1. Introduction

For bridge engineering application, the fundamental function of the bridge deck is to directly bear, distribute and transfer the wheel loads. The bridge deck may also react as part of the main girder to bear force acting on the bridge superstructure. Highway bridges normally adopt three types of bridge decks, namely, concrete deck, steel deck and steel-concrete composite deck [

1]. It is well known that under the action of wheel loads, the concrete decks produce small deformation due to its high stiffness of the deck system. However, its heavy dead load and low tensile strength of concrete limit its application in bridge engineering. Steel bridge deck is usually made of orthotropic steel deck (OSD), which has light weight, high bearing capacity and significant overloading capacity. However, this type of deck system can produce large deformation under wheel load due to its low structural stiffness. As a result, fatigue cracking and pavement damage are frequently reported after years of operation. The steel-concrete composite deck includes several types of structures, such as the orthotropic steel-concrete composite deck, the orthotropic steel-steel fiber reinforced concrete composite deck, and the orthotropic steel ultra-high performance concrete (steel-UHPC) composite deck. The first two can only be applicable to medium and small span bridges because of the large thickness overlay and its significantly increased dead loads. They may also be prone to cracks under concentrated wheel loading due to their low tensile strength of concrete. With the development of the UHPC, the orthotropic steel-UHPC composite deck is widely used in various type of bridge structures with different span length, especially in long-span bridges.

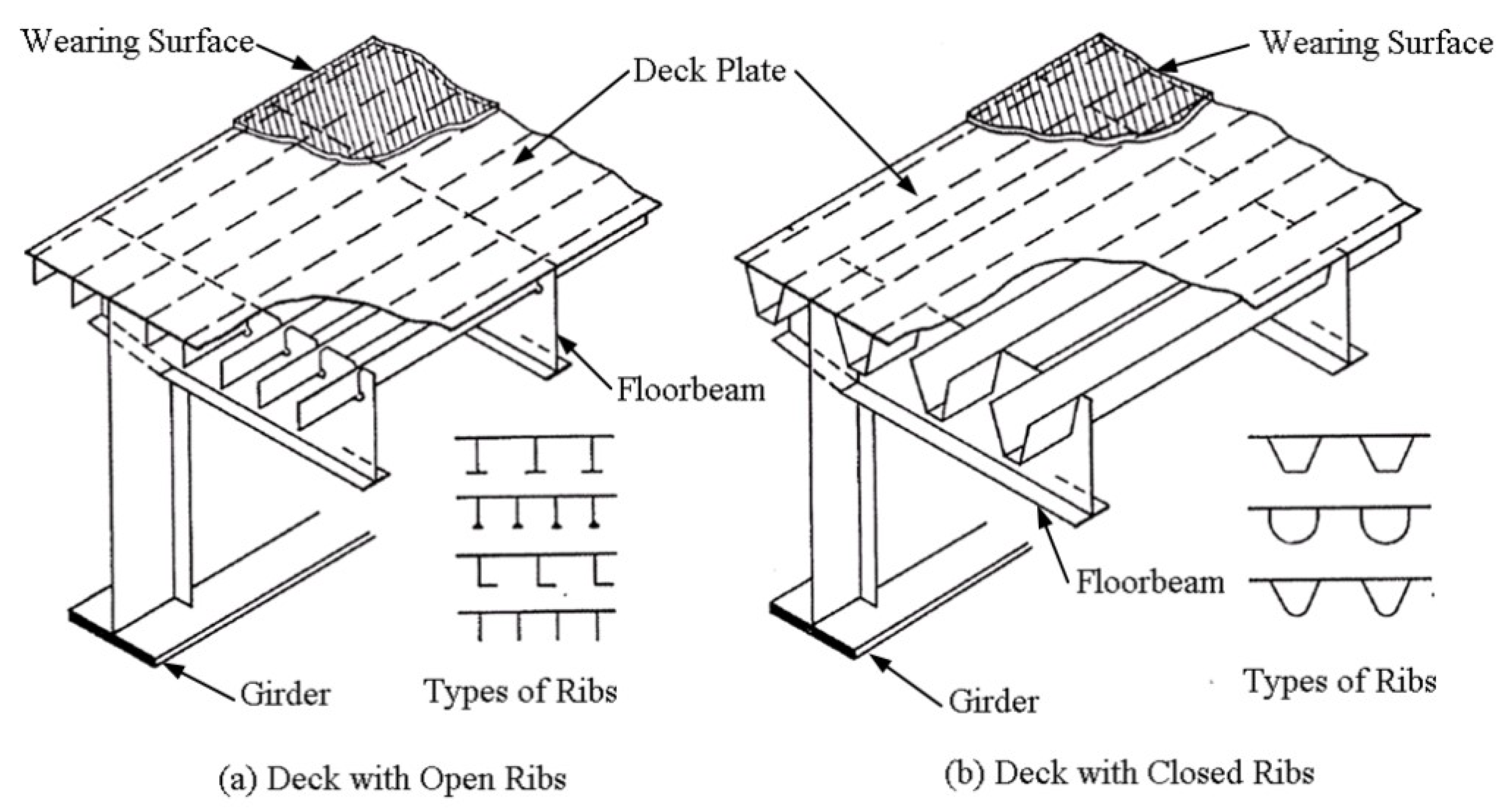

The OSD, consisting of the deck plate respectively stiffened by the floorbeam and the ribs in bridge transverse and longitudinal directions, presents different structural properties in two orthogonal directions. The OSD was first used in Germany as the bridge deck to build the steel bridge. After the Second World War, the growing demand for post-war traffic recovery make OSD widely used in bridge engineering[

2]. Since the Severn bridge in UK adopted the OSD steel box girder for the first time, the OSD has become the most popular deck system for long-span bridges.

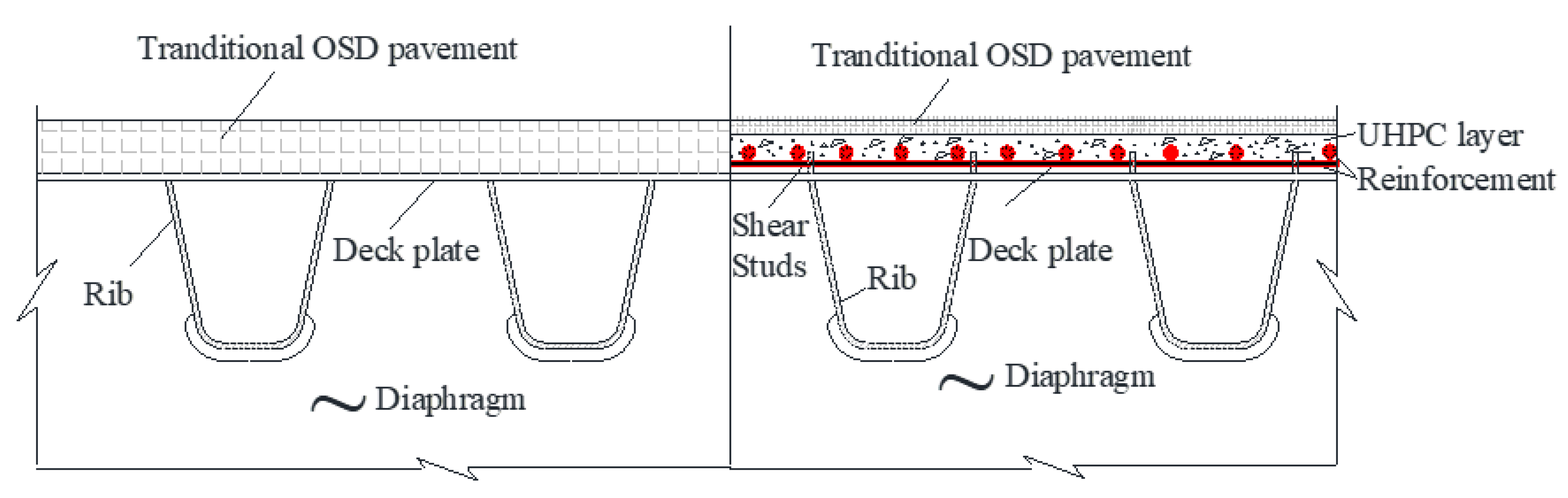

Figure 1 shows two structural forms consisted of open ribs or closed ribs, with the traditional pavement on the deck plate.

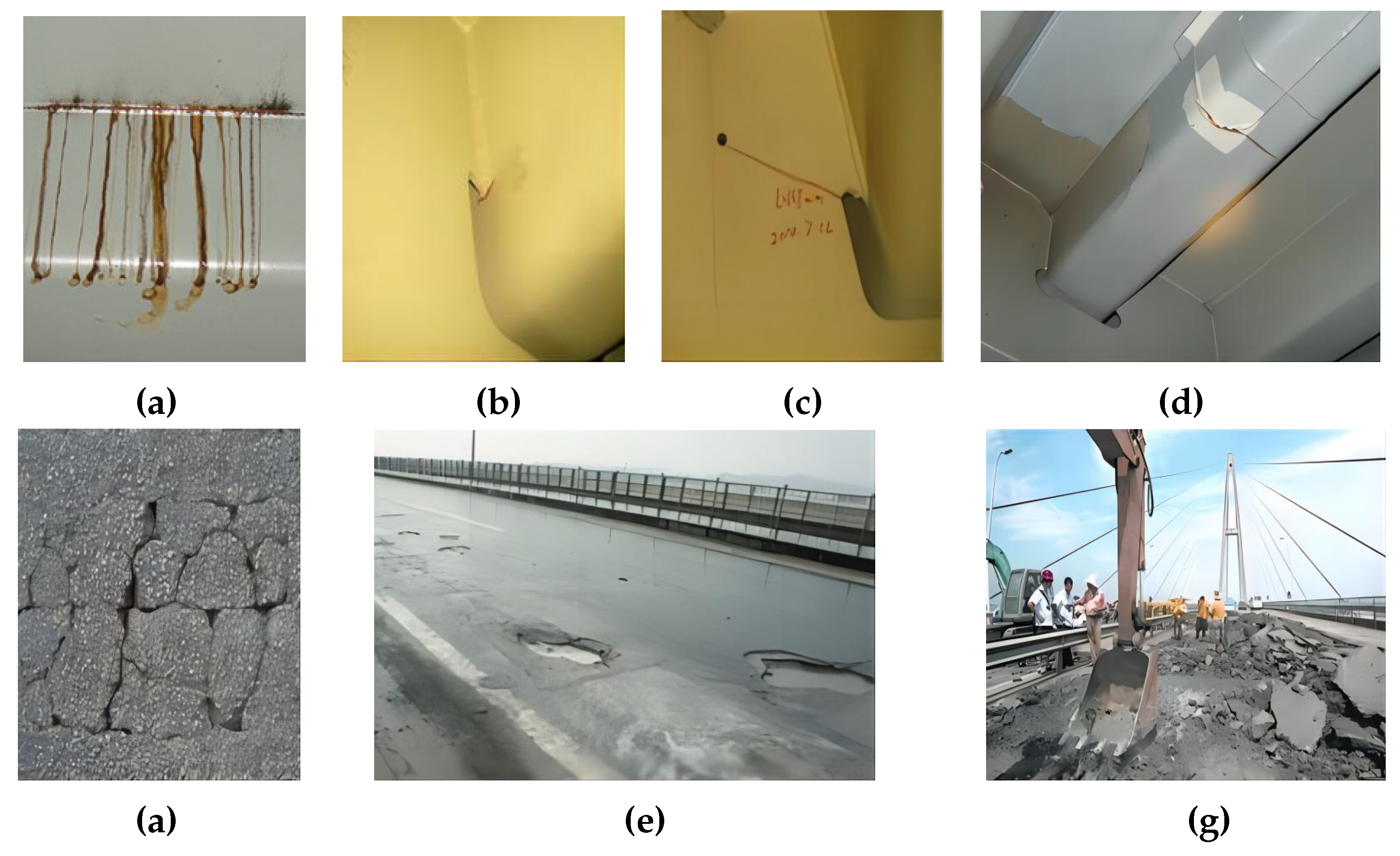

However, the OSD is not a perfect structure since its fatigue cracking is frequently reported on bridges, particularly for those with large traffic volume and serious overloading trucks, as shown in

Figure 2[

3]. The fatigue cracking may also lead to frequent maintenance and replacement of bridge deck pavement, which presents great impact on local traffic. Therefore, avoiding fatigue cracking and pavement damage is one of the major long-term considerations in bridge engineering community.

2. The Orthotropic Steel-UHPC Composite Deck

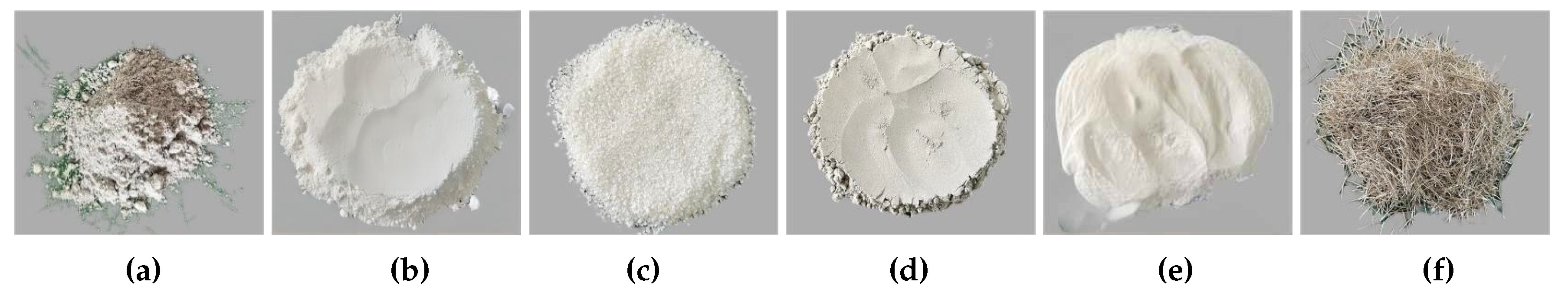

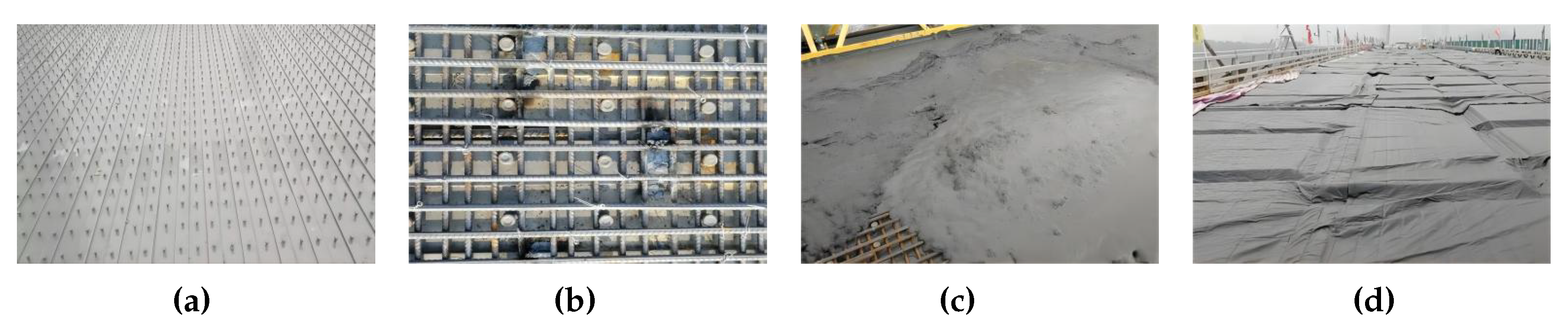

The UHPC is an innovative cement-based composite material, which was first developed by French scholars in 1993. The material consists of cement, silica fume, fine aggregate, fiber, water reducer and other materials, as shown in

Figure 3 and is constructed according to the principle of maximum compactness. The goal is to minimize the internal pores and micro-cracks of the material, so as to obtain excellent mechanical properties and durability, as shown in

Table 1.

Due to the use of fiber inside the UHPC, the tensile and deformation properties of concrete have greatly improved, and the compressive and flexural strength of UHPC can reach 3 times and 10 times that of normal concrete (NC), respectively, with its creep coefficient only about 5% of the NC. It is reported that its durability performance is significantly better than the NC. With the use of UHPC, it is expected to develop a more economical, environmentally friendly, stronger and more durable high-performance structure. Based on the above advantages, UHPC began more and more popular worldwide, and its preparation, production, construction and prefabrication technology have become mature in bridge engineering.

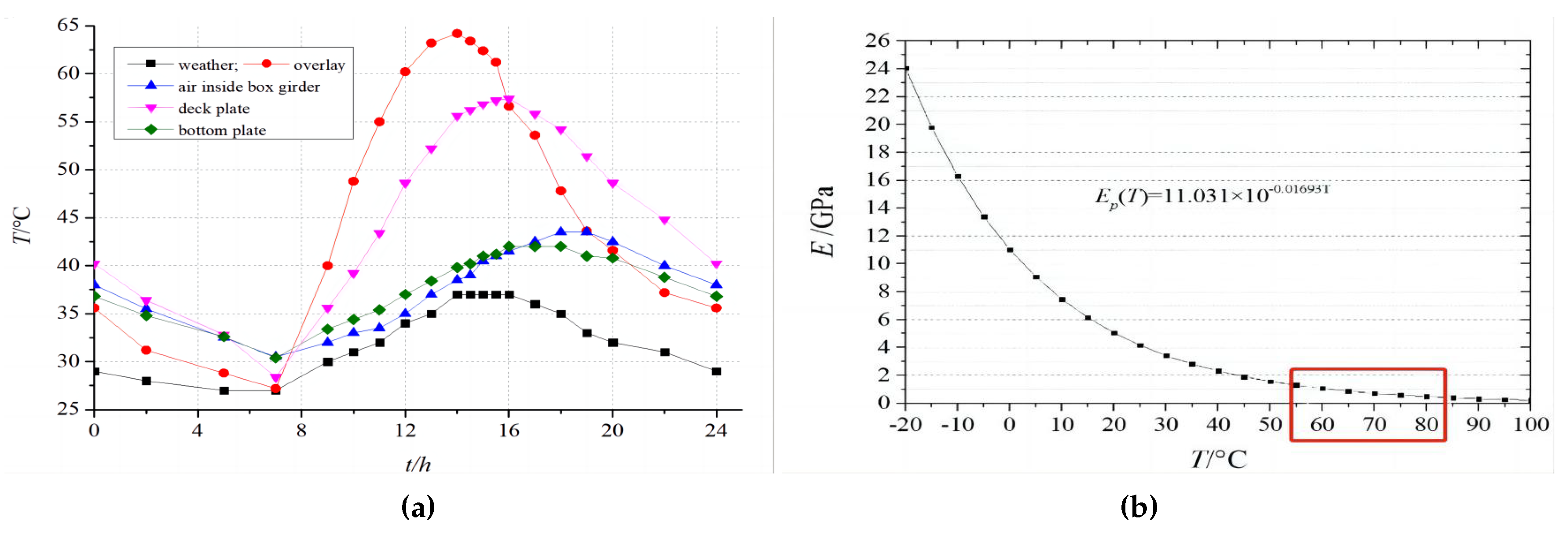

The traditional OSD uses asphalt, resin or composite paving materials, such as stone mastic asphalt (SMA), epoxy asphalt concrete (EAC), epoxy resin asphalt. The elastic modulus of these pavements, formed by organic glue, is significantly lower compared to steel or concrete, and decreases notably with the increase of temperature. When the temperature of the pavement is high or the sunshine is strong, the elastic modulus of the pavement decreases obviously. For example, in China Southern area, like Guangdong Province, the weather is hot and solar radiation is strong. The observed highest temperature of the pavement can reach about 65 °C[

4], and the elastic modulus of the pavement may only be a few hundred MPa, as shown in

Figure 4. Therefore, the contribution of pavement to bridge deck stiffness is very small, thus the stress at OSD details will be significantly increased under wheel loads, which may lead to fatigue cracking.

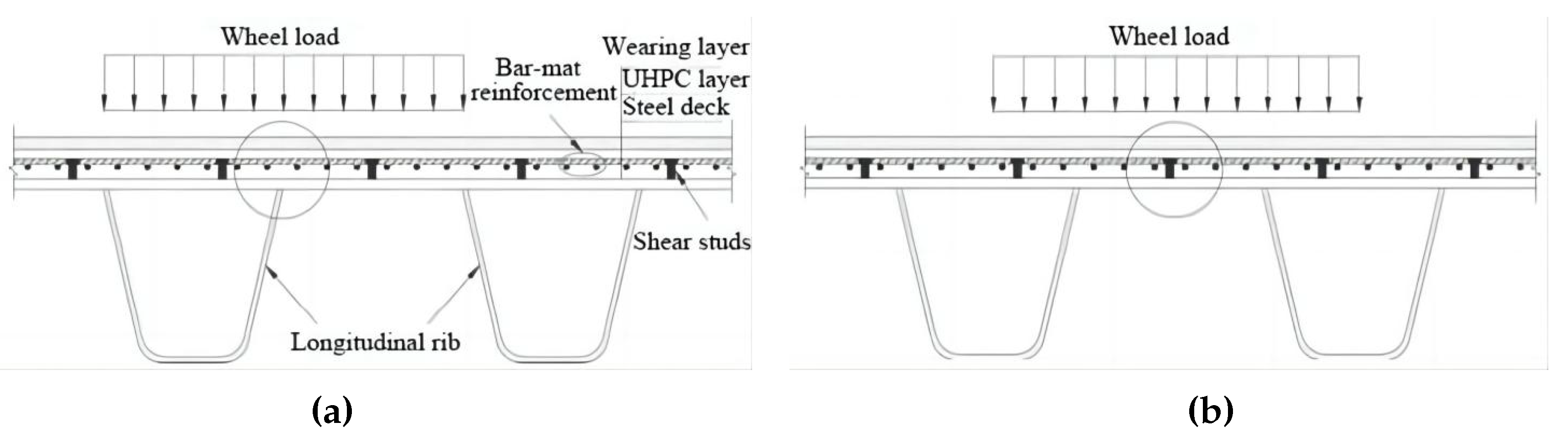

The orthotropic steel-UHPC composite deck consists of the shear connectors welded on the OSD deck plate, and the casted UHPC layer, as shown in

Figure 5. In order to reduce the dead loads, the thickness of UHPC layer is generally 35mm to 60mm. While in order to reduce the tensile stress in the thin UHPC layer, double-layer bidirectional (longitudinal and transverse) steel bars are arranged in the UHPC. Steam curing is usually used to reduce the shrinkage in the process of curing. In addition, in order to improve the driving conditions on the bridge deck, the traditional 20mm-40mm asphalt overlay will be paved on the UHPC.

Figure 6 is the major construction process of orthotropic steel-UHPC composite deck.

Engineering application has recognized many advantages of the orthotropic steel-UHPC composite deck. The UHPC layer is cement-based material, which improves performance of the upper asphalt pavement and can effectively reduce the debonding, cracking, rutting of the asphalt pavement. Meanwhile the steel-UHPC composite structure can improve the bridge deck stiffness, reduce the stress at details of the OSD under wheel load, and hence greatly increase its fatigue life of bridge deck. The UHPC layer presents high tensile strength and high ductility, which can satisfy the demanding of stress and deformation under wheel loads. In addition, the thin UHPC is light-weighted, which is helpful to reduce the seismic inertia force acting on the bridges, and to facilitate larger-span crossing[

5]. It is also found that the UHPC layer can be prefabricated together with the OSD, which is applicable for assembly construction to improve its quality control.

3. Engineering Application of Orthotropic Steel-UHPC Composite Deck

De Jong and Kolstein first proposed the combination of the UHPC and the OSD to repair existing steel bridge cracks[

6]. They first removed the bridge deck pavement of the Dutch Garland Bridge (Caland Bridge) and replaced it with RHPC (reinforced high-performance concrete). Then they carried out FEM and laboratory tests, and found that the local bending stress was reduced by 80% on the deck plate side. Although they proposed the idea to reduce the fatigue stress of OSD, the steel and UHPC are not treated as a composite structure since the UHPC layer and steel panels worked together by a thin bonding layer between them, in which the composite action is weak and only its load distribution function of the UHPC layer could be considered

Figure 7.

Deck replacement of Galand Bridge using glued UHPC layer.

Figure 7.

Deck replacement of Galand Bridge using glued UHPC layer.

In the next several years, the composite deck formed by steel and UHPC had attracted many researchers and engineers. In 2007, the world’s first steel-UHPC composite bridge, the Gärtnerplatz Bridge, was built over the Fulda River in Germany[

7]. In 2011, the overlay of a traditional OSD bridge built in 1970 was replaced in France by using UHPC material. Similar replacement on the Illzach Bridge in France [

8]was carried out using precasted UHPC plates and wet connection joints.

The application of UHPC in bridge engineering in Asia was relatively late, but it developed rapidly during the past decade. Currently, more than one hundred UHPC bridges have been built in Asia, some of which are steel-UHPC composite structures. In China, Shao Xudong[

9]first practiced the deck replacement of the Zhaoqing Mafang Bridge, by using the UHPC layer, as shown in

Figure 8. The thickness of cast-in-place UHPC layer was 50 mm and the thickness of surface asphalt pavement was 30 mm. The UHPC layer and the steel panel are connected by the way of "stud + epoxy resin adhesive". Compared with the traditional epoxy pavement on other spans of the bridge, over 12 years operation demonstrated that the composite deck system has obvious advantages.

In the following years, the steel-UHPC composite deck, in which the steel and UHPC layers work together through shear connections has been comprehensively studied, including its bending and shear behaviors and its fatigue performance. In the meantime, the steel-UHPC composite deck has been widely used as a new deck system in construction of steel bridges.

Table 2 shows newly built bridges using steel-UHPC composite deck in China, and

Table 4 shows deck replacement using the steel-UHPC composite structure. It is clear that the orthotropic steel-UHPC composite deck is increasingly popular and is used by different type of bridge structures, i.e., not limited for long-span bridges.

Figure 9 shows the orthotropic steel-UHPC composite decks under construction for four bridges.

4. Research History and Up-to-Date Progress

In order to meet the engineering requirement using the steel-UHPC composite deck, researches have been carried out through laboratory tests, field tests and FEM analysis, as to investigate its bending, shear, slip resistance, as well as the fatigue performance of OSD and shear connectors[

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23].

4.1. Flexural Behaviors

4.1.1. Load against Deflection

The flexure behaviors of the steel-UHPC composite deck can be evaluated in many aspects, such as strain and stress, displacement, crack width, nominal cracking stress, failure mode and ultimate load.

Laboratory test and FEM analysis found that the deck has higher tensile strength in bridge longitudinal direction than the transverse direction. The steel-UHPC composite deck directly bears the local wheel load and then transfers the load in the longitudinal and transverse direction. When the wheel loads ride the U rib laterally, as shown in

Figure 10, the composite plate above the U-rib web will bear negative bending moment, and the produced moment is highly dependent on the location of wheel center in transverse direction[

24].

For bending tests in bridge transverse direction, Shao[

12] carried out stripe model tests for steel-UHPC composite deck. He found that under positive moment, the load-displacement curve displayed four stages, i.e., the elastic, elasoplastic, crack propagating and yielding stage. For the same fiber type and its volume percentage, the bending capacity increased with the percentage of reinforcement in the first stage, and the load-displacement curve was a straight line without cracking on the UHPC surface. While in the second stage, the maximum bearing capacity also increased with the increase of reinforcement and deviation of nonlinear displacement appeared due to cracks initiation, indicating a decrease of structural stiffness. Crack propagation further decreased the structural stiffness, and significantly nonlinear feature can be observed when multiple cracks appeared. In the yielding stage, the displacement in the span center increased rapidly, with rapidly increased crack width at almost the same number of cracks. It is highlighted that the thickness of UHPC layer and reinforcement percentage have the greatest influence on the structural stiffness in the crack propagation stage. Zheng[

13] pointed out that under the concentrated wheel loads, the composite deck presented significantly local effects on stress, i.e., high stress only produced at the area directly underneath the wheel load, and local deck plate deformation produced notable higher stress than that produced by the overall panel deformation in bridge transverse direction.

Bending tests in bridge longitudinal direction also showed the three similar stages as that of in bridge transverse direction. In the elastic stage of steel-UHPC composite girder, cracks were not observed, and the curve of load against displacement was linear. At the crack propagation stage, although crack appeared on the surface, structural stiffness did not show significant decrease compared to the elastic stage. The reason is that the girder has a high structural stiffness and the UHPC layer only contributes small percentage to it. Even after the crack appeared, the UHPC layer still works well due to small width of the crack and the bridging effect of steel fibers in matrix. Therefore, the appeared cracks did not lower the structural stiffness of the steel-UHPC composite girder. Meanwhile, the load-midspan displacement and bearing capacity showed minor difference against different structural parameters. In the yielding stage, the longitudinal ribs yielded, leading to rapid increase of displacement and lose of bearing capacity[

25].

4.1.2. Stress Behavior

Dieng[

26] investigated the effects of deck replacement using the steel-UHPC composite structure. They found that the local deflection decreased by 45%and the strain at the deck plate side and the rib wall side of the RD detail decreased by 60% and 30% -50%, respectively. Kong[

21]estimated the tensile and compressive stress in the UHPC layer, by using stress superposition method based on refined full-bridge FEM model and a hybrid full-bridge model, respectively. They found that the longitudinal compressive stress was much lower than the UHPC compressive strength even under the most critical loading condition. Li[

27]compared the mechanics of deck with UHPC layer to that with an epoxy overlay. The decrease on maximum tensile stress, shear strain and deflection could reach 54.8%,78.9% and 39.1%, respectively.

In the transverse bending test, the strain along the section height is measured on the steel-UHPC composite deck. When the load level is low, the cross-section strain is linearly distributed. With the increase of load, non-linearity gradually appears. For reinforced steel-UHPC composite plate, nonlinear strain distribution along section height appeared at about 45% of the ultimate load, but it can be approximately considered that the strain distribution along the section height satisfied the plane section assumption. In the longitudinal bending test, the strain distribution along the section height is also linear when the load level is low. With the increase of load, non-linearity gradually appears. When the load is less than 76.7%-86% of the ultimate load, the plane section assumption still holds. Since the overall stiffness of the composite deck is very large, even after the crack appears, the crack growth rate is low, hence structural stiffness does not show obvious decrease. Therefore, for steel-UHPC composite beams, the strain distribution along the section height is basically consistent with the plane section assumption.

4.1.3. Effects of Reinforcement Percentage

Based on transverse bending tests, Shao[

28]found that the reinforcement percentage and the effective section height present notable effects on the flexural tensile strength of the composite deck. If the reinforcement ratio is doubled or tripled, the flexural tensile strength was increased by 15% and 40% respectively. Similarly, if the effective section height is increased by 20%, and the flexural tensile strength was increased by 30% to 50% under different reinforcement percentage. It is also found that the stress of the steel bar in the UHPC layer increased slowly, and the load-stress curve was approximately a straight line in the elastic stage. With the increase of load, the steel bar stress increased with the crack in UHPC. While in the ultimate bearing capacity stage, the steel bar stress reached 400MPa. In longitudinal bending test of the steel-UHPC composite deck, the stress of steel bar increased slowly in the elastic stage, and the load-stress curve was approximately linear. Further increase of load leaded to cracks in UHPC layer, and the stress of steel bar increased gradually. At the stage of ultimate bearing capacity, the stress of steel bar did not exceed 200MPa.

In order to effectively remove damaged UHPC area, such as damage at UHPC layer or at joint, Shao[

29] presented a way to pull the steel bar inside the UHPC layer to remove the damage area. In order to prove the feasibility of the demolition method, the full-scale test model was used to remove the UHPC layer in the designated area. The results shown that the demolition method could quickly remove the UHPC damaged area, and the repairing method could effectively improve the tensile strength of the joint by welding the stressed steel bar to a steel panel. Based on a cable-stayed bridge, Wu[

30]found that the reinforcement ratio, steel bar diameter, linear fiber length and its diameter had little effect on the initial crack stress of UHPC, but increasing the reinforcement ratio could enhance the bending bearing capacity of UHPC beam, while the end hook fiber could also significantly improve the initial crack stress UHPC beam. Full-scale bending test of a UHPC composite plate was carried by Fang[

31]. The results shown that when the reinforcement ratio of UHPC layer increases, the nominal cracking moment also increases. The existence of perforated steel bar and the decrease of the spacing between perforated plate and stud could effectively improve the post-cracking stiffness of the composite plate, while the hole diameter and spacing on the perforated steel plate had little influence on the mechanical properties of the composite plate. Based on the full-scale model test, the steel-UHPC composite plate using perforated plates as shear keys was investigated. The experimental results shown that under the concentrated load, the typical bending failure occurred in the steel-UHPC composite plate, while the punching failure occurred in the steel-C60 composite plate. The bearing capacity, stiffness and ductility of the steel-UHPC composite plate are much better than those of the steel-C60 composite plate with the same thickness; and the specimens with more perforated plate shear keys shown the improved mechanical performance[

32].

4.1.4. Crack Features

Shao[

15]carried out model tests of steel-UHPC composite deck considering reinforcement percentage, stud spacing, thickness of the protective layer and the UHPC layer. There were only few cracks s in unreinforced steel-UHPC composite members in the crack propagating stage, and those cracks developed rapidly after cracking with the increase of loading. While in highly reinforced steel-UHPC composite members, a few cracks appeared and was densely distributed with small crack width. Before the crack width reached 0.15mm, the load-maximum crack width curve is almost a straight line, and the crack extended rapidly after the steel bar yielded. Even after the crack width reached 0.2mm, the number of cracks tended to remain unchanged. In addition, for the cracking stress and average crack spacing, the reinforcement percentage and the protective layer thickness shown great influence, while the thickness of UHPC layer indicated minor effects. Luo[

33] pointed out that the reinforcement percentage and protective layer thickness were the two key factors affecting the average crack spacing and cracking stress of the UHPC, and increasing reinforcement percent and reducing the protective layer thickness were effective ways to reduce crack spacing. The most significant factor affecting the ultimate load was the reinforcement percentage, followed by the thickness of UHPC layer, the thickness of protective layer and the spacing of studs. In order to solve the cracking problem at local joint, Guo[

34] tested two structural measures on the steel-UHPC composite deck. The one was to use small stud spacing in some area, and the other was to weld part of longitudinal steel bars to the spliced steel plate. The results shown that the two measures reduced thee microcrack width and delayed the cracking on the top surface of UHPC layer at joint area, especially when the second measure or two combined measures were employed. Mo[

35]investigated the crack behavior of steel-UHPC composite deck under construction. It was found that the maximum longitudinal and transverse strain of the UHPC layer produced by passing trucks was 144

and 60

, respectively, with the most critical one occurred at bridge hangers. When the strain amplitude was less than 160

, it presented no obvious effects on the crack resistance of the UHPC layer. s

4.2. Performance Shear Connectors

Compared with the shear connectors in the steel-concrete composite beam, the studs in the steel-UHPC composite deck are obviously shorter, so suck type of short connection may present different shear performance. In order to address this problem, many scholars have studied the influence of stud diameter, height and concrete strength on shear capacity of the composite deck.

In order to reduce the amount of UHPC, it is necessary to use a thin UHPC layer, so short studs can only be used. Shao[

36]studied the shear resistance of short studs in the composite deck system, and pointed out that the bearing capacity of short studs was linearly proportional to the second power of stud diameter, while the stud length shown minor effects on the bearing capacity. Wang[

37]carried out an experimental study on the bearing capacity of large studs embedded in UHPC. The results shown that increasing diameter of the stud could significantly improve its shear strength, shear stiffness and ductility, but the aspect ratio of the stud and the thickness of UHPC layer had no significant effects. Based on model tests and FEM analysis, Li[

38]analyzed the shear resistance of short studs in UHPC. The results indicated that the shear capacity of short studs was mainly affected by their diameter and weld shape, and shear capacity increased with the increase of stud diameter. While loading mode, stud height and UHPC strength shown little influence. The shear stiffness was mainly affected by the stud diameter and treatment on interface between the steel deck plate and the UHPC layer, and good interface bonding helped improve the shear stiffness. Wu[

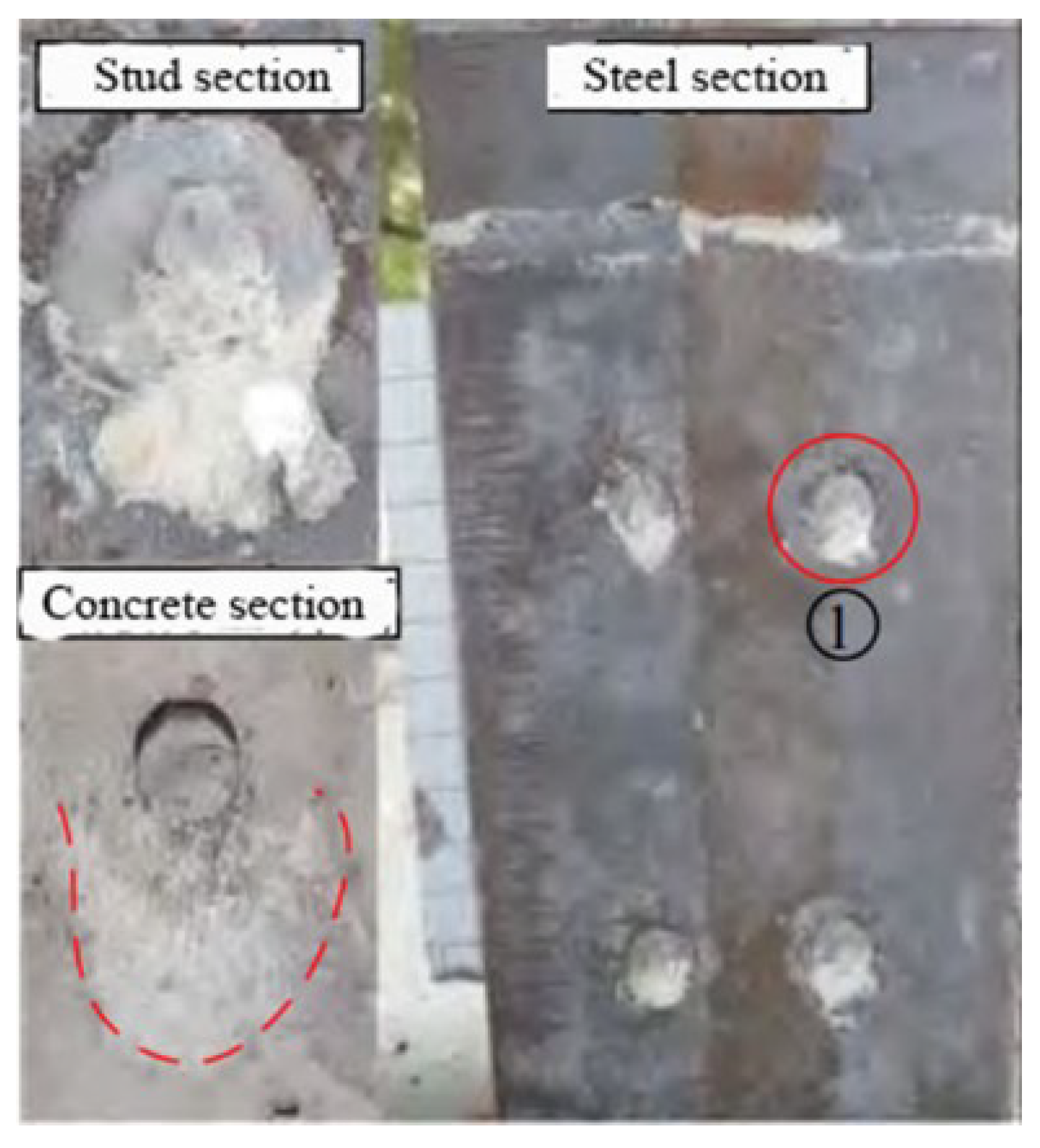

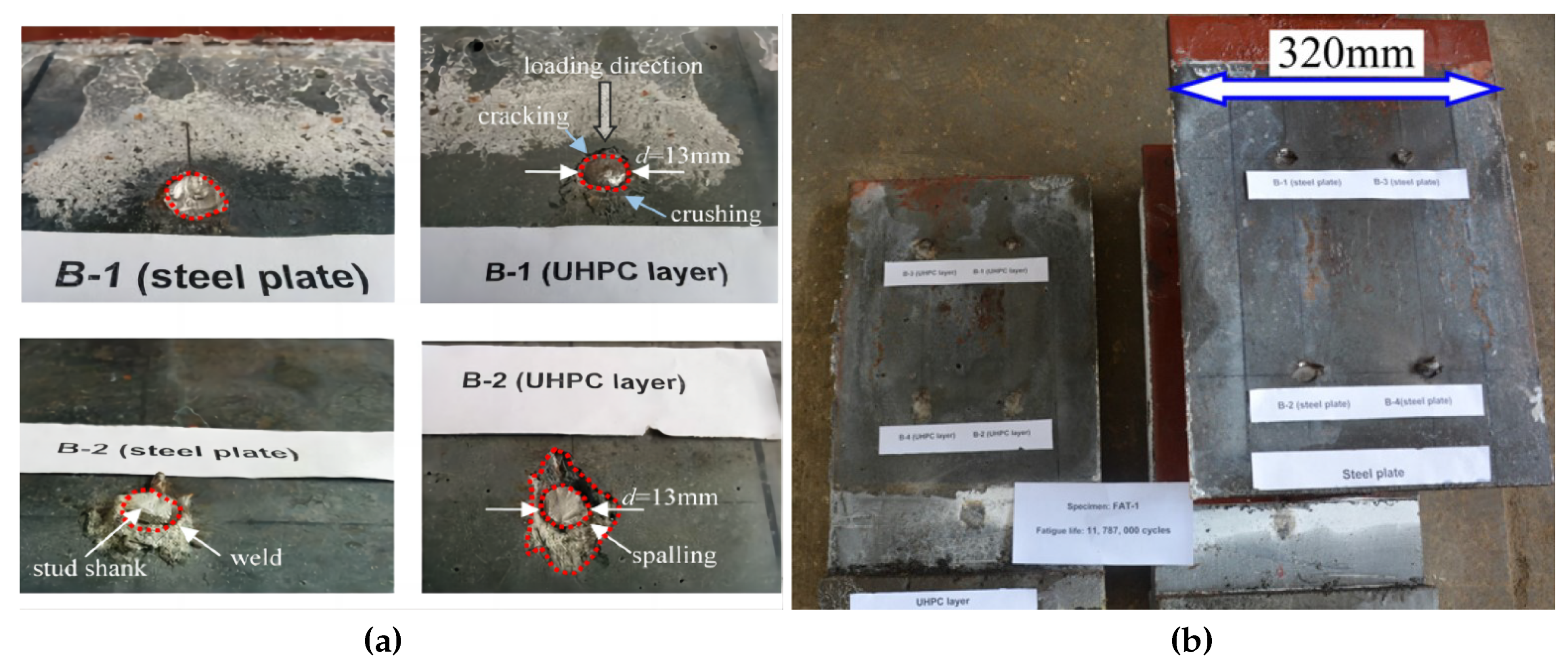

39]compared the mechanical properties and failure mode of studs in UHPC and normal concrete, and pointed out that the main failure mode of stud was shear fracture near the root of stud, as shown in

Figure 11. The shear stress reached a peak at the root and decreased rapidly along the direction of the stud cap. Compared with the traditional concrete specimen, the shear capacity and shear stiffness of UHPC specimen were higher, but the ductility was lower. Deng[

40]analyzed the stud shear strength in the steel-UHPC composite deck by FEM. The results shown that the transverse shear strength was twice as high as the longitudinal one. In addition, the vehicle wheel load had a great influence on the transverse shear strength, and the maximum transverse shear stress under biaxial load is about 1.33 times than that of uniaxial load.

Gan[

16]studied the static performance of a new type of shear connector combined with the reinforcement mesh. They suggested that the shear capacity of the welded shear connector increased with the weld length, and the interface bonding had no significant effects on the shear capacity. However, bonding could improve the shear stiffness in the elastic stage. Compared with the conventional shear stud, welded shear connector in UHPC shown higher shear capacity and shear stiffness. Zhang[

41]suggested a short steel bar connector, and evaluated its shear performance through push-out tests. There were two failure modes in the test. One indicated shear damage in weld and the other indicated UHPC local failure (pull-out of short steel bar). The bearing capacity of short steel bar connector increased with the weld length, and its shear capacity was higher than that of shear stud but was slightly lower than that of steel mesh welded connection.

4.3. Slip between UHPC and Steel Deck Plate

There are three kinds of slip form between the UHPC layer and the steel deck plate, driven by deck bending, shear deformation and fatigue failure of shear studs.

Laboratory model test carried out by Dieng[

26]indicated that the connection between steel plate and UHPC layer directly affected the overall performance of the steel-UHPC composite structure. When the connection between the two parts was strong, the tensile stress at the bottom of the UHPC layer significantly decreased, and the two parts were bending as a whole, hence the anti-slip ability was strong. While when the connection was weak, the tensile stress at bottom of the UHPC layer increased, and the local bending of the UHPC layer was obvious, therefore weak slip presented at the interface. Sun[

42]studied five common interfaces in unstream-curing steel-UHPC composite structures. Test results indicated that the UHPC provided low and unreliable adhesion to the steel plate, while the embossed steel-plate interface and the epoxy-based adhesive interface presented higher adhesion strength but brittle failure under tensile or shear loads without constraint. The welded pre-bent steel rebar and headed stud connection shown higher adhesion and ductility after initial interface failure, but an increase on shear capacity was observed after imposing constraint. He[

43]evaluated performance of polyurethane/epoxy resin-modified asphalt as the adhesive layer material for steel-UHPC composite deck. The results indicated that this material had good mechanical performance and could provide potential benefit if used as the adhesive layer material.

The shear stud used in steel-UHPC composite deck is shorter than the long shear studs in traditional steel-concrete composite structures, hence it does not meet the "plastic connector" type connector defined in the European code. Therefore, the elastic method should be considered when designing the short studs for the steel-UHPC composite deck.

The stiffness of shear keys is an important index for evaluating the shear performance of steel-UHPC composite structures. There are many ways to determine their shear stiffness, but the secant method is the simplest and most commonly used method. In this method, the secant slope of the line, connecting the origin and another point on the load-slip curve, is considered as the shear stiffness of the shear connector. Because calculation is carried out according to the load-slip curve of the test, and there is no need to determine the shear bearing capacity, so the secant method is not affected by the type of shear connector and the strength of concrete. For the determination of the point location of load-slip curve, both Johnson[

44] and the Japan Steel structure Association[

45] presented the corresponding suggestions. Cao[

46]carried out the push-out test for steel-UHPC composite deck using the shear studs, and obtained the shear stiffness with different secant vertices on the load-slip curve, and the shear stiffness of the stud was among 266kN/mm -396kN/mm. Compared with the shear stiffness of studs in steel-concrete composite structure, the increased shear stiffness of studs in steel-UHPC composite deck was evident.

Li[

47] also studied the shear slip and stiffness of studs in steel-UHPC composite deck, and pointed out that the shear-slip curve of studs indicated three stages, i.e., elasticity, elastoplasticity and softening, with the observed maximum slip of less than 3.5 mm. When the load was small, the load-slip curve is linear. With the continuous increase of load, the studs gradually yielded and the interface slip appeared and accelerated. When the load reached ultimate load, the load-slip curve tended to be horizontal and finally failure occurred. It was found that the stiffness corresponding to the slip of 0.1mm should be taken as the elastic shear stiffness. Tang[

48]studied the shear performance of combined studs and PBL shear connector in steel-UHPC composite deck and provided an empirical equation describing the load-slip behavior of the combined shear connector, which could provide the shear capacity and suggested value of shear stiffness.

4.4. Fatigue Improvement on Orthotropic Steel-UHPC Composite Deck

4.4.1. Fatigue Improvement on Orthotropic Steel-UHPC Composite Deck

Li[

49]carried out model tests and FEM analysis to investigate the effect of steel-UHPC composite deck on fatigue improvement on bridge deck. The results shown the maximum strain and vertical displacement decreased by 46.8%-90.9% at some critical locations, and the tensile strength of the UHPC could meet the maximum tensile stress in the deck produced by the wheel loads. Based on the parallel application of the asphalt pavement and the steel-UHPC composite deck on the Fochen Bridge, Zhang [

50] and Li[

51] performed truck loading test on the OSD to measure the stress under different loading scenarios. They found that measured stress in the two deck systems shared the same trends, however, the average stress decreased by about 20% and the maximum stress reduction of 46.2%, and the measured hot-spot stress at the cutout detail provided a fatigue life higher than the bridge design life.

In order to verify the effectiveness of the UHPC overlay on improving the fatigue life of the OSD, Yuan[

52]tested a full-scale OSD panel before and after apply the UHPC layer on the OSD. The study indicated that even cracks developed at the RD detail after cyclic loading on the OSD without overlay, no crack was observed on the steel-UHPC composite deck with repaired cracks after the same number of cyclic loads.

Wang [

53] proposed a rehabilitation method using the steel-UHPC deck with transverse steel strips on the deck plate of OSD, and they did not repair the cracked details. By this repairing technology, the fatigue stress at details of the OSD decreased greatly, reaching 78.8% - 86.4% at the RD detail. Peng’[

23]s study also shown the same benefit on the OSD after using the steel-UHPC composite deck.

Liu[

54] and Ding[

55]fabricated a full-scale strip model per the OSD design in Humen Bridge, and applied a UHPC layer on the steel plate connected by shear studs. The fatigue tests shown that after 200 million cyclic loading with constant-amplitude loading stress ranges of 9.6MPa and 14.4MPa, no cracks were found on the UHPC layer, and model stiffness did not drop. After the fatigue tests, the remaining flexural tensile strength of the UHPC layer were 42.8MPa and 25.6MPa, respectively, which demonstrated good fatigue performance of steel-UHPC composite deck.

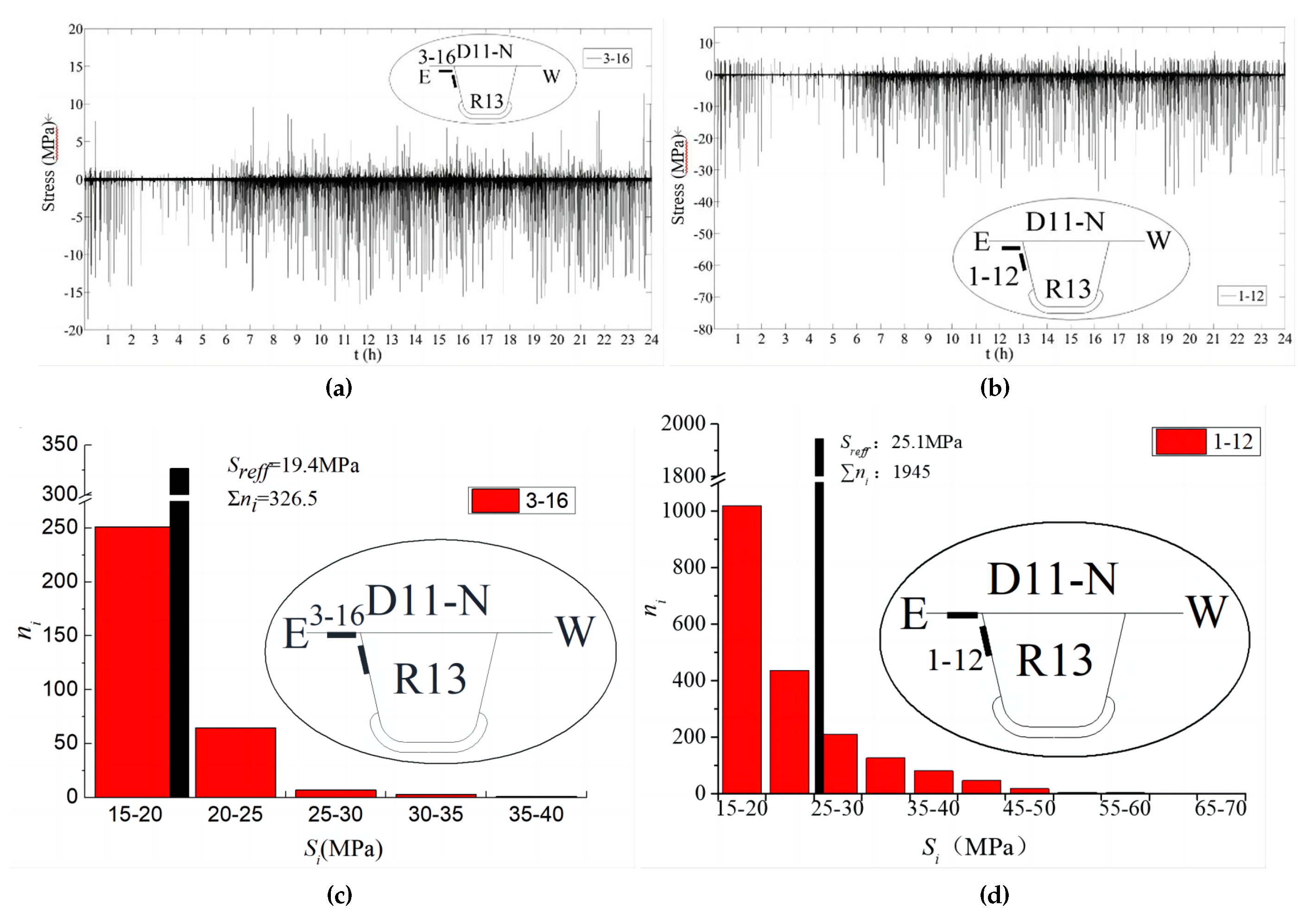

Based on the field monitoring and FEM analysis on the Fochen Bridge, Zhu[

56,

57,

58]presented measurement on stress behavior and fatigue life estimation at details of the OSD with the UHPC composite deck. They found that due to significant contribution of UHPC-deck plate composite system to deck stiffness, welded details connected to the deck plate experienced low stress ranges under direct wheel loads (

Figure 12). However, stress local effects under concentrated wheel loads still existed. The research concluded that all fatigue-prone details on the Fochen Bridge presented sufficient high resistance against fatigue cracking under the current traffic flows per AASHTO fatigue provisions. They also suggested guidance for the design of OSD with the steel-UHPC composite deck.

Tian[

59]also investigated the steel-UHPC composite deck through FEM analysis and a strip model test for the Junshan Yangtze River Bridge. They concluded that all of the hot-spot stress at fatigue details were lower the constant-amplitude fatigue limit. Deng[

60] and Zhu[

61] compared the fatigue reliability of the steel-UHPC composite deck to that of the OSD with asphalt overlay. The results shown that the steel-UHPC composite deck could effectively increase the fatigue reliability of fatigue-prone details and extended the fatigue life, and increase of UHPC layer thickness could increase the fatigue life of composite deck system.

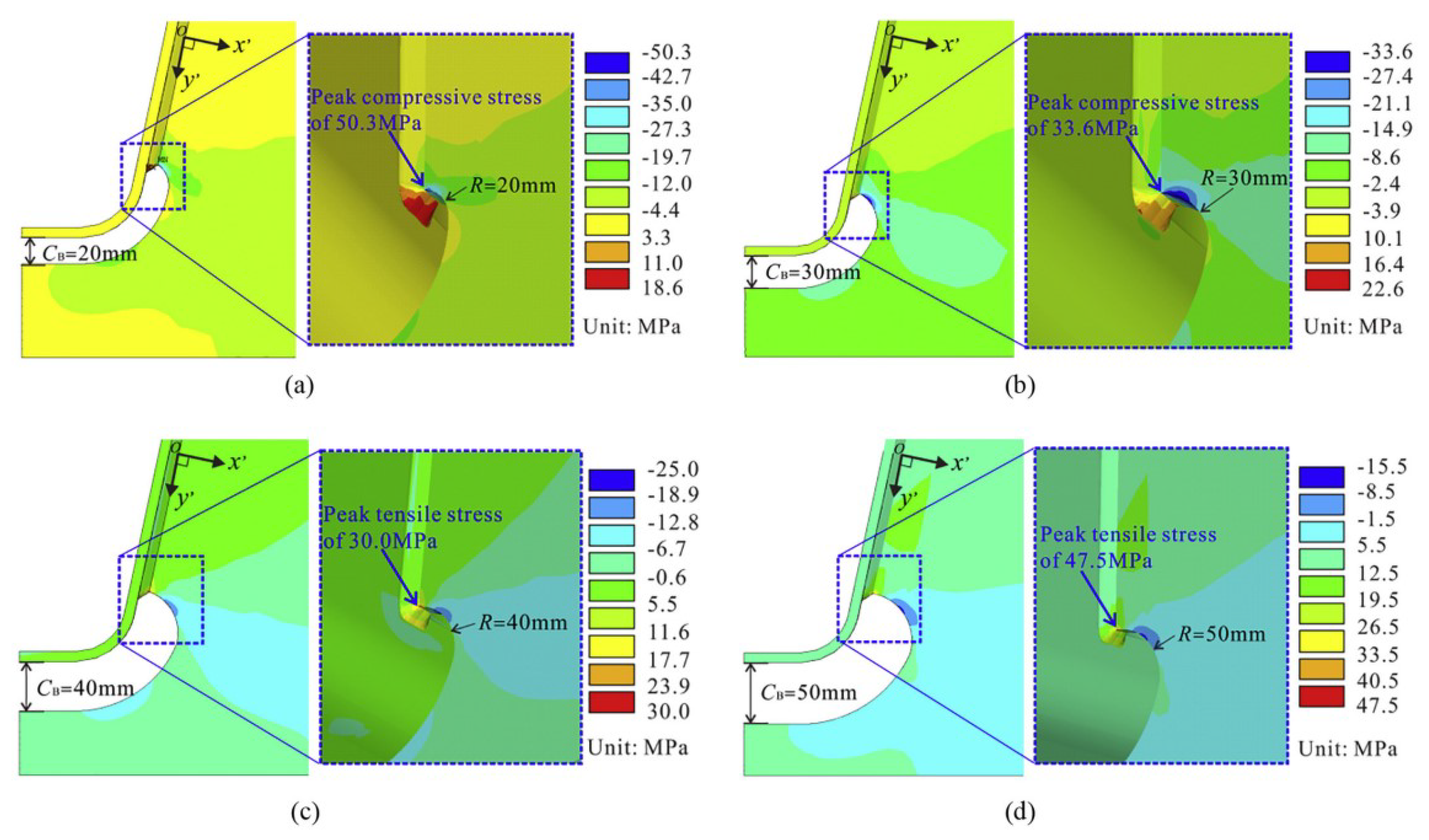

Zhu[

62,

63] built a steel-box girder model with the OSD stiffened by the UHPC, and the hot-spot stress was employed to obtain refined results from submodels. They compared the results with field measurement. It was found that a 45 mm thick UHPC layer on the OSB deck could reduce the stress range at deck plate side of the RD detail by up to 70.9%, and increasing on the cutout clearance could effectively decrease the stress range at floorbeam side of RF joint. They recommended a combined use of 50mm thick UHPC layer with 40mm cutout clearance to the steel-UHPC composite deck.

Chen[

64]carried out fatigue tests on two multi-span full scale models with the steel-UHPC composite deck. They observed longitudinal crack first initiated at weld toe of RF weld with wrap around, and then propagated along the rib wall, they also observed fine cracks on top surface of the UHPC layer. Although the maximum tensile strain of the UHPC approached to 700

-800

, after it entered into the inelastic range of the UHPC material, the observed UHPC inelasticity did not influence the overall performance of the composite decks.

Zhan[

65]established an OSD panel finite element model in ANSYS, considering different UHPC thickness, diaphragm thickness and stud spacing. The stress range at the typical fatigue details was calculated to evaluate their fatigue life based on the nominal stress method. The results found that the stress range at the RD details was greatly reduced under wheel loading, while the improvement on other details is relatively small. After using this composite deck, the RF detail became the fatigue critical detail, and increase the diaphragm thickness could greatly reduce the stress range at the RF details.

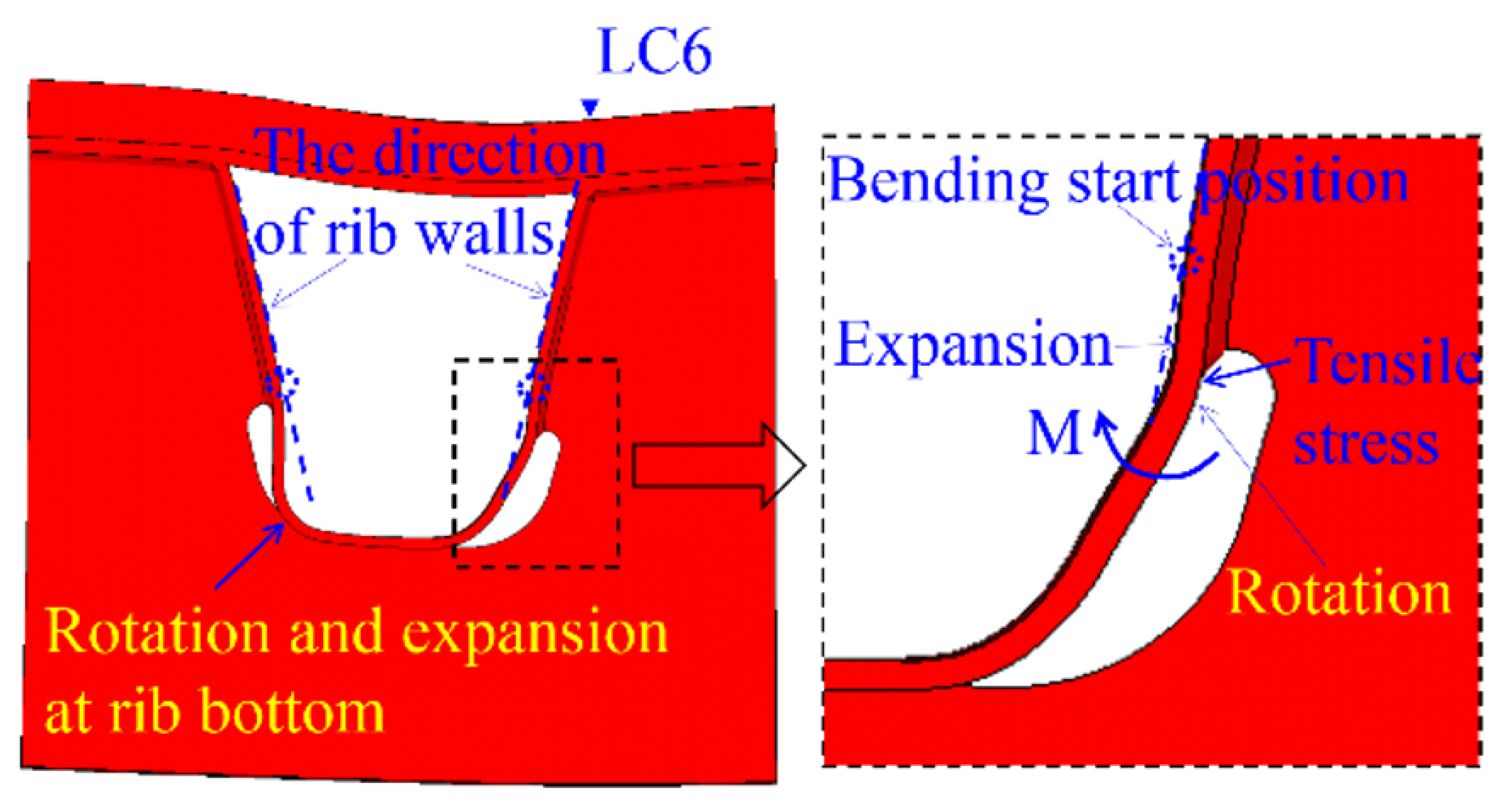

Based on a steel-UHPC composite deck bridge, Xiang[

66,

67]carried out both the field testing and multi-scale FEM analysis to investigate the fatigue behavior of wrap-around weld at rib-to-floorbeam (RF) joint. It was found that the stress behavior at fatigue details was extremely sensitive to the localized effect of axle loading instead of whole truck weight. Since significant stress concentration and high stress gradient exist in the wrap-around weld, it is essential to utilize the hot-spot stress approach rather than the nominal stress approach. The wrap-around weld presents an obvious out-of-plane bending deformation, which results from the torsion effect and Poisson’s effect, as shown in

Figure 14.

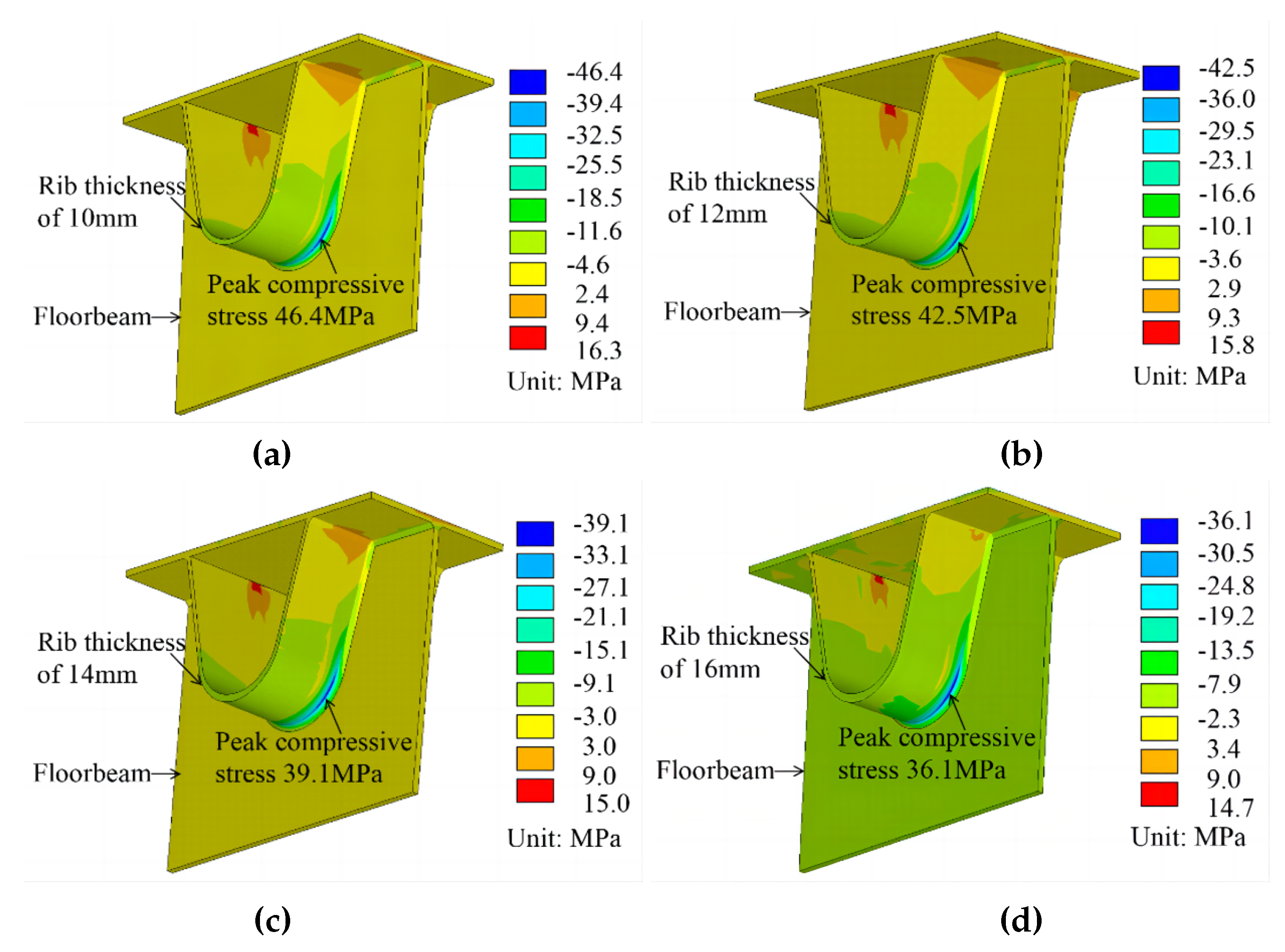

Considering the poor fatigue performance of RF joint, Xiang[

68,

69,

70]proposed a steel-UHPC composite deck with no extended cutout at the RF intersection. The refined FEM models were built to analyze the stress at fatigue-prone details. The results shown that there was a significant stress raiser at the RF joint, and Dong’s structural stress revealed that the surface stress at the rib side was dominated by bending stress. Variable rib thickness was proposed to achieve an infinite fatigue life.

Figure 15 shows the stress contours of the RF joint under various thicknesses at the rib belly, and it can be seen that increasing the thickness of the rib belly can effectively reduce the stress range of rib side at RF joint.

4.4.2. Fatigue Performance of Shear Studs

During the operation of steel-UHPC composite deck, the shear stud may suffer fatigue and fracture under cyclic and overloaded wheel load. The stud damage may deteriorate the composite action between the deck plate and the steel-UHPC layer, and hence weaken the load sharing effect of UHPC layer. Therefore, the fatigue performance of shear studs is critical to the durability and reliability of the steel-UHPC composite deck system.

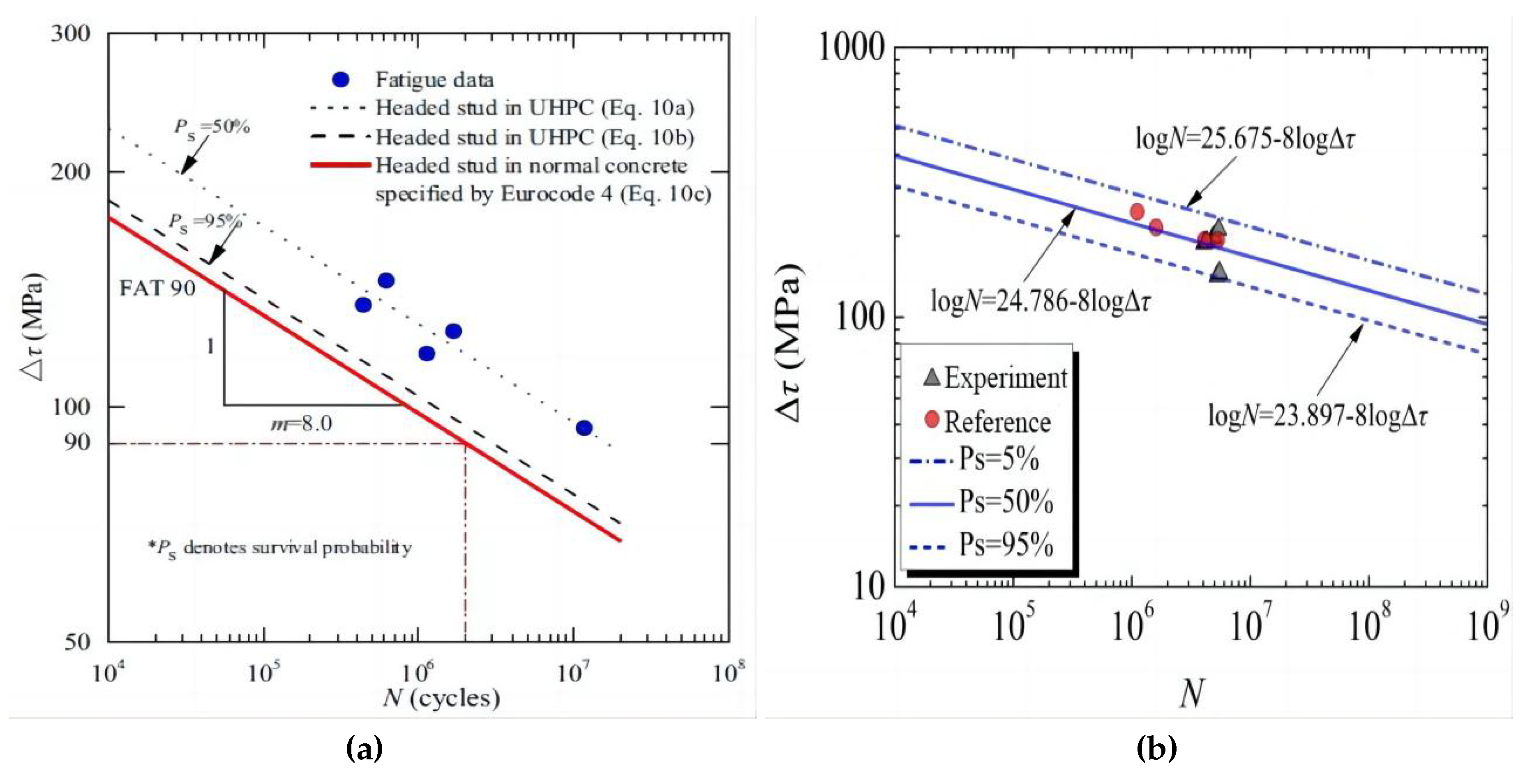

In order to study fatigue performance of the shear studs in the steel-UHPC composite deck, Li [

22]carried out fatigue tests on push-out models and a bending slab model, respectively. They found that the bonding between the steel deck plate and the UHPC layer significantly influenced shear fatigue of the composite deck, and adopting small stud spacing was an effective way to increase shear fatigue life of the composite deck. They concluded that even without the bonding effects, the interface of the composite deck did not show fatigue damage under equivalent wheel loading of 88.9 million cyclic loading with a shear stud arrangement of 125mm × 125mm. Cao [

71] studied the static and fatigue behavior of short-headed studs embedded in UHPC through push-out tests, and provided a design S-N curve with a 95% survival probability(

Figure 17 (a)). The test found that both the static and fatigue models failed due to the fracture of the headed studs, whereas the UHPC layer did not develop appreciable damage. Hence the short-headed studs developed a full strength embedded in UHPC.

Liu[

72]investigated the fatigue performance of shear studs in the steel-UHPC composite deck. When the spacing of shear studs was 250mm, although the shear stress range in the headed studs reached 119MPa, no fatigue damage was found after 200 million cyclic loadings. In Chen[

64]’ fatigue model test of the steel-UHPC composite deck. They reported shear connection failure under cyclic fatigue loading, which appeared in delamination at the interface between the UHPC layer and the steel deck plate. Stud shank shearing off at their connection with the steel deck plate was recognized as the main failure patterns, and the UHPC layer near the root of the stud was also partially damaged. A 300 mm two-way spacing of short headed studs could provide sufficient composite action between the thin UHPC layer and the orthotropic steel deck.

Focusing on the arrangement and its fatigue behavior of welded shear studs, Shi[

73,

74] carried out fatigue bending test on a full-scale OSD with UHPC composite deck. The test shown several typical fatigue failure modes of shear connectors, and the shear fatigue strength at 2 million cycles. They found that current design codes are conservative on design of stud connectors in steel-UHPC composite deck, and they provided the S-N curves with 95% survival probability, as shown in

Figure 17 (b) . They also provided equations to estimate the spacing of shear studs in bridge longitudinal and transverse directions.

4.4.3. Close Ribs versus Open Ribs

It is well recognized that, based on the same amount of steel, the bending and torsional resistance, as well as the stability of the OSD using the closed ribs are better than that of using the open ribs, hence modern steel deck tends to use closed rib, especially when the steel box girder is under compression. However, compared with the closed rib, the manufacturing process and the on-site installation of the open rib are relatively simple, and the welding quality is easy to control, since the RD details using open rib can be welded on both sides, which can ensure the welding penetration and its quality at this detail [

75].

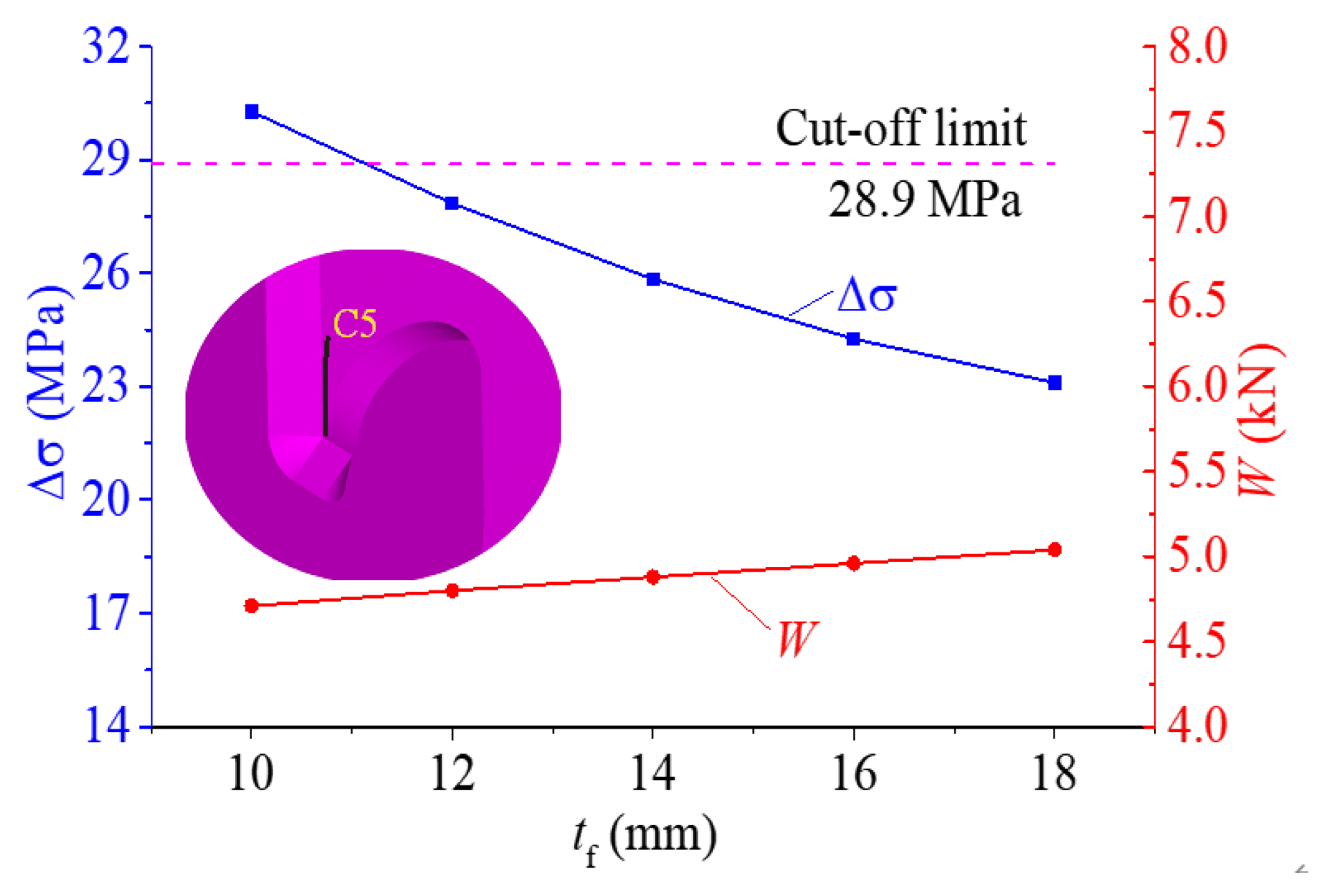

Zhang[

76]carried out laboratory test and FEM analysis on the steel-UHPC composite deck with open ribs. They found that this structure had better fatigue performance and was easy to manufacture. However, the most critical detail was the cutout, since the stress at this location could reach 90.6MPa. Xiang[

77]established multi-scale FEM models of the steel-UHPC composite deck using the open ribs. Under the wheel loading, the stress ranges at fatigue details were relatively low, except for floorbeam side of the RF detail where finite life was expected. By using the responsed surface method (RSM), the variation of stress ranges at the floorbeam detail against the floorbeam thicknesses was plotted in

Figure 18. Large floorbeam web thickness could significantly reduce the stress range at the detail without obviously increase in structure weight, and the stress range was below the fatigue cutoff limit of 28.9MPa.

Shao[

17]proposed that a light composite deck using large U ribs in OSD. Compared with the structure using traditional U ribs, although the amount of steel was basically unchanged, total weld length of the RD detail was reduced by 36%, and the fatigue performance of the OSD could be greatly improved. Liu[

78] also investigated the fatigue behavior of steel-UHPC composite deck with large-size U-ribs, as to improve the fatigue performance of the OSD.

5. Conclusions

- 1.

Reported studies show that the failure mode of shear studs in UHPC layer under the ultimate bearing capacity state is dominated by shear fractures. However, as the slendness of headed shear stud changes, the failure pattern of shear studs in composite decks needs to be further studied.

- 2.

In the existing studies, no cracking occurred in the UHPC layer of composite deck under the in-service loads. However, the relevant tests can only reflect the tensile stress in the local structure. The stress inside the UHPC layer shall consider the stress super position effect in both the whole bridge and local structure.

- 3.

The steel-UHPC composite deck shows good fatigue performance, since the stress range of all fatigue-prone details show different degree of reduction. It is more reasonable to evaluate the fatigue performance of the composite deck through the field test under in-service traffic flows. This approach can provide more real structural system, fabrication process, boundary conditions and traffic loading condition, which will facilitate a more reasonable estimation of fatigue.

- 4.

According to the current study, some reasonable parameters or structural layout in the traditional OSDs may not be the optimal solution for fatigue design of the steel-UHPC composite deck. However, new fatigue details applied to the composite deck need to be checked by bridge engineering practice.

Acknowledgments

Financial support for this study was provided by National Natural Science Foundation of China (51878269, 52278509 ), to which the writers gratefully appreciate.

References

- Zhao, Q. Steel bridge-steel structure and composite structure bridge; China Communications Press: Beijing,China, 2017; pp. 39–45. [Google Scholar]

- Wang, T.; Zhu, Z.W.; Xiang, J. J. Stress response characteristics of arcuate notch of orthotropic steel bridge panel under random traffic flow. Highway Engineering. 2016, 41, 66–71. [Google Scholar]

- Zhu, Z.W.; Huang, Y.; Wang, T.; et al. Fatigue performance evaluation of composite bridge panels of Fochen Extension Bridge under random traffic flow. Highway Engineering. 2016, 31, 3267–3277. [Google Scholar]

- Teng, H. J.; Zhu, Z.W.; Li, J. P. Research on Vertical Temperature Gradient of Steel Box Girders on Steel Bridge Deck Based on Field Measurements. Journal of Railway Science and Engineering. 2021, 18, 30–37. [Google Scholar]

- Wang, Q. H.; Qiao, H. S.; Dario, D. D.; et al. Seismic performance of optimal Multi-Tuned Liquid Column Damper-Inerter (MTLCDI) applied to adjacent high-rise buildings. Soil Dynamics and Earthquake Engineering 2021, 143, 106653. [Google Scholar] [CrossRef]

- F.B.P. de Jong.; M.H.Kolstein. Strengthening a bridge deck with high performance concrete. 2004 Orthotropic Bridge Conference, Sacramento, California, USA – August 25-27.

- Ekkehard, F.; Kai, B.; Michael, S. Gärtnerplatz – Bridge over River Fulda in Kassel: Multispan Hybrid UHPC-Steel Bridge. UHPFRC 2009 – November 17th & 18th – Marseille, France.

- Ziad, H.; Marco, N.; Claude, S.; et al. Innovative solution for strengthening orthotropic decks using uhpfrc: The Illzach Bridge. Symposium on Ultra-High Performance Fibre-Reinforced Concrete, UHPFRC 2013 – October 1-3, Marseille, France.

- Li, J.; Feng, X.T.; Shao, X. D.; et al. Study on overlay system of orthotropic steel bridge deck and RPC thin layer. Journal of Hunan University (Natural Sciences). 2012, 39, 1–12. [Google Scholar]

- Shao, X. D.; Cao, J. H.; Yi, D. T; et al. Study on basic performance of orthotropic steel plate and thin layer RPC composite bridge deck. China Journal of Highway and Transport. 2012, 02, 44–49. [Google Scholar]

- Shao, X. D.; Cao, W.; Huang, Z. Y. , et al. Application of super high performance concrete in structure. Journal of Civil engineering. 2021, 54, 1–13. [Google Scholar]

- Shao, X. D.; Wu, J. J.; Liu, R.; et al. Basic properties of Steel -UHPC lightweight composite bridge structure Waffle Bridge panels. China Journal of Highway and Transport. 2017, 30, 219–225. [Google Scholar]

- Shao, X. D.; Zheng, H.; Huang, X.J. , et al. Transverse behavior of steel -UHPC lightweight composite bridge panels. China Journal of Highway and Transport. 2017, 30, 70–77+85. [Google Scholar]

- Shao, X. D.; Chen, B.; Zhou, X. H.; et al. Wet joint bending test of steel-RPC lightweight composite deck structure. China Journal of Highway and Transport. 2017, 30, 210–217. [Google Scholar]

- Shao, X. D.; Luo, J.; Cao, J.H.; et al. Structural test and Crack Width calculation of Steel -UHPC lightweight composite deck. Journal of Civil engineering. 2019, 52, 61–75. [Google Scholar]

- Shao, X. D.; Gan, Y. D.; Li, J.; et al. Interface shear welding structure of steel - ultrathin UHPC composite bridge panel. China Journal of Highway and Transport. 2018, 31, 91–101. [Google Scholar]

- Shao, X. D.; Qv, W.T.; Cao, J.H.; et al. Basic mechanical properties of lightweight composite bridge panels with large U ribs. China Journal of Highway and Transport. 2018, 31, 94–103. [Google Scholar]

- Shao, X. D.; Zhou, Y. D.; Cao, J.H.; et al. Experimental study on flexural behavior of new continuous deck structure with steel beams. Journal of Civil engineering. 2019, 52, 80–92. [Google Scholar]

- Shao, X. D.; Zhang, H.W.; Li, J.; et al. Study on shear Behavior of Steel - ultrathin UHPC lightweight composite bridge deck short reinforcement connectors. Journal of Civil engineering. 2020, 53, 39–51. [Google Scholar]

- Li, W.G.; Shao, X. D.; Fang, H.; et al. Experimental study on flexural performance of Steel-UHPC composite plate. ournal of Civil engineering. 2015, 48, 93–102. [Google Scholar]

- Kong, L.F.; Shao, X. D.; Liu, R.; et al. Finite element analysis of flexural behavior of steel -UHPC lightweight composite beam bridge panel. Journal of Highway Communication Technology. 2016, 33, 88–95. [Google Scholar]

- Li, J.; Yang, B.; Shao, X. D.; et al. Study on shear fatigue Performance of Steel deck - thin layer CRRPC Composite Structure Stud connector. Journal of Civil engineering. 2016, 06, 67–75. [Google Scholar]

- Peng, B.; Shao, X. D. Study on fatigue performance of closed ribbed lightweight composite bridge panel. Journal of Civil engineering. 2016, 50, 89–96. [Google Scholar]

- Liao, Z. N.; Shao, X. D.; Qiao, Q. H.; et al. Static test and finite element simulation of steel-ultra-high performance concrete composite plate under lateral bending. Journal of Zhejiang University (Engineering Science). 2018, 52, 1954–1963. [Google Scholar]

- Luo, J. Theoretical study on structural mechanical properties and crack Width calculation of Steel-UHPC lightweight composite deck. Ph.D. Thesis, Hunan University, Hunan, China, 2013. [Google Scholar]

- Dieng, L.; Marchand, P.; Gomes, F.; et al. Use of UHPFRC overlay to reduce stresses in orthotropic steel decks. Journal of Constructional Steel Research 2013, 89, 30–41. [Google Scholar] [CrossRef]

- Li, J.; Li, J.; Shao, X. D.; et al. Static and fatigue test of steel Plate - ultrathin UHPC-TPO composite bridge deck. Journal of Civil engineering. 2017, 11, 98. [Google Scholar]

- Shao, X. D.; Zhang, Z.; Liu, M. L.; et al. Experimental study on bending and tensile strength of orthotropic steel -RPC composite bridge panel. Journal of Hunan University (Natural Sciences). 2012, 39, 7–13. [Google Scholar]

- Shao, X. D.; Li, Z. H.; Wu, J. J.; et al. Test of partial repair technology for steel-UHPC lightweight composite bridge panel. China Journal of Highway and Transport. 2017, 30, 58–64. [Google Scholar]

- Wu, J. J.; Shao, X. D.; Liu, R.; et al. Study on Structural type of Steel -UHPC lightweight composite beam Bridge Panel. Highway Engineering. 2017, 42, 76–81. [Google Scholar]

- Fang, Z.; Wu, X. N.; Tan, X. Y.; et al. Study on bending behavior of steel -UHPC composite bridge panel in transverse negative moment zone. Engineering Mechanics. 2022, 39, 1–13. [Google Scholar]

- Zhou, M.; Xiao, J. L.; Yang, T. Y.; et al. Experimental study and numerical simulation on flexural behavior of Steel-UHPC composite plates with perforated plate shear keys. China Journal of Highway and Transport. 2022, 39, 19–28. [Google Scholar]

- Luo, J.; Shao, X. D.; Cao, J.H.; et al. Transverse bending behavior of the steel-UHPC lightweight composite deck: Orthogonal test and analysis. Journal of Constructional Steel Research. 2019, 162, 105708. [Google Scholar] [CrossRef]

- Shao, X. D.; Guo, C.; Cao, J.H.; et al. Steel -STC lightweight composite deck bolt joint area design. China Journal of Highway and Transport. 2019, 32, 57–65. [Google Scholar]

- Shao, X. D.; Mo, R.; Cao, J.H.; et al. Study on crack resistance of Steel -UHPC lightweight composite bridge deck subjected to simulated traffic disturbance. Journal of Hunan University. 2022, 49, 1–13. [Google Scholar]

- Shao, X. D.; Zhou, H.Y.; Cao, J.H.; et al. Shear performance of steel - thin layer RPC composite bridge deck structural bolts. Journal of Highway Communication Technology. 2013, 30, 34. [Google Scholar]

- Wang, J. Q.; Qi, J. N.; Tong, T.; et al. Static behavior of large stud shear connectors in steel-UHPC composite structures. Engineering Structures. 2019, 178, 543. [Google Scholar] [CrossRef]

- Shao, X. D.; Li, M.; Cao, J. H.; et al. Experimental and Theoretical Analysis of Shear Properties of UHPC Medium Stud. China Journal of Highway and Transport. 2021, 01, 01–19. [Google Scholar]

- Wu, W. F.; Feng, Y. P.; Dai, J.; et al. Study on mechanical properties of stud shear bonds in Steel-UHPC composite structures. Engineering Mechanics. 2022, 39, 222–234+243. [Google Scholar]

- Deng, M.; Huo, N.; Shi, G.; et al. Shear strength analysis of the stud in steel-UHPC composite bridge deck. Conference Series Earth and Environmental Science. 2017, 100. [Google Scholar] [CrossRef]

- Shao, X. D.; Zhang, H. W.; Li, J.; et al. Study on shear Behavior of Steel - ultrathin UHPC lightweight composite bridge deck short reinforcement connectors. Journal of Civil engineering. 2020, 53, 39–51. [Google Scholar]

- Sun, Q. L.; Lu, X.Y.; Nie, X.; et al. Experimental study on tensile and shear properties of non-steamed UHPC-steel plate structure interface. Engineering Mechanics. 2017, 34, 167–174+192. [Google Scholar]

- He, Q. S.; Zhang, H. L.; Li, J.; et al. Performance evaluation of polyurethane/epoxy resin modified asphalt as adhesive layer material for steel-UHPC composite bridge deck pavements. Construction and Building Materials. 2021, 291. [Google Scholar] [CrossRef]

- Johnson, R. May, 1., (1975). Zhang, H. L., Li, J.; et al. Partial-interaction design of composite beams. Structural Engineer. 2021, 8, 305–311. [Google Scholar]

- ISSC. Guidelines for performance-based design of steel-concrete hybrid structures. Japan Society of Civil Engineers. Tokyo, Japan, 2002,1-201.

- Cao, J. H. Study on the Basic performance of steel - thin layer ultra-high performance concrete lightweight composite deck structure. Ph.D. Thesis, Hunan University, Hunan, China, 2016. [Google Scholar]

- Li, C.; Chen, B. C.; Hu, W. X.; et al. Calculation of shear capacity, slip and stiffness of Steel -UHPC composite plate stud. Engineering Mechanics. 2022, 10, 1–14. [Google Scholar]

- Shao, X. D.; Tang, Y.; Wang, Z. J.; et al. Experimental study on Steel -UHPC interface stud and PBL mixed shear connector. Journal of Hunan University (Natural Sciences). 2022, 08, 1–14. [Google Scholar]

- Li, J.; Feng, X. T.; Shao, X. D.; et al. Mechanical calculation of new STC steel bridge deck pavement system and comparative analysis of real bridge test. China Journal of Highway and Transport. 2014, 27, 39–50. [Google Scholar]

- Zhang, L. W.; Zhao, H.; Tan, C. J.; et al. Force analysis of UHPC- Steel lightweight composite bridge deck curved notch. China Journal of Highway and Transport. 2016, 29, 75–81. [Google Scholar]

- Li, J. P.; Zhu, Z. W. Stress Behaviors at Rib-to-Floorbeam Weld and Cutout Details under Controlled Truck Loading. Applied Science. 2022, 12, 3012. [Google Scholar] [CrossRef]

- Yuan, Y.; Wu, C.; Jiang, X. Experimental study on the fatigue behavior of the orthotropic steel deck rehabilitated by UHPC overlay. Journal of Constructional Steel Research. 2019, 157, 1–19. [Google Scholar] [CrossRef]

- Wang, Y.; Shao, X. D.; Chen, J.; et al. UHPC reinforcement technology for Heavy fatigue cracked steel bridge deck. Journal of Civil engineering. 2020, 53, 92–101. [Google Scholar]

- Liu, M. L.; Shao, X. D.; Zhang, Z.; et al. Orthotropic steel plate ultra-thin RPC composite bridge deck Bending fatigue performance test of structures. Journal of Highway and Transportation Research and Development. 2012, 29, 46–52. [Google Scholar]

- Ding, N.; Shao, X. D. Study on fatigue performance of lightweight composite bridge panels. Journal of Civil engineering. 2015, 48, 74–81. [Google Scholar]

- Zhu, Z.W.; Yuan, T.; Xiang, Z.; et al. Behavior and Fatigue Performance of Details in an Orthotropic Steel Bridge with UHPC-Deck Plate Composite System under In-Service Traffic Flows. Journal of Bridge Engineering. 2017, 23, 04017142. [Google Scholar] [CrossRef]

- Li, J. P.; Zhu, Z. W. Effects of full internal bulkheads on fatigue behaviors of orthotropic steel decks. Journal of Constructional Steel Research. 2022, 196, 107400. [Google Scholar] [CrossRef]

- Zhu, Z. W.; Li, J. P.; Chen, X. W.; et al. Stress behaviors of rib-to-deck double-sided weld detail on orthotropic steel deck. Journal of Constructional Steel Research. 2021, 187, 106947. [Google Scholar] [CrossRef]

- Tian, Q. X.; Gao, L. Q.; Zhou, S. M. Study on mechanical behavior of super high performance concrete-teel orthotropic composite deck. Bridge Construction. 2017, 47, 13–18. [Google Scholar]

- Zhu, Z. W.; Li, J. P.; Huang, Y.; et al. Hot-spot stress models of cutout detail on orthotropic steel bridge decks. Journal of Constructional Steel Research 2021, 183, 106762. [Google Scholar] [CrossRef]

- Deng, L.; Xian, Y. L.; Shao, X. D.; et al. Fatigue reliability assessment of lightweight steel-UHPC composite bridge panels. Journal of Central South University (Science and Technology). 2018, 49, 711–717. [Google Scholar]

- Zhu, Z. W.; Xiang, Z.; Zhou, Y. E. Fatigue behavior of orthotropic steel bridge stiffened with ultra-high performance concrete layer. Journal of Constructional Steel Research. 2019, 157, 132–142. [Google Scholar] [CrossRef]

- Xiong, C. Q.; Zhu, Z. W.; Li, J. P.; et al. Response Surface-Based Finite Element Model Updating of Steel Box-Girder Bridges with Concrete Composite Decks. Advances in Civil Engineering. 2022, 4298933. [Google Scholar] [CrossRef]

- Chen, S. M.; Huang, Y.; Gua, P.; et al. Experimental study on fatigue performance of UHPC-orthotropic steel composite deck. Thin-Walled Structures. 2019, 142, 1–18. [Google Scholar] [CrossRef]

- Zhan, J.; Shao, X. D.; Qv, W. T.; et al. Multi-parameter analysis of steel-STC lightweight composite deck structure. Journal of Highway Communication Technology. 2018, 35, 73–81. [Google Scholar]

- Xiang, Z.; Zhu, Z. W. Simulation study on fatigue behavior of wrap-around weld at rib-to-floorbeam joint in a steel-UHPC composite orthotropic bridge deck. Construction and Building Materials. 2021, 289, 123161. [Google Scholar] [CrossRef]

- Zhu, Z. W.; Xiang, Z.; Zhou, E. Fatigue behavior of orthotropic steel bridge stiffened with ultra-high performance concrete layer. Journal of Constructional Steel Research. 2019, 157, 132–142. [Google Scholar] [CrossRef]

- Xiang, Z.; Zhu, Z. W. Fatigue behavior of orthotropic composite bridge decks without cutout at rib-to-floorbeam intersection. Journal of Constructional Steel Research 2023, 201, 107596. [Google Scholar] [CrossRef]

- Zhu, Z. W.; Xiang, Z.; Li, J. P. Fatigue damage investigation on diaphragm cutout detail on orthotropic bridge deck based on field measurement and FEM. Thin-Walled Structures. 2020, 157, 107106. [Google Scholar] [CrossRef]

- Zhu, Z. W.; Xiang, Z. Fatigue cracking investigation on diaphragm cutout in a self-anchored suspension bridge with orthotropic steel deck. Structure and Infrastructure Engineering. 2019, 15, 1279–1291. [Google Scholar] [CrossRef]

- Cao, J.; Shao, X.; Deng, L.; et al. Static and Fatigue Behavior of Short-Headed Studs Embedded in a Thin Ultrahigh-Performance Concrete Layer. Journal of Bridge Engineering. 2017, 22, 04017005. [Google Scholar] [CrossRef]

- Liu, C.; Fan, J. S.; Nie, J. G.; et al. Research on fatigue performance of bolted connectors in Steel-ultra-high performance concrete composite deck System. Engineering Mechanics. 2018, 35, 92–98+145. [Google Scholar]

- Shi, Z. C.; Su, Q. T.; Chen, L. Fatigue behavior and design and arrangement of welded studs in Steel-UHPC composite bridge panel. China Journal of Highway and Transport. 2022, 09, 1–19. [Google Scholar]

- Shi, Z. C.; Su, Q. T.; Florentia, K.; et al. Behavior of short-headed stud connectors in orthotropic steel-UHPC composite bridge deck under fatigue loading. International Journal of Fatigue. 2022, 160. [Google Scholar] [CrossRef]

- Xiang, Z. Study on Rational structure of steel -UHPC composite orthotropic bridge panel. Ph.D. Thesis, Hunan University, Hunan, China, 2016. [Google Scholar]

- Zhang, S.; Shao, X.; Cao, J.; et al. Fatigue Performance of a Lightweight Composite Bridge Deck with Open Ribs. Journal of Bridge Engineering. 2016, 21, 04016039. [Google Scholar] [CrossRef]

- Xiang, Z.; Zhu, Z. W. Multi-objective optimization of a composite orthotropic bridge with RSM and NSGA-II algorithm. Journal of Constructional Steel Research. 2022, 188, 106938. [Google Scholar] [CrossRef]

- Liu, Y. M.; Zhang, Q. H.; Meng, W. N.; et al. Transverse fatigue behaviour of steel-UHPC composite deck with large-size U-ribs. Engineering Structures. 2019, 180, 388–399. [Google Scholar] [CrossRef]

Figure 1.

Typical structural layout of OSD.

Figure 1.

Typical structural layout of OSD.

Figure 2.

Material used to form UHPC: (a) Rib-to-deck crack; (b) Rib-to-floorbeam crack; (c) Cutout crack; (d) Rib splice crack; (e) Overlay crack; (f) Overlay pit; (g) Overlay remove.

Figure 2.

Material used to form UHPC: (a) Rib-to-deck crack; (b) Rib-to-floorbeam crack; (c) Cutout crack; (d) Rib splice crack; (e) Overlay crack; (f) Overlay pit; (g) Overlay remove.

Figure 3.

Material used to form UHPC: (a) Cement; (b) Silica fume; (c) Quartz sand; (d) Fly ash; (e) Water reducer; (f) Fiber.

Figure 3.

Material used to form UHPC: (a) Cement; (b) Silica fume; (c) Quartz sand; (d) Fly ash; (e) Water reducer; (f) Fiber.

Figure 4.

Measured temperature of deck overlay and its elastic modulus of EAC against temperature: (a) Measured temperature of steel girder and its overlay; (b) Elastic modulus of EAC against temperature.

Figure 4.

Measured temperature of deck overlay and its elastic modulus of EAC against temperature: (a) Measured temperature of steel girder and its overlay; (b) Elastic modulus of EAC against temperature.

Figure 5.

UHPC construction process.

Figure 5.

UHPC construction process.

Figure 6.

UHPC construction process: (a) Welded shear stud; (b) Steel mesh; (c) Pouring UHPC; (d) Steam curing.

Figure 6.

UHPC construction process: (a) Welded shear stud; (b) Steel mesh; (c) Pouring UHPC; (d) Steam curing.

Figure 8.

Mafang Bridge using steel-UHPC composite deck: (a) Under construction; (b) After 12 years in service.

Figure 8.

Mafang Bridge using steel-UHPC composite deck: (a) Under construction; (b) After 12 years in service.

Figure 9.

Bridge deck under construction: (a) Fochen New Bridge; (b) Hangrui Dongting Lake Bridge;(c) Queshi Bridge;(d) Fengxi Bridge.

Figure 9.

Bridge deck under construction: (a) Fochen New Bridge; (b) Hangrui Dongting Lake Bridge;(c) Queshi Bridge;(d) Fengxi Bridge.

Figure 10.

Wheel load on orthotropic steel-UHPC composite deck in bridge transverse direction: (a) Negative moment zone at top of longitudinal rib; (b) Positive moment zone between longitudinal ribs.

Figure 10.

Wheel load on orthotropic steel-UHPC composite deck in bridge transverse direction: (a) Negative moment zone at top of longitudinal rib; (b) Positive moment zone between longitudinal ribs.

Figure 11.

Photo of stud shear failure.

Figure 11.

Photo of stud shear failure.

Figure 12.

Measured stress time histories and stress spectrum [

54]:

(a) 24 hours stress time records at RD-D;

(b) 24 hours stress time records at RD-R;

(c) One-week stress spectrum at RD-D;

(d) One-week stress spectrum at RD-R.

Figure 12.

Measured stress time histories and stress spectrum [

54]:

(a) 24 hours stress time records at RD-D;

(b) 24 hours stress time records at RD-R;

(c) One-week stress spectrum at RD-D;

(d) One-week stress spectrum at RD-R.

Figure 13.

Stress contour plots for four different cutout clearances.

Figure 13.

Stress contour plots for four different cutout clearances.

Figure 14.

Distortion of rib wall under wheel loads.

Figure 14.

Distortion of rib wall under wheel loads.

Figure 15.

The stress contour of RF joint using various thicknesses at rib belly:(a) 10mm; (b) 12mm; (c) 14mm; (d) 16mm.

Figure 15.

The stress contour of RF joint using various thicknesses at rib belly:(a) 10mm; (b) 12mm; (c) 14mm; (d) 16mm.

Figure 16.

Static (a) and fatigue (b) failure mode of shear stud of steel-UHPC composite models.

Figure 16.

Static (a) and fatigue (b) failure mode of shear stud of steel-UHPC composite models.

Figure 17.

S-N curves for shear stud in UHPC composite deck.

Figure 17.

S-N curves for shear stud in UHPC composite deck.

Figure 18.

Variation of stress ranges of RF detail against floorbeam thicknesses.

Figure 18.

Variation of stress ranges of RF detail against floorbeam thicknesses.

Table 1.

UHPC main mechanics and durability index

Table 1.

UHPC main mechanics and durability index

| Compressive strength /MPa |

120 ∼230 |

| Flexural Strength /MPa |

15 ∼60 |

| Elasticity modulus /GPa |

40 ∼60 |

| Creep coefficient |

0.2-0.3(High temperature steam curing) |

| Diffusion coefficient of chloride ion/(m2/s) |

< 0.2×10−12

|

| Electrical resistivity /(k cm) |

131.96 ∼50.01 |

Table 2.

Newly built bridge using orthotropic steel-UHPC composite deck in China

Table 2.

Newly built bridge using orthotropic steel-UHPC composite deck in China

| Bridge Name |

Location |

Span arrangement/m |

Type |

Year |

| Fochen |

Foshan, Guangdong |

58.51+112.8+58.51 |

① |

2014 |

| Hexi Trans. Hub |

Changsha, Hunan |

54 |

① |

|

| Beiguan Tonghuihe |

Tongzhou, Beijing |

11.5+60+18.5 |

② |

2015 |

| Haihe |

Tianjin |

310+4×48 |

③ |

|

| Longxi Interchange Ramp |

Jiangmen, Guangdong |

28+50+28 |

① |

|

| Shendang |

Jiaxing, Zhejiang |

72 |

① |

|

| Jiaoshanmen |

Jiaxing, Zhejiang |

36.5 |

① |

2016 |

| Beiguan Street |

Tongzhou, Beijing |

30+40+70+40+30 |

② |

|

| Lichuan |

Dongguan, Guangdong |

138 |

③ |

|

| Fengxi |

Zhuzhou, Hunan |

300 |

④ |

|

| Chetian River |

Guiyang, Guizhou |

32+56+32 |

① |

|

| Tongguan |

Changsha, Hunan |

50+50 |

① |

|

| Wuyi |

Huzhou, Zhejiang |

60+128+60 |

① |

|

| Gangxia North Trans. Hub |

Shenzhen, Guangdong |

30+2×46+34+32 |

① |

2017 |

| Shele |

Taiyuan, Shanxi |

30+150+150+30 |

③ |

|

| Hangrui Dongting Lake |

Yueyang, Hunan |

1480 |

④ |

|

| Zhaohua |

Xiangtan, Hunan |

168+228 |

④ |

|

Table 3.

Newly built bridge using orthotropic steel-UHPC composite deck in China(Continuous)

Table 3.

Newly built bridge using orthotropic steel-UHPC composite deck in China(Continuous)

| Bridge Name |

Location |

Span arrangement/m |

Type |

Year |

| Fute Bay |

Foshan, Guangdong |

112+2×200+112 |

① |

|

| Jinan Guodian Interchang |

Jinan, Shandong |

21.5+22+26+22+20 |

① |

|

| Beiyuan Expressway West |

Jinan, Shandong |

30+47+30 |

① |

|

| Da’an North Interchange |

Baicheng, Jilin |

31.2 |

① |

2018 |

| Tiansheng Harbour and Ferry |

Nantong, Jiangsu |

141.5+336+141.8 |

② |

|

| Beijiang River Fourth |

Qingyuan, Guangdong |

100+218+100 |

③ |

|

| Maogang River |

Shanghai |

110+225+110 |

③ |

|

| Tianbaowan |

Chengdu, Sichuan |

230 |

① |

|

| Hongfenglu |

Changsha, Hunan |

30+70+30 |

① |

|

| Longsheng |

Huizhou, Guangdong |

40+185+40 |

② |

|

| Haiwen |

Haikou, Hainan |

230+230 |

③ |

|

| Zhongxing |

Ningbo, Zhejiang |

64+86+400+86+64 |

③ |

2019 |

| Jingzhou Yangtze River |

Jingzhou, Hubei |

98+182+518+182+98 |

③ |

|

| Yunlongwan |

Chengdu, Sichuan |

30+80+205+80+30 |

④ |

|

| Qinglongzhou |

Yiyang, Hunan |

60+110+260+110+60 |

④ |

|

| Dashahe 1st Road Crossing |

Shenzhen, Guangdong |

75 |

② |

|

| Hutong Yangtze River |

Suzhou, Jiangsu |

140+462+1092+462+140 |

③ |

|

| Jiangxinzhou Yangtze River |

Nanjing, Jiangsu |

80+218+2×600+218+80 |

③ |

|

| Rongjiang |

Jieyang, Guangdong |

400 |

③ |

2020 |

| Xinglinbao |

Zhangjiakou, Hebei |

217 |

③ |

|

| Taizicheng No.1 |

Zhangjiakou, Hebei |

50+100+100+50 |

③ |

|

| Honghe |

Yuanyang, Yunnan |

700 |

④ |

|

| Qiushi Road Steel |

Urumqi, Xinjiang |

42+68+68+42 |

① |

|

| Shennong Lake |

Changzhi, Shanxi |

130+130 |

③ |

2021 |

| Qipanzhou |

Huangshi, Hubei |

340+1038+340 |

④ |

|

| Shachong |

Dongguan, Guangdong |

9+88+9 |

② |

|

| Binhai Bay |

Dongguan, Guangdong |

60+200+200+60 |

③ |

|

| Sangyuanzi Yellow River |

Lanzhou, Gansu |

949+328+959 |

③ |

|

| Fulong Xijiang Grand |

Foshan, Guangdong |

500 |

③ |

2022 |

| Yellow River Fenghuang |

Jinan, Shandong |

70+168+428+428+168+70 |

④ |

|

Table 4.

Deck replacement using steel-UHPC composite structure

Table 4.

Deck replacement using steel-UHPC composite structure

| Bridge Name |

Location |

Span arrangement/m |

Type |

Year |

| Mafang |

Zhaoqing, Guangdong |

14×64 |

① |

2011 |

| Queshi |

Shantou, Guangdong |

518 |

③ |

2016 |

| Riyue-Chengwen Road Expressway |

Chengdu, Sichuan |

37+46+46 (Left)

46+46+42 (Right) |

① |

|

| Junshan |

Wuhan, Hubei |

48+204+460+204+48 |

③ |

2018 |

| Lanzhou Donggang Interchange |

Lanzhou, Gansu |

595 |

① |

2019 |

| Songpu |

JShanghai |

419.6 |

① |

|

| Shengli Yellow River |

Dongying, Shandong |

682 |

③ |

2020 |

| Hongtang |

Fuzhou, Fujian |

50+150+150+50 |

④ |

|

| Yichang Yangtze River |

Yichang, Hubei |

960 |

④ |

2021 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).