1. Introduction

In contemporary discourse, the fourth industrial revolution and its implications for companies have become a focal point. The necessary changes that companies must implement as they embark on the path of digitalization are also a significant consideration. To shed light on these aspects, we conducted an exploratory quantitative questionnaire-based study involving leaders of small, medium, and large enterprises in Hungary and Austria. Our study focused on assessing their preparedness for Industry 4.0, their plans related to this paradigm, and the key factors they consider when introducing Industry 4.0 initiatives. Furthermore, we examined whether there is a correlation between the areas in which companies have implemented developments supporting Industry 4.0 and their overall readiness. To complement our quantitative analysis, we conducted a series of four semi-structured interviews - as part of an explanatory research approach - involving two Hungarian and two Austrian companies. These interviews aimed to provide qualitative insights into the level of digital preparedness among companies and to offer recommendations for businesses venturing into the realm of digitalization.

Each industrial revolution has brought both benefits and challenges at the societal and economic levels for countries involved in such transformations. To navigate through these transformations, a holistic approach is required, encompassing innovative and sustainable systemic solutions, rather than focusing solely on technological advancements [

1]. In her study, [

2] highlighted several key areas of impact. She suggests that Industry 4.0 can influence the work environment, skill development, economic growth, and macroeconomics. Furthermore, she emphasizes the importance of sustainability and environmental considerations, the changing landscape of political and business processes, digitalization, as well as the emergence of numerous new intelligent factories and the establishment of smart manufacturing practices. If changes traverse the entire value chain, they can completely transform production processes, industry structures, and even impact internal division of labor within companies [

3]. The increasing levels of digitization impose entirely new requirements on employees within organizations and completely reshape corporate strategies. According to [

4], the realization of Industry 4.0 occurs when products, tools, and services are interconnected, and not only people but also machines engage in information exchange within cyber-physical systems. Digital technologies, or rather the new opportunities they create, radically transform previous organizational and social interaction interfaces and contents, fundamentally rewriting "traditional solutions," such as supplier relationships or customer engagement [

5,

6,

7,

8]. Digital technologies and platforms enable revolutionary innovations that transcend companies and industries, blurring industry boundaries and frameworks [

9], thereby introducing further turbulence into the competitive environment. [

10] identified the following success factors necessary for companies to effectively implement digital business models in practice: Integrating digital transformation into the corporate strategy, Coordinating technical content with stakeholders within the value network, Proactively ensuring IT and data security, Developing a tailored data strategy, Engaging in active communication with employees, Providing training opportunities for employees, Implementing new disruptive business models within the organization.

In the future, it is advisable for companies to increasingly strive to meet their needs at the local level and satisfy them using local resources [

11]. [

12] argues that agility and preparedness for the future are crucial in a changing world. The emergence of new technologies creates lower capital-intensive job opportunities and eliminates distance constraints, which company leaders need to prepare for. Our research focuses on the readiness for Industry 4.0 in Hungary and Austria. We considered it important to compare the digital development and direction of these two neighboring Central European countries due to their many similarities. They share a common history in terms of trade and economy, which has connected them, and they remain important trading partners even after their separation. The two countries also have similar geographical and population characteristics: Hungary has an area of 93,022 km2 and a population of 9.71 million, while Austria has an area of 83,871 km2 and a population of 8.96 million. We were curious to explore whether there are similarities in their readiness for Industry 4.0 and how they are progressing with their digital transition. In their study, [

13] highlight that Industry 4.0 exhibits variations in terms of digitalization across different levels. For Hungary, the aim is to catch up with leaders and integrate into the international value chain, while Austria is in a flourishing phase of development, with their main objective being to ensure the country's dynamic progress. Initially, we examined the digital development of Austria and Hungary using the Digital Economy and Society Index (DESI) macro indicator.

1.1. Annual indicator measuring the development of the digital economy and society in Hungary and Austria

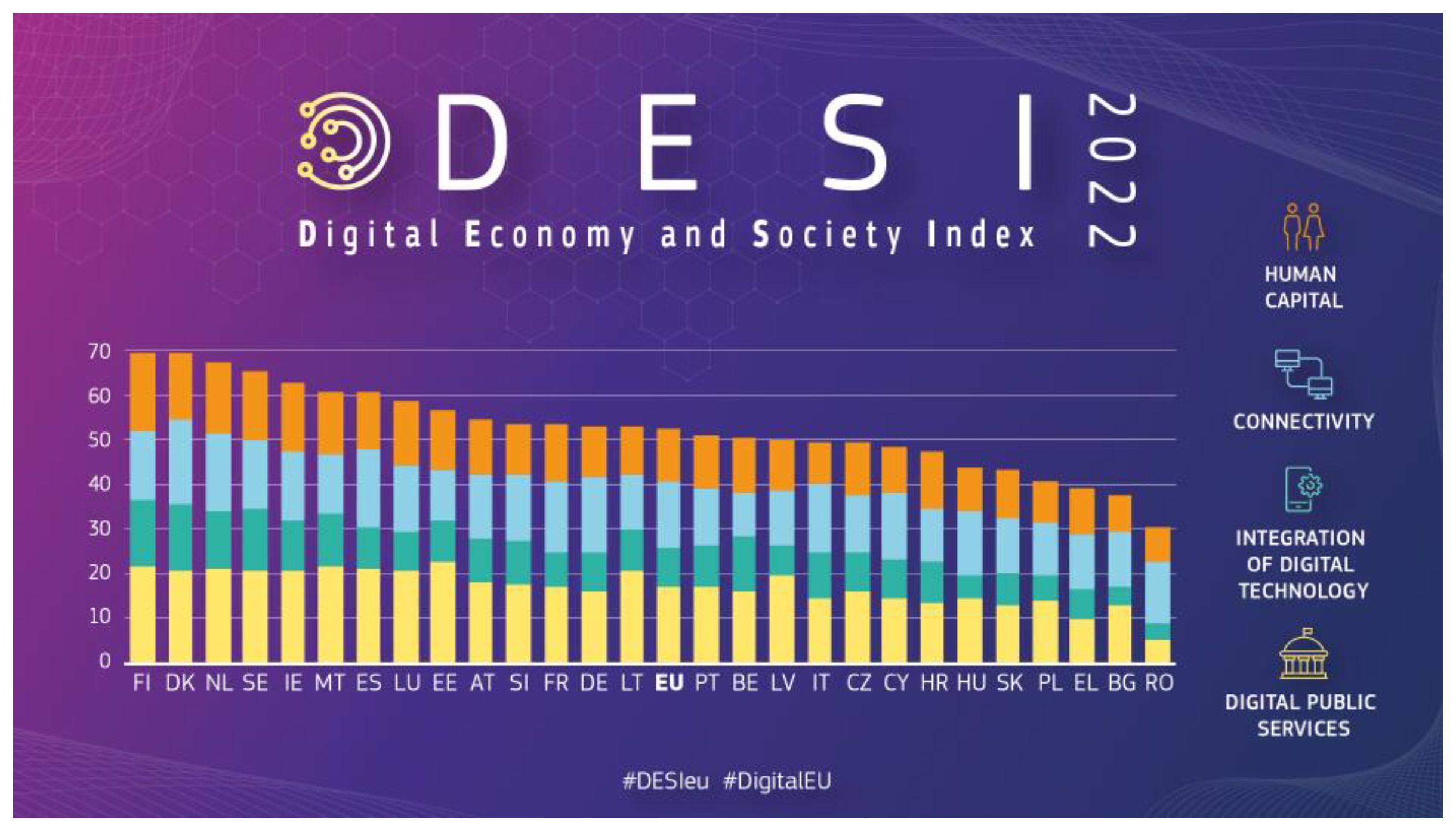

The DESI (Digital Economy and Society Index) is an indicator that measures the digital economy and society development in EU member states. It provides a framework for EU countries to discuss their economic and budgetary plans and track progress throughout the year. The index allows monitoring of the achievements of member states in terms of digital competitiveness, considering aspects such as human capital, broadband connectivity, the use of digital technologies by businesses, and the availability of digital public services (

Figure 1).

In 2022, Hungary ranks 22nd among the 27 EU member states, while Austria occupies the 10th position. In terms of human capital, Austria surpasses the EU average in almost all indicators, with the exception of the "Enterprises providing ICT training" indicator, where Austria is slightly below the EU average. Hungary performs well in the area of internet access. It takes a leading role in terms of the penetration of broadband systems with speeds of at least 1 Gbps (13.2% of lines), compared to the EU average of 1.3%. Hungary also demonstrates strong preparedness for 5G, the advanced version of the 4G LTE network, as well as widespread utilization of wired broadband systems and networks with speeds of at least 100 Mbps. Ensuring 100% coverage of gigabit networks in all households by 2030 is a crucial objective of the Digital Decade strategy. The strategy is built around four main pillars: digital infrastructure, digital skills, digital economy, and digital governance. Hungary aims to surpass the EU average in terms of digital development by the middle of the decade and be among the top 10 EU economies in terms of digitalization by 2030 [

15].

Austria surpasses the EU average in terms of 5G network coverage. However, the coverage and utilization of very high-capacity fixed networks remain below the EU average. Ensuring higher-speed coverage in rural areas continues to be a significant challenge that Austria needs to address in order to achieve nationwide gigabit connectivity by 2030 [

16].

Hungary ranks 23rd in terms of human capital and performs below the EU average in most indicators. Only 49% of Hungarians possess basic digital skills, which significantly lags behind the EU average of 54%. Other indicators also demonstrate relatively low levels of digital skills. To address the shortcomings in digital skills, Hungary has developed an ambitious policy framework. The new digital strategy outlines three priority areas for digital skills: 1.) Development of digital competencies (based on the DigComp4 framework); 2.) Increase in the number and qualification of IT professionals and engineers; 3.) Support for structural changes in education and vocational training to enhance digital skills. Hungary still faces challenges within the framework of the DESI index concerning the integration of digital technologies in businesses and the provision of digital public services. The goal of the Hungarian National Social Inclusion Strategy 2030 is to improve the digital literacy of students, parents, and teachers. It is important to focus on the development of digital infrastructure, reduction of online risks, and enhancement of IT infrastructure in schools [

15].

In terms of human capital, Austria ranks 11th among the 27 EU member states, positioning itself above the EU average. Austria follows two main strategies regarding digital skills. The Digital Action Plan focuses on education and training with the goal of equipping everyone with basic digital skills and competencies. The KTI Strategy (Research, Technology, and Innovation) for 2030 sets three objectives: innovation, excellence, and knowledge. To ensure that every individual possesses basic skills, the Austrian government has introduced measures for all age groups. Starting from 2022, digital basic education is included as a mandatory subject in the curriculum. Through the Digi Scheck initiative, the Federal Ministry of Labor and Economics provides a financial subsidy of EUR 500 for courses accessible to apprentices to enhance their professional skills, particularly in the field of digitalization, resource management, or climate protection. This subsidy is available for a maximum of three courses per year. Additionally, Austria launched over 1790 activities during the 2021 EU Codex Week. In order to develop basic digital skills, the "Digi-Bonus" program will be launched in 2022, which will provide training opportunities and financial support. The program targets individuals who face difficulties in internet usage or have limited knowledge on how to handle digital tasks in their professional and personal lives. Businesses, especially SMEs, will also be encouraged to promote the development of their employees' skills in the following areas: IT management, cybersecurity, cloud services, and e-commerce. A federal funding program with a budget of 2.6 million euros has been initiated to provide vouchers for "Digital Pro Bootcamps," where participants will undergo a four-week training program [

16].

Hungary has largely completed the implementation of the National Information and Communications Strategy for the 2014-2020 period and the Digital Prosperity Program 2.0 ("DJP 2.0") launched in 2017. In the autumn of 2021, a new strategic framework was adopted for the next 10 years: the National Digitalization Strategy (NDS) for the 2021-2030 period [

15].

In Austria, numerous projects and activities are planned for the 2022-2024 period in the field of scientific and technological disciplines, with a focus on the following areas: ICT, artificial intelligence (AI), cybersecurity, the internet and digital technology, and information and communication technologies. Furthermore, in the academic year 2023/24, a new technical university for digitalisation and digital transformation - TU DuDT (Technische Universität für Digitalisierung und Digitale Transformation in Linz) - will be established in the academic year 2023/24 [

16]. 93 percent of Austrian households now have internet access with a minimum speed of 30 Mbps. However, the country lags behind in terms of coverage of Very High-Capacity Networks (VHCN), significantly below the EU average. The high usage rate of mobile broadband internet (91%) among individuals indicates that Austrian households utilize mobile broadband as a supplement or substitute for fixed-line connections. In the field of digital public services, Austria's digital action plan strategy aims to provide a one-stop service for businesses and individuals. The Government Program 2020-2024 outlines the step-by-step implementation of this objective [

16].

The European Community, the OECD, and the European Union have taken numerous initiatives to catalyze the widespread industrial adoption of information and communication technologies and automation [

17,

18]. Industry 4.0 also requires appropriate qualifications, problem-solving skills, and scientific preparedness from university students and educators, as they represent potential future workforce [

19]. Given the economic environment characterized by slow growth, low inflation, and limited fiscal space, the resources required for the development of Industry 4.0 and the digital economy (initial investment, training and learning time requirements, a more flexible labor market, etc.) and the risks associated with the widespread and rapid transition to Industry 4.0, gradual progress is advantageous rather than disadvantageous. This should be reflected in the time horizon of support policies and institutional functioning [

20,

21,

22,

23].

There is a significant difference in digital development between Hungary and Austria, but the two countries have different cooperative advantages. For example, in Hungary, labor is cheaper than in Austria, yet well-educated. Austria started the digital transition much earlier and at a higher level than Hungary, where digitalization began several years later after the regime change, in small steps. Closing this gap can take a long time, if it is possible or necessary at all. Therefore, based on the results of the DESI macro indicators, it became evident that Austria is advanced and making good progress in digital transformation, while Hungary is moderately developed. As a result, we further examined the micro-level to assess the validity of the DESI results at the company level.

1.2. The Impact of the Fourth Industrial Revolution on the Operations of Hungarian and Austrian Companies

According to [

24], in Hungary, there are two significant obstacles to Industry 4.0 and Industry 5.0: knowledge and resource gaps. It is advisable to acquire knowledge and the best digitalization training through various programs from existing foreign, primarily German corporate groups. The resource gap can be reduced through state and EU programs. This is no longer just about the explosive development of the industry but about the digitalization of the entire economy, which affects society as a whole. It is crucial for companies to respond to new technological opportunities to prevent significant lag. [

25] demonstrated in their study that employees working in Industry 4.0 need to possess better professional knowledge and technical skills to successfully introduce new technology in a company. Employees need to have highly developed communication skills, be committed to precise task execution, and be capable of working both independently and in teams. They should also be open to sharing knowledge.

During the literature review, we found additional inhibiting factors that may hinder the digital transformation of companies. According to [

26] factors hindering development can include the lack of a clear, coherent strategy, distrust in data security, lack of standards, fear of unknown-sized investments, and the inability of companies to control their intellectual assets. In a study conducted by [

27], qualitative interviews were conducted with a total of 68 companies in Austria. Based on the findings, no single obstacle was considered significant enough to completely prevent Industry 4.0. However, companies perceive the highest risks in IT and data security, the shortage of skilled workforce, and unresolved technical problems. Ethical conflicts and obstacles arising from economic framework conditions are considered the least relevant. Generally, the identified obstacles represent challenges for companies rather than fundamental barriers.

[

28] found in their research that digitalization and technology adoption have begun in Hungary, but there is still a significant lag compared to other more advanced countries. They identified the lack of a clear digital strategy in value-creating (production and logistics) processes and the lack of management support as the major obstacles to implementing Industry 4.0. Many companies are hesitant due to the unknown economic benefits of digital investments and concerns about high costs. Moreover, many companies are not adequately prepared for secure data storage and management. [

29] found that the fourth industrial revolution poses challenges to companies in various areas. They identified a new factor not discussed in previous studies: concerns about profitability and uncertainties in grant schemes that can hinder the adoption of Industry 4.0 technologies. [

30] also identified the major barriers that can hinder the adoption of new technologies related to Industry 4.0, including implementation costs, market competition, and resistance to acceptance. One of the primary obstacles to the widespread adoption of Industry 4.0, not only in Hungary but also in developed countries, is data security or the lack thereof. Interestingly, it is not the manufacturing companies but rather the customers who are concerned about their data falling into unauthorized (hacker) hands. They struggle to decide which poses a greater risk: storing data in the manufacturer's own database or in a remote, mysterious cloud [

31]. [

32] addressed the managerial challenges arising from the implementation of Industry 4.0 in his literature review. According to [

33], leaders understand digital transformation, but they do not always know how to apply it in their organizations and manage the resulting changes most effectively. They believe it is crucial to consider business-level transformation and recommend a structured approach to change management.

The literature review identified significant inhibiting factors that further encourage companies to prepare for change in a timely manner, develop well-thought-out strategies, as the lack of a digital strategy, in particular, can lead to lagging behind.

1.3. Directions of Industry 5.0

The Industry 5.0 revolution is still in its early stages, but it is essential to mention that its exploration can be an important area for further research. This new wave, referred to as Industry 5.0, is expected to promote mass production alongside user-centric customization, beyond the scope of the Industry 4.0 ecosystem. Industry 5.0 is expected to support various industrial verticals, such as healthcare, smart agriculture, drones, smart grids, and production ecosystems of supply chains. The goal of Industry 5.0 is to connect human intervention with automated processes, thereby making industrial workflows more explainable. In Industry 5.0, autonomous workforce understands human desires and intentions. Consequently, people would work closely with their robotic counterparts without fear, as the former understands them and interacts with them [

34].

[

35] identified the following six fundamental technologies in their study on Industry 5.0: 1. Personalized human-machine interaction technologies that connect and integrate the strengths of humans and machines. 2. Bioinspired technologies and smart materials that enable the use of embedded sensors and enhanced functionalities in materials that are also recyclable. 3. Digital twins and simulation for modeling entire systems. 4. Data transfer, storage, and analysis technologies capable of managing data and system interoperability. 5. Artificial intelligence, such as recognizing cause-and-effect relationships in complex, dynamic systems, leading to actionable intelligence. 6. Technologies for energy efficiency, renewable energy sources, storage, and autonomy. [

36] state that Industry 4.0 and Industry 5.0 share several common characteristics. This is mainly because Industry 5.0 is an advancement of Industry 4.0. The definition of Industry 5.0 is dominated by two fundamental concepts. One relates to the technical approach, while the other focuses on biological aspects. Industry 5.0 is described as a revolution that places particular emphasis on human factors. Another interesting area is the manufacturing paradigms of the two revolutions. Industry 4.0 (thanks to vertical and horizontal integration) is dedicated to realizing the concept of mass customization. Industry 5.0, which focuses on people, refers to new ideas and craft manufacturing paradigms. Technological advancements and revolutions are occurring at an increasingly rapid pace, so companies need a clear strategy for their corporate developments, what they want to achieve, and how. Businesses need to recognize that those who are more innovative and responsive to market changes will be successful in offering high-quality products to their customers.

2. Materials and Methods

A quantitative questionnaire survey was conducted to explore the readiness of small, medium, and large companies in Hungary and Austria regarding Industry 4.0 and their future plans related to it. The following research questions were addressed:

What is the current status of Industry 4.0 implementation in Hungarian and Austrian companies?

What are the key considerations for companies when implementing Industry 4.0?

Additionally, the study examined whether there is a correlation between the areas where development supporting Industry 4.0 implementation took place in Hungarian and Austrian companies.

When constructing the questionnaire, we relied primarily on the "National Technology Platform for Industry 4.0" questionnaire project developed by MTA Sztaki, which assessed the needs, expectations, and current state of Industry 4.0 in the surveyed companies in the industry and strategic economic management. Data collection was conducted through in-person interviews, online surveys, and email correspondence, involving a total of 155 companies, 101 Hungarian and 54 Austrian. We examined the readiness, current status, future plans, and opportunities of the surveyed companies regarding Industry 4.0. On the qualitative side, four semi-structured interviews were conducted, two with Hungarian companies and two with Austrian companies. The interviews aimed to explore the digital preparedness of the companies, their future plans, and provide recommendations for businesses embarking on the path of digitalization. The complete survey was conducted in 2021-2022. The 54 Austrian questionnaires were uniformly collected online, which allowed for the highest response rate. The Hungarian questionnaires were conducted using two methods: face-to-face interviews using snowball sampling for half of the sample, and Computer Assisted Telephone Interview (CATI) with the assistance of Ipsos Zrt. for the other half, utilizing the Opten database. From the database, companies operating in the industries identified in the target group (Mechanical Engineering, Automotive Industry, Logistics, Electronics Industry, Chemical Manufacturing), which are most likely to be affected by the digitalization transition, were selected. The analysis was performed using the IBM SPSS 25.0 software package. For examining the relationships between variables, principal component analysis was chosen. The Hungarian sample was weighted, and this was done in a two-dimensional manner based on the economic main activity and the size of the company, as we had highly accurate data on these aspects. The population sample of the target group is presented in the following two tables, according to the distribution of main activities (

Table 1 and

Table 2).

As seen in the 1. table, it is evident that most responses came from companies in the logistics and machinery repair/manufacturing sectors. The other three sectors, namely machinery manufacturing, electronic manufacturing, and chemical manufacturing, had a roughly equal number of participating companies, with 12 companies from machinery manufacturing, 12 companies from electronics, and 10 companies from chemical manufacturing. Among Hungarian companies, small businesses were the most active, with 58 companies participating in the questionnaire, while only 17 large companies were included.

Among Austrian companies, no responses were received from small businesses, only from medium and large enterprises. 27 medium-sized and 27 large companies participated in the questionnaire. Most responses came from the machinery manufacturing and repair sector, while the other sectors were roughly evenly distributed.

3. Results

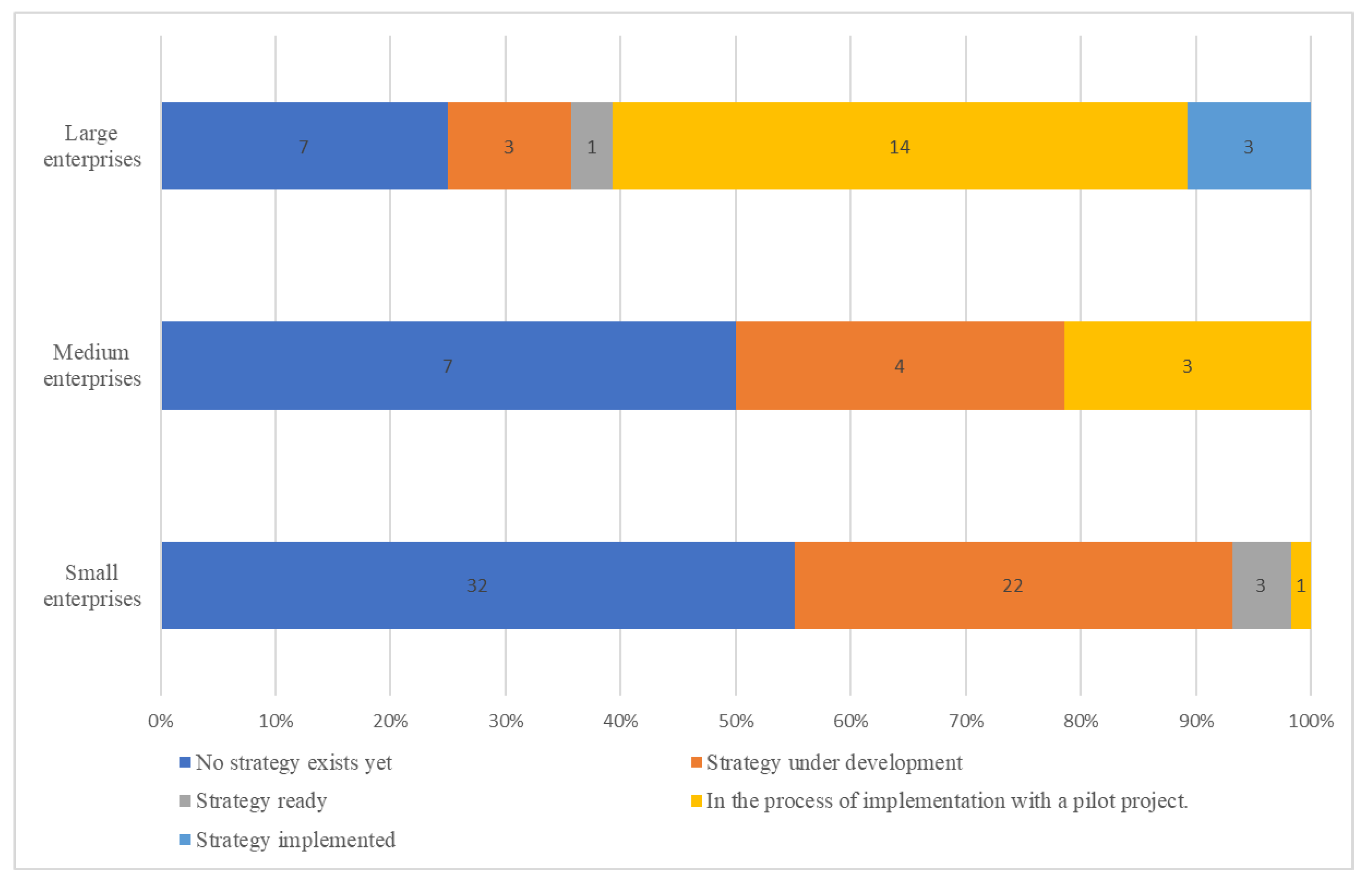

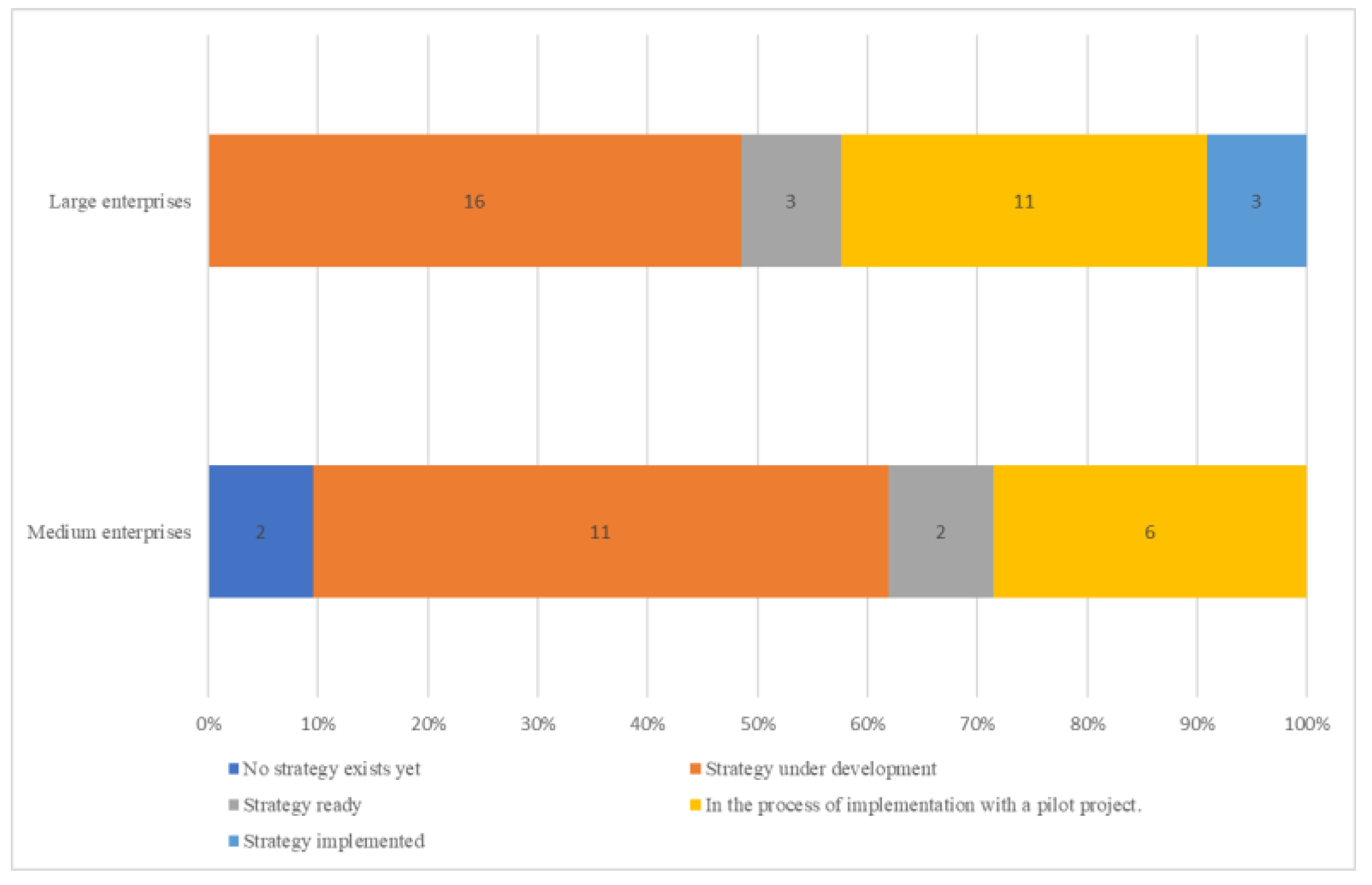

Our first research question focused on the current level of preparedness for Industry 4.0 strategies among Hungarian and Austrian companies. For this question, we created the following two summary charts (

Figure 2 and

Figure 3). "Implemented Industry 4.0 strategy" refers to projects that have been successfully completed and companies that are actively using Industry 4.0 technologies.

Among large Hungarian companies, 75% have an Industry 4.0 strategy, which means that the strategy is either being developed, implemented, completed, or is already in use. Medium-sized companies indicated this option at a rate of 50%, while 44.07% of small companies chose one of the listed options, which is surprisingly high. Among small companies, 33 have no Industry 4.0 strategy at all, and none of them have fully implemented it. Only one company is in the process of implementation with a pilot project. [

37] research examined hypotheses regarding differences between SMEs and large companies in terms of implementing Industry 4.0. The results of the comparisons also show that SMEs have a lower level of Industry 4.0 implementation. This confirms the assumption that large companies have more opportunities to adopt new technologies and transform into smart factories. However, this situation may change in the future if new technologies become more accessible to smaller companies, for example, through leasing.

Figure 3 clearly shows that all responding Austrian large companies have an Industry 4.0 strategy in some form. Among them, 16 companies are in the process of developing the strategy, 3 have completed it, 3 have already implemented and are actively using Industry 4.0 technologies, and 11 companies are in the process of implementation with pilot projects underway. Among medium-sized companies, 90.48% already have an Industry 4.0 strategy in some phase, and only two companies have no strategy at all.

There is also a significant difference at the company level between the two countries. Among the surveyed Austrian medium-sized companies, 90.48% have an Industry 4.0 strategy, while in Hungary, approximately half of the surveyed companies, both medium-sized and small, have such a strategy. Among Hungarian large companies, 75% have an Industry 4.0 strategy, while all the surveyed Austrian companies have begun their journey towards Industry 4.0 technologies.

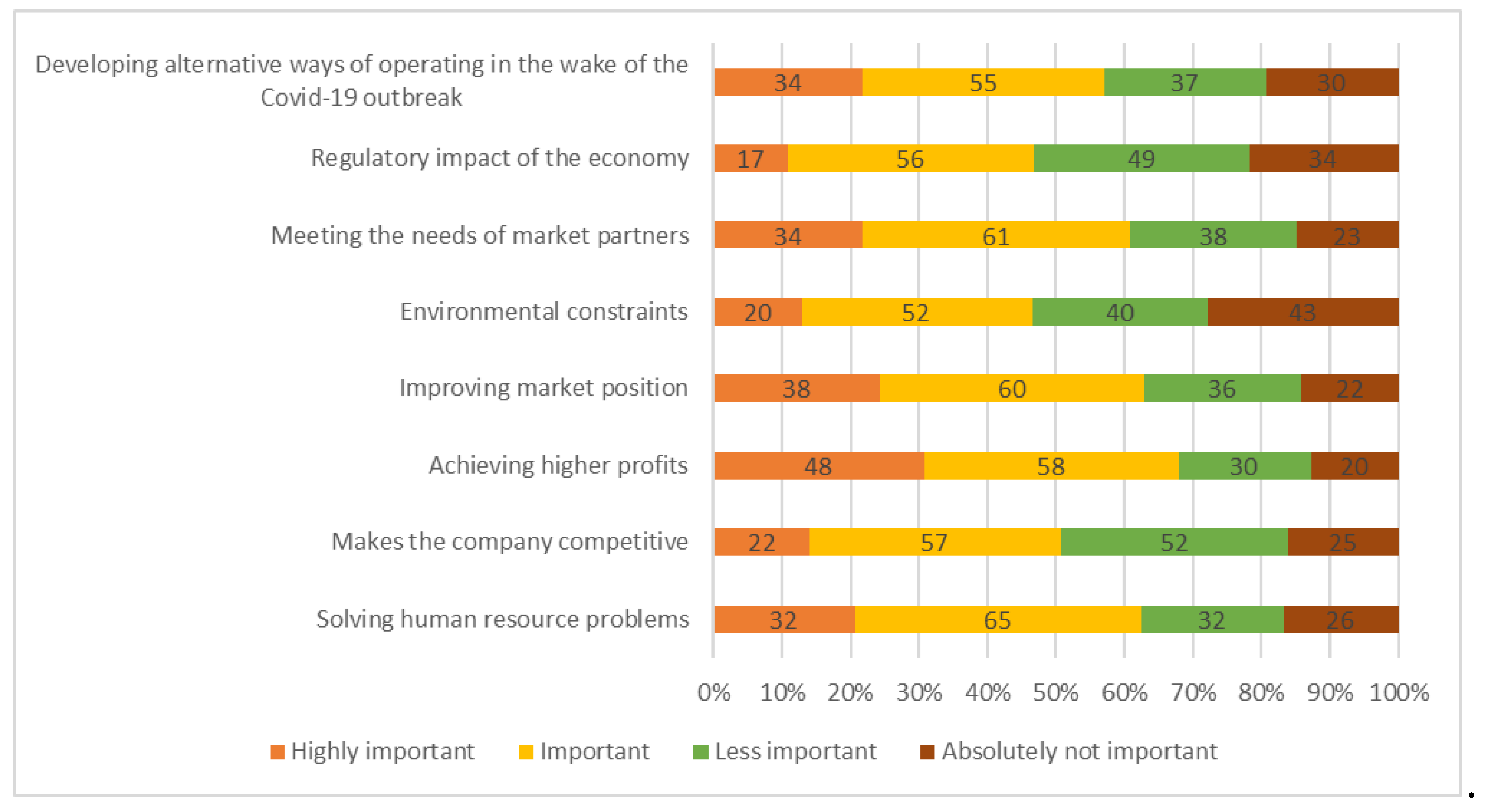

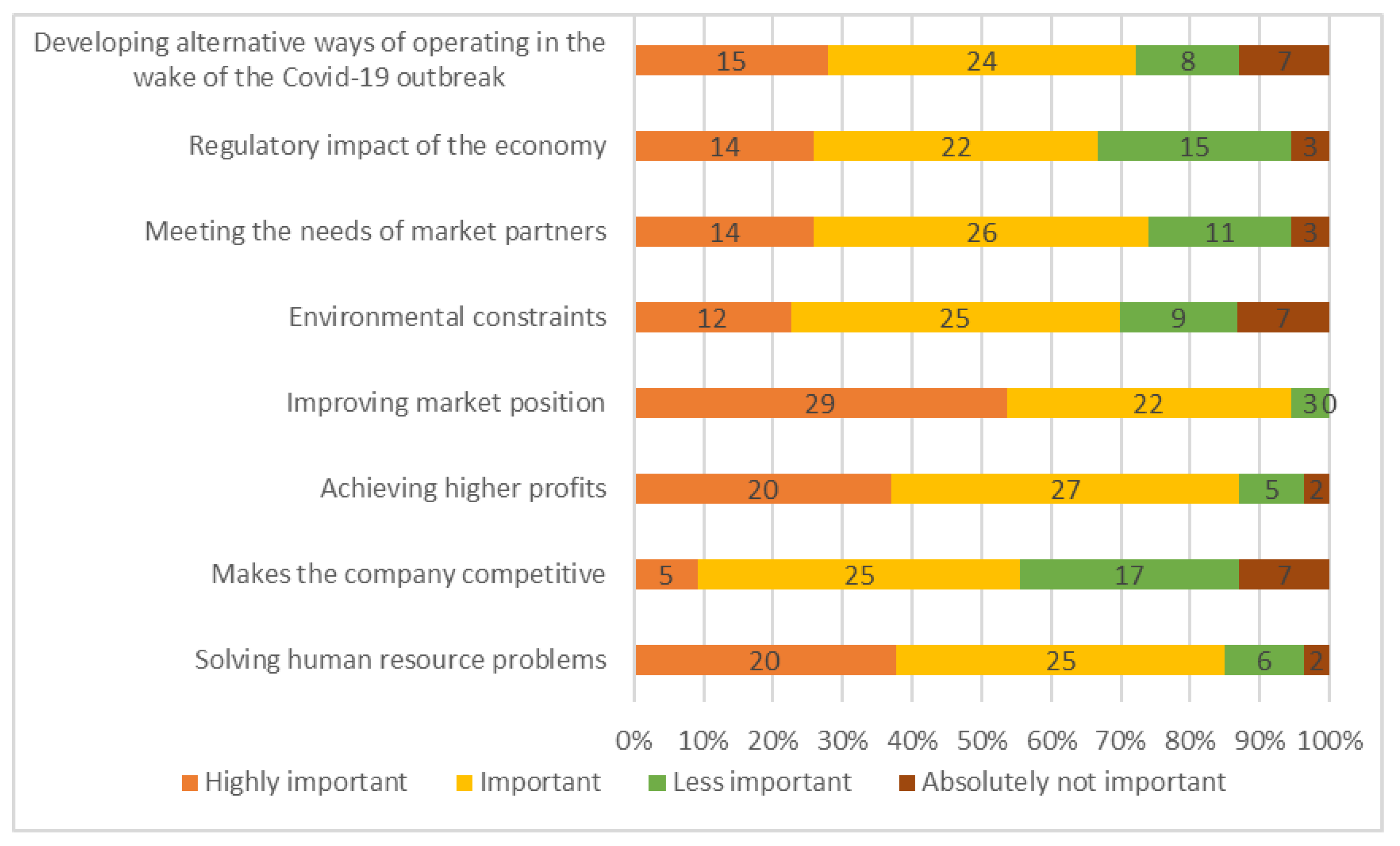

For the 2nd research question, we examined the aspects that company leaders consider important when introducing and developing digital transformation. Respondents were able to select multiple options from the provided possibilities.

Figure 4 and

Figure 5 were created for this topic, with the first figure focusing on Hungarian companies and the second figure on Austrian companies.

Among Hungarian companies, 48 firms consider the opportunity for higher profits to be of paramount importance when it comes to the implementation of an Industry 4.0 strategy. Investment in Industry 4.0 technologies involves a significant volume of resources, and many companies decide to invest when they have projects that can "cover" these costs. Therefore, it is natural and not surprising that achieving higher profits is a prominent consideration for Hungarian companies. However, other important factors include addressing the issue of human resources, meeting the expectations of market partners, ensuring competitiveness, and the regulatory impact on the economy. Regarding the development of alternative modes of operation in response to the consequences of the COVID-19 pandemic, opinions are divided: 30 companies do not consider it important at all, while 24 companies consider it to be of significant importance. What is deemed "not important at all" is the environmental imperative, as indicated by 42.57% of the companies.

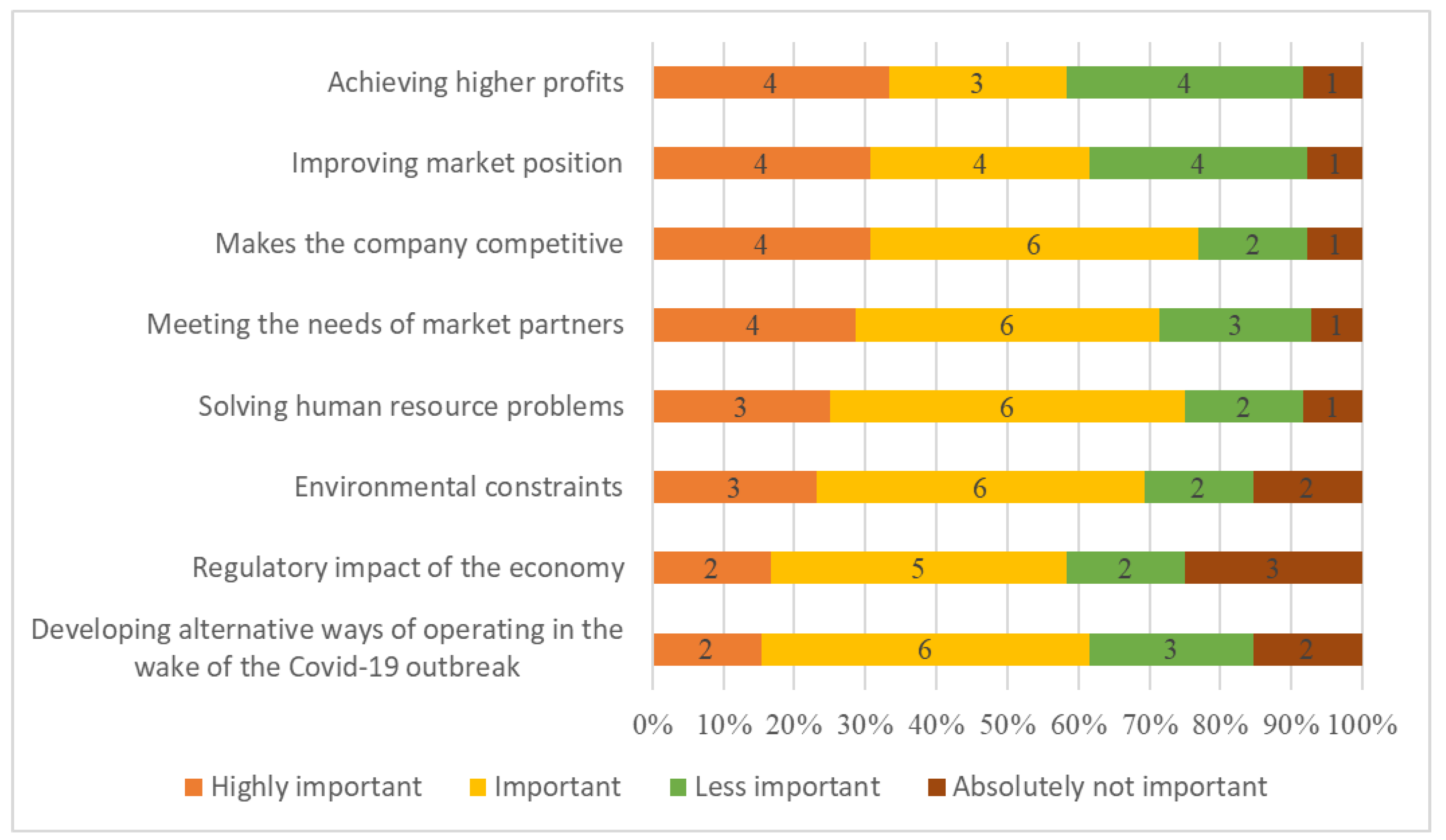

In Austrian companies, improving market position was a prominent consideration, with 29 out of 54 companies, accounting for 53.7%, choosing this option. Additionally, 20 companies, or 37% of the respondents, considered the solution to the human resources issue to be of significant importance. Interestingly, none of the companies regarded improving market position as not important at all in relation to the implementation of the Industry 4.0 strategy. In contrast, 42.15% of Hungarian companies did not consider improving market position to be important. In this research question, we also found it important to examine which industry sector the companies belonged to that considered certain attributes as particularly important. In the case of Hungarian companies, the machinery manufacturing and repair industry had the highest number of attributes marked as of paramount importance. This is clearly illustrated in the following figure (

Figure 6).

The figure shows that among companies in the machinery manufacturing, industrial machinery and equipment repair, and electrical equipment manufacturing industry, 4 companies each highlighted the importance of achieving higher profits, improving market position, competitiveness, and meeting market partners' requirements. However, the prominently marked attributes are also noteworthy. Six companies consider competitiveness, meeting market partners' requirements, solving the human resources problem, environmental compliance, and developing alternative operational modes due to the consequences of the COVID-19 pandemic as important. These results are not surprising, as this industry is closely linked to modern manufacturing and production lines. Machinery and equipment manufactured in this industry can be found in various sectors where modern technology has already been introduced, such as energy services, production and manufacturing facilities, and manufacturing and repair workshops for transportation vehicles. According to the Hungarian Central Statistical Office (KSH) report in 2022, electrical equipment manufacturing experienced the highest growth rate (20%) in Hungary, driven by the establishment of plants engaged in the production of electric motors and batteries, as well as gradual production growth.

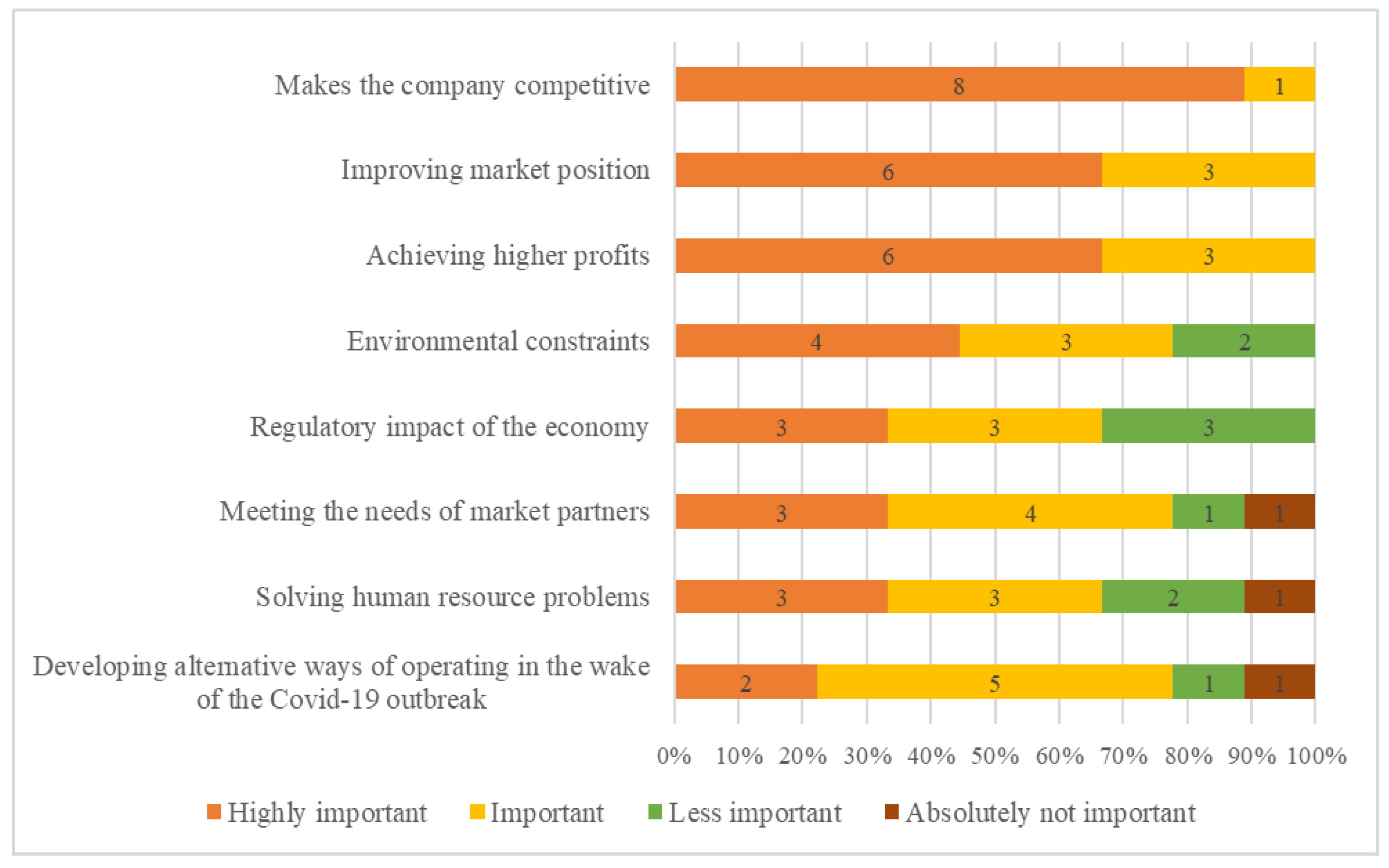

In the case of the Austrian sample, surprisingly, companies operating in the chemical industry identified the most prominently important attributes. This is depicted in

Figure 7.

Among companies operating in the chemical industry, 8 companies highlighted competitiveness, accounting for 14.81% of the companies. Additionally, 6 companies emphasized the improvement of market position and achieving higher profits through the implementation of Industry 4.0-supporting developments. All attributes were marked, although only 2 companies considered developing alternative operational modes due to the consequences of the COVID-19 pandemic as important. The chemical industry, along with the pharmaceutical industry, is one of the most important industrial sectors in Austria, contributing 9.9% to the economy. According to the latest available data from the Annual Report of the Austrian Chemical Industry Federation (FCIO) for the year 2020, the Austrian chemical industry comprises a total of 233 companies with 46,000 employees. Due to the crisis, it experienced a slight decline of -0.8%. As the third-largest industrial sector, the chemical industry is a key sector in Austria. In terms of research and development expenditures, chemical industry companies are also at the forefront: currently, 11% of all investments in research and development in the Austrian economy come from the chemical industry [

38].

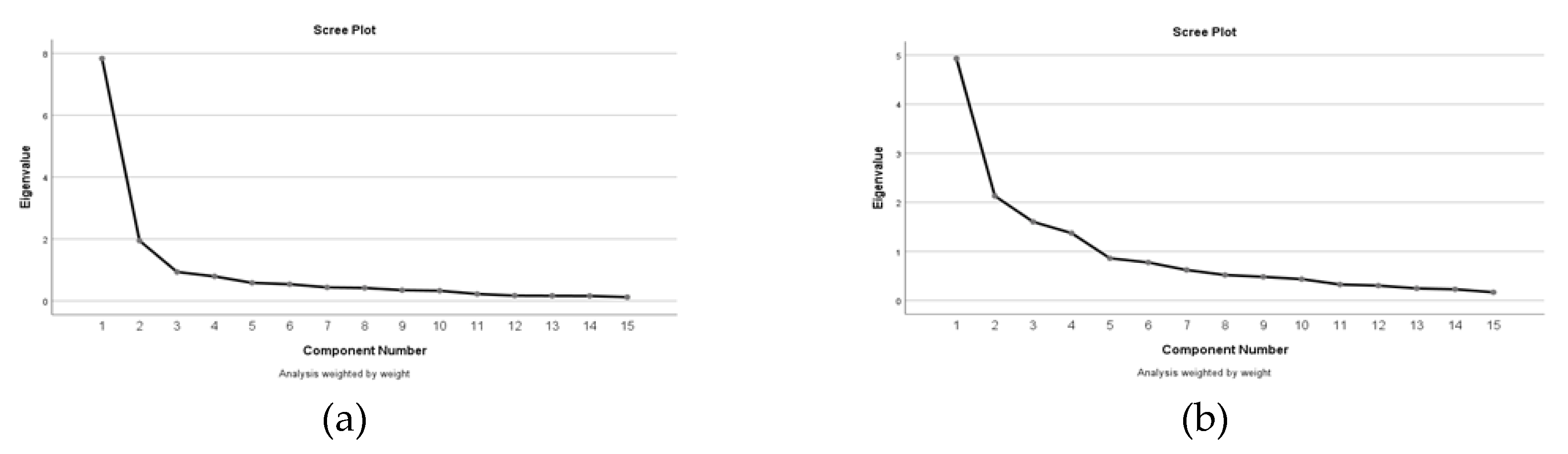

We conducted the analysis of the 3rd research question using principal component analysis. When determining the factors, we initially applied an a priori criterion, meaning that we pre-determined the number of factors. There were two main reasons for this approach. Firstly, since we were working with relatively few variables, we did not want to overly fragment the factors. Secondly, for the sake of easier understanding and visualization, we decided to determine 2 factors in each factor analysis. Additionally, as commonly used by researchers when determining the number of factors, we applied the Kaiser criterion, which examines the eigenvalues of the individual components. If the eigenvalue is lower than 1, it indicates that the added value is less than that of a single variable, thus not contributing significantly to the understanding of relationships. The KMO (Kaiser-Meyer-Olkin) measure is the most important indicator of whether the variables are suitable for factor analysis. Values above 0.9 are considered excellent, while values below 0.5 are considered unacceptable [

39]. The following tables show the KMO and Bartlett's test results.

Table 3.

The satisfaction principal component - KMO and Bartlett test results for the Hungarian subsample.

Table 3.

The satisfaction principal component - KMO and Bartlett test results for the Hungarian subsample.

| Kaiser-Meyer-Olkin Measure of Sampling Adequacy. |

|

,889 |

| Bartlett's Test of Sphericity |

Approx. Chi-Square |

1099,588 |

| |

df |

105 |

| |

Sig. |

,000 |

The table clearly shows that the KMO value is 0.889, which is considered very good. The KMO value represents the average of the Measures of Sampling Adequacy (MSA) presented in the anti-image correlation matrix. The KMO value of 0.889 supported the conduct of the principal component analysis. The following 4th table presents the KMO and Bartlett's test values for the Austrian questionnaire regarding the 3rd research question.

Table 4.

The satisfaction principal component - KMO and Bartlett test results for the Hungarian subsample.

Table 4.

The satisfaction principal component - KMO and Bartlett test results for the Hungarian subsample.

| Kaiser-Meyer-Olkin Measure of Sampling Adequacy. |

|

,738 |

| Bartlett's Test of Sphericity |

Approx. Chi-Square |

313,425 |

| |

df |

105 |

| |

Sig. |

,000 |

The KMO value is 0.738, which is considered adequate, supporting the use of factor analysis for the Austrian sample as well.

The Scree Plot is used for the graphical representation of eigenvalues and provides assistance in determining the number of factor dimensions. According to the elbow rule, it is advisable to maximize the number of factors where the scree plot has a sharp break, indicating a change in the slope of the curve.

The figures, both the 1st Hungarian and the 2nd Austrian Scree Plot, clearly show that the eigenvalue of the 3rd principal component is below 1 and from that point on, the curve flattens out, indicating minimal information content. Therefore, we do not use these components.

The research question addressed whether there is a correlation between the areas where Industry 4.0-supporting development projects were implemented in Hungarian and Austrian companies. First, we present the results for Hungarian companies.

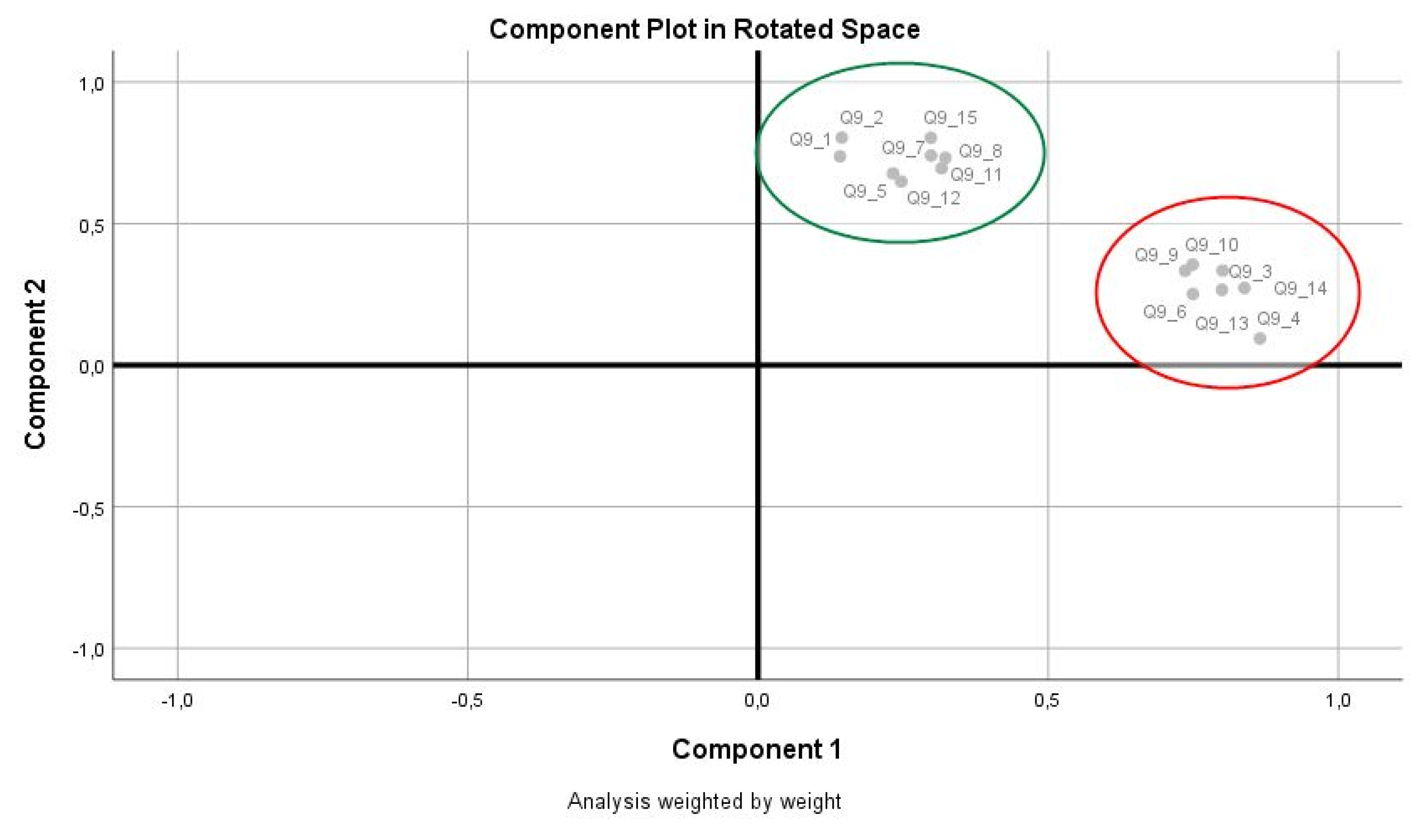

In the above figure (

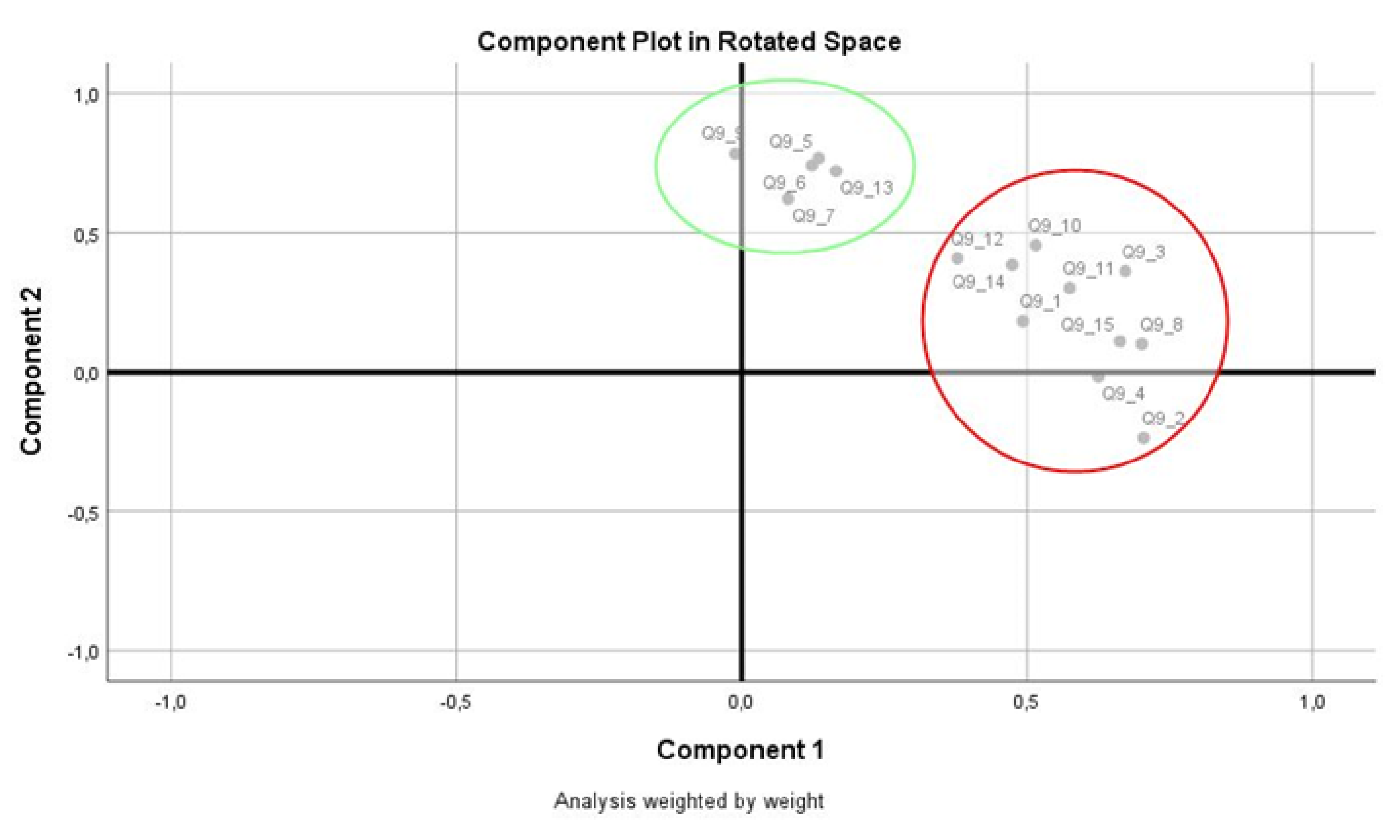

Figure 9), the two distinct components are clearly visible. We also created a diagram based on the Austrian responses (

Figure 10), where the two components are also separated.

The principal component analysis was performed to determine the 2-2 determinant principal components. As a result of the analysis, we combined the 15 variables into 2 principal components. The principal components were given the following labels:

Table 5.

Distribution of Variables - Hungarian Companies.

Table 5.

Distribution of Variables - Hungarian Companies.

| Principal Component 1 -Production and sales development |

|

Principal Component 2 – Development of areas supporting production and sales |

|

| Research and Development |

1 |

Procurement |

3 |

| Production, Manufacturing |

2 |

Logistics |

4 |

| Sales |

5 |

Services (internal support activities) |

6 |

| Information Technology |

7 |

Information Security |

9 |

| Supply Chain Management |

8 |

Quality Control |

10 |

| Sustainability and Environmental Consciousness |

11 |

Customer Relationship Management |

13 |

| Employee Training and Development |

12 |

Finance/Accounting |

14 |

| Production Planning |

15 |

|

|

According to Industry 4.0, the two main areas in the case of Hungarian companies that operate similarly and have undergone developments are the improvement of manufacturing and sales, as well as the enhancement of areas supporting manufacturing and sales. It is evident that where there have been improvements in procurement and logistics, other supporting areas such as quality assurance are also strong.

Table 6.

Distribution of Variables - Austrian companies.

Table 6.

Distribution of Variables - Austrian companies.

| Principal Component 1 – Internal process improvement |

|

Principal Component 2 – Customer-specific area enhancement |

|

| Research and Development |

1 |

Sales |

5 |

| Production, manufacturing |

2 |

Service (internal support activities) |

6 |

| Procurement |

3 |

Information Technology |

7 |

| Logistics |

4 |

Information Security |

9 |

| Supply Chain Management |

8 |

Customer Relationship Management |

13 |

| Quality Control |

10 |

|

|

| Environmental consciousness, sustainability |

11 |

|

|

| Employee training and development |

12 |

|

|

| Finance/Accounting |

14 |

|

|

| Production Planning |

15 |

|

|

According to Industry 4.0, the two main areas in the case of Austrian companies that operate similarly are the improvement of internal processes and the enhancement of customer-specific areas. There is a strong correlation in areas such as sales, service, information technology, information security, and customer relationship management, while research and development, for example, is independent of sales improvement. In Austria, an increasing number of companies are integrating their systems with customers to serve them even faster and more efficiently. The scope of Industry 4.0 technology extends beyond the boundaries of the company.

In summary, the results of the third research question indicate a correlation between different areas in terms of the implementation of Industry 4.0 developments in companies. Both Hungarian and Austrian companies mainly focused on internal developments, but the results show that Austria is more open to external collaborations and the enhancement of customer-specific areas. According to [

40] the primary area of development is production, followed by other areas if there are additional areas where development can extend to.

Presentation of the interview results

On the qualitative side, a total of 4 semi-structured interviews were conducted, with 2 Hungarian and 2 Austrian companies. We aimed to explore the current state of digital preparedness and future plans of Hungarian and Austrian companies, as well as gather recommendations for businesses embarking on the path of digitalization. In Hungary, two interviews were conducted. The first interview was with László Fükő, the plant manager of a tool manufacturing large corporation in Borsod-Abaúj-Zemplén county, where they are already using Industry 4.0 technologies. The second interview was conducted with István Liker, the CEO of Liker Motors Kft, a small and medium-sized enterprise (SME). This provided insights into the digital readiness of SMEs in different market situations and business perspectives. During the Austrian interviews, Michael Vinatzer, the CEO of Transalpina GmbH, presented the digitalization journey of a dynamically growing small company. Additionally, we had a discussion with Dr. Ewald Koppensteiner, the CEO of HPW Metallwerk, about the operations of an Austrian large corporation that belongs to the leading suppliers in the automotive industry.

During the qualitative research, László Fükő said that digitalisation is an inevitable process, but the most important thing is to have a "lean" process in the company. Lean and digitalisation alone are not the same as Industry 4.0, they are just preconditions. The advantage of digitalisation is that information is clean, transparent, from A to B, without distortion. A lot of live labour can be replaced by digitised and automated electronic processes, and efficiency can be increased by leaps and bounds. The downside is that in a manual process, it is easier for people to intervene and make changes when they are needed. Another possible disadvantage is the need for appropriate know-how and the capacity to utilize it. This means having people who can maintain and improve the operating digital systems, and these individuals need to be skilled and well-paid. The expert's recommendation for SMEs is to start with lean processes and streamlining before moving on to digitalization.

Regarding SMEs, István Liker, the CEO of Liker Motors Kft., mentioned that the company celebrated its 40th anniversary last year and specializes in manufacturing and repairing electric motors. They have over 200 employees and produce over 70,000 electric motors annually, all handmade. Therefore, digitalization is of utmost importance to them, as well as continuous development. Not only accounting and payroll, but the entire production, inventory management, recipe handling, and all processes within the company are computerized and programmed. The efficiency gains from digitalization are usually not measured in numbers, but rather in employee performance, which also determines their compensation. István believes that smaller companies that embark on digitalization often burden themselves with additional tasks. For those who want to digitalize, it is crucial to carefully consider which computer software or system to use for digitalization, as introducing a new system is easier than replacing an existing one.

During the interview with Michael Vinatzer, the CEO of Transalpina GmbH in Austria, we learned that their company specializes in the import and wholesale of high-quality semi-finished products and raw materials for the industry. They serve numerous clients in the EU and, more recently, in Asia as well. They recently opened a small manufacturing facility where they use CNC machines to produce specialized products and prototypes for their clients. Due to the size of their company, Industry 4.0 currently doesn't make much sense for them. They have too few machines and a small production volume, making it challenging for the machines to communicate with each other. However, they are increasingly using digital tools for communication with their customers and suppliers, whether it's transmitting test certificates digitally, expediting complaint processing, or managing their inventory electronically for their customers or themselves. This further confirms that the industry must cope with the fact that customers are becoming fully integrated into their processes in the medium and long term [

41]. All their production processes are programmable and programmed. However, the machines do not communicate with each other. They are programmed and work according to the program, but they need to be overwritten if, for example, a tool breaks during machining. The company measures its efficiency with metrics, but they do not have specific key figures that directly measure the efficiency changes resulting from digitalization. They often get the best ideas related to digitalization when visiting their customers and suppliers. Today, very few companies in Europe are not digitalized in some form. In Austria, digitalization is already necessary to meet all legal requirements, including regular tax payments. Every company has electronic programs, and their bookkeeping is more or less electronic.

During the interview with Dr. Ewald Koppensteiner, the CEO of HPW Metallwerk GmbH, he explained that the company has 230 employees in Linz. They specialize in the development and manufacturing of special wires. One area of focus is winding wires, specifically flat copper wires and small aluminum flat wires, electrically insulated, for heavy electrical engineering, mainly for large generators and motors. The third area is the production of high-performance cables for the automotive industry. Everything is automated, from control and regulation to supervision, even the testing of product properties, all in a sequential and automated manner. Testing is performed for every millimeter of the manufactured wire. The development and optimization of this process took years, and it represents the applied concept of Industry 4.0. All data is stored and can be evaluated, allowing the system to provide the customer with detailed information about the product parameters throughout the entire length being produced. This required significant efforts in process engineering but resulted in higher quality products. As a result, they have become market leaders in Europe. The high level of automation was primarily possible because these products need to be manufactured in very large quantities. In Austria, during the Covid times, there were financing opportunities for investments related to the development of digitalization. This was a temporary project, and the Austrian government provided investment support for it. From the interviews and the questionnaire survey, it is evident that among the surveyed companies, there are some where the prerequisites for implementing the developments at a faster pace are not met, while others are progressing rapidly with the development of digitalization. In the case of HPW Metallwerk GmbH, it is clear that if a company is a supplier to the automotive industry, it "buys a ticket" for continuous development, where they have to keep up with the pace dictated by their customers. If they cannot keep up with the pace, they will fall behind in the competition. The interviews also confirmed that decision-making processes regarding a new strategy can be carried out quickly in privately-owned Hungarian companies, as they do not have to wait for approval from a parent company.

4. Discussion

Digitalization is one of the drivers of economic growth and is emerging in an increasing number of industries. Industry 4.0 primarily refers to innovative manufacturing technology, efficiency, and competitiveness applied to the production of modern products, where repetitive tasks are entrusted to robots and artificial intelligence. We first examined the Digital Economy and Society Index (DESI) of Austria and Hungary and concluded that Austria is advanced and making good progress in the digital transition, while Hungary is moderately advanced. We then further investigated whether this relevant difference is also noticeable at the level of Hungarian and Austrian companies. Through our research, we provided insights through quantitative analysis of 101 Hungarian and 54 Austrian companies to assess their Industry 4.0 readiness, the extent to which the technology has been implemented, and conducted qualitative interviews with two Austrian and two Hungarian company leaders. Both the quantitative and qualitative surveys revealed significant differences between the two countries. In the case of surveyed Austrian medium-sized companies, 90.48% have an Industry 4.0 strategy, while in Hungarian companies, only half of the surveyed firms, including both medium-sized and small businesses, have such strategies. Among Hungarian large companies, 75% have an Industry 4.0 strategy, while all surveyed Austrian companies have embarked on the Industry 4.0 technology path. One possible reason for this difference is what [

27] mentioned in their qualitative study, namely that the identified obstacles largely represent challenges for Austrian companies, but not fundamental barriers. None of the identified obstacles were considered relevant enough to completely hinder the implementation of Industry 4.0 technology in a company.

In the second research question, we investigated the expectations of leaders regarding Industry 4.0 technologies. Among Hungarian companies, 48 firms considered the possibility of achieving higher profits to be of outstanding importance in relation to the implementation of Industry 4.0 strategies. However, the resolution of human resource issues, meeting the requirements of market partners, and competitiveness were also considered important factors. For Austrian companies, improving market position was clearly the most prominent aspect. In this research question, we also examined the industries to which the companies prioritizing specific attributes belong. In the case of Hungarian companies, the machinery manufacturing and repair industry had the highest number of attributes marked as of outstanding importance. This may be due to the industry's connection to modern manufacturing, where the products of machinery and mechanical equipment are highly relevant.

In the case of the Austrian sample, companies operating in the chemical industry identified the highest number of attributes marked as of outstanding importance. The chemical industry is the third-largest industrial sector in Austria, and companies in this sector also excel in research and development expenditures.

Finally, the third research question aimed to examine whether there is a correlation between the areas where the implementation of Industry 4.0 supporting developments took place in Hungarian and Austrian companies. According to Industry 4.0, the two main areas for Hungarian companies that operate similarly and have undergone developments are the improvement of manufacturing and sales, as well as the enhancement of areas supporting manufacturing and sales. In the case of Austrian companies, the focus is on the improvement of internal processes and the development of customer-specific areas. For Austrian companies, the scope of Industry 4.0 technology extends beyond the companies themselves, as an increasing number of companies are integrating their systems with customers to enhance service efficiency.

From the interviews, it also became evident that among the interviewed companies, there are those that lack the prerequisites to implement developments at a faster pace, while others are progressing rapidly in digitalization. Business leaders are compelled to respond quickly to changes, and if they fail to do so and reject new business paradigms, they may experience how easily they can be replaced by business partners [

42].

Our research has concluded that there are relevant differences in digital maturity between the two examined countries at both macro and micro levels. However, it is crucial to note that Hungarian leaders also believe in the importance of digital transformation. If they allocate more resources to this endeavor, the industrial transition can be more successful and accelerated within companies. Therefore, it is of utmost importance for the government to support the preparation for digital transition through management education and allocate resources in this field. This way, the statement mentioned above would demonstrate the necessary actions as well.