Submitted:

24 May 2023

Posted:

25 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

3. Results and Discussion

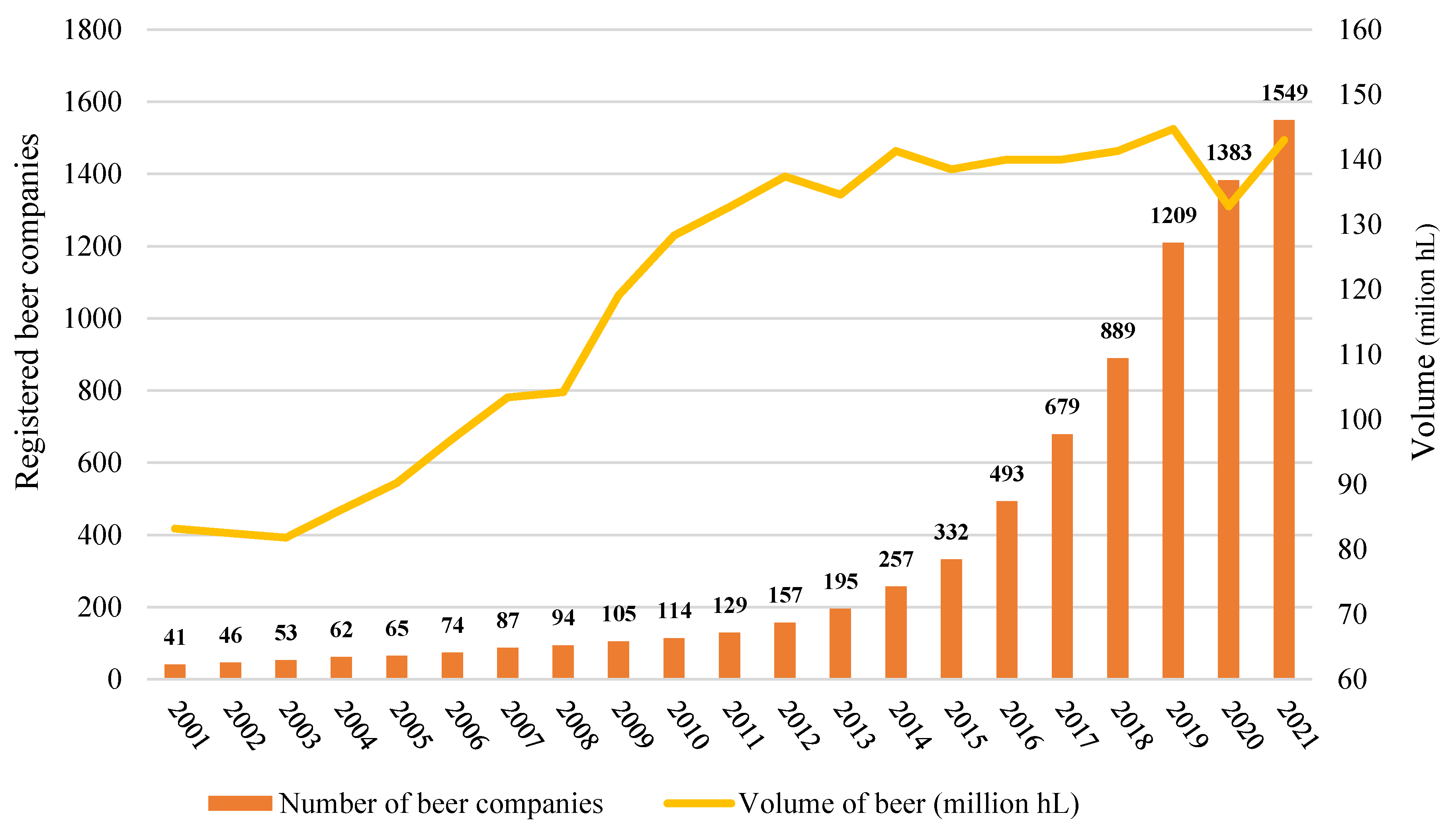

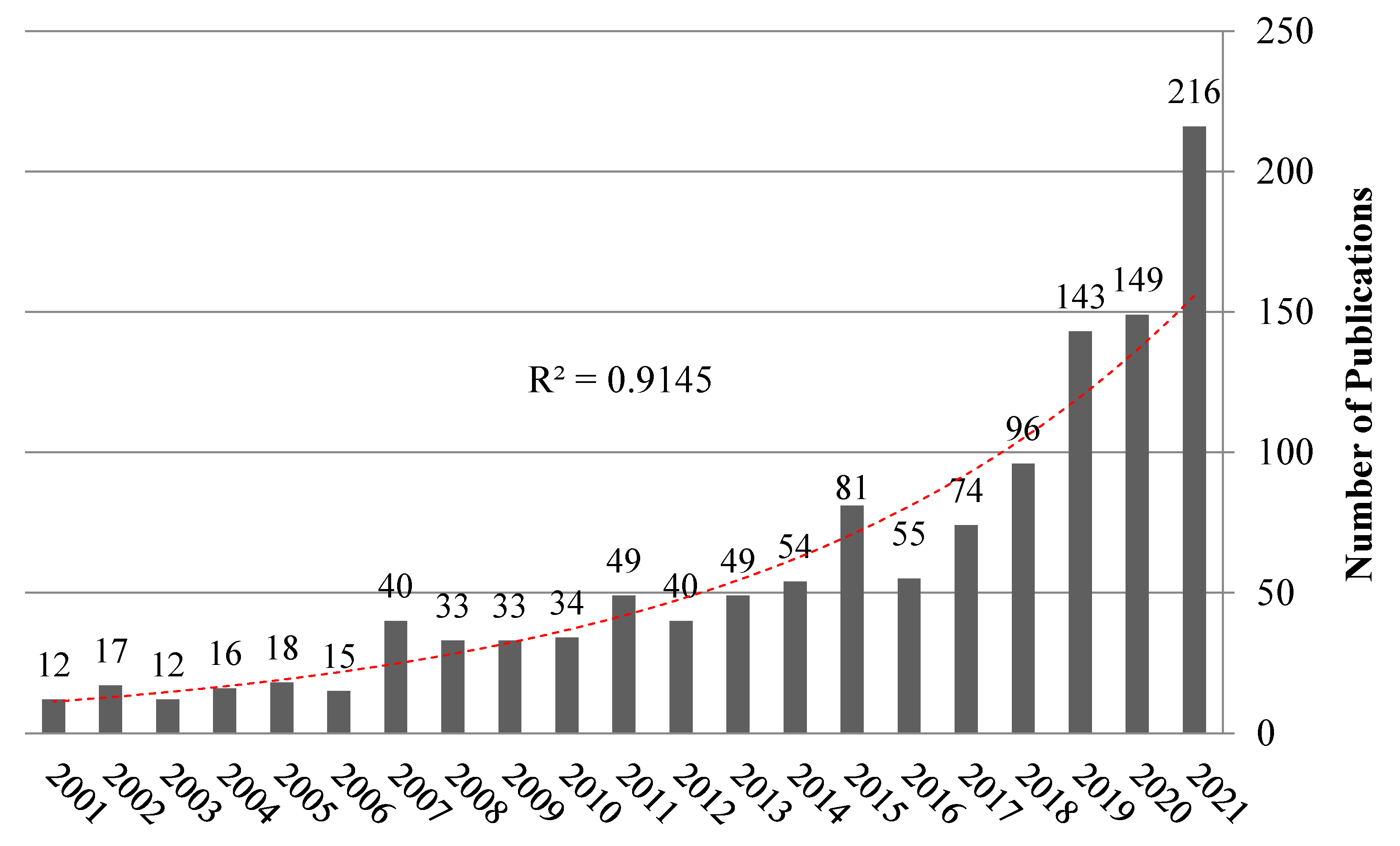

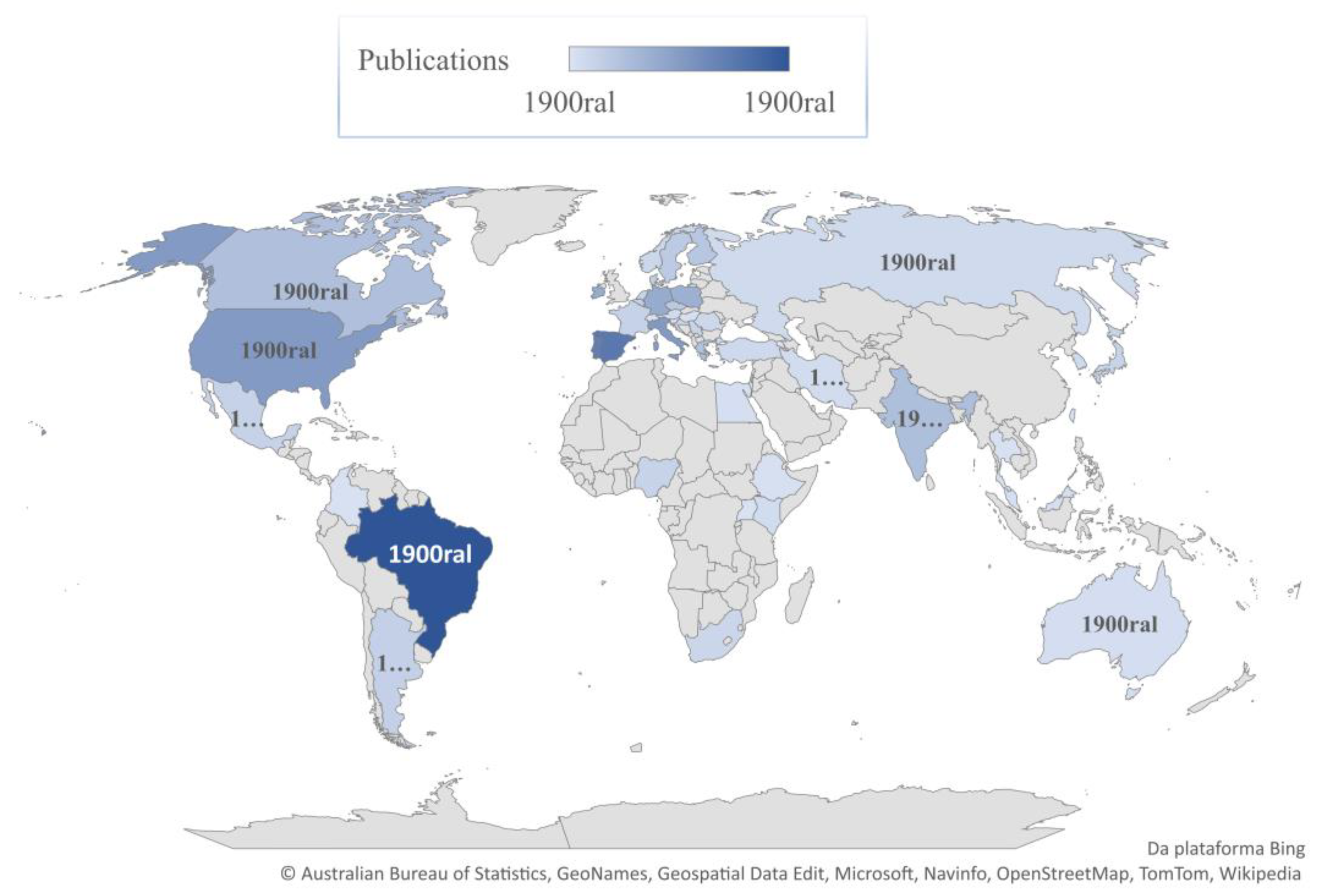

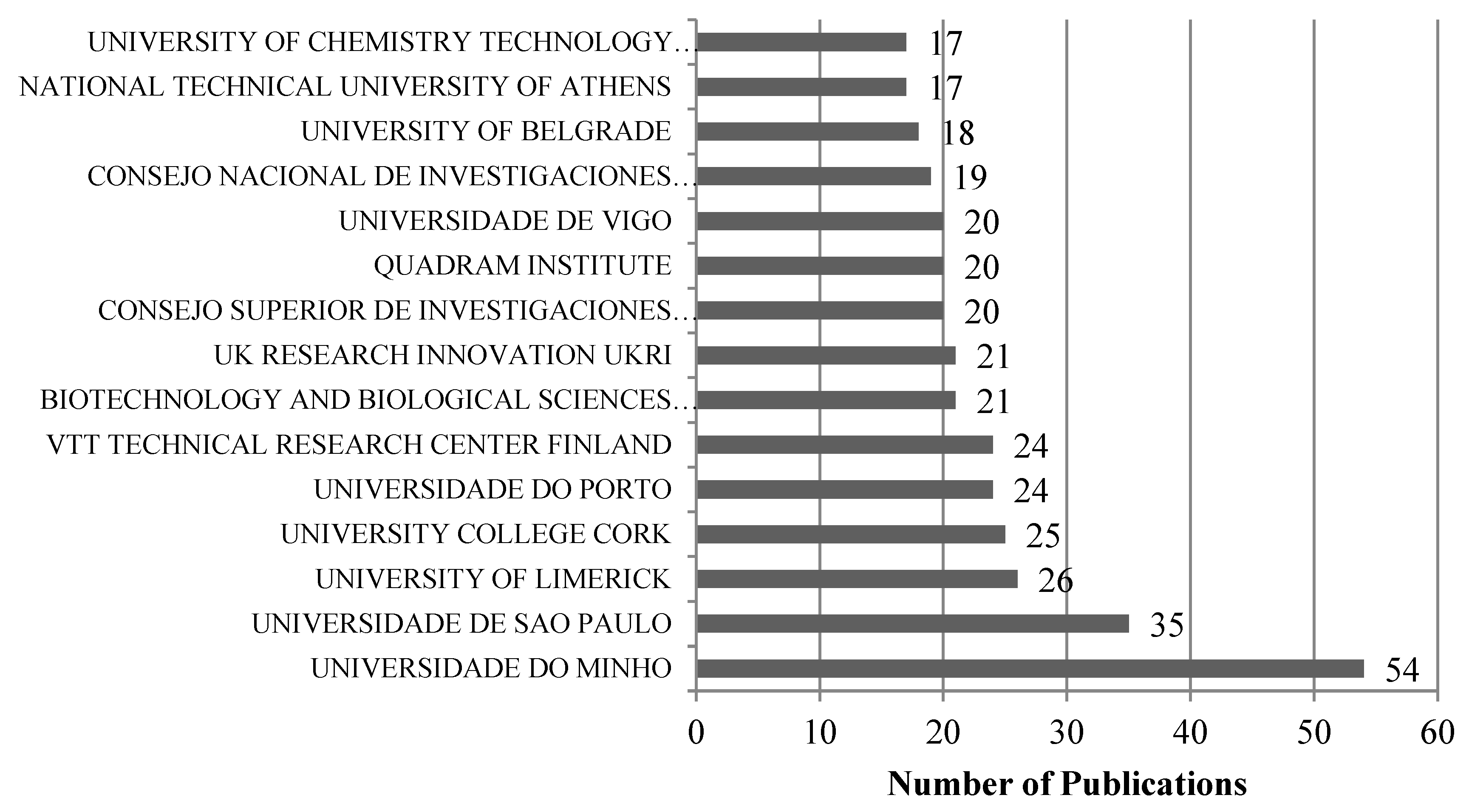

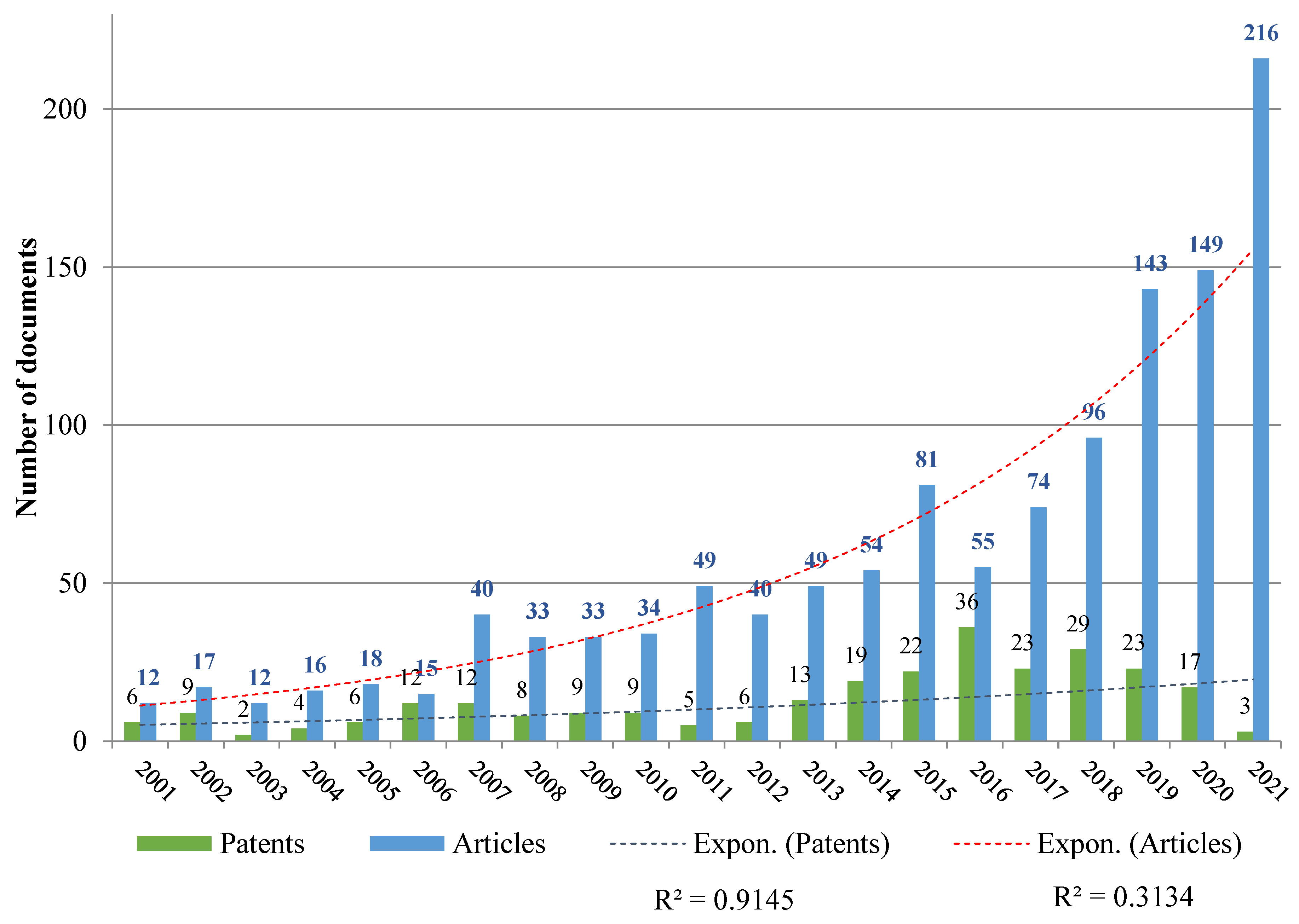

3.1. Technological and scientific roadmap study based on journal publications

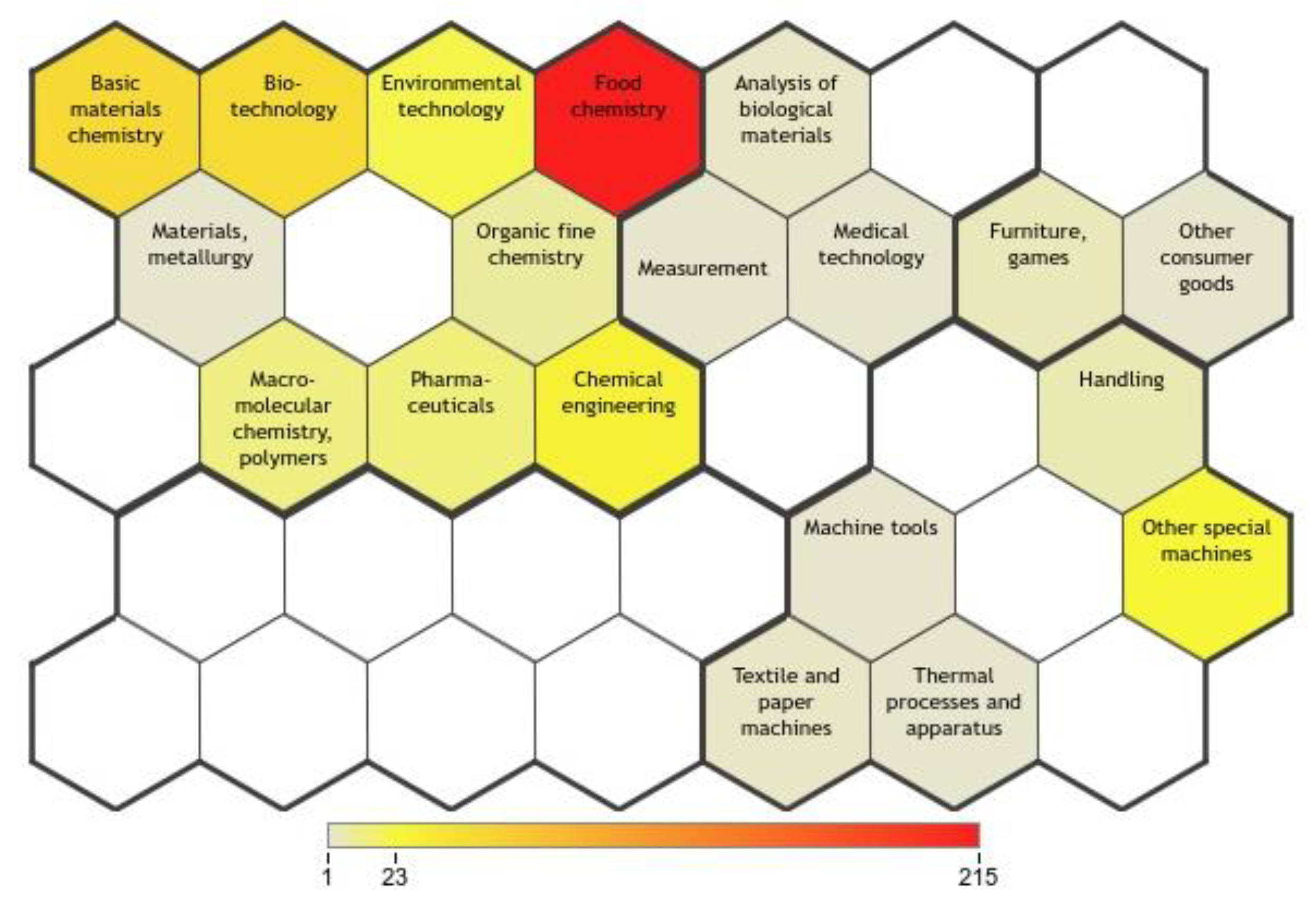

3.2. Technological and scientific forecasting study based on patents

4. Discussion

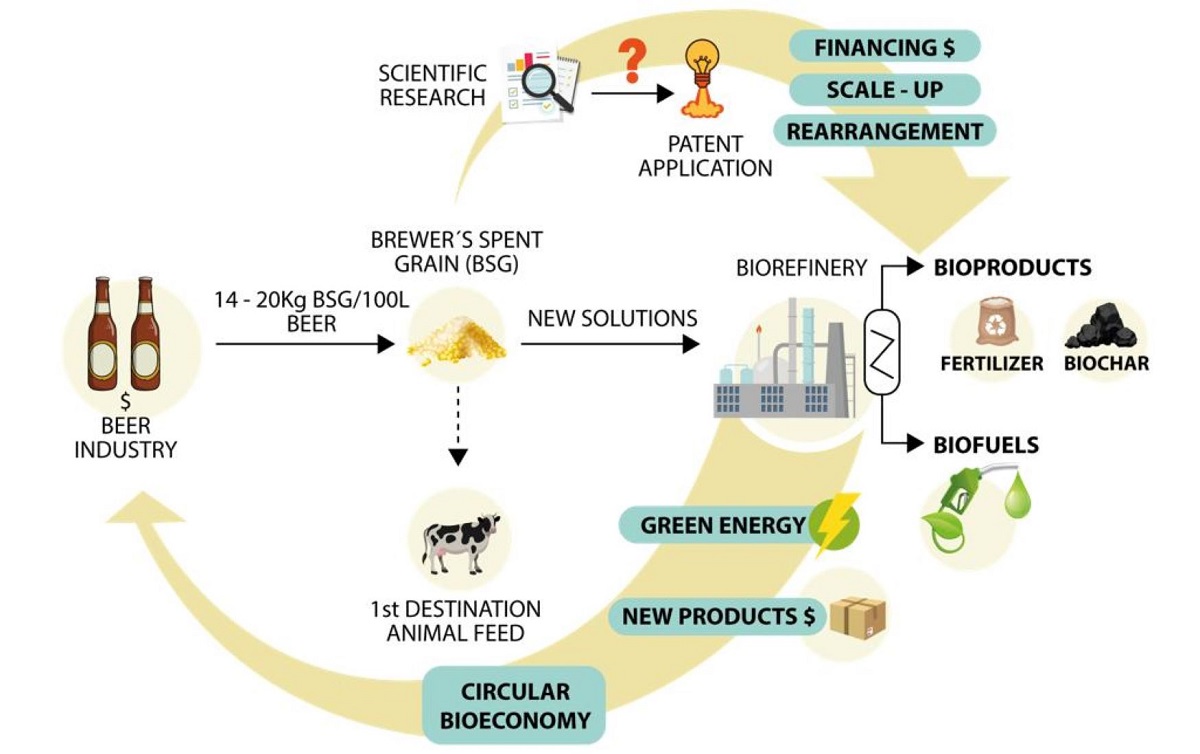

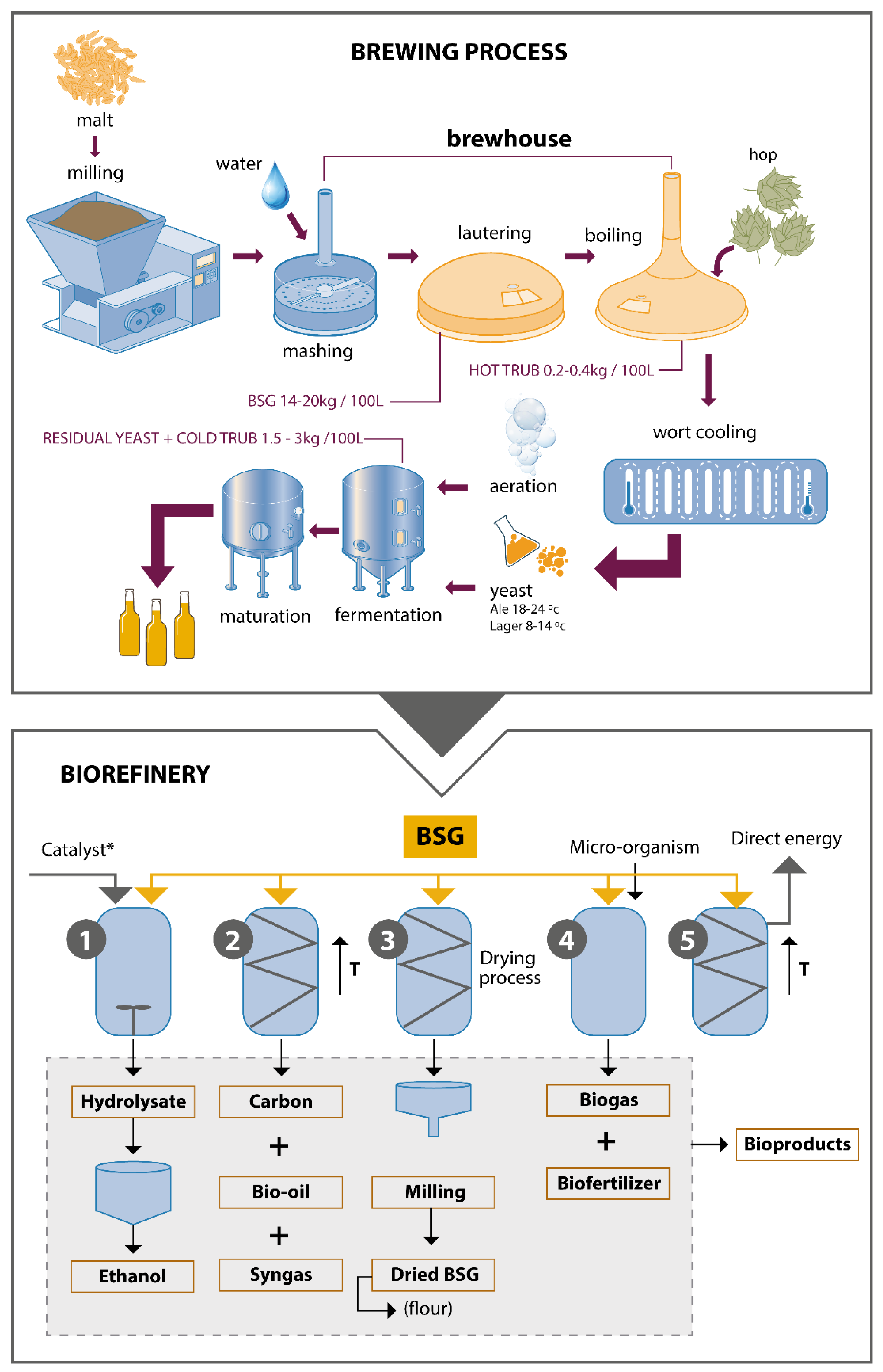

4.1. The biorefinery concept in a brewery context

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lima, L.A.; Fernandes, T.L.; Tenório, L.X. da S.; Silva, M.L. da; Evaristo, R.B.W.; Ghesti, G.F.; Martin, A.R. SINOPSE DO CENÁRIO CERVEJEIRO: O ADVENTO DA PRODUÇÃO E O MERCADO NA REGIÃO CENTRO OESTE. Cad. Prospecção 2017, 10, 650. [Google Scholar] [CrossRef]

- Ghesti, G.; Barros, C.; Muller, C.; Parachin, N.; Pinheiro, L. Análise Sensorial Para Cervejas; LaBCCERva - Laboratório de Bioprocessos Cervejeiros e Catálise em Energias Renováveis - Instituto de Química - Universidade de Brasília: Brasília, 2018;

- MAPA Anuário Da Cerveja: 2021; 2022;

- Marcusso, E.F. Da Cerveja Como Cultura Aos Territórios Da Cerveja : Uma Análise Multidimensional Da Cerveja Como Cultura Aos Territórios Da Cerveja : Uma Análise Multidimensional. 2021, 403.

- MAPA Anuário Da Cerveja: 2019; Ministério da Agricultura, Pecuária e Abastecimento: Brasília, 2020; ISBN 978-65-86803-00-6.

- Chetrariu, A.; Dabija, A. Brewer’s Spent Grains: Possibilities of Valorization, a Review. App. Sci. 2020, 10, 5619. [Google Scholar] [CrossRef]

- Karlović, A.; Jurić, A.; Ćorić, N.; Habschied, K.; Krstanović, V.; Mastanjević, K. By-Products in the Malting and Brewing Industries—Re-Usage Possibilities. Ferment. 2020, 6, 6030082. [Google Scholar] [CrossRef]

- Bianco, A.; Fancello, F.; Garau, M.; Deroma, M.; Atzori, A.S.; Castaldi, P.; Zara, G.; Budroni, M. Microbial and Chemical Dynamics of Brewers’ Spent Grain during a Low-Input Pre-Vermicomposting Treatment. Sci. Total Environ. 2022, 802, 149792. [Google Scholar] [CrossRef]

- Saqib, N.U.; Sharma, H.B.; Baroutian, S.; Dubey, B.; Sarmah, A.K. Valorisation of Food Waste via Hydrothermal Carbonisation and Techno-Economic Feasibility Assessment. Sci. Total Environ. 2019, 690, 261–276. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Dragone, G.; Roberto, I.C. Brewers’ Spent Grain: Generation, Characteristics and Potential Applications. J. Cereal Sci. 2006, 43, 1–14. [Google Scholar] [CrossRef]

- Bolwig, S..; Mark, M.S..; Happel, M.K..; Brekke, A. Beyond Animal Feed?: The Valorisation of Brewers’ Spent Grain. In Waste to Value: Valorisation Pathways for Organic Waste Streams in Circular Bioeconomies; Taylor & Francis: London, 2019; pp. 107–126 ISBN 9780429460289. .

- Fărcaş, A.C.; Socaci, S.A.; Mudura, E.; Dulf, F.V.; Vodnar, D.C.; Tofană, M.; Salanță, L.C. Exploitation of Brewing Industry Wastes to Produce Functional Ingredients. In Brewing Technology; InTech, 2017.

- Meneses, N.G.T.; Martins, S.; Teixeira, J.A.; Mussatto, S.I. Influence of Extraction Solvents on the Recovery of Antioxidant Phenolic Compounds from Brewer’s Spent Grains. Sep. Purif. Technol. 2013, 108, 152–158. [Google Scholar] [CrossRef]

- Olajire, A.A. The Brewing Industry and Environmental Challenges. J. Clean. Prod. 2020, 256, 102817. [Google Scholar] [CrossRef]

- Lynch, K.M.; Steffen, E.J.; Arendt, E.K. Brewers’ Spent Grain: A Review with an Emphasis on Food and Health. J. Inst. Brew. 2016, 122, 553–568. [Google Scholar] [CrossRef]

- Ortiz, I.; Torreiro, Y.; Molina, G.; Maroño, M.; Sánchez, J.M. A Feasible Application of Circular Economy: Spent Grain Energy Recovery in the Beer Industry. Waste and Biomass Valorization 2019, 10, 3809–3819. [Google Scholar] [CrossRef]

- Buffington, J. The Economic Potential of Brewer’s Spent Grain (BSG) as a Biomass Feedstock. Adv. Chem. Eng. Sci. 2014, 04, 308–318. [Google Scholar] [CrossRef]

- Faccenda, A.; Zambom, M.A.; Castagnara, D.D.; Avila, A.S. de; Fernandes, T.; Eckstein, E.I.; Anschau, F.A.; Schneider, C.R. Use of Dried Brewers’ Grains Instead of Soybean Meal to Feed Lactating Cows. Rev. Bras. Zootec. 2017, 46, 39–46. [Google Scholar] [CrossRef]

- Gebremedhn, B.; Niguse, M.; Hagos, B.; Tesfamariam, T.; Kidane, T.; Berhe, A.; Gebresilassie, L.; Gebreegziabher, L.; Gebremariam, T.; Gebremeskel, Y. Effects of Dietary Brewery Spent Grain Inclusion on Egg Laying Performance and Quality Parameters of Bovans Brown Chickens. Brazilian J. Poult. Sci. 2019, 21. [Google Scholar] [CrossRef]

- Ikram, S.; Huang, L.; Zhang, H.; Wang, J.; Yin, M. Composition and Nutrient Value Proposition of Brewers Spent Grain. J. Food Sci. 2017, 82, 2232–2242. [Google Scholar] [CrossRef]

- Ferreira, S.; Monteiro, E.; Brito, P.; Castro, C.; Calado, L.; Vilarinho, C. Experimental Analysis of Brewers’ Spent Grains Steam Gasification in an Allothermal Batch Reactor. Energies 2019, 12, 912. [Google Scholar] [CrossRef]

- Ferreira; Monteiro; Calado; Silva; Brito; Vilarinho Experimental and Modeling Analysis of Brewers´ Spent Grains Gasification in a Downdraft Reactor. Energies 2019, 12, 4413. [CrossRef]

- Evaristo, R.B.W.; Ferreira, R.; Petrocchi Rodrigues, J.; Sabino Rodrigues, J.; Ghesti, G.F.; Silveira, E.A.; Costa, M. Multiparameter-Analysis of CO2/Steam-Enhanced Gasification and Pyrolysis for Syngas and Biochar Production from Low-Cost Feedstock. Energy Convers. Manag. X 2021, 12, 100138. [Google Scholar] [CrossRef]

- Balogun, A.O.; Sotoudehniakarani, F.; McDonald, A.G. Thermo-Kinetic, Spectroscopic Study of Brewer’s Spent Grains and Characterisation of Their Pyrolysis Products. J. Anal. Appl. Pyrolysis 2017, 127, 8–16. [Google Scholar] [CrossRef]

- Mahmood, A.S.N.; Brammer, J.G.; Hornung, A.; Steele, A.; Poulston, S. The Intermediate Pyrolysis and Catalytic Steam Reforming of Brewers Spent Grain. J. Anal. Appl. Pyrolysis 2013, 103, 328–342. [Google Scholar] [CrossRef]

- Borel, L.D.M.S.; Lira, T.S.; Ribeiro, J.A.; Ataíde, C.H.; Barrozo, M.A.S. Pyrolysis of Brewer’s Spent Grain: Kinetic Study and Products Identification. Ind. Crops Prod. 2018, 121, 388–395. [Google Scholar] [CrossRef]

- Wilkinson, S.; Smart, K.A.; Cook, D.J. A Comparison of Dilute Acid- and Alkali-Catalyzed Hydrothermal Pretreatments for Bioethanol Production from Brewers’ Spent Grains. J. Am. Soc. Brew. Chem. 2014, 72, 143–153. [Google Scholar] [CrossRef]

- Plaza, P.E.; Gallego-Morales, L.J.; Peñuela-Vásquez, M.; Lucas, S.; García-Cubero, M.T.; Coca, M. Biobutanol Production from Brewer’s Spent Grain Hydrolysates by Clostridium Beijerinckii. Bioresour. Technol. 2017, 244, 166–174. [Google Scholar] [CrossRef] [PubMed]

- Rojas-Chamorro, J.A.; Cara, C.; Romero, I.; Ruiz, E.; Romero-García, J.M.; Mussatto, S.I.; Castro, E. Ethanol Production from Brewers’ Spent Grain Pretreated by Dilute Phosphoric Acid. Energy & Fuels 2018, 32, 5226–5233. [Google Scholar] [CrossRef]

- Severini, C.; Azzollini, D.; Jouppila, K.; Jussi, L.; Derossi, A.; De Pilli, T. Effect of Enzymatic and Technological Treatments on Solubilisation of Arabinoxylans from Brewer’s Spent Grain. J. Cereal Sci. 2015, 65, 162–166. [Google Scholar] [CrossRef]

- Tišma, M.; Jurić, A.; Bucić-Kojić, A.; Panjičko, M.; Planinić, M. Biovalorization of Brewers’ Spent Grain for the Production of Laccase and Polyphenols. J. Inst. Brew. 2018, 124, 182–186. [Google Scholar] [CrossRef]

- Hassan, S.S.; Tiwari, B.K.; Williams, G.A.; Jaiswal, A.K. Bioprocessing of Brewers’ Spent Grain for Production of Xylanopectinolytic Enzymes by Mucor Sp. Bioresour. Technol. Reports 2020, 9, 100371. [Google Scholar] [CrossRef]

- Llimós, J.; Martínez-Avila, O.; Marti, E.; Corchado-Lopo, C.; Llenas, L.; Gea, T.; Ponsá, S. Brewer’s Spent Grain Biotransformation to Produce Lignocellulolytic Enzymes and Polyhydroxyalkanoates in a Two-Stage Valorization Scheme. Biomass Convers. Biorefinery 2020. [Google Scholar] [CrossRef]

- Santos, D.M. dos; Bukzem, A. de L.; Ascheri, D.P.R.; Signini, R.; Aquino, G.L.B. de Microwave-Assisted Carboxymethylation of Cellulose Extracted from Brewer’s Spent Grain. Carbohydr. Polym. 2015, 131, 125–133. [Google Scholar] [CrossRef]

- Mishra, P.K.; Gregor, T.; Wimmer, R. Utilising Brewer’s Spent Grain as a Source of Cellulose Nanofibres Following Separation of Protein-Based Biomass. BioResources 2016, 12. [Google Scholar] [CrossRef]

- Fontana, K.B.; Lenzi, G.G.; Watanabe, E.R.L.R.; Lenzi, E.K.; Pietrobelli, J.A.M.T.; Chaves, E.S. Biosorption and Diffusion Modeling of Pb(II) by Malt Bagasse. Int. J. Chem. Eng. 2016, 2016, 1–11. [Google Scholar] [CrossRef]

- Gonçalves, G. da C.; Nakamura, P.K.; Furtado, D.F.; Veit, M.T. Utilization of Brewery Residues to Produces Granular Activated Carbon and Bio-Oil. J. Clean. Prod. 2017, 168, 908–916. [Google Scholar] [CrossRef]

- Wakizaka, H.; Miyake, H.; Kawahara, Y. Utilization of Beer Lees Waste for the Production of Activated Carbons: The Influence of Protein Fractions on the Activation Reaction and Surface Properties. Sustain. Mater. Technol. 2016, 8, 1–4. [Google Scholar] [CrossRef]

- Mello, L.R.P.F.; Mali, S. Use of Malt Bagasse to Produce Biodegradable Baked Foams Made from Cassava Starch. Ind. Crops Prod. 2014, 55, 187–193. [Google Scholar] [CrossRef]

- Formela, K.; Hejna, A.; Zedler, Ł.; Przybysz, M.; Ryl, J.; Saeb, M.R.; Piszczyk, Ł. Structural, Thermal, and Physico-Mechanical Properties of Polyurethane/Brewers’ Spent Grain Composite Foams Modified with Ground Tire Rubber. Ind. Crops Prod. 2017, 108, 844–852. [Google Scholar] [CrossRef]

- Zedler, Ł.; Colom, X.; Cañavate, J.; Saeb, M.; T. Haponiuk, J.; Formela, K. Investigating the Impact of Curing System on Structure-Property Relationship of Natural Rubber Modified with Brewery By-Product and Ground Tire Rubber. Polymers (Basel). 2020, 12, 545. [Google Scholar] [CrossRef] [PubMed]

- Dovichi Filho, F.B.; Castillo Santiago, Y.; Silva Lora, E.E.; Escobar Palacio, J.C.; Almazan del Olmo, O.A. Evaluation of the Maturity Level of Biomass Electricity Generation Technologies Using the Technology Readiness Level Criteria. J. Clean. Prod. 2021, 295. [Google Scholar] [CrossRef]

- Moura, P.; Henriques, J.; Alexandre, J.; Oliveira, A.C.; Abreu, M.; Gírio, F.; Catarino, J. Sustainable Value Methodology to Compare the Performance of Conversion Technologies for the Production of Electricity and Heat, Energy Vectors and Biofuels from Waste Biomass. Clean. Waste Syst. 2022, 3, 100029. [Google Scholar] [CrossRef]

- Beims, R.F.; Simonato, C.L.; Wiggers, V.R. Technology Readiness Level Assessment of Pyrolysis of Trygliceride Biomass to Fuels and Chemicals. Renew. Sustain. Energy Rev. 2019, 112, 521–529. [Google Scholar] [CrossRef]

- Amparo, K.K. dos S.; Ribeiro, M. do C.O.; Guarieiro, L.L.N. Estudo de Caso Utilizando Mapeamento de Prospecção Tecnológica Como Principal Ferramenta de Busca Científica. Perspect. em Ciência da Informação 2012, 17, 195–209. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Moncada, J.; Roberto, I.C.; Cardona, C.A. Techno-Economic Analysis for Brewer’s Spent Grains Use on a Biorefinery Concept: The Brazilian Case. Bioresour. Technol. 2013, 148, 302–310. [Google Scholar] [CrossRef]

- Geum, Y.; Farrukh, C.; Lee, S. An integrated framework for assessing the technology roadmapping process from multiple perspectives: The case at the sector level. J. Engin. Tech. Manag. 2023, 67, 101732. [Google Scholar] [CrossRef]

- BRASIL LEI No 12.305, DE 2 DE AGOSTO DE 2010. Available online: http://www.planalto.gov.br/ccivil_03/_ato2007-2010/2010/lei/l12305.htm (accessed on 30 March 2021).

- Su, Y.; Zhang, P.; Su, Y. An Overview of Biofuels Policies and Industrialization in the Major Biofuel Producing Countries. Renew. Sustain. Energy Rev. 2015, 50, 991–1003. [Google Scholar] [CrossRef]

- Dias, M. de O.; Falconi, D. The Evolution of Craft Beer Industry in Brazil. J. Econ. Bus. 2018, 1. [Google Scholar] [CrossRef]

- Maiello, A.; Britto, A.L.N. de P.; Valle, T.F. Implementation of the Brazilian National Policy for Waste Management. Rev. Adm. Pública 2018, 52, 24–51. [Google Scholar] [CrossRef]

- BRASIL DECRETO No 3.927, DE 19 DE SETEMBRO DE 2001. Available online: http://www.planalto.gov.br/ccivil_03/decreto/2001/d3927.htm.

- Veiga, C.C. da; Filho, V.J.M.F.; Mendonça, F.M. de; Coutinho, R. DIFFICULTIES TO BRIDGING THE PATH FROM INVENTION TO INNOVATION IN THE BRAZILIAN PUBLIC UNIVERSITIES ENVIRONMENT. In Proceedings of the 10th International Symposium on Technological Innovation, 2019; pp. 565–574.

- BRASIL LEI No 11.196, DE 21 DE NOVEMBRO DE 2005. Available online: http://www.planalto.gov.br/ccivil_03/_ato2004-2006/2005/lei/l11196.htm (accessed on 30 March 2021).

- UFRJ AMBEV Opens Innovaiton and Technology Center at the Science Park Available online: https://www.parque.ufrj.br/en/ambev-opens-innovation-and-technology-center-at-the-science-park/.

- Budzianowski, W.M. High-Value Low-Volume Bioproducts Coupled to Bioenergies with Potential to Enhance Business Development of Sustainable Biorefineries. Renew. Sustain. Energy Rev. 2017, 70, 793–804. [Google Scholar] [CrossRef]

- Bonfiglio, A.; Esposti, R. Analysing the Economy-Wide Impact of the Supply Chains Activated by a New Biomass Power Plant. The Case of Cardoon in Sardinia. Bio-based Appl. Econ. 2015, 5. [Google Scholar] [CrossRef]

- Venkata Mohan, S.; Hemalatha, M.; Chakraborty, D.; Chatterjee, S.; Ranadheer, P.; Kona, R. Algal Biorefinery Models with Self-Sustainable Closed Loop Approach: Trends and Prospective for Blue-Bioeconomy. Bioresour. Technol. 2020, 295, 122128. [Google Scholar] [CrossRef]

- Manikandan, N.A.; Pakshirajan, K.; Pugazhenthi, G. A Closed-Loop Biorefinery Approach for Polyhydroxybutyrate (PHB) Production Using Sugars from Carob Pods as the Sole Raw Material and Downstream Processing Using the Co-Product Lignin. Bioresour. Technol. 2020, 307, 123247. [Google Scholar] [CrossRef]

- Katakojwala, R.; Mohan, S.V. A Critical View on the Environmental Sustainability of Biorefinery Systems. Curr. Opin. Green Sustain. Chem. 2021, 27, 100392. [Google Scholar] [CrossRef]

- Ghatak, H.R. Biorefineries from the Perspective of Sustainability: Feedstocks, Products, and Processes. Renew. Sustain. Energy Rev. 2011, 15, 4042–4052. [Google Scholar] [CrossRef]

- Ceapraz, I.L.; Kotbi, G.; Sauvee, L. The Territorial Biorefinery as a New Business Model. Bio-based Appl. Econ. 2016, 5. [Google Scholar] [CrossRef]

- Vu, H.P.; Nguyen, L.N.; Vu, M.T.; Johir, M.A.H.; McLaughlan, R.; Nghiem, L.D. A Comprehensive Review on the Framework to Valorise Lignocellulosic Biomass as Biorefinery Feedstocks. Sci. Total Environ. 2020, 743, 140630. [Google Scholar] [CrossRef] [PubMed]

- R. Gallo, J.M.; A. Trapp, M. The Chemical Conversion of Biomass-Derived Saccharides: An Overview. J. Braz. Chem. Soc. 2017, 28, 1586–1607. [Google Scholar] [CrossRef]

- Puligundla, P.; Mok, C. Recent Advances in Biotechnological Valorization of Brewers’ Spent Grain. Food Sci. Biotechnol. 2021, 30, 341–353. [Google Scholar] [CrossRef]

- Bonifácio-Lopes, T.; Teixeira, J.A.; Pintado, M. Current Extraction Techniques towards Bioactive Compounds from Brewer’s Spent Grain – A Review. Crit. Rev. Food Sci. Nutr. 2020, 60, 2730–2741. [Google Scholar] [CrossRef]

- Cherubini, F. The Biorefinery Concept: Using Biomass Instead of Oil for Producing Energy and Chemicals. Energy Convers. Manag. 2010, 51, 1412–1421. [Google Scholar] [CrossRef]

- Sauvée, L.; Viaggi, D. Biorefineries in the Bio-Based Economy: Opportunities and Challenges for Economic Research. Bio-based Appl. Econ. 2016, 5. [Google Scholar] [CrossRef]

| Application | TRLa | References b |

| Animal feed | 9 | [18,10] |

| Syngas production by gasification | 6-7 | [21,22,23] |

| Pyrolysis | 7-8 | [24,25,26] |

| Bioethanol, Biobuthanol | 6-7 | [27,28,29] |

| Enzymes production, Enzymatic hydrolysis | 5-6 | [30,31,32,33] |

| Cellulose and derivatives | 5-6 | [34,35] |

| Carbonaceous materials – absorptive properties | 5-6 | [36,37,38] |

| Polimeric materials | 2-3 | [39,40,41] |

| Research | Keyword | Boolean operator | Keyword | Boolean operator | Keyword | Research Articles - Web of Science | Patents - Orbita |

|---|---|---|---|---|---|---|---|

| 1 | spent | AND | grain* | AND | brew* | 1089 | 143 |

| 2 | spent | AND | grain* | AND | beer | 217 | 82 |

| 3 | bagasse | AND | malt | - | - | 58 | 46 |

| 4 | bagasse | AND | malt | AND | brew* | 21 | 10 |

| 5 | bagasse | AND | malt | AND | beer | 6 | 10 |

| 6 | brew* | AND | residue* | AND | malt | 94 | 60 |

| 7 | brew* | AND | residue* | AND | bagasse | 40 | 25 |

| Combination | 1 OR 2 OR 3 OR 4 OR 5 OR 6 OR 7 | 1236 | 295 | ||||

| Code | Titlea | Application date (d/m/y) | Status |

|---|---|---|---|

| PI 9302590-4 | Process for obtaining briquettes or pelleted barley bagasse and product obtained by the process | 30/07/1993 | Revoked |

| PI 9700063-9 | Malt bagasse industrialization process | 02/01/1997 | Revoked |

| PI 0000814-1 | The improved drying process for malt bagasse, and hydrolyzed malt bagasse and pelleted thus obtained | 09/03/200 0 | Revoked |

| PI 0005374-0 | Process for obtaining pelleted product | 13/11/2000 | Granted in 26/01/2016 |

| PI 0104799-0 | Processing of residues extracted from the production of beer for human feeding, resulting in product and industrial food application | 08/08/2001 | Archived |

| C1 0000814-1 | Improved malt bagasse drying process | 24/10/2001 | Revoked |

| PI 0204191-0 | Installation and process for composting production to animals from brewery waste | 09/10/2002 | Archived |

| PI 0804169-5 | Process for obtaining activated carbon and their uses | 26/09/2008 | Revoked / Under recourse analysis |

| PI 1101711-2 | Process ethyl hexanoate production by biotechnological route using synthetic medium and agro-industrial residues and their use | 25/04/2011 | Grated in 11/03/2014 – Green Patent |

| BR 10 2013 031848 5 | Production of microbial dextranase by solid-state fermentation using malt bagasse as a substrate and/or support | 11/12/2013 | Archived |

| BR 10 2018 073305 2 | Hydrolysis of cassava peel and husk using amylolytic enzymes produced by the fungus | 12/11/2018 | Published / Pending analysis |

| BR 10 2018 076458 6 | Process of transformation of organic waste from the aquaculture industry by insects | 19/12/2018 | Archived |

| Patent Title | Patent Number |

|---|---|

| Functional spent grain protein and extraction method thereof | CN113912667 |

| Method for producing a composition comprising β-glucan and an oxidized derivative of unsaturated fatty acid from brewer’s grain | JP2019017370 |

| Bio-plastic composite containing brewer’s spent grains and a method for making the same | EP3235875 |

| Brewer’s spent-grain based protein powder | EP3500112 |

| Composition consisting of brewer’s spent grains and polylactic acid and a method for making the same | EP3235870 |

| Methods and apparatus for producing protein and fiber concentrates from spent grain | WO2021/023597 |

| Modified spent grain protein and preparation method and application thereof | CN113896778 |

| A method for reducing an amount of microorganisms in brewers’ spent grains | EP3750409 |

| Method of reducing moisture in brewers’ spent grain | US20190254315 |

| Low-cost production of canthaxanthin and xanthophyll pigments using micrococcus luteus and brewer’s spent grain | IN201711031489 |

| Methods and apparatus for producing protein and fiber concentrates from spent grain | WO2021/023597 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).