0. Introduction

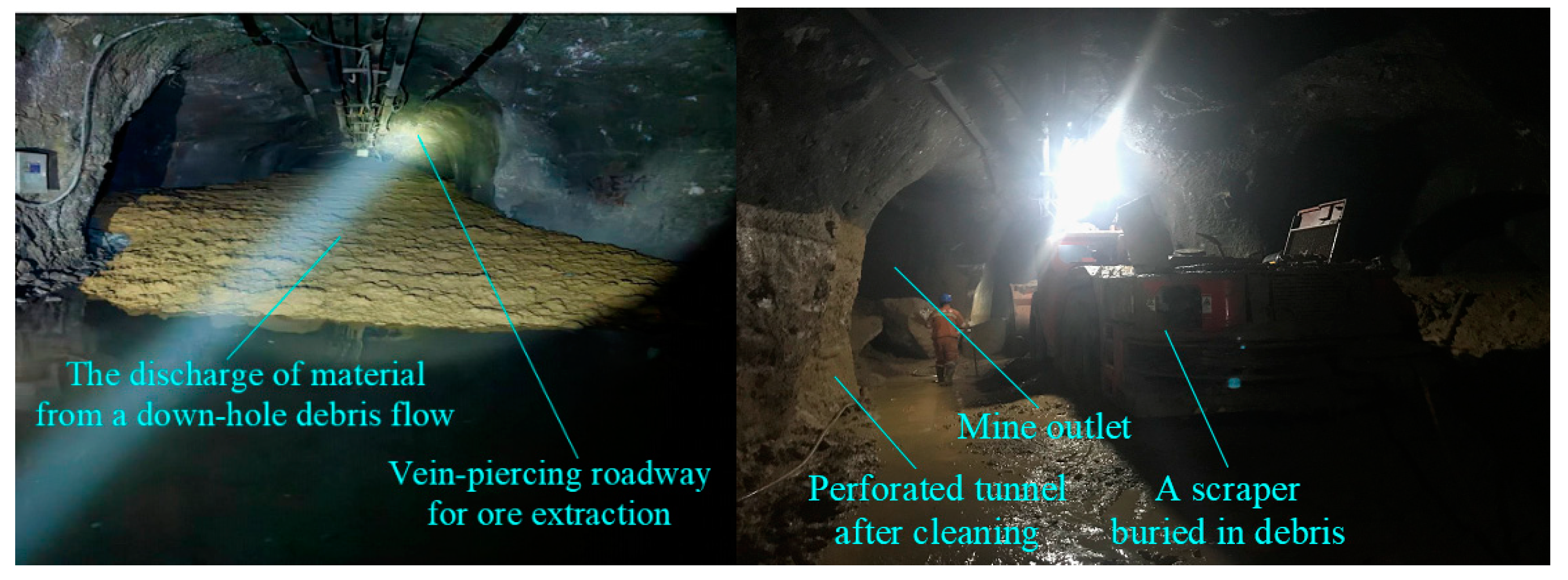

Natural caving is a mining method with high mechanization, good safety, high production efficiency and low cost. It is the only low-cost underground mining method comparable to open-pit mining. At present, has been widely used in foreign countries, but the domestic application is also showing a rising trend. There are caving mines with fine moraine or granular materials on the ground surface. Because of the small particle size in the upper covering layer of the caving ore, the existence of fine particles in the mine production will bring some unconventional disasters to the mine production. The Plan copper mine, for example, is a natural caving mine with fine moraine on the surface. With the increase of mining depth, the scope of surface subsidence is continuously expanding. After the mine enters the flood season, it is easy to form the underground debris flow accident when the debris (Moraine) overlying the stope is mixed with the rainwater and enters the stope through various channels [

1,

2,

3]. Since 2019-2022, more than 10 underground debris flow accidents have occurred in the mine. Because the occurrence of down-hole debris flow has burst, burst carrying huge energy makes it extremely destructive. It not only restricts the production capacity of the mine, but also threatens the safety and efficiency of the mine [

4,

5,

6].

Although debris flow is the source, topography (channel), rainfall and other factors of non-synergistic variation of the coupling effect. But the difference between underground debris flow and surface debris flow is that underground debris flow is hidden and invisible because it occurs underground, this also makes the study of the down-hole debris flow disasters caused great difficulties. At present, only a few domestic and foreign scholars have carried out relevant research on it. Niu Xiangdong et al. [

7] studied the start-up mechanism of underground moraine recharge debris flow under different rainfall intensities in the Plan copper mine by means of field investigation and laboratory simulation experiments. The results show that heavy rainfall provides hydrodynamic conditions for the formation of down-hole moraine recharge debris flow. In the process of pure ore drawing, it is difficult for surface moraine to form channel in ore bed, and it is difficult to form underground debris flow accident under different rainfall intensity. The formation of flow passage of ground moraine in ore bed is the precondition of formation of underground debris flow. Based on the accident-causing theory, Deng Junping [

8] analyzed the mud bursting accident in coal mine from the aspects of human behavior, material state, management level and environmental conditions. It is considered that the formation of mud bursting accident is the result of many factors. Frequent production blasting activity and vibration of trackless transportation and loading equipment are the inducing factors of mud bursting. The basic principles and methods to prevent and control mud bursting accidents are put forward. Song Weidong et al. [

9] used analytic hierarchy process (AHP-RRB- and expert questionnaire. The index system of influencing factors of underground debris flow in Chengchao iron mine was studied. The results show that the main influencing factors include rainfall and duration, the thickness and property of surface loess layer, surface subsidence, mining activity and artificial discharge of surface water. It is pointed out that the water source condition is the most important factor to control the underground debris flow, and the formation of surface subsidence pit is the second. By using PFC

3D particle flow numerical simulation software, du Jianhua et al. [

10] studied the mechanism of underground debris flow in Chengchao iron mine. It is pointed out that the mechanical essence of the formation of underground debris flow is the surface cracking and subsidence caused by caving mining, which leads to the accumulation of a large amount of viscous fluid composed of rock debris, mud sand and water mixture on the surface in the goaf. Due to the influence of mining activities such as drawing and blasting, when the thickness of overburden is too thin to resist the pressure of debris flow, the disaster phenomenon is caused by the sudden explosion and rapid flow under the action of gravity. Pormando Silalahi et al. [[

12], in relation to the Jayawijaya orebody in Papua, which is mined using a gravity flow system. It is considered that the long-distance movement of ore can lead to the change of particle shape and size, and form fine and loose particles. Debris flow material is composed of small (diameter < 5cm), saturated loose particles and water.

In the process of ore drawing in a caved mine, the action of ore drawing is bound to produce continuous shearing action on the mud body (mud inclusion of moraine in Plan mine) mixed into the ore bed, the shear effect of ore drawing will be one of the important factors that influence the formation of underground debris flow. But according to the present scholar regarding the down-ole debris flow disaster accident aspect research. Only a few scholars put forward that the inducing factors can affect the formation of underground debris flow, which mainly include mining activity, blasting vibration and ore drawing vibration. However, no study on the effect of ore drawing shear factor on underground debris flow is involved. Therefore, in view of the complexity of the down-ole debris flow disaster, the severity and the urgency of prevention and control. Based on the background of the underground debris flow in Plan copper mine, this study will conduct in-depth study on the impact of ore drawing shear factors on the underground debris flow in order to minimize the probability of the occurrence of the underground debris flow accident. At the same time, it can fill up the deficiency of the systematic research on underground debris flow and improve and broaden the research field of mine debris flow.

1. Analysis of influence of drawing shear factor

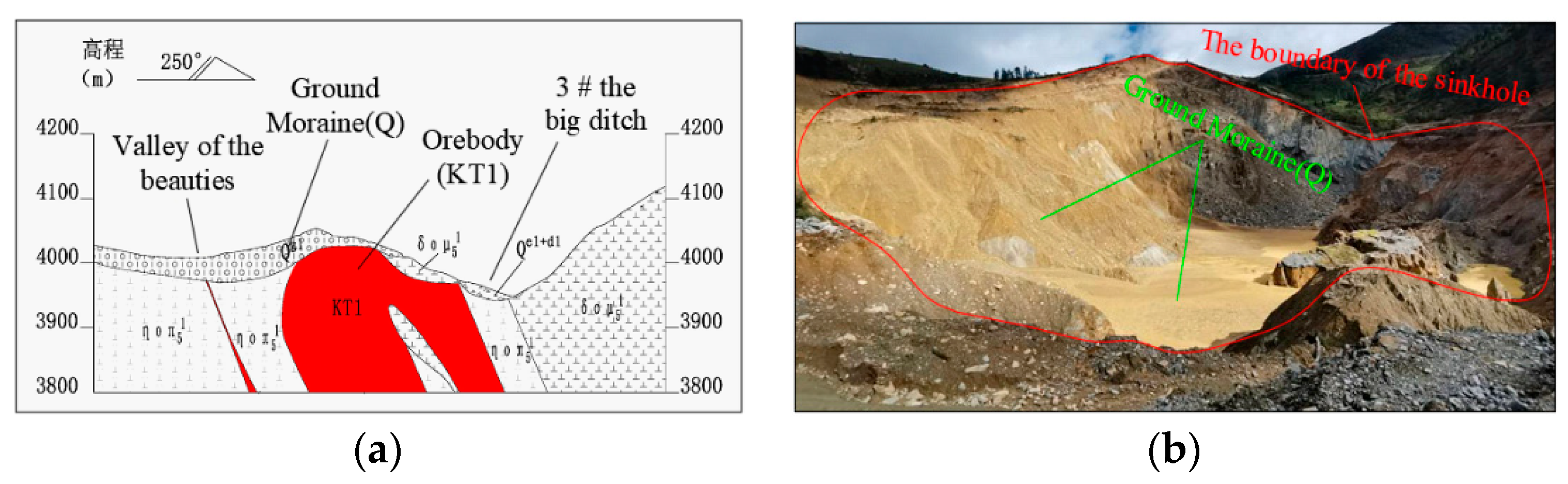

The Plan copper mine, which is owned by Yunnan Diqing Non-ferrous Metal Co., Ltd., is mined by natural caving. The annual mining production scale is 12 million tons. As a result of the relatively thick Quaternary (Q) loose moraine cover on the surface of the mining area, which is shown in

Figure 1, it belongs to a mine with a large amount of quaternary loose granular material on the surface. Because of the existence of loose particles in ground moraine, the mine is easy to induce the down-hole debris flow accident during rainy season, which brings serious threat to the safety of mine production. At present, there have been more than 10 underground debris flow accidents in Pulang copper mine since 2019, as shown in

Table 1 and

Figure 2.

Analysis of

Table 1 of the Plan mine between 2019-2022 occurred between the underground debris flow accident information can be seen. During the period of 2019-2022, at least 7 of the 10 underground debris flow accidents occurred under the influence of drawing shear without the influence of blasting vibration. Therefore, drawing shear is one of the important factors affecting the formation of underground debris flow, which should be paid more attention to by mine and scholars. Therefore, this paper will carry out the study on the effect of drawing shear factor on the down-ole debris flow in the process of drawing ore in mine production.

2. Analysis of paste structure characteristics

2.1. The material source of debris flow slurry

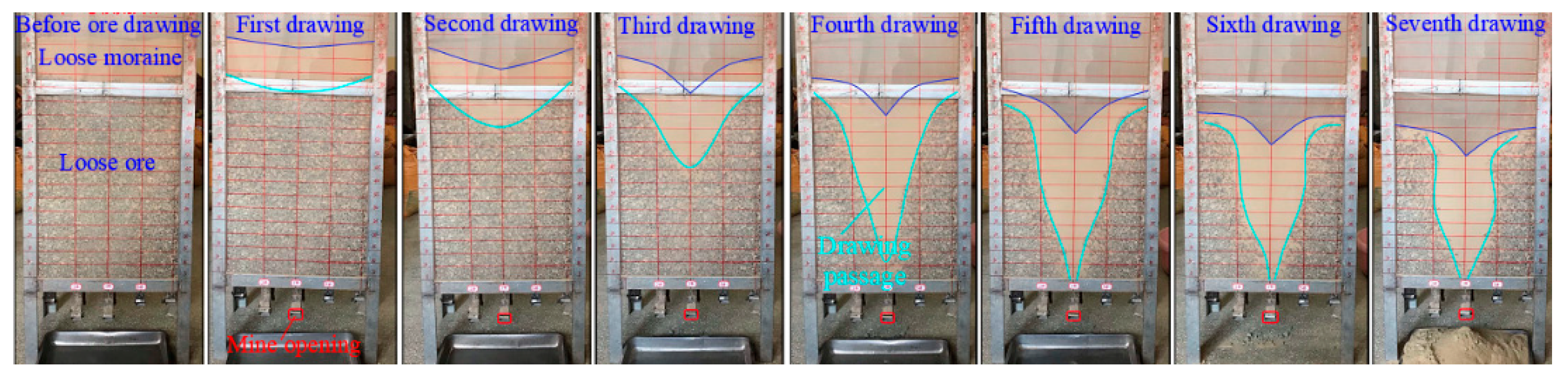

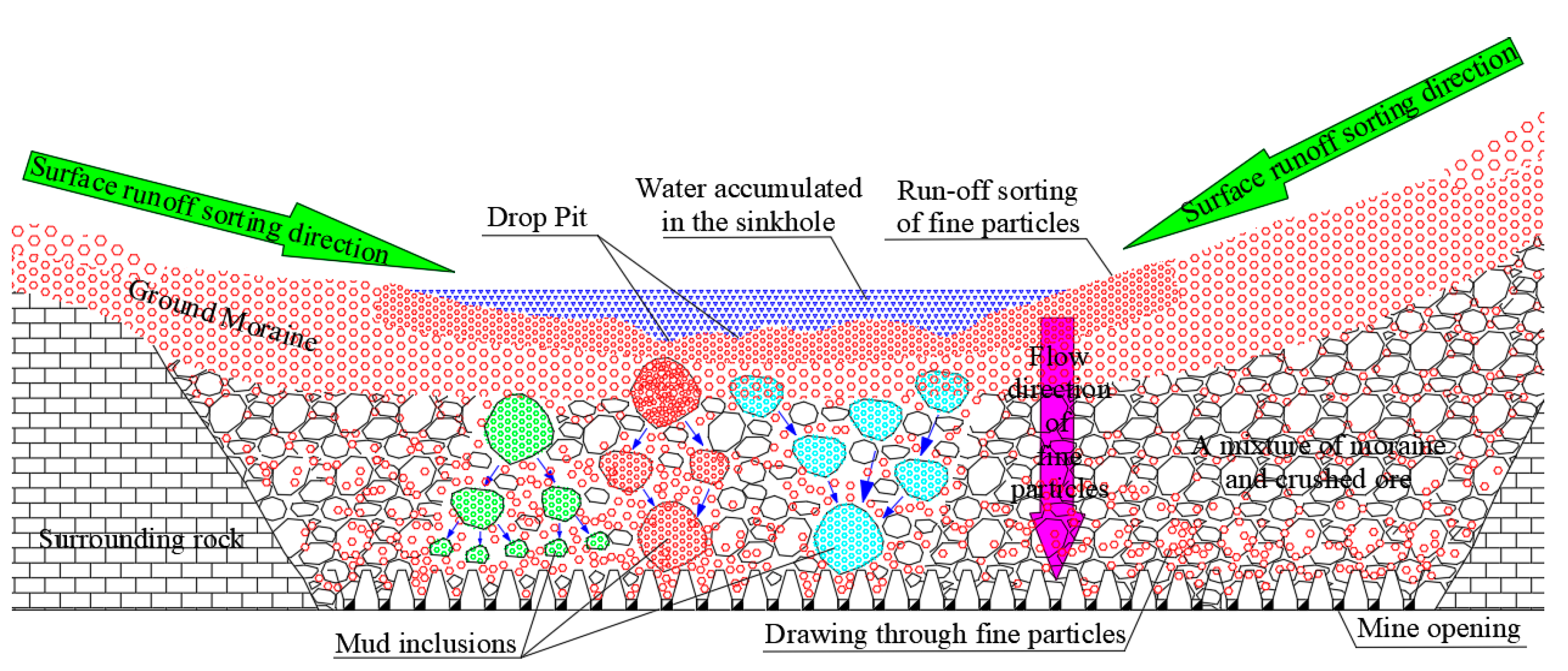

In the process of natural caving production in the Plan copper mine, with the continuous release of ore, it is inevitable that the ore will be depleted and the fine moraine material on the surface of the Quaternary system will enter into the caving ore bed, as well as uneven ore drawing in the formation of ore bed channel storage of a large number of moraine, as shown in

Figure 3. During the rainy season of the mine, the atmospheric rainfall and surface runoff in the subsidence pit will continuously penetrate into the ore layer, making the moraine fully absorb water and saturate, and exist in the ore layer in the form of moraine mud inclusion and slurry, see

Figure 4. In the process of ore drawing in mine production, the action of ore drawing will produce continuous shearing action on mud inclusion and slurry of moraine. The direct object of ore drawing shear is the mud inclusion and slurry of moraine stored in the caving ore bed. In order to carry out laboratory rheological test and thixotropy test for moraine mud inclusions and pastes, field sampling of moraine slurry is needed, as shown in

Figure 5.

2.2. Analysis of slurry composition of debris flow

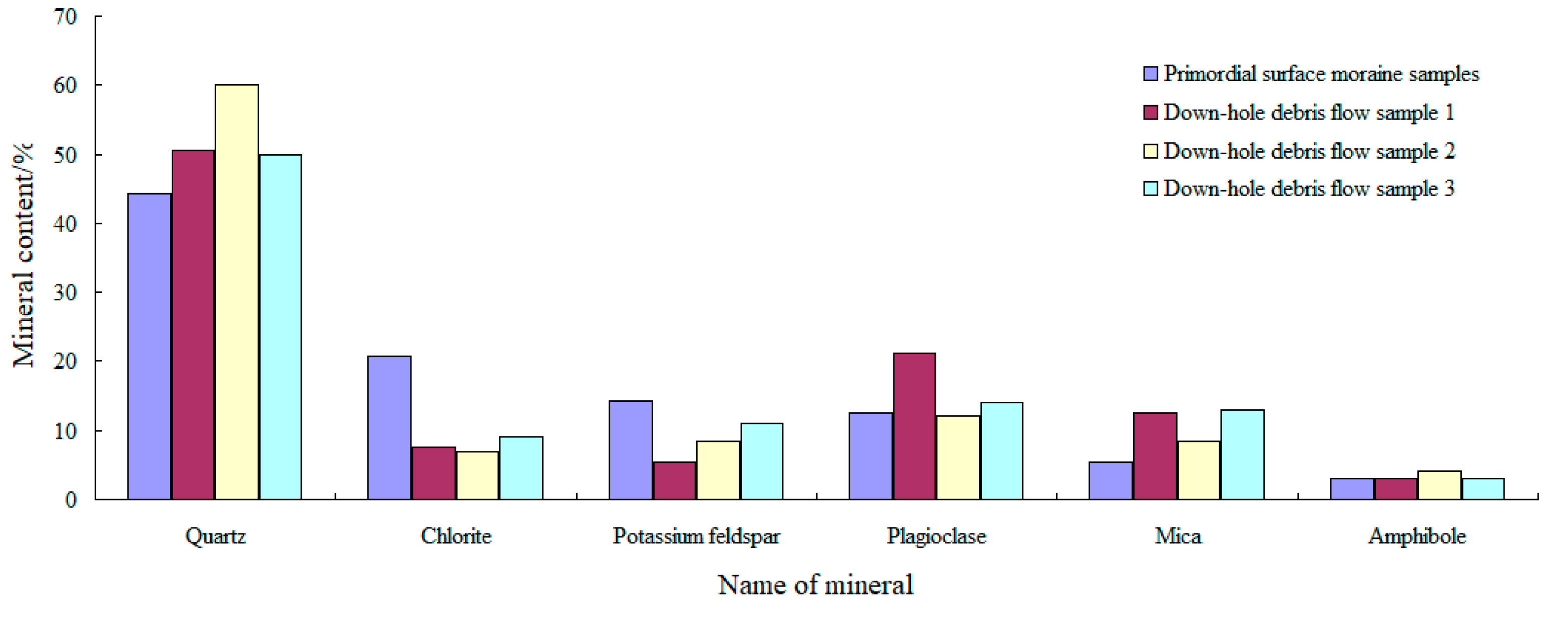

In order to find out the mineral composition of the original surface moraine and the slurry of the underground debris flow in the Plan copper mine, and to compare and analyze the difference of the mineral composition of the surface moraine before and after the underground debris flow. X-ray diffraction analysis of mineral composition of 1 Group of Primordial Surface Moraine and 3 groups of down-hole debris flow slurry samples was carried out, as shown in

Table 2 and

Figure 6.

Table 2 and

Figure 6 show that the mineral composition of the moraine on the original surface of the Plan copper deposit is basically the same as that of the slurry of the underground debris flow, are composed of quartz, plagioclase, mica, potassium feldspar, chlorite and amphibole. It shows that all the mud-rock flow slurry materials come from surface moraine, and there is no other external material mixed in.

2.3. Rheological characteristics of debris flow slurry

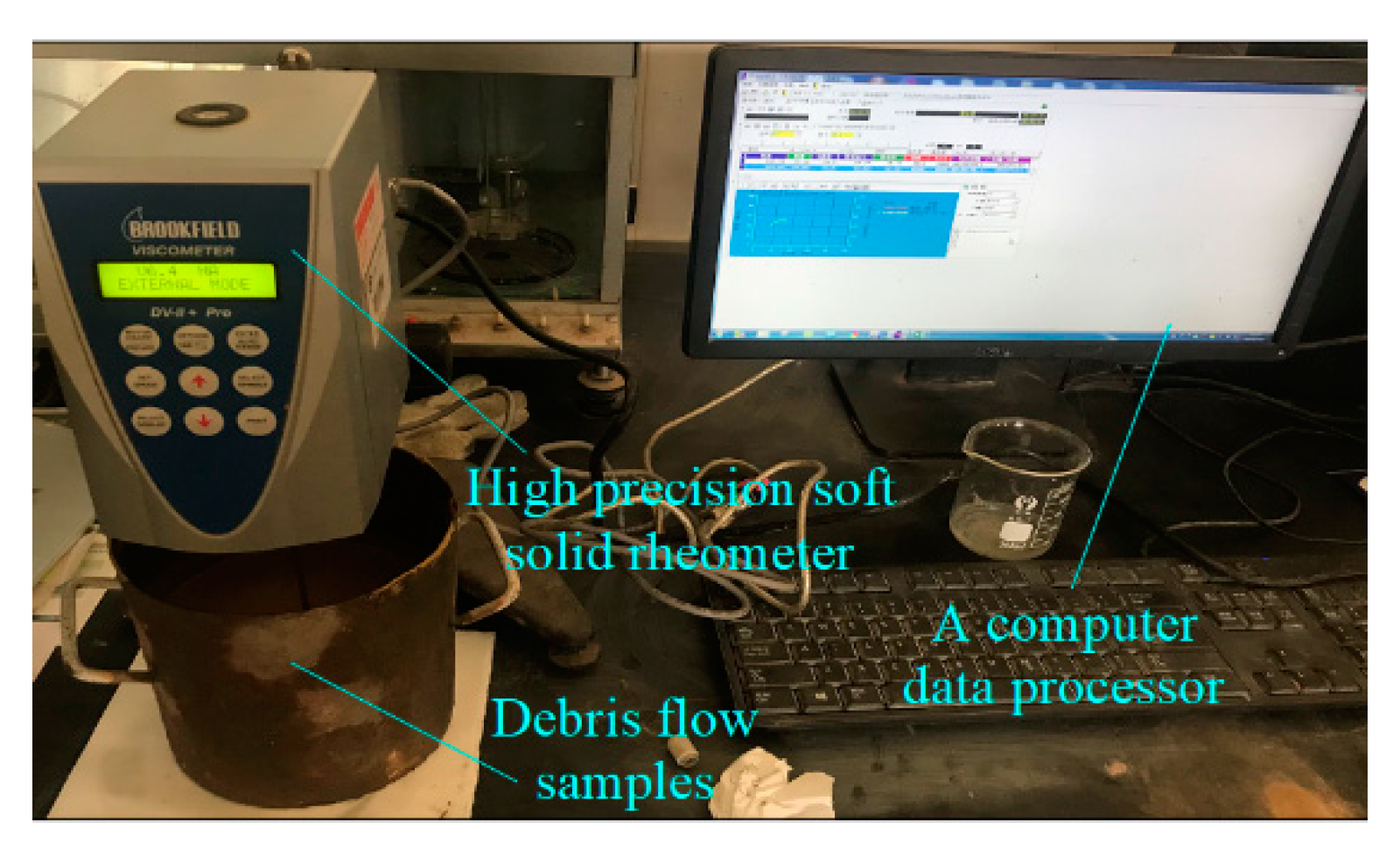

Using high-precision soft solid rheometer, as shown in

Figure 7. To test the rheological parameters (yield stress, viscosity, etc.) of debris flow slurry under different concentrations. The rheological equation was obtained, and the key factors affecting the rheological parameters of debris flow were analyzed.

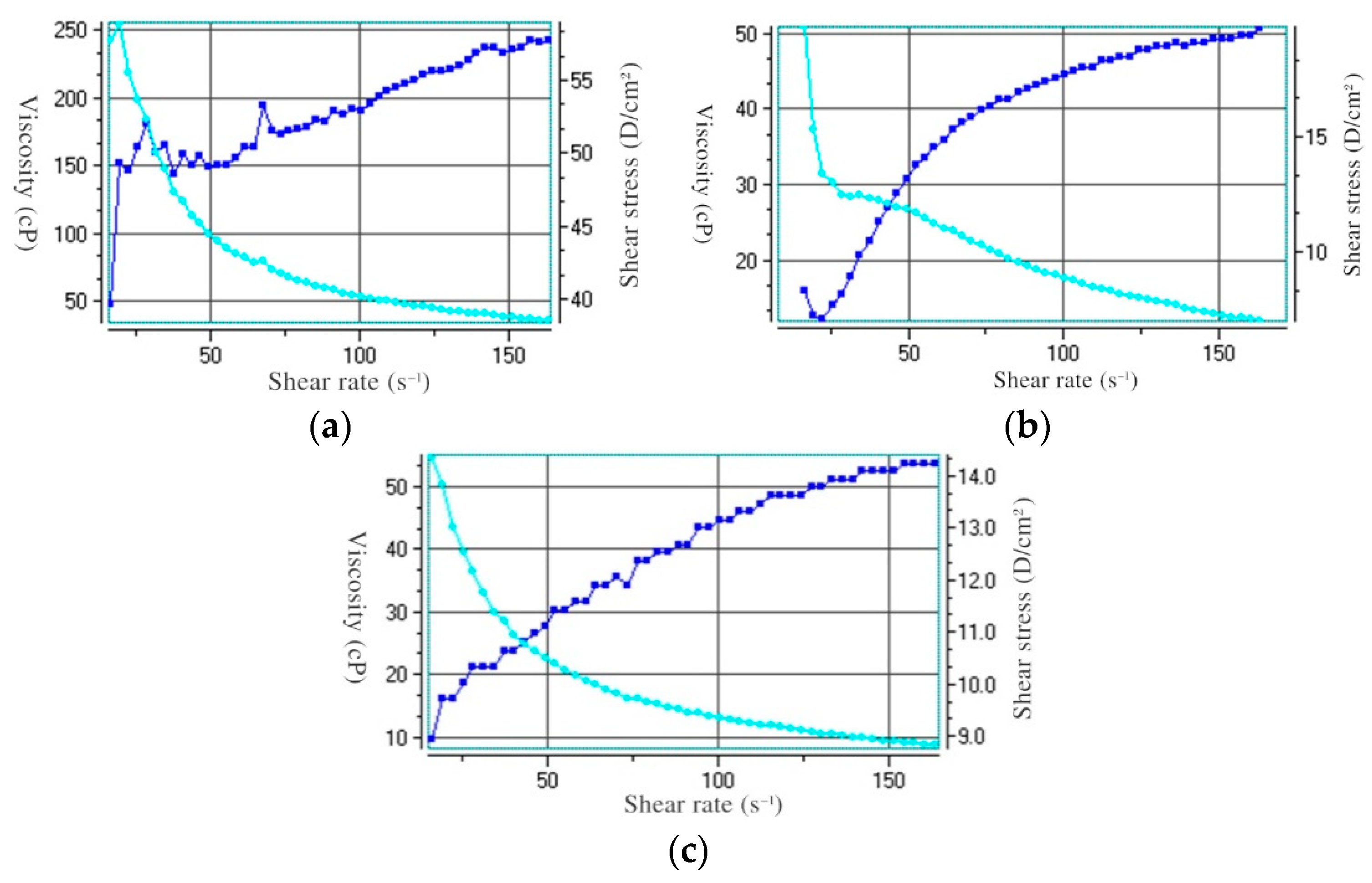

The rheological properties of three different concentrations (moisture content) under the conditions of the down-hole debris flow slurry samples. The moisture content of sample 1, Sample 2 and sample 3 is 63.81%, 71.07% and 78.11% respectively. The rheological curves of samples 1,2 and 3 of down-hole debris flow are shown in

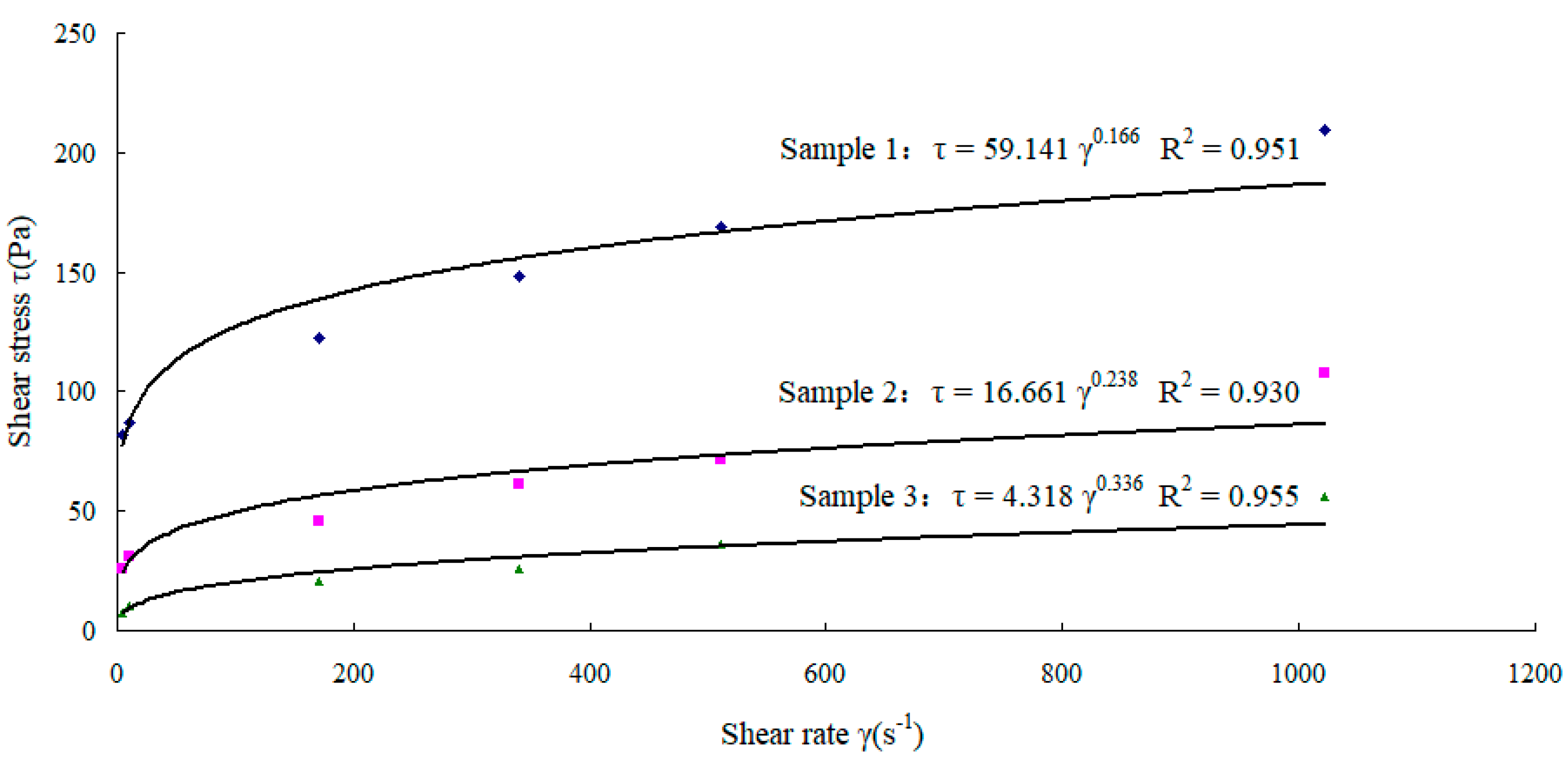

Figure 8. The relationship between the shear stress and the shear rate of the specimen at three different concentrations (moisture content) is shown in

Table 3 and

Figure 9. The statistical table of shear stress and shear rate test results is shown in

Table 4.

According to

Figure 9 and

Table 4, the relationship between shear stress and shear rate of slurry samples 1,2 and 3 of down-hole debris flow is power law, which is in accordance with plastic fluid constitutive model.

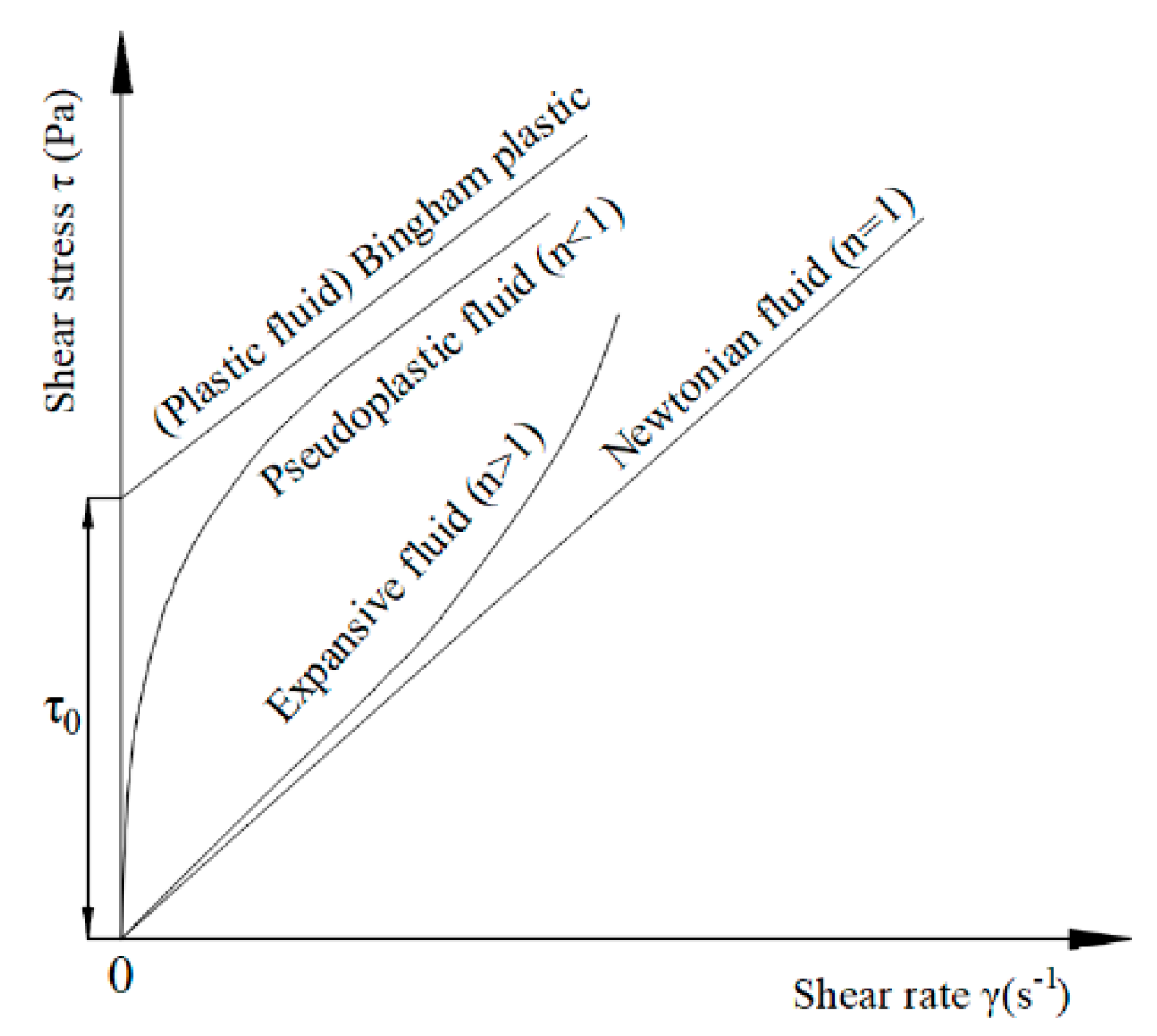

Plastic fluid is a kind of rheological curve, the characteristic is that when the shear stress is less than τ。, it can not flow, but greater than τ, then began to flow. Pseudoplastic fluid is also a kind of rheological curve, which is characterized by the fact that it can flow once applied, and its viscosity decreases with the increase of shear rate [

12,

13,

14,

15]. Newton fluid on the rheological curve, shear stress and shear rate is a straight line through the origin of the relationship. The swelling fluid is another type of rheological curve, which can flow with an external force, and the viscosity increases with the increase of shear rate [

16,

17,

18]. The trend of rheological curves for different types of fluids is shown in

Figure 10.

According to

Table 4, the rheological indexes of sample 1, Sample 2 and sample 3 are all less than 1. According to the rheological curve trend of different types of fluids in

Figure 10, it can be further judged that samples 1,2 and 3 of down-hole debris flow are all pseudoplastic fluids.

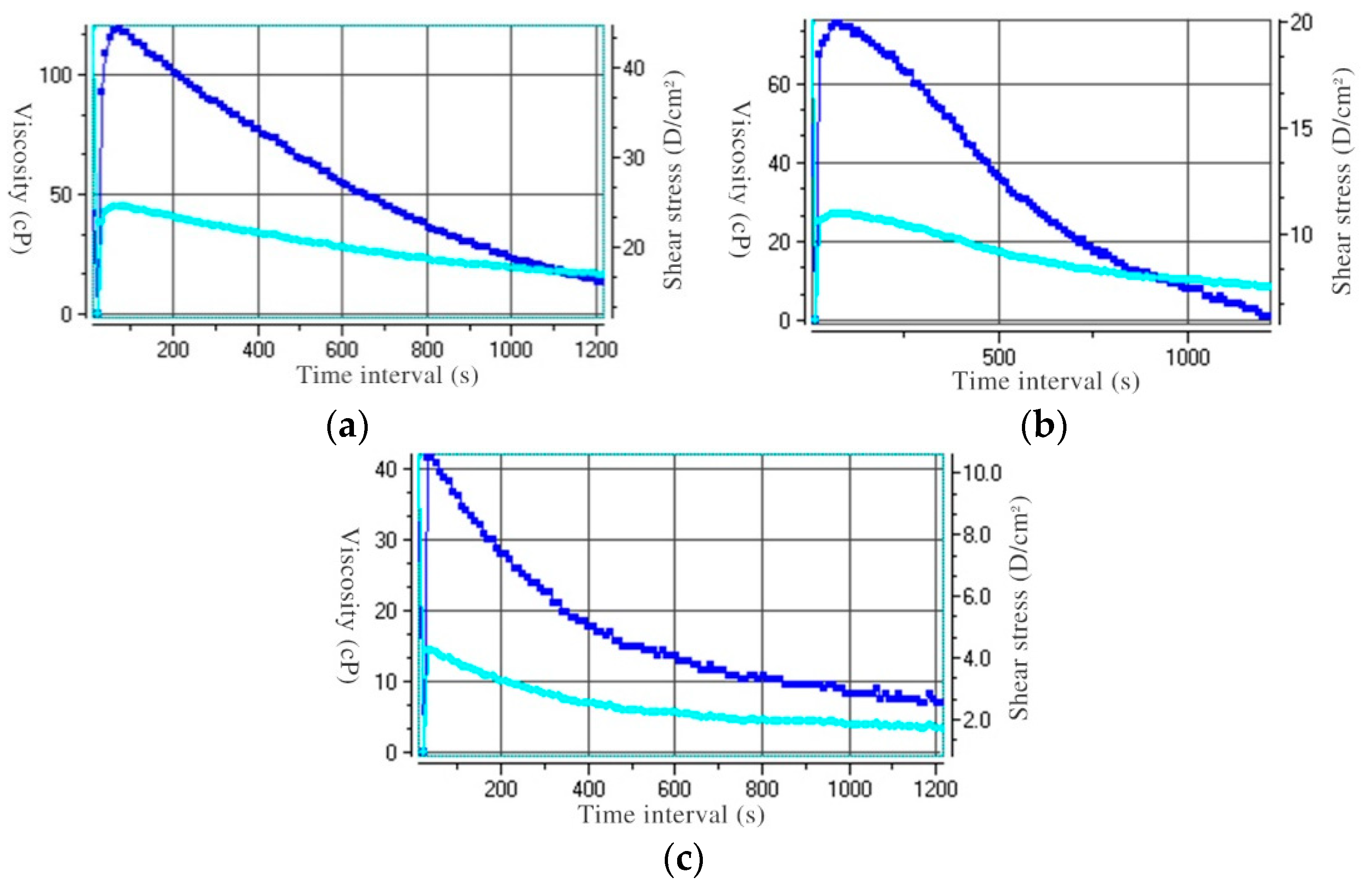

2.4. Analysis on thixotropy of mud-rock flow slurry

At a constant temperature, if the shear rate remains constant, the shear stress and apparent viscosity of the fluid will decrease with time. In other words, their rheological properties are controlled by the time of stress action. This Fluid is called a Thixotropic Fluid. Most time-dependent fluids are thixotropic. Structure is formed between particles in thixotropic fluid. Structure is destroyed when flowing and restored when stopping flowing. However, the destruction and restoration of the structure are not completed immediately and take some time. Therefore, the flow properties of thixotropic fluids are obviously time-dependent. More precisely, the slurry under shear deformation, if the viscosity temporarily reduced, the slurry is thixotropy.

The thixotropy tests of slurry samples 1,2 and 3 of the Plan mine underground debris flow were carried out using a fluid thixotropy model. The thixotropy curves are shown in

Figure 11.

According to the flow characteristics of thixotropic fluid, the viscosity and shear stress of debris flow samples 1,2 and 3 in Plan copper mine decreased with time. It shows that sample 1, Sample 2 and sample 3 belong to thixotropic fluid.

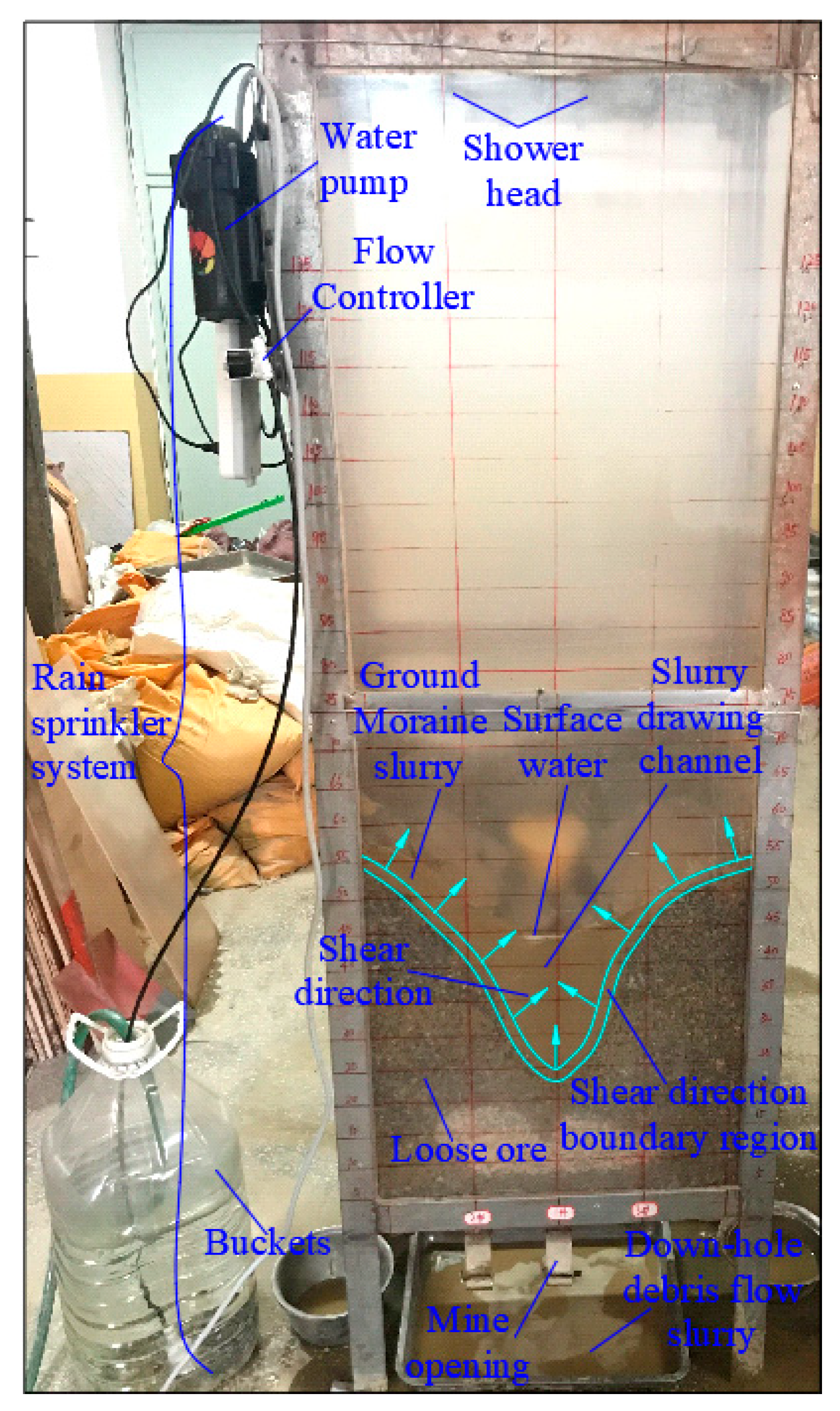

3. Effect of ore drawing shear on underground debris flow

The movement of debris flow material exists in the form of slurry, which is a complex non-Newtonian fluid. Based on the analysis of rheology and thixotropy of slurry, the slurry of debris flow in Plan copper mine is not only a pseudoplastic fluid but also a thixotropy fluid. It is indicated that once the shear force of drawing occurs, its viscosity will decrease with the increase of shear rate and time, and finally become a flowable slurry.

In the process of ore drawing in mine production, along with the continuous release of ore bulk at the ore drawing mouth, the inclusions and pastes of moraine mud in the caving ore bed will be sheared by the flow of ore bulk during the rainy season. The slurry of down-hole debris flow belongs to pseudoplastic fluid and thixotropic fluid. In the process of ore drawing, the shear force produced by the flow of ore particle will shear the slurry in the area of the drawing shear boundary (the contact interface between moraine slurry and ore particle), see

Figure 12. The viscosity of the slurry in the shear boundary of ore drawing decreases, the fluidity increases, and the slurry becomes flowable, and finally releases with the ore bulk through the ore drawing mouth. In addition, ore drawing is a continuous process. The shear force produced by the flow of ore particles will continuously produce shear action on the new moraine slurry in the ore drawing channel, and will continuously “Activate” the moraine slurry in the ore drawing channel and continue to release, see

Figure 12. Because the slurry of down-hole debris flow is the surface moraine slurry, the surface moraine slurry will provide abundant material source for down-hole debris flow slurry. Eventually, it will form a certain scale and destructive down-hole debris flow disaster accident.

4. Conclusions

In the process of caving mining, the shearing action of drawing will produce continuous shearing action on the mud body in the loose ore body (the mud inclusion of moraine in Plan mine), which is one of the important factors influencing the formation of underground debris flow. Based on the background of the underground debris flow in Plan copper mine, the study was carried out to study the effect of ore drawing shear factors on the underground debris flow. The following main conclusions were drawn:

(1)Based on the information analysis of more than 10 underground debris flow accidents in Plan mine from 2019 to 2022. Many down-hole debris flow accidents are affected by ore drawing shear, which is one of the important factors affecting the formation of down-hole debris flow.

(2)Based on the rheology and thixotropy of the slurry, it is analyzed that the slurry of the underground debris flow in Plan copper mine is not only a pseudoplastic fluid but also a thixotropy fluid. It is indicated that once the shear force of drawing occurs, its viscosity will decrease with the increase of shear rate and time, and finally become a flowable slurry.

(3)Based on the analysis of the structure characteristics of the slurry of the underground debris flow in Plan copper mine. Based on the rheology and thixotropy of slurry, the influence of drawing shear factor on the formation mechanism of underground debris flow is analyzed. It is considered that the shear force produced by the flow of ore particles firstly produces shear action on the paste in the shear boundary region of ore drawing, which results in the decrease of viscosity and the enhancement of fluidity, make it “Activation” and then become a flowable paste, along with the bulk ore flow through the ore mouth. The continuous ore drawing process will continuously shear the new moraine slurry in the ore drawing channel. The moraine slurry in the ore drawing channel is continuously shear-activated and continuously discharged. Finally, a certain scale and destructive down-hole debris flow accident is formed.

Author Contributions

Conceptualization, Xiangdong Niu and Kepeng Hou; methodology, Kepeng Hou; software, Xiangdong Niu and Kepeng Hou; validation, Xiangdong and Huafen Sun; writing—original draft preparation, Xiangdong Niu and Huafen Sun. All authors have read and agreed to the published version of the manuscript.

Funding

This study receives no financial support.

Data Availability Statement

The basic data supporting the research results are all in the article.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- LI Zhijun, NIU Xiangdong, ZENG Qingtian, et al. Experimental study on critical threshold value of rainfall induced by natural caving method for underground debris flow [J]. Nonferrous Metals(Mining Section), 2022, 74(05):79-85.

- Gunes A, Demirdag S, Demirbas E. O, et al. Investigating the Usability of Pyrotechnic Rock Breaker Materials in Natural Stone Quarrying [J]. Journal of Mining Science, 2023, 58(06):973-991. [CrossRef]

- ZHANG Jianhua, CHENG Xiaojiao, WEN Hu, et al. Prediction and Control of Coal Spontaneous Combustion in a Multi-fault Fully Mechanized Top Coal Caving Face at the Mine Field Boundary [J]. Combustion Science and Technology, 2022, 194(09):1895-1913. [CrossRef]

- Pal Roy Pijush, Sawmliana Chhangte, Singh Rakesh Kumar. Design of blasting patterns to induce effective caving in continuous miner depillaring panel – a case study [J]. Mining Technology, 2021, 130(04):209-220. [CrossRef]

- NIU Xiangdong, HOU Kepeng, SUN Huafen, et al. Experimental study on the flow mechanism of fine-grained moraine in the process of uniform ore drawing[J]. Journal of Mining And Strata Control Engineering, 2023. [CrossRef]

- HUANG Huatao, LUO Genping, WANG Huan, et al. Research and application of mud inrush control in stope of Block Caving Method[J]. World Nonferrous Metals, 2020(10):55-56.

- NIU Xiangdong, XIE Jinyi, HOU Kepeng, et al. Experimental study on rainfall threshold and outbreak time of downhole debris flow induced by the Prang Copper Mine[J]. Nonferrous Metals Engineering, 2020, 10(07):100-106.

- DENG Junping. Study on the cause and prevention of mud bursting accident in a mine based on accident causation theory [J]. Mining Technology, 2019, 19(5):98-101.

- SONG Weidong, WANG Yanhui, DU Jianhua, et al. Study on the indicator system of influencing factors on the underground debris flow [J]. Metal Mine, 2009, (9):155-159.

- DU Jianhua, KUANG Zhongxiang, SONG Weidong, et al. Numerical simulation study occurrence mechanism of underground Mud-Rock Slides [J]. Metal Mine, 2008, (4):18-22.

- PORMANDO Silalahi, DANNY Satrio Wicaksono, IWAN Sriyanto, et al. Geological aspects for the wet muck material forming at the deep ore zone (DOZ) block cave mine, Papua, Indonesia[J]. Deep Ore Zone Block Caving Production Mine Geologis, 2012.

- LI Xingyue, ZHAO Jidong. Numerical simulation of dam break by a coupled CFD-DEM approach [J]. Japanese Geotechnical Society Special Publication, 2016, 2(18):691-696. [CrossRef]

- ZHANG Chuanhu, CHEN Songgui, SUN Qicheng, et al. Free-surface Simulations of Newtonian and Non-Newtonian Fluids with the Lattice Boltzmann Method [J]. Free-surface Simulations of Newtonian and Non-Newtonian Fluids with the Lattice Boltzmann Method, 2016, 90(03):2999-1010. [CrossRef]

- Perrine FREYDIER, Guillaume CHAMBON, Mohamed NAAIM. Internal Dynamics of a Free-Surface Viscoplastic Flow Down an Inclined Channel [J]. International Journal of Erosion Control Engineering, 2016, 9(03):101-106. [CrossRef]

- DENG Zhao, CHEN Shengshui, ZHONG Qiming, et al. Research on the numerical model for the routing of viscous debris flow considering the interface [J]. European Journal of Environmental and Civil Engineering, 2021, 25(03):468-484. [CrossRef]

- Schippa Leonardo, Doghieri Ferruccio, Pellegrino Anna Maria, et al. Thixotropic Behavior of Reconstituted Debris-Flow Mixture [J]. Water, 2021, 13(02):153-164. [CrossRef]

- Brandvold Allison, S. , AlChaar Ghassan K., Kriven Waltraud M. Isolating the effects of thixotropy in geopolymer pastes [J]. Journal of the American Ceramic Society, 2023, 106(05):2797-2807. [CrossRef]

- GUO Liping, HAN Xue, FENG Tao. Study on the prediction method of thixotropy of water-in-oil waxy crude oil emulsions [J]. Petroleum Science and Technology, 2023, 41(11):1218-1230. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).