1. Introduction

A modern electric drive consists of an AC motor, a controllable voltage source inverter (VSI) and a digital control system. This article focuses on VSI control using the space vector method (SV-PWM) and using numerical methods for analysis. Here, approximation is definitely a new approach to analyze VSI operation.

Typically, electric drives with induction motors use VSI to feed the stator windings. This drive design was discussed in [1-9]. VSI is a power electronics circuit that can be controlled by various methods, which are described in detail, for example, in [3,4,6,7,10-12].

The aim of the article is to approximate the THD characteristics of the stator current and torque ripple of a squirrel-cage induction motor, not the RL circuit as in most articles. These characteristics are determined for steady state, where the argument of the function is the switching frequency of the inverter transistors (SV-PWM control by two methods is considered). On the other hand, the value of the approximated functions is the THD of the stator current and the ripple of the motor electromagnetic torque .

Voltage Source Inverters (VSI) with space vector PWM (SV-PWM or SVM) control are studied. The research concerns THD of motor current and torque ripple. Measurements every 2kHz and the least squares approximation method are used for approximation. The approximated characteristics show the changes in THD and torque ripple with the PWM switching frequency of the inverter transistors. The effect of dead time (dead-band) when switching transistors in one branch of the inverter is also analyzed. The aim is to make comparative studies for different patterns of SV-PWM control of a VSI. In practice, there are two types of pattern (pattern#1, pattern#2) for genaration of averaged stator voltage in SV-PWM. These methods are described in detail in [

6,

12,

13] where examples of programming TMS320F240 processors from Texas Instruments are shown. Pattern#2 is also called discontinuous PWM modulation (DPWM) in the literature [

6].

Other methods of controlling power transistors (sinusoidal PWM (SPWM) or elimination of the third harmonic) [

6,

7], have been omitted, because their practical use in vector control systems (FOC, DTC) of induction motors is useless. In vector control methods, it is necessary for the inverter to respond immediately to set voltage values in

and

coordinates.

A comparison of SPWM and SVPWM methods found in many publications [6,12,14-17], but in most cases they are implemented for a RL load circuit. In the articles, the authors focus their discussion on the differences due to the control methods and the determination of the THD for the method. An example is [

17] where THD tests are performed for a switching frequency of 10kHz.

Many articles [16-21] consider the THD problem with the SVPWM control method for an RL load and a single switching frequency of transistors. That makes a difference to the present article, where a wide range of PWM frequency changes is analyzed.

In the article [

22], a new SVPWM control method was proposed for high-speed PMSM motors, where THD analysis was also performed. In addition, the article considered the problem of execution time of the proposed SVPWM control algorithm.

Analysis of electromagnetic torque ripples is usually reduced to the DTC method, where ripples of large amplitude are inherently present. These articles focus on minimizing these ripples [23-26]. The authors are not aware of publications where THD tests for different patterns in SVPWM inverter control were combined. Thus leads to the presentation of new results in the field of power supply of induction motors.

In this article, AC machine is used as a load. On the other hand, based on the knowledge and results from the above-mentioned publications, it was concluded that SVPWM is a better method than SPWM. For this reason, SPWM was omitted from further consideration.

The analysis is carried out for a supply frequency of 50 Hz, because for lower frequencies the results are better, as is obvious-more PWM periods.

The novelty in this paper lies in the detailed approach to feeding an induction motor rather than an RL circuit from an SV-PWM-controlled VSI (the authors are not aware of any publications in which a similar approach was used). Also novel here is the use of mean-square approximation to determine THD(f_PWM) characteristics and similarly for torque ripple. Based on this, the minimum switching frequency of the VSI transistors can be determined.

The authors are also not known of any publications that analyze THD changes for different PWM frequencies. Therefore, the following article is a new addition to the missing knowledge of feeding IM with VSI using the SV-PWM method.

2. Theoretical background: Spectral analysis and numerical approximation

2.1. Spectral analysis [28,29]

The coefficients Cn are known as the amplitude spectrum and the phase ϕn is the phase spectrum. Therefore, the frequency spectrum of a periodic function is discrete (1), (2).

The effect of the harmonic currents is frequently taken into account by calculating the total harmonic distortion (THD). The definition of THD is based upon the Fourier expansion of nonsinusoidal waveforms. For a distorted current waveform, the total harmonic distortion is defined as [

6,

7,

10]:

where

Ih is the amplitude of the harmonic current of

hth order,

I1 is the fundamental component of the waveform (50 or 60 Hz component), and

hmax is the maximum number of harmonics to be included (typically 40). The THD is used as performance index for distorted voltages as well. It is common to multiply the THD by 100% to obtain a percentage of distortion.

2.2. The approximation

In fact, the only approximation method used practically is the least squares method, where the n measurement points

are fitting to an approximating function(model function)

. Where

is set of function parameters and while

is any linear (linear regression-not applicable here) or nonlinear function. The method of least squares can be considered as a quality index J minimization problem, where the result will be a set of

parameters:

The solution to this minimization problem is a set of

parameters that define the approximating function. The

J is named squared norm of the residual. The accuracy of the approximation is determined by the value of

J, the smaller the better the approximation. In Matlab, it is the best to use the

lsqcurvefit function, which determines the

coefficients and gives

J as the

resnorm:

where x (in Matlab) denotes the parameters of the

of equation (9). For example, if we measure THD of current for different values of switching frequencies of VSI transistors, for example, every fPWM=2kHz then it is possible to make an approximation of THD changes from

fPWM (

THD=f(fPWM)). The accuracy of the approximation depends on the function adopted.

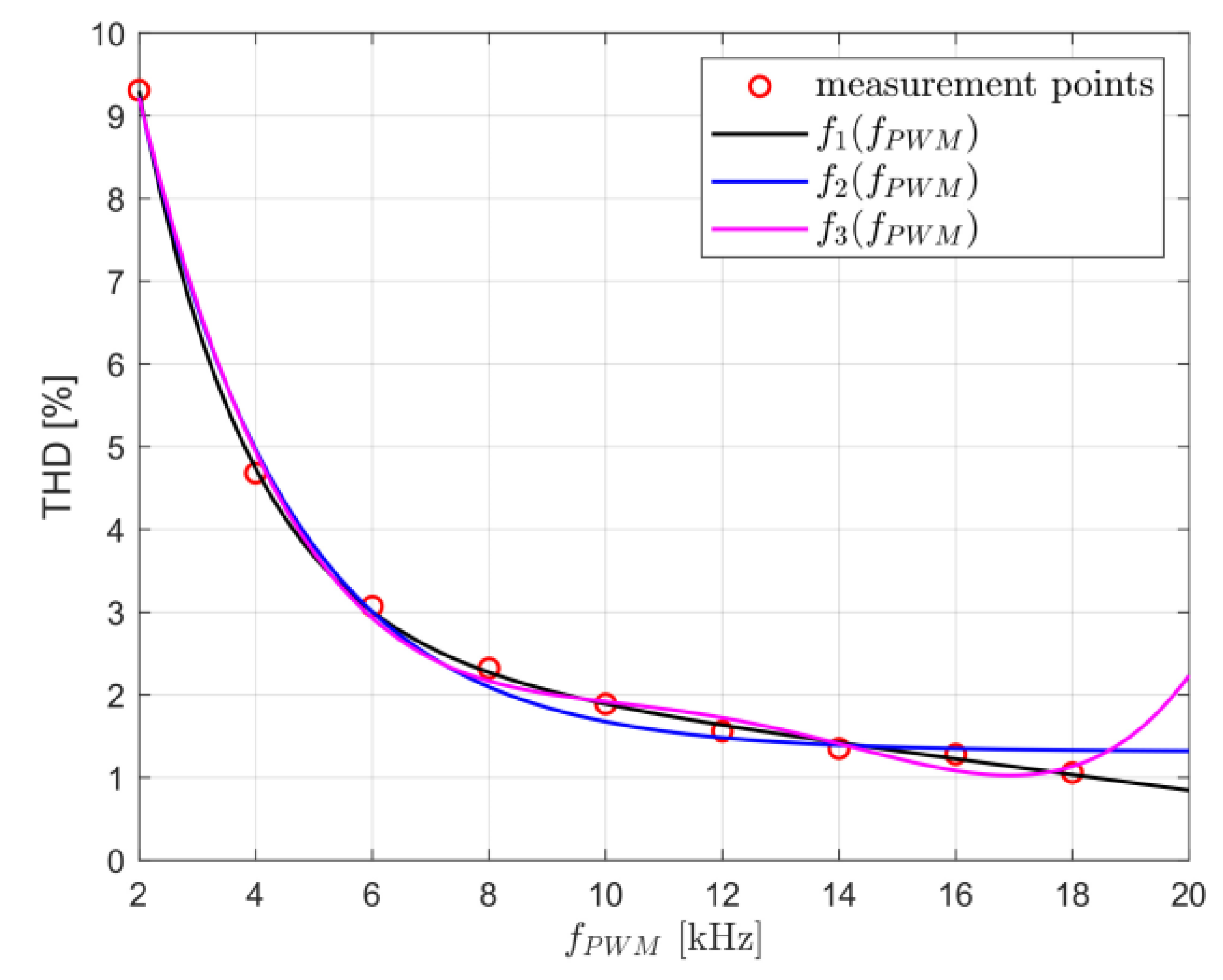

Figure 1 shows the approximation of measurement points by 3 different functions:

.

The values of resnorm (from the lsqcurvefit function) or J are as follows for each function: . This means that the best fit to the measurement points is for function , which differs from only by a linear factor, while increasing the order of the polynomial in function it makes no sense, because it leads to interpolation, and this is no longer averaging the results. This example precedes the rest of the study, but it is the f_1 function that will be used in the approximation of THD changes from .

3. VSI with SV-PWM control

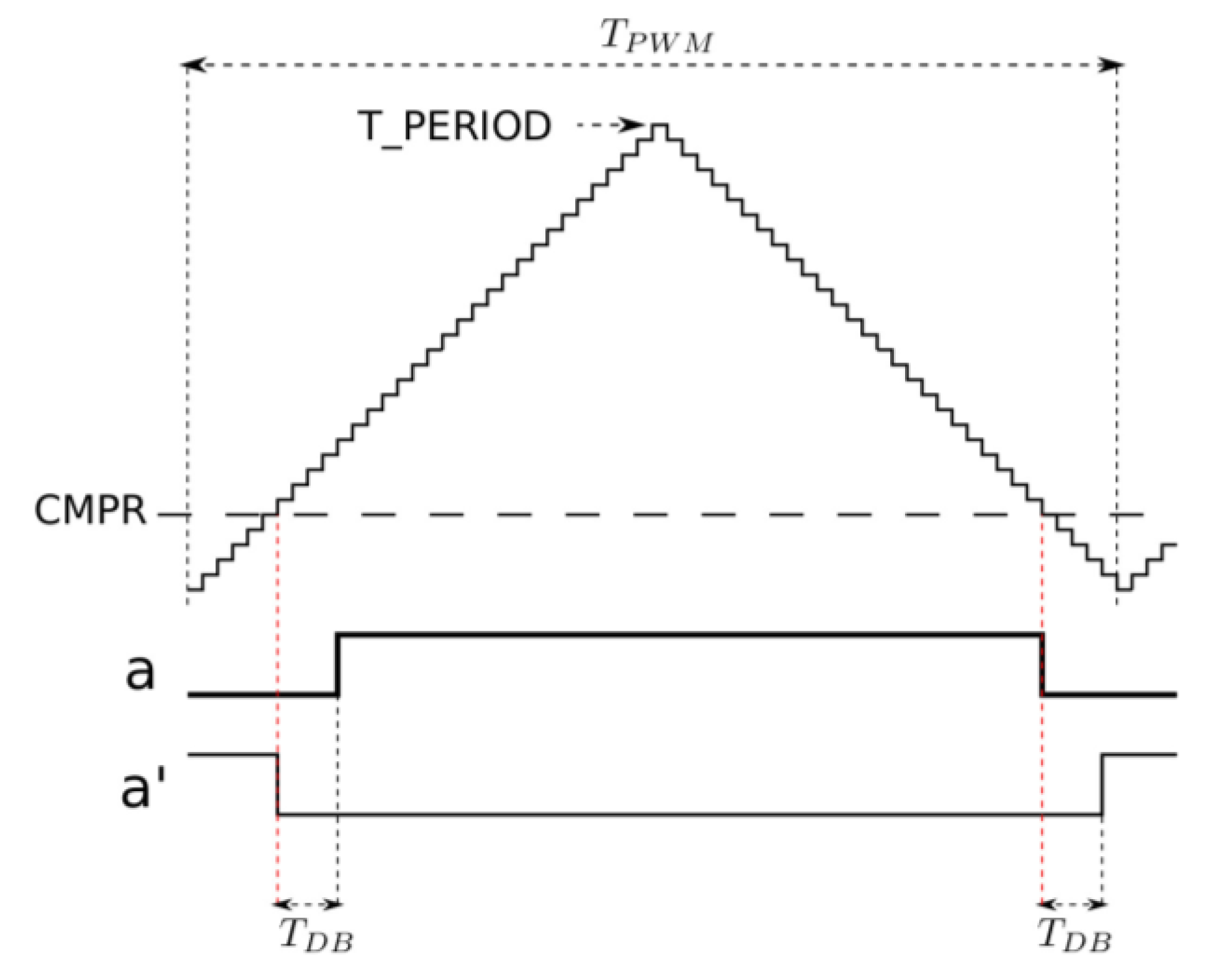

Nowadays, voltage modulation of the SV-PWM inverter is the most popular, the hardware is based on a timer with 3. values for comparison. The result is 3. rectangular waves that control the inverter transistors. Due to the longer transistor turn-off time than turn-on time, a turn-on-deadband (dead time) delay is used. In the following, SV-PWM methods and the effect of deadband will be discussed and compared in the simulation section.

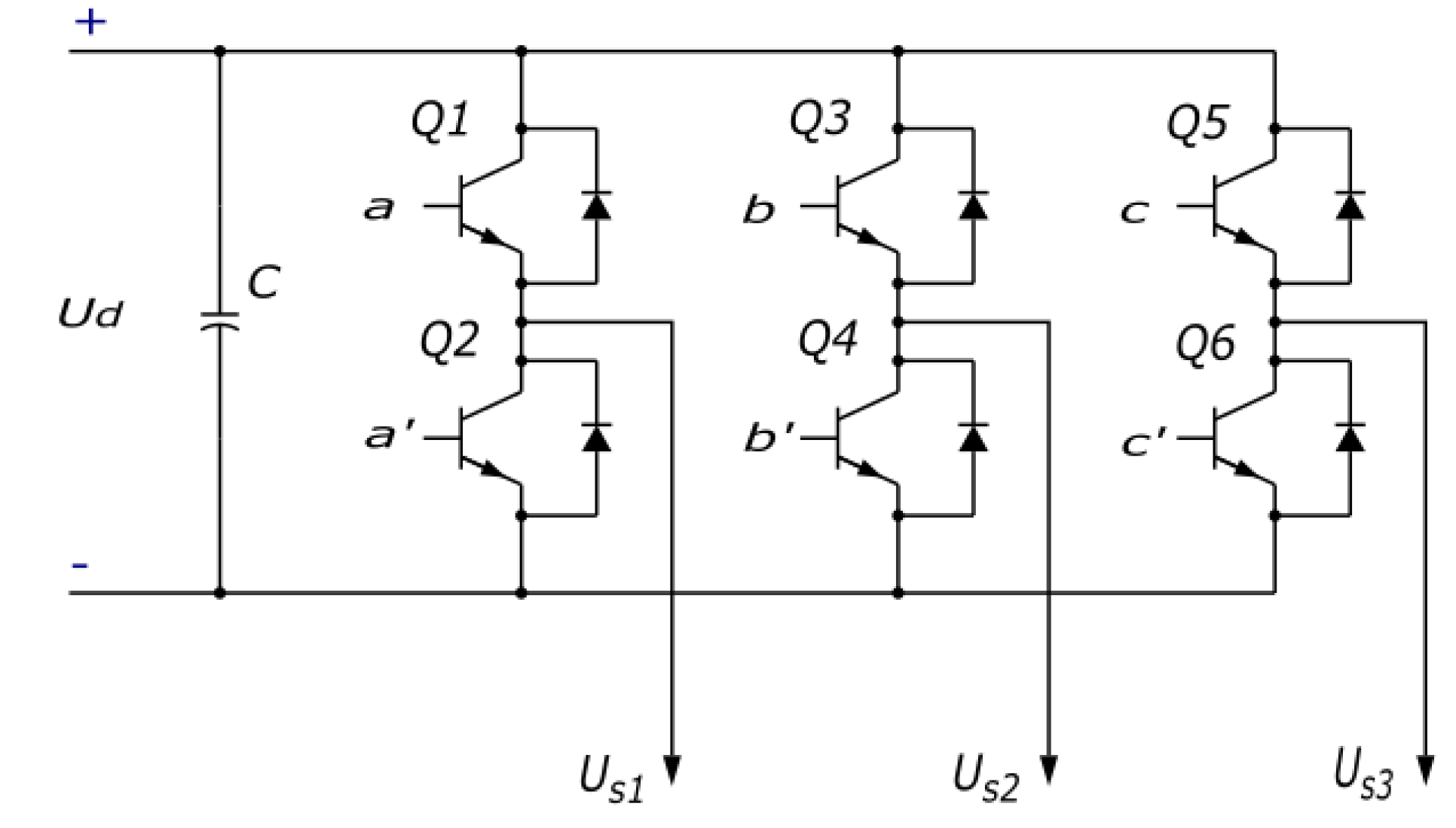

The Voltage Source Inverter is shown in

Figure 2, where the logic signals (a,a'), (b,b') and (c,c') are complementary, i.e. if a=1, then a'=0, and so on. In addition, there is a delay between turning off the transistor and turning it on -

deadband.

The controls a, a′, b, b′, c, c′ are assumed to be logical (0, 1), while US1, US2 , US3 are the motor phase voltages. It follows that there are eight possible control settings (a, b, c) that determine the switching sequence of the power transistors (Q1 ÷ Q6).

The transistors are controlled by PWM signals of appropriate fills with the appropriate switching frequency which leads to the generation of 3-phase average (in small time) sinusoidal voltage waveforms.

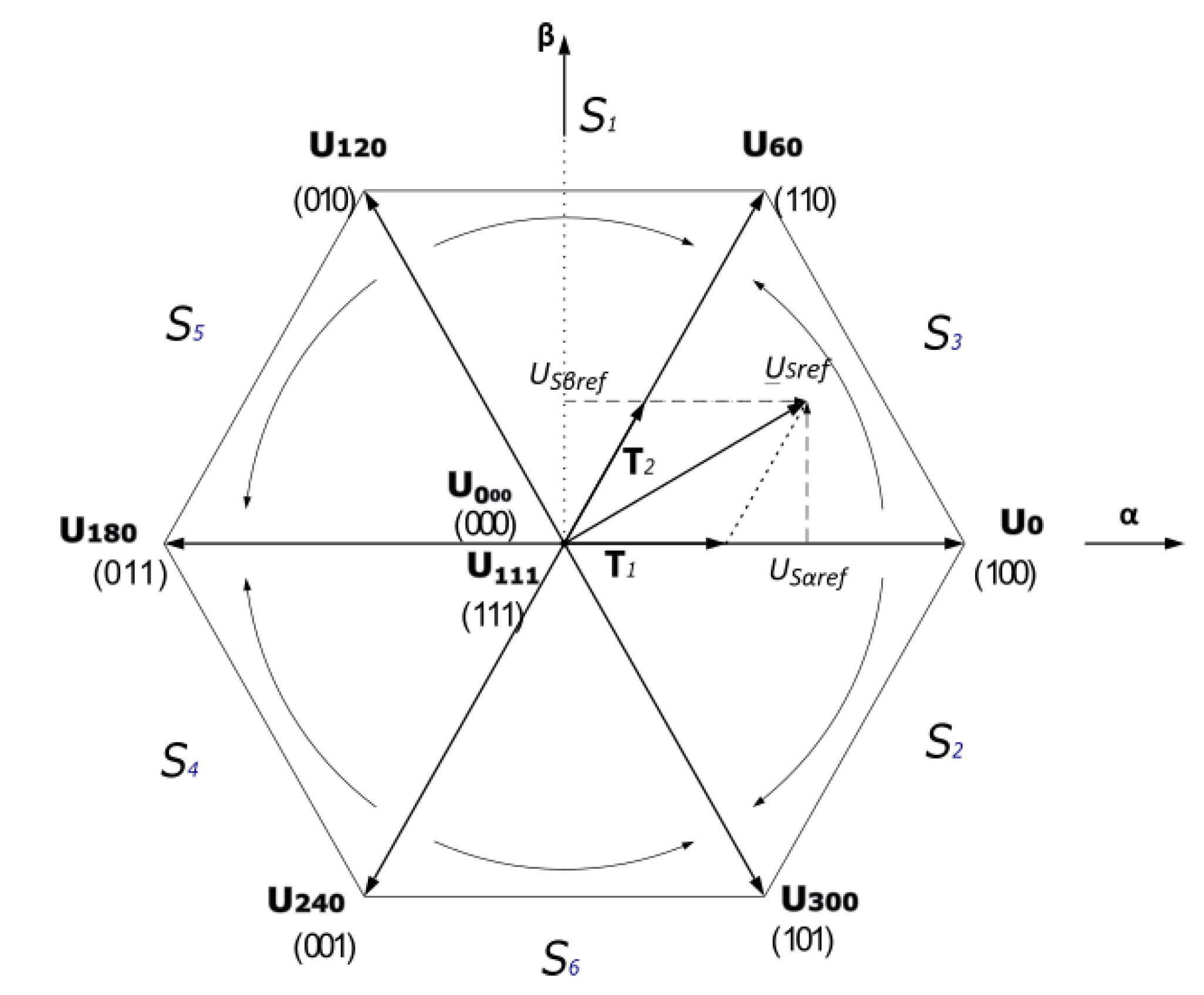

3.1. The metod

The method is based on controlling six transistors in the three-phase bridge voltage inverter circuit shown in

Figure 2. In such a system, the different states of the control inputs (a, b, c), together with the PWM space vector (SV-PWM), form a hexagon of output voltages with an additional two null controls (

). These eight vectors are called base space vectors:

,

,

,

,

,

,

. The geometric interpretation of the voltage space vectors is shown in

Figure 3.

The reference voltage

represents the interfacial mean value in the (α, β) coordinate system:

where T

1 and T

2 are the individual turn-on times of the given base vectors

and

, and

is the period of PWM signal generation. When

, then in addition to T

1 and T

2 times, modulation requires the supply of the vectors

or

at time T

0. Then:

Various relationships can be used to determine T1 and T2 times (3), (4), (5), (6), (7) and the results obtained are identical. There are two SV-PWM methods, referred to as Pattern#1 (Three-phase SVM with Symmetrical Placement of Zero Vectors) and Pattern#2 Two-phase SVM. This type of modulation is called discontinuous pulse width modulation (DPWM) (8), (3). These modulation methods differ in the generation times of zero-voltage vectors with a duration of T0.

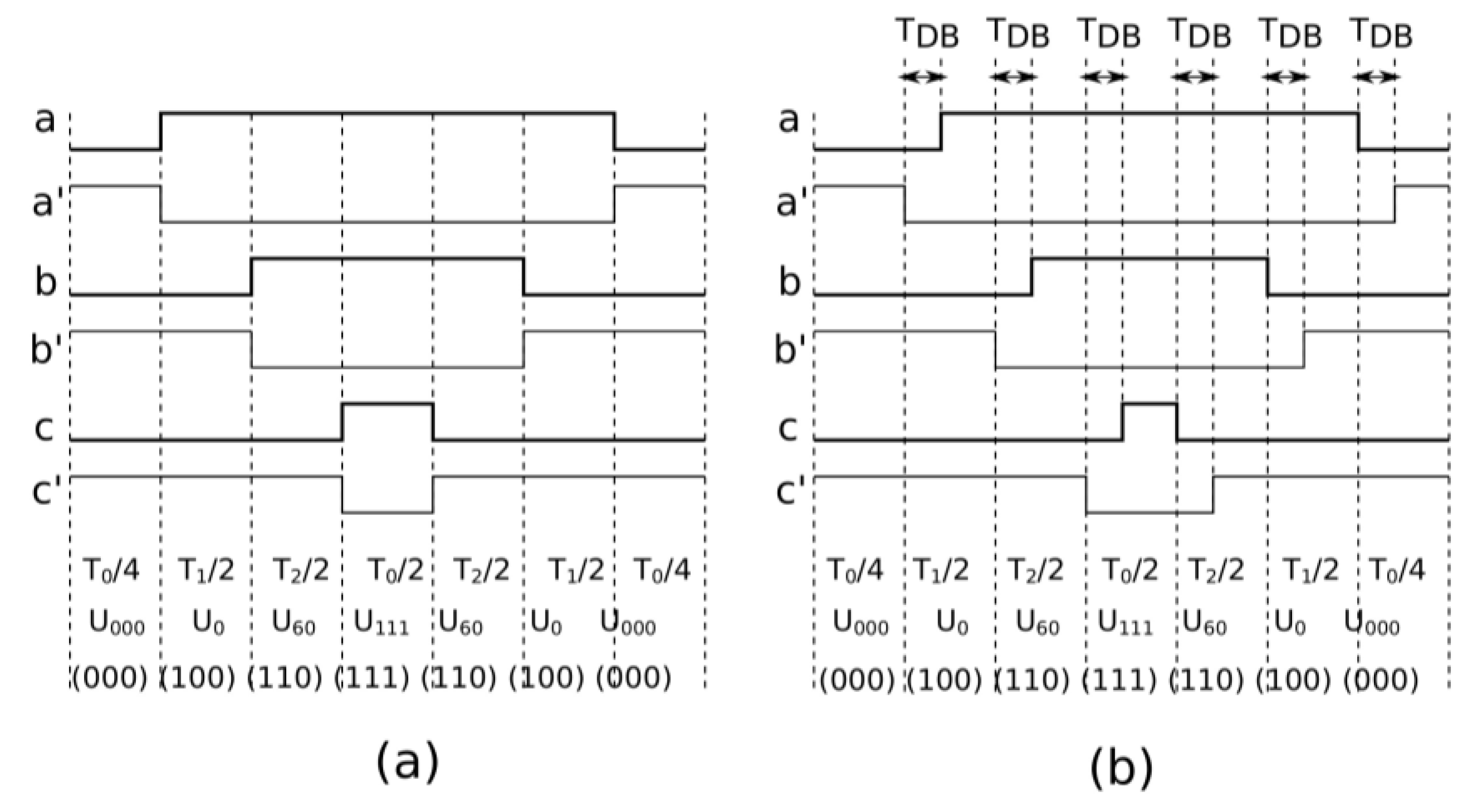

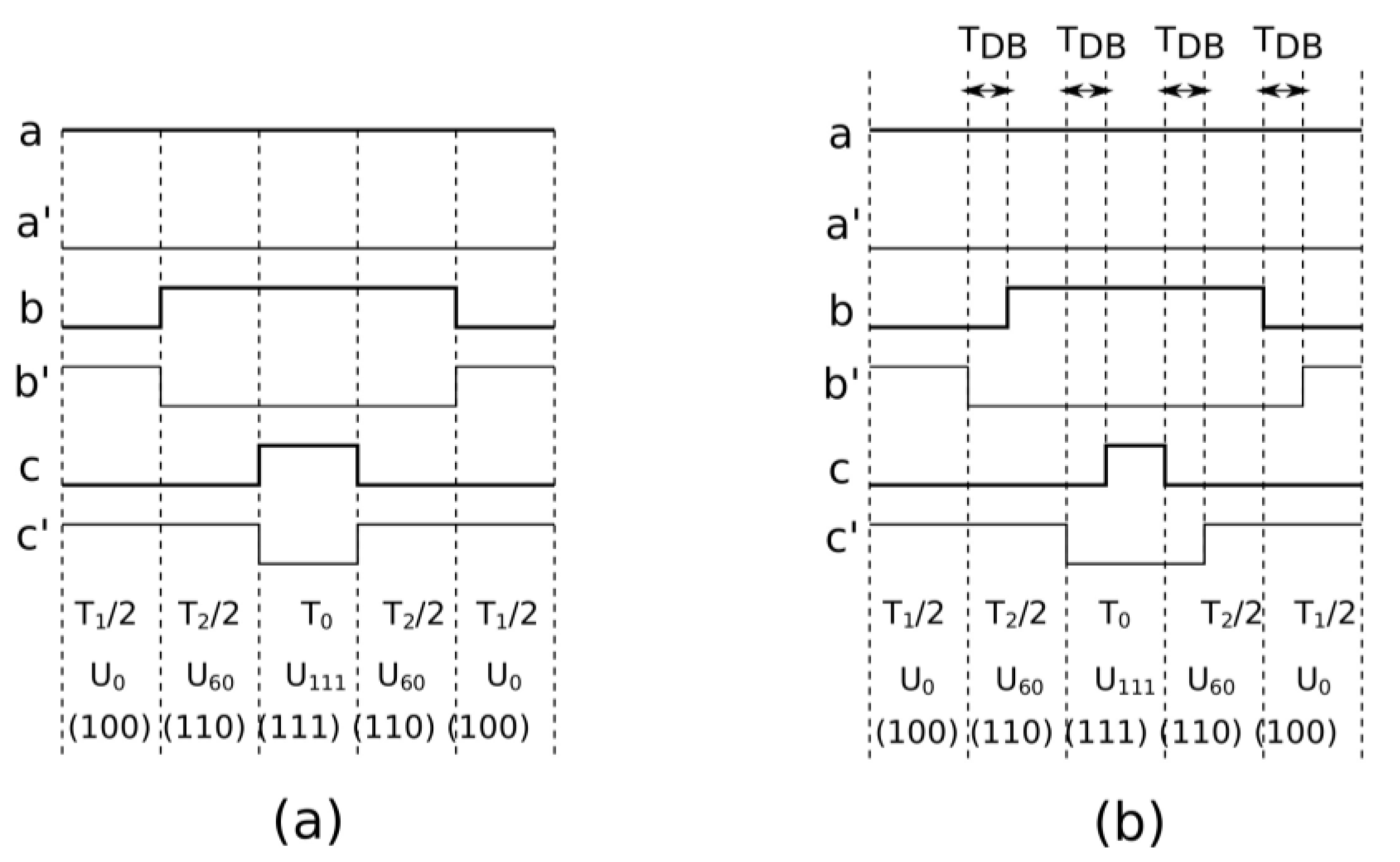

3.2. Switching Pattern #1

The SV-PWM with switching Pattern#1 is the most popular SVM method. An example of transistor control for this method and sector from 0

o to 60

o is shown in the figure. Presented here is the ideal case and applications of dead times

TDB when transistors in one branch are switched.

Figure 4.

Comparison of SV-PWM with Pattern#1: (a) ideal without dead time, (b) including dead time TDB.

Figure 4.

Comparison of SV-PWM with Pattern#1: (a) ideal without dead time, (b) including dead time TDB.

Usually dead time is small and a few us, but it will still affect the voltage waveform distortion and therefore the motor current waveform distortion. Quantitative results will be presented in the chapter on simulation studies.

3.2. Switching Pattern #2 (DPWM)

In Pattern #2 there is less symmetry of PWM waveforms, the T0 time of zero voltage generation is not divided into 3 intervals, but is generated once. An example for the first sector is presented in

Figure 5.

In this modulation method, the number of transistor switching is reduced by 1/3, but at the same time, due to the asymmetry of the waveforms, the harmonic content (THD) is increased. Note also that the amount of TDB generation also decreases by 1/3 compared to the Pattern #1 method. So, it is interesting to see how THD will change as the switching frequency of fPWM transistors increases. These results will be presented in the next section.

4. Induction motor model

The mathematical model of the induction motor is well known from the literature [1-9], so it will be presented briefly, using only the most important equations. It will be reduced to the classical form of Rotor Field-Oriented Control (RFOC), which will be used in the analysis of the power supply from the SV-PWM modulator.

Vector analysis and synthesis of induction motor drives use transformations to the alpha-beta and d-q system:

where

is the angle of alignment of the coordinate system (d-q), which is aligned with the position of the rotor linked flux

(where ϱ_R is the angle between the stator axis and the rotor flux vector). After assuming such a reference system, it can be written {Leonhard}:

thus,

and the coordinate system (d-q) is rotating at a speed

.

The final mathematical model when decomposed into d-q components takes the form:

where

pulsation (speed) of slip, and

is rotor electromagnetic time constant. And the voltage equations are in the form:

The model is summarized by the equation of motion (Newton's 2nd principle of dynamics):

The above equations are a system of nonlinear differential equations that are difficult to analyze, and practically only numerical methods can be used here to determine precisely the operating conditions of the induction motor.

5. Simulations and approximation

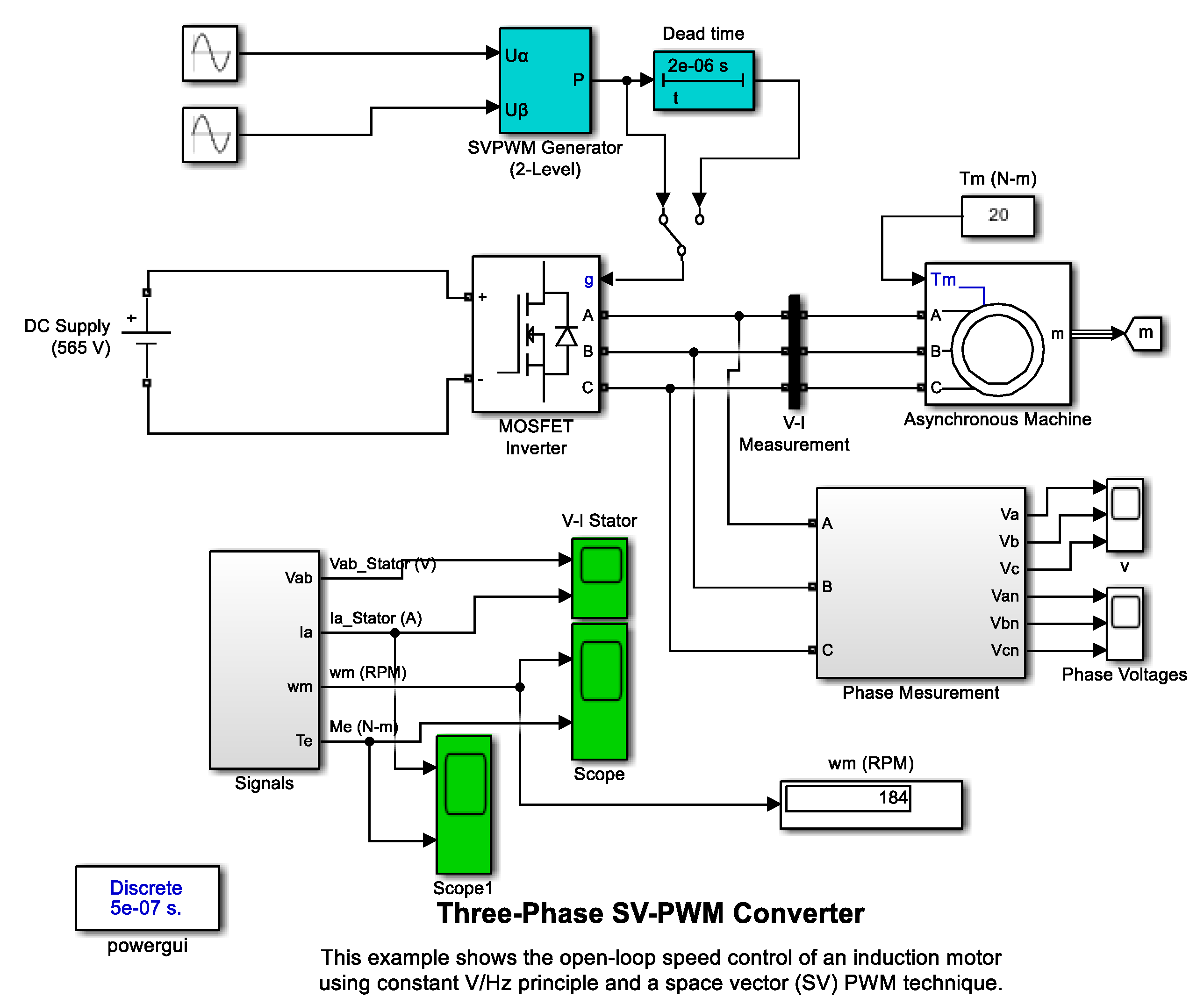

The simulation research used the standard simulation

power_svpwm1.slx (Matlab 2020b), which is supplemented with the Dead time (deadband) block from the simulation

power_microturbineDT.slx is shown in

Figure 6.

Squirrel-cage preset model no 2 from Asynchronous Machine menu is used: 7,46kW, UN=460Vrms, pole pairs=2. SVPWM Generator allows you to select the modulation method: Pattern #1 or Pattern #2, in addition you can select PWM frequency and Sample time. Dead time block should have select type: On delay and time delay as time value in seconds. In the research, the setting was 1μs or 2 μs.

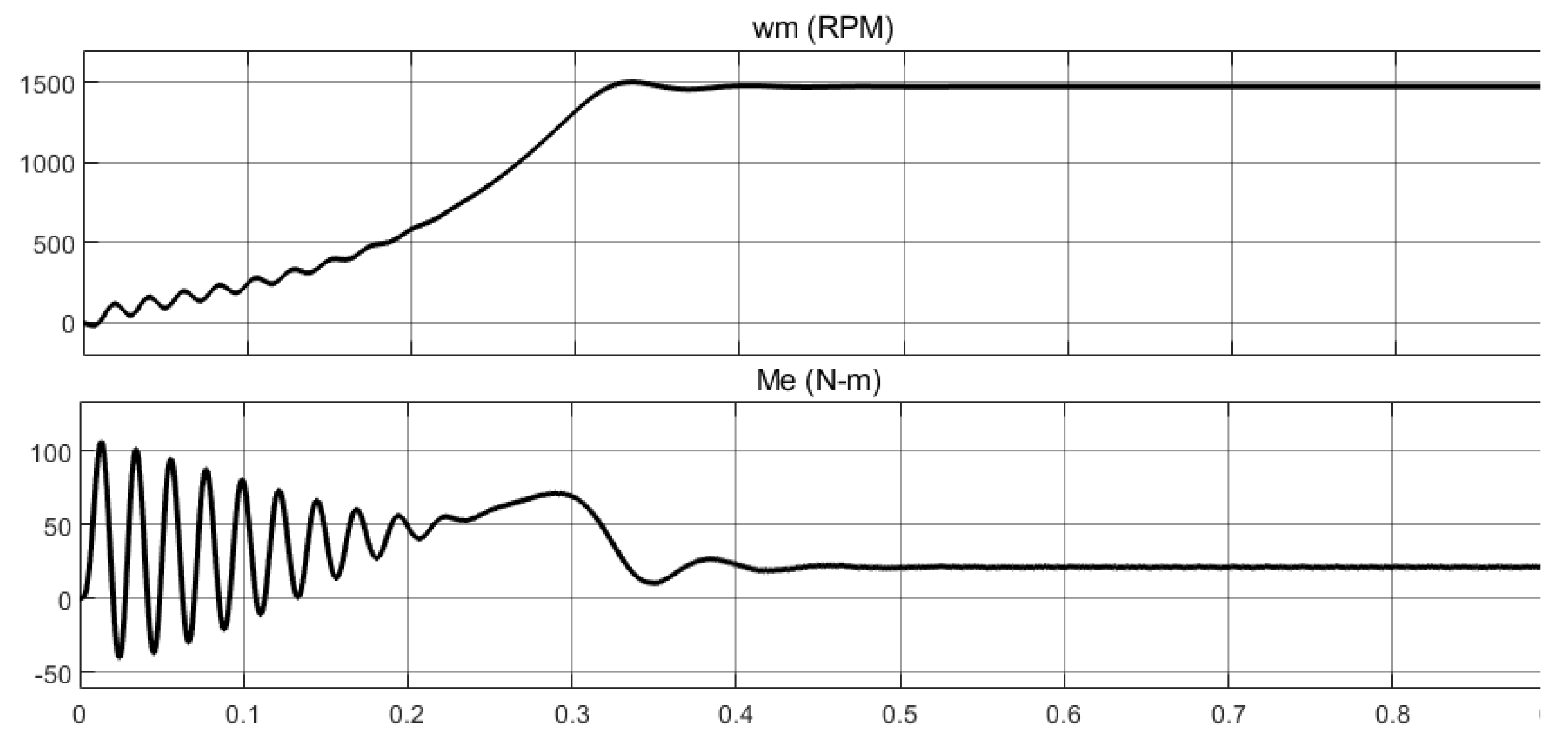

All tests were conducted for a motor start connected to a power supply with a fixed Us and f1, where f1 is the power supply frequency of 50 Hz. Results were obtained for steady-state operation. An example startup for a transistor switching frequency of

and dead time of 0μs is shown in

Figure 7.

When the supply voltage is applied to the motor's stator windings, torque oscillations occur, which are transferred to angular velocity oscillations. The reason for the oscillations is the design of the induction motor, which is described by a nonlinear mathematical model where two circuits are coupled to each other, equations (21) and (22). A detailed description of the phenomena is presented in subsection 5.2.

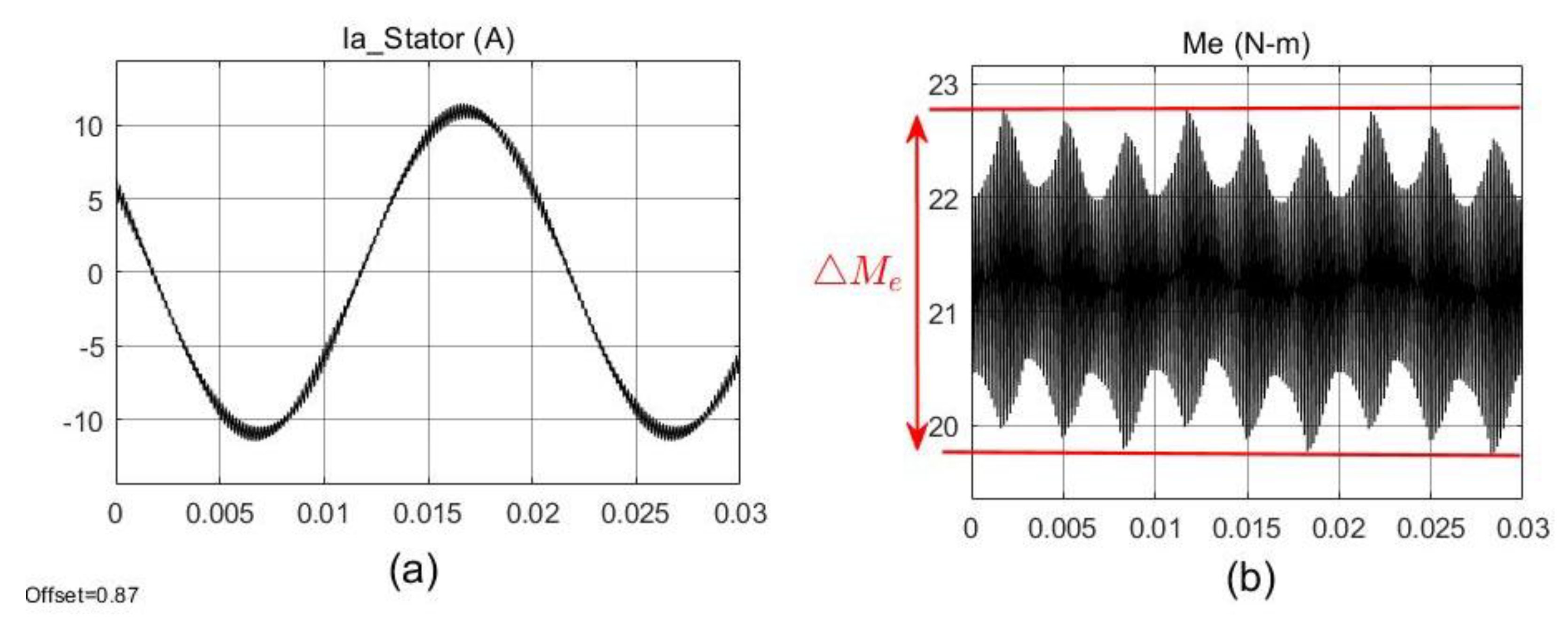

The steady-state current

and electromagnetic torque

is shown in

Figure 8. Using such measurements,

Table 1 presents the effect of

frequency on THD and torque ripple (

) was determined.

The experiment was done for different VSI switching frequencies (f_PWM), different control strategies Pattern #1 and Pattern #2, and different dead times (deadband). The results of the experiment are current THD and IM electromagnetic moment ripple. The amplitude of changes in the electromagnetic torque (torque ripple) was determined from the Me waveform as shown in

Figure 8. Determining the maximum and minimum values from the presented waveform introduces reading errors, but the approximation has the property of averaging the results (it will be shown in the next part of the paper). Therefore, approximation use is justified.

The obtained results are summarized in

Table 1. Simulations were carried out by setting the Solver as Fixed-step and the integration step to 1 10^-7. Experiments were realized with smaller integration times, but the results did not differ, so the previously given one was stayed. For the shortest dead time, i.e. 1 us, 10 samples per delay time are obtained, so according to the sampling theorem.

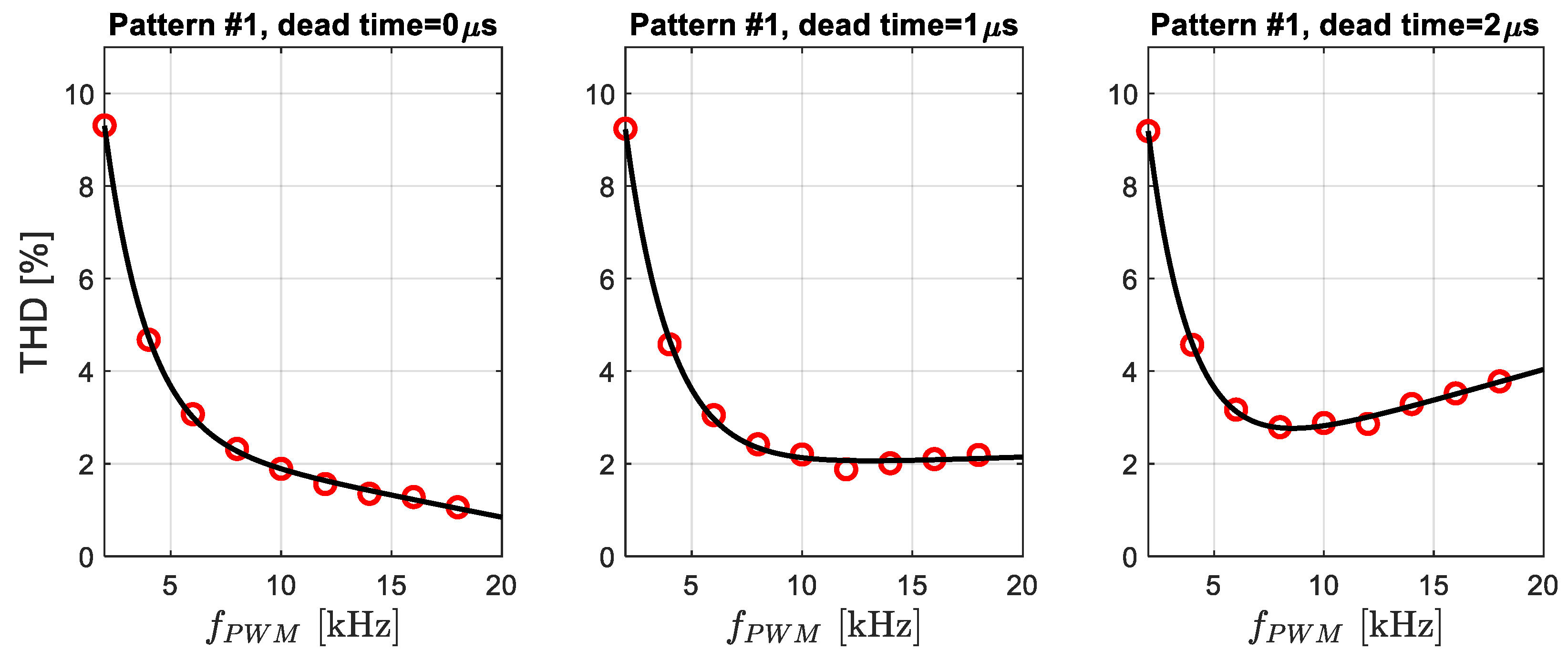

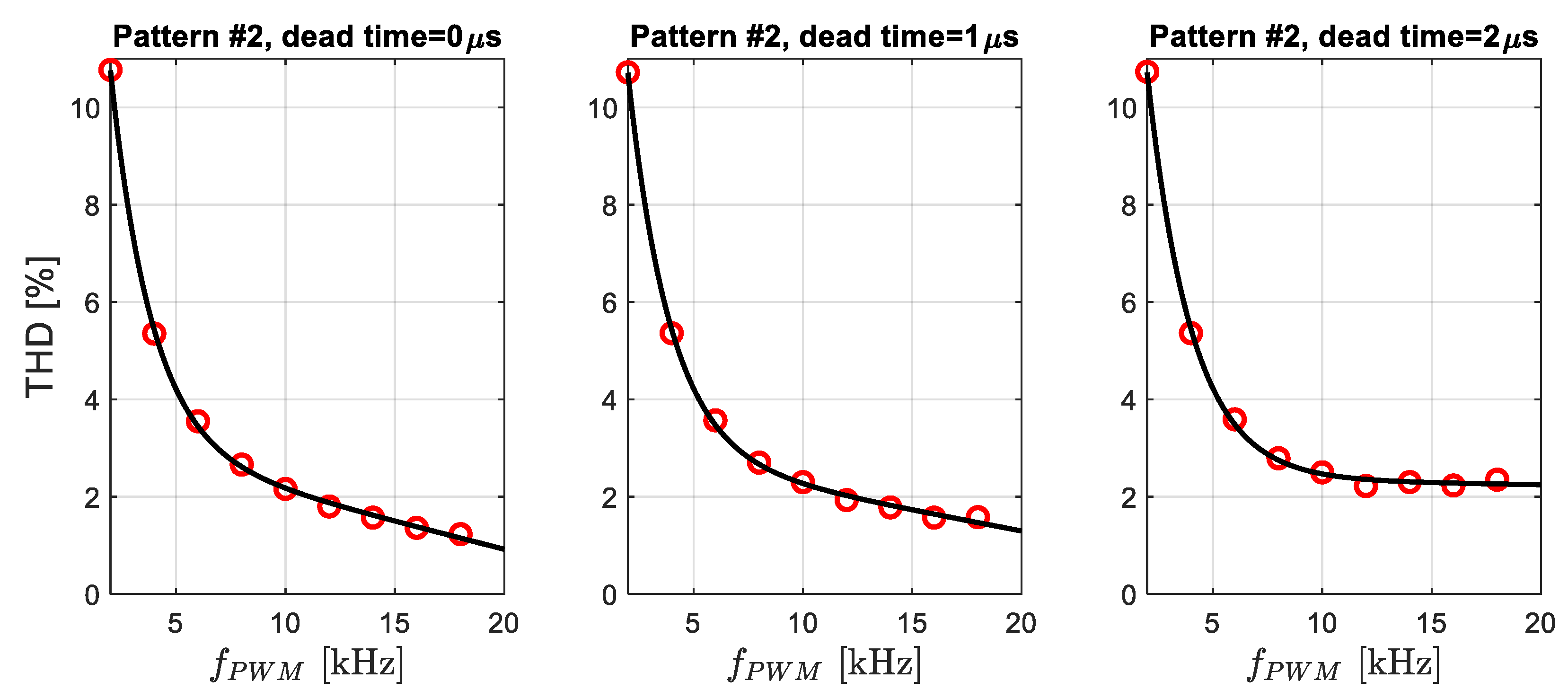

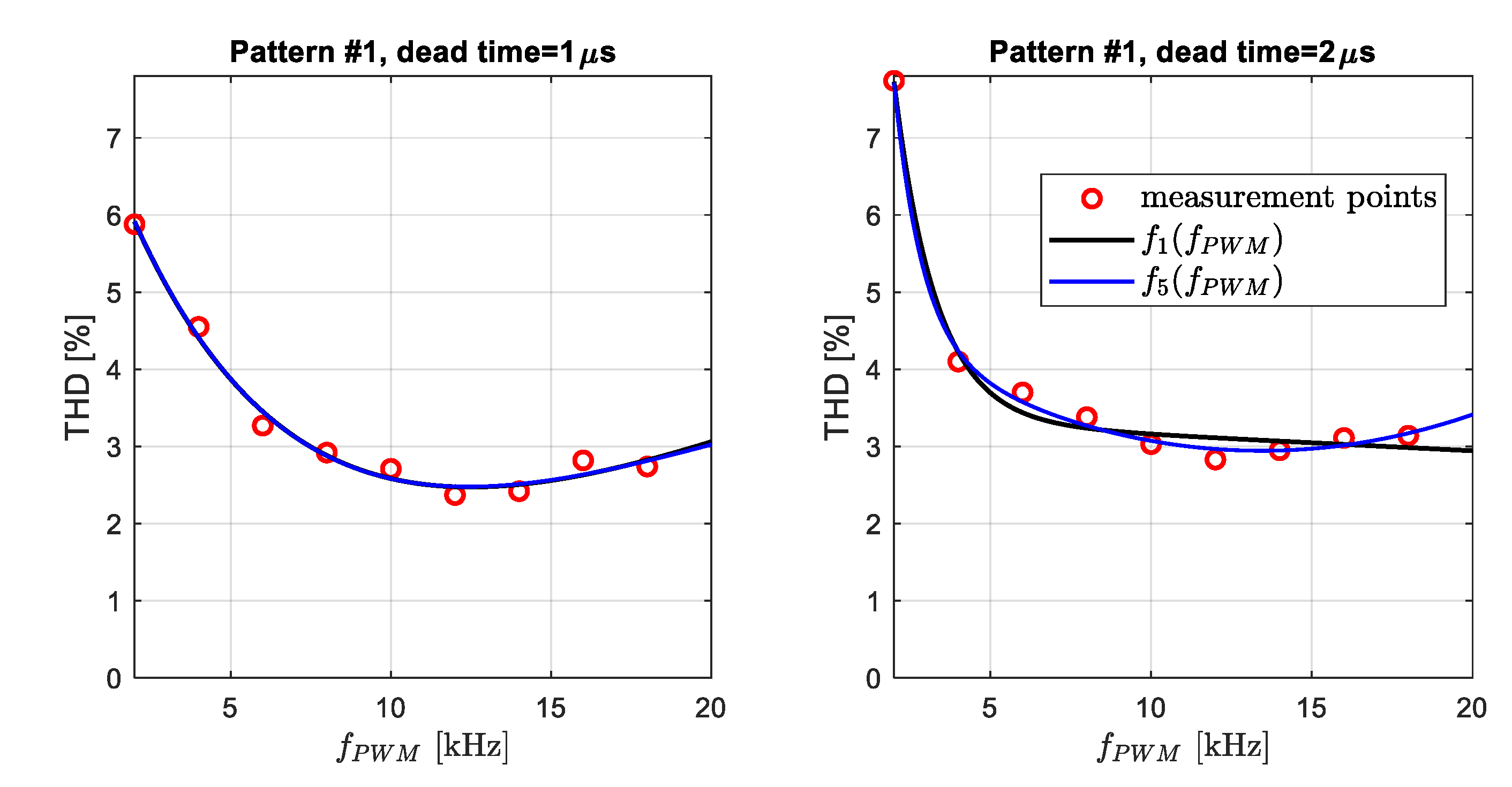

5.1. Approximation of current THD

An approximation of the measurement data for the various cases in

Table 1. was performed and grouped together and shows:

The results are presented by applying titles to each figure, rather than (a), (b), (c), so the results are more readable.

The first graphs in the figures show THD changes for ideal inverter control, that is, for perfect transistors (T_DB=0us). They are only for comparison with the other cases.

Analyzing the obtained results, it can be seen that lower switching frequencies of transistors f_PWM than 6kHz should not be used. From this frequency THD is less than 4%, that is, approximately the current waveform deviates from the sinusoid by about 4%. This is usually an acceptable value for induction motors.

The approximation function was (10). Comparing the characteristics in figures aTHD1 and aTHD2, it can be seen that the effect of dead time in the switching of inverter transistors:

TDB =0us, then modulation Pattern #1 has better characteristics than Pattern #2 - this is the ideal case and this result is obvious

TDB=1us, up to 10kHz better THD is obtained for Pattern #1 modulation, but above 10kHz Pattern #2 modulation has better THD.

TDB=2us, up to 8kHz SV-PWM with switching Pattern #1 obtains better results than for Pattern #2, while for higher switching frequencies of transistors the situation is reversed and it can be seen that a large value of dead time negatively affects the implementation of switching Pattern #1. This is due to the higher number of transistors switching to generate the voltage .

Summarizing the results obtained and looking only through the spectrum of currents (THD), it can be concluded that up to a PWM frequency of 8kHz it is best to use Pattern #1 modulation, while above 8kHz it is best to use Pattern #2 modulation. These results will be confirmed with torque ripple analysis.

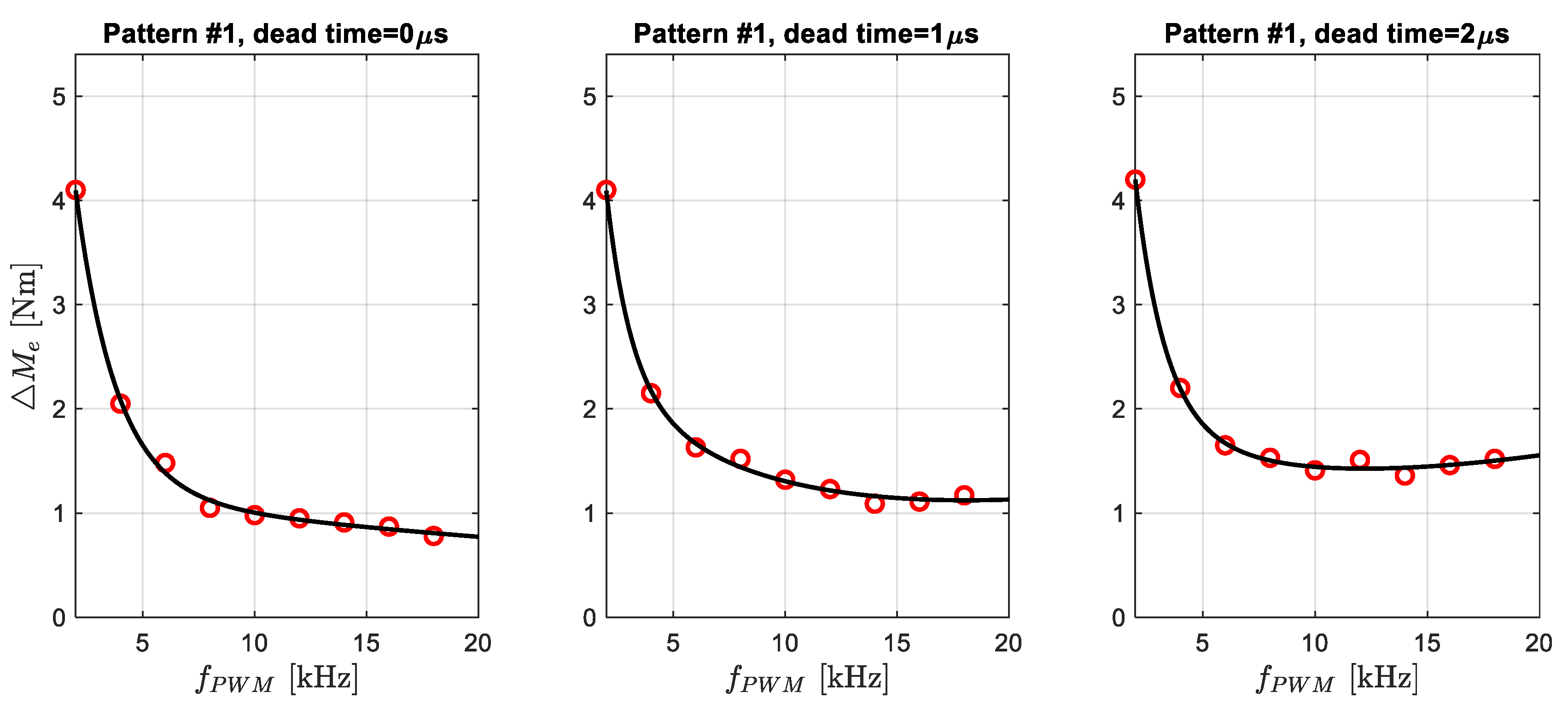

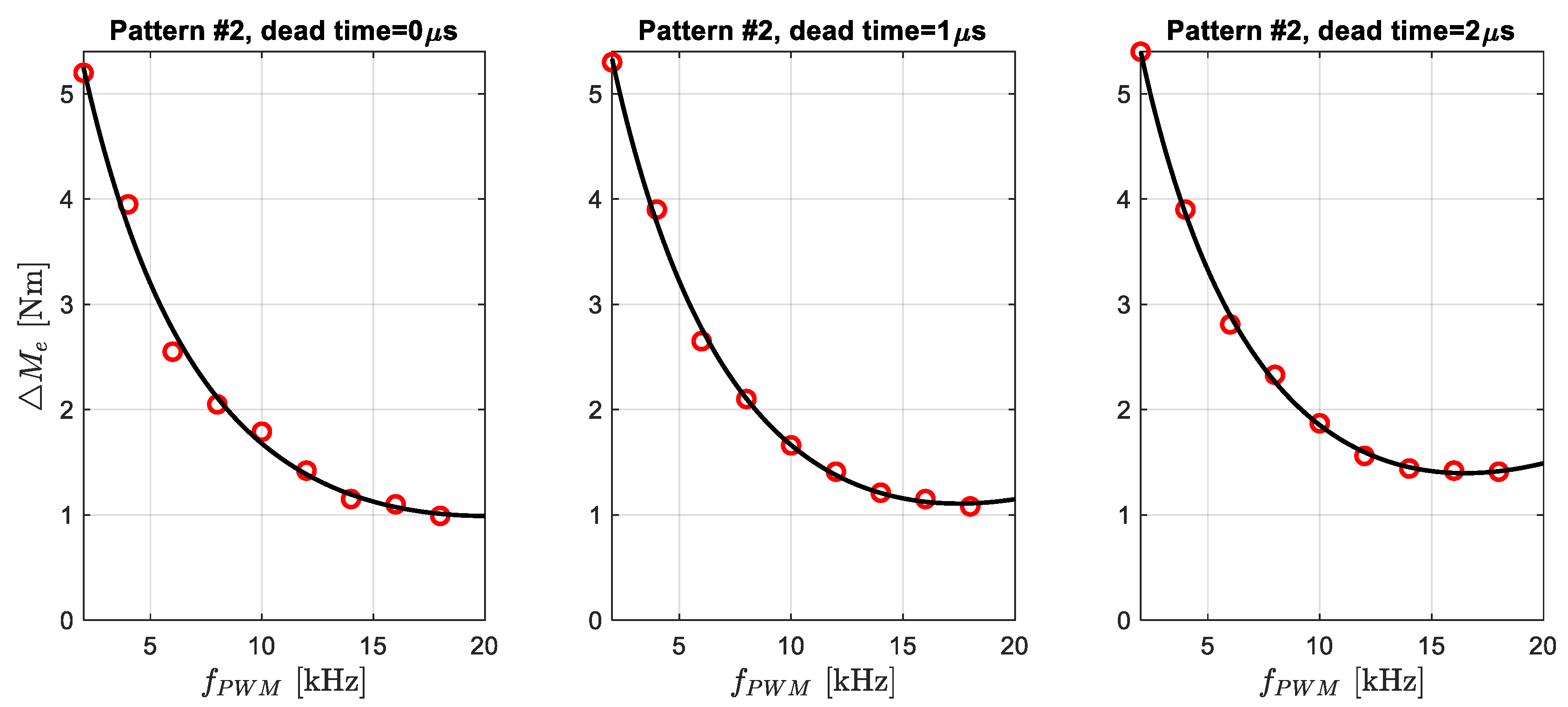

5.2. Torque ripples approximation

The next results were obtained for the estimation of the electromagnetic torque ripples

and are shown in the following figures, respectively for Pattern #1 (

Figure 11) and Pattern #2 (

Figure 12). After many trials, a function with six coefficients was chosen as the best function to approximate the obtained results:

Torque ripples

were estimated as shown in

Figure 11, i.e. the accuracy of the data presented is approximate. For this reason, the use of the approximating function (10) here is most advisable and it will average out the measurement errors.

for switching Pattern#1.

for switching Pattern#2.

A quick comparison of simulation results after approximation leads to the conclusion: for switching Pattern #1, moment ripples below 2% are obtained for f_PWM=6kHz, and for switching Pattern #2 for 10kHz. 2% was chosen as a value already satisfactory to the . But this is not the end of the conclusions, a more detailed analysis of the obtained results should be made. .

Analysis of elctromagnetic torque ripples is not as obvious as for current THD. A different approximating function was used here because the measurement points are arranged differently. In addition, no significant rise in the characteristic for switching Pattern #1 in the higher frequency range can be seen here. Above 10kHz, the compared characteristics (for Pattern #1 and #2) differ by less than 0.5Nm, and as the frequency increases, these differences decrease and for 16kHz and 18kHz they are already practically indistinguishable.

To analyze the changes in , it is necessary to return to the induction motor model (section 4). The inverter powers the motor, not the RL circuit, which means that in addition to currents, voltages and linked fluxes, there is an electromagnetic torque and back electromotive forces.

The ordinary differential equations of an induction motor induction motor are nonlinear, this is especially evident in the voltage equations (21) and (22). The electromagnetic torque is generated according to relation (23) and is the product of two currents

and

. The q-axis current is determined directly from the geometric transformation (16), and the

current is the result of filtering (19). When the motor is fed with signals such as those in

Figure 4 and

Figure 5, it is impossible to speak of steady state. In addition, in equations (21) and (22), you can see the phenomenon of coupling between the two circuits (in the d and q axis), i.e. the current

is produced by the voltage

, but affects the current

(expression

in (22)).

In addition, the current also affects the current (expression ).. In the other direction, coupling also occurs, i.e., current is produced by voltage and affects currents and (expression in (21)). Hence, the induction motor is a strongly nonlinear system and with SV-PWM control there is a permanently dynamic state, which we can only determine using numerical methods. The effect of circuit coupling is analytically impossible changes in , which are different from THD().

6. Experiments

Simulation results showed the similarity of the current THD and torque ripple . For this reason, experimental research was presented for THD current analysis. Additionally, the lab stand shown below does not have a torque sensor, so measuring is impossible.

6.1. Experimental setup

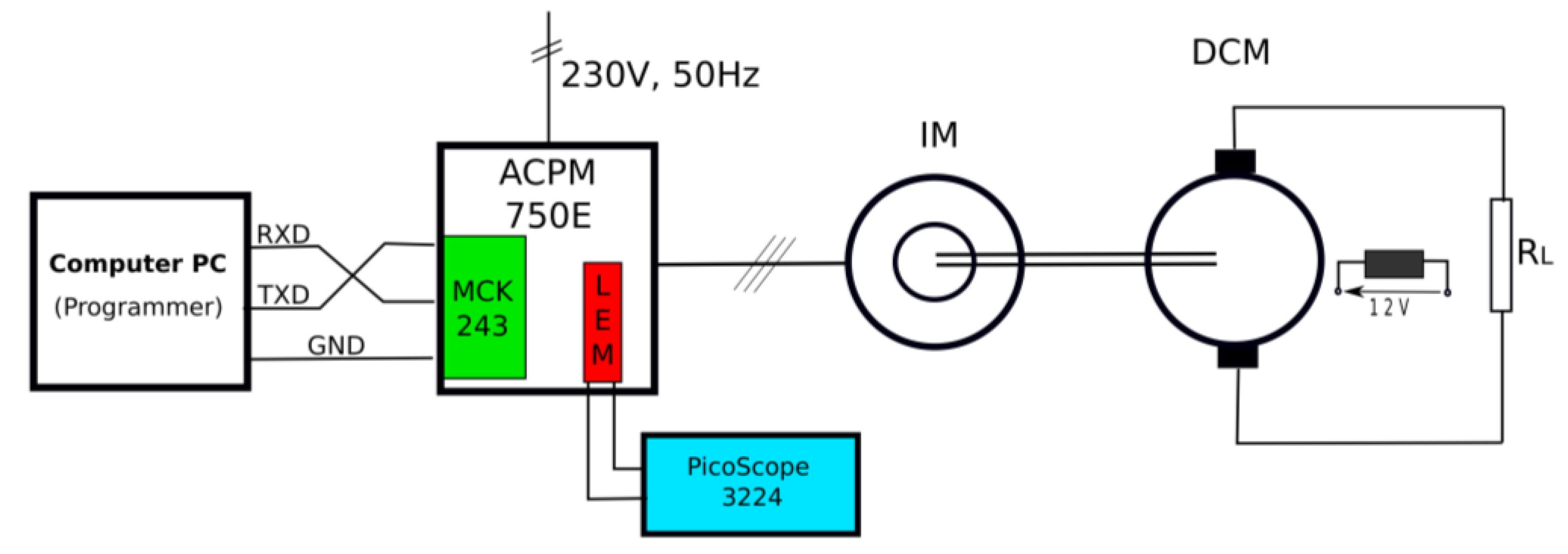

The experimental setup is shown in

Figure 13, where Technosoft's DMCS-as software installed on a PC was used.

The squirrel cage induction motor IM (350W, 2850rpm, number of pole pairs=1) is loaded with a DCM generator, where the load torque is varied by the excitation current. The ACPM 750E and MCK243 are also Technosoft products and are respectively a VSI (750W) and a control circuit with a TMS320F243 processor. The control circuit generates PWM signals for the inverter transistors according to Pattern#1, where the switching frequency and dead-band can be changed. For this reason, experimental results for Pattern#2 are not included, but confirmation of simulation results is expected.

The LEM (stator current measurement) transducer is located on the ACPM board and the current waveform can be recorded. The PicoScope3224 is used for this purpose. PicoScope 3224 is the USB PC Oscilloscopes with data logger. This model is the two-channel version and has the following features:

20 MS/s maximum sampling rate

512,000 sample buffer

12-bit resolution

USB 2.0 interface

±20 mV to ±20 V measuring ranges

10 MHz analogue bandwidth and spectrum analyser range

The 12-bit resolution allows the THD to be accurately determined for 3128 samples per period (this leads to a sampling frequency of 156,4kHz), such is the value set in the PicoScope 7 control software.

6.2. Measurement results

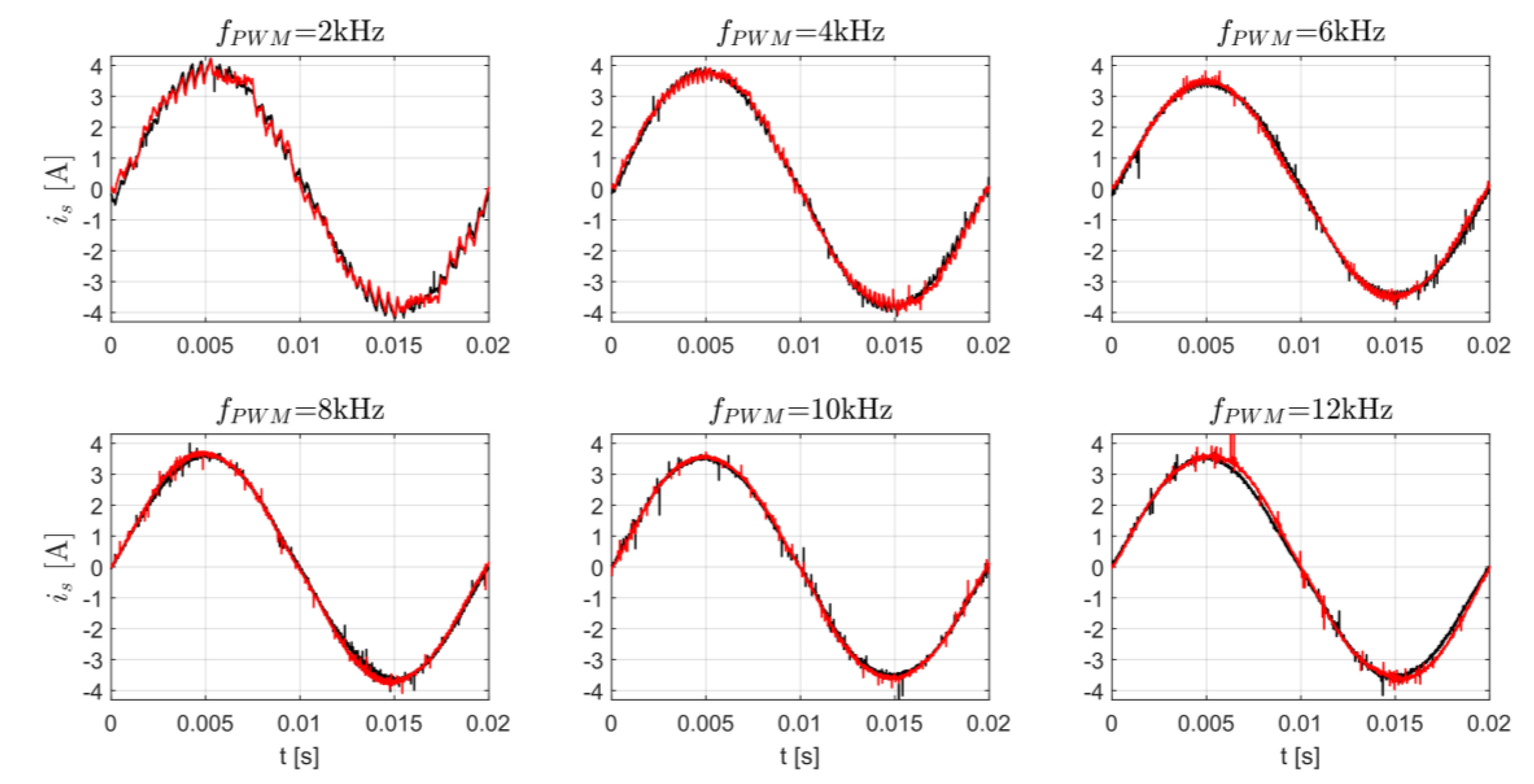

The results of the experiments are shown in

Figure 14 and

Figure 15, where the current waveforms for PWM modulation with Pattern#1 and different dead times

are compared. The following figures show comparisons for different switching frequencies

, as signed in their titles.

Figure 14 and

Figure 15 show the raw results of the measurements, i.e. no signal filtering was applied. Therefore, you can clearly see the measurement noise here, which is random and will not affect the result of the FFT, and therefore the THD.

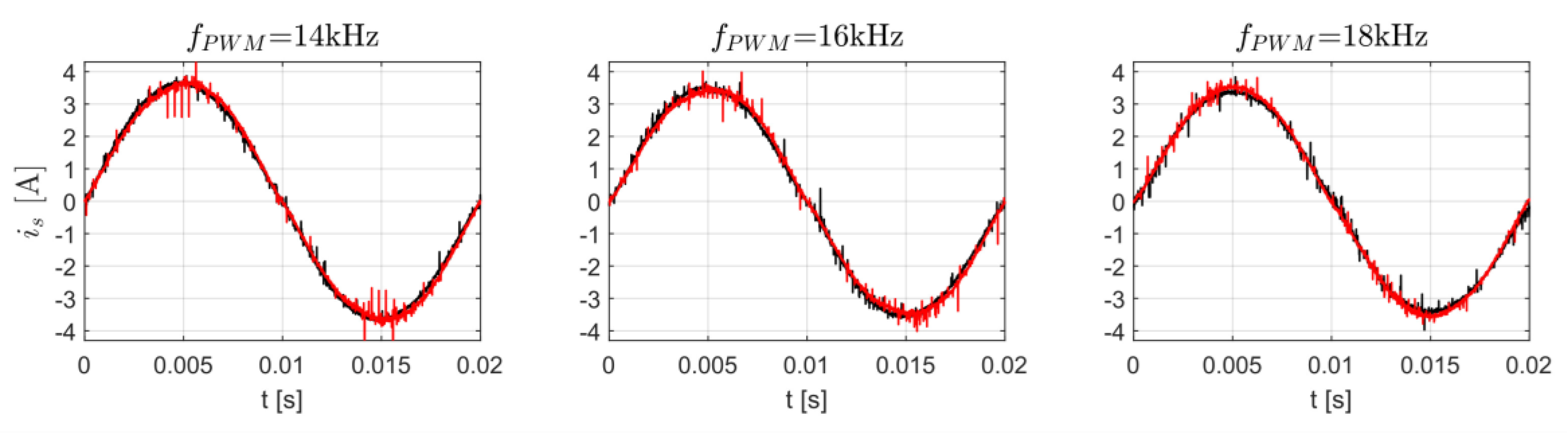

6.3. THD analysis

The results of the measurements are presented in

Table 2 and

Figure 16, which shows a comparison of THD for selected PWM frequencies and dead time (Pattern#1 modulation method). The tests were performed at the same frequencies as in the simulation studies. To describe the effect of dead band on current THD, a gamma factor is introduced, which determines the percentage of time it takes

relative to the PWM period:

In one period of PWM 2 times there is a dead band (Figures 4b and 5b), thus in relation (25) the multiplier is 2.

For time

, a satisfactory approximating function (10) is obtained, but for dead time

the results are not satisfactory, thus it should be completed with additional expansion. For this reason, the function

is supplemented by a quadratic factor:

The results presented in

Figure 16 differ slightly from those in

Figure 9 in terms of values. However, the shape of the characteristics is similar in both figures. The reason for this is definitely the induction motor, in the simulation studies (

Figure 9) Squirrel-cage preset model 02: 10HP (7.46kW), 400V, 60Hz, 1760rpm was used. On the other hand, in the experimental study it was motor: 350W, 230V, 50Hz, 2860rpm.

The gamma factor in

Table 2 varies linearly and it can be seen that for higher frequencies

is greater than 2% (

) or even 4% (

). Reaching up to 3.6% and 7.2%, respectively.. This becomes the cause of increasing THD. In addition, in the simulations, the counters (triangle carriers) are assumed to operate on floating-point numbers. While, in microcontrollers, they are mostly implemented based on 16-bit timers. This introduces additional errors in the voltage signals.

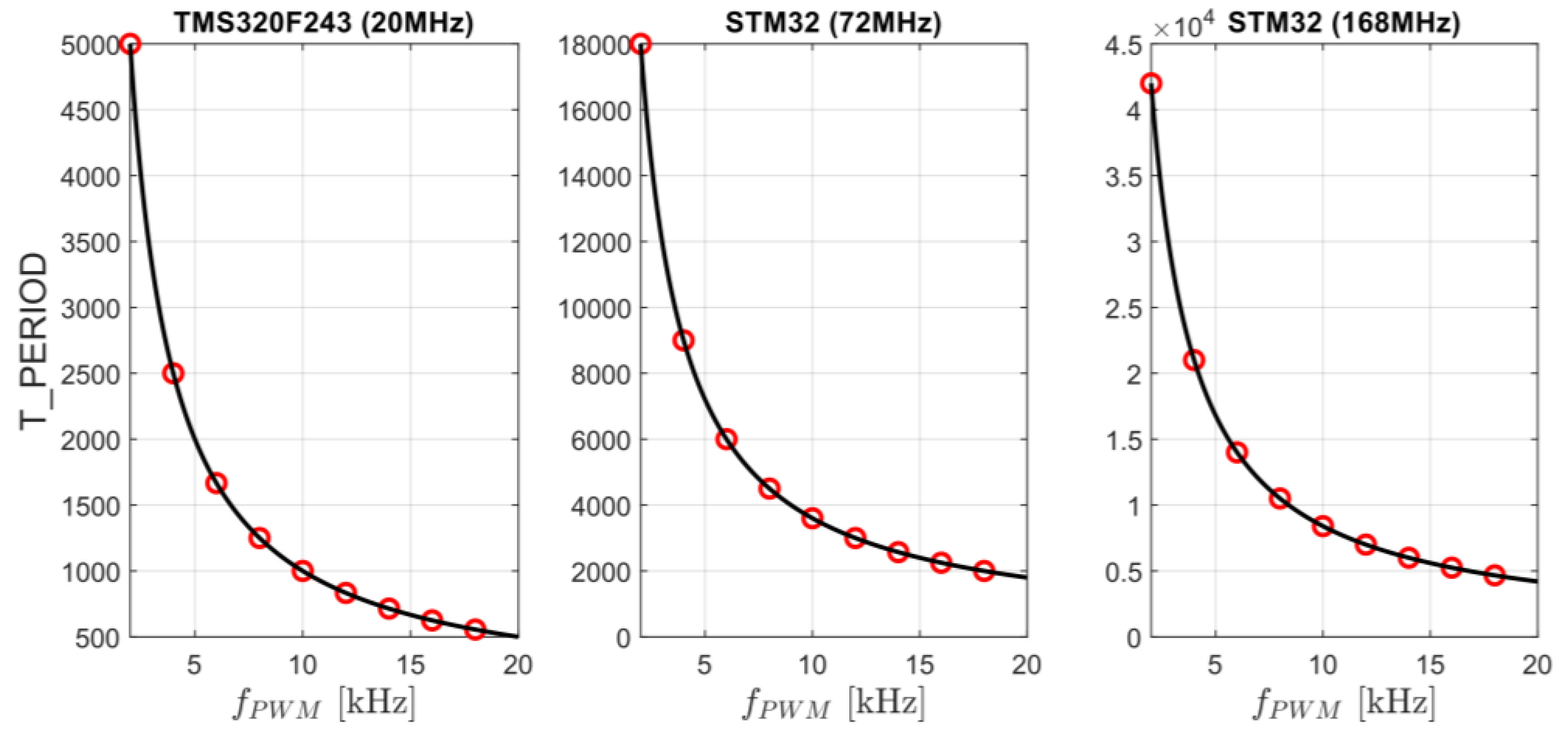

6.4. Hardware SV-PWM realization analysis

A typical PWM generation process for one branch of the inverter is shown in

Figure 17. Where CMPR is the value compared with the content of the timer, T_PERIOD is the value to which the timer counts.

The timer counts clock pulses of period

in a discrete mode, i.e. using unsigned int numbers. This leads to further errors. The value T_PERIOD to which the timer counts is determined identically for all processors ( symmetrical PWM):

The TMS320F243 processor used in the experiment has =20MHz, so it is easy to calculate with what accuracy the timer measures time. For example, if =2kHz, then T_PERIOD=5000. 5000 is the number of discrete states when measuring time, thus the measurement accuracy for the PWM period is 1/5000 (LSB), which is a little more than 12 bits. For such a low frequency, this value is not high.

The maximum value of T_PERIOD, to which the timer counts, changes according to the hyperbolic function when

changes according to formula (27). So, the function that describes the change in T_PERIOD(

) and takes into account the processor clock

is extremely simple and requires no approximation:

Figure 18 shows a comparison of T_PERIOD values as a function of processor clock frequency. The currently popular processors (STM32) with frequencies higher than 20MHz are included.

In the

Figure 18 you can see how important the clock frequency is, even doing a comparison for the frequency

=10kHz you can observe (after converting to resolution in bits) that for

=20MHz the resolution is about 10 bits, for 72MHz it is already less than 12 bits, and for 168MHz it is more than 13 bits. This means that the clock frequency significantly affects the accuracy of timing, so the accuracy of PWM generation.

6.5. Comments

The presented results and analysis of the hardware implementation show that the accuracy of voltage generation in VSI is affected by many factors. But it is shown that the simulation results represent a first estimate of THD, which is an ideal result to which additional errors related to the practical implementation of SV-PWM control should be added. Moreover, the results in

Figure 9 and

Figure 16 are close to each other, this, of course, is due to the accurate implementation of power electronic circuit models in Matlab-Simulink.

4. Conclusions

The article focuses on the induction motor stator current (THD) waveforms, not the RL circuit - as in most publications, which affect the torque ripple.

The paper uses least-squares approximation to determine the THD characteristics of the current and torque ripple as a function of the switching frequency of the transistors for VSI. This is a new approach to determining these characteristics that averages out measurement errors. Several VSI approximating functions were proposed and those with the smallest error were selected.

Dead time in transistor switching was included in the study. Two transistor switching strategies (Pattern#1, Pattern#2) were analyzed for which the above-mentioned characteristics were determined. Based on simulation results, it can be observed that the Pattern#1 method gives better results for lower PWM frequencies (up to 10kHz), while Pattern#2 should be used above 10 kHz.

Experimental tests showed higher-than-expected current THD values, so an analysis of the implementation of SVPWM control based on processors (TMS320 and STM32) was carried out. This analysis shows that the accuracy of the realization (resolution) of the PWM signal depends on the clock frequency that the counter counts. The analysis showed that not at all the highest frequency guarantees the lowest THD of current and torque ripple.

Finally, switching losses in the VSI must also be taken into account, which are discussed in detail in [

6]. It is known from this publication that Pattern#2 realizes 33% less switching than Pattern#1 and this leads to a 50% reduction in VSI losses. Hence, drive systems should be optimized so that THD of current and losses in VSI are as low as possible. Can any general rule of thumb be given? Based on the research, THD of current can be considered satisfactory from 8kHz onward, and this frequency can be considered optic for drives operating up to 50Hz.

On the other hand, from the results obtained, it can be determined that =6kHz is the lowest switching frequency of transistors for which the stator current "resembles " a sinusoid.

In conclusion, in the article is presented:

- approximation of THD() and characteristics, which, taking into account dead time, present THD changes,

- two SVPWM modulation methods (Pattern#1, Pattern#2) are compared,

-experimental results are presented,

-analysis of PWM hardware implementation.

The results obtained determine that the best THD of the current is in the 8-12kHz range, which also affects the torque ripple.

Of course, in practice, the frequency should be chosen taking into account the losses in the VSI, but this remains a task for designers.

Future work should include issues of the effect of PWM switching frequency on total losses in the drive, i.e. motor eddy currents and losses in the VSI. The research will be able to be extended to analyze the operation of other AC motors.

Author Contributions

Methodology, G.S..; software, G.S, S.S, J.G. and R.N.; formal analysis, G.S.; resources, G.S.; data curation, G.S; writing—original draft preparation, G.S., J.G., S.S, R.N.; writing—review and editing, J.G., S.S. and G.S.; visualization, G.S. and R.N.; supervision, G.S. All authors have read and agreed to the published version of the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Leonhard, W. Control of Electrical Drives; Springer-Verlag: Berlin, 2001. [Google Scholar]

- Krishnan, R. Electric Motor Drives. Modelling, Analysis and Control; Prentice Hall: Upper Saddle River, 2001. [Google Scholar]

- Trzynadlowski, A. Control of Induction Motors; Academic Press: San Diego, 2000. [Google Scholar]

- Bose, B. Power Electronics and Motor Drives: Advances and Trends; Elsevier Science: Burlington, 2006. [Google Scholar]

- Kaźmierkowski, M.; Tunia, H. Automatic Control of Converter-Fed Drives; Elsevier Science: Amsterdam, 1994. [Google Scholar]

- Kaźmierkowski, M.; Krishnan, R.; Blaabjerg, F. Control in Power Electronics; Academic Press: San Diego, 2002. [Google Scholar]

- Boldea, I.; Nasar, S. A. Electric Drives, 3rd ed.; CRC Press: Boca Raton, 2016. [Google Scholar]

- Sieklucki, G. Automation of the drive; (in Polish). Wydawnictwa AGH: Kraków, Poland, 2009. [Google Scholar]

- Sieklucki, G.; Bisztyga, B.; Zdrojewski, A.; Orzechowski, T.; Sykulski, R. Models and methods in electrical drives control; (in Polish). Wydawnictwa AGH: Kraków, Poland, 2004. [Google Scholar]

- Mohan, N.; Undeland, T. M.; Robbins, W. P. Power Electronics: Converters, Applications, and Design, 3rd ed.; Wiley: Hoboken, New Jersey, 2002. [Google Scholar]

- Rashid, M. Power Electronics Handbook, 4th ed.; Elsevier: Amsterdam, 2017. [Google Scholar]

- Pirog, S. Power electronics : systems with network and hard commutations; Wydawnictwa AGH: Kraków, Poland, 2006. (in Polish) [Google Scholar]

- Yu, Z. Space-Vector PWM With TMS320C24x/F24x Using Hardware and Software Determined Switching Patterns; Application Report SPRA524; Digital Signal Processing Solutions; Texas Instruments, 1999.

- Singh, S.; Tiwari, A.N. Simulation and Comparison of SPWM and SVPWM Control for Two Level Inverter. International Journal of Computing and Applications, Volume 13, Number 2, (July-December 2018), pp 267-273, ISSN: 0973-5704.

- Nagar, K.; Sharma, A.K.; Palwalia, D.K.; Sharma, A. Harmonic Analysis of Three Phase SPWM and SVPWM Converters. International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering, Vol. 3, Issue 11, November 2014, ISSN (Online): 2278 – 8875. [CrossRef]

- Sudaryanto, A.; Purwanto, E.; Ferdiansyah, I.; Nugraha, S. D.; Qudsi, O. A.; Rifadil, M. M.; Rusli, M. R. Design and Implementation of SVPWM Inverter to Reduce Total Harmonic Distortion (THD) on ThreePhase Induction Motor Speed Regulation Using Constant V/F. Conference: 2020 3rd International Seminar on Research of Information Technology and Intelligent Systems (ISRITI) , December 2020. [CrossRef]

- Singh, S.; Tiwari, A.N. Simulation and Comparison of SPWM and SVPWM Control for Two Level Inverter. Conference: 2017, First International Conference on Smart Technologies in Computer and Communication (SmartTech-2017) At: Amity University Rajasthan (AUR), India, March 2017.

- Akhmetov, Z.; Ruderman, A. Analytical current THD evaluation for threephase voltage source inverters. IET Power Electronics, 2020, Vol. 13 Iss. 6, pp. 1286-1289. [CrossRef]

- Investigations on Harmonic Spreading Effects of SVPWM Switching Patterns in VSI fed AC Drives. IEEE - International Conference On Advances In Engineering, Science And Management (ICAESM -2012) -31, 2012, pp.

- Ahmed, A.; Ercelebi, E. Simulation and Study of SVPWM Inverter for (VFD) Applications. International Journal of Electronics and Electrical Engineering Vol. 5, No. 2, April 2017, pp. 158-170. [CrossRef]

- Prasad, N. V. Kamisetti.; Srivastava, S. P. THD Reduction in High Power V/F Drives by using Hybrid Synchronized Space Vector Pulse width Modulation. 2015 International Conference on Energy Systems and Applications (ICESA 2015), Dr. D. Y. Patil Institute of Engineering and Technology, Pune, India 30 Oct - 01 Nov, 2015 , pp. 571-576. [CrossRef]

- Hu, H.; Wang, H.; Liu, K.; Wei, J.; Shen, X. A Simplified Space Vector Pulse Width Modulation Algorithm of a High-Speed Permanent Magnet Synchronous Machine Drive for a Flywheel Energy Storage System. Energies 2022, 15, 4065. [Google Scholar] [CrossRef]

- Peter, J.; Ramchand, R. Vector Control of Space Vector based Hybrid PWM fed IM Drive with reduced torque ripple. 2020 International Conference on Power, Instrumentation, Control and Computing (PICC) | 978-1-7281-7590-4/20/$31.00 ©2020 IEEE |. [CrossRef]

- Pandya, S. N.; Chatterjee, J. K. Torque Ripple Reduction in Direct Torque Control based Induction Motor Drive Using Novel Optimal Controller Design Technique. IEEE - 2010 Joint International Conference on Power Electronics, Drives and Energy Systems & 2010 Power India, December 20-23, 2010, India: New Delhi. [CrossRef]

- Pandya, S. N.; Chatterjee, J. K. Torque Ripple Minimization in Direct Torque Control Based Induction Motor Drive Using Optimal Multirate Sampling Technique. IEEE - 2010 Joint International Conference on Power Electronics, Drives and Energy Systems & 2010 Power India, December 20-23, 2010, India: New Delhi. [CrossRef]

- Reddy, T. B.; Amarnath, J.; Subbarayudu, D. New Hybrid SVPWM Methods for Direct Torque Controlled Induction Motor Drive for Reduced Current Ripple. 2006 International Conference on Power Electronic, Drives and Energy Systems, December 12-15, 2006, India: New Delhi. [CrossRef]

Figure 1.

Example of approximation

Figure 1.

Example of approximation

Figure 2.

Voltage Source Inverter (VSI).

Figure 2.

Voltage Source Inverter (VSI).

Figure 3.

Base voltage vectors in the reference system (α, β).

Figure 3.

Base voltage vectors in the reference system (α, β).

Figure 5.

Comparison of SV-PWM with Pattern #2: a) ideal without dead time, b) including dead time TDB.

Figure 5.

Comparison of SV-PWM with Pattern #2: a) ideal without dead time, b) including dead time TDB.

Figure 6.

Simulation diagram.

Figure 6.

Simulation diagram.

Figure 7.

Starting of IM.

Figure 7.

Starting of IM.

Figure 8.

Steady state of the stator current (a) and electromagnetic torque (b) - .

Figure 8.

Steady state of the stator current (a) and electromagnetic torque (b) - .

Figure 9.

THD current approximation for switching Pattern #1.

Figure 9.

THD current approximation for switching Pattern #1.

Figure 10.

THD current approximation for switching Pattern #2.

Figure 10.

THD current approximation for switching Pattern #2.

Figure 11.

Approximation of the torque ripple

Figure 11.

Approximation of the torque ripple

Figure 12.

Approximation of the torque ripple

Figure 12.

Approximation of the torque ripple

Figure 13.

Experimental setup.

Figure 13.

Experimental setup.

Figure 14.

Comparisons stator current waveforms for different switching frequency (black - , red - ), kHz.

Figure 14.

Comparisons stator current waveforms for different switching frequency (black - , red - ), kHz.

Figure 15.

Comparisons stator current waveforms for different switching frequency (black - , red - ), kHz.

Figure 15.

Comparisons stator current waveforms for different switching frequency (black - , red - ), kHz.

Figure 16.

Approximation of current THD for switching Pattern#1.

Figure 16.

Approximation of current THD for switching Pattern#1.

Figure 17.

Symmetrical PWM generation (up/down mode) – discrete case approach.

Figure 17.

Symmetrical PWM generation (up/down mode) – discrete case approach.

Figure 18.

Comparison of the maximum value of T_PERIOD in the timer for different processors (different clock frequencies). Processor names and clock frequencies are in the titles of the characteristics.

Figure 18.

Comparison of the maximum value of T_PERIOD in the timer for different processors (different clock frequencies). Processor names and clock frequencies are in the titles of the characteristics.

Table 1.

Comparison THD and torque ripple for different PWM frequency, different dead band, different modulation pattern.

Table 1.

Comparison THD and torque ripple for different PWM frequency, different dead band, different modulation pattern.

| FPWM [kHz] |

[μs] |

THD |

|

[Nm] |

| Pattern #1 |

Pattern #2 |

|

Pattern #1 |

Pattern #2 |

| 2 |

0 |

9,31% |

10,77% |

4,1 |

5,2 |

| 2 |

1 |

9,24% |

10,72% |

4,1 |

5,3 |

| 2 |

2 |

9,19% |

10,73% |

4,2 |

5,4 |

| 4 |

0 |

4,63% |

5,35% |

2,1 |

3,95 |

| 4 |

1 |

4,58% |

5,36% |

2,15 |

3,9 |

| 4 |

2 |

4,57% |

5,36% |

2,2 |

3,9 |

| 6 |

0 |

3,07% |

3,55% |

1,45 |

2,55 |

| 6 |

1 |

3,05% |

3,57% |

1,63 |

2,65 |

| 6 |

2 |

3,17% |

3,59% |

1,65 |

2,8 |

| 8 |

0 |

2,32% |

2,66% |

1,1 |

2,05 |

| 8 |

1 |

2,42% |

2,70% |

1,59 |

2,1 |

| 8 |

2 |

2,79% |

2,79% |

1,53 |

2,25 |

| 10 |

0 |

1,89% |

2,16% |

0,95 |

1,79 |

| 10 |

1 |

2,20% |

2,30% |

1,32 |

1,66 |

| 10 |

2 |

2,88% |

2,50% |

1,76 |

1,88 |

| 12 |

0 |

1,56% |

1,80% |

1,03 |

1,42 |

| 12 |

1 |

1,88% |

1,93% |

1,57 |

1,41 |

| 12 |

2 |

2,86% |

2,22% |

1,41 |

1,63 |

| 14 |

0 |

1,35% |

1,57% |

0,9 |

1,15 |

| 14 |

1 |

2,01% |

1,78% |

1,09 |

1,21 |

| 14 |

2 |

3,29% |

2,30% |

1,4 |

1,45 |

| 16 |

0 |

1,28% |

1,36% |

0,7 |

0,65 |

| 16 |

1 |

2,10% |

1,57% |

1,11 |

1,15 |

| 16 |

2 |

3,52% |

2,23% |

1,48 |

1,45 |

| 18 |

0 |

1,06% |

1,23% |

0,78 |

0,99 |

| 18 |

1 |

2,17% |

1,58% |

1,17 |

1,08 |

| 18 |

2 |

3,78% |

2,35% |

1,62 |

1,49 |

Table 2.

Comparison THD for different PWM frequency, different dead band for pattern #1.

Table 2.

Comparison THD for different PWM frequency, different dead band for pattern #1.

| fPWM [kHz] |

|

[%] |

|

1 μs |

2 μs |

1 μs |

2 μs |

| 2 |

5,88% |

7.74% |

0,4 |

0,8 |

| 4 |

4,55% |

4,11% |

0,8 |

1,6 |

| 6 |

3,27% |

3,70% |

1,2 |

2,4 |

| 8 |

2,92% |

3,38% |

1,6 |

3,2 |

| 10 |

2,71% |

3,03% |

2,0 |

4,0 |

| 12 |

2,37% |

2,83% |

2,4 |

4,8 |

| 14 |

2,42% |

2,95% |

2,8 |

5,6 |

| 16 |

2,82% |

3,11% |

3,2 |

6,4 |

| 18 |

2,74% |

3,14% |

3,6 |

7,2 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).