Introduction

In recent years, the demand for protein-fortified products is increasing worldwide. Among baked foods, biscuits and cookies are the most widely consumed products. Due to biscuit’s low protein content, nutritional value is typically a challenge for the biscuit industry. Higher incidence of protein deficiency-protein calorie malnutrition causes severe nutritional issue which now plaguing the world, especially in underdeveloped nations. Addressing the protein deficit diet is the need of the hour. Studies by (Brink and Belay, 2006) directs that use of 100% wheat flour in biscuits manufacturing results in higher calorie, fat and lower in protein, the main ingredient of biscuit dough is wheat flour which is low in protein (7–10%) (Yamazaki and Greenwood, 1981) and deficient in some essential amino acids such as lysine, tryptophan and threonine (Claughton and Pearce, 1989) (Singh et al. 1996).To increase the nutritional profile of biscuits, it is necessary to integrate some protein-rich component to enhance the protein profile of the biscuits. Over the past decades many studies have been made on development of high protein biscuits using gluten–soy protein blends (Singh and Mohamed, 2007), chickpea, broad bean or isolated soy protein (Rababah et al. 2006), Whey protein (de Almeida Marques et al. 2016), green gram flour (Shukla et al. 2016), soy (Awasthi et al. 2012), carrot powder and cowpea flour (Phebean et al. 2017).Various research findings have proved that combining wheat flour (cereal) with a protein source (legume/dairy) will tend to alleviate the protein malnutrition. Whereas fortification done by either a plant sourced or an animal sourced protein.

Whey protein is a type of protein found in dairy products, a by-product of the cheese-making process. Whey is long considered as a waste and it cause serious disposal and environmental issue. As a novel method of waste valorisation whey can be converted into valuable product for human consumption, which could mitigate its environmental burden. Whey protein is a valuable ingredient that can be added to many food commodities and has the potential to serve as an excellent substitute for some high-priced ingredients (Jayaprakasha, 1992). While ISP is a vegetable protein, has high protein content. (Arrese et al., 1991) reported soy protein serves various functionalities such as water holding capacity and emulsifying properties. It is relatively inexpensive compared to other protein sources. This current study was carried out to find and compare the effect of fortification of various proportions of Whey Protein Concentrate (WPC) and Isolates Soy Protein (ISP) on nutritional, sensory attributes of biscuits.

Material and Methods

Materials: Wheat flour, whey protein concentrate, isolated soy protein powder and all other necessary baking ingredients sugar, shortening agent, milk powder, baking powder, salt, eggs.

Formulation and Preparation of fortified Biscuits: (1) The whey protein concentrate (WPC) was added to wheat flour at 0, 5, 10, 15, and 20% as shown in (

Table 1). (2) The isolated soy protein (ISP) powder was added to wheat flour at at 0, 5, 10, 15, and 20% as shown in (

Table 2). Biscuit were prepared according to the method described by (Akubor & Onimawo., 2003). The prepared biscuits were baked in the oven for 15 minutes at 180˚C. For further evaluation, the biscuits were packed and kept in airtight containers after cooling for 30 minutes.

Proximate Analysis: proximate analysis of the formulated biscuits such as moisture, protein, fat, crude fibre, and ash contents were determined according the procedures as described by Association of Official Analytical Chemist (AOAC 2000).

Sensory analysis of formulated biscuits: Panellists assessed the formulated biscuits sensory qualities. The panellists assessed biscuits for its colour, taste, texture, flavour, and overall acceptability. Each sensory attribute was rated on a 9 point hedonic scale: extremely liked ‒ 9, very much liked ‒ 8, moderately liked ‒ 7, slightly liked ‒ 6, neither liked nor disliked ‒ 5, slightly disliked ‒ 4, moderately disliked ‒ 3, very much disliked ‒ 2 and extremely disliked ‒ 1.

Table 2.

Treatment used in formulation of blend of wheat flour and isolated soy protein.

Table 2.

Treatment used in formulation of blend of wheat flour and isolated soy protein.

| Treatment |

Wheat flour (g) |

Isolated soy protein (g) |

Sugar (g) |

Shortening (g) |

Egg (g) |

Milk powder (g) |

Salt (g) |

Baking powder (g) |

Vanilla essence (drops) |

| T0 |

100 |

0 |

60 |

20 |

40 |

5 |

1 |

.5 |

2 |

| T1 |

95 |

5 |

60 |

20 |

40 |

5 |

1 |

.5 |

2 |

| T2 |

90 |

10 |

60 |

20 |

40 |

5 |

1 |

.5 |

2 |

| T3 |

85 |

15 |

60 |

20 |

40 |

5 |

1 |

.5 |

2 |

| T4 |

80 |

20 |

60 |

20 |

40 |

5 |

1 |

.5 |

2 |

Result and Discussion

Proximate analysis of formulated biscuits:

The proximate analysis of the formulated biscuit with whey protein concentrate is shown in (

Table 3) and biscuits with isolated soy protein in (

Table 4). The moisture content of both WPC and ISP biscuits tend to increase with increase in the concentration of protein, According to (Taha et al. 2006) increasing the protein level of biscuits markedly boosted the moisture content. Biscuits fortified with WPC shows significant increase in fat, ash, fibre content and greater than control biscuit. Studies by (de Almeida Marques et al. 2016) found that ash contents are known to increase upon the addition of whey protein powder, ash content increased up to (1.41%) at higher proportion WPC 20%, increased ash content denoted higher mineral profile of the biscuits. A slight increase in fat content with increasing level of WPC is observed, which is mainly due to the fat in WPC and other baking ingredients. On comparison ISP fortified biscuits show significant reduction in fat, ash and fibre content with higher concentration.

Both ISP and WPC fortified biscuits had more protein content than control. In the WPC biscuits the protein content nearly increased four times the initial value. The protein content was highest for WPC 20% (29.11%) and lowest for WPC 5% (14.54%) whereas the control falls at WPC 0% (10.78), these findings are in accordance with the studies of (Parate et al. 2011). In case of ISP the biscuits show a linear increase in protein content, highest for ISP 20% (20.04%) and lowest for ISP 5% (12.01%). (Mohsen et al. 2009) reported value for ISP fortified biscuit’s protein at various substitution levels were similar to the current findings.WPC biscuits peaked than ISP biscuits in protein content and wide variations were seen in all the proportions.

Sensory analysis of formulated biscuits:

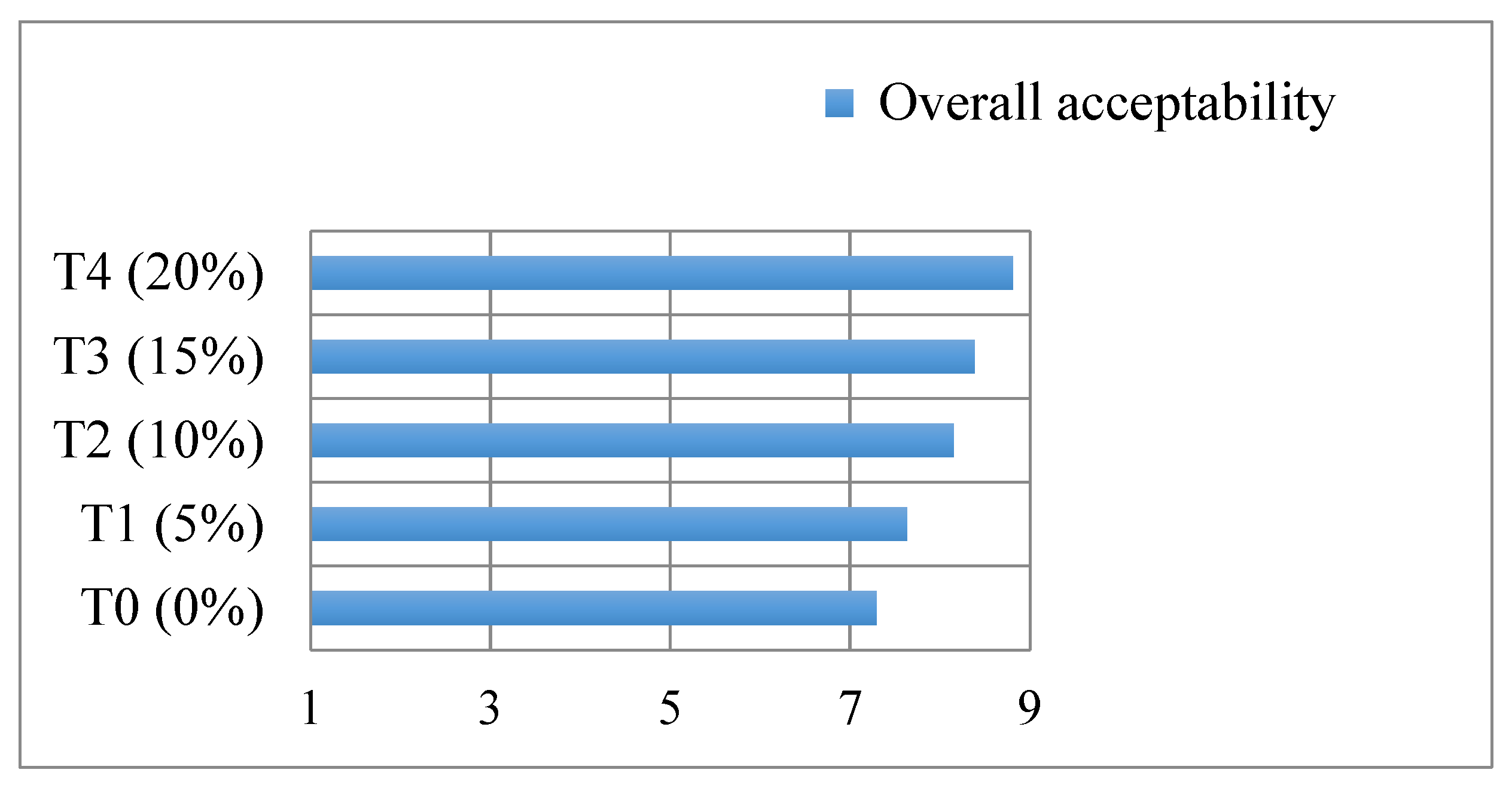

The report of sensory analysis of WPC fortified biscuits shown in (

Table 5) and ISP fortified biscuits shown in (

Table 6). The colour, flavour, taste and texture of WPC biscuits increase with increase in the concentration. The effect of fortification of WPC on overall acceptability is expressed in

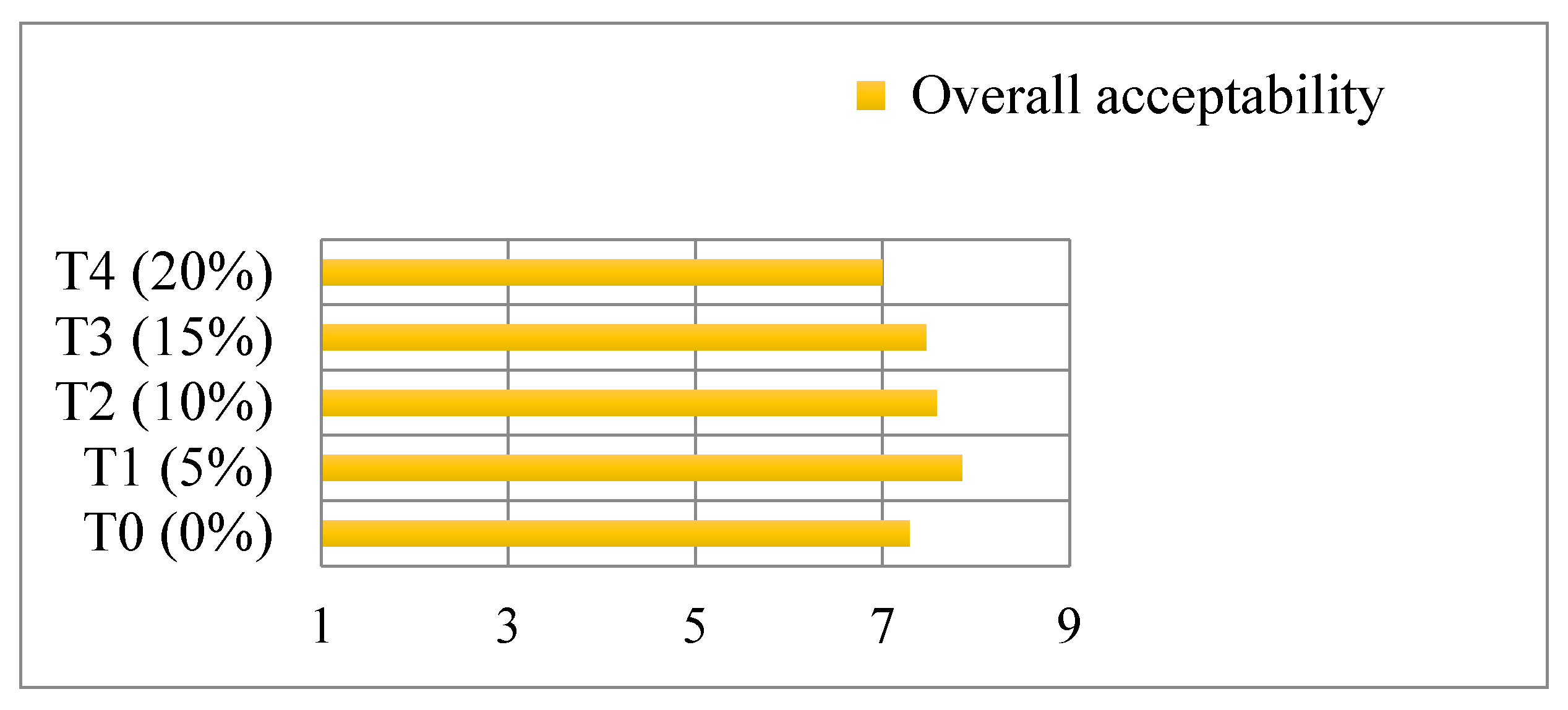

Figure 1.and higher overall acceptability was observed at WPC 20%. The effect of fortification of ISP on overall acceptability is expressed in

Figure 2. Where the overall acceptability increase slightly at 5% concentration and then marked down when proportion of ISP is increased.

The sensory analysis of ISP fortified biscuits were not in agreeable scale, with increase in concentration the colour of biscuits darkened, texture becomes sandy and crumbled, grainy and grassy notes were observed and those reduces the overall acceptability of ISP fortified biscuits. Studies by (Lee & Brennand, 2005) claims the darkening of biscuits may arise due the reaction between the reducing sugars and the amino acids-Millard reaction and also found that up to 15% of ISP does not reduces the acceptability of fried cookies. The surface of the biscuits becoming rougher as the amount of ISP increased. ISP fortified biscuits 5% to 10% proportion is considerable; whereas the WPC fortified biscuits were considerable even up to 20%.

Conclusions

This study highlighted that both the whey protein concentrate and isolated soy protein tend to improve the nutritional parameter of the formulated biscuits to higher extend and can be accepted as protein enhanced products. Among all the analysed samples at various proportions 20% WPC records the highest protein content and both the sensory and quality parameter is more desirable. This research suggest that WPC fortified biscuits can be the wiser choice than ISP fortified, as the sensory characteristics of ISP biscuits were adversely affected, even though ISP up to 10% are acceptable. The major drawbacks of ISP sensory attributes can even be rectified by further processing, since it serves as a source of vegan protein and a valuable ingredient that may be utilized in the production of novel bakery product. Furthermore people who are lactose intolerant can consume ISP biscuits as an alternative to WPC biscuits for protein fortification.

References

- AACC, (2000). Approved methods of the American Association of Cereal Chemists. 10th Edition. American association of Cereal Chemist, Inc. USA. Moisture- p.1‐2.

- Akubor, P.I. & Onimawo, I.A. (2003). Functional properties and performance of soy bean and maize flour blends in cookies. Plant Foods for Human Nutrition 58, 1–12.

- Arrese, E.L., Sorgentini, D.A., Wagner, J.R. & Anon, M.C. (1991). Electrophoretic, solubility and functional properties of commercial soy protein isolates. Journal of Agricultural and Food Chemistry 39, 1029–1032. [CrossRef]

- Awasthi, I., Siraj, P., Tripathi, M., & Tripathi, V. (2012). Development of Soy fortified high protein and high calorie supplementary biscuits. Indian Journal of Scientific Research 3(1), 51–58.

- Brink, M and Belay, G (2006); Plant resources of Tropical Africa, Cereals and Pulses Prota Foundation/ Backhuys Publishers/CTA, Wageningen, pp 129-133.

- Claughton, S.M. & Pearce, R.J. (1989). Protein enrichment of sugar snap cookies with sunflower protein isolate. Journal of Food Science 54, 354–356. [CrossRef]

- De Almeida Marques, G., de São José, J. F. B., Silva, D. A., & da Silva, E. M. M. (2016). Whey protein as a substitute for wheat in the development of no added sugar cookies. LWT-Food Science and Technology 67, 118–126. [CrossRef]

- Jayapraskasha, H. M. , (1992). Membrane processing applications for production of whey powder and whey protein concentrates. Ph.D. Thesis, National Dairy Research Institute, Deemed University, Karnal, India.

- Mohsen, Sobhy M., et al. “Effect of Substitution of Soy Protein Isolate on Aroma Volatiles, Chemical Composition and Sensory Quality of Wheat Cookies. International Journal of Food Science & Technology. vol. 44, no. 9, Wiley, Sept. 2009, pp. 1705–12. [CrossRef]

- Parate, Vishal & Dilip, Jalgaon & Kawadkar, K & Maharaj, Rashtrasant & Kawadkar, Dilip & Sonawane, Shriram. (2011). Study of Whey Protein Concentrate Fortification in Cookies Variety Biscuits. International Journal of Food Engineering. 7. [CrossRef]

- Phebean, I. O., Akinyele, O., Toyin, A., Folasade, O., Olabisi, A., & Nnenna, E. (2017). Development and quality evaluation of carrot powder and cowpea flour enriched biscuits. International Journal of Food Science and Biotechnology 2(2), 67–72.

- Rababah TM, Al-Mahasneh MA, Ereifej KI. Effect of chickpea, broad bean, or isolated soy protein additions on the physicochemical and sensory properties of biscuits. Journal of Food Science 2006, 71, S438-S442. [CrossRef]

- Shukla, R. N., Mishra, A. A., & Gautam, A. K. (2016). Development of protein enriched biscuit fortified with green gram flour. Food Science Research Journal 7(1), 112–118. [CrossRef]

- Singh M, Mohamed A. Influence of gluten–soy protein blends on the quality of reduced carbohydrates cookies. LWT 2007, 40, 353–360. [CrossRef]

- Singh, R.; Singh, G. and Chavhan, G.S. (1996). Effect of incorporation of defatted soy flour on the quality of biscuits. Journal of Food Science and Technology Vol. 33(4), 355–357.

- aha, M.R., Majdi, A.A. & Khalil, I.E. (2006). Effect of chickpea, broad bean, or isolated soy protein additions on the physicochemical and sensory properties of biscuits. Journal of Food Science 71, 438–442. [CrossRef]

- Yamazaki WT, Greenwood C (1981). Soft wheat: Production, breeding, milling and uses. American Association of Cereal Chemists, ST, Paul, Minnesota, USA, pp. 45-49.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).