1. Introduction

Nowadays, there is a growing need for the use of fully mechanized technologies, logging and transport machines in the forestry, both because of higher productivity, and also because of the elimination of physically demanding work operations and increased work safety [

1]. Fully mechanized logging technology, including harvesters and forwarding machines, is commonly used in forestry in many parts of the world [

2], mainly due to its high productivity [

3] and high work safety [

4]. The forwarding machine is a self-loading forest tractor, used when skidding timber from the extraction site to the pick-up point [

5]. Forwarding machines can basically be divided into 2 types, namely the tractor with a timber trailer and forwarding tractor or forwarder. While a tractor with a timber trailer is a combination of two otherwise separate means, namely a tractor and a trailer, a forwarding tractor is a special compact machine [

1]. Of these two types of machines, the cheaper option is the first option, i.e. a forwarder trailer unit equipped with a hydraulic crane. Forwarder trailer units can be combined with agricultural tractors [

6]. The advantage of such combination is that the tractor can also be used for other purposes, e.g. at a time when the amount of harvested wood decreases, and the cost of purchasing the trailer will thus be recouped more quickly [

7]. A forwarder and a tractor with timber trailer normally skid wood harvested by a harvester, but also wood harvested by a chainsaw. The wood extracted and cut in this way is then loaded onto the load bed by the forwarding machine and piled at the pick-up point, which is located along the forest roads. This point must be accessible in order for the trucks to be able to transport the wood from the forest [

8].

The productivity of forwarding machines is affected by many factors. The first significant group are factors that are directly related to the machine operator. Specifically, it concerns the skills and experience of the given operator [

9,

10], which, among other things, is also related to the previous performance of the profession (e.g. storing wood, sorting assortments, ...) [

2,

8,

11]. Productivity is further influenced by the approaching distance and the size of the load [

12,

13,

14]. Other factors affecting productivity may include trunk volume [

15] and number of assortments [

11,

16,

17], terrain-related factors such as terrain slope [

18,

19]. Last but not least, these factors can include work organization factors [

20] and technical parameters such as the load capacity of the used machine [

17,

21].

The operator is undoubtedly one of the most important components in the use of logging and transport technology [

22,

23]. Operating the machine puts significant physical and mental demands on the operator. Today's machines provide the operator with suitable ergonomic conditions, but despite this, the operator is forced to sit in ergonomically inappropriate positions during the work shift, and must also perform delicate, cyclically repetitive movements [

5]. An important factor is the exposure of the operator to whole-body vibrations [

4,

24], which can be understood as the transfer of mechanical energy generated by the operation of the machine to the body of a sitting or standing operator [

25]. Regarding the magnitude of whole-body vibrations, [

26] proved in their research that the highest vibration values occur when the machine is moving, and the lowest when the machine is in a stationary position. Such a working environment can be the cause of physical and mental disorders of the operators and is therefore considered unhealthy [

27,

28,

29,

30]. The comfort of operators when operating unloading machines has a significant effect on productivity and work safety [

31]. While operating the machine, the quality of the view from the cabin is also very important. If the operator's view from the cabin is insufficient, the safety of workers, their health and, last but not least, work performance may be at risk [

32]. When developing forestry machines, it is necessary to follow ergonomic principles that contribute to reducing mental and physical stress and reducing the probability of operator errors [

33].

In addition to mental stress, the operator of unloading machines is also exposed to physical stress, which is often assessed by the operator's heart rate [

34,

35]. Heart rate indicates the number of heartbeats in 1 minute [

36], the heartbeat is a pressure wave that is caused by the ejection of blood from the heart [

37]. Heart rate monitoring methods have been widely applied to understand real-time changes in physical and mental workload, as well as to determine cardiac workload as a predictor of cardiovascular activities to monitor operator health and safety [

38,

39,

40]. In addition to monitoring the heart rate during physical load, it is also very important to monitor the operator's resting heart rate, which can be used as a predictor of cardiovascular diseases, cerebrovascular accidents and sudden death [

41]. Thus, heart rate as a physiological marker of homeostasis can provide an early warning in certain abnormal conditions [

42].

Currently, small wearable devices are widely used to measure heart rate. The most common type of device with a heart rate measurement function is the so-called smart watch, which is sold in large quantities today. Heart rate measurements with these devices are commonly used for the assessment of training intensity, sleep cycle monitoring, and in other health-related areas [

43]. Furthermore, there are attempts to use this measurement to assess relaxation and stress [

44], distinguish emotions [

45] and distinguish between sleep and wakefulness [

46].

2. Materials and Methods

2.1. Research Sample

This research was carried out in the territory of the Czech Republic, specifically in the territory of the South Moravian Region and the Vysočina Region in cooperation with five operators of tractor with a timber trailer and two forwarder operators. The age of the operators was diverse and ranged from 21 to 65 years. The operators were not taking any medication at the time of the research and had no health problems that could affect the measurement results. Anthropometric measurements of the operators showed that their height ranged from 170-190 cm. The weight of the operators was quite variable and varied between 77-106 kg. The operators were very different from each other in terms of length of time in the profession, with the least experienced operator having 2 months of experience and the most experienced operator having had 20 years of experience.

2.2. Heart Rate Measurement

The heart rate of the operators was measured and recorded using a “Garmin fenix5X” smart watch. The watch was always put on the operator's left hand at the beginning of the shift and the measurement was then started. Each operator wore the watch for the entire duration of the work shift, after which the measurement on the watch was stopped and the acquired data was saved. The measurement took place for each operator in only one shift. Simultaneously with the measurement of the heart rate, the work activities performed by the operator during the working day were recorded in a time sequence. Subsequently, the acquired data was transferred via Bluetooth from the watch to the mobile application "Garmin Connect" from the developer Garmin. The data thus transferred was already available online on the "Garmin Connect" web application, where the data could be analyzed. All measured data of individual operators was available in this web application. The last step was to select the desired operator whose heart rate values were analyzed from the heart rate chart.

2.3. Sub-activities

For the purposes of evaluating the operators' heart rates, their work shifts were divided into several sub-activities. Specifically, the following activities were created:

• Maintenance - This activity started the operator's working day and included, for example, checking the hydraulic and engine oil levels, checking the air filter, checking the condition and inflation of the tires, checking and cleaning all tight spaces, checking for defects and cracks on the machine, optical inspection of the hydraulic crane (tightness of hoses, joints, hydraulic cylinders), replenishment of fuel, etc.

• Driving – This activity included driving on public roads, or a mere crossing between workplaces in a particular forest stand.

• Forwarding - This was a part of the production process that included the work operations of clearing, load assembly, forwarding, sorting at the pick-up point and landfilling of wood.

• Break – The operator used the break time for a snack or lunch, or to inspect the workplace.

In order to assign the obtained heart rate data to individual sub-activities, a simple picture of the working day was taken simultaneously with the measurement, which contained the name of the activity and its duration, on the basis of which the subsequent assignment to the timeline of the heart rate graph took place.

2.4. Statistical Data Processing

The data that was obtained as part of the heart rate sensing during the operators' working hours was divided into individual sub-activities, which were compared with each other. Specifically, the data from the individual sub-activities of the operator were compared with each other, and then the sub-activities of the work shift were also compared between individual operators. Furthermore, the possibility of affecting the pulse rate by the operator himself or by the given sub-activities was investigated.

For these purposes, data analysis was performed in TIBCO's STATISTICA 14 software. For correct evaluation, the data were first subjected to the Shapiro-Wilk test. This test verified whether the data in the file has a normal distribution or not. The data were then evaluated as normally distributed if the test result exceeded the specified p-value of 0.05 (5% significance level). This p-value size was also used in the following test, which was a Two-Factor ANOVA to determine the influence of the pulse rate by the operator (1st factor) or the activity (2nd factor) that was performed. If there was a situation where the result of this test did not exceed the specified p-value for any of the factors, then the given factor affects the heart rate.

The second to last step in the statistical data processing was the use of a Post Hoc test to compare the sub-activities with each other. For this purpose, the Scheffe’s test was used, the p-value of which was set at 0.05. If the test result did not exceed the selected value, then the given sub-activities differed from each other in their data. The last step was the processing of the data of the sub-activities of individual operators with descriptive statistics, while a box plot was created for a better representation of the data.

3. Results

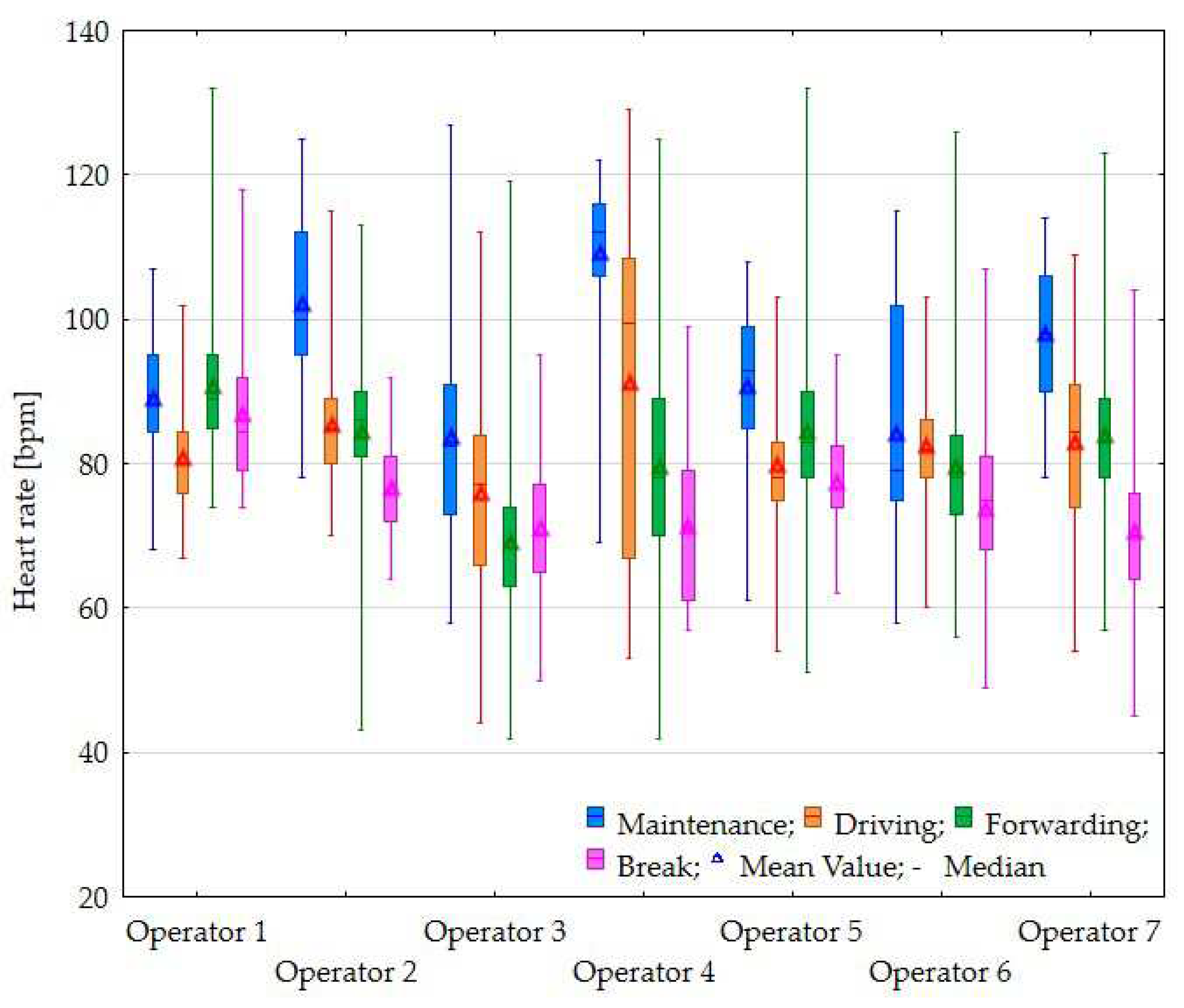

The highest heart rate recorded was 132.0000 beats per minute (bpm). This value was reached by the heart rate of two operators (number 1 and 5) during the Forwarding activity, which can be seen in

Figure 1. The lowest heart rate was also detected during this operation, and that was for operators 2, 3 and 4. The lowest heart rate was 42.0000 bpm and was recorded equally by Operator 3 and 4. In

Figure 1, Operator 4 can be seen to have a significant spread of heart rate while Driving, which confirms the difference between the mean heart rate value (91.1786 bpm) and the median (99.5000 bpm), which shows the extreme values within the entire data set. A similar phenomenon was also observed with this operator and his heart rate during Maintenance. In this case, however, the mean pulse value was 109.0488 bpm and the median was 112.0000 bpm (see table 1). Furthermore, in

Figure 1, one can notice the high heart rate in Maintenance, where there is a large concentration of data in high values.

In

Table 1, you can see basic statistical data on pulse frequencies in given activities for individual operators. Operator 1 had a mean heart rate of 89.0962 bpm during Maintenance, which was 12.9396 bpm less than Operator 2's. The difference between the mean heart rate of Operator 1 and 3 was 5.3961 bpm, with Operator 3 having a lower heart rate. When compared to Operator 4, the difference was 19.9526 bpm against him. A very small difference in the mean value of heart rate during Maintenance was achieved when comparing Operator 1 and 5, where the difference was only 1.5705 bpm in favour of Operator 1. Operator 6 had a mean heart rate of 84.2609 bpm during Maintenance, which was 8.8843 bpm less than Operator 7.

Lower heart rate values for all operators were achieved during Driving compared to Maintenance. A mean heart rate of 80.8250 bpm was recorded for Operator 1 and 85.4296 bpm for Operator 2. Operator 3 had a lower heart rate than Operator 1 by 4.9019 bpm. Another operator, i.e. number 4, on the other hand, exceeded Operator 1 with his mean heart rate by 10.3536 bpm. A small difference between the mean heart rate values within Driving was noted between Operator 1 and 5, where it was only 0.9548 bpm. Higher values, but still a small difference when compared to Operator 1, could be observed for Operators 6 and 7. Specifically, the difference between Operator 1 and 6 was 1.5632 bpm and between 1 and 7 only 2.0356 bpm, both values favouring Operator 1.

In

Table 1, we can also see the pulse frequency values of the operators during Forwarding, where the greatest dispersion of values was observed for all operators. Operator 1 had an average heart rate of 90.6998 bpm, which was 6.9998 bpm more than Operator 2. A very high difference in mean heart rate magnitude was noted between Operator 1 and 3. The value of this difference was 21.6840 bpm to the disadvantage of Operator 1. A smaller difference, but still considerably high, was also between Operator 1 and 4, where it reached 11.1501 bpm. A similar value between the mean heart rate was also found between Operator 1 and 6. This was a difference of 11.1427 bpm. An already considerably smaller difference of 6.3878 bpm was noted between Operator 1 and 5, with the latter operator having a lower heart rate. Operator 7 then had a 6.8425 bpm slower heart rate during Forwarding compared to Operator 1.

Another activity recorded for all operators was Break. During this activity, the mean heart rate reached the lowest values compared to other machine operator activities. Operator 1 had the highest pulse value of all. Specifically, this value was 86.7963 bpm, which was 10.2496 bpm higher than Operator 2's mean heart rate and 15.7871 bpm higher than Operator 3's. Operator 4 had a heart rate of 71.3636 bpm during Break, which was 15.4327 bpm less than Operator 1, whose heart rate was 9.4838 bpm faster than Operator 5. The last two operators also had a lower heart rate compared to Operator 1 by 13.0595 bpm for Operator 6 and 16.3473 for Operator 7.

Another sub-goal, apart from the detection of heart rate values for forwarder operators, was also an effort to demonstrate the influence of operators on heart rate. The result can be observed in

Table 2, where the statistical evaluation is found. Specifically, the test result demonstrated the influence of operators on heart rate values, as the p-value of the test was less than the set significance level of the test (0.05). The same result was also achieved when determining the effect of individual activities on heart rate magnitude. In this case, the resulting test value was also less than 0.05 (see

Table 2). The effect on the heart rate was also proven during concurrent action of operators and activities. In this case, the calculated value was again lower than the p-value (0.05). In summary, it can be said that the magnitude of the heart rate differs both between operators and between activities.

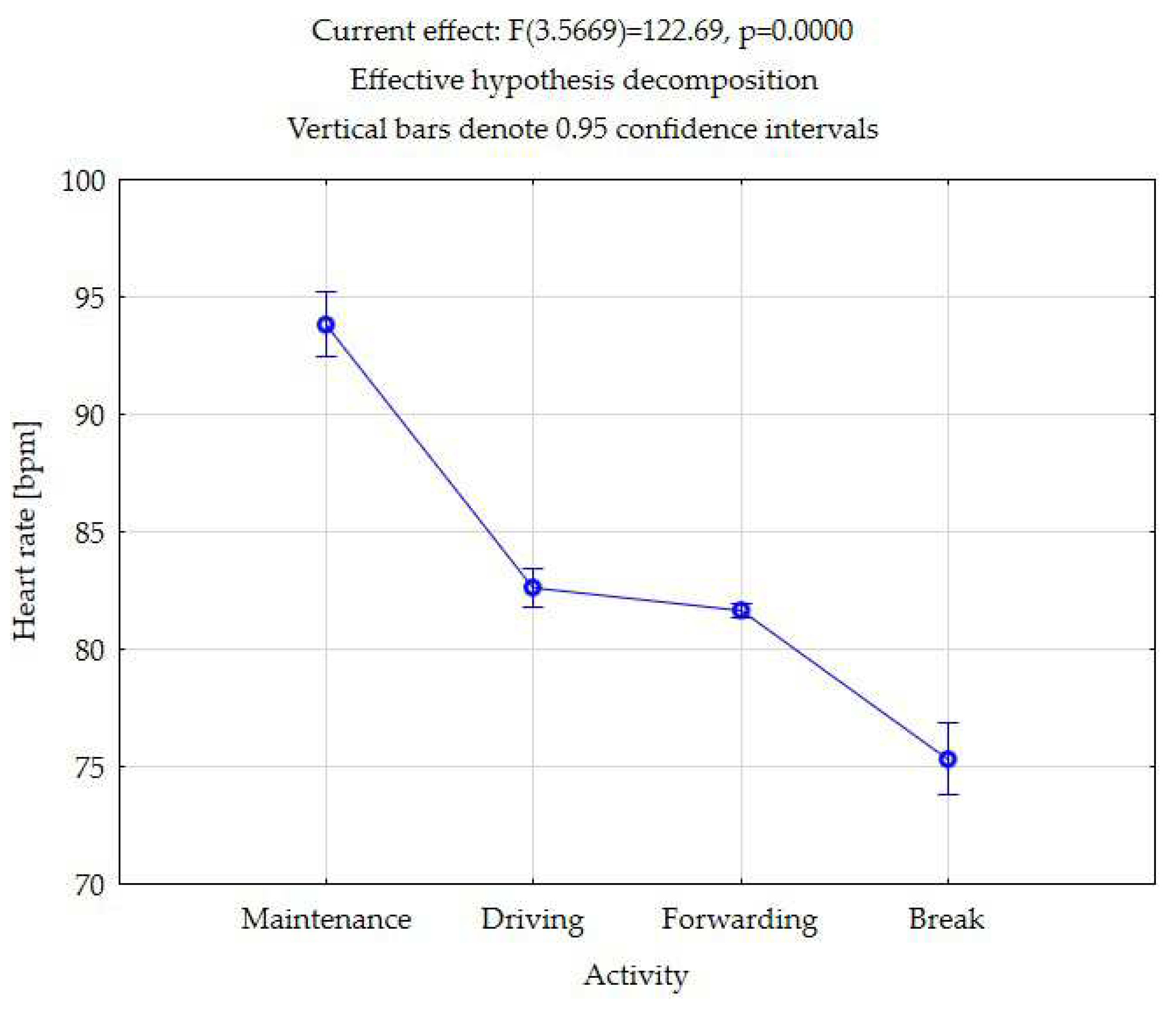

Figure 2 shows a comparison of individual activities with one another without the influence of the operator. In particular, it is possible to see a significant equality of the pulse frequency between Driving and Forwarding, which is also confirmed by the results of the statistical test within the framework of their comparison in

Table 3. The differences between these operations were not statistically proven (p-value of the test 0.674682). Furthermore, in

Figure 2, we can notice the large differences in heart rate values between Maintenance and Break. This difference is statistically significant (p-value was less than 0.05). The statistical results then showed a difference between heart rates and all other combinations within the compared activities (see

Table 3).

In summary, it was found that the operators reached the highest heart rates during the Maintenance of the machine entrusted to them. However, the highest heart rate fluctuations were registered in the operators during the Forwarding activity. During this activity, the highest heart rate of the entire measurement process was recorded, which was 132.0000 bpm, but also the lowest heart rate. It was only 42.0000 bpm. Furthermore, the results showed that both the operator and the activity he performs affect the pulse rate. The activities themselves did not differ from each other in only one of the six cases of comparison. Specifically, it was Driving and Forwarding.

4. Discussion

At the beginning of this section, it is important to discuss the main limitations of this study, namely the small number of respondents, the difference of individual operators, the inaccuracy of the measuring device and the absence of repeated measurement of one operator.

The first limitation was the small number of respondents, 7 of whom were surveyed for the purpose of this study. During the preparatory work, there was of course an effort to get as many operators of the tractor with a timber trailer and the forwarder as possible, but it turned out that obtaining a larger sample of respondents is very difficult. The main reason was the small number of operators who work with these machines in a given location. The second reason was the inability of the operators to participate in the research, both due to time constraints and for personal reasons. As claimed by [

1], this technique places significant demands on the worker with these machines, who must perfectly control the machine and be familiar with all the details of its deployment in various conditions. According to [

5], operating the machine places significant physical and mental demands on the operator, which corresponds to the previous statement. [

47], who in his work deals with the human factor in the use of logging and transport machines, mentions that the work of operator of forwarding machines is a demanding activity that requires a responsible approach and the ability to quickly make many complex decisions. These facts may contribute to the fact that this profession is less attractive for forestry workers, and it is also difficult to obtain a large sample of respondents. It should be noted, however, that despite the smaller number of operators, a relatively large amount of data was obtained, the analysis of which yielded results that are applicable for the purposes of determining the physical demands of individual activities.

As for the difference between individual operators, it was quite large. The age of the operators ranged from 21 to 65 years. This means that the performance of this profession is not strictly limited by age. However, more important than age was the state of health of the operator, which could significantly influence the results of heart rate measurements. However, none of the examined operators were found to have any health complications or use of medication that could affect heart rate values. The operators were also very different from each other in terms of length of time in the profession, which ranged from 2 months to 20 years. According to [

9,

10,

48], the skills and experience of the given operator are an important factor in work productivity, but the heart rate during the performance of this profession was not affected by it. It should be noted that obtaining a sample of respondents whose mutual variability is small is practically impossible, mainly due to the reasons that are involved in a smaller number of operators.

Another limitation of this study is the possible inaccuracy of the heart rate recording device, specifically the “Garmin fenix5X” smart watch. Regarding the accuracy of heart rate measurement by Garmin watches, [

49] in their study on the accuracy of the watch during rest and during activity found that the measurement provided valid heart rate values, but deviations can also occur, mainly due to changes in skin colour, poor tissue perfusion, imperfect contact between the skin and the optical device, changes in wrist positions, etc. These factors can be partially eliminated by using a chest belt. On the other hand, it should be noted that the reduced accuracy of this technology is to some extent compensated by better usability and comfort. [

50] mention in their publication that these wrist-worn devices show good accuracy in measuring heart rate with only a small negative bias. However, the accuracy was significantly impaired in the case when, for example, the activity indicator was not used [

50]. Based on the findings of these authors, it can be concluded that this device, a smart watch, is suitable for the purposes of this study, mainly due to its user-friendliness, as the device does not excessively burden the respondent and does not disturb his work comfort, etc.

Last but not least, a limiting factor of this study was the absence of repeated measurements, specifically measurements on several working days of individual operators. As part of this study, an attempt was made to perform repeated measurements of each operator, but in practice this procedure proved to be unfeasible. The reason was the complex planning of a multi-day field investigation depending on the operators' time options. One of the other reasons for the absence of repeated measurements was that, in addition to forwarding wood, some operators performed other activities as part of their work shift, such as harvesting wood, building fences, etc. In these cases, the measurement would have to be tied to the days when the worker is skidding wood.

This study clearly shows that the most demanding activity within the operator's working day in terms of physical load was machine Maintenance. During this activity, the machine operator performs tasks that require greater physical strength, a greater number of movements, more frequent changes in working positions, etc. According to [

51,

52], even small changes in working position can cause significant changes in heart rate. Among the tasks performed by the operator as part of maintenance can be listed, for example, cleaning the machine (snow, deposits, dirt, ...), checking defects and cracks on the machine, checking the tightness of hoses, etc. [

53] mentions that a high heart rate during machine maintenance indicates a high physical demand, which corresponds with the results of this study. According to [

54], heart rate is considered a good predictor of cardiovascular activities in the range of 100-140 bpm, which was also the case in this study. According to [

55], heart rate correlates with workload and can be used to predict work-related health risks. The relationship between workload and heart rate is evident even when the operator was not working. The operator's Break turned out to be the least physically demanding activity in terms of physical load, which corresponds to [

53], who found in his study that the operator's heart rate decreases during breaks. During the break, the operator is at rest and does not perform any physically or mentally demanding activities that would increase his heart rate. According to [

1], operating the machine places great demands on the operator in terms of mental stress. As reported by [

53] in their study, mentally demanding activities are associated with an increase in heart rate. By improving the ergonomic parameters of machine control, it is possible to reduce the burden on the operator during the work shift, or increase its performance. An example can be the use of the IBC (Intelligent Boom Control) system, which enables precise, quick and easy control of the hydraulic crane. According to [

48], novice operators experienced a 27% increase in productivity and a 53% reduction in errors in hydraulic crane control when using the IBC system.

5. Conclusions

In our research we have analyzed the heart rate of the operator of the forwarding machine and the dependence of its values on the work activities that the operator performs during the work shift. It was found that the operator's heart rate reached the highest values during daily machine maintenance. The largest fluctuations in heart rate values were recorded during Forwarding, with both a high of 132.0000 bpm and a low of 42.0000 bpm. The results of this study demonstrated the influence of the pulse frequency by the operator himself, as well as by the activity he performs. The activities that did not differ from each other in terms of heart rate were Driving a machine and Forwarding wood.

The degree of physical strain of the operator can affect the productivity of the work, the safety and health of the operator, etc. The evaluation of the physical strain of operators of forwarding machines is therefore an important area that should be given attention in further research. For a future deeper understanding of this issue, it would be advisable to use more accurate devices, to carry out repeated measurements of operators and, for example, to provide a more homogeneous group of respondents. The heart rate sensing method described in this article is a relatively convenient, user-friendly, and research-friendly method of data acquisition. This method therefore meets the requirements that are placed on data collection as part of a field investigation.

Author Contributions

Conceptualization, D.S., V.M. and E. A.P.; methodology, D.S. and V.M.; software, V.M.; validation, V.M. and D.S.; formal analysis, V.M.; investigation, V.M. and D.S.; resources, D.S.; data curation, V.M.; writing—original draft preparation, D.S., V.M. and E.A.P.; writing—review and editing, D.S. and E. A.P.; visualization, D.S. and V.M.; supervision, E. A.P.; project administration, D.S. and E. A.P.; funding acquisition, E. A.P. All authors have read and agreed to the published version of the manuscript.

Funding

The publication makes use of findings acquired during the solution of research project no. 2019-1-UK01-KA202-061846 European Forest Machine Operators Certification. The research was supported by the Department of Engineering, Faculty of Forestry and Wood Technology, Mendel University in Brno, Czech Republic. The authors gratefully acknowledge funding from the Specific research on BUT FSI-S-23-8235.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Neruda, J.; Ulrich, R.; Kupčák, V.; Slodičák, M.; Zemánek, T. Harvestorové technologie lesní těžby; Mendelova univerzita v Brně: Brno, Czech republic, 2013; 165 p; ISBN 978-807375-842-4. [Google Scholar]

- Nurminen, T.; Korpunen, H.; Uusitalo, J. Time Consumption Analysis of the Mechanized Cut-to-length Harvesting System. Silva Fenn. 2006, 40, 335–363. [Google Scholar] [CrossRef]

- Dvořák, J.; Malkowský, Z.; Macků, J. Influence of Human Factor on the Time of Work Stages of Harvesters and Crane-Equipped Forwarders. J. For. Sci. 2008, 54, 24–30. [Google Scholar] [CrossRef]

- Axelsson, S. The Mechanization of Logging Operations in Sweden and its Effect on Occupational Safety and Health. Int. J. For. Eng. 1998, 9, 25–31. [Google Scholar] [CrossRef]

- Gerasimov, Y.; Sokolov, A. Ergonomic evaluation and comparison of wood harvesting systems in Northewest Russia. Appl. Ergon. 2014, 45, 318–338. [Google Scholar] [CrossRef]

- Więsik, J. Wood hauling aggregate with self-loading trailer. Principles of creation and effective use. Part 1. Description of wood forwarding process and principles of machine aggregation. Tech. Rol. Ogrod. Leśna 2017, 4, 18–21. [Google Scholar]

- Naskrent, B.; Polowy, K.; Grzywiński, W.; Sobczak, A. Timber extraction in thinned stands using agricultural tractor coupled with a trailer with a hydraulic crane. Sylwan 2019, 163, 121–129. [Google Scholar] [CrossRef]

- Väätäinen, K.; Ala-Fossi, A.; Nuutinen, Y.; Röser, D. The Effect of Single Grip Harvester´s Log Bunching on Forwarder Efficiency. Balt. For. 2006, 12, 64–69. [Google Scholar]

- Tervo, K.; Palmroth, L.; Koivo, H.N. Skill Evaluation of Human Operators in Partly Automated Mobile Working Machines. IEEE Trans. Autom. Sci. Eng. 2010, 7, 133–142. [Google Scholar] [CrossRef]

- Manner, J. What is (not) an operator effect in forest work science? Silva Fenn. 2021, 55, 1–4. [Google Scholar] [CrossRef]

- Manner, J.; Nordfjell, T.; Lindroos, O. Effects of the number of assortments and log concentration on time consumption of forwarding. Silva Fenn. 2013, 47, 1–19. [Google Scholar] [CrossRef]

- Spinelli, R.; Owende, P.; Ward, S.; Tornero, M. Comparison of short-wood forwarding systems used in Iberia. Silva Fenn. 2004, 38, 85–94. [Google Scholar] [CrossRef]

- Tiernan, D.; Zeleke, G.; Owende, P.M.O.; Kanali, C.L.; Lyons, J.; Ward, S.M. Effect of working conditions on forwarder productivity in cut-to-length timber harvesting on sensitive forest sites in Ireland. Biosyst. Eng. 2004, 87, 167–177. [Google Scholar] [CrossRef]

- Ghaffariyan, M.R.; Sessions, J.; Brown, M. Machine productivity and residual harvesting residues associated with a cut-to-length harvest system in southern Tasmania. South. For.: J. For. Sci. 2012, 74, 229–235. [Google Scholar] [CrossRef]

- Acuna, M.A.; Kellogg, L.D. Evaluation of Alternative Cut-to-Length Harvesting Technology for Native Forest Thinning in Australia. Int. J. For. Eng. 2009, 20, 17–25. [Google Scholar] [CrossRef]

- Gingras, J.F.; Favreau, J. Effect of Log Length and Number of Products on the Productivity of Cut-to-Length Harvesting in the Boreal Forest. Advantage 2005, 6, 1–8. [Google Scholar]

- Eriksson, M.; Lindroos, O. Productivity of harvesters and forwarders in CTL operations in northern Sweden based on large follow-up datasets. Int. J. For. Eng. 2014, 25, 179–200. [Google Scholar] [CrossRef]

- Ghaffarian, M.R.; Stampfer, K.; Sessions, J. Forwarding Productivity in Southern Austria. Croat. J. For. Eng. 2007, 28, 169–175. [Google Scholar]

- Strandgard, M.; Mitchell, R.; Acuna, M. Impact of Slope on Forwarder Load Size and Productivity. In Proceedings of the 48th FORMEC Symposium, Linz, Austria, 1 December 2015; pp. 101–105. [Google Scholar]

- Zimbalatti, G.; Proto, A.R. Productivity of Forwarders in South Italy. In Proceedings of the 44th FORMEC Symposium, Padova, Italy, 11–14 July 2010. [Google Scholar]

- Proto, A.R.; Macri, G.; Visser, R.; Harrill, H.; Russo, D.; Zimbalatti, G. A Case Study on the Productivity of Forwarder Extraction in Small-Scale Southern Italian Forests. Small-Scale For. 2017, 17, 71–87. [Google Scholar] [CrossRef]

- Mola-Yudego, B.; Picchi, G.; Röser, D.; Spinelli, R. Assessing chipper productivity and operator effects in forest biomass operations. Silva Fenn. 2015, 49, 1342. [Google Scholar] [CrossRef]

- Malinen, J.; Taskinen, J.; Tolppa, T. Productivity of cut-to-length harvesting by operators’ age and experience. Croat. J. For. Eng. 2018, 39, 15–22. [Google Scholar]

- Bovenzi, M.; Zadini, A.; Franzinelli, A.; Borgogni, F. Occupational musculoskeletal disorders in the neck and upper limbs of forestry workers exposed to hand-arm vibration. Ergonomics 1991, 34, 547–562. [Google Scholar] [CrossRef]

- Burström, L.; Nilsson, T.; Wahlström, J. Whole-body vibration and the risk of low back pain and sciatica: A systematic review and meta-analysis. Int. Arch. Occup. Environ. Health 2014, 88, 403–418. [Google Scholar] [CrossRef]

- Staněk, L.; Mergl, V. Whole Body Vibrations during Fully Mechanised Logging. Forests 2022, 13, 630. [Google Scholar] [CrossRef]

- Poje, A.; Spinelli, R.; Magagnotti, N.; Mihelic, M. Exposure to noise in wood chipping operations under the conditions of agro-forestry. Int. J. Ind. Ergon. 2015, 50, 151–157. [Google Scholar] [CrossRef]

- Yovi, E.Y.; Yamad, Y. Addressing occupational ergonomics issues in indonesian forestry: Laborers, operators, or equivalent workers. Croat. J. For. Eng. 2019, 40, 351–363. [Google Scholar] [CrossRef]

- Albizu-Urionabarrenetxea, P.M.; Tolosana-Esteban, E.; Roman-Jordan, E. Safety and health in forest harvesting operations. Diagnosis and preventive actions. A review. For. Syst. 2013, 22, 392–400. [Google Scholar] [CrossRef]

- Sedmíková, M.; Löwe, R.; Jankovský, M.; Natov, P.; Linda, R.; Dvořák, J. Estimation of over-and under-bark volume of scots pine timber produced by harvesters. Forests 2020, 11, 626. [Google Scholar] [CrossRef]

- Häggström, C.; Lindroos, O. Human, technology, organization and environment – a human factors perspective on performance in forest harvesting. Int. J. For. Eng. 2016, 27, 67–78. [Google Scholar] [CrossRef]

- Zvěřina, L.; Cibulka, M.; Staněk, L.; Ulrich, R. Analysis of Field View from Tractor and Trailer Units Using the Method of Terrestrial Laser Scanning. Forests 2022, 13, 1383. [Google Scholar] [CrossRef]

- Marzano, F.; Souza, A.; Minette, L. Proposal for an ergonomic conformity index for evaluation of harvesters and forwarders. Rev. Arvore 2017, 41, e410401. [Google Scholar] [CrossRef]

- Arman, Z.; Nikooy, M.; Tsioras, P.A.; Heidari, M.; Majnounian, B. Physiological workload evaluation by means of heart rate monitoring during motor-manual clearcutting operations. Int.J. of For. Eng. 2021, 32, 91–102. [Google Scholar] [CrossRef]

- Cheţa, M.; Marcu, M.V.; Borz, S.A. Workload, Exposure to Noise, and Risk of Musculoskeletal Disorders: A Case Study of Motor-Manual Tree Feeling and Processing in Poplar Clear Cuts. Forests 2018, 9, 300. [Google Scholar] [CrossRef]

- McCraty, R.; Shaffer, F. Heart rate variability: New Perspectives on Physiological Mechanisms, Assessment of Self-regulatory Capacity, and Health risk. Glob. Adv. Health Med. 2015, 4, 46–61. [Google Scholar] [CrossRef] [PubMed]

- Fiľo, P. Nové metody v ergonomii; Mendelova univerzita v Brně: Brno, Czech republic, 2013; 104 p; ISBN 978-80-7375-870-7. [Google Scholar]

- Garet, M.; Boudet, G.; Montaurier, C.; Vermorel, M.; Coudert, J.; Chamoux, A. Estimating relative physical workload using heart rate monitoring: a validation by whole-body indirect calorimetry. Eur. J. Appl. Physiol. 2005, 94, 46–53. [Google Scholar] [CrossRef]

- Hoover, A.; Singh, A.; Fishel-Brown, S.; Muth, E. Real-time detection of workload changes using heart rate variability. Biomed. Signal Process. Control 2012, 7, 333–341. [Google Scholar] [CrossRef]

- Afshari, D.; Shirali, G. The effect of heat exposure on physical workload and maximum acceptable work duration (MAWD) in a hot and dry climate. Urban Clim. 2019, 27, 142–148. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, W.; Li, F. Association between Resting Heart Rate and Coronary Artery Disease, Stroke, Sudden Death and Noncardiovascular Diseases: A Meta-Analysis. Can. Med. Assoc. J. 2016, 188, 384–392. [Google Scholar] [CrossRef]

- Alugubelli, N.; Abuissa, H.; Roka, A. Wearable Devices for Remote Monitoring of Heart Rate and Heart Rate Variability-What We Know and What Is Coming. Sensors 2022, 22, 8903–8924. [Google Scholar] [CrossRef]

- Yokoyama, K.; Hayashi, E.; Ito, H.; Kawahara, Y. Estimation of Heart Rate Variability from Heartrate Measured with Wristwatch-Type Heartrate Monitor. IEEJ Trans. Electron. Inf. Syst. 2022, 142, 46–54. [Google Scholar] [CrossRef]

- Can, Y.S.; Chalabianloo, N.; Ekiz, D.; Ersoy, C. Continuous Stress Detection Using Wearable Sensors in Real Life: Algorithmic Programming Contest Case Study. Sensors 2019, 19, 1849. [Google Scholar] [CrossRef]

- Quiroz, J.C.; Geangu, E.; Yong, M.H. Emotion Recognition Using Smart Watch Sensor Data: Mixed-Design Study. JMIR Ment. Health 2018, 5, e10153. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Tsujikawa, M.; Onishi, Y. Sleep/wake classification via remote PPG signals. In Proceedings of the 41st Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Berlin, Germany, 23-27 July 2019; pp. 3226–3230. [Google Scholar]

- Hӓggstrӧm, C. Human Factors in Mechanized Cut-to-Length Forest Operations. Doctoral thesis, Swedish University of Agricultural Sciences, Umeå, 2015.

- Zemánek, T.; Fiľo, P. Influence of Intelligent Boom Control in Forwarders on Performance of Operators. Croat. J. For. Eng. 2022, 43, 47–64. [Google Scholar] [CrossRef]

- Støve, M.P.; Haucke, E.; Nymann, M.L.; Sigurdsson, T.; Larsen, B.T. Accuracy of the wearable activity tracker Garmin Forerunner 235 for the assessment of heart rate during rest and activity. J. Sports Sci. 2019, 37, 895–901. [Google Scholar] [CrossRef] [PubMed]

- Reddy, R.K.; Pooni, R.; Zaharieva, D.P.; Senf, B.; Youssef, J.E.; Dassau, E.; Doyle lii, F.J.; Clements, M.A.; Rickels, M.R.; Patton, S.R.; et al. Accuracy of Wrist-Worn Activity Monitors During Common Daily Physical Activities and Types of Structured Exercise: Evaluation Study. JMIR Mhealth Uhealth 2018, 6, e10338. [Google Scholar] [CrossRef] [PubMed]

- Jones, A.Y.M.; Kam, C.; Lai, K.W.; Lee, H.Y.; Chow, H.T.; Lau, S.F.; Wong, L.M.; He, J. Changes in heart rate and R-wave amplitude with posture. Chin. J. Physiol. 2003, 46, 63–69. [Google Scholar] [PubMed]

- Šipinková, I.; Hahn, G.; Meyer, M.; Tadlánek, M.; Hájek, J. Effect of respiration and posture on heart rate variability. Physiol. Res. 1997, 46, 173–179. [Google Scholar]

- Tynkkynen, M. Assessing Harvester Operators' Mental Workload Using Continuous ECG Recording Technique. Int. J. Cogn. Ergonomics 2001, 5, 213–219. [Google Scholar] [CrossRef]

- Helander, M. A Guide to Human Factors and Ergonomics, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2006; pp. 224–255. ISBN 0-203-68775-2. [Google Scholar]

- Hnilica, R.; Jankovský, M.; Dado, M. Model Assessment of the Complex Workload of Harvester Operator. Forests 2022, 13, 1196. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).