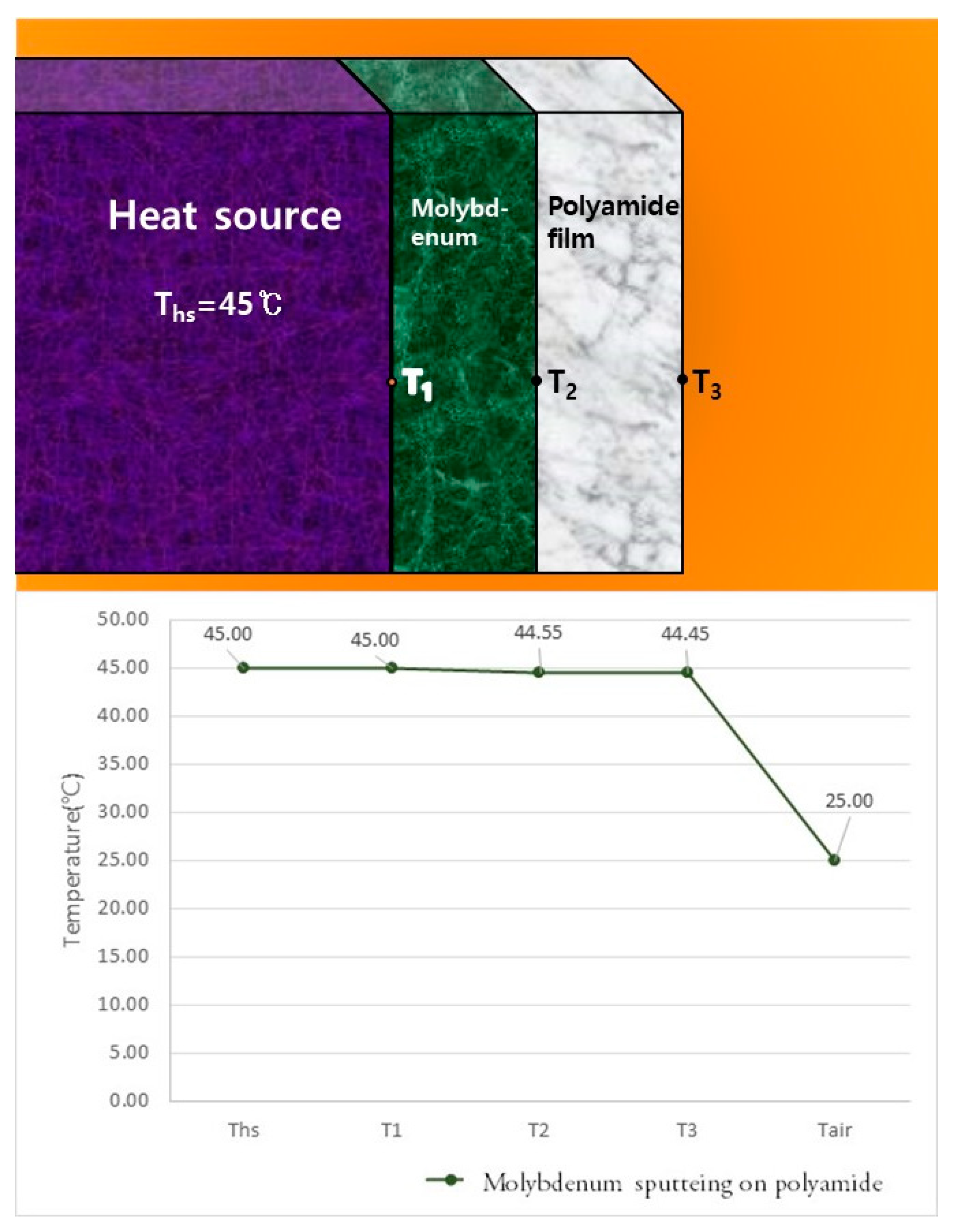

As shown in

Figure 1 and Equation (11), for Material 1, the theory of heat transfer by conduction was used for calculation. The theory of heat transfer by convection and radiation was used in the calculation of Material 2.

In Equation (11), 'Q' represents the total heat transfer rate, Q1 and Q2 represent the heat transfer rates of Material 1 and Material 2, respectively, and Q3 represents the heat transfer rate to the atmosphere. Q=Q1=Q2=Q3, when calculated under normal conditions.

In addition, X

1 and X

2 represent the thickness ('k

1') of Material 1 and Material 2(k

2), ε represents the radiation rate, ' σ '' represents the Stefan-Boltzmann constant, and 'h' represents the heat transfer coefficient. The 'Q' value was derived using the trial and error method, and then the surface temperature was calculated. If the orientation of the metal sputtering specimen was changed, the figures for Material 1 and Material 2 were replaced for calculation [

32]. It should be noted that the actual test material is fabric, but the calculation was carried out under the assumption that it was a solid material.