Submitted:

28 May 2023

Posted:

30 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Motivation

1.2. Literature Review

1.3. Scientific Contributions

2. System Configuration and Its Preferences

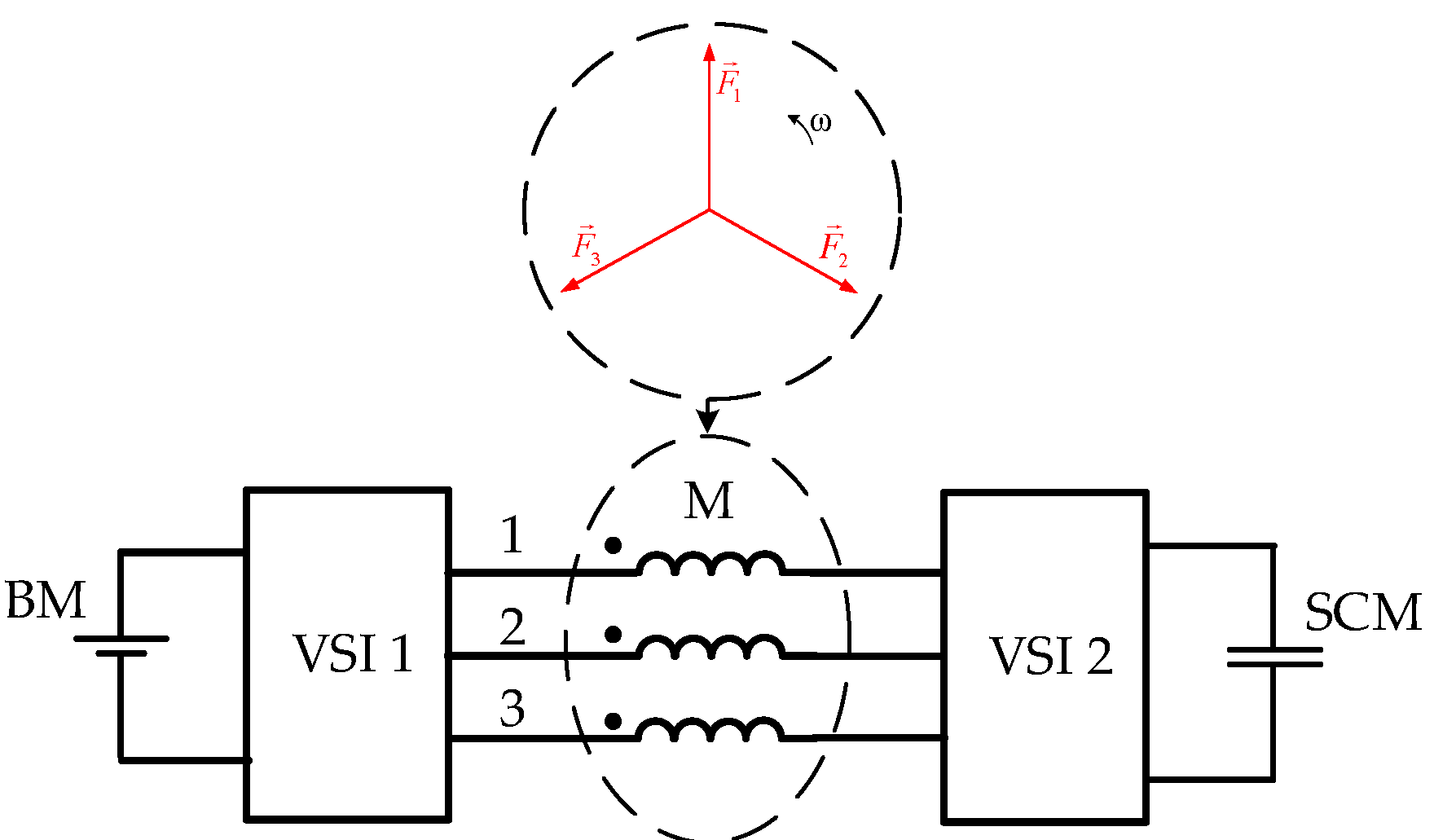

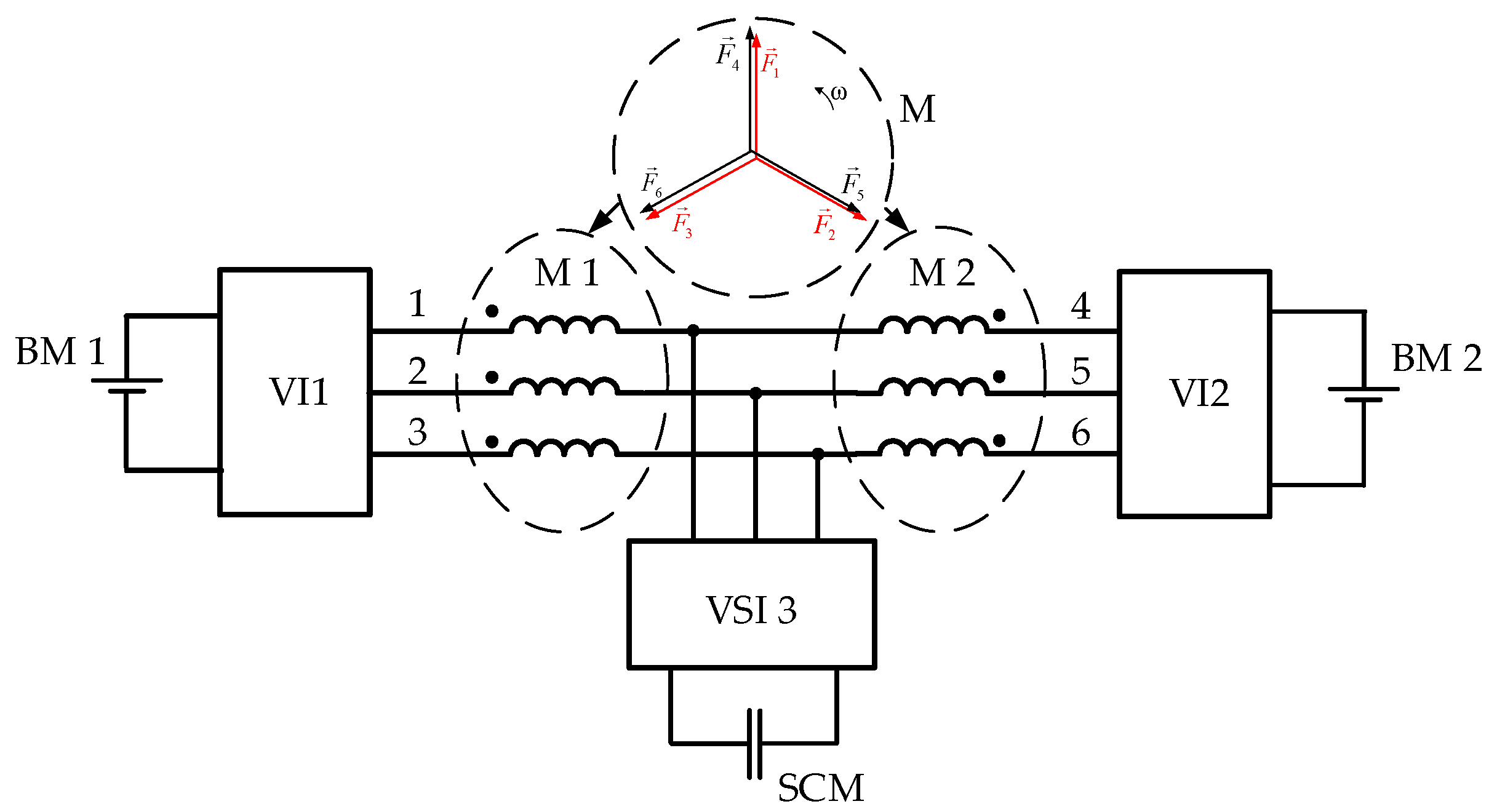

2.1. Brief Review of Our Previous Studies

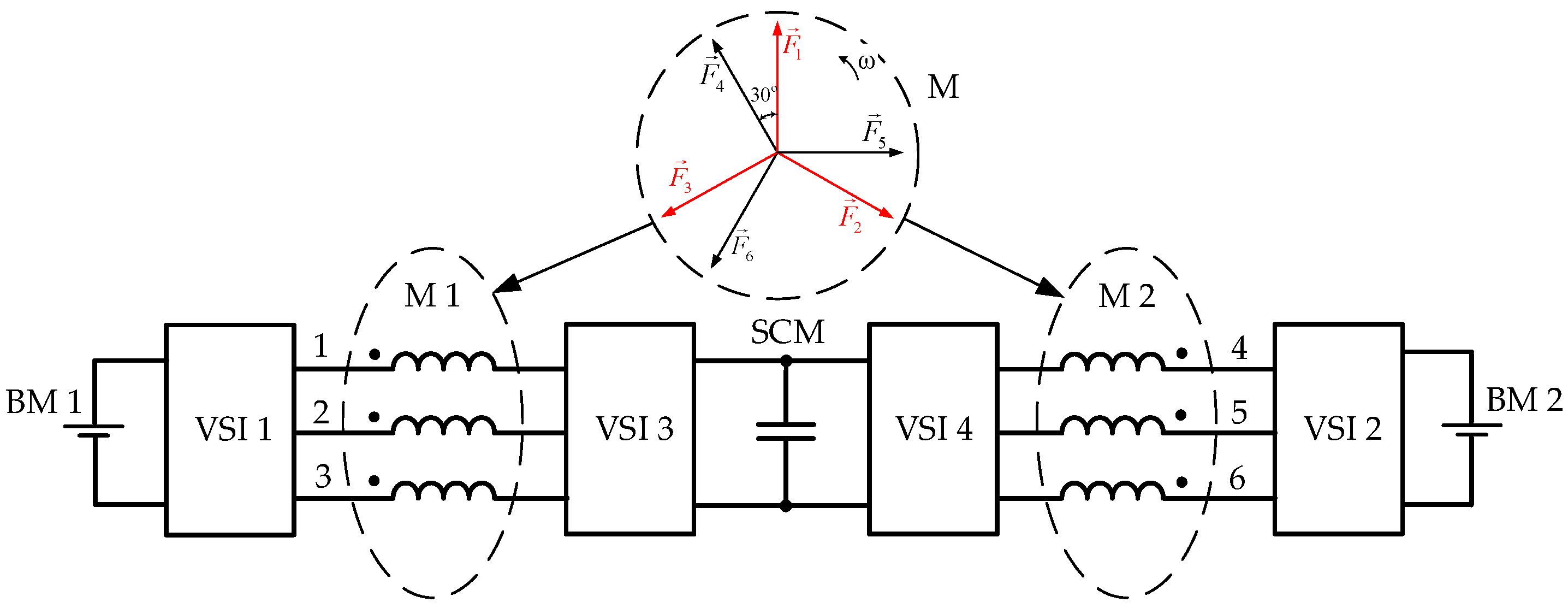

2.2. Proposed H–H Configuration of Modular Powertrain System

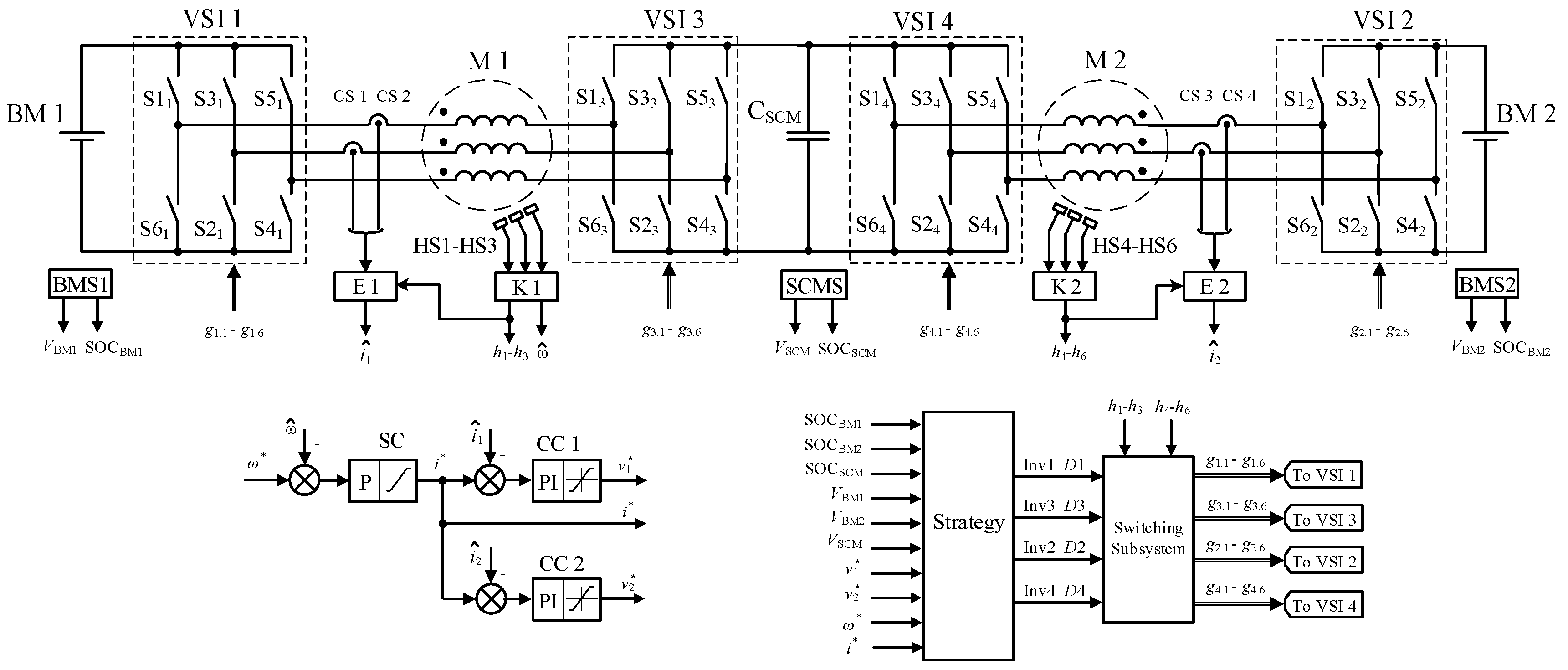

2.2. Description of Scheme of the Modular Powertrain of Н–Н configuration

3. Control System Development

3.1. Speed and Torque Control Subsystems

3.2. Switching Subsystem of the DTP BLDCM modules

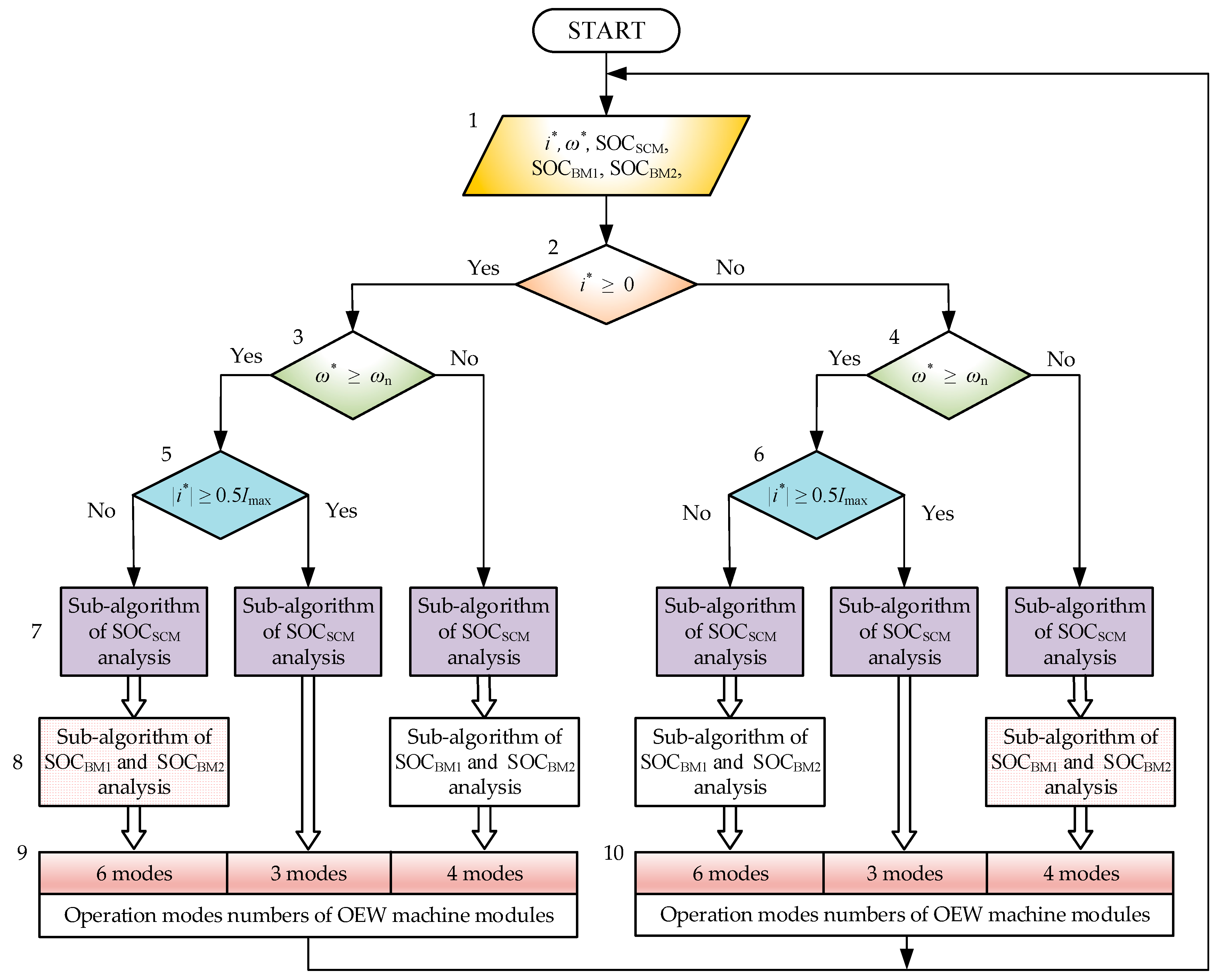

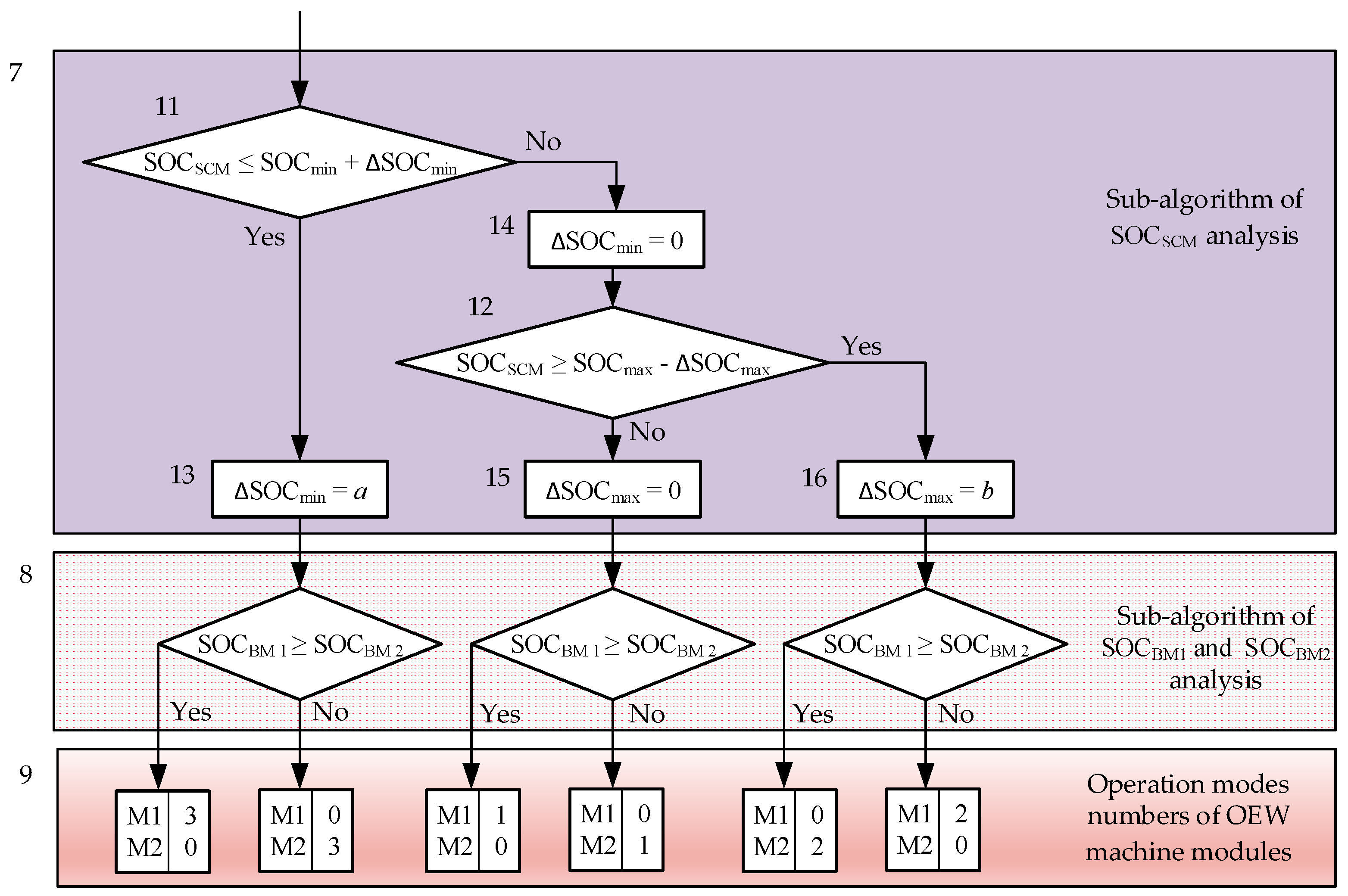

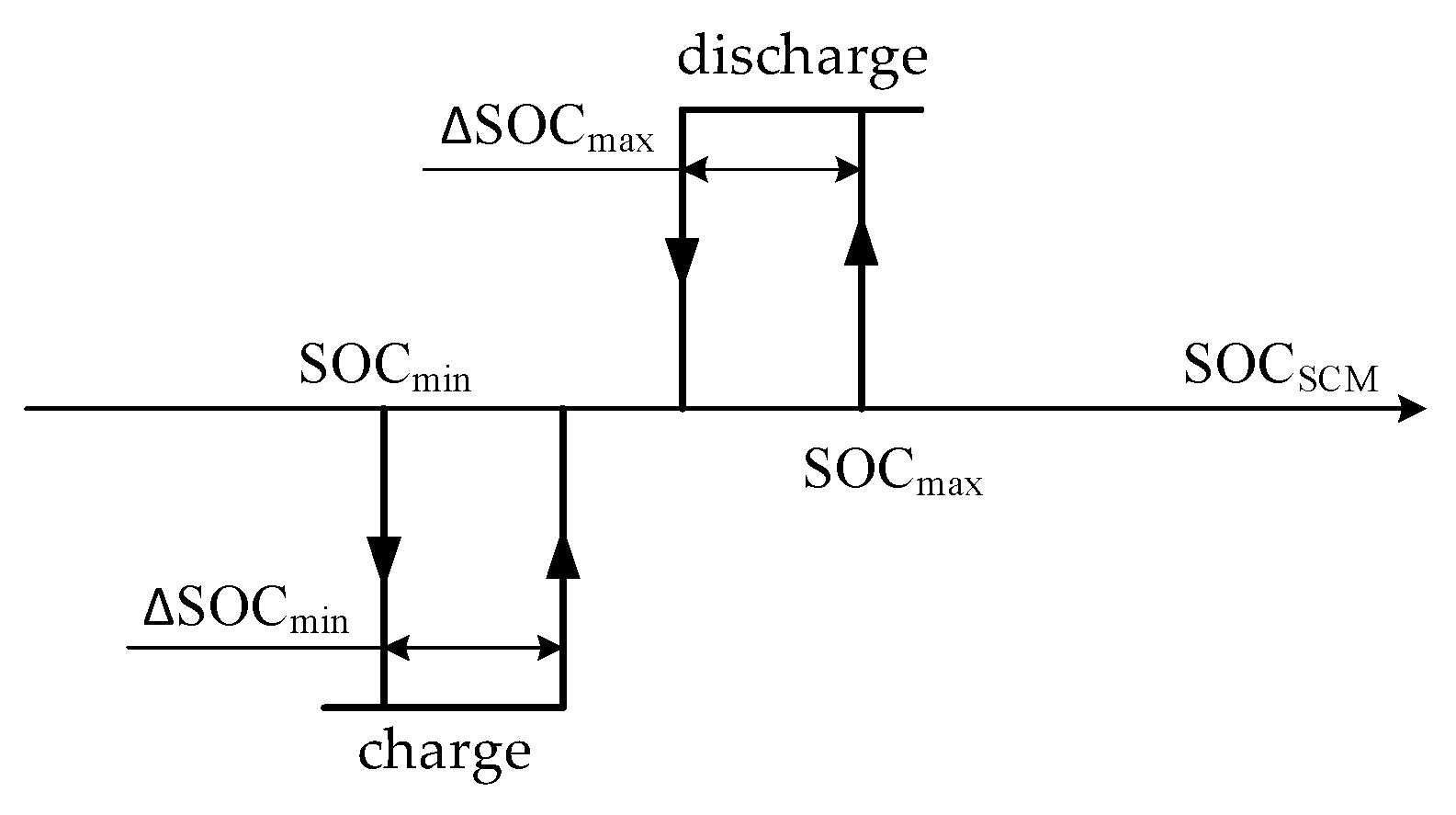

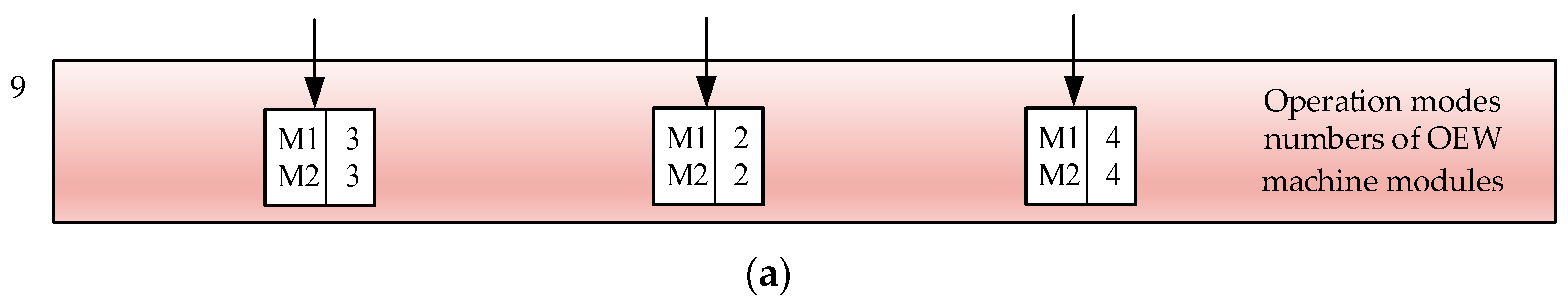

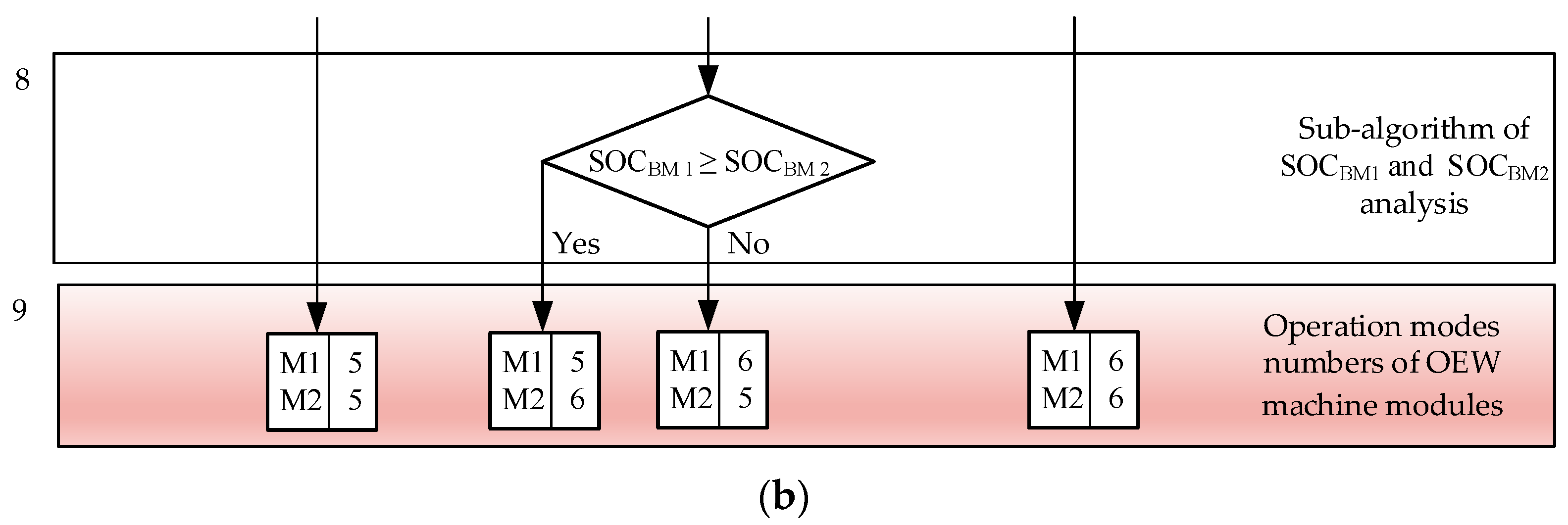

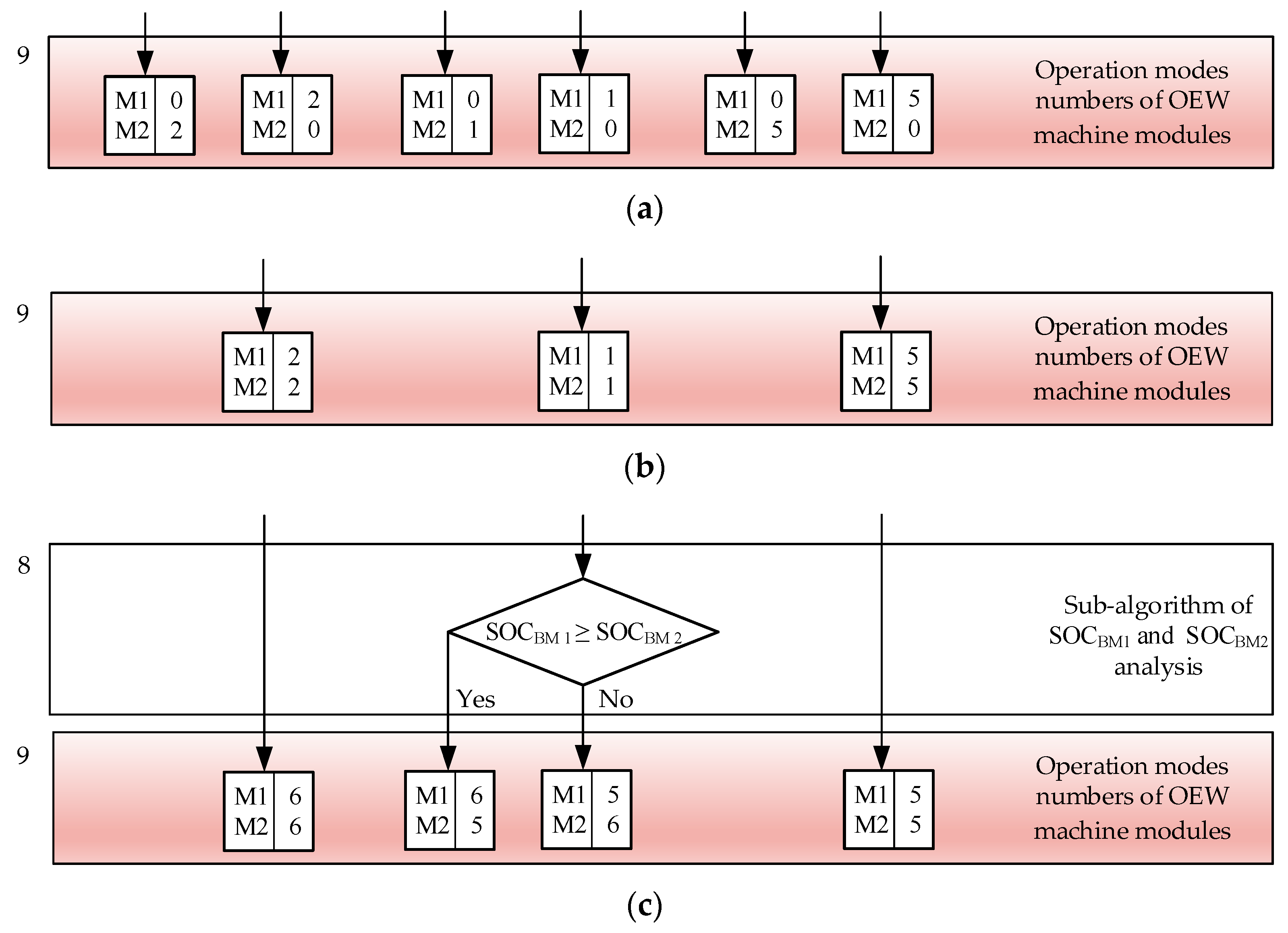

3.3.Operation Mode Control Subsystem and EMS (Strategy)

4. Simulation Results and Their Discussion

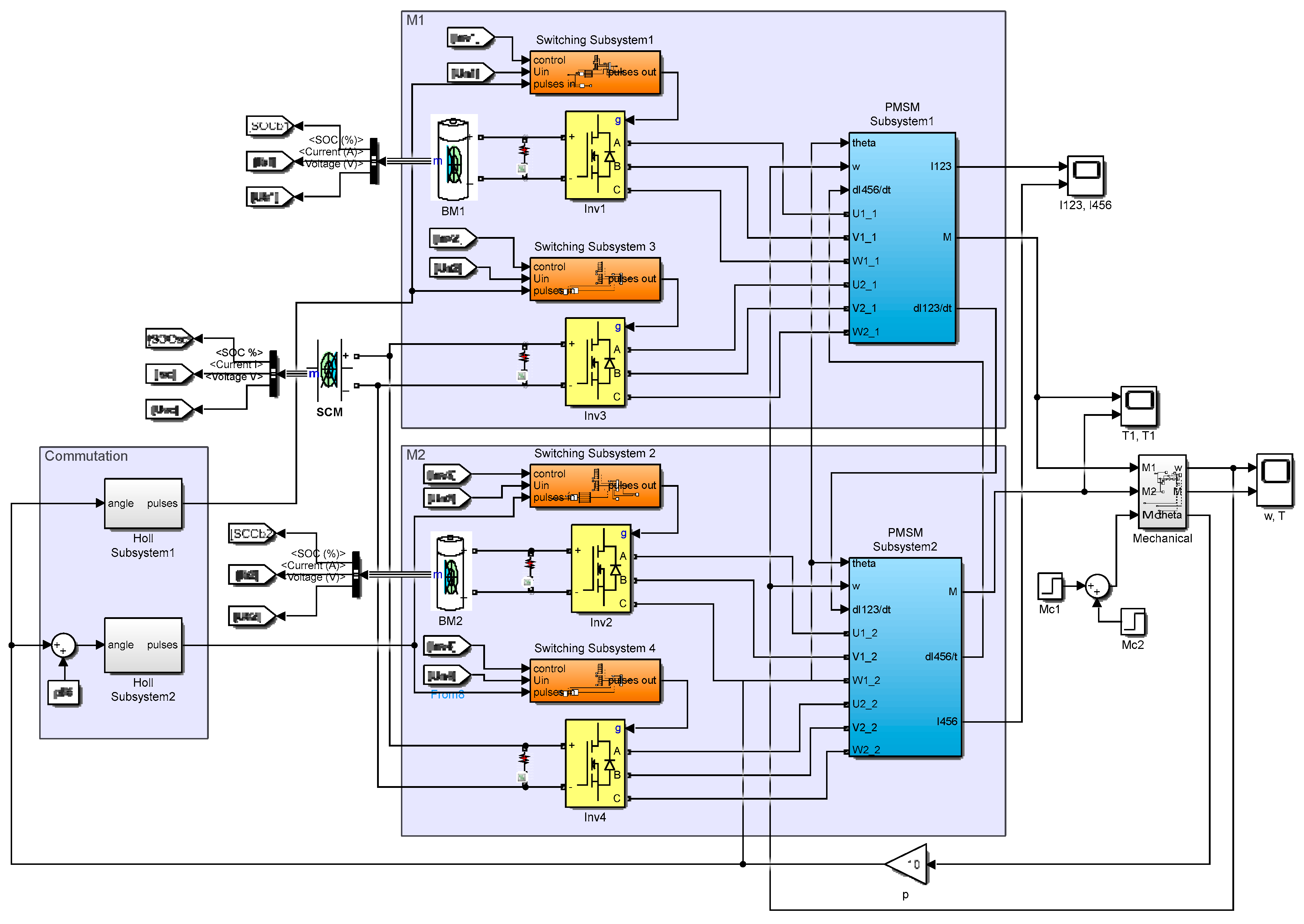

4.1. EV Powertrain Model Description

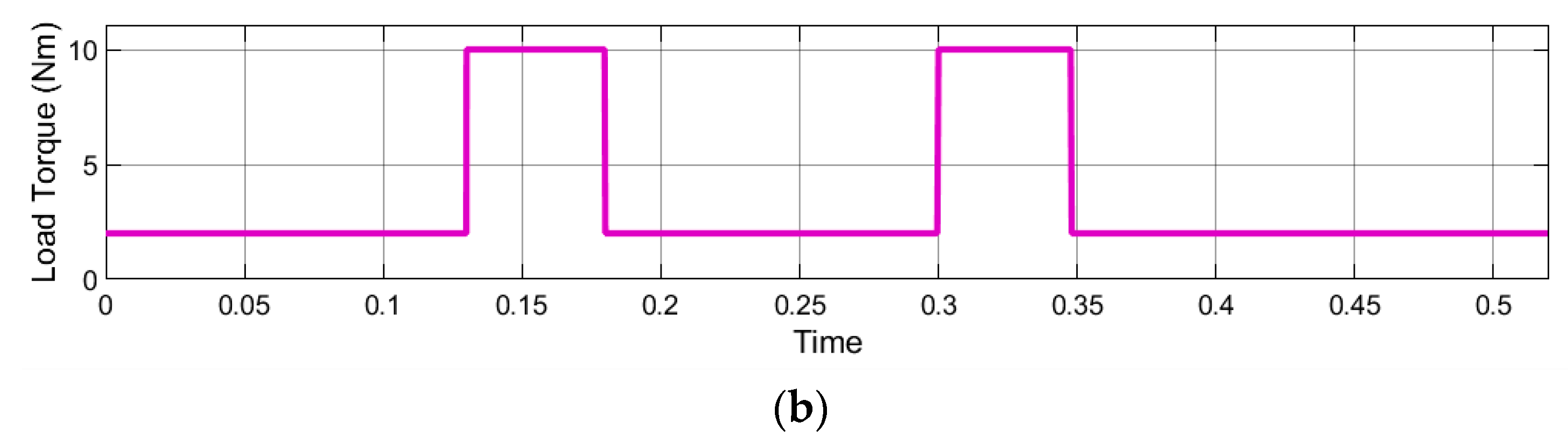

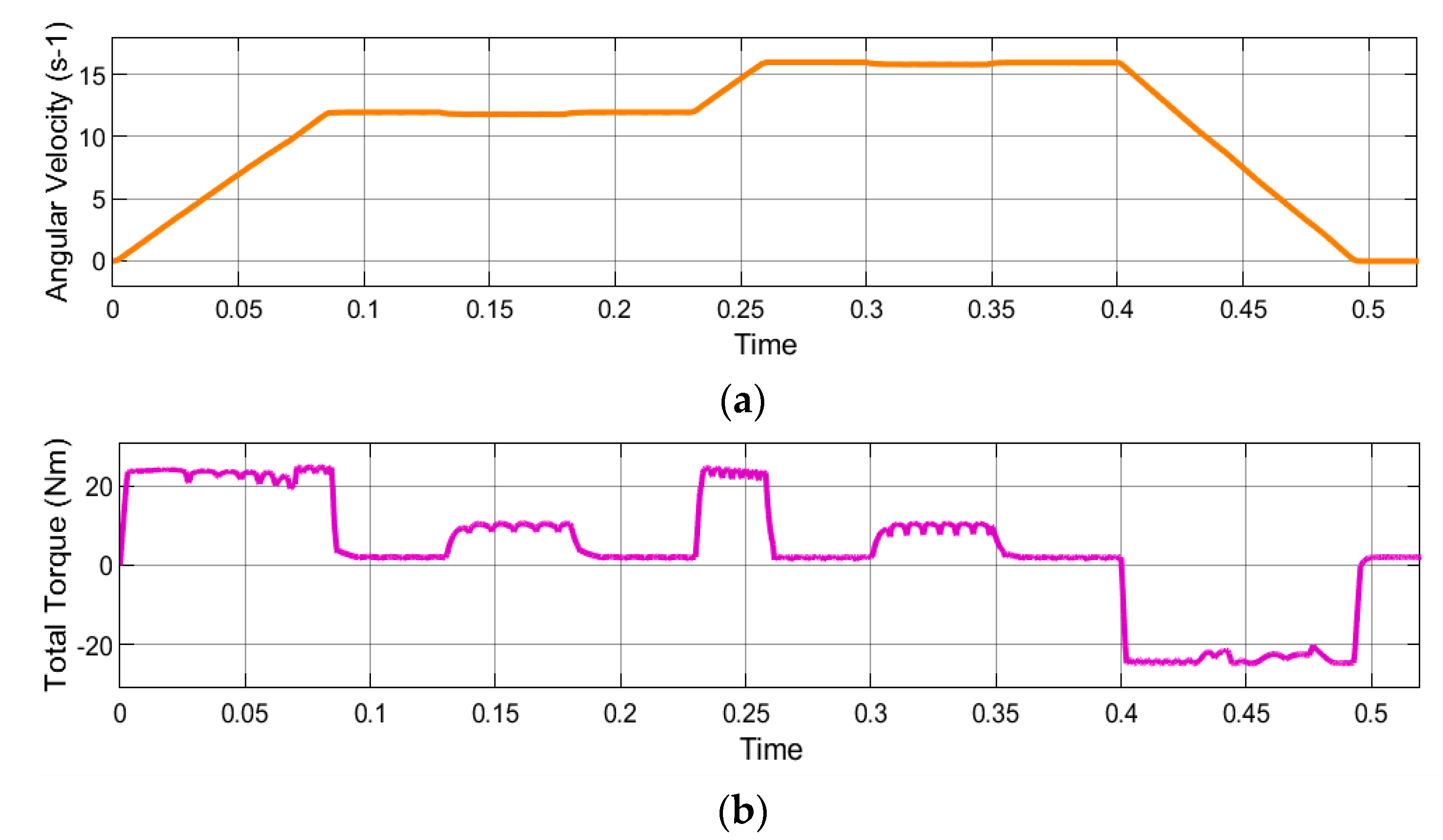

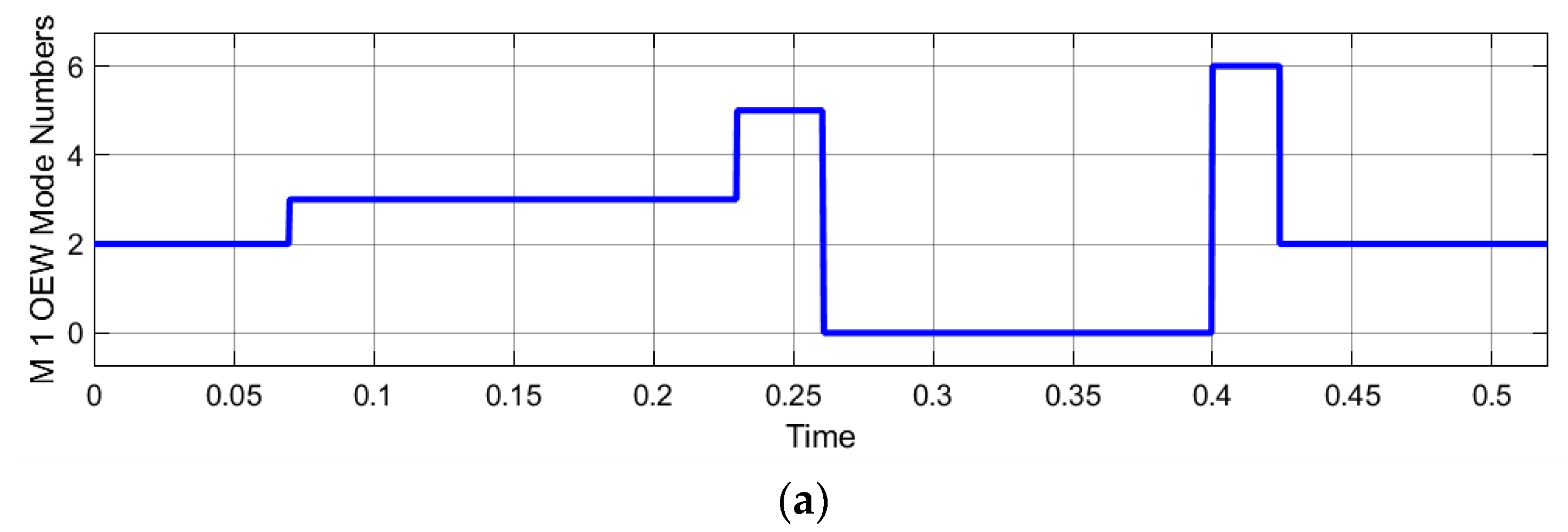

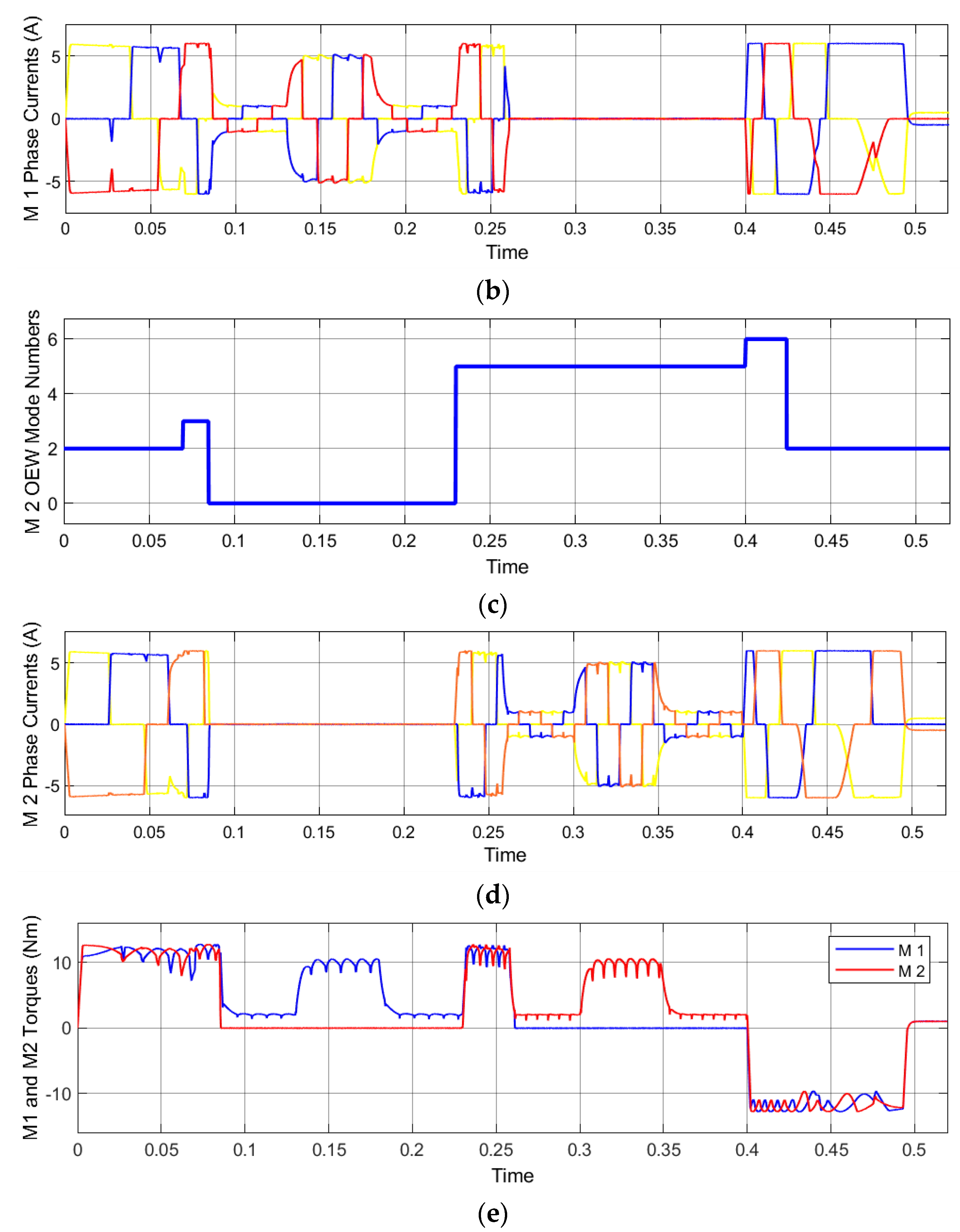

4.2. Simulation Results

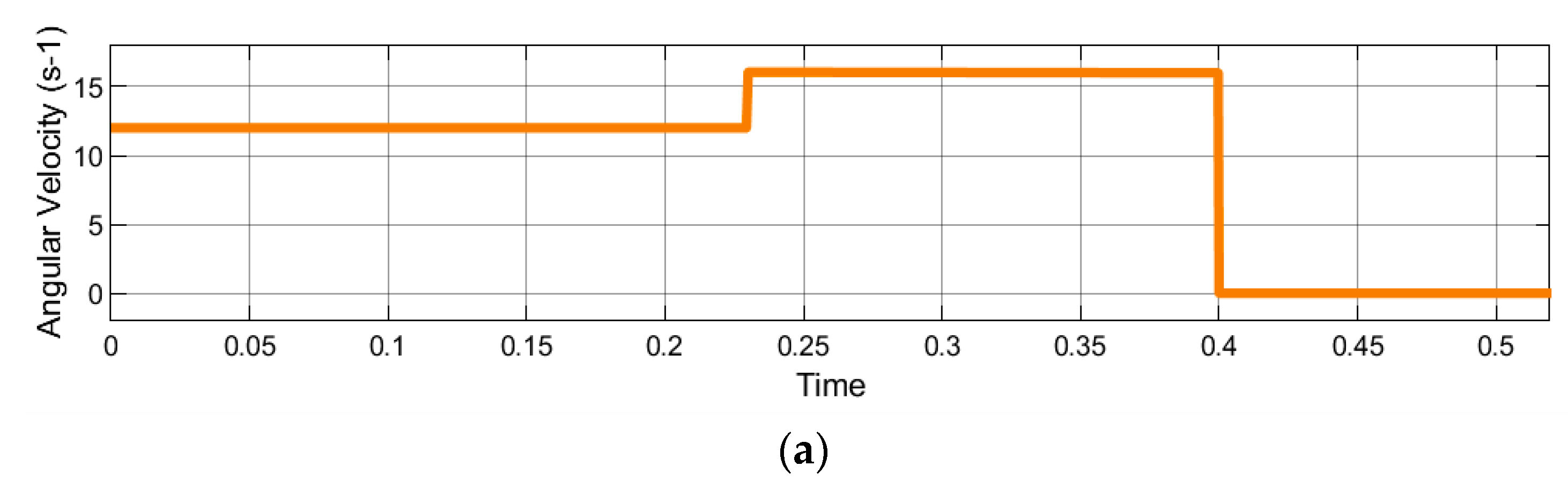

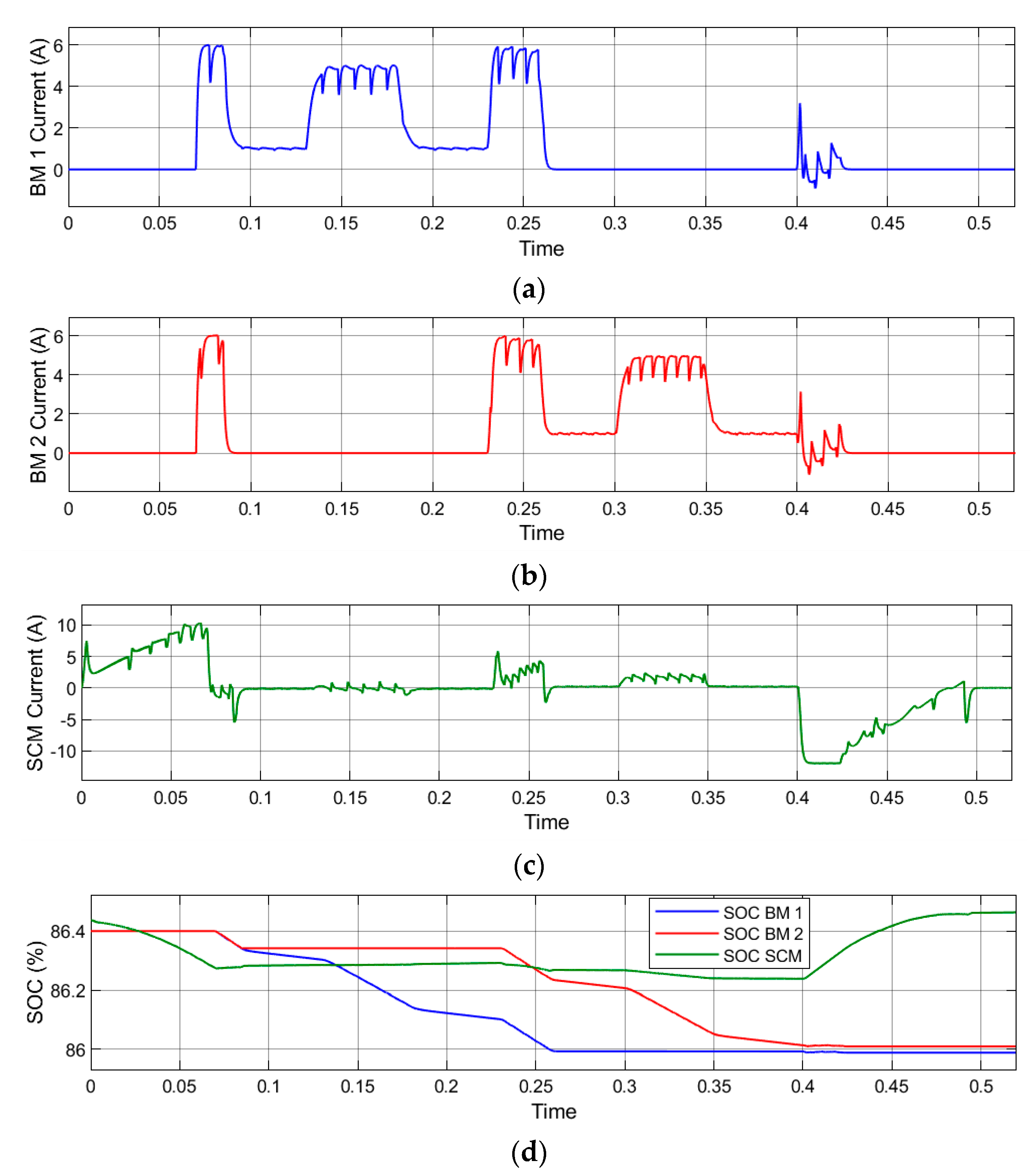

4.2. Results Discussion

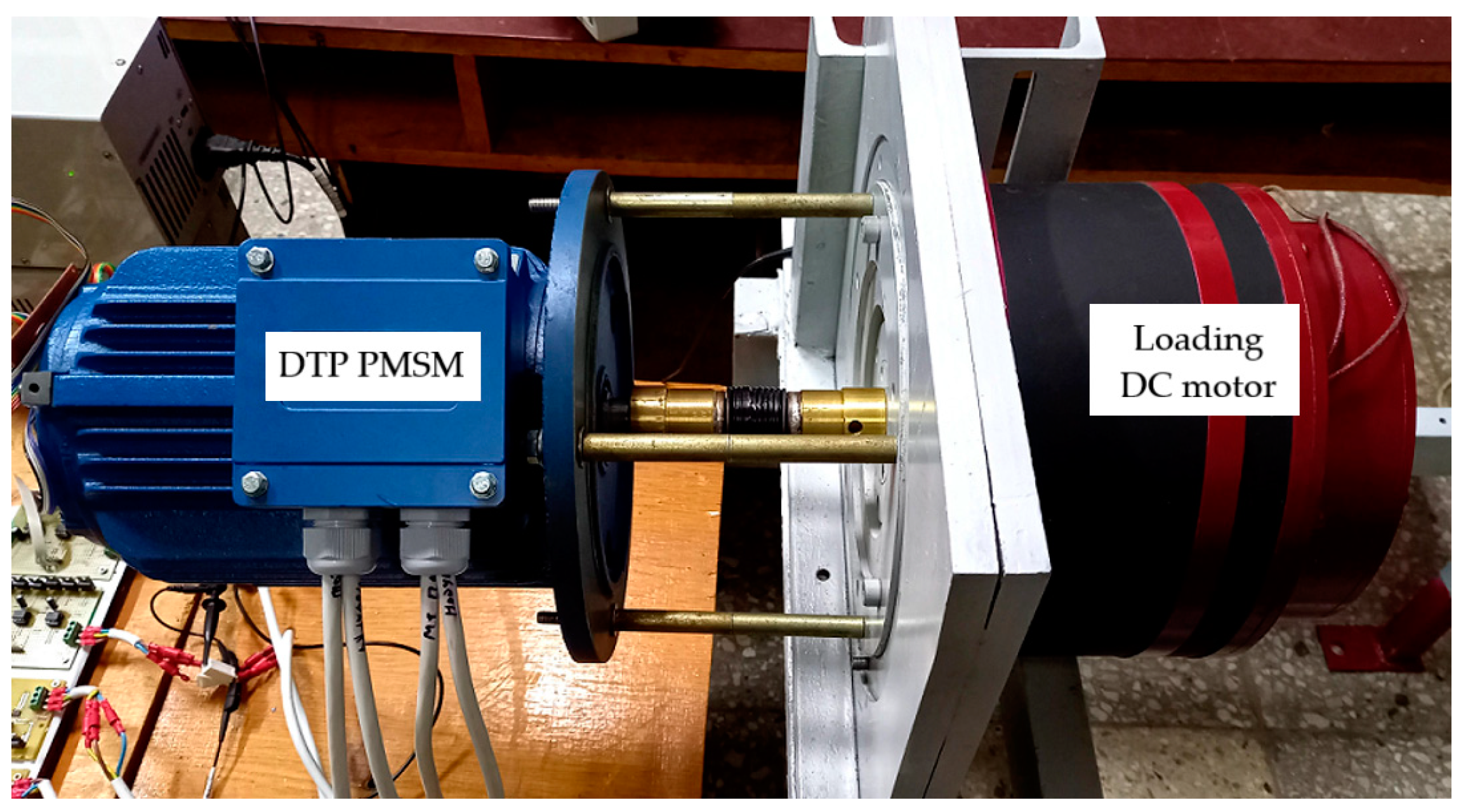

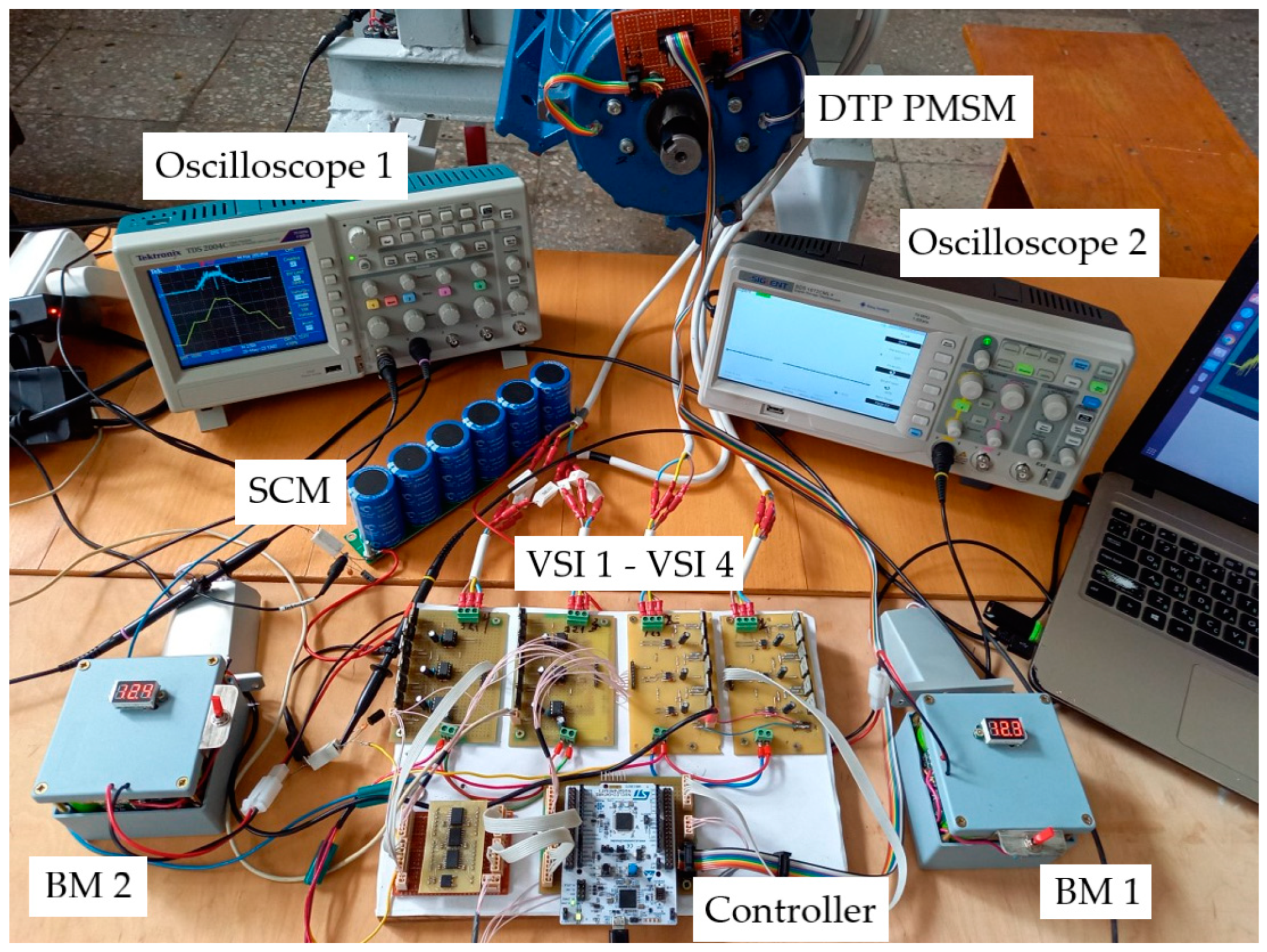

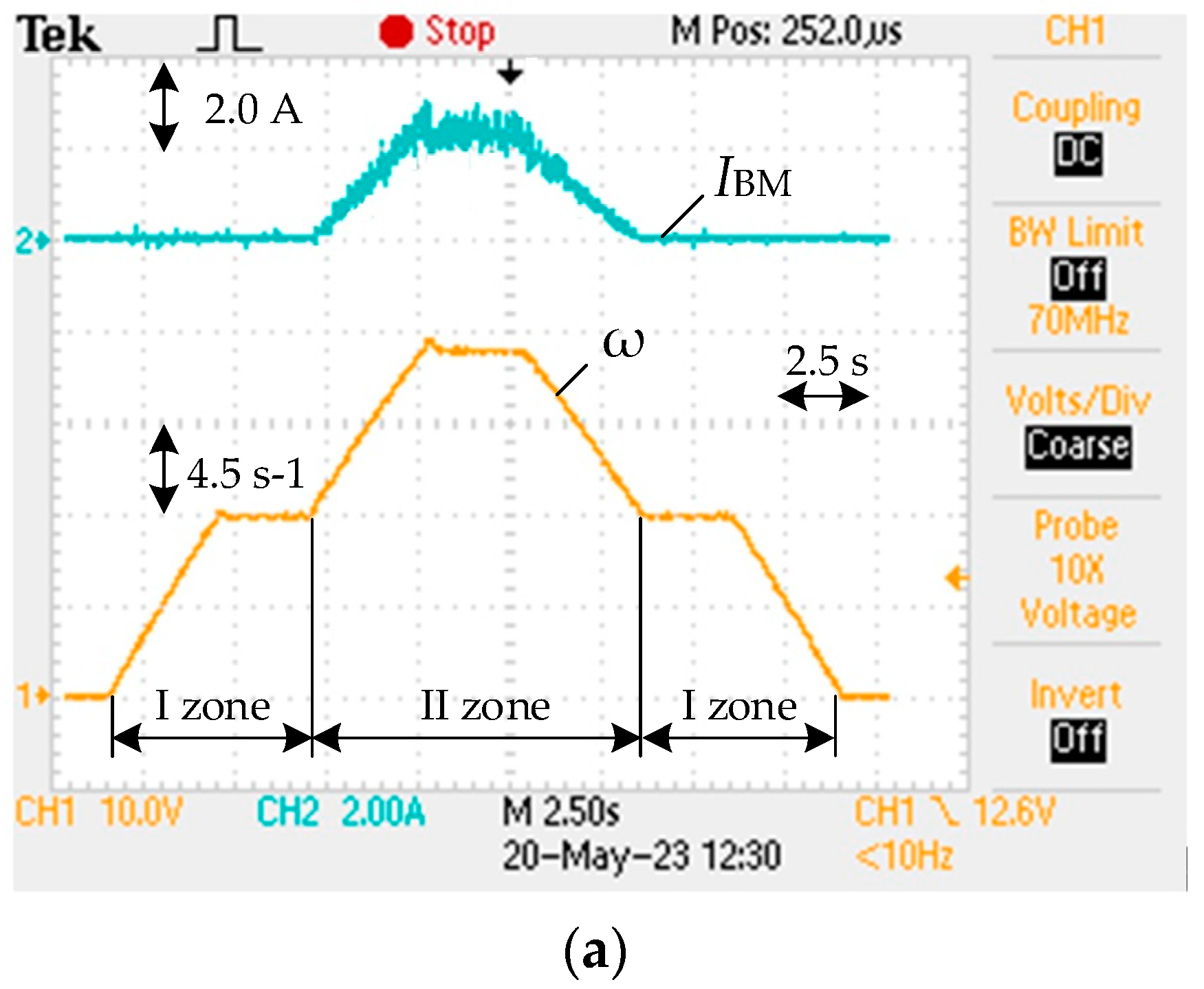

5. Experimental Verification

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Skouras, T.; Gkonis, P.; Ilias, C.; Trakadas, P.; Tsampasis, E.; Zahariadis, T. Electrical vehicles: current state of the art, future challenges, and perspectives. Clean Technol. 2019, 2 (1), 1–16. https://doi.org/10.3390/cleantechnol2010001. [CrossRef]

- Stippich, A. Key components of modular propulsion systems for next generation electric vehicles. CPSS Trans. Power Electron. Appl. 2017, 2 (4), 249–258. https://doi.org/10.24295/CPSSTPEA.2017.00023. [CrossRef]

- Un-Noor, F.; Padmanaban, S.; Mihet-Popa, L.; Mollah, M.; Hossain, E. A comprehensive study of key electric vehicle (EV) components, technologies, challenges, impacts, and future direction of development. Energies 2017, 10 (8), 1217. https://doi.org/10.3390/en10081217. [CrossRef]

- Kuznetsov, B.; Bovdui, I.; Nikitina, T.; Kolomiets, V.; Kobilyanskiy, B. Multi-motor plant related electric drives robust control synthesis. In Proceedings of the 2020 IEEE 4th International Conference on Intelligent Energy and Power Systems (IEPS); IEEE: Istanbul, Turkey, 2020; pp 242–245. https://doi.org/10.1109/IEPS51250.2020.9263169. [CrossRef]

- Hemsen, J.; Kieninger, D.; Eckstein, L.; Lidberg, M. R.; Huisman, H.; Arrozy, J.; Lomonova, E. A.; Oeschger, D.; Lanneluc, C.; Tosoni, O.; Debal, P.; Ernstorfer, M.; Mongellaz, R. Innovative and highly integrated modular electric drivetrain. World Electr. Veh. J. 2019, 10 (4), 89. https://doi.org/10.3390/wevj10040089. [CrossRef]

- Mahmoudzadeh Andwari, A.; Pesiridis, A.; Rajoo, S.; Martinez-Botas, R.; Esfahanian, V. A Review of battery electric vehicle technology and readiness levels. Renew. Sustain. Energy Rev. 2017, 78, 414–430. https://doi.org/10.1016/j.rser.2017.03.138. [CrossRef]

- Hemmati, R.; Saboori, H. Emergence of hybrid energy storage systems in renewable energy and transport applications – A Review. Renew. Sustain. Energy Rev. 2016, 65, 11–23. https://doi.org/10.1016/j.rser.2016.06.029. [CrossRef]

- Kouchachvili, L.; Yaïci, W.; Entchev, E. Hybrid battery/supercapacitor energy storage system for the electric vehicles. J. Power Sources 2018, 374, 237–248. https://doi.org/10.1016/j.jpowsour.2017.11.040. [CrossRef]

- Benmouna, A.; Becherif, M.; Chen, J.; Chen, H.; Depernet, D. Interconnection and damping assignment passivity based control for fuel cell and battery vehicle: simulation and experimentation. Int. J. Hydrog. Energy 2019, 44 (39), 22467–22477. https://doi.org/10.1016/j.ijhydene.2019.02.045. [CrossRef]

- Yang, B.; Zhu, T.; Zhang, X.; Wang, J.; Shu, H.; Li, S.; He, T.; Yang, L.; Yu, T. Design and implementation of battery/smes hybrid energy storage systems used in electric vehicles: a nonlinear robust fractional-order control approach. Energy 2020, 191, 116510. https://doi.org/10.1016/j.energy.2019.116510. [CrossRef]

- Paul, T.; Mesbahi, T.; Durand, S.; Flieller, D.; Uhring, W. Sizing of lithium-ion battery/supercapacitor hybrid energy storage system for forklift vehicle. Energies 2020, 13 (17), 4518. https://doi.org/10.3390/en13174518. [CrossRef]

- Yang, B.; Wang, J.; Zhang, X.; Wang, J.; Shu, H.; Li, S.; He, T.; Lan, C.; Yu, T. Applications of battery/supercapacitor hybrid energy storage systems for electric vehicles using perturbation observer based robust control. J. Power Sources 2020, 448, 227444. https://doi.org/10.1016/j.jpowsour.2019.227444. [CrossRef]

- Ostroverkhov, M.; Trinchuk, D. Increasing the efficiency of electric vehicle drives with supercapacitors in power supply. In Proceedings of the 2020 IEEE 7th International Conference on Energy Smart Systems (ESS); IEEE: Kyiv, Ukraine, 2020; pp 258–261. https://doi.org/10.1109/ESS50319.2020.9160291. [CrossRef]

- Berrueta, A.; Ursua, A.; Martin, I. S.; Eftekhari, A.; Sanchis, P. Supercapacitors: electrical characteristics, modeling, applications, and future trends. IEEE Access 2019, 7, 50869–50896. https://doi.org/10.1109/ACCESS.2019.2908558. [CrossRef]

- Wang, Y.; Yang, Z.; Li, F. Optimization of energy management strategy and sizing in hybrid storage system for tram. Energies 2018, 11 (4), 752. https://doi.org/10.3390/en11040752. [CrossRef]

- Hannan, M. A.; Hoque, Md. M.; Hussain, A.; Yusof, Y.; Ker, P. J. State-of-the-art and energy management system of lithium-ion batteries in electric vehicle applications: issues and recommendations. IEEE Access 2018, 6, 19362–19378. https://doi.org/10.1109/ACCESS.2018.2817655. [CrossRef]

- Jagadeesh, I.; Indragandhi, V. Review and comparative analysis on dc-dc converters used in electric vehicle applications. IOP Conf. Ser. Mater. Sci. Eng. 2019, 623 (1), 012005. https://doi.org/10.1088/1757-899X/623/1/012005. [CrossRef]

- Shchur, I.; Bilyakovskyy, I.; Turkovskyi, V. Improvement of switched structure semi-active battery/supercapacitor hybrid energy storage system for electric vehicles. IET Electr. Syst. Transp. 2021, 11 (3), 241–255. https://doi.org/10.1049/els2.12017. [CrossRef]

- Zhaohui, S.; Dongchang, Q.; Mian, W.; Guozhu, C. Study of modular cascaded dc-dc converter with interleaved control for energy storage system. In Proceedings of the 2015 IEEE 24th International Symposium on Industrial Electronics (ISIE); IEEE: Buzios, Rio de Janeiro, Brazil, 2015; pp 417–421. https://doi.org/10.1109/ISIE.2015.7281504. [CrossRef]

- Al Mashhadany, Y. I. High-Performance Multilevel Inverter Drive of Brushless DC Motor. Int J Sustain. Green Energy 2015, 4 (3–1), 1–7. https://doi.org/10.11648/j.ijrse.s.2015040301.11. [CrossRef]

- Lee, Y.; Ha, J.-I. Hybrid modulation of dual inverter for open-end permanent magnet synchronous motor. IEEE Trans. Power Electron. 2015, 30 (6), 3286–3299. https://doi.org/10.1109/TPEL.2014.2325738. [CrossRef]

- Loncarski, J.; Leijon, M.; Srndovic, M.; Rossi, C.; Grandi, G. Comparison of output current ripple in single and dual three-phase inverters for electric vehicle motor drives. Energies 2015, 8 (5), 3832–3848. https://doi.org/10.3390/en8053832. [CrossRef]

- Jia, Y.-F.; Chu, L.; Xu, N.; Li, Y.-K.; Zhao, D.; Tang, X. Power sharing and voltage vector distribution model of a dual inverter open-end winding motor drive system for electric vehicles. Appl. Sci. 2018, 8 (2), 254. https://doi.org/10.3390/app8020254. [CrossRef]

- Sandulescu, P.; Meinguet, F.; Kestelyn, X.; Semail, E.; Bruyere, A. Control strategies for open-end winding drives operating in the flux-weakening region. IEEE Trans. Power Electron. 2014, 29 (9), 4829–4842. https://doi.org/10.1109/TPEL.2013.2283107. [CrossRef]

- Lu, S.; Corzine, K. A.; Ferdowsi, M. A Unique ultracapacitor direct integration scheme in multilevel motor drives for large vehicle propulsion. IEEE Trans. Veh. Technol. 2007, 56 (4), 1506–1515. https://doi.org/10.1109/TVT.2007.896970. [CrossRef]

- Vilathgamuwa, D. M.; Jayasinghe, S. D. G.; Lee, F. C.; Madawala, U. K. A Unique battery/supercapacitor direct integration scheme for hybrid electric vehicles. In In Proceedings of the IECON 2011 - 37th Annual Conference of the IEEE Industrial Electronics Society; IEEE: Melbourne, Vic, Australia, 2011; pp 3020–3025. https://doi.org/10.1109/IECON.2011.6119791. [CrossRef]

- Jayasinghe, S. D. G.; Vilathgamuwa, D. M.; Madawala, U. K. A Dual inverter based supercapacitor direct integration scheme for wind energy conversion systems. In Proceedings of the 2010 IEEE International Conference on Sustainable Energy Technologies (ICSET); IEEE: Kandy, Sri Lanka, 2010; pp 1–6. https://doi.org/10.1109/ICSET.2010.5684459. [CrossRef]

- Barrero, F.; Duran, M. J. Recent advances in the design, modeling, and control of multiphase machines—part i. IEEE Trans. Ind. Electron. 2016, 63 (1), 449–458. https://doi.org/10.1109/TIE.2015.2447733. [CrossRef]

- Negahdari, A.; Yepes, A. G.; Doval-Gandoy, J.; Toliyat, H. A. Efficiency enhancement of multiphase electric drives at light-load operation considering both converter and stator copper losses. IEEE Trans. Power Electron. 2019, 34 (2), 1518–1525. https://doi.org/10.1109/TPEL.2018.2830310. [CrossRef]

- Patel, V. I.; Wang, J.; Nugraha, D. T.; Vuletic, R.; Tousen, J. Enhanced availability of drivetrain through novel multiphase permanent-magnet machine drive. IEEE Trans. Ind. Electron. 2016, 63 (1), 469–480. https://doi.org/10.1109/TIE.2015.2435371. [CrossRef]

- Shchur, I.; Jancarczyk, D. Electromagnetic torque ripple in multiple three-phase brushless DC motors for electric vehicles. Electronics 2021, 10 (24), 3097. https://doi.org/10.3390/electronics10243097. [CrossRef]

- Salem, A.; Narimani, M. A review on multiphase drives for automotive traction applications. IEEE Trans. Transp. Electrification 2019, 5 (4), 1329–1348. https://doi.org/10.1109/TTE.2019.2956355. [CrossRef]

- Fu, Z.; Liu, J.; Xing, Z. Performance analysis of dual-redundancy brushless DC motor. Energy Rep. 2020, 6, 829–833. https://doi.org/10.1016/j.egyr.2020.11.125. [CrossRef]

- Bogusz, P.; Korkosz, M.; Prokop, J. A study of dual-channel brushless DC motor with permanent magnets. In Proceedings of the 2016 13th Selected Issues of Electrical Engineering and Electronics (WZEE); IEEE: Rzeszow, Poland, 2016; pp 1–6. https://doi.org/10.1109/WZEE.2016.7800189. [CrossRef]

- Shchur, I.; Turkovskyi, V. Comparative study of brushless DC motor drives with different configurations of modular multilevel cascaded converters. In Proceedings of the 2020 IEEE 15th International Conference on Advanced Trends in Radioelectronics, Telecommunications and Computer Engineering (TCSET); IEEE: Lviv-Slavske, Ukraine, 2020; pp 447–451. https://doi.org/10.1109/TCSET49122.2020.235473. [CrossRef]

- Shchur, I.; Turkovskyi, V. Multilevel DC link inverter fed BLDC motor drive with modular battery/supercapacitor HESS for electric vehicle. In Proceedings of the 2020 IEEE Problems of Automated Electrodrive. Theory and Practice (PAEP); IEEE: Kremenchuk, Ukraine, 2020; pp 1–6. https://doi.org/10.1109/PAEP49887.2020.9240871. [CrossRef]

- Shchur, I. Z.; Turkovskyi, V. P. Integrated system of modular power supply and multilevel control of brushless DC motor for electric vehicles. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2020, 6, 68–75. https://doi.org/10.33271/nvngu/2020-6/068. [CrossRef]

- Shchur, I.; Turkovskyi, V.; Boichuk, B. Dual battery powered drive system using an open-end winding brushless DC motor. In Proceedings of the 2021 IEEE 3rd Ukraine Conference on Electrical and Computer Engineering (UKRCON); IEEE: Lviv, Ukraine, 2021; pp 327–332. https://doi.org/10.1109/UKRCON53503.2021.9575807. [CrossRef]

- Shchur, I.; Turkovskyi, V. Open-end winding dual three-phase BLDC motor drive system with integrated hybrid battery-supercapacitor energy storage for electric vehicle. In Proceedings of the 2021 IEEE International Conference on Modern Electrical and Energy Systems (MEES); IEEE: Kremenchuk, Ukraine, 2021; pp 1–6. https://doi.org/10.1109/MEES52427.2021.9598697. [CrossRef]

- Makarchuk, O.; Kharchyshyn, B.; Kasha, L. Analysis of the magneto-mechanical characteristic of double three-phase PMSM. In Proceedings of the 2021 IEEE 3rd Ukraine Conference on Electrical and Computer Engineering (UKRCON); IEEE: Lviv, Ukraine, 2021; pp 333–338. https://doi.org/10.1109/UKRCON53503.2021.9575684. [CrossRef]

- Shchur, I.; Mazur, D.; Makarchuk, O.; Bilyakovskyy, I.; Turkovskyi, V.; Kwiatkowski, B.; Kalandyk, D. Improved Matlab/Simulink model of dual three-phase fractional slot and concentrated winding PM motor for EV applied brushless DC drive. Archives of Control Sciences 2022, 32 (4), 677–707. https://doi.org/10.24425/acs.2022.143667. [CrossRef]

| θ(° el.) | Switching states | θ(° el.) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VSI 1 | VSI 2 | ||||||||||||

| S11 | S21 | S31 | S41 | S51 | S61 | S12 | S22 | S32 | S42 | S52 | S62 | ||

| 0–30 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0–30 |

| 30–60 | 1 | 0 | 0 | 1 | 0 | 0 | 30–60 | ||||||

| 60–90 | 1 | 0 | 0 | 1 | 0 | 0 | 60–90 | ||||||

| 90–120 | 0 | 0 | 1 | 1 | 0 | 0 | 90–120 | ||||||

| 120–150 | 0 | 0 | 1 | 1 | 0 | 0 | 120–150 | ||||||

| 150–180 | 0 | 0 | 1 | 0 | 0 | 1 | 150–180 | ||||||

| 180–210 | 0 | 0 | 1 | 0 | 0 | 1 | 180–210 | ||||||

| 210–240 | 0 | 0 | 0 | 0 | 1 | 1 | 210–240 | ||||||

| 240–270 | 0 | 0 | 0 | 0 | 1 | 1 | 240–270 | ||||||

| 270–300 | 0 | 1 | 0 | 0 | 1 | 0 | 270–300 | ||||||

| 300–330 | 0 | 1 | 0 | 0 | 1 | 0 | 300–330 | ||||||

| 330–360 | 1 | 1 | 0 | 0 | 0 | 0 | 330–360 | ||||||

| θ(° el.) | Switching states | θ(° el.) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VSI 3 | VSI 4 | ||||||||||||

| S13 | S23 | S33 | S43 | S53 | S63 | S14 | S24 | S34 | S44 | S54 | S64 | ||

| 0–30 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0–30 |

| 30–60 | 0 | 0 | 0 | 0 | 1 | 1 | 30–60 | ||||||

| 60–90 | 0 | 0 | 0 | 0 | 1 | 1 | 60–90 | ||||||

| 90–120 | 0 | 1 | 0 | 0 | 1 | 0 | 90–120 | ||||||

| 120–150 | 0 | 1 | 0 | 0 | 1 | 0 | 120–150 | ||||||

| 150–180 | 1 | 1 | 0 | 0 | 0 | 0 | 150–180 | ||||||

| 180–210 | 1 | 1 | 0 | 0 | 0 | 0 | 180–210 | ||||||

| 210–240 | 1 | 0 | 0 | 1 | 0 | 0 | 210–240 | ||||||

| 240–270 | 1 | 0 | 0 | 1 | 0 | 0 | 240–270 | ||||||

| 270–300 | 0 | 0 | 1 | 1 | 0 | 0 | 270–300 | ||||||

| 300–330 | 0 | 0 | 1 | 1 | 0 | 0 | 300–330 | ||||||

| 330–360 | 0 | 0 | 1 | 0 | 0 | 1 | 330–360 | ||||||

| Switches | Inverter Operation Modes | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| S1 | 0 | 1 (0) | Switching according to the 120-degree conductivity with voltage regulation | Switching according to the 120-degree conductivity without voltage regulation |

| S3 | 0 | 1 (0) | ||

| S5 | 0 | 1 (0) | ||

| S2 | 0 | 0 (1) | ||

| S4 | 0 | 0 (1) | ||

| S6 | 0 | 0 (1) | ||

| Machine modules M 1 (М 2) | OEW machine module mode number | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | ||

| VSI 1 (VSI 2) |

mode | 1 | 3 | 2 | 4 | -3 | 4 | 3 |

| iDC | iDC = 0 | iDC > 0 | iDC = 0 | iDC > 0 | iDC < 0 | iDC > 0 | iDC > 0 | |

| VSI 3 (VSI 4) |

mode | 1 | 2 | 3 | -3 | 4 | 3 | 4 |

| iDC | iDC = 0 | iDC = 0 | iDC > 0 | iDC < 0 | iDC > 0 | iDC > 0 | iDC > 0 | |

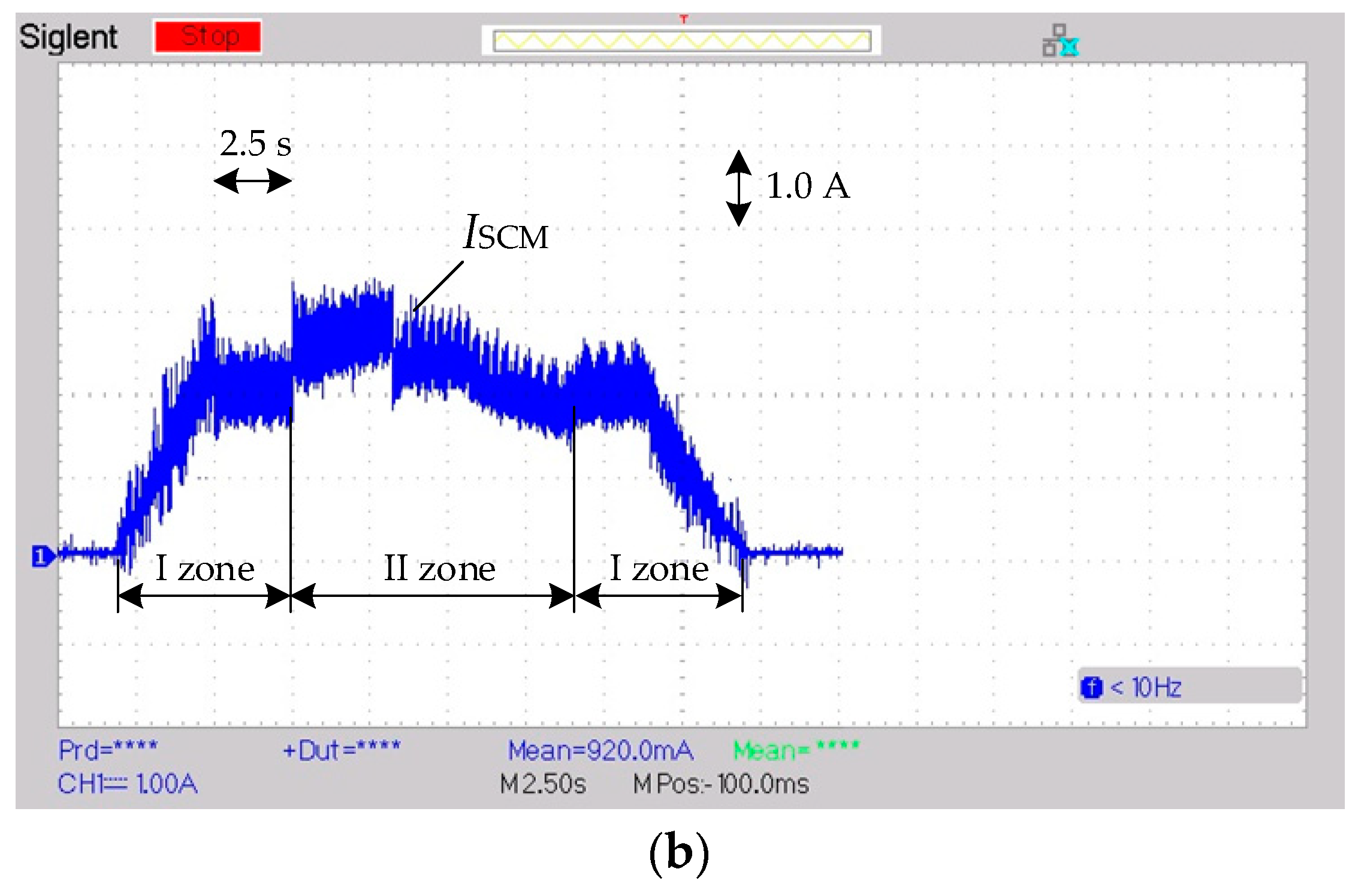

| Zone of operation | I zone | I zone | I zone | I zone | I zone | II zone | II zone | |

| OEW module mode number | Modes of operation of the BM and SCM |

|---|---|

| 1 | BM feeds the motor module |

| 2 | SCM feeds the motor module |

| 3 | BM feeds the motor module and charges the SCM |

| 4 | SCM feeds the motor module and charges the BM |

| 5 | BM and SCM feed the motor module (iBM > iSCM) |

| 6 | BM and SCM feed the motor module (iBM < iSCM) |

| Machine modules M 1 (М 2) | OEW machine module mode number | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | ||

| VSI 1 (VSI 2) |

mode | 1 | -3 | 2 | -4 | 3 | -4 | -3 |

| iDC | iDC = 0 | iDC < 0 | iDC = 0 | iDC < 0 | iDC > 0 | iDC < 0 | iDC < 0 | |

| VSI 3 (VSI 4) |

mode | 1 | 2 | -3 | 3 | -4 | -3 | -4 |

| iDC | iDC = 0 | iDC = 0 | iDC < 0 | iDC > 0 | iDC < 0 | iDC < 0 | iDC < 0 | |

| Zone of operation | I zone | I zone | I zone | I zone | I zone | II zone | II zone | |

| OEW module mode number | Modes of operation of the BM and SCM |

|---|---|

| 1 | BM receives the motor module braking energy |

| 2 | SCM receives the motor module braking energy |

| 3 | BM receives the motor module braking energy and discharge energy of the SCM |

| 4 | SCM receives the motor module braking energy and discharge energy of the BM |

| 5 | BM and SCM receive the motor module braking energy (|iBM| > |iSCM|) |

| 6 | BM and SCM receive the motor module braking energy (|iBM| < |iSCM|) |

| Parameter | Value |

|---|---|

| Rated DC voltage for one module (V) | 24 |

| Rated torque (Nm) | 10 |

| Rated angular velocity (s-1) | 24 |

| Number pair of poles | 10 |

| Moment of inertia (kg‧m2) | 0.15 |

| Phase winding resistance (Ω) | 0.250 |

| Phase winding self-inductance (mH) | 5.39 |

| Winding mutual inductance (mH) | 1.59 |

| Flux linkage by PM (Wb) | 0.112 |

| Parameter | Value |

|---|---|

| Rated power (W) | 350 |

| Rated DC voltage for one module (V) | 24 |

| Rated phase rms current (A) | 7.4 |

| Rated torque (Nm) | 20 |

| Rated angular speed (rpm) | 165 |

| Number pair of poles | 17 |

| Moment of inertia (kg‧m2) | 0.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).