1. Introduction

In recent years, the advent of the industry 4.0 has been possible due to the evolution of the technologies together with the integration of advanced communication systems [

1,

2] and smart sensors [

3]. Despite this technological growth, the induction motor (IM) remains as the medullar column to provide to the industrial processes with mechanical rotative power, linear motion, and to propel mechanisms in general [

4]. The typical applications of this machine are as pumps, fans, compressors, manufacturing, materials processing, refrigeration, transportation, conveyors, shredders, etc., [

5]. The electrical rotating machines are electromechanical systems used in industry because of its benefits such as low cost, high efficiency, high output torque ratio, high power to weight ratio, easiness of maintenance, reliability, applicability, low noise emissions, among others [

6,

7]. According to the reported literature, the induction machines are one of the most common and widespread motors over the globe in industry, constituting around the 80% from the total industrial equipment [

8], and they consume approximately between the 40% and the 80% of the total energy generated for these companies [

9,

10,

11]. Therefore, considering this information, any industrial process downtime due to motor failures would impact directly in aspects like overall costs, maintenance planning, equipment damage or replacement, possibility of user risks or injuries, and even environmental effects (because energy consumed by IMs is generated majorly through conventional fuels) [

12]. Now, typically the ensemble of an IM considers several components that allow its proper operations being the principal ones the stator, the rotor, the windings, the rolling bearings, and the fan [

13]. Recently, several scientific reviews have analyzed and concluded that, in relation with the motor components the most typical faults and their corresponding percentages ranges of occurrence are the following [

14,

15,

16]: bearing faults between 40% to 50%, stator winding faults between 28% to 38%, rotor related faults between 5% to 10%, and other associated faults between 12% to 28%. From previous information, it can be noted that the faults associated with the stator windings are the second major problems that appear in the components of the IM. But also, in turn, a specific failure related to the stator circuit are the inter-turn short-circuits (ITSC) faults [

17] that affect the IM performance with high probability of severe equipment damage, and for this reason they are still a topic of interest.

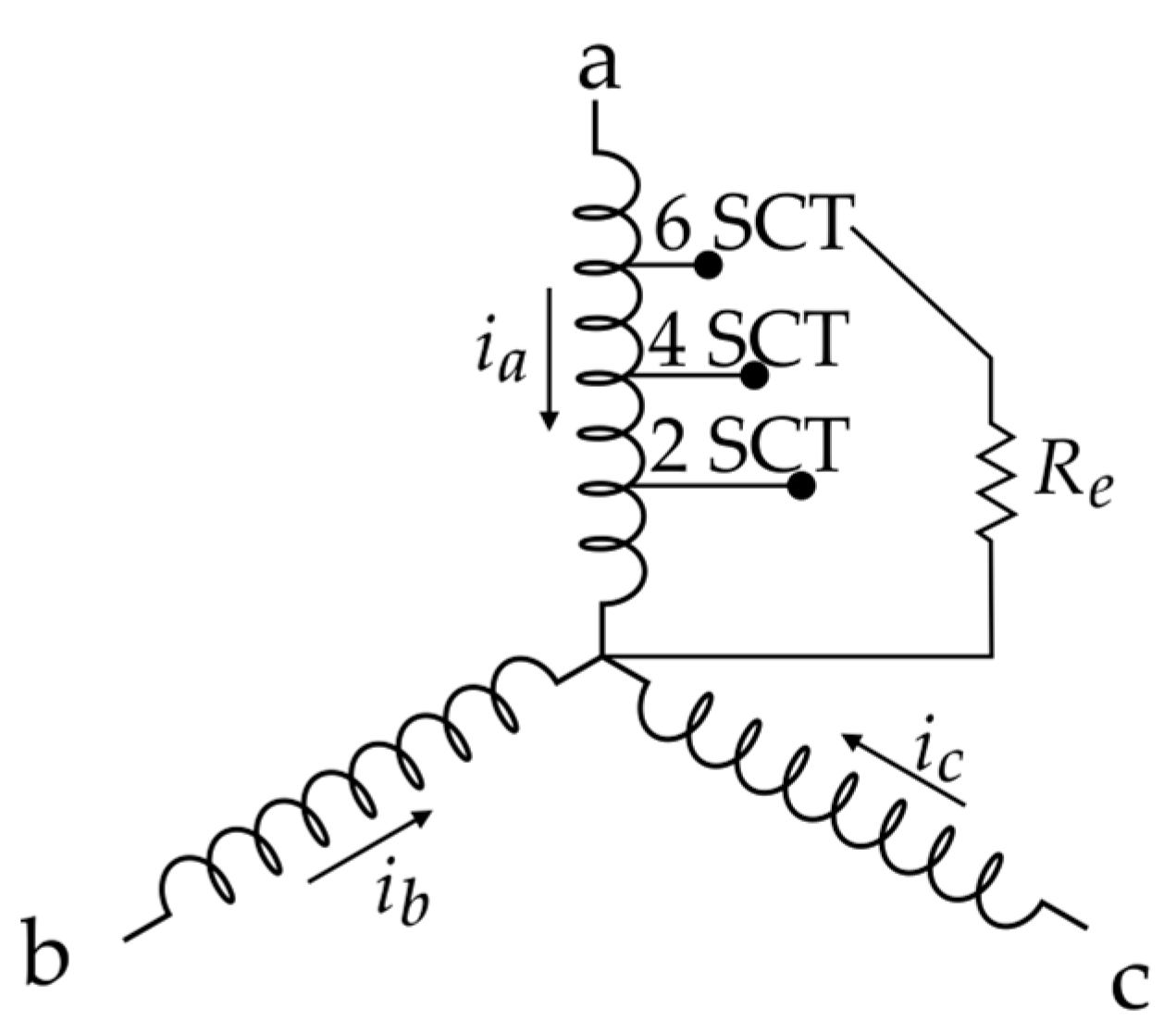

Particularly speaking about the ITSC faults in electric rotative machines, in the literature much research has been carried out addressing this phenomenon. It has been reported that ITSC faults are the most common and frequent electrical problems, and they represent approximately between 30% and 40% of all types of stator circuit damages [

18]. These faults are understood as damage in the winding insulation and they can occur at different locations of the coil turns in a single phase [

19]. The general circumstances that cause failures in the electric motors are harsh environments at industry like high temperatures, humidity, mechanical tension due to overloads, contamination, grease, vibrations, electric discharges and over voltages, among others [

20]. However, for the particular case of the ITSC the causes are, for example, flows of current with an intensity that exceeds the nominal operating conditions, generating in consequence a release of energy in the form of heat and mechanical stress, or the use of fast switching PWM inverters that accelerates the insulation degradation [

19,

21]. Some effects of the ITSC faults in the motors are of course malfunctioning on its operation, performance reduction, local magnetic saturation, asymmetric behavior of the motor, to mention some [

20,

22]. With the purpose of better understand the inter-turn short circuits, several investigations have developed models of these faults, such as the case of the finite element models (FEM) [

18,

23], parametric mathematical models based on electrical circuits [

24,

25], and combined FEM-parametric models [

26,

27]. The objective of such models is the development of methodologies for detecting such faults in simulation environments, but assuming or omitting other conditions that could happen in real systems.

Regarding the classical methodologies, there exist several works that have developed approaches addressing ITSC detection. For example, in [

6] the implementation of an improved wavelet packet transform (WPT) was done over the rotor current and the motor vibration signals in LabVIEW for permanent magnet synchronous motors (PMSM). In other works, like in [

28], a Kalman filter excludes the frequency components corresponding to the 3rd, 5th, and 7th harmonics in the current signal measured from an IM, then the time-frequency spectrogram of the signal is used to obtain a gray level image and its corresponding histogram. With this information, the considerable deviations of the histograms distributions from a normal distribution are used for the detection of the ITSC. On the other hand, some works focused their efforts on the development of methodologies based on non-intrusive signal like magnetic flux in motor for detecting ITSC faults. Such as the case of the research in [

29], that present a statistical methodology for detecting ITSC faults that uses a correlation coefficient between two external magnetic field signals measured by two sensors located symmetrically in the motor vicinity. The correlation obtained is based on the Pearson correlation coefficient applied on induction and synchronous machines. In this same area, the approach described in [

30] also makes use of non-invasive stray magnetic field sensors for discriminating ITSC on salient pole synchronous generators (SPSG). To achieve the discrimination of the fault, the system model is developed by means of finite element method (FEM), and by introducing a unique pattern observed on the time-frequency domain signal processing through the short time Fourier transform (STFT). By its part, an online approach for detecting ITSC in PMSM is developed in [

31] using stray magnetic field measured from the stator yoke. For this purpose, the inter-turn short-circuits dynamic, and the stray magnetic flux dynamic are implemented through FEM considering 24 sensitive tunneling magnetoresistive (TMR) sensor units. In other work, the harmonic analysis of different electric signal is performed in [

32] for detecting ITSCs in the stator windings of squirrel cage IMs. The signals considered are stator phase current, external magnetic flux, and electromagnetic torque at different load levels. The validation of this proposal was through simulation by means of FEM. Meanwhile, in [

33] is presented a methodology for diagnosing ITSC faults for line start PMSM through the frequency analysis of acoustic signals. The acoustic signals are decomposed through the fast Fourier transform (FFT) analyzing their amplitudes. It is worth mentioning that many works address the ITSC faults diagnosis on motors through infrared thermographic analysis, such as the work in [

34] that develops an online non-intrusive algorithm which extracts features from the infrared histogram of the images profile taken from the hottest region of the machine surface. In this same line, the research in [

35] describes an online non-invasive technique that detects the ITSC fault and its severity through two methods. The first method uses transient thermal monitoring during motor starting, and the second method implements pseudo coloring technique on infrared image of the motor on the steady state. On the same line, the work in [

36] presents a methodology for diagnosing ITSC faults in the stator winding based on an infrared thermopile sensor array (IRSA) and a hall-effect sensor array (HESA). With these arrays direct contactless measurements of temperature and magnetic flux distribution along the end-winding region is done. Later, deviations in thermal and magnetic symmetries induced by the faults are assessed for detection. By its part, the work presented in [

37] develops a metal-coated fiber Bragg grating (FBG) sensor to monitor the temperature and magnetic field around the end winding of IMs. The sensor measurements are decoupled by a filtering stage and the separated data is analyzed in the time-frequency domain for detecting the ITSC. From previous works discussion it is notorious the effort done for diagnosing the inter-turn short circuits on electric motors in what can be defined as classical ways acquiring signals and processing them by means of space transformations. However, they are mostly validated through model simulations omitting some real operating condition, and they do not consider data fusion to improve the detection reliability.

Recently, some methodologies addressed the use of data driven, machine learning, and deep learning techniques for detecting and diagnosing motor faults associated to ITSC with high accuracy. For example, an online fault detection framework is developed in [

38] by collecting data from IMs, performing multiple extraction/selection of features, finding the most sensitive ones, and enhancing the classification task by integrating multiple classifiers. Meanwhile, in [

39] a methodology for incipient ITSC diagnosis on PMSM based on data driven digital twins is described. For this purpose, a theoretical analysis of the three-phase current residuals under ITSC is carried out, and a digital twin model of a healthy target motor is defined through nonlinear auto-regressive model with exogenous inputs (NARX) network, at last the incipient faults are detected through current residual. Now, in relation to the machine learning (ML) approaches, several works have developed methodologies, such as in [

40], where the support vector machines (SVM) and the convolutional neural networks (CNN) techniques are implemented for diagnosing ITSC on PMSM. In such work, it was demonstrated that SVM have more efficient training than CNN considering that the first technique requires much fewer data. In the same context, an developed algorithm combines the discrete wavelet transform (DWT) for multiresolution analysis (MRA), the statistical features extraction, and ML techniques, processes voltage signals generated by axial leakage flux from an IM for detecting incipient ITSC [

41]. In other case, a fault diagnosis method applied on PMSM is presented in [

42], where a sparse representation is used for extracting the first and second largest sparse coefficient of current and vibration signals, and for composing four-dimensional feature vectors. Then, the feature vectors are input to the SVM for final diagnosis of ITSC, this is convenient for small samples sets. Similarly, the study presented in [

43] explores the potential of several ML classifiers and the signal processing for the online condition monitoring of ITSC in the field winding of SPSG. In that work the data set for the ML is generated by applying the FFT on the power spectral density of the air gap magnetic field, DWT energies, and time series feature extraction based on hypothesis test. At last, but not least, the deep learning techniques are also present in the ITSC faults diagnosis. For instance, in [

44] is described an approach based on the conditional generative adversarial net (CGAN) and an optimized sparse auto encoder (OSAE) applied on PMSM, an important attribute of this approach is the use of small samples sets. Other work explores the use of neural networks as efficient diagnosing tools for estimating the percentage of stator winding shorted turns on three-phase IMs. The implementation was done in MATLAB under different load conditions [

45]. From the previous discussion of the works reported in the literature, it can be noted that data-driven, machine learning, and deep learning are techniques and schemes that provide reliable approaches for detecting ITSC. Mostly of them use the analysis of two measured signals, such as current and vibration, or current and stray magnetic flux form the motor. But it would be interesting to explore the potential of using currents, vibrations, and stray magnetic flux signals of different sensor channels (or sensor axes), perform features extraction, and make data fusion and classification.

The contribution of this work is with an integrated methodology based on a statistical machine learning strategy and data fusion of several physical signals measured from an induction motor for detecting the early occurrence of ITSC faults. At first place, the physical signals from the motor corresponding to the phase currents, the vibrations, and the external magnetic stray flux are acquired. Next, several statistical features are extracted from the time-domain signals to compose sets of sensitive matrices of features related to the fault condition, which will integrate a general high dimension matrix providing meaningful information about the fault not directly from the time-domain signals but considering its statistical data patterns. Posteriorly, a feature level fusion is carried out through the linear discriminant analysis, which will reduce the matrix of features of high dimensionality to a two-dimensional representation having those significant features for being used in the last classification stage. Finally, a classifier with simple structure based on the neural networks is implemented for performing the final diagnosis. The proposed methodology is capable of detecting different machine conditions, and for this case four conditions are considered: the healthy state of the motor and three fault conditions with different severities of ITSC (2, 4, and 6 coil turns in short circuit). The experimental tests considered the motor operation under four operating frequencies (15 Hz, 30Hz, 50Hz and 60Hz). The obtained results demonstrate the reliability and efficiency of the proposed methodology.

2. Materials and Methods

Electrical rotating machines like the induction motor (IM) is subjected to electrical stresses that can lead to the sudden occurrence of faults, in this sense, the stator inter-turn short-circuits (ITSC) are common faults caused by problems associated with the stator winding insulation. Consequently, an amplitude increase is produced in the harmonic component of the stator current signature when IMs are operating under the influence of ITSC, similarly, the air-gap flux density is also modified when ITSC occur. In this regard, classical approaches based on MCSA perform the detection of ITSC by analyzing the spectra of stator currents and/or magnetic stray-flux through Equation (1).

where

represents the supply frequency,

is the per unit slip,

is the pair of poles in the IM and

and

are integers that can be defined as

and

On the other side, although electrical problems such as ITSC produce direct affections over those electrical patterns like stator currents or magnetic stray flux, the abnormal appearance of vibrations is additionally produced since the magnetic field asymmetry being altered by the three-phase asymmetry of the IM windings. Theoretically, a characteristic fault-related vibrations frequency component of the stator appears at ; moreover, the occurrence of vibrations due to ITSC leads also to characteristic harmonic components that can be located at and in a vibration spectrum. Accordingly, regardless that ITSC in IMs can be detected through different physical magnitudes like stator currents, magnetic flux and vibrations, the accurate assessment depends on the considered signal processing. Hence, processing techniques achieved in the time domain, frequency domain and time-frequency domain are commonly used to analyze signals and to extract characteristic fault-related patterns produced by the occurrence of faults.

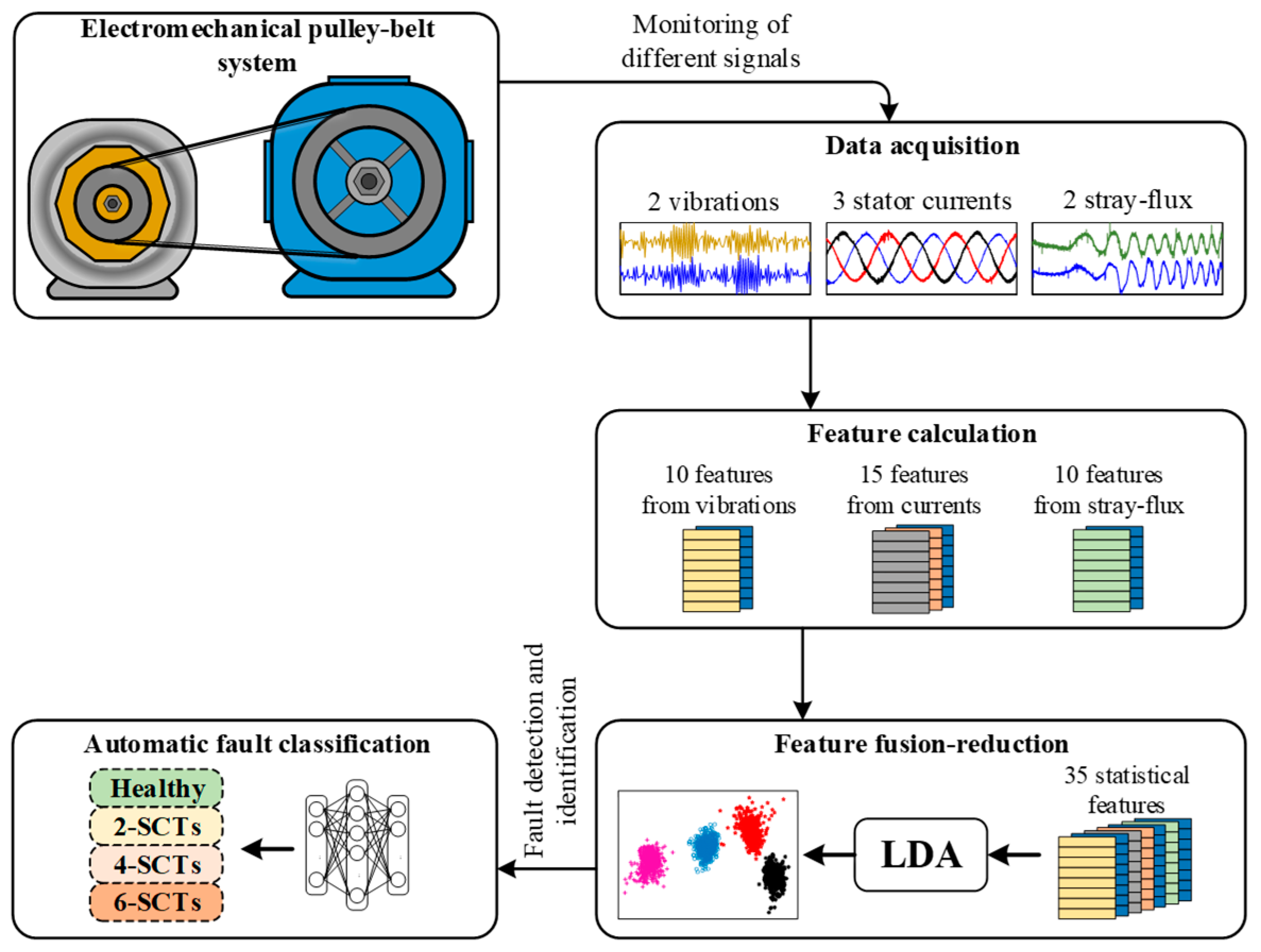

Aiming to contribute to the field of condition monitoring and fault detection, in this work is proposed a diagnosis methodology for detecting the incipient occurrence of ITSC in IMs through the estimation of a set of statistical time-based domain features from different physical magnitudes such as stator currents, magnetic stray-flux and vibrations. Additionally, the computed statistical features are then pooled to carry out a feature-level fusion by means of the linear discriminant analysis (LDA) technique. Finally, the automatic identification of incipient ITSC in IMs is achieved by a proposed neural network (NN) classifier. The flow chart of the proposed method is shown in

Figure 1 and consists of five main steps: i) Electromechanical pulley-belt system, ii) Data acquisition, iii) Feature calculation, iv) Feature fusion-reduction, and v) Automatic fault classification.

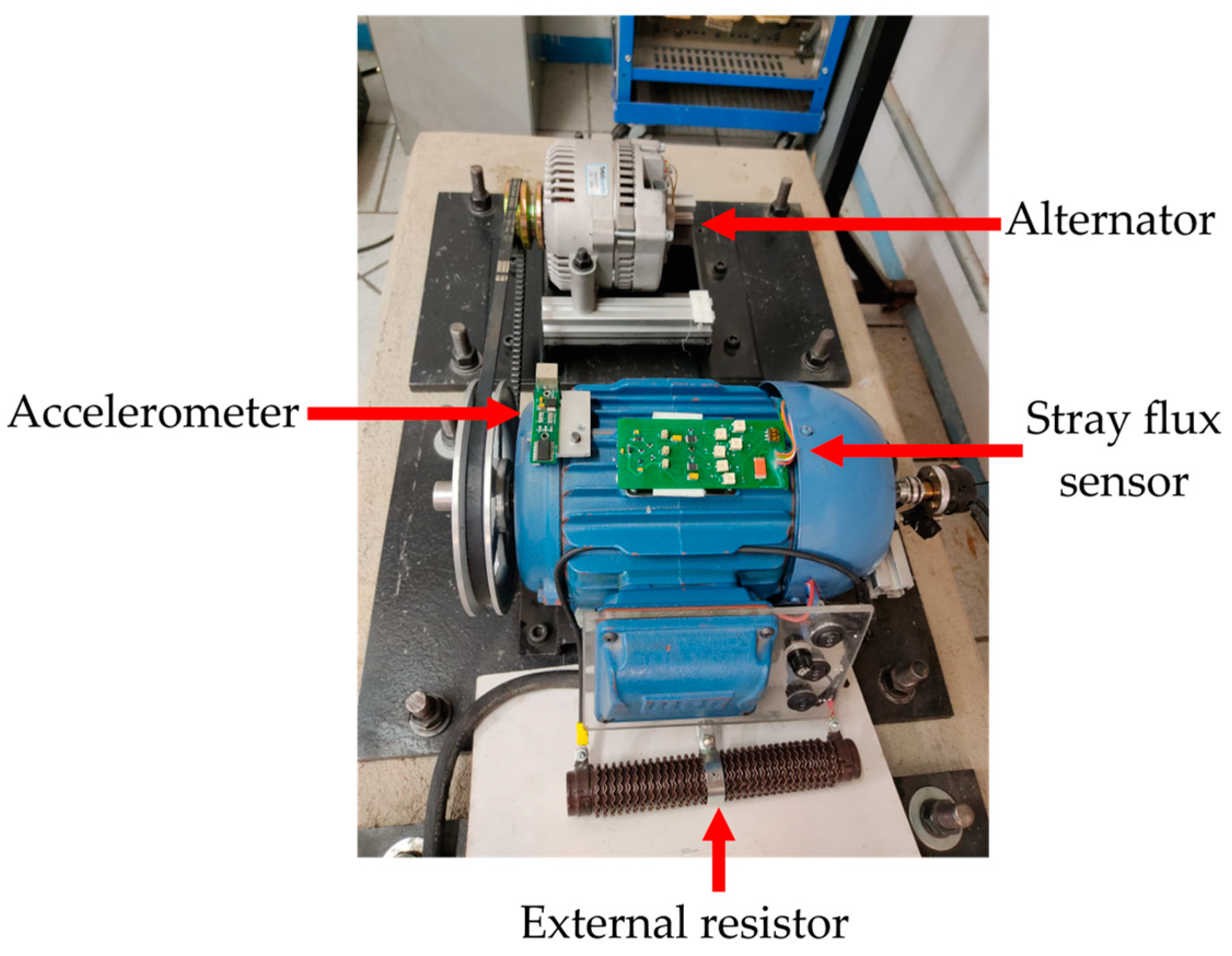

2.1. Electromechanical Pulley-Belt System

The electromechanical pulley-belt system is the system under evaluation and is composed by an IM coupled to an automotive alternator (AA) by means of a pulley-belt system. Particularly, in the IM are tested four different conditions comprising the healthy state (HLT) and three incipient conditions of ITSC such as 2-SCTs, 4-SCTs and 6-SCTs. Each one of the aforementioned conditions is iteratively tested in the IM under different operating conditions in order to monitor its behavior through multiple sensors that allow the measurement of vibrations, stator currents, and magnetic stray flux.

2.2. Data Acquisition

The data acquisition is carried out by a self-designed and proprietary data acquisition system (DAS) based on a field programmable gate array (FPGA), hence, the proprietary DAS allows the continuous monitoring of the IM operation by means of the measurement of vibrations, stator currents, and magnetic stray flux signals. Specifically, the vibrations are measured from the radial () and tangential () axes of the IM, the stator currents belong to the three lines currents () of the IM, and the magnetic stray flux comprises the measurement of the axial () and radial () components. In this regard, for each performed test, the aforementioned signals are continuously recorded and stored in a personal computer for further analysis; moreover, the acquisition of the signals is carried out during 150 seconds of the continuous operation of the IM.

2.3. Feature Calculation

The feature calculation is achieved with the aim of characterizing the previously acquired signals and it is mainly based on the estimation of a set of statistical time-domain features. The features calculation is individually applied to each one of the acquired signals, thereby, a signal

composed by

samples is first segmented into equal parts of one second, where every second of the signals has a length

as Equation (2) depicts:

Once the signal segmentation is carried out, from each segmented part is estimated a meaningful set of five statistical time-domain features leading to obtain a characteristic feature matrix for each considered physical magnitude. Certainly, from the vibration signals are estimated

and

for the radial and tangential axis, respectively; from the stator signatures are estimated

,

and

correspondingly for each current line and, from the axial and radial magnetic stray-flux components are estimated

and

, respectively. The set of statistical time-domain features as well as the corresponding mathematical expressions are summarized in

Table 1, Equations (3) to (7). These statistical features are proposed due to their capability to model trends, distributions, asymmetries, forms, dispersion, and changes in signals; additionally, their low computational cost can lead to quick responses when implemented.

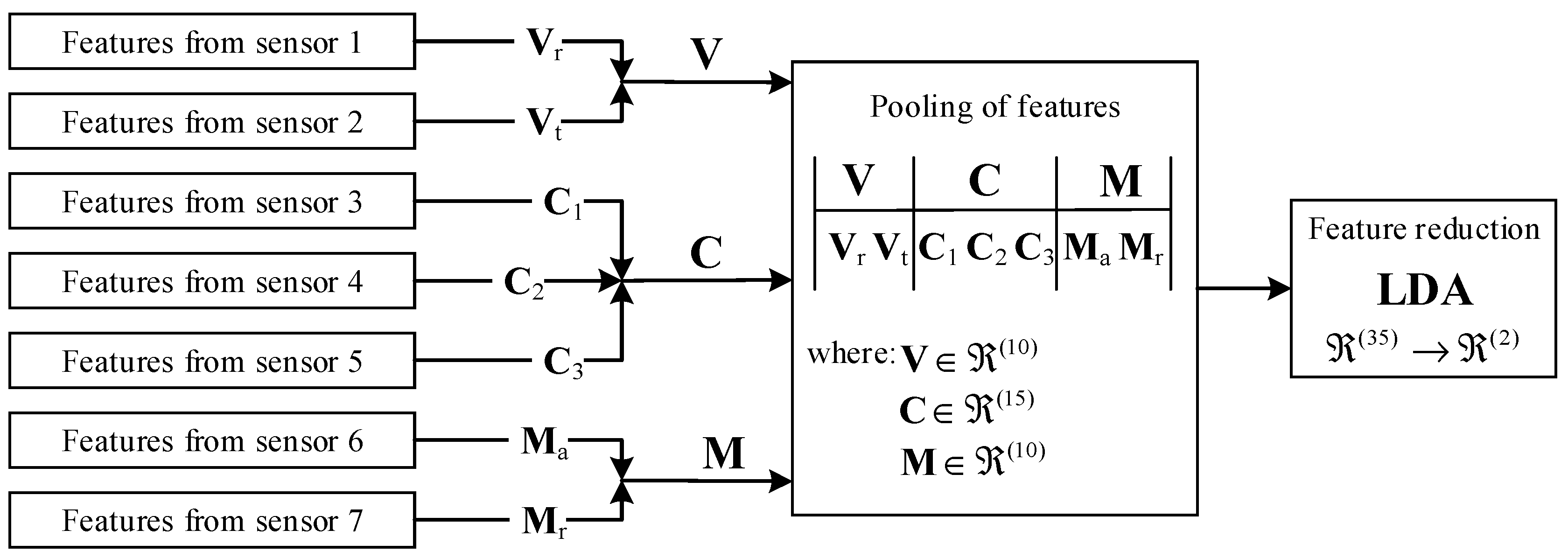

2.4. Feature Fusion-Reduction

The feature fusion is performed within a feature-level fusion approach in which all previously estimated feature matrices (

,

,

,

,

,

and

) are then pooled into a single set. Thus, the single data set considers the fusion of information since all characteristic feature matrices are concatenated as

Figure 2 shows. In this sense, it should be clarified that three global features matrices

,

and

are considered for representing each one of the physical magnitudes within the feature-level fusion approach. Afterward, the pooled single data set

are subsequently subjected to a reduction and space transformation procedure, in which, a new set of extracted features are obtained by means of applying the LDA techniques. The space transformation allows to achieve a dimensionality reduction from

to

, in fact, the new achieved representation into the 2

D space facilitates the visualization of all evaluated conditions due to the resulting features representing the linear combination (in different weights) of the original feature space.

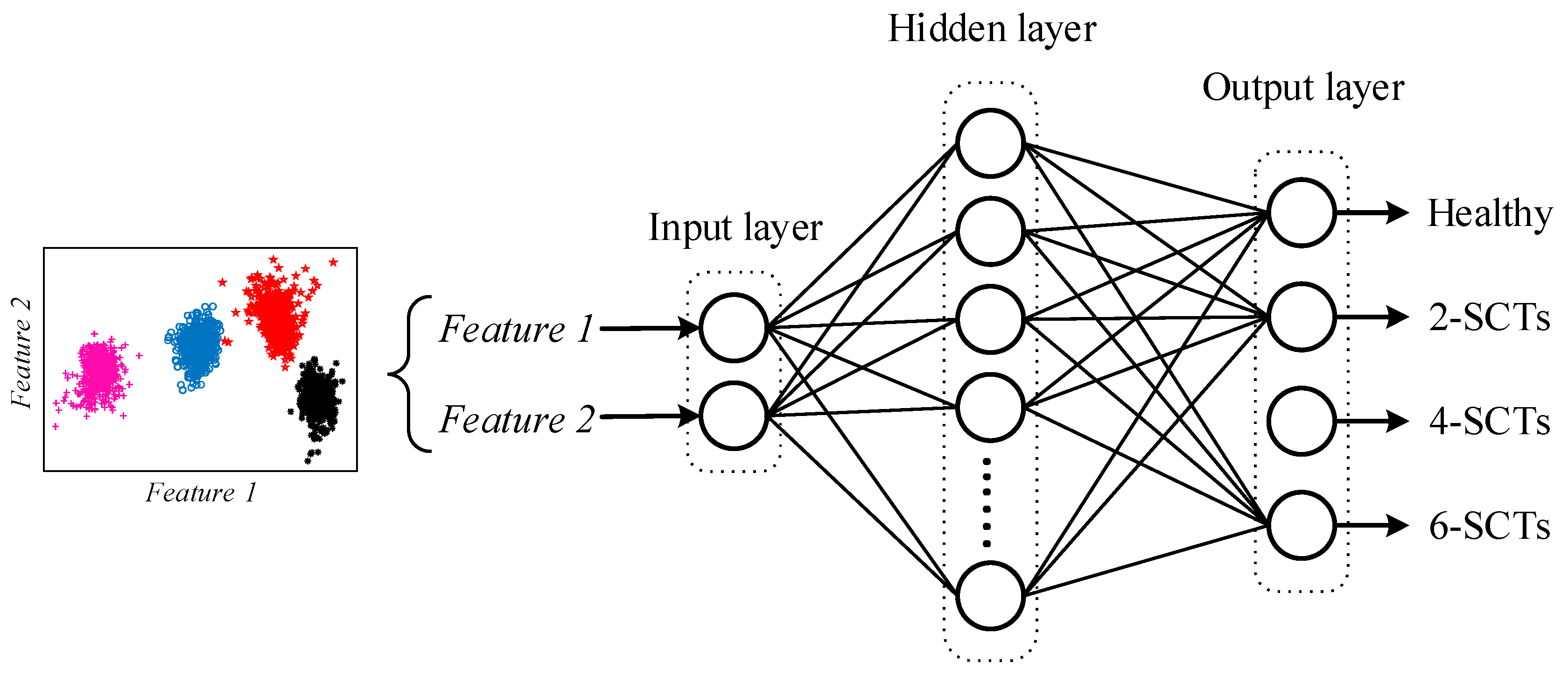

2.5. Automatic Fault Classification

The automatic fault classification of incipient ITSC in IMs is carried out by a NN-based classifier with a simple structure, the main objective of this stage is to evaluate the set of features extracted by the LDA technique. In this sense, the proposed NN classifier consists of three main layers such as input, hidden and output, where, the input layer is represented by two neurons in order to represent each one of the extracted features in the 2

D space, the hidden layer has ten neurons as is recommended in the literature [

46] and, four neurons in the output layer representing each one of the evaluated conditions. In addition, the NN-based classifier is trained and tested under a

five-fold cross-validation scheme with the aim of obtaining statistically significant results, during the training are considered fifty epochs and a back-propagation algorithm. Moreover, the NN classifier considers a sigmoid function as the activation function allowing to evaluate the percentage of correspondence with each membership function in the output layer. A representation of the proposed NN structure is presented in

Figure 3.

4. Results and Discussion

The proposed diagnosis methodology is validated under a real data set acquired from several experiments that are performed in a laboratory test bench, thus, as the proposed method describes, the acquisition of two vibrations signals ( and ), three stator currents signatures () and two magnetic stray-flux signals ( and ) are continuously measured during the experimental evaluation of the healthy condition (HLT) and three incipient conditions of ITSC (2-SCTs, 4-SCTs and 6-SCTs). In addition, each one of the conditions under study is tested under different operating frequencies in the VFD (15 Hz, 30 Hz, 50 Hz and 60 Hz), consequently, during each test are acquired approximately 450 kSamples for each vibration signal, 900 kSamples for each stator current signature, and 600 kSamples for each magnetic stray flux signal.

Subsequently, the feature estimation is carried out in order to characterize the acquired signal for each performed test, in this regard, Equation (2) is applied to each one of the stored physical magnitudes in order to segment them in equal parts of one second; hence, for vibrations signals the length

used in Equation (2) is equal to

, meanwhile,

is equal to

and

for the stator currents and magnetic stray flux, respectively. Once the segmentation of the signals is accomplished, the estimation of the meaningful set of five statistical time domain features is individually estimated from each segmented part for each acquired signal. Then, for each studied condition is estimated a set of characteristic feature matrices

,

,

,

,

,

and

, where each feature matrix has five statistical features with 150 consecutive samples. Due to each condition under study is tested at different operating frequencies, a Global Feature Matrix (

) is generated for the HLT condition and for the three incipient conditions of ITSC (2-SCTs, 4-SCTs and 6-SCTs); thus, in such

are considered the pooling of all feature matrices for all physical magnitudes and all operating frequencies; i.e., the

for the HLT condition is generated following Equation (8) as

, whereas

,

,

are the

for the faulty conditions of 2-SCTs, 4-SCTs and 6-SCTs. It should be mentioned that each

is composed by 35 statistical time domain features estimated from different physical magnitudes with 600 consecutive samples, 150 samples per operating frequency.

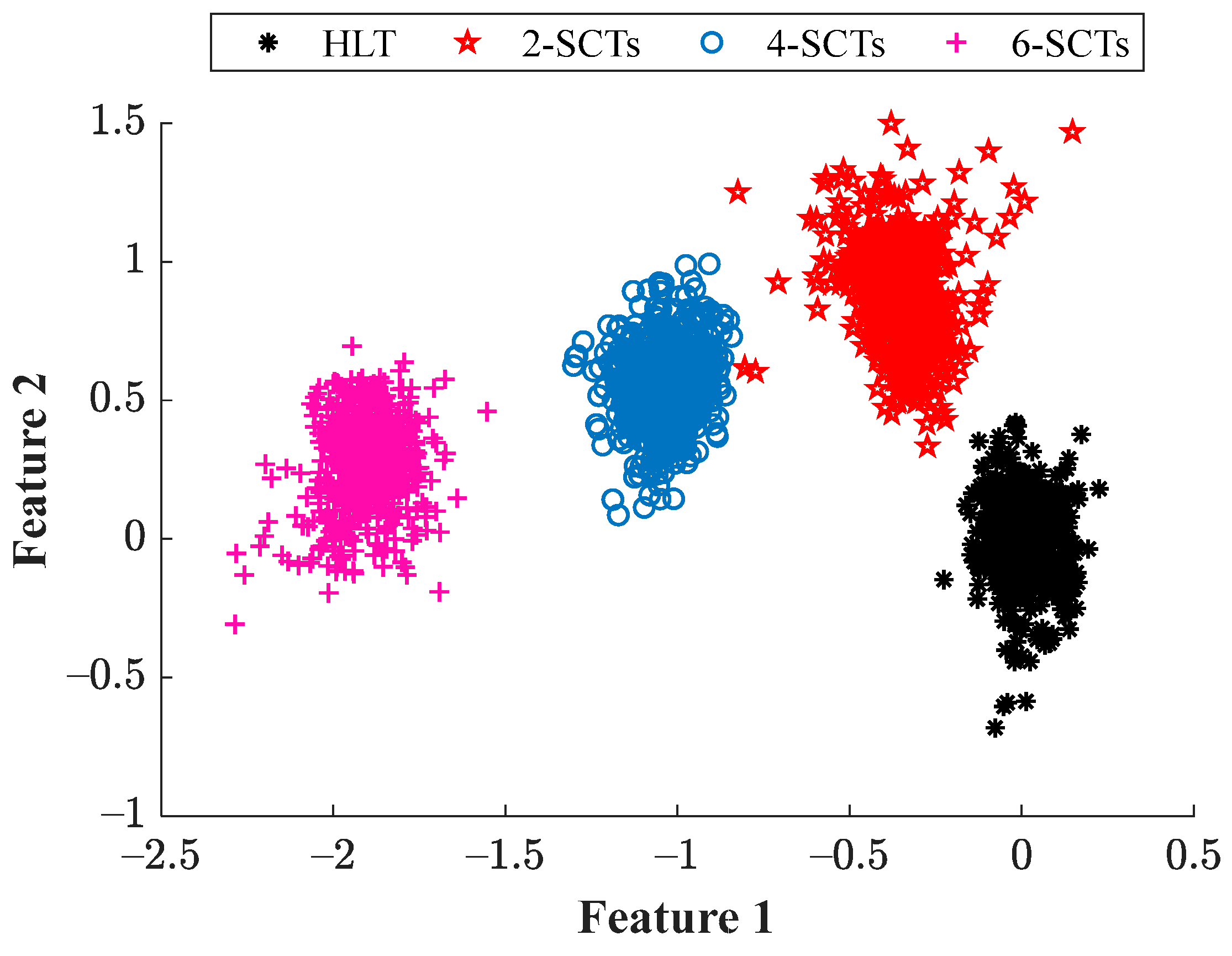

Next, the

s for all considered conditions are then subjected to the dimensionality reduction procedure through the application of the LDA technique, thereby, the

are then grouped following Equation (9) and during the reduction procedure is performed a space transformation from

to

. Consequently, the use of the LDA allows the visualization of all considered conditions into a 2

D plane, in

Figure 6 is shown the resulting projection in which it is possible to appreciate that all studied conditions appear separated from each other. Additionally, it must be highlighted that the extracted features (Feature 1 and Feature 2) that are projected into the 2

D plane also represent the linear combination, in different weights, of all considered features. In this regard, in

Table 3 are summarized the weights assigned by the LDA during the feature reduction process, from

Table 3 it can be analyzed the importance and contribution of each estimated feature; precisely, large absolute values mean a high-importance whereas small absolute values can be understood as non-relevant features.

Later, the extracted features by the LDA technique are then evaluated under a five-fold cross-validation scheme through the proposed NN-based classifier with the aim of carrying out the final diagnosis outcome; thereby, for each considered condition, 480 samples are used for training purposes and 120 samples are used for validation purposes. The training of the NN is achieved under a back-propagation approach during 70 epochs and, as an activation function is used a sigmoid function. Hence, the global classification ratio achieved during the training is 100%, whereas, a 99.4 % is reached during the validation; in addition, in

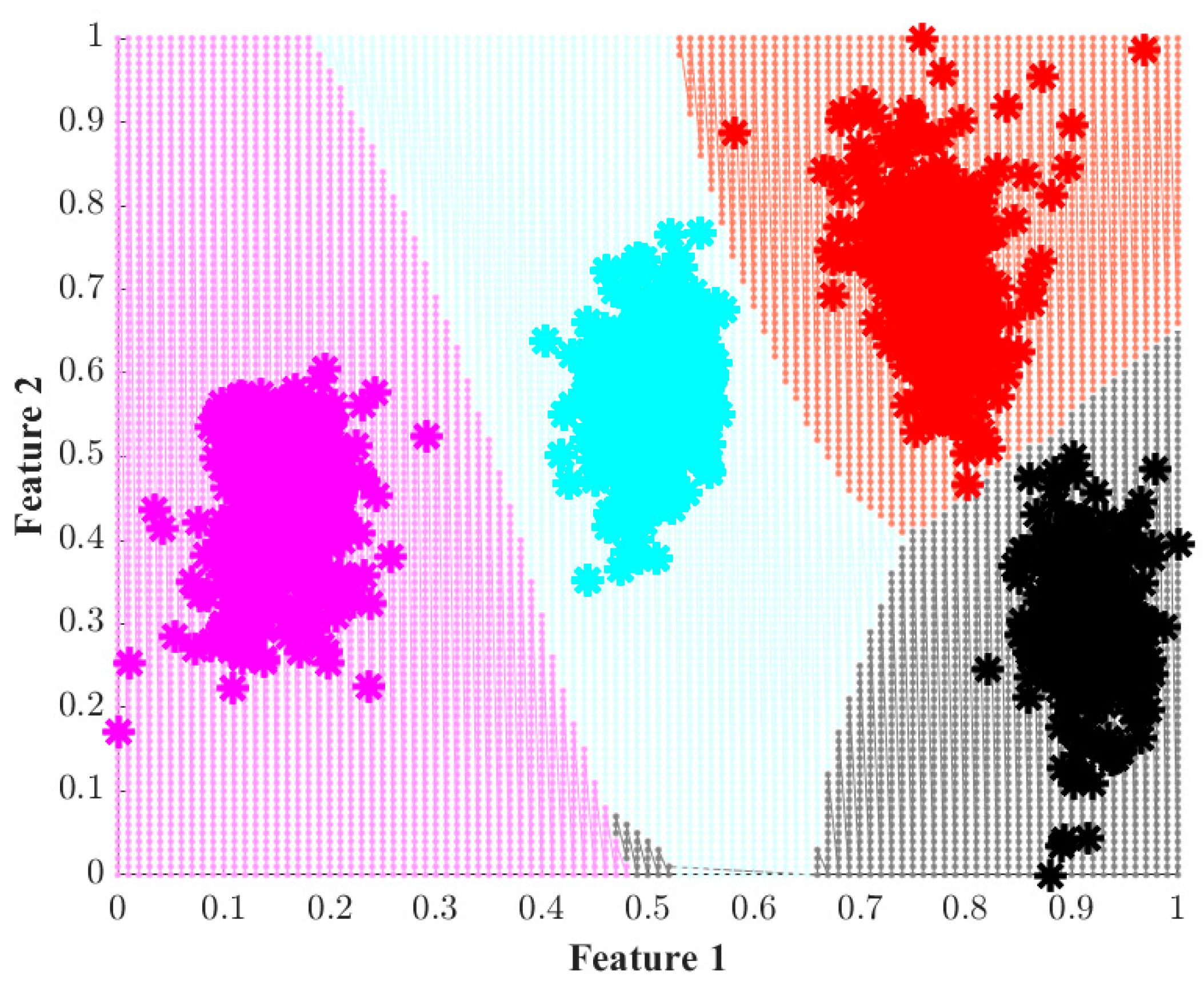

Table 4 are summarized the individual classifications. From

Table 4 it can be appreciated that the proposed methodology leads to a high-performance classification avoiding positive falses which is a critical issue that may lead to the machine breakdown. On the other side, the use of the proposed NN classifier also facilitates the estimation of the decision regions on the 2

D plane, hence, the decision regions for each tested conditions are shown in

Figure 7, from the modeled classification regions in

Figure 7 it can be observed that a specific regions has been assigned for each particular condition and, the assessment of new or unknown samples can be carried out in order to determinate the actual condition of IMs that suddenly operates under ITSC.

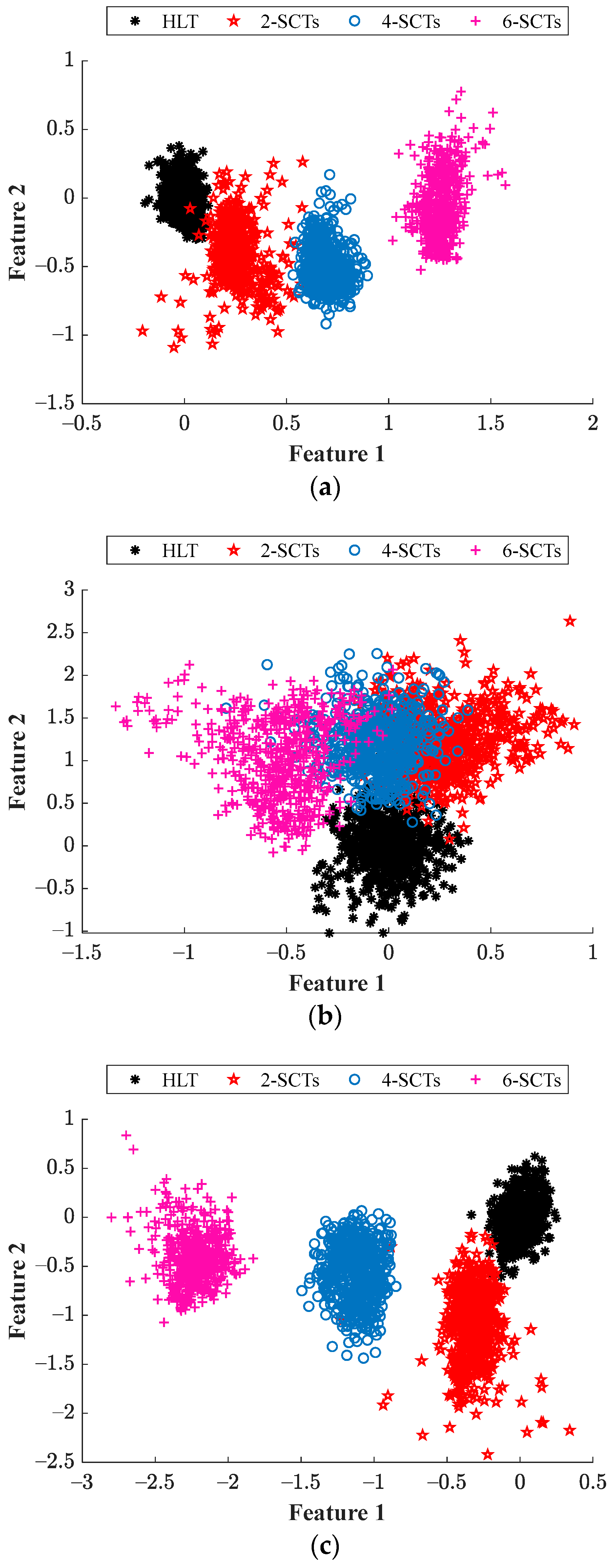

Finally, in order to highlight that the use of different physical magnitudes such as vibrations, stator currents and magnetic stray-flux leads to an accurate detection of incipient ITSCs in IMs, the characteristic feature matrices estimated from different signals are combined between them whit the objective of analyze their performance. In this regard, a first combination considers only vibrations and stator currents, in a second combination are used vibrations and magnetic stray-flux and, the third combination includes stator currents with magnetic stray-flux. Then, each one of these combinations are subjected to the feature reduction procedure through the LDA and the resulting 2

d projections are shown from

Figure 8a–c, respectively for each combination. As appreciated, the most critical case is when vibrations and magnetic stray-flux are combined since samples of all considered conditions appear to overlap between them; on the other hand, an improvement is obtained when the combinations of vibrations and stator currents as well as stator currents with magnetic stray-flux; however, for these combinations, the classifier may produce misclassifications between the HLT and 2-SCTs conditions. To finish the validation, the extracted features from

Figure 8a to

Figure 8c are also evaluated under the same NN structure and the global classification rations achieved during the training and validations are summarized in

Table 5. The obtained results show that this proposal can lead to an accurate identification of ITSCs in IMs, moreover, the characterization of vibrations, stator currents and magnetic stray-flux by means of statistical features offers a trade-off between simplicity efficiency when trends and changes are modeled from raw time-domain signals.