1. Introduction

1.1. Background

The number of marine accidents arising from technical issues has continued to decrease as the quality, regulations, and systems related to the safe operation of ships have been stipulated and enforced by international maritime conventions. Despite such efforts, marine accidents are caused not only by technical factors, but also human and organizational factors, which are complexly interlinked owing to the large-scale, high-speed, and automation of ships. Thus, it is necessary to systematically analyze the causes to prevent the recurrence of marine accidents [

1]. Marine accidents are characterized by large-scale damage to property and the environment, as well as threaten human life. Since marine accidents mainly occur because of human error, lack of technical skills, and organizational factors, it is necessary to systematically analyze the causes of marine accidents and prepare practical countermeasures [

2].

Ships constitute the core of maritime transportation, and the active introduction of smart information technology according to the 4th industrial revolution into the navigation, cargo, and engine systems of ships has improved the level of informatization, automation, and intelligence while increasing the complexity of the design and operation of ship systems. Consequently, even if all internal factors of the ship automation system appear to operate normally from the outside, an unpredictable accident can occur internally at any time owing to the interaction among these factors [

3]. Since large ship accidents occur as a result of multiple causes rather than one cause in a complex manner, the conventional accident analysis method that views marine accidents from the perspective of causality of one-to-one correspondence is limited in systematically analyzing complex marine accidents to identify the cause and prevent the occurrence of similar accidents [

4].

The level of technology for various types of informatization, automation, intelligence, and digitization that supports ship automation and unmanned systems has continually been upgraded. Nevertheless, the analysis of the systematic causality of marine accidents caused by complex factors, including human error, is still in its early stages [

5]. This study analyzes the systematic causality of human error factors in various marine accidents that could occur during the arrival and departure of mega container ships, which are at the peak of speed increase and ship enlargement. As an example, this study reviews the accident case of Milano bridge at Busan New Port.

1.2. Aim of the study

Owing to the increase in hub-port calls of mega container ships, the marine traffic of Busan New Port and marine accidents that could occur in the process of port berthing are emerging as worsening problems that require urgent solutions. Since knowledge of the increase in speed and automation of mega container ships is still lacking in port and port service workers, a comprehensive response system for unexpected marine accidents is also insufficient [

6]. Ultimately, a method to dramatically reduce marine accidents should include analyzing a causality system responsible for marine accidents involving mega container ships.

The crane contact accident of the mega container ship Milano Bridge at Busan New Port in 2020 is considered as a representative case in this study. The functional resonance analysis method (FRAM), an appropriate technique for accident cause analysis and risk assessment, was used to logically explore the complex organizational–technical, human–technical, and organizational–human relationships related to this accident [

7]. In addition, this study aimed to safety of navigation and prevent marine accidents by presenting improvement plans. Moreover, this study is expected to contribute to the preparation of a systematic marine-accident investigation and safety-management system that identifies fundamental safety issues rather than focusing on ex-post responses, such as finding the reasons attributable to the port-crane contact accident of mega container ships or imposing liability.

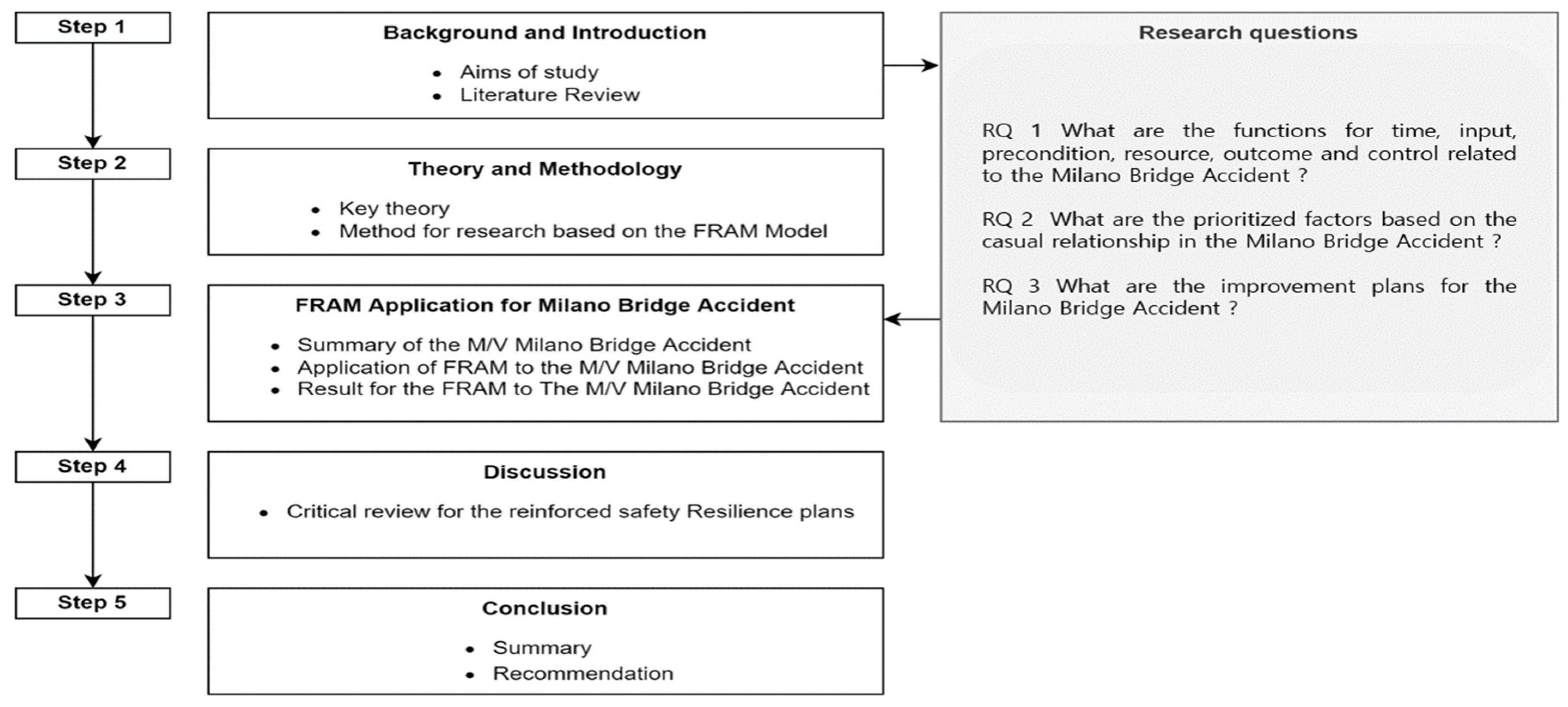

As shown in

Figure 1, research questions and their details were derived to prepare systematic marine accident investigation and safety management measures.

1.3. Literature review

First, while considering the limitations of a simple linear accident analysis method, analyzing the causes of accidents, is essential to prevent the occurrence of similar accidents and to reduce the repeated loss of capital. According to Low et al. [

8], early accident analysis systems such as domino and fault-tree models reinforce safety by identifying and eliminating system problems based on simple linear causalities. Despite being one of the most understandable and clearest theories for defining thought processes, the domino theory has the limitation of emphasizing individual responsibility and faults while condensing numerous possible causes into one. Wang [

9] highlighted the necessity of combining the domino model with a Bayesian network (BN) or machine-learning algorithms to discover potential evolutionary patterns of thinking. Fault-tree analysis (FTA) is a representative method in system safety engineering [

10] that uses logical symbols to create a fault tree, which is analyzed deductively, quantitatively, and probabilistically to express the cause of an accident [

11]. However, FTA cannot perform a composite analysis of the relationship with other functions or systems, scalability, and variability of accident causes, although it is suitable for identifying the root cause of an accident [

12]. The final causes of accidents in FTA, domino models, event tree analysis (ETA), and failure modes and effects analysis (FMEA) models have been attributed to people or equipment [

13]. Moreover, they have the same limitation, i.e., the nonlinear complexity of the system cannot be sufficiently explained [

14].

Second, many studies have used the IMO casualty investigation code (2008) published on January 1, 2010, by the International Maritime Organization (IMO) as a common approach to human causes in marine accident investigations and as a method for the systematic identification of accident causes [

15]. The accident investigation and analysis method of the casualty investigation code has the limitation of simple linear thinking analysis because the goal (1st), aspects (2nd), and criteria (3rd) are connected in a simple linear fashion. Moreover, Chan highlighted that research on human errors is limited, although the majority of the primary causes of marine accidents are related to human errors [

16]. Although the emphasis on the importance of human factors has recently increased, there have been cases wherein finding the cause of accidents lies solely on the actions of job performers. Celik et al. predicted that ship accidents would occur in the future owing to system complexity and automation, human errors, potential design-based failures, and human-centered system designs [

17]. Recently, the system development and complexity of ships and ports, such as smart ships, digital ships, maritime autonomous surface ships, and automated ports, have increased rapidly. Panagiotidis et al. predicted that a systematic investigation and analysis of marine accidents considering the relationships between human factors and complex and diverse systems would be required [

1].

Third, previous studies on the analysis and research of marine accidents have mainly focused on improving the limitations of linear accident analysis and have investigated various methods to systematically and visually express and analyze the causes of human factors. For example, Rasmussen proposed the Accimap approach, an accident analysis method that visually represents decision-makers and their decisions involved in creating a system that allows the occurrence of accidents [

18]. The Accimap approach is applicable to the analysis of accidents for planning, management, and organization, which can influence causality and accidents. Lee et al. applied the Accimap approach to investigate the Sewol Ferry accident and analyzed not only ships but also related organizations, institutions, and systems [

19]. However, indirect cause analysis was impossible as only the functions of the subjects directly related to the accident were shown. The human factors analysis and classification system (HFACS) framework for accident investigation is an accident analysis method for human factors based on the Swiss cheese model. First developed for the investigation of aviation accidents in 1997 [

20], the HFACS can systematically investigate the human factors of accidents and explain the effects of human errors, related causes, and sub-causes in detail. Schröder-Hinrichs et al. identified sub-causes of engine room fires and developed an HFACS-MSS (machinery spaces on ships) framework, whereas Özkan developed HFACS-PV for the validity or scope of the analysis and varied greatly depending on the determination of the condition level [

16]. Limitations in the expression of detailed accident analysis results have also been observed [

21]. Leveson suggested systems theoretic accident model and process (STAMP) as a constraint-based model focused on the inappropriate control or enforcement of safety-related constraints on complex system designs, developments, and operations [

22]. Moreover, setting up accident prevention measures is easy because STAMP can find the cause through an in-depth analysis of human errors related to complex systems [

17]. Osiris proposed a process for designing a marine safety-management system based on STAMP [

23]. To show the interactions and dynamics between the functions of each system at a glance by modeling variability and nonlinear dependencies, Hollnagel proposed the FRAM [

24]. The FRAM can be used to account for complex accidents and identify hazards in dynamic systems, and can be modeled to include almost any function or subsystem of the subjects. The root cause or variability of a failure or accident can be easily traced by following the connections between functions expressed based on six functions or activity characteristics instead of a hierarchical structure.

Fourth, regarding the analysis of marine accidents using FRAM, Eren (Salihoglu & Bal Beşikçi, 2021) analyzed the cause of accidents using FRAM for the stranding accident of Prestige [

25]. Similar to the purpose of this study, the authors inferred potential causes by tracing the variability between functions in a normal system and explained that FRAM is essential for the analysis of marine accidents. In the study performed prior to the accident, the definition of functions was limited to the ship system and the cause analysis and variability of the port system were not considered. When a ship is sailing, it can be viewed as a single system; however, when the ship enters and leaves a port, it is connected to the port system. Hence, when the accident site is a port, the expansion of the volatility and functional resonance becomes more complicated. Lee & Chung analyzed the Herald of Free Enterprise capsizing accident and the collision accident of the M/T Hebei spirit [

26], whereas Yu et al. analyzed the Clipper Adventurer grounding accident using FRAM. Thus far, no study has analyzed the connectivity between ports and ships or applied the Milano Bridge accident to the FRAM [

27].

Finally, the key research gaps that differentiated this study from previous studies were analyzed through literature research. The purpose of marine-accident investigation is to verify the simultaneous and complex causes of accidents, which are gradually becoming important in the investigation of the cause of an accident that confirms linear causality. Furthermore, marine accidents are not caused by a single human error. Hence, it is necessary to analyze the relationship between human–organizations (port authorities, shipping companies, ship management companies, and governments, etc.) and human–technical linked complex systems. Therefore, it is necessary to systematically analyze the cause of the accident using this connection at the center. A review of previous studies has confirmed the differences between FRAM and other accident investigation methods. FRAM is more suitable than FTA and ETA for explaining nonlinear complexity and can better present visual accident analysis than accident analysis methods using HFACS and STAMP. Furthermore, the quantitative expression of connectivity between functions is considered more effective.

2. Theory and methods

2.1. Theory of FRAM

The FRAM used in this study originated from psychological and cybernetics research conducted in the 1950s and the 1960s, and the principles of structured software development from the late 1960s. It was developed for resilience engineering [

28]. Furthermore, FRAM is a systematic approach for determining how parts of a task and a series of actions usually occur. The model can be used to explain a selected event or performance based on the functions required to perform the activity, potential couplings between functions, and the general variability of functions [

7]. This study provides the basic data necessary to understand and predict the causality of human error and accidents by modeling a nonlinear interaction of system functions using FRAM to analyze the 2020 Milano Bridge crane contact accident at Busan New Port. Moreover, to effectively determine the causes of recent marine accidents in complex systems of ships and ports, it is necessary to understand the connection variability between individuals and organizations, individuals and systems, and organizations and systems. Because FRAM is a functional modeling technique that can systematically analyze the causes of complex marine accidents, it can be used in the future to develop algorithms for autonomous maritime surface ships, smart ship management, and investigation and judgment of marine accidents [

25].

2.2. Method for research based on FRAM

In this study, FRAM was adopted since sequential causes and causality could be explained in a complex and conceptual manner, as FRAM was suitable for accident cause analysis and risk assessment in complex organizational–technical, human–technical, and organizational–human relationships from the perspective of preventing the recurrence of port contact accidents of mega container ships, such as the Milano Bridge. FRAM supports the systematic analysis of variability in function performance and nonlinear interactions between functions that are essential in accident analysis, such as the analysis of marine accidents with variably linked complex causes. It is an optimal research method with excellent expression of phenomena that can overcome the limitations of existing thought analysis techniques, such as HPES, HPIP, HFACS, TRACEr, HEAR, and the casualty investigation code IMO [

25]. Moreover, FRAM provides useful information and explains situations to manage performance variability by analyzing and modeling the functions and interactions of a system operating under normal conditions. Furthermore, it analyzes the possible performance variability and its ripple effects.

Therefore, the following four steps were followed to analyze the Milano Bridge crane contact accident at Busan New Port using FRAM.

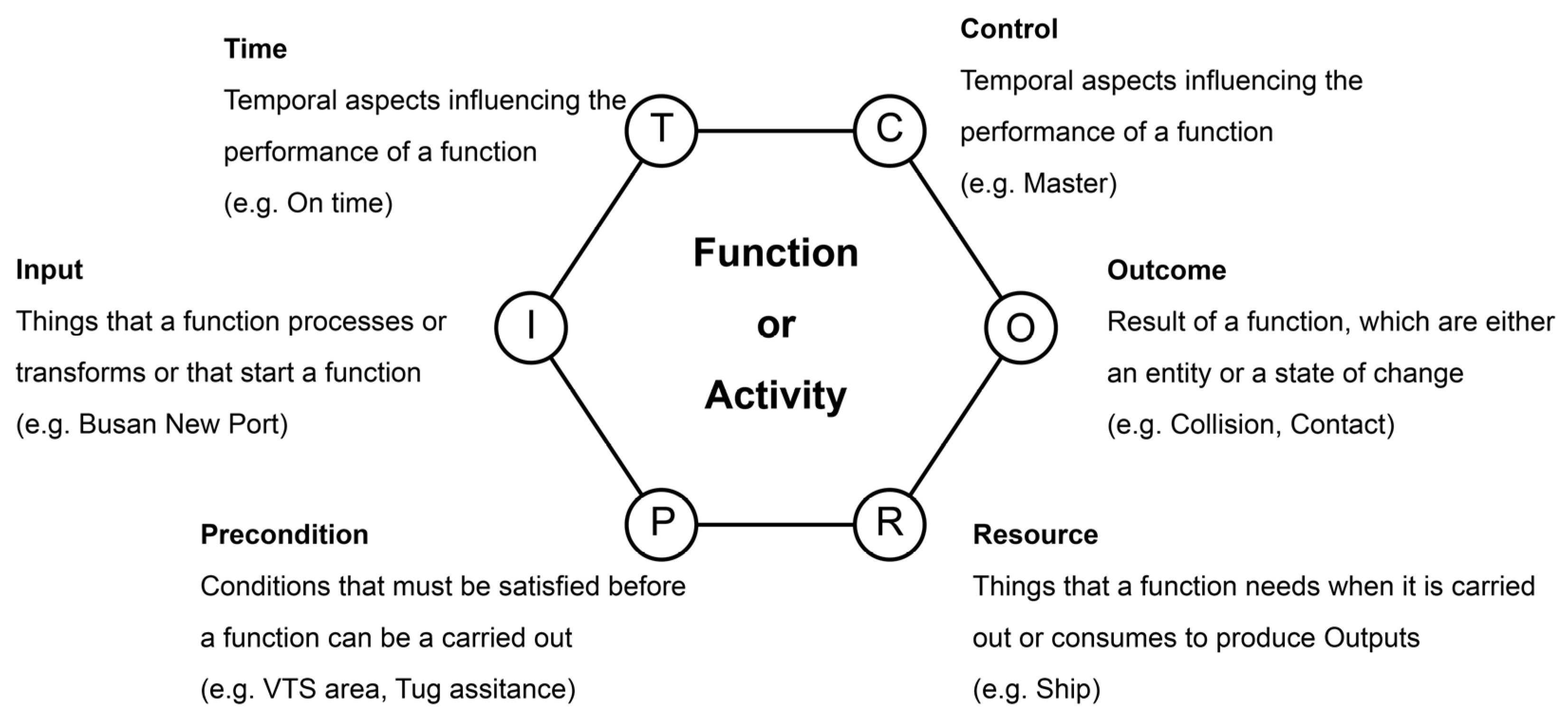

Step 1 involved identifying and describing the system functions related to the FRAM modeling target, which was the Milano Bridge crane contact accident at Busan New Port. All the functions that signified the interactions between various systems related to the accident were examined, and the interconnections between the functions that must be performed to achieve the actual purpose were identified. Moreover, related functions were determined by categorizing the functions into six aspects based on the accident results, as shown in

Figure 2 [

29].

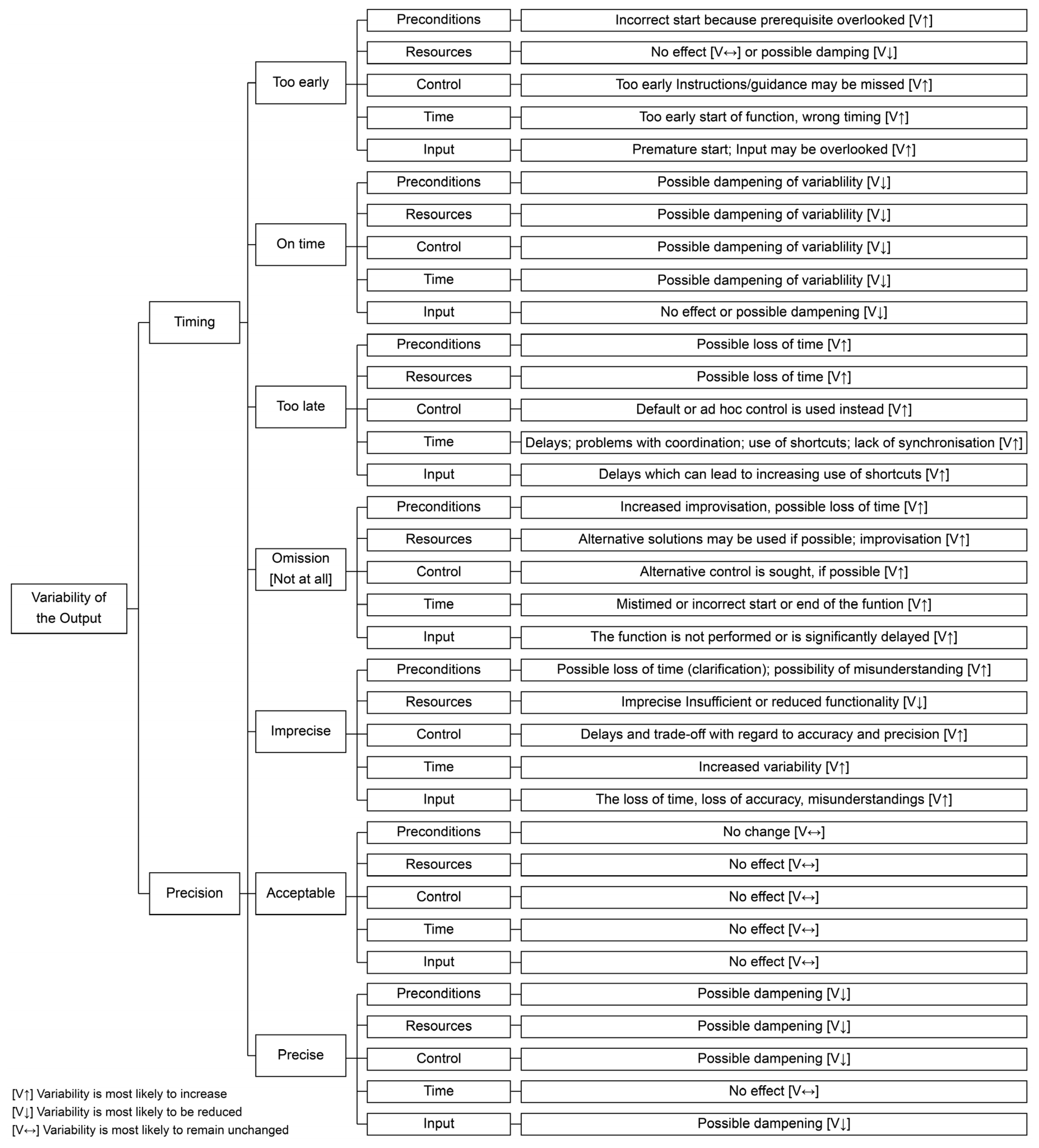

Step 2 involved the estimation of the potential variability of each function, which was then evaluated by categorizing them into six aspects. For each function, the elements of precondition, resource, control, time, and input, excluding outcome, were selected to minimize variability, which may occur because of the precision and application timing differences of each element. Hollnagel presented a variability that occurred due to the timing and precision difference of each element, as shown in

Figure 3 [

29].

Step 3 involved the analysis of the potential variability of each function identified as the cause of the Milano Bridge Busan New Port-crane contact accident using FRAM. The analyzed individual functional resonance accidents had subsequent variability based on the connection of each function. The consequences of variability were explained using connections between the six aspects of each function.

Step 4 involved the analysis of each function identified as the cause of the Milano Bridge Busan New Port-crane contact accident using the FRAM. Furthermore, the variability of the resultant function was analyzed to determine effective improvement plans. The variability of the function and ripple paths was identified by analyzing the Milano Bridge Busan New Port-crane contact accident using the FRAM model. Based on this, we can understand the causal relationship between the causes and effects of marine accidents. When conducting a risk assessment, technical, managerial, and organizational improvement plans can be developed from a logical point of view to develop future improvement plans by predicting the likelihood of multiple potential accidents based on variability and ripple paths.

The preconditions for configuring the FRAM model were classified by function and are listed in

Table 1. To analyze the Milan Bridge accident using FRAM, the system and characterized functions were identified as the first step. Based on the Guided Question for each element presented by Hollnagel [

29], functions and characteristics of the physical elements of the ship, port, and natural environment were classified for the Milan Bridge accident.

3. Milano Bridge accident and FRAM application data

3.1. Cause analysis summary of the Milano Bridge accident

3.1.1. Accident analysis from a material perspective

When analyzing the arrival track of the Milano Bridge at the time of the accident, the port entry speed was 3 knots faster than that in other cases near the “To” islet, where a large angle course alteration was inevitable. Usually, the course alteration to starboard begins after passing by the “To” islet and most large ships decelerate to approximately 3 knots until they enter the sea in front of Pier No.3, where auxiliary means such as tugboats are ready for use. The pilot chose to increase the ship speed to accelerate the turn, expecting the rudder effect to occur early and the rotational angular velocity to increase with speed during the diagonal turn. When the Milano Bridge started to alter its course to starboard at a high speed of 9.5 knots, its ability to maneuver, such as propulsion and turning performance, was significantly reduced owing to the exposure of its propeller. The increase in the turning angular velocity at the beginning of the course alteration was delayed and the advancement of the ship by the rudder force was extended, resulting in an increased turning diameter. Particularly, the remaining distance from Pier No.3 to the expected berth is approximately 0.45 miles when the large angular course alteration of approximately 90° terminates. In a normal berthing situation, ships should be sufficiently decelerated before deploying the tugboats and bow thrusters.

However, the deceleration of the Milano Bridge was not sufficiently achieved for safe berthing. To avoid the risk of collision with the vessel berthing at the port, acceleration was reattempted to increase the ship speed for the starboard turn. Consequently, the use of standby means for maneuvering, such as tugboats or bow thrusters, was difficult when the ship accelerated to avoid collision. Furthermore, emergency measures such as emergency anchoring cannot be used. Numerous attempts have been made to increase the ship speed and turn to the starboard as the Milano Bridge approached Pier 3, increasing the risk of collision with berthing vessels.

A master should appraise all information related to a planned voyage or route, establish a detailed passage plan, and execute the established passage plan while monitoring all such processes. The passage plan should include the entire navigation process from one berth to another, including the pilotage area where the pilots board [

30].

In addition, when a vessel enters and departs from a port with the assistance of a pilot in the pilotage area, the master and pilot should communicate effectively and exchange information to ensure the safe movement of the vessel in accordance with the passage plan formulated using mutual information on the condition of the vessel, its maneuverability, and the pilotage plan [

31].

Despite being aware of the exposed propeller caused by the low draft of the Milano Bridge since its departure from the repair shipyard in Zhejiang, China, the master of the ship did not establish an appropriate passage plan to safely enter the Port of Busan. Pilot “A” boarded the ship and provided a checklist for exchanging pilot information, but the passage plan information for berthing at the Busan New Port or the condition and maneuverability of the ship was not exchanged. Furthermore, pilot “A” was aware of the exposed propeller caused by the low draft before piloting the vessel and was concerned about the decrease in maneuverability brought on by the exposed propeller. Thereafter, the master did not actively intervene or provide adequate guidance. Moreover, pilot “A” neither established any communication nor sought any advice from the master. Subsequently, the ship failed to decelerate and turn at the right instant, creating circumstances that prevented the ship from securing sufficient time and space to respond to emergency measures, such as tugboats, thrusters, and emergency anchoring, immediately before the accident.

3.1.2. Deriving a Milano Bridge accident function based on FRAM

In this study, a system was modeled to analyze the Milano Bridge Busan New Port-crane contact accident. Six aspects of the derived core functions were analyzed, and the relevance between the functions was identified. In this study, 22 functions, including three in the background, were derived, which provided the background knowledge necessary to understand the significance of the main functions of modeling. The derived functions were characterized using six aspects, and the prospect of variability was analyzed. In the characterization process, the functions were divided into technical, human, and organizational functions, and the potential output variability with respect to time and accuracy was evaluated and summarized for each function.

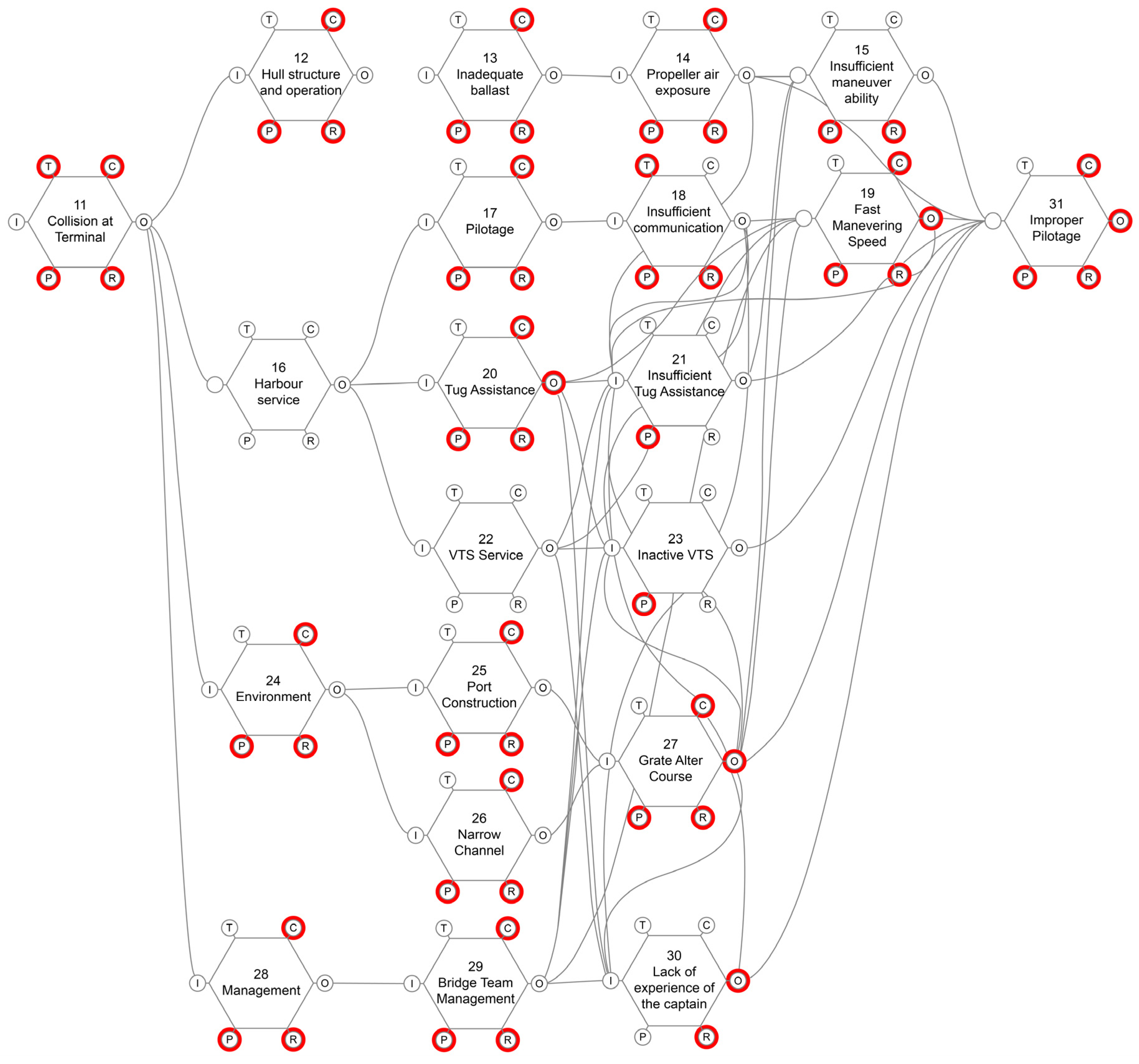

The accident was modeled using FRAM Model Visualizer Pro (FMV) [

7]. When six aspects of each function were defined while characterizing the derived function, the FMV automatically connected the links between the functions using definitions. While discussing Step 1 of the four procedural analysis steps of FRAM, five aspects, excluding the outcome of one function, were considered to have been derived from the outcome of another function. In FRAM, each function has six aspects as shown in

Table 2. Among them, the outcome of one function is connected to the input of another function, and the other four (precondition, resource, time, and control) affect the activation of the element according to the connectivity with the outcome connected to the input. For example, if the F11 Outcome and F12 Input have connectivity, the remaining four aspects are activated based on the correlation with the F11 Outcome.

3.1.3. Analysis of the result of the Milano Bridge accident by function using FRAM

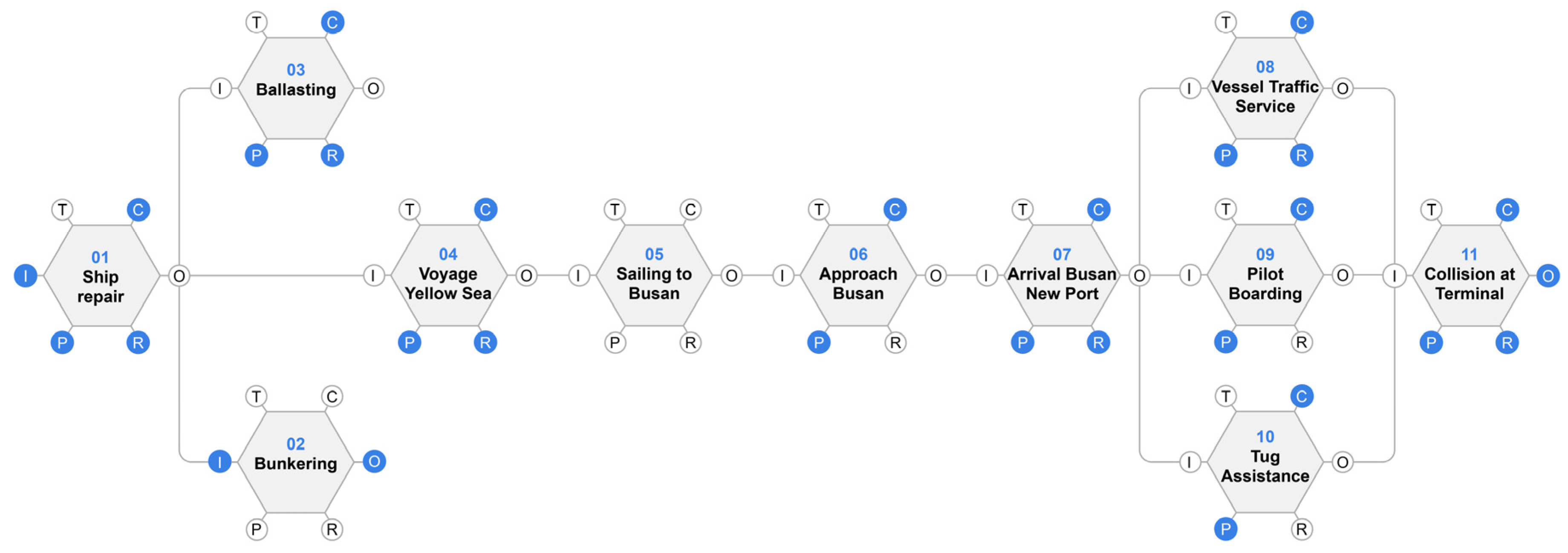

A time series analysis of the Milano Bridge accident was performed in the order in which the accident occurred after the ship was built in a Japanese shipyard, passed through a repair shipyard in China, and then entered Busan New Port. After complete repair shipbuilding in China, supplying fuel and ballast water, sailing the Yellow Sea, and entering the Busan coast, the ship entered the Busan New Port area through port services, such as pilotage, tugboats, and VTS. However, a collision occurred when the ship entered the port and an accident occurred.

Figure 4 illustrates how 31 functions related to marine accidents are organized into a time series, from ship construction to container terminal accidents.

Unlike before the accident, the more complex causes were assumed to be related, as each granular factor was evaluated by function 11(Collision at terminal) using FRAM. The Milano Bridge accident was caused by a communication gap between the master and pilot of the ship, as they failed to explain the details of the voyage plan to each other, combined with the lack of adequate support from the port traffic infrastructure, which included the VTS, safety routes, and navigation aids. The functions applied to analyze the inappropriate pilotage that caused the accident are summarized and listed in

Table 2.

Figure 5 shows the time series multiple analysis results of evaluating each factor subdivided into a multilayered structure for the Milano Bridge crane contact accident. The Milano Bridge accident occurred because of a combination of functions, such as vessel structure and management function 12, port service function 16, port environment function 24, and management function 28. In addition to the human errors introduced by the pilots, masters, and VTS controllers, technical factors that contribute to these human errors were derived. The factors included sufficient tugboat support; improvements to the ship operation environment in the port to minimize large angular course alternations; and comprehension, education, and simulation of the maneuvering characteristics that were observed when the ballast water of the ship was insufficient.

The results of the FMV were easily grasped visually by schematizing the relationship between various functions, but quantitative information was not presented. If the importance of each function related to an accident is quantified, the priority can be determined to prevent similar accidents. The detailed elements of priority evaluation consisted of aspect activation by function, open-source network analysis for accident analysis reports, and the connection between each function. The priority was quantitatively evaluated using a cumulative product equation for each function. A uniform scale, considering the characteristics of each element, was applied to analyze the comparative advantage. The selection of each element for the priority evaluation equation and their classifications were conducted by deriving arbitrary weights for priority evaluation of each function within the targeted accident and by limiting the comparison through cumulative multiplication of the accident functions, as expressed as

where

is the function priority,

is the aspect activation factor,

is based on text mining, and

is the connectivity of functions.

The number of activations between functions related to the accident was elevated during the aspect activation of the FRAM. A weighted factor (

) was applied to all six aspects of each activity, whereas a sensitivity ranging from 0 (without active aspect) to 6 (when all aspects were active) was applied based on the individual activation number. Further, using open-source network analysis and visualization software packages written in the Java program Gephi, semantic network analysis was conducted to understand the significance of meaningful words in language text and to analyze various meanings and characteristics of language text by forming a network [

32]. The criterion for deriving the weight of text mining was designated as frequency / 5 (minimum frequency) based on the label frequency, where the relation occurred in the function. For values less than five, the criterion for deriving the weight of text mining was defined as 0.0, and the results are shown in

Table 3.

Connectivity with functions was determined by analyzing the number of functions linked to each function according to FRAM. To compare the connectivity, a weight of 0.5 was arbitrarily set based on the number of connections, and the connectivity of the "In" and "Out" factors for each function is listed in

Table 4.

The factor (by factor) results were derived for each function, and their priority was evaluated accordingly. As shown in

Table 5, the resultant value of

was evaluated from a minimum of 0.0 to a maximum of 38.4 as a result of the priority evaluation.

3.2. Evaluation of the results for each Milano Bridge accident function based on FRAM

The Milano Bridge accident was analyzed using functions based on the FRAM model, and the priority of each function was derived based on the sensitivity of three factors (open-source network analysis, aspect activation, and inter-function connectivity). At the end of the evaluation, functions with an of 10.0 or higher were F15, F18, F19, F21, and F27, which were then used to evaluate the cause of the accident.

For example, when the accident occurred, the ability to maneuver function 15 was insufficient [

33]. Function 15, the controller of the accident, was related to the master of the ship and was applied from the instant the ship departed from China until collision. Since ballast water was managed by the navigators of the vessel, a combination of technical and human functional errors occurred.

In addition to the human factors affecting the ship operation and personal factors of the pilot, the Milano Bridge collision accident analyzed using FRAM may have been caused by external factors such as VTS control, environmental characteristics of the port, and tugboat. Furthermore, the accident may have been caused by inappropriate work situations, such as overconfidence in the experiential skills of the master, navigator, and pilot; inappropriate communication problems; lack of VTS control; and insufficient towing power. Therefore, when marine accidents are analyzed from a systemic perspective, the causes of accidents include not only individual factors, but also environmental and systemic factors. Therefore, a systemic response strategy is required to prevent marine accidents.

4. Discussion

This study discovered that the Milano Bridge accident, which was caused by factors related to human error, is still a major concern for marine safety management and large ship berthing operations, even though technical causes are decreasing with the introduction of ship safety management and technological development. The results obtained by analyzing the Milano Bridge accident using FRAM identified the importance of technical, human, and organizational factors in marine accidents and linked them with accident results. Thus, this study aimed to lay the foundation for the analysis of system causes from a preventive perspective to reduce human error and prevent marine accidents including pilotage and ports in the event of future marine accidents at ports. For this purpose, a causality system was analyzed by classifying various complex factors using the port contact accident that occurred during the entry of the Milano Bridge into Busan New Port as a reference.

The summary for RQ 1 is as follows. In the case of large-scale marine accidents, complex cause-and-effect relationships may be entangled in addition to simple causes. In this study, in order to systematically analyze the causal relationship by taking the Milano Bridge harbor collision accident, which is a large-scale marine accident, as an example, complex organization-technology, people-technology, and organization-human relationships related to this accident were logically explored through FRAM. For a logical analysis through FRAM, the factors of the Milano Bridge accident were divided into each function, and the six aspects (time, input, precondition, resource, outcome and control) of these individual functions were analyzed in detail. The causal relationship of each function based on the six aspects was derived through the FRAM model. However, when deriving a causal relationship through the FRAM model, a linear connection is suggested, and additional derivation of the importance of each factor is required.

The summary for RQ 2 is as follows. In this study, a quantitative evaluation was performed to derive the importance of the factors of the Milano Bridge accident derived through the FRAM model and to suggest improvement measures accordingly. For quantitative evaluation, three factors were derived and cumulative multiplication was performed for each function. The evaluation was performed by defining the three factors as the aspect activation factor, based on text mining, and the connectivity of functions. Through the application of FRAM, the causes of the Milan bridge accident were identified as a complex interplay of various factors, including not only human errors of the captain and the pilot but also technological factors that contributed to their errors. In detail, functions and improvement measures derived as important causes of accidents are summarized as follows. In order to derive accident priority for each function (), such as technical factors identified through FRAM, the importance of each function related to accidents is based on activation of aspects of each function, frequency analysis of keywords related to accident analysis, and in-out connectivity of functions. It was evaluated quantitatively through the cumulative multiplication method. As a result of the evaluation, function 15 (Inadequate ballast) is 12.5, function 18 (Insufficient communication) is 12.6, function 19 (Fast maneuvering speed) is 28.8, function 21 (Insufficient tug assistance) is 22.8, and function 27 (Large alteration of courses) was derived as 38.4. The detailed cause analysis and improvement plans for function 15, 18, 19, 21, and 27 are as follows.

The summary for RQ 3 is as follows. Function 15 (Inadequate ballast) is technically caused by the propeller of the ship being exposed to the surface due to insufficient ballast water, and due to human factors, lack of understanding and mutual information exchange among master, pilot, navigator, and shipyard regarding the effect of ventilation in the propeller. Improvement plans include the ability to maneuver declines, similar to the effect of ventilation in the propeller, and the pilot and master need to exchange sufficient information with each other (must exchange information on specific matters), perform additional research on the operational characteristics of mega container ships and training related personnel.

Function 18 (Insufficient communication) was caused by master, navigator, and pilot facing inappropriate communication problems. The improvement plan is training and education for developing leadership and teamwork using customized simulators.

Function 19 (Fast maneuvering speed) is that the pilot should generate an effective rudder force for the ship in empirical terms by increasing the ship speed continuously to overcome the problem of maneuverability. However, in the Milano Bridge accident, effective rudder force is not generated even when the ship speed increases because the propeller is exposed on the water surface. The improvement plan is training and ship simulation on special situations and hazards, taking into consideration the circumstances of ships and ports.

Function 21 (Insufficient tug assistance) requires sufficient horsepower of a tugboat for emergency response through tugboats in ports where large ships enter and depart. However, in the case of Busan New Port where the Milano Bridge accident occurred, there was insufficient horsepower of the tugboat at the port for hull control assistance. The improvement plan is to secure sufficient tugboats with high horsepower because ships at the container port are getting larger and assist in ship control during emergencies.

Function 27 (Large alteration of courses) is a natural characteristic of Busan New Port, and ships must perform large angular course alterations close to 90° to enter the port. Insufficient distance from the pier in the port after large angular course alteration was a contributing factor to the Milano Bridge accident. The improvement plan is to minimize large angular course alteration and secure the distance from the pier by removing obstacles that disturb port entry and departure of ships.

5. Conclusion

Analyses and risk assessments based on systems thinking are crucial for the systematic understanding and prevention of accidents. This study analyzed an actual marine accident that occurred in South Korea using FRAM. Based on FRAM, functions of the targeted system were derived. The performance variability of each function was identified, and the situation leading to the accident was analyzed from the perspective of performance variability and its ripple effects. In addition to the actual accident analysis, a risk assessment was performed to predict possible accident scenarios using prediction scenario analysis. The expected power fluctuations and ripple effects of the variability were analyzed, and a response strategy to manage the variability was derived based on the analysis results.

Traditional accident analysis techniques adopt an accident model with a linear causality that assumes a specific way in which accidents occur and supports accident analysis based on this assumption. Traditional accident analysis techniques assume an accident model with linear causality. However, the inference from their effect-to-cause did not guarantee completeness, although the inference from their cause-to-effect guaranteed completeness and logic, because several causes could influence the outcome in various ways [

27]. Thus, a side effect of fitting the actual accident occurrence to the linear causality model exists, unlike the actual accident occurrence mode. Therefore, hindsight bias has been highlighted as a weakness of conventional accident analysis methods [

34]. The greatest advantage of FRAM-based accident analysis is that it does not assume a specific accident model but focuses on the interaction between the functions of the system and interprets the actual situation in which the accident has occurred. This allows for different methods of diagnosing the causes and influences that affect an accident (outcome) as much as possible. Similar observations were made in this case study.

This study is significant because FRAM, a systematic accident analysis technique that can supplement the limitations of conventional accident analysis, was applied to an actual marine-accident case to secure the application of FRAM and simultaneously confirm its applicability in the maritime industry. However, more case studies on accidents in various navigation situations are necessary to further enhance their applicability to the maritime risk mitigation. Similar to other modeling techniques, the quality of the FRAM model is proportional to the quality of understanding and analysis of the system. A limitation of this study is that the systems and accident analyses were based on facts primarily derived from the literature on accident reports and navigation systems, without field research, such as interviews with parties directly related to the accident. As this study focuses on using FRAM with various factors to evaluate the priority of marine-accident analysis, there are limitations associated with focusing only on six aspects that can be analyzed: keyword analysis of marine-accident reports, functional connectivity, and weighting based on descriptive statistics.

The result of this study is that the functional relationships between organization-technology, human-technology, and organization-human are visually represented in FRAM during pilotage to prevent accidents that may occur and to respond appropriately to emergencies. It is expected to contribute to the formation of a governance structure that maintains and actively utilizes the communication system.

Author Contributions

Conceptualization, Y.Y. and Y.A.; Methodology, C.L.; Validation, Y.A. and C.L.; Investigation, Y.Y.; Resources, Y.Y.; Data Curation, Y.A. and C.L.; Writing—original draft preparation, Y.A.; Writing—review and editing, Y.Y. and C.L.; Visualization, Y.A. and Y.Y.; Supervision, C.L.; Project Administration C.L. and Y.A.; Funding acquisition, C.L. and All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by a grant from the National R&D Project, “Core Technologies Development for advancement of LNG bunkering SIMOPs,” funded by the Ministry of Oceans and Fisheries, South Korea, grant number RS-2023-00255929.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funder had no role in the design of the study; collection, analyses, or interpretation of data; writing of the manuscript; or decision to publish the results.

References

- Panagiotidis, P., Giannakis, K., Angelopoulos, N., & Liapis, A. (2021). Shipping accidents dataset: Data-driven directions for assessing accident’s impact and improving safety onboard. Data, 6(12), 129. [CrossRef]

- Sánchez-Beaskoetxea, J., Basterretxea-Iribar, I., Sotés, I., & Machado, MdlM. M. (2021) Human error in marine accidents: Is the crew normally to blame? Maritime Transport Research, 2, 100016. [CrossRef]

- Nielsen, D., & Jungnickel, D. (2003). Maritime accident investigation and temporal determinants of maritime accidents: A case study. WMU Journal of Maritime Affairs, 2(1), 49–59. [CrossRef]

- Sepehri, A., Vandchali, H. R., Siddiqui, A. W., & Montewka, J. (2022). The impact of shipping 4.0 on controlling shipping accidents: A systematic literature review. Ocean Engineering, 243, 110162, ISSN 0029-8018. [CrossRef]

- Wróbel, K. (2021). Searching for the origins of the myth: 80% human error impact on maritime safety. Reliability Engineering and System Safety, 216, 107942. [CrossRef]

- Zhang, M., Conti, F., Le Sourne, H., Vassalos, D., Kujala, P., Lindroth, D., & Hirdaris, S. (2021). A method for the direct assessment of ship collision damage and flooding risk in real conditions. Ocean Engineering, 237, 109605, ISSN 0029-8018. [CrossRef]

- Patriarca, R., Di Gravio, G., Woltjer, R., Costantino, F., Praetorius, G., Ferreira, P., & Hollnagel, E. (2020). Framing the FRAM: A literature review on the functional resonance analysis method. Safety Science, 129, 104827, ISSN 0925-7535. [CrossRef]

- Low, B. K. L., Man, S. S., & Chan, A. H. S. (2018). The risk-taking propensity of construction Workers-An application of quasi-expert interview. International Journal of Environmental Research and Public Health, 15(10), 2250. Retrieved from http://www.mdpi.com/journal/ijerph. [CrossRef]

- Wang, L., Huang, R., Shi, W., & Zhang, C. (2021). Domino effect in marine accidents: Evidence from temporal association rules. Transport Policy, 103, 236–244, ISSN 0967-070X. [CrossRef]

- Watson, H. A. (1961), Launch control safety study. Murray Hill, NJ: Bell Telephone Laboratories.

- Tanaka, H., Fan, L. T., Lai, F. S., & Toguchi, K. X. (2003). Fault-tree analysis by fuzzy probability. IEEE Transactions on Reliability, R–32(5), 453–457. [CrossRef]

- Ashraf, A. M., Imran, W., & Véchot, L. (2022). Analysis of the impact of a pandemic on the control of the process safety risk in major hazards industries using a Fault Tree Analysis approach. Journal of Loss Prevention in the Process Industries, 74, 104649, ISSN 0950-4230. [CrossRef]

- Kee, D. (2016). Needs for changing accident investigation from blaming to systems approach. Journal of the Ergonomics Society of Korea, 35(3), 143–153. [CrossRef]

- Dohyung, K. (2017). Comparison of systemic accident investigation techniques based on the Sewol Ferry capsizing. Journal of the Ergonomics Society of Korea, 36, 485–498. [CrossRef]

- Chan, S. R., Hamid, N. A., & Mokhtar, K. (2016). A theoretical review of human error in maritime accidents. Advanced Science Letters, 22(9), 2109–2112. [CrossRef]

- Schröder-Hinrichs, J. U., Baldauf, M., & Ghirxi, K. T. (2011). Accident investigation reporting deficiencies related to organizational factors in machinery space fires and explosions. Accident; Analysis and Prevention, 43(3), 1187–1196. [CrossRef]

- Celik, M., Lavasani, S. M., & Wang, J. (2010). A risk-based modelling approach to enhance shipping accident investigation. Safety Science, 48(1), 18–27. [CrossRef]

- Rasmussen, J. (1997). Risk management in a dynamic society: A modelling problem. Safety Science, 27(2–3), 183–213. [CrossRef]

- Lee, S., Moh, Y. B., Tabibzadeh, M., & Meshkati, N. (2017). Applying the AcciMap methodology to investigate the tragic Sewol Ferry accident in South Korea. Applied Ergonomics, 59(B), 517–525. [CrossRef]

- Weigmann, D. A., & Shappell, S. A. (1997). Human factors analysis of postaccident data: Applying theoretical taxonomies of human error. International Journal of Aviation Psychology, 7(1), 67–81. [CrossRef]

- Uğurlu, Ö., Yıldız, S., Loughney, S., & Wang, J. (2018). Modified human factor analysis and classification system for passenger vessel accidents (HFACS-PV). Ocean Engineering, 161, 47–61, ISSN 0029-8018. [CrossRef]

- Leveson, N. (2004). A new accident model for engineering safer systems. Safety Science, 42(4), 237–270. [CrossRef]

- Valdez Banda, O. A., & Goerlandt, F. (2018). A STAMP-based approach for designing maritime safety management systems. Safety Science, 109, 109–129. [CrossRef]

- Hollnagel, E., & Goteman, O. (2004). The functional resonance accident model. In Cognitive system engineering in process control. CSEPC (pp. 155–161), Barriers and Accident Prevention. Aldershot, UK: Ashgate.

- Salihoglu, E., & Bal Beşikçi, E. (2021). The use of functional resonance analysis method (FRAM) in a maritime accident: A case study of Prestige. Ocean Engineering, 219, 108223. [CrossRef]

- Lee, J., & Chung, H. (2018). A new methodology for accident analysis with human and system interaction based on FRAM: Case studies in maritime domain. Safety Science, 109, 57–66, ISSN 0925-7535. [CrossRef]

- Yu, Y., Fu, S., Chen, J., & Xi, Y. (2021). A preliminary model for maritime accident analysis by using functional resonance analysis method (FRAM). In Proceedings of the 2021 6th International Conference on Transportation Information and Safety (ICTIS), Wuhan, China (pp. 1029–1034). [CrossRef]

- Ye, G., Tan, Q., Gong, X., Xiang, Q., Wang, Y., & Liu, Q. (2018). Improved HFACS on human factors of construction accidents: A China perspective. Advances in Civil Engineering, 2018, 1–15. [CrossRef]

- Hollnagel, E., & FRAM. (2018), A handbook for the practical use of the method.

- Ding, Y., Li, R., Shen, H., Li, J., & Cao, L. (2022). A novel energy-saving route planning algorithm for marine vehicles. Applied Sciences, 12(12), 5971. [CrossRef]

- Weintrit, A. (2020). Initial description of pilotage and tug services in the context of e-navigation. Journal of Marine Science and Engineering, 8(2), 116. [CrossRef]

- Ahn, Y.-G., Kim, T., Kim, B.-R., & Lee, M.-K. (2022). A study on the development priority of smart shipping items—Focusing on the expert survey. Sustainability, 14(11), 6892. [CrossRef]

- Kozlowska, A. M., Dalheim, Ø. Ø., Savio, L., & Steen, S. (2020). Time domain modeling of propeller forces due to ventilation in static and dynamic conditions. Journal of Marine Science and Engineering, 8(1), 31. [CrossRef]

- Retrieved from https://functionalresonance.com/brief-introduction-to-fram/ (accessed date: 01st May. 2023).

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).