1. Introduction

Charcoal is a significant product. Global consumption in 2022 was approximately 55 million tonnes. About two-thirds of that is as a primary cooking fuel, the majority thereof in what the United Nations classifies as ‘least developed countries’. Much of the rest is consumed in chemicals, metallurgy and water filtration, while perhaps 3-5% is used to fire barbeque grills in the developed world [

1,

2].

Combustion alone of 55 million tonnes amounts to 207 million tonnes of carbon dioxide equivalent (CO

2e) emitted per year, about the same annually as emitted by the country of Pakistan or about 0.5% of the world’s total. There are also significant carbon emissions in the production of charcoal, typically about equal to those of combustion [

3] – which would mean that for its full life-cycle, charcoal accounts for about 1% of global carbon emissions. These emissions are of natural concern to governments of countries where charcoal is heavily used, and also to grillers in the developed world [

4]. Charcoal production is also concerning, because it is a main cause of forest degradation in some developing countries [

5].

Most charcoal production is highly inefficient. The most popular production method, via earth-mount or earth-pit, yields only 10-15% product per unit of input wood. Even modern charcoal kilns yield only in the range of 35% [

5]. Higher efficiency production would reduce carbon emissions and the amount of feedstock wood required. Therefore this study was undertaken, to explore the carbon intensity and carbon efficiency of production pathways to charcoal.

2. Materials and Methods

The Materials and Methods should be described with sufficient details to allow others to replicate and build on the published results. Please note that the publication of your manuscript implicates that you must make all materials, data, computer code, and protocols associated with the publication available to readers. Please disclose at the submission stage any restrictions on the availability of materials or information. New methods and protocols should be described in detail while well-established methods can be briefly described and appropriately cited.

Research manuscripts reporting large datasets that are deposited in a publicly available database should specify where the data have been deposited and provide the relevant accession numbers. If the accession numbers have not yet been obtained at the time of submission, please state that they will be provided during review. They must be provided prior to publication. Interventionary studies involving animals or humans, and other studies that require ethical approval, must list the authority that provided approval and the corresponding ethical approval code.

This study has estimated a carbon intensity (CI) in 2022 of all significant process pathways to grill charcoal. The pathways have been identified through desk research and discussions with experts in the charcoal industry. The footprint is a function of CO2e emissions in:

Production of the wood and its conversion to charcoal, and

Combustion of any fossil components of the charcoal. As a default, biogenic components of the charcoal are counted as zero-carbon-dioxide in combustion, as is conventional.

The functional unit is megajoules (MJ) of charcoal at its lower heating value (LHV), so the CI is expressed as g CO2e/MJ. Waste wood used as feedstock is presumed to be zero carbon at the point of its collection.

In the balance of this section, each of the pathways is described and a mass/energy balance of production is presented. The next section reports how these mass/energy balances are converted to CIs.

2.1. Current Pathways to Charcoal

Production of charcoal is generally recognised to date back some six thousand years [

6]. Over that time, several pathways have been developed, and all of those are still in use – so all of them have been assessed in this study (

Table 1).

In historical order, the oldest pathway is that of earth mounds/pits, still used widely in the developing world. At some point, kilns of brick (and later metal) were introduced: these are still used today as well. Around 1750, retorts were first used in Germany and Sweden, because these increased the yield of non-charcoal ‘pyrolysis oils’. By around 1890 some of these had evolved into wood distillation plants that were designed to 1) supply charcoal for metallurgy plus 2) maximise output of pyrolysis oils such as acetic acid and methanol that were demanded by various industries. Production by wood distillation peaked in the early 1900s, reaching some half-million tonnes per year of charcoal in the USA alone [

7]. This declined in the following decades, as pyrolysis oil supplies were steadily displaced by petrochemical routes. Only one wood distillation plant is still operating: a plant in Germany run by a company named proFagus. In the past two decades or so, processes to produce biochar have been trialled by numerous researchers.

The first four pathways are still used to make commercial charcoal, and biochar is of broad interest, so all of these have been selected for analysis of their carbon intensities (CIs). Another pathway that uses a fluidized bed is included in the initial analysis.

2.2. Descriptions and Balances of Charcoal Pathways

In the following subsections (2.2.1-2.2.6), each pathway to charcoal (

Table 1) is described and a mass/energy balance is presented. Then the theory/calculation for conversion of those balances into CIs is presented (

Section 3), followed by presentation and discussion of results (

Section 4).

2.2.1. Earth Mounds/Pits

This is the original pathway to charcoal. It is done out in the open, usually not far from the source of the wood. Usually, but not always, the wood is pre-dried in the air or sun, which reduces moisture content to 15-20%. So the first stage of the process involves steaming off that water, before pyrolysis sets in. If the ground is readily broken, often a pit will be dug. The wood is stacked in the pit and covered with soil and grass/leaves to limit ingress of air and so prevent combustion. If the ground is rocky, hard or shallow, making pit-digging difficult or impossible, a mound will be built of the wood, and this is covered with soil, grass and/or leaves. A controlled fire is then lit, with restricted air access, to start the pyrolysis process. External fuel is not needed; indeed it is not desired, because that could lead to combustion rather than pyrolysis. Typically it takes several days for the charcoal to form and cool enough that it can be removed and prepared for market [

5,

8,

9].

The only significant input to the process is the wood. As a default, it is presumed to be carbon zero at collection, i.e. it is a waste. Alternate scenarios are considered in the discussion (Section 6.1).

Charcoal is the only product produced. According to extensive tests performed at real production sites in the developing world by [

10], the carbon content can be near to that specified for lump charcoal in the developed world: approximately 80% (see Subsection 6.2). Its lower heating value is around 30 MJ/kg.

There are two parameters to the mass balance. The first is weight yield of charcoal relative to the dry mass of the input wood. A survey of reported yields returns a range from 10-36% (

Table 2). Only two of the sources, (US Environmental Protection Agency and National Risk Management Research Laboratory, 1999) and [

11], are based on actual measurements of real operations. The 36% reported by [

12] says it is for earth mounds/pits, but it is taken from other sources that mainly refer to kilns. The [

13] estimate is based on FAO data. So, for this study it was decided to split the difference between the actuals and the authoritative FAO: 20% is the default yield.

The second is air emissions from pyrolysis. With one exception, a survey of methane emissions yields a range of 30-40 g methane/kg charcoal product (

Table 3). Because the figure from (US Environmental Protection Agency and National Risk Management Research Laboratory, 1999) is based on extensive measurements of real operations, after adjustment for yield it has been selected as the default: 47 g methane/kg charcoal. In line with conventional carbon accounting, the carbon dioxide from the wood pyrolysis is biogenic carbon that has a global warming potential (GWP) of zero.

The energy balance is entirely biogenic, so therefore also rated at a GWP of zero.

2.2.2. Kiln, Ceramic or Metal

The main difference of a kiln to an earth mount/pit is the insulation: that of a kiln is far greater and easier to control. This shortens processing time from days to hours, and it reduces the risk of pyrolysis turning into a fire (combustion). Kilns come in two main types of material: brick, cement or some other ceramic; and metal. Brick kilns are, by nature, stationary. Metals kilns can be mobile. [

8]. Kilns are frequent in both the developing and developed world [

14].

The only significant input to the process is the wood. As a default, it is presumed to be carbon zero at collection, i.e. it is a waste. Alternate scenarios are considered in the discussion (Section 6.1).

Charcoal is the only product produced at carbon contents of around 80%, i.e. to commercial specification for grill charcoal in the developed world [

7]. Its lower heating value is around 30 MJ/kg.

There are two parameters to the mass balance. The first is

weight yield of charcoal relative to the dry mass of the input wood. A survey of reported yields returns a range from 24-48% (

Table 4). The apparent mistake in methane emissions makes the data from [

13] possibly suspect, and [

15] report that they used wet wood in their testing, so these figures have been discarded. The average of the remaining figures is taken as default: 41%. This is still below the maximum theoretical yield of 50% [

7].

The second is

air emissions from the pyrolysis process. A survey of methane emissions yields a range of 12-55 g methane/kg charcoal product (

Table 5). Even if the figure from [

13] were discarded, the average would not change, and all the other sources are authoritative. So after adjustment for yield the average is selected as the default: 28 g methane/kg charcoal. In line with conventional carbon accounting, the carbon dioxide from the wood pyrolysis is biogenic carbon that has a global warming potential (GWP) of zero.

The energy balance is entirely biogenic, so therefore also rated at a GWP of zero.

2.2.3. Retort

In earth pathways and kilns, most volatiles from the pyrolysis of wood to charcoal are directly vented to atmosphere

3. A retort is, by contrast, a closed vessel. When making charcoal in a retort, non-condensable gases such as carbon dioxide and methane are again vented, but hydrocarbons that are liquid at ambient conditions are returned to the reactor. These are further carbonised and/or oxidised, contributing to the pyrolysis. Temperatures can be controlled more closely, and processing time is shorter than that for kilns [

8,

9].

It is possible to run retorts with only one significant input: wood [

8,

9,

17]. However, external fuel is typically added to the retort process to 1) increase throughput and 2) to fire an after-combustion-chamber to fully combust hydrocarbons before they are emitted from the plant’s stack [

18,

19].

As a default, wood is presumed to be carbon zero at collection, i.e. it is a waste. This is definitely the case for the two sources of data that come from actual operators: [

18], which supplies over 50% of the USA market; and [

19]. Alternate scenarios are considered in the discussion (Subsection 6.1). Charcoal is the only product

4, produced at carbon content of around 80+%, i.e. to commercial specification for grill charcoal. Its lower heating value is around 30 MJ/kg.

There are three parameters to the mass balance. The first is

weight yield of charcoal relative to the dry mass of the input wood. A survey of reported yields returns a range from 24-42% (

Table 6). The default is taken as the average: 35%. This might seem odd, in that it is lower than the default for kilns, but it reflects operating practice in the world’s largest market for retort charcoal, the USA.

The second is

external fuel/energy to fire/drive the process. Figures are reported only by [

18,

19]. Their averages are, per kg of charcoal: 0.16 kg LPG; 0.07 kg natural gas; and 0.29 kWh of electricity. Clean Fuels b.v., which has licensed four plants with a combined capacity of 15.5 kilotonnes/year, reports that its design does not use external fuels [

17].

The third is

air emissions from the pyrolysis process. Only two sources report methane emissions (

Table 7). The default is the average of the two: 0.02 g methane per kg charcoal. In line with conventional carbon accounting, the carbon dioxide from the wood pyrolysis is biogenic carbon that has a global warming potential (GWP) of zero.

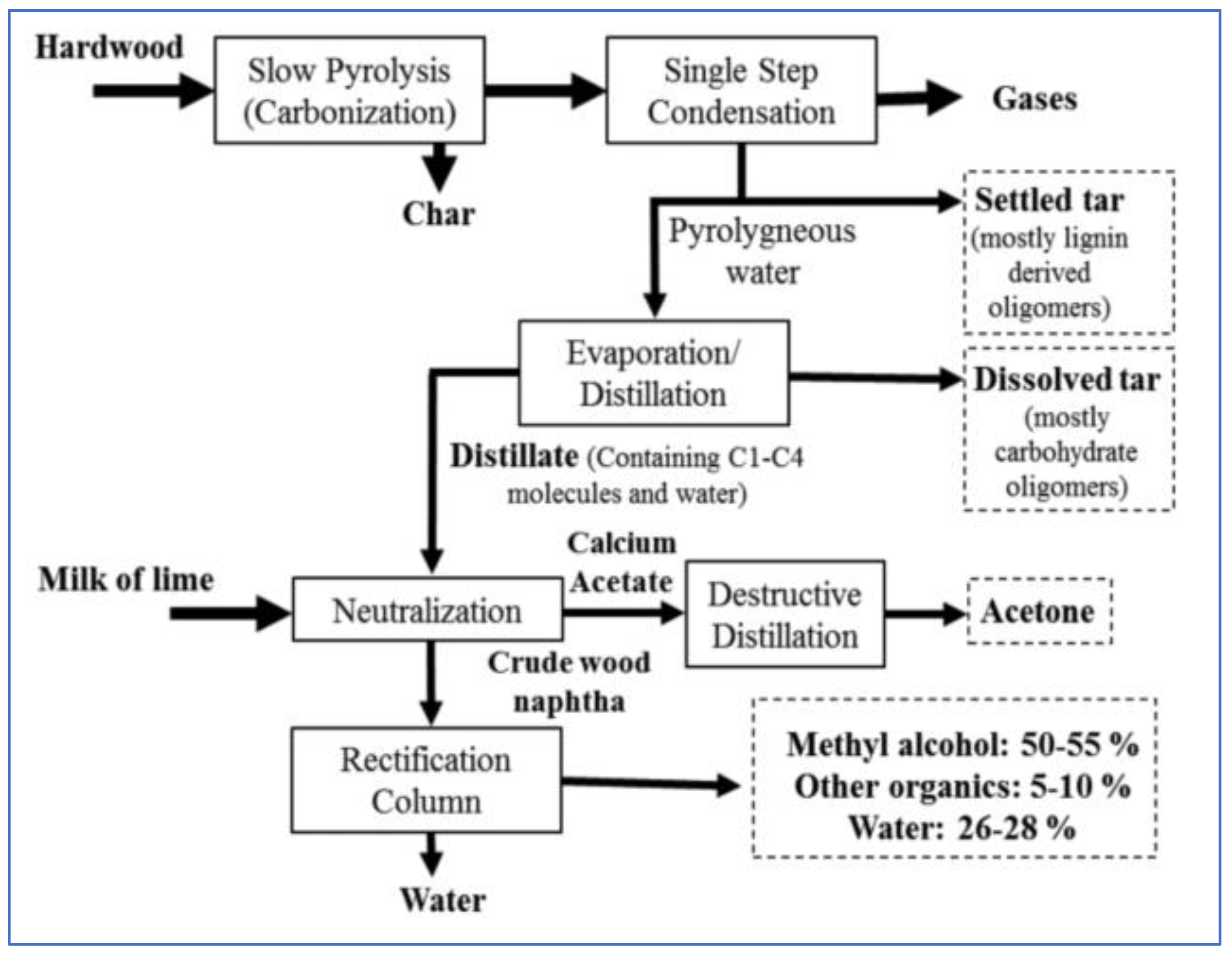

2.2.4. Wood Distillation

Wood distillation could be called a ‘retort plus’ process, because it starts with a retort (see preceding subsection) that makes charcoal. Non-condensable gases are vented, also as they are in a retort, but condensables are recovered and processed into separate products: typically acetic acid, methanol plus various tars

6 (

Figure 1).

The wood-distillation industry was the precursor to the petrochemical industry. Before petrochemical production, most industrially important organic chemicals were obtained from wood. In the industry’s peak around 1920, some 50 plants were operating in the USA, and plants were known of in Australia, Belgium Canada, Germany and Poland

7 [

14] [

21]. Most of the wood-distillation plants were shut down in the 1930s, as they were made uneconomic by petrochemicals. Some of them were simplified into retorts – their core operation – by removal of the distillation equipment: they continued to produce charcoal for the growing barbeque market; and the condensables were no longer distilled but instead burned to fire the retort [

7]. The only wood distillation plant known to still be in full operation is that run by proFagus at Bodenfelde, Germany.

With the rise of renewable fuels since around the millennium, numerous processes and projects have arisen to convert wood into liquid and sometimes gaseous fuels. According to [

22]

8 these are part of a broad industrial classification called ‘biorefineries’. Two of these biorefineries pyrolyse wood at commercial scale: Empyro Bioliquids in the Netherlands; and Pyrocell in Sweden. But unlike wood distillation, they are focused only on the condensable, liquid products for use as fuels or chemicals. Production of these is maximised at 60-75% weight of the feedstock by use of so-called ‘fast pyrolysis’

9. Char is produced, but it is not recovered; rather it is recycled for use as process heat [

23,

24]

10.

Inputs to the wood distillation plant are air-dried wood, natural gas to boost some of the processing and electricity to power the equipment. In principle, the plant could run without natural gas, using only the ‘wood gas’ that it recycles to fuel, but at some one-third to one-half lower throughput plus a higher risk of process failure and shutdown [

19]. As a default, wood is presumed to be carbon zero at collection, i.e. it is a waste. This is the case for proFagus. Alternate scenarios are considered in the discussion (Section 6.1). Charcoal is the main product, produced at carbon content of around 80+%, i.e. to commercial specification for grill charcoal. Its lower heating value is around 30 MJ/kg.

There are three parameters to the mass balance. The first is

yield of products relative to the dry mass of the input wood. A survey of literature shows a range of 51-82% (

Table 8). (United States Forest Service et al., 1961, p 3) says that 50% is the maximum theoretical yield of charcoal, so product yields are approaching the theoretical limit. The 82% yield reported by [

25] is a summary of Polish research: the yields appear to be maximum possibles; for a specific operation they appear to be overstated. proFagus yields are of actual operation in 2022. The yields from [

21] are for a plant at Iron Mountain, Michigan, USA, that closed in 1961.

The second parameter is

external fuel/energy to fire/drive the process. Of the sources reporting (

Table 8), only proFagus has presented figures for gas and electricity consumption. These are comparable to those reported above (Subsection 4.2.3) but kept confidential because they come from only one source. Negligible water input is required for the process, because wood distillation generates plentiful water [

19].

The third is

air emissions from the pyrolysis process. None of the sources reporting (

Table 8) present methane emissions. This study presumes they will be similar to those for retorts (

Table 7).

2.2.5. Fluidised Bed

Two Australian organisations, a company called Enecon and the government agency Commonwealth Scientific and Industrial Research Organisation (CSIRO), have conducted studies of making charcoal for metallurgical applications using a fluidised bed process [

26,

27]. This has never been commercialised. The data published are not detailed enough to derive a carbon intensity or a carbon efficiency for the pathway.

2.2.6. Biochar

Production of biochar is a relatively recent development that has yet to be commercialised. The function of biochar is not really that of charcoal – to be a cooking fuel or a carbon source for metallurgy. Instead, it is aimed at reducing the volume of forest waste and sequestering biogenic carbon. As [

28] reports, carbon content of biochar – typically around 65% - is well below that of charcoal

11. That is to say: grill charcoal and biochar are not nearly equivalent as products, so the carbon intensity/efficiency of biochar was not further pursued in this study.

3. Theory/Calculation

Carbon intensities (CIs) of many fuels have been calculated for decades now, first by researchers and then also by producers, consumers and regulators. Major regulatory programmes such as California’s Low Carbon Fuel Standard, the European Union’s Renewable Energy Directive and the USA’s Renewable Fuel Standard set out rules for calculation that have been applied to thousands of batches/shipments of fuels.

With some exceptions, these rules are straightforward: greenhouse gas emissions are estimated for each stage of the fuel-supply-chain – in this case those GHGs are carbon dioxide and methane. The GHGs are summed from cradle-to-gate; the sum is then normalised according to the heat content of the fuel (usually the lower heating value, typically expressed in megajoules or kilowatt-hours). For this study those general rules have been followed, using 100-year Global Warming Potentials published by the United Nation’s Intergovernmental Panel on Climate Change in its Sixth Assessment Report. Calculation was done in Excel spreadsheets, using the data presented in the preceding chapter.

The exceptions – i.e. the rules that are not straightforward – are presented and discussed along with the results in the next chapter.

Carbon efficiencies (CEs) of fuels are – at least in this paper – not the same as carbon intensities. This is presented and discussed in the next chapter as well.

4. Results and Discussion

The base-case CIs and CEs of the four relevant pathways were calculated (

Table 9): CIs per kg and MJ of charcoal; CEs as kg dry wood per kg of charcoal. The retort pathway was calculated as two sub-cases: with and without extra process fuel.

The least carbon-intensive pathway is a retort without extra fuel. Although theoretically possible, it is unclear if this pathway is ever used in commercial practice, because using extra fuel improves process economics and in some cases is required by air-quality regulations. After that, in significant distance to each other, come the remaining pathways, which account for nearly all charcoal production globally.

The CIs of Earth mounds/pits and Kilns come entirely from their methane emissions. In a Retort these are reduced dramatically. However, in the Retort with extra fuel, that fuel brings the CI about halfway between Kilns and Earth mounds/pits. As noted (

Table 9), the Retort with extra fuel understates the CI its leading brand, Kingsford, which contain nearly 10% fossil coal [

4]. Of the commercial pathways, Wood distillation’s CI comes in significantly lowest, because it is distributed across a greater volume of product, charcoal plus the condensables.

The best CE is also attributed to Wood distillation: 1.6 kg of incoming dry wood per kg of sold product. Retorts and Kilns are nearly double that, at 2.5-2.9 kg/kg; Earth mounds/pits are nearly double that again, at 5 kg/kg.

As noted in the preceding chapter, there are some exceptions to the calculation rules which are mostly straightforward. Four exceptions have been identified in the course of this work: these are discussed in the following subsections, in the author’s perception of descending importance.

4.1. Biogenic Carbon

CIs have historically treated all wood fuels as carbon neutral [

29], and this is still mostly the case. Some studies give it a Global Warming Potential (GWP) of zero; others assign a -1 GWP to CO2 that is sequestered via wood growth and a +1 to that released by burning. Either way, the result is carbon neutral.

For harvested wood that is not subsequently burned, but instead left to decompose in the forest, some studies such as [

30,

31] account for the changes in carbon stock. Some models of solid waste landfills also account for decomposition of wood (and other biogenic materials such as paper), mainly with respect to their methane

13 emissions [

32].

A special case is sometimes defined for tree trunks (called stemwood, roundwood and/or primary woody biomass) used as fuel. It could instead be used as lumber (Joint Research Centre of the EU Commission et al., 2020, p 111 of the main report) or simply left standing [

33]. In 2022 this became commercially significant, as the European Commission and the European Parliament considered limiting the carbon neutral status of this in its latest revision of the Renewable Energy Directive, and the Greenhouse Gas Protocol considered similar limitations in an update of its guidance

14. The thrust of the European deliberations is whether to consider alternate uses of such wood, which would give it a carbon positive CI.

In this study, the base-case assumption is that incoming wood to charcoal production is waste or residue, so it is carbon neutral at the point of collection – as is any other waste. This is known to be the case in production at proFagus, Kingsford and many other producers in the developed world [

4]. In the developing world, where most charcoal is both made and consumed, this is often not the case: charcoal from stemwood can be carbon positive and lead to deforestation [

3,

34,

35].

If the incoming wood were not considered as waste, the CIs would be dramatically higher, albeit the pathway rankings would change only slightly (

Table 10), with wood distillation coming out ahead of retort without extra fuel.

For this reason, this study introduces CE (

Table 9, column 4) as well as CI. The quantities reported without carbon neutrality (

Table 10) are what is actually emitted to atmosphere. Global warming – or, more precisely, radiative forcing – is caused by carbon dioxide, regardless of it being biogenic or fossil.

4.2. Quality Effects

Composition of charcoal used for grilling affects the quality of cooking, the main factors being heat of the grill and burn-rate of the charcoal. Vendors of premium charcoal contend that theirs generate higher temperatures and longer burns. At the same time, an analysis of 74 charcoal brands sold in seven countries [

36] shows that charcoal composition varies widely. Contaminant content ranges from <1-27%! The ratio of pure carbon to hydrocarbons is critical to grill performance. A high carbon content is desired for high temperature and long burn. Some hydrocarbon is desired for ignition, but no more than necessary. In briquettes, the aim is to mix carbon-hydrocarbon so to allow evenness in burning.

Minimum carbon content is specified in commercial standards, which can be correlated broadly to production pathways presented in previous chapters [9‒11,37]. Mainly, it can be said that charcoal from Earth mounds/pits sometimes generates charcoal of low carbon content, because mound/pit temperatures sometimes fail to reach or sustain the 450+ C needed to torrefy the wood.

As for the other pathways, it is possible that inadequate temperatures will lead to lower carbon content, but this cannot be correlated to the pathways as such. It probably can be correlated to good practice in operations, which would be different from one production site to the next. So while quality effects surely exist, they cannot be estimated at a pathway level.

Two other, more important quality effects are that of: 1) the efficiency of the grill used to cook with the charcoal, which can vary greatly; and 2) ‘practise’ of the grill operator, i.e. wastefulness or conservation with respect to fuel. These go beyond the aim of this study, but they are covered elsewhere [

3,

4].

4.3. Products, Wastes and Residues

Whether the inputs to the process are classed as products, wastes or residues is considered above (Subsection 4.1).

The classification of the outputs is simpler. Substances collected and offered for sale are products. Volatiles from the wood that are burned in charcoal pyrolysis are not products: they can be considered intermediates that are consumed. They are, in that respect, similar to refinery gas consumed in petroleum refineries that is produced from the incoming petroleum.

4.4. Division of Burden (Allocation)

In multi-product processes, CI must somehow be shared out among the products, if product-specific CIs are to be reported. This applies to only one of the pathways, Wood distillation, because it is the only multi-product pathway. In the base case and the main sensitivity (

Table 9 and

Table 10), the CI was allocated by economic value, using 2022 market prices. As a check, the CI was also allocated by weight of product: charcoal’s CI was 9% lower. Given the range of CIs by pathway (

Table 9 and

Table 10), this is a negligible difference.

5. Conclusions

Grill charcoal’s carbon intensity (CI) ranges greatly, depending on the pathway by which it is produced. So, too, does its carbon efficiency (CE). CE is not usually considered in studies such as this, yet it is important for climate impact.

Wood distillation, a commercial process that once was common but now is rare, comes out considerably better on CI and CE than other commercial processes: Earth mounds/pits, Kilns and Retorts.

6. Vitae

To come, after peer review.

Author Contributions

There is only one author of this paper.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Supporting data is available upon request from the author.

Conflicts of Interest

The author declares no conflict of interest.

References

- UN Food and Agricultural Organization Forestry Production and Trade 2022; Rome, 2022;

- Bailis, R. Wood in Household Energy Use. Encycl. Energy 2004, 6, 509–526.

- Johnson, E. Charcoal versus LPG Grilling: A Carbon-Footprint Comparison. Environ. Impact Assess. Rev. 2009, 29, 370–378. [CrossRef]

- Johnson, E.; Gafford, A. USA Carbon Footprints of Grills, by Fuel & Grill Type, 2022–27. Fuels 2022, 3, 475–485. [CrossRef]

- UN Food and Agricultural Organization Sustainable Charcoal Production for Food Security and Forest Landscape Restoration; 2020;

- Emrich, W. History and Fundamentals of the Charcoal Process BT - Handbook of Charcoal Making: The Traditional and Industrial Methods. In; Emrich, W., Ed.; Springer Netherlands: Dordrecht, 1985; pp. 1–18 ISBN 978-94-017-0450-2.

- United States Forest Service; Toole, A.W.; Lane, P.H.; (Jr), C.A.; Smith, W.R.; Peter, R. Charcoal Production, Marketing, and Use; 1961;

- UN Food and Agricultural Organization The Charcoal Transition: Greening the Charcoal Value Chain to Mitigate Climate Change and Improve Local Livelihoods; 2017; ISBN 9789251096802.

- Adam, J.C. Improved and More Environmentally Friendly Charcoal Production System Using a Low-Cost Retort-Kiln (Eco-Charcoal). Renew. Energy 2009, 34, 1923–1925. [CrossRef]

- US Environmental Protection Agency; National Risk Management Research Laboratory Greenhouse Gases from Small-Scale Combustion Devices in Developing Countries: Charcoal-Making Kilns in Thailand; 1999;

- Louppe, D. Carbonisation, Fabrication Du Charbon de Bois. Projet Makala; 2014;

- Werner, F.; Althaus, H.; Künniger, T.; Jungbluth, N. Life Cycle Inventories of Wood as Fuel and Construction Material; 2007;

- Huitink, C.L. Burning Nigerian Forests on European Barbecues, Utrecht University, 2018.

- United States Forest Service; Baker, A.. Charcoal Industry in the U.S.A. In Proceedings of the Symposium on Forest Products Research International--Achievements and the Future; 1985; Vol. 5, pp. 12–22.

- Charvet, F.; Matos, A.; da Silva, J.F.; Tarelho, L.; Leite, M.; Neves, D. Charcoal Production in Portugal: Operating Conditions and Performance of a Traditional Brick Kiln. Energies 2022, 15. [CrossRef]

- Santos, S. de F. de O.M.; Piekarski, C.M.; Ugaya, C.M.L.; Donato, D.B.; Braghini, A.; de Francisco, A.C.; Carvalho, A.M.M.L. Life Cycle Analysis of Charcoal Production in Masonry Kilns with and without Carbonization Process Generated Gas Combustion. Sustain. 2017, 9. [CrossRef]

- Reumerman, P.J.; Frederiks, B.; Clean Fuels BV Charcoal Production with Reduced Emissions. A Description of the Carbo Group Charcoal Production Technology. 12th Eur. Conf. Biomass Energy, Ind. Clim. Prot. 2002.

- Kingsford Manufacturing Company Permit Revision to Increase Char Production Cap at the Kingsford Manufacturing Beryl Plant; Beryl, W VA, USA, 2016;

- proFagus Gmbh ProFagus Operations at Bodenfelde; 2022;

- Chiang, T.I.; Clifton, D. The Feasibility of Manufacturing Charcoal and Charcoal Briquettes by Converting Barks in Georgia; 1971;

- Nelson, W.G. Waste-Wood Utilization by the Badger-Stafford Process. Ind. Eng. Chem. 1930, 22, 312–315.

- International Energy Agency; Annevelink, B.; Chavez, L.G.; Ree, R. Van; Gursel, I.V. Global Biorefinery Status Report 2022; 2022; ISBN 9791280907141.

- Pinheiro Pires, A.P.; Arauzo, J.; Fonts, I.; Domine, M.E.; Fernández Arroyo, A.; Garcia-Perez, M.E.; Montoya, J.; Chejne, F.; Pfromm, P.; Garcia-Perez, M. Challenges and Opportunities for Bio-Oil Refining: A Review. Energy and Fuels 2019, 33, 4683–4720. [CrossRef]

- Meier, D. Pyrolysis Oil Biorefinery. Adv. Biochem. Eng. Biotechnol. 2019, 166, 301–337. [CrossRef]

- Lewandowski, M.; Milchert, E.; Organic, C. Modern Technology of Dry Distillation of Wood. CHEMIK 2011, 1304–1306.

- Norgate, T.; Somerville, M.; Jahanshahi, S. The Greenhouse Gas Footprint of Charcoal Production. CSIRO Miner. Down Under Flagsh. 2006, 1–12.

- Stucley, C. INTEGRATED PROCESSING OF OIL MALLEE TREES FOR ACTIVATED CARBON, EUCALYPTUS OIL AND RENEWABLE ENERGY. In Proceedings of the Oil Mallees - Profitable Landcare; 1999; pp. 1–5.

- Han, H.S.; Jacobson, A.; Bilek, E.M.; Sessions, J. Waste To Wisdom: Utilizing Forest Residues for the Production of Bioenergy and Biobased Products; 2018;

- Johnson, E. Goodbye to Carbon Neutral: Getting Biomass Footprints Right. Environ. Impact Assess. Rev. 2009, 29, 165–168.

- Joint Research Centre of the EU Commission; CONCAWE; EUCAR Well-to-Tank Report v5: Well-to-Wheels Analysis of Future Automotive Fuels and Powertrains in the European Context; 2020;

- Liski, J.; Palosuo, T.; Peltoniemi, M.; Sievänen, R. Carbon and Decomposition Model Yasso for Forest Soils. Ecol. Modell. 2005, 189, 168–182. [CrossRef]

- Demetrious, A.; Crossin, E. Life Cycle Assessment of Paper and Plastic Packaging Waste in Landfill, Incineration, and Gasification-Pyrolysis. J. Mater. Cycles Waste Manag. 2019, 21, 850–860. [CrossRef]

- Johnson, E.; Tschudi, D. Baseline Effects on Carbon Footprints of Biofuels: The Case of Wood. Environ. Impact Assess. Rev. 2012, 37, 12–17.

- Atlantic Consulting Biomass’ Forgotten Carbon Cost: Burning Harvested Wood Increases the Carbon Footprint of Electricity; 2011;

- Johnson, E. Substituting LP Gas for Wood: Carbon and Deforestation Impacts; 2012;

- Jelonek, Z.; Drobniak, A.; Mastalerz, M.; Jelonek, I. Environmental Implications of the Quality of Charcoal Briquettes and Lump Charcoal Used for Grilling. Sci. Total Environ. 2020, 747, 141267. [CrossRef]

- United States Forest Service Hardwood-Distillation Industry; 1956;

| 1 |

The figure reported, in column 2, is here adjusted to reflect the default charcoal/dry wood yield of 20%. |

| 2 |

The figure reported, in column 2, is here adjusted to reflect the default charcoal/dry wood yield of 41%. |

| 3 |

Or, possibly, to some pollution control device, although this is not believed to be at all common. |

| 4 |

The figure reported, in column 2, is here adjusted to reflect the default charcoal/dry wood yield of 41%. |

| 5 |

The condensables for lignocellulosics (which would include wood) are classified by [23] as six major fractions: water 15-30 wt %, light oxygenates 8-26 wt %, monophenols 2-7 wt %, water insoluble oligomers derived from lignin 15-25 wt %, and water-soluble molecules 10-30 wt %. |

| 6 |

|

| 7 |

|

| 8 |

Charcoal is maximised, in contrast, by ‘slow pyrolysis’. |

| 9 |

Also there are numerous projects underway to gasify wood and to ferment it into ethanol. The former avoids production of char; the latter does not create char. |

| 10 |

The GREET model (of 2021, Version 1.3.0.13857) of carbon intensities published by the USA Department of Energy appears to present biochar and charcoal as the same thing. Upon closer inspection, its ‘Charcoal Production from Wood’ process is not charcoal, but bio-char. |

| 11 |

Per kg of all outgoing products, not just charcoal. |

| 12 |

Biogenic methane is usually NOT classed as carbon neutral, i.e. it is included in the CI – which is the case in this study. |

| 13 |

proFagus produces other products, as detailed in Section 3.2.4. However, in this discussion, the data have been limited to its retorting of charcoal only. |

| 14 |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).