1. Introduction

With reduced available land area and the increasingly prominent problems of environmental pollution, the construction of underground sewage treatment plants that occupy less space, save land resources, have less environmental pollution, and can coordinate with the surrounding environment will gradually become a hot spot in the industry, and become a new development trend and direction of large-scale urban sewage treatment projects [

1]. The applicable conditions and scope of the underground sewage treatment plant include small amount of sewage, less available land on the ground, special requirements for the above-ground landscape, low groundwater level, easy-to-excavate geology, and the buried depth of the sewage return pipe is not very large [

1,

2]. It has a certain distance from residential buildings, is not a depression and does not accumulate rainwater, and the sewage discharge requirements are not very strict. Generally speaking, underground sewage treatment plants are suitable for construction in areas where thermal insulation needs to be considered, less requisitionable land area, and higher environmental requirements [

4,

5].

However, major problems such as ventilation, deodorization, and hidden safety risks also bring challenges to the construction of underground sewage treatment plants; problems such as flooding during the rainy season, rising effluent, sludge digestion, and inability to reserve space for upgrading and transformation [

6]. It also needs attention, and factors such as the limitation of land resources in China and the gradual improvement of effluent quality standards also restrict the design and application of underground sewage treatment plants to a certain extent. It is believe that, except for the design scale and design water quality, which are not significantly different from those of traditional above-ground sewage treatment plants. There are at least 10 aspects of process design in underground sewage treatment plants that are different from above-ground sewage treatment plants, including structural layout, process optimization , energy saving and consumption reduction, ventilation and deodorization, lighting and daylighting, fire safety, operation and maintenance, maintenance and technical transformation, flood control and drainage, emergency treatment technology. It is necessary to have core technologies that match those of underground sewage treatment plants in terms of pretreatment, biological treatment, and post-treatment enhancement. Based on relevant research and reports, there are corresponding norms and standards for underground sewage treatment plants in the United States, Japan, and the European Union. However, in China, due to the late start of research and development of underground sewage treatment plants; there are still no unified technical standards or norms to guide the engineering design and operation of underground sewage treatment plants.

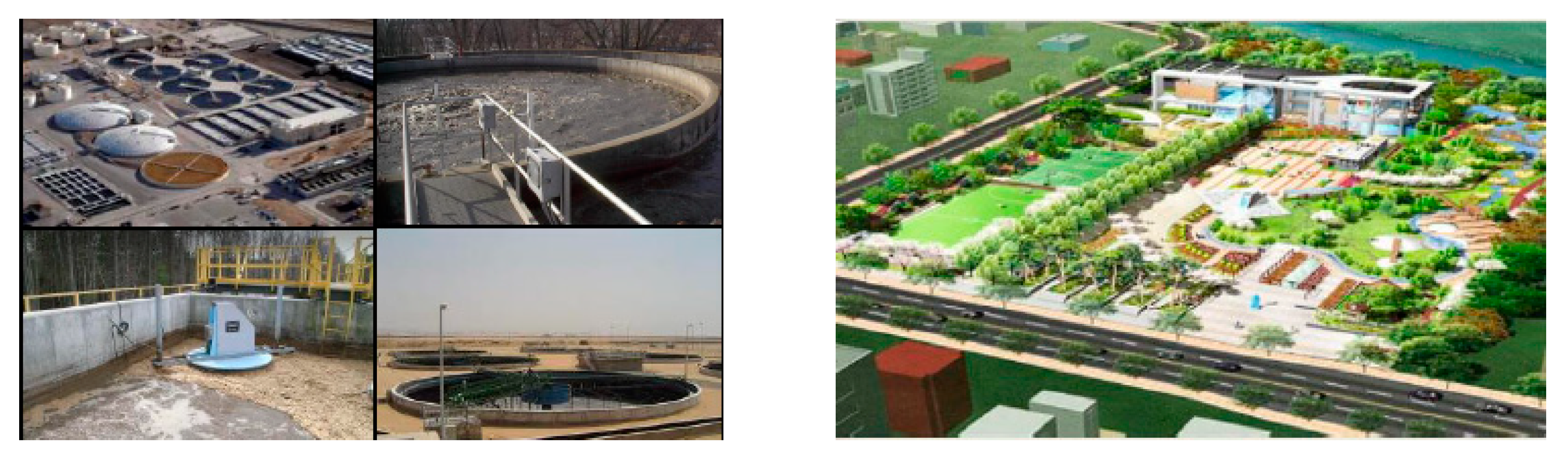

In view of related problems existing in above-ground sewage treatment plants, people have to try to change the design and construction ideas of sewage treatment plants. In this context, the underground sewage treatment plant with small footprint, space-saving, and low environmental pollution has gradually entered people's field of vision. It can solve the problem of the impact of noise and odor in sewage treatment on the lives of residents around the water plant, and can be treated nearby, does not need long-distance pipe network, does not affect the urban environment, and can also beautify the urban environment, which meets the needs of urban ecological civilization construction and development. The comparison effect of above-ground and underground sewage treatment plants is shown in

Figure 1.

This paper introduces the technical points and characteristics of the engineering design of underground sewage treatment plants, based on systematically analyzing the problems existing in the engineering design of underground sewage treatment plants, , Furthermore, it will explain the existing problems and countermeasures, and initially puts forward a set of suitable for guiding the engineering technical implementation plan of the construction, operation and maintenance management of underground sewage treatment plants in China, and provides technical reference for the compilation of China's "engineering technical specifications for underground sewage treatment plants".

2. Methodology and developmental processes

The occupied area and space are relatively small due to the underground design of the sewage treatment plant, so higher requirements are put forward for the size and performance of the main process equipment of sewage treatment. Some traditional sewage treatment processes used in above-ground sewage treatment plants are generally not used as the main body of underground sewage treatment plants or used alone due to factors such as large area, general denitrification and phosphorus removal efficiency, and large surplus sludge output. Some approaches with small footprint, large volume load, high treatment efficiency, and less residual sludge are widely used in the secondary or advanced treatment process of underground sewage treatment plants [

1,

2]. The following is an inventory of the technical process routes commonly used in underground sewage treatment plants in China.

2.1. MBR process

Membrane bioreactor (Membrane Bio-Reactor, MBR) is a new type of water treatment technology that combines activated sludge process and membrane separation technology. The MBR process has the advantages of high-quality and stable effluent (Grade A, and can reach the standard of surface IV water), less residual sludge production (1/2 of the traditional process), small footprint, high efficiency of nitrogen and phosphorus removal, and can realize the whole process It has the advantages of automatic control and so on, and it is one of the most advanced sewage treatment and recycling processes in the world.

Based on these advantages, the MBR process is especially suitable for the sewage treatment process of underground sewage treatment plants with limited floor space and high automation requirements, and has obvious advantages over other treatment processes. At present, many of the fully underground sewage treatment plants under construction and already built in China have adopted the MBR process (

Table 1). This process is highly intensive, has little impact on the surrounding environment, and the treated effluent can be directly used reload water in landscape river [

3,

4]. In addition, the MBR membrane filtration process is used to replace the traditional secondary sedimentation tank for advanced treatment, which can increase the sludge concentration in the biochemical tank while saving land, thereby improving the treatment efficiency of the system [

5].

Based on industry experts views, the MBR core technology of underground sewage treatment plants are relatively mature at present, and the area per ton of water is 0.26m2, and the investment per ton of water is about 4,000-5,000 yuan/ton. For areas with developed economy, highly tense land resources and high environmental requirements, underground sewage treatment plants with MBR as the main treatment process will become a new concept and development trend.

2.2. A2O, improved A2O and its combination process

Anaerobic-Anoxic-Oxic (A

2O) process is a commonly used sewage treatment process, which can be used in secondary and tertiary sewage treatment and reclaimed water reuse, and has good denitrification phosphorus removal effect. In order to further improve the processing capacity of the A

2O process, an anoxic pool can be added before the anaerobic pool at the front end of the A

2O process to enhance the effect of denitrification and denitrification. In this article , these upgraded A

2O processes are collectively referred to as improved A

2O processes. The improved A

2O process has the advantages of high nitrogen and phosphorus removal efficiency, effective inhibition of filamentous bacteria expansion, and low operating costs. In order to obtain higher and more stable effluent quality, the underground sewage treatment plant with improved A

2O as the main process is often used in combination with other process equipment during design, such as MBR, MBBR, deep bed filter, fiber rotary disc filter. Please refer to the

Table 2.

Among the various A

2O and their combined processes listed in

Table 2, the A

2O+biofilm combined pool (HYBAS) process adopted by Shenzhen Buji underground sewage treatment plant and the segmented influent A

2O used by Beijing Daoxianghu reclaimed water plant craftsmanship has distinctive features. Among them, the HYBAS process has the advantages of the activated sludge process and the fluidized bed biofilm (MBBRTM) process. Combining the two organic approaches in the same tank can significantly increase the sludge concentration and volume load, thereby improving the organic matter removal of the system and denitrification and phosphorus removal efficiency; the sub-influent A

2O biological denitrification and phosphorus removal process is mainly to solve the problem that the traditional A

2O process is difficult to realize simultaneous denitrification and phosphorus removal stably. At present, this process has been applied as the main process of Beijing Daoxianghu underground sewage treatment plant.

2.3. Other sewage treatment processes

- (1)

Moving bed biofilm reactor (MBBR) process

The MBBR process is a process in which a certain amount of suspended carriers are added to the reactor for microbial implantation to form a biofilm to achieve biological nitrogen and phosphorus removal and organic matter removal. The MBBR process has both the advantages of the traditional fluidized bed and biological contact oxidation methods. The sludge yield is low, no need to set up sludge return equipment, no need for packing supports, and overcomes the limitations of the traditional activated sludge method and fixed biofilm method of disadvantages and limitations. This process is widely used because of its low investment and convenient operation and management. The underground sewage treatment plant in Qingdao High-tech Zone is one of the most representative MBBR engineering cases. Although the cost per ton of water of the underground design is slightly higher than that of the above-ground design of the same scale. The MBBR process takes up less space and the operation and management costs are lower. Therefore, the comprehensive operating cost of the entire underground sewage treatment plant does not have obvious disadvantages compared with the above-ground design.

- (2)

Multi-stage AO process

The multi-stage AO process (Biolak process) is to set up multiple anoxic and aerobic areas in the same structure, so that the sewage can realize multi-stage anoxic and aerobic biochemical reaction processes, and the pre-anaerobic reaction area has reached a relatively high level. The multi-stage AO process of multi-stage water inflow is to enter the anaerobic zone, anoxic zone, facultative oxygen zone and aerobic zone of the biological pool in sections, so that the carbon source in the sewage can be selectively supplied to different functional zones, which is preferentially used for anaerobic phosphorus release and denitrification, which can effectively save carbon sources. Furthermore, it can also increase the sludge concentration and reduce the volume of the biological pool. The multi-stage AO series connection can cancel the internal reflux equipment, and the digestion liquid of the upper stage can completely enter the anoxic zone of the lower stage for denitrification, to strengthen the denitrification effect and improve the denitrification efficiency. The multi-stage AO process with multi-stage water inflow is one of the improved processes of A2O, which can distribute carbon sources more reasonably and reduce investment and operating costs. It has been applied in the underground sewage treatment plant in Guang'an City, Sichuan Province, China.

3. The development of underground sewage treatment plants

In recent years, underground sewage treatment plants have gained more and more attention in the process of urban sewage treatment in China and abroad because of their advantages of less land occupation, less noise and odor pollution, and better landscape than traditional above-ground sewage treatment plants with wide range of applications. The construction and application of underground sewage treatment plants developed in the world, with a history of more than 80 years [

13]. Finland built the world's first underground sewage treatment plant in 1932; most of Sweden's sewage treatment plants are underground, leading the world both in terms of quantity and quality. In addition, countries such as Japan, South Korea, the Netherlands, the United Kingdom, Norway, France, Switzerland, Monaco, and the Czech Republic have also built underground sewage treatment plants, which have effectively resolved the contradiction between sewage treatment, environmental pollution, and urban land use, and achieved great results of economic and social benefits. China started late in the construction of underground sewage treatment plants. Hong Kong operated the first underground sewage treatment plant with a treatment capacity of 12,000 tons per day in 1995. Large and medium-sized cities in some provinces of China have gradually begun to build underground sewage treatment plants, the smallest of which is Guilin City Leping sewage treatment plant (10,000 tons/day), the largest operating scale is Shenzhen Buji sewage treatment plant (200,000 tons/day), and the scale of Beijing Huaifang underground sewage treatment plant under construction has reached 600,000 tons tons/day.

3.1. Status quo of development and application

Cities in developed countries such as Europe, the United States, Japan, and South Korea attach great importance to the use of underground space. The purpose is mainly in two aspects: to prevent the impact of extremely cold weather on the sewage treatment effect, such as Sweden, Finland, Norway and other Nordic countries; and to save urban land resources, such as Singapore, Japan, South Korea, the Netherlands and other countries . Foreign countries have experienced quite a long period of time in the development and utilization of underground space, and urban underground drainage and sewage treatment systems have also made great progress. A considerable number of underground sewage treatment plant projects have been built and obtained good environmental, economic and social benefits.

Table 3, summarizes some of the low-water treatment plants operating in developed countries.

Finland is the first country in the world to build underground sewage treatment plants [

2]. In 1932, Finland began to build underground sewage treatment plants, but due to technical limitations, it failed to further develop. Until 1991, the underground space development technology at that time was relatively mature, and starting from the premise of environmental protection, land resources and economic benefits. Finland decided to build a large-scale underground sewage treatment plant in the center of the capital Helsinki - Viking. The McKee Center sewage treatment plant is used to treat municipal domestic sewage and reduce pollution problems in the Gulf of Finland. The underground sewage treatment plant was completed in 1994, with a design scale of 328,000 tons per day and a total project cost of US

$215 million, of which the underground sewage treatment plant itself cost US

$198 million. The establishment of the treatment plant has accelerated the development of underground sewage treatment plants in Finland, effectively realized environmental protection, land resource conservation and economic benefits, and is of great significance to improving the living environment of Helsinki and preventing environmental pollution.

Sweden also developed an underground sewage treatment plant earlier, with a history of more than 70 years. In 1942, Stockholm, the capital of Sweden, took advantage of the local superior geological conditions and advanced rock excavation technology to build the world's first modern one. For underground sewage treatment plant, the ground of the whole plant area is arranged as a park. The entrance of the underground sewage treatment plant adopts ingenious architectural art, which greatly beautifies the city appearance and increases the green area for the city at the same time [

4]. Most of the sewage treatment plants in Sweden adopt the underground construction mode. Although most of them are built in densely populated areas, the underground construction mode ensures that the lives of the surrounding residents are basically not affected in any way.

Korea is also at the forefront of the world in the application of underground sewage treatment plants. In recent years, in order to save land, most of the newly built underground sewage treatment plants in South Korea have adopted the underground construction mode, which is said to account for about 50% of all sewage treatment plants in South Korea. One of the more representative cases is the upgrading and renovation project of the Suyeong above-ground sewage treatment plant in the center of Busan. With the rapid development of social economy, Seoul, South Korea is facing various problems such as higher requirements for effluent water quality, shortage of urban land, and increasing requirements for the living environment of people around the water plant. It is imperative to change the original Suyeong sewage treatment plant into an underground type. It is also listed as one of the important contents of urban sewage treatment infrastructure construction in Busan City in the next 20 years. The upgraded underground sewage treatment plant adopts a three-stage treatment scheme of pretreatment + biochemical treatment + membrane filtration, with a designed treatment scale of 100,000 tons per day.

The Dokhaven sewage treatment plant in the Netherlands is located in the center of Rotterdam, the second largest city in the Netherlands. It is the only underground sewage treatment plant in the Netherlands, and only the central control room is built on the ground. Built in 1987, this sewage treatment plant has been in operation for 28 years. The sewage treatment adopts the AB process, and the sludge generated in the mainstream section is transported to the Sluisjesdijk sludge treatment plant 600 meters away for anaerobic digestion. The reason for choosing the AB process is that the process occupies a small area, and its compactness is just suitable for the lack of planned land for construction, and the effluent standard at that time had no restrictions on nitrogen and phosphorus. The reason why the water plant chooses the underground construction mode is because the land where the water plant is located is multi-purpose and has little impact on the surrounding environment.

From the above-mentioned cases of underground sewage treatment plants in foreign countries, it can be seen that rich construction experience, leading technology and advanced landscape design concepts have enabled some underground sewage treatment plants in the above countries to achieve economic and social benefits while also achieving economic and social benefits. It has achieved huge environmental benefits, and it is worth learning and learning from in China, when building underground sewage treatment plants.

4. China’s development and application status

4.1. The background of underground sewage treatment plants in China

- (1)

The cost of renovation and relocation of above-ground sewage treatment plants is huge

The noise, odor and other pollution generated during the operation of the above-ground sewage treatment plant will adversely affect the physical and mental health of the surrounding residents. With the continuous development of China's urban economy and the continuous improvement of people's requirements for the quality of living environment, the sewage treatment plants previously built in the city center have to face the problem of renovation and relocation, and the cost is huge. The underground sewage treatment plant can be built in the center of the city. The underground closed design can prevent noise, odor and other pollution, which is suitable for the sewage treatment needs of future urban development.

- (2)

High water quality and quantity requirements for river replenishment

With the development of the economy and the continuous increase of the total amount of urban sewage discharge, the water quality of the water environment is deteriorating day by day. Urban rivers have not played their due role in beautifying the environment. The existing above-ground sewage treatment plants have low sewage treatment efficiency, and the effluent water quality is generally closely related. Underground sewage treatment plants generally adopt more advanced treatment processes and equipment, and the effluent water quality is above grade A or higher, which can be used to replenish water in urban rivers and improve the quality of the water environment.

- (3)

Rapid growth of urban land prices

The construction of above-ground sewage treatment plants will occupy a large amount of urban land resources. With the continuous increase of urban land prices, the construction cost of above-ground sewage treatment plants will be significantly increased. Furthermore, the environmental pollution of the above-ground sewage treatment plant will also cause the depreciation of surrounding land resources. In addition, isolation belts need to be set up between the factory area and surrounding residential areas and commercial areas, which will waste land resources and affect the image of the city.

In this context, people gradually realize that the underground sewage treatment plant that takes up less space, saves land resources, has less environmental pollution, and can be coordinated with the surrounding environment meets the needs of urban development and water pollution prevention in China. Underground sewage treatment plants have achieved rapid development in recent years.

4.2. Development status

There are few underground sewage treatment plants in China, and this technology started relatively late. In addition, China's water treatment industry as a whole has a relatively limited understanding of the advantages and development prospects of underground sewage, so relatively little capital investment. Since the 1990s, due to the increasing demand for intensive land use and environmental landscape in cities, the construction of underground sewage treatment plants has been promoted to a certain extent. Underground sewage treatment plant projects have a clear upward trend in China, and some directly built is an underground reclaimed water plant, providing a new model for the construction of urban sewage treatment facilities and the recycling of water resources.

Although the total number of underground sewage treatment plants in China has increased a lot compared with the past, compared with the current more than 3,800 above-ground sewage treatment plants in the country, the proportion of underground sewage treatment plants is still very small. At present, the choice of building an underground sewage treatment plant is mainly due to the consideration of planning, land, environment and other constraints. Although the number of underground sewage treatment plants accounted for a relatively low proportion (~3%) of China's sewage treatment at the end of the "Twelfth Five-Year Plan" period, the growth trend was obvious throughout the "Twelfth Five-Year Plan" period. The amount of treated water and total investment has increased for about 10.4% and 20.8% of the treated water volume and total investment of sewage treatment plants respectively.

Underground sewage treatment plant projects have been launched in Beijing, Shanghai, Guangzhou, Kunming, Hefei, Qingdao, Suzhou, Guilin, Xiamen, Shijiazhuang, Wenzhou, Taiyuan and other cities so for, and nearly 40 underground sewage treatment plants have been put into operation running or under construction, the total processing capacity is near to 4.9 million tons/day. Among them, there are 22 underground sewage treatment plants in operation, with a total treatment capacity of nearly 1.9 million tons, as shown in

Table 4. There are 17 underground sewage treatment plants under construction, with a total treatment capacity of more than 3 million tons.The treatment scale of treatment plants is showing an increasing trend, as shown in

Table 5. Most of these underground sewage treatment plants are led or participated in the design and construction of the four major sewage treatment companies, including China Water Environment Group, Beijing Enterprises Water, Origin Water, and Sound Group. According to the statistics, the four major enterprises have more than 20 underground sewage treatment plant projects under construction and in operation.

At present, the construction of underground sewage treatment plants in China is booming, and related technologies are also playing an increasingly important role in the field of international sewage treatment. Among them, the Pantai underground sewage treatment plant in Malaysia [

15] and the second Changi NEWater plant in Singapore are notable representatives [

16].

The Pantai underground sewage treatment plant in Malaysia is located in Kuala Lumpur. It adopts the construction method of all underground treatment structures. The designed scale of sewage treatment is 320,000 tons per day, covering an area of 10.5 hectares. It is the first underground sewage treatment plant invested by a Chinese company overseas. The project adopts the improved A2/O denitrification and phosphorus removal process, and adopts the ClO2 disinfection scheme after the low-load secondary sedimentation tank effluent, a standard. The sludge is digested and concentrated, then dehydrated and transported outside for disposal. It is used in the biogas power generation plant, and the waste heat is used for refrigeration; the regenerated water is filtered and decolorized by ozone through the "ultrafiltration membrane" for the recycling of ground landscape water. In order to protect the environment and effectively utilize the upper space of the sewage plant, the functional division of the Pantai sewage treatment plant project is clear, the layout is reasonable, and compact, which meets the requirements of production, life, and consumption, and is coordinated with the upper leisure park. The production area is completely separated from the park leisure area. Management can provide nearly 140,000 m2 of leisure parks and green landscapes.

Singapore Changi No. 2 NEWater Plant DBOO project is currently under construction, with a project scale of 228,000 tons/day, using "microfiltration + reverse osmosis "The dual-mode technology process treats the effluent from the secondary sedimentation tank of Singapore's Changi Sewage Reuse Plant into NEWater, which is discharged after ultraviolet disinfection treatment, and the NEWater is transported to the Singapore NEWater pipeline network system.

5. Problems and challenges

In China, the reason for choosing to build an underground sewage treatment plant is due to environmentally friendly conditions; land conservation and resource reuse [

17]. However, the following problems cannot be ignored:

- (1)

The construction cost

The construction of an underground sewage treatment plant requires deep foundation pit excavation and layered layout [

18], which is difficult and costly. In general, the investment cost of an underground sewage treatment plant (4000-6000 yuan/ton) is 2-3 times that of an above-ground sewage treatment plant of the same scale (2000 yuan/ton) [

19,

20]. The underground sewage treatment plant occupies a limited area, so it is necessary to choose a process and corresponding equipment with a compact structure, high treatment efficiency, and higher requirements for operation and maintenance, thus relatively increasing the overall cost of process equipment, operation, maintenance and maintenance costs. The underground needs to add deodorization and ventilation equipment, and the operating cost is also high. The power consumption of these two items may reach 30-50% of the entire underground plant [

21,

22].

- (2)

High risks and great potential safety hazards

Due to the fully enclosed underground design, the toxic and harmful gases generated during the sewage treatment process need to be airtightly treated and disposed off before being discharged into the atmosphere, but there is a risk of odorous gas leakage, which will affect the health of underground workers [

23]. Studies have pointed out that hydrogen sulfide, ammonia, and volatile organic compounds such as methyl mercaptan and methyl sulfide produced in the sewage treatment process of underground sewage treatment plants will cause serious harm to human health. The noise pollution in the sewage treatment process will also have an impact on the health of workers [

24]. The potential safety hazards of underground sewage treatment plants cannot be ignored. When the water treatment plant is powered off or encounters heavy rainfall, water backflow and sewage leakage may occur, resulting in the hidden danger of water plant being flooded [

25,

26]. It is said that at least three gates should be installed in the underground sewage treatment plant to ensure the waterlogging prevention of the sewage treatment plant. Furthermore, the underground sewage treatment plant also has fire hazards due to its underground closed construction form. It is necessary to set up corresponding fire protection zones according to different sub-areas of underground structures [

27].

- (3)

Single ground landscape design

The above-ground landscape design of the underground sewage treatment plant can increase the value of the above-ground space and its surrounding land, thereby offsetting the relatively high construction, operation and maintenance costs generated by the underground construction, driving the social and economic development around the water plant, and promoting the ecological environment, environmental harmony and social development. Although the above-ground landscape design of underground sewage treatment plants in China has achieved certain development, there are still problems such as insufficiently advanced concepts and concepts, relatively single models, and insufficient functions [

28]. There is still a lot of room for improvement in the aboveground landscape design of underground sewage treatment plants in China. For example, diversification and functional design can be carried out around the carrier of underground sewage treatment plants, and multi-functional places can be established [

29,

30,

31].

- (4)

Lack of normative document guidance

Standardization is an essential factor to ensure the smooth development of underground sewage treatment plants, and the lack of corresponding standards and technical specifications is also a problem faced by underground sewage treatment plants. It is known that in the United States, Japan, and the European Union, there are corresponding norms and standards for underground sewage treatment plants [

32]. In China, the construction and operation and maintenance of underground sewage treatment plants can only rely on traditional experience or directly "move" the above-ground sewage treatment plants to deep underground foundation pits. There is no national technical standard to uniformly standardize underground sewage treatment plants However, the existing "urban sewage treatment project construction standards" and "urban sewage treatment plant pollutant discharge standards" can only meet the construction, operation and pollution index discharge standards of above-ground urban sewage treatment plants. The requirements of relevant regulations cannot be used in the specification requirements of engineering design, construction, equipment installation, operation and maintenance of underground sewage treatment plants [

33].

- (5)

Insufficient government subsidy policy and capital investment

Currently, the Chinese government has not issued a document to provide specific subsidies for the construction of underground sewage treatment plants, only found that there are relevant subsidy policies in some places, such as repurchase at high prices for landscape water. For example, the Tangxi River Reclaimed Water Plant in Hefei City, Anhui Province, uses membrane technology, consumes a lot of electricity, and the operating cost per ton of sewage treated is more than 1 yuan. Therefore, the operation of the underground sewage treatment plant mainly relies on subsidies from the local government. Repurchase reclaimed water at a price of more than one yuan and use it as landscape water in wetland parks to ensure that the income and expenditure of the underground sewage treatment plant can basically be balanced and maintain its long-term operation [

9]. In terms of capital investment, although the investment in the construction of underground sewage treatment plants in China has increased significantly during the "Twelfth Five-Year Plan" period, there is still a significant gap compared with the investment in above-ground sewage treatment plants, accounting for only 10% of the total investment. As China's urban land resources become increasingly rare and people's requirements for the quality of the living environment continue to improve, China is bound to increase capital investment in the construction of underground sewage treatment plants.

Overall, the construction of underground sewage treatment plants in China is booming at present, but the existing problems cannot be ignored. How to overcome and alleviate the above problems through technological innovation, economic measures and policy support is the key to determine the application and development prospects of underground sewage treatment plants in China in the future.

6. Purpose and objectives

In April 2015, the "Water Pollution Prevention and Control Action Plan" (also known as "Water Ten Measures") was officially promulgated, which pointed out the direction for China's "13th Five-Year Plan" period for water pollution control. As the top priority of China's water environment control, the treatment of urban domestic sewage will also be greatly developed. In the future, urban domestic sewage treatment will not only pay attention to the treatment cost and effluent quality, but also pay attention to the socio-economic and environmental benefits generated by sewage treatment. Therefore, underground sewage treatment plants with significant advantages in these aspects will surely become a new choice and development trend for large-scale urban sewage treatment projects in China in the future.

In view of the many problems in the construction and application of underground sewage treatment plants in China, this paper intends to conduct research on the design form and main process optimization selection of underground sewage treatment plants, engineering structure design and ground landscape design, etc. It also analyzes and discusses the key issues in the development and application of underground sewage treatment plants suitable for China's national conditions in the future, and provides technical support and theoretical basis for the in-depth promotion and wide application of underground sewage treatment plants in China in the future.

This article combines the literature research and the field research of some underground sewage treatment plants in operation in China, and intends to carry out relevant research from the following aspects:

Based on the on-site investigation of some of the underground sewage treatment plants in operation in China, to understand and grasp the engineering investment, effluent water quality, and social, economic and environmental benefits of different design forms and different treatment processes of underground sewage treatment plants, The advantages and disadvantages of different design forms and main processes of underground sewage treatment plants in terms of cost and benefit are compared and analyzed, and the optimal design form and process of underground sewage treatment suitable for different treatment scales and effluent quality requirements are proposed according to local conditions.

- (2)

Engineering design

In view of the fact that the design and construction of underground sewage treatment plants are significantly different from those of above-ground sewage treatment plants in China to guide the construction and operation of underground sewage treatment plants. This paper intends to start from the perspective of underground sewage treatment plants. Design of treatment scale and degree of treatment, project site selection and construction form design, underground layout and structure design, main process design, single structure design, ventilation and deodorization design, daylighting and lighting design, fire protection and safety design, operation and maintenance design, above-ground Research on the engineering design content of underground sewage treatment plants in terms of landscape and underground building linkage design, so as to give preliminary suggestions on the content of engineering technical specifications for underground sewage treatment plants in China, in order to guide the design of underground sewage treatment plants Provide technical reference with operations.

- (3)

Aboveground landscape design

In view of the relatively backward design concept, relatively single model, and insufficient functions in the above-ground landscape design of underground sewage treatment plants in China. Some key contents of the landscape design are respectively discussed in terms of design style, design features, design concept, eco-friendliness, and maintenance costs. Discussion; combined with actual engineering cases, the cost and benefit of above-ground landscape design are analyzed, and proposals for above-ground landscape design of underground sewage treatment plants are given, and the value and significance of above-ground landscape design for underground sewage treatment plants are pointed out.

- (4)

The model and technology development direction

Aiming at the current problems of China's underground sewage treatment plants, such as single construction mode, insufficient landscape design innovation, and narrow development ideas for above-ground space, from the aspects of design concept innovation, breakthroughs in key sewage treatment technologies, diversification of investment and operation methods, and large-scale and In terms of the promotion of semi-underground underground sewage treatment plants. The key content of the development and application of underground sewage treatment plants in China in the future is preliminarily discussed, in order to further improve the social, economic and environmental benefits of underground sewage treatment plants and save underground pollution. It provides a reference for the construction cost of the traditional sewage treatment plant and its promotion and application.

In view of different design forms of sewage treatment plants such as underground, semi-underground, above-ground, above-ground fully enclosed, and different sewage treatment processes such as A2O, MBR, and SBR, which are currently used in urban sewage treatment plants in China, this section lists relevant researches. The case outlines the treatment scale, service area, overall investment, design form, secondary and advanced treatment main process, influent and effluent water quality, engineering characteristics, etc. of each sewage treatment plant, providing a basis for subsequent comparative analysis.

6.1. Fully underground

- (1)

Shenzhen Buji Sewage Treatment Plant——A2O-Biofilm Co-pool Process

Shenzhen Buji Sewage Treatment Plant is located in Buji Street, Shenzhen. It started construction in April 2008 and started trial operation in April 2011. The construction period is nearly 3 years. The designed sewage treatment capacity is 200,000 tons/day. The load can reach 260,000 tons/day. The planned land area of the project is 5.95 hectares. After deducting the area occupied by river improvement and diversion, the actual land area is 4.6 hectares, the total investment is 590 million yuan, the service population is 450,000, and the sewage discharge implements the first-class.

The planned land of Buji Sewage Treatment Plant is narrow, long, narrow and irregular. In order to effectively save land resources and improve land use efficiency, an all-underground design is adopted. The main structures are all located underground, and the upper space is built as a municipal leisure park. The construction area of the leisure park is about 4.30 hectares. The thickness of the top layer of the underground structure is 1.5m, and deep-rooted large tropical plants are planted. The overall construction of the factory environment and leisure park landscape can not only coordinate with the surrounding topography, but also integrate with the street park and green belt of Yuebao Road Section, which fully embodies the harmonious concept of integration of man and nature.

The HYBAS process is a composite process of biofilm and activated sludge. It has the advantages of activated sludge process and fluidized bed biofilm (MBBRTM) process. The two are organically combined in the same pool, and it is equipped with double-layer advection type secondary sedimentation. The pool not only operates stably and ensures that the effluent water quality reaches the standard of Class A or above, but also can effectively save the land used for project construction, so that the actual land occupation per ton of water of the project is only 0.23 m2/ton, which is much smaller than that in the "Urban sewage treatment project The land occupation index of the same scale sewage treatment plant in the Project Construction Standard (0.75 m2/ton/day). The sewage advanced treatment unit uses a D-type filter, and the phosphorus removal effect is improved by adding PAC.

- (2)

Kunming Ninth Sewage Treatment Plant - MBR Process

Kunming No. 9 Sewage Treatment Plant is one of the key projects in the "Twelfth Five-Year Plan" for Dianchi Lake treatment. It was officially put into operation at the beginning of 2014. Its operation has further improved the overall sewage treatment capacity of Kunming City, making Kunming a city around Dianchi Lake. The sewage treatment capacity has increased to 1.91 million tons per day, effectively reducing the pollution load discharged into Dianchi Lake. The project investment of Kunming Ninth Sewage Treatment Plant is 650 million yuan, of which the total construction investment is close to 450 million yuan, and the construction investment per ton of water is 4,500 yuan, which can be reduced to about 4,000 yuan after process optimization. The sewage treatment plant covers an area of 2.8 hectares, with a treatment capacity of 100,000 tons per day, a service area of 22.85 square kilometers, and a population of nearly 300,000.

The whole underground double-layer design is adopted. The sewage treatment facilities and maintenance units are located on the second floor and the first floor of the basement respectively. Only one office building is on the ground, and the other spaces are built into open landscape parks which make the sewage treatment plant and the surrounding, achieving environment harmony and unity, improving the comprehensive quality of the city. Kunming No. 9 sewage treatment plant adopts membrane bioreactor (MBR) treatment process. Sewage is treated successively through screens, grit chambers, fine screens, biochemical tanks, and membrane tanks. Finally, it is lifted by the produced water pump and discharged after disinfection.

The MBR process has the advantages of high treatment efficiency, good effluent quality, compact equipment, and small footprint. It is very suitable for use in underground sewage treatment plants, making the main indicators of effluent water quality of the water plant better than the "Pollutant Discharge of Urban Sewage Treatment Plants" Standard" (GB18918-2002) Class A standard, similar to Class II water standard. The 40,000 tons/day reclaimed water produced by the Ninth Sewage Treatment Plant can be used for surrounding landscaping and municipal miscellaneous purposes, effectively improving the efficiency of water resource recycling.

- (3)

Beijing Daoxianghu Reclaimed Water Plant——Segmented Water Inlet A2O Process

Beijing Daoxianghu Reclaimed Water Plant is located in the northwest of Haidian District, Beijing. It officially started construction in August 2013 and will be put into operation in 2016. The water plant is based on the reconstruction of the original above-ground sewage treatment plant. It covers an area reduced from the original 17 hectares to the current 4.47 hectares, a reduction of nearly three-quarters. The treatment capacity is 160,000 tons per day, and the service area is about 34.5km2, the investment in the first phase of the project is about 480 million yuan, and the treatment capacity is 80,000 tons/day. It is currently the largest underground sewage treatment plant and reclaimed water plant in the northern region.

The Daoxianghu reclaimed water plant adopts the A2O denitrification and phosphorus removal technology in the influent. The problem of insufficient sources makes the effluent meet the quasi-IV surface water standard. On the one hand, the treated reclaimed water is directly used for the water landscape of the ground garden of the factory area, and on the other hand, it is used for water replenishment of rivers and lakes and urban miscellaneous water.

At the same time, the water plant adopted technologies such as rectangular sedimentation tanks entering and exiting each other, multi-stage and multi-stage biological deodorization technology, water source heat pump heat recovery technology [

34], precise aeration, precise dosing and natural lighting, etc., to achieve low carbon run.

The water reclamation plant makes full use of the vertical space and is divided into landscape park, covering soil layer, maintenance operation layer and sewage treatment layer from top to bottom. The basement negative floor is the maintenance operation layer, and the top is covered with soil for comprehensive utilization as urban green space resources; the lower structure is the main body of sewage treatment, and sewage treatment facilities are set up. After the completion of the project, it has played a very good role in improving the surrounding ecological environment, residents' public service facilities and cultural development. At the same time, it has carried out the high-end technology research and development mission of BEWG headquarters [

35,

36,

37,

38,

39].

The ground space of the Daoxiang Lake Reclaimed Water Plant is positioned to create a low-carbon demonstration park with distinctive characteristics, including an ecological park, a vitality park, a cultural park and a high-end technology research and development base, making it a green engine for regional development, improving the ecological environment and driving The surrounding land has appreciated in value, and has become a public service center and activity center for surrounding citizens and factory employees, focusing on displaying traditional Chinese culture and local culture, and carrying the high-end technology research and development mission of BEWG Headquarters. It is understood that Daoxianghu Reclaimed Water Plant will rely on Beijing Enterprises Water Group, Tsinghua University, Renmin University of China, Beijing University of Technology and other top enterprises and colleges to carry out comprehensive cooperation to build it into a domestic first-class "recycled aquatic product research base" [

39,

40,

41].

6.2. Semi-underground

- (1)

Beijing Xiaojiahe reclaimed water plant - A2O process

Beijing Xiaojiahe reclaimed water plant carried out an in-situ upgrade on the basis of the original Xiaojiahe sewage treatment plant. Without adding an inch of land, the original 20,000 tons/day treatment capacity was upgraded to 80,000 tons/day after the transformation. The effluent water quality has been improved from the original Class A to the Beijing Landmark B standard, the main indicators of which meet the surface water category IV water standard, and the treated clean water can be directly injected into the Qinghe River, which can provide high-quality and safe recycled water sources [

42,

43,

44].

Xiaojiahe reclaimed water plant is a BOT project invested and built by Sound Group, covering an area of 2 hectares. The upgrading project started in August 2013 and is currently in progress. The water plant adopts a semi-underground construction form, all sewage treatment facilities are buried underground, and productive buildings, offices, and living areas are built on the ground to minimize the harmful impact on the environment. After completion, the greening rate of the plant area is greater than 30%. Compared with the area of the original sewage treatment pool which only accounted for 15% of the plant area, the area of the sewage treatment pool of the reconstructed underground sewage treatment plant has increased by nearly 4 times [

45].

After the transformation, the main process of sewage treatment adopts the "A

2O-energy-saving MBR" process. The pulse aerator used is independently developed by Sound Group, which can mechanically produce pulse bubbles, which can make the fiber membrane shake intermittently to prevent membrane pores from clogging , and can greatly reduce the required blast volume, and the electricity required for ton of water treatment can be saved by 0.15 kWh, making the energy consumption of the process less than 1/3 of the membrane aeration energy consumption compared with the traditional MBR process, and can save tens of thousands of kWh of electricity per day. The effluent adopts ozone-ultraviolet combined oxidation and disinfection method, and is equipped with odor collection and biological deodorization devices, which will hardly cause pollution to the production and life of surrounding residents [

47,

48,

49].

- (2)

Nanpian sewage treatment plant in wenzhou city - BAF Process

Nanpian Sewage Treatment Plant has a total land area of 8.72 hectares, and a total sewage treatment scale of 80,000 tons/day. The first phase of the project covers an area of 4.12 hectares, with an estimated total investment of 249 million yuan and a treatment scale of 40,000 tons/day. The construction started in early 2013 and started operation in April 2015. The project construction lasted 2 years.

The sewage treatment plant is the first "high standard, full deodorization, combined, full coverage" garden sewage treatment plant in Zhejiang Province. The semi-underground design is adopted, the sewage treatment facilities are all buried underground, and the repair and maintenance buildings, office and living areas are unified on the ground. The factory area is covered with garden-style greening except for the roads. A green "roof" is added on the roof of the main factory building and the comprehensive building, and local Wenzhou tree species, sweet-scented osmanthus, magnolia and other fragrant plants are planted to make the factory area fragrant [

50]. Overflow, giving people the impression of a green park full of vitality, completely overturning people's views on sewage treatment plants being dirty and smelly.

The sewage treatment of the underground sewage treatment plant adopts the French Veolia biological aerated filter BAF process [

51,

52,

53]. The main process flow is Mutiflo high-efficiency sedimentation tank plus Biostyr aerated biological filter and Actiflo sand-added high-efficiency sedimentation tank, which has the advantages of good treatment effect and stable operation [

54,

55,

56,

57,

58]. The modular combination of each processing structure effectively saves the land used for equipment, making the construction area of the main factory building in the first phase (including some public auxiliary facilities in the second phase) only cover an area of more than 7,000 square meters, and the rest is used for landscape greening design. The water plant has a high degree of automation and can realize fully automatic operation; the main plant adopts a fully enclosed deodorization design, and the odor is collected through pipelines and sent to the biological deodorization system for treatment before being discharged, without affecting the surrounding environment [

59,

60,

61].

6.3. Fully enclosed above ground

The first phase of the sewage treatment plant in the east district of Guangzhou economic and technological development zone has an investment of about 70 million yuan [

62,

63,

64]. The sewage treatment capacity is 25,000 tons/day [

65]. The construction investment per ton of water is close to 2,800 yuan/ton, and the sewage treatment cost is about 1.14 yuan/ton [

66,

67,

68]. The service scope of the eastern district sewage treatment plant is the eastern district of Guangzhou economic and technological development zone, with a total service area of 7 square kilometers [

68,

69,

70]. The eastern district sewage treatment plant occupies a relatively small area, and the first phase covers an area of about 1.6 hectares [

71].

The water plant adopts the cass process, and completes the denitrification and phosphorus removal process through four stages of water inflow agitation-aeration-sedimentation-skimming in a period of 6 hours. The automatic control system adopts the most advanced profibus bus control, remote three-level control, and realizes online monitoring of turbidity, PH, dissolved oxygen, liquid level, flow [

72]. This water plant is the earliest sewage treatment plant covered with steel structure in the country, which not only minimizes the noise and odor impact on the surrounding environment, but also makes the appearance of the sewage plant feel like a modern factory [

73].

6.4. Open on the ground

Beijing Xiaohongmen sewage treatment plant is the second largest sewage treatment plant in Beijing, with a planned drainage area of 223.5km2 and a service population of about 1.925 million [

74,

75]. The water plant adopts the A

2O process, with a treatment capacity of 600,000 tons per day, a total investment of about 1.2 billion yuan, a ton of water construction investment cost of about 2,000 yuan, and a sewage treatment cost of about 1.12 yuan per ton of sewage [

75,

76,

77]. The water plant covers a total area of 47 hectares. The main construction contents of the plant area include plant civil construction, process equipment, process pipeline installation, electrical and automatic control system installation, lighting, lightning protection grounding, heating, ventilation, plant road construction and greening, etc. The sewage passes through the grille, lifting pump room, aerated grit chamber, primary sedimentation tank, A

2O tank (anaerobic, anoxic, aerobic tank volume ratio is 1:3:6.7), secondary sedimentation tank, and is disinfected discharged outside the plant, the sewage discharge standard is "water pollutant discharge standard for urban sewage treatment plants" [

77,

78].

The operation of the water plant has effectively improved the water quality of the Liangshui River and the surrounding ecological environment. While carrying out sewage treatment, the sewage treatment plant has also strengthened the construction of reclaimed water. The reclaimed water treatment capacity in the plant is 1500 cubic meters per day, which is used in the plant area Water for greening, toilet flushing, landscape and equipment flushing. Since April 2006, it has also supplied 300,000 tons of recycled water per day to Daxing Liangfeng irrigation canal as irrigation water for farmland in the area [

79].