Submitted:

17 May 2023

Posted:

22 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

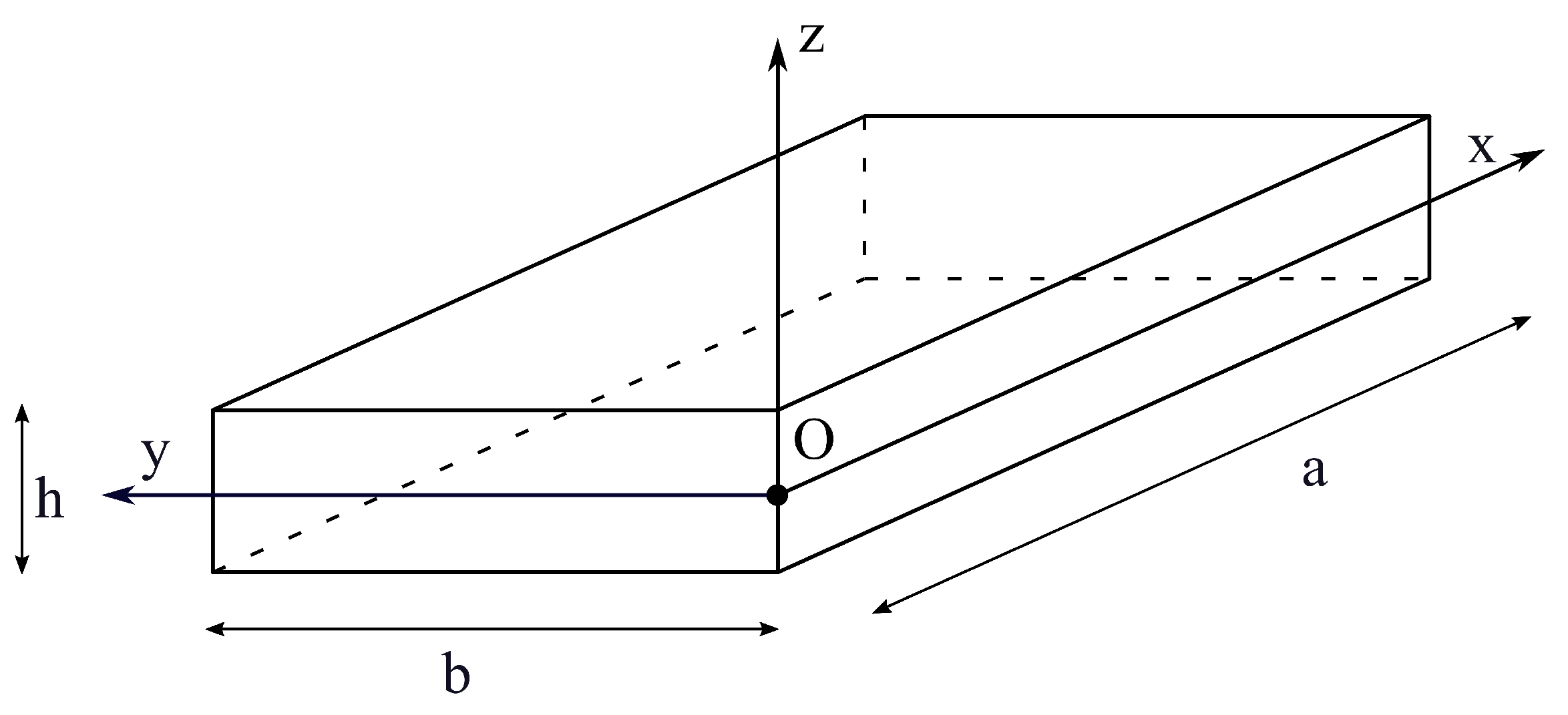

2. Carrera’s Unified Formulation

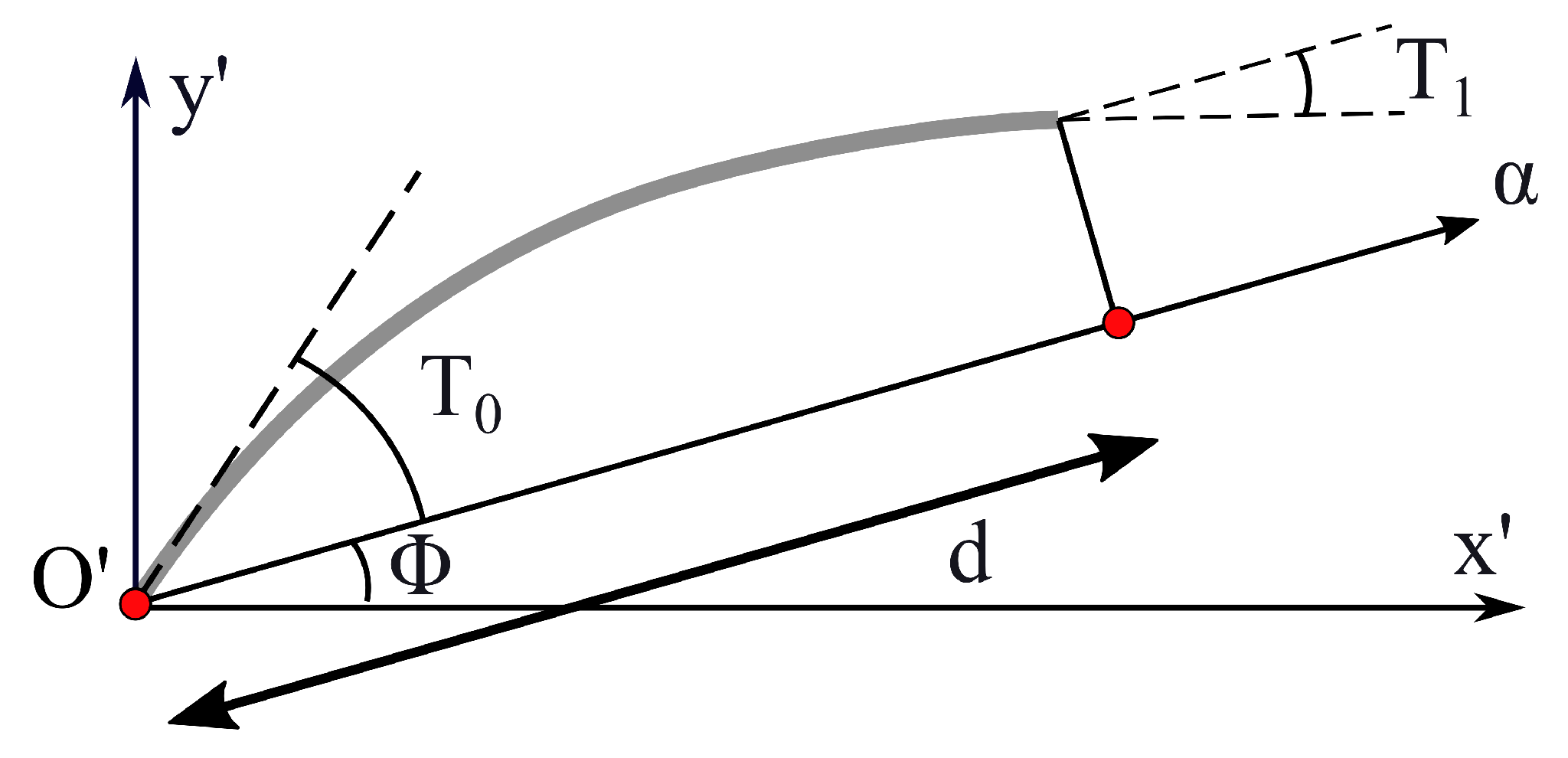

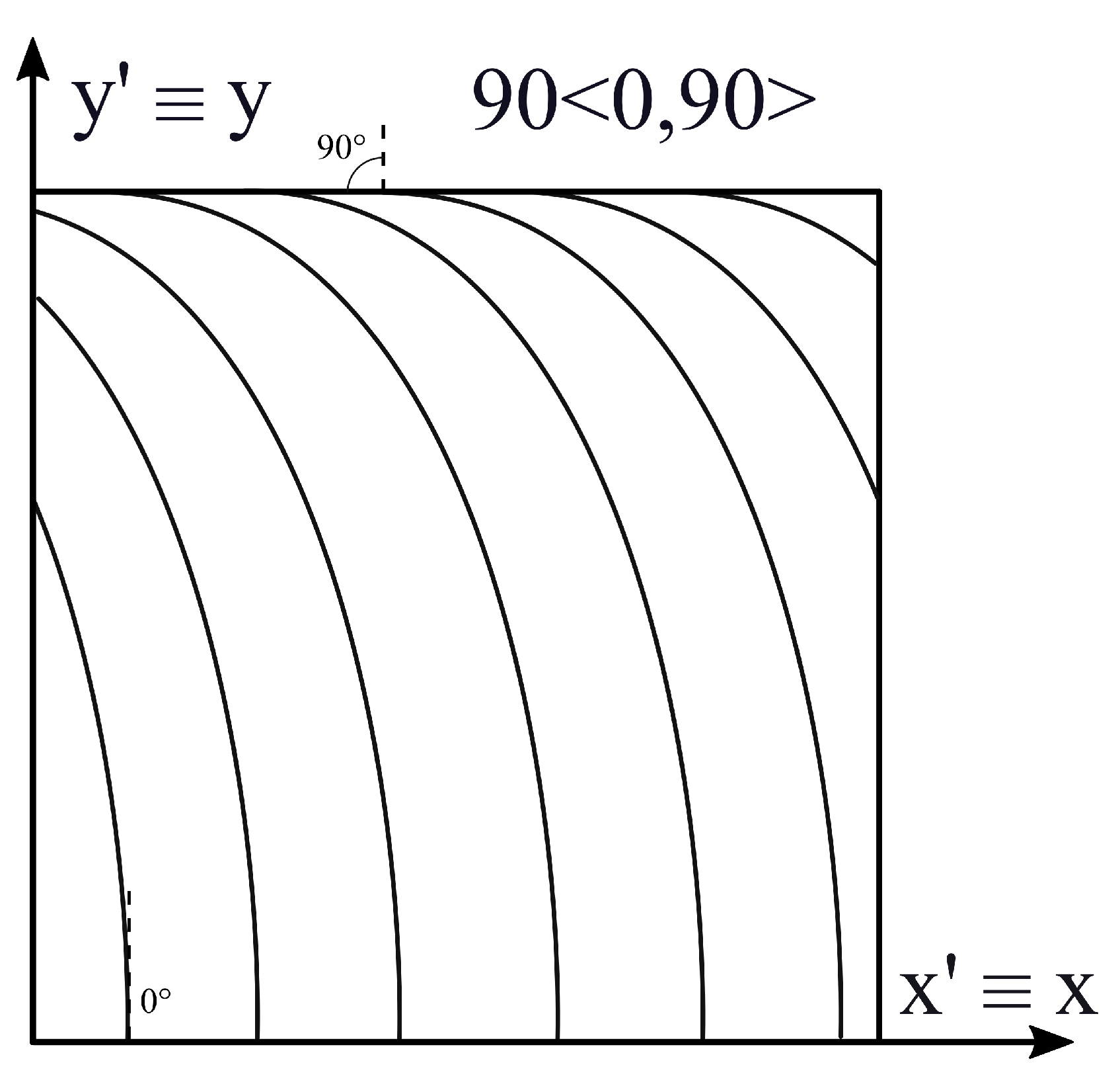

2.1. Variable Stiffness Composite Plates

2.2. Variational Statements

2.3. Kinematic Assumptions

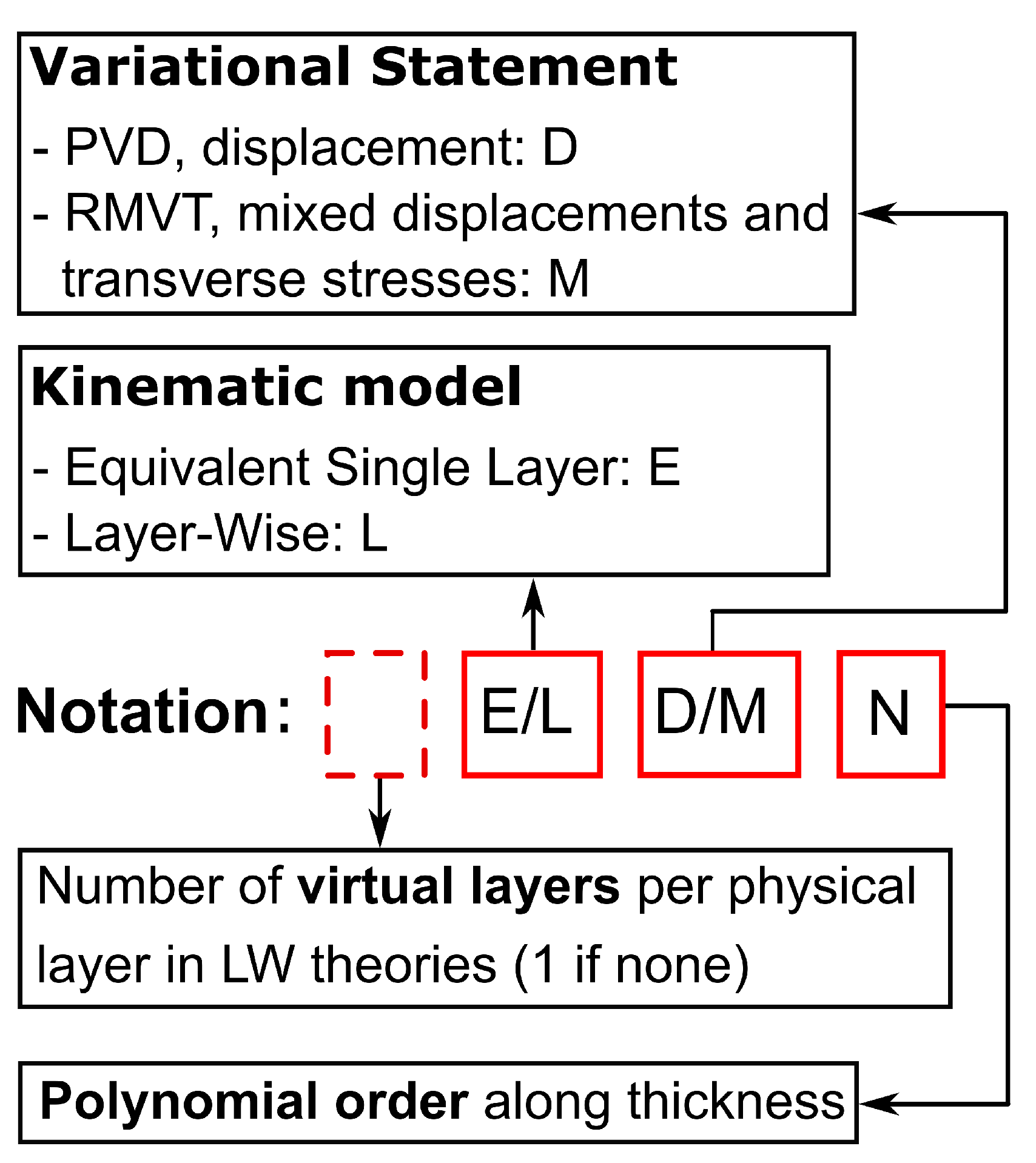

2.4. Acronym System

2.5. FE Stiffness Matrices

3. Numerical Results and Discussion

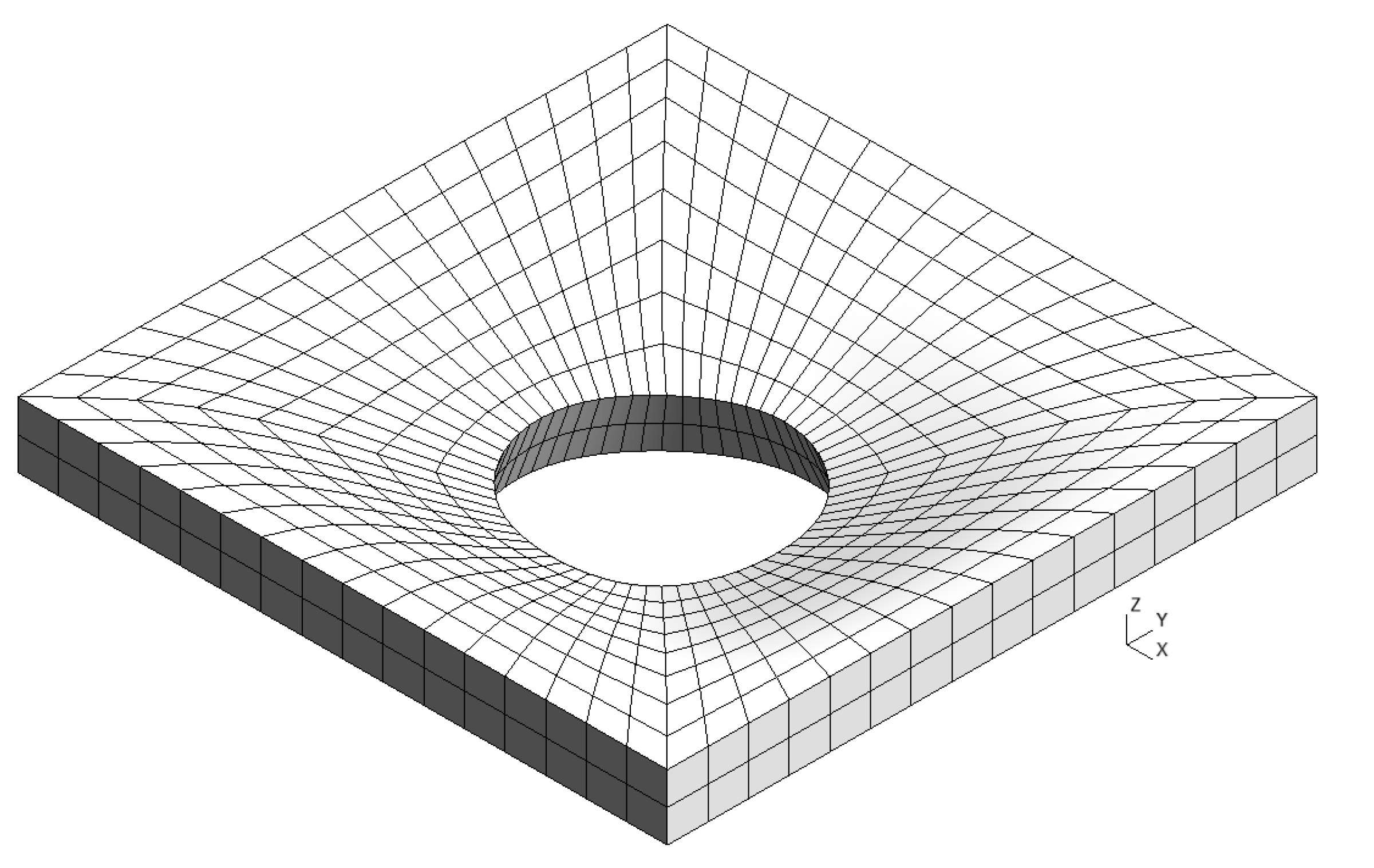

3.1. Monolayer plate

3.2. Multilayer plate

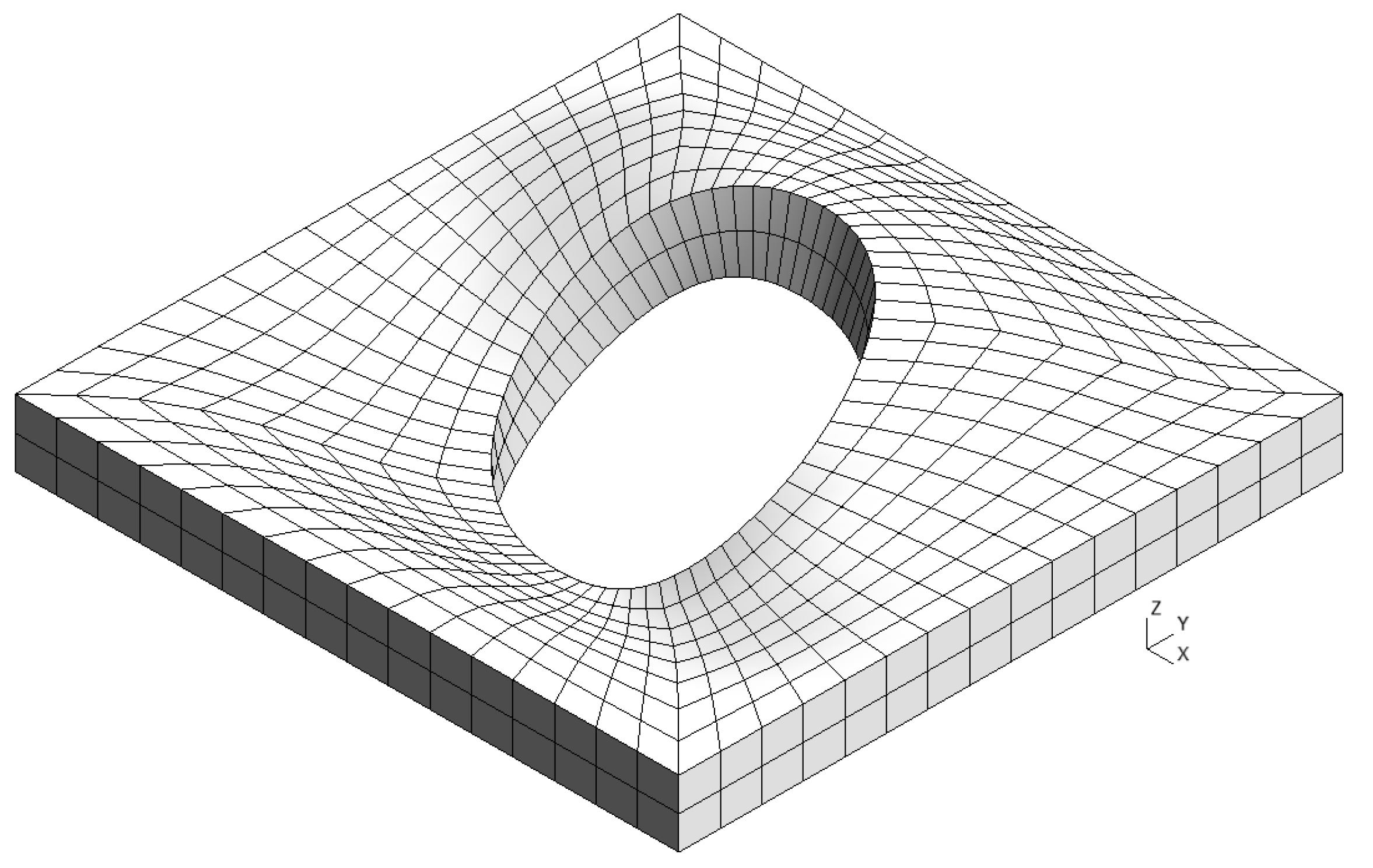

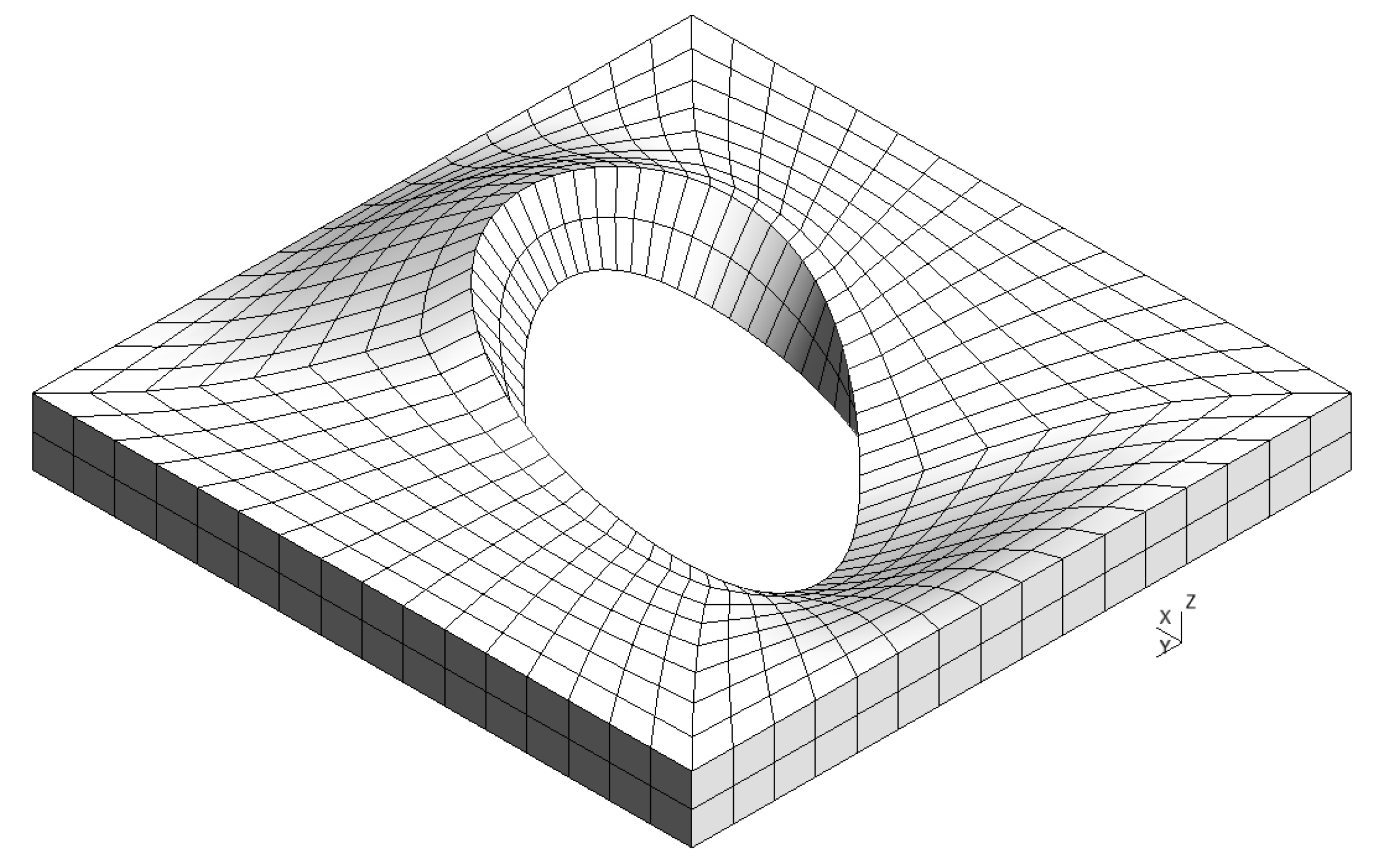

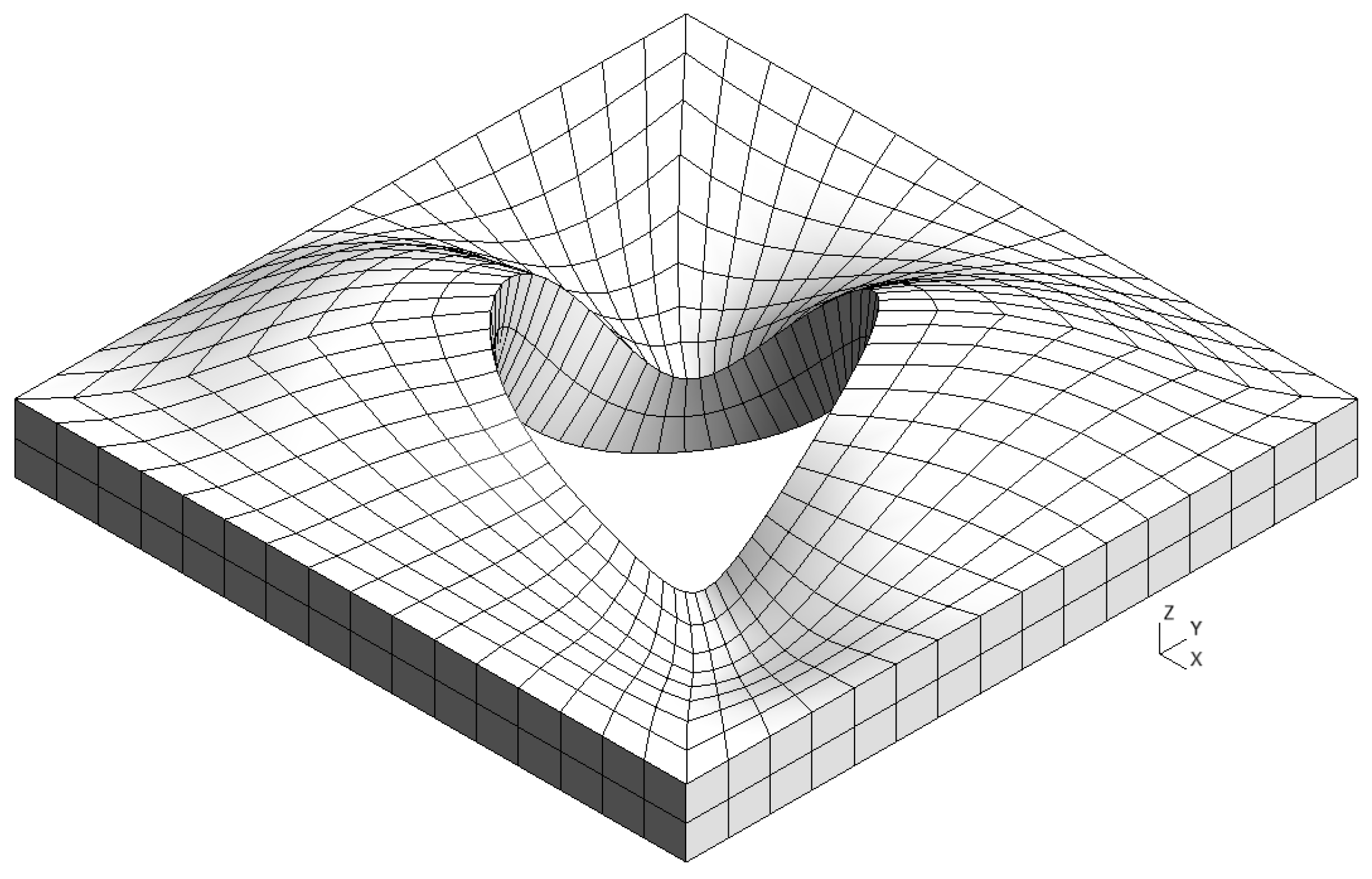

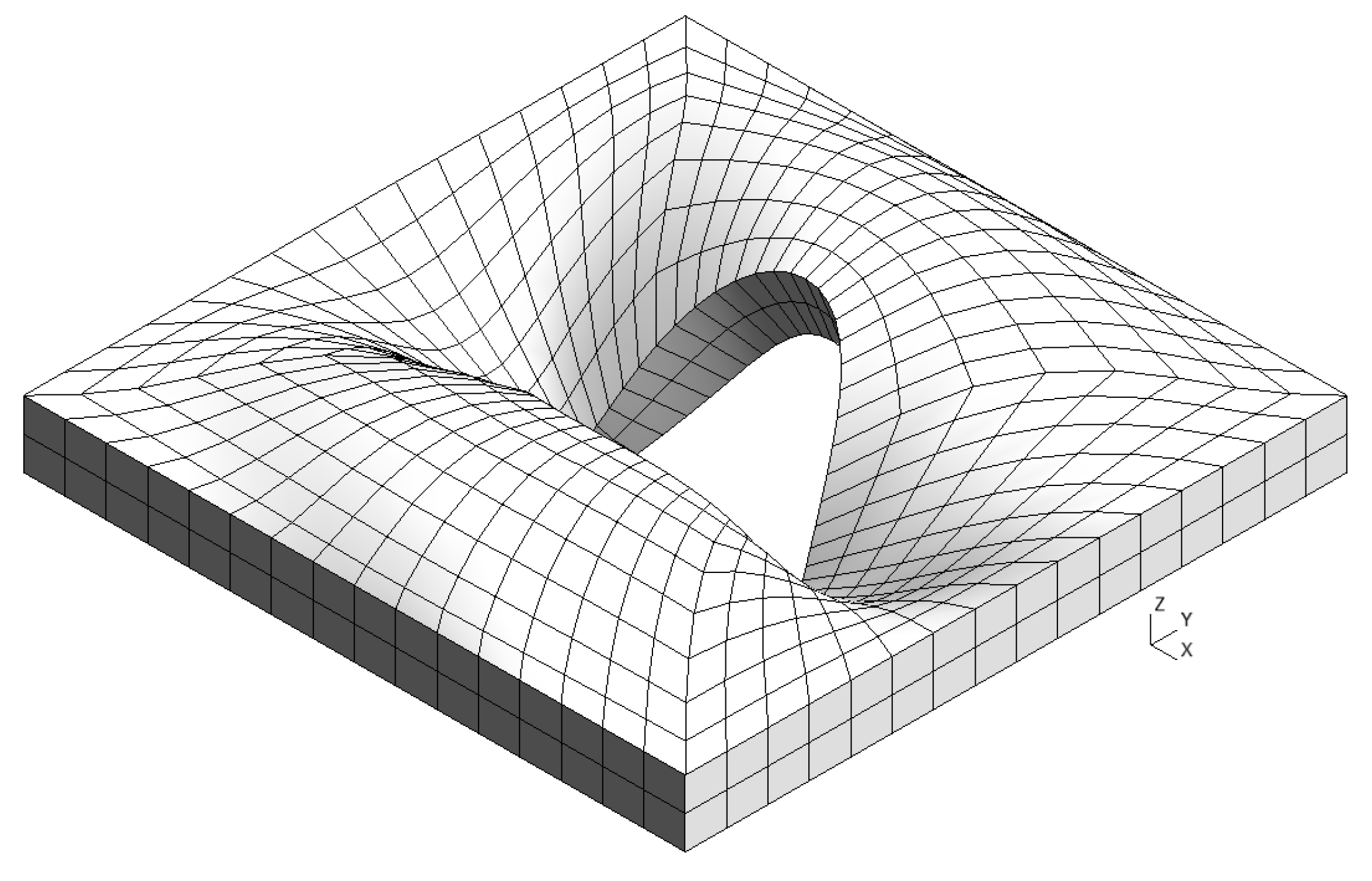

3.3. Multilayer plate with central hole

4. Conclusions

- Classical theories (FSDT and CLT) provide the best trade off between accuracy and computational costs for thin plates (), whereas they are not able to correctly predict the behavior of thicker plates ( and 5), specially at high frequencies. The loss of accuracy is more evident for CLT results, since this theory does not consider transverse shear stresses, which become important in thick plates. This error is particularly evident in the second and third, where the inversion of modes can be observed.

- PVD results show monotonic convergence to the reference solution: the lower the DOF number, the higher the frequency value. For a given mode, frequencies values decrease when higher-order models are employed, and they get closer to reference solution.

- In all the cases, layer-wise mixed theories yield the best match of the reference 3D solution, independently from the plate geometry or fibres variational law. In every case, a second-order model is more accurate and less computationally expensive than a fourth-order layer-wise PVD model. This is justified by the fact that RMVT considers both displacements and transverse stresses as primary variables, assuring a better approximation of the transverse stresses field into the problem domain improving the overall solution accuracy.

Acknowledgments

References

- Hyer, M. W.; Charette, R. F. Innovative design of composite structures: The use of curvilinear fiber format in composite structure design. 1990.

- Hyer, M. W.; Lee, H. H. Innovative design of composite structures: the use of curvilinear fiber format to improve buckling resistance of composite plates with central circular holes. 1990. [Google Scholar]

- Akhavan, H.; Ribeiro, P. Natural modes of vibration of variable stiffness composite laminates with curvilinear fibers. Compos. Struct. 2011, 93, 3040–3047. [Google Scholar] [CrossRef]

- Ribeiro, P.; Akhavan, H. Non-linear vibrations of variable stiffness composite laminated plates. Compos. Struct. 2012, 94, 2424–2432. [Google Scholar] [CrossRef]

- Hachemi, M.; Hamza-Cherif, S. M.; Houmat, A. Free vibration analysis of variable stiffness composite laminate plate with circular cutout. Aust. J. Mech. Eng. 2017. [Google Scholar]

- Zhao, W.; Kapania, R. K. Prestressed vibration of stiffened variable-angle tow laminated plates. AIAA J. 2019, 57, 2575–2593. [Google Scholar] [CrossRef]

- Honda, S.; Narita, Y. Natural frequencies and vibration modes of laminated composite plates reinforced with arbitrary curvilinear fiber shape paths. J. Sound Vib. 2012, 331, 180–191. [Google Scholar] [CrossRef]

- Rodrigues, J. D.; Ribeiro, P.; Akhavan, H. Experimental and finite element modal analysis of variable stiffness composite laminated plates. In Proceedings of the 11th Biennial International Conference on Vibration Problems (ICOVP-2013), 2013, 30. [Google Scholar]

- Stodieck, O.; Cooper, J. E.; Weaver, P. M.; Kealy, P. Improved aeroelastic tailoring using tow-steered composites. Compos. Struct. 2013, 106, 703–715. [Google Scholar] [CrossRef]

- Abdalla, M. M.; Setoodeh, S.; Gürdal, Z. Design of variable stiffness composite panels for maximum fundamental frequency using lamination parameters. Compos. Struct. 2007, 81, 283–291. [Google Scholar] [CrossRef]

- Blom, A. W.; Setoodeh, S.; Hol, J.; Gürdal, Z. Design of variable-stiffness conical shells for maximum fundamental eigenfrequency. Comput. Struct. 2008, 86, 870–878. [Google Scholar] [CrossRef]

- Carvalho, J.; Sohouli, A.; Suleman, A. Fundamental Frequency Optimization of Variable Angle Tow Laminates with Embedded Gap Defects. J. Compos. Sci. 2022, 6, 64. [Google Scholar] [CrossRef]

- Montemurro, M.; Catapano, A. On the effective integration of manufacturability constraints within the multi-scale methodology for designing variable angle-tow laminates. Compos. Struct. 2017, 161, 145–159. [Google Scholar] [CrossRef]

- Catapano, A.; Montemurro, M.; Balcou, J.-A.; Panettieri, E. Rapid prototyping of variable angle-tow composites. Aerotecnica Missili & Spazio 2019, 98, 257–271. [Google Scholar]

- Montemurro, M.; Catapano, A. A general B-Spline surfaces theoretical framework for optimisation of variable angle-tow laminates. Compos. Struct. 2019, 209, 561–578. [Google Scholar] [CrossRef]

- Fiordilino, G. A.; Izzi, M. I.; Montemurro, M. A general isogeometric polar approach for the optimisation of variable stiffness composites: Application to eigenvalue buckling problems. Mech. Mater. 2021, 153, 103574. [Google Scholar] [CrossRef]

- Carrera, E. Theories and finite elements for multilayered, anisotropic, composite plates and shells. Arch. Comput. Meth. Eng. 2002, 9, 87–140. [Google Scholar] [CrossRef]

- Carrera, E. Theories and finite elements for multilayered plates and shells: a unified compact formulation with numerical assessment and benchmarking. Arch. Comput. Meth. Eng. 2003, 10, 215–296. [Google Scholar] [CrossRef]

- Carrera, E.; Giunta, G.; Brischetto, S. Hierarchical closed form solutions for plates bent by localized transverse loadings. J. Zhejiang Univ. Sci. A 2007, 8, 1026–1037. [Google Scholar] [CrossRef]

- Carrera, E.; Giunta, G. Hierarchical models for failure analysis of plates bent by distributed and localized transverse loadings. J. Zhejiang Univ. Sci. A 2008, 9, 600–613. [Google Scholar] [CrossRef]

- Giunta, G.; Catapano, A.; Belouettar, S. Failure indentation analysis of composite sandwich plates via hierarchical models. J. Sandw. Struct. Mater. 2013, 15, 45–70. [Google Scholar] [CrossRef]

- Giunta, G.; Biscani, F.; Belouettar, S.; Ferreira, A. J. M.; Carrera, E. Free vibration analysis of composite beams via refined theories. Compos. Part B Eng. 2013, 44, 540–552. [Google Scholar] [CrossRef]

- Viglietti, A.; Zappino, E.; Carrera, E. Analysis of variable angle tow composites structures using variable kinematic models. Comp. Part B: Eng. 2019, 171, 272–283. [Google Scholar] [CrossRef]

- Fallahi, N.; Viglietti, A.; Carrera, E.; Pagani, A.; Zappino, E. Effect of fiber orientation path on the buckling, free vibration, and static analyses of variable angle tow panels. Facta Univ., Ser. Mech. Eng. 2020, 18, 165–188. [Google Scholar] [CrossRef]

- Sánchez-Majano, A. R.; Azzara, R.; Pagani, A.; Carrera, E. Accurate Stress Analysis of Variable Angle Tow Shells by High-Order Equivalent-Single-Layer and Layer-Wise Finite Element Models. Materials 2021, 14, 6486. [Google Scholar] [CrossRef] [PubMed]

- Pagani, A.; Sánchez-Majano, A. R. Influence of fiber misalignments on buckling performance of variable stiffness composites using layerwise models and random fields. Mech. Adv. Mater. Struct. 2022, 29, 384–399. [Google Scholar] [CrossRef]

- Pagani, A.; Sánchez-Majano, A. R. Stochastic stress analysis and failure onset of variable angle tow laminates affected by spatial fibre variations. Compos. Part C: Open Access 2021, 4, 100091. [Google Scholar] [CrossRef]

- Sánchez-Majano, A. R.; Pagani, A.; Petrolo, M.; Zhang, C. Buckling sensitivity of tow-steered plates subjected to multiscale defects by high-order finite elements and polynomial chaos expansion. Materials 2021, 14, 2706. [Google Scholar] [CrossRef] [PubMed]

- Vescovini, R.; Dozio, L. A variable-kinematic model for variable stiffness plates: Vibration and buckling analysis. Compos. Struct. 2016, 142, 15–26. [Google Scholar] [CrossRef]

- Demasi, L.; Biagini, G.; Vannucci, F.; Santarpia, E.; Cavallaro, R. Equivalent Single Layer, Zig-Zag, and Layer Wise theories for variable angle tow composites based on the Generalized Unified Formulation. Compos. Struct. 2017, 177, 54–79. [Google Scholar] [CrossRef]

- Carrera, E.; Demasi, L. Classical and advanced multilayered plate elements based upon PVD and RMVT. Part 1: Derivation of finite element matrices. Int. J. Numer. Methods Eng. 2002, 55, 191–231. [Google Scholar] [CrossRef]

- Carrera, E.; Demasi, L. Classical and advanced multilayered plate elements based upon PVD and RMVT. Part 2: Numerical implementations. Int. J. Numer. Methods Eng. 2002, 55, 253–291. [Google Scholar] [CrossRef]

- Reddy, J. N. Mechanics of laminated composite plates and shells: theory and analysis. CRC press: 2003.

- Gürdal, Z.; Tatting, B. F.; Wu, C. K. Variable stiffness composite panels: effects of stiffness variation on the in-plane and buckling response. Compos. Part A Appl. Sci. Manuf. 2008, 39, 911–922. [Google Scholar] [CrossRef]

- Honda, S.; Oonishi, Y.; Narita, Y.; Sasaki, K. Vibration analysis of composite rectangular plates reinforced along curved lines. J. Syst. Des. Dyn. 2008, 2, 76–86. [Google Scholar] [CrossRef]

- Carrera, E. On the use of the Murakami’s zig-zag function in the modeling of layered plates and shells. Comput. Struct. 2004, 82, 541–554. [Google Scholar] [CrossRef]

- Bathe, K.-J. Finite element procedures. 2006.

| Case | [GPa] | [GPa] | [GPa] | |

|---|---|---|---|---|

| 1 | ||||

| 2 | ||||

| 3 |

| Model | DOF |

|---|---|

| Abaqus 3D | 997’515 |

| 3LM4 | 34’398 |

| 2LM2 | 13’230 |

| 3LD4 | 17’199 |

| 2LD2 | 6’615 |

| ED4 | 6’615 |

| ED2 | 3’969 |

| FSDT | 2’646 |

| CLT | 2’646 |

| Mode | |||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Abaqus 3D | 7.397 | 16.354 | 37.158 | 48.025 | 63.349 |

| 3LM4 | 7.399 | 16.334 | 37.164 | 47.988 | 63.310 |

| 2LM2 | 7.398 | 16.333 | 37.162 | 47.986 | 63.309 |

| 3LD4 | 7.400 | 16.362 | 37.179 | 48.053 | 63.378 |

| 2LD2 | 7.400 | 16.362 | 37.179 | 48.054 | 63.379 |

| ED4 | 7.400 | 16.362 | 37.179 | 48.053 | 63.378 |

| ED2 | 7.401 | 16.368 | 37.186 | 48.069 | 63.399 |

| FSDT | 7.398 | 16.363 | 37.171 | 48.054 | 63.388 |

| CLT | 7.403 | 16.414 | 37.213 | 48.175 | 63.537 |

| Mode | |||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Abaqus 3D | 72.229 | 151.762 | 338.517 | 389.336 | 431.011 |

| 3LM4 | 72.244 | 151.751 | 338.577 | 389.554 | 431.004 |

| 2LM2 | 72.233 | 151.705 | 338.432 | 389.546 | 430.824 |

| 3LD4 | 72.250 | 151.796 | 338.625 | 389.587 | 431.151 |

| 2LD2 | 72.269 | 151.906 | 338.939 | 389.589 | 431.577 |

| ED4 | 72.253 | 151.810 | 338.669 | 389.588 | 431.207 |

| ED2 | 72.466 | 153.069 | 342.179 | 389.592 | 435.990 |

| FSDT | 72.437 | 153.021 | 342.036 | 389.510 | 435.853 |

| CLT | 73.825 | 163.064 | 365.813 | 389.510 | 472.565 |

| Mode | |||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Abaqus 3D | 136.723 | 264.080 | 389.391 | 556.394 | 704.284 |

| 3LM4 | 136.742 | 264.077 | 389.557 | 556.404 | 704.295 |

| 2LM2 | 136.667 | 263.747 | 389.550 | 555.332 | 703.121 |

| 3LD4 | 136.755 | 264.119 | 389.638 | 556.511 | 704.442 |

| 2LD2 | 136.875 | 264.684 | 389.643 | 558.145 | 706.381 |

| ED4 | 136.774 | 264.224 | 389.640 | 556.855 | 704.832 |

| ED2 | 138.015 | 269.553 | 389.651 | 570.563 | 721.354 |

| FSDT | 137.947 | 269.463 | 389.510 | 570.329 | 721.159 |

| CLT | 146.479 | 319.929 | 389.510 | 696.687 | 895.089 |

| Mode | |||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Abaqus 3D | 92.18 | 130.68 | 194.96 | 237.56 | 274.60 |

| Ref. [23] | 92.90 | 132.28 | 198.97 | 240.46 | 278.75 |

| LM4 | 92.35 | 131.01 | 195.77 | 238.25 | 275.60 |

| LM2 | 92.34 | 130.99 | 195.74 | 238.23 | 275.58 |

| LD4 | 92.36 | 131.03 | 195.81 | 238.30 | 275.67 |

| LD2 | 92.36 | 131.04 | 195.84 | 238.31 | 275.69 |

| ED4 | 92.37 | 131.06 | 195.88 | 238.32 | 275.72 |

| ED2 | 92.49 | 131.23 | 196.16 | 238.97 | 276.48 |

| FSDT | 92.38 | 131.01 | 195.75 | 238.74 | 276.20 |

| CLT | 93.04 | 131.85 | 197.00 | 242.48 | 280.40 |

| Mode | |||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Abaqus 3D | 606.67 | 896.70 | 1208.24 | 1313.26 | 1458.25 |

| Ref. [23] | 609.79 | 903.63 | 1216.00 | 1328.41 | 1469.33 |

| LM4 | 606.90 | 897.26 | 1208.80 | 1314.85 | 1459.23 |

| LM2 | 606.33 | 896.52 | 1206.86 | 1313.56 | 1457.30 |

| LD4 | 607.22 | 897.73 | 1209.64 | 1315.80 | 1460.16 |

| LD2 | 608.65 | 901.20 | 1213.06 | 1322.93 | 1465.20 |

| ED4 | 609.84 | 905.18 | 1214.60 | 1331.82 | 1469.17 |

| ED2 | 633.68 | 941.96 | 1272.39 | 1396.16 | 1540.10 |

| FSDT | 632.82 | 940.46 | 1271.42 | 1393.96 | 1538.74 |

| CLT | 921.28 | 1287.71 | 2368.22 | 1885.61 | 2699.22 |

| Mode | |||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Abaqus 3D | 794.730 | 1201.916 | 1439.956 | 1701.328 | 1810.250 |

| LM4 | 794.760 | 1202.101 | 1440.092 | 1701.788 | 1811.113 |

| LM2 | 792.734 | 1199.331 | 1433.897 | 1696.266 | 1805.942 |

| LD4 | 795.213 | 1202.777 | 1441.080 | 1702.986 | 1812.317 |

| LD2 | 799.063 | 1209.706 | 1448.714 | 1713.982 | 1820.716 |

| ED4 | 802.019 | 1216.744 | 1450.930 | 1723.900 | 1825.405 |

| ED2 | 845.154 | 1294.481 | 1523.246 | 1847.193 | 1930.364 |

| FSDT | 844.048 | 1292.846 | 1522.478 | 1845.945 | 1928.631 |

| CLT | 1790.121 | 2411.198 | - | - | - |

| Mode | |||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Abaqus 3D | 87.079 | 106.407 | 147.559 | 184.034 | 197.096 |

| LM4 | 87.281 | 106.622 | 147.070 | 184.554 | 197.522 |

| LM2 | 87.259 | 106.593 | 147.045 | 184.500 | 197.489 |

| LD4 | 87.327 | 106.704 | 147.911 | 184.789 | 197.969 |

| LD2 | 87.336 | 106.719 | 147.952 | 184.821 | 198.022 |

| ED4 | 87.331 | 106.708 | 147.921 | 184.798 | 197.984 |

| ED2 | 87.364 | 106.768 | 148.169 | 184.931 | 198.228 |

| FSDT | 87.184 | 106.538 | 148.047 | 184.525 | 198.029 |

| CLT | 87.387 | 106.942 | 150.080 | 185.420 | 199.725 |

| Mode | |||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Abaqus 3LD4 | 72.645 | 86.745 | 104.279 | 136.366 | 140.278 |

| Ref. [5] | 72.432 | 86.626 | 103.910 | 135.828 | 139.747 |

| LM4 | 72.699 | 86.830 | 104.307 | 136.467 | 140.408 |

| LM2 | 72.573 | 86.700 | 104.051 | 136.137 | 140.143 |

| LD4 | 72.744 | 86.888 | 104.376 | 136.558 | 140.516 |

| LD2 | 73.107 | 87.263 | 105.144 | 137.567 | 141.231 |

| ED4 | 72.868 | 86.990 | 104.630 | 136.851 | 140.725 |

| ED2 | 73.977 | 88.609 | 107.143 | 140.522 | 143.556 |

| FSDT | 74.075 | 88.782 | 107.645 | 141.221 | 143.885 |

| CLT | 84.751 | 104.166 | 143.133 | 190.321 | 174.656 |

| Mode | |||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Abaqus 3D | 54.333 | 64.456 | 70.572 | 90.875 | 98.086 |

| LM4 | 54.326 | 64.456 | 70.541 | 90.866 | 98.098 |

| LM2 | 54.038 | 64.201 | 70.036 | 90.292 | 97.612 |

| LD4 | 54.388 | 64.514 | 70.619 | 90.956 | 98.191 |

| LD2 | 54.875 | 64.963 | 71.421 | 91.868 | 98.955 |

| ED4 | 54.554 | 64.623 | 70.913 | 91.224 | 98.408 |

| ED2 | 56.062 | 66.756 | 73.181 | 94.442 | 101.535 |

| FSDT | 56.253 | 66.985 | 73.702 | 95.219 | 102.017 |

| CLT | 76.928 | 95.975 | 119.513 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).