Submitted:

30 May 2023

Posted:

31 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

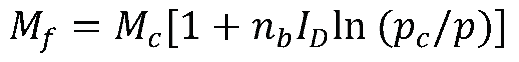

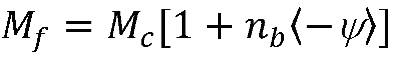

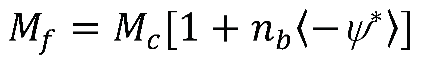

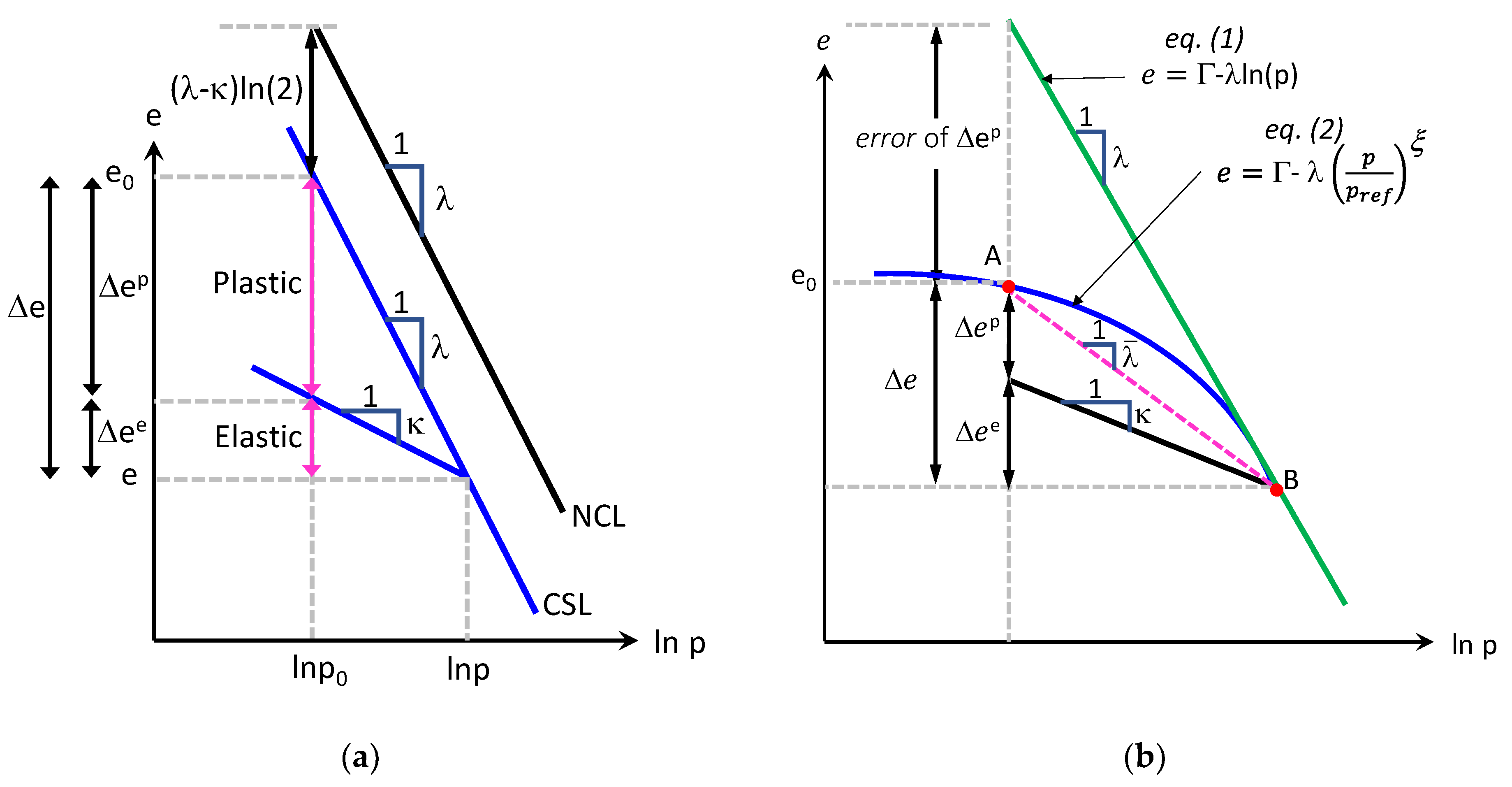

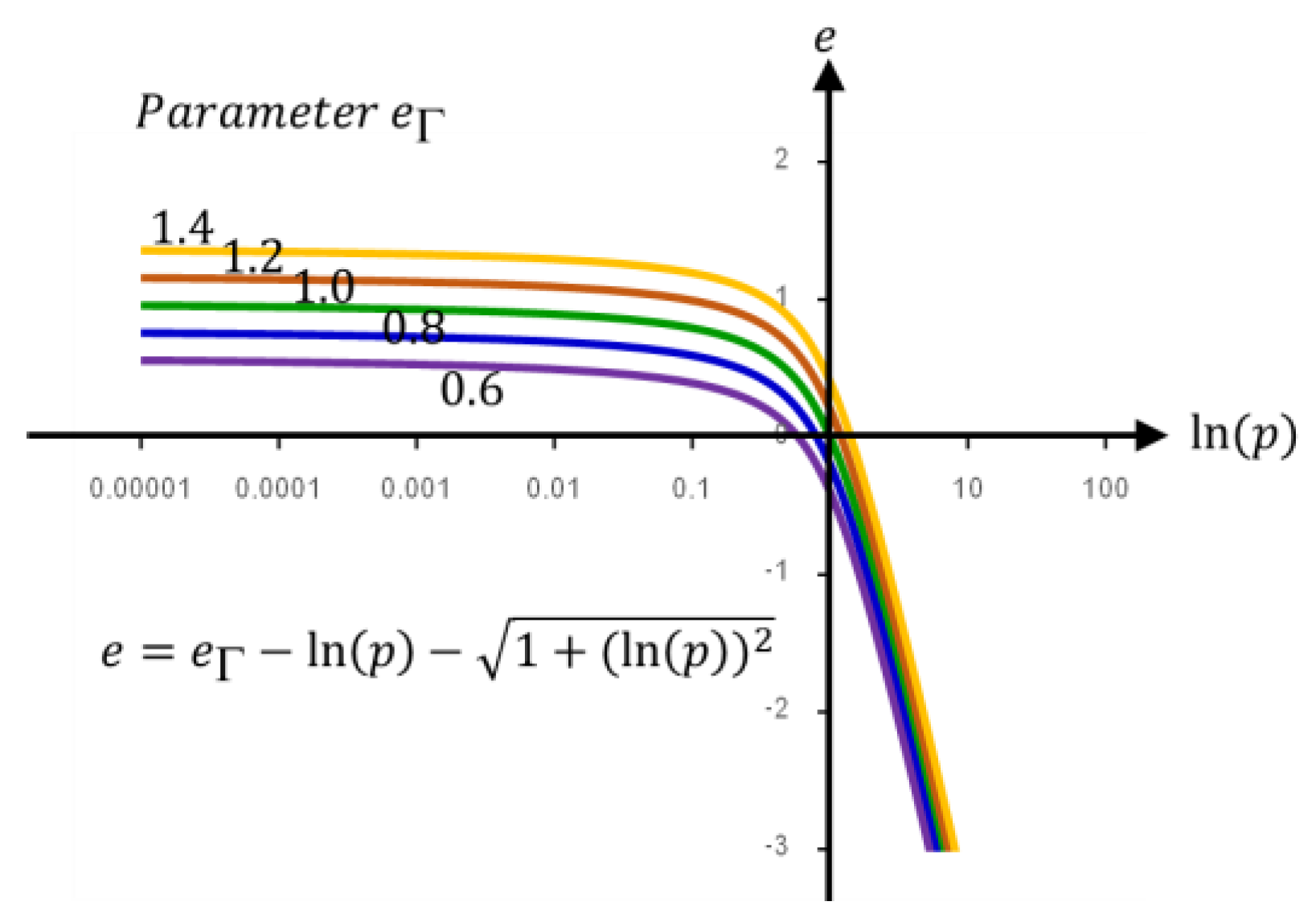

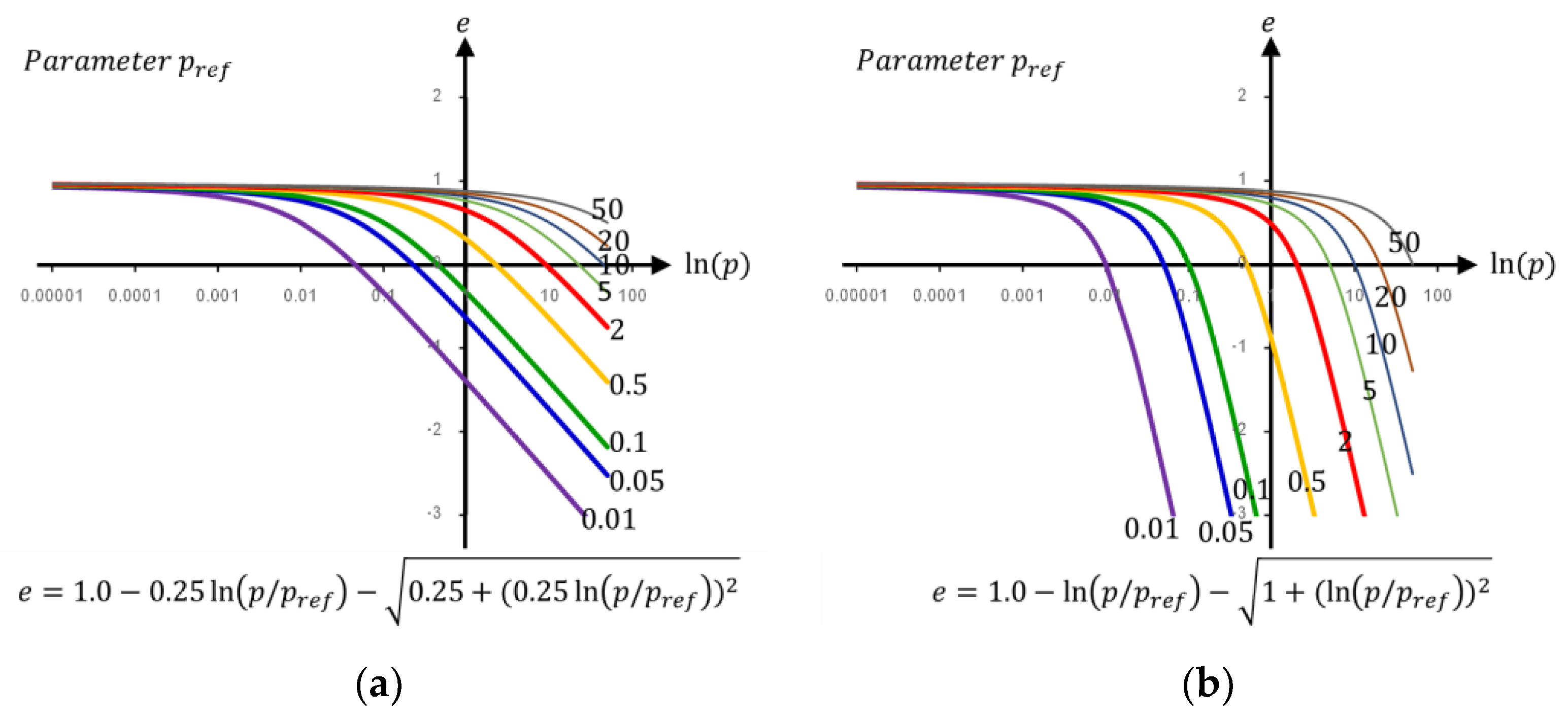

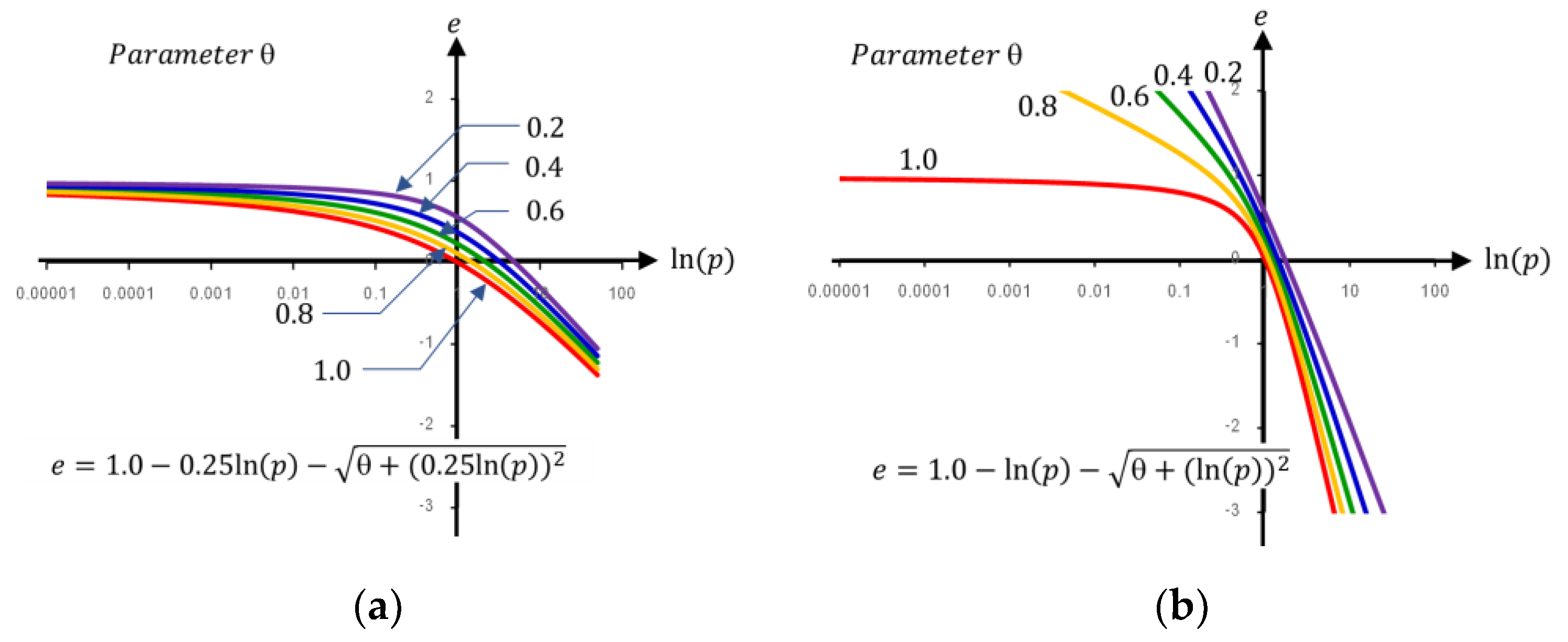

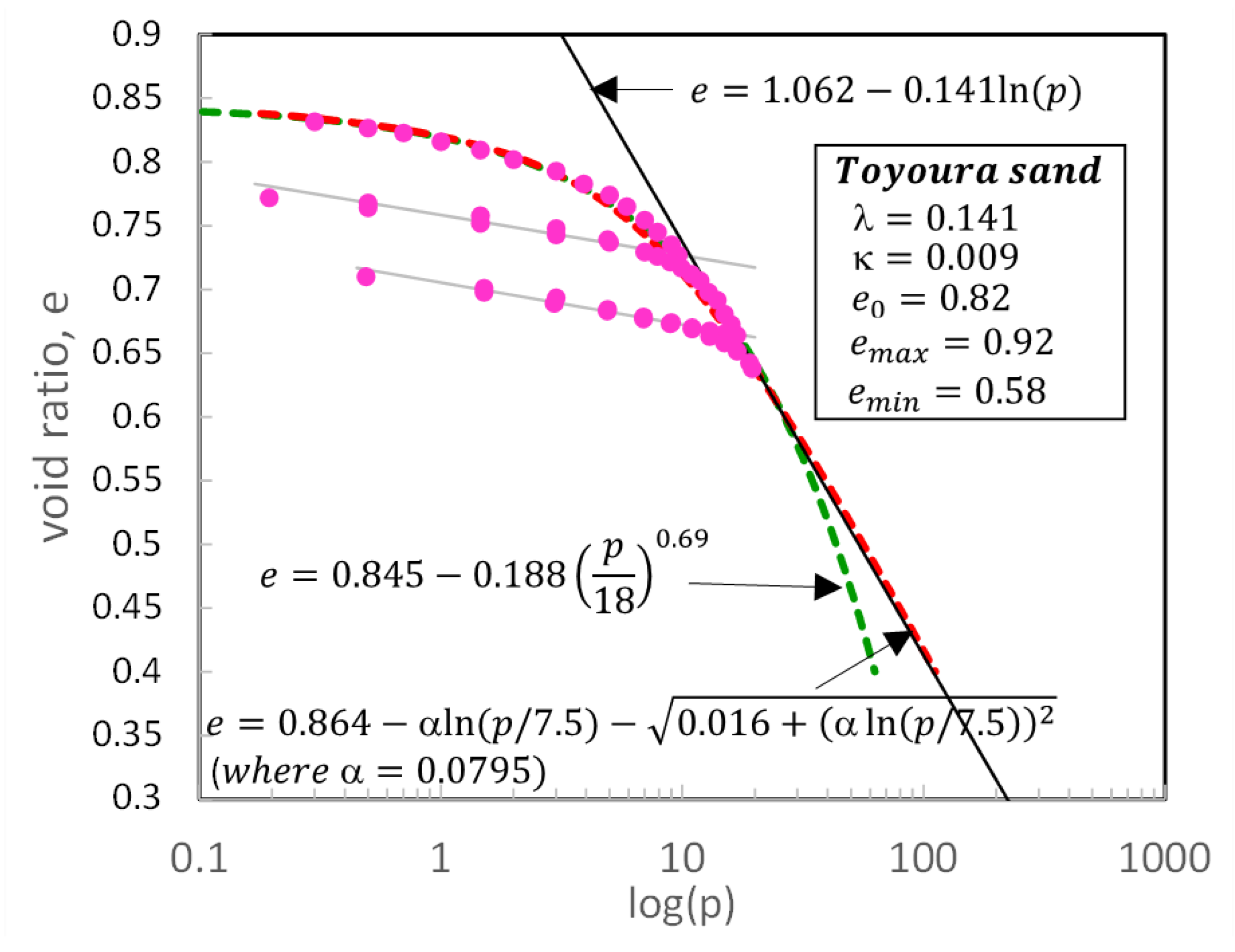

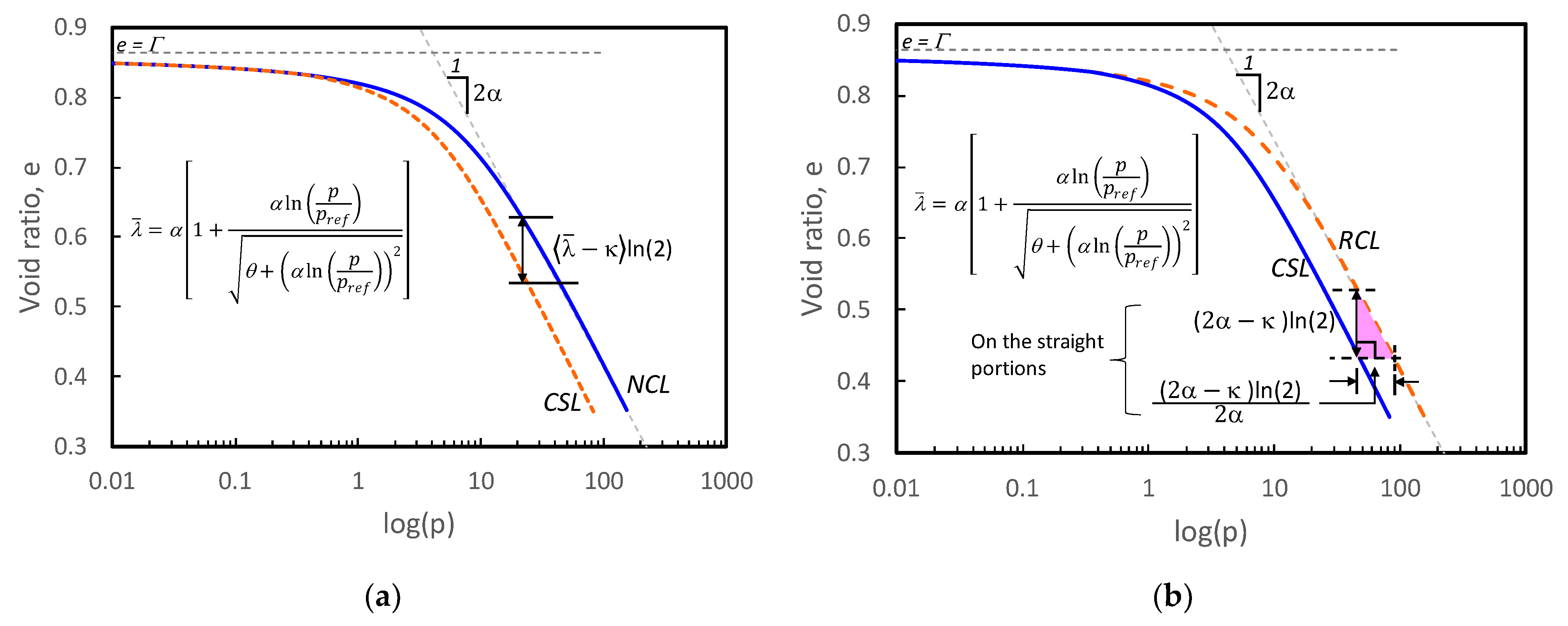

2. The Critical State Line in e-ln(p) plane

- 1)

- The equation should provide both the curved portion and the connecting straight line

- 2)

- One of the fitting parameters should be the desired slope of the straight portion

- 3)

- The equation should consist of the parameters that can adjust to fit various curvatures and locations

- 4)

- All parameters should be determined from a conventional test

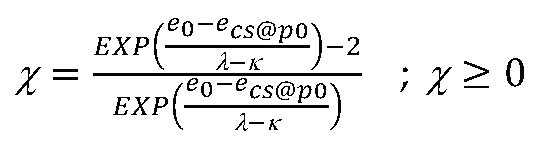

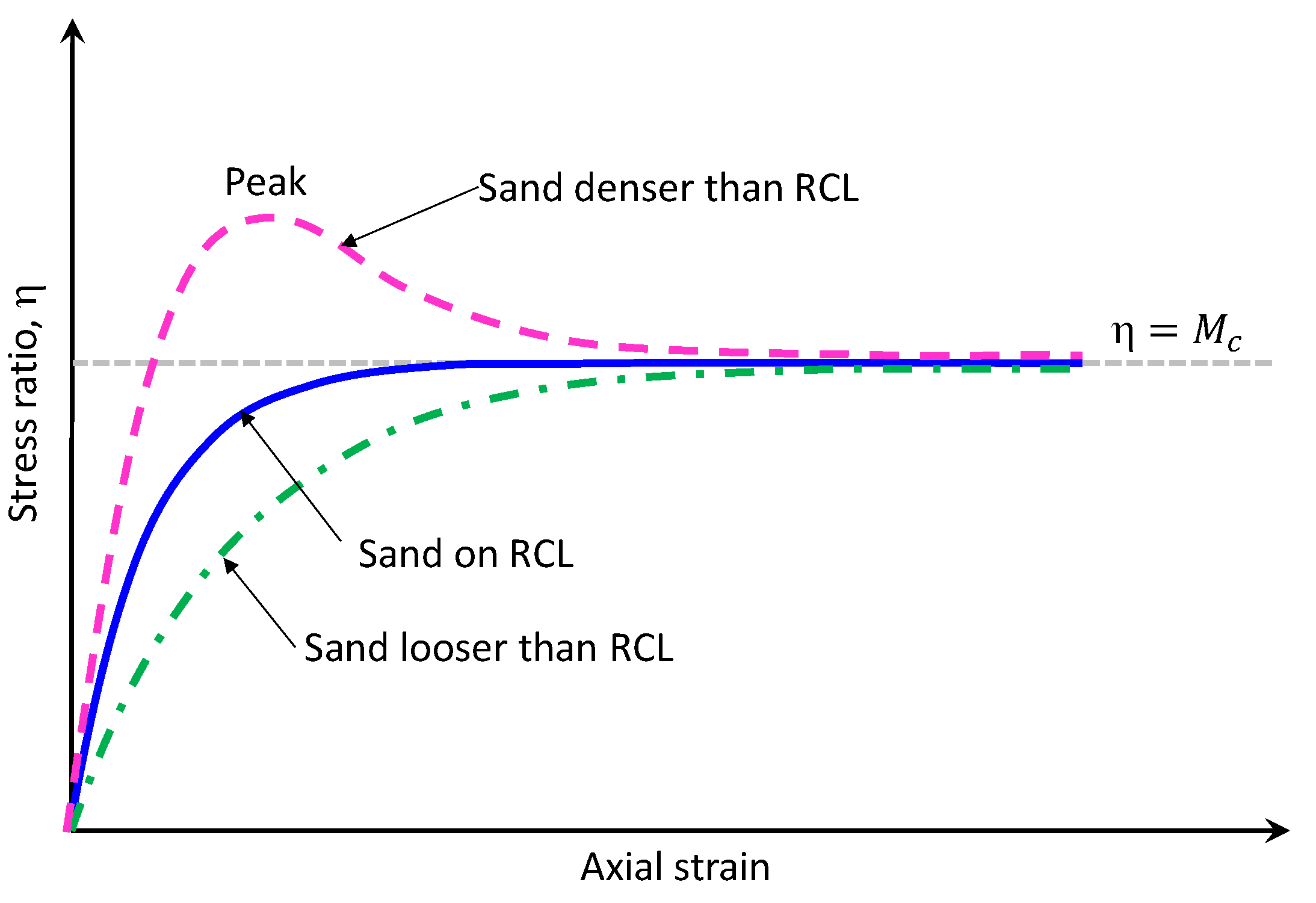

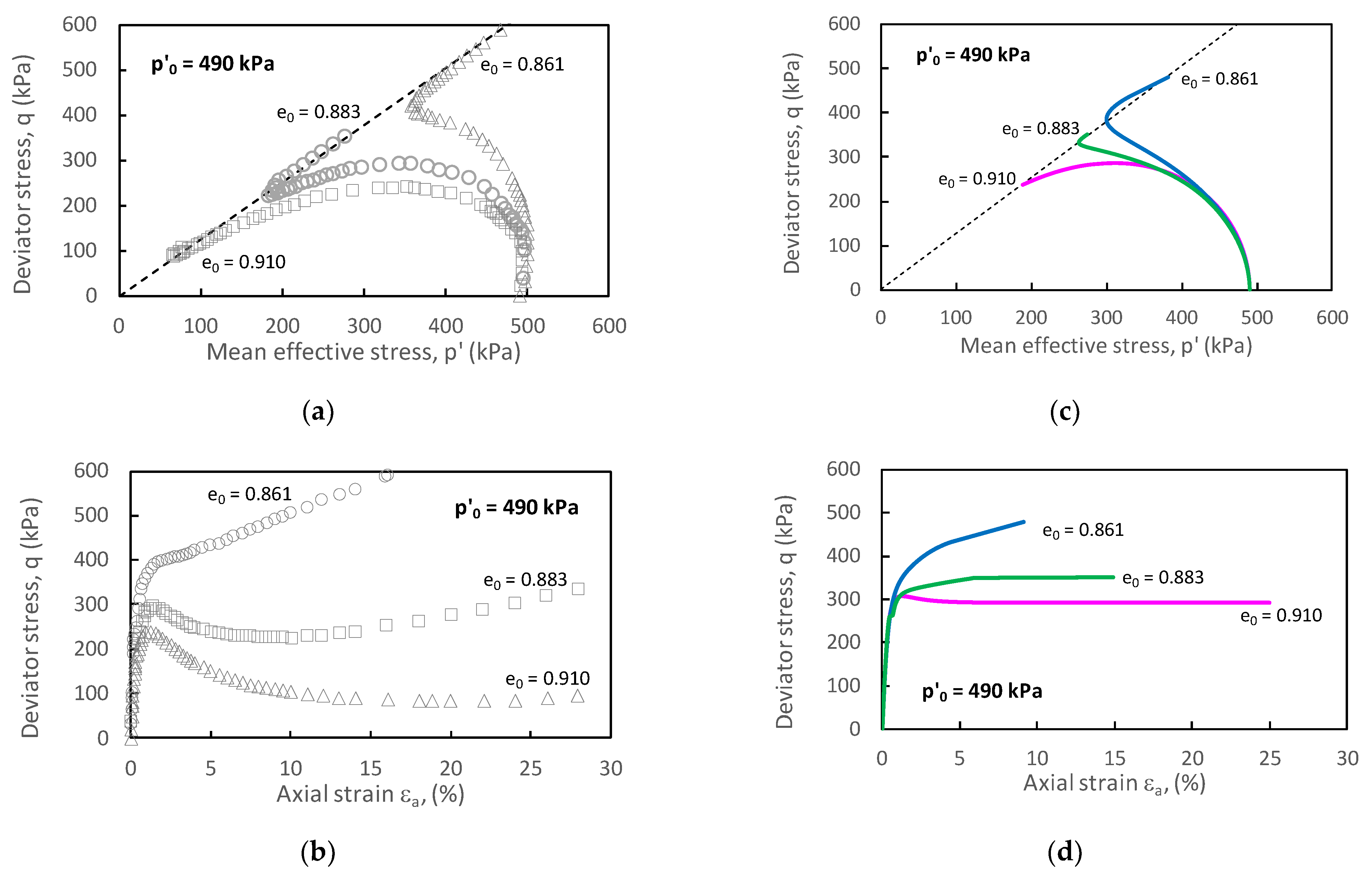

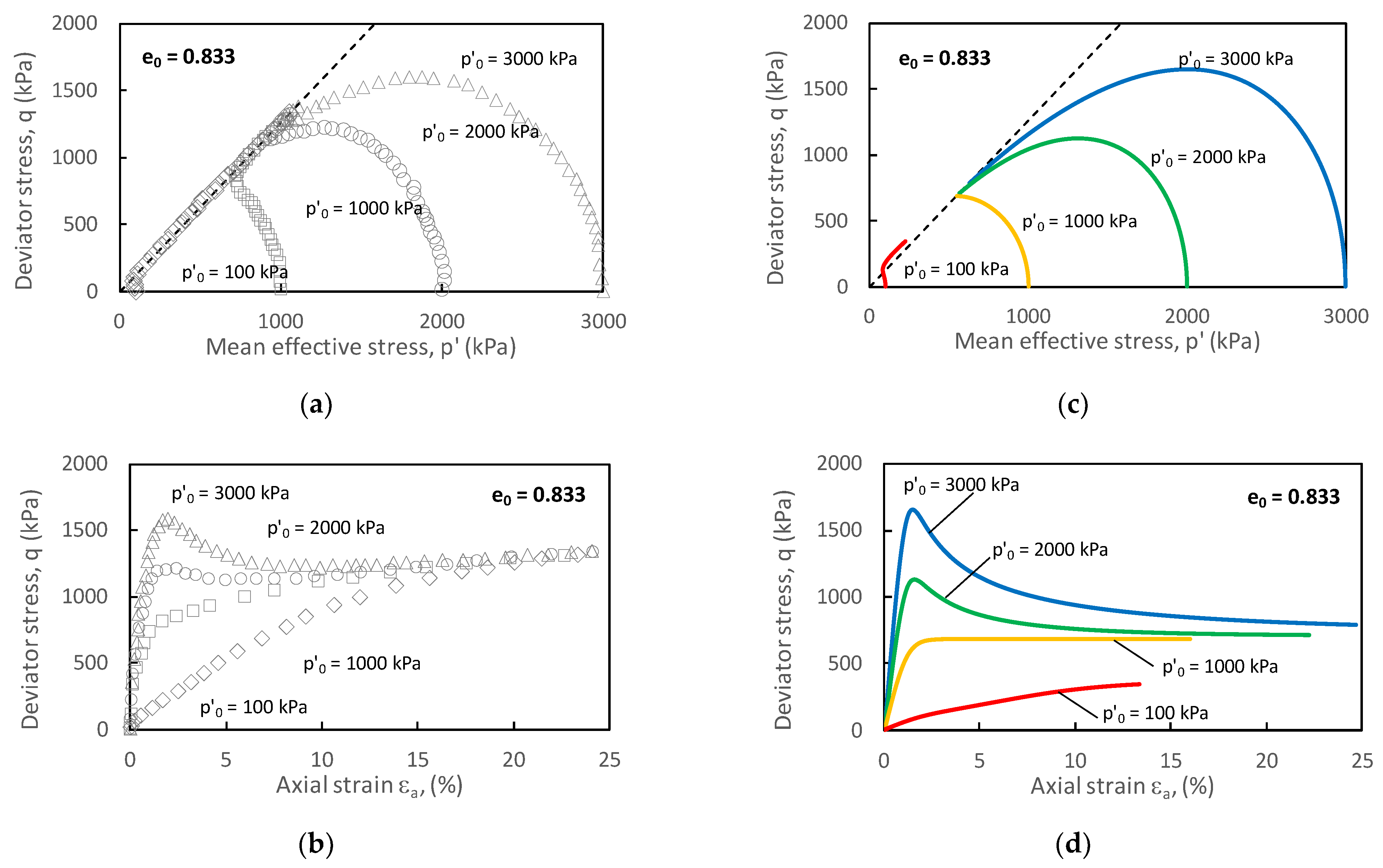

3. Critical State Model for Clean Sand

- 1)

- Sand on RCL exhibits only volume contraction during shearing, and the stress ratio reaches its maximum value at the critical state, where and is the slope of the critical state line on p-q plane.

- 2)

- Sand that is looser than the RCL (sheared from a point above the RCL) exhibits only volume contraction, but with the larger amount than sand on the RCL and finally reaches the same maximum stress ratio as sand on the RCL at .

- 3)

- Sand that is denser than the RCL (sheared from a point below the RCL) exhibits volume contraction in early stage, followed by dilation (the stress ratio is greater than the maximum stress ratio of sand on the RCL, i.e., (, and finally converges to the stress ratio

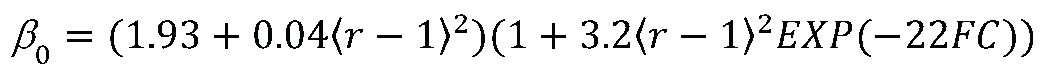

3.1. Hardening parameter H

3.2. Yield function

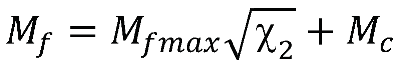

3.3. Peak strength of dense sand

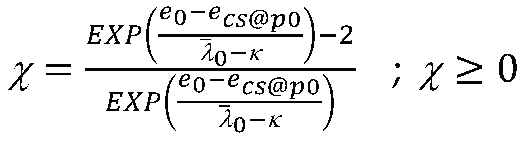

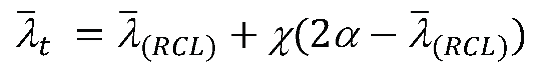

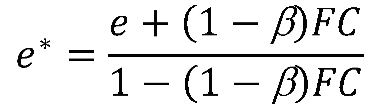

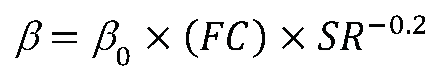

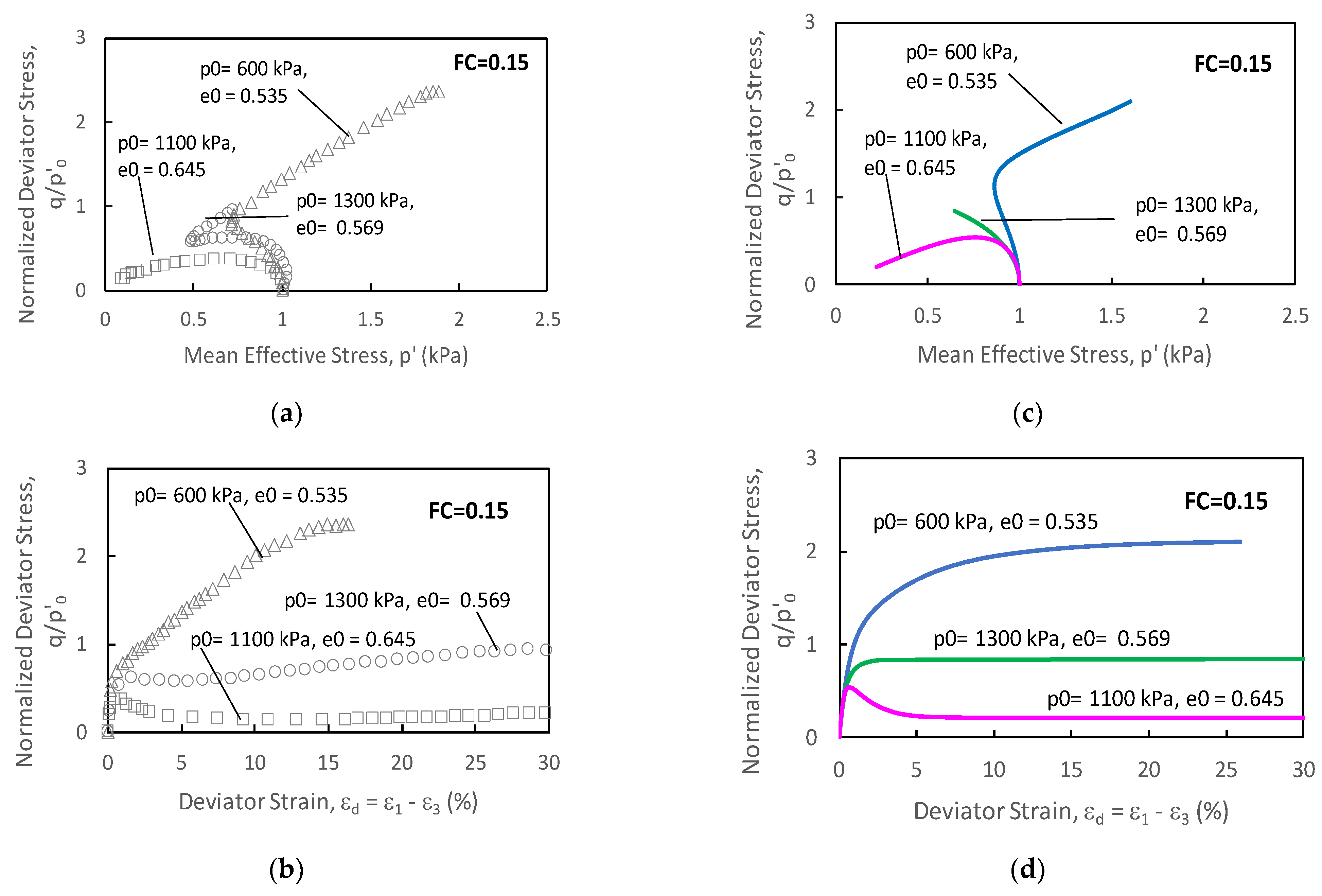

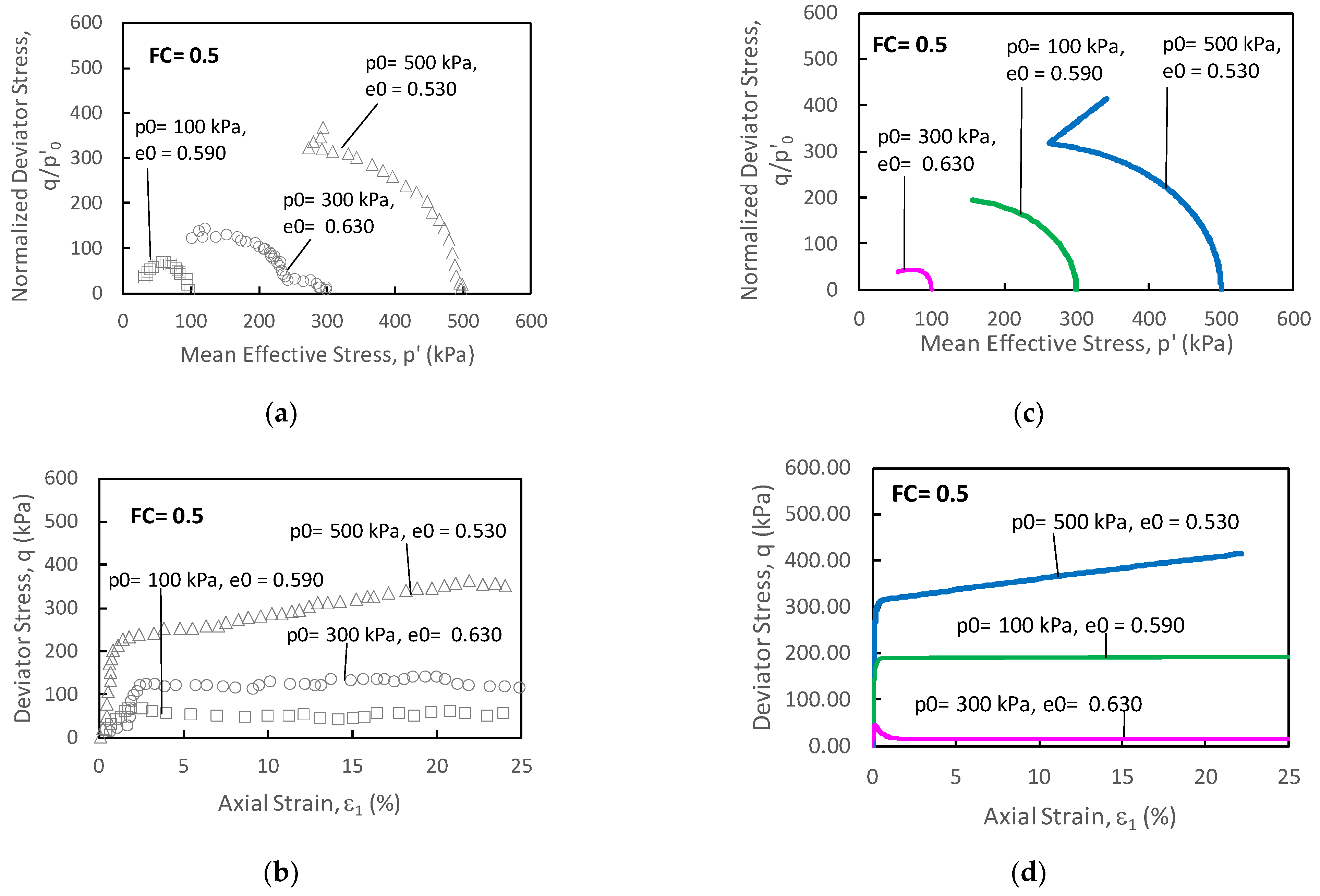

4. Critical State Model for silty sand

5. Conclusions

References

- Roscoe, K. H.; Burland, J. B. On the generalized stress strain behavior of “wet” clay. In Engineering Plasticity; Cambridge Univ. Press, 1968; pp. 535–609. [Google Scholar]

- Miura, N.; Murata, H.; Yasufuku, N. Stress-Strain Characteristics of Sand in a Particle-Crushing Region. Soils Found. 1984, 24, 77–89. [Google Scholar] [CrossRef]

- Miura, N.; Murata, H.; Yasufuku, N. Stress-strain characteristics of sand in a particle-crushing region. Soils and Foundations 1990, 17, 241–252. [Google Scholar] [CrossRef]

- Matsuoka, H.; Yao, Y.-P.; Sun, D. The Cam-Clay Models Revised by the SMP Criterion. Soils Found. 1999, 39, 81–95. [Google Scholar] [CrossRef]

- Yao, Y.P.; Sun, D.A.; Luo, T.A. Critical state model for sands dependent on stress and density. International Journal for Numerical and Analytical Methods in Geomechanics, 2004, 28, 323–337. [Google Scholar] [CrossRef]

- Yao, Y.; Sun, D.; Matsuoka, H. A unified constitutive model for both clay and sand with hardening parameter independent on stress path. Comput. Geotech. 2007, 35, 210–222. [Google Scholar] [CrossRef]

- Suebsuk, J.; Horpibulsuk, S.; Liu, M.D. A critical state model for overconsolidated structured clays. Comput. Geotech. 2011, 38, 648–658. [Google Scholar] [CrossRef]

- Cao, L. F.; Teh, C. I.; Chang, M. F. Undrained cavity expansion in modified Cam clay I: Theoretical analysis. Geotechnique 2001, 51, 323–334. [Google Scholar] [CrossRef]

- Grimstad, G.; Degago, S.A.; Nordal, S.; Karstunen, M. Modeling creep and rate effects in structured anisotropic soft clays. Acta Geotech. 2010, 5, 69–81. [Google Scholar] [CrossRef]

- Yin, Z.-Y.; Xu, Q.; Hicher, P.-Y. A simple critical-state-based double-yield-surface model for clay behavior under complex loading. Acta Geotech. 2013, 8, 509–523. [Google Scholar] [CrossRef]

- Miranda, P.; Vargas, E.; Moraes, A. Evaluation of the Modified Cam Clay model in basin and petroleum system modeling (BPSM) loading conditions. Mar. Pet. Geol. 2019, 112, 104112. [Google Scholar] [CrossRef]

- Miranda, P.; Vargas, E.; Moraes, A. Evaluation of the Modified Cam Clay model in basin and petroleum system modeling (BPSM) loading conditions. Mar. Pet. Geol. 2019, 112, 104112. [Google Scholar] [CrossRef]

- Ou, C. Y.; Liu, C. C.; Chin, C. K. Anisotropic viscoplastic modeling of rate-dependent behavior of clay. International Journal for Numerical and Analytical Methods in Geomechanics 2011, 35, 1189–1206. [Google Scholar] [CrossRef]

- Li, X.S.; Wang, Y. Linear Representation of Steady-State Line for Sand. J. Geotech. Geoenvironmental Eng. 1998, 124, 1215–1217. [Google Scholar] [CrossRef]

- Yang, Z.X.; Li, X.S.; Yang, J. Quantifying and modelling fabric anisotropy of granular soils. Géotechnique 2008, 58, 237–248. [Google Scholar] [CrossRef]

- Yang, J.; Wei, L.; Dai, B. State variables for silty sands: Global void ratio or skeleton void ratio? Soils Found. 2015, 55, 99–111. [Google Scholar] [CrossRef]

- Murthy, T. G.; Loukidis, D.; Carraro, J. A. H.; Prezzi, M.; Salgado, R. Undrained monotonic response of clean and silty sands. Géotechnique 2007, 57, 273–288. [Google Scholar] [CrossRef]

- Rahman, M.; Lo, S.R.; Baki, A.L. Equivalent granular state parameter and undrained behaviour of sand–fines mixtures. Acta Geotech. 2011, 6, 183–194. [Google Scholar] [CrossRef]

- Rahman, M. M.; Lo, S. C.; Dafalias, Y. F. Modelling the static liquefaction of sand with low-plasticity fines. Géotechnique 2014, 64, 881–894. [Google Scholar] [CrossRef]

- Duriez, J.; Vincens, É. Constitutive modelling of cohesionless soils and interfaces with various internal states: An elasto-plastic approach. Comput. Geotech. 2015, 63, 33–45. [Google Scholar] [CrossRef]

- Thevanayagam, S.; Martin, G. Liquefaction in silty soils—screening and remediation issues. Soil Dyn. Earthq. Eng. 2002, 22, 1035–1042. [Google Scholar] [CrossRef]

- Lashkari, A. Recommendations for extension and re-calibration of an existing sand constitutive model taking into account varying non-plastic fines content. Soil Dynamics and Earthquake Engineering 2014, 61–62, 212–238. [Google Scholar] [CrossRef]

- Taiebat, M.; Dafalias, Y.F. Simple Yield Surface Expressions Appropriate for Soil Plasticity. Int. J. Géoméch. 2010, 10, 161–169. [Google Scholar] [CrossRef]

- Been, K.; Jefferies, M.G. A state parameter for sands. Géotechnique 1985, 35, 99–112. [Google Scholar] [CrossRef]

- Manzari, M.T.; Dafalias, Y.F. A critical state two-surface plasticity model for sands. Géotechnique 1997, 47, 255–272. [Google Scholar] [CrossRef]

- Manzari, M.T.; Dafalias, Y.F. Simple plasticity sand model accounting for fabric change effects. ASCE J Eng Mech 2004, 130, 622–634. [Google Scholar] [CrossRef]

- Wan, R.; Guo, P. A simple constitutive model for granular soils: Modified stress-dilatancy approach. Comput. Geotech. 1998, 22, 109–133. [Google Scholar] [CrossRef]

- Wang, Z.L.; Dafalias, Y.F.; Li, X.S.; Makdisi, F.I. State pressure index for modeling sand behavior. ASCE J Geotech Geoenviron Engng 2002, 128, 511–519. [Google Scholar] [CrossRef]

- Vesić, A.S.; Clough, G.W. Behavior of Granular Materials Under High Stresses. J. Soil Mech. Found. Div. 1968, 94, 661–688. [Google Scholar] [CrossRef]

- Lashkari, A. On the modeling of the state dependency of granular soils. Comput. Geotech. 2009, 36, 1237–1245. [Google Scholar] [CrossRef]

- Verdugo, R. PhD dissertation, University of Tokyo, 1992; p. 1992.

- Verdugo, R.; Ishihara, K. The Steady State of Sandy Soils. Soils Found. 1996, 36, 81–91. [Google Scholar] [CrossRef]

- Ni, Q.; Tan, T.S.; Dasari, G.R.; Hight, D.W. Contribution of fines to the compressive strength of mixed soils. Géotechnique 2004, 54, 561–569. [Google Scholar] [CrossRef]

- Stamatopoulos, C.A. An experimental study of the liquefaction strength of silty sands in terms of the state parameter. Soil Dyn. Earthq. Eng. 2010, 30, 662–678. [Google Scholar] [CrossRef]

- Ventouras, K.; Coop, M.R. On the behavior of Thanet sand: an example of an uncemented natural sand. Géotechnique 2009, 59, 727–738. [Google Scholar] [CrossRef]

- Cubrinovski, M.; Rees, S. Effects of fines on undrained behavior of sands. ASCE geotechnical publication 2008, 1–11. [Google Scholar]

- Rahman, M.M.; Lo, S.R.; Gnanendran, C.T. On equivalent granular void ratio and steady state behavior of loose sand with fines. Can Geotech J 2008, 45, 1439–1456. [Google Scholar] [CrossRef]

- Papadopoulou, A.; Tika, T. The Effect of Fines on Critical State and Liquefaction Resistance Characteristics of Non-Plastic Silty Sands. Soils Found. 2008, 48, 713–725. [Google Scholar] [CrossRef]

- Huang, Y.-T.; Huang, A.-B.; Kuo, Y.-C.; Tsai, M.-D. A laboratory study on the undrained strength of a silty sand from Central Western Taiwan. Soil Dyn. Earthq. Eng. 2004, 24, 733–743. [Google Scholar] [CrossRef]

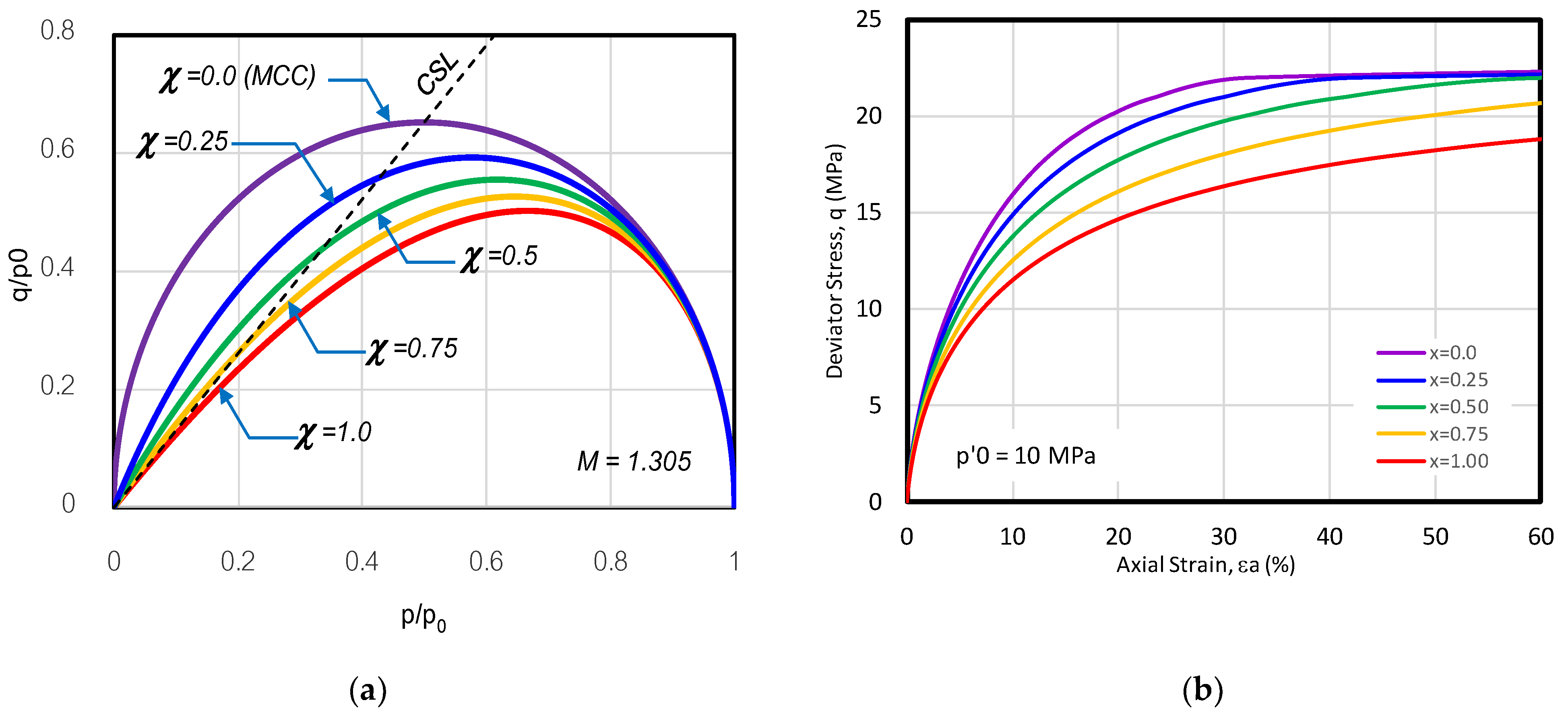

| Soil Model | Γ | α | θ | λ | κ | ν | ||

|---|---|---|---|---|---|---|---|---|

| MCC and Sand Model [5] | 1.97 | - | - | - | 0.141 | 0.009 | 1.305 | 0.3 |

| Proposed Model | 0.864 * | 0.0795 * | 0.016 * | 7.5 * | - | 0.009 | 1.305 | 0.3 |

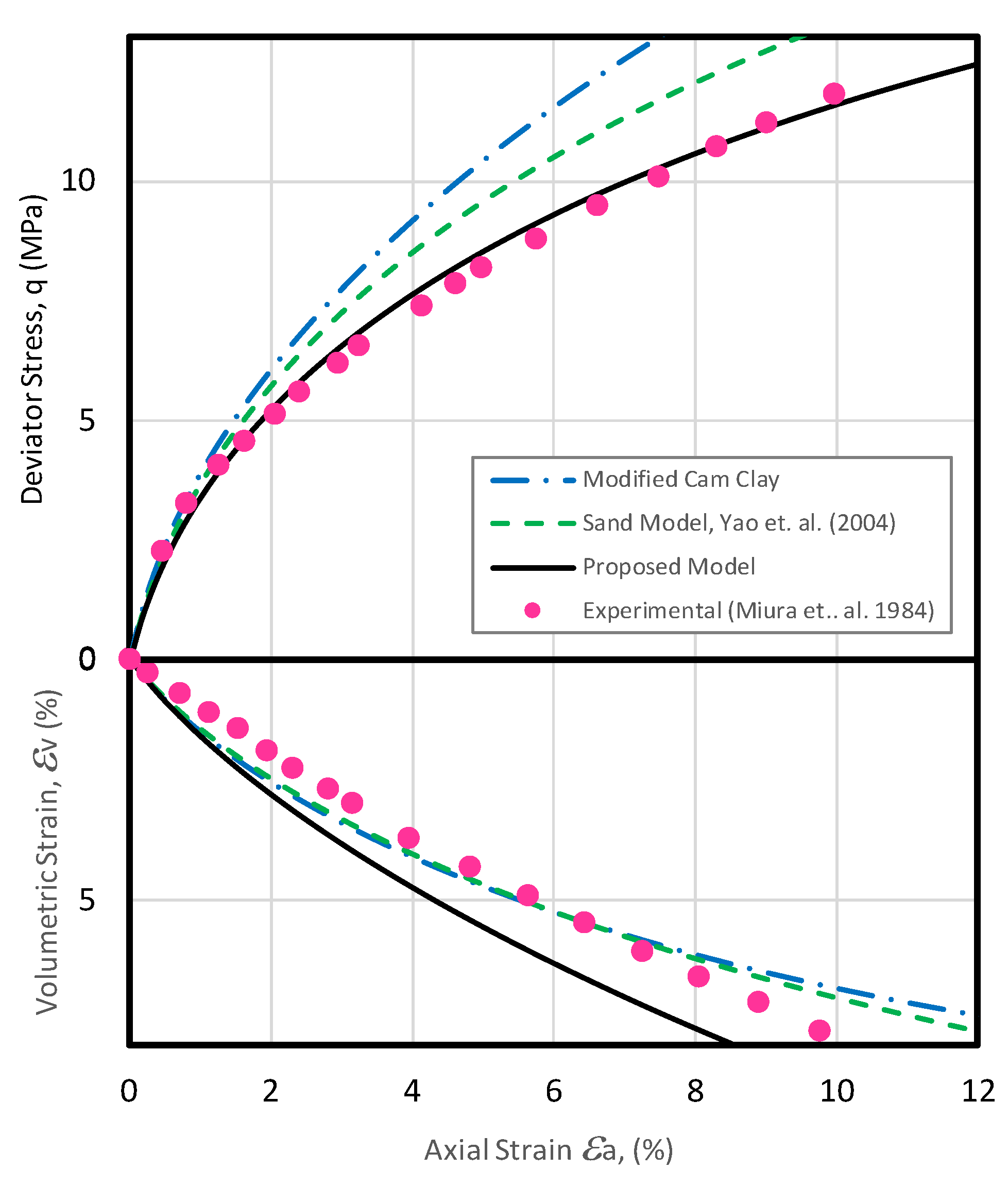

| Soil Parameter | Γ | α | θ | κ | ν | |||

|---|---|---|---|---|---|---|---|---|

| Proposed Model | 0.864 * | 0.0795 * | 0.004 * | 3.06 * | 0.02 | 1.265 | 0.25 | 1.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).