3.2.1. The Nodal Degrees of Freedom Error Correction

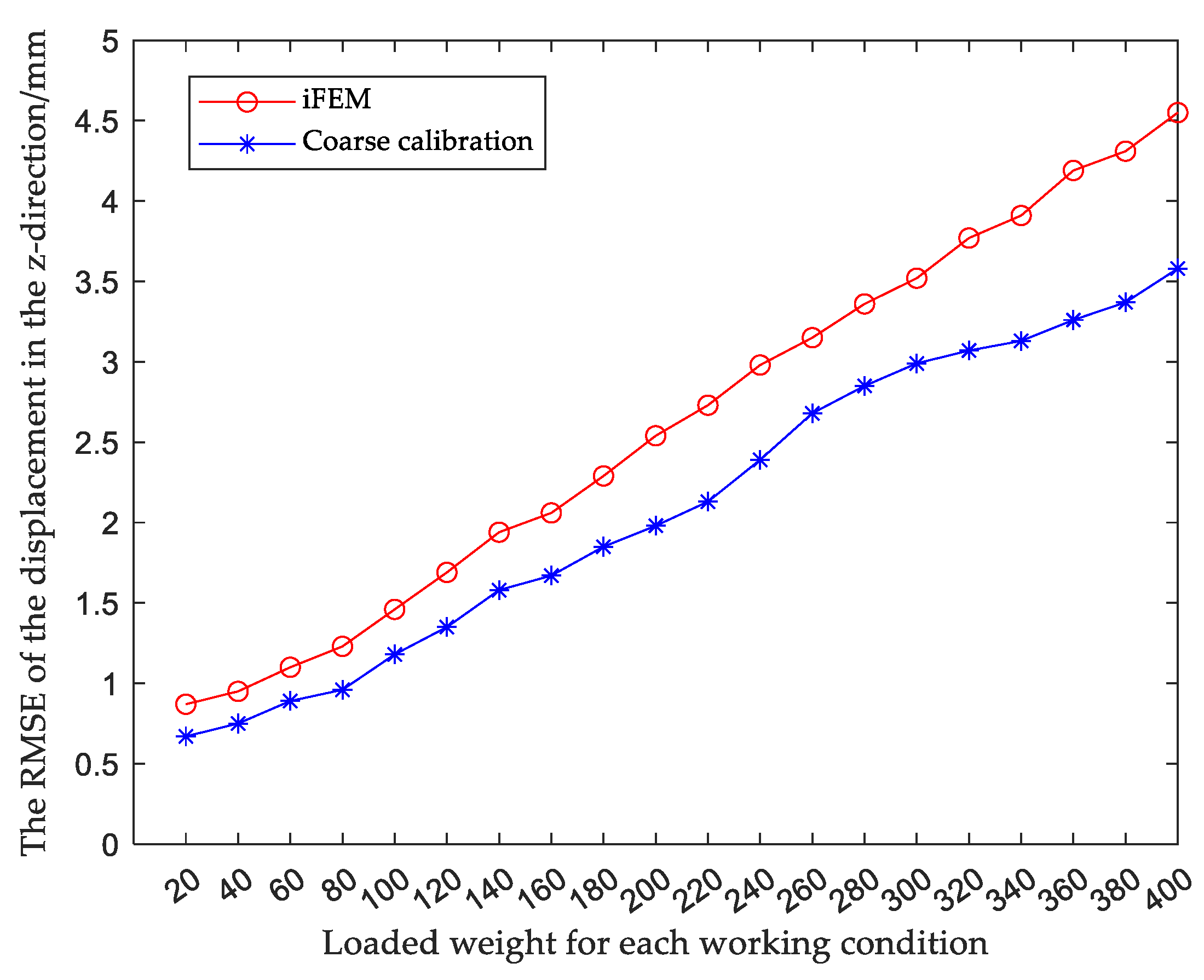

For the errors that still exist between the displacements reconstructed based on the iFEM and the actual displacements after the coarse calibration, the displacement-nodal degree of freedom error correction model is further proposed. As shown in Eq. (18), the theoretical displacement of the inverse finite element reconstruction is denoted as

, and the actual displacement is denoted as

where

i=1,... ,n denotes the ordinal number of observation points and Δ

di denotes the reconstruction error. Displacement at any position in the structure can be obtained from the shape function

H(x) and the discrete nodal during the reconfiguration displacement. As a result, correcting the reconstruction error in the nodal DOF enables calibration of the entire displacement.

The relationship between displacement error and nodal DOF error can be expressed as Eq. (19).

where the number of nodal DOF is c. The displacement field error Δ

di of the inverse finite element reconstruction is derived by Eq. (19) to the nodal DOF error Δ

uj(

j= 1, ... , c), then the displacement-nodal DOF model can be expressed as Eq. (20)

where

Δdz=[

Δ, Δ, ... ,Δ]

T,

H=[

H1.H2,... ,Hn]

, β is denoted as the residuals after displacement error correction and obeys Gaussian distribution. i.e.,

, and

is the row vector of G*N

i for Δd

z.It follows that Δd

x and Δ

dy can also be expressed analogously by Eq. (20).

The matrix

H in Eq. (20) is the ill-conditioned matrix. The actual measured strain value of the sensor receives interference from random noise, which makes the estimated value

Δu having error with the actual value, the error is reduced by Bayesian regularization algorithm using prior information. From Bayesian theory,

p(

Δu,σ2|Δdx)is used to represent the joint posterior distribution of the unknown parameters, as defined as shown in Eq. (21):

where

p(

Δu,σ2) denotes the joint prior distribution, rewriting Eq. (21) into multiplicative form. where it is assumed that the residuals are independently Gaussian distributed, i.e.,

, the non-informative prior of

σ2 is taken into account, i.e.,

. Assuming that the prior distribution of Δ

u is Gaussian, i.e.,

, the posterior distribution in logarithmic form

is represented

where

,The conditional posterior distribution of Δ

u in Eq. (23) is calculated using the conjugate distribution method as

N(Δ

uj,) .

For σ

2, the conditional posterior distribution is the inverse chi-square distribution, expressed as

Therefore, Markov Chain Monte Carlo samples are produced from the posterior

p(

Δu,σ2|Δdx)via a Gibbs sampler for calibration amounts

Δu ,the steps are as follows: (1) initialize

Δu and

σ2; (2) perform Gibbs sampling on

Δu in Eq. (23); (3)The inverse chi-square distribution from Eq. (24) is selected

σ2. The specific process details are shown in

Figure 4.

The calibration values of each kinematic variable in the nodal DOF error are derived from the Bayesian regularization algorithm and are combined with the actual measured strain values to form the sample data, defining in Eq. (25).

where

Qj denotes the

j th (j=1,2, ... , h) sample data under working conditions,

denotes the

l th (

l=1,2,... ,L) strain value measured by the sensor. ∆

ui (

i=1,2,...,m) denotes the error calibration value of the kinematic variable in the nodal DOF error.

3.2.2. Training Data Filtering and Sample Size Expansion

The error correction method has limitations: the nodal DOF errors can only be calibrated under specific working conditions. Therefore, in order to obtain the error calibration between strain values and nodal DOF under arbitrary working conditions, a self-constructed fuzzy network is used for calibration. The selection of appropriate training data affects the training effect of self-constructed fuzzy networks, and this paper employed the residual analysis to screen the sample data. In addition, the training effect of the self-constructed fuzzy network is also related to the number of training samples, so the number of training samples should be expanded before entering the training network.

The residual is the difference between the actual observed value and the fitted value of the sample. The reliability and reasonableness of the data is analyzed using the residual, defined as follows.

where

y represents the actual observed value,

represents the fitted value, and

e represents the residual.

In this paper, considering that high-dimensional data can cause excessive computation, and the screening of sample data requires residual analysis for each kinematic variable in the calibration values of DOF to ensure the reasonableness of screening training data.

The new sample point is obtained by downscaling the original sample data

Qj in Eq. (25)

Decompose each sample point is decomposed into Fi (i=1,2,... ,m) of the form, where each vector Fi consists of L measured strain values and 1 kinematic variable of nodal DOF error,and denote the kinematic variables as Δui (i=1,2,... ,m).

The sample fit values were obtained before the sample data were screened based on the magnitude of the residuals. In this paper,

the Non Uniform Rational B-spline (NURBS) curve fitting method is used to fit the data

Fi, as shown in

Figure 4.

The NURBS curve of order

c can be expressed as a segmented rational polynomial vector function, the mathematical definition is as follows.

where

ki (i=0,1,... ,h) denote the weight factors, respectively, associated with the control vertex

Mi (i=0,1,...,h),due to the lack of expert experience, the weighting constants

ki=1 (i=0,1,... ,h).

Ei,c(

t) denotes the c-th order B-spline basis function, which is a non-decreasing sequence of parameter.

T=[t

0,t

1,…,t

h+c+1] is the nodal vector and determined by the c-th order segmented polynomial.

The basis function can be recursively expressed by.

The parameterization of the data points reflects the nature of the curve constructed with the data points. Based on the nodal vector of basis functions and control points to construct the NURBS-fitted curves. A centripetal parameterization method is applied to the sample data as shown in Eq. (30).

As required by the definition domain of the non-closed curve, multiple knot with repetition degree c+1 are taken at the two endpoints of the definition domain. According to the distribution of the sample and the method of centripetal parameterization, the non-uniform vector method is used for the construction, shown in Eq. (31).

The

c-th order NURBS curve is constructed by m+1 sampling points

Fi (i=0,1,... ,m). The approximation function is obtained by using the least squares method to approximate the parameter sequence

(i=0,1,... ,m), shown in Eq. (32).

where the control points are set to

A0=

F0,

Am=

Fh,then

Si=

Fi-F0E0,c(

)

-FhEp,c(

). and the partial derivatives of the control points in Eq. (32) are equal to 0.

The matrix form is expressed as.

where the

E matrix is a matrix with h-1 rows and m-1 columns and

ET is the transpose matrix of

E. The

E,

S, and

M matrices are shown in Eq. (34).

The specific steps to obtain the sample fit values using NURBS curve fitting are as follows:

(1) the data are parameterized by Eq. (29) to obtain (i=1,2,... ,m). and the basis function Ei, c(t).

(2) After obtaining , the nodal vector T is obtained by Eq. (30).

(3) The control point Mi (i=1,2,... ,h) is obtained according to Eq. (33).

(4) The constructed NURBS fitting curve is then derived from Eq. (28).

(5) When the NURBS fitted curve is obtained, the values of the sample data parameters are substituted into the curve Eq. of Eq. (28), and then the values on the fitted curve corresponding to the original sample data can be obtained.

Similarly, the fitted data

i (

i=1,2,... ,m) for the rest of the samples under a working condition can be obtained as shown below.

When screening training data using residual analysis, the error in the kinematic variables Δui (i=1,2,...,m) varies considerably in order of magnitude due to the actual situation, which affects the residual analysis. The transformation matrix H in Eq. (2) is related to the observed coordinates of the position sensor (check point) and other factors, and the order of magnitude of each column of the transformation matrix H varies greatly. According to Eq. (19), Δdi for the same working conditions is generally under the same order of magnitude, so it leads to kinematic variable errors Δui (i=1,2,...,m) obtained from the solution of different orders of magnitude.

According to the analysis described above, the main factor affecting the magnitude of the kinematic variable error is the column vector of transformation matrix

H. Therefore, the weighting constants are calculated as shown in Eq. (36).

where

ai (i=1, 2, ... ,m) denotes the weighting constants corresponding to the mth kinematic variable error, and H

ki denotes the

k-th row and

i-th column of the transformation matrix.

When the position of the position sensor is fixed, the matrix H is fixed under any working condition, so the weighting constants corresponding to the kinematic variable error are also unchanged. At this time, The integrated residual value

et of sample under one working condition can be obtained from the Euclidean distance, which is calculated as shown in Eq. (37).

In summary, the integrated residuals of the samples (j=1,2,....,h) under the remaining working conditions can be obtained.

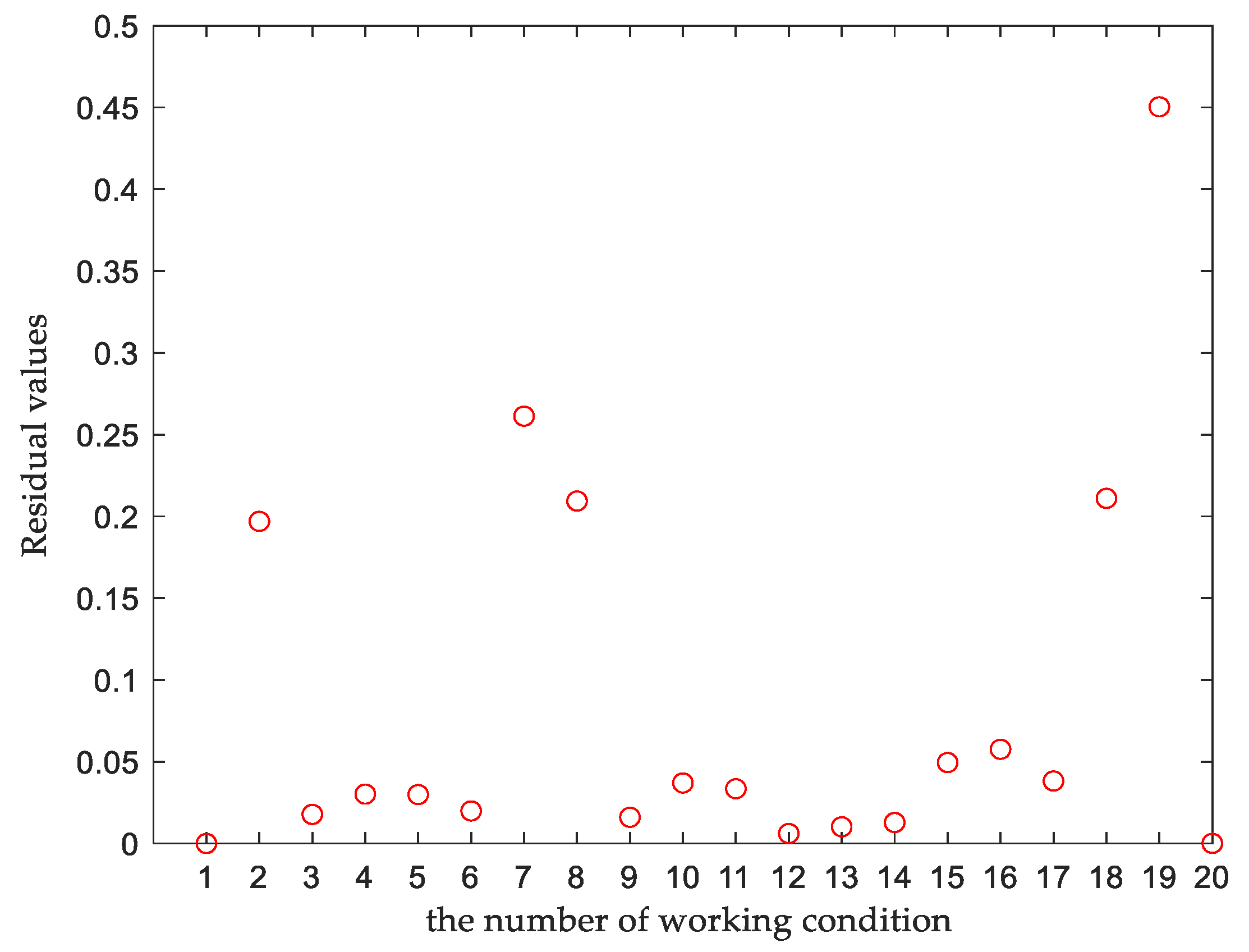

The screened training data consists of three parts: boundary samples, representative samples and normal samples after equidistant sampling. the boundary samples are the sample points where the structure is in the minimum and maximum load states in the experiment. After extensive experiments and summaries, it is concluded the normal sample points in the remaining sample points are all the values with small fluctuation range of residuals, And the residual values of representative sample points are more than twice the fluctuation range of the residual values of normal sample points.

The specific steps of the screening training data method are: (1) The NURBS curve fitting method is adopted to obtain the corresponding fitting data of sample points. (2) Subtracting the corresponding fitting data from the sample data to obtain the residual values of each sample point under different working conditions. (3) Selecting the boundary samples, representative samples, and normal samples obtained by equidistant sampling as the training samples for constructing the self-constructed fuzzy neural network.The training sample set

Fsc are screened from all samples

Qj is denoted as:

Expanding the number of screened training samples through the NURBS curve fitting method. After obtaining the fitting curve, a specific step is taken to extend the sample quantity by substituting values of ranging from 0 to 1 into Eq. (28). Then, self-constructed fuzzy network is trained based on the extended samples.

3.2.3. Self-Constructed Fuzzy Network Calibration

Due to the nonlinearity and coupling relationship between the strain values in the sample data and the nodal DOF calibration values, it is difficult to establish a mathematical model. However, SCFN can effectively solve this nonlinearity problem. After screening all samples for suitable training samples and extending them, the SCFN is trained based on the extended samples. A strain-nodal DOF calibration model is established. The SCFN enhances the generalization ability of the strain-nodal DOF calibration value and improves the accuracy of the reconstructed displacement by calibrating the nodal DOF. SCFN is divided into two steps [

31]: (1) Adding the affiliation function and generating the corresponding fuzzy rules. (2) Adaptively adjust the results of the fuzzy rules.

In this paper, because the triangular affiliation function has a simple structure, it is convenient to calculate the membership degree and efficient. Thus, SCFN chooses the triangular membership function and the 0th order T-S fuzzy model, which is represented by the fuzzy rule set as follows.

where

Sn (n=1,2,...,N)denotes the nth fuzzy rule,

(k=1,2,... , K) is denoted as the input strain value, and

denotes the membership degree corresponding to

in the nth rule.

denotes the output of the nth fuzzy rule and

is the value corresponding to its fuzzy rule output.

The system output of SCFN ̂

represents the nodal DOF error, and when a certain input activates m rules (n≥m), the system output is derived from the

of these

m outputs by weighted averaging, as shown in Eq. (33).

The

in Eq. (40) denotes the weighting constants of the rule, and the weighting constants are calculated by taking the smallest method, as shown in Eq. (41).

The SCFN is initialized with one rule, and the membership functions and rule number are added or removed based on the error and completeness criteria. When the number of training samples is k+1, the error standard of SCFN is represented by root mean square error η

t, and the formula is shown below.

where denotes the actual output,

U(c) denotes the desired output, η

a is denoted as a predetermined error threshold, and if η

t>η

a, it means that the system error does not meet the requirements and the membership function needs to be increased.

In SCFN, each input value at least corresponds to one membership function, if its membership degree is greater than the completeness threshold α, the completeness of the membership function meets the requirements, if is less than α, it is necessary to increase the membership function and fuzzy rules. The completeness threshold is generally set to 0.5.

After adding the membership function and fuzzy rule, the fuzzy rule also needs to be adaptive adjustment to make it closer to the output value. The specific expression for adjusting the

nth rule of the fuzzy controller at the

ith moment is as follows.

where

an(

i) denotes the rule adjustment result at moment

i,

V is used to adjust the adaptive speed during rule adjustment,

φn(

i-1) denotes the weighting constants of the nth rule at moment

i-1,

P(

i-1) denotes the desired output of the nth rule at moment

i-1, and

(i) is the current system output.

Each rule is added and adaptively adjusted according to the standard correspondence, and then used to train the SCFN. when ηt≤ηa, the training is stopped to jump out of the iteration and generate the fuzzy network, and the trained fuzzy rules are saved to obtain the calibrated nodal freedom results.

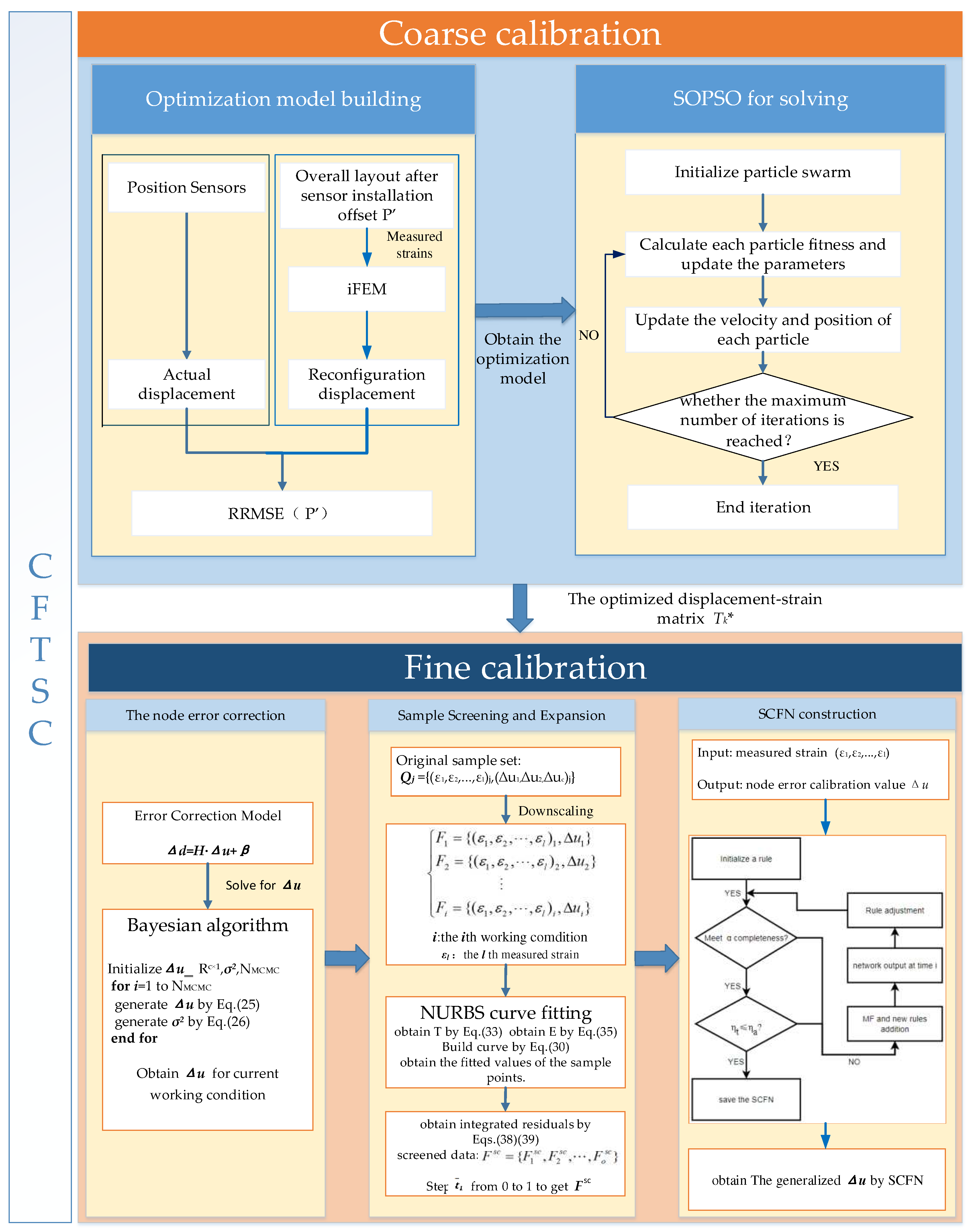

Summarize the above, The method flow framework for CFTSC method is shown in

Figure 5.

Figure 5.

Flow framework of CFTSC method.

Figure 5.

Flow framework of CFTSC method.