1. Introduction

The warm mixing technology allows the asphalt to reach the viscosity needed for mixing at lower temperature and therefore is able to reduce the mixing temperature by 30~40℃ during the asphalt mixture production, resulting in less energy consumption, better construction convenience and less ageing of asphalt1~4. Whereas, problems also arise that moisture susceptibility may deteriorate as a consequence of lower mixing and compacting temperature5~7. Relative studies have pointed out that the moisture damage of mixture is attributed to the adhesion failure between asphalt and aggregate and therefore researchers have introduced various methods as well as indicators to characterize the adhesion properties812. Currently, methods such as boiling method, photoelectric colorimetry, surface free energy(SFE) test and atomic force microscopy (AFM) have been applied to the investigation of the adhesion between asphalt and aggregate, among which the SFE obtains more attention because of its unnecessity of compacted specimen preparation, simplicity of test process and the economic advantage13.

Elphingstone introduced SFE to asphalt mixture research for the first time to studied the interfacial cracking prediction in hot mix asphalt(HMA) mixture14. Cheng measured the SFE indexes of different asphalts and aggregates and calculated the cohesion work of asphalt and the adhesion work of asphalt-aggregate interface. The comparison between SFE test and conventional moisture susceptibility test confirms the feasibility of SFE indicators to evaluate the moisture susceptibility15. Zhang et al. compared the SFE test result with adhesion grade and TSR obtained from laboratory test of 6 different WMA and the relevance among them were studied16.

There are more factors impacting the moisture susceptibility of WMA compared to HMA17. In addition to the commonly accepted factors of HMA, the involvement of warm mixing additives and the mixing procedure applied also attracted attentions of researchers on their impact to moisture susceptibility of WMA. Hurley et al. found that the influence of different warm mixing additives on different aggregates is distinct18~20. Zaumanis noted that the poor adhesion between asphalt and aggregates may occur due to the unevaporated water remained during some warm mixing process, thus leading to negative performance of WMA21.

Present researches have made remarkable investigation on the SFE theory and the influencing factors of moisture susceptibility of WMA, while it still can be noticed that few researches draw concerns on the influence of moisture content and the mixing process. In this research, on the basis of SFE theory, a novel indicator for evaluating the asphalt-aggregate adhesive property with different moisture contents is proposed. At the meantime, a three-phase model of aggregate-asphalt-warm mixing additive is introduced enhanced from the conventional two-phase model by taking the process of dry mixing method into consideration. The influence of several factors on the moisture susceptibility is analyzed using the advanced indicator and model put forward in this paper and the freeze-thaw splitting test is applied for the verification of SFE test.

2. Surface Free Energy Theory

The SFE theory provides a quantitative measurement method for adhesion properties between aggregates and asphalt. Having the SFE components of asphalts and aggregates contributes to an insight prediction of moisture susceptibility.

2.1. Two-phase model

In the traditional two-phase model, the adhesion process of asphalt and aggregate can be expressed as asphalt + stone → asphalt-stone. The amount of energy change per unit area of the adhesion interface is the adhesion work(

Was). The larger the

Was is, the stronger the asphalt-stone interface is. The adhesion work without moisture can be calculated according to

Equation (1). When water related damage appears in the asphalt pavement, water enters the void, and then gradually adheres with aggregate by replacing asphalt. This process requires work by external forces, which is called the adhesion work with moisture(

Wasw), the physical meaning of which is the energy change per unit after two contacted materials is separated by water

22. The larger the W

asw is, the weaker the asphalt-stone interface is. The adhesion work with moisture can be calculated according to

Equation (2).

where,

,

and

represent the surface free energy of asphalt, stone and water respectively, mJ·m

-2;

,

and

represent the stone-water, stone-water and asphalt-water interface energy, mJ·m

-2;

is the van der Waals component, mJ·m

-2;

and

is the Lewis acid term and base term, mJ·m

-2.

In addition, some researchers have proposed some comprehensive indicators by considering the adhesion work with/without moisture and cohesion work of asphalt, such as ER

1, ER

2, ER

1·SSA, ER

2·SSA, etc. Among them, ER

2 is proved to be well-correlated with indicator of moisture susceptibility, and furthermore, a threshold value is recommended in a NCHRP report

23~24. Therefore, in this paper, ER

2 is used as the comprehensive indicator, noted as ER. The larger the ER value, the better the moisture susceptibility of corresponding asphalt mixture. ER can be calculated as

Equation (3).

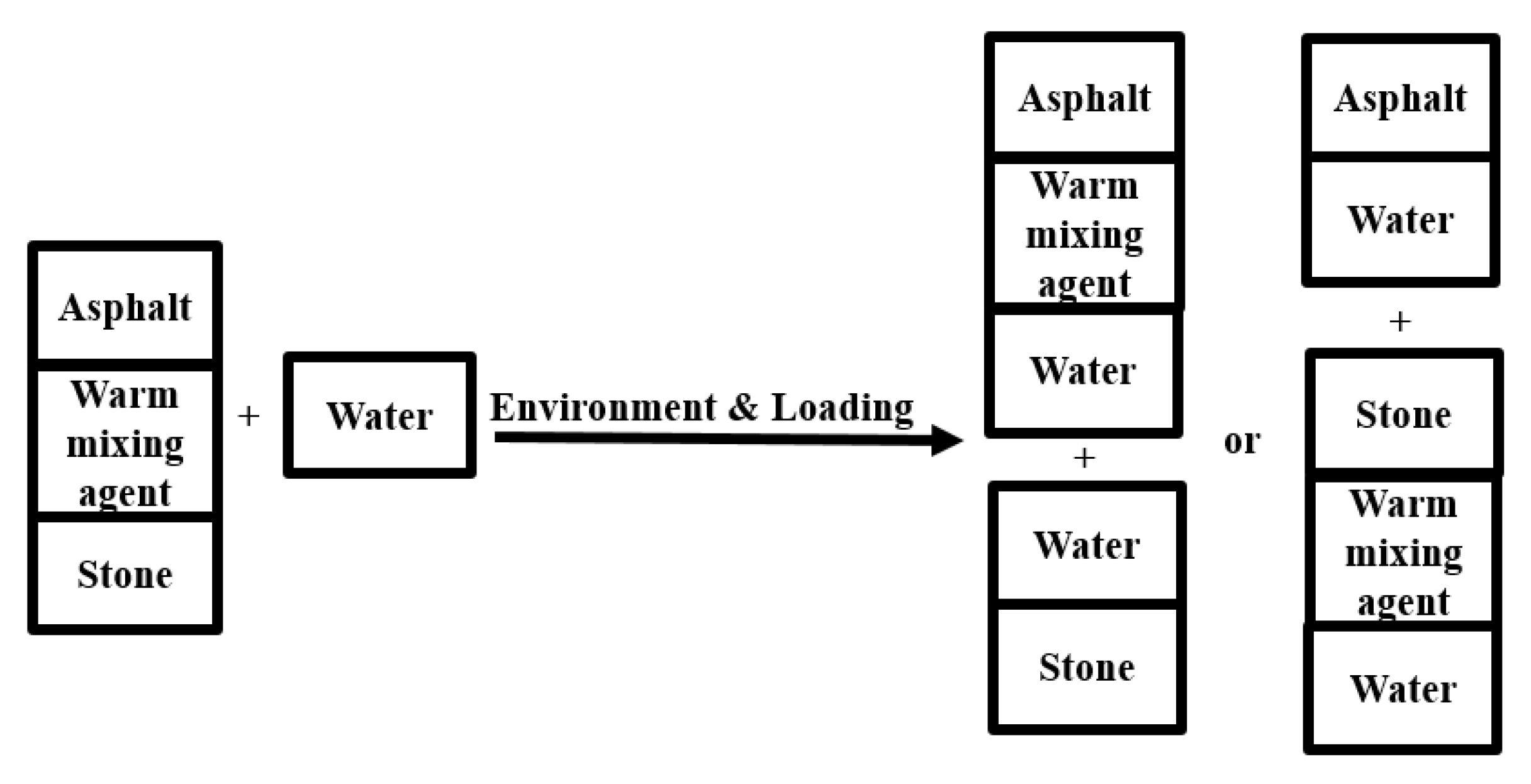

2.2. Three-phase adhesion model

In the conventional two-phase adhesion model, only asphalt(or warm mix additive modified asphalt) and aggregate are considered, as shown in

Figure 1a), which is suitable for wet mixing process. However, in the engineering practice of WMA, the dry mixing is also widely used during which the aggregates are first mixed with warm mix additives and afterwards with asphalt, as shown in

Figure 1b). This process is absolutely inconsistent with the original two-phase model. Hence, a corresponding three-phase model needs to be established which takes warm mix agent into account. The adhesion in dry mixing method can be expressed as asphalt + extra agent + stone → asphalt-extra agent-stone. According to its energy change, the corresponding formula of adhesion work without moisture(W

ase) can be introduced, as shown in

Equation (4).

where,

γae and

γse denote the interfacial energy of asphalt-extra agent and aggregate-extra agent, respectively, mJ

·m

-2;

is the surface free energy of extra agent.

The adhesion failure process with moisture of three-phase model is complex. The interfacial failure caused by water may occur at two interfaces. One is the warm mixing agent-asphalt interface, and the other is the warm mixing agent-aggregate interface, as shown in

Figure 2. Assuming a 50/50 split between the two scenarios, then the formula of adhesion with moisture is calculated as Equation (5), and ER can be calculated as Equation (6).

The three-phase model can characterize the process of dry mixing method and the corresponding adhesion indicators can be calculated. It enables the SFE theory to study the effect of mixing process on water stability of WMA.

3. Materials and Methods

3.1. Materials

In this research, two kinds of asphalt are involved including base asphalt with penetration 60/80 and I-D linear SBS modified asphalt. Each index of both asphalt meets the requirement of

Technical Specification for Construction of Highway Asphalt Pavements standards, a Chinese standard

25. The specific properties are shown in

Table 1.

Additionally, five kinds of warm mixing agents shown in

Figure 3 are employed in this study. Among them, agent A and B are fine and course white particles respectively. Agent C and D are both brown viscous liquids. Agent E is white latex. The mixing content is summarized in

Table 2.

Three kinds of aggregates, including limestone, basalt and granite, which are commonly used in the field of road engineering, are selected for further research. The density indexed are shown in

Table 3.

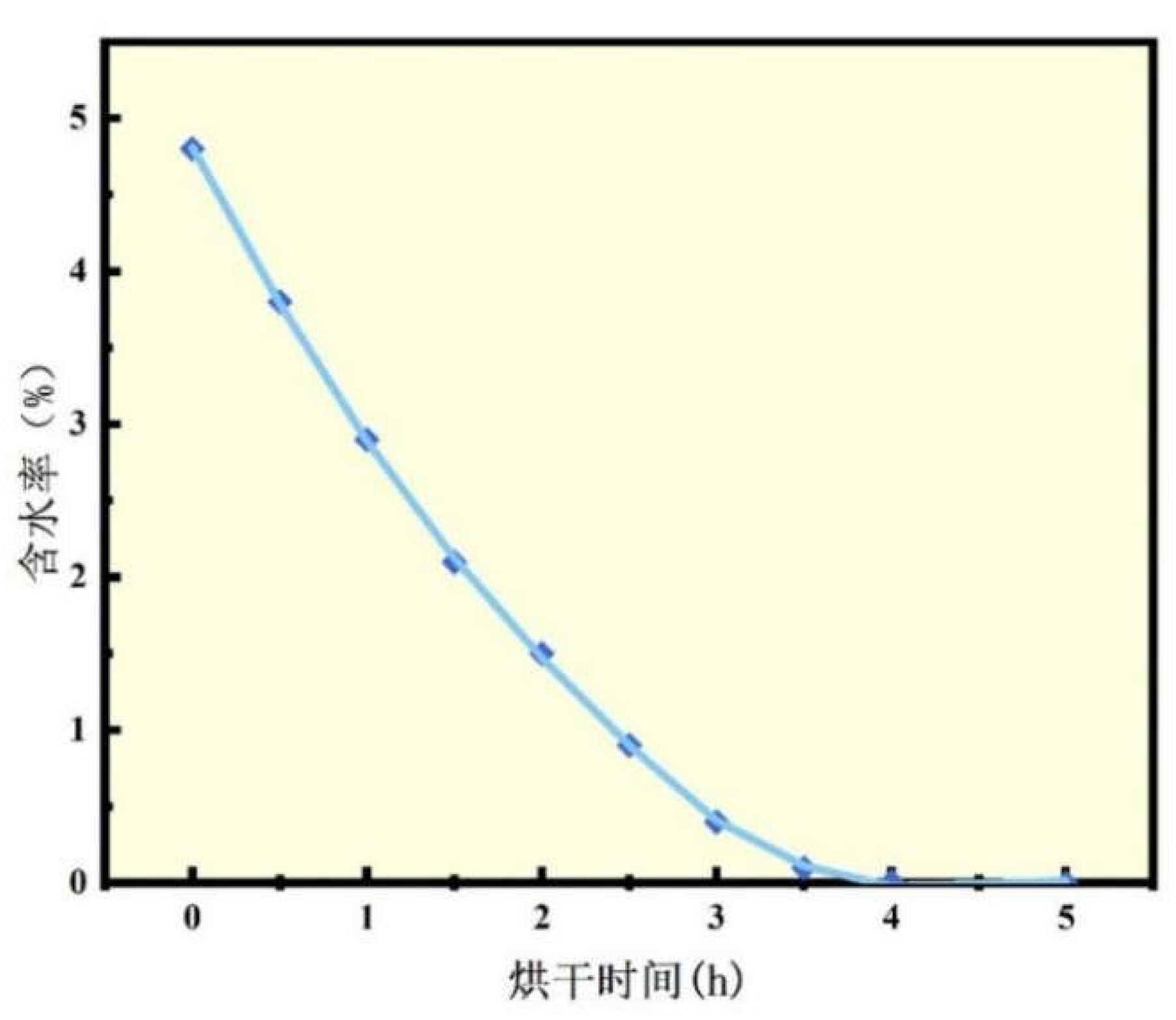

In order to study the factor of aggregate moisture content, limestone with different moisture contents is obtained by soaking limestone in water for three hours and placing it in a 145°C oven for different time. The quality is recorded every half an hour and therefore the relationship between the moisture content of the aggregate and the drying time can be acknowledged, which is shown in

Table 4 and

Figure 4.

3.2. Experimental methods

3.2.1. Surface free energy testing technology

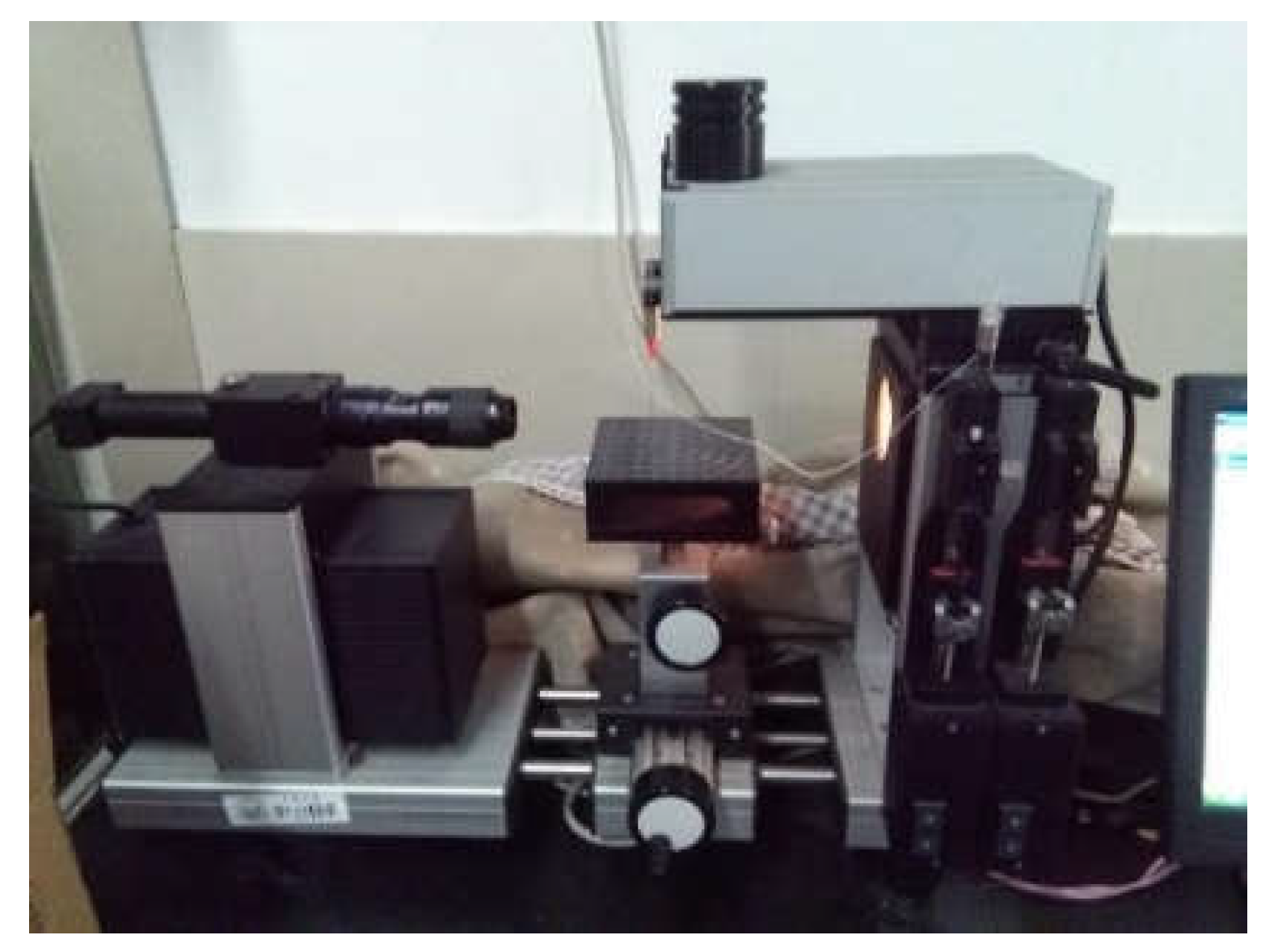

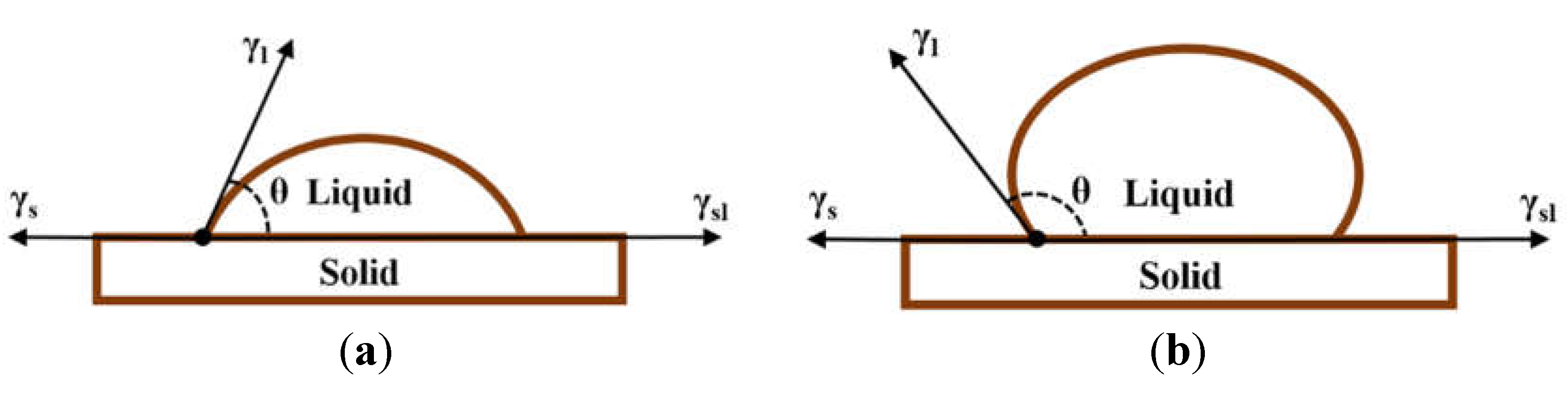

The sessile drop method is employed in this research to test the surface free energy of asphalt and aggregates. The instrument used is the contact angle system OCA as shown in

Figure 5, of which the theoretical basis is the Young's equation (

Equation (7)) deduced in

Figure 6. Combining it with the LW-AB model (Lewis Acid/Base Model) of

Equation (8),

Equation (9) can be obtained. Regarding the solid as the object to be measured, by increasing the number of known liquids, the linear equation set shown in

Equation (10) can be established and the surface free energy parameters can be obtained when the equation is solved.

where,

represents the contact angle between the test solid and known liquid;

and

represent the surface free energy of solid and liquid respectively, mJ·m

-2;

represents the solid-liquid interface energy, mJ·m

-2;

represent different known liquids.

In the NCHRP report, the surface energy parameters of five known liquids suitable for testing asphalt and aggregates are given, which are listed in Table 524. Some preliminary researches have been done to select proper liquids based on conditional number(CN) to reduce the impact of parameters on test results. As a consequence, distilled water, diiodomethane and glycerin are chosen for the following test.

3.2.2. Freeze-thaw splitting test

According to corresponding standard of China, the moisture susceptibility is evaluated using freeze-thaw splitting test[

26]. The test requires two groups of four specimens prepared by 50 times of Marshall compaction in each side and one group, namely the freeze-thaw group, needs to undergo freeze-thaw conditioning while the other group is the control group stored in ambient environment. Both groups are tested at 25℃ and the splitting strength can be obtained by

Equation (11). The tensile strength ratio(TSR) can be calculated as

Equation (12).

where,

TSR is tensile strength ratio (%);

ST1 and

ST2 are splitting tensile strength (kPa) under dry and freeze-thaw conditioning, respectively;

PT is the maximum load (N);

h is the height of the specimen, mm.

4. Results and Discussion

The factors affecting the moisture susceptibility of WMA, which are complicated, can be studied by using SFE theory. The characteristics of raw materials, the mixture design, and the mixing temperature will all make a difference[

27]. In this paper, the influence of aggregate type, aggregate moisture content, warm mix additives, asphalt type and mixing method on the water stability of WMA is studied utilizing SFE theory.

4.1. Surface free energy components

The test samples and the testing procedures are shown in

Figure 7. The parameters based on surface free energy can be calculated after contact angles are measured and the results are shown in

Table 6.

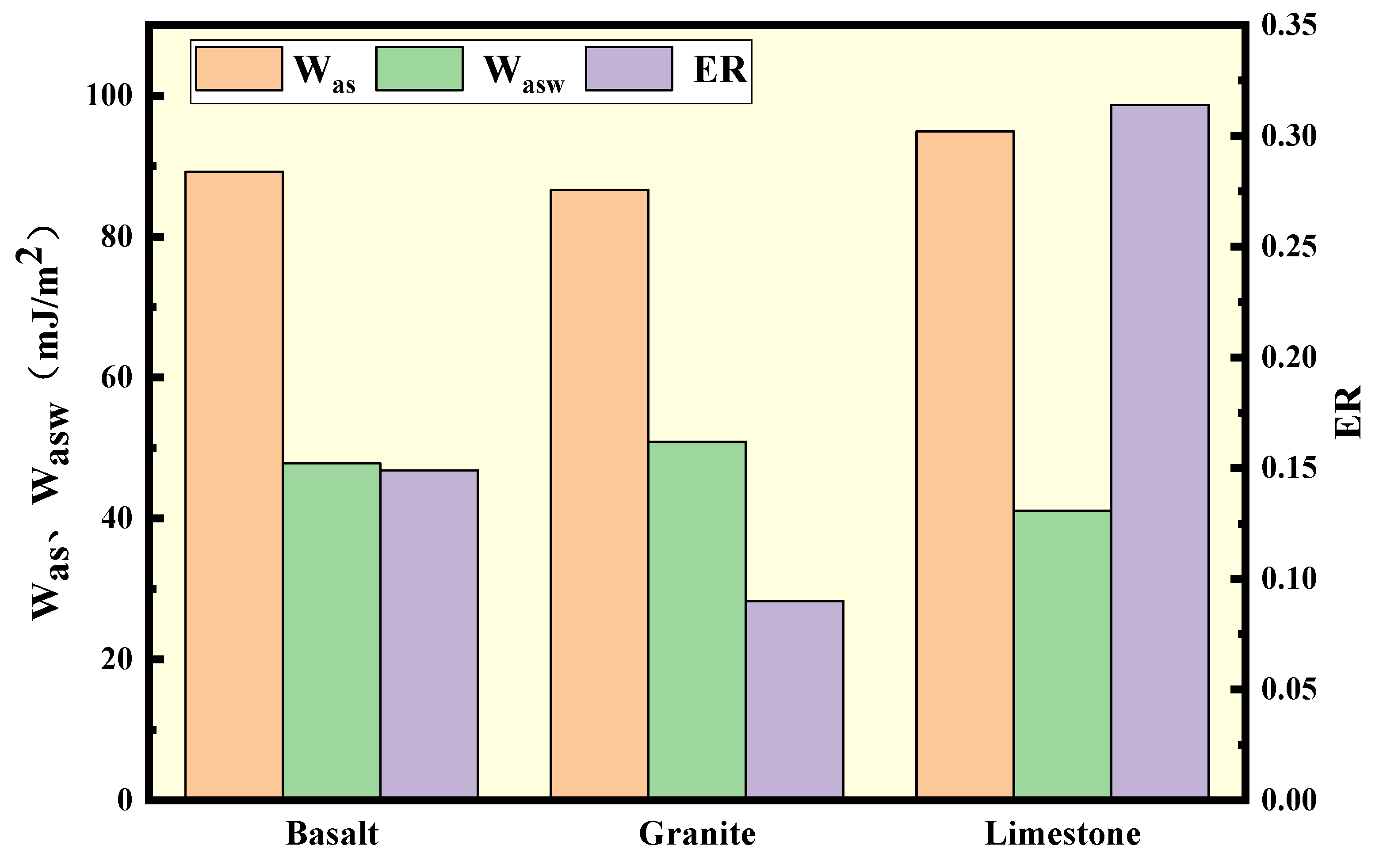

4.2. The effect of aggregate type

In order to explore the effect of aggregate type on the water stability of WMA, the adhesion parameters of basalt, granite, limestone with agent A modified base asphalt are calculated and shown in

Figure 8. The TSR test values of corresponding mixtures are prepared and tested for verification. The mixture gradation is AC-20. Results are shown in

Table 7.

It can be seen from the viewpoint of adhesion indicators that the type of aggregate has a significant influence on the asphalt-aggregate adhesion. The ranking result is limestone > basalt > granite ordered by Was, Wasw as well as ER. The ranking of TSR results shows favorable consistence with the adhesion indicators.

4.3. The effect of aggregate moisture content

None of the existing adhesion indicators consider the effect of aggregate moisture content. Calculation models of adhesion work with and without moisture respectively simulate conditions of no water and adequate water. In this paper, the effective adhesion work is proposed based on the moisture content of aggregate in the mixtures. The physical meaning of effective adhesion is the value of the surface energy change on a unit area of the aggregate after the adhesion among water, asphalt and aggregate. The value is positively correlated with asphalt content and adhesion work without moisture, and negatively correlated with moisture content and adhesion work with moisture as shown in

Equation (13). The larger the effective adhesion work, the better the adhesion between asphalt and aggregate.

where,

is the effective adhesion work, mJ/m

2;

ω and

Pa represent the aggregate moisture content and asphalt content, respectively.

The adhesion work with and without moisture between warm-mixing agent A modified asphalt and different aggregates are calculated as shown in Table 8. Analysis of the results shows that for all combinations of asphalts and aggregates, Wasw is less than Was, meaning that water is more prone to achieve adhesion to aggregate than asphalt. This indicates that the presence of water influences the adhesion between asphalt and aggregate thus creating weakened adhesion areas at the interface of asphalt and aggregates, which can result in easier water invasion into the asphalt-aggregate interface and moisture damage.

Table 8.

Value of and .

Table 8.

Value of and .

| Asphalt type |

(mJ/m2) |

(mJ/m2) |

|

Agent Amodified asphalt

|

Basalt |

Granite |

Limestone |

Basalt |

Granite |

Limestone |

| 89.210 |

86.652 |

94.992 |

47.819 |

50.880 |

41.100 |

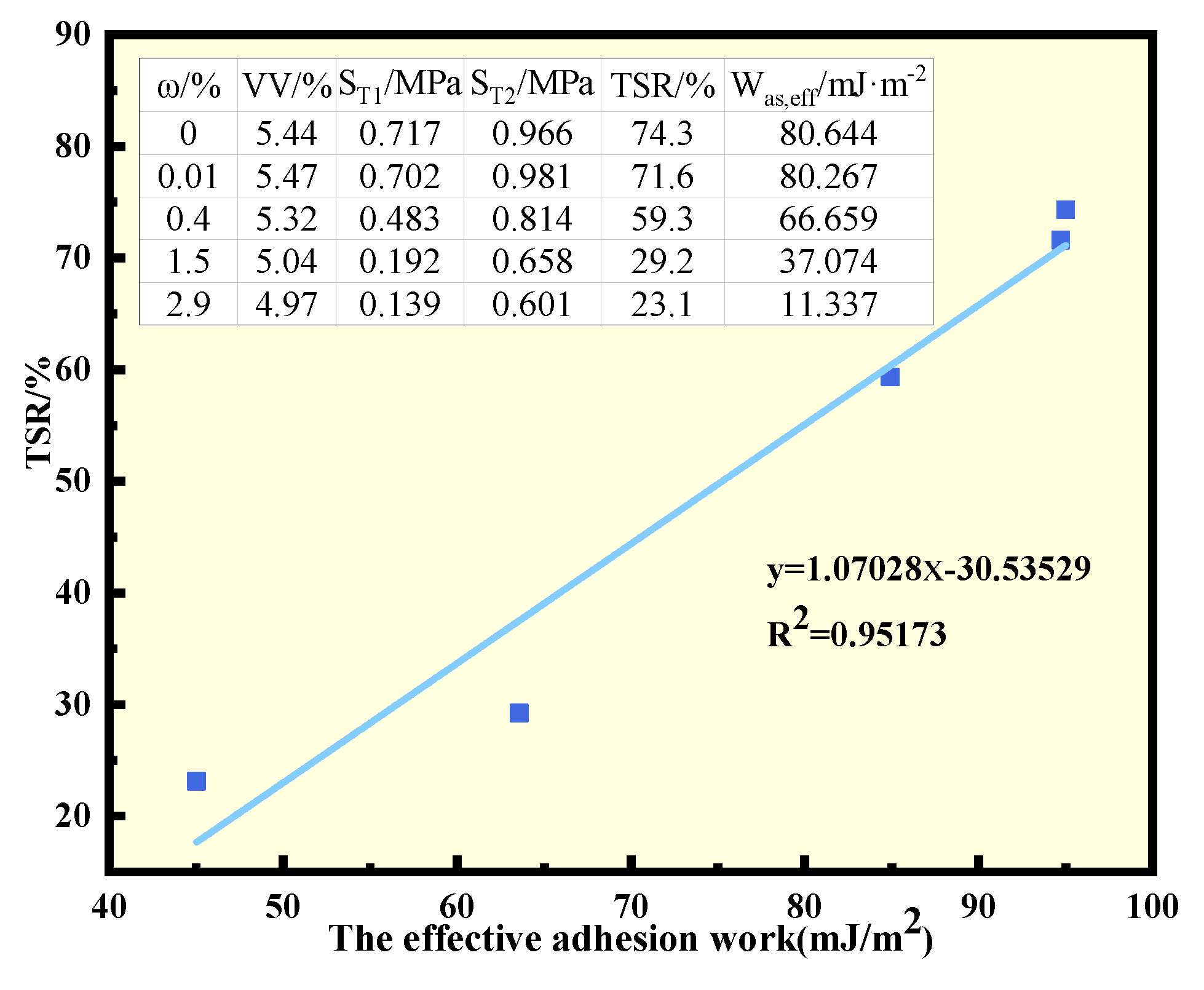

Meanwhile, specimens using warm mixing additive agent A and limestone with moisture contents of 0%, 0.01%, 0.4%, and 1.5% respectively are prepared for freeze-thaw splitting test. The mixing temperature is 135℃, the gradation is AC-13, and the asphalt content is 5.0%. The TSR results and effective adhesion work of mixtures with different moisture contents are summarized and then subjected to linear regression analysis shown in

Figure 9.

From the figure, it can be seen that the effective adhesion work decreases significantly as the moisture content of aggregate increases, indicating that the presence of water in the aggregate significantly degrades the adhesion of the asphalt to the aggregate. The TSR values verified this phenomeno. As the moisture content of the aggregate increases, the splitting strength without freeze-thaw cycles decreases slightly, while that with freeze-thaw conditioning decreases sharply, leading to a dramatic decline in TSR.

Linear regression analysis shows that the correlation coefficient between TSR and Was,eff calculated reaches 0.95 which means strong correlation. This proves the validity of the effective adhesion work in evaluating the water stability of the WMA.

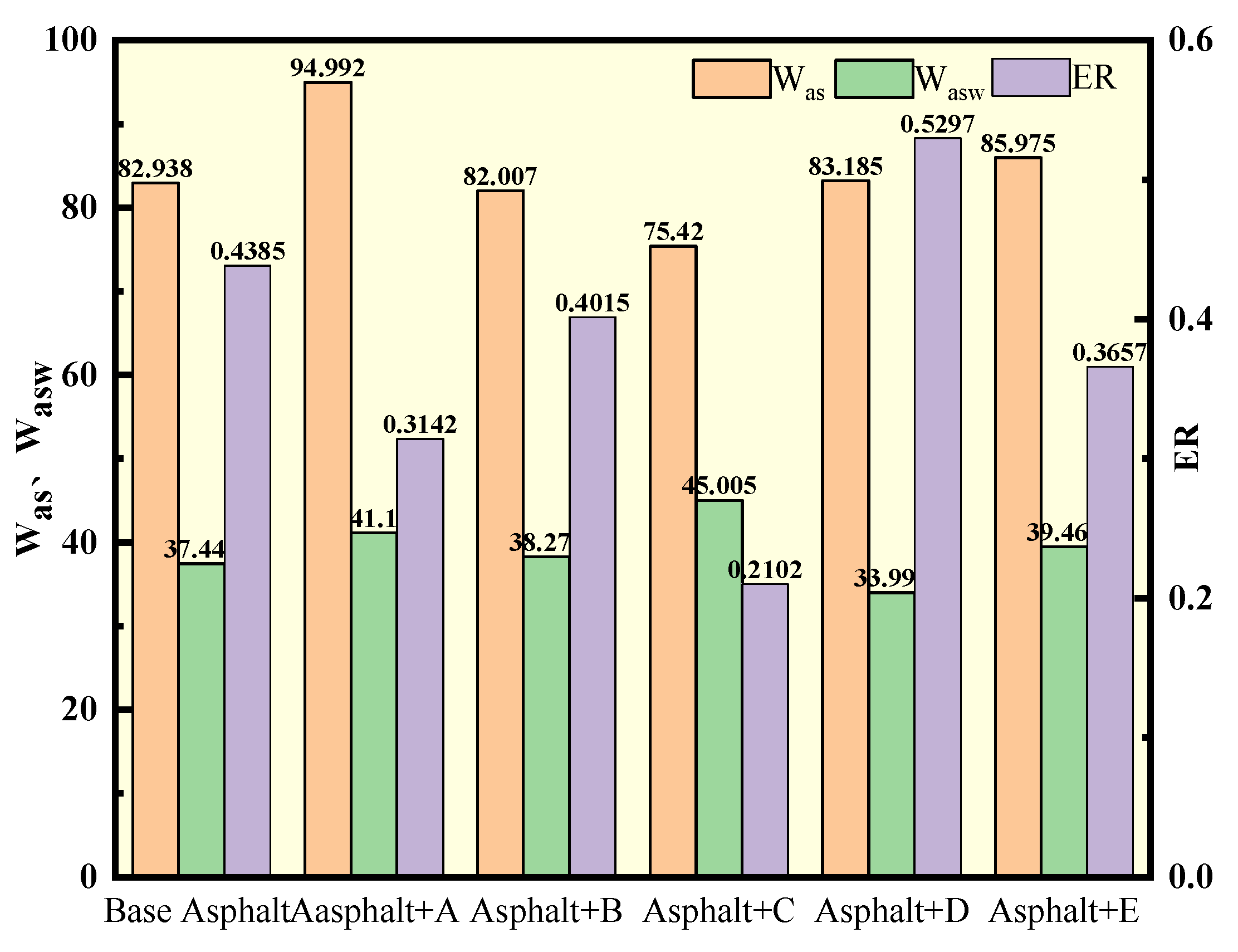

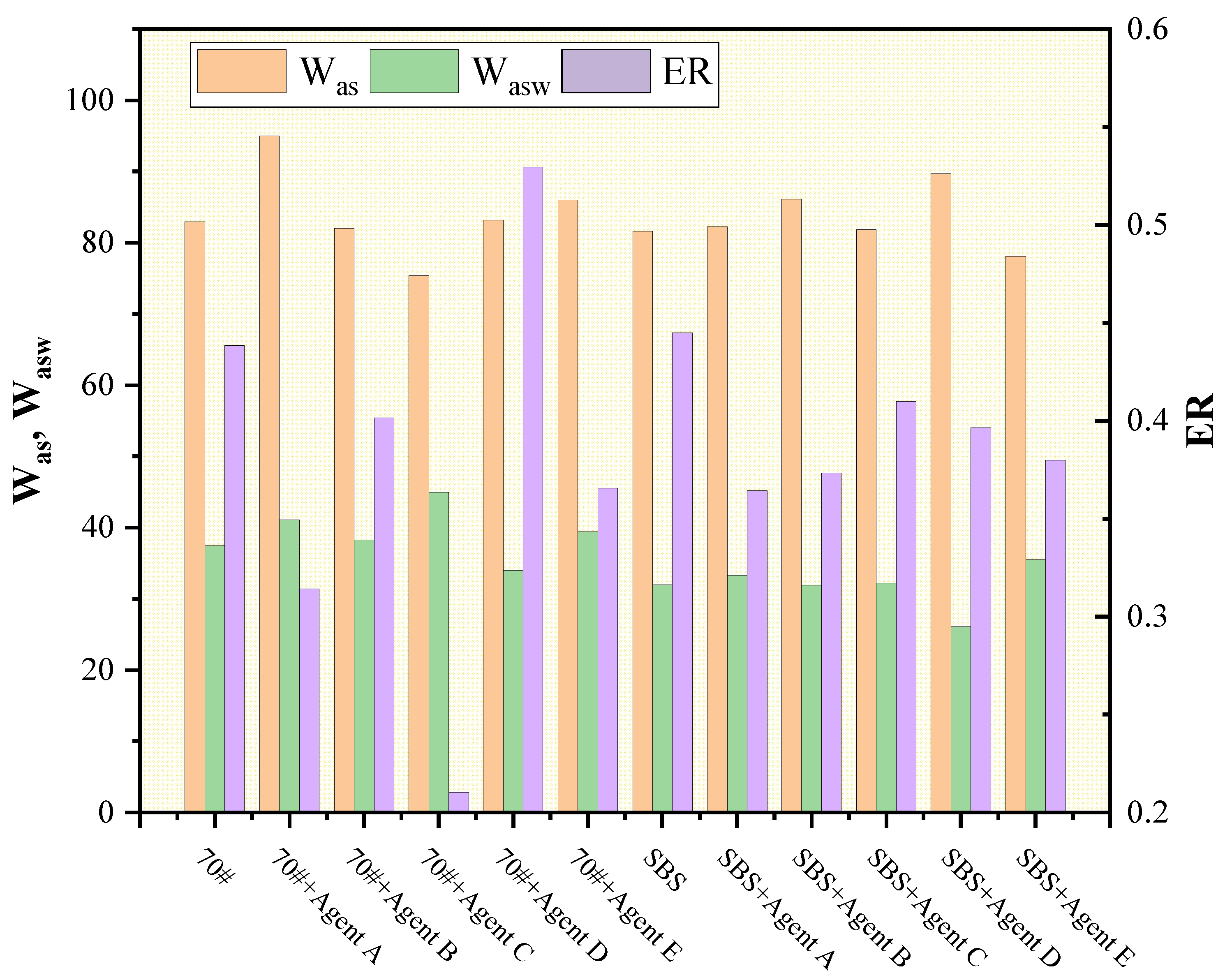

4.4. The effect of warm-mixing agent type

It has been researched that warm-mixing agents have an important effect on the performance of WMA

1820. In this section, the adhesion indicators of different warm-mixing modified base asphalts to limestone are calculated. The results are shown in

Table 8 and

Figure 10.

Table 8.

Adhesion indicators of asphalts and limestone.

Table 8.

Adhesion indicators of asphalts and limestone.

| Asphalt type |

(mJ/m2) |

(mJ/m2) |

ER |

| Base asphalt |

82.938 |

37.442 |

0.4385 |

| Agent A modified asphalt |

94.992 |

41.100 |

0.3142 |

| Agent B modified asphalt |

82.007 |

38.276 |

0.4015 |

| Agent C modified asphalt |

75.420 |

45.005 |

0.2102 |

| Agent D modified asphalt |

83.185 |

33.994 |

0.5297 |

| Agent E modified asphalt |

85.975 |

39.468 |

0.3657 |

The ranking based on calculation of the three adhesion indicators are different. The result ranked by the Was is A>E>D>B>C while Wasw and ER D>B>E>A>C. The difference emerges due to the consideration of the effect of moisture. When lacking the consideration of water, agent A and D are able to promote the adhesion as the value announces while all the agents deteriorate the adhesion when moisture is taken into account as and ER, with oil-based warm-mixing agent D having the least effect.

To verify the above findings, WMA samples using warm-mixing agent A, D and E are compacted and the TSR test is conducted. The mixture gradation is AC-20, aggregate is limestone. Results are shown in the

Table 9.

Table 9.

TSR of WMA using different warm-mixing agents.

Table 9.

TSR of WMA using different warm-mixing agents.

| Agent |

HMA |

Agent A |

Agent D |

Agent E |

| TSR/% |

91.9 |

81.3 |

86.6 |

81.5 |

From the view of TSR, all the warm-mixing agent degrade the moisture susceptibility among which mixture with agent D is least affected. The ranking by TSR test result is consistent with and the calculation of Wasw and ER. The reason may be the possible introduction of moisture brought by agent A and E. Agent A is a kind of water soluble solid and thus can easily absorb water while agent E is in a form of emulsion containing water. Agent D is oil-based thus hydrophilic, and will not be a cause for the introduction of water. Overall, all the indicators except come to consensus that the water stability of WMA with oil-based warm-mixing agent is better.

4.5. The effect of asphalt type

To investigate the effect of asphalt type on the moisture stability of WMA, the adhesion indicators are calculated based on the SFE parameters of base asphalt, SBS modified asphalt and limestone aggregates, and the result is shown in

Figure 11. The freeze-thaw splitting test is conducted for verification on the hot mix and warm mix simultaneously with limestone and base asphalt or SBS modified. The warm mix additive is agent C and the mixing temperature is 30℃ lower than HMA. The test result is shown in

Table 10.

Table 10.

TSR of mixture with different asphalt and warm mix additive C.

Table 10.

TSR of mixture with different asphalt and warm mix additive C.

| Asphalt type |

Mixture type |

TSR/% |

| SBS |

HMA |

91.0 |

| WMA-C |

93.4 |

| 70# |

HMA |

76.7 |

| WMA-C |

68.9 |

It can be inferred from the result that when different warm mix additive is applied to different asphalt, the adhesion properties between asphalt and aggregate are distinct. In other words, there is compatibility between asphalt and warm mix agents. From the calculation result of ER, agent D is the best among the 5 agents for base asphalt while agent C for SBS modified asphalt. The choice of asphalt can determine the application of warm mix agents and therefore result in distinct performances of WMA mixture.

In the meantime, when applying different asphalt to warm mixing, the effect on the moisture susceptibility is distinct. To take the combination of asphalt + agent C as an example, the introduction of it results in an extreme decrease in ER for base asphalt while the ER for SBS modified asphalt is almost equivalent to original asphalt and is much higher than agent C modified base asphalt. This is verified by the TSR result. Also, it is worthy to notice that the TSR result of base asphalt mixture is consistent with ER value which both shows a sharp decrease while that of SBS modified asphalt shows a slight enhancement and is not consistent with ER. There may be other more sophisticated mechanism for the interaction between polymer modified asphalt and warm mix agent that compensates the slight decline in SFE parameters.

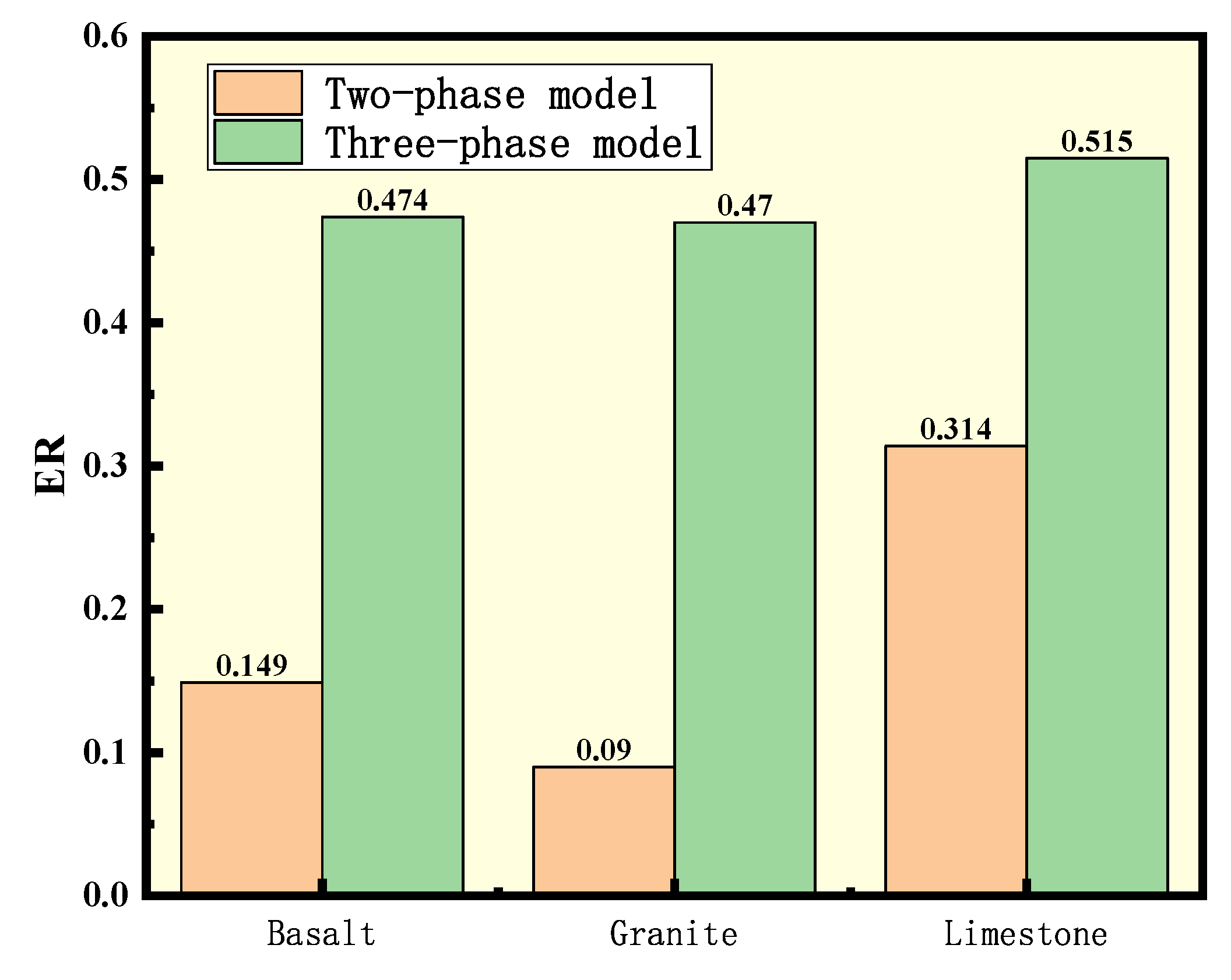

4.6. The effect of mixing process

As interpreted above, the conventional two-phase asphalt-aggregate adhesion model is suitable for the wet mixing method, in which the warm mixing additives are added into asphalt to modified asphalt first and then mixed with aggregates. When confronting with additives needing dry mixing method, the adhesion of asphalt, aggregate and warm-mixing agent should be characterized by the three-phase model proposed in previous sections. In this article, the adhesion indicator ER of agent E with base asphalt based on two- and three-phase model is calculated and shown in

Figure 12. Dry mixing and wet mixing WMA mixture specimens using AC-13 gradation for TSR test are prepared with agent E, limestone and base asphalt for validation. The mixing temperature is 135°C. The freeze-thaw splitting test result is shown in

Table 11.

Table 11.

TSR values of different mixing method.

Table 11.

TSR values of different mixing method.

| Mixing method |

VV/% |

ST1/MPa |

ST2/MPa |

TSR/% |

| Dry |

5.44 |

0.717 |

0.966 |

81.7 |

| Wet |

5.47 |

0.567 |

0.850 |

74.3 |

For different types of aggregates, the ER values of the three-phase model are greater than those of the two-phase model, indicating better adhesion prepared by dry mixing method. The TSR result demonstrates the theoretical calculation, with mixture prepared by dry mixing method superior to that by wet mixing method. This consistency also indicates that the three-phase model proposed in this paper is effective for predicting the water stability of the WMA prepared by the dry mixing method.

5. Conclusion

Using surface free energy theory, the influence of several factors on the moisture susceptibility of WMA focusing on the adhesion properties of asphalt-aggregate interface is studied, and the following conclusions can be drawn:

Aggregate type, moisture content of aggregate, warm-mixing agent type, asphalt type and mixing process have significant effects on the water stability of WMA. And the conclusions of adhesion indicators based on SFE and conventional moisture susceptibility test method result are consistent. Specifically, water content of aggregate state as the most significant factor affecting the moisture susceptibility. The presence of water greatly affects the performance of the mixture. Therefore, the dryness of aggregate should be strictly controlled in WMA.

Based on the surface free energy theory, the effective adhesion work considering the water content of the aggregate is proposed to characterize the aggregate-asphalt adhesion condition under different water contents. This indicator is highly correlated with TSR value and can be used as a convenient index to predict the moisture susceptibility of WMA.

The three-phase model of asphalt-warm mixing agent-aggregate is proposed according to the production process of dry mixing method. The corresponding calculation equations of adhesion indicators are also derived. The consistency between the adhesion indicator and TSR indicates that the three-phase model is applicable to the adhesion process of WMA prepared by the dry mixing method.

References

- Sampath A. Comprehensive evaluation of four warm asphalt mixture regarding viscosity, tensile strength, moisture sensitivity, dynamic modulus and flow number[J]. 2010. [CrossRef]

- Rubio M C, Martínez G, Baena L, et al. Warm mix asphalt: an overview[J]. Journal of Cleaner Production, 2012, 24: 76-84. [CrossRef]

- Hanz A, Mahmoud E, Bahia H. Impacts of WMA production temperatures on binder aging and mixture flow number[J]. Journal of the Association of Asphalt Paving Technologists, 2011, 80. [CrossRef]

- Estakhri, Cindy, Joe Button, and Allex E. Alvarez. Field and laboratory investigation of warm mix asphalt in Texas. No. FHWA/TX-10/0-5597-2. Texas Transportation Institute, 2010.

- Kakar M R, Hamzah M O, Valentin J. A review on moisture damages of hot and warm mix asphalt and related investigations[J]. Journal of Cleaner Production, 2015, 99: 39-58.

- Xu S, Xiao F, Amirkhanian S, et al. Moisture characteristics of mixtures with warm mix asphalt technologies–A review[J]. Construction and Building Materials, 2017, 142: 148-161. [CrossRef]

- Kim Y R, Zhang J, Ban H. Moisture damage characterization of warm-mix asphalt mixtures based on laboratory-field evaluation[J]. Construction and Building Materials, 2012, 31: 204-211.

- Alavi M Z, Hajj E Y, Hanz A, et al. Evaluating adhesion properties and moisture damage susceptibility of warm-mix asphalts: Bitumen bond strength and dynamic modulus ratio tests[J]. Transportation research record, 2012, 2295(1): 44-53.

- Caro S, Masad E, Bhasin A, et al. Moisture susceptibility of asphalt mixtures, Part 1: mechanisms[J]. International Journal of Pavement Engineering, 2008, 9(2): 81-98.

- Caro S, Masad E, Bhasin A, et al. Moisture susceptibility of asphalt mixtures, Part 2: characterisation and modelling[J]. International Journal of Pavement Engineering, 2008, 9(2): 99-114. [CrossRef]

- Wasiuddin N M, Zaman M M, O'Rear E A. Effect of sasobit and aspha-min on wettability and adhesion between asphalt binders and aggregates[J]. Transportation Research Record, 2008, 2051(1): 80-89.

- Kakar M R, Hamzah M O, Valentin J. A review on moisture damages of hot and warm mix asphalt and related investigations[J]. Journal of Cleaner Production, 2015, 99: 39-58.

- Ma W, Huang T, Guo S, et al. Atomic force microscope study of the aging/rejuvenating effect on asphalt morphology and adhesion performance[J]. Construction and Building Materials, 2019, 205: 642-655. [CrossRef]

- Elphingstone G M J. Adhesion and cohesion in asphalt-aggregate systems[J]. 1998.

- Cheng D. Surface free energy of asphalt-aggregate system and performance analysis of asphalt concrete based on surface free energy[J]. 2003.

- Zhang D, Luo R. Using the surface free energy (SFE) method to investigate the effects of additives on moisture susceptibility of asphalt mixtures[J]. International Journal of Adhesion and Adhesives, 2019, 95: 102437.

- Xu S, Xiao F, Amirkhanian S, et al. Moisture characteristics of mixtures with warm mix asphalt technologies–A review[J]. Construction and Building Materials, 2017, 142: 148-161. [CrossRef]

- Hurley G C, Prowell B D. Evaluation of Evotherm for use in warm mix asphalt[J]. NCAT report, 2006, 2: 15-35.

- Hurley G C, Prowell B D. Evaluation of Sasobit for use in warm mix asphalt[J]. NCAT report, 2005, 5(6): 1-27.

- Hurley G C, Prowell B D. Evaluation of Aspha-Min zeolite for use in warm mix asphalt[J]. NCAT report, 2005 (05-04).

- Zaumanis M. Warm mix asphalt investigation[J]. 2011.

- Liu Y M, Han S, Li B. Research on Adhesion between Asphalt and Aggregate Based on Surface Energy Theory[J]. Journal of Building Materials, 2010, 13(6):769-772.

- Bhasin A, Little D N, Vasconcelos K L, et al. Surface free energy to identify moisture sensitivity of materials for asphalt mixes[J]. Transportation Research Record, 2007, 2001(1): 37-45.

- Little D N, Bhasin A. Using surface energy measurements to select materials for asphalt pavement[R]. 2006.

- China, P. R. (2004). Ministry of Communications. JTG F40-2004 Technical Specification for Construction of Highway Asphalt Pavements [S].

- China, P. R. (2004). Ministry of Communications. JTG E20-2011 Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering[S].

- Mehrara A , Khodaii A. A review of state of the art on stripping phenomenon in asphalt concrete[J]. Construction and Building Materials, 2013, 38(2):423-442. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).