1. Introduction

Hydrotalcites (HTlc) represents a class of nanostructured layered materials, made of positively charged metal hydroxide layers compensated by exchangeable charge balancing anions. [

1] They can be generally described with the following formula: [M

II1−x M

IIIx (OH)

2]

x+ [A

n− x/n]

x− · mH

2O. Here M

II is a divalent cation such as Mg, Ni, Zn, Cu, or Co; M

III is a trivalent cation such as Al, Cr, Fe, or Ga; A

n− is an anion of charge n and m is the molar amount of co-intercalated water. Due to the presence of large interlayer spaces and to the large number of exchangeable anions, HTlc may act both as a good ion exchanger and as a good absorbent. These characteristics clearly indicate them as potentially useful in a variety of applications, ranging from green to bio technologies. [

2]

Some categories of HTlc may be thus used in biological applications. To do that, a high level of biocompatibility is needed, and the possible selection of metal atoms is strongly limited. However, thanks to the fact that the metal atoms forming the anionic layers (MII and MIII) can be varied in a wide range, a suitable choice is not difficult to find. Additionally, this choice at the production stage also allows selecting the properties of the particles. For instance, one can obtain magnetic nanoparticles, when the atoms are such as Ni and Fe and other couples.

Keratins are naturally abundant non-food proteins found for instance in hair, wool, horns, nails, and feathers. Wool keratin has been widely employed in tissue engineering and wound healing applications, due to its biodegradability, biocompatibility, and bioactivity. In a recent publication, Keratin sponges containing magnetic HTlc nanoparticles have been used to prepare innovative 3D scaffolds. [

3] These HTlc have been synthesized coupling Mg and Fe, that, besides a high biocompatibility, present magnetic properties. The scaffolds obtained have been employed for experiments on osteoblasts under the effect of a static magnetic field externally applied. The results have shown an enhancement of cellular activity. MgFe HTlc have been already used in the past, namely for green applications. [

4] Though their structure and composition have been well characterized, [

5] they have not been fully characterized in terms of their magnetic properties.

In the first instance, the single components need to be tested separately. Keratin and HTlc powders have been analyzed using a Physical Property Measurement System (PPMS) with a Vibrating Sample Magnetometer (VSM) option that allows measuring magnetization versus a static field in a temperature range from 300K down to 2.5K. [

6] In a second moment, the HTlc need to be locally studied in a real environment, i.e., the keratin matrix used as scaffolds. To do this, they have been dispersed in a keratin water solution, as for the sponge fabrication, and the solution has been spin-coated on pieces of Si/SiO2 wafers. In this way, the magnetic properties of the samples could be locally analyzed with the help of a Magneto Optical Kerr Effect (MOKE) technique [

7].

These films have also been investigated with Optical Microscopy to visualize the distribution of HTlc and with Atomic Force Microscopy (AFM) to map the film topography. These data can be finally correlated with the reflectivity maps obtained with a DMO NanoMOKE® and with the Kerr rotation values correlated with the local magnetic behaviour. Our results indicate that MgFe HTlc powder is fully paramagnetic down to 2.5K. Once dispersed in the keratin matrix and spin-coated in films, the HTlc present themselves in clusters of various dimensions. They still have a paramagnetic behaviour down to 7.5K. Keratin is weakly paramagnetic as determined with NanoMOKE, although diamagnetic regions can be found at the interfaces between HTlc clusters and keratin. These data are fully described in the following Results section, and an interpretation of the results is provided in the Discussion section.

2. Materials and Methods

MgFe-HTlc nanoparticles, with an average diameter of around 30 nm, were prepared using the double-microemulsion water-in-oil technique, as described in the literature. [

1] They can be represented by the following formula [Mg

0.76Fe

0.24(OH)

2]Br

0.12(CO

3)

0.06∙0.65H

20. Briefly, two microemulsions were prepared dispersing 3.12 g of CTAB, 3.9 mL of n-butanol, 9 mL of isooctane, and 3.4 mL of aqueous phase. The aqueous phase of the first microemulsion consisted of Mg (NO

3)

2 0.4 M and Fe (NO

3)

3 0.125 M. The aqueous phase of the second microemulsion was an NH

3 solution 5.0 M. Equal volumes of the two microemulsions were then mixed to obtain the precipitation of HTlc in the reverse micelles. The resulting system was aged at 70°C for 16 h. Afterwards, the nanoparticles were recovered by centrifugation (12,000 rpm, 10 min) and the precipitate was washed with an ethanol–chloroform mixture (1:1 v/v) (3 x 30 mL) and then with water (3 x 30 mL).

High molecular weight keratin powder (≈ 50 kDa) extracted from raw wool was kindly donated by Kerline Srl (Italy). The HTlc/keratin films were prepared spin-coating (in air) a water solution on Si/SiO2 substrates, previously plasma-treated for 3 minutes. The solution contains 10% of keratin and 2.5 or 5% of HTlc powder, weight percentages. The spinning conditions were the following: 4000 rpm, acceleration 4000 rpm/s, 60 sec. No thermal treatments were carried out. The final thickness was around 220nm.

The HTlc powder has been characterized using a PPMS (from Quantum Design) doted of a Vibrating Sample Magnetometer (VSM). The magnetic moment can be measured as a function of the temperature m(T), the magnetic field m(H), and the time m(t). To perform the M(T) measurement, the sample has been cooled down to 2.5K, in absence of magnetic field. After this, a magnetic field of 100 mT has been applied and the sample has been warmed up to 300 K to obtain the Zero Field Cooling curve (ZFC). Successively, it has been cooled again at 2.5 K, to perform the Field Cooling curve (FC). For the M(H) measurements, the target temperature has been fixed and the magnetic field has been swept from 0 T to 9 T, from 9 T to -9 T and again from -9 T to 9 T. For more details about the sequences of the measurements please refer to Reference [

6].

NanoMOKE® is an instrument based on Magneto-Optic Kerr Effect (MOKE). It combines the capabilities of the Durham Magneto-Optics NanoMOKE3 with the flexibility of a closed cycle optical Cryostation. This system allows characterizing the surface magnetic properties of the samples from room to low temperatures with a few micrometers lateral resolution. The experimental setup is based on a scanning laser microscope, operating at λ = 660nm with an integrated optical system made of a pair of galvanometric mirrors. The measurements have been performed in a longitudinal configuration, i.e., the external magnetic field is applied parallel to the sample surface (in-plane magnetization).

Atomic force microscopy (AFM) was performed using a hybrid system that was assembled using a commercial head (SMENA, NT-MDT), home-built electronics, home-developed software, and a commercial digital lock-in amplifier (Zurich HF2LI). [

8] The setup was operated in intermittent contact mode (ICM). The cantilevers employed are commercially available from MikroMasch, the HQ:NSC35 model (nominal force constant from 5.4 to 16 N/m and resonance frequency from 130 to 300 kHz).

3. Results

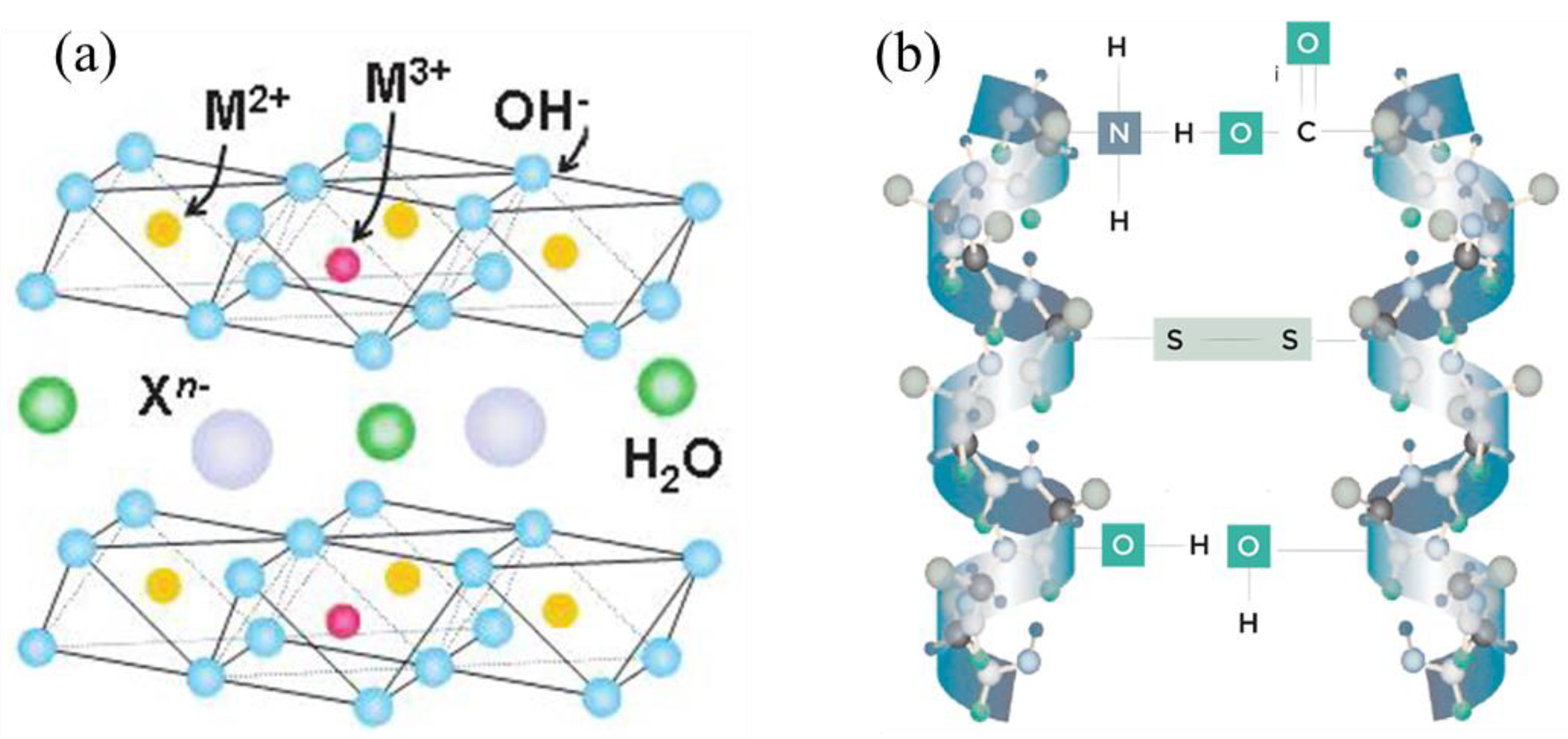

In

Figure 1, we report in (a) a sketch of the structure of HTlc and in (b) the schematic representation of keratin. As already mentioned, the HTlc synthesized for this research are made with Mg and Fe, to use a magnetic biocompatible structure. The Keratin employed is derived from wool and is soluble in water.

First, we have characterized the magnetic properties of the single materials in the powder form. In our case, this consists in considering a portion of the MgFe HTlc powder and an equivalent portion of keratin powder. These portions of materials have been separately inserted in the sample holder of a PPMS-VSM and measured.

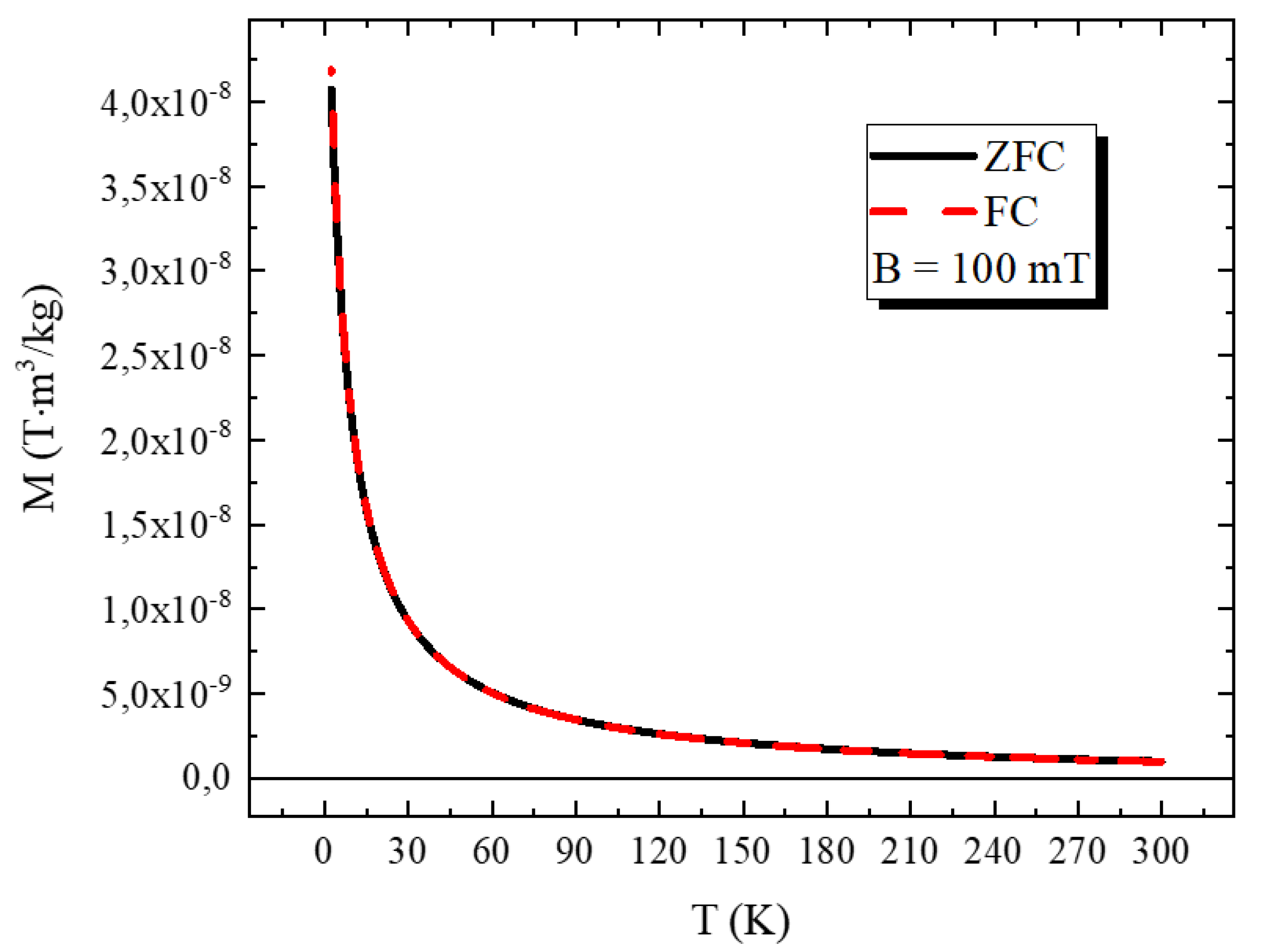

In

Figure 2, we present a graph of the magnetization (M) versus temperature (T) obtained with the PPMS using the VSM option. The data show that the behavior of the HTlc powder appears to be paramagnetic, with a M continuously increasing with reducing T down to 2.5K, and with the Zero Field Cooling (ZFC) and the Field Cooling (FC) curves fully overlapping.

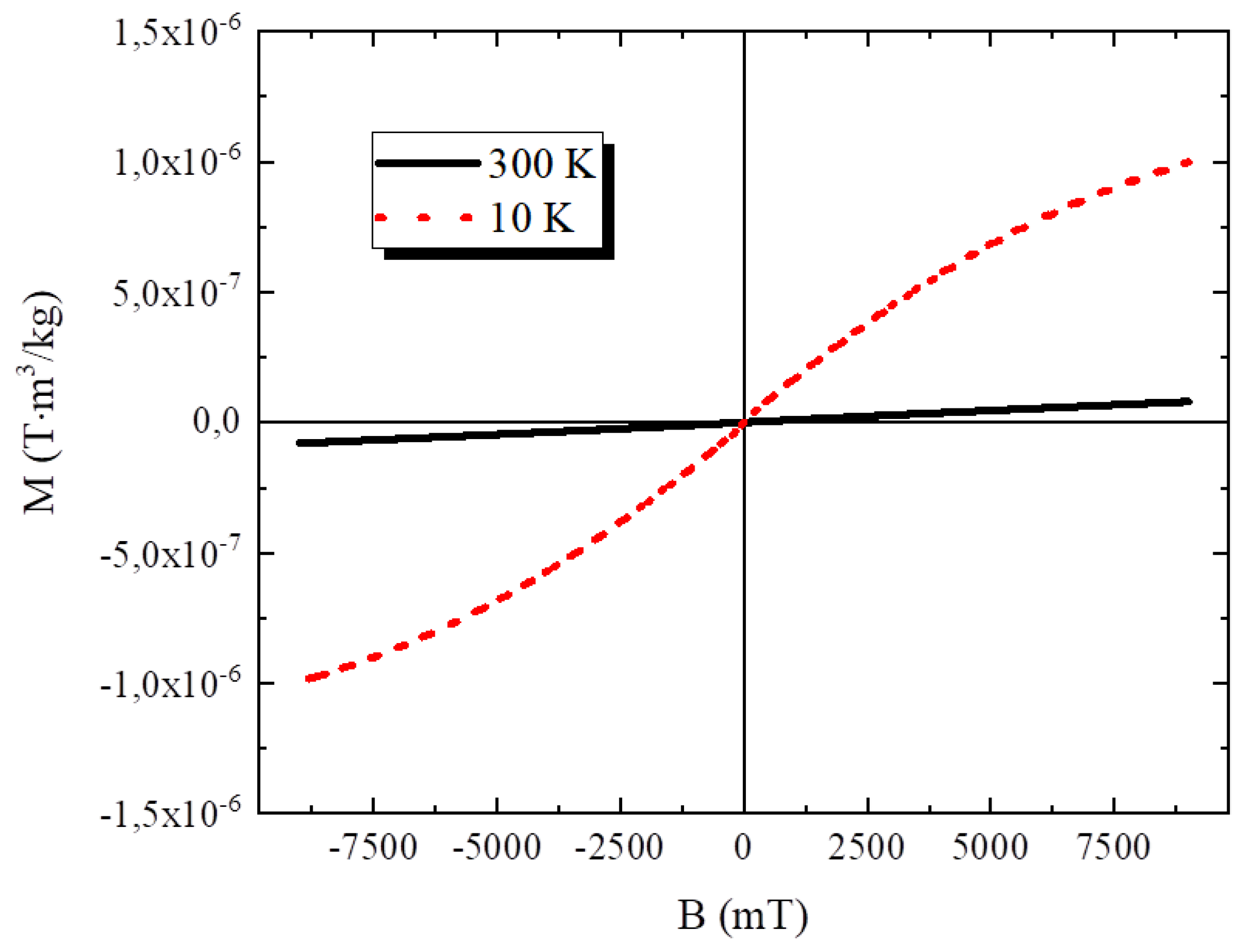

In

Figure 3, we present the plots of M versus the magnetic field (B), obtained at 10 and 300K. At 300K the curve is linear with a smaller signal amplitude, whereas at 10K the amplitude is much larger, and the curve slightly bends at high B values. However, the cycle does not present hysteresis, coherently with paramagnetic behaviour.

The same experiment carried out on keratin powder has not provided a clear indication of its magnetic behaviour. Keratin shows a very weak signal and the magnetic contribution from the plastic sample holder is comparable with, and thus covers, it at all T values.

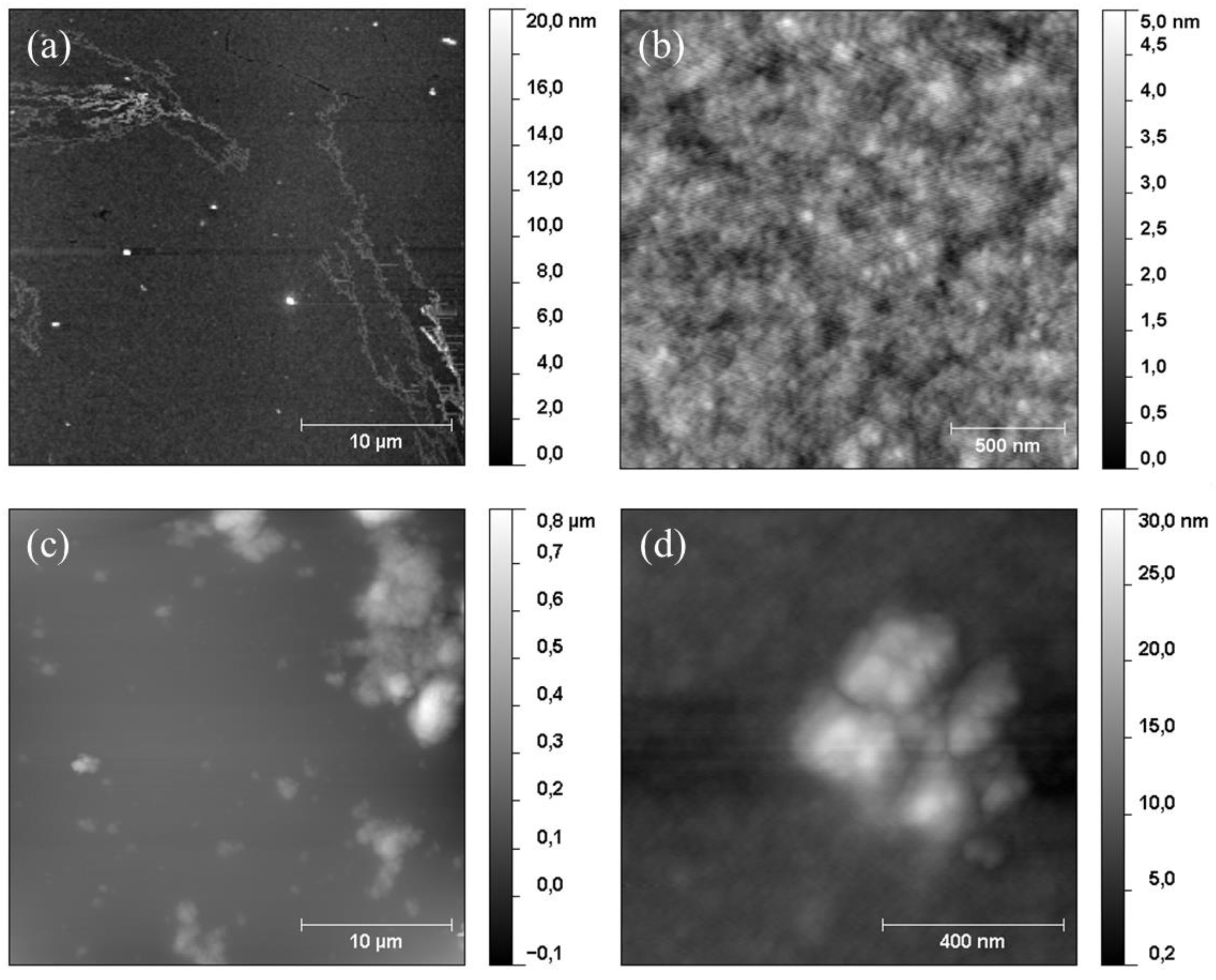

After that, we have characterized the properties of spin-coated thin films, obtained from water solutions of HTlc and keratin. The film thickness is around 220nm for all the samples. In

Figure 4, we present some topographical images acquired with Atomic Force Microscopy (AFM) of: (a, b) a keratin film and (c, d) keratin mixed with 2.5% of HTlc powder in weight. Pure keratin has a very flat surface that is only characterized by the presence of some dendritic motives. These features have a thickness of a few nanometers. They are probably due to local reorganization of the molecules at the free surface determining some crystallization.

All the HTlc/keratin films instead have a much higher roughness for both a HTlc concentration of 2.5 and 5% in weight. Focusing on the morphology of the 2.5% sample, we observe several clusters whose height ranges from a few tens up to hundreds of nanometers. These clusters have various dimensions and emerge from the surrounding keratin matrix. Though the preparation methods are different, the SEM images reported in Ref. [

3] indicate that the distribution and cluster dispersion may be similar to the case of HTlc dispersed in sponge scaffolds used for the osteoblast growth.

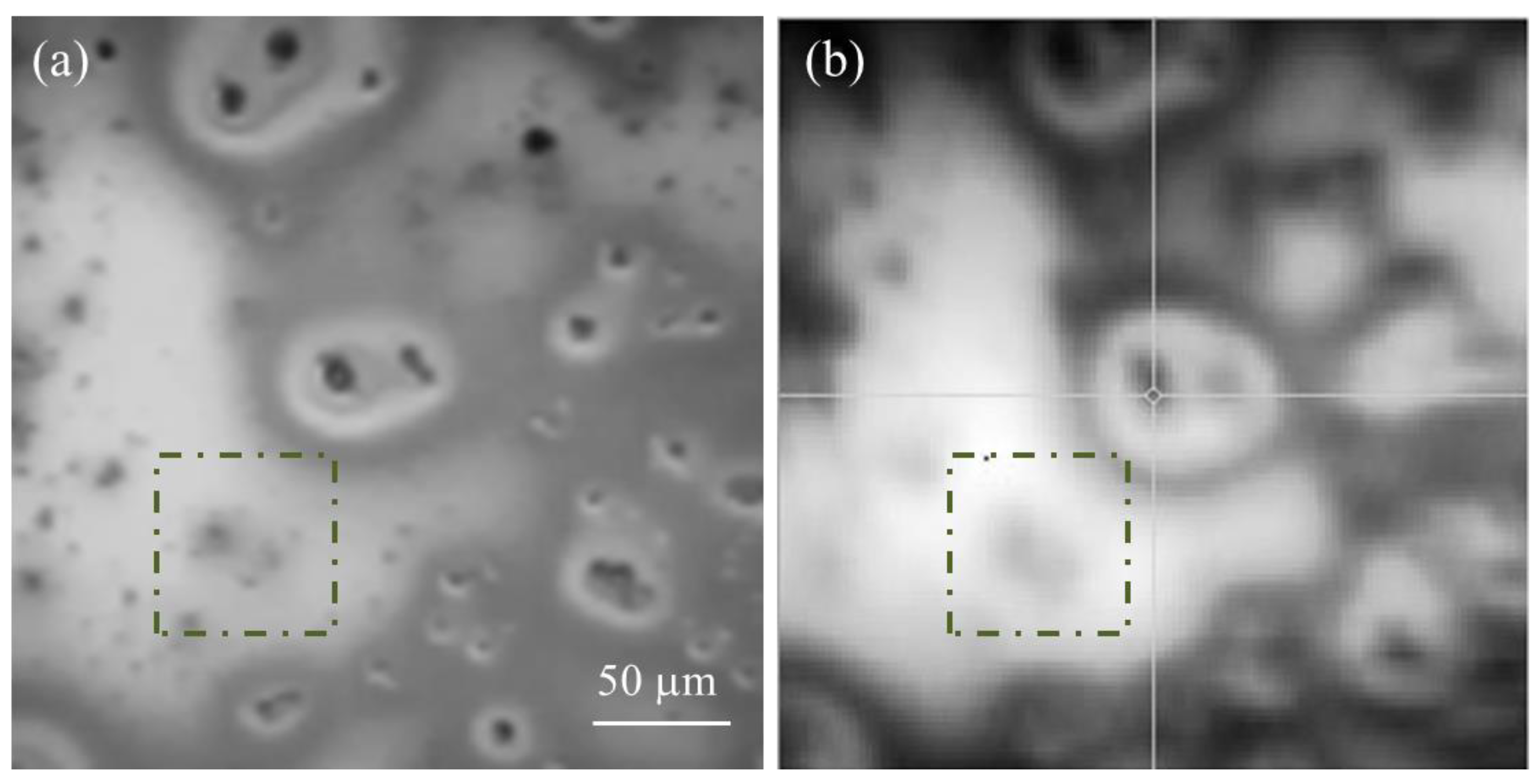

In

Figure 5, we report two pictures of the same area of a 2.5% sample. They are (a) an optical microscopy image and (b) a reflectivity map, recorded with NanoMOKE, that is obtained scanning the laser spot over the surface while recording the reflectivity. This map shows large variations in reflectivity from area to area because the clusters are dark. The optical image helps to correlate the reflectivity data with the presence of clusters. One further consideration needs to be immediately made: the reflectivity data of the films with clusters, obtained with NanoMOKE, is not as accurate as the optical one. This is due to the laser spot that has a finite lateral dimension, as it is the result of focalization. Its size is indicated by the manufacturer in a diameter of a few microns. From this comparison, we can divide the reflectivity maps in three regions, depending on the reflectivity value: low values larger HTlc clusters; intermediate values mixed areas, i.e., keratin with smaller clusters; high values keratin-only, possibly with some scattered nanoparticles not detectable either with optical microscopy or AFM.

In the following we now present the data obtained from an analysis of the various films with NanoMOKE. Our instrument can operate from 300K down to 7.5K. MOKE is the only instrument available that can map the local magnetic properties of a surface and therefore is suitable for filmed materials with good reflectivity. [

7] The software allows one to measure the Kerr rotation due to the application of an external magnetic field, that, in the configuration we have used, is parallel to the plane of the sample surface.

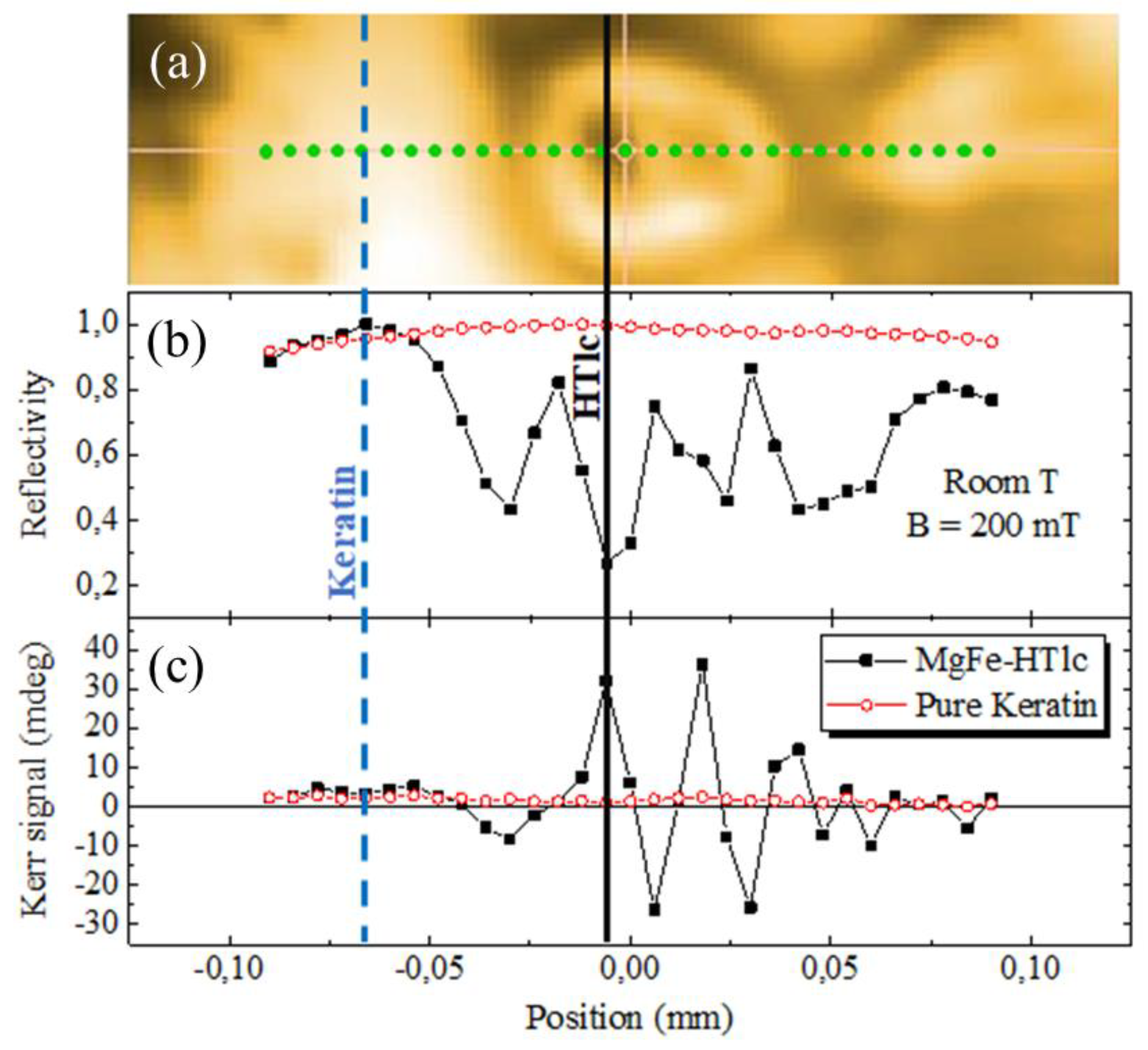

In

Figure 6, we first report a line scan performed at 300K on the region (a) already shown in

Figure 5. The acquisition has been performed with a pixel distance of 4 microns. This region has been selected to include clusters of different dimensions and some keratin-only areas. In the graphs, we also report data from a line of the same length and pixel distance on a film of keratin. Thus, we have plotted (b) the reflectivity and (c) the maximum Kerr rotation measured at the maximum field applied (200 mT) for a keratin film and a 2.5% 220nm sample.

The maximum Kerr rotation is obtained on large clusters. They have a peak value of around 20 mdeg, whereas the keratin-only region on the left shows a much smaller signal. These data agree with what is observed on powders. They also prove not only that NanoMOKE can identify clusters and keratin, but that it can provide a wealth of information. In particular, the instrument is sensitive to the local properties that may change at the interfaces of clusters and keratin.

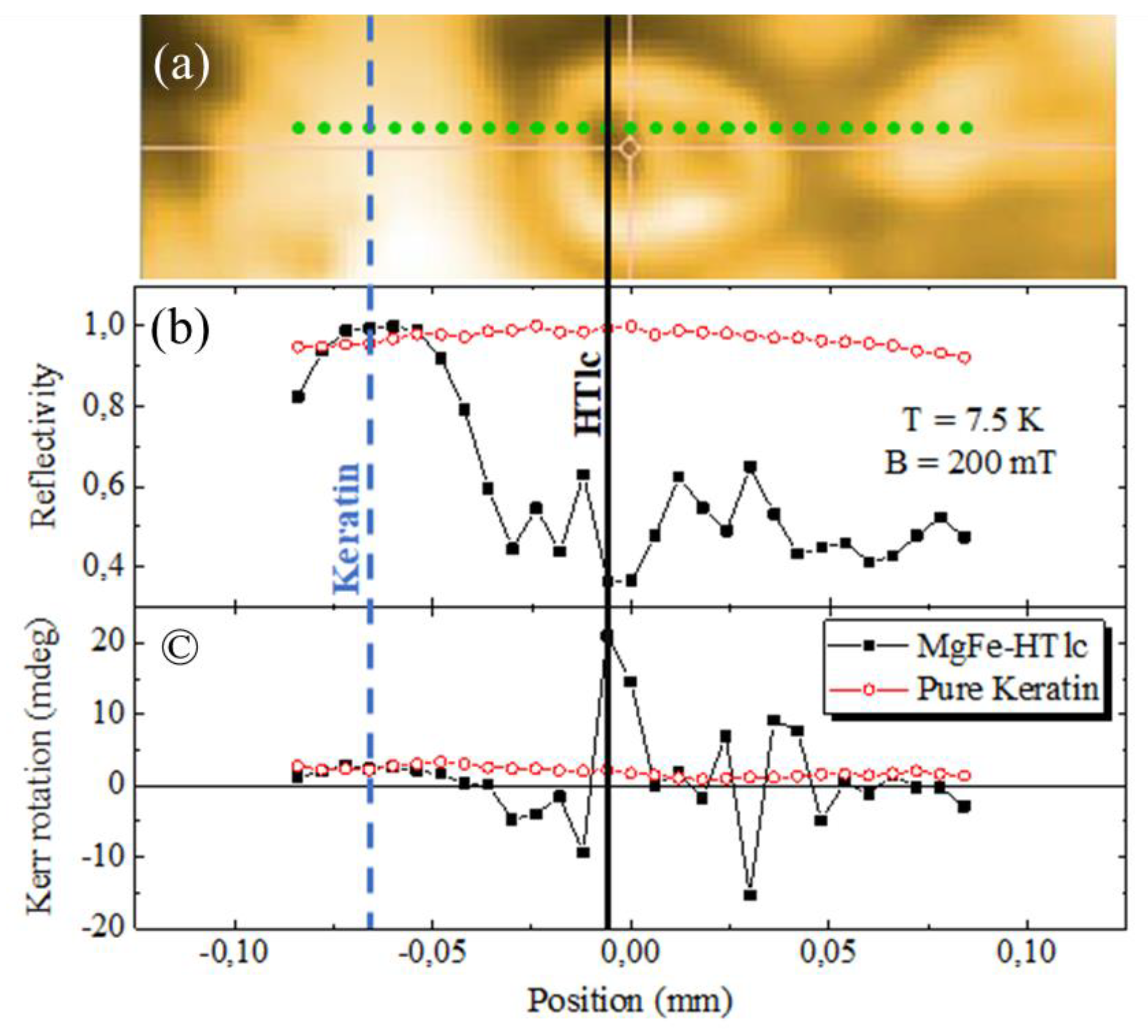

In

Figure 7, we then report data obtained from a line scan carried out in the same regions as in

Figure 6 but at 7.5K. The trend of the lines can be considered substantially similar both for the clusters and for the keratin regions. The little discrepancies measured in reflectivity and Kerr rotation may be due to the uncertainty in choosing and stabilizing the sampling position.

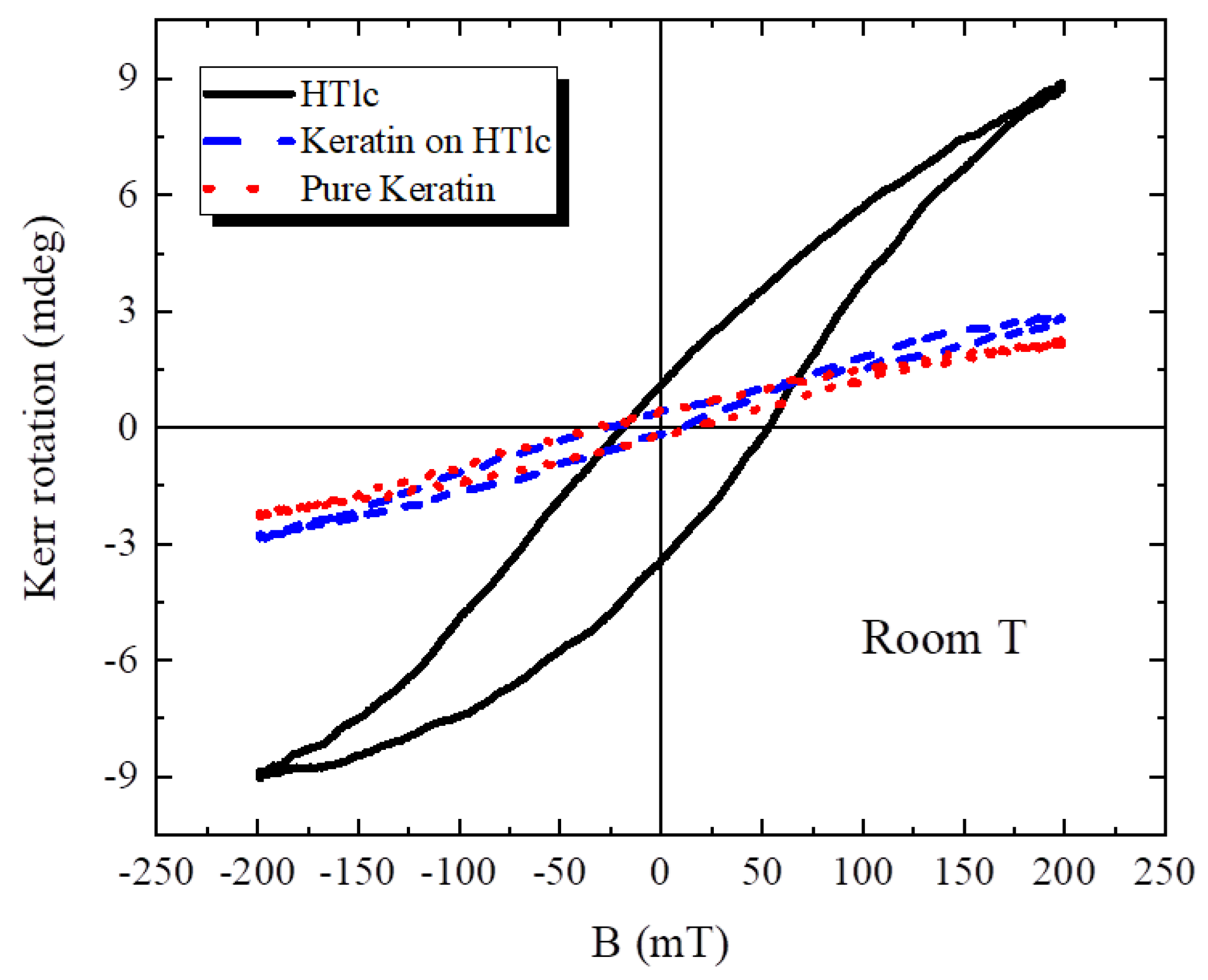

In

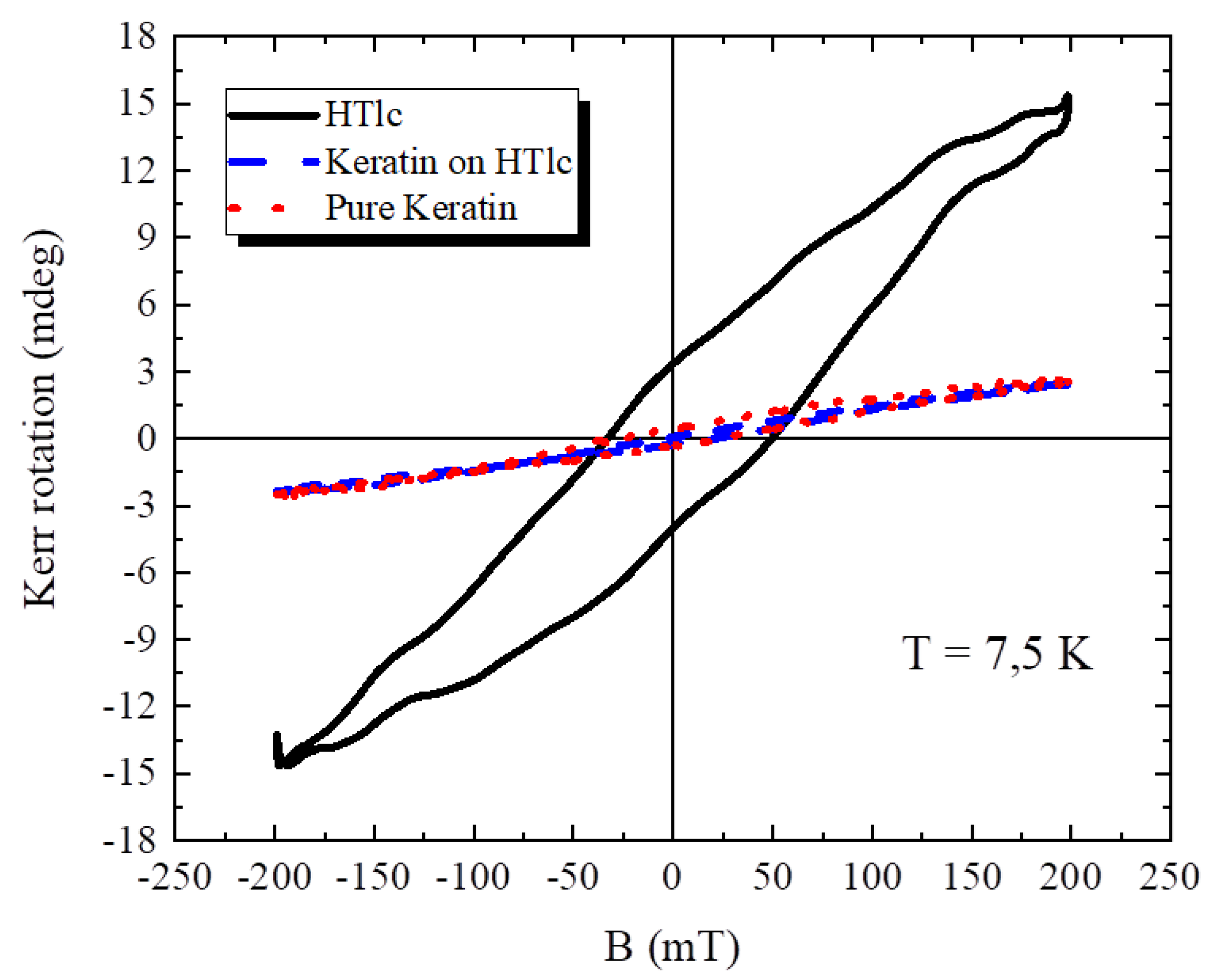

Figure 8, we show the characteristics of the entire cycle, i.e., Kerr rotation versus B curve for three specific regions at 300K: a pure keratin film, keratin-only in a 2.5% 220 nm film, and clusters in a 2.5% 220nm film. The data obtained for the keratin film show a low signal, very similar to the keratin-only regions. The regions with larger clusters present a much higher signal, that is in full agreement with the powder data with PPMS-VSM.

In

Figure 9, we present the Kerr rotation versus B curve for the same three regions reported in

Figure 8 but recorded at 7.5K. The data obtained are very similar to the ones collected at 300K. The only major difference is represented by an increase of the maximum Kerr rotation for the HTlc cluster. The little discrepancies measured in the Kerr rotation may be due to the uncertainty of the sampling position.

In

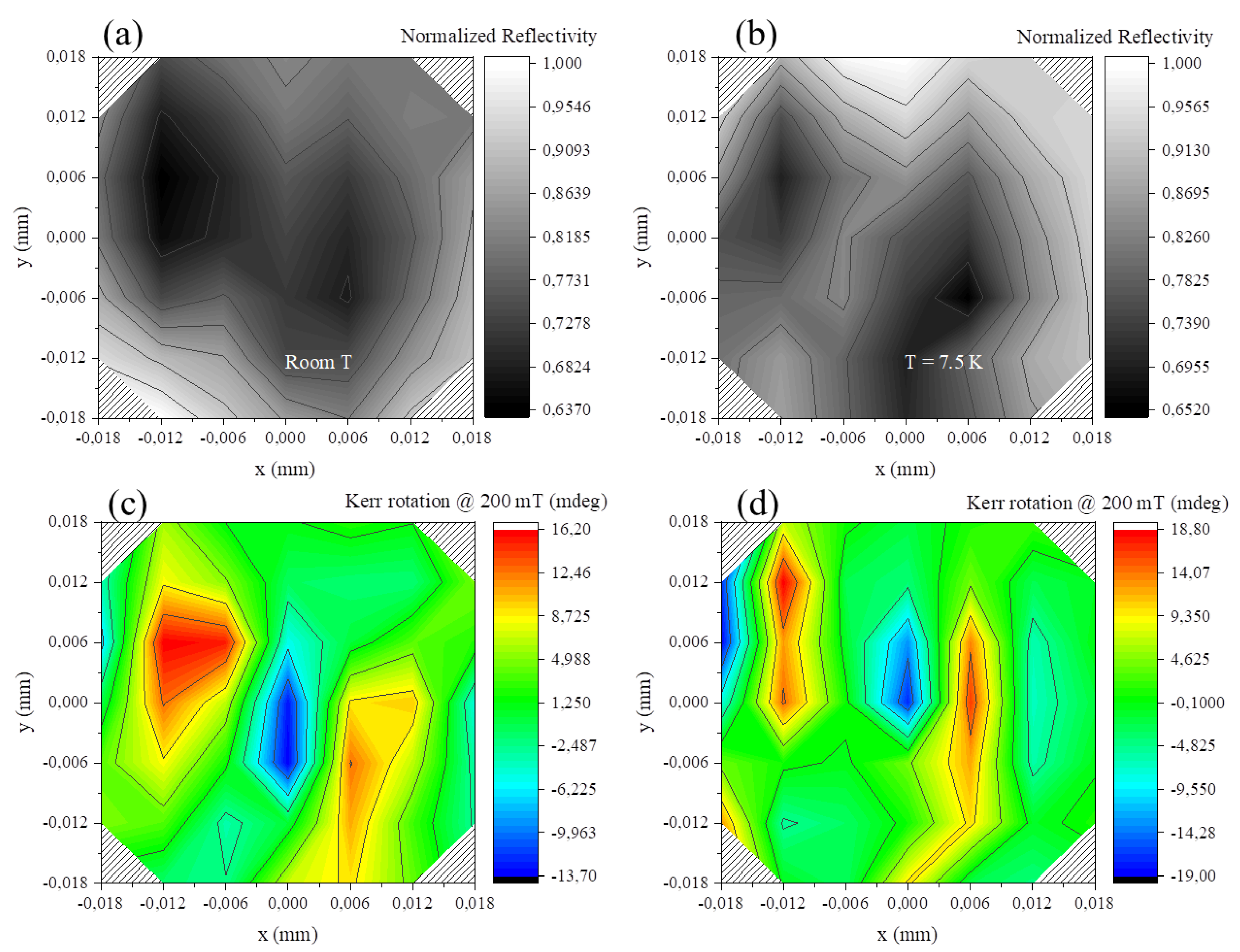

Figure 10, we finally present two bidimensional maps obtained on the area indicated with a square in

Figure 5. In (a, b) we report the reflectivity maps of the same region where the acquisitions were made. The measurements were performed at (c) 300K and (d) 7.5K. The area was chosen as we wanted to focus our investigation on relatively small clusters that are embedded in the matrix avoiding the large ones, which may have a more complex behavior due to the shape of the cluster.

These maps are plotted using a false color representation, that shows the maximum Kerr rotation measured at given x and y location for a field of 200 mT. The color bar visible on the right-hand side indicates the correspondence between color and maximum Kerr rotation. Sampling has been done with a pixel distance of 6 microns. The maps are quite clear in evidencing a stronger Kerr rotation of the clusters and a weaker one of the keratin-only regions.

The other parts shown in the map have a more complex contrast: the signal value sometimes corresponds to a negative Kerr rotation that could be associated to a diamagnetic behaviour, like in the case of the area located in the middle of the clusters. This proves once more the fact that NanoMOKE is rather sensitive to variations from point to point and can provide detailed information of the local magnetic properties.

4. Discussion

As already underlined, for a complete study of nanoparticles such as HTlc, to be employed within a polymer matrix in a composite structure, one needs to start from a careful analysis of the single components. In our case, the powder behaviour of the MgFe HTlc can be clearly described, as the powder shows a fully paramagnetic trend that is maintained from 300 down to 2.5K. In addition, the M versus B curve does not show hysteresis at both 300 and 10K. These are interesting observations in themselves. Other magnetic HTlc, like those made with Ni and Fe, show a super-paramagnetic behaviour, i.e., the M versus T plot presents a discontinuity at a few K, which can be identified with a blocking temperature TB. [

9] This result might be an indication that the overall properties of the MgFe HTlc are determined by the single magnetic atoms, i.e., that the Mg and Fe atoms do not form a crystalline lattice and do not interact with each other forming more extended magnetic domains.

On the other hand, keratin powder has a very weak response that only with NanoMOKE can be identified as paramagnetic. It is relevant to consider that the transmittance data of keratin in foils indicate that it is partially transparent, [

10] around 70% in the red region of wavelength. This is even more important when keratin is employed as a thin film. We can then assume that our thin films allow the transmission of laser through the whole thickness, thus sampling both keratin and the Si/SiO2 substrate. However, we have found that Si/SiO2 substrates have a weak diamagnetic signal, as it is reported in the literature for smooth Si/SiO2 interfaces. [

11] This is evidence that the keratin response is dominating the whole signal at all T values. In the literature available on this topic, we have only been able to find a paper that reports measurements performed with EPR and that indicates that a keratin molecule has paramagnetic centers. [

12]

In the HTlc/keratin films, the locations where keratin or the HTlc clusters are prevalent, the Kerr rotation versus B curves are in full agreement with the data obtained for the relative powders. Thus, a complete correlation between the PPMS-VSM graphs and the NanoMOKE maps has been found, both for the keratin and cluster regions. The main difference is however represented by the hysteresis of the Kerr rotation versus B curves. The PPMS-VSM curves do not show any opening of the cycle, whereas the NanoMOKE curves do at 300K and 7.5K. To explain this observation, it is relevant to clarify that the two techniques operate into two different time regimes. Specifically, the rate of the amplitude variation of the external field applied is quite different for the two cases: 1600 mT/sec for the NanoMOKE and only 10 mT/sec for PPMS-VSM. Therefore, they differ by more than 2 orders of magnitude. This might explain the differences in the curves, i.e., the system might not be able to fully relax magnetically when NanoMOKE experiments are performed.

Finally, the complexity of the data that can be contained in a NanoMOKE map provides enough evidence for the high sensitivity of this technique. The reflectivity map shown in

Figure 10 presents a bright location in between two dark ones (where some HTlc clusters are located) where the Kerr rotation becomes strongly negative. A possible explanation might be that in this area keratin thins down and we are sampling the Si/SiO2 substrate or that the magnetic field generated by the clusters combines to produce such a Kerr rotation. Though this complexity cannot be fully accounted for now, one can arguably sustain that this technique is rather powerful as it indicates local phenomena not easily predictable in advance. Further theoretical and experimental work are however necessary to fully explain the physical phenomena that determine the whole variety of information.

5. Conclusions

In this study, we have employed a range of different experimental techniques to characterize the magnetic properties of powder MgFe HTlc and thin films of MgFe HTlc dispersed in a keratin matrix. Specifically, our approach combines the use of a PPMS using the VSM option for the magnetic analysis of powder down to 2.5K, and NanoMOKE to map magnetically the surface of thin films with a few micrometers’ resolution down to 7.5K. In addition, we have also employed Optical and Atomic Force Microscopy to investigate the morphological properties of the studied film surfaces and correlate them with the magnetic ones.

Our findings show that keratin, a biocompatible material, presents a very weak paramagnetic behaviour in films at all temperature values. On the other hand, MgFe HTlc synthesized for bio applications have a fully paramagnetic behaviour in powder but also when dispersed in a keratin matrix. In particular, NanoMOKE allows mapping thin films with a remarkable lateral micrometric resolution and a high sensitivity, providing a wealth of details with regards to the local magnetic behaviour. This is a powerful approach viable for future investigations of other HTlc and magnetic nanoparticles, isolated or mixed within polymeric matrixes.

Author Contributions

M.P., F.D. and T.P. conceived and designed the experiments; F.D. and M.M. performed the experiments; F.D., M.M., A.G. and M.P. analyzed the data; T.P., M.S., R.Z. and G.S. contributed materials/analysis tools. All the authors contributed to the paper writing and agreed to the published version of the manuscript.

Acknowledgments

The authors would like to thank S. Paziani and D. Vitaglione from Quantum Design Italia for their availability and precious support in facing and solving some issues encountered during the measurements.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bellezza, F.; Cipiciani, A.; Costantino, U.; Nocchetti, M.; Posati, T. Hydrotalcite-like Nanocrystals from Water-in-Oil Microemulsions. Eur. J. Inorg. Chem. 2009, 2009, 2603–2611. [Google Scholar] [CrossRef]

- Wang, Q.; O’Hare, D. Recent Advances in the Synthesis and Application of Layered Double Hydroxide (LDH) Nanosheets. Chem. Rev. 2012, 112, 4124–4155. [Google Scholar] [CrossRef] [PubMed]

- Giannelli, M.; Barbalinardo, M.; Riminucci, A.; Belvedere, K.; Boccalon, E.; Sotgiu, G.; Corticelli, F.; Ruani, G.; Zamboni, R.; Aluigi, A.; et al. Magnetic Keratin/Hydrotalcites Sponges as Potential Scaffolds for Tissue Regeneration. Appl. Clay Sci. 2021, 207, 106090. [Google Scholar] [CrossRef]

- Das, J.; Das, D.; Dash, G.P.; Parida, K.M. Studies on Mg/Fe Hydrotalcite-like-Compound (HTlc): I. Removal of Inorganic Selenite (SeO32-) from Aqueous Medium. J. Colloid Interface Sci. 2002, 251, 26–32. [Google Scholar] [CrossRef] [PubMed]

- Bellezza, F.; Nocchetti, M.; Posati, T.; Giovagnoli, S.; Cipiciani, A. Synthesis of Colloidal Dispersions of NiAl, ZnAl, NiCr, ZnCr, NiFe, and MgFe Hydrotalcite-like Nanoparticles. J. Colloid Interface Sci. 2012, 376, 20–27. [Google Scholar] [CrossRef] [PubMed]

- Galluzzi, A.; Leo, A.; Masi, A.; Varsano, F.; Nigro, A.; Grimaldi, G.; Polichetti, M. Magnetic Vortex Phase Diagram for a Non-Optimized CaKFe4As4 Superconductor Presenting a Wide Vortex Liquid Region and an Ultra-High Upper Critical Field. Appl. Sci. 2023, 13, 884. [Google Scholar] [CrossRef]

- Qiu, Z.Q.; Bader, S.D. Surface Magneto-Optic Kerr Effect. 2000, 1243. [CrossRef]

- Dinelli, F.; Pingue, P.; Kay, N.D.; Kolosov, O.V. Subsurface Imaging of Two-Dimensional Materials at the Nanoscale. Nanotechnology 2017, 28, 85706. [Google Scholar] [CrossRef] [PubMed]

- Coronado, E.; Galén-Mascarós, J.R.; Martí-Gastaldo, C.; Ribera, A.; Palacios, E.; Castro, M.; Burriel, R. Spontaneous Magnetization in Ni-Al and Ni-Fe Layered Double Hydroxides. Inorg. Chem. 2008, 47, 9103–9110. [Google Scholar] [CrossRef] [PubMed]

- Posati, T.; Aluigi, A.; Donnadio, A.; Sotgiu, G.; Mosconi, M.; Muccini, M.; Ruani, G.; Zamboni, R.; Seri, M. Keratin Film as Natural and Eco-Friendly Support for Organic Optoelectronic Devices. Adv. Sustain. Syst. 2019, 3, 1–8. [Google Scholar] [CrossRef]

- Kopnov, G.; Vager, Z.; Naaman, R. New Magnetic Properties of Silicon/Silicon Oxide Interfaces. Adv. Mater. 2007, 19, 925–928. [Google Scholar] [CrossRef]

- Baitimirov, D.R.; Starichenko, D. V.; Pravlshkina, T.A.; Konev, S.F.; Shvachko, Y.N. Paramagnetism of Melanoprotein Fibres. Fibre Chem. 2006, 38, 506–512. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).