1. Introduction

With the arrival of the on-demand economy based on digital technology, customers have exhibited new behavior patterns and actively participated in the design and production of products, driving digital transformation and creating sustainable value for customers [

1]. Businesses are now offering customized production and services to their customers. Whether it is the third technological revolution or the widely acclaimed Industry 4.0 strategy in Germany, customized strategies are regarded as an important trend for future development in manufacturing, especially regarding their impact on sustainable development [

2].

Although research has found that customized sustainable innovation strategies can improve company performance by meeting customer needs [

3,

4], unfortunately, It is rare to find research that thoroughly explores and integrates how customer predictive ability affects the process of sustainable innovation practices in customized enterprises, hereafter referred to as innovation. In an era where the role of customer participation in innovation is becoming increasingly important and urgent [

5,

6,

7], it is necessary to analyze and explore the relationship between customer predictive ability and innovation in customized production, as well as systematically discuss the mechanism and process by which customer predictive ability affects a company's customized innovation.

Based on existing research on customer-oriented customized production, the focus has been on customer participation [

8,

9], customer value [

10,

11], and factors influencing customer acceptance of customization [

12]. There are few studies that involve the influence of customer ability on the customized production process, particularly in relation to innovation. If such an influence exists, a company's in-depth and leading understanding of customer ability can not only help the company determine the scope and advantages of new technologies earlier but also test the commercial value of the technology earlier [

13].

It is widely recognized that customer orientation is not a new concept [

14,

15], Customers' involvement has a significant impact on brand management and sustainable practices [

16]. As a result, Companies focus on meeting the needs of customers, Providing products/services to customers is a complex decision-making process, which must fully consider the preferences and non-preferences of customers to achieve customer satisfaction and the optimization of company resources [

17]. However, Lengnick-Hall broke the narrow boundaries of solely relying on customers and believed that the expansion of the customer role was the first step towards developing sustainable competitive quality [

18]. Subsequent research supplemented customer capabilities, such as the strong service recovery ability of customers in self-service technology environments [

19]. In participating in production services, customer loyalty, customer expertise, customer communication skills, customer emotional commitment, and interaction became factors that could potentially improve the level of joint production [

20]. As the role of customers in different services is dynamic, Chervonnaya proposed the "chameleon" characteristic of customers, and built a framework for customer capability resources by seeking objective rules through the trajectory of customer roles and skills [

21].

This study links customer predictive ability to innovation. Previous scholars have explained the value of customer predictive ability. De Haan systematically compared different customer feedback indicators to test customers' predictive ability for companies and industries [

22]. The test results showed that customers who ranked higher performed better in predictive ability, and focusing on extreme cases was better than using full-scale predictive ability. Based on similar studies [

23,

24,

25], understanding the impact of customer predictive ability on corporate innovation research has important strategic value, especially when leading customer predictive ability provides useful information as a strategic management reference tool for industry managers.

In the context of the digital transformation and innovation of the manufacturing industry, it is a crucial issue to maintain a balance between the shipping industry (an consumer Market) and the shipbuilding industry (an production market). Stopford believes that the challenge facing the shipping industry in relation to future demand is to find a strategic way to retain the best and most effective shipbuilding capabilities, while promoting a global transportation system that meets regulatory, environmental, and shipowner requirements [

26]. Therefore, unlike other traditional industries, the shipbuilding industry continues to focus on providing more differentiated customized production and services for shipping.

The shipbuilding industry is a typical representative of the manufacturing industry centered on customized production, emphasizing the personalized development of customers. The design, supervision, and acceptance of ship products are based on the requirements of ship owners. In the late 1980s, customer demands for various products led to the development of "customized production" [

27]. Due to the short history of the development of customized production and the lack of typical research objects, there are few studies on innovation in customized production. The significant characteristics of small-batch customization, high unit value, and long construction cycles inherent in the shipbuilding industry determine the connotation of "service-oriented manufacturing" in the shipbuilding industry. Moreover, the shipbuilding industry relies heavily on the operating environment of the shipping market. Customers not only care about product quality, but also hope to have products and put them into operation in a timely manner [

28]. Therefore, this study excavates the innovation problem of customer predictive ability (ship owners) in customized production through the historical laws of shipbuilding and shipping. This study addresses the following two questions:

Question 1:Is there a correlation between customer predictive ability and customized production?

Question 2:Is this correlation a causal relationship?

2. literature review

2.1. Predictive Ability

Executives consider some form of prediction with almost every decision they make. Prediction is no longer a luxury but a necessity [

29]. Therefore, making as detailed predictions as possible about various possible development paths and potential events is not only beneficial but also essential. Boucher was the first to conduct predictive analysis research and found that 100 organizations engaged in long-term forecasting activities, with more than 60% of them belonging to industrial enterprises [

30]. Rexer believes that one-third of predictive analytics applications focus on customer targeting and segmentation, customer acquisition, customer churn, and customer lifetime value management [

31]. It is known that predictive technology has become commonplace in industrial enterprises, especially for customer prediction.

Chamlibers believes that the first task of prediction is to carefully select the appropriate correct prediction method. The wider the range of known predictive possibilities, the more significant the predictive outcome will be [

29]. This mainly depends on the characteristics and types of applications [

32]. Three basic methods are proposed for prediction: qualitative techniques, time-series analysis and speculation, and causal relationship methods. Among them, the second method mainly relies on historical data, focusing on the development trend and changes in the trend to achieve the purpose of prediction. Time-series analysis is a more descriptive and purposeful prediction activity aimed at effectively utilizing past data (especially for more than five years) to seek to understand potential stochastic processes and patterns to predict future values [

33].

2.2. Innovation in Manufacturing

To measure the innovation performance of manufacturing, it is essential to understand innovation in manufacturing. Tidd and Bessant defined manufacturing innovation as something that neither changes the product nor the basic process but only changes some elements in the process, trying to identify the factors that affect innovation [

34]. At the same time, the scope of manufacturing innovation covers the entire product life cycle, and manufacturing innovation has diversity and dynamics [

35]. Based on this, Roger believes that the standard for measuring manufacturing innovation should focus on the number and types of new ideas that manufacturing attempts [

36]. Therefore, innovation has been identified as a key research issue in production [

37,

38]. In most developed and developing economies, innovation research is still a focus of manufacturing, but it is not well understood [

38,

39]. In fact, many manufacturing companies are more customer-oriented and use innovation research such as mass customization to meet customers' special customization needs [

42].

Currently, the advancement of technology and the pressure of global challenges are driving the high integration of technology and increasingly complex customer demands [

43,

44]. Successful companies not only respond to current customer or organizational needs, but also to their own needs and must predict future trends. The ability to predict through the development of ideas, products, or services to quickly and effectively meet future needs is a necessary condition for development and can maintain competitive advantage [

45]. Therefore, the ability to predict innovation and increase the ability of companies to enter or create new markets becomes the key factor that ultimately affects success [

46,

47].

In the late 1980s, customer demands for various products led to the development of "mass customization" [

27]. Currently, we are experiencing the fourth industrial revolution (known as "Industry 4.0"), in which new technologies and innovative ideas are emerging and being widely used to meet growing consumer demand. The contradiction between customer demand for personalized products and the relative scarcity of such products is becoming increasingly prominent [

48], and customized production has become an important means for enterprise digital transformation and upgrading. Blecker believes that customization is the future paradigm, and the goal is to provide personalized products and services for customers, involving systemic customization in marketing, design, manufacturing, after-sales, and so on [

49]. In other words, a customized production strategy is a customer-oriented and innovative value creation process.

2.3. The impact of customers on innovation

Through investigating the main subjective and environmental factors affecting customer participation in corporate innovation, Wang proposed that customers' active participation can increase a company's knowledge storage and improve the efficiency of enterprise innovation [

50]. Analysis of past literature on customer participation in innovation shows that the situational conditions for customer participation in innovation have not been clearly defined, but some literature has studied the impact of customer ability on innovation,Customers prefer the value of integration with digital capabilities, which gives them many choices in digital innovation [

51]. We expect that in the rapidly developing on-demand economy (in which organizations are particularly prone to the capability trap), obtaining customers with diverse experiences is particularly valuable. And The effect of organizational learning on performance depends on the variations of the customer-focused strategy [

52]. Based on earlier research on customer experience diversity, actively participating customers are an important driving force for the entire production process, and can greatly enhance a company's innovation ability, but with strict limitations. Only "lead users" can be the object of cooperation with enterprises [

53]. Those with more diverse product experiences and more related technical knowledge are known as lead users [

54]. Based on this, most researchers believe that working with "lead users" can promote companies to discover and create innovation [

55]. Other studies have found that clients or consultants from international markets are crucial to innovation [

56]. On the contrary, customers' short-term perspectives may mean a disaster for a company's innovation ability [

57].

Therefore, a key challenge that businesses face is prediction, and innovation must be based on a more forward-looking understanding of demand prospects [

58]. In this study, the scholars developed and tested theories about customer types that help organizations obtain timely and even preferential access to information about changing preferences of customers in their market, and adjust their market positioning accordingly to enhance their innovation capability [

59].

3. Empirical study

3.1. Research background

This passage discusses the relationship between customer prediction ability and innovation in customized production. The research examines whether this relationship is causal and uses the shipping industry as an example to demonstrate the theme. The decision-making process of shipowners in investing in new ships involves a significant amount of capital investment, and they are primarily interested in economic advantages that can be generated by using new or improved methods and technology in new ships. In the shipping market structure, the dry bulk cargo market accounted for 44.8% of the global shipping structure in 2021, and its prosperity is highly correlated with global economic development. The fees in the dry bulk cargo market are the "barometer" of the entire market. Hughes proposed that shipowners believe that profits are determined by how much income the ship can earn, and transportation costs are constant. Therefore, freight is called the "profit potential" of shipping [

60]. BDI index is a robust indicator of the shipping market situation, which displays the demand for freight capacity and the supply of dry bulk ships. When supply exceeds demand, shipowners may decide to increase new ship orders to seek more profits, leading to an oversupply of capacity, breaking market equilibrium, and causing the BDI index to decline. Conversely, when demand exceeds supply, shipowners may decide to build new ships to increase capacity and improve earnings, causing the BDI index to rise.

Therefore, we have reason to believe that the shipping market can provide good information for shipowners when making decisions about customizing the production of new ships. The BDI has been widely used as a world trade economic indicator. Many stakeholders make serious efforts to predict accurately so that they can make wise investment and trading decisions. Most customers will take similar ship investment behaviors, namely the investment selection of new ships, which represents the size of customer prediction ability. Therefore, the collective investment behavior of customers is a true reflection of the shipbuilding market, and the size of customer prediction ability largely affects the shipbuilding market. Therefore, the BDI index and new ship delivery volume can well reflect customer prediction ability.

Of course, shipowners typically consider many issues when making investment decisions about ships, such as ship speed, hull strength, ship design style, ship seaworthiness, etc. They also consider whether it meets common interests, future sustainability, meets environmental requirements, and most importantly, whether the stable reliability and service life of the ship can create economic benefits, that is, the economic profit brought by the ship entering the market. Gu Jianzhou, Vice Chairman of the Hong Kong Shipowners Association, pointed out that quality, technology, and service are particularly important factors in the eyes of shipowners [

61].

Therefore, shipowners pay close attention to the value advantages brought by new methods and technological innovations in the new ship production process, that is, the innovation value in the ship production process. When shipowners predict that the market is in a good state, they will pay more attention to innovative production factors. Conversely, shipowner behavior will be more conservative, and innovative enthusiasm will be affected.

For the variable of innovation in customized production, patents are often used to measure the level of innovation. A large amount of research has found a positive correlation between patents and innovation [

62,

63,

64], using patent data to evaluate the source of breakthrough innovation. Therefore, using patents to analyze innovation performance has become a recognized method, and here innovation is measured by the amount of ship patents.

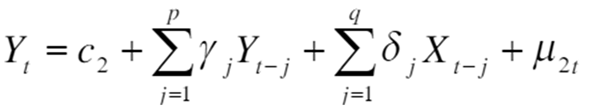

Due to the time required for information flow between markets and the construction time of ships, there is a time lag relationship between the shipping market and the shipbuilding market, which is manifested in a very subtle way. This article identifies three key variables: freight rates, new ship delivery volume, and the number of patents, and

Figure 1 shows the dynamic relationship between the three, which is the research model of this article.

Based on the above analysis, this paper uses the BDI index and new ship delivery volume to reflect customer forecasting ability, and the number of ship patents to reflect innovation in customized production, proposing two research hypotheses:

H1: New ship delivery volume has a certain degree of impact on freight rates.

H2:There is a causal relationship between customer forecasting ability and innovation in customized production.

3.2. Data source

The dry bulk shipping market is generally considered to be a close-to-perfectly competitive market with intense competition, so the focus of the study is on the dry bulk market. The BDI index is an indicator of the dry bulk shipping market, composed of four freight rate indices (Capesize BCI, Panamax BPI, Supramax BSI, and Handysize), according to their importance and weight in the shipping market. Considering the nature and scale factors of the BDI index itself, dry bulk carriers with a DWT of over 20,000 tons were selected as the research sample: Capesize bulk carriers (over 100,000 tons), Panamax bulk carriers (60,000-75,000 tons), Handymax bulk carriers (40,000-59,000 tons), and Handysize bulk carriers (20,000-50,000 tons), to analyze the relationship between the delivery volume of these four types of new ships and freight rates. For this study, the BDI index and delivery volume data for the four types of new ships from 1999 to 2019 were selected as the sample for econometric analysis. All data was obtained from the Clarkson database in the UK and had no missing values. In addition, ship patent data were selected to reflect the level of innovation in customized production. Patent data was obtained from the US Patent Database, using "ship/shipping/shipbuilding" as the search keywords, removing duplicate data, and obtaining the number of patents for each keyword from 1999 to 2019, represented by SP1, SP2, and SP3, respectively.

3.3. Method

In this paper, the focus is on exploring the relationship between shipping and shipbuilding in time series analysis, so the widely used machine learning algorithm, the random forest model, is employed. Random forest is an ensemble learning algorithm proposed by Breiman in 2001 and is considered a typical success story in ensemble learning algorithms.

The random forest model constructed in this paper focuses on the correlation between variables. The model selects or averages the classification results of several weak learners to form a strong classifier, thereby improving the prediction accuracy by aggregating multiple models while preventing overfitting and ensuring high accuracy and generalization performance of the overall model. At the same time, it has good adaptability to data and can provide a ranking of the importance of each independent variable to the dependent variable, which has high reference value for subsequent statistical regression analysis and provides statistical test efficiency.

In this paper, the BDI value is used as the sample label, and 4 categories of new ships are used as sample features. A random forest model is constructed using the Python language for empirical analysis, which can effectively reflect the relationship between the two, and the importance of the delivery volume of new ships to freight rates (BDI) is obtained.

At the same time, the SHapley Additive ExPlanations (SHAP) value is introduced to explain the model. Shapley value is a game theory concept proposed by economist Lloyd Shapley. It clearly shows how much each feature contributes to the model's prediction, and this method can help us explain the model [

64]. By calculating the SHAP value of each feature for each of the 4 samples in the random forest model, and performing this operation for each subset of features, the absolute average value of all samples on different features can be obtained, which calculates the marginal contribution of adding the feature to the model, and then considers the average marginal contribution of the feature under different feature sequences. This is the Shapley value of the feature.

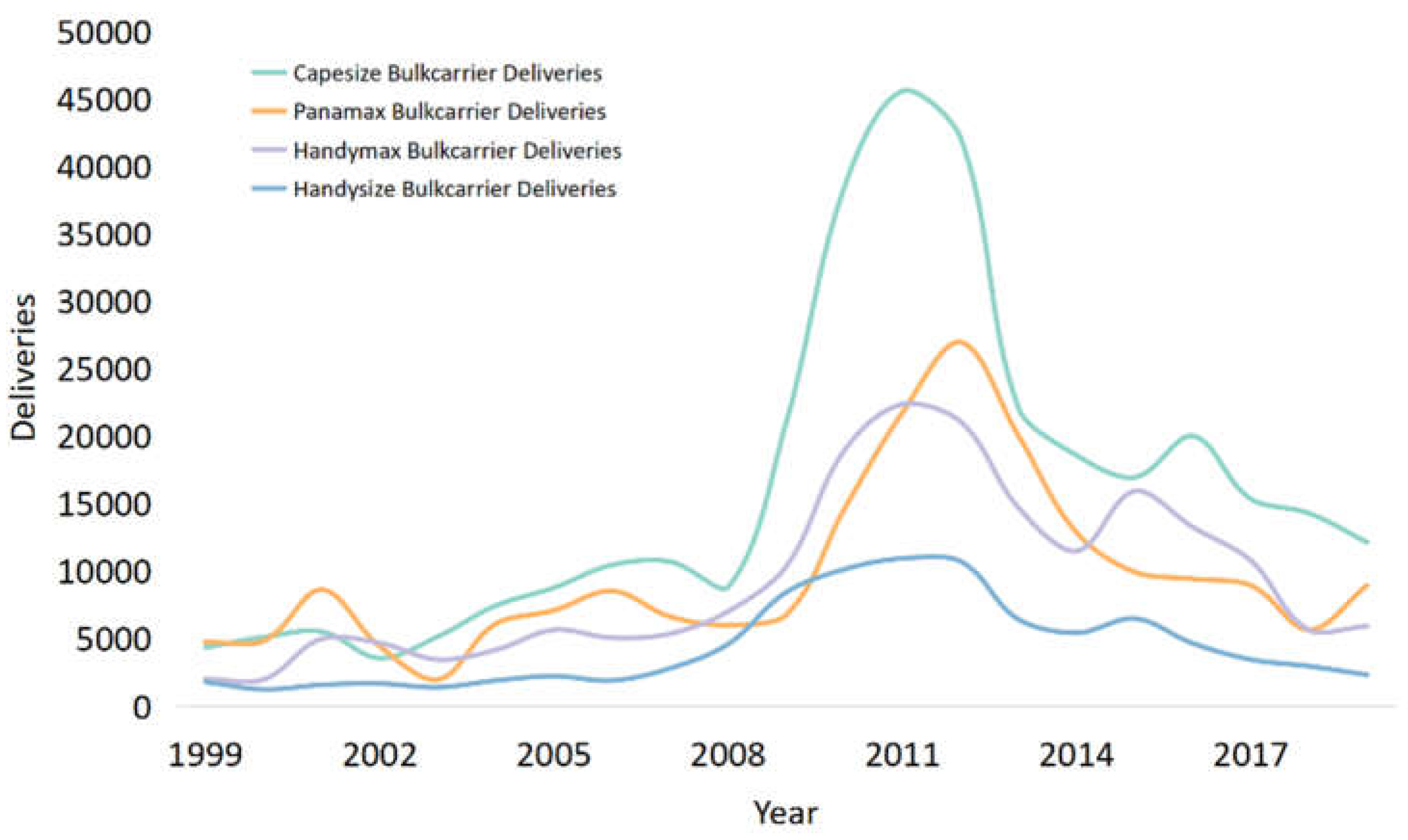

After determining the relationship between BDI and the delivery volume of new ships, it is necessary to further study whether there is a causal relationship between the two and innovation in customized production. First, principal component analysis is used to reduce the dimensionality of BDI and the delivery volume of new ships, and the variance contribution rate is determined to select 2 principal components. Then, the two principal components are tested for unit root and Granger causality with the four categories of ship patent values, to determine whether there is a causal relationship between the variables, that is, "who causes the change of whom". The Granger causality test formula is as follows:

Formula 1. Granger causality test formula

4. Results

The experiment of this study was divided into two parts. The first experiment analyzed the relationship between H1: the impact of new ship delivery on freight rates using the random forest model with machine learning algorithms. The second experiment used principal component analysis and Granger causality test to analyze H2: whether there is a causal relationship between customer prediction ability and innovation in customized production.

4.1. Random forest experiment

(1) Descriptive statistical analysis

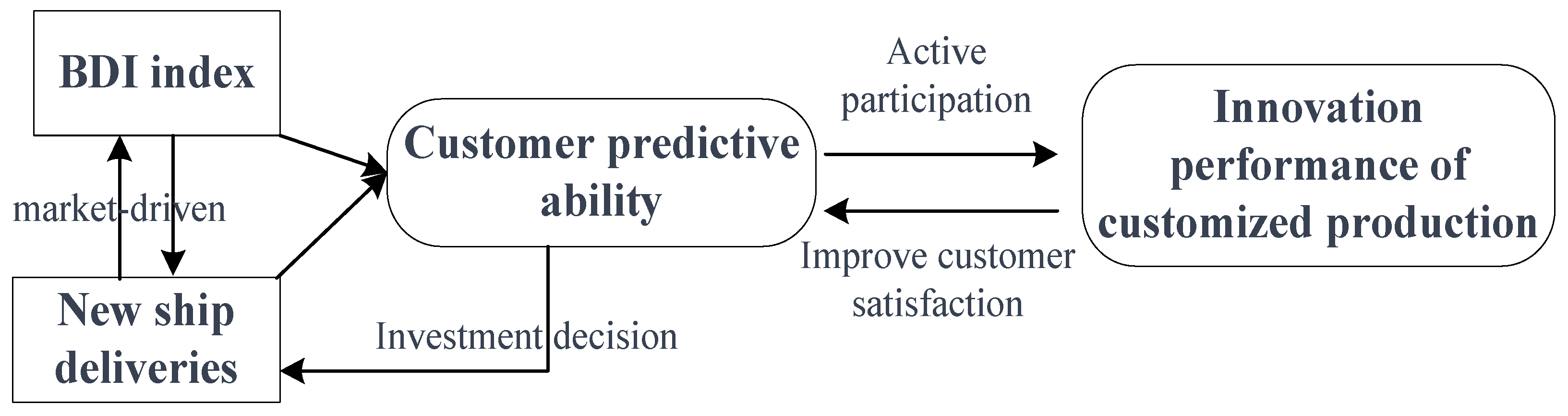

The BDI is an authoritative index that measures the international shipping situation in the world and is a leading indicator reflecting international trade conditions.

Figure 2 shows the time series of BDI, indicating that the BDI index began to show a growth trend in 2003 and broke through 6,000 points in 2007, reaching its historical high point in freight rates. At the same time, the global new ship orders began to grow in 2003 and reached a historical high of 270 million DWT in 2007, indicating that speculative capital has flooded into the capacity of shipbuilding and downstream shipping industry.

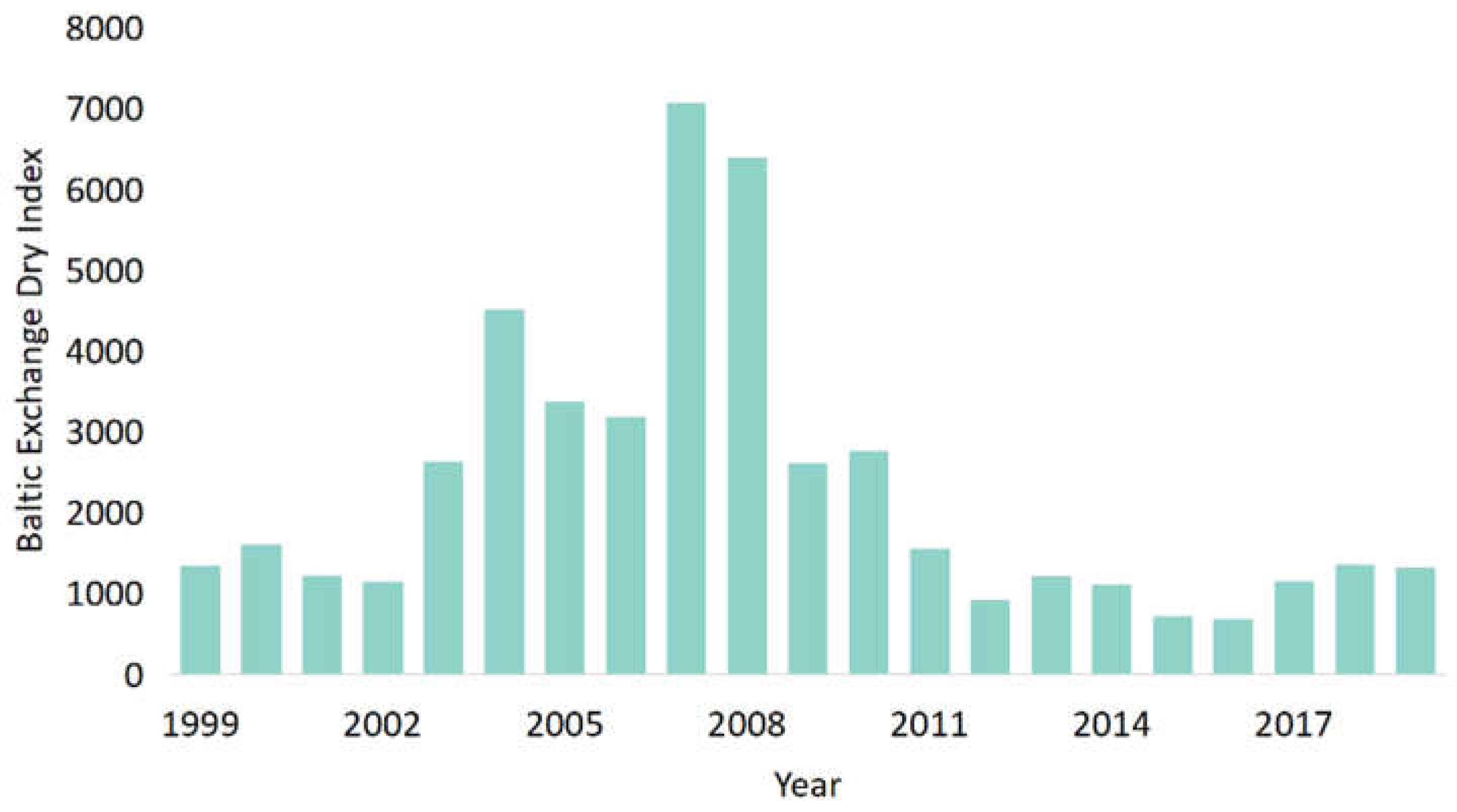

Shipbuilding is different from other manufacturing industries due to its long cycle and complex influencing factors. This study focuses on large bulk carrier tonnage, which takes about 3-5 years from order to delivery of new ships.

Figure 3 shows that the delivery of new ships for the four ship types began to increase sharply in 2008, reached the highest value in 2011 and then began to decline, but remained higher than the level before 2008, which is consistent with the trend of the growth in new ship orders since 2003. Under this circumstance, the shipping industry's capacity level performed well. However, the outbreak of the subprime mortgage crisis in 2008 led to a decline in demand, gradually forming a mismatch with the abundant supply side (new ship delivery volume), and resulting in a large amount of idle shipping capacity in the shipping industry. The excess production capacity of shipbuilding brought about supply pressure, which entered a period of capacity adjustment. Therefore, the BDI index plummeted in 2009 and remained low, causing a long period of low freight rates in the shipping industry. The shipbuilding industry went through deep integration, and overall production capacity remained surplus. It can be seen that there is a significant relationship between the BDI index and new ship delivery volume.

(2) Building a Random Forest Model

Based on the data in

Figure 2 and

Figure 3, it is found that there is a significant relationship between freight rates and the delivery volume of the four types of new dry bulk carriers. As it is difficult to discover linear correlations, this paper uses a random forest model to analyze the relationship between freight rates and the delivery volume of the four types of new dry bulk carriers. The experiment was conducted using the Python toolkit scikit-learn (sklearn). The number of decision trees and the number of variables in the binary tree involved in this toolkit are the most important parameters affecting the model fitting effect. After parameter optimization, the main parameter values are the number of decision trees Nestimators=100 and the maximum tree depth MaxDepth=5. Since the amount of data used in this paper is 21 years, and the focus is on explaining the model itself, only the performance of the constructed model on the training set is considered. When constructing the model, the features of the four types of new ship delivery volume are renamed, and the renaming results are shown in

Table 1.

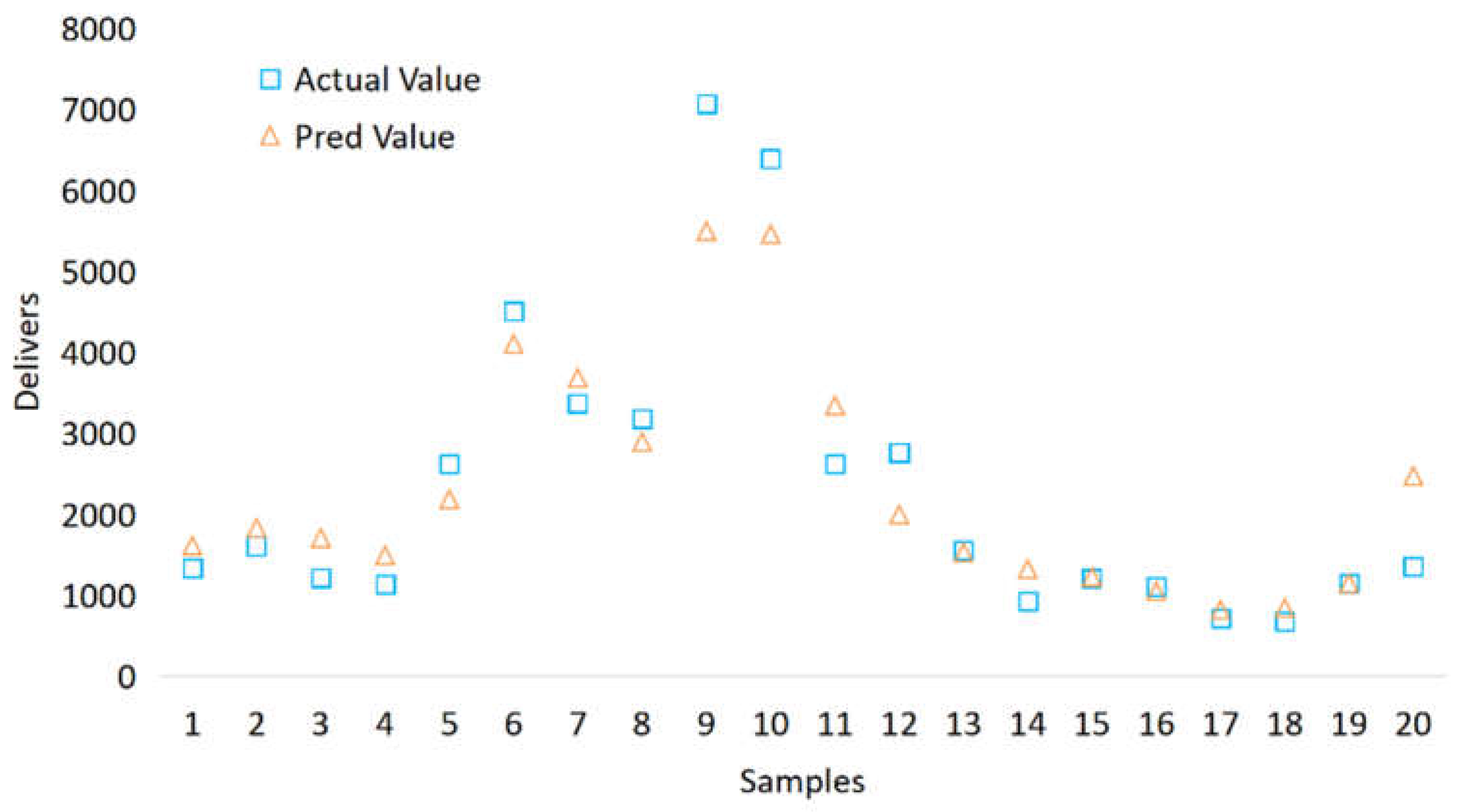

The prediction results and the visualization results of the actual situation obtained by the random forest prediction model calculation are shown in

Figure 4. After training, the model's prediction accuracy on the training set is 89%, and the accuracy is high. The predicted freight rate is roughly the same as the actual freight rate, which can be considered as relatively accurate for constructing the relationship model between freight rates and the delivery volume of the four types of new dry bulk carriers. Therefore, hypothesis 1 is validated, and there is a correlation between the delivery volume of new ships and freight rates.

(3) Shap values for model interpretation

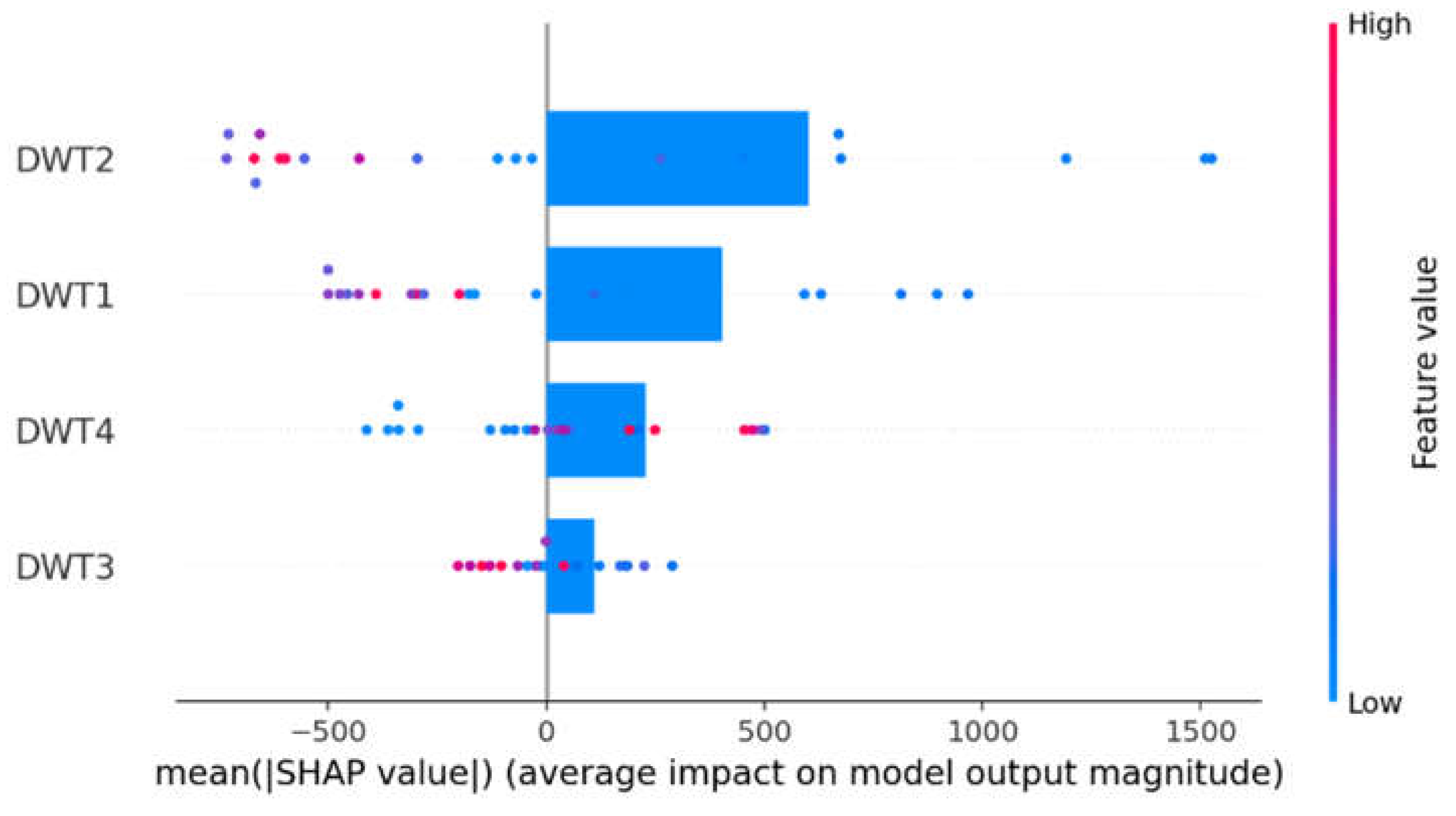

①Global Shap interpretation

SHAP values are an effective method for interpreting predictions from machine learning models. As shown in the importance ranking of SHAP values in

Figure 5, DWT2 has the highest importance for the model prediction, followed by DWT1, DWT4, and DWT3. The impact rankings are in the order of Panamax type > Capsize type > Handysiz type > Handymax type, indicating that different ship types have different degrees of impact on BDI. This suggests that the mutual impact of freight rates among large dry bulk carriers is smaller than that of small dry bulk carriers. This has a very important role in enabling shipowners to analyze the relationships between various sub-markets in the dry bulk shipping market, as well as to make investment and shipbuilding decisions by configuring the capacity of each market with new ship deliveries, guiding BDI fluctuations, and enjoying premiums from the shipbuilding and shipping markets.

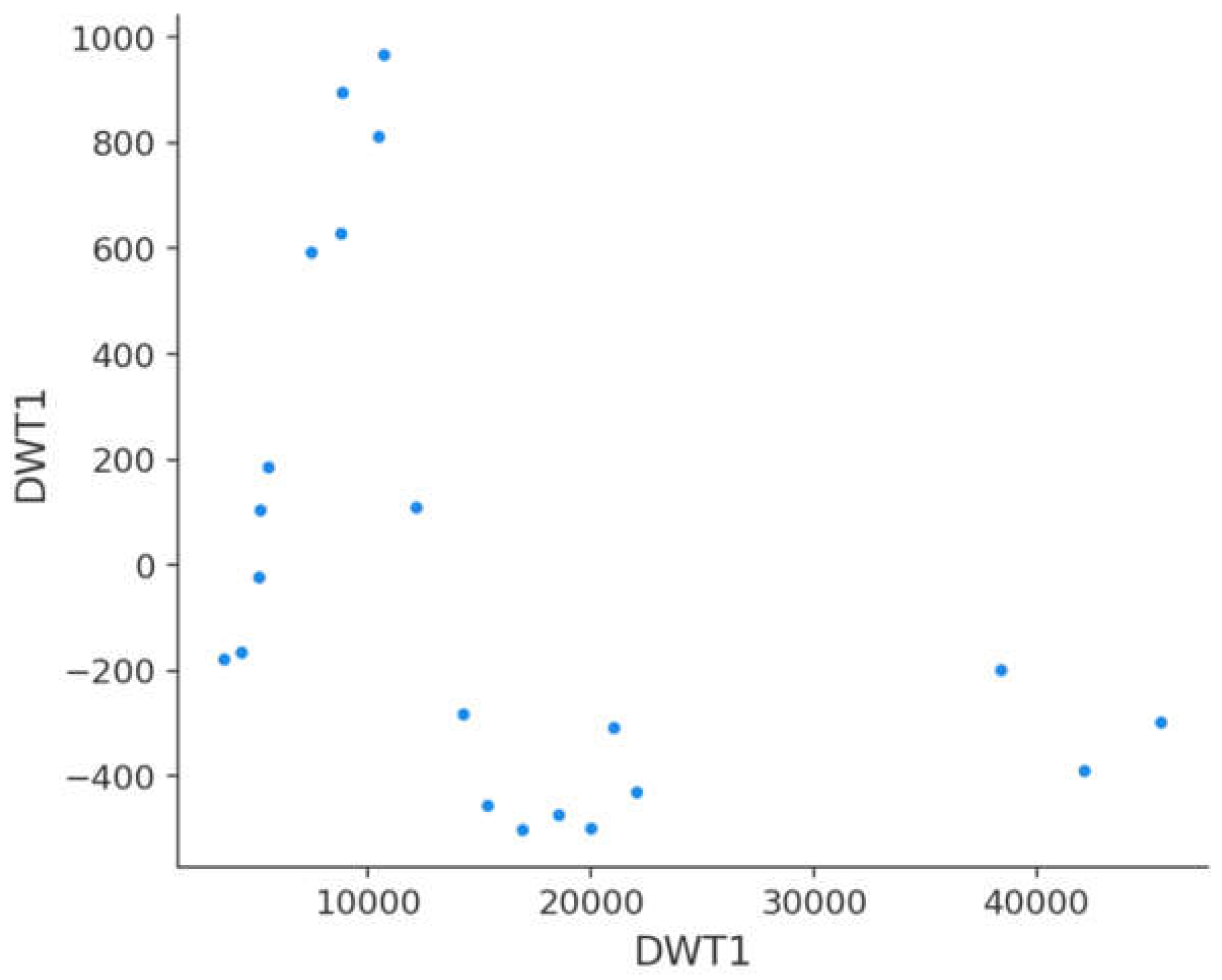

②Individual SHAP explanation

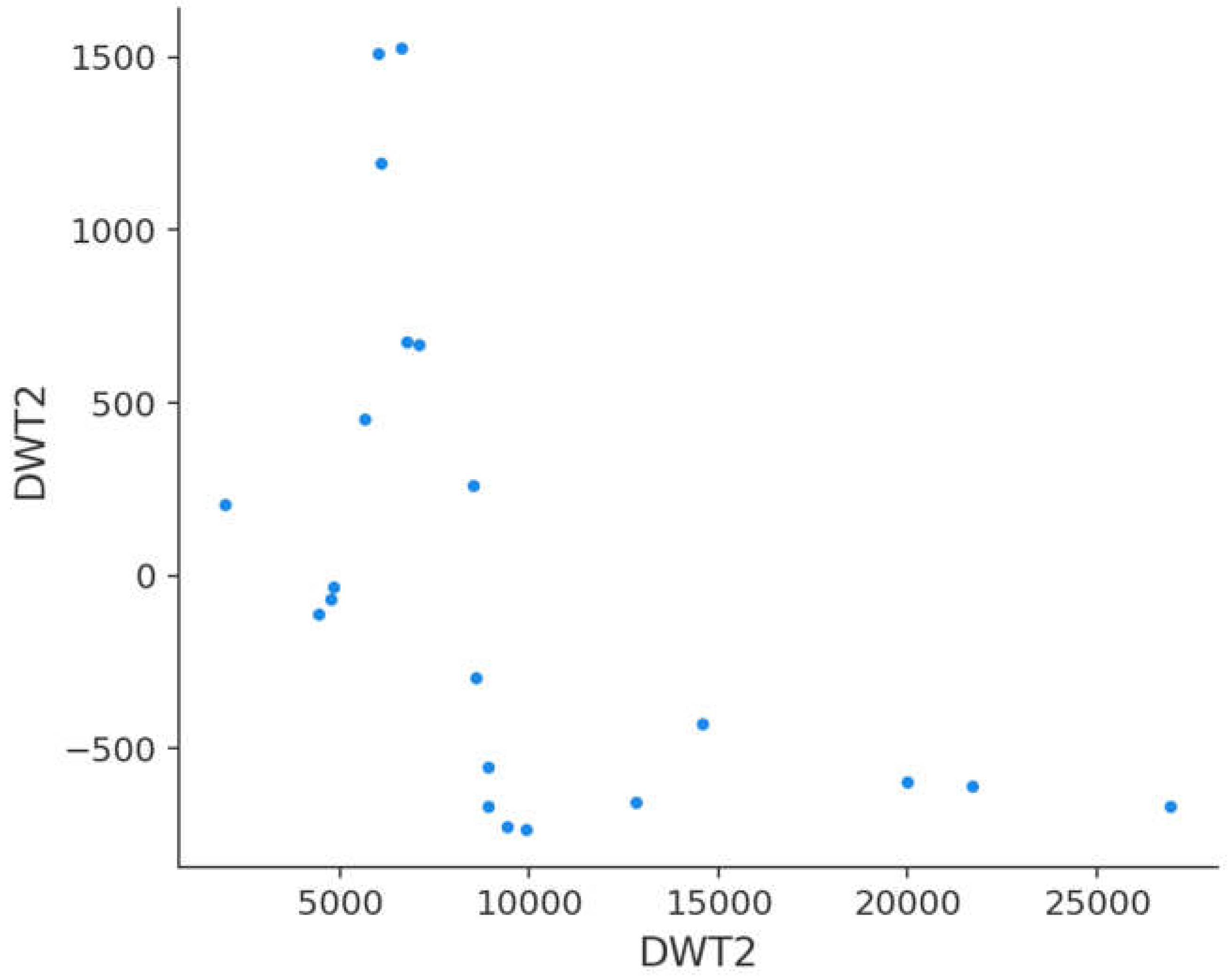

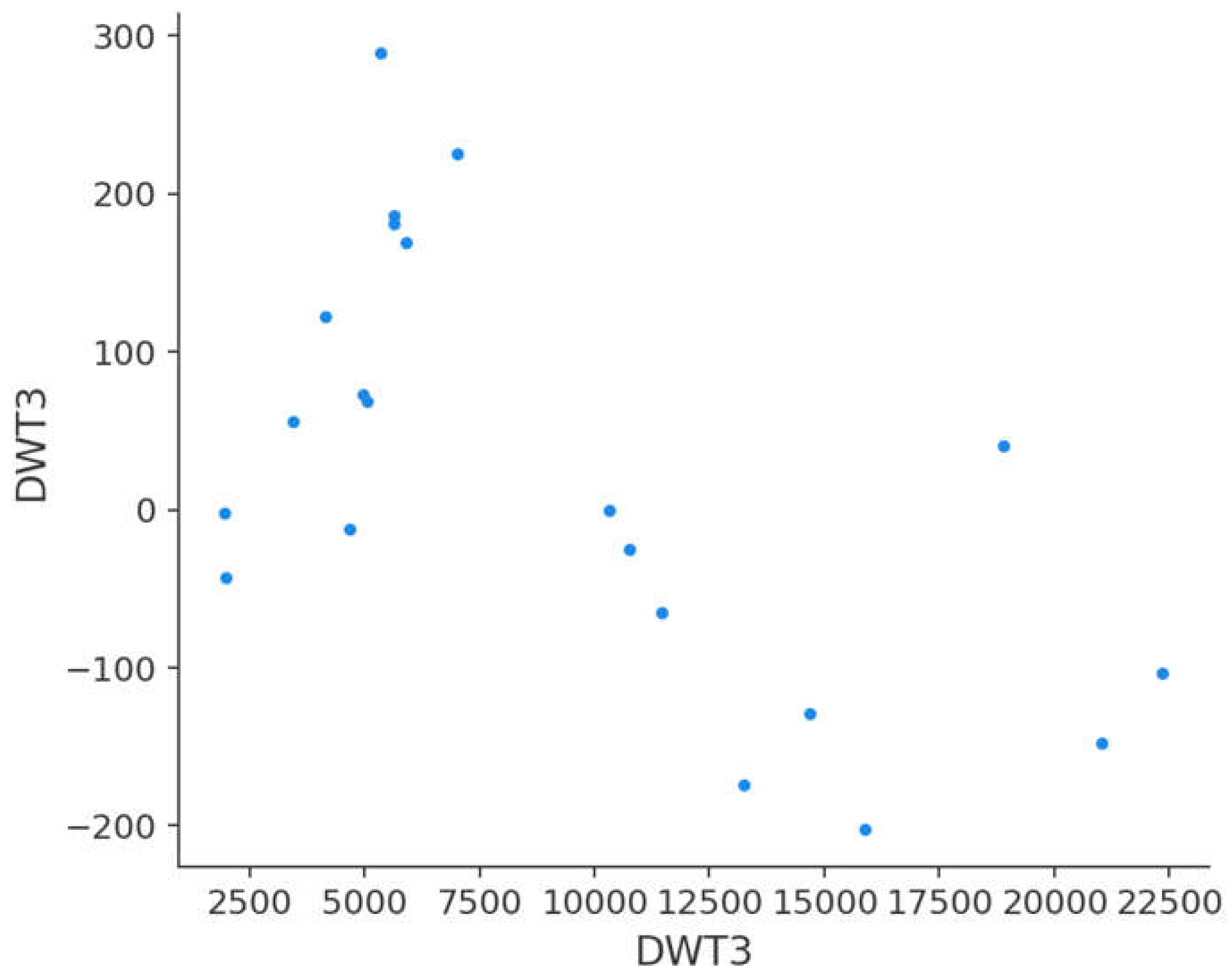

Figure 6 shows that an increase in DWT1 leads to a decrease in BDI, and the effect of DWT1 on BDI tends to stabilize when DWT1 is greater than 15,000. The impact trajectory of DWT2 on BDI (

Figure 7) is similar to that of DWT1. An increase in DWT2 leads to a decrease in BDI, and the effect of DWT2 on BDI tends to stabilize when DWT2 is greater than 10,000. The impact of DWT3 on BDI is overall a reverse U-shape (

Figure 8), that is, when DWT3 is less than 7,500, an increase in DWT3 leads to an increase in BDI. When DWT is greater than 7,500, an increase in DWT3 leads to a decrease in BDI.

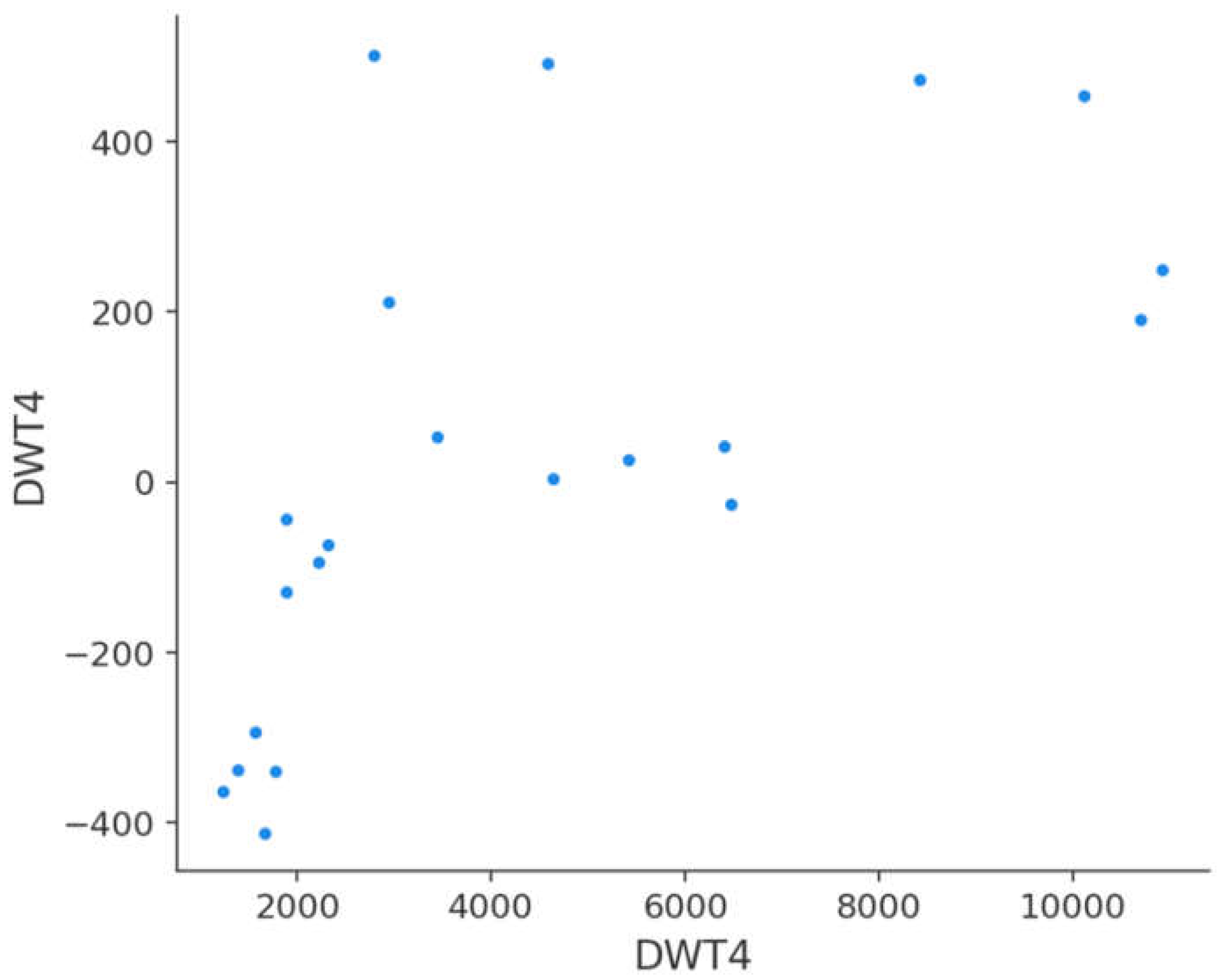

Figure 9 shows that DWT4 has a positive correlation with BDI. An increase in DWT4 leads to an increase in BDI, and the effect of DWT4 on BDI becomes more volatile when DWT4 is greater than 4,000.

Therefore, the random forest experiment proves that there is a correlation between new ship deliveries and BDI, and different ship types have different degrees of influence on BDI. Compared to small dry bulk carriers, large dry bulk carriers have a greater impact on BDI.

4.2. Granger Causality Experiment

(1) Principal Component Analysis

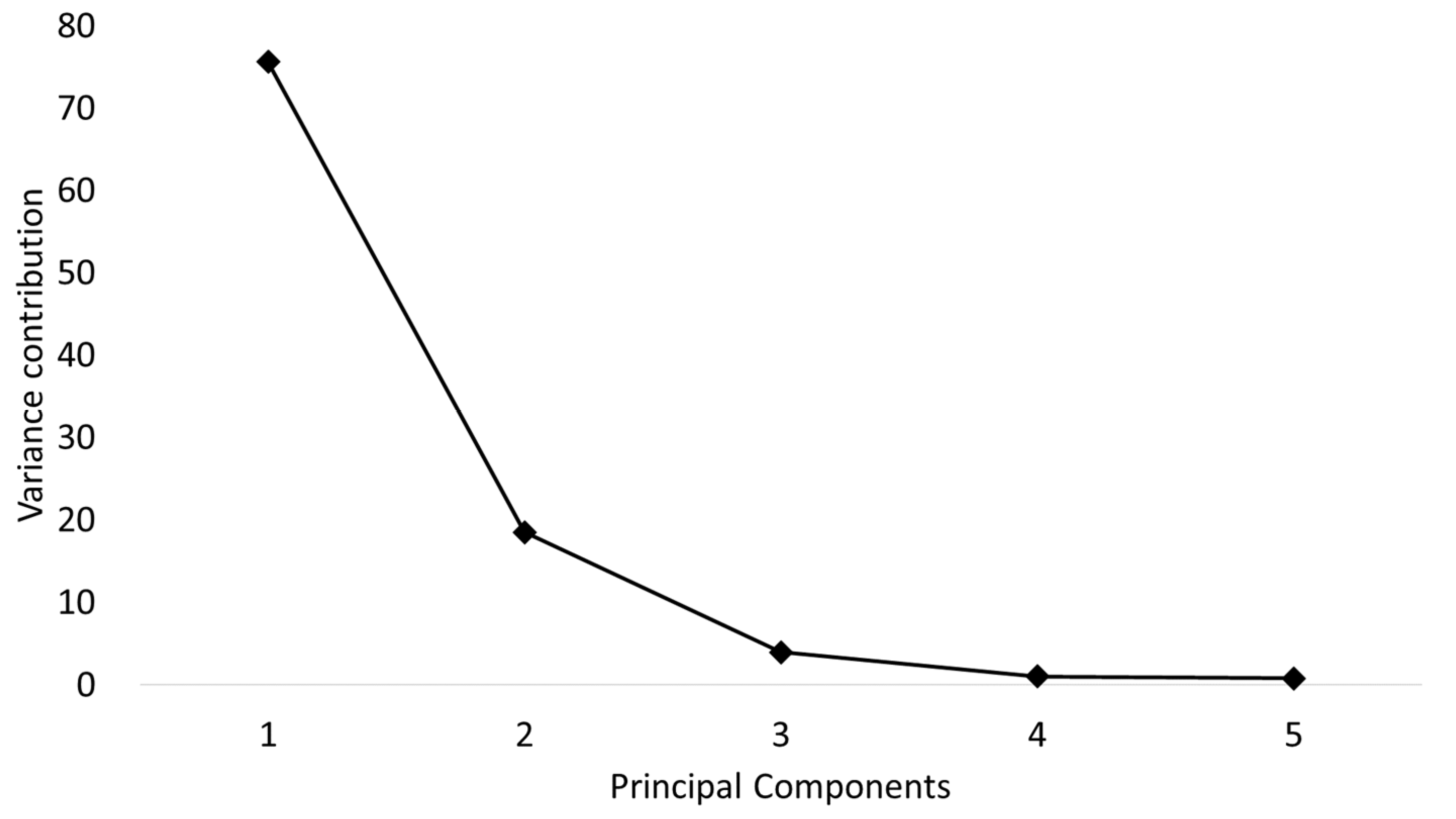

Due to the large number of variables, analyzing causality is cumbersome. Therefore, principal component analysis is first used to reduce the dimensionality of the five variables. The scree plot is obtained using SPSS analysis.

Based on

Figure 10, the cumulative variance contribution rate reaches 94.16%. Two principal components are extracted, which can explain most of the information in the original data.

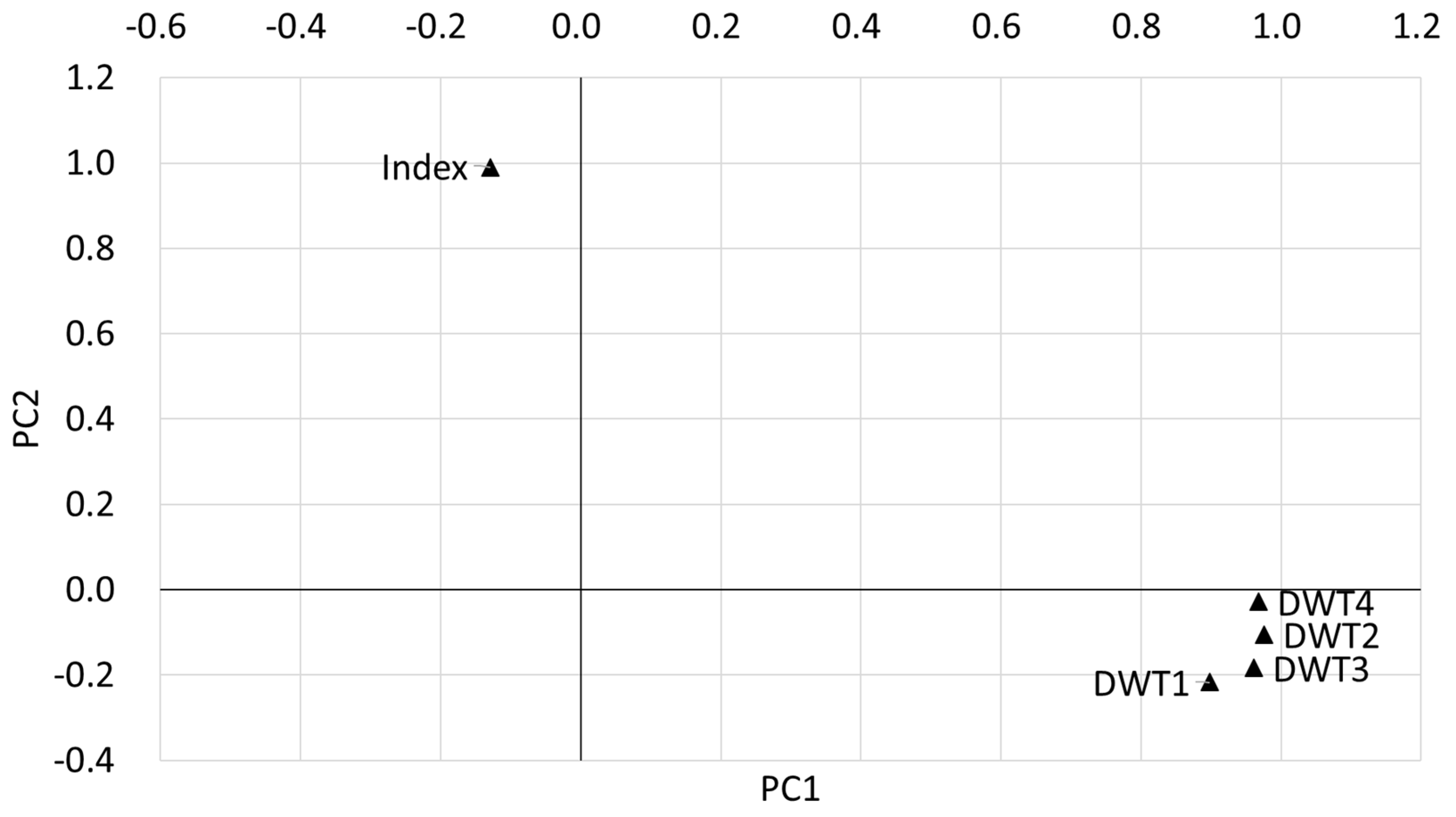

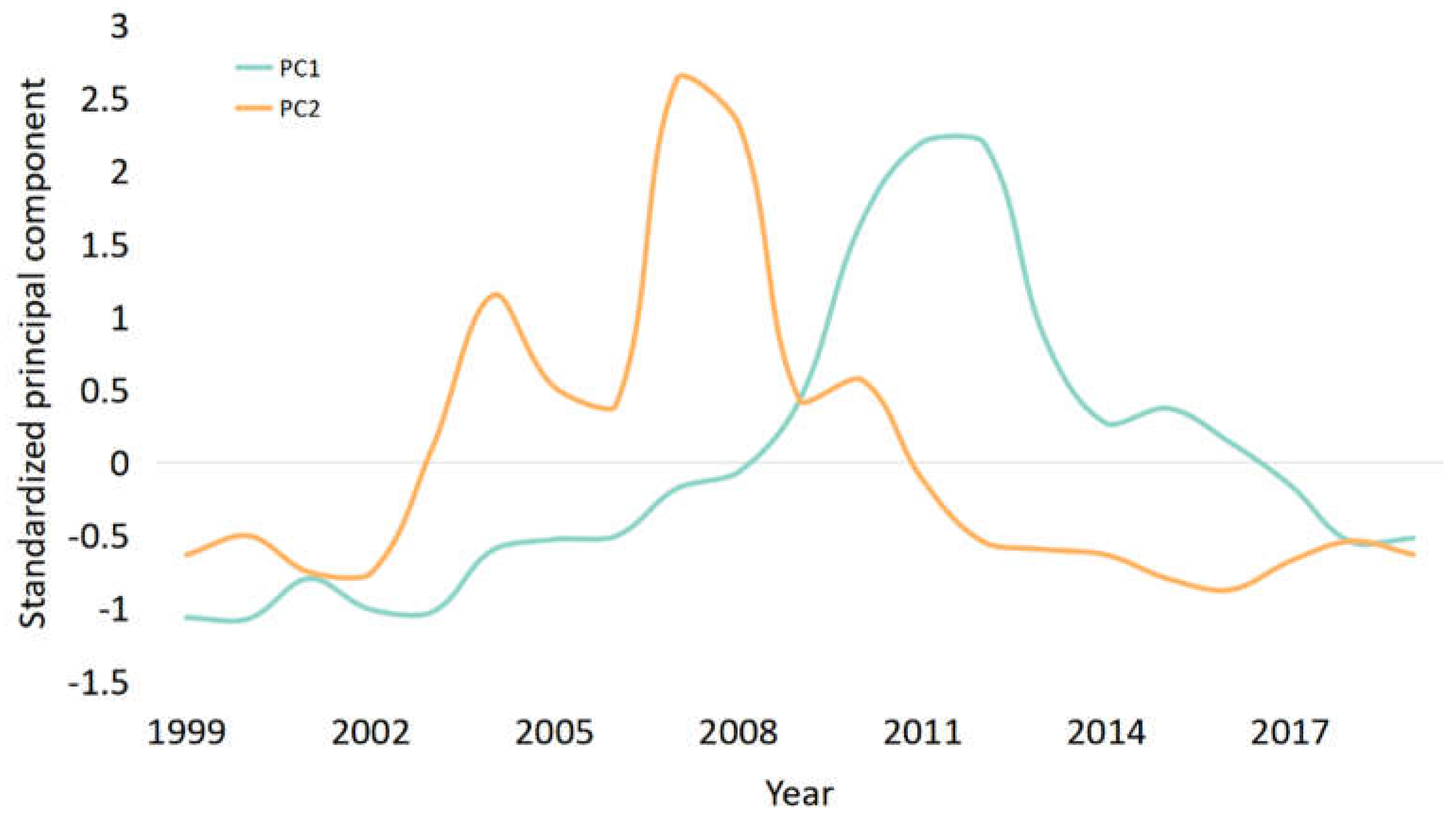

Figure 11 shows that the first principal component mainly consists of four types of new ship deliveries, while the second principal component represents BDI. The line chart of standardized values for the first and second principal components is shown in

Figure 12.

(2) Granger Causality Test

To ensure the stationarity of the time series, the ADF unit root test is first performed on the two principal components and four patent quantities, but as they failed to pass the unit root test, they need to be first-order differenced. After first-order differencing, all data can pass the unit root test (

Table 2), indicating that the differenced data is a stationary sequence and can be subjected to regression analysis.

We used Stata14.0 software to conduct Granger causality test experiments, regressing variables at lag one, lag two, etc. and determining the optimal lag period based on the AIC and BIC values. We found that when p=q=3, the AIC and BIC values were the smallest in our study. Therefore, we determined the lag period to be 3 periods and analyzed the causal relationships between PC1, PC2 and SP1, SP2, SP3, and SP4 separately. The results of the lag three regression are shown in

Table 3.

According to Table 5, hypotheses 1-8 all have p-values less than 0.01, indicating their significance at the 99% confidence level. Therefore, the original hypothesis is accepted, and PC1 is the Granger cause of SP1-SP4, while PC2 is also the Granger cause of SP1-SP4. New ship delivery and freight rates cause innovation changes to varying degrees. From the data, the larger the chi-square value, the smaller the p-value and the stronger the significance. Therefore, PC1 has a larger chi-square value than PC2, indicating that new ship delivery has a greater impact on innovation. In addition, for hypotheses 13-16, SP1-SP4 are the Granger causes of PC2, and innovation has a certain impact on the fluctuation of freight rates. However, for hypotheses 9-12, the p-value is greater than 0.1, indicating a lack of significance. The original hypothesis is rejected, and SP1-SP4 are not the Granger cause of PC1, indicating that innovation does not have an impact on new ship delivery.

5. Conclusions

The shipbuilding industry is not only a typical customized manufacturing industry, but also conforms to the characteristics of transportation equipment industry. Meeting customer (ship owners) needs and paying attention to the shipping market is an essential strategy to ensure that the built ships meet the transportation requirements of customers. This article studies the relationship between customer demand and the shipping market. In the market conditions, most customers will adopt similar ship investment behaviors, that is, the investment selection of new ships. Therefore, the collective investment behavior of customers is the true reflection of the shipbuilding market situation.

Through research, it was found that customers make decisions on whether to deliver and put new ships into operation by observing the market trend of the BDI index. The investment in the delivery of new ships can bring fluctuations in the BDI index, and there is an obvious correlation between the two, which reflects the development and changes of customer prediction ability. Customer prediction ability has environmental and market sensitivity, mainly focusing on how to obtain returns through ship operations in the freight market. By analyzing the changes in the values of specific attributes within a certain range, they can predict changes in the attributes and make choices for ship investments.

The study also made a very important discovery: customer prediction ability is the Granger cause of innovation in customized production. Customer prediction ability can affect innovation in customized production, and innovation will have a certain impact on market price fluctuations. Gu Jianzhou, Vice Chairman of the Hong Kong Shipowners Association, pointed out that quality, technology, and service are particularly important factors in the eyes of ship owners. Major ship research scholars at home and abroad (Canadian scholar Daniel Todd, American scholar Adal Kancharla, British economist Michael Beebstock, and Chinese scholar Ma Jianwei) unanimously believe that the top three factors influencing shipowner demand are shipbuilding technology, ship price, and service time. Therefore, shipbuilding companies should pay special attention to changes in customer prediction ability through market dynamics. When the BDI index rises and the material market is in good condition, the prospect value of ships will increase, and customers will adopt loose investment decisions. Shipbuilding companies can reasonably accept shipbuilding orders and increase technological changes and innovation in shipbuilding. However, when freight rates and material market conditions are poor, customer investment decisions will become cautious and conservative, and shipbuilding companies need to actively take measures to transfer or resolve risks.

This article only selected bulk carriers as the research object, and through strict statistical tests, examined the relationship between customer prediction ability and innovation in shipbuilding production. In future ship innovation research, the selection of research objects can be expanded to include oil tankers and container ships that dominate the ship product market, as well as other manufacturing industries. By seeking more comprehensive influencing factors and analyzing their relationships, more research support can be provided for customer prediction ability and innovation in customized production.

Author Contributions

Huayan Shen and Yu Gao jointly designed the research ideas and contents. Huayan Shen was responsible for the text writing, Yu Gao was responsible for the demonstration of research methods and models, Zhiyong Ou was responsible for data collection and processing, also Huayan Shen and Zhiyong Ou were responsible for the revision and editing of articles.

Funding

This work was supported by a generous grant provided by Characteristic innovation projects of colleges and universities in Guangdong Province, Guangdong Provincial Department of Education.No: 2022WTSCX339.

Conflicts of Interest

The authors do not have any conflict of professional, financial and personal interests relating to the research described in this paper.

References

- Daradkeh, F.M.; Hassan,T.H.; Palei, T.; Helal, M.Y .; Mabrouk,S.; Saleh, M.I.; Salem, A.E.;Elshawarbi, N.N. Enhancing Digital Presence for Maximizing Customer Value in Fast-Food Restaurants.Sustainability,2023, 15, 5690:1-18. [CrossRef]

- César Martínez-Olvera. An Entropy-Based Formulation for Assessing the Complexity Level of a Mass Customization Industry 4.0 Environment. Mathematical Problems in Engineering. 2020:1-19. [CrossRef]

- Mishra, A.A., R.Shah,“In Union Lies Strength: Collaborative Competence in New Product Development and Its Performance Effects”, Journal of Operations Management, 2009, 27(4): 324-338. [CrossRef]

- Milé Terziovski.Innovation practice and its performance implications in small and medium enterprises (SMEs) in the manufacturing sector: a resource-based view.Strategic Management Journal,2010,31(8):892-902.

- Lin, H., S.X. Zeng, H.J. Liu, C.Li,How Do Intermediaries Drive Corporate Innovation? A Moderated Mediating Examination, Journal of Business Research, 2016, 69(11): 4831-4836. [CrossRef]

- Cui, A. S., F. Wu, Utilizing Customer Knowledge in Innovation: Antecedents and Impact of Customer Involvement on New Product Performance, Journal of the Academy of Marketing Science, 2016, 44(4): 516-538. [CrossRef]

- Dai zhihua, Peng yunfeng. Research on innovation performance of new product development considering customer participation.Journal of systems management 2014, 23(6): 778-787.

- Greenwald, A. G., and Leavit, C. Cognitive theory and audience involvement, In L.Alwitt and A. Mitchell(Eds), Psychological Processes and Advertising Effects. Lawrence Erlbaum, Hilldale, NJ,221-240.

- Nambisan S.Designing virtual customer environments for new product development:Toward a theory.Academy of management review,2002,27(3):392-413.

- Mills, P. K., Chase, R. B., and Margulies, N. Motivating the clientlemployee system as a service production strategy.Academy of Management Review, 1983,8(2): 301-310.

- Remy, E., and Kopel, S. Social linking and human service sector.The Service Industries Journal.2002,22(1):35-55.

- Nordin,F. & Kowalkowski,C. Solutions Offerings: A Critical Review and Reconceptualization,Journal of Service Management,2010,21(4):441~459. [CrossRef]

- Cooper, Robert G.; Kleinschmidt, Elko J. New product performance: Keys to success,profitability & cycle time reduction.Journal of Marketing Management.1995,11(4):315-337. [CrossRef]

- Dean J.W.,Jr, Bowen,D.E. Management theory and total quality: Improving research and practice through theory development.Academy of management review,1994,19:392-418. [CrossRef]

- Drucker,P.F.The practice of management.New York:Harper,1954.

- Jang, Y .-J.; Kim, E. Social and Personal Norms in Shaping Customers’ Environmentally Sustainable Behavior in Restaurants’ Social Media Communities.Sustainability 2023, 15, 6410:1-14. [CrossRef]

- Martínez-Torres, M. Customer preferences versus managerial decision-making in open innovation communities: the case of Starbucks. Technology Analysis and Strategic Management, 2015,27(10):1226-1238. [CrossRef]

- Lengnick-Hall, C. A. Customer contributions to quality: A different customer-oriented firm.academy of Management Review, 1996,2l (3): 791-824. [CrossRef]

- Beibei Dong; Kenneth R. Evans; Shaoming Zou. The effects of customer participation in co-created service recovery.Original empirical research. 2008, 36(1):123–137. [CrossRef]

- Seigyoung Auh; Simon J. Bell; Colin S. McLeod; Eric Shih. Co-production and customer loyalty in financial services. Journal of Retailing,2007,83(3):359–370. [CrossRef]

- Chervonnaya,O.Customer Role and Skill Trajectories in Services.International Journal of Service Industry Management. 2003, 14:347-363. [CrossRef]

- De Haan, Evert; Verhoef, Peter C.; Wiesel, Thorsten. The predictive ability of different customer feedback metrics for retention. International Journal of Research in Marketing, 2015,32(2):195-206. [CrossRef]

- Ittner,C., Larcker,D.Innovation in performance measurement:Trands and Research implication.Journal of Management Accounting Research,1998, 10:205-308.

- Mittal, Vikas and Kamakura, Wagner A.Satisfaction, Repurchase Intention and Repurchase Behavior: Investigating the Moderating Effects of Customer Characteristics. Journal of Marketing Research, 2001(07):131-142. [CrossRef]

- Keiningham, Timothy L.Cooil, Bruce; Aksoy, et al. The value of different customer satisfaction and loyalty metrics in predicting customer retention, recommendation, and share-of-wallet.Managing Service Quality: An International Journal, 2007,17(4):361-384. [CrossRef]

- Stopford, Martin. Maritime Economics 3e. Routledge.2009.

- BJ Pine. Mass customization: the new frontier in business competition.Harvard business press,1993. [CrossRef]

- Alptekin ULUTAŞ, Gabrijela POPOVIC, Pavle RADANOV, Dragisa STANUJKIC, Darjan KARABASEVIC. A new hybrid fuzzy psi-piprecia-cocoso mcdm based approach to solving the transportation company selection problem. Technological and Economic Development of Economy, 2021, 27(5): 1227-1249. [CrossRef]

- Chamlibers, J. C., Mullick, S. K. and Smith, D. D. How to Choose the right forecasting technique.Harvard Business Review, 1971.49:45-74.

- Boucher, T. O., & Yalçin, A. Introduction. Design of Industrial Information Systems, 2006:1-25.

- Rexer, K., De Veaux, R., Britton, G., & Taylor, J. Endorsements for Practical Text Mining & Statistical Analysis for Non-structured Text Data Applications. Elsevier,2012.

- Makridakis, S. and Wheelwrighlt, S. Forecasting: Methods and Applications. New York: Wiley, 1978.

- Derek Bunn. Forecasting with more than one model. Journal of Forecasting, 1989, 8:161-166. [CrossRef]

- Tidd J, Bessant J, Pavitt K. Managing Innovation; Integrating Technological, Market And Organizational Change. New York: John Wiley & Sons,2001.

- Moore,W.L., Tushman,M.L.,Managing Innovation over the product life cycle.Readings in the management of innovation,1982:131-150.

- Roger G.Schroeder;Gary D.Scudder;Dawn R.Elm.Innovation in manufacturing.Journal of operations management.1989,8(1):1-15.

- Robert W. Grubbstrom; Hans H. Hinterhuber. Production economics: Issues and challenges for the 90's.International journal of Production Economics,1991, 23(1-3):1-2. [CrossRef]

- Wong.Hartanto,Huang.Chin-Yin.Innovation in production research. International Journal of Production Economics, 2014,147:1-2.

- Bongsug (Kevin) Chae. An evolutionary framework for service innovation: Insights of complexity theory for service science.International journal of Production Economics,2012,135(2):813-822. [CrossRef]

- Verma,Rohit.Ettlie,John E.Rosenthal,Stephen R.Service innovation in manufacturing. Journal of Service Management, 2012,23(3):440-454. [CrossRef]

- Machuca,J.,González-Zamora,M.Service operations research[J].Journal of Operations Management,2007,25:585–603. [CrossRef]

- Maccarthy,PG Brabazon,J Bramham.Fundamental modes of operation for mass customization.International Journal of Production Economics,2003,85(3):289-304. [CrossRef]

- Andrea Caputo. Marzi, Giacomo; Pellegrini, Massimiliano Matteo. The Internet of Things in manufacturing innovation processes.Business Process Management Journal, 2016,22(2):383–402. [CrossRef]

- Shepherd, C. Ahmed, P.K. From product innovation to solutions innovation: a new paradigm for competitive advantage.European Journal of Innovation Management, 2000, 3 (2):100-106. [CrossRef]

- Porter, M.E. Competitive Advantage. New York, NY,1985.

- Li, Q., Maggitti, P.G., Smith, K.G., Tesluk, P.E. and Katila, R. Top management attention to innovation: the role of search selection and intensity in new products introduction.Academy of Management Journal, 2013,56 (3):893-916. [CrossRef]

- Teece, D.J.Business models, business strategy and innovation.Long Range Planning,2010,43(2):172-194. [CrossRef]

- Yang Yiweng,Wang Yi,Sun Guohui .Research on Recommendation System from the Perspective of Consumers.Journal of Central University of Finance and Economics, 2016(9):79-85.

- Blecker, T., Abdelkafi, N. Mass Customization: State-of-the-Art and Challenges.International Series in Operations Research & Management Science, 2006:1-25.

- Li, J.; Lin, Z.; Zhang, X. The Study on the Effectiveness of Sustainable Customer Relationship Management: Evidence from the Online Shopping Industry .Sustainability,2023, 15, 5911:1-21. [CrossRef]

- Almunawar, M. N., & Anshari, M. Digital enabler and value integration: revealing the expansion engine of digital marketplace. Technology Analysis and Strategic Management, 2021:1–11. [CrossRef]

- Yuliansyah, Y., Rammal, H.G. Organizational learning, innovativeness and performance of financial service firms in an emerging market: examining the mediation effects of customer-focused strategy.Business Process Management Journal,2021,27(4):1126-1141. [CrossRef]

- von Hippel, Eric.Lead-Users: A Source of Novel Product Concepts. Management Science, 1986,32(7):791-805.

- Lilien, G., Morrison Pamela, D. Searls, K. Sonnack, M.and von Hippel, E. Performance Assessment of the Lead User Generation Process for New Product Development. Management Science, 2002, 48:1042-1059. [CrossRef]

- Urban, G. and von Hippel, E., Lead User Analyses for the Development of New Industrial Products ,Management Science, 1988,35(5):569-82. [CrossRef]

- Samuel Amponsah ODEI , Jan STEJSKAL.Firms pursuit of innovations through internationalization:a treatment effect estimation. Technological and Economic Development of Economy, 2020, 26(4): 837-866. [CrossRef]

- Christensen, C. M. and J. L. Bower, “Customer Power, Strategic Investment and the Failure of Leading Firms ”,Strategic Management Journal, 1996(17): 197-218. [CrossRef]

- G. Gavetti, D. Levinthal.Looking forward and looking backward: Cognitive and experiential search, Administrative Science Quarterly.2000, 45 (1):113-137. [CrossRef]

- Hsu, G., Kovács, B., & Koçak, Ö.. Experientially diverse customers and organizational adaptation in changing demand landscapes: A study of US cannabis markets, 2014–2016. Strategic Management Journal. 2019(07):1-28. [CrossRef]

- Hughes,C.ship performance,London:llp.1996.

- Gu Jianzhou. Standards in the eyes of shipowners , Shanghai shipbuilding. 2006(02) :10-11+15.

- Philipp Schautschick; Christine Greenhalgh; Empirical studies of trade marks - The existing economic literature,Economics of innovation and new technology,2016(03):358-390. [CrossRef]

- Kim B, Gazzola G,Yang J,et al.Two-phase edge outlier detection method for technology opportunity discovery.Scientometrics, 2017,113(1):1-16. [CrossRef]

- Chen Lliang,Luo min,Comparative study on technological innovation ability of colleges and universities from the perspective of patent trend analysis,Library and information research,2023(1):114-123.

- Yang C, Chen M Y, YuanQ. The application of XGBoostand SHAP to examining the factors in freight truck-related crashes: An exploratory analysis.Accident Analysis and Prevention,2007, 1(1): 81-85.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).