Submitted:

18 May 2023

Posted:

18 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Generation performance grading maps of asphalt pavement for Xinjiang

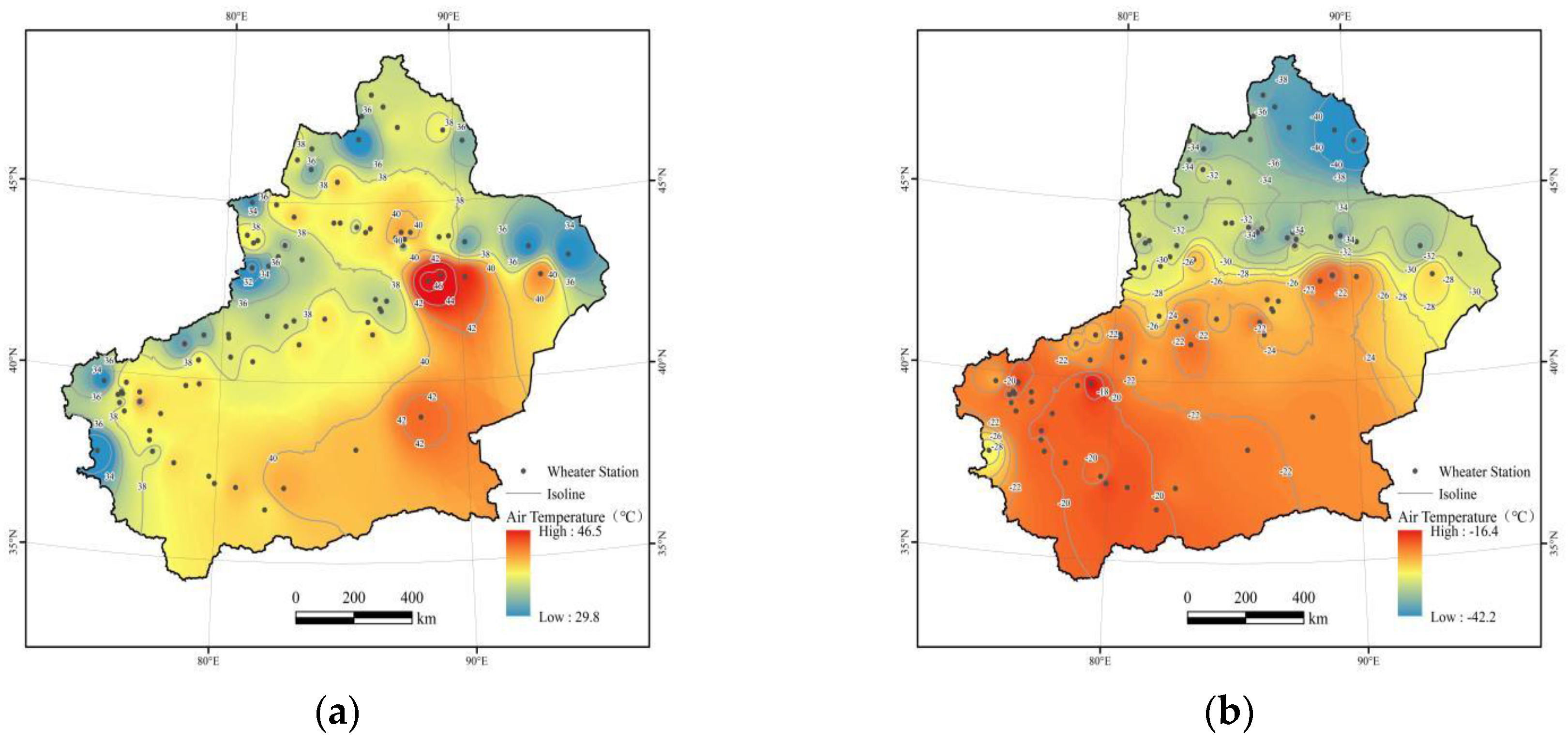

2.1. Temperature data collection and analysis

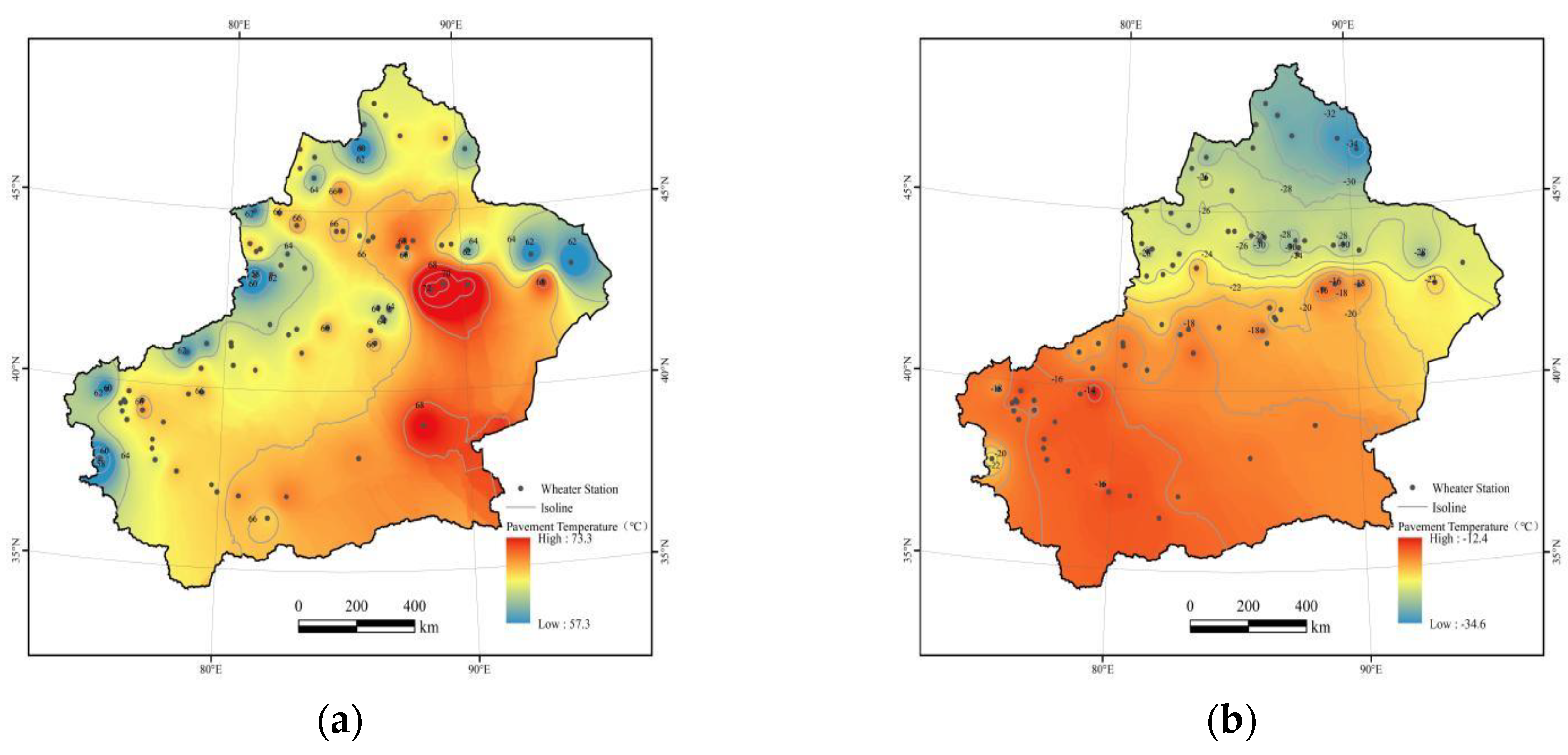

2.2. Pavement temperature calculation

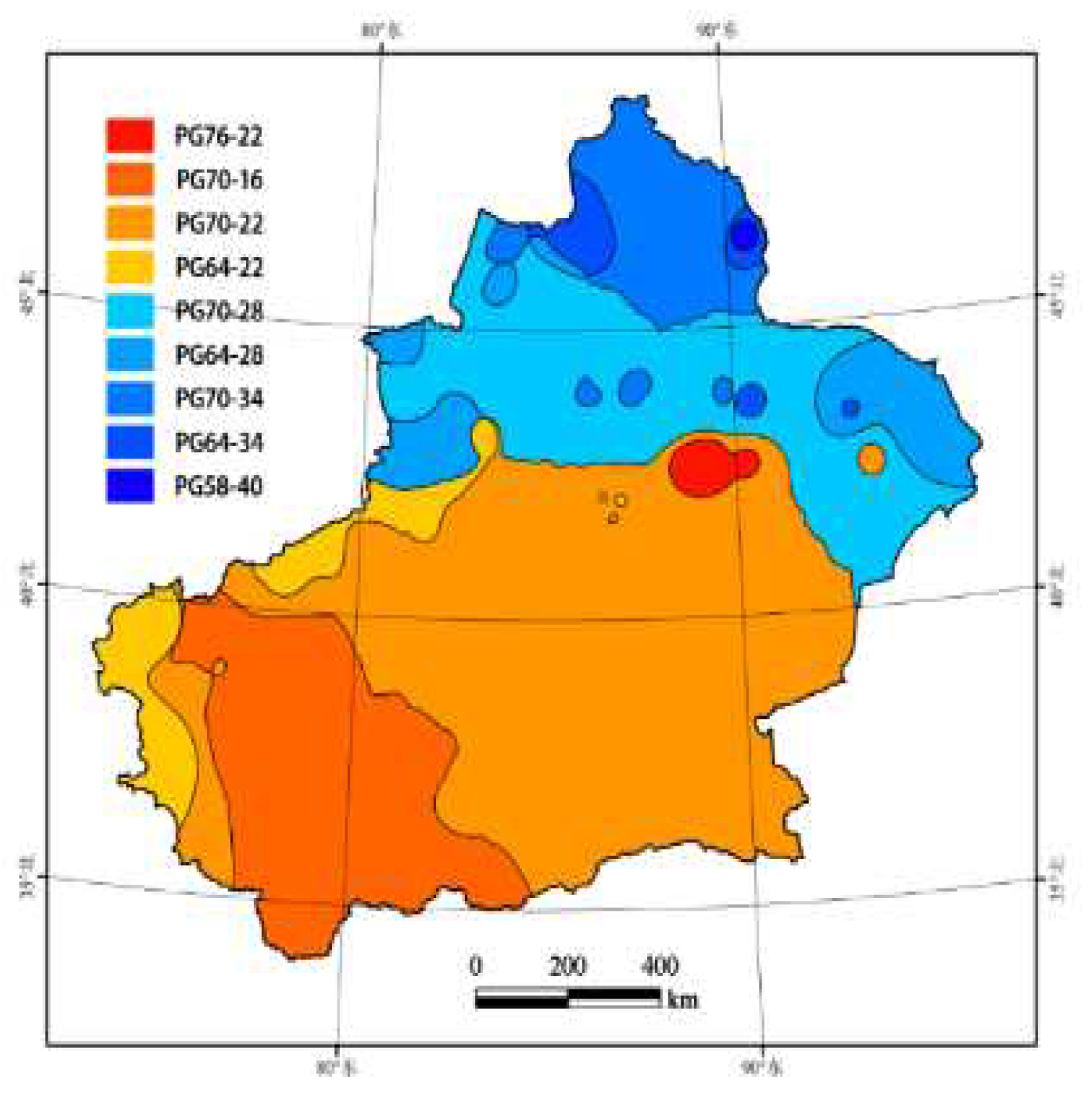

2.3. Generating performance grading maps for Xinjiang

3. Materials and Methods

3.1. materials

3.2. Performance methods

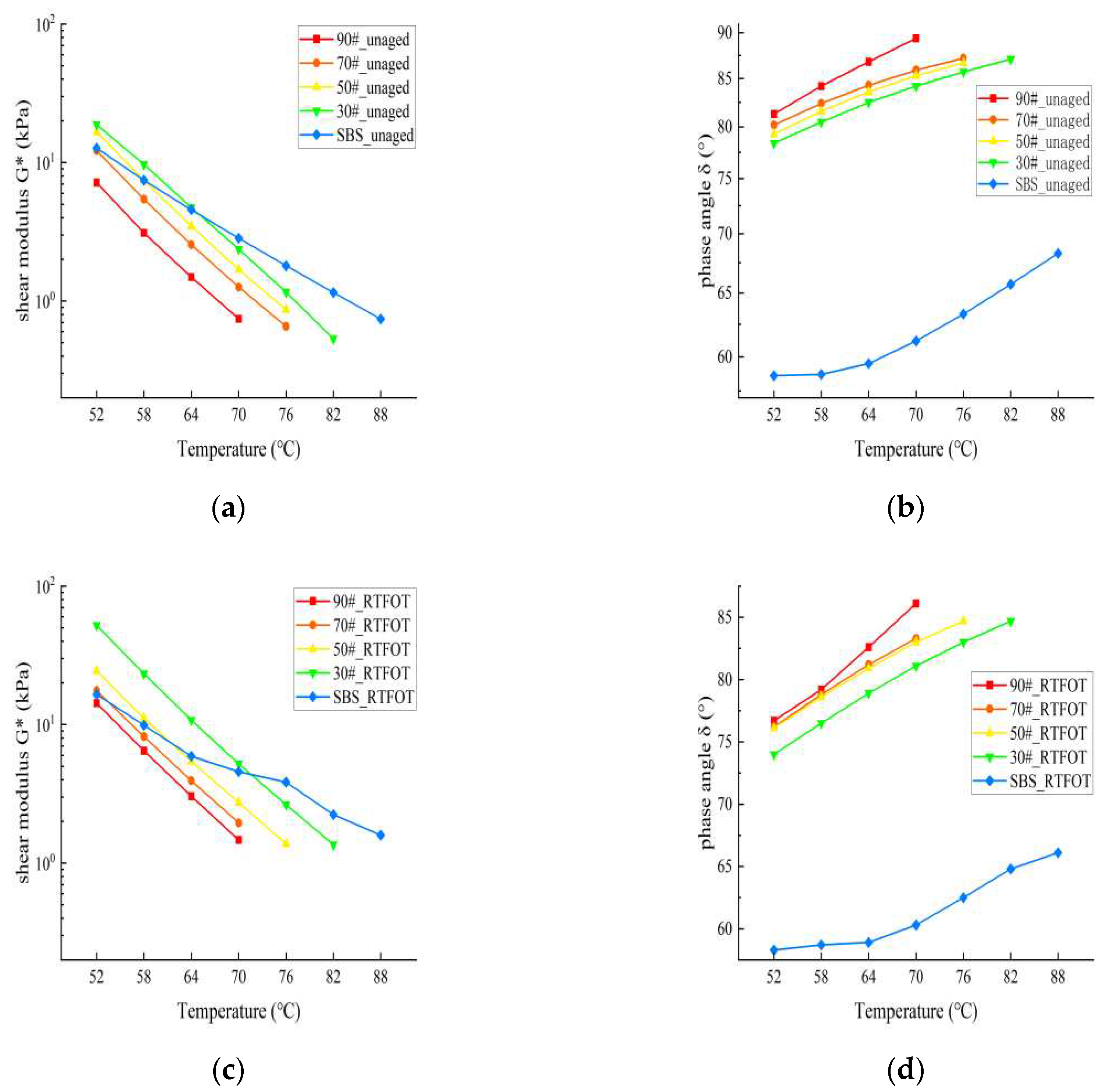

3.2.1. Dynamic shear rheometer (DSR)

3.2.2. Bending beam rheometer (BBR)

4. Results and discussion

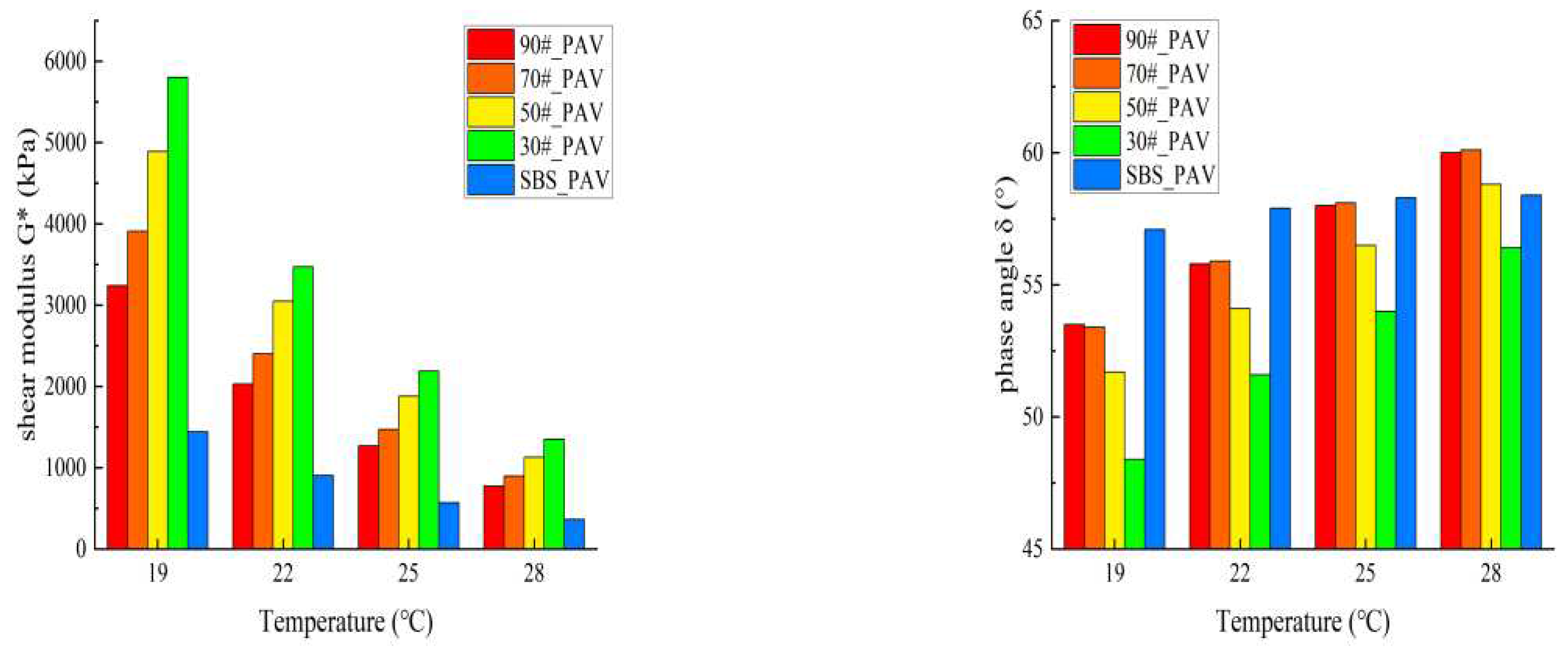

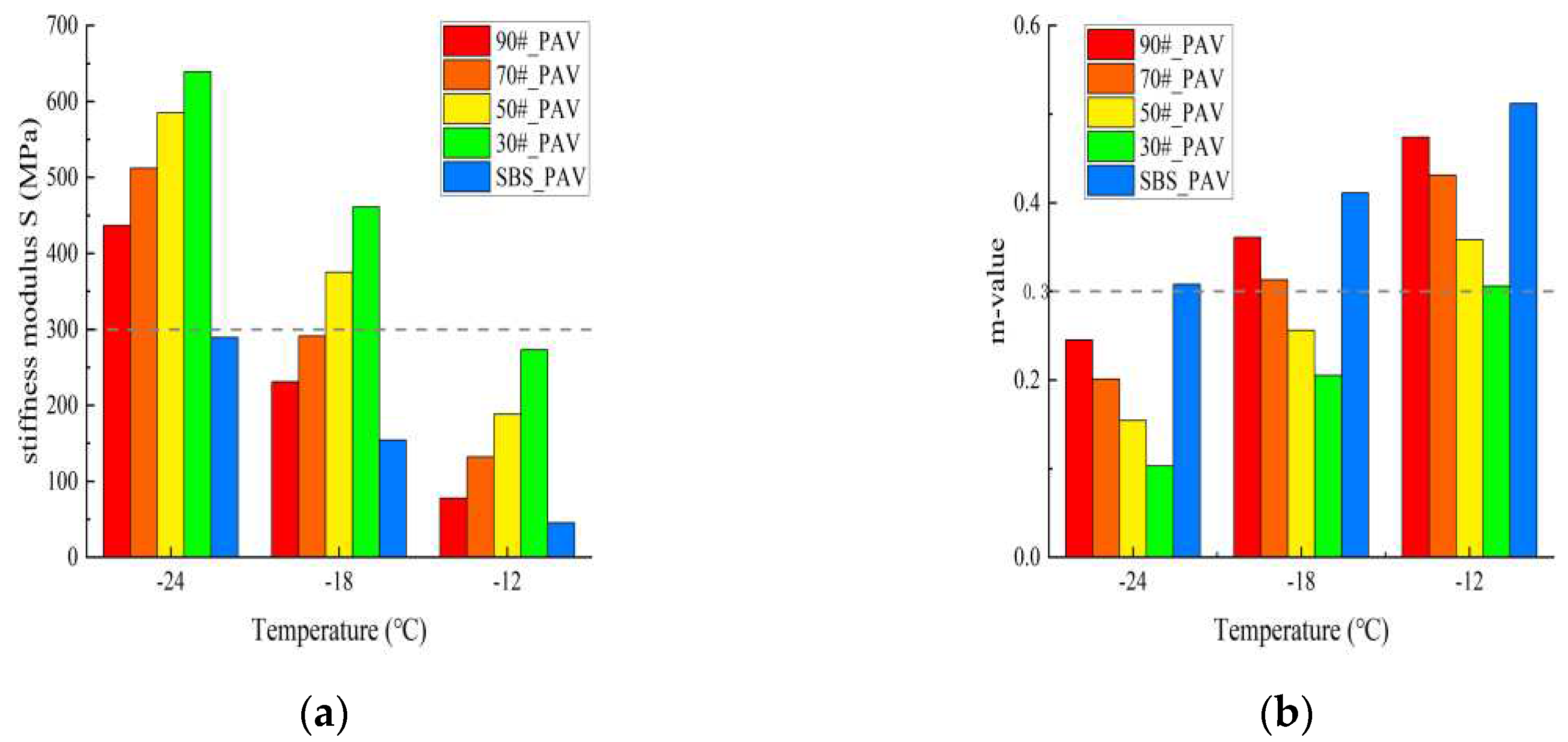

4.1. High-temperature PG

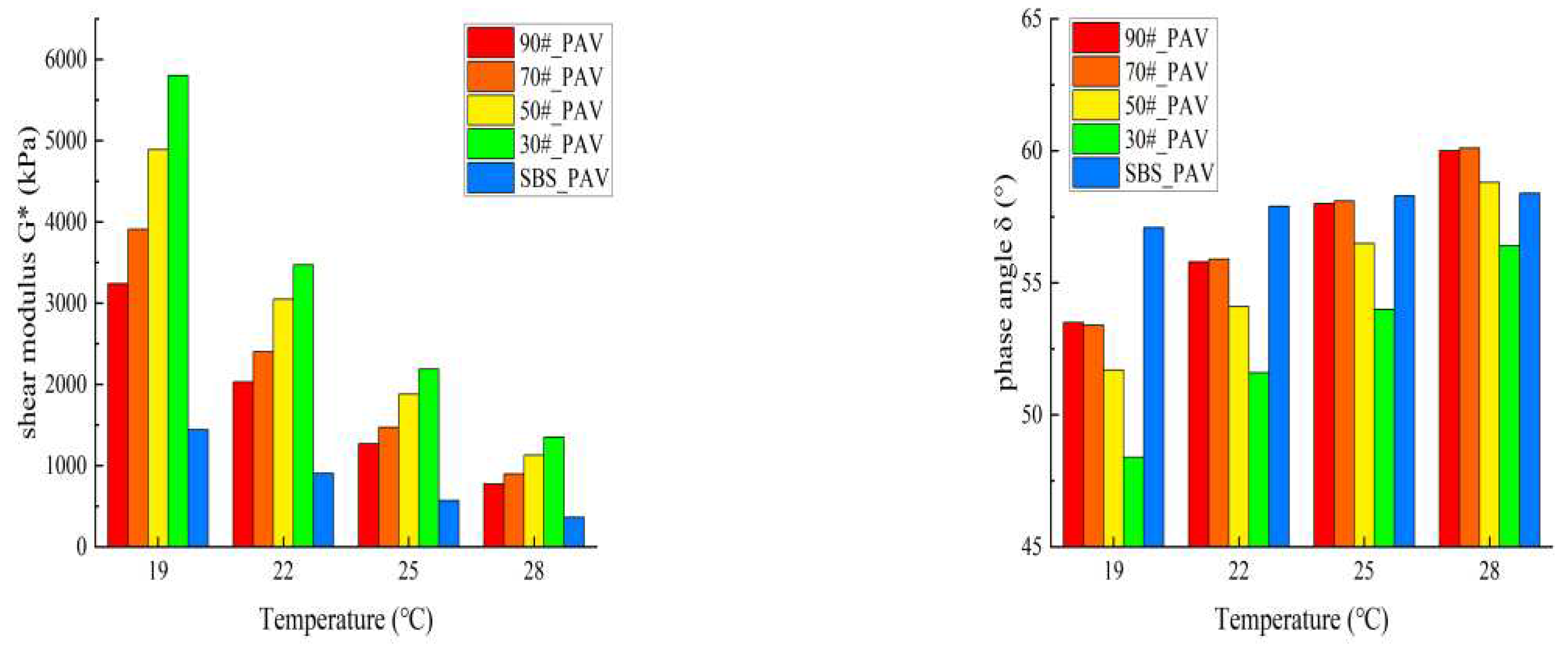

4.2. Intermediate temperature PG

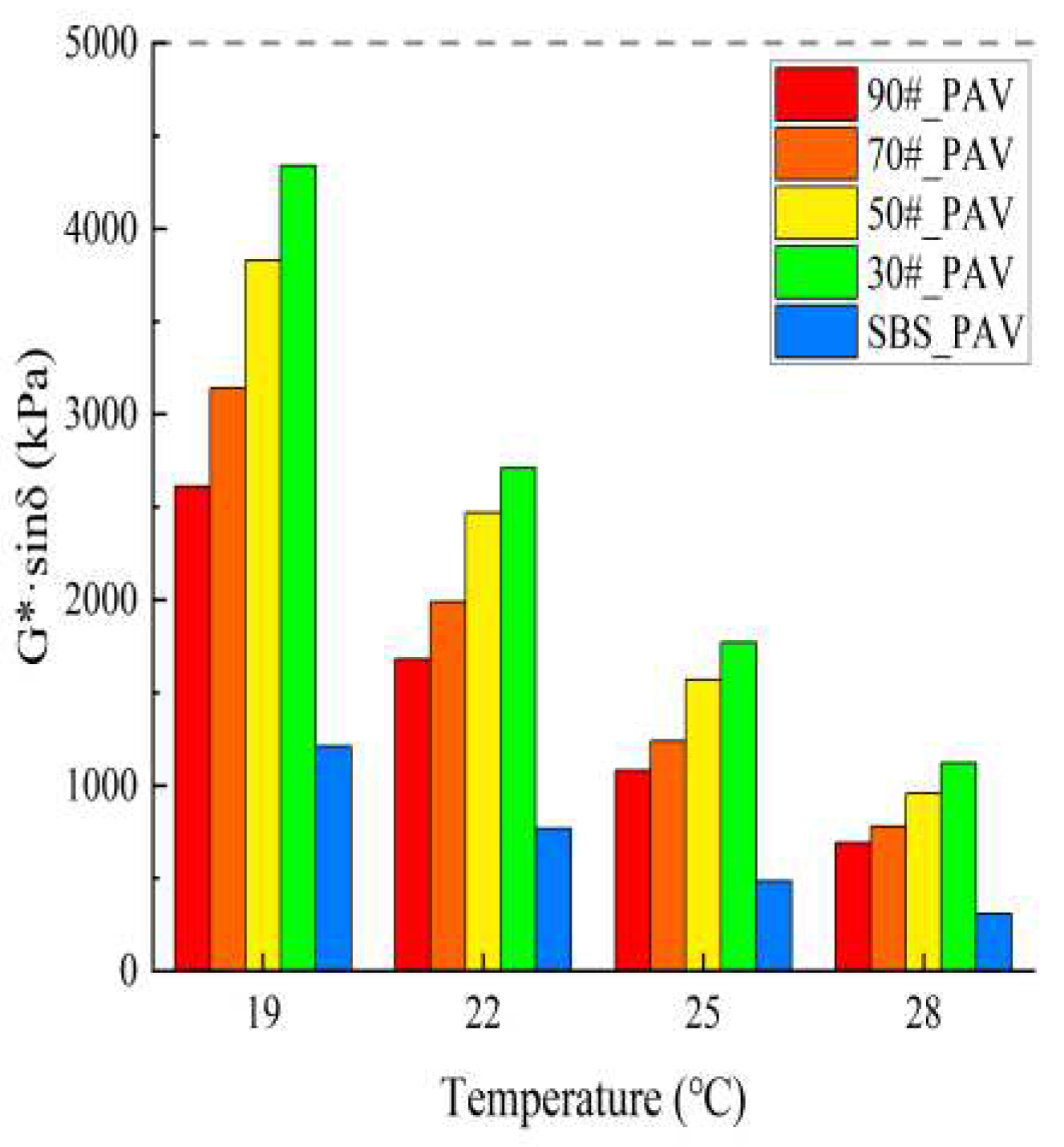

4.3. Low temperature PG

4.4. Intermediate temperature PG

5. Summary and conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- 1. Haoran Zhu, Gang Xu, Minghui Gong, Jun Yang. Recycling long-term-aged asphalts using bio-binder/plasticizer-based rejuvenator. Construction and Building Materials. [CrossRef]

- İslam Gökalp, Volkan Emre Uz. Utilizing of Waste Vegetable Cooking Oil in bitumen: Zero tolerance aging approach. Construction and Building Materials. 2019, 227. [Google Scholar]

- 3. Yan K Z, Hong Z, You L Y, et al. Influence of ethylene-vinyl acetate on the performance improvements of low-density polyethylene-modifeied bitumen. Journal of Cleaner Production. [CrossRef]

- Yinfei Du, Jiaqi Chen, Zheng Han, Weizheng Liu. A review on solutions for improving rutting resistance of asphalt pavement and test methods. Construction and Building Materials. 2018, 168. [Google Scholar]

- Wenyao Liu, Kezhen Yan, Dongdong Ge, Ming Chen. Effect of APAO on the aging properties of waste tire rubber modified asphalt binder. Construction and Building Materials. 2018, 175. [Google Scholar]

- Xing, M. Yang, H. Zhao, Z. Yu, T. Effect of Asphalt Pavement Base Layers on Transverse Shrinkage Cracking Characteristics. Sustainability. 2023, 15, 7178. [Google Scholar] [CrossRef]

- 7. Kun Zhang, John Kevern. Review of porous asphalt pavements in cold regions: the state of practice and case study repository in design, construction, and maintenance. Journal of Infrastructure Preservation and Resilience. [CrossRef]

- Miao, Y. Sheng, J. Ye, J. An Assessment of the Impact of Temperature Rise Due to Climate Change on Asphalt Pavement in China. Sustainability 2022, 14, 9044. [Google Scholar] [CrossRef]

- 9. Haitao Zhang, Mingyang Gong, Yingli Huang, Miomir Miljković. Study of the high and low-temperature behavior of asphalt based on a performance grading system in Northeast China. Construction and Building Materials. [CrossRef]

- Hamid, A. Baaj, H. El-Hakim, M. Temperature and Aging Effects on the Rheological Properties and Performance of Geopolymer-Modified Asphalt Binder and Mixtures. Materials 2023, 16, 1012. [Google Scholar] [CrossRef]

- Moghaddam, T.B. Baaj, H. The use of compressible packing model and modified asphalt binders in high-modulus asphalt mixdesign. Road Materials and Pavement Design 2020, 21, 1061–1077. [Google Scholar] [CrossRef]

- Jizhe Zhang, Alex K. Apeagyei, Gordon D. Airey, James R.A. Grenfell. Influence of aggregate mineralogical composition on water resistance of aggregate–bitumen adhesion. International Journal of Adhesion and Adhesives 2015, 62, 45–54. [Google Scholar] [CrossRef]

- Huang, G. Zhang, J. Hui, B. Zhang, H. Guan, Y. Guo, F. Li, Y. He, Y. Wang, D. Analysis of Modulus Properties of High-Modulus Asphalt Mixture and Its New Evaluation Index of Rutting Resistance. Sustainability 2023, 15, 7574. [Google Scholar] [CrossRef]

- Zhang, H. Yang, X. Li, Y. Fu, Q. Rui, H. Laboratory Evaluation of Dynamic Characteristics of a New High-Modulus Asphalt Mixture. Sustainability 2022, 14, 11838. [Google Scholar] [CrossRef]

- Chen, Y. Wang, H. Xu, S. You, Z. High modulus asphalt concrete: A state-of-the-art review. Construction and Building Materials 2020, 237, 117653. [Google Scholar] [CrossRef]

- Hemmati, N. Vigneswaran, S. Kim, H.H. Lee, M.-S. Lee, S.-J. Laboratory Evaluation of Asphalt Binders Containing Styrene-Butadiene-Styrene (SBS) and Processed Oil. Materials 2023, 16, 1235. [Google Scholar] [CrossRef] [PubMed]

- Weidong Huang, Naipeng Tang. Characterizing SBS modified asphalt with sulfur using multiple stress creep recovery test. Construction and Building Materials. 2015, 93. [Google Scholar]

- 18. Huang Junxian, Liu Yu, Muhammad Yaseen, Li Jia Qing, Ye Yuting, Li Jing, Li Zhuang, Pei Ruinan. Effect of glutaraldehyde-chitosan crosslinked graphene oxide on high temperature properties of SBS modified asphalt. Construction and Building Materials. [CrossRef]

- Mugume, R. Kakoto, D. Effect of Inappropriate Binder Grade Selection on Initiation of Asphalt Pavement Cracking. Sustainability. 2020, 12, 6099. [Google Scholar] [CrossRef]

- Q. Li, H. Zhang, Z. Chen, Improvement of short-term aging resistance of styrenebutadiene rubber modified asphalt by Sasobit and epoxidized soybean oil. Construction and Building Materials. 2021, 121870. [Google Scholar]

- J. D Angelo. Current Status of Superpave Binder Specification. Road Materials and Pavement Design. 2009, 13–24. [Google Scholar]

- Matheus David Inocente Domingos, Adalberto Leandro Faxina. Accelerated short term ageing effects on the rheological properties of modifified bitumens with similar high PG grades. Road Materials and Pavement Design. 2015, 469–480, 469–480.

- 23. Jian Zou, Reynalao Roque, Sanghyun Chun & George Lopp. Long-term fifield evaluation and analysis of top-down cracking for Superpave projects. Road Materials and Pavement Design. [CrossRef]

- 24. John D'Angelo, Fee Frank. Superpave binder tests and specifications: how have they performed in the real world? Association of Asphalt Paving Technologists Proc.

- 25. Tao Wang, Feipeng Xiao, Serji Amirkhanian, Weidong Huang, Mulian Zheng. A review on low temperature performances of rubberized asphalt materials. Construction and Building Materials. [CrossRef]

- David, A. Anderson, Donald W. Christensen, Hussain U. Bahia, Raj Dongre, M.G. Sharma, Charles E. Antle, Joe Button. Binder Characterization and Evaluation Volume 3: Physical Characterization. Strategic Highway Research Program: Washington,.

- Tester, A.M.P. Testing for Fatigue Cracking in the Asphalt Mixture Performance Tester. FHWA: Washington.

- 28. Roque Reynaldo, Yan Yu, Lopp George. Evaluation of the Cracking Performance of Asphalt Binders at Intermediate Temperatures. University of Florida: Gainesville,.

- 29. Yaning Qiao, Joao Santos, Anne M.K. Stoner, Gerardo Flinstch. Climate change impacts on asphalt road pavement construction and maintenance: An economic life cycle assessment of adaptation measures in the State of Virginia, United States. Journal of Industrial Ecology. [CrossRef]

- Chao Wang, Xianxin Zhou, Guodong Gao. Study on Climate Impacts on Asphalt Pavement in Tibet, China. Journal of Geoscience and Environment Protection. 2019, 49–59. [Google Scholar]

- American Asphalt Association, Reference manual for high performance asphalt pavement foundation, Beijing People’s Transport Press. 2005.

- Ibrahim, M. Asi. Performance evaluation of SUPERPAVE and Marshall asphalt mix designs to suite Jordan climatic and traffic conditions. Construction and Building Materials. 2006, 21, 8. [Google Scholar]

- Hossam, F. Hassan, Ali Al-Nuaimi, Salim Al-Oraimi, Tufool M.A. Jafar. Development of asphalt binder performance grades for Omani climate. Construction and Building Materials. 2007, 22, 8. [Google Scholar]

- A. M.M. Saleh, Metwally A. Trad. Generation of asphalt performance grading map for Egypt based on the SUPERPAVE? program. Construction and Building Materials. 2011, 25, 5. [Google Scholar]

- M. Waseem Mirza, Zahid Abbas, Mujasim Ali Rizvi. Temperature Zoning of Pakistan for Asphalt Mix Design. Pakistan Journal of Engineering and Applied Sciences. 2011, 49–60. [Google Scholar]

- Peerapong Jitsangiam, Prinya Chindaprasirt, Hamid Nikraz. An evaluation of the suitability of SUPERPAVE and Marshall asphalt mix designs as they relate to Thailand’s climatic conditions. Construction and Building Materials. 2013, 40. [Google Scholar]

- Hassan Awadat Salem, Djordje Uzelac, Bojan Matic. Temperature Zoning of Libya Desert for Asphalt Mix Design. Temperature Zoning of Libya Desert for Asphalt Mix Design. Applied Mechanics and Materials. 2014, 3489, 638–640. [Google Scholar]

- Francesco Viola, Clara Celauro. Effect of climate change on asphalt binder selection for road construction in Italy. Transportation Research Part D. 2015, 37. [Google Scholar]

- Cota, J. Martínez-Lazcano, C. Montoya-Alcaraz, M. García, L. Mungaray-Moctezuma, A. Sánchez-Atondo, A. Improvement in Durability and Service of Asphalt Pavements through Regionalization Methods: A Case Study in Baja California, Mexico. Sustainability, 2022, 14, 5123. [Google Scholar] [CrossRef]

- 40. Zhao Kaiwen, Ma Xianyong, Zhang Hongwei, Dong Zejiao. Performance zoning method of asphalt pavement in cold regions based on climate Indexes: A case study of Inner Mongolia. Construction and Building Materials. [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Renmin Communication Press: Beijing China, 2011.

- JTG F40-2004; The Chinese Technical Specification for Construction of Highway Asphalt Pavement. Renmin Communication Press: Beijing, China, 2004.

- T. W. Kennedy, G. T. W. Kennedy, G. Huber, E. Harrigan, R. Cominsky, C. Hughes, H. Quintus, J. Moulthrop Superior performing asphalt pavements (Superpave): The product of the SHRP asphalt research program, 1994.

| Station | Longitude(°) | Latitude(°) | Average of seven days average maximum temperature (°C) | Standard deviation | Maximum design temperature of road surface (°C) | Average of seven days average minimum temperature (°C) | Standard deviation | Minimum design temperature of road surface (°C) |

|---|---|---|---|---|---|---|---|---|

| Fuhai | 87.48 | 47.11 | 38.0 | 2.2 | 65.50 | -39.0 | 3.1 | -31.83 |

| Habahe | 86.32 | 48.04 | 37.4 | 2.4 | 64.99 | -37.8 | 4.1 | -30.80 |

| Buerjin | 86.85 | 47.70 | 37.4 | 2.4 | 64.97 | -39.0 | 3.8 | -31.83 |

| Jimunai | 85.87 | 47.44 | 35.4 | 2.8 | 63.05 | -34.8 | 4.1 | -28.22 |

| Fuyun | 89.53 | 46.99 | 38.4 | 2.8 | 65.88 | -41.0 | 4.1 | -33.55 |

| Qinghe | 90.38 | 46.67 | 35.0 | 2.2 | 62.61 | -42.2 | 3.4 | -34.58 |

| Tacheng | 82.59 | 46.46 | 38.2 | 1.9 | 65.65 | -33.2 | 4.1 | -26.84 |

| Emin | 83.62 | 46.52 | 36.5 | 2.0 | 64.03 | -36.5 | 4.5 | -29.68 |

| Yumin | 82.98 | 46.20 | 38.0 | 2.2 | 65.44 | -34.2 | 4.4 | -27.70 |

| Tuoli | 83.60 | 45.94 | 34.8 | 1.9 | 62.37 | -31.4 | 3.6 | -25.29 |

| Hebukesaier | 85.72 | 46.79 | 32.2 | 1.5 | 59.95 | -34.8 | 3.8 | -28.22 |

| Wusu | 84.62 | 44.45 | 38.9 | 1.7 | 66.17 | -30.6 | 2.5 | -24.61 |

| Kelamayi | 84.77 | 45.59 | 39.5 | 1.7 | 66.83 | -32.3 | 3.2 | -26.07 |

| Kuitun | 84.89 | 44.45 | 38.9 | 1.6 | 66.17 | -30.4 | 2.5 | -24.43 |

| Shawan | 85.62 | 44.33 | 37.7 | 1.3 | 65.02 | -31.5 | 3.1 | -25.38 |

| Manasi | 86.20 | 44.29 | 39.1 | 1.8 | 66.35 | -33.1 | 2.8 | -26.76 |

| Shihezi | 86.00 | 44.18 | 39.2 | 1.5 | 66.44 | -38.5 | 4.6 | -31.40 |

| Changji | 87.30 | 44.02 | 40.3 | 2.1 | 67.48 | -37.1 | 3.8 | -30.19 |

| Wulumuqi | 87.61 | 43.79 | 37.7 | 2.1 | 64.98 | -29.4 | 3.0 | -23.58 |

| Wujiaqu | 87.54 | 44.17 | 41.0 | 2.1 | 68.16 | -36.8 | 2.6 | -29.94 |

| Fukang | 87.94 | 44.16 | 40.2 | 1.8 | 67.39 | -32.5 | 3.0 | -26.24 |

| Miquan | 87.68 | 43.97 | 40.0 | 1.9 | 67.19 | -33.0 | 4.0 | -26.67 |

| Qitai | 89.59 | 44.02 | 38.2 | 1.7 | 65.47 | -37.1 | 3.3 | -30.19 |

| Jimusaer | 89.18 | 44.00 | 38.2 | 1.6 | 65.47 | -32.2 | 3.2 | -25.98 |

| Mulei | 90.28 | 43.83 | 34.4 | 1.8 | 61.83 | -32.6 | 3.9 | -26.33 |

| Balikun | 93.01 | 43.59 | 33.0 | 2.0 | 60.48 | -35.0 | 3.3 | -28.39 |

| Yiwu | 94.69 | 43.25 | 32.8 | 1.7 | 60.26 | -31.3 | 2.6 | -25.21 |

| Hami | 93.44 | 42.78 | 41.4 | 1.4 | 68.43 | -26.6 | 2.6 | -21.17 |

| Tulufan | 89.18 | 42.93 | 46.2 | 1.3 | 73.02 | -19.8 | 2.6 | -15.32 |

| Shanshan | 90.21 | 42.86 | 43.8 | 1.4 | 70.73 | -22.5 | 2.2 | -17.64 |

| Tuokesun | 88.65 | 42.79 | 46.5 | 1.6 | 73.30 | -20.4 | 2.0 | -15.84 |

| Hejing | 86.39 | 42.31 | 36.7 | 1.3 | 63.90 | -24.2 | 1.9 | -19.10 |

| Heshuo | 86.86 | 42.26 | 36.6 | 1.2 | 63.80 | -25.6 | 2.2 | -20.31 |

| Yanqi | 86.57 | 42.05 | 37.2 | 1.5 | 64.36 | -26.0 | 2.6 | -20.65 |

| Bohu | 86.63 | 41.98 | 36.5 | 1.1 | 63.69 | -25.6 | 2.7 | -20.31 |

| Kuerle | 86.06 | 41.68 | 38.7 | 1.7 | 65.76 | -20.8 | 1.9 | -16.18 |

| Yuli | 86.25 | 41.33 | 39.3 | 1.3 | 66.30 | -24.3 | 2.5 | -19.19 |

| Ruoqiang | 88.17 | 39.02 | 42.3 | 1.5 | 68.96 | -22.3 | 1.9 | -17.47 |

| Qiemo | 85.53 | 38.14 | 40.2 | 1.4 | 66.87 | -21.6 | 1.8 | -16.87 |

| Minfeg | 82.68 | 37.06 | 40.6 | 1.7 | 67.15 | -21.1 | 2.4 | -16.44 |

| Yutian | 81.95 | 36.45 | 39.2 | 1.4 | 65.75 | -19.7 | 2.3 | -15.24 |

| Cele | 80.78 | 37.04 | 40.0 | 1.5 | 66.57 | -19.2 | 2.3 | -14.81 |

| Hetian | 79.94 | 37.12 | 39.1 | 1.5 | 65.72 | -18.4 | 2.7 | -14.12 |

| Moyu | 79.71 | 37.31 | 38.9 | 1.3 | 65.55 | -20.8 | 2.1 | -16.18 |

| Pishan | 78.29 | 37.62 | 39.3 | 1.5 | 65.96 | -19.9 | 2.5 | -15.41 |

| Tashiuergan | 75.23 | 37.77 | 30.2 | 1.5 | 57.29 | -28.7 | 1.8 | -22.97 |

| Yecheng | 77.42 | 37.89 | 37.7 | 1.4 | 64.46 | -20.0 | 2.8 | -15.49 |

| Zepu | 77.26 | 38.20 | 38.5 | 1.4 | 65.25 | -20.1 | 2.3 | -15.58 |

| Shache | 77.25 | 38.45 | 38.8 | 1.5 | 65.56 | -19.5 | 2.5 | -15.06 |

| Maigaiti | 77.64 | 38.95 | 39.1 | 1.4 | 65.90 | -19.8 | 2.3 | -15.32 |

| Yingjisha | 76.17 | 38.93 | 38.6 | 1.2 | 65.42 | -20.8 | 3.1 | -16.18 |

| Yuepuhu | 76.77 | 39.23 | 40.1 | 1.3 | 66.88 | -20.7 | 2.5 | -16.10 |

| Jiashi | 76.73 | 39.50 | 39.4 | 1.3 | 66.24 | -20.6 | 2.5 | -16.01 |

| Shule | 76.05 | 39.41 | 38.3 | 1.5 | 65.18 | -19.5 | 2.5 | -15.06 |

| Shufu | 75.86 | 39.37 | 37.9 | 1.2 | 64.79 | -19.5 | 2.6 | -15.06 |

| Aketao | 75.95 | 39.15 | 37.6 | 1.2 | 64.48 | -21.8 | 2.8 | -17.04 |

| Kashi | 75.99 | 39.46 | 37.8 | 1.3 | 64.70 | -20.6 | 2.8 | -16.01 |

| Wuqia | 75.25 | 39.71 | 32.4 | 1.5 | 59.57 | -23.6 | 1.9 | -18.59 |

| Atushi | 76.16 | 39.73 | 39.0 | 1.4 | 65.87 | -18.5 | 2.5 | -14.20 |

| Bachu | 78.59 | 39.78 | 39.0 | 1.2 | 65.88 | -20.0 | 2.2 | -15.49 |

| Tumukeshu | 79.13 | 39.85 | 39.2 | 1.3 | 66.08 | -16.4 | 2.7 | -12.40 |

| Aheqi | 78.44 | 40.93 | 33.9 | 1.6 | 61.11 | -24.2 | 2.2 | -19.10 |

| Keping | 79.05 | 40.51 | 38.7 | 1.2 | 65.66 | -22.8 | 2.8 | -17.90 |

| Awati | 80.37 | 40.64 | 37.8 | 1.6 | 64.81 | -21.5 | 2.3 | -16.78 |

| Wushi | 79.22 | 41.21 | 35.1 | 1.2 | 62.28 | -24.4 | 2.9 | -19.28 |

| Wensu | 80.24 | 41.27 | 37.6 | 1.4 | 64.67 | -22.0 | 2.6 | -17.21 |

| Akesu | 80.26 | 41.17 | 37.9 | 1.2 | 64.95 | -21.5 | 2.2 | -16.78 |

| Alaer | 81.29 | 40.54 | 38.4 | 1.2 | 65.37 | -23.5 | 2.7 | -18.50 |

| Shaya | 83.19 | 41.05 | 39.0 | 1.5 | 65.99 | -20.8 | 2.5 | -16.18 |

| Kuche | 82.96 | 41.71 | 37.4 | 1.3 | 64.52 | -21.9 | 2.5 | -17.13 |

| Xinhe | 82.63 | 41.55 | 37.6 | 1.3 | 64.70 | -22.6 | 2.5 | -17.73 |

| Baicheng | 81.84 | 41.82 | 36.5 | 1.4 | 63.67 | -27.0 | 3.2 | -21.51 |

| Luntai | 84.25 | 41.77 | 39.1 | 1.5 | 66.15 | -24.3 | 3.0 | -19.19 |

| Zhaosu | 81.13 | 43.15 | 29.8 | 1.8 | 57.39 | -30.1 | 3.0 | -24.18 |

| Tekesi | 81.83 | 43.21 | 34.3 | 1.5 | 61.69 | -29.6 | 3.3 | -23.75 |

| Gongliu | 82.23 | 43.48 | 36.7 | 1.5 | 64.00 | -30.1 | 3.5 | -24.18 |

| Xinyuan | 83.26 | 43.42 | 36.5 | 1.5 | 63.80 | -25.3 | 3.4 | -20.05 |

| Nileke | 82.51 | 43.80 | 35.9 | 1.6 | 63.26 | -32.0 | 3.5 | -25.81 |

| Yining | 81.33 | 43.91 | 38.2 | 1.7 | 65.46 | -31.2 | 4.2 | -25.12 |

| Chabuchaer | 81.15 | 43.84 | 38.7 | 1.6 | 65.94 | -33.7 | 4.7 | -27.27 |

| Huocheng | 80.87 | 44.05 | 38.7 | 1.6 | 65.95 | -30.7 | 3.7 | -24.69 |

| Wenquan | 81.03 | 44.97 | 33.4 | 1.9 | 60.96 | -31.6 | 2.0 | -25.47 |

| Bole | 82.10 | 44.93 | 38.8 | 1.5 | 66.11 | -32.8 | 2.7 | -26.50 |

| Jinghe | 82.88 | 44.60 | 39.5 | 1.5 | 66.76 | -33.2 | 2.7 | -26.84 |

| Technical Indexes | Unit | 90# | 70# | 50# | 30# | SBS | |

| Penetration (25°C,100g,5s) | 0.1mm | 87 | 72 | 55.8 | 32.8 | 76 | |

| Penetration index, PI | - | -1.11 | -0.34 | -0.22 | -0.02 | 0.53 | |

| Softening point, TR&B | °C | 45.3 | 49.0 | 50.2 | 55.6 | 65.6 | |

| Ductility(15°C,5cm/min) | cm | >100 | >100 | >100 | 61 | / | |

| Ductility(10°C,5cm/min) | cm | >100 | >100 | >100 | 8 | 42.1a | |

| Density@15°C | g/cm3 | 0.983 | 0.986 | 0.985 | 0.986 | 0.985 | |

| Dynamic viscosity@60°C | Pa·S | 252 | 421 | 879 | 1783 | 1.977b | |

| Solubility | % | 0.983 | 0.986 | 0.985 | 0.986 | 0.985 | |

| After RTFOT(163°C 85min) | Mass change | % | -0.035 | -0.035 | -0.064 | -0.088 | -0.185 |

| Penetration ration @25°C | % | 77 | 75 | 74 | 77 | 84 | |

| Ductility(15°C,5cm/min) | cm | >100 | >100 | 27 | 9 | / | |

| Ductility(10°C,5cm/min) | cm | 40 | 11 | / | / | 25.1c | |

| Parameter | Condation | Specfication | PG | ||||

| 90# | 70# | 50# | 30# | SBS | |||

| G*/sinδ | Original | ≥1kPa | 67.5 | 71.8 | 74.4 | 76.8 | 84.9 |

| G*/sinδ | RTFOT | ≥2.2kPa | 66.7 | 69.0 | 72.1 | 77.6 | 83.2 |

| Upper PG | 64 | 64 | 70 | 76 | 82 | ||

| G*·sinδ | PAV | ≤5000kPa | 22 | 22 | 28 | 31 | 28 |

| Intermediate PG | 22 | 22 | 28 | 31 | 28 | ||

| S | PAV | ≤300MPa at 60 sec | -30.0 | -28.2 | -25.6 | -22.9 | -34.3 |

| m-value | PAV | ≥0.3kPa at 60 sec | -31.3 | -28.7 | -25.4 | -22.4 | -34.5 |

| Lower PG | -28 | -28 | -22 | -22 | -34 | ||

| PG | 64-28 | 64-28 | 70-22 | 76-22 | 82-34 | ||

| Continuous PG | 66.7-30 | 69-28.2 | 72.1 - 25.4 | 76.8-22.4 | 83.2-34.3 | ||

| Difference between cont. high and cont. low PG | 96.7 | 97.2 | 97.5 | 99.2 | 117.5 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).