Submitted:

15 May 2023

Posted:

16 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

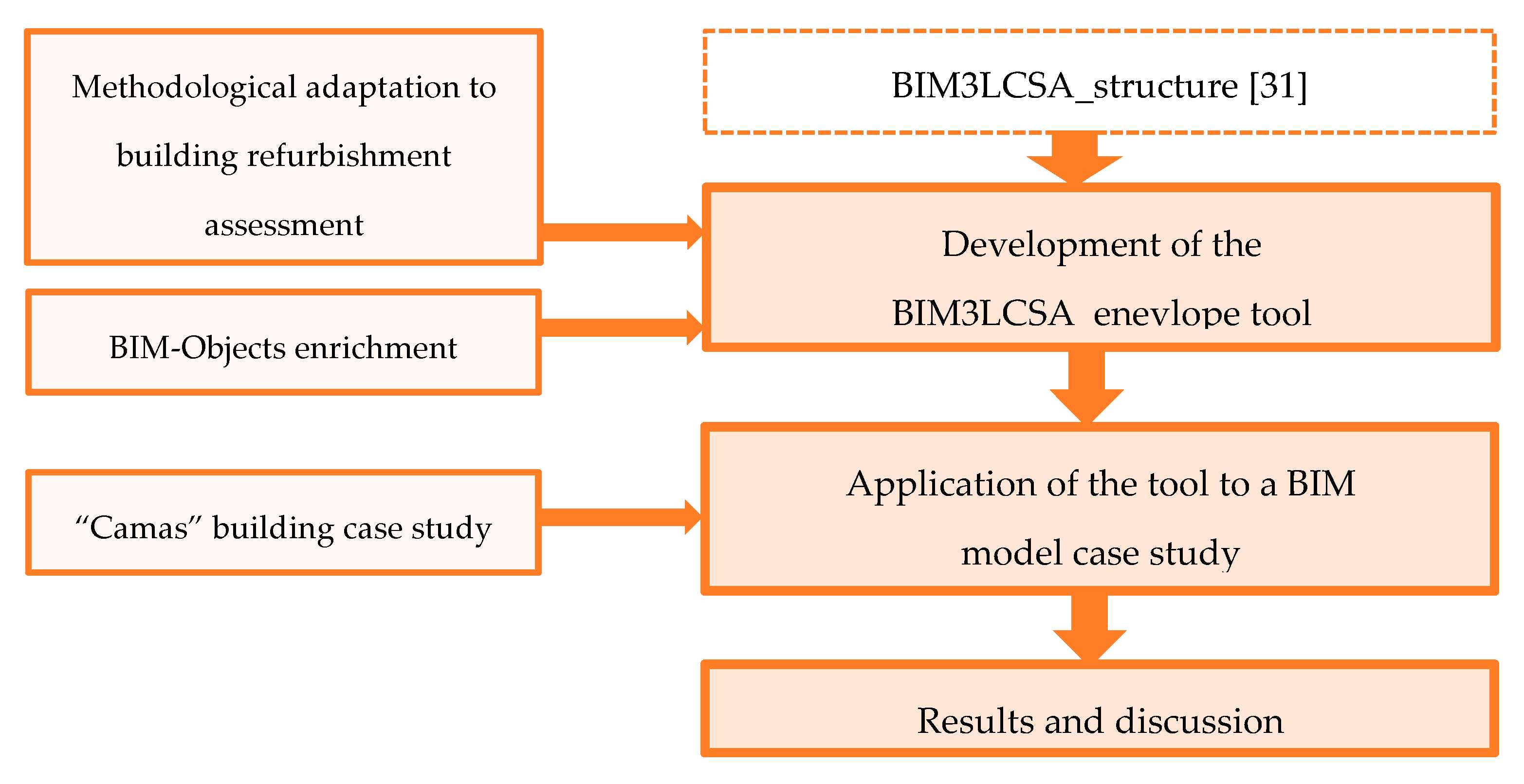

2. Materials and Methods

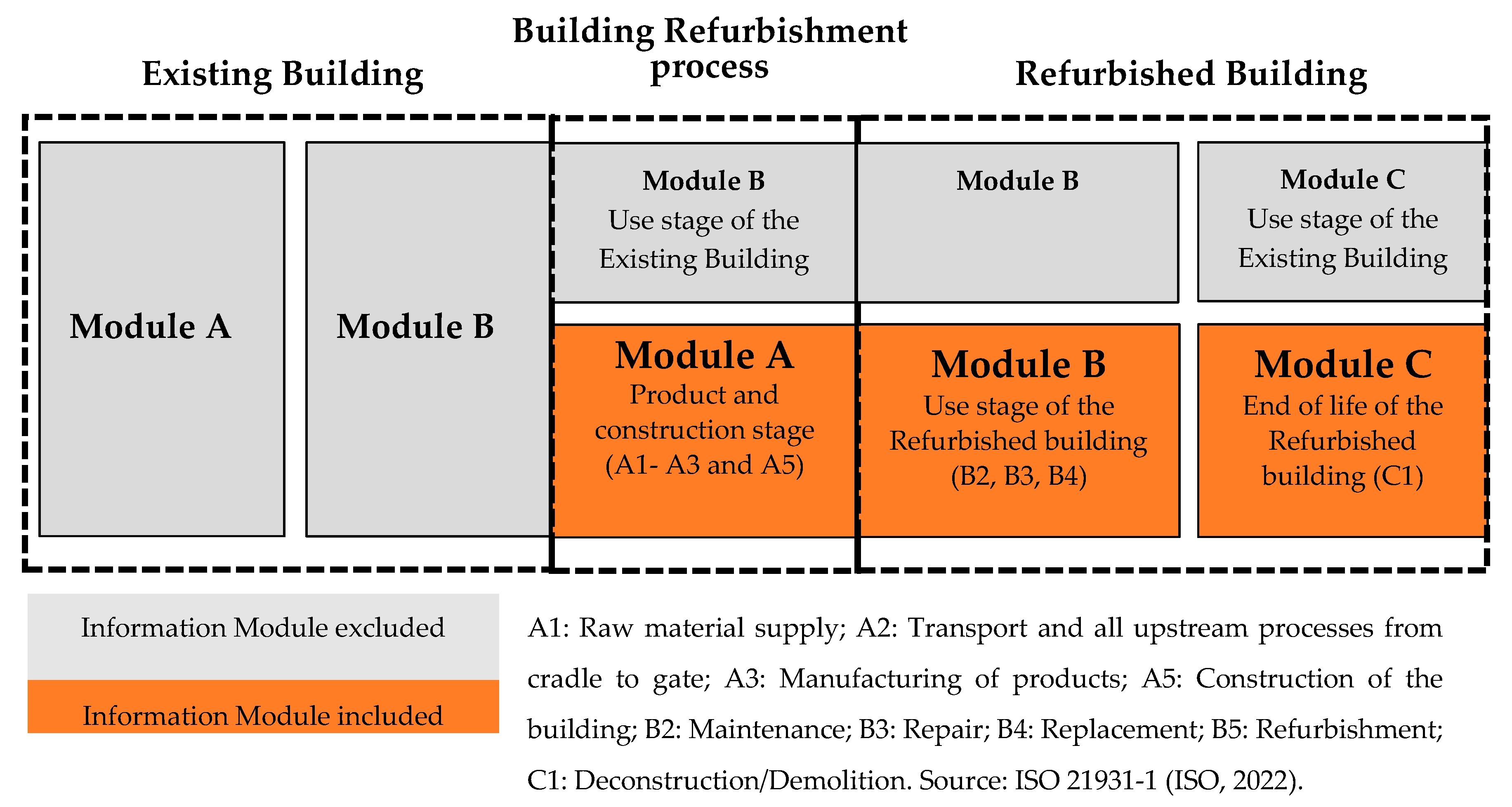

2.1. Tool adaptation to the building refurbishment process

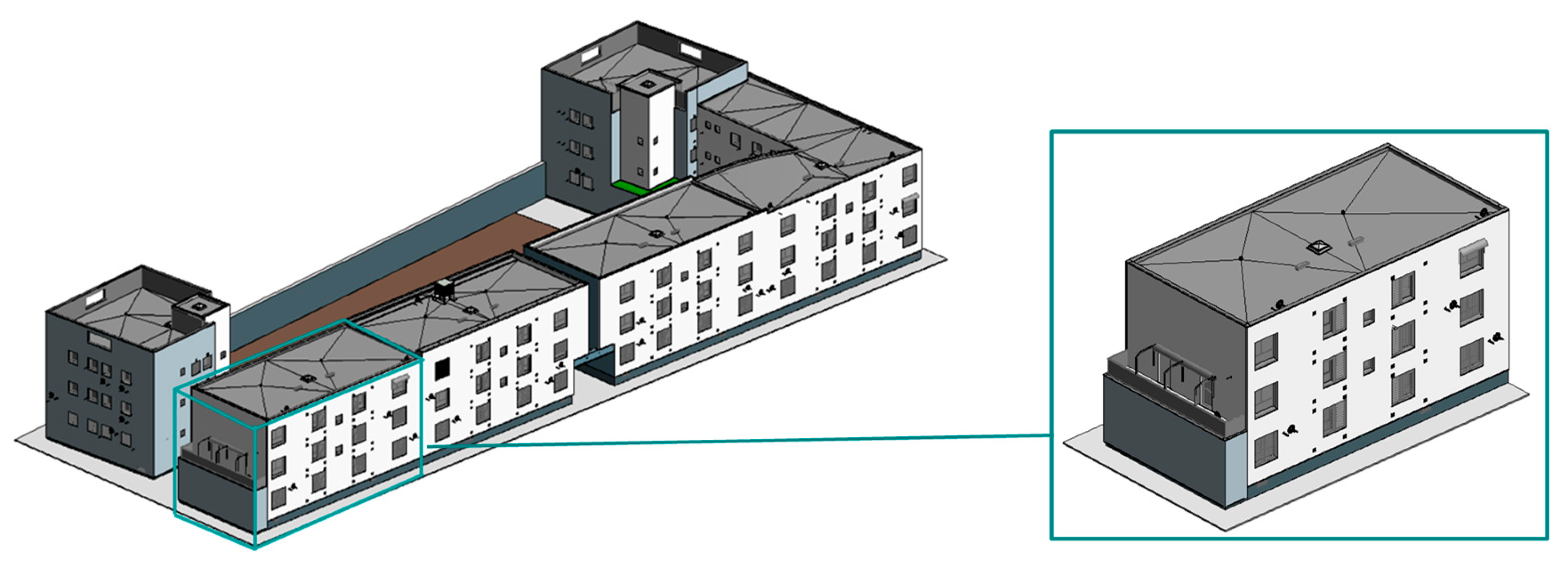

2.2. Case study description

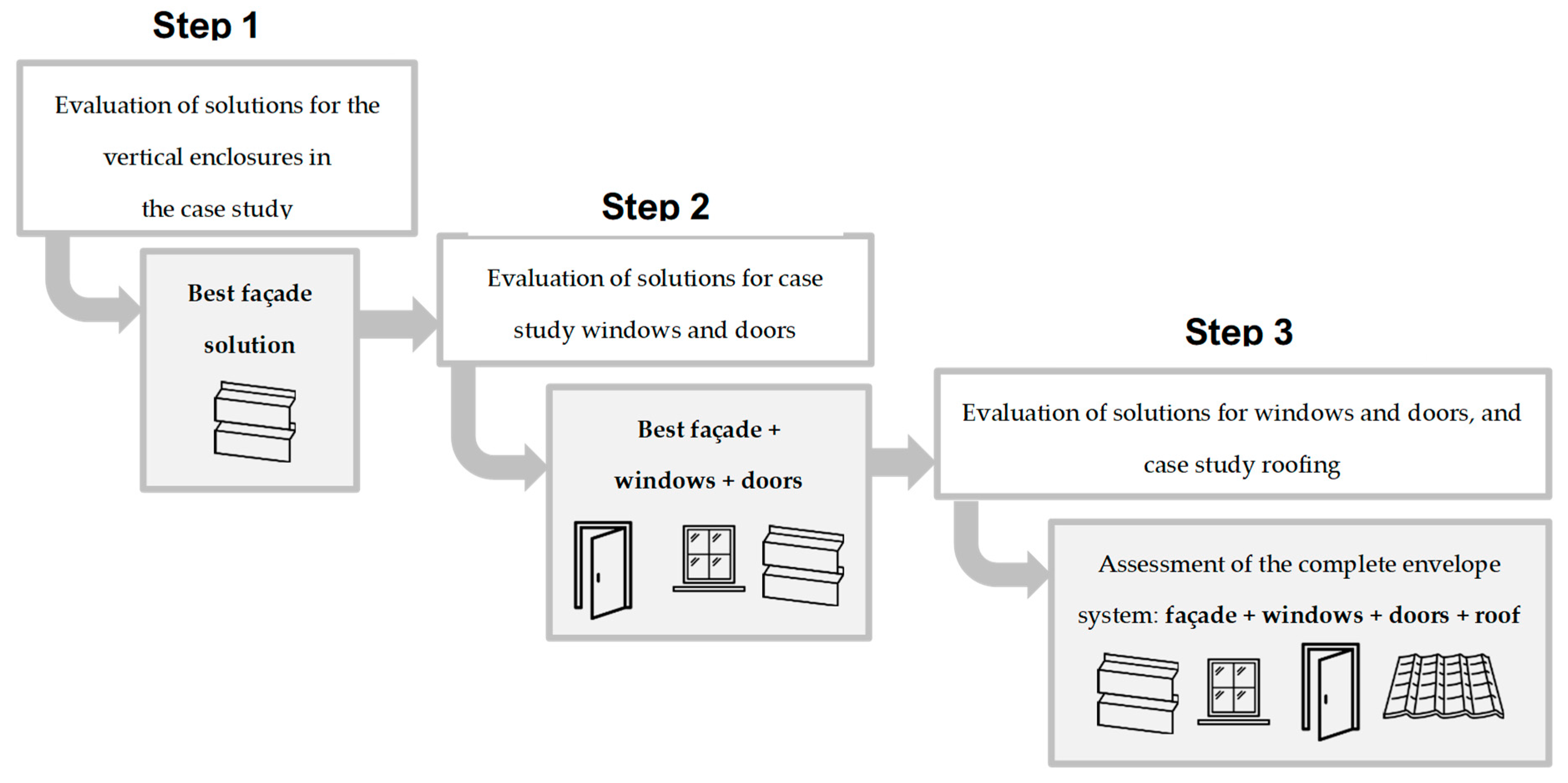

2.3. Tool application to the case study

2.3.1. Life cycle sustainability assessment applied to the case study

2.3.2. Definition of building information included in the assessment

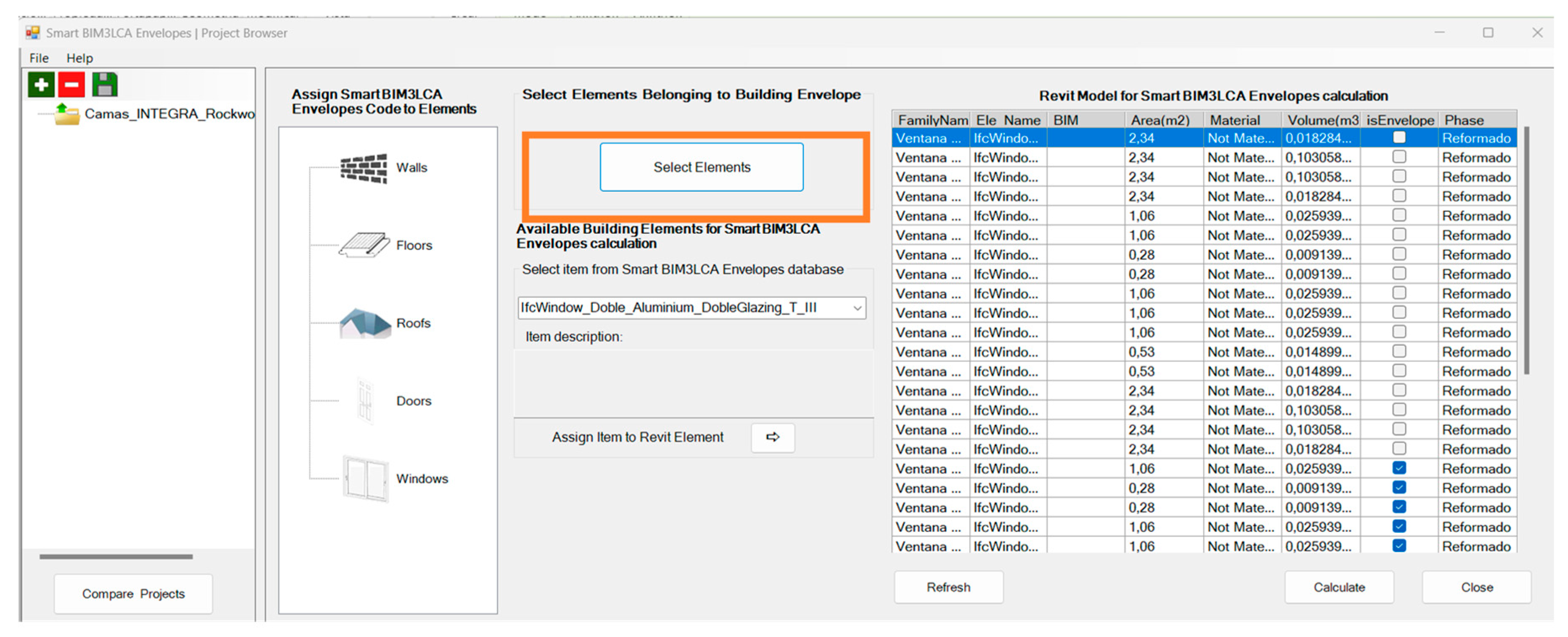

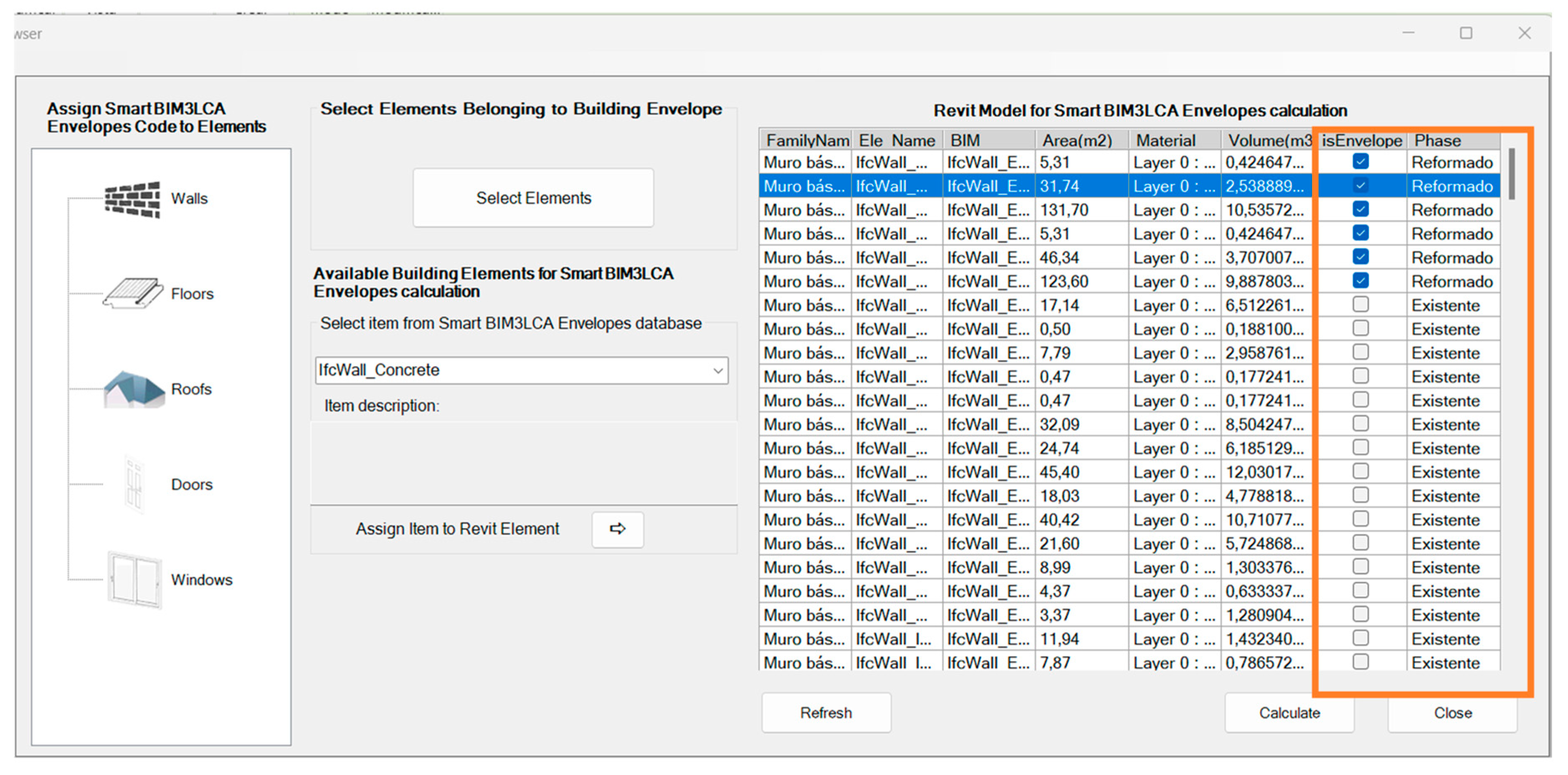

2.3.3. Definition of building elements included in the assessment

2.3.4. Definition of impact categories and indicators

3. Results and discussion

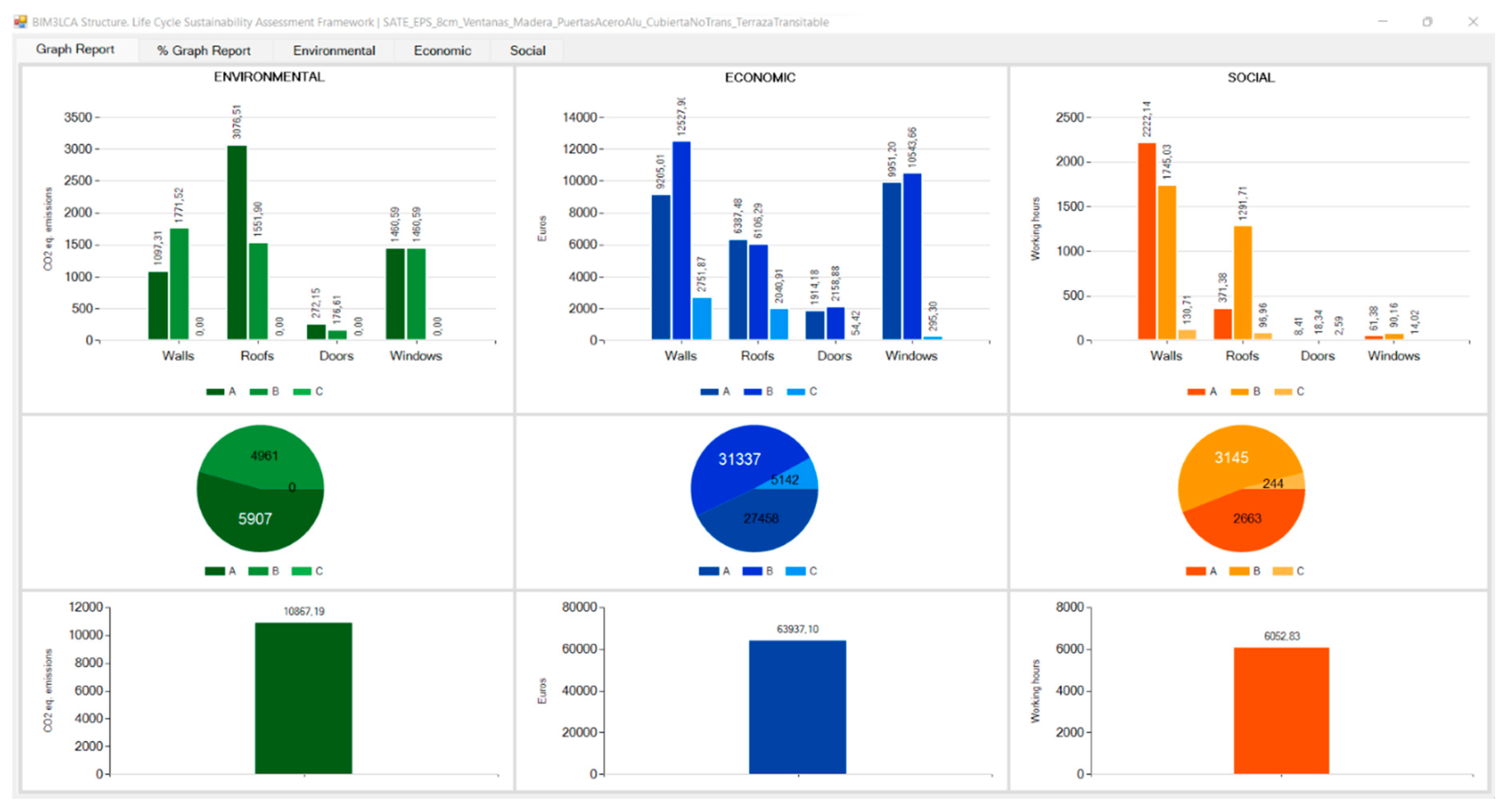

3.1. Case study LCSA results

3.2. Advantages of the tool developed

3.3. Limitations and future developments

4. Conclusions

5. Patents

Author Contributions

Funding

Acknowledgements

Conflicts of Interest

Appendix A

| Solution 1 | Solution 2 | Solution 3 |

| ETICS | Ventilated façade | Interior insulation |

| New materials | New materials | New materials |

| 1. Cement or lime mortar for masonry and rendering/plastering 1000<d<1250: 1.50cm 2. EPS Expanded Polystyrene or mineral wool (0.029 W/m.k): 6.00cm 3. Cement or lime mortar for masonry and rendering/plastering 1000<d<1250: 1.50cm |

1. Cement or lime mortar for masonry and plastering/rendering 1000<d<1250: 1.50cm 2. Cellulose cement board: 0.80cm 3. Air chamber: 6.00cm 4. Gypsum plasterboard (PYL) 750<d<900:1.00cm 5. EPS Expanded Polystyrene or Mineral wool (0.029 W/m.k): 6.00cm 6. Cement or lime mortar for masonry and rendering/plastering 1000<d<1250: 1.50cm |

7. EPS Expanded Polystyrene or Mineral Wool (0.029 W/m.k): 6.00cm 8. Gypsum plasterboard 750<d<900: 1.30cm 9. Gypsum mortar: 1.50cm |

| Existing materials | Existing materials | Existing materials |

| 4. ½ foot perforated brick metric or Catalan 40mm <G< 60mm: 11.50 cm 5. Cement or lime mortar for masonry and plastering 1000<d<1250: 1.50cm 6. PUR Hydroflurocarbide HFC projection (0.028 W/m.k): 2.00com 7. Double hollow brick board (60mm<E<90mm):7.00cm 8. Gypsum mortar:1.50cm |

7. ½ foot perforated brick metric or Catalan 40mm <G< 60mm: 11.50 cm 8. Cement or lime mortar for masonry and plastering 1000<d<1250: 1.50cm 9. PUR Hydroflurocarbide HFC projection (0.028 W/m.k): 2.00com 10. Double hollow brick board (60mm<E<90mm):7.00cm 11. Gypsum mortar:1.50cm |

1. Cement or lime mortar for masonry and plastering/rendering 1000<d<1250: 1.50cm 2. ½ foot perforated brick metric or Catalan 40mm <G< 60mm: 11.50 cm 3. Cement or lime mortar for masonry and plastering 1000<d<1250: 1.50cm 4. PUR Hydroflurocarbide HFC projection (0.028 W/m.k): 2.00com 5. Double hollow brick board (60mm<E<90mm):7.00cm 6. Gypsum mortar: 1.50cm |

| Solution 1 | |

| Non-trafficable roof | Trafficable roof |

| Existing materials | Existing materials |

| 1. 5 cm gravel layer with aggregate between 16 and 32 mm diameter: 5.00cm 5 cm mortar layer reinforced with fiberglass mesh: 5.00cm Geotextile anti-zonation separator filter: 0.10cm 80mm extruded polystyrene insulation panel: 8.00cm Geotextile anti-zonation separator filter: 0.10cm Separation sheet and waterproofing sheet IBM-4.8:0.10cm Existing slope formation cleaned and resurfaced: 6.00cm Ceramic interlocking 25cm:25.00cm |

Ceramic tiles 14x28cm: 2.00cm 5 cm gravel layer with aggregate between 16 and 32 mm diameter: 5.00cm 5 cm mortar layer reinforced with fiberglass mesh: 5.00cm Geotextile anti-zonation separator filter: 0.10cm 80mm extruded polystyrene insulation panel: 8.00cm Geotextile anti-zonation separator filter: 0.10cm Separation sheet and waterproofing sheet IBM-4.8:0.10cm Existing slope formation cleaned and resurfaced: 6.00cm Ceramic interlocking 25cm:25.00cm |

References

- IEA (International Energy Agency) Global Status Report for Buildings and Construction: Towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector; 2019.

- 2. Climate Change 2021: The Physical Science Basis | Climate Change 2021: The Physical Science Basis . Available online: https://www.ipcc.ch/report/ar6/wg1/ (accessed on 22 April 2023).

- European Commission; European Parliament The European Green Deal. Eur. Comm. 2019. [CrossRef]

- European Commission Renovation Wave. Available online: https://ec.europa.eu/energy/topics/energy-efficiency/energy-efficient-buildings/renovation-wave_en (accessed on 22 April 2023).

- IEA EBC IEA EBC ANNEX 57. Available online: http://www.annex57.org/ (accessed on 22 April 2023).

- BOE Ley 7/2021 de Cambio Climático y Transición Energética; 2021.

- Finansdepartementet Klimatdeklaration För Byggnader; 2020.

- J. Quelle-Dreuning MPG-Grenswaarde Een Feit! (In Dutch)Duurz. Gebouw. Februari 2 (2017) 66–67.; 2017.

- Euorpean Parliament Amendments 14/03/2023 for Energy Performance of Buildings Directive (Recast); 2023.

- ISO ISO 14067:2013 Greenhouse Gases — Carbon Footprint of Products — Requirements and Guidelines for Quantification and Communication. Int. Organ. Stand. 2013.

- Kloepffer, W. Life Cycle Sustainability Assessment of Products (with Comments by Helias A. Udo de Haes, p. 95). In Proceedings of the International Journal of Life Cycle Assessment; 2008.

- Valdivia, S; Ugaya, C.; Sonnemann, G.; Hildenbrand, J. Valdivia S; Ugaya, C.; Sonnemann, G.; Hildenbrand, J.; (eds) Towards a Life Cycle Sustainability Assessment. Making Informed Choices on Products.; Paris, 2011; ISBN 978-92-807-3175-0.

- Kohler, N.; Moffatt, S. Life-Cycle Analysis of the Built Environment. UNEP Ind. Environ. 2003, 26, 17–19. [Google Scholar]

- Soust-Verdaguer, B.; Galeana, I.B.; Llatas, C.; Montes, M.; Hoxha, E.; Passer, A. How to conduct consistent environmental, economic, and social assessment during the building design process. A BIM-based Life Cycle Sustainability Assessment method. J. Build. Eng. 2021, 45, 103516. [Google Scholar] [CrossRef]

- ISO 21931-1:2022 Sustainability in Building Construction -- Framework for Methods of Assessment of the Environmental, Economic and Social Performance of Construction Works -- Part 1: Buildings; 2022.

- Obrecht, T.P.; Röck, M.; Hoxha, E.; Passer, A. BIM and LCA Integration: A Systematic Literature Review. Sustainability 2020, 12, 5534. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A. Critical review of bim-based LCA method to buildings. Energy Build. 2017, 136, 110–120. [Google Scholar] [CrossRef]

- Llatas, C.; Soust-Verdaguer, B.; Passer, A. Implementing Life Cycle Sustainability Assessment during design stages in Building Information Modelling: From systematic literature review to a methodological approach. J. Affect. Disord. 2020, 182, 107164. [Google Scholar] [CrossRef]

- Mora, T.D.; Bolzonello, E.; Cavalliere, C.; Peron, F. Key Parameters Featuring BIM-LCA Integration in Buildings: A Practical Review of the Current Trends. Sustainability 2020, 12, 7182. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Pyl, L. Development of a BIM-based Environmental and Economic Life Cycle Assessment tool. J. Clean. Prod. 2020, 265, 121705. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Vandenbergh, T.; Pyl, L. BIM-based life cycle assessment and life cycle costing of an office building in Western Europe. J. Affect. Disord. 2019, 169, 106568. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Pyl, L. Informetric analysis and review of literature on the role of BIM in sustainable construction. Autom. Constr. 2019, 103, 221–234. [Google Scholar] [CrossRef]

- IEA EBC IEA EBC ANNEX 72 Available online:. Available online: http://www.iea-ebc.org/projects/ongoing-projects/ebc-annex-72/ (accessed on 22 April 2023).

- Hollberg, A.; Genova, G.; Habert, G. Evaluation of BIM-based LCA results for building design. Autom. Constr. 2019, 109, 102972. [Google Scholar] [CrossRef]

- Vilches, A.; Garcia-Martinez, A.; Sanchez-Montañes, B. Life cycle assessment (LCA) of building refurbishment: A literature review. Energy Build. 2016, 135, 286–301. [Google Scholar] [CrossRef]

- Mileto, C.; Vegas, F.; Llatas, C.; Soust-Verdaguer, B. A Sustainable Approach for the Refurbishment Process of Vernacular Heritage: The Sesga House Case Study (Valencia, Spain). Sustainability 2021, 13, 9800. [Google Scholar] [CrossRef]

- Dauletbek, A.; Zhou, P. BIM-based LCA as a comprehensive method for the refurbishment of existing dwellings considering environmental compatibility, energy efficiency, and profitability: A case study in China. J. Build. Eng. 2022, 46. [Google Scholar] [CrossRef]

- Kim, K.P. BIM-Enabled Sustainable Housing Refurbishment—LCA Case Study. In Sustainable Construction Technologies: Life-Cycle Assessment; 2019.

- Tushar, Q.; Zhang, G.; Bhuiyan, M.A.; Navaratnam, S.; Giustozzi, F.; Hou, L. Retrofit of Building Façade Using Precast Sandwich Panel: An Integrated Thermal and Environmental Assessment on BIM-Based LCA. Buildings 2022, 12, 2098. [Google Scholar] [CrossRef]

- KT Innovations; Autodesk Tally-Autodesk Available online:. Available online: http://choosetally.com/ (accessed on 22 April 2023).

- Soust-Verdaguer, B.; Moreno, J.A.G.; Llatas, C. Utilization of an Automatic Tool for Building Material Selection by Integrating Life Cycle Sustainability Assessment in the Early Design Stages in BIM. Sustainability 2023, 15, 2274. [Google Scholar] [CrossRef]

- Figueiredo, K.; Pierott, R.; Hammad, A.W.; Haddad, A. Sustainable material choice for construction projects: A Life Cycle Sustainability Assessment framework based on BIM and Fuzzy-AHP. J. Affect. Disord. 2021, 196, 107805. [Google Scholar] [CrossRef]

- Llatas, C.; Soust-Verdaguer, B.; Hollberg, A.; Palumbo, E.; Quiñones, R. BIM-based LCSA application in early design stages using IFC. Autom. Constr. 2022, 138. [Google Scholar] [CrossRef]

- BuildingSMART. Available online: https://www.buildingsmart.org (accessed on 28 May 2020).

- Revit, A. Autodesk Revit. Architecture 2021, 1, About Revit Architecture. [Google Scholar]

- BIM Forum Level Of Development (LOD) Specification Part I & Commentary. 2020.

- Ministerio para la Transición Ecológica y el Reto Demográfico Condiciones Técnicas De Los Procedimientos Para La Evaluación De La Eficiencia Energética, 2020.

- CTE Spanish Building Technical Code. Real Decreto 314/2006 17 marzo 2006, BOE 74, 11816–11831.

- Junta de Andalucía Agencia de Vivienda y Rehabilitación de Andalucía. Available online: https://www.juntadeandalucia.es/avra/ (accessed on 22 April 2023).

- EN 17412-1 Building Information Modelling - Level of Information Need - Part 1: Concepts and Principles.; 2021.

- Andalusian Government BCCA. Base de Costes de La Construcción de Andalucía. Clasificación Sistemática de Precios Básicos, Auxiliares y Unitarios; 2017.

- Soust-Verdaguer, B.; Potrč Obrecht, T.; Alaux, N.; Hoxha, E.; R M Saade, M.; Röck, M.; Garcia-Martinez, A.; Llatas, C.; Gómez de Cózar, J.; Passer, A. Using Systematic Building Decomposition for Implementing LCA: The Results of a Comparative Analysis as Part of IEA EBC Annex 72. J. Clean. Prod. 2023, 284. [Google Scholar]

- Ecoinvent. Database. 2019. Available online: https://www.ecoinvent.org/ (accessed on 12 November 2019).

- Hollberg, A.; Lützkendorf, T.; Habert, G. Top-down or bottom-up? – How environmental benchmarks can support the design process. J. Affect. Disord. 2019, 153, 148–157. [Google Scholar] [CrossRef]

- Michalak, J.; Czernik, S.; Marcinek, M.; Michałowski, B. Environmental burdens of External Thermal Insulation Systems. Expanded Polystyrene vs. Mineral Wool: Case Study from Poland. Sustainability 2020, 12, 4532. [Google Scholar] [CrossRef]

- Füchsl, S.; Rheude, F.; Röder, H. Life cycle assessment (LCA) of thermal insulation materials: A critical review. Clean. Mater. 2022, 5. [Google Scholar] [CrossRef]

- Tingley, D.D.; Hathway, A.; Davison, B. An environmental impact comparison of external wall insulation types. J. Affect. Disord. 2015, 85, 182–189. [Google Scholar] [CrossRef]

- Mertens, M.; Slaughter, R. R2pi Project Report; 2019.

- Ren, J. Multi-criteria decision making for the prioritization of energy systems under uncertainties after life cycle sustainability assessment. Sustain. Prod. Consum. 2018, 16, 45–57. [Google Scholar] [CrossRef]

- Hossaini, N.; Reza, B.; Akhtar, S.; Sadiq, R.; Hewage, K. AHP based life cycle sustainability assessment (LCSA) framework: a case study of six storey wood frame and concrete frame buildings in Vancouver. J. Environ. Plan. Manag. 2014, 58, 1217–1241. [Google Scholar] [CrossRef]

| Solution 1 | Solution 2 | Solution 3 | |

|---|---|---|---|

| Type of solution | ETICS | Ventilated façade | Interior insulation |

| U-value | 0.30 W/(m²K) | 0.30 W/(m²K) | 0.30 W/(m²K) |

| Materials for insulation | EPS | EPS | EPS |

| Mineral wool | Mineral wool | Mineral wool |

| Solution and material 1 | Solution and material 2 | Solution and material 3 |

| Double glazing | Double glazing | Double glazing |

| Wood | PCV | Coated Aluminium |

| Solution and material 1 | Solution and material 2 | Solution and material 3 |

|---|---|---|

| Steel | Aluminium | Steel and Aluminum |

| Solution and material 1 |

|---|

| Non-trafficable roof finished in gravel with EPS (thermal insulation) |

| IFC Building Element |

BIM Forum Specifications |

|---|---|

| IfcDoor | LOD 200: Doors are either modelled as a single component or represented with single frame and panel. Approximate unit size, location, and type are provided. |

| IfcRoof | LOD 200: These are defined as generic objects separated by material type with an approximate total thickness represented by a single layer. Designs and locations are still flexible. |

| IfcWall | LOD 200: These collect the size, shape, location, and orientation of the element. They are defined as generic objects separated by material type with an approximate total thickness represented by a single layer. Designs and locations are still flexible. |

| IfcWindow | LOD 200: Windows approximated in terms of location, size, count, and type. Units are either modelled as a single monolithic component or depicted with single frame and glazing. |

| Main material solution | Environmental kg. CO2 eq. |

Economic € |

Social h working hours |

|

|---|---|---|---|---|

| 1 | Façade: ETICS -EPS, Windows: Wood |

5790.01 | 45274.93 | 4263.44 |

| 2 | Façade: ETICS -EPS, Windows: Coated Aluminum |

6094.88 | 59353.22 | 4258.11 |

| 3 | Façade: ETICS -EPS, Windows: PVC |

6743.41 | 57349.72 | 4256.71 |

| Combination of material solution | Environmental | Economic | Social | Total | |

|---|---|---|---|---|---|

| 1 | Façade: ETICS -EPS, Windows: Wood, Main exterior door: Steel, Exterior doors: Aluminium | 0 | 0 | 0 | 0 |

| 2 | Façade: ETICS -EPS, Windows: Wood, Main exterior door: Steel, Exterior doors: Steel | 0.88282628 | -0.88280478 | 0.8825072 | 0.882529 |

| 3 | Façade: ETICS -EPS, Windows: Wood, Main exterior door: Aluminium, Exterior doors: Aluminium | -1.11276295 | 1.11278286 | -1.11305839 | -1.113038 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).