1. Introduction

Materials with high energy and power have received extensive attention for high-power applications, such as microwaves, electromagnetic devices, pulsed power devices, hybrid electric vehicles, high-frequency inverters, and other energy storage devices [

1,

2,

3]. In particular, dielectric ceramics are the most promising materials for energy storage applications owing to their super-fast charge-discharge rate and excellent temperature stability as compared to electrochemical energy storage devices (batteries and electrochemical capacitors) and dielectric polymers [

4,

5,

6]. However, the dielectric capacitor's energy storage density and energy efficiency are much lower than those of polymers/batteries due to their low dielectric breakdown strength (DBS), which restricts their practical application in energy storage devices.

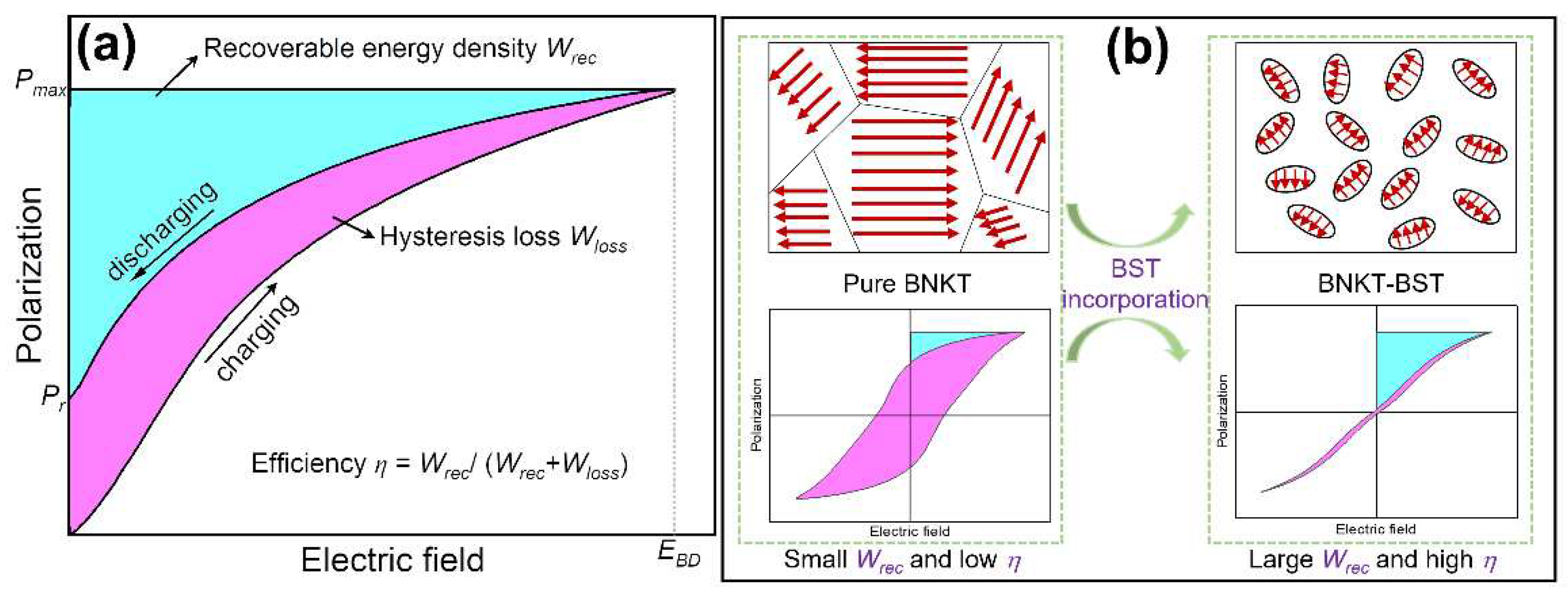

The recoverable energy density (W

rec) of a dielectric capacitor is governed by the applied electric field (E) and induced polarization (P), expressed by the following equation, usually estimated from the P–E loop, and is schematically shown in

Figure 1a by shaded area with cyan color [

7,

8,

9].

where P

max and P

r are the maximum polarization and remnant polarization, respectively (

Figure 1a

). Among all dielectrics, the relaxor ferroelectric (RFE) and antiferroelectric (AFE) materials with a perovskite structure are suitable candidates for energy storage applications since they possess a large P

max, small P

r, and slim P-E loops at higher fields. This leads to high energy efficiency (

η), which can be estimated by the following equation. [

8,

9].

where W

loss is the hysteresis loss. The breakdown electric field (E

BD) is also an essential factor for energy storage; i.e., a higher DBS is responsible for a large energy storage density. Thus, lead-based RFE and AFE materials have been widely investigated for energy storage applications [

10,

11]. However, lead is hazardous to the environment and human health and non-eco-friendly due to its toxicity, which has motivated the development of alternative lead-free materials. In recent years, lead-free RFEs and AFEs, such as BaTiO

3 (BT) [

12,

13], Bi

0.5Na

0.5TiO

3 (BNT) [

6,

14,

15], BiFeO

3 (BFO) [

16,

17], and NaNbO

3 (NN) [

18]-based materials with boosted energy storage performance have been reported for applications in energy storage devices.

The perovskite-structured BNT-based ceramics exhibit a strong ferroelectric response, since Bi

3+ has a lone pair of electrons (6s

2), which strongly hybridizes with the oxygen 2p orbital [

19]. Furthermore, the formation of highly-dynamic polar nano-regions (PNRs) are facilitated by the local random fields induced by valency differences and compositional inhomogeneity [

20,

21]. Moreover, the relaxor behavior of the material can be improved by adding another phase with a similar perovskite to form a solid solution or modifying the base compound with a suitable dopant, which enables slim P-E loops [

22]. Sayyed et al. [

23] investigated the local structural deformation and dielectric anomalies near the morphotropic phase boundary (MPB) of (1-x) Na

0.5Bi

0.5TiO

3-xSrTiO

3 ceramics. The ferroelectric response of (1-x) Na

0.5Bi

0.5TiO

3-SrTiO

3-xAgNbO

3 ceramics is similar to the antiferroelectric response and provided improved energy storage performance [

24]. Shi et al. [

25] reported that Zr and Sm doped 0.74Na

0.5Bi

0.5TiO

3-0.26SrTiO

3 ceramics significantly enhanced energy storage performance and the DBS. Bi

0.2Sr

0.7TiO

3 (BST) exhibits a strong polarization and wide phase transition temperature with diffused dielectric maxima. It was incorporated into BNT ceramics, suppressing the field-generated ferroelectric phase and achieving a large P

max and small P

r [

26,

27]. Recently, Li et al. reported a synergistic approach to enhance the energy storage response in BNT-based RFEs by introducing PNRs and lowered the transition temperature by stabilizing the AFE responses at low temperatures [

9].

In this work, we investigate a domain engineering process to improve energy storage performance by modifying Bi

0.5(Na

0.8K

0.2)

0.5TiO

3 (BNKT) RFEs with BST. It is demonstrated that the addition of BST can transform the ferroelectric microdomains of BNKT into highly-dynamic PNRs. This results in a macroscopic ferroelectric to relaxor ferroelectric transition as schematically illustrated in

Figure 1b. The favorable relaxor ferroelectric state formed by the domain engineering method simultaneously produces a large P

max and reduced P

r, which facilitates the enhancement of DBS with the BST, resulting in high energy density and high efficiency of the BNKT-BST RFES.

2. Materials and Methods

First, (1-x)Bi0.5(Na0.8K0.2)0.5TiO3-xBi0.2Sr0.7TiO3 (BNKT-BST; x = 0.15, 0.30, 0.40, 0.45 and 0.50) RFE ceramics were fabricated by a solid-state reaction method. To prepare BNKT and BST, high-purity raw materials of Bi2O3, (Sigma-Aldrich, 99.9%), Na2CO3 (Sigma-Aldrich, 99.5%), K2CO3 (Sigma-Aldrich, 99%), TiO2, (Sigma-Aldrich, 99%), and SrCO3 (Sigma-Aldrich, 98%) were weighed according to the nominal stoichiometric compositions and then ball-milled using a planetary ball mill for 24h with ZrO2 balls in ethanol. After the slurries were dried at 120 o C, the mixture of BNKT and BST powders was calcined at 800 °C and 950 °C for 2h and 3h, respectively, to form a pure phase of Bi0.5(Na0.8K0.2)0.5TiO3 and Bi0.2Sr0.7TiO3. Both BNKT and BST calcined powders were mixed and ball milled for 12h to prepare a BNKT-BST composition. Further, these powders were granulated with 5 wt.% polyvinyl alcohol and uniaxially pressed into disks at a pressure of 10 MPa in a 10 mm diameter and ~0.5 mm thickness followed by sintered at 1100 °C for 3h. To perform electrical measurements, a silver paste was coated on both sides of the sintered disks.

The phase formation of the BNKT-BST ceramic samples was examined using an X-ray diffractometer (Rigaku, TTRAX III 18 kW) with monochromatic Cu-Kα radiation (λ =1.5406 Å). Raman spectra was recorded using a Raman spectrometer (JOBIN YVON, LABRAM HR800) with a laser wavelength of 532.06 nm. Surface morphology was investigated by a field emission scanning electron microscope (FESEM) (JEOL, JSM-7610F). Temperature and frequency-dependent dielectric properties were measured from room temperature (RT) to 400 °C and 1 kHz – 1 MHz using an impedance analyzer (Hewlett Packard, 4294A). P-E and I-E loops were measured using a ferroelectric tester (Aix ACT, TF Analyzer 2000).

3. Results and discussion

3.1. Phase evolution and microstructure

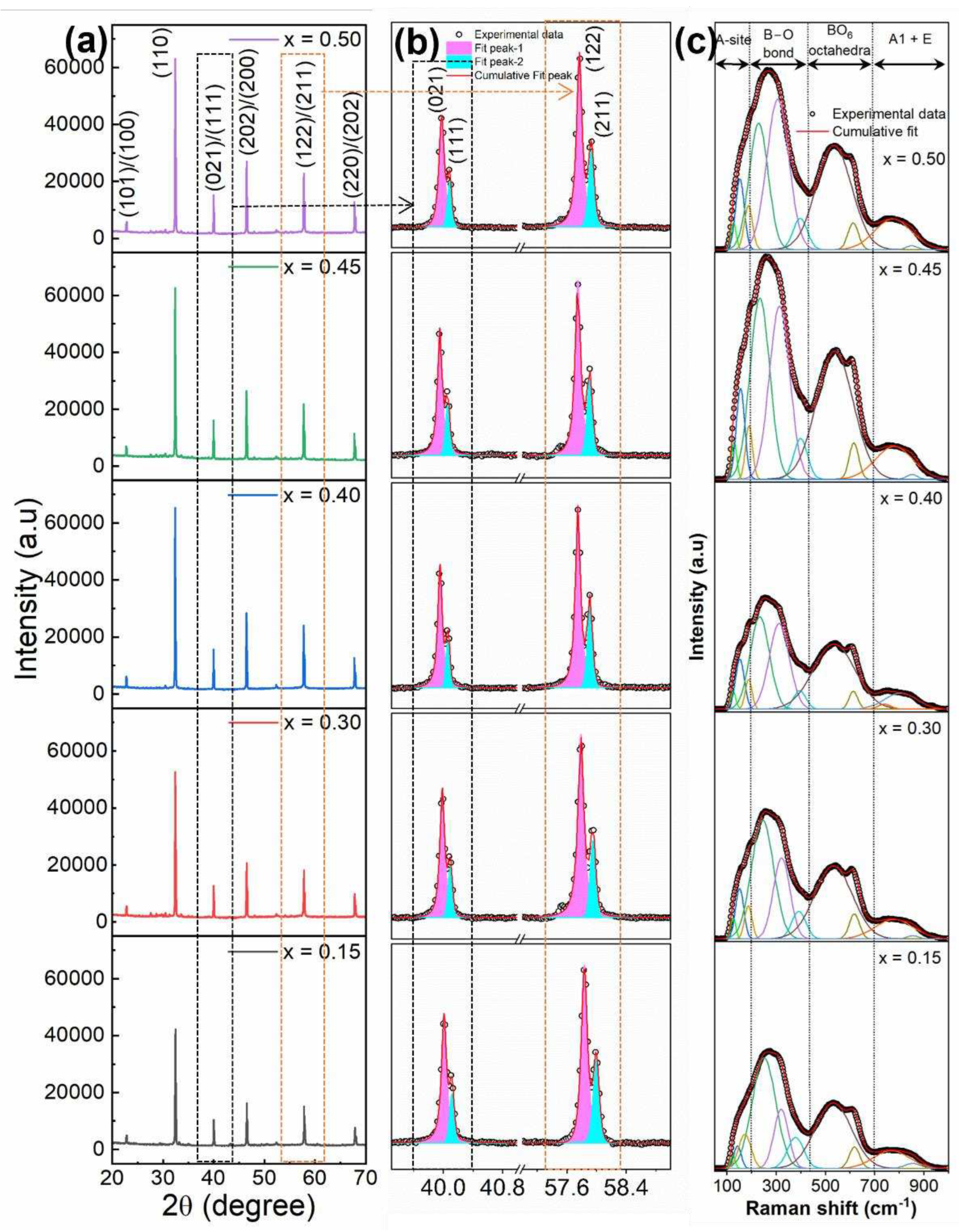

Figure 2a shows the X-ray diffraction (XRD) patterns of BNKT-BST ceramics (x = 0.15 – 0.50) in the 2θ range of 20–70°. All the samples revealed a rhombohedral and tetragonal crystal structure, which indicates the diffusion of BST into BNKT and the formation of a BNKT-BST as a homogeneous solid solution. At RT, the BNKT system exhibits a rhombohedral and tetragonal crystal structure near MPB at x = 0.16–0.2 [

28,

29]. The formation of MPB in BNKT-BST ceramics is confirmed by the splitting of the (021)/(111) and (122)/(211) peaks at 2θ around 40° and 58°, respectively, are shown in

Figure 2b. In addition, both the (021) and (122) peaks shifted slightly towards lower angles with increasing BST into BNKT, demonstrating enhanced lattice parameters. The enhancement of lattice parameters can be attributed to the ionic radius of Sr

2+ (1.44 Å), which is larger than that of Bi

3+ (1.36 Å), Na

+ (1.39 Å), and K

+ (1.38 Å), respectively, at the A-site [

30,

31,

32].

Figure 2c shows the Raman spectra of BNKT-BST along with spectral de-convolution in the Raman shift of 50–1000 cm

-1. The Raman spectra of all compositions are similar to the previous reports of BNKT-based ceramics [

33]. The Raman active bands are divided into four Raman vibration modes, as shown at the top of

Figure 2c. (i) the modes below 200 cm

−1 related to the vibration of A-site (Bi-O, Na-O, K-O, and Sr-O), (ii) the modes between 200–440 cm

−1 correspond to the vibrations of B–O (Ti-O), (iii) the modes between 440–700 cm

−1 correspond to the vibrations of BO

6 (TiO

6)-octahedra, and (iv) the modes above 700 cm

−1 are related to the A1 and E (longitudinal optical) overlapping modes [

33]. The modes appearing at 124–172 cm

-1, and 768 cm

-1 are shifted to higher wavenumber of 128–189 cm

-1 and 779 cm

-1 with BST, associated with the A-site, and A1+E vibrations caused by A-site disorder. Such disorder is induced by the incorporation of BST (Bi

3+, and Sr

2+) into the BNKT (Bi

3+, Na

+ and K

+) system [

34]. In addition, a noticeable change at 250 and 320 cm

-1 shifted towards lower wavenumber of 233, and 305 cm

-1 with BST, which is caused by an increase in the B-site disorder in the BNKT-BST system [

31]. Moreover, these modes are slightly broadened, confirming the disturbance of the long-range ferroelectric order and the formation of highly dynamic PNRs, and this improves the relaxor characteristics of BNKT-BST. This result is consistent with the XRD and electrical properties presented in Sections 3.2 and 3.3.

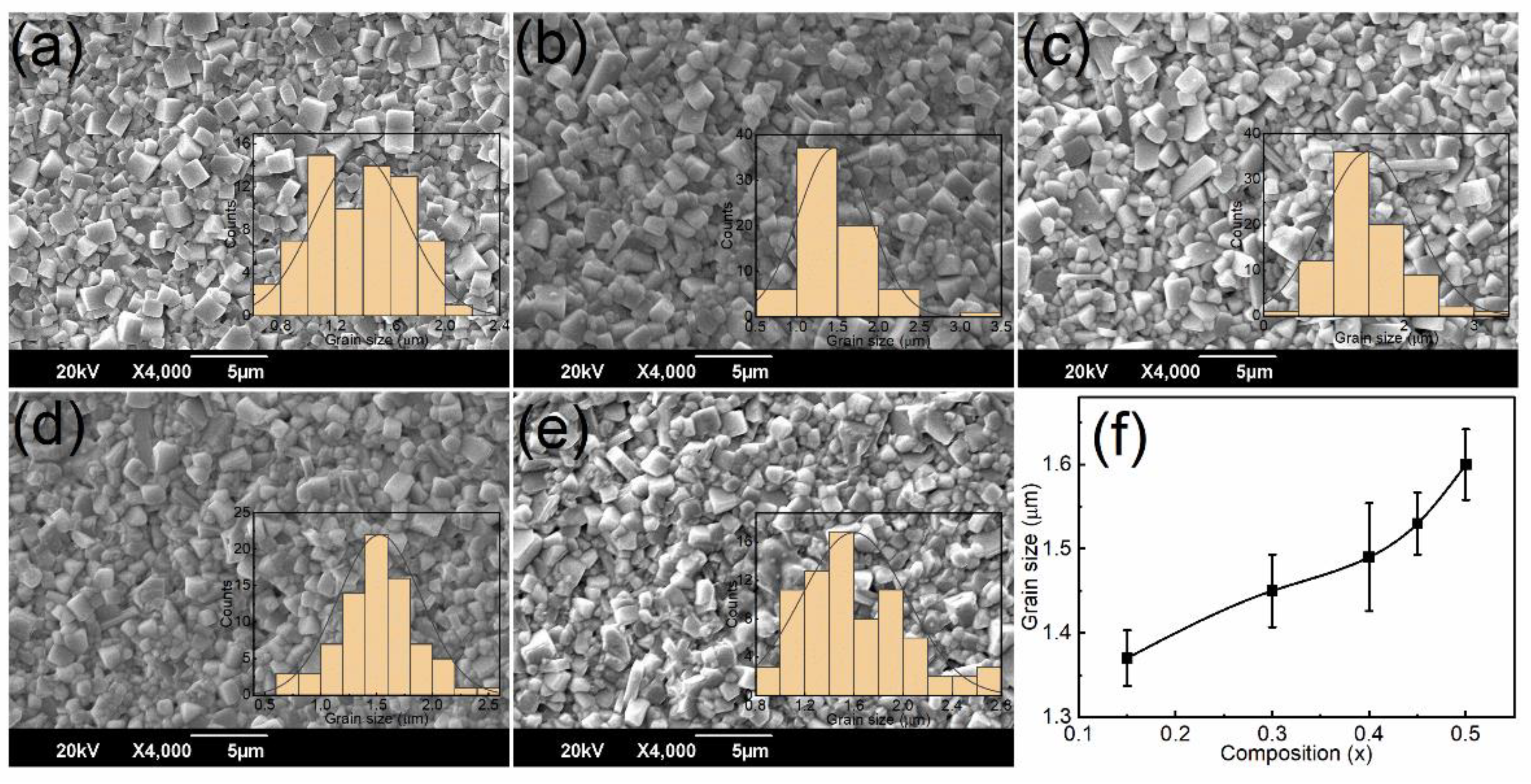

Figure 3 shows FESEM images of the BNKT-BST ceramics. All the ceramics display rectangular-shaped grains, which are homogeneously distributed.

Figure 3(d) clearly shows that the x=0.45 composition exhibits a highly dense microstructure and is more compact with smaller grains as compared to the other samples of BNKT-BST (x<0.45 and x=0.50). The average grain size of the BNKT-BST samples was calculated by the linear intercept method using Image-J software and found to be 1.37 µm for the x=0.15 composition and is gradually enhanced to 1.6 µm with the incorporation of BST. The grain size enhancement is caused by the generation of oxygen vacancies by Sr

2+ entering the perovskite of BNKT and substituting at the A-site of Bi

3+, Na

+, and K

+ [

35]. Previous reports investigated that the fine grain size with homogeneous and dense microstructure can withstand higher electric fields, leads to high DBS, and improve energy storage performance [

36,

37].

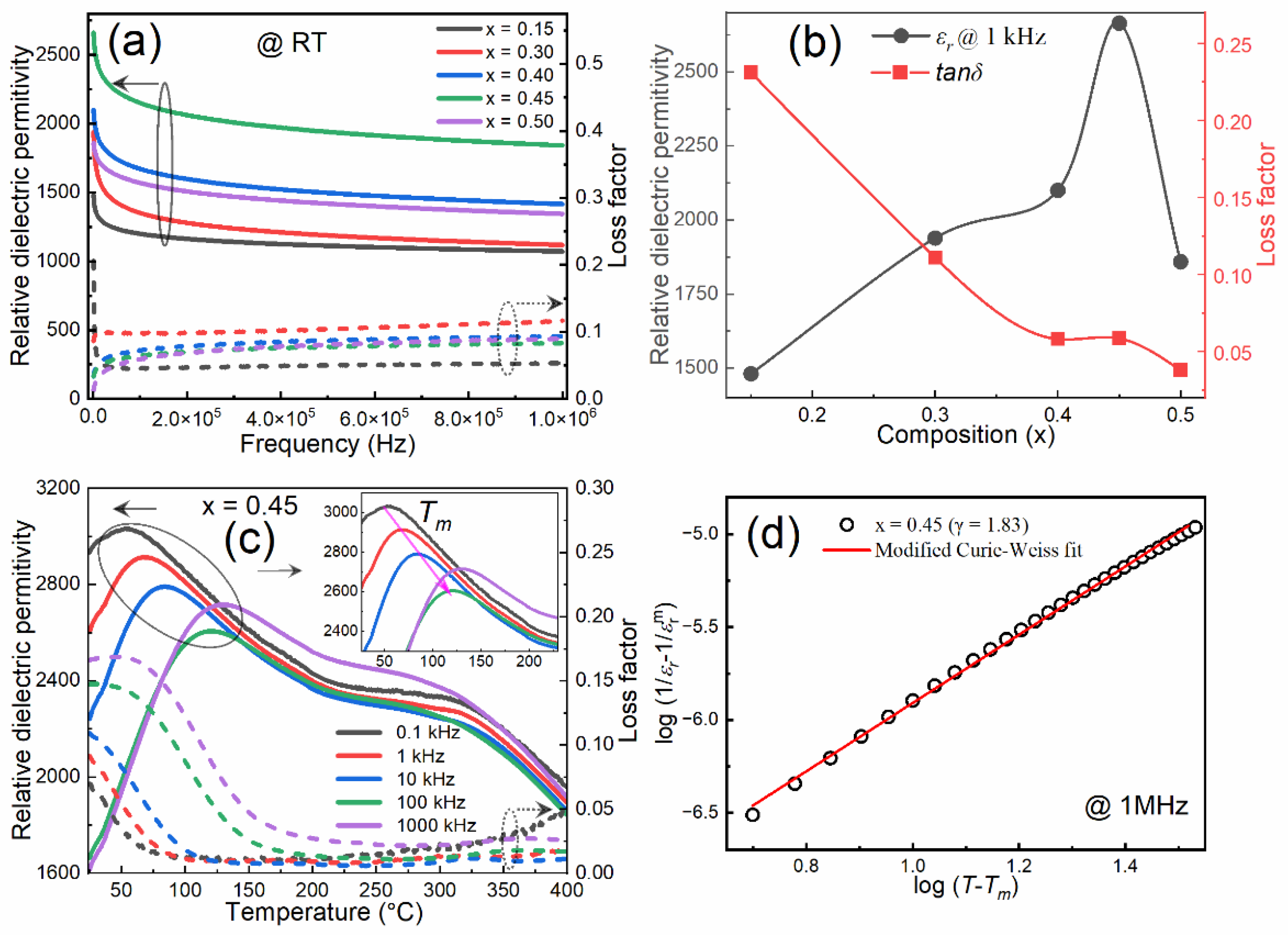

3.2. Dielectric properties and relaxor behaviour

Figure 4a displays the frequency variation of relative dielectric permittivity (

εr) and loss factor (

tanδ) of BNKT-BST ceramic capacitors, measured at RT in the range of 1 kHz to 1 MHz. The sample x=0.15 displayed a higher

εr of 1481 and

tanδ of 0.231 at 1 kHz than pure BNKT (

εr of 1273 and

tanδ of 0.047 at 1 kHz) reported in our previous report [

29]. These

εr values are gradually enhanced to 2664 and the

tanδ values are reduced to 0.058 for the x = 0.45 sample (

Figure 4b). The enhancement of the dielectric properties is attributed to the incorporation of BST into BNKT and the dense microstructure.

Figure 4c displays the temperature variation of

εr and

tanδ of BNKT-BST for the x = 0.45 composition, measured from RT to 400 °C at various frequencies (0.1 kHz to 1 MHz). It was observed that the dielectric maximum temperature (

Tm) shifted towards a lower temperature ~53 °C as compared to pure BNKT (300 °C) [

29]. The incorporation of BST into BNKT can disturb the long-range ferroelectric order, resulting in a lowered

Tm. This lower

Tm leads to the formation of highly-dynamic PNRs due to the mismatch of the ionic radius at the A-site of BNKT-BST. In addition, the

Tm shifted towards higher temperatures, and dielectric peaks diffused with an increase in frequency. This frequency dispersion with a diffuse phase transition reveals typical relaxor ferroelectric characteristics [

38,

39]. The degree of the relaxor characteristics was determined using the modified Curie-Weiss law by the following equation [

40,

41].

where,

is the maximum relative dielectric permittivity at the maximum temperature

Tm,

T is the temperature,

γ is the degree of relaxation, and C is the Curie constant. Generally, the

γ value is 1 for normal ferroelectrics and between 1 and 2 for relaxor ferroelectrics [

40]. The obtained

γ value is 1.83 indicating typical relaxor ferroelectric characteristics, which is consistent with Raman results.

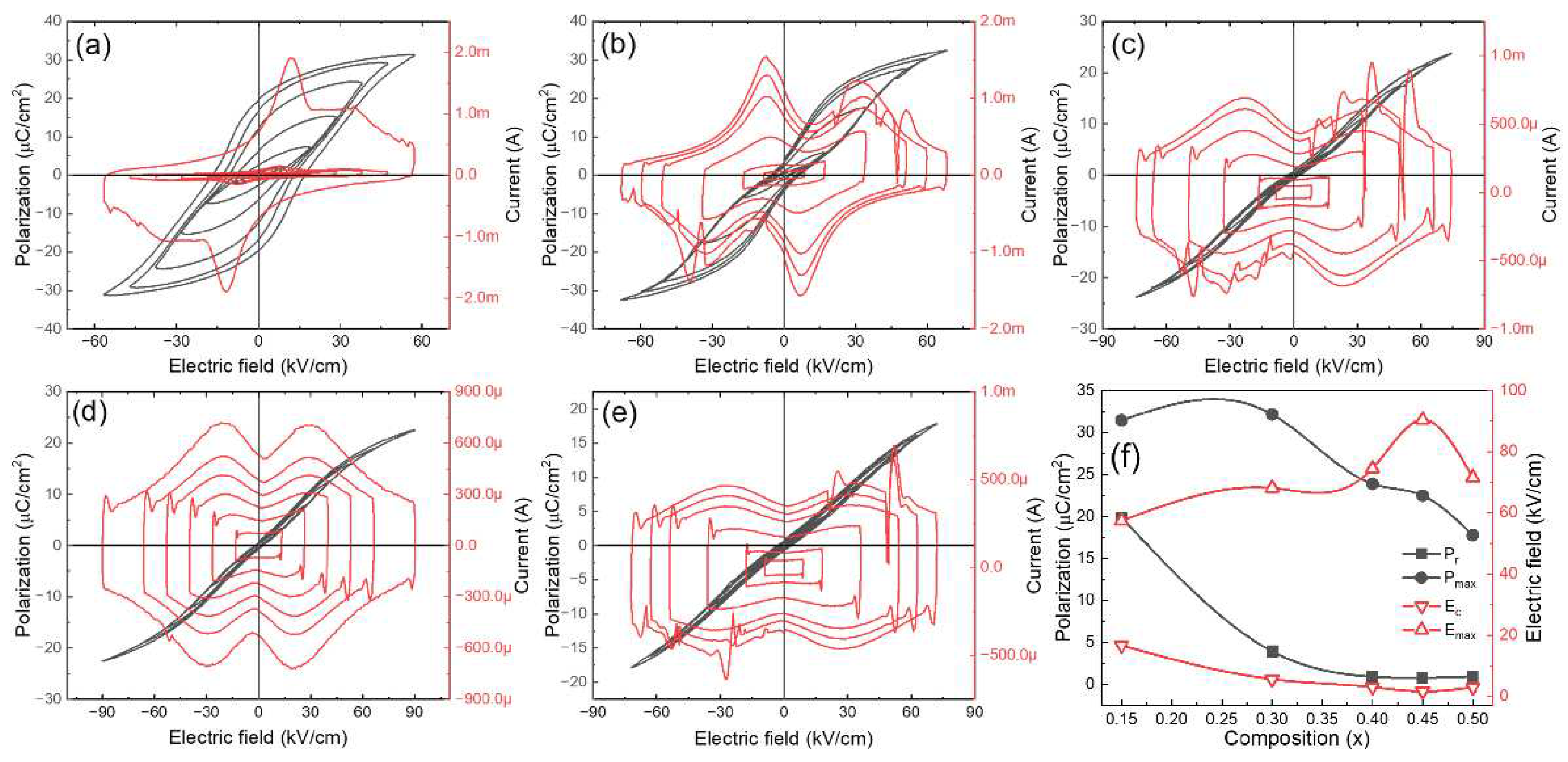

3.3. FE-RFE transformation, domain evolution, and energy storage performance

Figure 5 displays the RT bipolar P-E hysteresis loops and current (I)-electric field (E) curves of BNKT-BST ceramic capacitors measured at various electric fields and 10 Hz. The BNKT-BST (x=0.15) sample exhibits a typical ferroelectric (FE) characteristic, displaying high remnant polarization P

r of 19.89 µC/cm

2, high maximum polarization P

max of 31.46 µC/cm

2, and a high coercive field E

c of 16.66 kV/cm. These values gradually decreased, whereas the E

max or E

BD increased from 57.42 kV/cm to 90 kV/cm with the incorporation of BST (x=0.45), which is favorable for high energy storage density (

Figure 5f). It was evident that the two peaks in the I-E curves (x≥0.30) and slim P-E loops are attributed to the formation of highly dynamic PNRs, which can be commonly seen in RFEs [

42]. In general, the P-E loops present in normal FEs are due to the macroscopic domain wall motion, while in RFEs, highly-dynamic PNRs exist instead of macrodomains, resulting in slim P-E loops [

43].

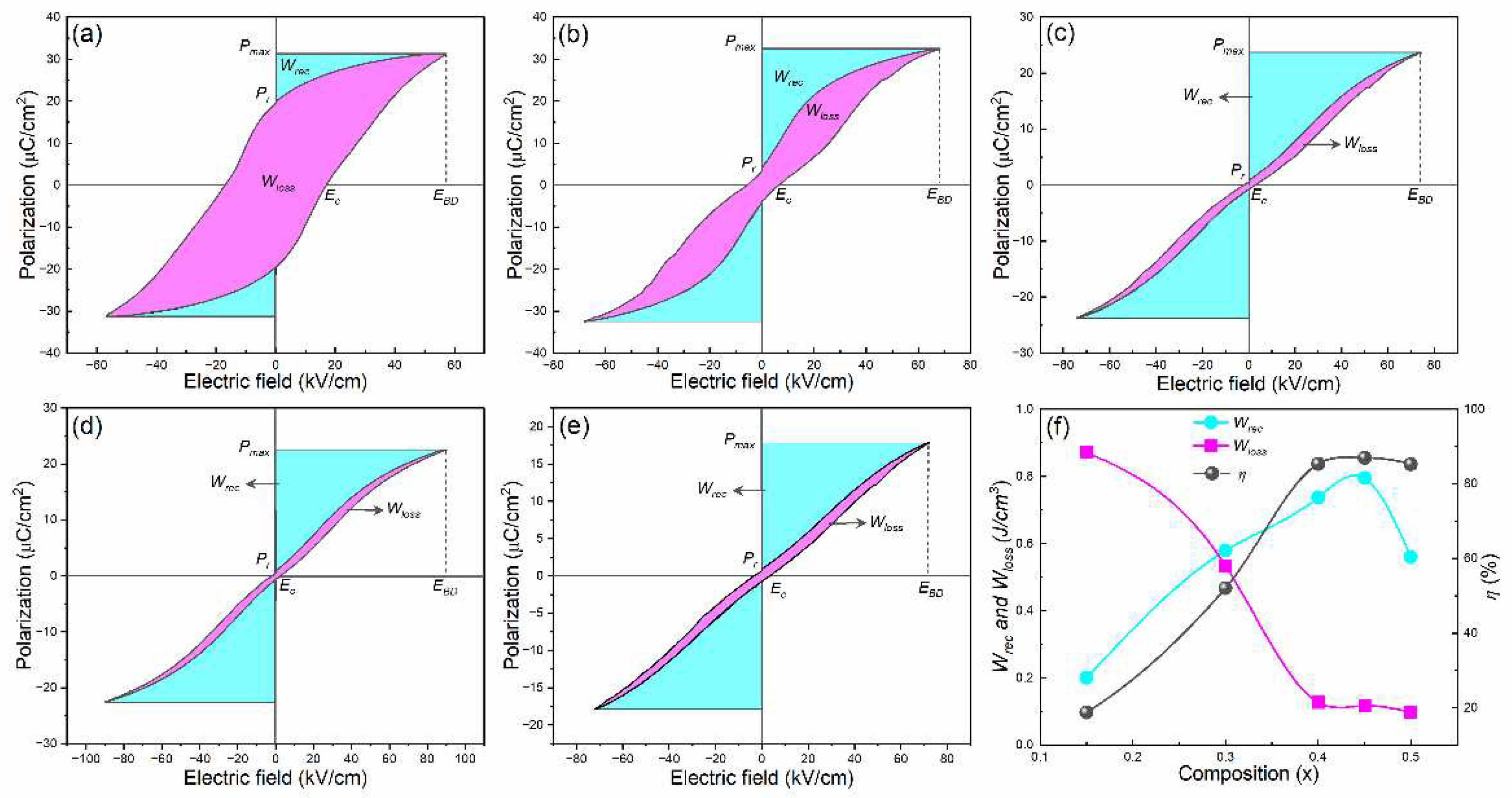

Further, the W

rec was calculated by equation (1) from P-E loops, which are shown in

Figure 6 (cyan shaded area). The W

loss is calculated by the enclosed area of the P-E loops in the first quadrant (magenta shaded area), and

η is calculated by equation (2) [

44]. The W

rec values gradually increased and the W

loss values decreased with the substitution of BST, and the composition x=0.45 displays a high energy density of 0.81 J/cm

3 at E

BD of 90 kV/cm and high energy efficiency of 86.95% (

Figure 6f). The improvement in the energy storage performance is achieved by the domain engineering method by modifying BNKT with BST. It can be understood that the substitution of BST can transform the ferroelectric microdomains of BNKT into highly-dynamic PNRs, resulting in a macroscopic FE to RFE transition. This domain evolution and transformation of FE to RFE transition in present samples as schematically shown in

Figure 1b. The highly-dynamic PNRs induced large P

max and low P

r, which together improved the DBS with the incorporation of BST, resulting in high energy storage density and high energy efficiency of the BNKT-BST RFEs [

44]. The obtained W

rec and

η of 0.55 BNKT- 0.45 BST are comparable/superior to other lead-free RFEs and are promising for energy storage capacitors [

42,

44,

45,

46,

47].

4. Conclusions

The domain-engineered relaxor ferroelectric BNKT-BST ceramics were fabricated by a solid-state reaction method and demonstrated structural, microstructural, dielectric, and ferroelectric properties in detail. XRD, Raman spectra, and FESEM studies revealed the formation of a rhombohedral–tetragonal phase, highly dynamic PNRs, and dense microstructure. The dielectric properties are improved with BST, and a high εr of 2664 and low tanδ of 0.058 at 1 kHz were obtained for x=0.45 composition. The incorporation of BST into BNKT can disturb the long-range ferroelectric order, causing lowered Tm and the formation of highly-dynamic PNRs. In addition, the Tm shifts toward high temperature with frequency and diffuse phase transition, indicating relaxor ferroelectric characteristics of BNKT-BST ceramics, and is confirmed by the modified Curie Weiss law. The rhombohedral–tetragonal phase, fine grain size, and lowered Tm with relaxor properties simultaneously contribute to a high Pmax and low Pr. This improved the DBS and gives rise to giant energy-storage density and high energy efficiency of the BNKT-BST RFEs, which makes this material is a good candidate for pulse driving energy storage applications.

Author Contributions

Conceptualization, measurement, data curation, investigation, visualization, writing—original draft preparation, review and editing, S. P.; data curation, formal analysis, H. C.; data curation, Y.L.; writing – review & editing, K. P.; writing – review & editing, K. C.; validation, project administration, writing – review & editing, supervision, G. H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by an NRF grant funded by the Korean government (MSIT) (No. 2022R1A2C4001497).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shen, Y.; Zhang, X.; Li, M.; Lin, Y.; Nan, C.-W. Polymer Nanocomposite Dielectrics for Electrical Energy Storage. Natl Sci Rev 2017, 4, 23–25. [Google Scholar] [CrossRef]

- Yao, Z.; Song, Z.; Hao, H.; Yu, Z.; Cao, M.; Zhang, S.; Lanagan, M.T.; Liu, H. Homogeneous/Inhomogeneous-Structured Dielectrics and Their Energy-Storage Performances. Advanced Materials 2017, 29, 1601727. [Google Scholar] [CrossRef] [PubMed]

- Palneedi, H.; Peddigari, M.; Hwang, G.-T.; Jeong, D.-Y.; Ryu, J. High-Performance Dielectric Ceramic Films for Energy Storage Capacitors: Progress and Outlook. Adv Funct Mater 2018, 28, 1803665. [Google Scholar] [CrossRef]

- Li, Q.; Chen, L.; Gadinski, M.R.; Zhang, S.; Zhang, G.; Li, H.U.; Iagodkine, E.; Haque, A.; Chen, L.-Q.; Jackson, T.N.; et al. Flexible High-Temperature Dielectric Materials from Polymer Nanocomposites. Nature 2015, 523, 576–579. [Google Scholar] [CrossRef] [PubMed]

- Kumar, N.; Ionin, A.; Ansell, T.; Kwon, S.; Hackenberger, W.; Cann, D. Multilayer Ceramic Capacitors Based on Relaxor BaTiO3-Bi(Zn1/2Ti1/2)O3 for Temperature Stable and High Energy Density Capacitor Applications. Appl Phys Lett 2015, 106, 252901. [Google Scholar] [CrossRef]

- Li, J.; Li, F.; Xu, Z.; Zhang, S. Multilayer Lead-Free Ceramic Capacitors with Ultrahigh Energy Density and Efficiency. Advanced Materials 2018, 30, 1802155. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Shen, Y.; Zhang, S.; Zhang, Q.M. Polymer-Based Dielectrics with High Energy Storage Density. Annu Rev Mater Res 2015, 45, 433–458. [Google Scholar] [CrossRef]

- Xie, A.; Zuo, R.; Qiao, Z.; Fu, Z.; Hu, T.; Fei, L. NaNbO 3 -(Bi 0.5 Li 0.5 )TiO 3 Lead-Free Relaxor Ferroelectric Capacitors with Superior Energy-Storage Performances via Multiple Synergistic Design. Adv Energy Mater 2021, 11, 2101378. [Google Scholar] [CrossRef]

- Li, T.; Jiang, X.; Li, J.; Xie, A.; Fu, J.; Zuo, R. Ultrahigh Energy-Storage Performances in Lead-Free Na 0.5 Bi 0.5 TiO 3 -Based Relaxor Antiferroelectric Ceramics through a Synergistic Design Strategy. ACS Appl Mater Interfaces 2022, 14, 22263–22269. [Google Scholar] [CrossRef]

- Zhang, G.; Zhu, D.; Zhang, X.; Zhang, L.; Yi, J.; Xie, B.; Zeng, Y.; Li, Q.; Wang, Q.; Jiang, S. High-Energy Storage Performance of (Pb 0.87 Ba 0.1 La 0.02 )(Zr 0.68 Sn 0.24 Ti 0.08 )O 3 Antiferroelectric Ceramics Fabricated by the Hot-Press Sintering Method. Journal of the American Ceramic Society 2015, 98, 1175–1181. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, X.; Peng, W.; Xu, C.; Dong, X.; Cao, F.; Wang, G. Temperature-Dependent Stability of Energy Storage Properties of Pb 0.97 La 0.02 (Zr 0.58 Sn 0.335 Ti 0.085 )O 3 Antiferroelectric Ceramics for Pulse Power Capacitors. Appl Phys Lett 2015, 106, 262901. [Google Scholar] [CrossRef]

- Yuan, Q.; Li, G.; Yao, F.-Z.; Cheng, S.-D.; Wang, Y.; Ma, R.; Mi, S.-B.; Gu, M.; Wang, K.; Li, J.-F.; et al. Simultaneously Achieved Temperature-Insensitive High Energy Density and Efficiency in Domain Engineered BaTiO3-Bi(Mg0.5Zr0.5)O3 Lead-Free Relaxor Ferroelectrics. Nano Energy 2018, 52, 203–210. [Google Scholar] [CrossRef]

- Zhao, P.; Wang, H.; Wu, L.; Chen, L.; Cai, Z.; Li, L.; Wang, X. High-Performance Relaxor Ferroelectric Materials for Energy Storage Applications. Adv Energy Mater 2019, 9, 1803048. [Google Scholar] [CrossRef]

- Yin, J.; Zhang, Y.; Lv, X.; Wu, J. Ultrahigh Energy-Storage Potential under Low Electric Field in Bismuth Sodium Titanate-Based Perovskite Ferroelectrics. J Mater Chem A Mater 2018, 6, 9823–9832. [Google Scholar] [CrossRef]

- Qi, H.; Zuo, R. Linear-like Lead-Free Relaxor Antiferroelectric (Bi 0.5 Na 0.5 )TiO 3 –NaNbO 3 with Giant Energy-Storage Density/Efficiency and Super Stability against Temperature and Frequency. J Mater Chem A Mater 2019, 7, 3971–3978. [Google Scholar] [CrossRef]

- Wang, G.; Li, J.; Zhang, X.; Fan, Z.; Yang, F.; Feteira, A.; Zhou, D.; Sinclair, D.C.; Ma, T.; Tan, X.; et al. Ultrahigh Energy Storage Density Lead-Free Multilayers by Controlled Electrical Homogeneity. Energy Environ Sci 2019, 12, 582–588. [Google Scholar] [CrossRef]

- Pan, H.; Li, F.; Liu, Y.; Zhang, Q.; Wang, M.; Lan, S.; Zheng, Y.; Ma, J.; Gu, L.; Shen, Y.; et al. Ultrahigh–Energy Density Lead-Free Dielectric Films via Polymorphic Nanodomain Design. Science (1979) 2019, 365, 578–582. [Google Scholar] [CrossRef] [PubMed]

- Qi, H.; Zuo, R.; Xie, A.; Tian, A.; Fu, J.; Zhang, Y.; Zhang, S. Ultrahigh Energy-Storage Density in NaNbO 3 -Based Lead-Free Relaxor Antiferroelectric Ceramics with Nanoscale Domains. Adv Funct Mater 2019, 29, 1903877. [Google Scholar] [CrossRef]

- Li, F.; Hou, X.; Wang, J.; Zeng, H.; Shen, B.; Zhai, J. Structure-Design Strategy of 0–3 Type (Bi0.32Sr0.42Na0.20)TiO3/MgO Composite to Boost Energy Storage Density, Efficiency and Charge-Discharge Performance. J Eur Ceram Soc 2019, 39, 2889–2898. [Google Scholar] [CrossRef]

- Liu, N.; Liang, R.; Zhou, Z.; Dong, X. Designing Lead-Free Bismuth Ferrite-Based Ceramics Learning from Relaxor Ferroelectric Behavior for Simultaneous High Energy Density and Efficiency under Low Electric Field. J Mater Chem C Mater 2018, 6, 10211–10217. [Google Scholar] [CrossRef]

- Wu, Y.; Fan, Y.; Liu, N.; Peng, P.; Zhou, M.; Yan, S.; Cao, F.; Dong, X.; Wang, G. Enhanced Energy Storage Properties in Sodium Bismuth Titanate-Based Ceramics for Dielectric Capacitor Applications. J Mater Chem C Mater 2019, 7, 6222–6230. [Google Scholar] [CrossRef]

- Hu, Q.; Tian, Y.; Zhu, Q.; Bian, J.; Jin, L.; Du, H.; Alikin, D.O.; Shur, V.Y.; Feng, Y.; Xu, Z.; et al. Achieve Ultrahigh Energy Storage Performance in BaTiO3–Bi(Mg1/2Ti1/2)O3 Relaxor Ferroelectric Ceramics via Nano-Scale Polarization Mismatch and Reconstruction. Nano Energy 2020, 67, 104264. [Google Scholar] [CrossRef]

- Sayyed, S.; Acharya, S.A.; Kautkar, P.; Sathe, V. Structural and Dielectric Anomalies near the MPB Region of Na0.5Bi0.5TiO3–SrTiO3 Solid Solution. RSC Adv 2015, 5, 50644–50654. [Google Scholar] [CrossRef]

- Ma, W.; Zhu, Y.; Marwat, M.A.; Fan, P.; Xie, B.; Salamon, D.; Ye, Z.-G.; Zhang, H. Enhanced Energy-Storage Performance with Excellent Stability under Low Electric Fields in BNT–ST Relaxor Ferroelectric Ceramics. J Mater Chem C Mater 2019, 7, 281–288. [Google Scholar] [CrossRef]

- Shi, L.N.; Wang, Y.G.; Ren, Z.H.; Jain, A.; Jiang, S.S.; Chen, F.G. Significant Improvement in Electrical Characteristics and Energy Storage Performance of NBT-Based Ceramics. Ceram Int 2022, 48, 26973–26983. [Google Scholar] [CrossRef]

- Kong, X.; Yang, L.; Cheng, Z.; Zhang, S. Bi-modified SrTiO 3 -based Ceramics for High-temperature Energy Storage Applications. Journal of the American Ceramic Society 2020, 103, 1722–1731. [Google Scholar] [CrossRef]

- Wei, T.; Liu, K.; Fan, P.; Lu, D.; Ye, B.; Zhou, C.; Yang, H.; Tan, H.; Salamon, D.; Nan, B.; et al. Novel NaNbO3–Sr0.7Bi0·2TiO3 Lead-Free Dielectric Ceramics with Excellent Energy Storage Properties. Ceram Int 2021, 47, 3713–3719. [Google Scholar] [CrossRef]

- Pham, K.-N.; Hussain, A.; Ahn, C.W.; Kim, W.; Jeong, S.J.; Lee, J.-S. Giant Strain in Nb-Doped Bi0.5(Na0.82K0.18)0.5TiO3 Lead-Free Electromechanical Ceramics. Mater Lett 2010, 64, 2219–2222. [Google Scholar] [CrossRef]

- Pattipaka, S.; James, A.R.; Dobbidi, P. Dielectric, Piezoelectric and Variable Range Hopping Conductivity Studies of Bi0.5(Na, K)0.5TiO3 Ceramics. J Electron Mater 2018, 47, 3876–3890. [Google Scholar] [CrossRef]

- Gupta, S.K.; McQuade, R.; Gibbons, B.; Mardilovich, P.; Cann, D.P. Electric Field-Induced Strain in Sr(Hf 0.5 Zr 0.5 )O 3 -Modified Bi 0.5 (Na 0.8 K 0.2 ) 0.5 TiO 3 Piezoelectric Ceramics. J Appl Phys 2020, 127, 074104. [Google Scholar] [CrossRef]

- Pattipaka, S.; James, A.R.; Dobbidi, P. Enhanced Dielectric and Piezoelectric Properties of BNT-KNNG Piezoelectric Ceramics. J Alloys Compd 2018, 765, 1195–1208. [Google Scholar] [CrossRef]

- Tong, X.-Y.; Song, M.-W.; Zhou, J.-J.; Wang, K.; Guan, C.-L.; Liu, H.; Fang, J.-Z. Enhanced Energy Storage Properties in Nb-Modified Bi0.5Na0.5TiO3–SrTiO3 Lead-Free Electroceramics. Journal of Materials Science: Materials in Electronics 2019, 30, 5780–5790. [Google Scholar] [CrossRef]

- Jaita, P.; Saenkam, K.; Rujijanagul, G. Improvements in Piezoelectric and Energy Harvesting Properties with a Slight Change in Depolarization Temperature in Modified BNKT Ceramics by a Simple Technique. RSC Adv 2023, 13, 3743–3758. [Google Scholar] [CrossRef]

- Chu, B.; Hao, J.; Li, P.; Li, Y.; Li, W.; Zheng, L.; Zeng, H. High-Energy Storage Properties over a Broad Temperature Range in La-Modified BNT-Based Lead-Free Ceramics. ACS Appl Mater Interfaces 2022, 14, 19683–19696. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, J.; Shen, J.; Yang, X.; Wu, C.; Han, K.; Zhao, Z.; Chen, W. Enhanced Piezoelectric Property and Promoted Depolarization Temperature in Fe Doped Bi1/2(Na0.8K0.2)1/2TiO3 Lead-Free Ceramics. Ceram Int 2017, 43, 16395–16402. [Google Scholar] [CrossRef]

- Huang, Y.; Zhao, C.; Wu, B.; Wu, J. Multifunctional BaTiO 3 -Based Relaxor Ferroelectrics toward Excellent Energy Storage Performance and Electrostrictive Strain Benefiting from Crossover Region. ACS Appl Mater Interfaces 2020, 12, 23885–23895. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, Z.; Tian, Y.; Wang, G.; Wang, W.; Yang, M.; Wang, X.; Zhang, F.; Pu, Y. Progress, Outlook, and Challenges in Lead-Free Energy-Storage Ferroelectrics. Adv Electron Mater 2020, 6, 1900698. [Google Scholar] [CrossRef]

- Shvartsman, V.V.; Lupascu, D.C. Lead-Free Relaxor Ferroelectrics. Journal of the American Ceramic Society 2012, 95, 1–26. [Google Scholar] [CrossRef]

- Liu, G.; Wang, Y.; Han, G.; Gao, J.; Yu, L.; Tang, M.; Li, Y.; Hu, J.; Jin, L.; Yan, Y. Enhanced Electrical Properties and Energy Storage Performances of NBT-ST Pb-Free Ceramics through Glass Modification. J Alloys Compd 2020, 836, 154961. [Google Scholar] [CrossRef]

- Uchino, K.; Nomura, S.; Cross, L.E.; Jang, S.J.; Newnham, R.E. Electrostrictive Effect in Lead Magnesium Niobate Single Crystals. J Appl Phys 1980, 51, 1142–1145. [Google Scholar] [CrossRef]

- Gupta, S.K.; McQuade, R.; Gibbons, B.; Mardilovich, P.; Cann, D.P. Electric Field-Induced Strain in Sr(Hf 0.5 Zr 0.5 )O 3 -Modified Bi 0.5 (Na 0.8 K 0.2 ) 0.5 TiO 3 Piezoelectric Ceramics. J Appl Phys 2020, 127, 074104. [Google Scholar] [CrossRef]

- Li, Q.; Wang, C.; Yadav, A.K.; Fan, H. Large Electrostrictive Effect and Energy Storage Density in MnCO3 Modified Na0.325Bi0.395Sr0.245□0.035TiO3 Lead-Free Ceramics. Ceram Int 2020, 46, 3374–3381. [Google Scholar] [CrossRef]

- Yang, L.; Kong, X.; Li, F.; Hao, H.; Cheng, Z.; Liu, H.; Li, J.-F.; Zhang, S. Perovskite Lead-Free Dielectrics for Energy Storage Applications. Prog Mater Sci 2019, 102, 72–108. [Google Scholar] [CrossRef]

- Wu, J.; Mahajan, A.; Riekehr, L.; Zhang, H.; Yang, B.; Meng, N.; Zhang, Z.; Yan, H. Perovskite Srx(Bi1−xNa0.97−xLi0.03)0.5TiO3 Ceramics with Polar Nano Regions for High Power Energy Storage. Nano Energy 2018, 50, 723–732. [Google Scholar] [CrossRef]

- Yan, Y.; Zeng, X.; Deng, T.; Chen, F.; Yang, L.; He, Z.; Jin, L.; Liu, G. Rheological, Mechanical, and Electrical Properties of Sr0.7Bi0.2TiO3 Modified BaTiO3 Ceramic and Its Composites. Journal of the American Ceramic Society 2023, 106, 3052–3065. [Google Scholar] [CrossRef]

- Nayak, S.; Venkateshwarlu, S.; Budisuharto, A.S.; Jørgensen, M.R.V.; Borkiewicz, O.; Beyer, K.A.; Pramanick, A. Effect of A-site Substitutions on Energy Storage Properties of BaTiO3-BiScO3 Weakly Coupled Relaxor Ferroelectrics. Journal of the American Ceramic Society 2019, 102, 5919–5933. [Google Scholar] [CrossRef]

- Cao, W.P.; Li, W.L.; Dai, X.F.; Zhang, T.D.; Sheng, J.; Hou, Y.F.; Fei, W.D. Large Electrocaloric Response and High Energy-Storage Properties over a Broad Temperature Range in Lead-Free NBT-ST Ceramics. J Eur Ceram Soc 2016, 36, 593–600. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).