Submitted:

31 May 2023

Posted:

01 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Barriers in implementing CE strategies in SEMs

1.2. Information Technology and CE

2. Materials and Methods

- map their business processes according the LCA method

- calculate the Product CF

- gain a better insight of the carbon impact of their business

- identify carbon-intensive procedures in their business cycle

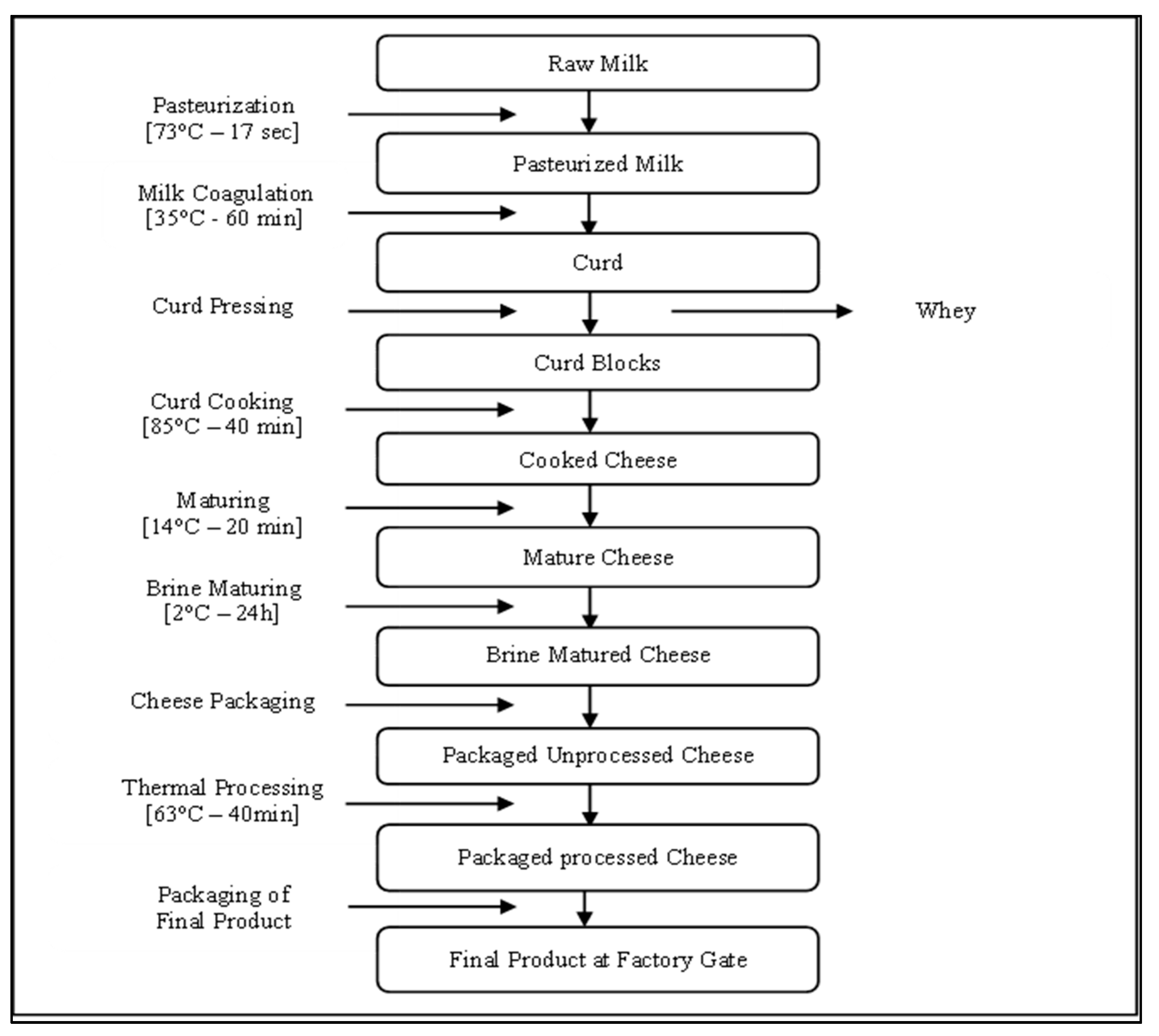

2.1. Case study

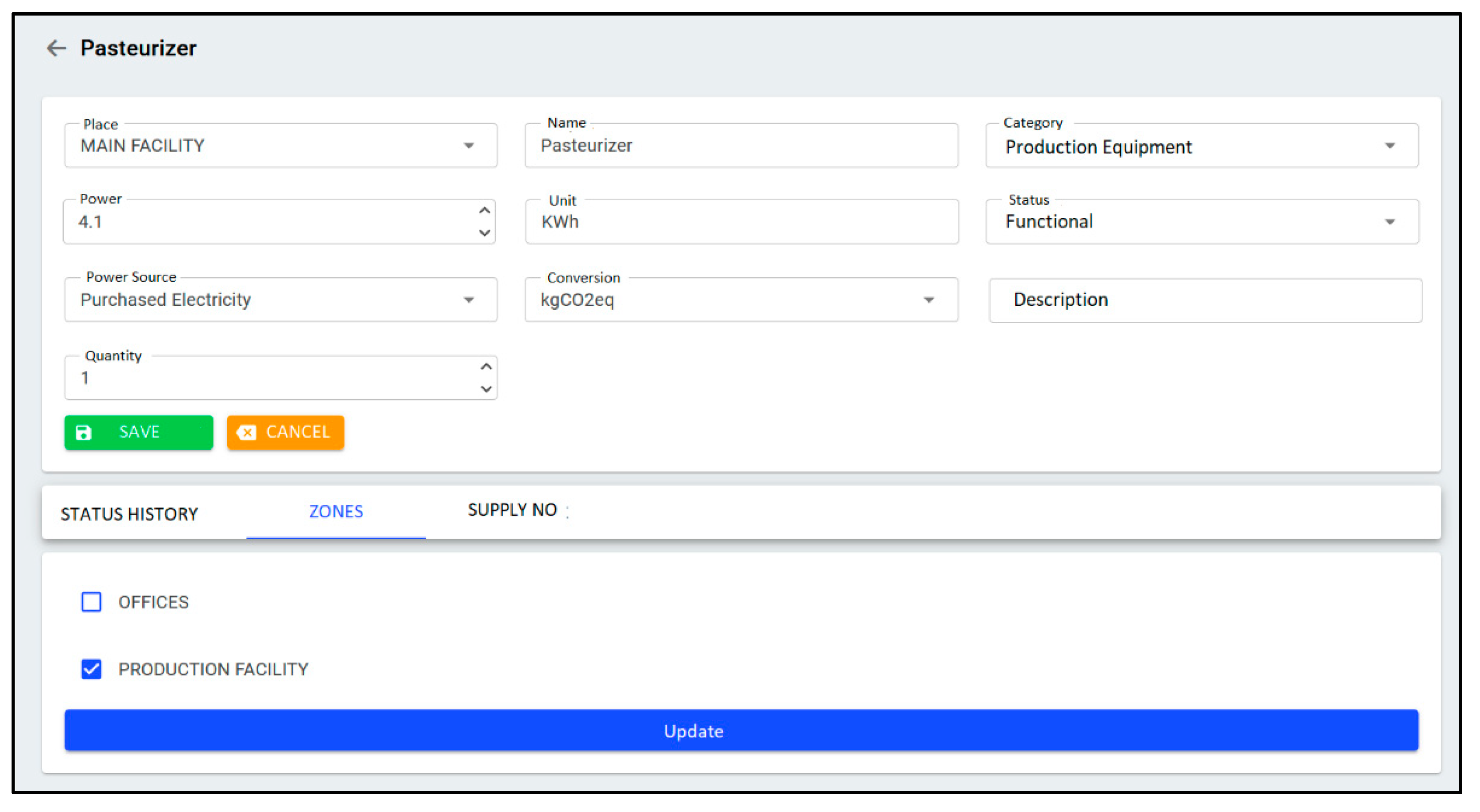

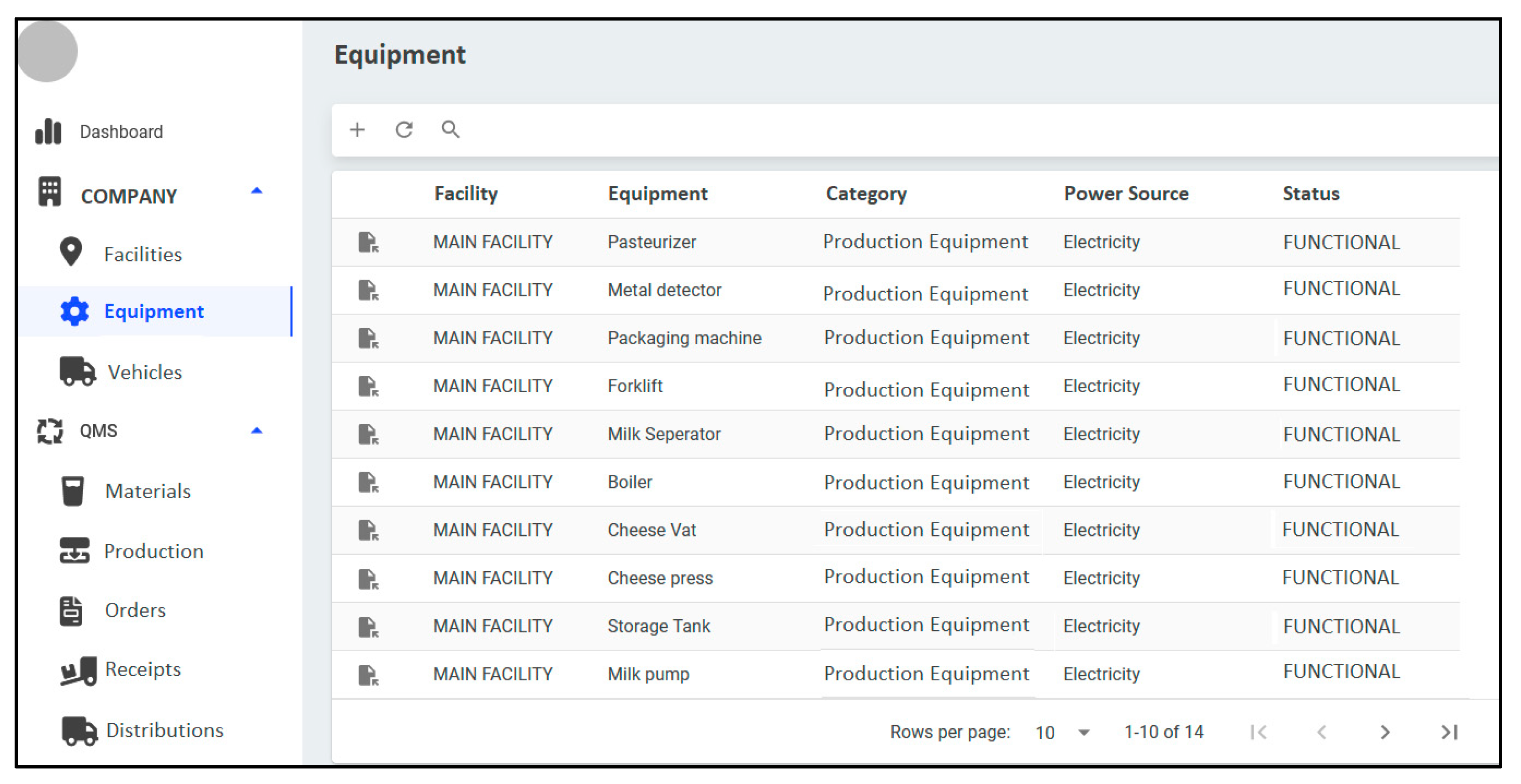

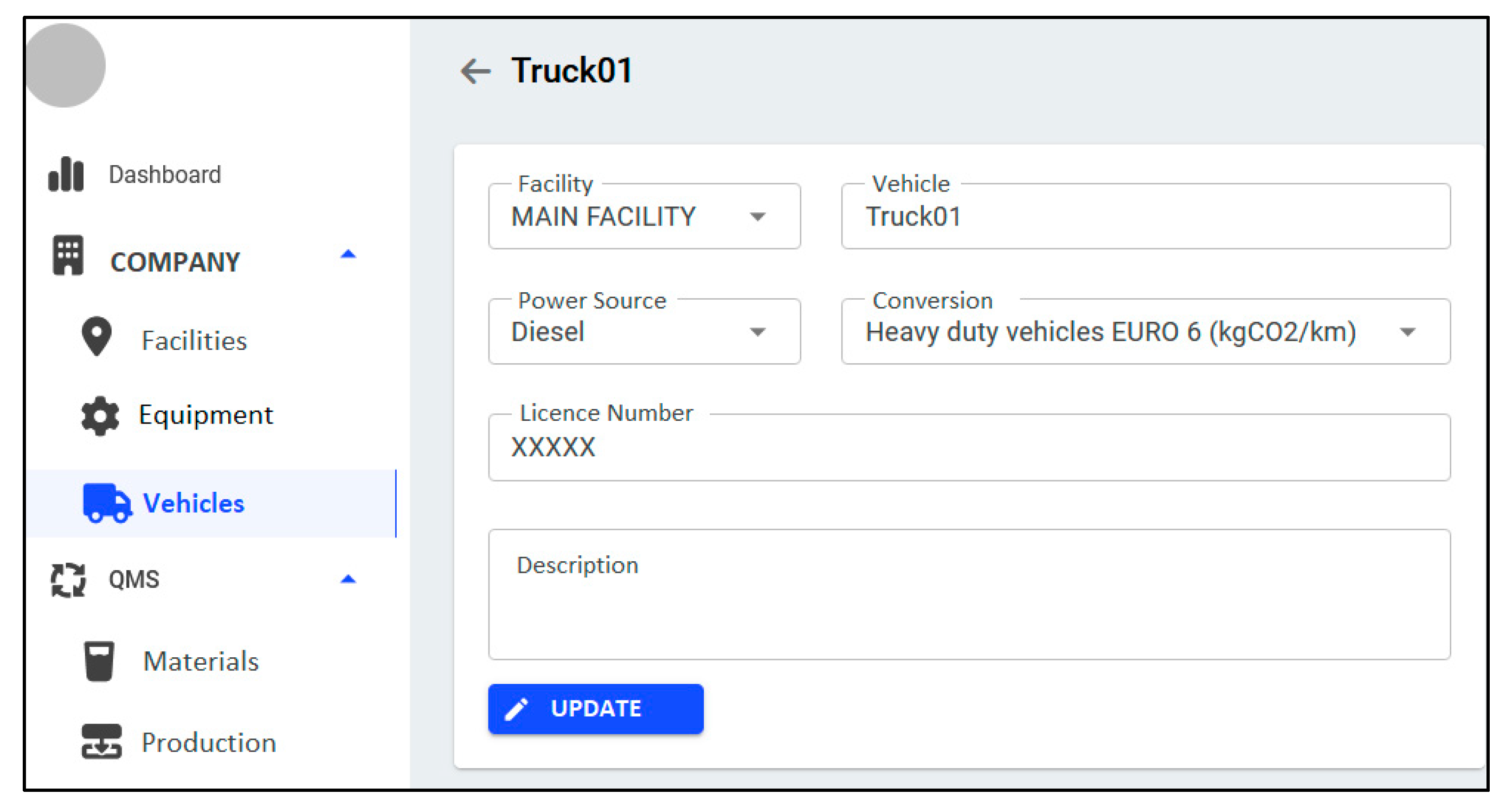

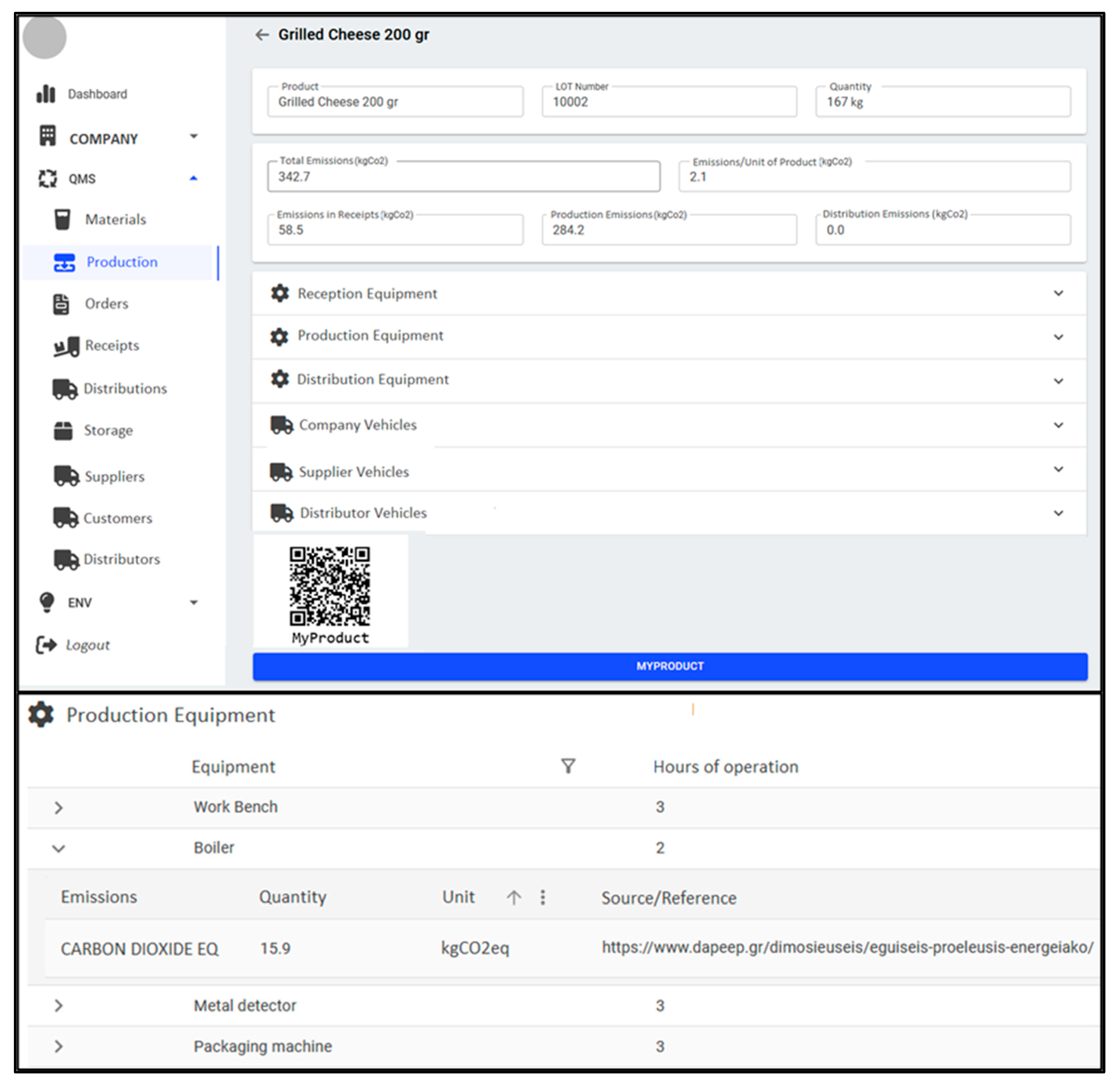

3. Tool's description and Results

- the dashboard, which provides an overview of the company’s emissions at corporate level

- the company, where the user can map the structure of the company by adding different departments (facilities), equipment used in those departments and company-owned vehicles.

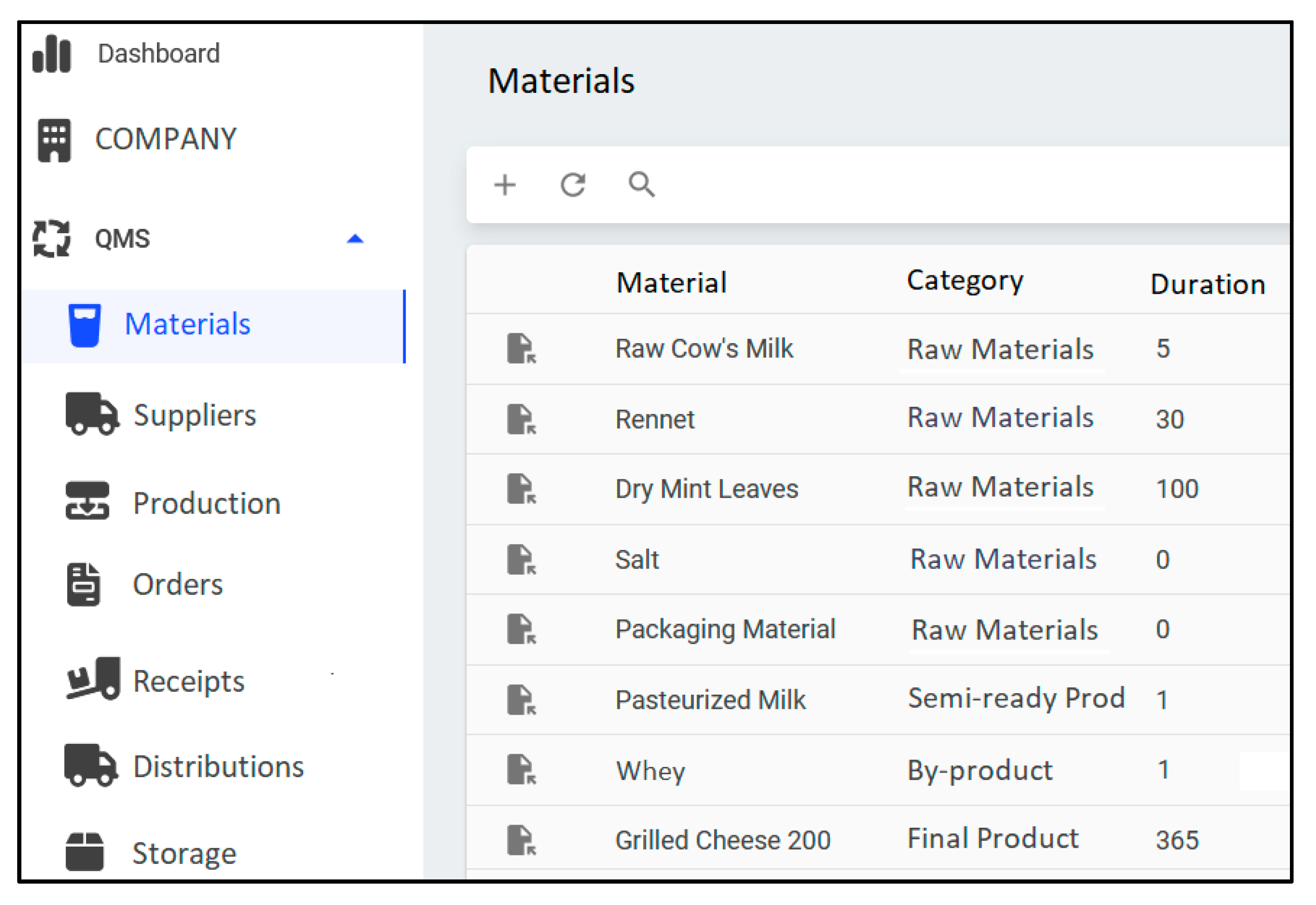

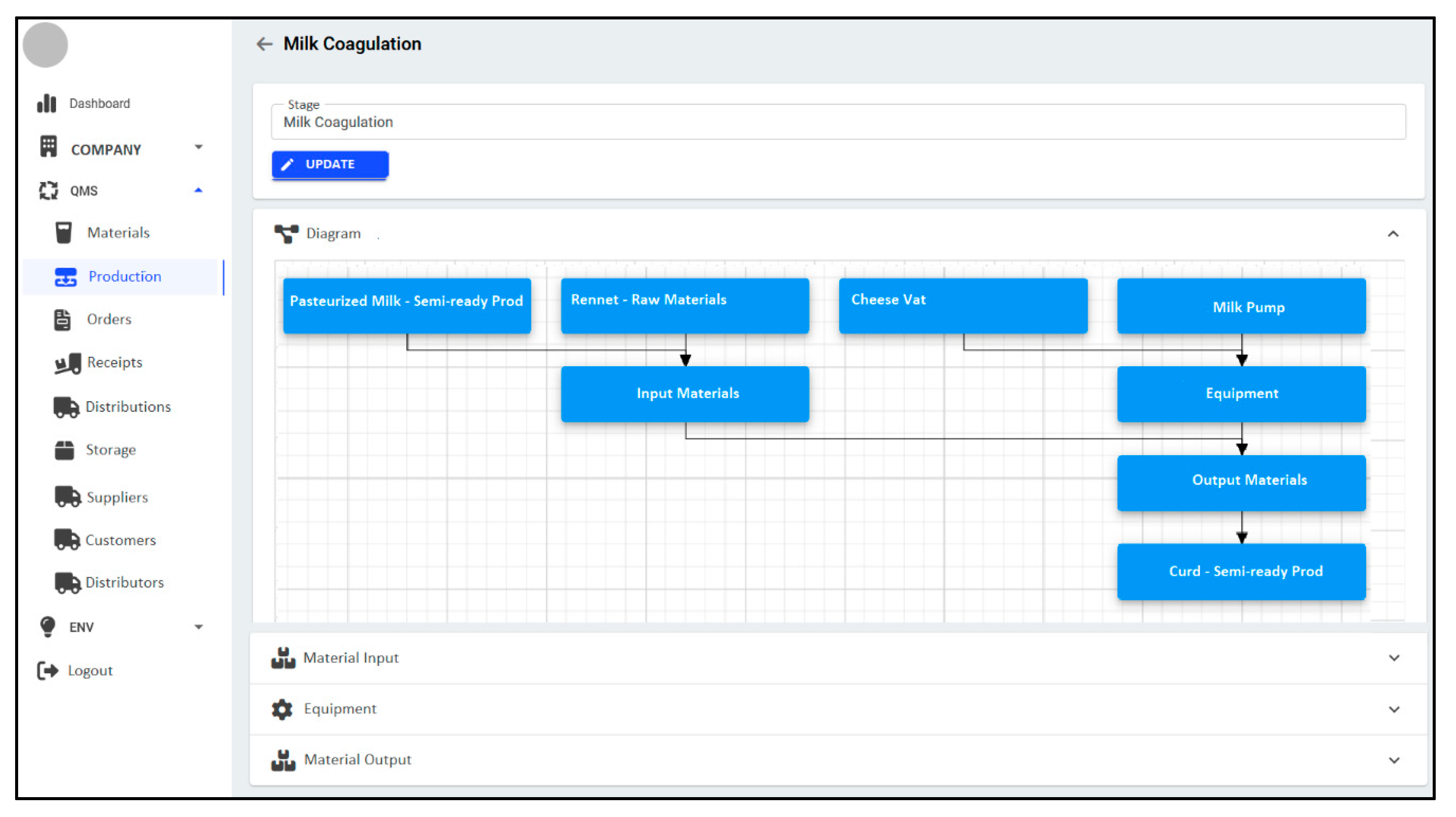

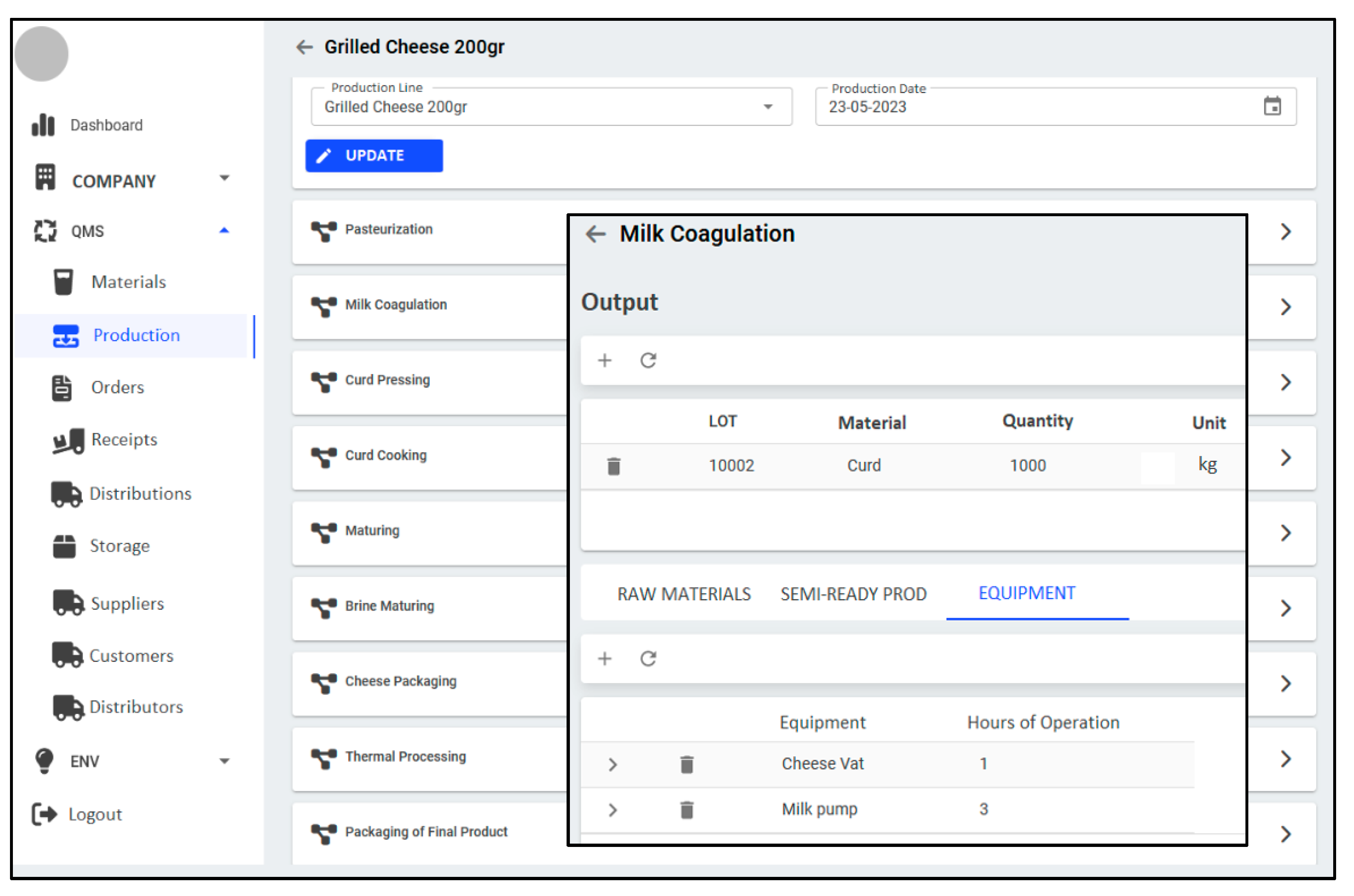

- the QMS (abbreviation for Quality Management System), where the user can design the production process, create an inventory of materials (raw materials, semi-ready products and final products), suppliers, customers and distributors, and manage orders, receipts and storage of the materials.

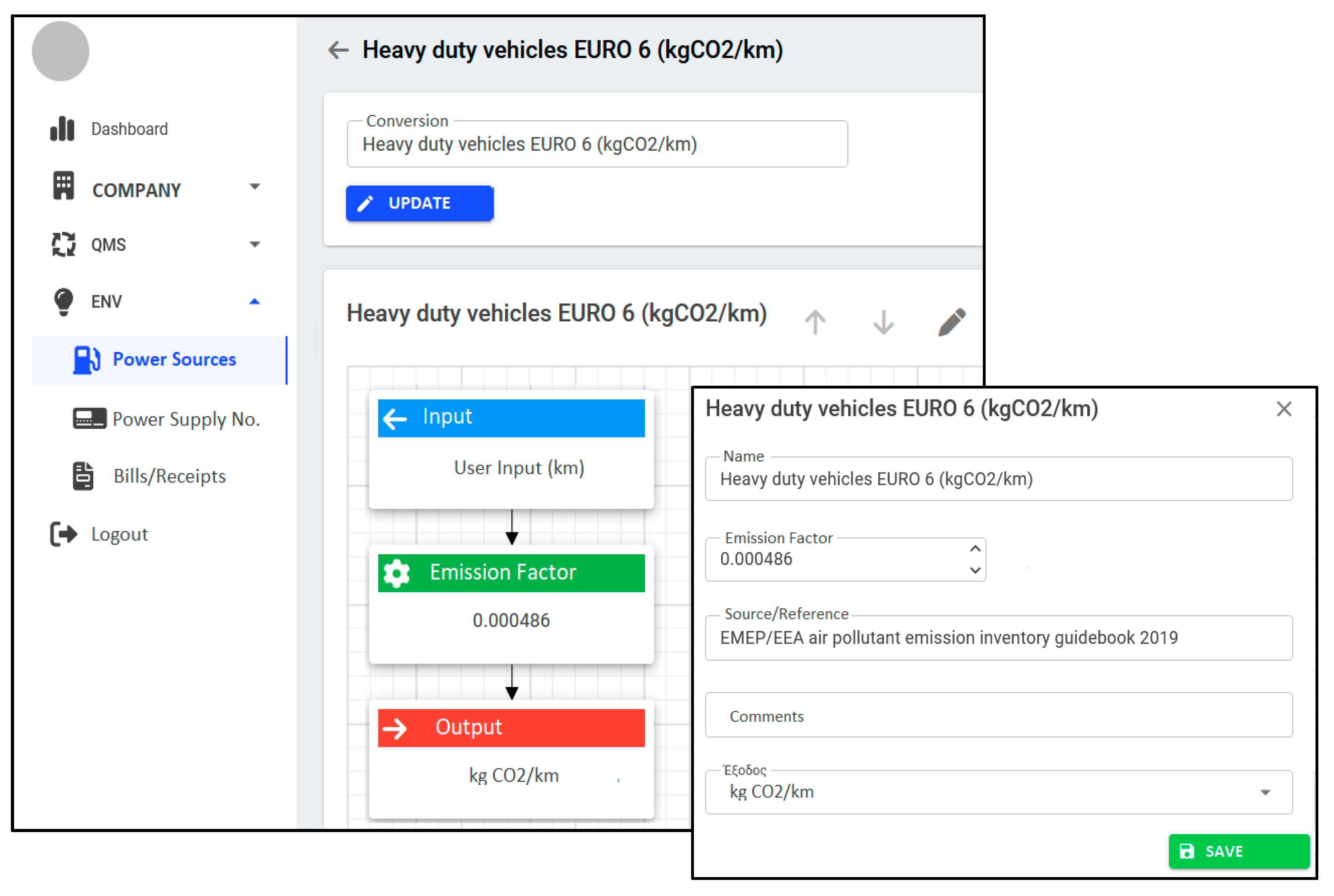

- the ENV, where the user can manage any energy relate information, i.e., add power sources and their respective emission factors and keep a record of energy related bills.

4. Discussion and Conclusions

6. Patents

Funding

Conflicts of Interest

References

- IPCC. AR6 Synthesis Report: Climate Change, 2023—IPCC. https://www.ipcc.ch/report/sixth-assessment-report-cycle/.

- The GHG Protocol. Corporate Standard, 2004. https://ghgprotocol.org/corporate-standard.

- The GHG Protocol. Product Standard, 2011. https://ghgprotocol.org/product-standard.

- IDF. Bulletin of the IDF N°520/2022: The IDF global Carbon Footprint... FIL-IDF. 2022. IDF https://shop.fil-idf.org/products/the-idf-global-carbon-footprint-standard-for-the-dairy-sector.

- ISO 14044:2006. Environmental management—Life cycle assessment—Requirements and guidelines, 2006, ISO. https://www.iso.org/standard/38498.html.

- UNEP. Global Guidance Principles for Life Cycle Assessment Databases: A Basis for Greener Processes and Products: ’Shonan Guidance Principles’ /: Produced by the UNEP/SETAC Life Cycle Initiative, 2011. UNEP.

- PAS 2050:2011 Specification for the assessment of the life cycle greenhouse gas emissions of goods and services, 2011. European Standards https://www.en-standard.eu/pas-2050-2011-specification-for-the-assessment-of-the-life-cycle-greenhouse-gas-emissions-of-goods-and-services/.

- Directorate-General for Internal Market; DIW econ; PwC; Gorgels, S.; Priem, M.; Blagoeva, T.; Martinelle, A.; Milanesi, G. Annual Report on European SMEs 2021/2022: SMEs and Environmental Sustainability : Background Document; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- Dangelico, R.M.; Pontrandolfo, P. Being ‘Green and Competitive’: The Impact of Environmental Actions and Collaborations on Firm Performance. Bus. Strategy Environ. 2015, 24, 413–430. [Google Scholar] [CrossRef]

- Revell, A.; Stokes, D.; Chen, H. Small Businesses and the Environment: Turning over a New Leaf? Bus. Strategy Environ. 2010, 19, 273–288. [Google Scholar] [CrossRef]

- Lucas, M.T. Understanding Environmental Management Practices: Integrating Views from Strategic Management and Ecological Economics. Bus. Strategy Environ. 2010, 19, 543–556. [Google Scholar] [CrossRef]

- Brammer, S.; Hoejmose, S.; Marchant, K. Environmental Management in SMEs in the UK: Practices, Pressures and Perceived Benefits. Bus. Strategy Environ. 2012, 21, 423–434. [Google Scholar] [CrossRef]

- Leonidou, L.C.; Christodoulides, P.; Kyrgidou, L.P.; Palihawadana, D. Internal Drivers and Performance Consequences of Small Firm Green Business Strategy: The Moderating Role of External Forces. J. Bus. Ethics 2017, 140, 585–606. [Google Scholar] [CrossRef]

- Madueno, J.H.; Jorge, M.L.; Conesa, I.M.; Martínez-Martínez, D. Relationship between Corporate Social Responsibility and Competitive Performance in Spanish SMEs: Empirical Evidence from a Stakeholders’ Perspective. BRQ Bus. Res. Q. 2016, 19, 55–72. [Google Scholar] [CrossRef]

- Brundtland, G.H. Our Common Future—Call for Action. Environ. Conserv. 1987, 14, 291–294. [Google Scholar] [CrossRef]

- Hajian, M.; Jangchi Kashani, S. 1-Evolution of the Concept of Sustainability. From Brundtland Report to Sustainable Development Goals. In Sustainable Resource Management; Hussain, C.M., Velasco-Muñoz, J.F., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–24. [Google Scholar] [CrossRef]

- Mondini, G. Sustainability Assessment: From Brundtland Report to Sustainable Development Goals. Valori e valutazioni 2019, No. 23.

- Schaltegger, S.; Wagner, M. Sustainable Entrepreneurship and Sustainability Innovation: Categories and Interactions. Bus. Strategy Environ. 2011, 20, 222–237. [Google Scholar] [CrossRef]

- Boulding, K. The Economics of the Coming Spaceship Earth. In Environmental Quality in a Growing Economy; Jarrett, H., Ed.; Johns Hopkins University Press: Baltimore, MD, USA, 1966. [Google Scholar]

- Pearce DW, Turner PK. The economics of natural resources and the environment. Harvester Wheatsheaf, Hemel Hempstead, 1990.

- Lacy, P.; Keeble, J.; McNamara, R.; Rutqvist, J.; Haglund, T.; Cui, M.; Cooper, A.; Pettersson, C.; Kevin, E.; Buddemeier, P. Circular Advantage: Innovative Business Models and Technologies to Create Value in a World without Limits to Growth; Accenture: Chicago, IL, USA 2014; Volume 24. [Google Scholar]

- Steinberg, G.; Rodysill, J. How Closing the Supply Chain Loop Opens the Door to Long-Term Value, 2021. Available online: https://www.ey.com/en_gl/consulting/how-closing-the-supply-chain-loop-opens-the-door-to-long-term-value.

- Gartner. 3 Supply Chain Strategies to Accelerate Circular Economy Outcomes, 2021. Available onlinehttps://www.gartner.com/smarterwithgartner/3-supply-chain-strategies-to-accelerate-circular-economy-outcomes.

- Hannon, E.; Magnin-Mullez, C.; Vanthournot, H. The circular economy: Moving from theory to practice, 2016. Available onlinehttps://www.mckinsey.com/capabilities/sustainability/our-insights/the-circular-economy-moving-from-theory-to-practice.

- Ellen MacArthur Foundation and McKinsey & Company. Towards the Circular Economy: Accelerating the Scale-up Across Global Supply Chains; World Economic Forum: Geneva, Switzerland, 2014; Available online: https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-3-accelerating-the-scale-up-across-global. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy–A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the Business Models for Circular Economy—Towards the Conceptual Framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef]

- Nußholz, J.L.K. Circular Business Models: Defining a Concept and Framing an Emerging Research Field. Sustainability 2017, 9, 1810. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards Circular Economy Implementation: A Comprehensive Review in Context of Manufacturing Industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Blomsma, F.; Brennan, G. The Emergence of Circular Economy: A New Framing Around Prolonging Resource Productivity: The Emergence of Circular Economy. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef]

- de Melo, T.A.C.; de Oliveira, M.A.; de Sousa, S.R.G.; Vieira, R.K.; Amaral, T.S. Circular Economy Public Policies: A Systematic Literature Review. Procedia Comput. Sci. 2022, 204, 652–662. [Google Scholar] [CrossRef]

- Su, B.; Heshmati, A.; Geng, Y.; Yu, X. A Review of the Circular Economy in China: Moving from Rhetoric to Implementation. J. Clean. Prod. 2013, 42, 215–227. [Google Scholar] [CrossRef]

- McDowall, W.; Geng, Y.; Huang, B.; Barteková, E.; Bleischwitz, R.; Türkeli, S.; Kemp, R.; Doménech, T. Circular Economy Policies in China and Europe. J. Ind. Ecol. 2017, 21, 651–661. [Google Scholar] [CrossRef]

- Mhatre, P.; Panchal, R.; Singh, A.; Bibyan, S. A Systematic Literature Review on the Circular Economy Initiatives in the European Union. Sustain. Prod. Consum. 2021, 26, 187–202. [Google Scholar] [CrossRef]

- Arsova, S.; Genovese, A.; Ketikidis, P.H.; Alberich, J.P.; Solomon, A. Implementing Regional Circular Economy Policies: A Proposed Living Constellation of Stakeholders. Sustainability 2021, 13, 4916. [Google Scholar] [CrossRef]

- Avdiushchenko, A.; Zając, P. Circular Economy Indicators as a Supporting Tool for European Regional Development Policies. Sustainability 2019, 11, 3025. [Google Scholar] [CrossRef]

- Camilleri, M.A. European Environment Policy for the Circular Economy: Implications for Business and Industry Stakeholders. Sustain. Dev. 2020, 28, 1804–1812. [Google Scholar] [CrossRef]

- Ignatyeva, M.; Yurak, V.; Dushin, A.; Strovsky, V.; Zavyalov, S.; Malyshev, A.; Karimova, P. How Far Away Are World Economies from Circularity: Assessing the Capacity of Circular Economy Policy Packages in the Operation of Raw Materials and Industrial Wastes. Sustainability 2021, 13, 4394. [Google Scholar] [CrossRef]

- Ikiz Kaya, D.; Pintossi, N.; Dane, G. An Empirical Analysis of Driving Factors and Policy Enablers of Heritage Adaptive Reuse within the Circular Economy Framework. Sustainability 2021, 13, 2479. [Google Scholar] [CrossRef]

- Macarthur, E. Founding Partners of the towards the Circular Economy Economic and Business Rationale for an Accelerated Transition. 2012.

- Zamfir, A.-M.; Mocanu, C.; Grigorescu, A. Circular Economy and Decision Models among European SMEs. Sustainability 2017, 9, 1507. [Google Scholar] [CrossRef]

- Oncioiu, I.; Căpuşneanu, S.; Türkeș, M.C.; Topor, D.I.; Constantin, D.-M. O.; Marin-Pantelescu, A.; Ștefan Hint, M. The Sustainability of Romanian SMEs and Their Involvement in the Circular Economy. Sustainability 2018, 10, 2761. [Google Scholar] [CrossRef]

- Barón, A.; de Castro, R.; Giménez, G. Circular Economy Practices among Industrial EMAS-Registered SMEs in Spain. Sustainability 2020, 12, 9011. [Google Scholar] [CrossRef]

- Dey, P.K.; Malesios, C.; De, D.; Budhwar, P.; Chowdhury, S.; Cheffi, W. Circular Economy to Enhance Sustainability of Small and Medium-Sized Enterprises. Bus. Strategy Environ. 2020, 29, 2145–2169. [Google Scholar] [CrossRef]

- Dey, P.K.; Malesios, C.; Chowdhury, S.; Saha, K.; Budhwar, P.; De, D. Adoption of Circular Economy Practices in Small and Medium-Sized Enterprises: Evidence from Europe. Int. J. Prod. Econ. 2022, 248, 108496. [Google Scholar] [CrossRef]

- Prieto-Sandoval, V.; Jaca, C.; Santos, J.; Baumgartner, R.J.; Ormazabal, M. Key Strategies, Resources, and Capabilities for Implementing Circular Economy in Industrial Small and Medium Enterprises. Corp. Soc. Responsib. Environ. Manag. 2019, 26, 1473–1484. [Google Scholar] [CrossRef]

- Mura, M.; Longo, M.; Zanni, S. Circular Economy in Italian SMEs: A Multi-Method Study. J. Clean. Prod. 2020, 245, 118821. [Google Scholar] [CrossRef]

- Bassi, F.; Dias, J.G. The Use of Circular Economy Practices in SMEs across the EU. Resour. Conserv. Recycl. 2019, 146, 523–533. [Google Scholar] [CrossRef]

- Bassi, F.; Guidolin, M. Resource Efficiency and Circular Economy in European SMEs: Investigating the Role of Green Jobs and Skills. Sustainability 2021, 13, 12136. [Google Scholar] [CrossRef]

- Madueno, J.H.; Jorge, M.L.; Conesa, I.M.; Martínez-Martínez, D. Relationship between Corporate Social Responsibility and Competitive Performance in Spanish SMEs: Empirical Evidence from a Stakeholders’ Perspective. BRQ Bus. Res. Q. 2016, 19, 55–72. [Google Scholar] [CrossRef]

- Rizos, V.; Behrens, A.; Van der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papadelis, S.; Hirschnitz-Garbers, M.; et al. Implementation of Circular Economy Business Models by Small and Medium-Sized Enterprises (SMEs): Barriers and Enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef]

- de Jesus, A.; Mendonça, S. Lost in Transition? Drivers and Barriers in the Eco-Innovation Road to the Circular Economy. Ecol. Econ. 2018, 145, 75–89. [Google Scholar] [CrossRef]

- Ritzén, S.; Sandström, G.Ö. Barriers to the Circular Economy–Integration of Perspectives and Domains. Procedia CIRP 2017, 64, 7–12. [Google Scholar] [CrossRef]

- Hina, M.; Chauhan, C.; Kaur, P.; Kraus, S.; Dhir, A. Drivers and Barriers of Circular Economy Business Models: Where We Are Now, and Where We Are Heading. J. Clean. Prod. 2022, 333, 130049. [Google Scholar] [CrossRef]

- Hart, J.; Adams, K.; Giesekam, J.; Tingley, D.D.; Pomponi, F. Barriers and Drivers in a Circular Economy: The Case of the Built Environment. Procedia CIRP 2019, 80, 619–624. [Google Scholar] [CrossRef]

- García-Quevedo, J.; Jové-Llopis, E.; Martínez-Ros, E. Barriers to the Circular Economy in European Small and Medium-Sized Firms. Bus. Strategy Environment 2020, 29, 2450–2464. [Google Scholar] [CrossRef]

- Ormazabal, M.; Prieto-Sandoval, V.; Puga-Leal, R.; Jaca, C. Circular Economy in Spanish SMEs: Challenges and Opportunities. J. Clean. Prod. 2018, 185, 157–167. [Google Scholar] [CrossRef]

- Tura, N.; Hanski, J.; Ahola, T.; Ståhle, M.; Piiparinen, S.; Valkokari, P. Unlocking Circular Business: A Framework of Barriers and Drivers. J. Clean. Prod. 2019, 212, 90–98. [Google Scholar] [CrossRef]

- Govindan, K.; Hasanagic, M. A Systematic Review on Drivers, Barriers, and Practices towards Circular Economy: A Supply Chain Perspective. Int. J. Prod. Res. 2018, 56, 278–311. [Google Scholar] [CrossRef]

- Vermunt, D.A.; Negro, S.O.; Verweij, P.A.; Kuppens, D.V.; Hekkert, M.P. Exploring Barriers to Implementing Different Circular Business Models. J. Clean. Prod. 2019, 222, 891–902. [Google Scholar] [CrossRef]

- Sarja, M.; Onkila, T.; Mäkelä, M. A Systematic Literature Review of the Transition to the Circular Economy in Business Organizations: Obstacles, Catalysts and Ambivalences. J. Clean. Prod. 2021, 286, 125492. [Google Scholar] [CrossRef]

- Adams, K.T.; Osmani, M.; Thorpe, T.; Thornback, J. Circular Economy in Construction: Current Awareness, Challenges and Enablers. Proc. Inst. Civ. Eng. -Waste Resour. Manag. 2017, 170, 15–24. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence From the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- Cantú, A.; Aguiñaga, E.; Scheel, C. Learning from Failure and Success: The Challenges for Circular Economy Implementation in SMEs in an Emerging Economy. Sustainability 2021, 13, 1529. [Google Scholar] [CrossRef]

- Garcés-Ayerbe, C.; Rivera-Torres, P.; Suárez-Perales, I.; Leyva-de la Hiz, D.I. Is It Possible to Change from a Linear to a Circular Economy? An Overview of Opportunities and Barriers for European Small and Medium-Sized Enterprise Companies. Int. J. Environ. Res. Public Health 2019, 16, 851. [Google Scholar] [CrossRef]

- Tan, J.; Tan, F.J.; Ramakrishna, S. Transitioning to a Circular Economy: A Systematic Review of Its Drivers and Barriers. Sustainability 2022, 14, 1757. [Google Scholar] [CrossRef]

- Ardanza, A.; Moreno, A.; Segura, Á.; de la Cruz, M.; Aguinaga, D. Sustainable and Flexible Industrial Human Machine Interfaces to Support Adaptable Applications in the Industry 4.0 Paradigm. Int. J. Prod. Res. 2019, 57, 4045–4059. [Google Scholar] [CrossRef]

- Awan, U.; Sroufe, R.; Shahbaz, M. Industry 4.0 and the Circular Economy: A Literature Review and Recommendations for Future Research. Bus. Strategy Environ. 2021, 30, 2038–2060. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H.C. Relationships between Industry 4.0, Sustainable Manufacturing and Circular Economy: Proposal of a Research Framework. Int. J. Organ. Anal. 2020, 30, 864–898. [Google Scholar] [CrossRef]

- Beltrami, M.; Orzes, G.; Sarkis, J.; Sartor, M. Industry 4.0 and Sustainability: Towards Conceptualization and Theory. J. Clean. Prod. 2021, 312, 127733. [Google Scholar] [CrossRef]

- Bressanelli, G.; Saccani, N.; Perona, M.; Baccanelli, I. Towards Circular Economy in the Household Appliance Industry: An Overview of Cases. Resources 2020, 9, 128. [Google Scholar] [CrossRef]

- Demestichas, K.; Daskalakis, E. Information and Communication Technology Solutions for the Circular Economy. Sustainability 2020, 12, 7272. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; de Sousa Jabbour, A.B.L.; Sarkis, J.; Godinho Filho, M. Unlocking the Circular Economy through New Business Models Based on Large-Scale Data: An Integrative Framework and Research Agenda. Technol. Forecast. Soc. Chang. 2019, 144, 546–552. [Google Scholar] [CrossRef]

- Jinil Persis, D.; Venkatesh, V.G.; Raja Sreedharan, V.; Shi, Y.; Sankaranarayanan, B. Modelling and Analysing the Impact of Circular Economy; Internet of Things and Ethical Business Practices in the VUCA World: Evidence from the Food Processing Industry. J. Clean. Prod. 2021, 301, 126871. [Google Scholar] [CrossRef]

- Kerin, M.; Pham, D.T. A Review of Emerging Industry 4.0 Technologies in Remanufacturing. J. Clean. Prod. 2019, 237, 117805. [Google Scholar] [CrossRef]

- Kumar, N.M.; Chopra, S.S. Leveraging Blockchain and Smart Contract Technologies to Overcome Circular Economy Implementation Challenges. Sustainability 2022, 14, 9492. [Google Scholar] [CrossRef]

- Laskurain-Iturbe, I.; Arana-Landín, G.; Landeta-Manzano, B.; Uriarte-Gallastegi, N. Exploring the Influence of Industry 4.0 Technologies on the Circular Economy. J. Clean. Prod. 2021, 321, 128944. [Google Scholar] [CrossRef]

- Lopes de Sousa Jabbour, A.B.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the Circular Economy: A Proposed Research Agenda and Original Roadmap for Sustainable Operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- Mboli, J.S.; Thakker, D.; Mishra, J.L. An Internet of Things-Enabled Decision Support System for Circular Economy Business Model. Softw. Pract. Exp. 2022, 52, 772–787. [Google Scholar] [CrossRef]

- Miaoudakis, A.; Fysarakis, K.; Petroulakis, N.; Alexaki, S.; Alexandirs, G.; Ioannidis, S.; Spanoudakis, G.; Katos, V.; Verikoukis, C. Pairing a Circular Economy and the 5G-Enabled Internet of Things: Creating a Class of ?Looping Smart Assets? IEEE Veh. Technol. Mag. 2020, 15, 20–31. [Google Scholar] [CrossRef]

- Mörth, O.; Emmanouilidis, C.; Hafner, N.; Schadler, M. Cyber-Physical Systems for Performance Monitoring in Production Intralogistics. Comput. Ind. Eng. 2020, 142, 106333. [Google Scholar] [CrossRef]

- Nicolescu, R.; Huth, M.; Radanliev, P.; De Roure, D. Mapping the Values of IoT. J. Inf. Technol. 2018, 33, 345–360. [Google Scholar] [CrossRef]

- Pagoropoulos, A.; Pigosso, D.C.A.; McAloone, T.C. The Emergent Role of Digital Technologies in the Circular Economy: A Review. Procedia CIRP 2017, 64, 19–24. [Google Scholar] [CrossRef]

- Patwa, N.; Sivarajah, U.; Seetharaman, A.; Sarkar, S.; Maiti, K.; Hingorani, K. Towards a Circular Economy: An Emerging Economies Context. J. Bus. Res. 2021, 122, 725–735. [Google Scholar] [CrossRef]

- Ranta, V.; Aarikka-Stenroos, L.; Väisänen, J.-M. Digital Technologies Catalyzing Business Model Innovation for Circular Economy—Multiple Case Study. Resour. Conserv. Recycl. 2021, 164, 105155. [Google Scholar] [CrossRef]

- Rejeb, A.; Suhaiza, Z.; Rejeb, K.; Seuring, S.; Treiblmaier, H. The Internet of Things and the Circular Economy: A Systematic Literature Review and Research Agenda. J. Clean. Prod. 2022, 350, 131439. [Google Scholar] [CrossRef]

- Rocca, R.; Rosa, P.; Sassanelli, C.; Fumagalli, L.; Terzi, S. Integrating Virtual Reality and Digital Twin in Circular Economy Practices: A Laboratory Application Case. Sustainability 2020, 12, 2286. [Google Scholar] [CrossRef]

- Rusch, M.; Schöggl, J.-P.; Baumgartner, R.J. Application of Digital Technologies for Sustainable Product Management in a Circular Economy: A Review. Bus. Strategy Environ. 2023, 32, 1159–1174. [Google Scholar] [CrossRef]

- Sarc, R.; Curtis, A.; Kandlbauer, L.; Khodier, K.; Lorber, K.E.; Pomberger, R. Digitalisation and Intelligent Robotics in Value Chain of Circular Economy Oriented Waste Management–A Review. Waste Manag. 2019, 95, 476–492. [Google Scholar] [CrossRef] [PubMed]

- Tavera Romero, C.A.; Castro, D.F.; Ortiz, J.H.; Khalaf, O.I.; Vargas, M.A. Synergy between Circular Economy and Industry 4.0: A Literature Review. Sustainability 2021, 13, 4331. [Google Scholar] [CrossRef]

- Turner, C.; Oyekan, J.; Garn, W.; Duggan, C.; Abdou, K. Industry 5.0 and the Circular Economy: Utilizing LCA with Intelligent Products. Sustainability 2022, 14, 14847. [Google Scholar] [CrossRef]

- Wang, L.; Törngren, M.; Onori, M. Current Status and Advancement of Cyber-Physical Systems in Manufacturing. J. Manuf. Syst. 2015, 37, 517–527. [Google Scholar] [CrossRef]

- Watanabe, E.H.; da Silva, R.M.; Junqueira, F.; dos Santos Filho, D.J.; Miyagi, P.E. An Emerging Industrial Business Model Considering Sustainability Evaluation and Using Cyber Physical System Technology and Modelling Techniques. IFAC-PapersOnLine 2016, 49, 135–140. [Google Scholar]

- IPCC-TFI. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/index.html (accessed on 22 May 2023).

- EMEP/EEA air pollutant emission inventory guidebook 2019—European Environment Agency. Available online: https://www.eea.europa.eu/publications/emep-eea-guidebook-2019 (accessed on 22 May 2023).

- Peña, C.; Civit, B.; Gallego-Schmid, A.; Druckman, A.; Pires, A.C.-; Weidema, B.; Mieras, E.; Wang, F.; Fava, J.; Canals, L.M.; et al. Using Life Cycle Assessment to Achieve a Circular Economy. Int. J. Life Cycle Assess. 2021, 26, 215–220. [Google Scholar] [CrossRef]

- Bjørnbet, M.M.; Vildåsen, S.S. Life Cycle Assessment to Ensure Sustainability of Circular Business Models in Manufacturing. Sustainability 2021, 13, 11014. [Google Scholar] [CrossRef]

- Rigamonti, L.; Mancini, E. Life Cycle Assessment and Circularity Indicators. Int. J. Life Cycle Assess. 2021, 26, 1937–1942. [Google Scholar] [CrossRef]

- Møller, H.; Lyng, K.-A.; Röös, E.; Samsonstuen, S.; Olsen, H.F. Circularity Indicators and Added Value to Traditional LCA Impact Categories: Example of Pig Production. Int. J. Life Cycle Assess. 2023. [CrossRef]

- Bracquené, E.; Dewulf, W.; Duflou, J.R. Measuring the Performance of More Circular Complex Product Supply Chains. Resour. Conserv. Recycl. 2020, 154, 104608. [Google Scholar] [CrossRef]

- Glocic, E.; Young, S.B.; Sonnemann, G. Confronting Challenges of Combining and Comparing Material Circularity Indicator with Life Cycle Assessment Indicators: A Case of Alkaline Batteries. In SETAC Europe 30th Annual Meeting-Abstract Book; 2020.

- Lonca, G.; Muggéo, R.; Imbeault-Tétreault, H.; Bernard, S.; Margni, M. Does Material Circularity Rhyme with Environmental Efficiency? Case Studies on Used Tires. J. Clean. Prod. 2018, 183, 424–435. [Google Scholar] [CrossRef]

- Pauer, E.; Wohner, B.; Heinrich, V.; Tacker, M. Assessing the Environmental Sustainability of Food Packaging: An Extended Life Cycle Assessment Including Packaging-Related Food Losses and Waste and Circularity Assessment. Sustainability 2019, 11, 925. [Google Scholar] [CrossRef]

- Stanchev, P.; Vasilaki, V.; Egas, D.; Colon, J.; Ponsá, S.; Katsou, E. Multilevel Environmental Assessment of the Anaerobic Treatment of Dairy Processing Effluents in the Context of Circular Economy. J. Clean. Prod. 2020, 261, 121139. [Google Scholar] [CrossRef]

- Mantalovas, K.; Di Mino, G. Integrating Circularity in the Sustainability Assessment of Asphalt Mixtures. Sustainability 2020, 12, 594. [Google Scholar] [CrossRef]

- Saadé, M.; Erradhouani, B.; Pawlak, S.; Appendino, F.; Peuportier, B.; Roux, C. Combining Circular and LCA Indicators for the Early Design of Urban Projects. Int. J. Life Cycle Assess. 2022, 27, 1–19. [Google Scholar] [CrossRef]

- Stillitano, T.; Spada, E.; Iofrida, N.; Falcone, G.; De Luca, A.I. Sustainable Agri-Food Processes and Circular Economy Pathways in a Life Cycle Perspective: State of the Art of Applicative Research. Sustainability 2021, 13, 2472. [Google Scholar] [CrossRef]

- Wrålsen, B.; O’Born, R. Use of Life Cycle Assessment to Evaluate Circular Economy Business Models in the Case of Li-Ion Battery Remanufacturing. Int. J. Life Cycle Assess. 2023, 28, 554–565. [Google Scholar] [CrossRef]

- Djekic, I.; Miocinovic, J.; Tomasevic, I.; Smigic, N.; Tomic, N. Environmental Life-Cycle Assessment of Various Dairy Products. J. Clean. Prod. 2014, 68, 64–72. [Google Scholar] [CrossRef]

- Finnegan, W.; Yan, M.; Holden, N.M.; Goggins, J. A Review of Environmental Life Cycle Assessment Studies Examining Cheese Production. Int. J. Life Cycle Assess. 2018, 23, 1773–1787. [Google Scholar] [CrossRef]

- Mahath, C.S.; Mophin Kani, K.; Dubey, B. Gate-to-Gate Environmental Impacts of Dairy Processing Products in Thiruvananthapuram, India. Resour. Conserv. Recycl. 2019, 141, 40–53. [Google Scholar] [CrossRef]

- Egas, D.; Ponsá, S.; Colon, J. CalcPEFDairy: A Product Environmental Footprint Compliant Tool for a Tailored Assessment of Raw Milk and Dairy Products. J. Environ. Manag. 2020, 260, 110049. [Google Scholar] [CrossRef] [PubMed]

- González-García, S.; Castanheira, É.G.; Dias, A.C.; Arroja, L. Environmental Life Cycle Assessment of a Dairy Product: The Yoghurt. Int. J. Life Cycle Assess. 2013, 18, 796–811. [Google Scholar] [CrossRef]

- Berton, M.; Bovolenta, S.; Corazzin, M.; Gallo, L.; Pinterits, S.; Ramanzin, M.; Ressi, W. Environmental Impacts of Milk Production and Processing in the Eastern Alps: A “Cradle-to-Dairy Gate” LCA Approach. J. Clean. Prod. 2021, 303, 127056. [Google Scholar] [CrossRef]

- Clune, S.; Crossin, E.; Verghese, K. Systematic Review of Greenhouse Gas Emissions for Different Fresh Food Categories. J. Clean. Prod. 2017, 140, 766–783. [Google Scholar] [CrossRef]

- González-García, S.; Hospido, A.; Moreira, M.T.; Feijoo, G.; Arroja, L. Environmental Life Cycle Assessment of a Galician Cheese: San Simon Da Costa. J. Clean. Prod. 2013, 52, 253–262. [Google Scholar] [CrossRef]

- Kim, D.; Thoma, G.; Nutter, D.; Milani, F.; Ulrich, R.; Norris, G. Life Cycle Assessment of Cheese and Whey Production in the USA. Int. J. Life Cycle Assess. 2013, 18, 1019–1035. [Google Scholar] [CrossRef]

- Palmieri, N.; Forleo, M.B.; Salimei, E. Environmental Impacts of a Dairy Cheese Chain Including Whey Feeding: An Italian Case Study. J. Clean. Prod. 2017, 140, 881–889. [Google Scholar] [CrossRef]

- Canellada, F.; Laca, A.; Laca, A.; Díaz, M. Environmental Impact of Cheese Production: A Case Study of a Small-Scale Factory in Southern Europe and Global Overview of Carbon Footprint. Sci. Total Environ. 2018, 635, 167–177. [Google Scholar] [CrossRef] [PubMed]

- Bava, L.; Bacenetti, J.; Gislon, G.; Pellegrino, L.; D’Incecco, P.; Sandrucci, A.; Tamburini, A.; Fiala, M.; Zucali, M. Impact Assessment of Traditional Food Manufacturing: The Case of Grana Padano Cheese. Sci. Total Environ. 2018, 626, 1200–1209. [Google Scholar] [CrossRef] [PubMed]

- Santos, H.C.M.; Maranduba, H.L.; de Almeida Neto, J.A.; Rodrigues, L.B. Life Cycle Assessment of Cheese Production Process in a Small-Sized Dairy Industry in Brazil. Environ. Sci. Pollut. Res. 2017, 24, 3470–3482. [Google Scholar] [CrossRef] [PubMed]

- van Middelaar, C.E.; Berentsen, P.B.M.; Dolman, M.A.; de Boer, I.J.M. Eco-Efficiency in the Production Chain of Dutch Semi-Hard Cheese. Livest. Sci. 2011, 139, 91–99. [Google Scholar] [CrossRef]

- Laca, A.; Gómez, N.; Laca, A.; Díaz, M. Overview on GHG Emissions of Raw Milk Production and a Comparison of Milk and Cheese Carbon Footprints of Two Different Systems from Northern Spain. Environ. Sci. Pollut. Res. 2020, 27, 1650–1666. [Google Scholar] [CrossRef]

- Dalla Riva, A.; Burek, J.; Kim, D.; Thoma, G.; Cassandro, M.; De Marchi, M. Environmental Life Cycle Assessment of Italian Mozzarella Cheese: Hotspots and Improvement Opportunities. J. Dairy Sci. 2017, 100, 7933–7952. [Google Scholar] [CrossRef]

- Kristensen, T.; Søegaard, K.; Eriksen, J.; Mogensen, L. Carbon Footprint of Cheese Produced on Milk from Holstein and Jersey Cows Fed Hay Differing in Herb Content. J. Clean. Prod. 2015, 101, 229–237. [Google Scholar] [CrossRef]

- Capper, J.L.; Cady, R.A. A Comparison of the Environmental Impact of Jersey Compared with Holstein Milk for Cheese Production1. J. Dairy Sci. 2012, 95, 165–176. [Google Scholar] [CrossRef]

| Category | Barriers–Main themes | Relevant Research |

|---|---|---|

| Internal | ||

| Economic/Financial | Large capital requirements Lack of capital/financial resources Unclear financial case/return of investment |

[45,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68] |

| Technological | Product design and quality Lack of technology and technical skills |

[28,54,55,56,57,60,61,62,63,64,65,66,67,68,69] |

| Organizational | Incompatibility with current organizational structure Administrative burden Weak management support |

[54,56,57,60,61,62,63,64,67] |

| Informational | Insufficient information and knowledge, especially regarding the benefits of CE | [54,56,57,58,59,61,62,63,64,67,69] |

| Cultural | Hesitant company culture Attitude towards sustainability and circularity Risk aversion |

[50,54,56,58,61,62,66,67,69] |

| External | ||

| Institutional/Regulatory | Unclear international policy regarding CE Weak government support |

[54,55,57,58,61,62,63,64,66,67,68,69] |

| Supply Chain | Finding appropriate suppliers and partners Failure to collaborate with suppliers and partners |

[54,56,57,58,61,62,63,64,66,67] |

| Cultural | Consumer awareness “Intention-action gap” [69] |

[54,55,57,61,62,63,64,66,67,69] |

| Technology | Definition | Relevant Research |

|---|---|---|

| IoT | A computational system that allows the collection and sharing of products, services, processes and data in real time [81,93] | [70,71,73,74,75,77,78,80,81,82,84,85,86,87,88,89,91,93,94] |

| Cloud Computing | Technology that allows remote access of business processes, facilitates user interaction and information sharing and enables the visualization of all manufacturing resources and processes [89,93] | [73,74,75,81,87,89,93,96] |

| AI | Technology that incorporates machine learning capabilities in manufacturing processes [93] | [72,73,80,86,87,89,92,93,94] |

| Big Data | Technology systems that capture, store, manage and process high volumes of data [93] | [71,72,73,74,76,80,86,90,91,93,95] |

| CPS | Technology that enables automation of industrial operations in real time [89,93] | [73,75,81,84,89,90,93,95,96] |

| Blockchain | A system that enables decentralized data storage and sharing of computational resources [79] | [73,75,79,89,91] |

| AR and VR | Technologies that allow the use of digital tools to access virtual spaces in physical spaces [93] | [75,78,80,90,91,93] |

| Additive manufacturing | Technology that allows prototyping of parts of products (3D printing) [89] | [74,80,81,89,90,93] |

| 5G | Flexible and low energy consumption technology that allows connectivity between systems that rely on IoT devices [82] | [75,82,83,89] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).