Submitted:

07 June 2023

Posted:

08 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

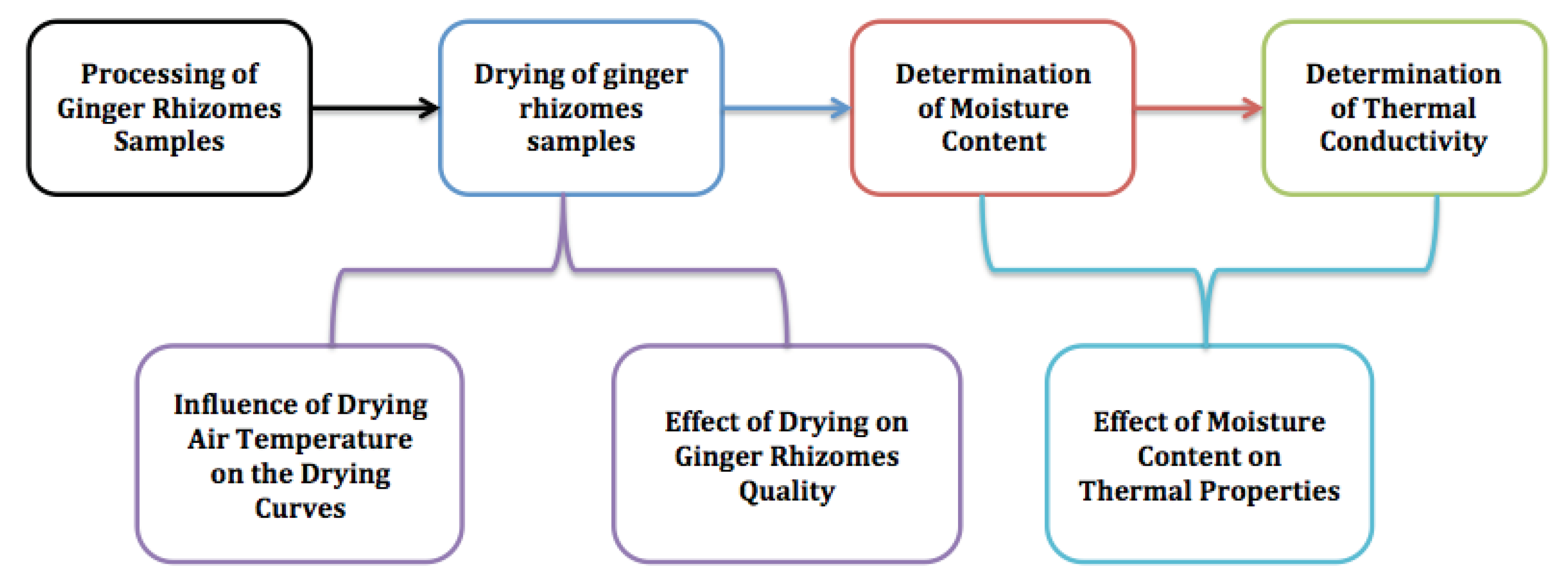

2. Materials and Methods

2.1. Raw Material: Ginger Rhizomes

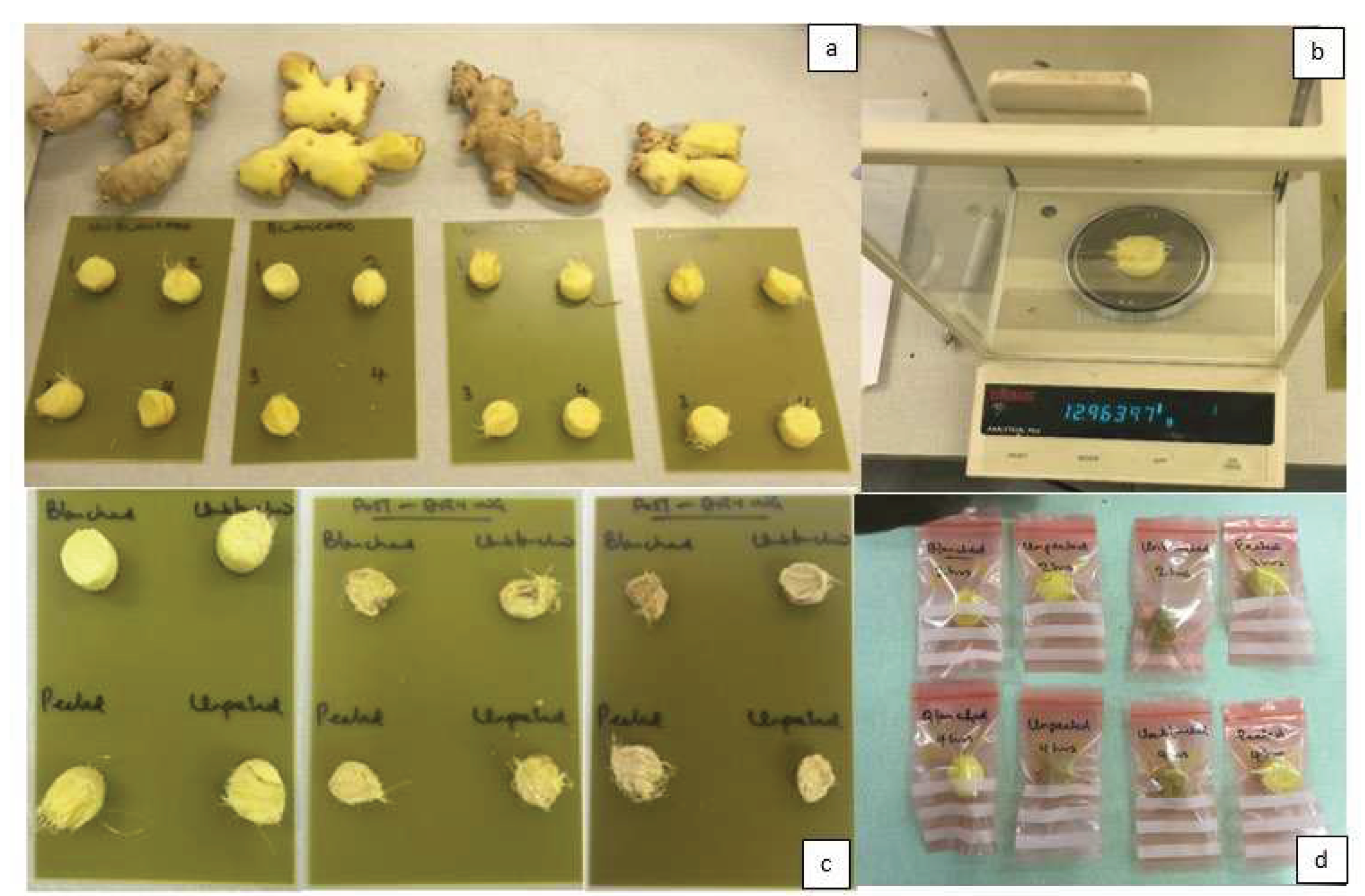

2.2. Processing of Raw Material

- Blanched Ginger Rhizomes: Blanched ginger rhizomes have been briefly exposed to boiling water or steam to inactivate enzymes, reduce microbial load, and partially soften the tissue. This pre-processing step can help retain colour, improve texture, and prolong the shelf life of the dried product. However, blanching may cause some loss of volatile compounds responsible for ginger's characteristic aroma and flavour.

- Unblanched Ginger Rhizomes: Unblanched ginger rhizomes are raw and have not been subjected to heat treatment before drying. They retain their original colour, aroma, and flavour but may take longer to dry than blanched samples due to the active enzymes and higher initial microbial load. Unblanched samples may also have a shorter shelf life than their blanched counterparts.

- Peeled Ginger Rhizomes: Peeled ginger rhizomes have had their outer skin removed, exposing the inner flesh. This pre-processing step can result in a more uniform drying process and improved product quality, as removing the skin can facilitate moisture loss and enhance heat transfer. Peeled ginger may also be more visually appealing and easier to process or grind after drying.

- Unpeeled Ginger Rhizomes: Unpeeled ginger rhizomes still have their outer skin intact, which may slow down the drying process due to the additional layer that moisture must penetrate to escape. This can lead to longer drying times and uneven drying. However, the skin can protect against the loss of volatile compounds and may help retain some of the ginger's aroma and flavour during drying.

2.3. Experimental instruction

2.3.1. Blanched

- Take a big pot and fill it halfway with water. Place it on the stove and turn the heat up to high. Add some salt to the water.

- Peel the outer layer of ginger by slicing it vertically and horizontally.

- Put the ginger into the pot of boiling water. Set a timer for 2 minutes.

- After blanching, remove the ginger from the pot and transfer it into ice-cold water to stop cooking immediately.

- Wait for 2 minutes before taking out the blanched ginger. Then, put them on a plate lined with paper towels to dry.

2.3.2. Unblanched

- Ginger that has not been washed and is still fresh.

2.3.3. Peeled

- First, rinse the ginger and remove any dirt.

- Then, take a piece of ginger and use a spoon to scrape off the skin from the edges.

2.3.4. Unpeeled

- Washed ginger and then kept unpeeled

2.4. Equipment

2.4.1. ARS-0680 Environmental Stress Chamber

2.4.2. TD1002A – Linear Heat Conduction Experiment

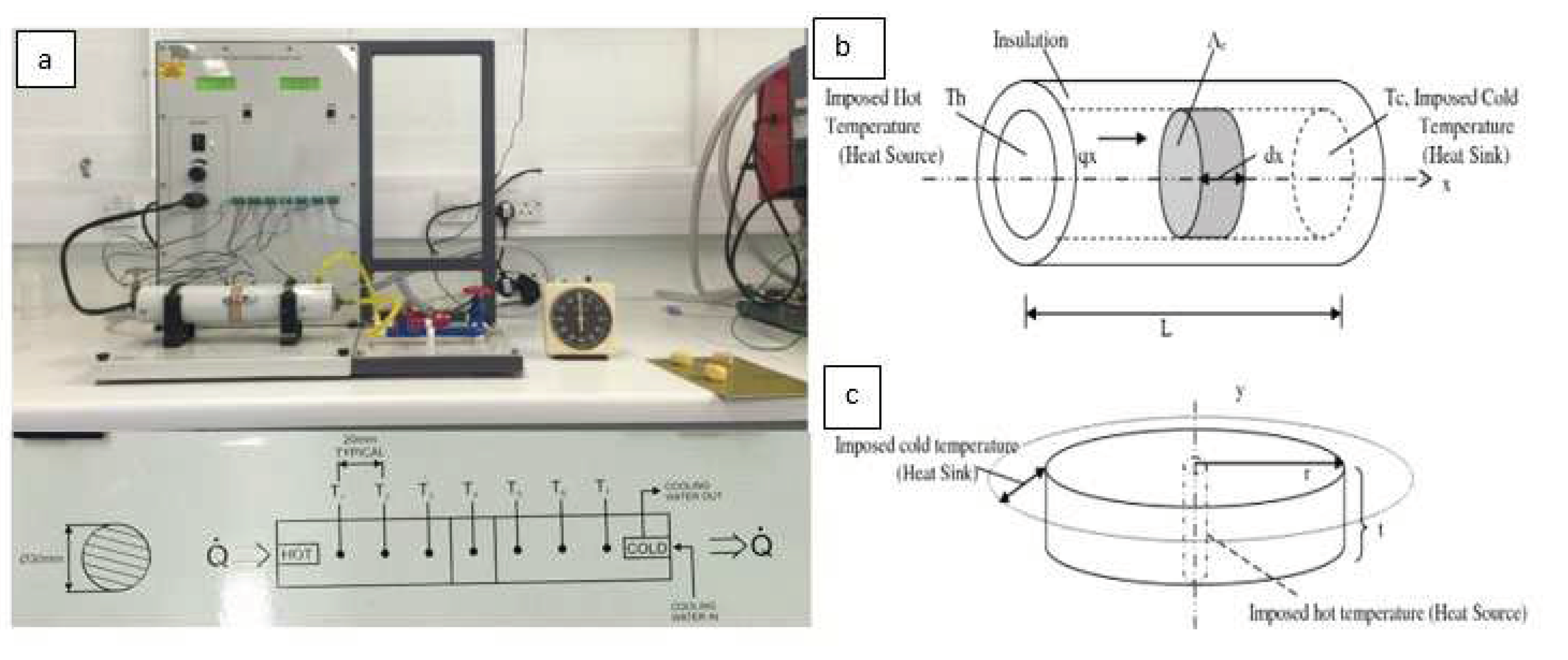

- Consistency and Reproducibility: Having a standard size and shape for all samples ensures that every experiment's conditions are identical. This consistency is critical for obtaining reliable and repeatable results. It ensures that any differences observed are due to the experimental variables being tested, not differences in the sample sizes.

- Heat and Mass Transfer: A sample's size and shape can affect the heat and mass transfer rates during drying. Smaller or thinner samples may dry faster due to a larger surface area exposed to the drying conditions, while larger or thicker samples may take longer to dry.

- Quality of Dried Product: The size and shape of the sample can also influence the quality attributes of the dried product, such as its texture, colour, and flavour. Consistent size and shape help ensure uniform quality in the dried product.

- Data Interpretation: When analysing and interpreting data obtained in this work, knowing that all samples were of the same size and shape eliminates one potential source of variability. This makes it easier to draw accurate conclusions from the data.

3. Methodology

3.1. ARS – 0680 Temperature and Humidity Chamber: Drying Experiment

- Blanched

- Unblanched (Pre-treatments)

- Peeled

- Unpeeled

3.2. Linear Heat Conduction Experiment

- Sample Preparation: Slice ginger rhizomes into uniform samples with a consistent thickness and cross-sectional area, ensuring the samples are large enough to fit into the TD1002A Linear Heat Conduction apparatus. Record the initial moisture content of the samples.

- Apparatus Set-up: Mount the ginger rhizome samples onto the TD1002A Linear Heat Conduction apparatus sample holder, ensuring proper contact with the heat source and the cooling system. Attach temperature sensors at regular intervals along the length of the samples to monitor the temperature gradient during the experiment.

- Drying Process: Using the ARS-0680 Environmental Stress Chamber, subject the ginger rhizome samples to convective drying under controlled conditions. Set the desired temperature, humidity, and air velocity within the chamber to simulate different drying scenarios. Continuously monitor and record the temperature readings from the sensors and the weight loss of the samples to determine the moisture content at different stages of the drying process.

- Data Collection and Analysis: Gather temperature and moisture content data at different stages during the experiment. Use this data to determine the temperature gradient across the samples and compute the associated thermal conductivity with the help of Fourier's Law of Heat Conduction. Create a graph to visualise the drying kinetics and explore the correlation between moisture content and thermal conductivity.

- Comparative Analysis: Compare the thermal conductivity values of ginger rhizomes under various moisture content levels and drying conditions, and evaluate how the moisture content impacts the thermal properties of dried ginger rhizomes.

- Conclusions and Recommendations: Drawing upon the experiment's outcomes, decide on the efficiency of convective drying when applied to ginger rhizomes and how moisture content impacts their thermal characteristics. Additionally, it suggests enhancing the drying procedure and elevating the standard of dried ginger rhizomes.

3.3. Experimental Procedure

- The first phase, known as the preheating phase, involves heating the ginger rhizomes to match the temperature of the surrounding air. During this stage, moisture removal from the samples is slow because most of the heat energy is used to raise the temperature of the ginger.

- The second phase, the constant rate drying phase, occurs when external factors such as humidity, temperature and air velocity govern the constant pace at which moisture is removed from the ginger rhizomes. This period is characterised by a straight line on the drying curve since there is continuous evaporation of surface moisture while moisture inside migrates towards it.

- Lastly, during the falling rate drying phase, internal factors such as resistance to moisture migration and reduced moisture content gradually decrease the moisture removal rate until an equilibrium point is reached. This stage can be further subdivided into two sub-phases:

- First Falling Rate Period and Second Falling Rate Period. In these periods, there is a gradual decrease in drying rate due to limited moisture migration from deep within the sample and tightening grip of remaining retained water bound with solid components of ginger rhizomes leading to a slower reduction in water content levels.

3.4. Determination of Moisture Content and Thermal Conductivity

3.4.1. Assessment of Moisture Levels

3.4.2. Method for Assessing Moisture Levels

- The initial weight of the ginger sample was documented using "Analytical Plus Electronic Balances" precise to 0.00001g.

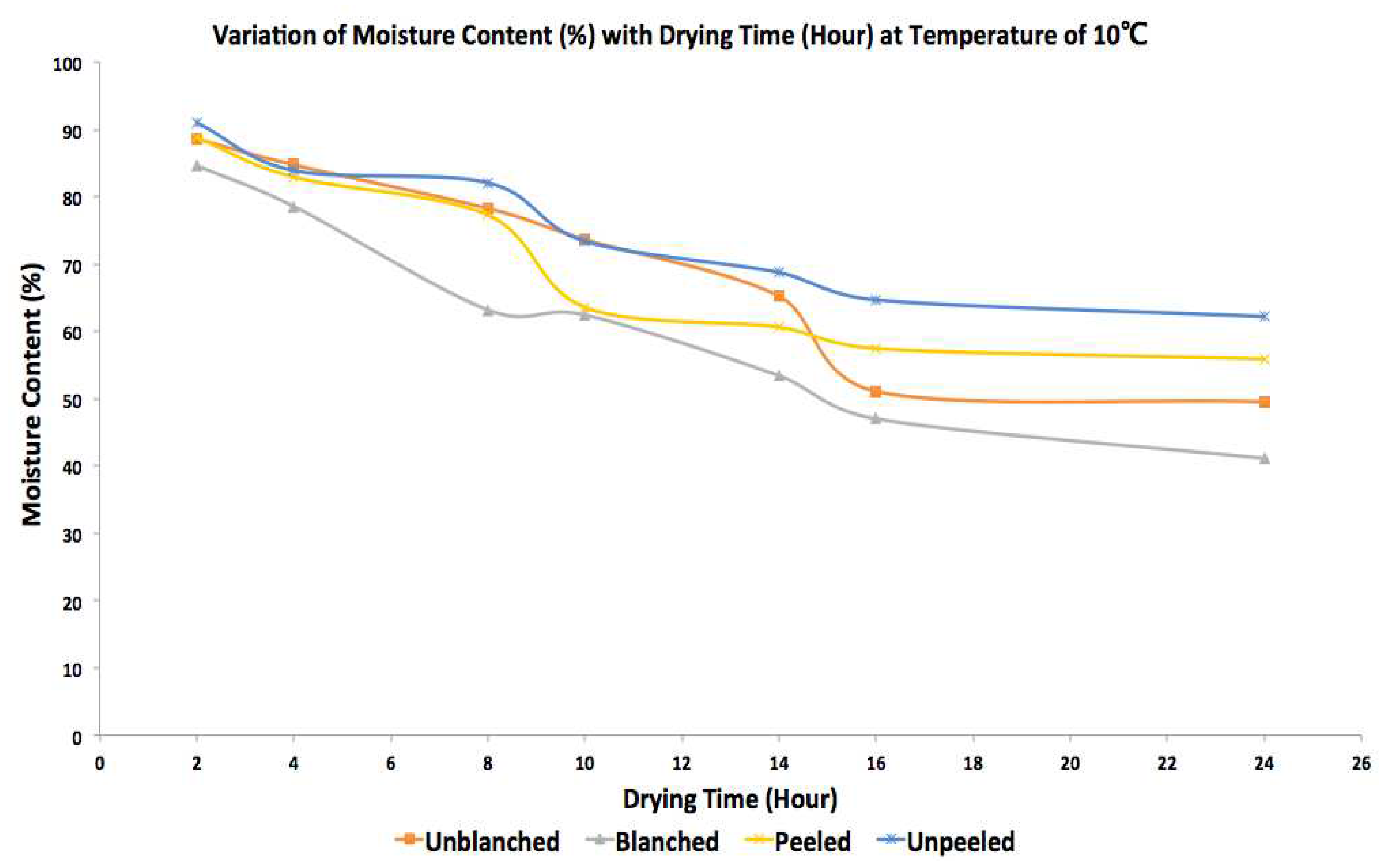

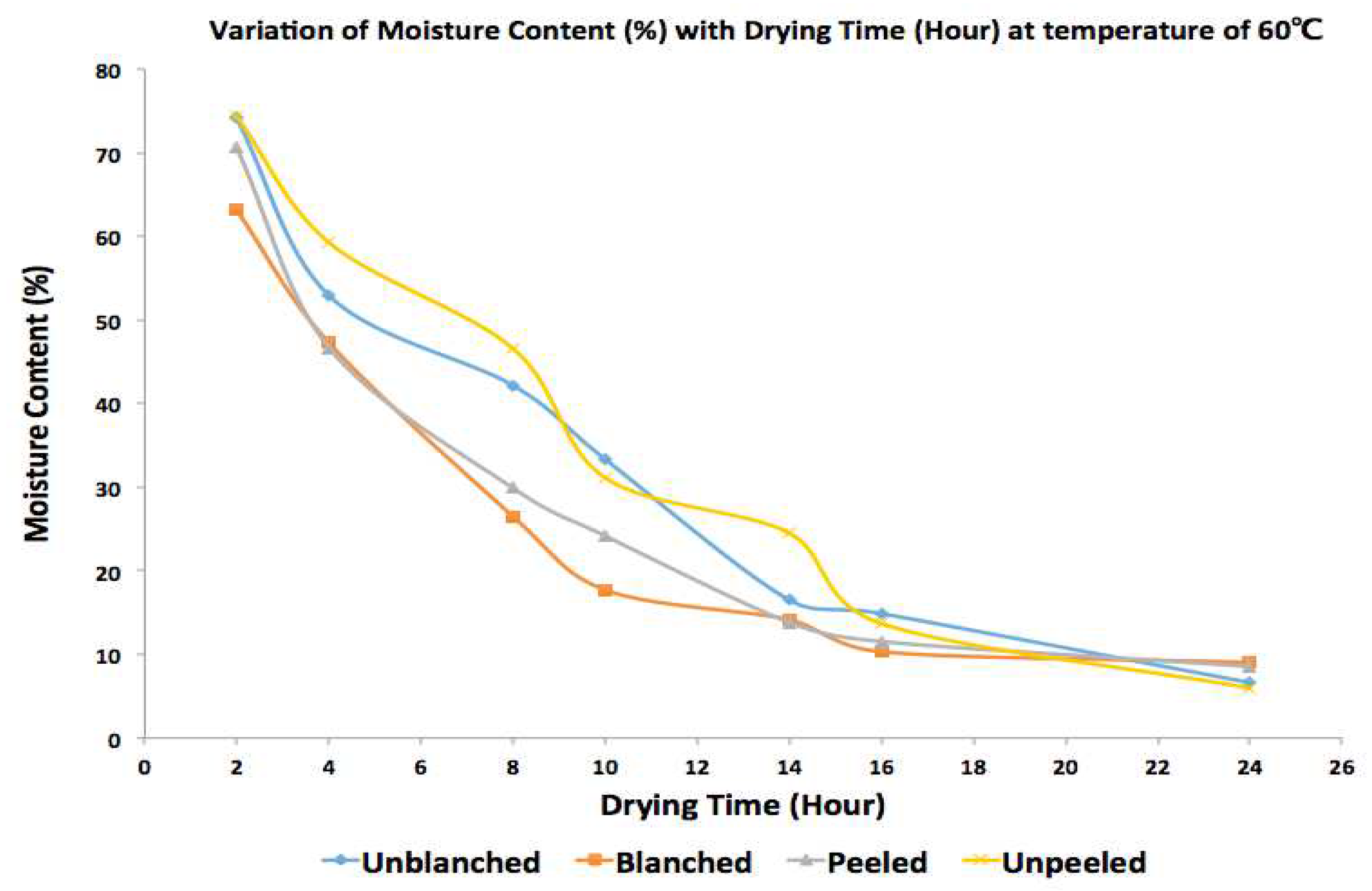

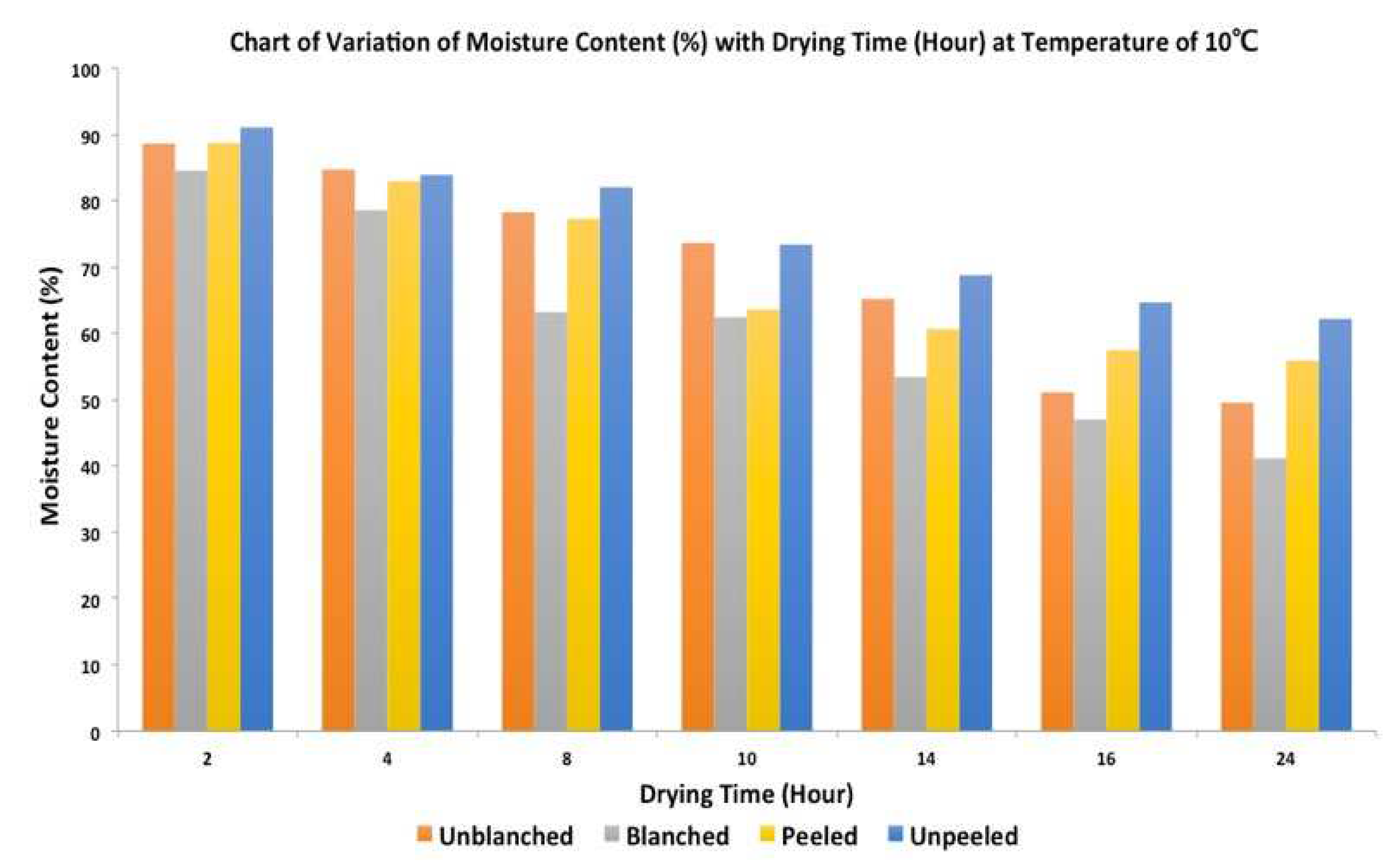

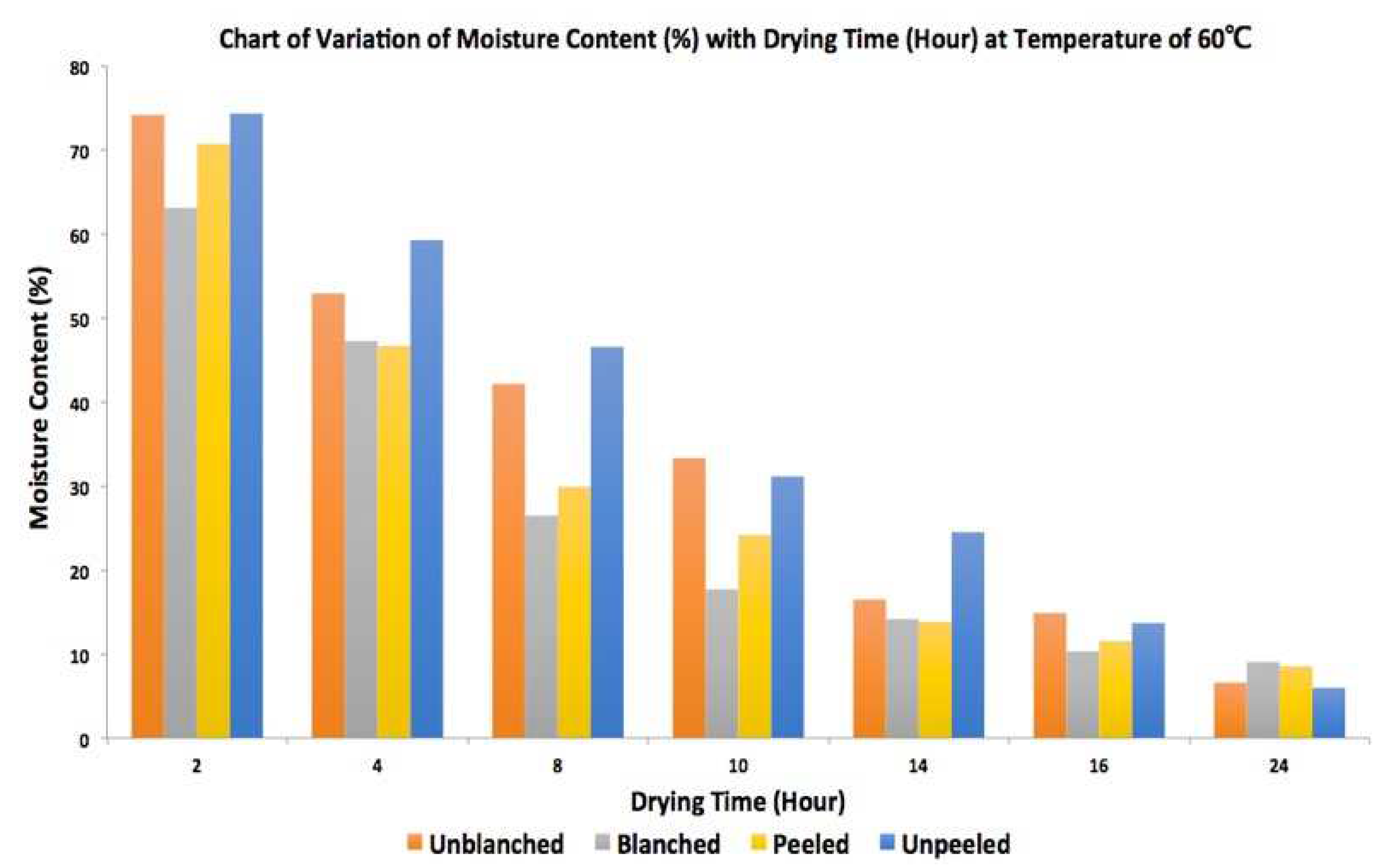

- The ginger was then transferred into a controlled environment at a steady temperature ranging from 10°C to 60°C for 2, 4, 8, 10, 14, 18, and 24 hours.

- The weight of the dried ginger samples was then measured at the time mentioned above intervals.

- The weighing of the ginger samples continued until a steady, final weight was achieved, indicating an equilibrium state had been reached.

- The ginger's initial moisture content (w.b) was then calculated using equation 3.1. This experiment consistently utilised the moisture content on a wet basis.

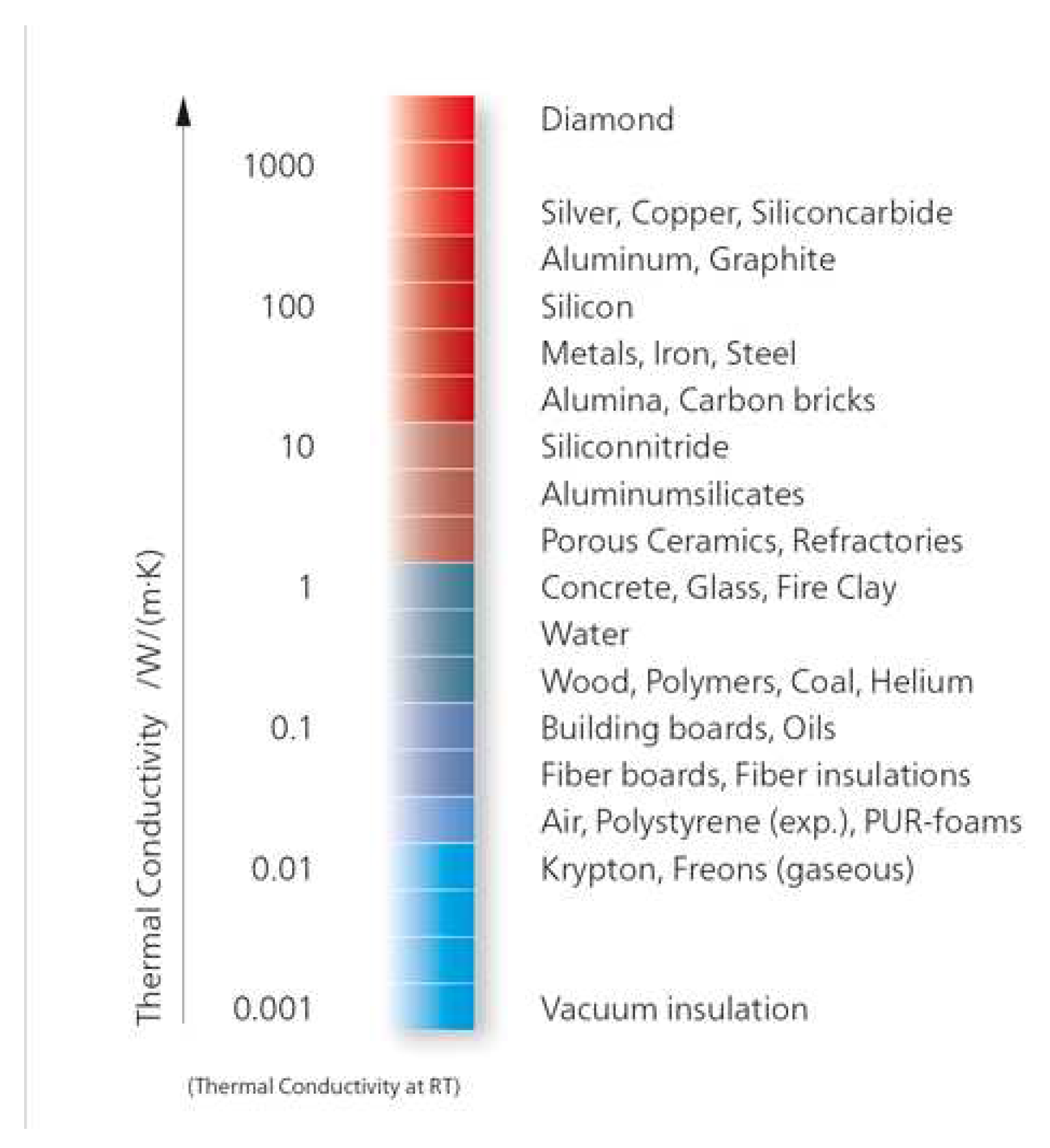

3.4.3. Determination of Thermal Conductivity

- Structure of materials

- Wetness of the content (Moisture Content)

- Materials density

- Temperature and pressure (operational settings) [10]

4. Results and Discussions

- 1.

- Impact of Drying Air Temperature on Drying Patterns: Increased drying air temperatures lead to a more rapid drying rate, mainly due to the enhanced heat and mass transfer between the ginger rhizome and the surrounding air. At higher temperatures, drying curves usually display a swift initial drying rate, which then transitions to a slower, more steady decline in moisture content. This results in shorter drying durations, a plus for large-scale processing and energy efficiency.

- 2.

- Impact of Drying on the Quality of Ginger Rhizomes: The temperature of the drying air significantly influences the quality of the dried ginger rhizomes. Drying can alter critical quality characteristics like colour, aroma, flavour, and texture.

- Colour: Elevated drying temperatures can cause browning or discolouration of ginger rhizomes due to non-enzymatic browning reactions or pigment oxidation.

- Aroma and Flavor: The drying procedure may result in the loss of volatile compounds responsible for ginger's unique aroma and flavour. Higher temperatures can intensify these losses, making a final product less aromatic and flavorful.

- Texture: High drying temperatures can induce case hardening, affecting the texture of dried ginger rhizomes and making them harder to grind or process.

4.1. Measurement of Moisture Content and Thermal Conductivity

4.2. Impact of Air Temperature on Drying Patterns and Its Effect on the Quality of Dried Ginger Rhizomes

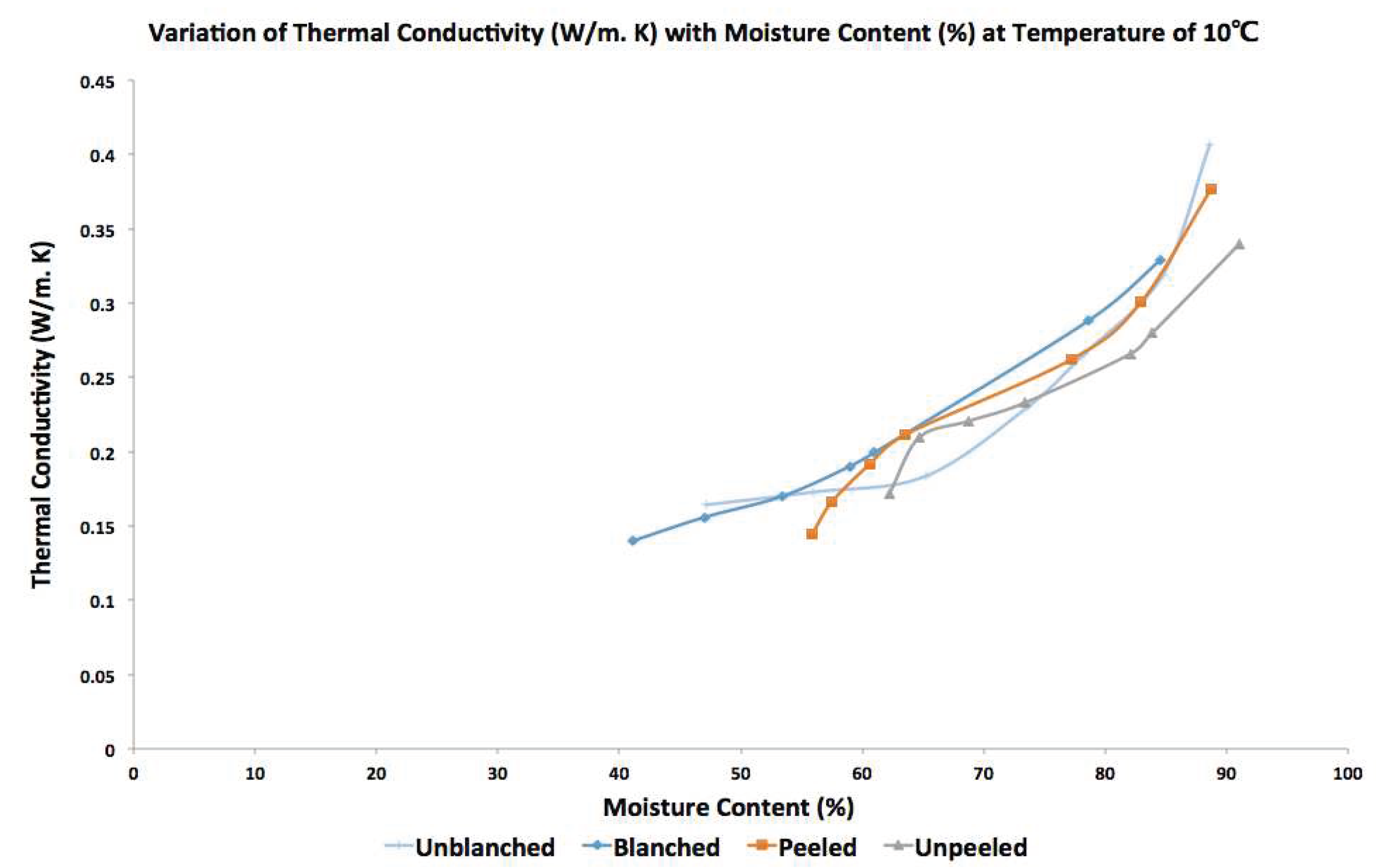

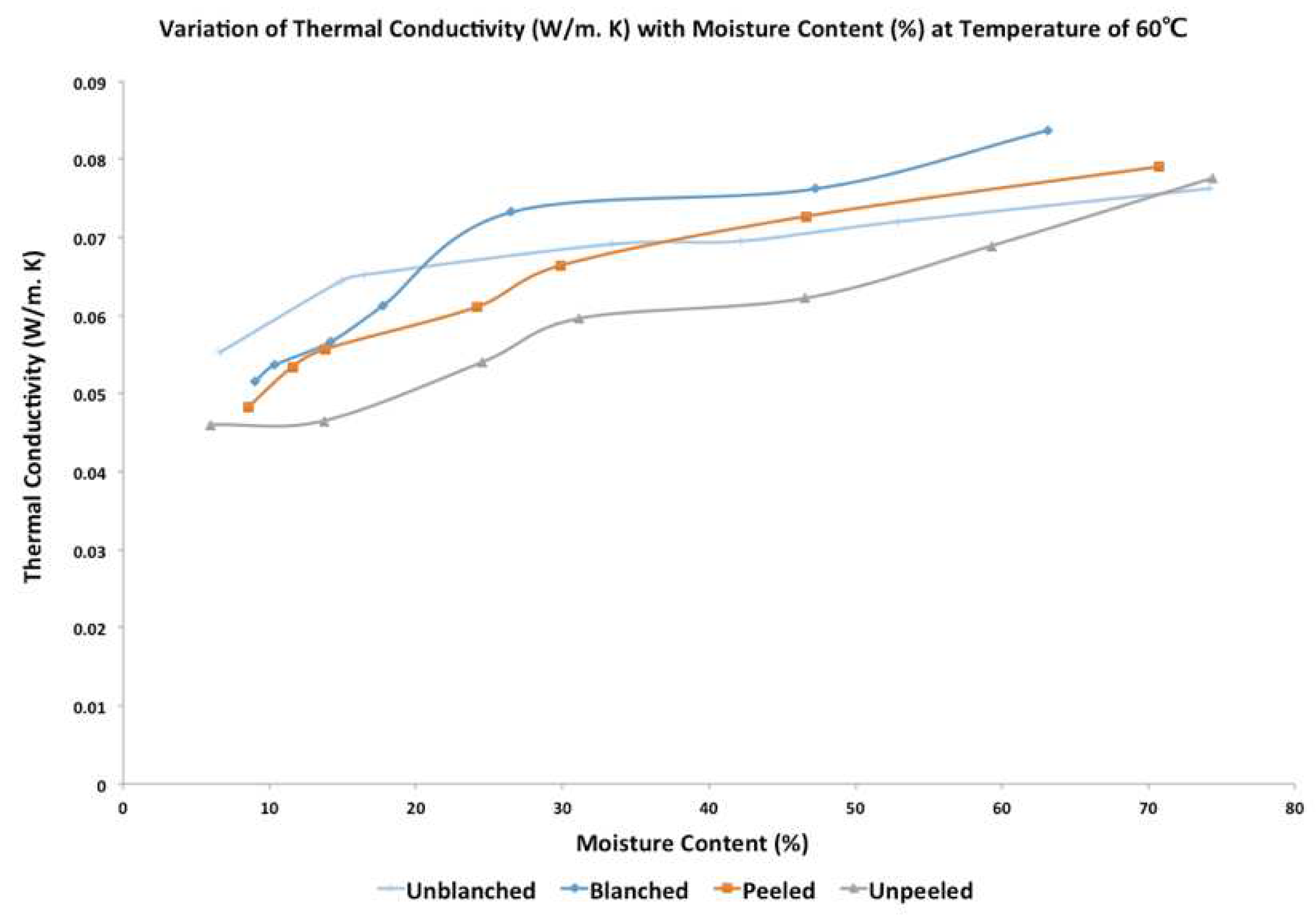

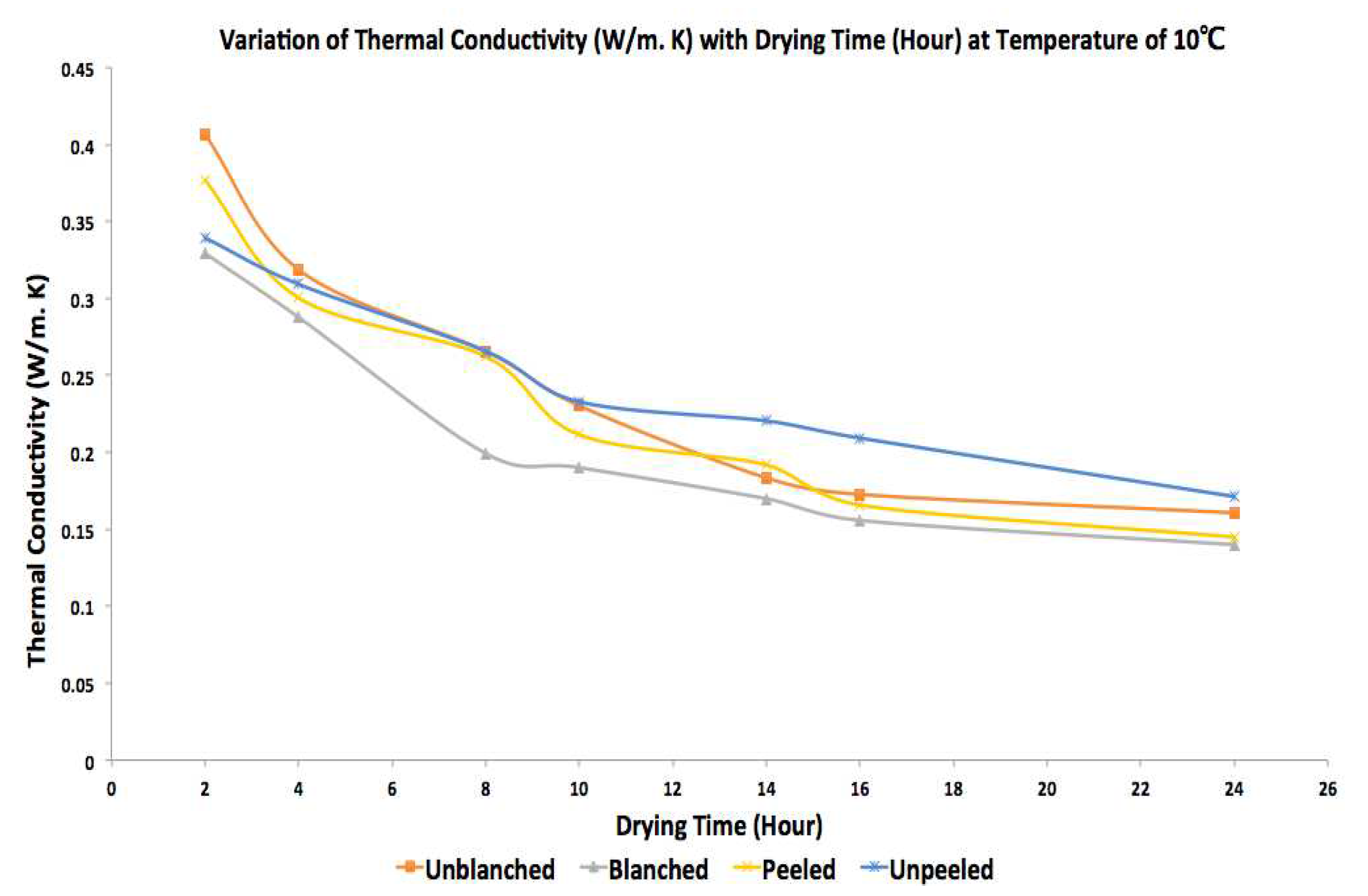

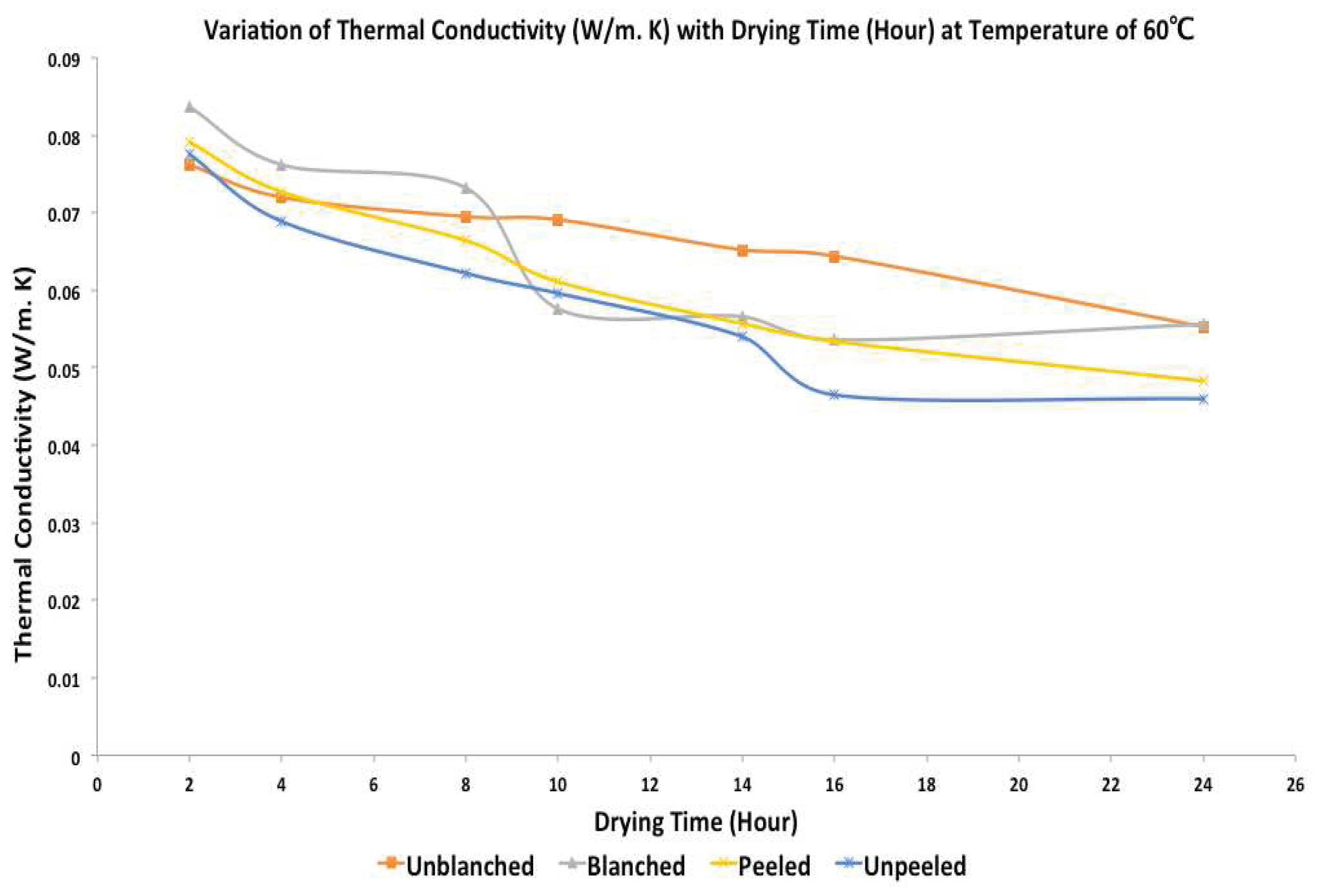

4.3. Effect of Moisture Content on Thermal Properties of Dried Ginger Rhizomes

- Thermal Conductivity: The thermal conductivity of ginger rhizomes strongly correlates with their moisture content. Higher moisture content typically leads to higher thermal conductivity values, as water is a more effective heat conductor than the solid elements of ginger. As the moisture content dwindles during the drying process, the thermal conductivity of the dried ginger rhizomes also lessens. This change in thermal conductivity can impact heat transfer and overall drying rates, influencing drying duration and energy utilisation.

- Specific Heat: Specific heat denotes the amount of heat necessary to elevate the temperature of a unit mass of a substance by one degree Celsius. The moisture content influences the specific heat of ginger rhizomes, given that water has a higher specific heat than solid constituents. As the moisture content diminishes, the specific heat of the dried ginger rhizomes also declines, translating into less heat needed to increase the material's temperature during drying.

- Thermal Diffusivity: Thermal diffusivity assesses the speed at which heat can be disseminated through a material. It is influenced by the material's thermal conductivity, specific heat, and density. As the moisture content of ginger rhizomes lessens, the thermal conductivity and specific heat decline while the density augments. These alterations can decrease thermal diffusivity, signifying that heat transfer through the dried ginger rhizomes becomes less effective as the drying process advances.

4.4. A Comparative Analysis of Drying Characteristics Between Nigerian Ginger Rhizomes and Other Varieties

- Initial moisture content: The moisture content of freshly harvested ginger varies depending on the specific cultivar, growing conditions, and the maturity stage at harvest time. The initial moisture content significantly impacts the drying process, including the required drying time and the appropriate drying method. Higher moisture content generally necessitates longer drying periods or more intense drying techniques. As a result, Nigerian ginger may exhibit different moisture content than other cultivars, consequently influencing its drying characteristics.

- Skin thickness: The thickness of the ginger's skin also influences the drying process. A thicker skin can impede moisture's evaporation during drying, prolonging the drying time. Additionally, skin thickness may affect crucial quality aspects of the dried product, such as its colour, texture, and flavour. Nigerian ginger might have a distinctive skin thickness compared to other cultivars, impacting its drying characteristics accordingly.

- Inherent properties: Each ginger cultivar possesses inherent properties, including size, shape, density, oil content, and chemical composition. These properties can significantly impact the rate and efficiency of the drying process. For instance, ginger rhizomes with higher oil content tend to dry more slowly due to the hygroscopic nature of oils. Similarly, larger or denser rhizomes might require more time to dry than smaller or less dense ones.

- Drying Time: Nigerian ginger rhizomes, like other cultivars, exhibit a typical drying curve with a rapid initial drying rate followed by a slower, more gradual decrease in moisture content. However, Nigerian ginger rhizomes may have a shorter drying time than other cultivars due to their thinner skin and lower initial moisture content. In contrast, cultivars with higher initial moisture content or thicker skin may require a longer drying time to reach the desired final moisture level.

- Energy Consumption: The energy consumption during the drying process depends on factors such as initial moisture content, drying temperature, and air velocity. Nigerian ginger rhizomes consume less energy during drying than other cultivars with higher initial moisture content or those requiring higher drying temperatures to achieve similar drying rates. Efficient drying strategies can be employed to minimise energy consumption for all cultivars.

- Product Quality: The quality of dried ginger rhizomes is influenced by drying conditions, processing techniques, and the cultivar. Nigerian ginger rhizomes are known for their pungent aroma and high oleoresin content, contributing to their desirable flavour and medicinal properties. While the drying process may lead to some loss of volatile compounds, the quality of Nigerian ginger rhizomes can be maintained by optimising drying conditions, such as temperature and air velocity, to minimise these losses. Other cultivars may exhibit different quality attributes, which should also be considered when optimising drying processes.

4.5. Analysis of Drying Curves

- High thermal conductivity of water: Water possesses a higher thermal conductivity compared to many common substances found in ginger rhizomes, such as organic compounds. Consequently, as the water content within the rhizome increases, it enhances the efficient transfer of heat, thereby elevating the effective thermal conductivity of the material.

- Continuity of the water phase: Water molecules are dispersed and isolated within the material at low moisture content. However, as the moisture content rises, these dispersed water molecules can form a continuous phase, creating pathways for more effective heat conduction.

- Evaporative cooling: The process of water evaporation requires latent heat energy. This phenomenon aids in distributing heat efficiently throughout the material, which can be interpreted as an increase in thermal conductivity.

- Water as a bridge: Water can act as a bridge between solid particles, enhancing contact between them and facilitating heat conduction.

- Volume expansion: Water tends to expand when heated, and in a porous material like ginger rhizomes, this expansion can lead to an overall expansion of the material itself. Consequently, the structure of the rhizome can change, potentially creating more pathways for heat conduction.

4.6. Impact of Air Temperature During Drying on Ginger Rhizomes

4.7. Impact of the Drying Process on Ginger Rhizomes

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- K. Nagendra Prasad et al., “Identification of phenolic compounds and appraisal of antioxidant and antityrosinase activities from litchi (Litchi sinensis Sonn.) seeds,” Food Chem, vol. 126, no. 4, pp. 1610–1618, 2011. [CrossRef]

- Alibas, “Microwave, air and combined microwave-convective drying parameters of pumpkin slices. LWT,” Food Science and Technology, vol. 40, no. 8, pp. 1445–1451, 2007. [CrossRef]

- Kaya, O. Aydın, and S. Dincer, “Experimental and theoretical analysis of the drying of carrot slices in a convective dryer,” Chem Eng Commun, vol. 195, no. 9, pp. 1197–1211, 2008.

- T. J. Afolabi, D. T. Oyekunle, and O. A. Adebo, “Optimisation of convective air-drying temperature for tigernut (Cyperus esculentus L.) using response surface methodology,” 2013.

- O. Oyedele, R. Akinoso, and S. A. Aboaba, “Comparison of hot air and solar drying of ginger (Zingiber officinale) rhizomes.,” J Food Process Preserv, vol. 41, no. 3, p. e12923, 2017.

- Dincer and S. Dost, “Experimental investigation of the drying kinetics of ginger slices.,” J Food Eng, vol. 81, no. 3, pp. 454–460, 2007.

- M. H. Nguyen, D. L. Nguyen, and T. T. H. Nguyen, “Drying characteristics and effective moisture diffusivity of ginger (Zingiber officinale Roscoe) using convective drying method,” Journal of Science and Technology Development, vol. 21, no. 2, pp. 11–18, 2018, doi: 10.33301/STDEV-1802.0004. [CrossRef]

- H. Feng, J. Tang, D. S. Mattinson, and J. K. Fellman, “Quality retention in strawberry and carrot purees dried with Refractance WindowTM system,” J Food Eng, vol. 146, pp. 89–94, 2015, doi: 10.1016/j.jfoodeng.2014.08.012. [CrossRef]

- 9. Doymaz, “Drying of ginger slices in a convective hot-air dryer,” Int J Food Sci Technol, vol. 46, no. 3, pp. 602–607, 2011, doi: 0.1111/j.1365-2621.2010.02513.x. [CrossRef]

- U. L. Opara, M. R. Al-Ani, and Y. S. Al-Shuaibi, . “Physico-chemical properties, vitamin C content, and antimicrobial properties of pomegranate fruit (Punica granatum L.),” Food Bioproc Tech, vol. 7, no. 11, pp. 3156–3167, 2014, doi: 10.1007/s11947-014-1282-6. [CrossRef]

- R. H. Myers, D. C. Montgomery, and C. M. Anderson-Cook, Response Surface Methodology: Process and Product Optimization Using Designed Experiments, 4th ed. Hoboken, New Jersey: John Wiley & Sons, Inc., 2016.

- S. Erenturk, K. Erenturk, and L. G. Tabil, “Infrared drying of carrot slices. Journal of Food Processing and Preservation,” J Food Process Preserv, vol. 34, no. 10, pp. 457–471, 2010, doi: 10.1111/j.1745-4549.2008.00333.x. [CrossRef]

- Y. Namsanguan, A. Tansakul, B. P. Lamsal, N. Chiewchan, and S. Devahastin, “Drying kinetics and quality of potato chips undergoing different drying processes,” J Food Eng, vol. 64, no. 3, pp. 335–340, 2004, doi: 10.1016/j.jfoodeng.2003.10.015. [CrossRef]

- G. A. Ikechukwu, “Prediction Of Thin Layer Drying Characteristics Of Ginger Rhizomes Slices In Convective Environment,” 2021.

- M. Bialik, A. Wiktor, K. Rybak, D. Witrowa-Rajchert, P. Latocha, and E. Gondek, “The impact of vacuum and convective drying parameters on kinetics, total phenolic content, carotenoid content and antioxidant capacity of Kiwiberry (Actinidia Arguta),” Applied Sciences (Switzerland), vol. 10, no. 19, pp. 1–13, 2020, doi: 10.3390/app10196914. [CrossRef]

- 16. K. Hamid, U. Sajjad, K. S. Yang, S. K. Wu, and C. C. Wang, “Assessment of an energy efficient closed loop heat pump dryer for high moisture contents materials: An experimental investigation and AI based modelling,” Energy, vol. 238, p. 121819, 2022, doi: 10.1016/j.energy.2021.121819. [CrossRef]

- Y. Çelik and B. B. Kenanoğlu, “After-ripening effect combined with drying methods on seed quality of aubergine seed lots harvested at different maturity stages,” Kuwait Journal of Science, no. September 2022, 2023, doi: 10.1016/j.kjs.2023.05.013. [CrossRef]

- Z. shan Zhang, H. jie Jia, X. dan Li, Y. lan Liu, A. chi Wei, and W. xue Zhu, “Effect of drying methods on the quality of tiger nuts (Cyperus esculents L.) and its oil,” Lwt, vol. 167, no. 100, p. 113827, 2022, doi: 10.1016/j.lwt.2022.113827. [CrossRef]

- S. Akther, J. S. Jothi, M. R. Badsha, M. M. Rahman, G. B. Das, and M. A. Alim, “Drying methods effect on bioactive compounds, phenolic profile, and antioxidant capacity of mango powder,” J King Saud Univ Sci, vol. 35, no. 1, p. 102370, 2023, doi: 10.1016/j.jksus.2022.102370. [CrossRef]

- M. F. Umunna, K. J. Simonyan, T. Paul, and I. Okosa, “DRYING CHARACTERISTICS OF INDIGENOUS GINGER RHIZOMES UNDER,” Journal of Agricultural Engineering and Technology (JAET), vol. 27, no. 2, pp. 54–68, 2022.

- J. Eze and K. Agbo, “Comparative studies of sun and solar drying of peeled and unpeeled ginger,” American Journal of Scientific and Industrial Research, vol. 2, no. 2, pp. 136–143, 2011, doi: 10.5251/ajsir.2011.2.2.136.143. [CrossRef]

- M. C. Ndukwu et al., “Drying kinetics and thermo-economic analysis of drying hot water blanched ginger rhizomes in a hybrid composite solar dryer with heat exchanger,” Heliyon, vol. 9, no. 2, p. e13606, 2023, doi: 10.1016/j.heliyon.2023.e13606. [CrossRef]

- Netzsch, “Thermal Analysis,” A Netzsch Group Ltd, 2023. http://www.netzsch-thermal-analysis.com/en/landing-pages/thermal-conductivity-diffusivity/definition-thermal-conductivity.html.

- K. Mahapatra, Y. Lan, and D. L. Harris, “Influence of moisture content and temperature on thermal conductivity and thermal diffusivity of rice flours,” Int J Food Prop, vol. 14, no. 3, pp. 675–683, 2011, doi: 10.1080/10942912.2011.555901. [CrossRef]

- 25. Á. Lakatos, I. Csáky, and F. Kalmár, “Thermal conductivity measurements with different methods: a procedure for the estimation of the retardation time,” Materials and Structures/Materiaux et Constructions, vol. 48, no. 5, pp. 1343–1353, 2015, doi: 10.1617/s11527-013-0238-7. [CrossRef]

- V. M. Mathobo, H. Silungwe, S. E. Ramashia, and T. A. Anyasi, “Effects of heat-moisture treatment on the thermal, functional properties and composition of cereal, legume and tuber starches—a review,” J Food Sci Technol, vol. 58, no. 2, pp. 412–426, 2021, doi: 10.1007/s13197-020-04520-4. [CrossRef]

- M. T. Hogue, B. K. Bala, M. A. Hossain, and M. S. Borhan, “Drying of ginger using solar hybrid dryer,” International Journal of Agricultural Research, Innovation and Technology, vol. 3, no. 1, pp. 29–34, 2013, doi: 10.3329/ijarit.v3i1.15174. [CrossRef]

- M. C. Ndukwu, “Development and evaluation of a solar dryer for ginger rhizomes,” Afr J Agric Res, vol. 4, no. 10, pp. 1037–1042, 2009.

- D. S. Jayas and S. Sokhansanj, Drying of Foodstuffs, S. S. H. R. Marcel Dekker Inc., 1999.

- P. Luangmalawat, S. Prachayawarakorn, A. Nathakaranakule, and S. Soponronnarit, “Effects of drying air temperature and humidity on drying kinetics and qualities of green tea leaves,” J Food Eng, vol. 89, no. 3, pp. 322–329, 2008, doi: 10.1016/j.jfoodeng.2008.05.008. [CrossRef]

- G. Attanasio, L. Cinquanta, D. Albanese, and M. Di Matteo, “Effects of drying temperatures on physico-chemical properties of dried and rehydrated chestnuts (Castanea sativa),” Food Chem, vol. 88, no. 3, pp. 583–590, 2004, doi: 10.1016/j.foodchem.2004.02.002. [CrossRef]

- Bart-Plange, A. Addo, S. K. Amponsah, and J. Ampah, “Thermal Conductivity of Two Varieties of Maize (Zea mays) and Cowpea (Vigna unguiculata) as a Function of Moisture Content and Temperature,” International Journal of Food Engineering, vol. 8, no. 4, pp. 1–20, 2012, doi: 10.1515/1556-3758.2659. [CrossRef]

- S. Perusulla, R. Viviana, and R. Mends, “Thermal conductivity of banana fruit during ripening,” Food Engineering, vol. 100, no. 4, pp. 604–609, 2010, doi: 10.1016/j.jfoodeng.2010.05.006. [CrossRef]

- M. C. Isa, A. K. Oladele, and G. O. Akinlade, “Thermal conductivity of egusi melon seed,” Int J Sci Eng Res, vol. 5, no. 6, pp. 1171–1176, 2014.

- R. K. Singh and T. K. Goswami, “Thermal conductivity of cumin seed as a function of moisture content and temperature,” J Food Sci Technol, vol. 37, no. 1, pp. 94–96, 2000.

- G. R. Chegini and B. Ghobadian, “Effect of spray-drying conditions on physical properties of orange juice powder,” Drying Technology, vol. 25, no. 2, pp. 473–479, 2007, doi: 10.1080/07373930601184831. [CrossRef]

- M. Goula, K. G. Adamopoulos, and N. A. Kazakis, “Influence of spray drying conditions on tomato powder properties,” Drying Technology, vol. 22, no. 5, pp. 1129–1151, 2004, doi: 10.1081/DRT-120038729. [CrossRef]

- F. D. B. Abadio, A. M. Domingues, S. V. Borges, and V. M. \Oliveira, “Physical properties of powdered pineapple (Ananas comosus) juice - effect of malt dextrin concentration and atomization speed,” J Food Eng, vol. 64, no. 3, pp. 285–287, 2004, doi: 10.1016/j.jfoodeng.2003.10.012. [CrossRef]

- S. Phoungchandang and A. Sertwasana, “Spray drying of ginger juice and physicochemical properties of ginger powders,” Songklanakarin Journal of Science and Technology, vol. 32, no. 3, pp. 327–335, 2010.

- 40. G. A. Ikechukwu and S. N. Omenyi, “Convective drying of ginger rhizomes,” in Lecture Notes in Engineering and Computer Science, 2017. doi: 10.1007/978-981-13-2191-7_7. [CrossRef]

- G. A. Ikechukwu, S. Mallik, J. E. E. Njoku, and J. Depriver, “Experimental analysis of thin layer drying of ginger rhizome in convective environment,” Advances in Science, Technology and Engineering Systems, vol. 5, no. 6, 2020, doi: 10.25046/aj0506137. [CrossRef]

- Y. Wang, M. Zhang, and A. S. Mujumdar, “Convective drying kinetics and physical properties of silver carp (Hypophthalmichthys molitrix) fillets,” Journal of Aquatic Food Product Technology, vol. 20, no. 4, 2011, doi: 10.1080/10498850.2011.575536. [CrossRef]

- R. Osae et al., “Variation in bioactive phytochemicals and sensory attributes of osmosonic convective dried ginger from four African countries,” J Sci Food Agric, vol. 100, no. 7, 2020, doi: 10.1002/jsfa.10351. [CrossRef]

- E. Jayashree, R. Visvanathan, and M. John, “Effect of pre-treatments on drying characteristics of ginger (Zingiber officinale) by convective drying,” J Food Sci Technol, vol. 49, no. 6, pp. 760–766, 2012, doi: 10.1007/s13197-010-0216-7. [CrossRef]

- M. Jiřičková, Z. Pavlík, and R. Černý, “Moisture-dependent thermal conductivity of agricultural materials,” J Food Eng, vol. 73, no. 2, pp. 186–191, 2006, doi: 10.1016/j.jfoodeng.2004.11.028. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions, or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).