Submitted:

26 May 2023

Posted:

29 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

- -

- Based on the theory of direct feedback linearization, a nonlinear speed and excitation robust controller of a DG is designed;

- -

- Applying the intelligent CPSOGSA to optimize the dynamic output function parameters of the robust controller, thus introducing the CPSOGSA for this problem solving multi-objective mixed robust controller

- -

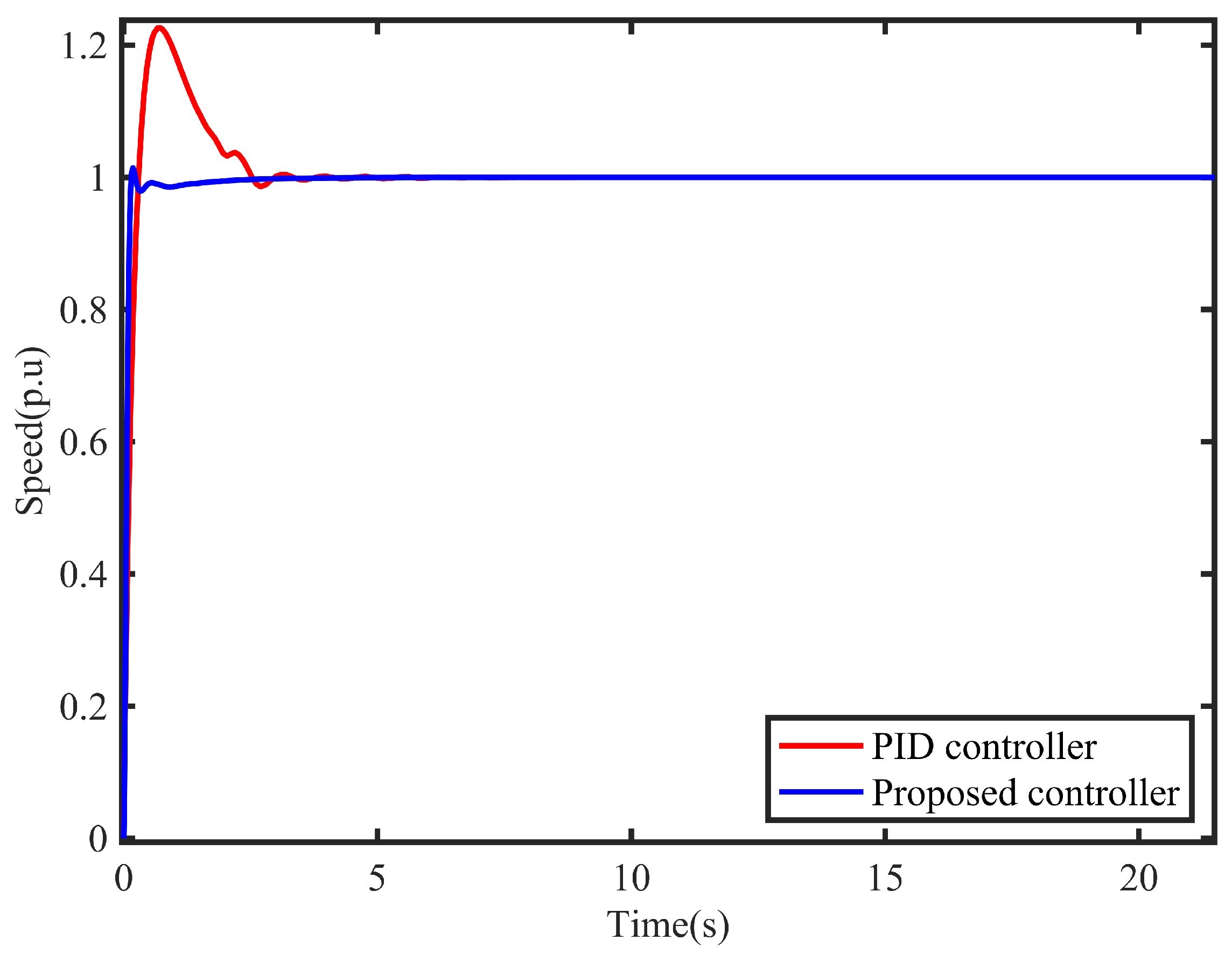

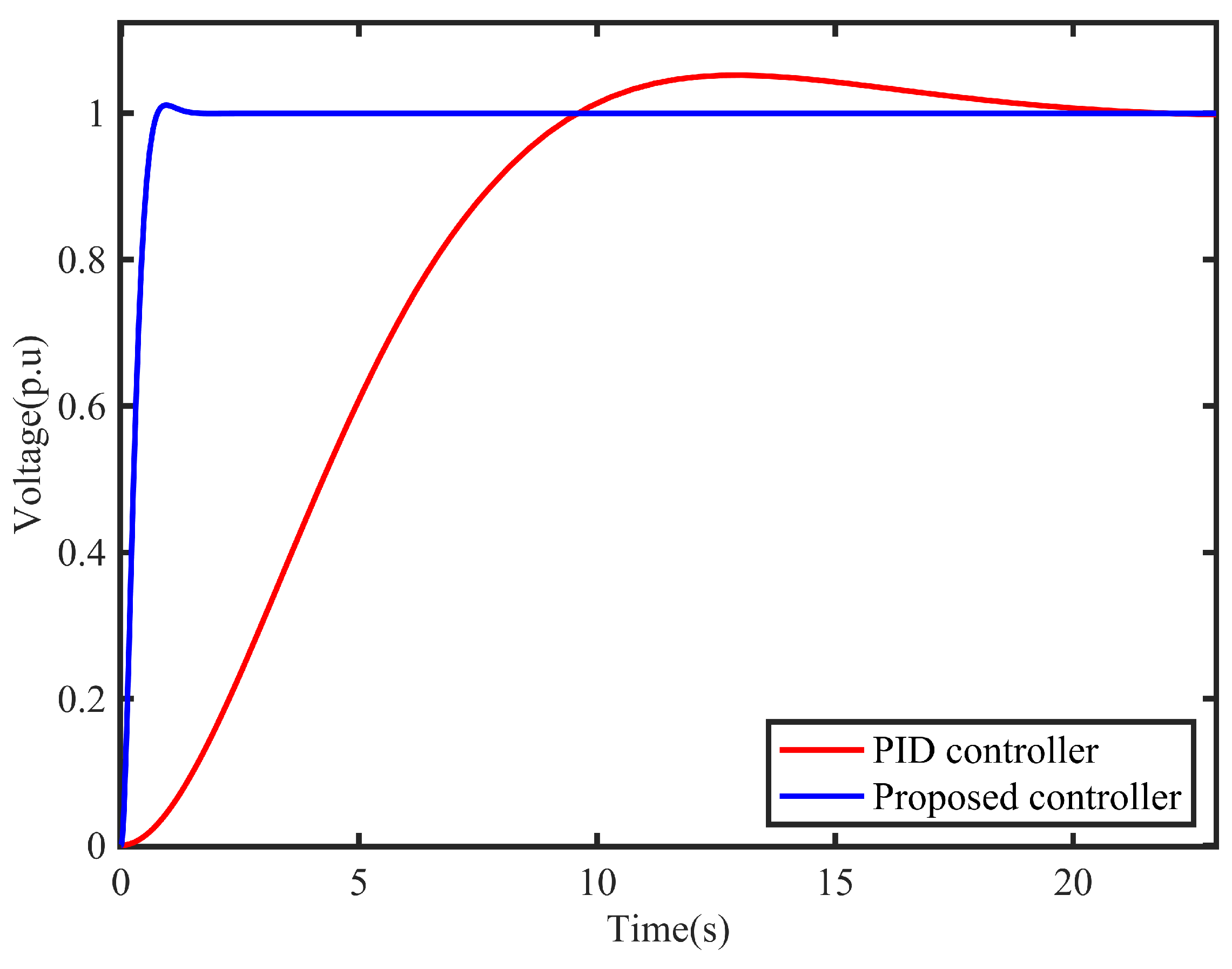

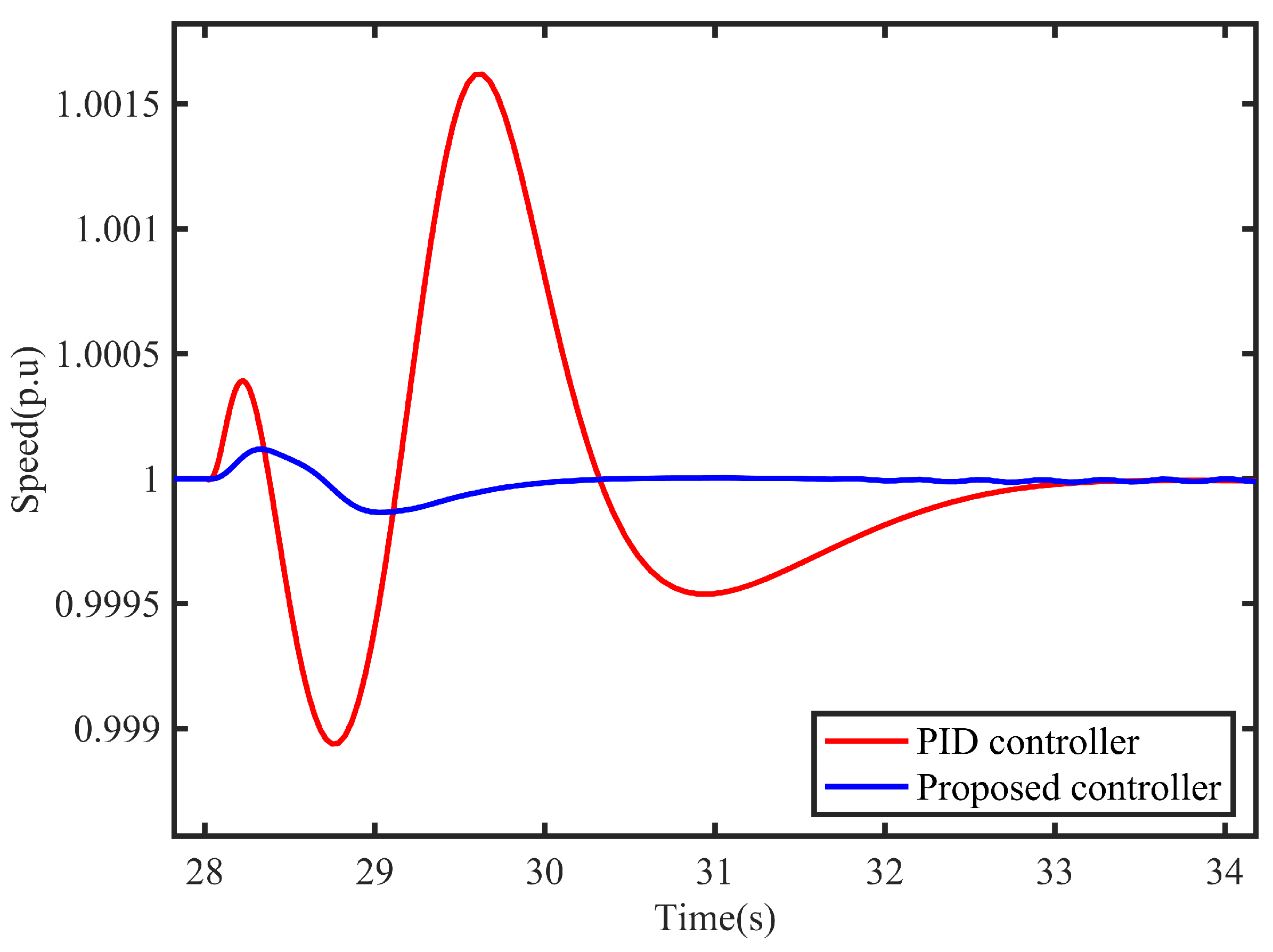

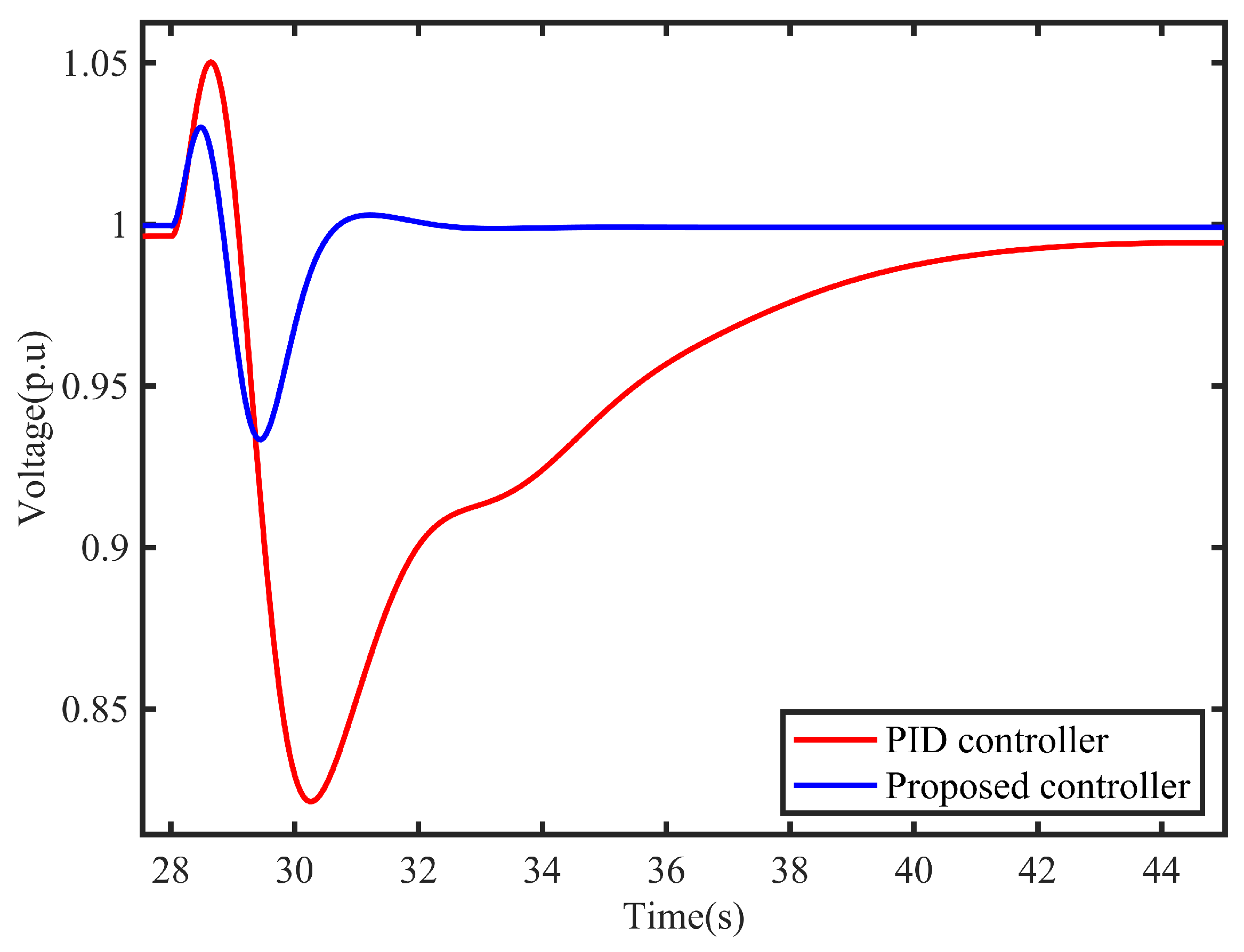

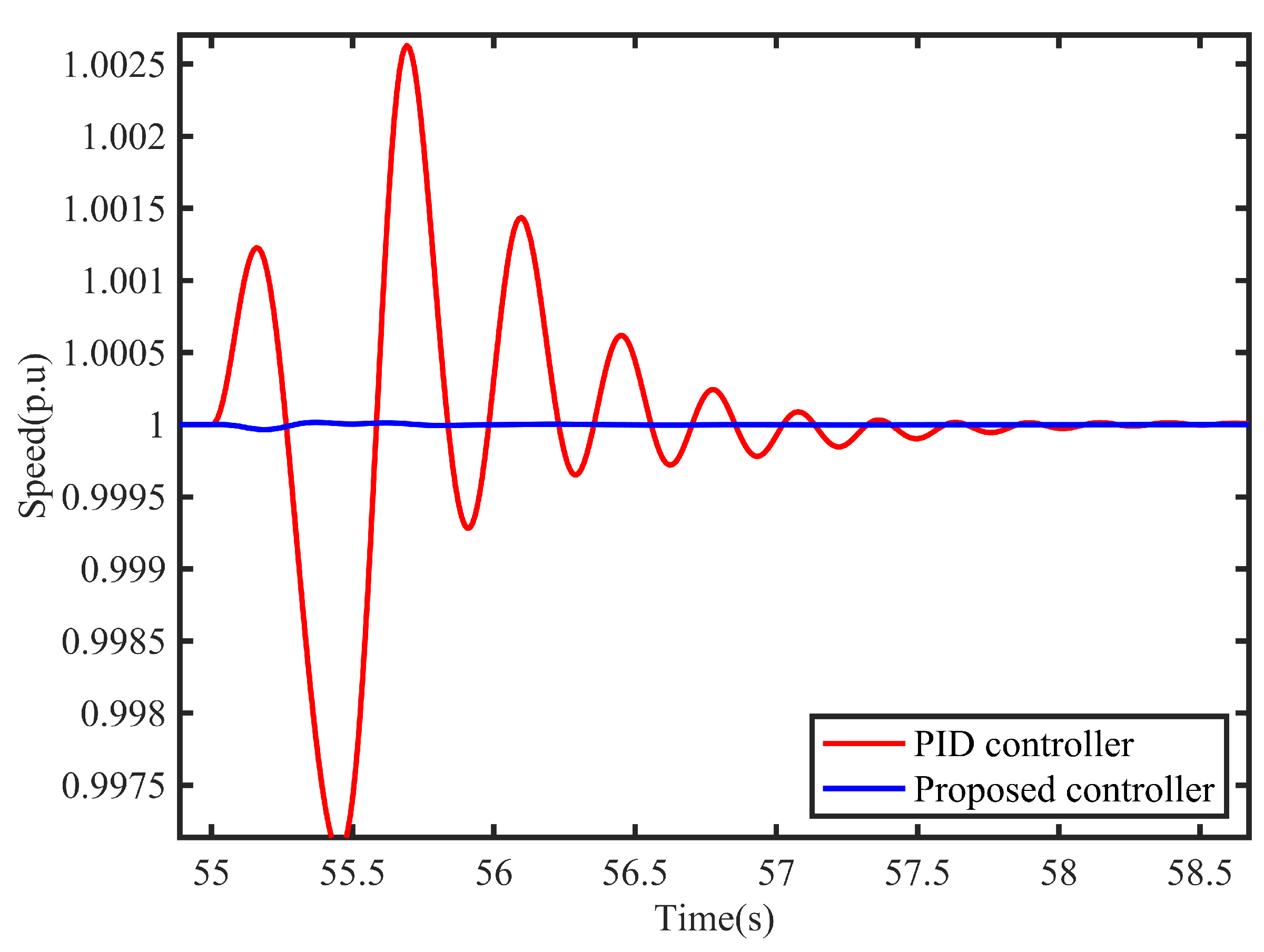

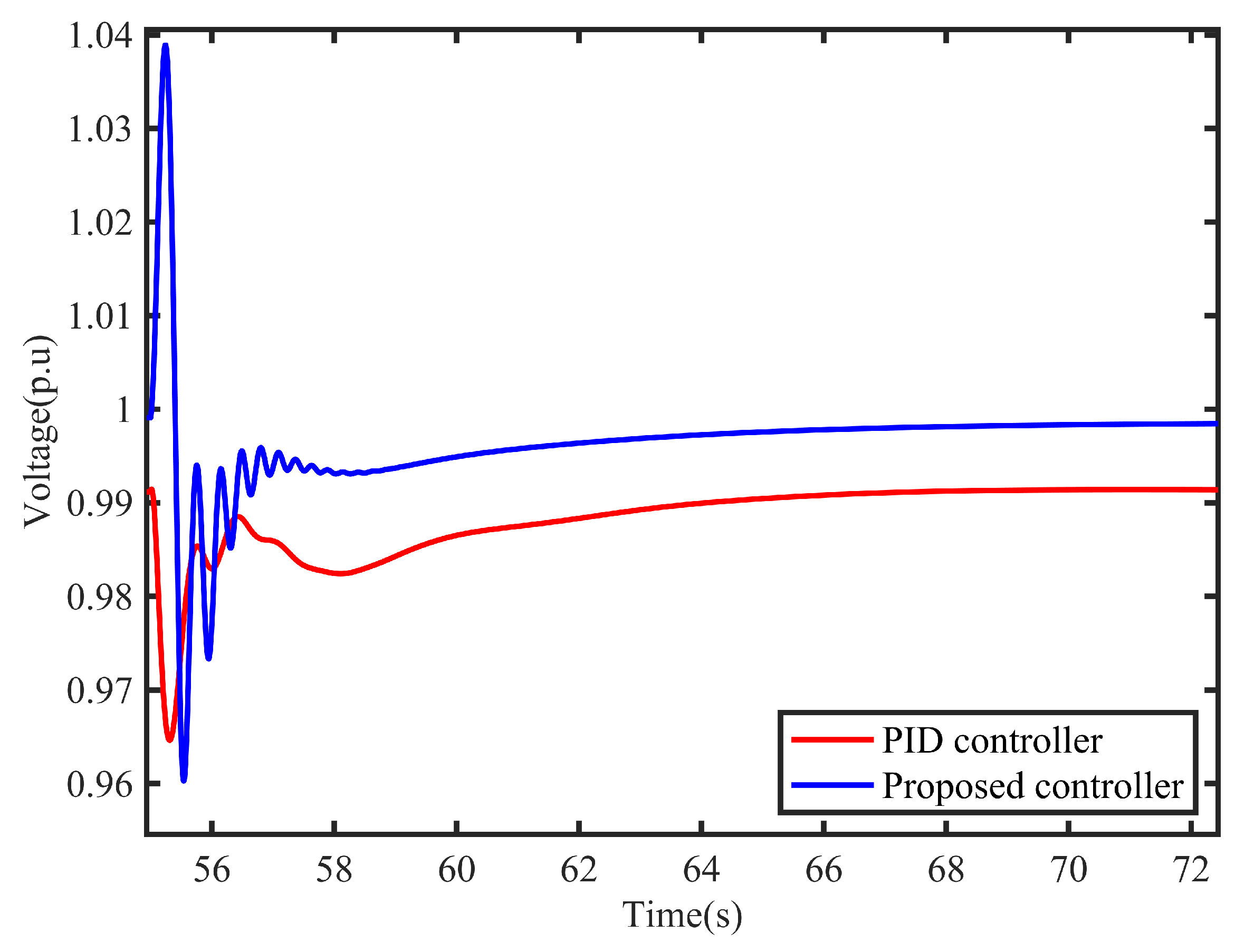

- The proposed method effectively suppresses frequency and voltage oscillations under various load disturbances and uncertainties;

- -

- Excellent damping efficiency, especially low overshoot, steady-state error, and settling time.

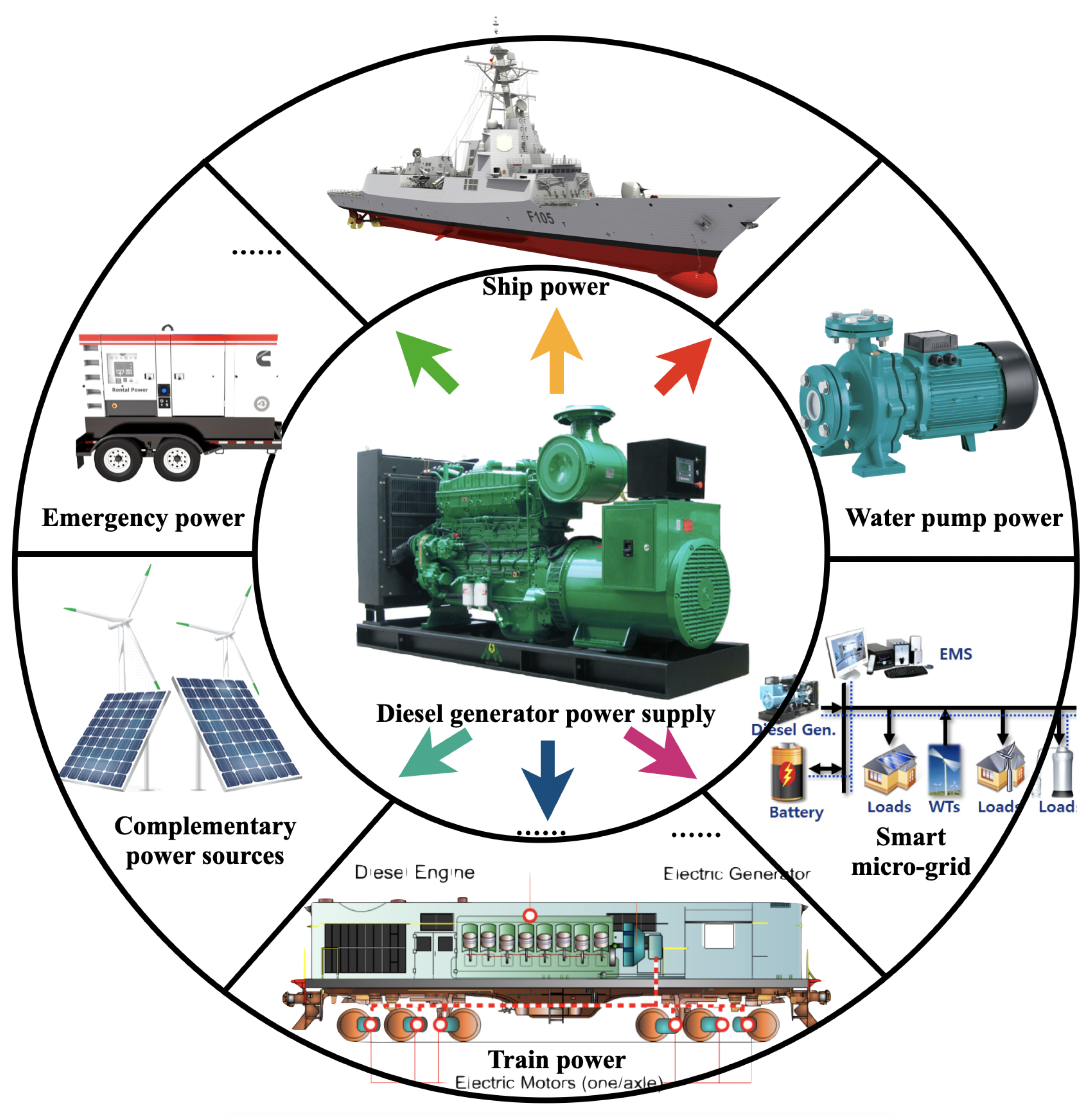

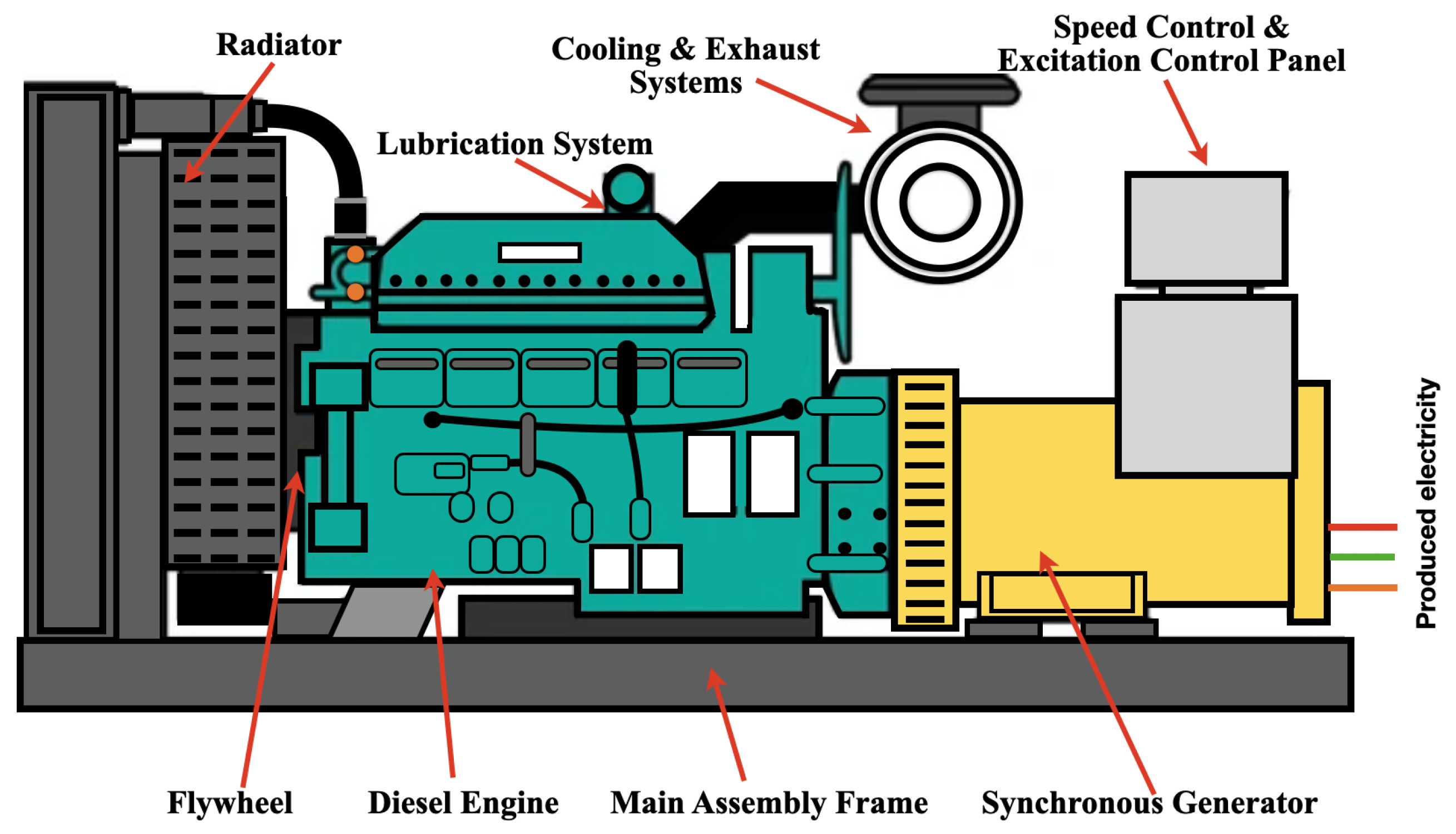

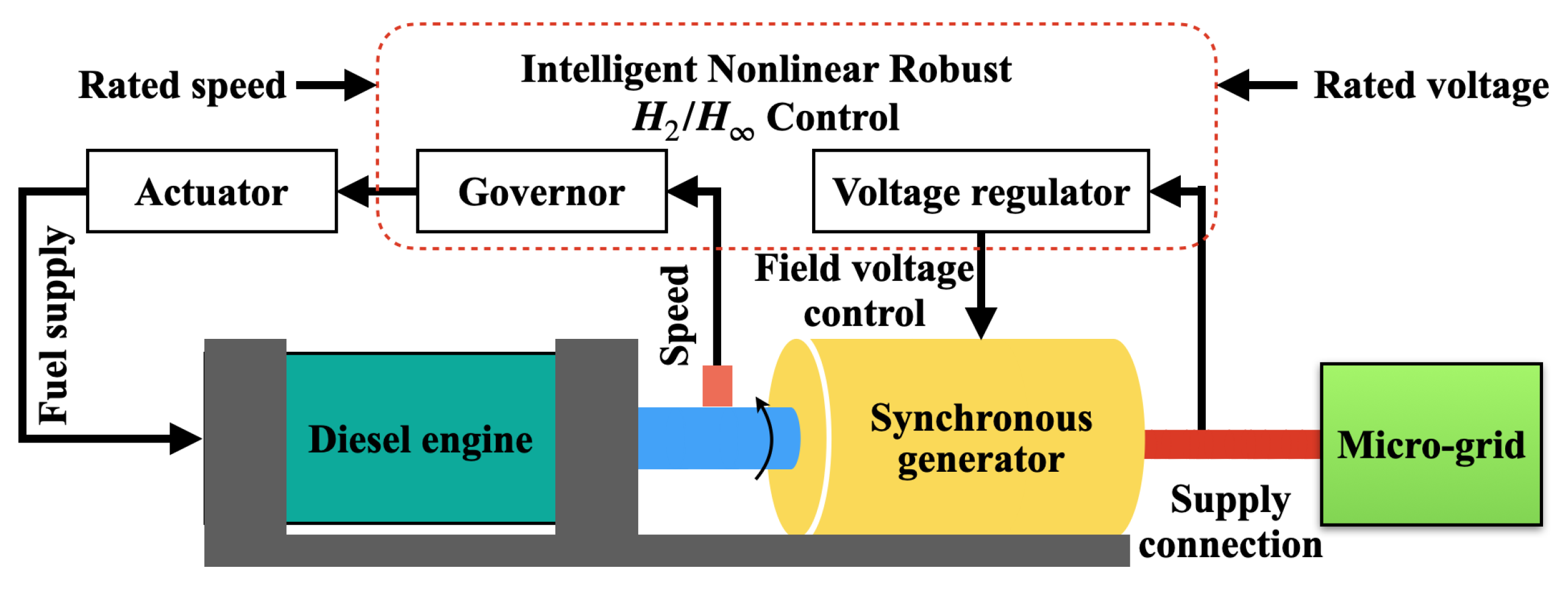

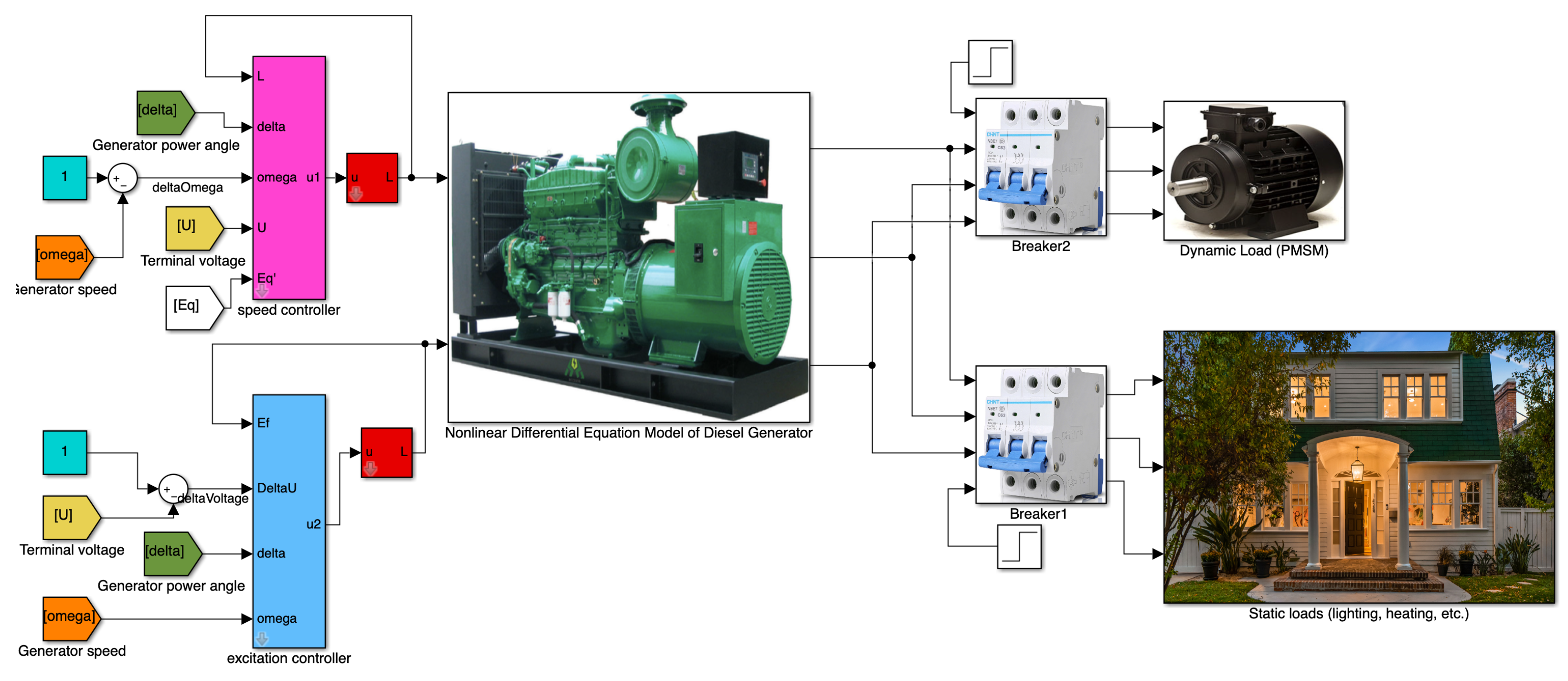

2. Modeling of diesel generator and its loads

2.1. Modeling of speed control part

2.2. Modeling of excitation control part

3. Design of nonliear synthetic controller

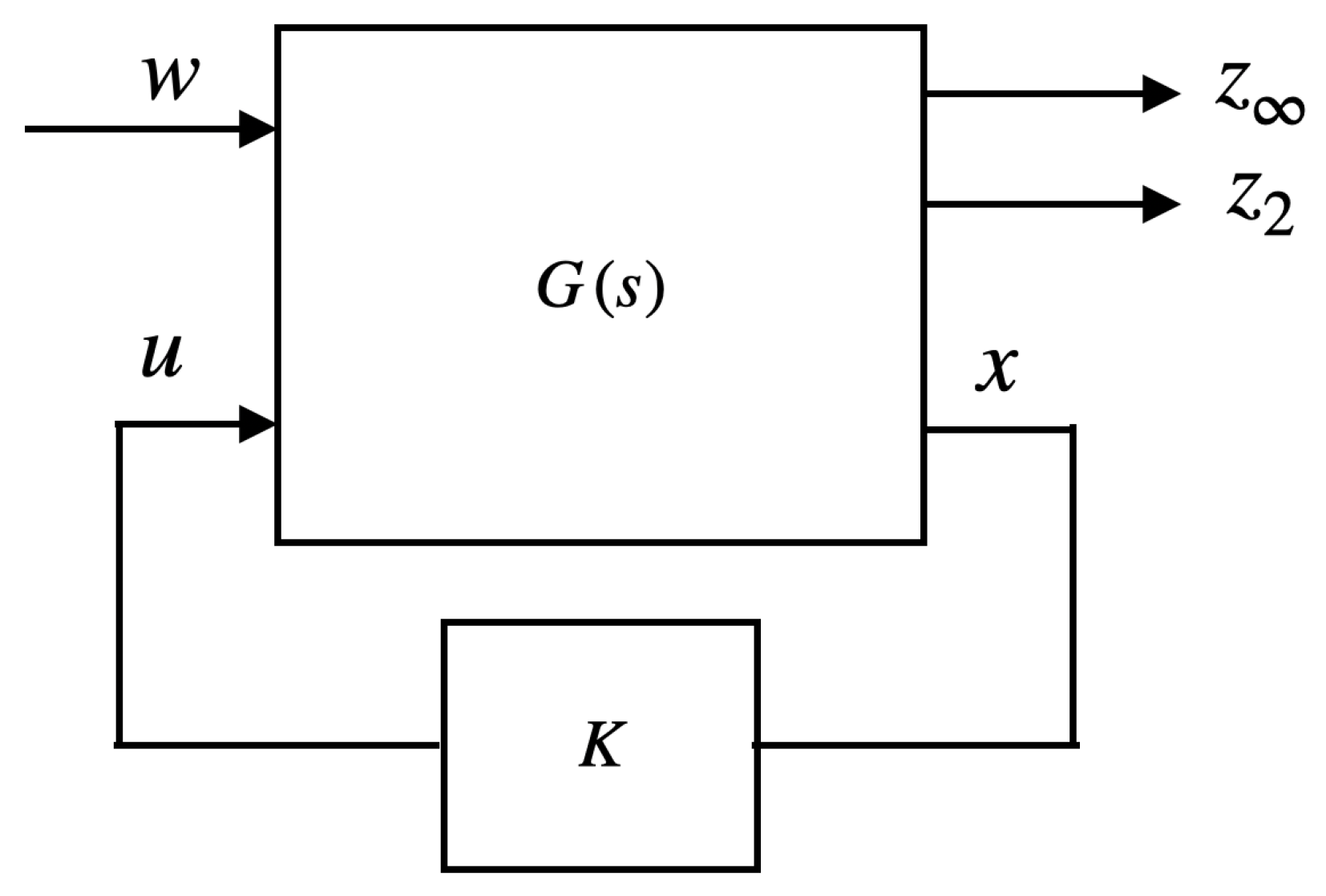

3.1. Multi-objective state-feedback theory

- -

- Keep the RMS gain ( norm) of below a certain specified value ;

- -

- Maintain the norm (LQG cost) of below a certain specified value ;

- -

- Minimized form of trade-off standard ;

- -

- Place the closed-loop pole in the designated area of the open left half-plane.

3.2. Design of speed controller

3.3. Design of excitation control controller

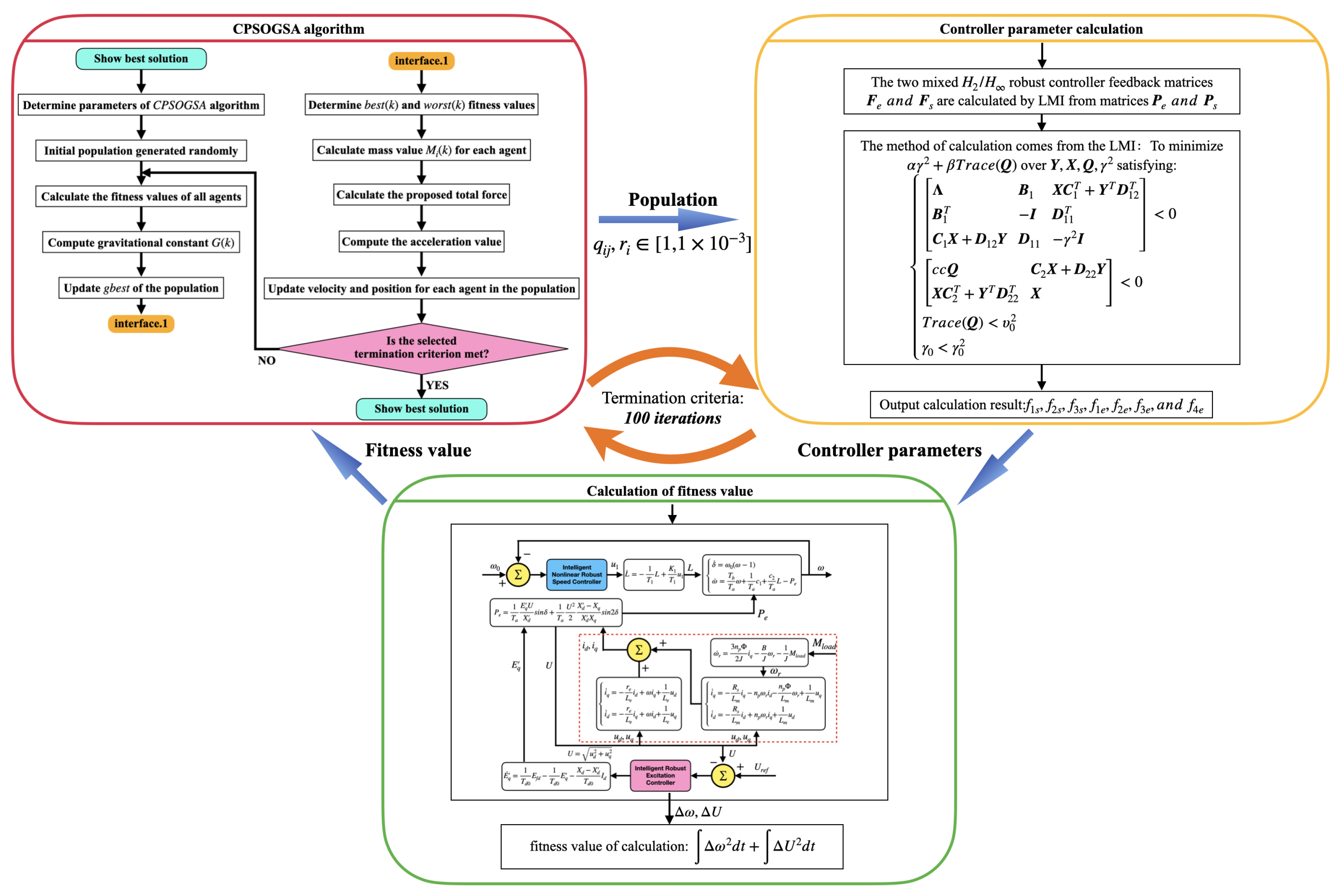

4. Artificial hybrid PSOGSA with chaotic maps approach and its application to multi-objective robust problem

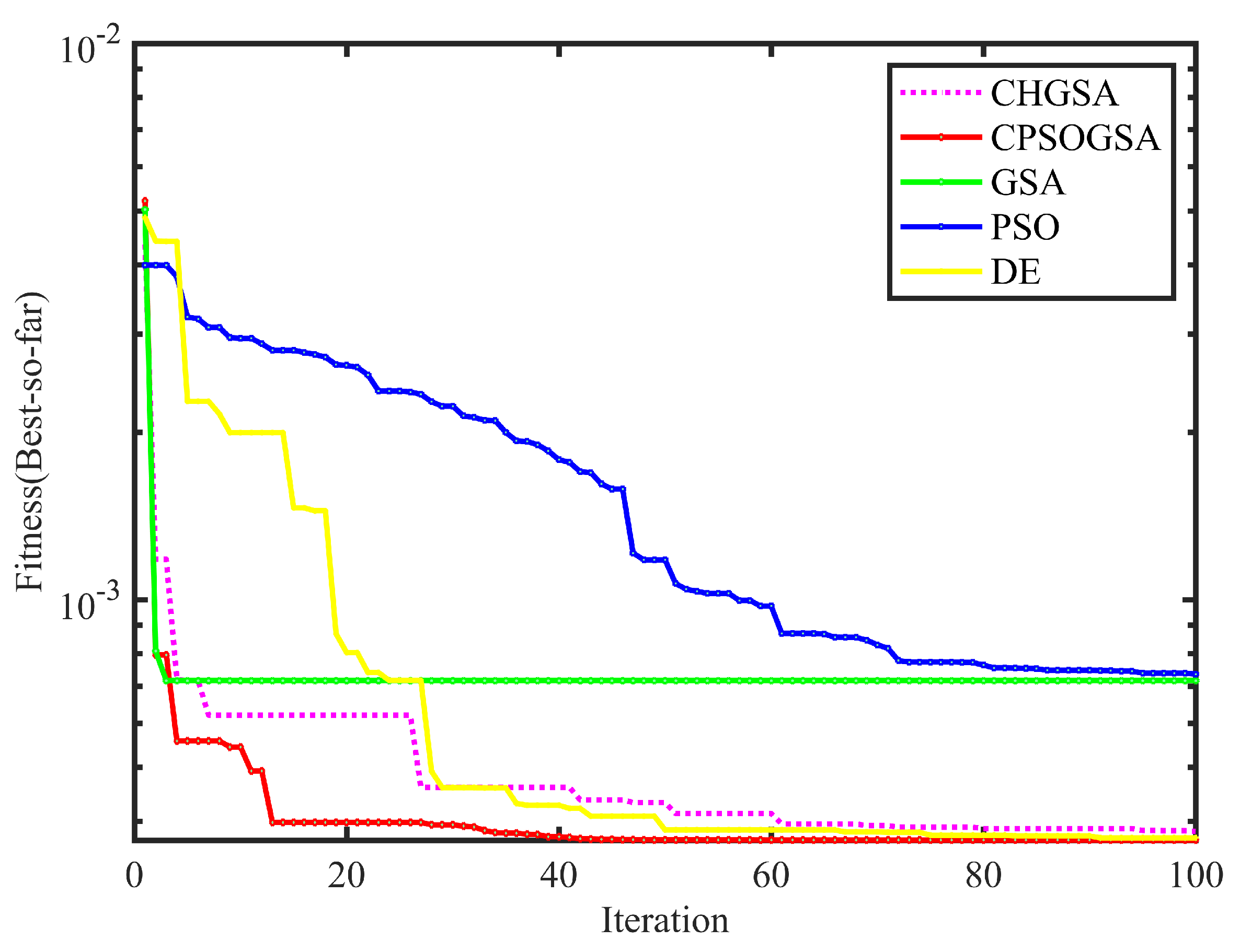

4.1. The proposed CPSOGSA algorithm

4.1.1. Particle swarm optimization

4.1.2. Gravitational search algorithm

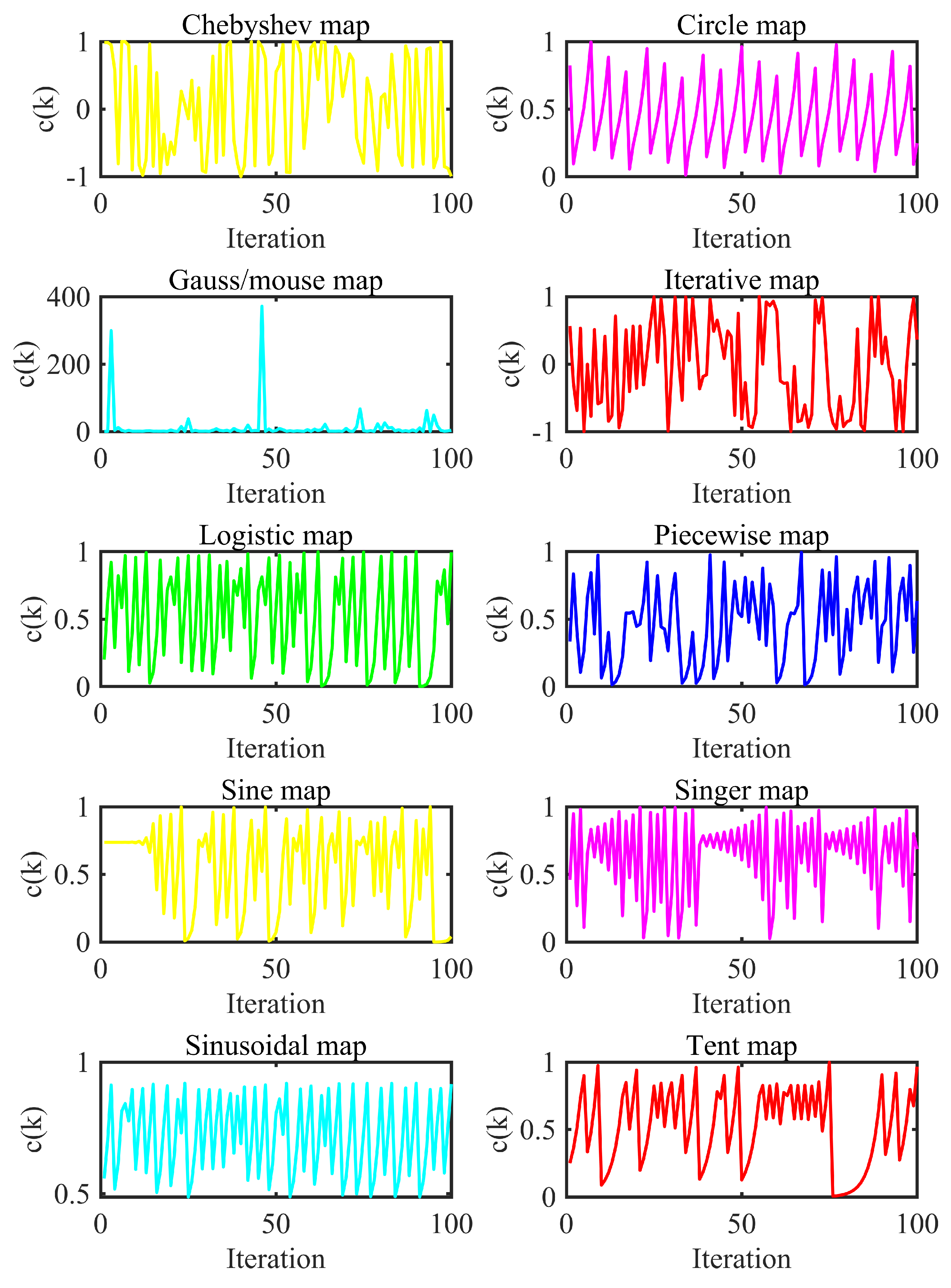

4.1.3. Modified hybrid particle swarm optimization and gravitational search algorithm with chaotic maps

4.2. Applying CPSOGSA to multi-objective robust problem

5. Numerical study

5.1. Simulation parameters

5.2. Simulation results

6. Conclusion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Muresan C I, Birs I, Ionescu C, et al. A review of recent developments in autotuning methods for fractional-order controllers[J]. Fractal and Fractional, 2022, 6(1): 37.

- Belboul Z, Toual B, Kouzou A, et al. Multiobjective optimization of a hybrid PV/Wind/Battery/Diesel generator system integrated in microgrid: A case study in Djelfa, Algeria[J]. Energies, 2022, 15(10): 3579.

- Amiryar M E, Pullen K R. Assessment of the carbon and cost savings of a combined diesel generator, solar photovoltaic, and flywheel energy storage islanded grid system[J]. Energies, 2019, 12(17): 3356.

- Hemeida A M, Omer A S, Bahaa-Eldin A M, et al. Multi-objective multi-verse optimization of renewable energy sources-based micro-grid system: Real case[J]. Ain Shams Engineering Journal, 2022, 13(1): 101543.

- Yu W, Li S, Zhu Y, et al. Management and distribution strategies for dynamic power in a ship’s micro-grid system based on photovoltaic cell, diesel generator, and lithium battery[J]. Energies, 2019, 12(23): 4505.

- Hasankhani A, Hakimi S M. Stochastic energy management of smart microgrid with intermittent renewable energy resources in electricity market[J]. Energy, 2021, 219: 119668.

- Hakimi S M, Hasankhani A, Shafie-khah M, et al. Stochastic planning of a multi-microgrid considering integration of renewable energy resources and real-time electricity market[J]. Applied Energy, 2021, 298: 117215.

- Hu J, Shan Y, Guerrero J M, et al. Model predictive control of microgrids–An overview[J]. Renewable and Sustainable Energy Reviews, 2021, 136: 110422.

- Marqusee J, Becker W, Ericson S. Resilience and economics of microgrids with PV, battery storage, and networked diesel generators[J]. Advances in Applied Energy, 2021, 3: 100049.

- Bouchekara H R E H, Javaid M S, Shaaban Y A, et al. Decomposition based multiobjective evolutionary algorithm for PV/Wind/Diesel Hybrid Microgrid System design considering load uncertainty[J]. Energy Reports, 2021, 7: 52-69.

- Guo Y, Lei X, Wang Q. Capacity coordination planning of isolated microgrid and battery swapping station based on the quantum behavior particle swarm optimization algorithm[J]. International Transactions on Electrical Energy Systems, 2021, 31(3): e12804.

- Rameshar V, Sharma G, Bokoro P N, et al. Frequency Support Studies of a Diesel–Wind Generation System Using Snake Optimizer-Oriented PID with UC and RFB[J]. Energies, 2023, 16(8): 3417.

- Ahmed M, Meegahapola L, Vahidnia A, et al. Stability and control aspects of microgrid architectures–a comprehensive review[J]. IEEE access, 2020, 8: 144730-144766.

- McGowan D J, Morrow D J, Fox B. Multiple input governor control for a diesel generating set[J]. IEEE transactions on Energy Conversion, 2008, 23(3): 851-859.

- Zou Y, Qian J, Zeng Y, et al. Optimized Robust Controller Design Based on CPSOGSA Optimization Algorithm and H-two/H-infty Weights Distribution Method for Load Frequency Control of Micro-Grid[J]. IEEE Access, 2021, 9: 162093-162107.

- Qian J, Guo Y, Zou Y, et al. Hamiltonian Modeling and Structure Modified Control of Diesel Engine[J]. Energies, 2021, 14(7): 2011.

- Latif A, Hussain S M S, Das D C, et al. Double stage controller optimization for load frequency stabilization in hybrid wind-ocean wave energy based maritime microgrid system[J]. Applied Energy, 2021, 282: 116171.

- Ali H, Magdy G, Xu D. A new optimal robust controller for frequency stability of interconnected hybrid microgrids considering non-inertia sources and uncertainties[J]. International Journal of Electrical Power & Energy Systems, 2021, 128: 106651.

- Valenzuela M A, Bentley J M, Lorenz R D. Evaluation of torsional oscillations in paper machine sections[J]. IEEE Transactions on Industry Applications, 2005, 41(2): 493-501.

- Al-Suod M M S, Oleksandr U. Optimization of the Speed Controller in Gas Diesel Device Including in the Autonomous Electric Power System[J]. WSEAS Transactions on Circuits and Systems, 2019, 18: 135-140.

- Iwanski G, Bigorajski Ł, Koczara W. Speed control with incremental algorithm of minimum fuel consumption tracking for variable speed diesel generator[J]. Energy Conversion and Management, 2018, 161: 182-192.

- Afzal Thoker Z, Ahmad Lone S. Dynamic performance improvement of wind-diesel power system through robust sliding mode control of hybrid energy storage system[J]. Wind Engineering, 2022, 46(4): 1065-1079.

- Wang R, Li X, Ahmed Q, et al. Speed control of a marine engine using predictive functional control based PID controller[C]//2018 Annual American control conference (ACC). IEEE, 2018: 3908-3914.

- Tran T A. The optimization of marine diesel engine rotational speed control process by fuzzy logic control based on particle swarm optimization algorithm[J]. Future Internet, 2018, 10(10): 99.

- Tran T A, Haidara G. A research on marine diesel engine speed controller by fuzzy logic control theory based on experimental investigation[J]. world, 2019, 17: 19.

- Ding Y, Shi W, Zhang Y, et al. Design of Neural Network Speed Controller for Marine Diesel Generator Set[J]. International Core Journal of Engineering, 2021, 7(6): 586-592.

- Asgari S, Suratgar A A, Kazemi M G. Feedforward fractional order PID load frequency control of microgrid using harmony search algorithm[J]. Iranian Journal of Science and Technology, Transactions of Electrical Engineering, 2021, 45(4): 1369-1381.

- He Y, Fan A, Wang Z, et al. Two-phase energy efficiency optimisation for ships using parallel hybrid electric propulsion system[J]. Ocean engineering, 2021, 238: 109733.

- Li J. Design and application of modern synchronous generator excitation systems[M]. John Wiley & Sons, 2019.

- Chakraborty C, Basak S, Rao Y T. Synchronous generator with embedded brushless synchronous exciter[J]. IEEE Transactions on Energy Conversion, 2019, 34(3): 1242-1254.

- Krishnamurthy S, Jahns T M, Lasseter R H. The operation of diesel gensets in a CERTS microgrid[C]//2008 IEEE Power and Energy Society General Meeting-Conversion and Delivery of Electrical Energy in the 21st Century. IEEE, 2008: 1-8.

- Gayatri M T L, Parimi A M, Kumar A V P. A review of reactive power compensation techniques in microgrids[J]. Renewable and Sustainable Energy Reviews, 2018, 81: 1030-1036.

- Patel R, Hafiz F, Swain A, et al. Nonlinear excitation control of diesel generator: A command filter backstepping approach[J]. IEEE Transactions on Industrial Informatics, 2020, 17(7): 4809-4817.

- Zhao P, Yao W, Wen J, et al. Improved synergetic excitation control for transient stability enhancement and voltage regulation of power systems[J]. International Journal of Electrical Power & Energy Systems, 2015, 68: 44-51.

- Ramakrishnan K. Delay-dependent stability of networked generator-excitation control systems: An LMI based approach[J]. IFAC-PapersOnLine, 2016, 49(1): 431-436.

- Berkoune K, Sedrine E B, Vido L, et al. Robust control of hybrid excitation synchronous generator for wind applications[J]. Mathematics and Computers in Simulation, 2017, 131: 55-75.

- Pramanik M A H, Roy T K, Ghosh S K, et al. Robust partial feedback linearizing excitation controller design for higher-order synchronous generator in smib systems to improve the transient stability[C]//2021 IEEE Texas Power and Energy Conference (TPEC). IEEE, 2021: 1-6.

- Orchi T F, Roy T K, Mahmud M A, et al. Feedback linearizing model predictive excitation controller design for multimachine power systems[J]. IEEE Access, 2017, 6: 2310-2319.

- Roy T K, Mahmud M A, Shen W, et al. Robust nonlinear adaptive backstepping excitation controller design for rejecting external disturbances in multimachine power systems[J]. International Journal of Electrical Power & Energy Systems, 2017, 84: 76-86.

- Mobarra M, Rezkallah M, Ilinca A. Variable speed diesel generators: Performance and characteristic comparison[J]. Energies, 2022, 15(2): 592.

- Mobarra M, Tremblay B, Rezkallah M, et al. Advanced control of a compensator motor driving a variable speed diesel generator with rotating stator[J]. Energies, 2020, 13(9): 2224.

- Huang M L, Song K M, Wei Z D. Nonlinear H-two/H-infinity synthetic controller for diesel-generator set[J]. Control Theory & Applications, 2011, 28(6): 885-893.

- Issa M, Ibrahim H, Lepage R, et al. A review and comparison on recent optimization methodologies for diesel engines and diesel power generators[J]. Journal of Power and Energy Engineering, 2019, 7(06): 31.

- Ramstedt M. Cylinder-by-Cylinder Diesel Engine Modelling: A Torque-based Approach[J]. 2004.

- Zhang Y, Zhang X, Qian T, et al. Modeling and simulation of a passive variable inertia flywheel for diesel generator[J]. Energy Reports, 2020, 6: 58-68.

- Huang M, Wang C. Nonlinear mathematical model of diesel generator sets in marine power stations[J]. Journal of Harbin Engineering University,2006(01):15-19+47.

- Huang M,Wang C. Nonlinear H-infty governor for diesel engines in marine power stations[J]. Journal of Electrical Engineering Technology,2006(10):56-61.

- Huang M.L.,Wei Z.D.,Song K.M.. Synchronous generator state feedback H-infty regulator for marine power plants[J]. Journal of Power Systems and Automation,2011,23(04):15-20.

- Zou Y, Hu W, Xiao Z, et al. Design of intelligent nonlinear robust controller for hydro-turbine governing system based on state-dynamic-measurement hybrid feedback linearization method[J]. Renewable Energy, 2023.

- Dao F, Zou Y, Zeng Y, et al. An intelligent CPSOGSA-based mixed H-two/H-infty robust controller for the multi-hydro-turbine governing system with sharing common penstock[J]. Renewable Energy, 2023.

- Li L, Qian J, Zou Y, et al. Optimized Takagi–Sugeno Fuzzy Mixed H-two/H-infty Robust Controller Design Based on CPSOGSA Optimization Algorithm for Hydraulic Turbine Governing System[J]. Energies, 2022, 15(13): 4771.

- Duman S, Li J, Wu L, et al. Optimal power flow with stochastic wind power and FACTS devices: a modified hybrid PSOGSA with chaotic maps approach[J]. Neural Computing and Applications, 2020, 32: 8463-8492.

- Rather S A, Bala P S. Constriction coefficient based particle swarm optimization and gravitational search algorithm for multilevel image thresholding[J]. Expert Systems, 2021, 38(7): e12717.

- Rather S A, Bala P S. A hybrid constriction coefficient-based particle swarm optimization and gravitational search algorithm for training multi-layer perceptron[J]. International Journal of Intelligent Computing and Cybernetics, 2020, 13(2): 129-165.

- Rather S A, Bala P S. Swarm-based chaotic gravitational search algorithm for solving mechanical engineering design problems[J]. World Journal of Engineering, 2020.

- Rather S A, Bala P S. Hybridization of constriction coefficient-based particle swarm optimization and chaotic gravitational search algorithm for solving engineering design problems[J]. Applied Soft Computing and Communication Networks: Proceedings of ACN 2019, 2020: 95-115.

| 1.136 | -0.492 | 1.515 | -0.215 | 2.053 | 0.213 |

| R | |||||

| 1.003 | 0.050 | 0.011 | 2.200 | 0.200 | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).