Submitted:

01 June 2023

Posted:

01 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

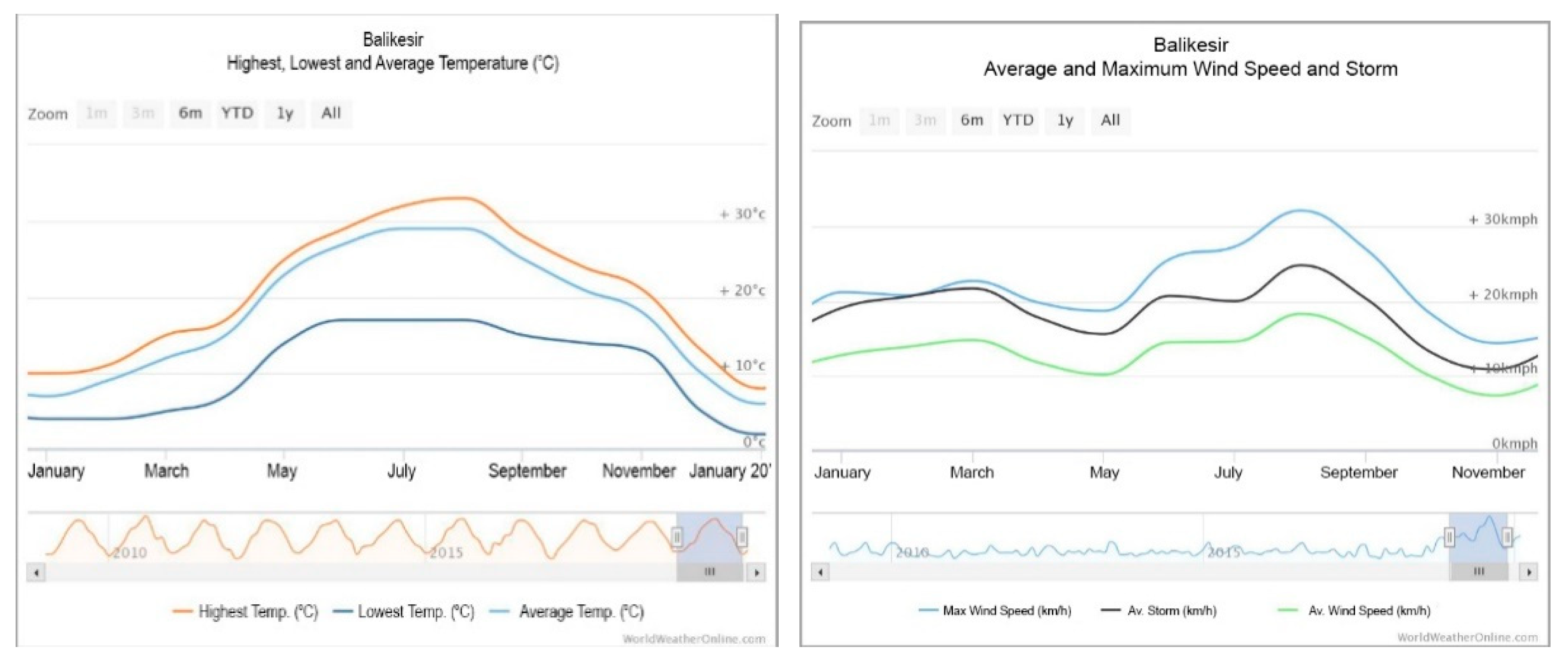

2. Materials and Methods

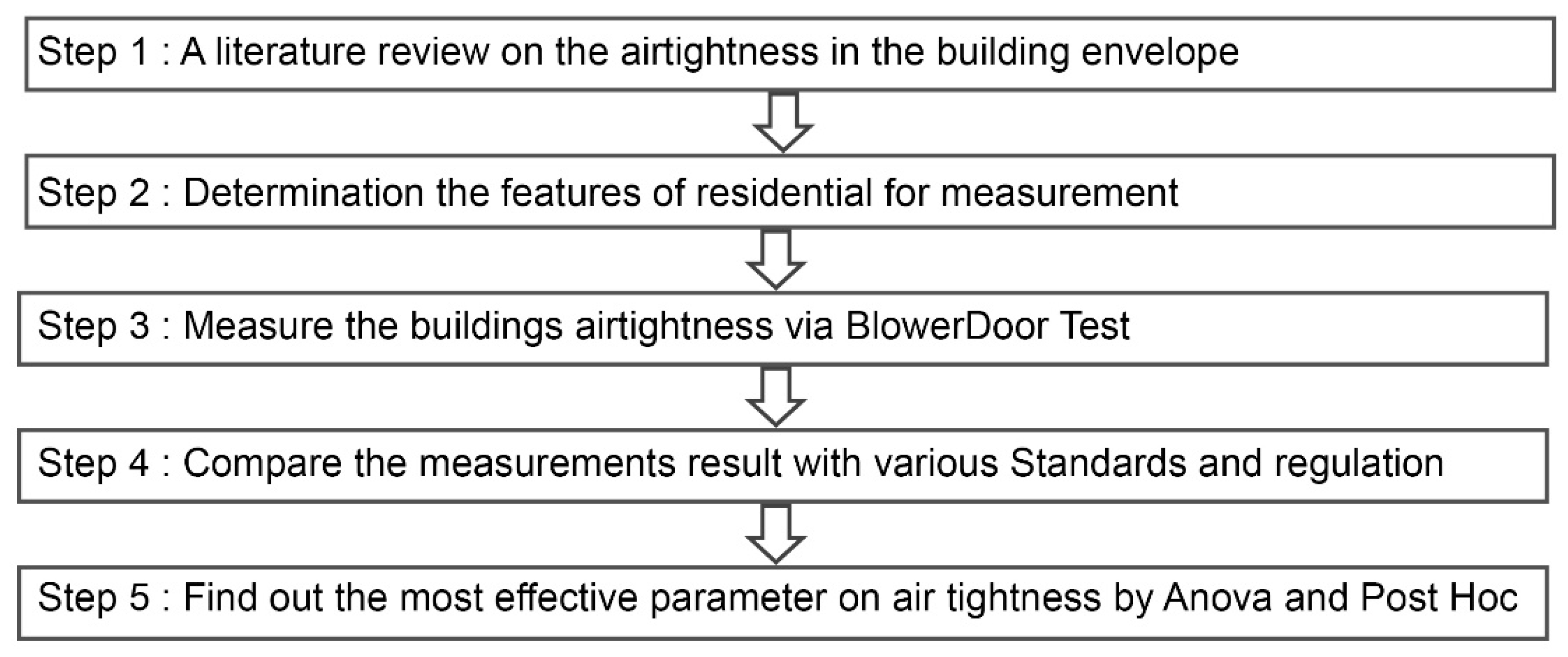

2.1. Climate Conditions

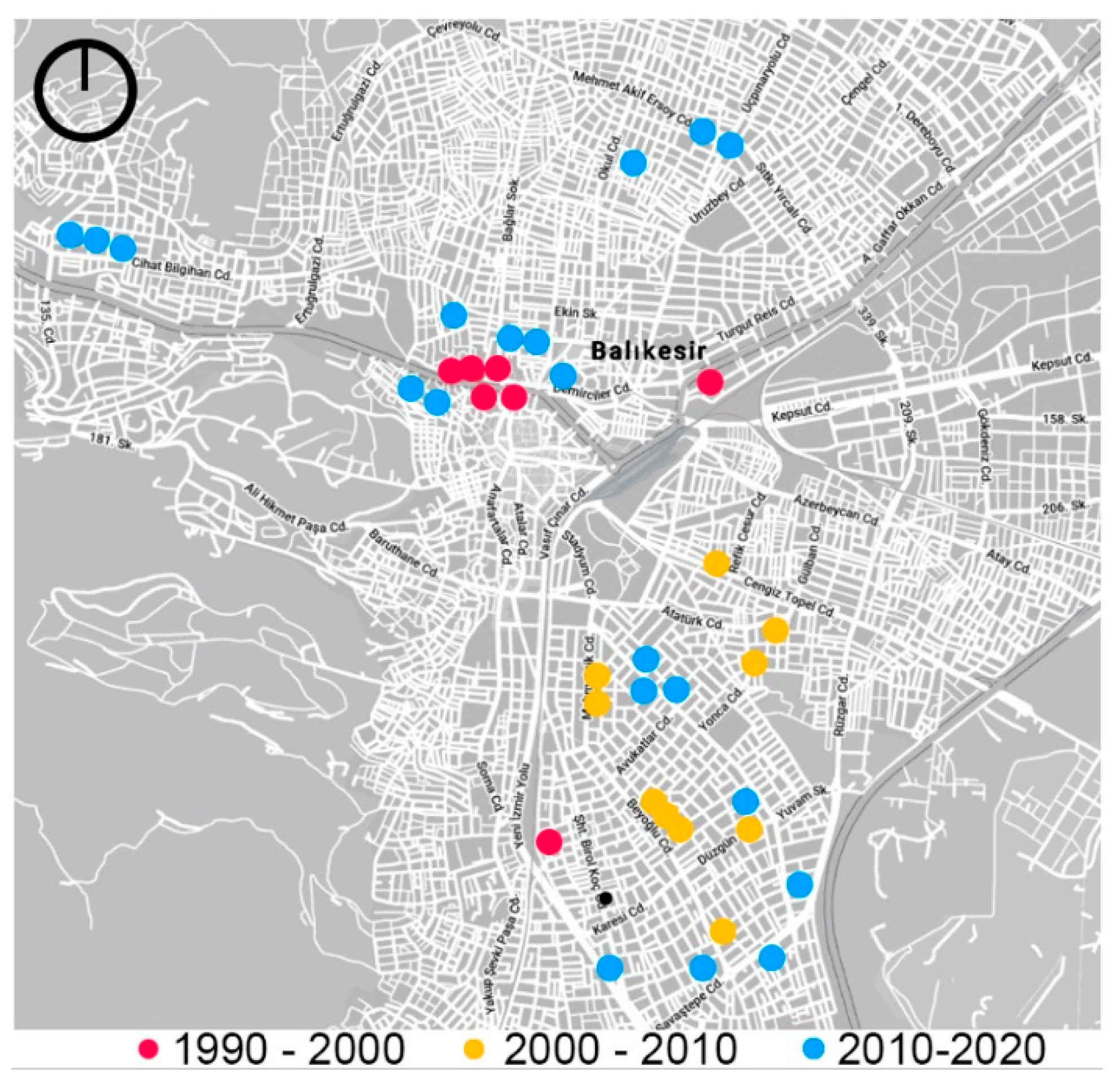

2.2. Case Buildings and Evaluations

House 1 – 1993 2 facades / Flat |

House 2 – 1993 2 facades / Flat |

House 5 – 2017 4 facades / Detached House |

House 7 – 2014 4 facades / Detached House |

House 12 – 2014 2 facades / Flat |

House 14 – 2002 1 façade / Flat |

House 15 – 2014 2 facades / Flat |

House 23 – 2007 2 facades / Flat |

House 22 – 2005 2 facades / Flat |

House 36 – 1993 2 façade / Flat |

House 40 – 2008 1 façade / Flat |

House 41 – 1995 2 façade / Flat |

| House number Construction Year | Number of Facades | Transparent/Opaque Surface Ratio |

Usage area m2 | Wall Material | Wall Insulation Materials | Joinery Type |

|---|---|---|---|---|---|---|

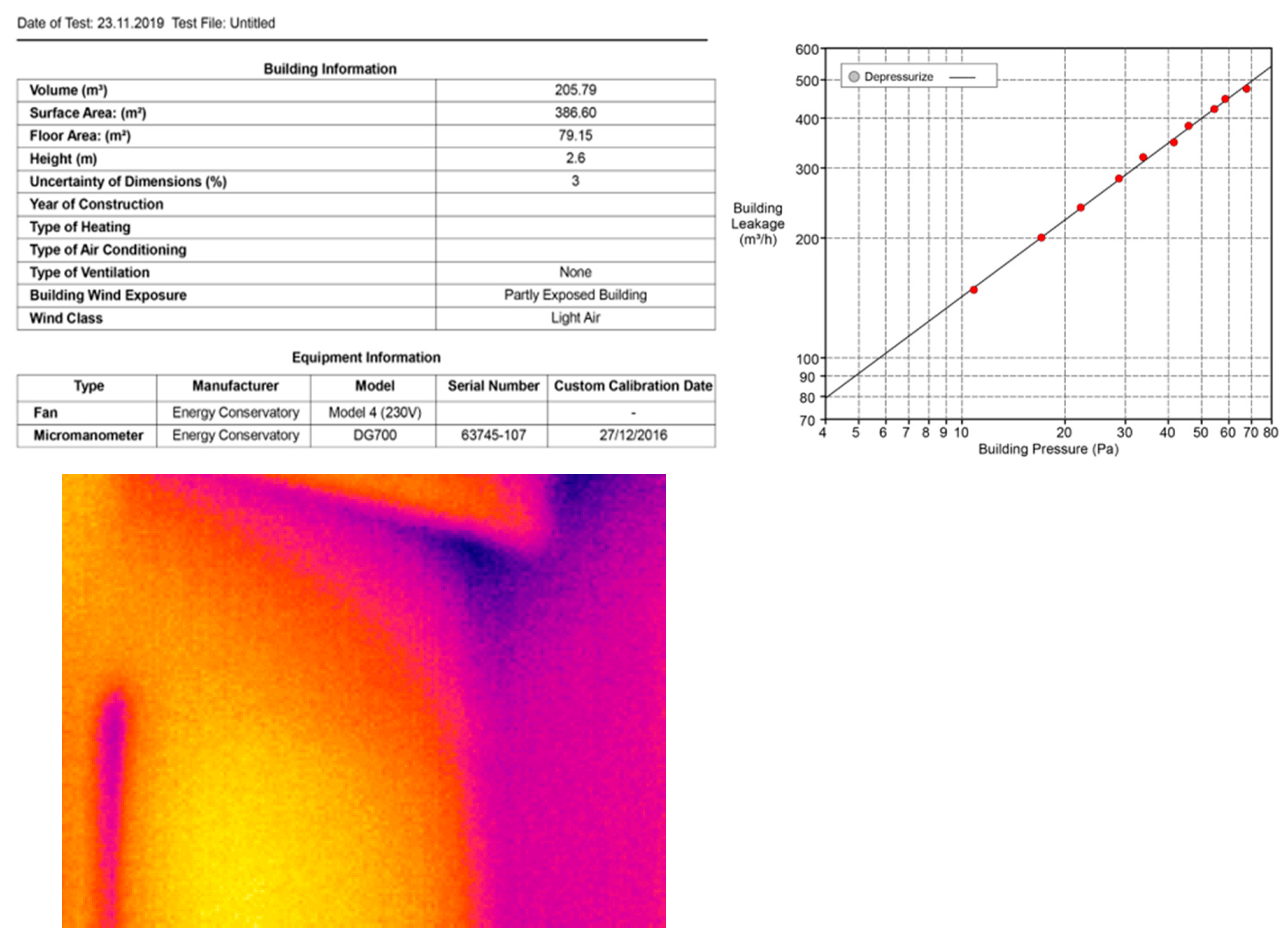

| B 1 – 1993 | 2 | 0,33 | 79,15 | Aerated Concrete | - | PVC |

| B 2 – 1993 | 2 | 0,32 | 74,15 | Aerated Concrete | - | PVC |

| B 3 – 1997 | 2 | 0,35 | 125,04 | Aerated Concrete | - | PVC |

| B 4 – 1993 | 2 | 0,37 | 64,81 | Aerated Concrete | - | PVC |

| B 5 – 2017 | 4 | 0,16 | 104,00 | Brick | - | PVC |

| B 6 – 2005 | 3 | 0,40 | 105,81 | Brick | XPS | PVC |

| B 7 – 2014 | 4 | 0,14 | 116,19 | Brick | - | PVC |

| B 8 – 2017 | 4 | 0,16 | 90,30 | Brick | - | PVC |

| B 9 – 2013 | 4 | 0,13 | 103,19 | Brick | - | PVC |

| B 10 – 2006 | 4 | 0,15 | 99,32 | Brick | - | PVC |

| B 11 – 2010 | 4 | 0,16 | 88,35 | Brick | - | PVC |

| B 12 – 2014 | 2 | 0,44 | 65,25 | Brick | XPS | PVC |

| B 13 – 2013 | 1 | 0,51 | 39,22 | Brick | XPS | Aluminum |

| B 14 – 2002 | 1 | 0,45 | 90,44 | Brick | XPS | PVC |

| B 15 – 2014 | 2 | 0,48 | 59,32 | Brick | XPS | PVC |

| B 16 – 2010 | 3 | 0,35 | 91,58 | Brick | XPS | PVC |

| B 17 – 2011 | 1 | 0,50 | 90,44 | Brick | XPS | PVC |

| B 18 – 2018 | 2 | 0,44 | 74,18 | Brick | XPS | PVC |

| B 19 – 2009 | 1 | 0,65 | 71,10 | Brick | XPS | PVC |

| B 20 – 2004 | 2 | 0,55 | 71,93 | Aerated Concrete | XPS | PVC |

| B 21 – 2003 | 3 | 0,43 | 91,58 | Brick | - | PVC |

| B 22 – 2005 | 3 | 0,40 | 66,72 | Brick | XPS | PVC |

| B 23 – 2007 | 2 | 0,50 | 62,65 | Aerated Concrete | - | PVC |

| B 24 – 2012 | 2 | 0,48 | 56,49 | Brick | XPS | PVC |

| B 25 – 2005 | 2 | 0,52 | 59,90 | Brick | - | PVC |

| B 26 – 2016 | 2 | 0,65 | 53,30 | Brick | XPS | PVC |

| B 27 – 2013 | 1 | 0,70 | 50,80 | Brick | XPS | PVC |

| B 28 – 2017 | 1 | 0,70 | 31,73 | Brick | XPS | Silicone Glass |

| B 29 – 2015 | 2 | 0,65 | 44,25 | Brick | XPS | PVC |

| B 30 – 2012 | 2 | 0,70 | 44,23 | Brick | XPS | PVC |

| B 31 – 2013 | 2 | 0,68 | 34,22 | Brick | XPS | Aluminum |

| B 32 – 2018 | 2 | 0,50 | 89,70 | Brick | XPS | PVC |

| B 33 – 2017 | 2 | 0,85 | 45,49 | Brick | XPS | Silicone Glass |

| B 34 – 2016 | 1 | 0,71 | 28,95 | Brick | XPS | PVC |

| B 35 – 2015 | 2 | 0,56 | 39,00 | Brick | XPS | PVC |

| B 36 – 1993 | 2 | 0,70 | 47,18 | Aerated Concrete | XPS | Aluminum |

| B 37 – 2009 | 2 | 0,64 | 29,70 | Brick | XPS | Aluminum |

| B 38 – 2017 | 1 | 0,70 | 43,79 | Brick | XPS | Aluminum |

| B 39 – 2015 | 1 | 0,60 | 39,26 | Brick | XPS | Aluminum |

| B 40 – 2008 | 1 | 0,50 | 37,25 | Brick | XPS | Aluminum |

| B 41 – 1995 | 2 | 0,67 | 61,09 | Brick | - | Wooden |

| B 42 – 2013 | 2 | 0,45 | 28,01 | Brick | XPS | Aluminum |

| B 43 – 1996 | 4 | 0,70 | 44,61 | Brick | - | Wooden |

2.3. BlowerDoor Test

2.4. Evaluation

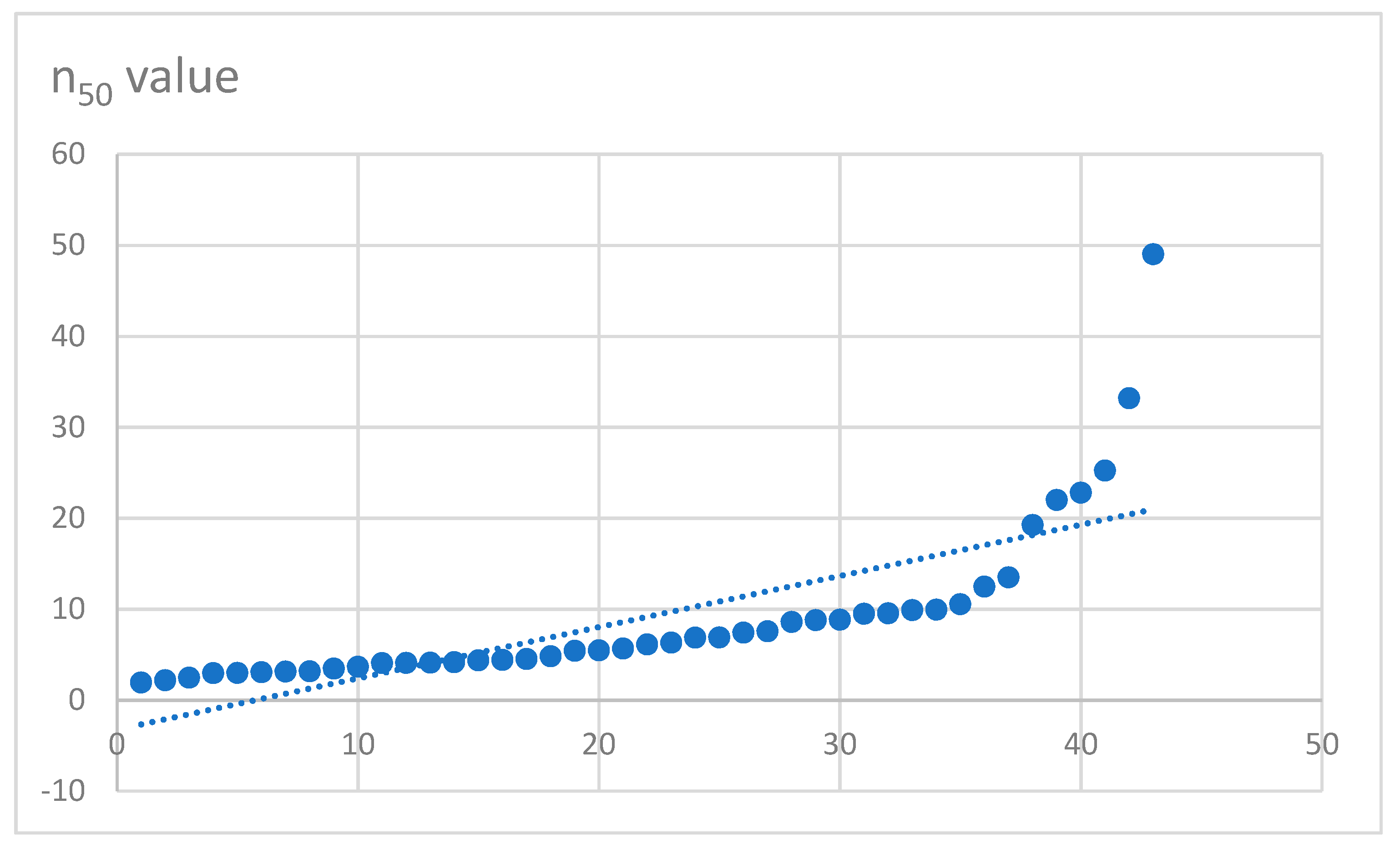

3. Findings

| House number | Usage area (m2) |

Building airtightness value n50 (1/h) |

w50 (m3/(h.m2)) |

q50 (m3/(h.m2) |

|---|---|---|---|---|

| B 1 | 79,15 | 1,94 | 5,05 | 1,03 |

| B 2 | 74,15 | 2,18 | 5,67 | 1,20 |

| B 3 | 125,04 | 2,47 | 9,71 | 4,48 |

| B 4 | 64,81 | 2,96 | 7,69 | 1,34 |

| B 5 | 104.00 | 2,99 | 7,20 | 1,76 |

| B 6 | 105.81 | 3,05 | 7,92 | 1,55 |

| B 7 | 116.19 | 3,13 | 8,77 | 1,67 |

| B 8 | 90.30 | 3,16 | 8,23 | 1,85 |

| B 9 | 103.19 | 3,46 | 6,69 | 1,87 |

| B 10 | 99.32 | 3,65 | 10,25 | 2,04 |

| B 11 | 88.35 | 4,05 | 11,35 | 2,17 |

| B 12 | 65.25 | 4,08 | 10,38 | 2,24 |

| B 13 | 39.22 | 4,12 | 20,58 | 3,99 |

| B 14 | 90.44 | 4,16 | 11,22 | 2,06 |

| B 15 | 59.32 | 4,35 | 11,09 | 2,23 |

| B 16 | 91.58 | 4,42 | 11,50 | 2,25 |

| B 17 | 90.44 | 4,50 | 12,15 | 2,23 |

| B 18 | 74.18 | 4,82 | 12,54 | 22,71 |

| B 19 | 71.10 | 5,42 | 14,08 | 3,02 |

| B 20 | 71.93 | 5,47 | 14,21 | 2,87 |

| B 21 | 91.58 | 5,67 | 14,74 | 2,89 |

| B 22 | 66.72 | 6,11 | 15,88 | 2,68 |

| B 23 | 62.65 | 6,30 | 16,39 | 3,43 |

| B 24 | 56.49 | 6,86 | 17,84 | 3,55 |

| B 25 | 59.90 | 6,89 | 17,91 | 3,69 |

| B 26 | 53.30 | 7,40 | 19,24 | 3,88 |

| B 27 | 50.80 | 7,56 | 19,65 | 4,16 |

| B 28 | 31.73 | 8,59 | 21,47 | 3,89 |

| B 29 | 44,25 | 8,79 | 22,84 | 3,59 |

| B 30 | 44,23 | 8,85 | 23,04 | 4,18 |

| B 31 | 34,22 | 9,48 | 23,71 | 4,28 |

| B 32 | 89,70 | 9,52 | 24,81 | 4,24 |

| B 33 | 45,49 | 9,88 | 24,69 | 5,65 |

| B 34 | 28,95 | 9,94 | 24,85 | 4,56 |

| B 35 | 39,00 | 10,53 | 27,37 | 4,95 |

| B 36 | 47,18 | 12,46 | 32,83 | 6,99 |

| B 37 | 29,70 | 13,48 | 33,70 | 6,46 |

| B 38 | 43,79 | 19,24 | 50,02 | 9,15 |

| B 39 | 39,26 | 21,99 | 57,17 | 11,92 |

| B 40 | 37,25 | 22,80 | 59,28 | 17,59 |

| B 41 | 61,09 | 25,23 | 9,71 | 4,48 |

| B 42 | 28,01 | 33,18 | 69,67 | 12,72 |

| B 43 | 46,61 | 49,02 | 193,29 | 49,66 |

| Mean | Standard Devision | |

|---|---|---|

| n50 | 9,16 | 9,21 |

| q50 | 23,93 | 30,22 |

| w50 | 5,65 | 8,11 |

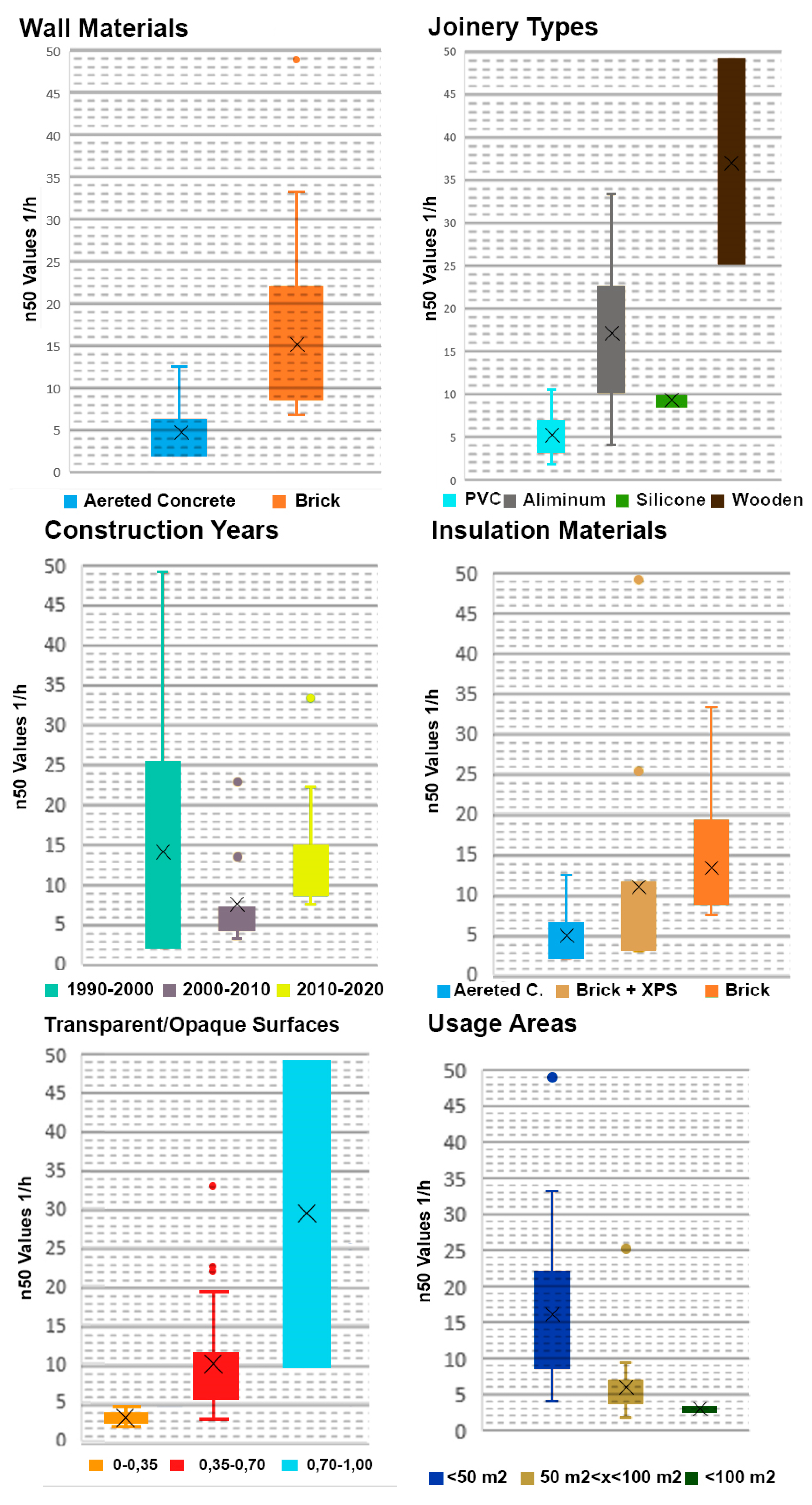

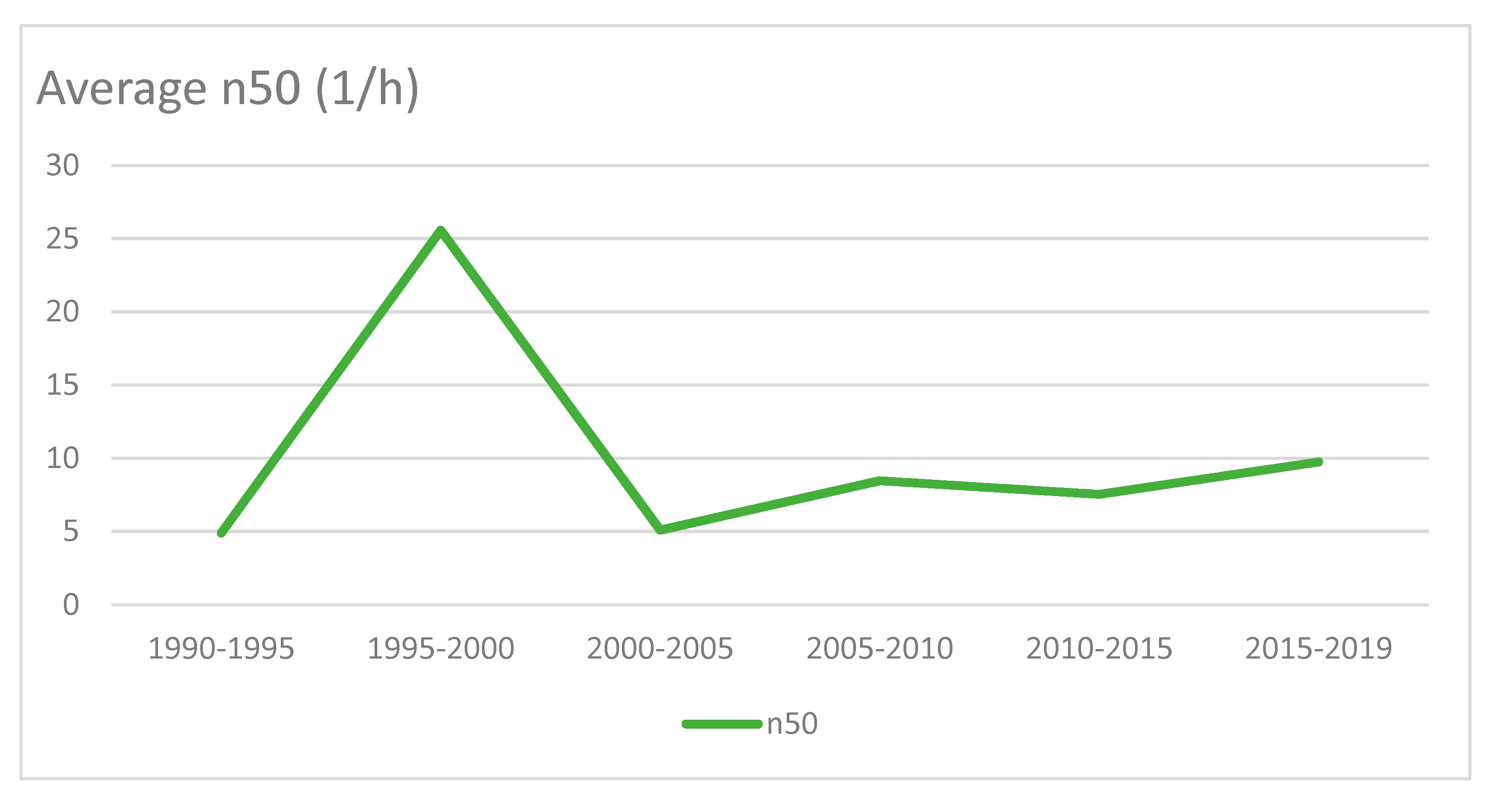

Evaluation of Measurement Results with Statistical Methods

| Sum of Squares | df | Mean Square | F | p | ||

|---|---|---|---|---|---|---|

| Building age | Between Groups | 184,182 | 2 | 92,091 | 1,089 | ,346 |

| Within Groups | 3381,965 | 40 | 84,549 | |||

| Total | 3566,147 | 42 | ||||

| Usage area | Between Groups | 1160,626 | 2 | 580,313 | 9,650 | <,001 |

| Within Groups | 2405,521 | 40 | 60,138 | |||

| Total | 3566,147 | 42 | ||||

| Joinery type | Between Groups | 2540,126 | 4 | 635,031 | 23,519 | <,001 |

| Within Groups | 1026,021 | 38 | 27,001 | |||

| Total | 3566,147 | 42 | ||||

| Insulation material | Between Groups | 21,233 | 1 | 21,233 | 0,246 | ,623 |

| Within Groups | 3544,914 | 41 | 86,461 | |||

| Total | 3566,147 | 42 | ||||

| Transparency ratio of facade | Between Groups | 638,482 | 2 | 319,241 | 4,362 | ,019 |

| Within Groups | 2927,664 | 40 | 73,192 | |||

| Total | 3566,147 | 42 | ||||

| Wall material | Between Groups | 157,561 | 1 | 157,561 | 1,895 | ,176 |

| Within Groups | 3408,586 | 41 | 83,136 | |||

| Total | 5,860 | 42 |

4. Conclusion

References

- Leprince, V.; Kapsalaki, M.; Carrié, F.R. Impact of Energy Policies on Building and Ductwork Airtightness, International Energy Agency, Energy Conservation in Buildings and Community Systems Programme, Ventilation Infor-mation Paper n° 37, September 2017, https://www.aivc.org erişim tarihi 27.03.2023.

- Kumar, D.; Alam, M.; Zou, P. X.; Sanjayan, J. G.; Memon, R. A. Comparative Analysis of Building Insulation Material Properties and Performance. Renewable and Sustainable Energy Reviews 2020, 131, 1100038. [Google Scholar] [CrossRef]

- Is Cooling The Future of Heating? Available online: https://www.iea.org/commentaries/is-cooling-the-future-of-heating (accessed on 11 March 2023).

- European Parliament, European Directive 2018/844 Amending Directive 2010/31/ EU on the Energy Performance of Buildings and Directive 2012/27, EU on energy efficiency, 2018.

- Kumar, D.; Alam, M.; Memon, R. A.; Bhayo, B. A. A Critical Review for Formulation and Conceptualization of an Ideal Building Envelope and Novel Sustainability Framework for Building Applications. Cleaner Engineering and Technology 2022, 11, 100555. [Google Scholar] [CrossRef]

- Munoz, J. F.; Pardal, C.; Echarri, V.; Agüera, J. F.; Larriva, R. A.; Calderín, M. M.; Poza-Casado, I.; Padilla-Marcos, M. A.; Meis, A. Energy Impact of the Air Infiltration in Residential Buildings in the Mediterranean Area of Spain and the Canary Islands. Energy and Buildings 2019, 188–189, 226–238. [Google Scholar] [CrossRef]

- Sadauskiene, J.; Paukstys, V.; Seduikyte, L.; Banionis, K. Impact of Airtightness on the Evaluation of Building Energy Performance in Lithuania, Energies 2014, Volume 7, pp 4972-4987.

- Leprince, V.; Carrié, F. R.; Kapsalaki, M. Building and Ductwork Airtightness Requirements in Europe – Comparison of 10 European Countries, 38th AIVC Conf. Vent, Heal. Low-Energy Build., Nottingham, UK, 2017, pp 192–201.

- Ministerio de Fomento del Gobierno de España, Código técnico de la Edificación (CTE). Documento básico HS 3: calidad del aire interior (in Spanish). Available online: http://www.codigotecnico.org/images/stories/pdf/salubridad/DBHS.pdf (accessed on 6 March 2023).

- TS 825 Thermal Insulation Standards in Buildings with Explanations and Examples (in Turkish), Izocam, January 2013, pp 27.

- Emmerich, S. J.; McDowell, T.; Anis, W. Investigation of the Impact of Commercial Building Envelope Airtightness on HVAC Energy Use, NIST Interagency/Internal Report (NISTIR) – 7238 2005, The USA.

- Sfakianaki, A.; Pavlou, K.; Santamouris, M.; Livada, I.; Assimakopoulos, M. N.; Mantas, P.; Christakopoulos, A. Airtightness Measurements of Residential Houses in Athens, Greece. Building and Environment 2008, 43, 398–405. [Google Scholar] [CrossRef]

- D’Ambrosio Alfano, F.R.; Dell’Isola, M.; Ficco, G.; Tassini, F. Experimental Analysis of Airtightness in Mediterranean Buildings Using The Fan Pressurization Method. Building and Environment 2012, 53, 16–25. [Google Scholar] [CrossRef]

- Zheng, X.; Mazzon, J.; Wallis, I.; Wood, C. J. Airtightness Measurement of an Outdoor Chamber Using The Pulse and Blower Door Methods Under Various Wind and Leakage Scenarios. Building and Environment 2020, 179. [Google Scholar] [CrossRef]

- Hsu, Y. S.; Zheng, X.; Cooper, E.; Gillott, M.; Wood, C. J. , Evaluation of The Indoor Pressure Distribution During Building Airtightness Tests Using The Pulse and Blower Door Methods. Building and Environment 2021, Volume 195, 107742. [Google Scholar] [CrossRef]

- Vinha, J.; Manelius, E.; Korpi, M.; Salminen, K.; Kurnitski, J.; Kiviste, M.; Laukkarinen, A. Airtightness of Residential Buildings in Finland. Building and Environment 2015, 93, 128–140. [Google Scholar] [CrossRef]

- Prignon, M.; Van Moeseke, G. Factors Influencing Airtightness and Airtightness Predictive Models: A Literature Review. Energy and Buildings 2017, 146, 87–97. [Google Scholar] [CrossRef]

- Hong, G.; Kim, D. D. Airtightness of Electrical, Mechanical and Architectural Components in South Korean Apartment Buildings Using The Fan Pressurization and Tracer Gas Method. Building and Environments 2018, 132, 21–29. [Google Scholar] [CrossRef]

- Almeida, R.M.S.F.; Ramos, N.M.M.; Pereira, P.F. A Contribution for The Quantification of The Influence of Windows on The Airtightness of Southern European Buildings. Energy and Buildings 2017, 139, 174–185. [Google Scholar] [CrossRef]

- Srba, J.; Böhm, M.; Berankov, J.; Trgala, K.; Oralkova, R. Estimation of Air Leakage Rate of Wood-Based Residential Buildings Constructed in The Czech Republic in The Years 2006-2014 Using Blower Door Test. Wood Research 2016, Volume 61, pp 599–605.

- Domhagen, F.; Wahlgren, P. Consequences of Varying Airtightness in Wooden Buildings. Energy Procedia 2017, 132, 873–878. [Google Scholar] [CrossRef]

- Geleziunas, V.; Banionis, K.; Paukstys, V.; Kumziene, J. Development of Airtightness Prediction Method of Masonry Walls. E3S Web of Conferences 2020, Volume 172. [CrossRef]

- Mortensen, L.H.; Bergsee, N.C. Air Tightness Measurements in Older Danish Single-Family Houses. Energy Procedia 2017, 132, 825–830. [Google Scholar] [CrossRef]

- Ashdown, M.; Crawley, J.; Biddulph, P.; Wingfield, J.; Lowe, R.; Elwell, C. Characterising the airtightness of dwellings: its improvement over time and relationship to construction techniques. International Journal of Building Pathology and Adaptation 2019. [Google Scholar] [CrossRef]

- Colijn, M.; Entrop, A.G.; Toxopeus, M.E. Evaluating The Effectiveness Of Improved Workmanship Quality On The Airtightness of Dutch detached Houses. Energy Procedia 2017, 132, 843–848. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Z.; Li, X.; Wang, H.; Ren, Y.; Zhao, D.; Xu, Z. Test and Simulation for The Airtightness of Backdraft Dampers in Residential Cooking Exhaust Shaft Systems. Journal of Building Engineering 2021, 44, 103007. [Google Scholar] [CrossRef]

- Hong, G.; Kim, C. Experimental Analysis of Airtightness Performance in High-Rise Residential Buildings for Improved Code-Compliant Simulations. Energy & Buildings 2022, 261, 111980. [Google Scholar] [CrossRef]

- Lee, D.S.; Jeong, J.W.; Jo, J.H. Experimental Study on Airtightness Test Methods in Large Buildings; Proposal of Averaging Pressure Difference Method. Building and Environment 2017, 122, 61–71. [Google Scholar] [CrossRef]

- Munoz, J. F.; Pardal, C.; Echarri, V.; Agüera, J. F.; Larriva, R. A.; Calderin, M. M.; Poza-Casado, I.; Padilla-Marcos, M. A.; Meiss, A. Energy Impact of The Air Infiltration in Residential Buildings in The Mediterranean Area of Spain and The Canary Islands. Energy and Buildings 2019, 188–189, 226–238. [Google Scholar] [CrossRef]

- Paukštys, V.; Cinelis, G.; Mockiene, J.; Daukšys, M. Airtightness and Heat Energy Loss of Mid-Size Terraced Houses Built of Different Construction Materials. Energies 2021, 14, 6367. [Google Scholar] [CrossRef]

- Kempton, L.; Daly, D.; Kokogiannakis, G.; Dewsbury, M. A Rapid Review of The Impact of Increasing Airtightness on Indoor Air Quality. Journal of Building Engineering 2022, 57, 104798. [Google Scholar] [CrossRef]

- Casado, I. P.; De Tio, P. R.; Temprano, M. F.; Marcos, M. A. P.; Meis, A. An Envelope Airtightness Predictive Model for Residential Buildings in Spain. Building and Environment 2022, 223, 109435. [Google Scholar] [CrossRef]

- Zheng, H.; Long, E.; Cheng, Z.; Yang, Z.; Jia, Y. Experimental Exploration on Airtightness Performance of Residential Buildings in The Hot Summer and Cold Winter Zone in China. Building and Environment 2022, 214, 108848. [Google Scholar] [CrossRef]

- Zheng, X.F.; Hsu, Y.S.; Pasos, A.V.; Smith, L.; Wood, C. J. A Progressive Comparison of The Novel Pulse and Conventional Steady State Methods of Measuring The Airtightness of Buildings. Energy and Buildings 2022, 261, 111983. [Google Scholar] [CrossRef]

- Banister, C.; Bartko, M.; Berquist, J.; Macdonald, I.; Vuotari, M.; Wills, A. Energy and Emissions Effects of Airtightness for Six Non-Residential Buildings in Canada With Comparison to Contemporary Limits and Assumptions. Journal of Building Engineering 2022, 58, 104977. [Google Scholar] [CrossRef]

- Climate of Balikesir Province. Available online: http://izmir.mgm.gov.tr/files/iklim/balikesir_iklim.pdf. (accessed on 15 January 2020).

- Balikesir Wheather Forecast. Available online: https://www.worldweatheronline.com/balikesir-weather/balikesir/tr.aspx. (accessed on 15 January 2020).

- Sherman, M, The Use of Blower-Door Data1. Indoor Air. 1995, pp 5. 215 - 224. [CrossRef]

- ISO 9972:2006. Available online: http://mosenergoconsult.ru/wp-content/uploads/2014/ISO-9972-2006-EN.pdf (accessed on 15 May 2020).

- AENOR, EN 13829:2000, Thermal performance of buildings. Determination of air permeability of buildings, Fan pressurization method. (ISO 9972:1996, modified), 2000.

- Analysis of variance. Available online: https://tr.wikipedia.org/wiki/Varyans_analizi. (accessed on 15 May 2020).

- G. A. Ferguson, Statistical analysis in psychology and education. New York: McGrawHill Book Company, 1981.

- B. J. Winer, Statistical principles in experimental design. New York: McGraw-Hill Book Company, 1971.

- Kayri, M. Araştırmalarda Gruplar Arası Farkın Belirlenmesine Yönelik Çoklu Karşılaştırma (Post-Hoc) Teknikleri, Fırat Üniversitesi Sosyal Bilimler Dergisi 2009.

- One-Way Analysis of Variance (ANOVA). Available online: https://mustafaotrar.net/istatistik/tek-yonlu-varyans-analizi-anova/. (accessed on 1 June 2020).

- SPSS. Available online: https://tr.wikipedia.org/wiki/SPSS. (accessed on 1 June 2020).

- Module 14 Structural Air Tightness, 25 Mayıs 2020, [Online], Erişim adresi: https://tippenergy.ie/wp-content/uploads/2011/09/Module-14-StructuralAirTightness.pdf.

| Multi-flat buildings on the floor | One-flat buildings on floor | Sealing condition of the building envelope |

|---|---|---|

| n50 < 2 | n50 < 4 | High |

| 2 ≤ n50 ≤ 5 | 4 ≤ n50 ≤ 10 | Medium |

| 5 < n50 | 10 < n50 | Low |

| Researcher, Year | Region& Period |

Aim | Type and number of examined building | Methodology and Tools | Main Findings & Results |

|---|---|---|---|---|---|

| Sfakianaki et al., 2008 [12] | Greece | Determining airtightness in housing stock in Athens. | Housing 20 |

Measurement BDT | The airtightness performance of the examined houses was found to be low. |

| Alfano et al., 2012 [13] | Italy | Airtightness measurements in Mediterranean climate. | Housing 20 |

Measurement BDT | The average air exchange rate found quite high in buildings built before 1970. |

| Šadauskienė et al., 2012 [7] | Lithuania | Developing a methodology considering airtightness. | Housing 27 |

Measurement BDT | The average airtightness value of buildings was classified. |

| Vinha et al., 2015 [16] |

Finland | To determine the airtightness of 226 residences in Finland. | Housing 226 |

Measurement BDT | Insulation material in buildings were effective on the average values of ACH50. |

| Srba et al., 2016 [20] | Czech Republic | Analyzing airtightness performance of low-energy and passive houses. | Housing 203 |

Measurement BDT | Air leakage rate values in low-energy and passive buildings were defined. |

| Prignon et al. 2017 [17] | - | Literature review about building envelope airtightness. | - | Literature review | Developing a new air tightness estimation tool for designers and contractors. |

| Lee et al. 2017 [28] | - | Investigating the most accurate tightness measurements of large buildings. | - | Literature review | Obtain accurate △P values in measuring the airtightness of large buildings underlined. |

| Colijn et al., 2017 [25] | Norway | Investigation the effect of the workmanship quality on airtightness. | Housing 44 |

Measurement BDT | Attention was drawn to the effect of workmanships quality on air tightness. |

| Mortensen et al., 2017 [23] | Denmark | Examining the airtightness performance of houses (built 1880-2007). | Housing 16 |

Measurement BDT | Airtightness performance of the houses with old construction year is better than expected. |

| Hong et al., 2018 [18] | South Korea | Measuring airtightness in new apartment buildings. | Housing 3 |

Measurement BDT | ACH50 ranged from 0.7 to 1.0 h-1. |

| Munoz et al., 2019 [6] | Spain | To examine the effect of airtightness on energy consumption. | Housing 225 |

Measurement BDT | Air infiltration impact was found 2.43 to 16.44 kWh/m2·year on heating and 0.54 to 3.06 kWh/m2·year on cooling demand. |

| Munoz et al., 2019 [29] | Spain | Investigation of airtightness in Mediterranean climate region. | Housing 129 |

Measurement BDT | The average air permeability rate (q50) in single-family dwellings was found more than flats. |

| Ashdown et al., 2019 [24] | UK | Investigation the distribution of airtightness for residences built by the same contractor. | Housing 901 |

Simulation ATTMA | Stated that the improvement of airtightness between 2008 and 2011. |

| Zheng et al., 2020 [14] | UK | To compare the airtightness results of BDT and Pulse Test. | Housing 1 |

Measurement BDT | Air permeability at 4 Pa by both methods found a percentage difference of less than 16%. |

| Hsu et al., 2021 [15] | China | Comparing BlowerDoor and pulse test methods. | Housing 1 |

Measurement BDT | Both the pulse technique and the traditional BDT fan pressurization method are compatible with each other. |

| Yang et al., 2021 [26] | China | Measuring the airtightness of backdraft dampers and their effect on air quality. | Housing 40 |

Measurement | The airtightness of backdraft dampers varies greatly with air leakage ranging from 7 to 846 m3/(h⋅m2) at a static pressure difference of 250 Pa. |

| Paukštys et al., 2021 [30] | Lithuania | Determine heat losses of Buildings affecting airtightness. | Housing 16 |

Measurement BDT | Hollow clay unit masonry caused 7-11% less airtightness compared to sand-lime block masonry. |

| Kempton et al., 2022 [31] | - | Examining the effect of airtightness on indoor air quality. | - | Literature review |

A positive correlation was found between the air exchange rate and PM2.5 and NO2 concentrations. |

| Casado et al., 2022 [32] | Spain | Model for building envelope airtightness of residential. | Housing 400 |

Measurement Model BDT |

A procedure presented for the airtightness prediction of residentials in Spain. |

| Zheng et al., 2022 [33] | China | Determining airtightness performance of residences. | Housing 14 |

Measurement BDT | Stricter regulations increase the building's airtightness performance. |

| Hsu et al., 2022 [15] | Nottingham | Airtightness under natural wind conditions in University. | Housing 1 |

Measurement Pulse Test | The maximum wind speed threshold is 5.0 m/s at 2.2 m above ground level. |

| Hong et al., 2022 [27] | South Korea | Performing experimental analysis of airtightness in residential. | Housing 12 |

Measurement BDT | Airtightness performance new buildings increased about 3-4 times compared to old buildings. |

| Zheng et al., 2022 [34] | UK | Compare BDT and Pulse Test results. | Housing 2 |

Measurement BDT- Pulse Test | Observed that it can cause a deviation of 42-60% between both test methods. |

| Banister et al., 2022 [35] | Canada | Building envelope sealing performance of office buildings. | Office 6 |

Measurement BDT | Air leakage rates found lower than the ASHRAE 90.1 standard limits values. |

| Dependent Variable: Airtightness | ||||||

| Bonferroni | ||||||

| (I) Building_age | (J) Building_age | Mean Difference (I-J) | Std. Error | Sig. | 95% Confidence Interval | |

| Lower Bound | Upper Bound | |||||

| 1990-2000 | 2000-2010 | 6,20597 | 4,44575 | ,511 | -4,9033 | 17,3153 |

| 2010-2020 | 5,15503 | 3,93197 | ,592 | -4,6704 | 14,9805 | |

| 2000-2010 | 1990-2000 | -6,20597 | 4,44575 | ,511 | -17,3153 | 4,9033 |

| 2010-2020 | -1,05095 | 3,32690 | 1,000 | -9,3644 | 7,2625 | |

| 2010-2020 | 1990-2000 | -5,15503 | 3,93197 | ,592 | -14,9805 | 4,6704 |

| 2000-2010 | 1,05095 | 3,32690 | 1,000 | -7,2625 | 9,3644 | |

| Dependent Variable: Airtightness | ||||||

| Bonferroni | ||||||

| (I) Usage_area | (J) Usage_area | Mean Difference (I-J) | Std. Error | Sig. | 95% Confidence Interval | |

| Lower Bound | Upper Bound | |||||

| <50 | 50-100 | 10,21232* | 2,57369 | <,001 | 3,7810 | 16,6436 |

| 100< | 13,13667* | 4,00460 | ,006 | 3,1298 | 23,1436 | |

| 50-100 | <50 | -10,21232* | 2,57369 | <,001 | -16,6436 | -3,7810 |

| 100< | 2,92435 | 3,82653 | 1,000 | -6,6376 | 12,4863 | |

| 100< | <50 | -13,13667* | 4,00460 | ,006 | -23,1436 | -3,1298 |

| 50-100 | -2,92435 | 3,82653 | 1,000 | -12,4863 | 6,6376 | |

| *. The mean difference is significant at the 0.05 level. | ||||||

| Dependent Variable: Airtightness | ||||||

| Bonferroni | ||||||

| (I) Facade_ratio | (J) Facade_ratio | Mean Difference (I-J) | Std. Error | Sig. | 95% Confidence Interval | |

| Lower Bound | Upper Bound | |||||

| 0-0,35 | 0,35-0,70 | -5,96963 | 3,44380 | ,272 | -14,5752 | 2,6359 |

| 0,70-1,00 | -12,62250* | 4,27760 | ,016 | -23,3116 | -1,9334 | |

| 0,35-0,70 | 0-0,35 | 5,96963 | 3,44380 | ,272 | -2,6359 | 14,5752 |

| 0,70-1,00 | -6,65287 | 3,44380 | ,181 | -15,2584 | 1,9527 | |

| 0,70-1,00 | 0-0,35 | 12,62250* | 4,27760 | ,016 | 1,9334 | 23,3116 |

| 0,35-0,70 | 6,65287 | 3,44380 | ,181 | -1,9527 | 15,2584 | |

| *. The mean difference is significant at the 0.05 level. | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).