1. Introduction

One of the issues that requires extensive knowledge in many fields is the design of aerospace structures. That process requires fulfilling criteria from many different disciplines [

1,

2], namely aerodynamics, strength of materials, production technology, materials science, aviation law, and finally general aviation knowledge, that cannot be described by simple relationships. This complexity means that there is no established procedure for the initial design and construction of aircraft, the optimal solution is achieved through iterative matching of parameters [

3,

4]. This is an extremely time-consuming process that requires a lot of work. Interpreting the calculation results is only a small part of this process. At the same time, confrontation of effects with design assumptions is required.

In the design activities of aircraft, flexibility is also very important, for example geometric models, the development of which involves constant changes in their structure; thus in the case of conventional methods these changes would force a large amount of work with each one-time change, and in the case of conventional methods, it would be necessary to involve many specialised engineers from various areas responsible for this project. In the case of the alternative, which is engineered based on Knowledge Base, we are dealing with a knowledge base that largely replaces the need for each intervention of specialists and streamlines many processes and activities performed for the concept being developed. A specific example may be parametric models or generative models, which are a direct solution derived from knowledge-based engineering tools, with the help of which it is possible to create models in the CAD environment, whose geometric parameters or design rules describing them are supported by a previously created knowledge base, the record of which was based on the general principles of building such creations, specialist knowledge or previous experience and drawn from them the basis of conclusions. Thanks to this, working with such models allows even less orientated users to create or modify them, because the most important processes and compliance with the necessary rules are carried out using algorithms and formulas referring to the database, and at the same time many of these activities are simplified and their finalisation takes much less time [

5].

2. Materials and Methods

Although design automation methods have been used for a long time, systems that automate the design process – Knowledge-Based Engineering (KBE) - are still not widely used, and if they are used, it is usually in the case of repetitive and labor-intensive development work [

6,

7]. Usually, such a system is not designed ad hoc, but is one of the elements of System Engineering approach [

8], allowing a systemic approach to product development processes and a modern approach to work organization through the application of the Concurrent Engineering [

9] idea. The development of such a system requires laborious preparation covering various stages of the process. The development team used the experience used in knowledge acquisition [

6] and in building Generative Models [

10] used in this case as a guiding element of the design automation system in the development of the current system. Particular attention was paid to the systematic and structural approach to the construction of Generative Models, emphasizing the structure of the model and the data related to the models, providing great flexibility in the application of the models and their reusability. This allows easy integration not only with the analytical methods of design verification presented in this article, but also with the High Fidelity simulation methods commonly used in design [

10] based on Finite Element Methods (FEM), but also with more systematic design methods such as Model-Based Design [

11] developed in aircraft design [

12] as well as Unmanned Aerial Vehicles (UAV) [

13,

14].

The main tasks to be carried out in the creation of such software are:

Development of a user interface with a database supporting analytical calculations in the verification of selected aircraft design features,

Development of a tool for fast and accurate recalculation of parameters of concept aircraft models with an appropriate interface,

Development of a set of procedures with a user interface allowing for verification of structural features,

Integration of design verification methods used in aircraft design with methods for determining structural features in developed generative models,

Integration of the database with the interface with the generative model in the CAD environment,

Performing calculations to check the correct operation of such software for selected cases of designed aircraft.

In addition, it was assumed that the environment in which all work will be carried out will be MS Excel to create a knowledge base with a user interface and ultimately the Siemens NX CAD environment for defining and generating 3D models.

The main result of work on the project was to create generative models allowing to obtain a complete geometric model of a given class of aircraft with the possibility of indicating the appropriate geometry and parameter values forming the entire structure using an appropriate interface based on an appropriately stored database.

Hereby presented works are widely based on master thesis projects of Robert Musik [

5] and Rafał Nalepa [

15]. Thesis titles are ‘Application of autogenerating modeling to aircraft design’ and ‘Software for the automation of the generation of conceptual models of aircraft’ respectively. When formulating the assumptions of the project, one of the established issues was to define a specific class of aircraft for which all calculations will be carried out and a set of knowledge will be made. Thus, gliders became the target class of aircraft, due to the simplicity of the structure they are characterised by, reducing the number of more complex analytical calculations and reducing the number of components for which a set of knowledge was needed. Among such problematic assemblies was, among others, a drive not found as standard in this type of aircraft construction.

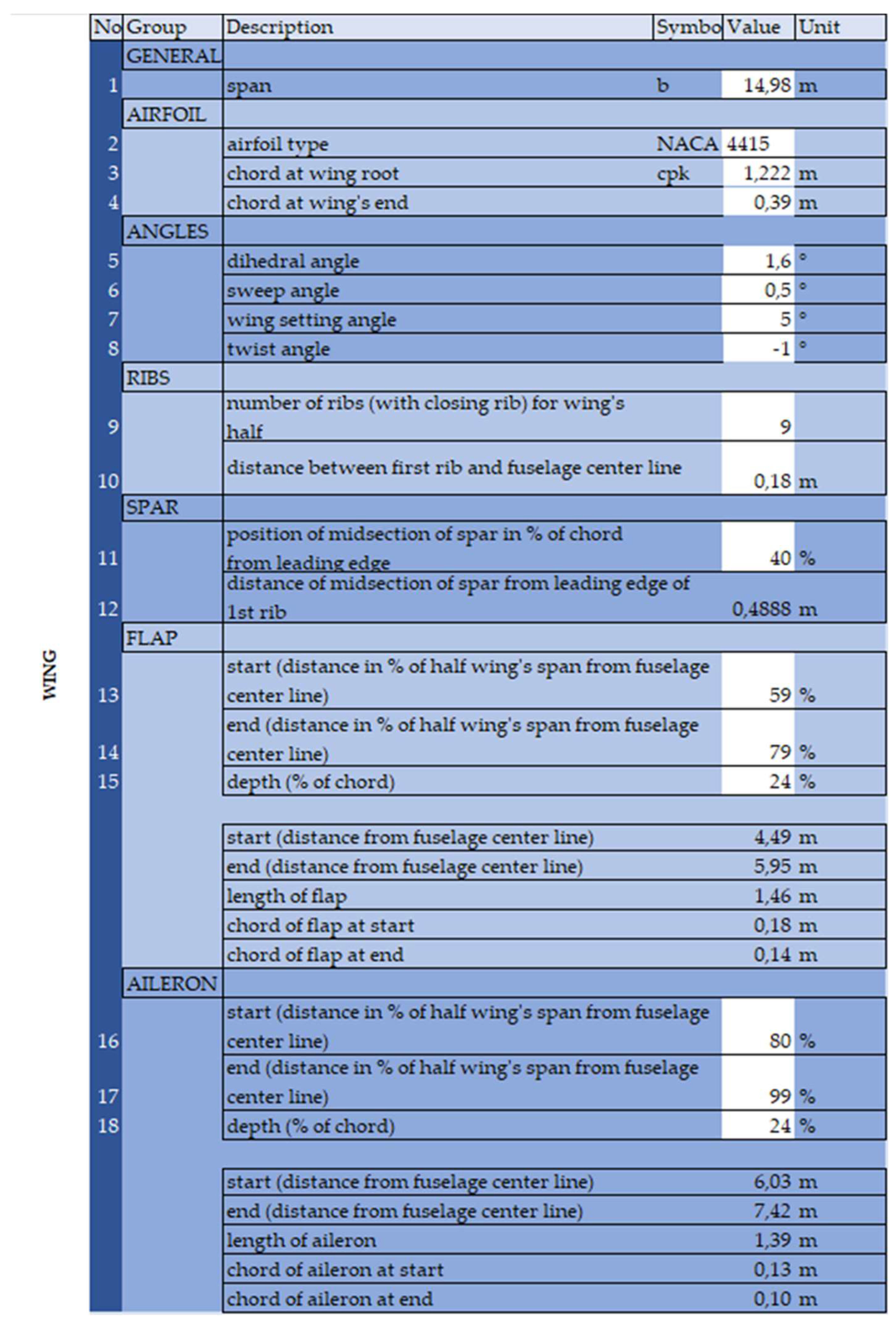

Based on calculations widely described in the literature [

16], spreadsheets were created to calculate glider parameters for use in the generative model. There is a separate part concerning glider geometry, strength parameters, flight parameters and other parameters. The geometry section provides a list of linear and angular dimensions necessary to complete the shape of a glider, along with basic data on the internal structure.

An important issue when creating generative models based on parameters calculated in external programmes is the method of data exchange. It must meet the assumption of automatic data update so that the imported parameters into the model match the parameters calculated in the programme. In the case of the integration of MS Excel spreadsheets and Siemens NX models, this means choosing specific tools and resigning from CAD software functions that do not meet this condition. The use of parameter selection within Siemens NX using the PTS Author interface creation tool was considered, but this possibility was rejected due to the difficulty of exporting and updating parameters in worksheets without using Visual Basic code.

Ultimately, it was decided that the optimal solution would be to completely separate the functions of the spreadsheets and the model, i.e. the spreadsheets would be responsible for preparing the relevant data, including validation, interface, calculation of dependent parameters, and the model in NX would only be a graphical representation of these data. Interference with the model will only be possible by changing the parameters in the sheets. This ensures that the data are always consistent and there is no need to compare the Siemens NX data with the data in the Excel workbook.

The chosen approach implies certain requirements for data exchange. The NX function is characterised by the fact that when you change parameters in a.xlsx file, you must save the workbook and then refresh the external connections in Siemens NX (Tools > Expressions > Update for External Change tab). In the NX version used, it is not possible to easily automate this activity.

Parameters from a workbook are read based on the functions available in NX: ug_excel_read, ug_cell_read, and ug_read_list. Some parameter definitions are not identical in the sheets and the CAD model, so some of them are recalculated in the NX 'expressions' module. This is especially true for the shape of the profile, which is entered based on equations - as opposed to the shape estimated in the worksheet using a set of points.

Simplifications in the initial modelling mean that certain elements – in particular the control surfaces – may overlap when checking the range of motion. This is due to the adopted philosophy of creating a model, where each of the elements is created separately without considering the influence of shapes of other elements.

In the current version of the software, the NACA 4-digit profile generator is based on equations that define the profile shape. They are compatible with [RN8]. From the name entered in the table, individual digits corresponding to the profile parameters are read, and on this basis the appropriate coefficients are entered into the equations.

The assembly file that is the output model contains the following part files:

In addition to these parts, the assembly contains mirrored parts of the wing half, aileron, flap, half horizontal stabilizer, and elevator. All these elements are connected by two types of connections – hinge type and anchor type. Hinge connections are applicable to all control surfaces. For each such connection, an axis of rotation and a point of contact shall be defined. The remaining constraints are based on local coordinate systems. Each model is built in such a way that its position is calculated relative to the point located on the extension of the leading edge of the wing on the longitudinal axis of the airframe. The constraints of individual elements connect the corresponding planes of the coordinate systems.

The coordinate system adopted in the calculation is fundamentally different from the coordinate system adopted in the CAD model. In excel sheets, geometries are considered in a two-dimensional coordinate system on section planes. The x-axis is the longitudinal axis of the airframe, while the y-axis is the axis perpendicular to the x-axis lying in the plane of the currently considered cross section.

Models of individual airframe elements have a common Cartesian coordinate system. The plane ZX of this system is the plane of symmetry of the aircraft, the plane YZ is the vertical plane tangent to the ZX plane passing through the point of intersection of the leading edge with the x-axis, and the plane XY is the horizontal plane passing through this point (

Figure 1).

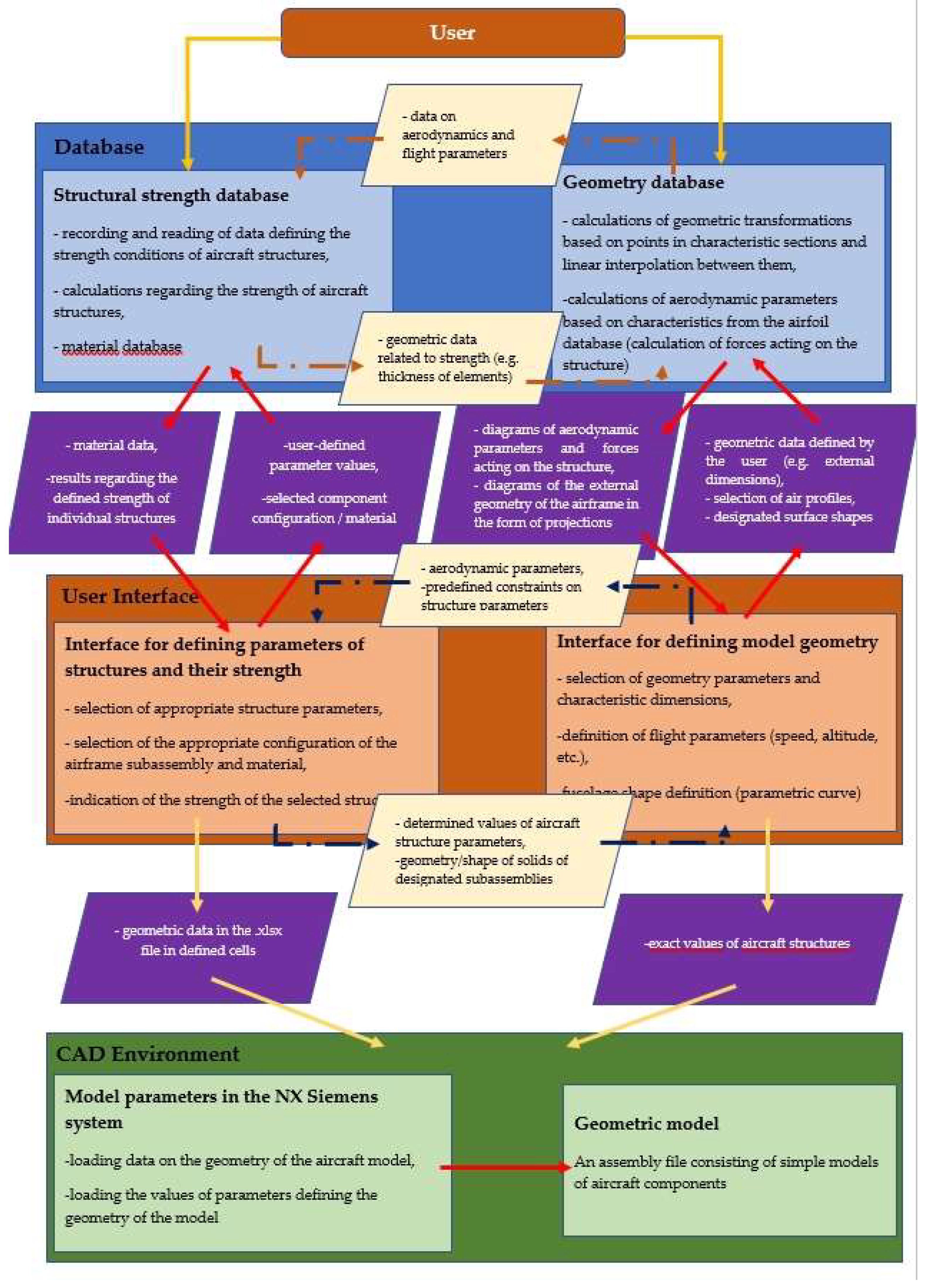

3. Software structure

The designed software consists of a modular workbook containing spreadsheets responsible for individual fields of aircraft construction and generative models created in Siemens NX program (

Figure 2).

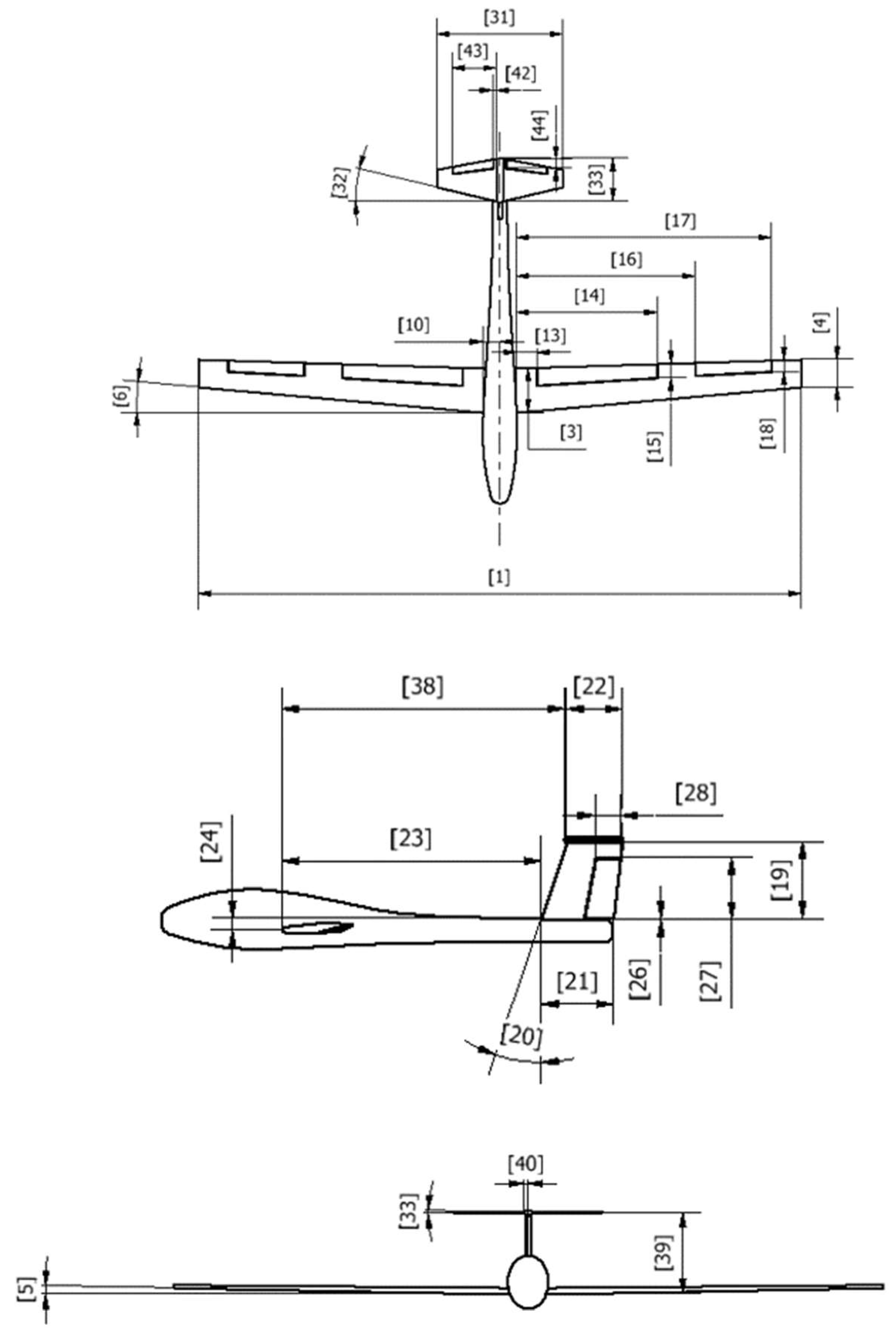

The geometry of the airframe is determined in the "Geometry interface" tab. It contains a list of geometrical parameters necessary for a complete description of the structure. In order to facilitate the identification of geometric parameters, schematic drawings with marked parameter identification numbers were created (

Figure 3). Each parameter has a unit that is used in the calculation and reflected in the model.

Aerodynamic parameters are used only for calculations within an Excel workbook. The situation is different in the case of the geometry of the airfoil. The representation elements of the profile shape are coordinates from a few to several dozen points in a two-dimensional form. They are stored in the .csv file. While Excel calculations are based on the interpolation of the points that define the profile, shapes based on airfoils in Siemens NX are defined by the equations of coordinates. For this reason, the format of the representation of points in the source file and the model is incompatible. The trade-off between simplicity: transforming the shape described by imported points to adjust the geometry, calculating dependent geometries (such as caisson radius, surface area, and spar height), and preparing equations for import by the generative model, and the complexity of formulas and the number of dependencies led to several restrictions on entering points’ coordinates into the worksheet.

After reading data from the xlsx file to create geometry in the model, elements are built by defining characteristic cross-sections. For all elements except the fuselage, the geometry is considered at the beginning and at the end of the element. The next step is to connect the cross-sections using linear interpolation, and in the case of the fuselage using guide curves.

In the case of a wing, a curve is created on a two-dimensional plane using the equations that define the airfoil. This two-dimensional representation is positioned appropriately in space using the "y" coordinate of the model - Wing buttock line (WBL). After the appropriate transformation of the generator's equations using the "law curve" tool, a curve is created, the values of which "x" and "z" are described using the transformed equations. For the root of the wing, the value of the coordinate "y" is equal to the distance of the first rib from the axis of the aircraft (WBL =0), while the coordinate "y" for the wing tip is equal to half the wingspan.

The skin of the wing half is formed as a surface extension through curves. Then this surface is thickened inwards by the thickness defined in the Excel sheets. This is one of the solids visible in the model.

Subsequent solids are the volumes of the ribs. They are created at equal distances in the number defined in the workbook. All of them are of equal thickness, and their outer outline is defined by the inner outline of the wing surface cross-section.

The next solid created is the spar. It is formed similarly to the plating – it is a swipe through two curves at the ends of the half of wing. The width and thickness of the shelves as well as the thickness of the web is defined by the user in spreadsheets, while the height of the spar is calculated in Excel sheets. The lack of differentiation in the thickness of the wing surface and the spacing of the ribs are a consequence of the simplification assumptions at this stage of design.

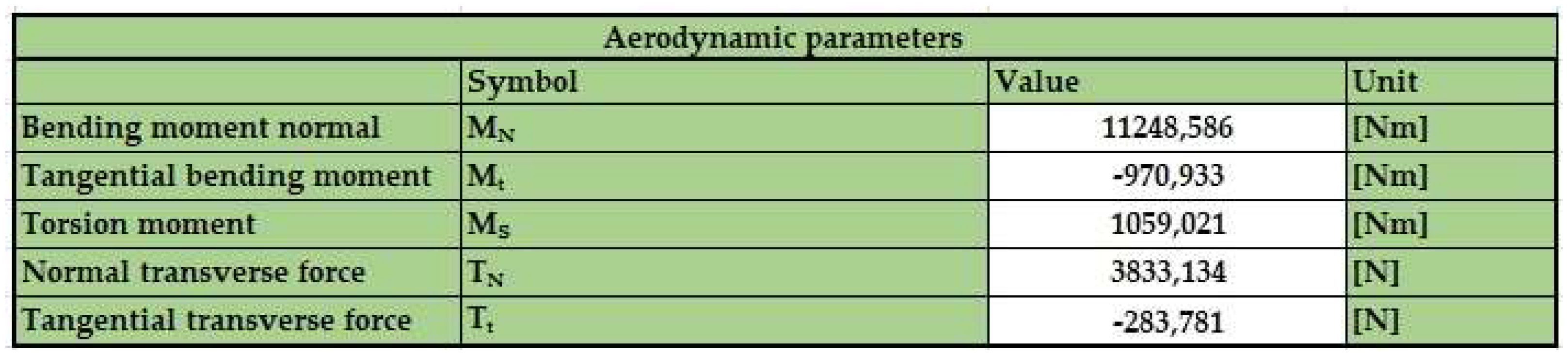

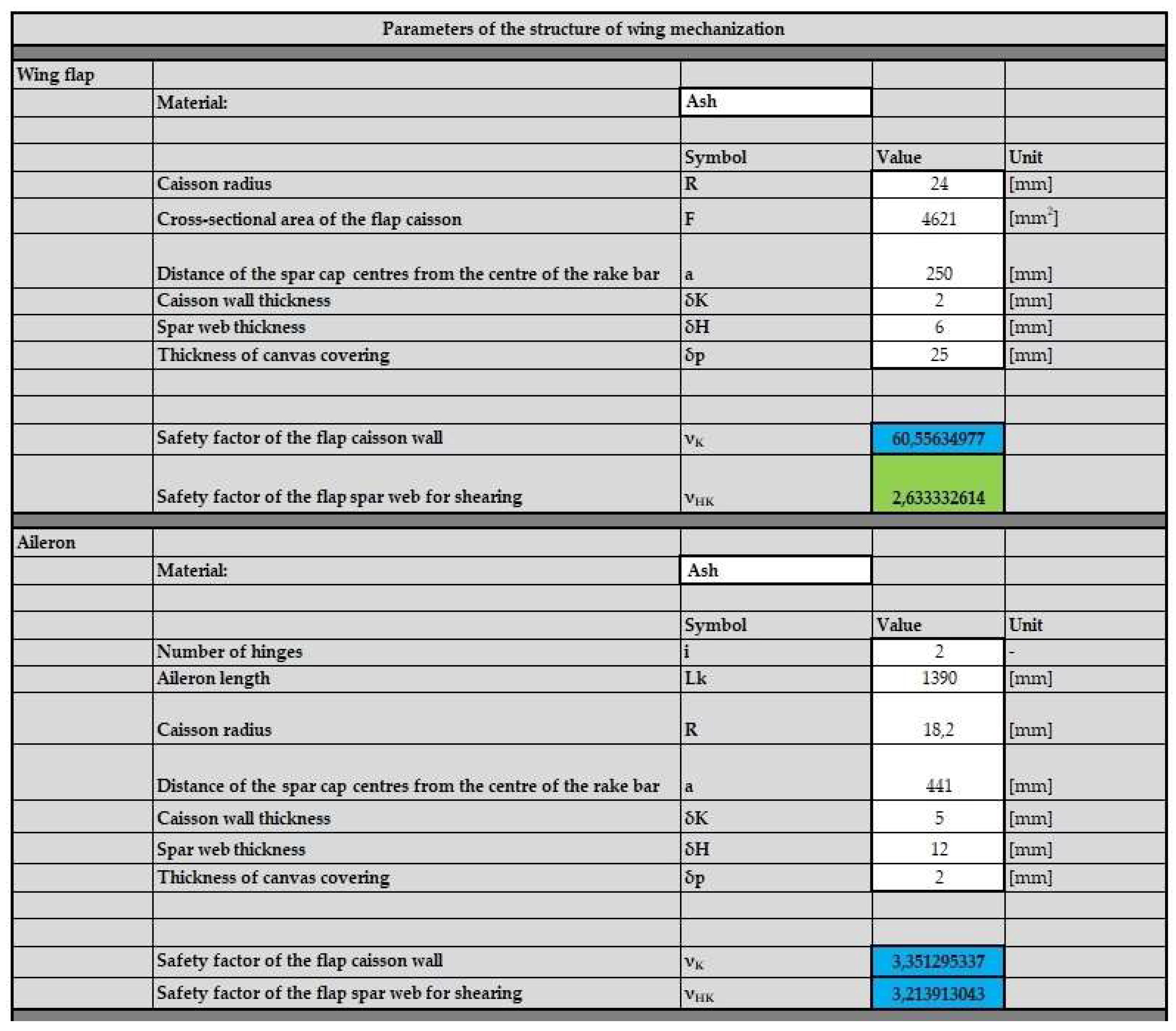

In the case of the strength of user-defined parameters of individual structures, the whole procedure is an iterative method consisting in adjusting each of the values until the indicators regarding the safety factor indicate the correctness of the selection of each of them.

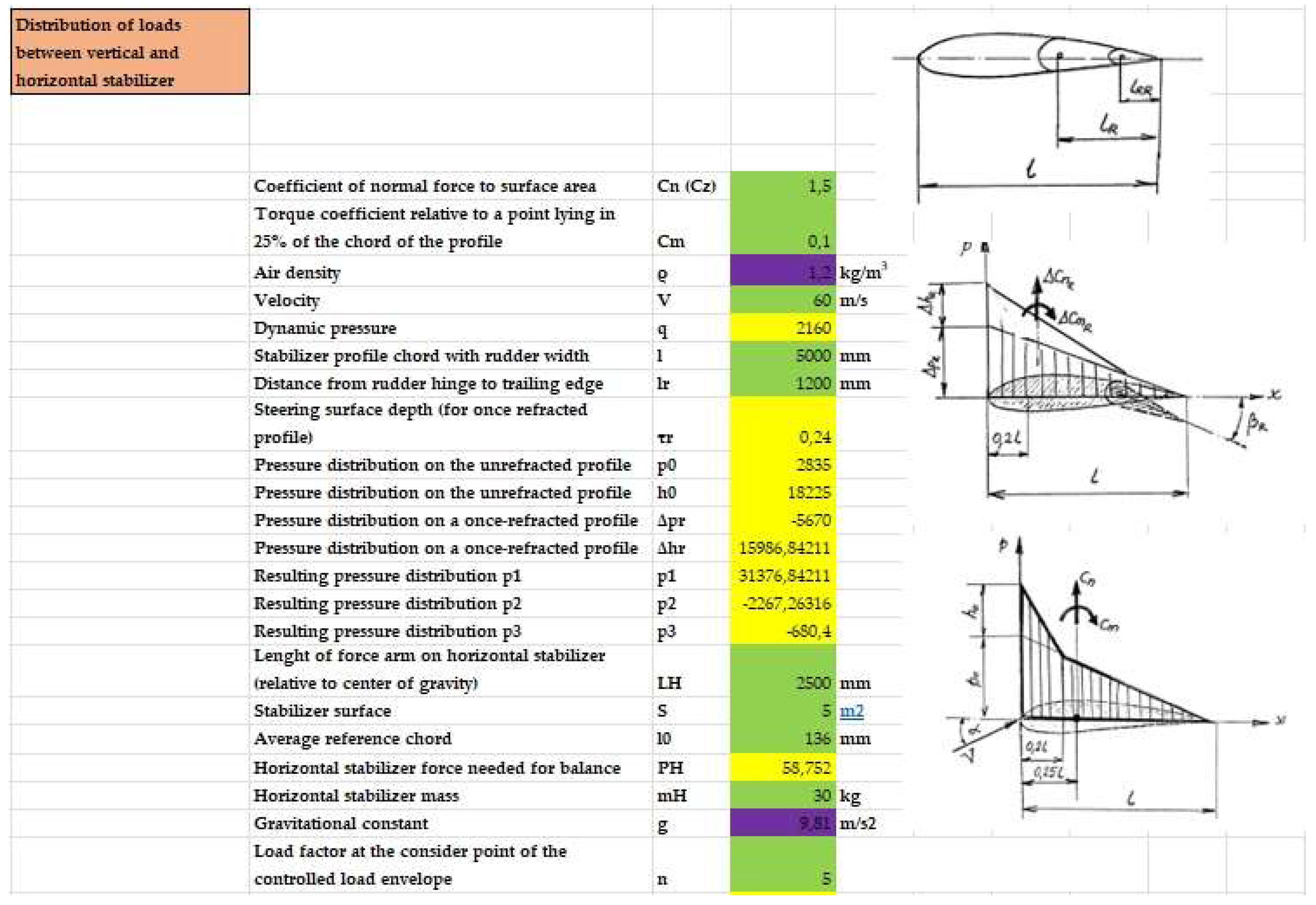

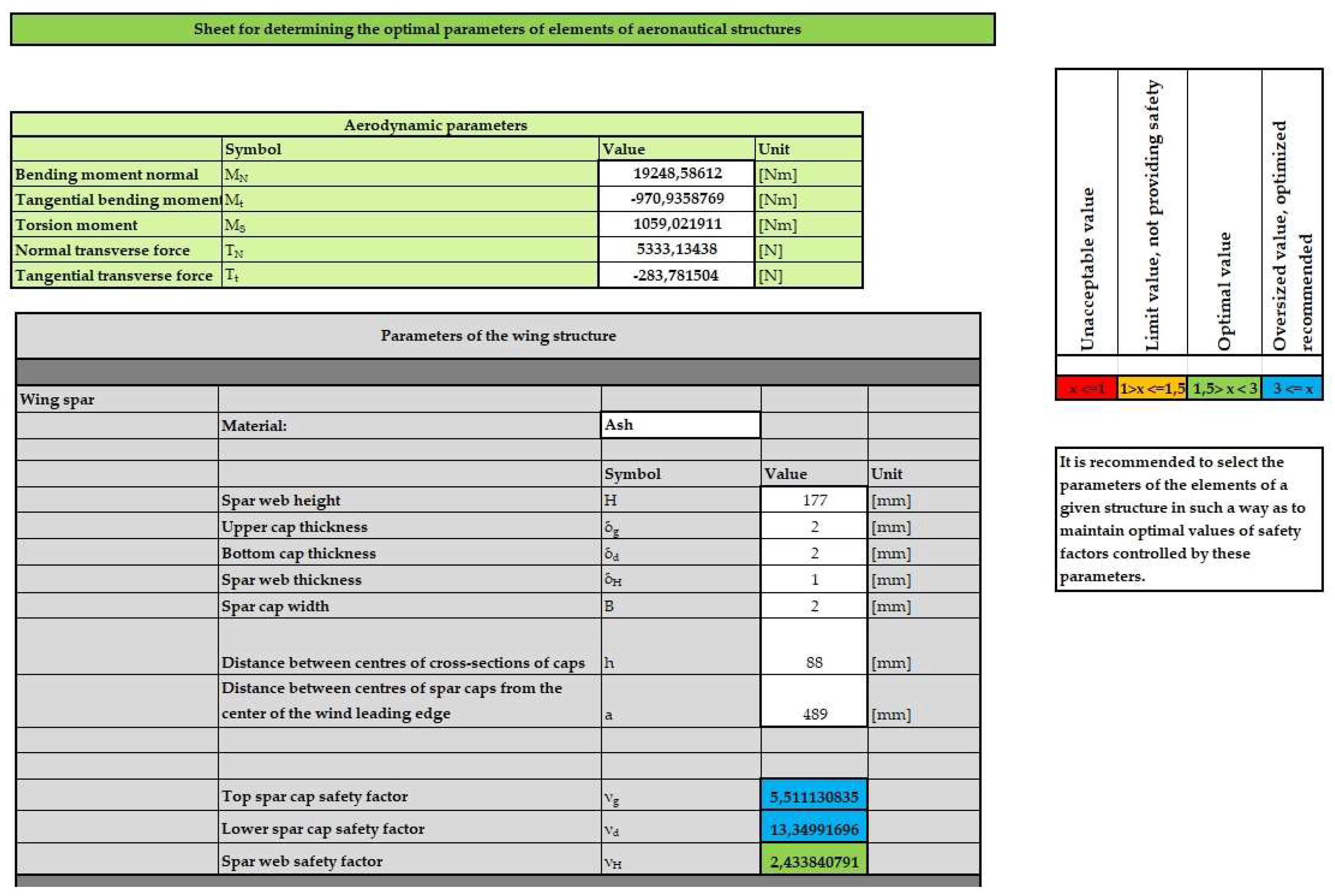

All calculations are carried out automatically in the Excel sheet tab dedicated to the given aircraft component on the basis of analytical methods (

Figure 4). This is where the formulas are located and the necessary links between them and the user interface are set, so that when the user enters a given parameter, it is automatically loaded and the strength of the component is calculated on its basis, taking into account predefined conditions containing aerodynamic parameters and aircraft flight conditions.

The wing is divided into individual sections containing described values, which contain constant values, predefined values, calculation quantities and resulting values from dependencies stored in a given sheet. Macro functions and actions available in this environment are used to perform operations. All calculations and links between them to give specific results are based on the literature on structural calculations for gliders [

16].

The results of the calculations boil down to presenting them in the form of a safety factor, which is to represent the multiplicity with which the structure meets the strength stress under the adopted parameters. The user is informed by displaying its exact value and color marking indicating the correct or inappropriate selection of one of the parameters (

Figure 5).

The value of the safety factor is influenced not only by the specific parameters stored, but also by the selected options from the drop-down lists for specific configurations of aircraft assemblies and the materials used for their construction, which directly affect the method of calculation carried out, and thus their results. Therefore, the user must iteratively select such quantities so that finally each indicated safety factor is within the optimal range in order to continue reading it in the Siemens NX environment.

When the selection of all options and parameters is completed, it is possible to save all operations and read them directly in the parameterization window of the Siemens NX system by updating all model references to the Excel worksheet cells containing the mentioned parameter values of all aircraft components.

The software consists of spreadsheets and a CAD model stored in one folder. After you enter the data and verify it in your spreadsheet, complete the work accordingly, open the model file, and update the CAD model parameters.

At this stage, the verification of the correctness of the data boils down to entering information about typical values and warnings about exceeding them – the acceptable range of parameters is much larger than recommended, hence there are no restrictions on input.

An aerodynamic data module is present in the interface. Such data also includes general flight and aircraft parameters that significantly affect performance – such as mass, flight velocity or planned flight altitude.

The strength calculation module, which has been prepared, is used to adjust the geometry to the loads occurring in flight. Entering data into this module occurs in the "Interface" tab.

The user interface consists of parameter tables with descriptions. Some parameters have been limited according to the capabilities of the software. The white fields are filled in by the user (

Figure 6).

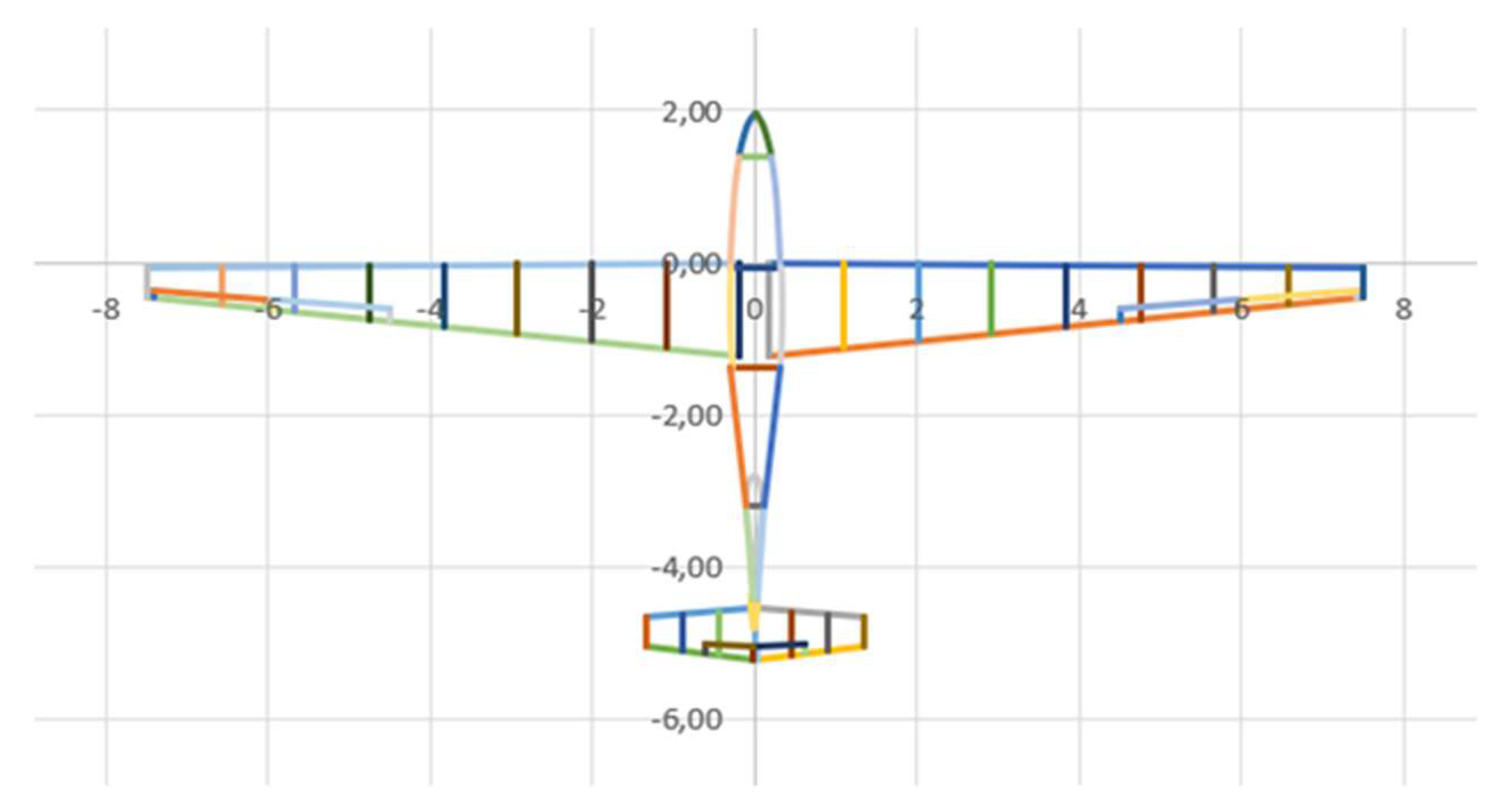

Working with the spreadsheet begins with entering the geometric parameters and basic flight mission data expected by the user. At this stage, it is possible to verify the correctness of the data by graphs imitating the shape of the airframe in the model (

Figure 7).

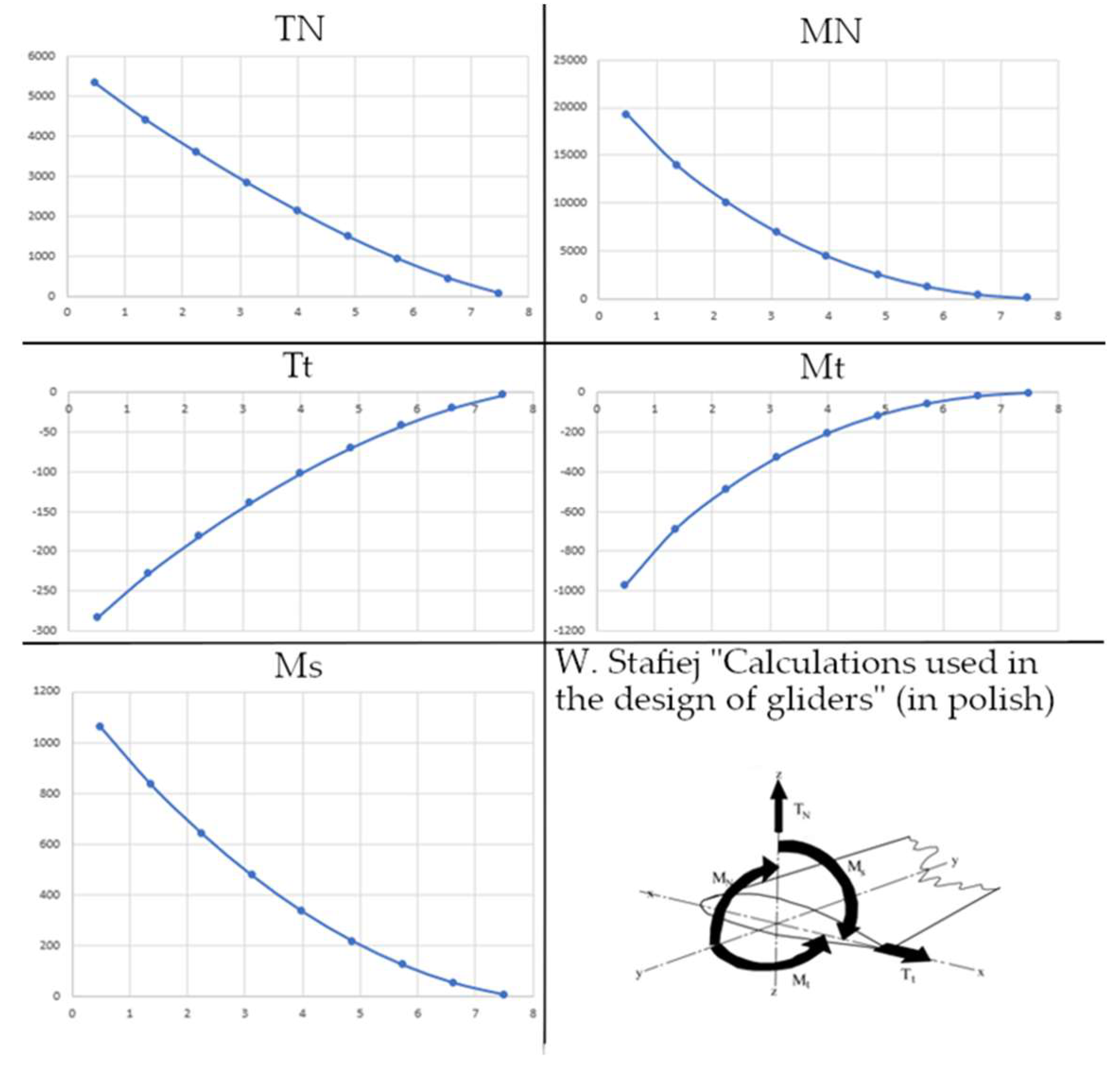

The next step is to match the geometrical parameters to the aerodynamic requirements. Spreadsheets automatically recalculate the parameters when the input changes. The wing is divided into parts, the boundaries of which are in the middle of the adjacent ribs. For each part, the aerodynamic parameters are calculated, and then they are folded accordingly into the resulting parameters. The wing half can be divided into up to 20 parts.

Aerodynamic parameters are checked by graphs and numerical data presented in tables. The obtained geometrical and aerodynamic parameters are used to determine the forces acting on individual elements of the airframe (

Figure 8). Based on these forces, geometric parameters related to the strength of the structure are selected.

The main purpose and method of operation of the module for strength calculation of individual airframe structures was to process the selected quantities by the user and inform as part of the calculations about the strength of each of them and the extent to which they fulfil the basic strength conditions.

The spreadsheet consists of a part for entering or reading data on the aerodynamic parameters of the airframe (

Figure 9), thanks to which it is possible to define the exact values of aerodynamic forces and moments of force acting on a given aircraft structure, and a part in which the user manually defines the physical values of each of the aircraft assemblies where he is automatically informed about the correctness of the defined data (

Figure 10).

Strength verification begins with the calculation of all individual aerodynamic forces for the aircraft assembly under consideration. Then, using drop-down lists, the user selects a specific configuration of the assembly (e.g., the layout of horizontal and vertical stabilizers), as well as the individual construction materials available for the described structures.

Once each of these quantities has been determined, the user proceeds directly to the determination of the values defining the individual elements of the airframe, each of which has a direct impact on the calculated structural strength, which is expressed in a safety factor, informing the user of its range and the degree to which it provides strength for that particular aircraft structure. Strength calculations are carried out directly through a database sheet on all strength data and relationships between quantities.

The selection of each value must be completed so that each safety factor displayed in the interface window indicates, as described, a sufficiently high strength of each structure.

After verification that the geometric, aerodynamic, and strength parameters are correct, it is mandatory to save the spreadsheet. Generative models in Siemens NX are updated to a saved set of parameters by manually forcing link updates - automatic update of parameters functionality is not supported in the current NX release.

The model generated by the software should be exported to step format with the selected option ‘export only visible parts’ and then corrected and detailed or used as a template for the detailed design. This is a task belonging to the next stage of the design process – it is not included in the developed software.

3.1. Database

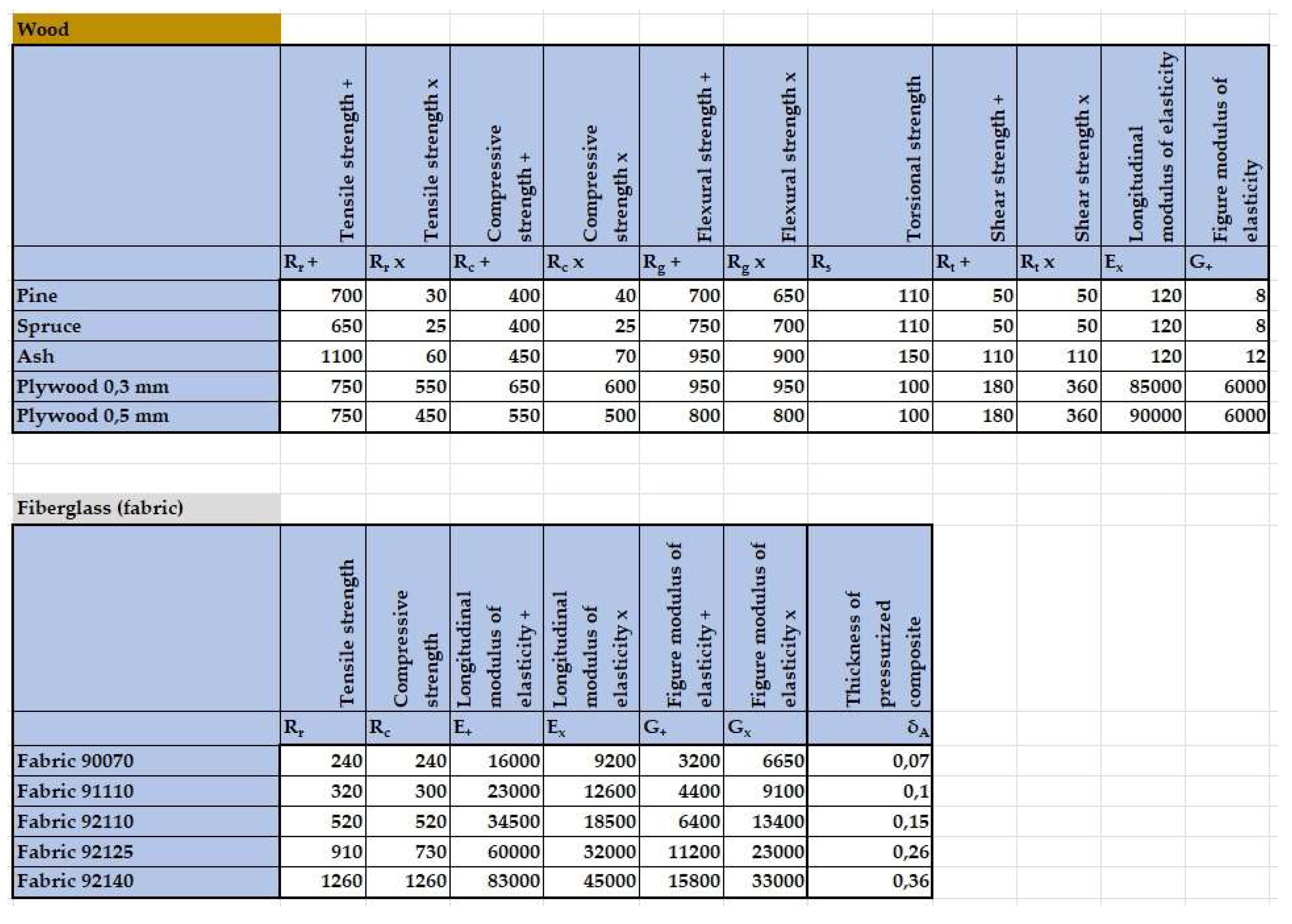

As part of the building the knowledge base, it was necessary to specify which of the other components would be developed within the scope of the project, thus it was determined that inside the database structure all information and verification calculations regarding such structures as: fuselage, wing mechanization elements, rudders and elevators, along with load, would be collected and placed. In addition to the selection of the list of a given component, which is the main component of the airframe, it was also decided to enable the user to select various configurations of the indicated structures, for which the knowledge base was additionally completed. Of these, the choice can be made in the type of construction, e.g. fuselage, deciding to choose a monocoque, semimonocoque, composite or wooden structure, etc. using the created databases of construction materials (

Figure 11).

The goal set in the preparation of the database was to obtain, in the final effect, such a set of information with the use of which it will be possible to perform verification calculations for selected aviation structures in terms of their fulfilling requirements of given conditions. This result was achieved primarily thanks to the use of appropriate sources of knowledge in this field of aviation technology and adapting their content to the needs of the developed software. As a result of all activities, a sheet containing data and calculations was created, by means of which they semi-automatically give the opportunity to define specific parameters of glider/aircraft components and enable the transfer of information on the extent to which they meet the specified strength conditions. The content of the document consists of tabs dedicated to such assemblies as:

In addition, there are tabs defining material constants used for strength calculations, as well as determining the magnitudes of forces and moments resulting from aerodynamic phenomena acting on the elements of the aircraft. Activities were initiated to create a knowledge base focused on a clear record of all dependencies in the sheet, appropriate markings of features to be defined by the user, automatically calculated quantities, and those that should be read from other spreadsheet tabs. Then, where necessary, mutual relations between sheet cells were prepared, using, among others, macro tools and functions available in MS Excel. At the very end, the operation of the resulting system was checked.

Initially, attempts were made to implement airfoil data in a form available directly in libraries – a file in csv format separated by commas. This would allow to enter any profile available in the external database. However, the available files turned out to be incompatible for several reasons.

On the one hand, the aerodynamic characteristics are generated exclusively for one Reynolds number (Re). On the other hand, the presented software calculates the Reynolds number and selects the appropriate characteristic depending on the parameters of the air flow. Using ready-made files available in profile libraries would entail the need to store several files in a folder or multiple sheets in a file for one profile. Bearing in mind that a sufficiently large profile library would require several times more files/sheets, such a solution was rejected as ineffective.

3.2. Interface

In the case of the user interface, all activities consisted primarily in the appropriate extension of the scope of database content support to allow parameters to be determined for all the aircraft structures considered. In addition, drop-down lists were implemented, which were to enable quick selection of the configuration of a given airframe assembly and selection of engineering material. In addition, in addition to the functions of the interface and the data contained in it, its appropriate colors have been selected and the entire workspace has been extracted so that it does not penetrate with the workbook background along with the filling and border of empty cells. The color scheme of all elements was based on the principles resulting from the perception and association of colors by man, thus the following colors were used for given functions:

Wing white – empty areas and free spaces requiring editing,

Red – communication about critical situations, communication about the error occurring,

Yellow – warning, place requiring the user's attention,

Green – message about the optimal choice,

Blue color – a color indicating a large stock in terms of determined parameters,

Light green – area concerning aerodynamic parameters, forces and moments,

Gray color – fill the interface canvas.

The main assumption of the interface is that there will be rows in which the designer will enter the values of geometric quantities assumed by him earlier, which after their introduction will be analyzed by passing them through the appropriate mathematical expressions and the feedback will be the return of safety factors of given components of the wing structure indicating the appropriate or inappropriate selection of one of the parameters.

Building appropriate tables in the interface tab made it possible to create further relationships of the cells used for entering the input data and cells used to return information in the form of safety factors with the appropriate cells contained in the tab with the calculation structure of strength parameters. Thus, the communication between the tabs was shaped, which allowed for proper data exchange between them.

4. Results

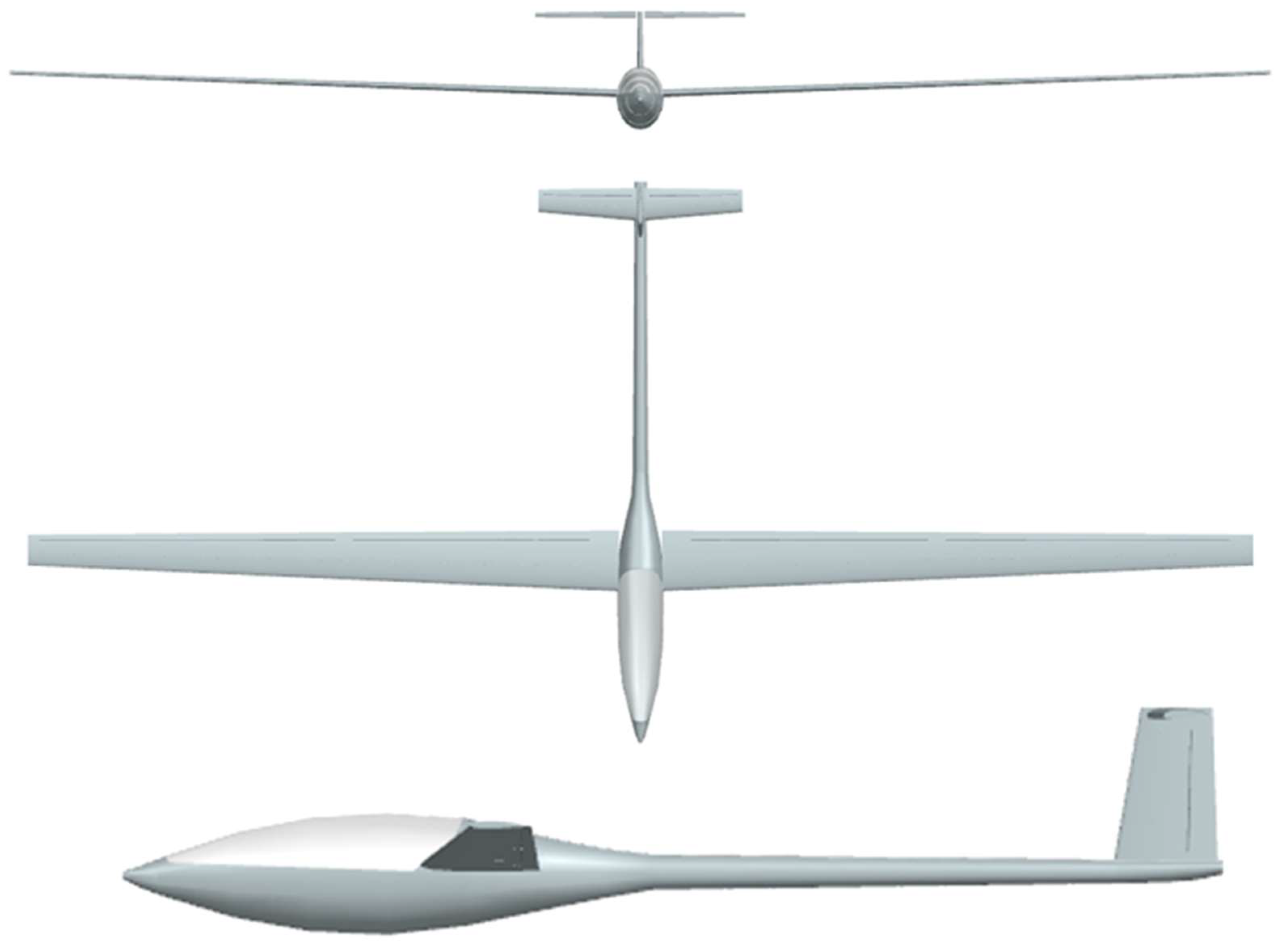

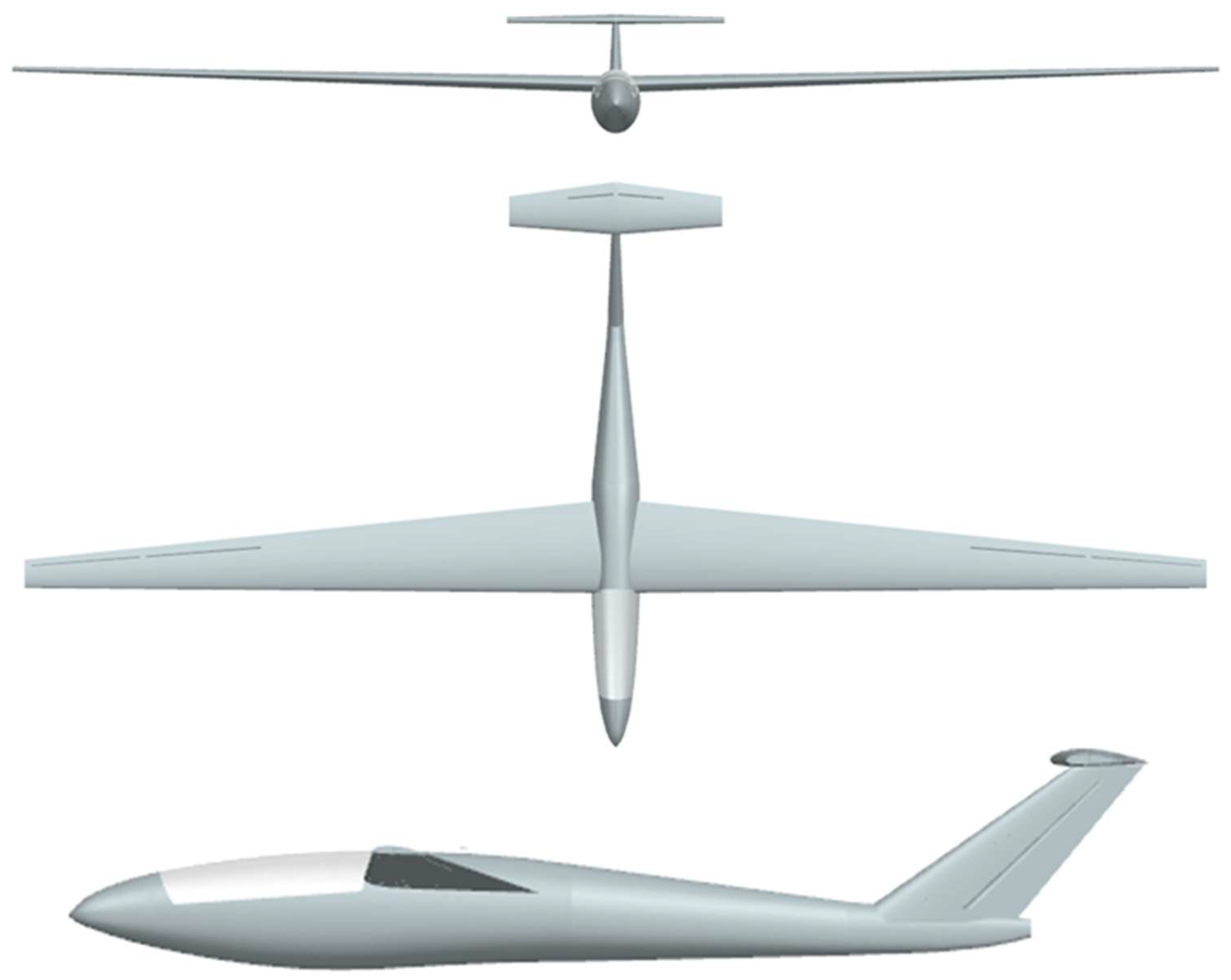

Checking the correctness of the models was carried out by modeling digital twins of production gliders, specifically the SZD-56-2 Diana 2 [

18] and SZD-32 Foka 5 [

19].

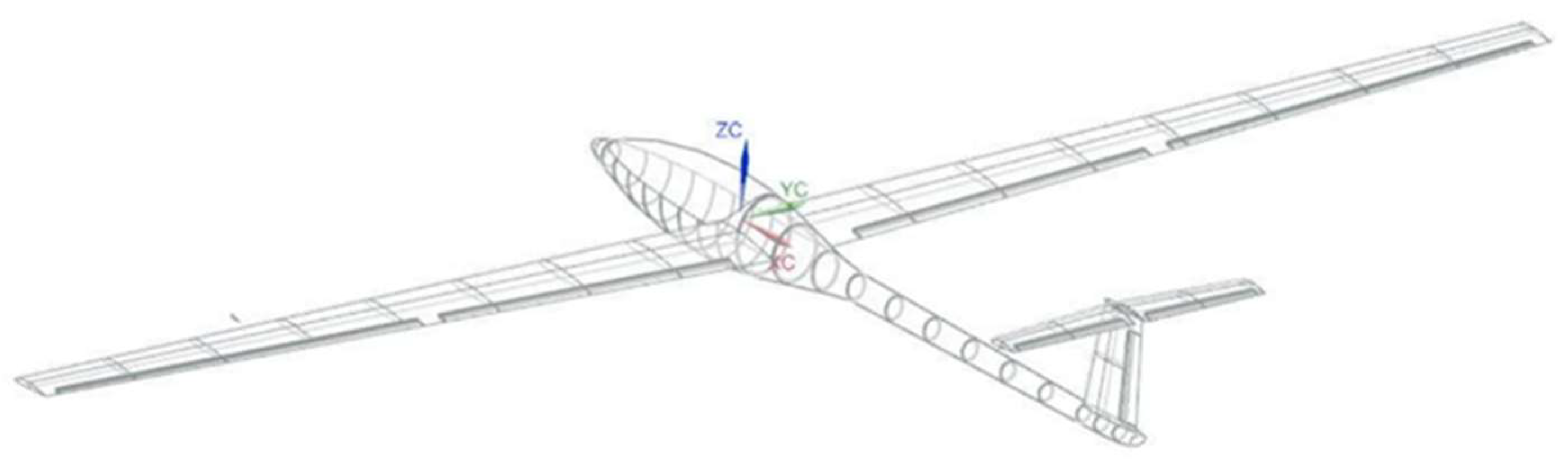

The Diana 2 glider is a medium-wing T-tail glider, which is an extremely modern composite construction with a variable profile wing. The manufacturer provides basic dimensions, such as a span of 15 m and a fuselage length of 6.88 m.

The complexity of modern designs resulted in great simplification of the parameters of the Diana 2 glider model. For this reason, an attempt was also made to reproduce the historical glider, SZD-32 Foka 5. The first flight occurred in 1966, and work on it began in the 50s of the twentieth century. It is a high-wing, wooden glider with a T-tail.

On the basis of the available glider views and published parameters all necessary dimensions to create an accurate representation of the geometry were estimated.

Using the software, glider models were created representing Diana 2 (

Figure 12) and Foka 5 (

Figure 13):

Due to the complexity of the construction, the necessary simplifications were made when transferring the shape of the Diana 2 glider to the software. The outline of the wing was changed to trapezoidal and other airfoils were used to create wing and stabilizer cross-sections. However, the shape of the fuselage was preserved. On the other hand, when modelling the Foka 5 glider, thanks to its simple design, shape simplifications are only minimal.

The geometrical parameters are practically identical to the design of Diana 2. The stall speed varies greatly – it is almost 1.6 times greater. This is probably due to the adopted simplifications of the wing. Diana 2 has an optimized wing profile by Prof. Kubryński – significantly modified along the wingspan, using advanced analyses. Comparing the stall speed of the resulting structure with Diana 1, with similar dimensions and less advanced design, the difference is no longer so high. In this case, it is overstated by 10 km/h, i.e., 1.12 times.

In the case of a historical glider with a simpler design, it was possible to reproduce both the shape and aerodynamic parameters, because the wing of Foka 5 was built in large part on the NACA4415 profile. After entering the new profile into the database, results consistent with the published flight parameters of the structure were obtained. The difference in calculations for stall speed was 1.8 km/h (3%), while the minimum drag speed of the wing was identical to the published one (

Table 1).

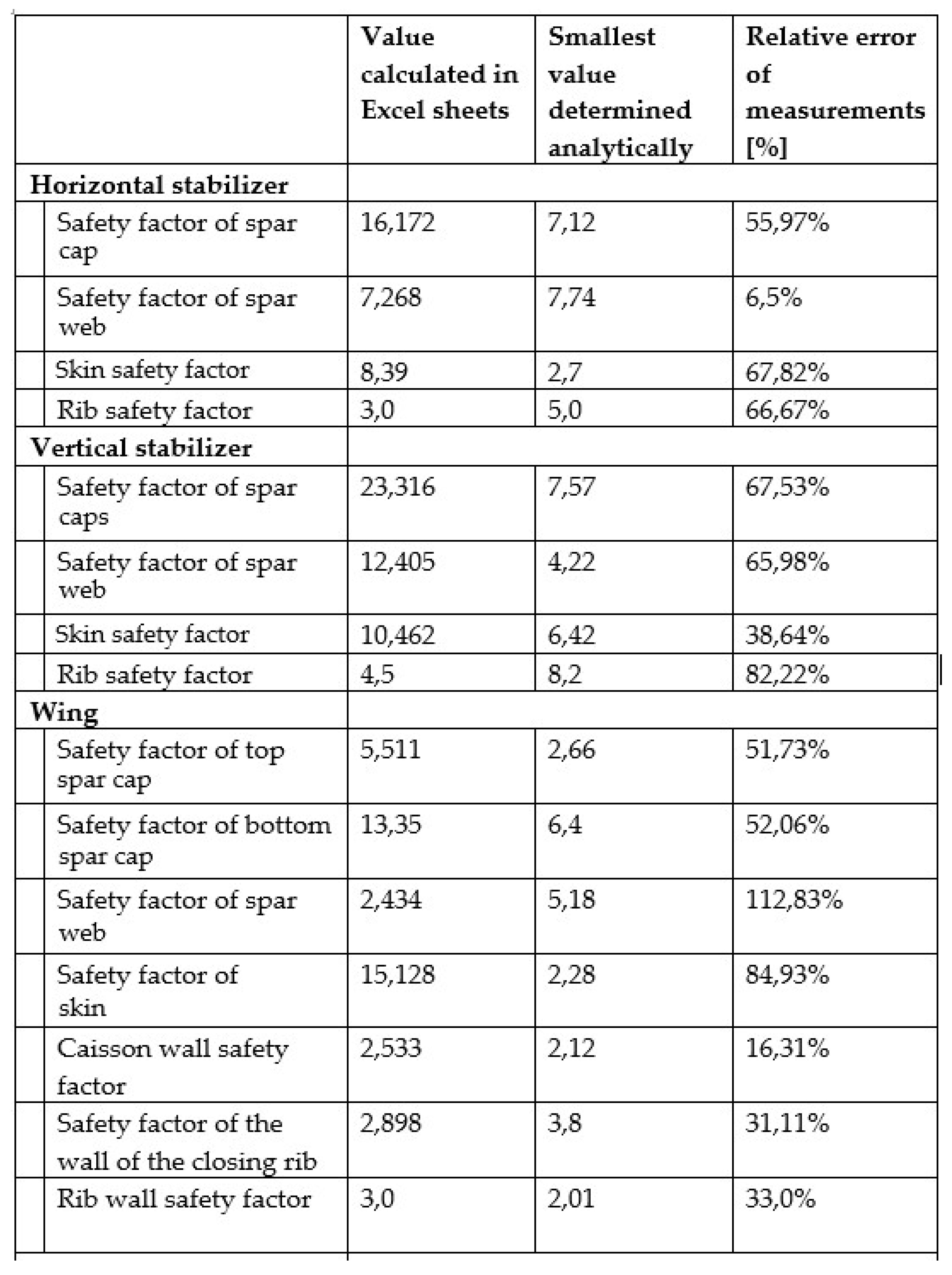

4.1. Strenght verification

The finalization of the software preparation process, thanks to which it is possible to determine and verify the structural features of aircraft structures, in addition to checking the correctness of the architecture itself, requires the evaluation of the results obtained using it. This task was decided to be accomplished through strength analysis applied to geometric models of given aircraft assemblies along with calculated quantities defining their exact parameters. For this purpose, the finite element method FEM was chosen, which was used using the appropriate module available in the Autodesk Inventor environment.

The most important assumption was to verify the calculated data defining the selected parameters of a given aircraft assembly using an Excel spreadsheet. Defining the following parameters using the functions contained in the sheet was associated with the indication of safety factors for such a structure, taking into account further elements such as:

The magnitude of these safety factors, depending on the predetermined range in which they were located, determined how many times the calculated stresses acting on the structure are smaller than the previously determined hazardous stress. Thanks to this, it was possible to select all sizes of the considered component, guaranteeing the consistency of the entire structure and its strength during the action of forces formulated with the help of a sheet.

The test was carried out on selected components separated from the aircraft. This procedure was primarily aimed at shortening the time needed for strength analysis and resulted from the lack of any representation of structural nodes between the modeled compositions. In accordance with the above, the following components were to be checked:

Wing flap,

Wing aileron,

Horizontal stabilizer.

At this stage, a decision was also made to simplify some models containing, among others, cutouts enabling ailerons or rudders to be placed in them. The decision was dictated primarily by the fact that at the stage of conception these elements do not have precise values defining their strength and calculations carried out with the use of the created software did not take them into account at this stage. Accordingly, their application in models subjected to strength analysis would result in such a structure not exhibiting the properties presented by the created knowledge base.

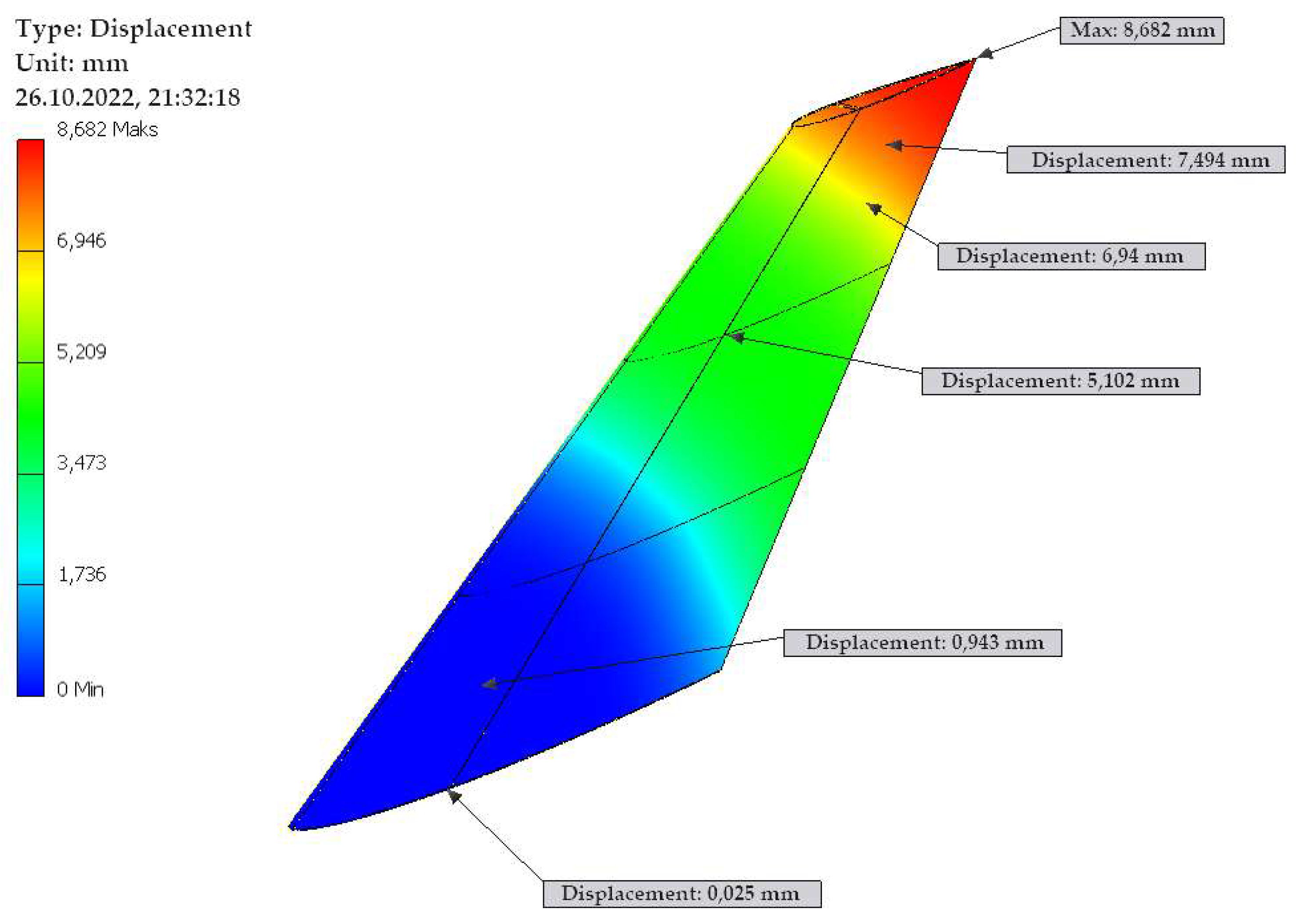

Figure 14.

Displacement distribution on the surface of the vertical stabilizer [

5].

Figure 14.

Displacement distribution on the surface of the vertical stabilizer [

5].

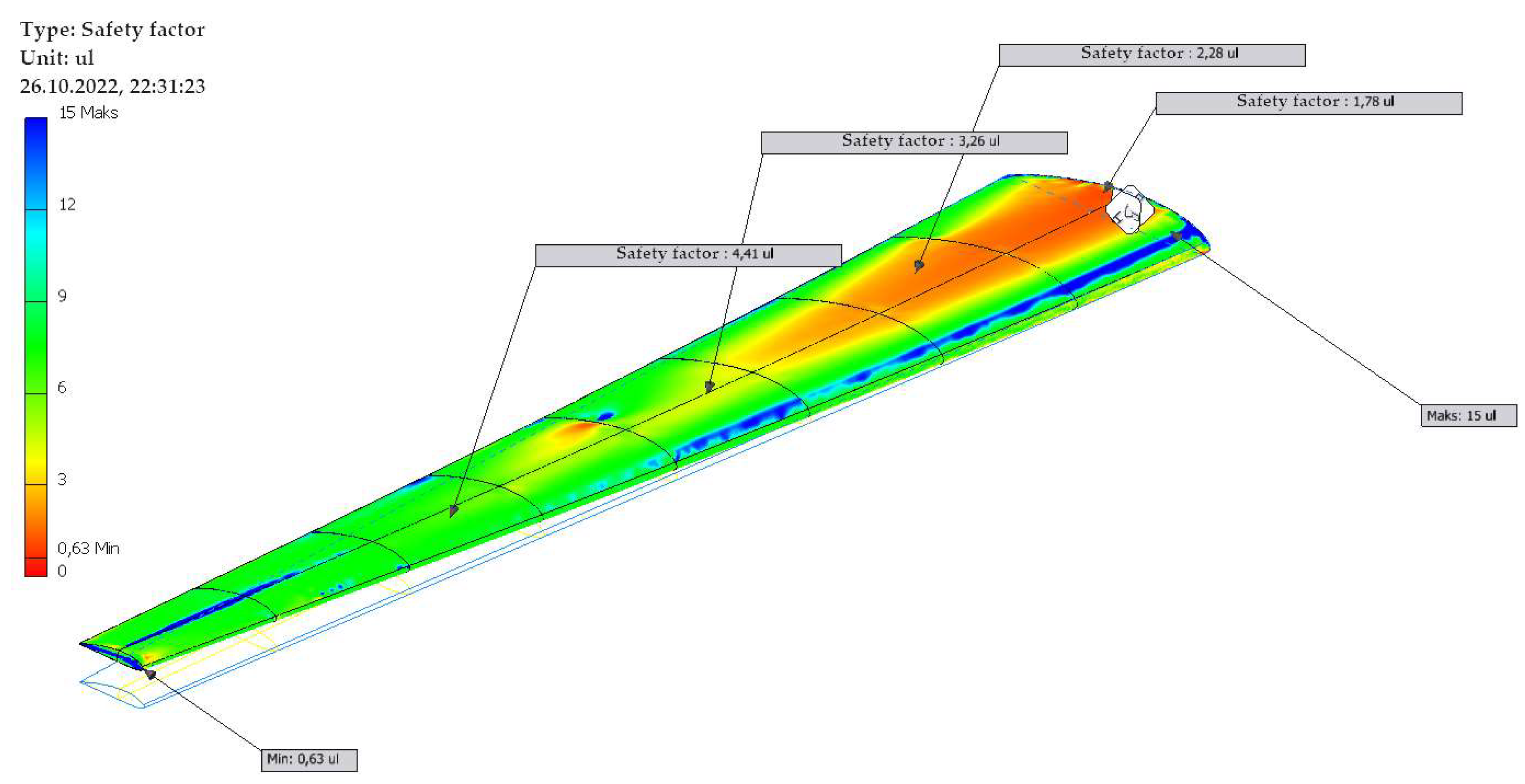

Figure 15.

Distribution of the safety factor on the glider wing surface [

5].

Figure 15.

Distribution of the safety factor on the glider wing surface [

5].

As part of the study, the relevant geometrical parameters of subsequent glider components were defined, for which the safety factor was to be 2.5 or more. On their basis, CAD models were generated, which were subjected to strength analysis. The indications of individual simulation results showed some errors resulting from incorrect interpretation of the program regarding contacts at the boundaries of the designated central surfaces. Despite these inconsistencies, it was possible to read the necessary values on the basis of other data and determine the degree of correctness of the selected parameters. A comparison of the results is shown in

Figure 16.

Almost all elements of the analyzed glider components met the assumption of a minimum value of the safety factor. On the basis of the compilation of the results determined with the help of spreadsheets and the values obtained as a result of the strength analysis, some deviations between them were noted. However, it should be noted that the basic values of the safety factor assumed for them were close to 2,5 and taking into account a certain tolerance related to the measurement error resulting from the strength analysis carried out, it can be assumed that these results meet the expectations to a sufficient extent. The remaining results fully met the assumptions regarding the level of the safety factor. Thus, the sufficient correctness of the interface and knowledge base to determine the above-mentioned parameters of aircraft structures has been confirmed.

5. Limitations and Solutions

The problem encountered was profile scaling. Points describing the profile on any scale were allowed. These points were imported using the method described in the chapter describing the wing half model, however, the profile was not subject to scaling, rotation, and translation in the spreadsheets, and only after import into the model using the "Scale Curve" function and using the "Pattern Feature" function several times. When the normalized points were imported into the range [0; 1] and the curve based on it was scaled, curve deformations were visible.

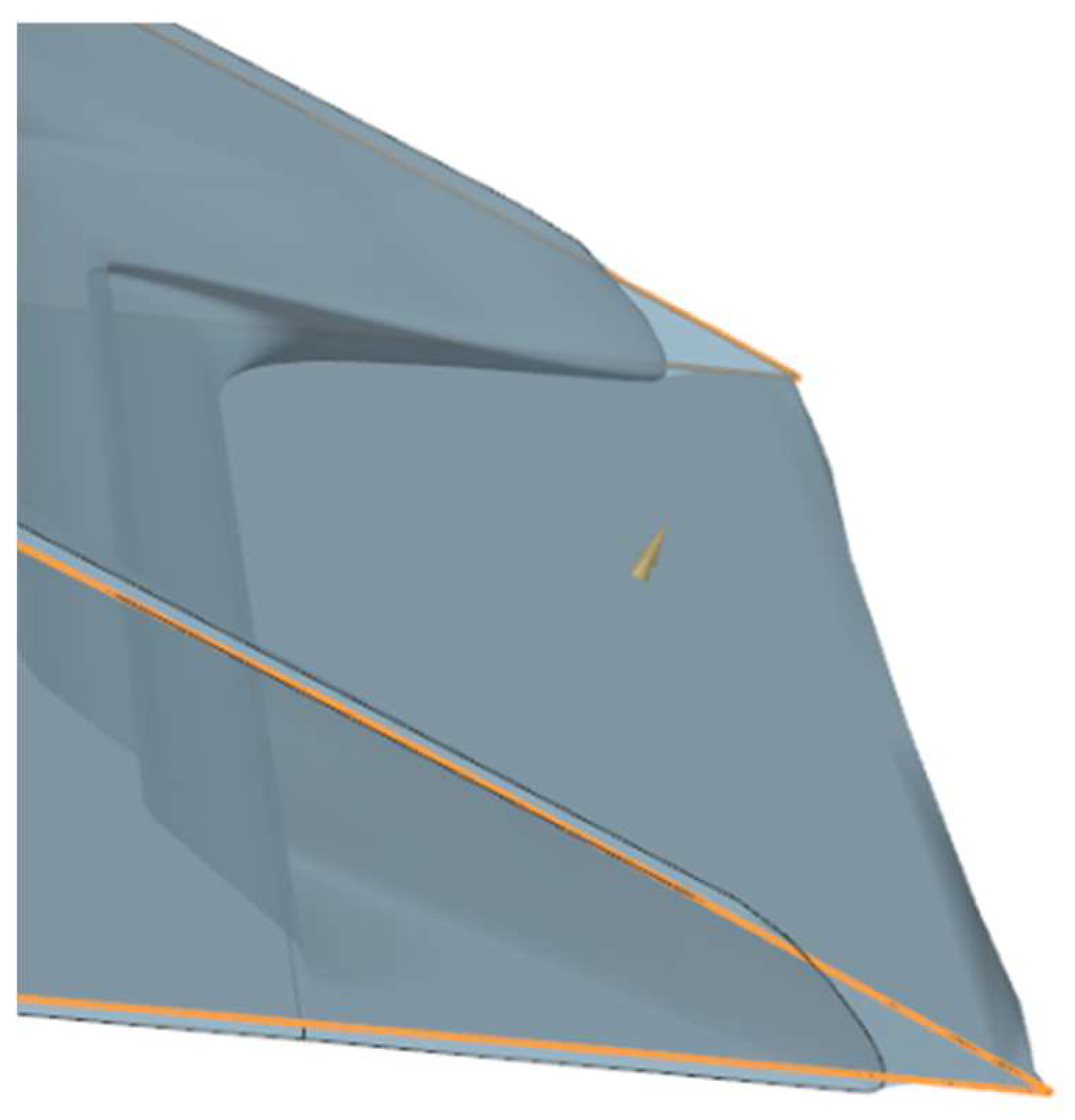

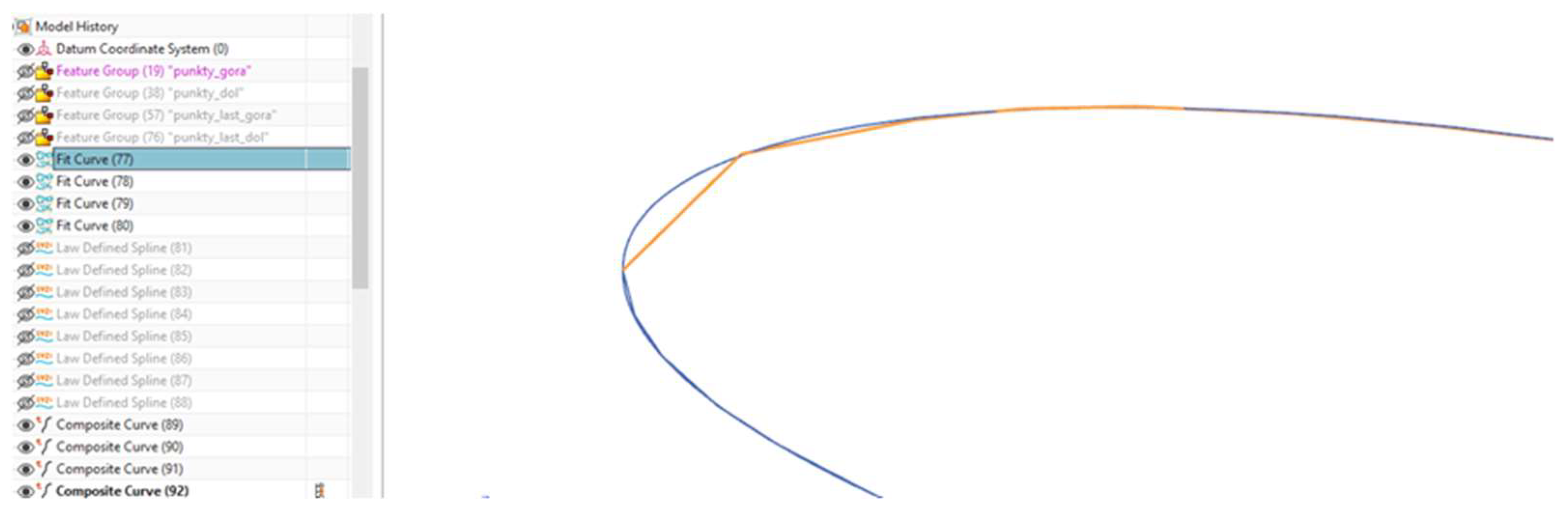

In addition, Siemens NX does not provide an approximation of a curve passing through points using a Catmull-Rom curve, but rather using a polynomial curve. During the work, problems related to the Runge phenomenon were revealed - at the ends of the profile there were deformations greater than the distances between successive points (

Figure 17).

It was considered necessary to enter the profile shape in an exact form, not approximated. For this purpose, a NACA profile generator was used, directly using the equations describing the shape of the profile. A comparison of shape reproduction accuracy is shown in

Figure 18.

This way, errors in the transformation of the external surface, such as those shown in

Figure 17, are eliminated.

It is possible to expand the capabilities of the software as the presented models are the implementation of the most basic functions. The modularity of both spreadsheets and models allows for trouble-free attachment of subsequent modules.

The first important limitation of the current version of the software is the ability to build geometry based solely on 4-digit NACA profiles. The equations for NACA 5-digit profiles are known, which means that such a generator could be adapted to the model without much difficulty. The generator contains two sets of equations: one for generating curve shape and second one for the scaling, rotation, and translation. To enter the generator of 5-digit NACA aerofoils, it would be required to add a conditional statement to the transforming equations to change the selection of curve equations from the 4-digit NACA profile generator to the NACA 5-digit profile generator introduced.

6. Summary

The presented work focuses on the design of software to support the design and generation of aircraft/glider geometry supporting verification calculations of structural features of aircraft structures, applicable to generative models for aircraft design. As part of this, detailed literature, studies were carried out on generative models and knowledge-based systems. In the next stage of work, the process of creating an appropriate database containing, among others, data on construction materials and calculations of individual quantities necessary to determine geometric parameters for the needs of generative models was presented. Next, the integration of design verification methods used in aircraft design with methods for determining structural features in the developed generative models and implementation of the entire composition into the Siemens NX system was solved. Sample parameters were defined and models were generated, which were subjected to strength analysis in order to check the correct operation of the entire software.

The designed software is a response to the needs resulting from current trends in the field of aviation engineering and is a great base for creating a full-fledged program that allows you to accelerate the design of aircraft structures. Further work on the software will certainly increase the range of possible types of aircraft, as well as the configurations available for them. This would make the software more universal and offer a wider audience and the possibilities of its use.

7. Conclusions

The development of the system required very tedious and time-consuming work consisting in testing many different options for model generation automation solutions and choosing the most effective solutions by compromise. In the development, very well-developed textbooks were used, constituting a compendium of design knowledge, which greatly improved the process of identifying knowledge. Usually, however, the designers of such systems are not in such a comfortable situation and the process of knowledge acquisition is also a bottleneck in the process of building systems based on Generative Models. The developed model is the basis for further design and can only be considered as a preliminary form of the entire aircraft. Many details of the structure, load-bearing structure, mechanization of the wing, integrated sub-systems will be designed using this model In the next steps. The developed system is an excellent basis for the initial design of the aircraft and its application allows for the quick generation of a verified aircraft concept.

Author Contributions

Conceptualization, WS; methodology, WS; software, RN and RM; validation, RN and RM.; formal analysis, WS, RN and RM ; investigation, WS, RN and RM; resources, WS, RN and RM ; data curation, RN and RM; writing—original draft preparation, WS, RN and RM ; writing—review and editing, WS, RN and RM ; visualization, RN and RM ; supervision, WS; project administration, WS.; funding acquisition, WS. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partially founded from EEA and Norway Grants 2014–2021 and was partially carried out in the framework of the project No. NOR/POLNOR/LEPolUAV/0066/2019 Long-endurance UAV for collecting air quality data with high spatial and temporal resolutions”.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Howe, D. Aircraft Conceptual Design Synthesis, 1st ed.; Professional Engineering Publishing Limited: London and Bury St Edmunds, UK, 2000. [Google Scholar]

- Sadraey, M. H. Aircraft Design: A Systems Engineering Approach, 3rd ed.; AIAA: Playa del Rey, California, USA, 2018. [Google Scholar]

- Danilecki, S. Aircraft Design (in polish), 1st ed.; Warsaw University of Technology: Warsaw, Poland, 2000; pp. 9–16. [Google Scholar]

- Raymer, D. P. Aircraft Design: A Conceptual Approach, 3rd ed.; AIAA: Playa del Rey, California, USA, 2018; pp. 2–10. [Google Scholar]

- Musik, R. Application of autogenerating modeling to aircraft design. Master Thesis, Silesian University of Technology, Gliwice, 2022. [Google Scholar]

- Skarka, W. Using knowledge-based engineering methods in designing with modular components of assembly systems. 11th International Design Conference (DEISIGN 2010); VOL 1-3, pp. 1837–1846.

- Devaraja Holla, V. Knowledge Based Engineering (KBE): Key product development technology to enhance competitiveness. Perspective 2018. [Google Scholar]

- Stjepandic, J.; Wognum, N.; Verhagen, W.J.C. Systems Engineering in Research and Industrial Practice Foundations, Developments and Challenges: Foundations, Developments and Challenges; Springer, January 2019; ISBN 978-3-030-33311-9. [Google Scholar] [CrossRef]

- Stjepandic, J.; Wognum, N.; Verhagen, W.J.C. Concurrent Engineering in the 21st Century. Foundations, Developments and Challenges; Springer Verlag London, February 2015; Volume 15, ISBN 978-3-319-13775-9. [Google Scholar] [CrossRef]

- Skarka, W.; Jałowiecki, A. Automation of a Thin-Layer Load-Bearing Structure Design on the Example of High Altitude Long Endurance Unmanned Aerial Vehicle (HALE UAV). Appl. Sci. 2021, 11, 2645. [Google Scholar] [CrossRef]

- Skarka, W. Model-Based Design and Optimization of Electric Vehicles, 25th ISPE Inc International Conference on Transdisciplinary Engineering 2018. TRANSDISCIPLINARY ENGINEERING METHODS FOR SOCIAL INNOVATION OF INDUSTRY 4.0 7. 566–575.

- Peciak, M.; Skarka, W. Assessment of the Potential of Electric Propulsion for General Aviation Using Model-Based System Engineering (MBSE) Methodology. Aerospace 2022, 9, 74, (accessed on 15.04.2023). [Google Scholar] [CrossRef]

- Mateja, K.; Skarka, W.; Peciak, M.; Niestrój, R.; Gude, M. Energy Autonomy Simulation Model of Solar Powered UAV. Energies 2023, 16, 479. [Google Scholar] [CrossRef]

- Peciak, M.; Skarka, W.; Mateja, K.; Gude, M. Impact Analysis of Solar Cells on Vertical Take-Off and Landing (VTOL) Fixed-Wing UAV. Aerospace 2023, 10, 247, (accessed on 11.05.2023). [Google Scholar] [CrossRef]

- Nalepa, R. Software for the automation of the generation of conceptual models of aircraft. Master Thesis, Silesian University of Technology, Gliwice, 2022. [Google Scholar]

- Stafiej, W. Calculations used in the design of gliders, 1st ed.; Warsaw University of Technology: Warsaw, Poland, 2000. [Google Scholar]

- The NACA airfoil series. Available online: https://web.stanford.edu/~cantwell/AA200_Course_Material/The%20NACA%20airfoil%20series.pdf (accessed on 11.05.2023).

- Diana 2. Available online: https://www.avionic.com.pl/avionicdiana2 (accessed on 11.05.2023).

- SZD-32 "Foka 5". Available online: http://www.samolotypolskie.pl/samoloty/2873/126/SZD-32-Foka-5 (accessed on 11.05.2023).

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).