1. Introduction

Coffee is one of the world’s main commodities representing the second most consumed beverage after water, with annual rates of 42.6 L per capita and a global intake of 3 billion 0.2 L cups of coffee per day [

1]. The person global consumption ranking is led by Scandinavian countries, headed by Finnish people with a yearly consumption around 9.4 Kg of roasted coffee per capita (equivalent to 6-8 cups of coffee per day). This superior demand turns the coffee beans into one of the globes’ top traded agro-industrial products. According to the International Coffee Organization, about 171.3 million 60 Kg bags of coffee beans are estimated to be produced in coffee year 2022/23, following a robust increasing biannual trend in forthcoming years due to the endless rising of consumer’ demands. Surprisingly, the mentioned production results insufficient to cover the predicted consumption estimations for a second consecutive year,

i.e., around 178.5 million bags [

2], which could explain the 1.9% volume growth expected for coffee market in 2024 [

3]. This agro-industrial and socioeconomic paradigm rationalizes the worldwide concern relative to the environmental impact of coffee cultivation and manufacturing, owing to the notable amount of by-products delivered by this food sector.

Waste management is one of the most challenging problems we are currently handling worldwide. Presently, food systems are highly inefficient since around one-third of the food produced is wasted and not consumed [

4]. Food is lost or wasted at every stage of the food supply chain, from farming to consumption. Therefore, to ensure a sustainable management of food waste, food by-products should be utilized before they become waste, thus increasing the food system’s sustainability which constitutes a milestone of the United Nations’ Sustainable Development Goals (SDGs). The SDGs seek to restructure the agriculture and food systems to decrease hunger, to achieve food security, and to improve nutrition while reducing food waste and losses along supply chains [

5]. A sustainable food system delivers food security and nutrition, not endangering the economic, social, and environmental foundations for producing safe and nutritious foods for future generations. Consequently, the food system generates benefits or economic value-added (economic sustainability), has widespread social benefits, including nutritional and health benefits, and is equitable in distributing the economic value-added (social sustainability), and a favorable or neutral environmental effect (environmental sustainability) [

6]. Undoubtedly, the coffee agroindustry must also face this challenge focused on waste management. Indeed, coffee by-products from wet and dry processing, coffee husk, parchment, pulp, mucilage, and silverskin, represent nearly 50% of the coffee cherry on a dry weight basis [

3]. The global coffee production delivers above 23 million tons of waste per year, estimating 0.2 and 0.5 tons of coffee pulp and coffee husk by 1 ton of coffee produced by wet and dry processes respectively, and 8 Kg of silverskin by 1 ton of roasted beans [

7,

8]. Even though the abovementioned coffee by-products have been traditionally used for low-value applications such as animal feed or composting for soil fertilization, coffee waste is liable to end up in landfills, which usually is spontaneously decomposed producing unpleasant smells and acidic leaches able to damage the neighboring soil by lixiviation. It also releases greenhouse gases with a direct impact on climate change, besides harming soil and water sources when these by-products are dumped into streams because of their cytotoxic and ecotoxic effects [

9]. Moreover, they are known for a remarkable character of resistance to natural degradation, involving long residence periods, resulting in a severe environmental and even energetic impact. Such circumstances raise the awareness like inspiring the scientific community to research on valorization strategies, which not only minimize the environmental and energetic impacts of coffee agroindustry but also could produce added-value products following the circular economy principles [

10]. Thereby, novel applications outcomes could result economically gainful for coffee agro-industry’ stakeholders by the straightforward marketing of added-value products. Furthermore, the valorization of coffee waste can contribute to the diversification of income streams for coffee farmers, reducing their dependence on volatile commodity prices [

11]. This can help to enhance the stability and resilience of coffee-producing regions, particularly in developing countries where coffee production is a major source of income. The economic potential of coffee waste is further supported by the growing demand for sustainable and healthy products in the global market [

12].

Biorefinery strategies for coffee waste are gaining importance as a means to reduce this environmental impact while generating economic value [

13]. The utilization of coffee waste for the production of functional food ingredients and nutraceuticals offers a sustainable solution to the waste problem, while also creating a value-added product with potential health benefits [

14]. The scientific research over the last few years has demonstrated that coffee waste still contains valuable compounds such as carbohydrates, proteins, lipids, and bioactive compounds such as dietary fiber, phenolic compounds and caffeine. Following the scientometric analysis published by Durán-Aranguren et al. [

7], the annual scientific production experienced a notable rise since 2010, with the highest rate of publications for coffee husk and coffee pulp by-products in recent years. The most renowned biorefinery valorization strategies approached until date are directed to the coffee by-products microbial transformation; their environmental applications as bioadsorbents, biopesticides or fertilizers source; their transformation into biofuels from thermochemical processing such as syngas or biodiesel; their contribution to produce sustainable materials such as ceramic aggregates or food packaging substitutes; or their bioactive compounds exploitation [

7]. Within the latest, their use as bioactive ingredients for food and nutraceuticals formulation from both raw materials and their extracts, seems one of the most comprehensive applications with greater growth prospects, with a doubtless sustainable benefit for human health because of their evidenced useful properties. In addition, the production of such food-like products from coffee waste offers a unique selling proposition for companies seeking to meet the worldwide demand for sustainable and healthy products. Validation of the new products derived from coffee by-products is essential to ensure their safety, efficacy, and market acceptance [

15]. A systematic approach is required to establish a strong scientific foundation for functional food claims and to validate the bioactive compounds and their potential health benefits [

16]. This validation process ensures confidence in the economic potential of coffee waste utilization and supports the development of sustainable and healthy products for the market [

17].

This comprehensive review aims to provide an in-depth overview of the biorefinery strategies and multistep approach to produce bioactive food ingredients and nutraceuticals from coffee by-products. It begins by summarizing the relevant aspects of coffee by-products and their potential as food ingredients with health benefits. The review explores three key biorefinery strategies: the production of bio-based chemicals and materials, green aqueous extraction of bioactive compounds for food applications, and utilization of coffee by-products in food processing. We cover a wide range of topics, including the characterization of coffee by-products, in vitro and in vivo research studies on the bioactivity and health benefits of coffee by-product-derived compounds, randomized control trials evaluating the efficacy and safety of coffee by-product-derived nutraceuticals in human subjects, and sensory analysis of food products containing coffee by-product-derived ingredients. Furthermore, the review addresses the regulatory considerations and challenges associated with the commercialization of coffee by-product-derived products, along with the technological innovations and optimization strategies for their production. It also explores the economic potential of coffee by-products, their implications for sustainable agriculture and food systems, and highlights future directions for research and innovation in this field.

2. Composition, Availability, and Technological and Safety Constraints of Coffee By-Products

Coffea arabica L. (Arabica coffee) and

Coffea canephora (Robusta coffee), all members of the Rubiaceae family, are the most important plant species in the international coffee trade [

18]. About 90% of the coffee cherry’s edible sections are wasted as agricultural wastes or by-products during the coffee beverage preparation. Coffee by-products have aroused considerable interest because of their abundance and their excellent chemical composition [

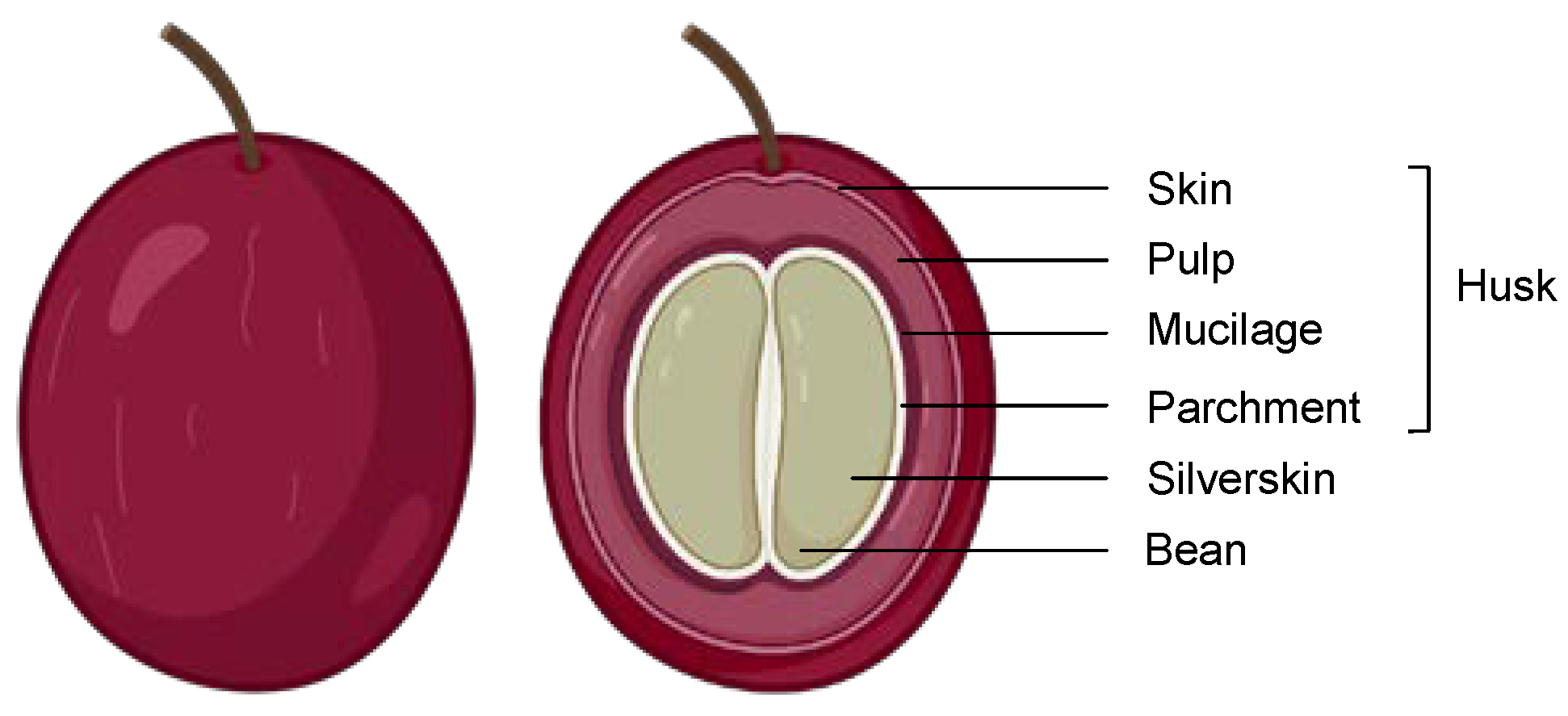

19]. The coffee cherry (

Figure 1) comprises an outer skin or pericarp, which uses to be green in unripe and red in ripe fruits, covering a soft and sweet pulp or outer mesocarp. Subsequently, a viscous and highly hydrated mucilage layer (pectin layer) and a thin yellowish endocarp, the parchment, are found. Ultimately, the silverskin covering two or three green coffee beans (endosperm) [

20].

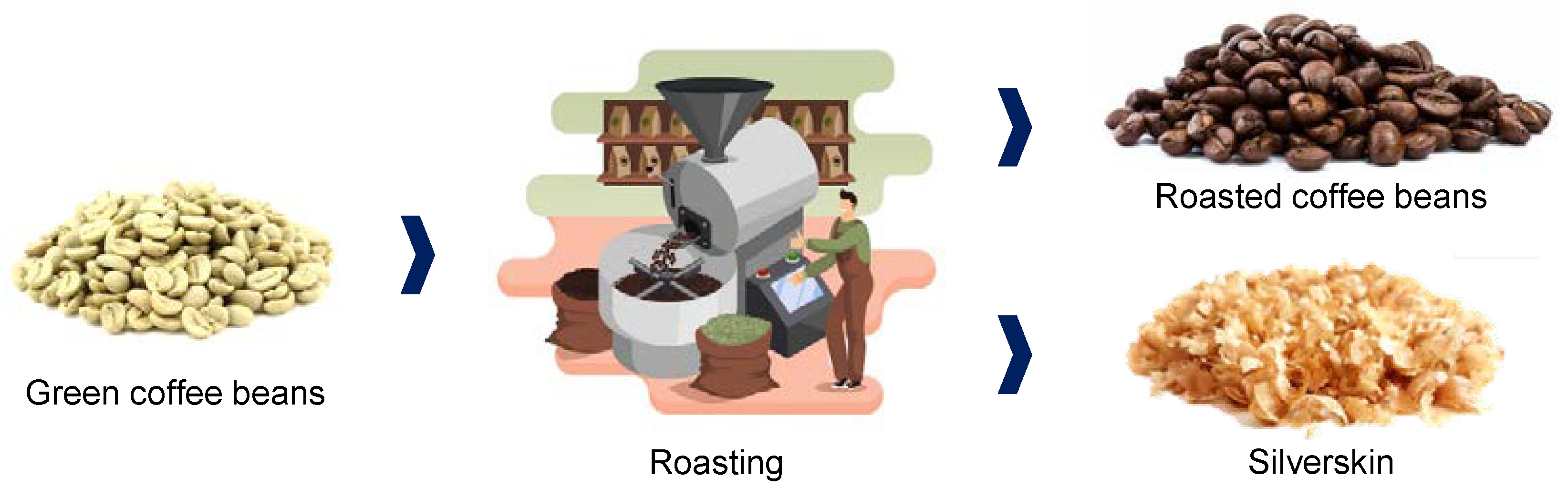

The coffee cherries are converted into green coffee beans by removing the cherry outer layers using either a wet or dry method (

Figure 2) [

21]. The dry method (

Figure 2A), widely used in Robusta-producing countries, is more technologically simple. The freshly picked cherries are uniformly distributed and sun-dried for 2–4 weeks in yards (natural drying) or mechanically dried until the moisture content is less than 12%. Subsequently, the coffee cherries are mechanically dehusked, and the skin, pulp, mucilage, and parchment are separated from the beans [

18,

22]. The wet processing (

Figure 2B), commonly used for Arabica coffees, is more commercially valued and needs various tools to extract the green bean. A depulper is used to remove the skin and pulp that covers the beans first [

22]. Once depulped, the mucilage is already covering the coffee bean, thus it is removed through a 24–72h fermentation [

18]. Then, the bean covered by the parchment is washed, drained, and dried until the moisture content is about 10% [

22]. Finally, a hulling machine is used to remove the parchment [

19].

Table 1.

Chemical composition of coffee by-products obtained along the coffee processing. Values expressed in dry matter.

Table 1.

Chemical composition of coffee by-products obtained along the coffee processing. Values expressed in dry matter.

| Component |

Husk |

Pulp |

Mucilage |

Parchment |

Silverskin |

| Type of processing |

Dry |

Wet |

Wet |

Wet |

Dry/wet |

| Processing step |

Pulping |

Pulping |

Hulling |

Pulping |

Roasting |

| Macronutrients (%) |

|

|

|

|

|

| Moisture |

13.0-15.0 |

78.0-81.0 |

80.0-84.0 |

8.1-10.0 |

4.0-7.0 |

| Protein |

6.0-16.0 |

8.7-17.0 |

8.9-17 |

3.1-17.4 |

7.9-20.6 |

| Lipids |

1.0-4.1 |

0.5-2.0 |

- |

0.3-4.1 |

1.2-3.0 |

| Total sugars |

26.0-30.1 |

10-15 |

- |

- |

0.4 |

| Dietary fiber |

32-43 |

21.5-28.0 |

30 |

64.3-92.6 |

52.0-69.8 |

| Ash |

1.4-6.2 |

8-9.5 |

0.7 |

0.5-1.0 |

5.8-9.5 |

| Bioactive compounds (mg/g) |

|

|

|

|

|

| Total phenolics |

10.1-15.0 |

10.0-13.0 |

- |

2.0-3.0 |

3.6-20.3 |

| Caffeine |

6.8-12.0 |

2.0-10.1 |

- |

0.1-1.3 |

0.7-9.5 |

| Tannins |

18-93 |

1.8-8.6 |

- |

- |

2.5-7.66 |

| Chlorogenic acids |

- |

1.8-3.37 |

- |

0.05 |

1.6-2.5 |

| Caffeoylquinic acid |

0.8 |

1.7-1.8 |

- |

- |

0.1-3.1 |

| Hydroxymethylfurfural |

- |

- |

- |

- |

0.2-3.2 |

| Melanoidins |

1.5 |

- |

- |

- |

1.7-2.3 |

| References |

[23,24,25,26,27] |

[28,29,30] |

[19,27,31,32] |

[15,33,34,35,36] |

[26,27,37,38,39,40,41] |

2.1. Husk

The coffee husk is the first by-product produced during the coffee processing. This by-product is generated in coffee-producing countries at 40 kg per 100 kg of green coffee beans [

42]. The definition and composition of the coffee husk depend on the processing employed. Dry coffee husks, obtained through the dry processing method (

Figure 3A), consist of the skin, pulp, mucilage, and parchment, and are rich in insoluble dietary fiber. They contain approximately 30% hemicelluloses, 25% cellulose, and 24% lignin (

Table 1) [

24,

25,

26,

27]. Coffee husks are also sources of phytochemicals, including phenolic compounds, which account for approximately 1.2% and mainly include anthocyanins and proanthocyanidins [

23].

Coffee husks generated through the wet method (known as

wet husk or

pulp) (

Figure 3B) are composed of skin and pulp and account and contain significant levels of phenolic compounds (1.5%) and caffeine (1.3%) [

28]. The wet husk contains four major groups of phenolic compounds: hydroxycinnamic acids, flavanols, flavonols, and anthocyanidins [

28]. The primary phenolic compounds in coffee husks are chlorogenic and protocatechuic acids, which account for more than 80% of the overall phenolic compounds [

29]. Other phenolic compounds identified in coffee husks are epicatechin, catechin, rutin, ferulic acid, and cyanidin-3-glucoside and 3-rutinoside [

19]. In addition, the coffee pulp presents low lipid content (0.5-2%), minerals (8-9.5%) and higher protein (8-17%), moisture (78%), and carbohydrates content (~58–85%) than coffee parchment (

Table 1). These differences in composition between dry and wet husk provide unique opportunities for their utilization in various applications, from dietary fiber enrichment to the extraction of bioactive compounds [

43]. Exploring these distinctions and utilizing the specific properties of dry and wet husk can lead to the development of innovative products and contribute to the sustainable utilization of coffee by-products.

The coffee husk is a substantial by-product generated during coffee processing, with a production rate of approximately 40 kg per 100 kg of green coffee beans in coffee-producing countries [

42]. Coffee husks obtained from the dry processing method account for nearly 45% of the coffee cherry [

20], while coffee husks from the wet processing method represent around 29% of the dry weight of the entire cherry [

22]. This indicates a significant quantity of coffee husk being generated annually (around 4 million tons), considering the global coffee production of 171.3 million 60 kg bags [

2]. With this global coffee production resulting in millions of tons of coffee husk annually, it is necessary to explore effective strategies for managing this by-product and maximizing its utilization potential.

In terms of technological and safety constraints, the coffee husk handling and disposal entrain a severe environmental problem due to its high moisture and low bulk density [

44]. These characteristics make handling, processing, and utilization of coffee husk more complex. Its fibrous composition and low compactability can hinder efficient extraction and incorporation into value-added products [

45]. Additionally, the high moisture content of coffee husk can contribute to difficulties in storage and transportation, as well as potential mold growth [

46]. To overcome the technological constraints and optimize the utilization of coffee husk, further research and development efforts are necessary. These efforts should focus on developing innovative technologies and processing methods that enable efficient extraction of valuable components, such as dietary fiber, phenolic compounds, and caffeine while ensuring safety and scalability [

47]. Although research is seeking value-added applications for coffee husk, such as in bioprocessing [

48], further exploration of alternative uses and applications can contribute to its value as a sustainable resource.

Recently, dried coffee husk from

Coffee arabica L. has been approved by the European Commission as a novel food to be used as an ingredient for infusions and non-alcoholic drinks, being its maximum use levels from 2-6 g of husk/ 100 mL [

49]. Considering the history of use of the coffee husk as food and the proposed uses and use levels, no toxicological studies were required by European Commission. The precautions and restrictions of use are related to caffeine intake, which should not exceed 150 mg/ L in the products containing this novel food. No safety concerns regarding the concentration of contaminants (e.g., heavy metals, pesticide residues, organic contaminants) which depends mainly on the production process (cultivation) that has been sufficiently described. Notwithstanding, quality control measures should be implemented throughout the processing of coffee husk to ensure safety and minimize potential contaminants [

50]. Regular testing for pesticide residues, heavy metals, mycotoxins, and other contaminants should be conducted to comply with food safety regulations and guarantee the quality and purity of coffee husk-derived ingredients [

15]. Addressing the technological and safety constraints associated with coffee husk will not only contribute to the efficient utilization of this by-product but also promote sustainability and reduce waste within the coffee industry [

22]. By implementing appropriate processing techniques and ensuring strict quality control measures, the coffee husk can be transformed into valuable ingredients and contribute to the circular economy.

2.2. Mucilage

The coffee mucilage is a pectin layer found between the pulp and the parchment (

Figure 4). After depulping, the mucilage remains attached to the coffee bean and being highly hydrated, is an impediment to further drying the beans. As a result, before the beans can be dried and processed, the mucilage must be degraded by wet fermentation, which is solubilized by yeast, bacteria, and fungi. The mucilage is an extremely hydrated sticky tissue, comprised of 1% of pectins with a high degree of esterification being uronic acid the major constituent, followed by arabinose, galactose, xylose, rhamnose, glucose as neutral non-cellulosic monosaccharides. In terms of composition, this coffee by-product is mainly constituted of water (84%), protein (7%), soluble sugars (4%), total dietary fiber (1.5%), caffeine (1%), and ash (1%) [

19]. The micronutrients found in coffee mucilage include Ca, Fe, Mg, K, P, and Na [

32]. Phenolic compounds, including flavonoids and tannins, have also been reported in coffee mucilage [

27].

This by-product is generated in countries that produce coffee using the wet method [

12]. The mucilage is produced at a level of 20 kg per 100 kg of fresh coffee cherries [

51]. Given its high moisture content, mucilage poses challenges for drying and processing, requiring wet fermentation to facilitate subsequent processing steps [

52]. Technological constraints associated with mucilage include the need for specialized equipment and controlled fermentation conditions to ensure proper degradation and removal of the mucilage layer [

53]. The sticky nature of mucilage can complicate handling and processing, requiring specific techniques for its removal without damaging the coffee bean [

54]. However, advances in processing technology and optimization of fermentation parameters have been explored to overcome these constraints and enhance the utilization of coffee mucilage in value-added applications [

52].

Nonetheless, it’s important to consider potential contaminations in coffee mucilage due to the fermentation process. Improper fermentation conditions or inadequate hygiene practices during wet fermentation may lead to microbial contamination, including the growth of undesirable microorganisms such as molds, bacteria, or yeasts [

53]. These contaminants can affect the quality and safety of coffee mucilage and its derived products. To mitigate potential contaminations, proper hygiene practices, strict quality control measures, and adherence to food safety regulations are crucial during wet fermentation and subsequent processing steps. Regular monitoring and testing for microbial contaminants should be implemented to ensure the safety of coffee mucilage-derived ingredients and products [

52]. By implementing appropriate quality assurance protocols, the risk of contamination can be minimized, allowing for the safe utilization of coffee mucilage in value-added applications.

2.3. Parchment

The coffee parchment is the yellowish fibrous endocarp covering and dividing the two hemispheres of the coffee seed. The coffee parchment is produced at 39 kg per 100 kg of fresh coffee cherries [

51]. In the wet processing, the coffee parchment is separated from other by-products after the beans have been dried and dehulled (

Figure 5). This process allows the collection of the parchment and its use separately from other by-products. In contrast, in the dry process, the coffee parchment is removed from the green bean, along with the skin, pulp, and mucilage, and is part of the coffee husk.

In terms of composition, the coffee parchment primarily consists of a high proportion of carbohydrates (~56%), predominantly in the form of dietary fiber. The main components of the dietary fiber are cellulose (40–49%), hemicellulose (25–32%), and lignin (33–35%) [

24,

34,

55,

56,

57]. It also contains low levels of fat (~0.3%), proteins (~3%), minerals (0.5–1%) and a variable moisture content (~8–10%). Caffeine and total phenolic compounds may account for approximately 1 and 2%, respectively [

36,

58].

As it represents 6% of the cherries’ dry weight It is produced at a rate of approximately 39 kg per 100 kg of fresh coffee cherries [

51]. Therefore, it is an abundant by-product of coffee processing. Technological constraints associated with coffee parchment include its fibrous nature, which can make it challenging to process and incorporate into various applications [

59,

60]. Further research and development efforts are needed to explore efficient and cost-effective methods for the extraction, purification, and utilization of the valuable components present in coffee parchment [

61]. This will help maximize its potential as a sustainable resource and enhance its value as a functional food ingredient [

35].

Coffee parchment is generally considered safe for consumption, with studies confirming the absence of pesticides and mycotoxins, except for a minimal content of ochratoxin A (OTA) below the European Commission limit [

15,

62]. A toxicity analysis was performed to complete the safety assessment, showing no adverse effects or mortality following the administration of 2 g/kg body weight of parchment to rats [

15]. However, it is important to note that coffee parchment, like other coffee by-products, should undergo rigorous quality control measures to ensure safety and minimize potential contaminants. Regular testing for pesticide residues, mycotoxins, and other contaminants should be conducted to ensure compliance with food safety regulations [

63]. This is especially important as coffee parchment is often used as a raw material to produce functional food ingredients and nutraceuticals, where the safety and purity of the starting material are crucial for the final product quality.

2.4. Silverskin

Green coffee beans are shipped to coffee-consuming countries, where their quality is evaluated based on odor and taste tests and the size, form, color, hardness, and the existence of defects [

21]. Once received, beans are checked to confirm their quality and stored until being roasted. The roasting process consists of three steps: drying, roasting, and cooling. During the drying process, water and volatile compounds are slowly released, and the color of the coffee beans changes from green to yellow. Roasting reactions alter both the beans’ physical and chemical properties, resulting in a complex mixture of Maillard reaction products [

22].

The silverskin, the thin tegument covering the bean, is detached at this point (

Figure 6). The coffee silverskin is the only by-product of the coffee roasting process [

18,

64]. This by-product contains low misture (4–7%), lipids (1.2–3%), and mineral content (5–9%). Proteins (8–20%) and carbohydrates (62–67%), mainly forming dietary fiber (52–70%) are the main component of the coffee silverskin [

15,

38,

39,

65]. The dietary fiber fraction comprises celluloses (~18–24%), hemicelluloses (~13–17%), and lignin (~29%) [

39]. Caffeine is the main phytochemcial in the coffee silverskin, followed by the chlorogenic acids (caffeoylquinic acids, dicaffeoylquinic acids, lactones of caffeoylquinic acids, coumaroylquinic acids, feruloylquinic acids, lactones of feruloylquinic acids, and feruloyl-caffeoylquinic acids) [

38,

40]. Other phenolic compounds found in coffee silverskin include caffeic, protocatechuic, and vanillic acids [

41].

The coffee silverskin represents about 4% of the green coffee beans [

18,

64]. The roasting of 4 tons of coffee yields approximately 30 kg of coffee silverskin [

66]. Considering that world coffee annual production (171.3 million 60 Kg bags of coffee beans) [

2], 76 thousand tons of coffee silverskin are produced next year worldwide in coffee transforming countries. Its fibrous and thin nature poses unique technological constraints for its processing and utilization in various applications [

67]. Challenges arise due to its low density and high inflammability, requiring careful handling and storage to ensure safety and prevent potential fire hazards [

68]. Moreover, the physical characteristics of coffee silverskin, including low compactability and poor flowability, may require specialized equipment and processing techniques to achieve effective extraction, purification, and incorporation into value-added products [

69]. To overcome these challenges and maximize the commercial viability of coffee silverskin as a sustainable resource, further research and development efforts are needed to explore innovative solutions and optimize processing methods [

70]. This includes the development of efficient and cost-effective technologies that enable the extraction and recovery of valuable components from coffee silverskin while ensuring safety and scalability [

71]. Exploring alternative uses and applications that potentiate the unique properties of coffee silverskin, such as its antioxidant and antimicrobial potential, can further enhance its value as a functional food ingredient and nutraceutical resource [

72].

The occurrence of chemical, biological, and processing contaminants has also been examined to guarantee the nutritional quality and safety of the ingredients derived from coffee silverskin [

15]. The absence of pesticides and mycotoxins was confirmed in the coffee silverskin, although it was close to the limit set by the European Commission for roasted coffee (400 μg kg

−1) but less than the amount established for instant coffee (900 μg kg

−1) [

73]. Nevertheless, no genotoxicity and cytotoxicity was observed in human liver cells treated with various concentrations of the coffee silverskin [

74]. Acute and sub-acute oral administration studies in animals have also demonstrated the safety of the coffee silverskin extract at the tested doses [

55]. Nevertheless, it remains essential to maintain strict quality control measures during processing and conduct regular testing for contaminants to ensure the safety of coffee silverskin-derived ingredients [

75]. Addressing the technological and safety constraints associated with coffee silverskin not only maximizes its utilization potential but also contributes to the circular economy by reducing waste and creating value from this by-product of the coffee roasting process [

76].

3. Biorefinery Strategies for Upcycling Coffee By-Products

3.1. Biorefinery as a Sustainable Approach for Circular Bioeconomy

Biorefinery is a sustainable approach for generating several products from multiple biomass materials by incorporating relevant conversion technologies [

77]. The biorefinery concept emerges as a possible solution to the present waste disposal challenges facilitating high value-added compounds production [

78]. This means complements the conventional waste use practices (animal feed, composting, incineration, and landfill). Biorefinery has been identified as the second generation of waste valorization and reuse strategies for higher-value marketable production products [

79]. Furthermore, this innovative valorization strategy has also been regarded as one of the most promising approaches to achieve a resource-efficient circular bioeconomy because it reduces human-induced environmental risks, creates new business possibilities, and uses energy more efficiently [

80].

Likewise, the circular bioeconomy seeks to increase human well-being and social justice while substantially reducing environmental risks and resource scarcity [

81]. The concept of the bioeconomy has long been associated with converting biological resources into goods and materials. The circular bioeconomy is a bioeconomy in which products and materials are recycled and reduced to a high degree [

82]. Recycling and other circular waste management strategies are critical components of the circular bioeconomy model, as shown by the sustainable, resource-efficient valorizing of biomass using biorefineries and repurposing residues and wastes [

83].

This biorefinery approach could result in active biomolecules for medicinal, cosmetic, food, and non-food applications. Proteins, polysaccharides, fibers and flavor compounds, are examples of high-value materials that can be processed and reused as food ingredients [

84,

85]. They are commonly used as texturizing, preserving, or coloring ingredients in the food industry, as well as active compounds in cosmetic or pharmaceutical products. These components must be obtained using extraction methods to isolate the targeted components from the matrix. In this regard, there are plenty of green chemical and biochemical procedures pursuing that goal through the process optimization to obtain higher extraction efficiency while reducing extraction time, energy use, the amount of solvent consumed in the process, environmental impact, economic costs, and waste generation [

86,

87]. Within them, the solute to solvent dissolution and its further diffusion abroad the matrix (solid-liquid extraction’s phenomenon) could be considered the most widely used strategy for compounds recovery, using both organic solvents and water (or their combinations). On this matter, the usefulness of water as a solvent for bioactive compounds extraction have been deeply explored since one of the associated advantages is compliance with the safety requirements for food-like applications. Indeed, water is the most eco-friendly traditional solvent to consider for green processes. At room temperature, ionic and polar compounds dissolve easily in water, while less polar compounds dissolve more easily at higher temperatures. Besides, water is non-toxic, non-flammable, inexpensive, and readily available [

88]. Such conventional extraction method is well-established and relatively easy to operate [

89]. However, for some purposes, the water-based extractions could result as nonselective procedures involving high economic, energetic and resources expenses [

3]. Thus, advanced chemical and physico-chemical techniques based on mass tranfers enhancement through the water’s solvation power tuning and/or cell wall weakening (

i.e., high pressurized hot water, microwave-assisted or ultrasound-assisted extraction), are gaining interest within scientific community because of their improved efficiency and selectivity rates, while being more environmentally sustainable compare with other alternatives [

90,

91].

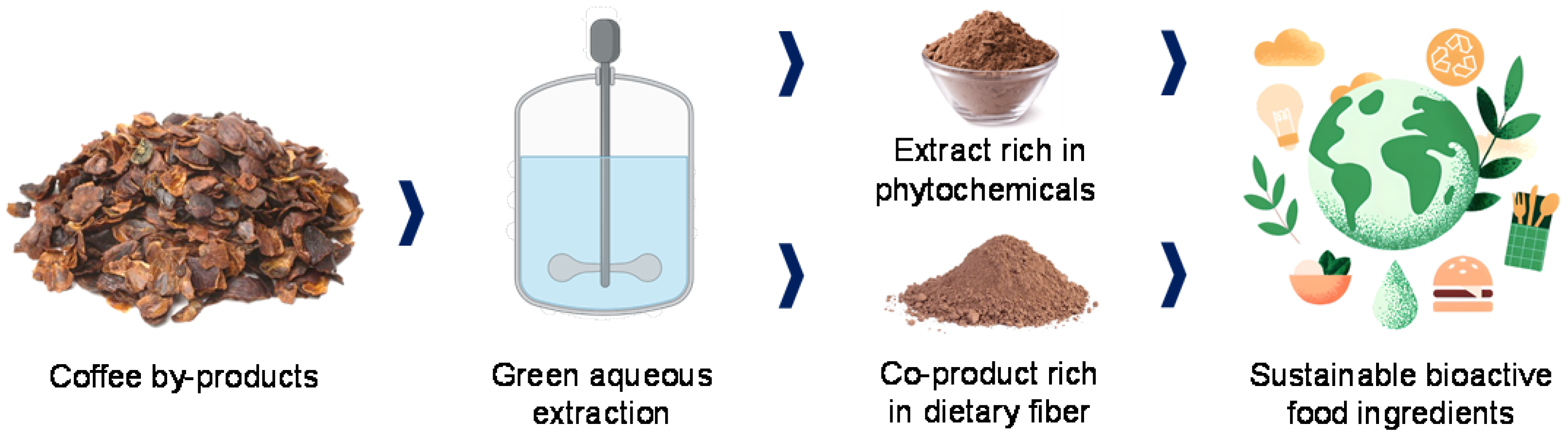

Therefore, water-based green extractions from coffee agroindustry by-products following a biorefinery approach (

Figure 7) involve obtaining the targeted compounds (

i.e., phenolic compounds) from the food matrices and valorizing the possible co-products generated (

i.e., enriched dietary fiber material), and conducting to high added-value products extent of toxic compounds and with proved safety.

3.2. Biorefinery and Coffee By-Products for Bioactive Food Ingredients Production

3.2.1. Husk

The conventional use of the coffee husk is to prepare the “

Cascara beverage”, traditionally consumed in Yemen and Ethiopia [

29], and composting in coffee-producing countries [

92,

93]. Current uses for the coffee husk include mushroom cultivation [

94], lignin extraction [

95], and recovery of biomolecules from the lignin alkali hydrolysate [

96], bioethanol production [

45,

97], biosorbents preparation [

98,

99], and animal feed [

46]. Other biotechnological applications proposed for this by-product are production of enzymes: amylase [

100], xylanase [

101], endoglucanase [

102], protease [

103], peptidase [

104], tannase [

105], among others [

106]; and biomolecules such as carotenoids [

107], gallic [

108], citric [

109], succinic [

110], lactic [

111], and gibberellic acids [

112], and fruity flavor compounds [

113].

However, recent studies have provided new evidence to support the use of coffee husk as a food ingredient for human consumption [

114,

115,

116]. Simple, low-cost, and eco-friendly aqueous extraction methods were used to produce extracts enriched in bioactive compounds with antioxidant, antiinflamatory, antimicrobial and anti-adipogenic properties [

117,

118,

119,

120], demonstrating the feasibility of using water as the only extractant of the coffee husk’s phenolic compounds. Aqueous extracts yielded around 7-29%, being composed of caffeine (1%), chlorogenic acids (0.3%), and protocatechuic acid (0.1%), among other phenolic compounds [

115,

117,

118]. Soluble sugars (glucose, fructose, and sucrose) were also present (~12%), as well as soluble proteins (5-7%). Most of the aqueous extracts are composed of soluble dietary fiber (~68%), which is solubilized together with phenolic compounds and other non-identified phytochemicals [

114,

115,

117].

Therefore, the existing evidence on the coffee husk aqueous extracts supports the potential use of the extracts to modulate metabolic syndrome biomarkers and, consequently, prevent cardiometabolic diseases. Likewise, the valorization of the whole coffee husk flour and water insoluble residue obtained after the aqueous extractions, which are rich in antioxidant dietary fiber [

114,

115], provide a more sustainable approach for the complete revalorization of coffee husk. All ingredients from the coffee husk revealed health-promoting properties associated with the prevention of metabolic syndrome. In conclusion, the coffee husk has shown a high concentration of dietary fiber and phenolic compounds. Considering its chemical composition and its biological activities demonstrated in multiple investigations, the coffee husk could be converted into two ingredients: an aqueous extract that could be used as a health-promoting food ingredient and another fraction that could be implemented as a source of antioxidant dietary fiber. This mixed high-fiber and phenolic compound content render coffee husk very appealing as a nutraceutical and ingredient in functional foods since combined antioxidant and fiber contents are likely to positively impact health, from the gastrointestinal tract to peripheral tissues.

3.2.2. Mucilage

Coffee mucilage, a by-product of coffee processing, holds promise for various applications in the food industry. It contains valuable nutrients, including protein, carbohydrates, fiber, fat, and potassium, which can be utilized in flour, baking mixes, nutritional supplements, and nutraceuticals [

121]. The fermentation of coffee mucilage involves microorganisms such as yeasts and lactic acid bacteria, which contribute to the breakdown of mucilage and the creation of flavor-active components. These components find use in food additives, flavorings, and extracts [

53]. Additionally, the extraction of simple sugars from coffee mucilage can serve as a substrate for anaerobic digestion, enabling the production of methane and bioethanol [

122,

123]. Fermentation of coffee mucilage can also yield ethanol, which finds application as a biofuel or in beverage production [

123,

124]. The microbial community involved in coffee mucilage fermentation significantly influences the process and impacts the final product quality [

125]. The introduction of yeasts in the fermentation process has been found to enhance coffee quality [

54]. Furthermore, coffee mucilage fermentation involves microorganisms that play a crucial role in mucilage degradation and the generation of flavor-active components [

52]. Research has investigated the fate of mucilage cell wall polysaccharides during coffee fermentation, revealing high levels of uronic acids in crude pectic substances [

126]. The microbial utilization of mucilage as a growth substrate results in the production of secondary metabolites, including organic acids, alcohols, esters, ketones, and aldehydes, which can affect the fermentation’s impact on final product quality [

31]. Moreover, coffee mucilage exhibits functional and technological properties suitable for producing bioplastics in the food industry [

127]. However, it is important to note that the substantial waste generated by the coffee industry can pose environmental risks [

123].

In addition to its potential environmental impact, coffee mucilage presents an opportunity for extracting bioactive compounds for use in food applications. The mucilage extract and flour derived from coffee fruits contain phenolic compounds, antioxidants, caffeine, lipidic compounds, dietary fiber, proteins and peptides, as well as aromatic and volatile compounds [

26]. By utilizing waste products like the coffee mucilage, bioactive molecules can be produced for pharmaceutical, cosmetic, food, and non-food applications [

26]. Furthermore, coffee mucilage exhibits industrial potential, with studies highlighting its value as a source of raw pectins, antioxidants, and flavonoids [

26]. Recent findings have demonstrated the inhibitory effect of coffee mucilage extracts on certain Gram-positive bacteria, although the specific compounds responsible for this activity remain unknown. The chemical composition of mucilage and its potential as a prebiotic that impacts gut microbiota are areas that require further exploration [

27]. Additionally, the potential of total mucilage, including cellulose, as a thickener or in other applications warrants further investigation [

128].

3.2.3. Parchment

Studies exploring coffee parchment use as food ingredient are recent, however, there exist significant health promoting and technologically appealing features of the product opening up its potential use as an ingredient in the food industry. The optimal conditions yielded high phytochemicals reported by Iriondo-deHond et al. [

15], who found a 2.3% yield and an extract containing high caffeine levels (1.3 mg g

−1) and a lower concentration of chlorogenic acid (0.14 mg g

−1). The main phenolic compounds in the coffee parchment are hydroxybenzoic and hydroxycinnamic acids (chlorogenic, vanillic, protocatechuic, and

p-coumaric acids) [

58]. These compounds are associated with the in vitro antioxidant and antifungal properties of the coffee parchment [

36,

58].

In addition, coffee parchment is also a potential source of dietary fiber. The coffee parchment is rich in insoluble dietary fibre (89%), mostly lignin (~30%), xylans (~28%) and cellulose (~10%). In previous studies, the presence of xylans [

129], cellulose, and lignin [

15], was similarly confirmed. The antioxidant capacity of the dietary fiber compared to the antioxidant potential associated with phenolic compounds were also studied, showing higher dietary fiber antioxidant potential than that of phenolic compounds associated, indicating that cell wall components (mainly lignin and xylans) may also be contributing to the antioxidant properties [

19].

Coffee parchment’s technological features (water holding capacity, water absorption, swelling capacities, oil holding capacity, and gelation capacities) open up the potential for food applications both as physiological and technological ingredients. The main factors influencing hydration properties are the polysaccharide composition and their organization within the cell walls. In general, coffee parchment showed good hydration properties, which would suggest that this by-product could be used as a functional ingredient to reduce calories or modify the viscosity and texture of formulated foods. Besides, hydration properties are also related to some physiological effects as hypoglycemic and hypolipidemic, exhibiting a potential for glucose adsorption, retarded diffusion, and inhibited α-amylase, which led to lower starch digestibility. Similarly, coffee parchment exhibited in vitro hypolipidemic properties including pancreatic lipase inhibition and cholesterol and bile salts binding[

34].

Recent investigations also explored the synthesis of xylo-oligosaccharides from coffee parchment [

129]. Xylo-oligosaccharides could be a valuable product since they possess prebiotic features as functional food ingredients with tremendous potential [

130]. The production of the aqueous extracts could also be utilized if the extracted phytochemicals are economically profitable (nutraceutical of pharmaceutical proposes). Following a biorefinery approach, the water-insoluble residue (WIR) could also be revalorized as a source of dietary fiber exhibiting similar properties as the non-extracted coffee parchment [

34].

The main use of parchment is addressed as a source of antioxidant dietary fiber. Coffee parchment has been added to gluten-free bread (2–4%) [

35]. The addition led to increases in dietary fiber, phenolic compounds, and antioxidant capacity without modifying the appearance of the bread and its texture properties. Consumer acceptance studies found that a 4% replacement provided the final product a distinct bitter taste due to the presence of caffeine. The work suggested that a debittering step should be considered to increase the coffee parchment quantity in gluten-free bread in order to enhance its sensory and nutritional properties. Therefore, using the water insoluble residue from the coffee parchment would allow producing bread with higher dietary fiber content and maintain its health-promoting properties. Similarly, cookies with 1–5% of coffee parchment flour were developed by Cubero-Castillo et al. as a strategy to increase the dietary fiber content and enhance cookies antioxidant capacity [

56]. In this research, adding coffee parchment flour in the cookie dough did not generate rejection in consumers.

Furthermore, the coffee parchment could be transformed into other renewable products. It may be a source of cellulose to produce cellulose-based goods [

131]. Lignocellulosic fibers and lignin are the world’s two of the most valuable natural resources and have great potential to increase bioplastics biodegradability by replacing synthetic fibers. Lignin has proven the ability to function as a bioplastic plasticizer, stabilizer, or bio-compatibilizer, resulting coffee parchment an outstanding candidate for sustainable packaging [

132]. Coffee parchment can also be a source of caffeine and phenolic compounds for edible films production with antifungal properties [

36]. Additionally, the coffee parchment has also been used to produce particleboard [

24,

133], as composite reinforcement [

134], and ultimately, as a source of renewable energy via combustion [

135].

Until now, coffee parchment applications as a food ingredient remain largely unexplored. Notwithstanding the favorable chemical composition of the coffee parchment aqueous extract and in vitro antioxidant capacity, this coffee by-product should be preferably used as a source of antioxidant dietary fiber since extraction yields are relatively low. Nonetheless, research pinpoints the need to fractionate coffee parchment, generating a soluble extract and an insoluble residue. Through a biorefinery approach, both fractions can be revalorized into differentiated products, avoiding more waste production. New coffee parchment applications in the food industry as a natural source of antioxidant dietary fiber should be strongly considered to revalue this by-product.

3.2.4. Silverskin

Studies have explored the aqueous extraction of coffee silverskin to develop food ingredient with healthy properties. Sustainable aqueous extraction of phytochemicals from coffee silverskin has been proposed according to del Castillo et al. patent (WO 2013/004873) [

136]. This extract is a sustainable source of bioactive compounds such as chlorogenic acid (2.8 mg g

−1) and caffeine (19.2 mg g

−1), but the major component in the coffee silverskin extract is soluble dietary fiber (22%) [

137].

Based on its chemical composition and biological activity observed, the green aqueous extract could be used as a healthy food ingredient. The coffee silverskin extract could be consumed as a food supplement or added to the most appropriate food matrix based on customer sensory acceptance. The food application of the coffee silverskin extract in beverages [

137], biscuits [

138], and bread[

114], have been described. Coffee silverskin extracts can also be applied to produce functional yogurts [

67]. Other sustainable potential uses for this extract include cosmeceuticals production, since compounds from the coffee silverskin protect skin cells from UV damage and prevent skin aging. Besides, the extract present adequate properties to be included in a cosmetic formulation [

139,

140].

The coffee silverskin flour and water insoluble residue (from the phytochemicals green extraction) can also be used as a fiber-rich food ingredient, with the ultimate goal of recycling the whole by-product. The coffee silverskin water insoluble residue contains 70% of dietary fiber, being the majority insoluble. Depending on the species, this fraction also comprises around 10–20% proteins and about 3% fat. In vitro antioxidant and prebiotic properties were also reported in this fraction [

65]. Likewise, dietary fiber fermentation releases short-chain fatty acids, which modulate anti-inflammatory gene and protein expression [

141]. OTA was detected in the coffee silverskin water insoluble residue at lower levels (2.9 μg kg

−1) than those permitted by the European Commission. However, no other mycotoxins or pesticides were found [

62]. Furthermore, it has used coffee silverskin dietary fiber to enhance the nutritional quality of biscuits by improving moisture, texture, thickness, and color of the novel biscuits [

138]. Coffee silverskin has been used as dietary fiber ingredients to formulate bread reducing its caloric density. Moreover, cakes with up to 30% coffee silverskin water insoluble residue as a flour substitute have been developed, improving moisture content, textural and sensory attributes [

142,

143]. Cakes with coffee silverskin water insoluble residue exhibited physical and sensory properties similar to the control cake [

142].

Alternative sustainable uses of coffee silverskin are polylactic acid production as a replacement for synthetic polymers [

144], cellulose isolation, and purification, for the development of sustainable packaging [

145], and biofilms [

146], the production of butanol [

147], succinic acid [

148], bio-oil [

149], composites [

69], adsorbent [

150], and as an energy source through pyrolysis [

151]. Antioxidants and value-added bioactive compounds are produced from coffee silverskin via pyrolysis [

152]. More research is being conducted demonstrating the presence of a plethora of bioactive compounds and coffee bean roasting-derived phytochemicals that provide health benefits in biological systems [

153].

According to circular economy strategies, the coffee should be fully revalorized either as flour or fractionated into two different ingredients (extract and water insoluble residue), generating zero residues. Research has corroborated the nutritional properties and biological activity of the coffee silverskin components. Thus, the different applications of coffee silverskin as a food ingredient and its safety validation have confirmed its viability as a sustainable food ingredient or nutraceutical for human consumption.

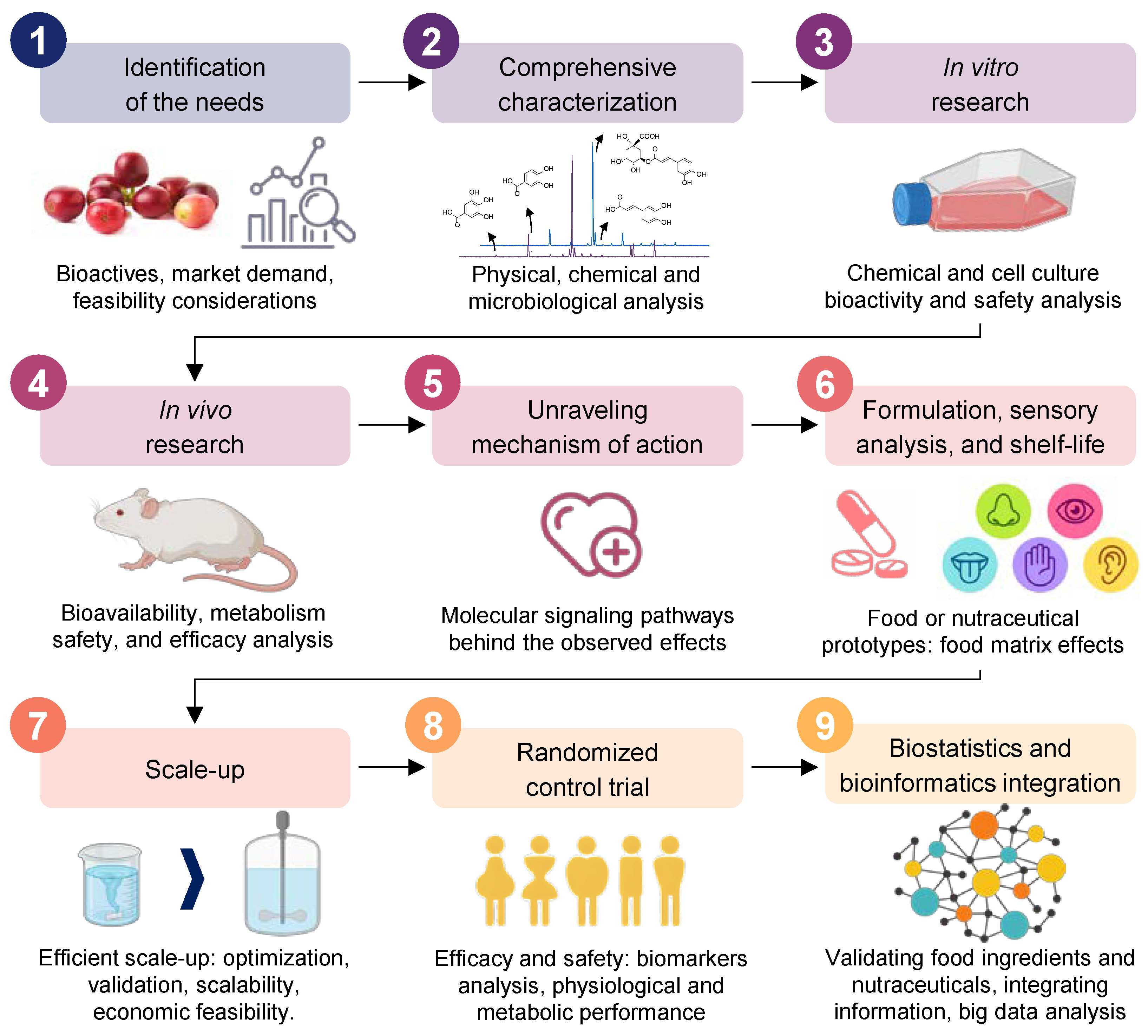

4. Stepwise Strategy for Valorizing and Validating Coffee By-Products as Bioactive Food Ingredients and Nutraceuticals

Based on the knowledge generated around the chemical composition of coffee by-products and the growing interest in their valorization as healthy food ingredients, specific research strategies need to be gradually addressed to gather all the information required to use coffee by-products as bioactive food ingredients and nutraceuticals for the prevention of chronic diseases [

154]. A stepwise approach is essential to ensure the revalorization of coffee by-products and enhance the sustainability of the food system (

Figure 8). Harmoniously, the green production of healthy food ingredients from these by-products can result in a strategy to prevent chronic diseases [

155].

4.1. Identification of the Needs

The first step is to identify the specific needs that the products should meet. This involves considering the desired bioactive compounds and functional properties, as well as the market demand and feasibility of the food products [

156]. Through this process, a clear set of goals and priorities is established, effectively guiding the development of these products.

One important issue in identifying the needs is the bioactivity of the compounds present in coffee by-products. They are known to contain various bioactive compounds such as phenolic compounds and caffeine, which have been linked to various health benefits [

89]. Therefore, it is important to determine which compounds are of interest and how they can be extracted and utilized in the development of functional food ingredients and nutraceuticals [

157]. Another consideration is the functional properties of the products. For example, if the goal is to develop a nutritional supplement, the product should have a high concentration of the desired bioactive compounds and be formulated in a way that ensures maximum absorption and bioavailability in the body [

158]. Similarly, if the target is to develop a food ingredient, the product should have desirable functional properties such as flavor, texture, and stability [

159].

In addition to considering the technical aspects of the products, it is important to contemplate market demand and feasibility. This involves assessing consumer preferences and trends, as well as the availability and the cost of raw materials and the processing methods [

160]. By taking these factors into account, the development of functional food ingredients and nutraceuticals from coffee by-products can be guided by market demand and feasibility, leading to more successful and sustainable products [

161].

4.2. Comprenhensive Characterization

After the needs have been identified, the next step is to comprehensively characterize the coffee by-products-derived food ingredients or nutraceuticals. This involves analyzing the composition and properties of the product to ensure it meets the identified needs and is safe for consumption, including a range of analyses such as chemical, physical, and microbiological analyses. These analyses provide information on the nutritional content, functional properties, and safety of the product [

162]. For example, proximate analysis can be used to determine the moisture, protein, fat, and carbohydrate content of the product, while rheological testing can be used to evaluate the texture and viscosity [

163]. Microbiological examination is also important to ensure that the product is free from harmful microorganisms [

164].

In addition to the traditional analyses, newer techniques such as metabolomics and proteomics can be used to provide a more detailed understanding of the composition of the product [

165]. Metabolomics can be used to identify and quantify small molecule metabolites in the product, while proteomics can be used to analyze the protein content and identify potential bioactive peptides [

166]. Comprehensive characterization is essential to ensure that the food ingredient or nutraceutical meets the identified needs and is safe for consumption [

167]. By analyzing the composition, properties, and safety aspects of the product, any potential issues can be identified and addressed, leading to a more successful and safer product. These techniques allow the characterization of extracts obtained using the biorefinery strategy and ingredients rich in bioactive compounds [

168]. To gain a comprehensive understanding of the constituents from coffee and its by-products, it is essential to employ a range of analytical tools. Spectrophotometric analysis methods such as UV-VIS and fluorimetry are complemented by the use of advanced techniques like LC-MS/MS, GC-MS/MS, and NMR to characterize the diverse array of bioactive compounds present [

169].

4.3. In Vitro Research

In vitro studies play a crucial role in the initial evaluation of the bioactivity and safety of coffee by-product-derived ingredients, as they provide a controlled laboratory environment to examine their effects on biological systems [

170]. Given the abundance of bioactive compounds found in coffee by-products and their diverse biological effects, employing multiple experimental approaches is necessary to gain a comprehensive understanding of their activity [

171]. These in vitro studies allow for the assessment of various properties, including antioxidant, anti-inflammatory, and antimicrobial activities of coffee by-product-derived compounds. Of particular interest is evaluating the antioxidant activity, as coffee by-products are known to contain phenolic compounds, which exhibit potent antioxidant properties [

16]. Phenolic compounds from coffee by-products have been recognized as bioactive components with antioxidant properties [

58,

115,

172]. In vitro studies have also been conducted to compare the phytochemicals from coffee by-products and their potential to reduce markers of inflammation, oxidative stress, adipogenesis, and insulin resistance [

41,

119,

173]. Coffee silverskin melanoidins, formed via the Maillard reaction, have been assessed for their bioactivity [

174]. The coffee husk has been evaluated as an innovative antioxidant dietary fiber ingredient [

43]. Additionally, in vitro assays can determine the potential of coffee by-product-derived ingredients to inhibit the growth of pathogenic bacteria [

175]. Moreover, in vitro studies serve as a valuable tool to optimize the processing conditions and formulation of food ingredients or nutraceuticals [

176]. For example, researchers can investigate the effects of different processing parameters, such as temperature and pH, on the bioactivity and stability of the final product. In vitro studies also aid in determining the optimal concentration of coffee by-product-derived compounds to maximize their bioactivity in the formulation [

89].

Furthermore, it is essential to conduct in vitro bioaccessibility, bioavailability, and toxicological studies to evaluate the release, absorption, and safety of bioactive compounds [

177]. Bioaccessibility studies have been conducted to evaluate the release and absorption of bioactive compounds from coffee by-products and the changes in antioxidant activity during in vitro gastrointestinal digestion [

33,

120,

153]. Safety studies allow for a comprehensive assessment of potential allergenicity, genotoxicity, and other safety aspects associated with the coffee by-product-derived ingredients [

37]. While in vitro research provides valuable insights into the bioactivity and safety of coffee by-product-derived compounds, it is important to acknowledge its limitations in predicting their effects in vivo [

178]. Hence, conducting subsequent in vivo studies using animal and human models is necessary to confirm the bioactivity and safety of these ingredients.

4.4. In Vivo Research

Animal studies provide valuable information on the bioactivity, safety, and efficacy of the coffee by-product-derived compounds [

179]. In vivo animal models can be used to evaluate the effect of the coffee by-product-derived ingredients on specific health conditions, such as obesity, diabetes, cardiovascular diseases, or neurodegenerative diseases [

180]. Animal studies can also provide valuable information on the bioavailability and metabolism of the compounds [

181]. For example, animal models can be used to evaluate the absorption and distribution of the compounds in the body, as well as their metabolism and excretion [

181]. Animal models can also be employed to assess the potential for adverse effects associated with the coffee by-product-derived compounds. Conducting thorough safety evaluations and toxicological studies in animal models is essential to ensure the absence of harmful contaminants or adverse effects associated with the coffee by-product-derived bioactive ingredients [

182]. Assessing potential allergenicity, genotoxicity, and long-term safety profiles is crucial [

183].

4.5. Unraveling Mechanism of Action

Unraveling the mechanism of action of coffee by-products and understanding how these compounds exert their beneficial effects is crucial for optimizing the final bioactive ingredients or nutraceutical and exploring new applications [

180]. Mechanistic studies typically employ in vitro and in vivo models to identify the cellular and molecular pathways targeted by coffee by-product-derived compounds. In vitro studies allow for the evaluation of the compounds’ effects on specific enzymes or signaling pathways, while in vivo studies may provide insights into the compounds’ impact on biomarkers of oxidative stress, inflammation, and other relevant biological processes [

184].

Numerous mechanisms of action have been proposed for the beneficial effects of bioactive compounds found in coffee by-products. These mechanisms include antioxidant and anti-inflammatory activities, as well as the regulation of signal transduction and gene expression [

185]. Phytochemicals present in coffee by-products can exhibit biological activity through various mechanisms, such as direct free radical scavenging, down-regulation of radical production, inhibition of enzymes involved in the production of reactive oxygen species (ROS), and up-regulation of antioxidant enzymes [

186]. Additionally, coffee by-product-derived bioactive compounds may contribute to the regulation of energy metabolism, making them potential candidates for combating obesity and metabolic disorders. These compounds can affect pathways involved in lipid metabolism, adipogenesis, and thermogenesis, thereby influencing body weight and energy balance [

119]. Furthermore, some coffee by-product-derived compounds, such as chlorogenic acids, have been associated with antidiabetic effects through their ability to enhance insulin sensitivity and regulate glucose metabolism [

187]. Therefore, a molecular nutrition approach is needed to assess the effect of coffee by-products bioactive compounds on whole-body physiology and health status at the molecular and cellular levels. The precise identification of the molecular pathways underlying human metabolism is essential for promoting health preventing disease [

188]. Mechanistic studies also provide valuable insights into the potential adverse effects associated with coffee by-product-derived compounds. Evaluating their interactions with specific receptors or signaling pathways can help identify possible side effects and guide the development of safe and effective products [

37].

4.6. Food and Nutraceutical Formulation, Sensory Analysis, and Shelf-Life Stability

After the identification of bioactive compounds and the evaluation of their efficacy and safety through in vitro and in vivo studies, the next step for upcycling coffee by-products into bioactive food ingredients and nutraceuticals is food production and sensory analysis [

156]. Food production involves the formulation and development of food prototypes that incorporate the coffee by-product-derived ingredients. This process requires careful consideration of various factors, such as the selection of suitable extraction, concentration, and purification methods to optimize the bioactive compound content and functionality [

189]. When formulating nutraceuticals, specific considerations need to be addressed. These include ensuring appropriate dosages of the bioactive compounds are incorporated, maximizing their bioavailability and bioactivity in the body, and complying with regulatory guidelines for health claims and safety [

190]. Nutraceutical formulations may require additional processing steps, such as encapsulation or microencapsulation, to protect the bioactive compounds and enhance their stability and delivery [

191]. One important aspect to consider during food and nutraceutical formulation is the effect of the food matrix on the bioactivity and bioavailability of the incorporated bioactive compounds [

192]. The interaction between the bioactive compounds and other components in the food matrix can influence their release, absorption, and subsequent physiological effects in the body. Understanding these interactions is crucial for optimizing the formulation to maximize the desired health benefits [

193].

Sensory analysis plays a critical role in food production, as it assesses the acceptability and palatability of the final product. This evaluation encompasses various sensory attributes, including appearance, aroma, taste, texture, and overall acceptability [

194]. By conducting sensory analysis, either through trained sensory panelists or consumer panels, valuable insights can be gained into the sensory characteristics of the product and potential areas for improvement [

194].

Furthermore, it is crucial to thoroughly study the stability and shelf-life of the final product. The assessment of potential degradation or loss of bioactivity in coffee by-product-derived ingredients during storage and transportation is of great importance. Stability testing is typically performed under various storage conditions to monitor changes in bioactivity, sensory attributes, and microbiological quality, ensuring that the product maintains its efficacy and safety throughout its intended shelf-life [

195].

4.7. Scale-Up

Scale-up involves transitioning from laboratory-scale production to larger-scale production to meet the demands of commercial production. During the scale-up process, the production process is optimized to ensure efficiency and accommodate increased volume. This may involve making adjustments to the production equipment, modifying the processing methods, and sourcing raw materials in larger quantities [

196]. Validation studies play a crucial role in the scale-up process, as they are conducted to ensure that the final product meets rigorous safety and quality standards. These studies verify the consistency and reliability of the product, addressing factors such as composition, stability, and microbiological safety [

32]. Additionally, it is important to assess the scalability of the production process, considering factors such as scalability of the extraction methods, availability of raw materials at a larger scale, and the environmental impact of the scale-up process [

197]. Furthermore, during scale-up, it is essential to evaluate the economic feasibility of the production process. This involves assessing the cost-effectiveness of the larger-scale production, including considerations such as raw material costs, equipment investments, labor requirements, and market demand [

198]. Economic feasibility studies help determine the viability of scaling up the production of bioactive food ingredients and nutraceuticals derived from coffee by-products, ensuring that the final product can be produced and marketed in a sustainable and economically viable manner.

4.8. Randomized Control Trial

Conducting randomized control trials (RCTs) is essential to evaluate the efficacy and safety of the final product in human subjects [

199]. RCTs employ a study design and methodology that includes randomization, blinding, and control groups to minimize bias and confounding variables. The study population should be carefully selected to ensure they meet the inclusion and exclusion criteria, and the sample size should be large enough to provide sufficient statistical power [

200]. In addition to assessing the efficacy of coffee by-product-derived nutraceuticals, it is important to consider their nutrikinetics, which involve studying their absorption, distribution, metabolism, and excretion in the human body [

201]. Furthermore, the gut microbiota plays a crucial role in the metabolism and bioactivity of bioactive compounds. Therefore, evaluating the impact of coffee by-product-derived nutraceuticals on the gut microbiota composition and function is important [

202]. Advancements in personalized and precision nutrition have highlighted the importance of considering individual variations in response to dietary interventions. Integrating personalized and precision nutrition approaches into RCTs can enhance the understanding of how coffee by-product-derived nutraceuticals interact with individual characteristics, leading to more effective and personalized nutritional interventions [

203]. Evaluation of safety is also a critical component of RCTs. Adverse events and side effects should be carefully monitored and reported [

200].

4.9. Biostatistics and Bioinformatics Integration

Building a strong and reliable scientific foundation for functional food claims requires demonstrating the bio-efficacy of functional food components in vivo, extending beyond in vitro experiments [

204]. Therefore, comprehensive evaluations are necessary to validate the functionality of coffee by-product-derived food ingredients, utilizing a range of experimental models including in vitro models, cell culture models, animal studies, and ultimately, human preclinical and clinical trials [

199]. These diverse approaches allow for a thorough understanding of the effects of coffee by-product-derived compounds on human health. To effectively integrate and interpret the wealth of information generated throughout the various steps, from extraction to characterization, in vitro and in vivo analyses, and human clinical trials, biostatistical and bioinformatic techniques play an indispensable role [

205,

206]. These techniques enable the synthesis and analysis of large and complex data sets, facilitating a more comprehensive understanding of the effects of coffee by-product-derived compounds on human health. Moreover, the advent of big data science and analysis has further enriched the capabilities of researchers. Through the application of advanced data analytics, researchers can extract valuable insights from vast amounts of information, uncovering patterns and associations that were previously inaccessible [

207]. Recent advancements in artificial intelligence have drawn attention to its capacity to learn and model both linear and non-linear relationships between variables, unveiling hidden and valuable information for decision-making [

208]. Utilizing artificial intelligence algorithms, such as machine learning and deep learning, can significantly enhance the analysis and interpretation of complex data sets related to coffee by-products. These approaches provide deeper insights into the chemical composition, biological activity, and toxicity of coffee by-product-derived compounds, supporting informed decision-making in the development of functional food ingredients and nutraceuticals [

209]. The integration of biostatistical and bioinformatic tools, coupled with emerging technologies like artificial intelligence and big data analysis, empowers researchers to unlock the full potential of coffee by-products and contribute to the development of innovative and evidence-based functional food ingredients and nutraceuticals [

210]. Consequently, after following a holistic approach for gathering the information needed to valorized coffee by-products as food ingredients, all the new knowledge generated about their chemistry, biological activity, and toxicity could be adequately managed, integrated, and interpreted.

5. Commercialization, Regulation, and Technological Innovation

5.1. Market Potential and Commercialization

The development of functional food ingredients and nutraceuticals from coffee by-products presents an opportunity for the coffee industry to expand its product portfolio and enter new markets [

189,

211]. The market potential for these products is significant, with increasing consumer demand for sustainable and health-promoting food options [

212]. In addition, the use of coffee by-products in these products can contribute to a circular economy and promote waste reduction, further enhancing the appeal of these products to environmentally conscious consumers [

213]. To fully realize the market potential of these products, however, it is important to consider the commercialization process. This includes identifying target markets, developing effective marketing strategies, and establishing distribution channels [

214]. Collaboration between coffee producers, processors, and food companies may be necessary to ensure the success of these products in the market [

215].

In this context, the main coffee by-products are traditionally consumed in several coffee-producing countries. However, there are few commercial products available in the market. In countries such as Yemen (called Qishr), and Ethiopia (called Hashara) and Bolivia (called Sultana), the coffee husk drink is quite common, with a different consuming way [

216]. The most common presentation of these coffee by-products is to prepare infusions with hot water adding different spices, consumed them either hot or cold. Baba Seed is a leading coffee company responsible to create a Qishr Sparkling Iced Tea, drink that’s helping to alleviate the environmental impact of coffee production [

217]. This beverage is prepared by brewing husks with spices (cinnamon and ginger) showing high phenolic compounds and low caffeine content (¼ of the caffeine of a cup of black coffee). On the other hand, Nescafé Nativ Cascara, is a registered product by Nestlé created from upcycled coffee berry husks, after farmers separate and sun-dry the coffee berry [

218]. The result is a refreshing, lightly sparkling, caffeinated beverage with floral and fruity notes. An American multinational chain of coffeehouses such as Starbucks Coffee Company launched in 2017 the Cascara Latte [

219]. In this case, cascara is not consumed as a tea, but as a syrup, boiling coffee cherry skin with sugar and water. It should be noted that the main coffee by-products are marketed around the world as tea bags. Being an innovation result to achieve more sustainable products and maximize resources, Tabifruit from the Spanish roaster Supracafé Ldt. commercialized coffee husk tea bags with different aromas (orange, passion fruit, maracuya, or berries) to enhance the sweet and fruity flavors of the coffee husk [

220]. Overall, the commercialization of coffee by-product-derived products requires a multifaceted approach that considers market potential, regulatory considerations, and technological innovation. Collaboration and continuous research and development will be essential to ensure the success of these products in the market.

5.2. Regulatory Issues and Standards

Regulatory considerations are an important aspect to consider in the development and commercialization of functional food ingredients and nutraceuticals derived from coffee by-products [

221]. The regulatory landscape for these products varies by region, and it is important to comply with the relevant regulations in order to ensure market success and consumer safety [

222,

223]. In Europe, functional food ingredients and nutraceuticals are regulated under the European Union’s novel food regulation. This regulation requires a safety assessment and authorization for any novel food or food ingredient that has not been consumed significantly in the EU prior to 1997. The authorization process can be lengthy and expensive, but it is necessary to ensure the safety and efficacy of these products [

224]. In Asia, regulations for functional food ingredients and nutraceuticals vary by country. In Japan, for example, functional food ingredients are regulated under the Foods for Specified Health Uses (FOSHU) system, which requires a scientific review of the health claims made by these products [

225]. In China, they are regulated under the Food Safety Law, which requires safety assessments and labeling requirements [

226]. In Canada, functional food ingredients and nutraceuticals are classified as either foods or natural health products (NHPs) based on their intended use and claims. Functional food ingredients that make health claims are categorized as NHPs and require authorization from Health Canada before they can be legally marketed. The authorization process for NHPs involves a comprehensive review of safety, efficacy, and quality evidence submitted by manufacturers [

227]. In the United States, these ingredients are regulated by the Food and Drug Administration (FDA) and are subject to safety and efficacy requirements. The FDA requires that these products be safe, effective, and labeled appropriately [

228].

To include the coffee by-products in the European food sector and ensure the protection of human health is important to know if these are considered as novel foods. European specific legislation about novel food is contained in regulation (EU)No2015/2283 and (EU) No. 2017/2468 and No. 2017/2469 [

224,

229,

230]. Dried

Coffea berries (husk or cascara) are considered novel. The term novel food included in this regulation is referred as “

a food is considered to be novel if it has not been regularly consumed by humans in the EU before 15 May 1997, when the first novel food Regulation came into force” [

231]. Moreover, there is another pathway for the approval of novel foods: a notification for a traditional food from a third country. Dried cherry pulp and its infusion specified in the implementing regulation from the European Commission as traditional foods have been recently published [

232]. For the silverskin, a consultation request is currently determining its novel food status. During the approval procedure, the food products must be evaluated for safety and toxicological aspects. Limitations on the utilization of coffee by-products are associated to their caffeine and acrylamide content (obtained after the roasting process). The caffeine content in foods formulated with coffee by-products should be below the European Food Safety Authority (EFSA) safety level for daily caffeine consumption of 400 mg for the general population and 200 mg for lactating women. The acrylamide limit established by the EFSA for coffee and instant coffee is 450 and 900 µg/kg, respectively [

233]. The absence of pesticides and mycotoxins is a required determination that must also be carried out.

In conclusion, navigating the regulatory landscape for functional food ingredients and nutraceuticals derived from coffee by-products can be complex, but it is essential to ensure compliance and safety. It is important for companies to work closely with regulatory agencies in their respective regions to ensure compliance and to stay up to date with evolving regulations.

5.3. Technological Innovation

Technological innovation is a crucial factor for the successful development and commercialization of functional food ingredients and nutraceuticals derived from coffee by-products. Patents play a pivotal role in protecting the intellectual property of these innovations and providing a competitive advantage in the market. There have been numerous patents developed to enhance the utilization value of coffee processing by-products for various applications (