Submitted:

16 May 2023

Posted:

17 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Literature Review

3. Methodology

4. Study Results

4.1. The Demographic Data

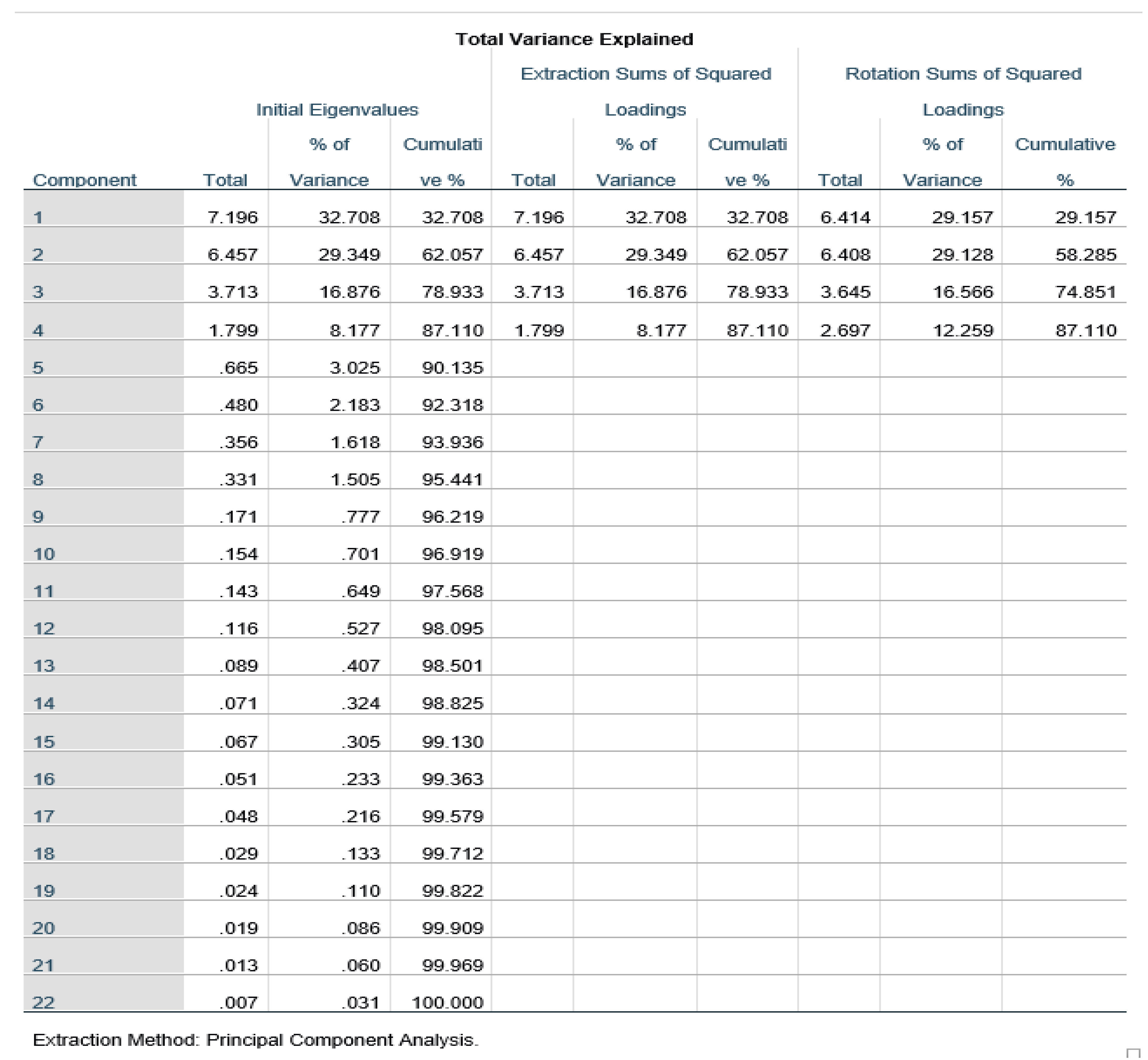

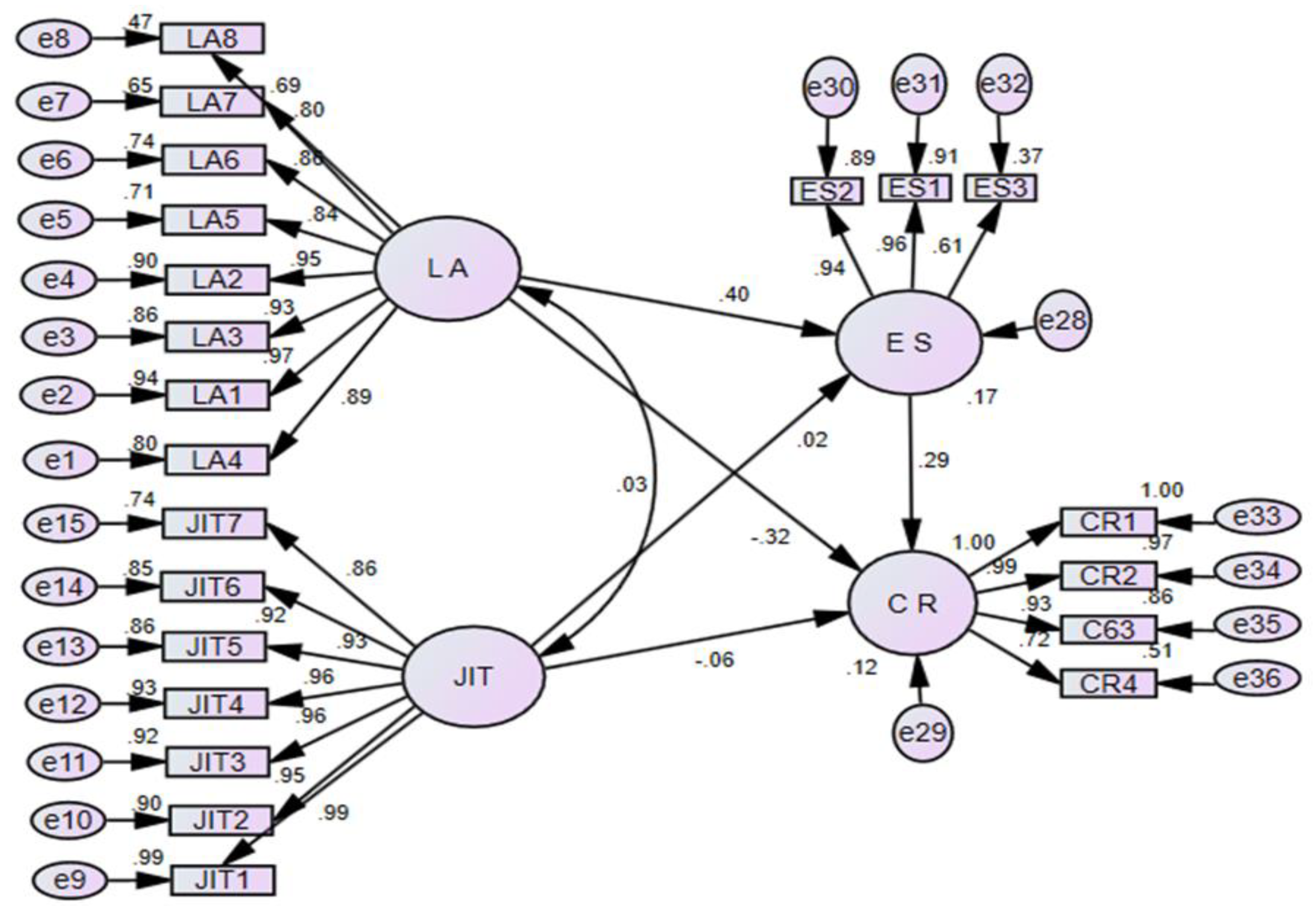

4.2. Exploratory Factor Analysis (EFA) & Confirmatory Factor Analysis (CFA)

| Data | Frequency | Percent % | |

|---|---|---|---|

| Age | less than 25 | 19 | 17.4 |

| 25 to 39 | 64 | 58.7 | |

| 40 to 55 | 25 | 22.9 | |

| over 55 | 1 | 0.9 | |

| Total | 109 | 100% | |

| Qualification | Bachelor | 73 | 67 |

| Higher Diploma | 23 | 21.1 | |

| Master | 8 | 7.3 | |

| PhD | 5 | 4.6 | |

| Total | 109 | 100% | |

| Job Title | Accountant | 66 | 60.6 |

| Production Manager | 12 | 11 | |

| Financial Manager | 14 | 12.8 | |

| Industrial Engineer | 17 | 15.6 | |

| Total | 109 | 100% | |

| Experience | Less than 5 years | 29 | 26.6 |

| 5 to 10 | 52 | 47.7 | |

| 11 to 20 | 20 | 18.3 | |

| More than 20 | 8 | 7.3 | |

| Total | 109 | 100% |

| Kaiser-Meyer-Olkin Measure of Sampling Adequacy. | .813 | |

|---|---|---|

| Bartlett’s Test of Sphericity | Approx. Chi-Square | 3970.614 |

| Df | 253 | |

| Sig. | .000 | |

| Factor | Component | ||||

|---|---|---|---|---|---|

| Code | 1 | 2 | 3 | 4 | |

| Value-Added Activity (VAA) | JIT1 | .985 | |||

| Setup Time Reduction (STR) | JIT2 | .967 | |||

| Inventory Level (IL) | JIT3 | .966 | |||

| Defect Products (DP) | JIT4 | .964 | |||

| Supplier Development (SD) | JIT5 | .933 | |||

| Resources Utilization (RU) | JIT6 | .921 | |||

| Competitive Advantage (CA) | JIT7 | .884 | |||

| Value-Added Activity (VAA) | LA4 | .923 | |||

| Setup Time Reduction (STR) | LA1 | .910 | |||

| Inventory Level (IL) | LA3 | .892 | |||

| Defect Products (DP) | LA2 | .891 | |||

| Resources Utilization (RU) | LA5 | .879 | |||

| Competitive Advantage (CA) | LA6 | .855 | |||

| Continuous Flow (CF) | LA7 | .826 | |||

| Customer Involvement (CI) | LA8 | .817 | |||

| Operating Hours Cost (OHC) | CR1 | .967 | |||

| Product Design Cost (DDC) | CR2 | .961 | |||

| Inventory Cost (IC) | C63 | .935 | |||

| Defects Cost (DC) | CR4 | .791 | |||

| Truthful Information (TI) | ES2 | .906 | |||

| Safety Products (SP) | ES1 | .899 | |||

| Transparency (T) | ES3 | .747 | |||

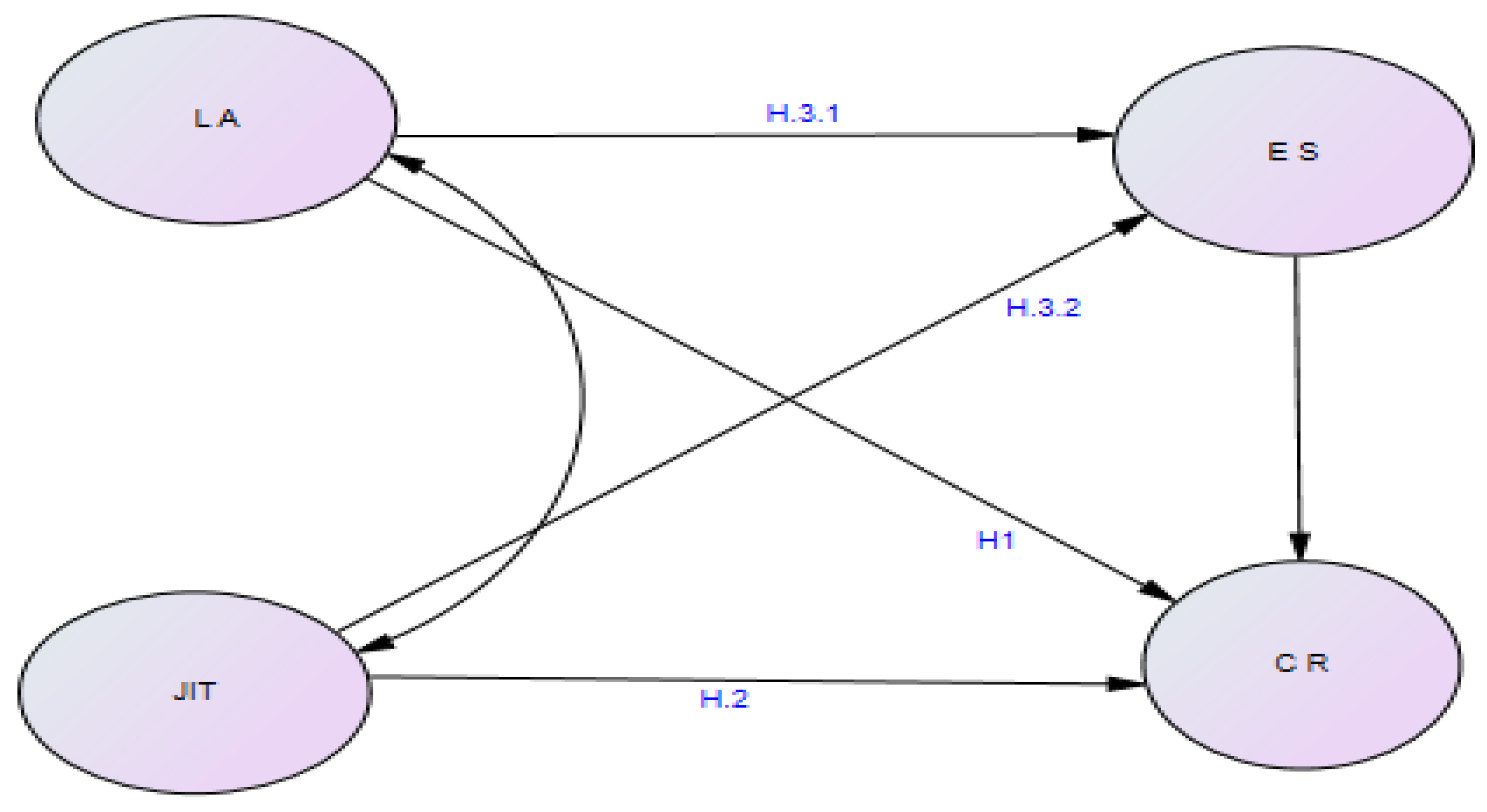

4.3. The Hypotheses Test

5. Conclusions

5.1. Discussion

5.2. The Study Implication

5.3. Limitations & Future Directions of Study

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alobaidy, R.J.A.E. Integration of lean accounting techniques and balanced scorecard to evaluate the performance of economic units; an exploratory or applied study in Iraq. Period. Eng. Nat. Sci. 2019, 7, 1812–1820. [Google Scholar] [CrossRef]

- Daferighe, E.E.; James, E.E.; Offiong, P.E. Lean Accounting and Waste Management in Brewery Industry in Nigeria. Advances in Research 2018, 15, 40484. [Google Scholar] [CrossRef]

- Ali, S.B.; Khan, Z.S.; Ashah, Z.; Ahmad, M. Lean Accounting System: Importance and Successful Implementation. J. Contemp. Issues Bus. Gov. 2021, 27, 2388–2398. [Google Scholar] [CrossRef]

- Ofileanu, D.; Topor, D.I. Lean Accounting an Ingenious Solution for Cost Optimization, International J. Acad. Res. Bus. Soc. Sci. 2014, 4, 342–352. [Google Scholar] [CrossRef]

- Mohamed, A.F.; Mwanyota, M.J. Effects of selected lean management practices on financial performance of private hospitals in Mombasa County, Kenya. Int. J. Supply Chain Manag. 2018, 3, 1–21, Available online: iprjb.org/journals/index.php/IJSCM/article/view/717. [Google Scholar]

- Almashkor, I.A.S. The Effect of Integration between Throughput Accounting and Lean Accounting on Cost Reduction. J. Manag. Inf. Decis. Sci. 2021, 24, 1–14. [Google Scholar]

- Kadhim, H.K.; Kadhim, A.A.H.; Azeez, K.A. The Integration of Lean Accounting and Activity-Based Public Budgeting for improving a firm’s Performance. Int. J. Innov. Creat. Change 2020, 11, 555–567, Available online: https://www.ijicc.net/. [Google Scholar]

- Al-Dulemi, K.; Shehadeh. M. A. Role of lean accounting in reduction production costs in Jordanian Manufacturing Corporation. Res. J. Financ. Account. 2018, 9, 2222–1697, Available online: https://iiste.org/Journals/index.php/RJFA/article/view/43837. [Google Scholar]

- Almusawi, E.; Almagtome, A.; Shaker, A.S. Impact of lean accounting information on the financial performance of healthcare institutions: A Case Study. J. Eng. Appl. Sci. 2019, 14, 589–599, https://www.researchgate.net/publication/340264004. [Google Scholar] [CrossRef]

- Muhammad, L.; Isah, A.I. Impact of Lean Accounting on Financial Performance of Private Hospitals in Kaduna State. Sokoto J. Manag. Stud. 2020, 22, 121–136. [Google Scholar]

- Airout, R.M.; Alhajahmad, F.B. The Impact of Using the Lean Accounting Tools on Improving the Lean Planning Level in the Jordanian Industrial Public Shareholding Companies. Int. J. Econ. Manag. Syst. 2022, 7, 211–227. [Google Scholar]

- Pawlik, E.; Ijomah, W.; Corney, J.; Powell, D. Exploring the Application of Lean Best Practices in Remanufacturing: Empirical Insights into the Benefits and Barriers. Sustainability 2022, 14, 149. [Google Scholar] [CrossRef]

- Marques, P.A.; Carvalho, A.M.; Santos, J.O. Improving Operational and Sustainability Performance in a Retail Fresh Food Market Using Lean: A Portuguese Case Study. Sustainability 2022, 14, 403. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, K. A study of lean construction and visual management tools through cluster analysis. Ain Shams Eng. J. 2021, 12, 1153–1162. [Google Scholar] [CrossRef]

- Okolocha, C.B.; Anugwu, C.C. Lean Manufacturing Approach and Operational Efficiency of Nigerian Pharmaceutical Companies in Anambra State. Saudi J. Bus. Manag. Stud. 2022, 7, 94–99. [Google Scholar] [CrossRef]

- Ghaithan, A.; Khan, M.; Mohammed, A.; Hadidi, L. Impact of Industry 4.0 and Lean Manufacturing on the Sustainability Performance of Plastic and Petrochemical Organizations in Saudi Arabia. Sustainability 2021, 13, 11252. [Google Scholar] [CrossRef]

- Lopez, P.R.A.; Santos, J.F. An accounting system to support process improvements: Transition to lean accounting. J. Ind. Eng. Manag. 2010, 3, 576–602. [Google Scholar] [CrossRef]

- Elsukova, T.V. Lean Accounting and Throughput Accounting: An Integrated Approach. Mediterr. J. Soc. Sci. 2015, 6, 3. [Google Scholar] [CrossRef]

- Almagtome, A.; Shaker, A.S. Impact of lean accounting information on the financial performance of healthcare institutions. J. Eng. Appl. Sci. 2019, 14, 589–599. [Google Scholar] [CrossRef]

- Aziz, K.; Awais. M.; Rahat, Q.; Ul Hasnain, S.S.; Shahzadi, I. Impact of outsourcing on lean operations in Pakistani healthcare industry. Int. J. Eng. Inf. Syst. 2017, 1, 116–123. [Google Scholar]

- Yavuz, O. Profitability by selling below the average unit cost: Lean cost accounting and a real application. Int. J. Manag. Sci. 2017, 4, 56–59, Available online: https://www.researchgate.net/publication/339435193. [Google Scholar]

- Okpala, K.E. Lean accounting and lean business philosophy in Nigeria: An exploratory research. Int. J. Econ. Financ. Manag. 2013, 2, 508–515, Available online: https://www.researchgate.net/publication/259621522. [Google Scholar]

- Andinyanga, U.S. Implementation Effect of Lean Accounting Practices on Financial Performance of Listed Industrial Goods Firms in Nigeria: A Literature Review. BUJAB 2022, 7, 486–496, Available online: http://35.188.205.12:8080/xmlui/handle/123456789/796. [Google Scholar]

- Madanhire, I.; Kagande, L.; Chidziva, C. Application of Just In Time (JIT) Manufacturing Concept in Aluminium Foundry Industry in Zimbabwe. Int. J. Sci. Res. 2013, 2, 334–347, https://www.ijsr.net/archive/v2i2/IJSROFF2013037.pdf. [Google Scholar]

- Fonseca, L.M.; Domingues, J.P. The best of both worlds? Use of Kaizen and other continuous improvement methodologies within Portuguese ISO 9001 certified organizations. TQM J. 2018, 30, 321–334. [Google Scholar] [CrossRef]

- Milewski, D. Managerial and Economical Aspects of the Just-In-Time System: Lean Management in the Time of Pandemic. Sustainability 2022, 14, 1204. [Google Scholar] [CrossRef]

- Siddiqui, A. The Importance of Just in Time Methodology and its Advantages in Health Care Quality Management Business. Biomed. J. Sci. Tech. Res. 2022, 42. [Google Scholar] [CrossRef]

- Arai, K. Lean Manufacturing and Performance Measures: Evidence from Japanese Factories. IUP J. Oper. Manag. 2021, 20, 7–34. [Google Scholar] [CrossRef]

- Kocamis, T.U. Lean Accounting Method for Reduction in Production Costs in Companies. Int. J. Bus. Soc. Sci. 2015, 6, 7–13, Available online: file:///C:/Users/a.ismael/Downloads/LeanAccountingMethodforReductioninProductionCostsinCompanies.pdf. [Google Scholar]

- Maskell, B.H.; Baggaley, B.; Grasso, L. Practical Lean Accounting: A Proven System for Measuring and Managing the Lean Enterprise, 2nd ed.; Taylor & Francis Group: New York, 2017; p. 475. [Google Scholar] [CrossRef]

- Sahoo, S. Lean manufacturing practices and performance: The role of social and technical factors. International J. Qual. Reliab. Manag. 2020, 37, 732–754. [Google Scholar] [CrossRef]

- Woehrle, S. Using dynamic value stream mapping and lean accounting box scores to support lean implementation. Am. J. Bus. Educ. 2010, 3, 67–75. [Google Scholar] [CrossRef]

- Sila, I.; Ebrahimpour, M. Critical linkages among TQM factors and business results. Int. J. Oper. Prod. Manag. 2005, 25, 1123–1155. [Google Scholar] [CrossRef]

- Shaqour, E.N. The impact of adopting lean construction in Egypt: Level of knowledge, application, and benefits. Shams Eng. J. 2022, 101551. [Google Scholar] [CrossRef]

- Hair, J.F.; Anderson, R.E.; Tatham, R.L.; William, C. Multivariate Data Analysis, 5th ed.; Upper Saddle River: Prentice Hall, NJ, USA, 1998; Available online: https://www.ijsr.net/archive/v2i2/IJSROFF2013037.pdf. [Google Scholar]

- Yin, L.; Liu, J. Impact of Environmental Economic Transformation Based on Sustainable Development on Financial Eco-Efficiency. Sustainability 2023, 15, 856. [Google Scholar] [CrossRef]

- : Mao, H.-Y.; Lu, W.-M.; Shieh, H.-Y. Exploring the Influence of Environmental Investment on Multinational Enterprises’ Performance from the Sustainability and Marketability Efficiency Perspectives. Sustainability 2023, 15, 7779. [Google Scholar] [CrossRef]

- Chen, P.-K.; Lujan-Blanco, I.; Fortuny-Santos, J.; Ruiz-de-Arbulo-López, P. Lean Manufacturing and Environmental Sustainability: The Effects of Employee Involvement, Stakeholder Pressure and ISO 14001. Sustainability 2020, 12, 7258. [Google Scholar] [CrossRef]

| Dimension | Description |

|---|---|

| Value-Added Activity (VAA) | This dimension is refers to any activity that increases the product value. It directly contributes to meeting customer needs, and customers are willing to pay for it [5]. |

| Setup Time Reduction (STR) | This element is crucial point that determines the pliability of a manufacturing arrangement such that it can readily accommodate diversification in the resource and programs. STR assess how much setup period can be minimized before production. [16]. |

| Inventory Level (IL) | Inventory costs money for storage & management, so inventory increases the financial risks. Only a minimal or nil inventory should be maintained. |

| Defect Product (DP) | This dimension is refers to a product that fails to meet the customer’s needs. It is be necessary to design a product that contributes to realizing a competitive advantage for the company [16]. |

| Supplier Development (SD) | This mensuration explores the continuous advancement of suppliers’ achievement by measuring supplier competencies and addressing basic interests [31]. |

| Resources Utilization (RU) | This dimension is refers to how much of the available resources are currently used by the company. This helps the company to plan how to utilize its resources in a more effective way [32]. |

| Competitive Advantage (CA) | This dimension refers to factor allowing a company to produce products better than its competitors. This factor allow the company to generate more sales than its market rivals [10]. |

| Continuous Flow (CF) | CF evaluates if there is a gradual permanents flow on the manufacturing floor, ensuring no big downtime [16]. |

| Customer Involvement (CI) | CI is fundamental measurement that describes whether client needs have been met and their gratification has been realized. This measure inspects the narrow relation between the company and client [33]. |

| Truthful Information (TI) | Information is truthful if it reflects reality. Information may be disclosed in a way that is contrary to actual position [34]. |

| Safety Products (SP) | This dimension refers to a product that provides a low risk, taking into account the reasonably foreseeable use of the product and the need to maintain a high level of protection for consumers [16]. |

| Transparency (T) | This dimension is refers to the basic democratic principle that obliges state agencies to publish information of public interest and make it accessible [34]. |

| Variable | Estimate | S.E. | C.R. | P-value | Result | ||

|---|---|---|---|---|---|---|---|

| CR | <--- | LA | -.304 | .098 | -3.107 | .002* | Accept |

| CR | <--- | JIT | -.058 | .085 | -.684 | .494 | Reject |

| Hypothesis | P-value | Result |

|---|---|---|

| CR <--- ES <--- LA | *** | Accept |

| CR <--- ES <--- JIT | *** | Accept |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).