Submitted:

14 June 2023

Posted:

15 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Bibliographic review

2.1. Substrates used and their importance

2.1.1. Glycerol

2.1.2. Sugarcane molasses

2.2. Anaerobic co-digestion

2.3. Artificial Neural Networks

2.3.1. Application of Neural Networks in biogas production

2.4. Fuzzy Logic

- Linguistic variable and linguistic value

- Membership functions

- Heuristic rules

- Logical operators

2.4.1. Application of fuzzy logic in biogas production

3. Objectives

3.1. General Objective

3.2. Specific Objectives

- Obtain a database from computer simulation employing the Monod two-substrate with an intermediate (M2SI) simple kinetic model;

- Train neural networks to predict methane production based on the database created;

- Train a neural network to provide the kinetic parameters of the M2SI model;

- Evaluate the quality of the results provided by artificial neural networks;

- Specify a membership function type for fuzzy logic;

- Define ranges of linguistic values for the linguistic variables of the fuzzy inference system;

- Apply a neuro-fuzzy methodology for parameterization of the fuzzy model;

- Evaluate the effectiveness of the fuzzy logic approach;

- Compare the results obtained using the artificial neural network and fuzzy logic approaches.

4. Materials and Methods

4.1. Monod two-substrate with an intermediate (M2SI) kinetic simulation model

- Endogenous metabolism is present in the process.

- An intermediate substrate (Si) is added in the hydrolysis step. This substrate is obtained from slow degradation (Ss). The Si is consumed by a specific group of microorganisms (Xe).

- There are two groups of microorganisms: Xe (degrades Se and Si) and Xs (grows on Ss)

4.2. Application of the neural networks

4.2.1. Training of the neural network for obtaining biomethane

4.2.2. Network training for prediction of the monod parameters

- Maximum microbial growth rate of Xe (µme);

- Maximum microbial growth rate of Xs (µms);

- Methane production yield from consumption of Se (YPSe);

- Fraction of Ss in the total substrate composition (fSs);

- Amplification factor (α).

4.3. Fuzzy Logic

5. Results and Discussion

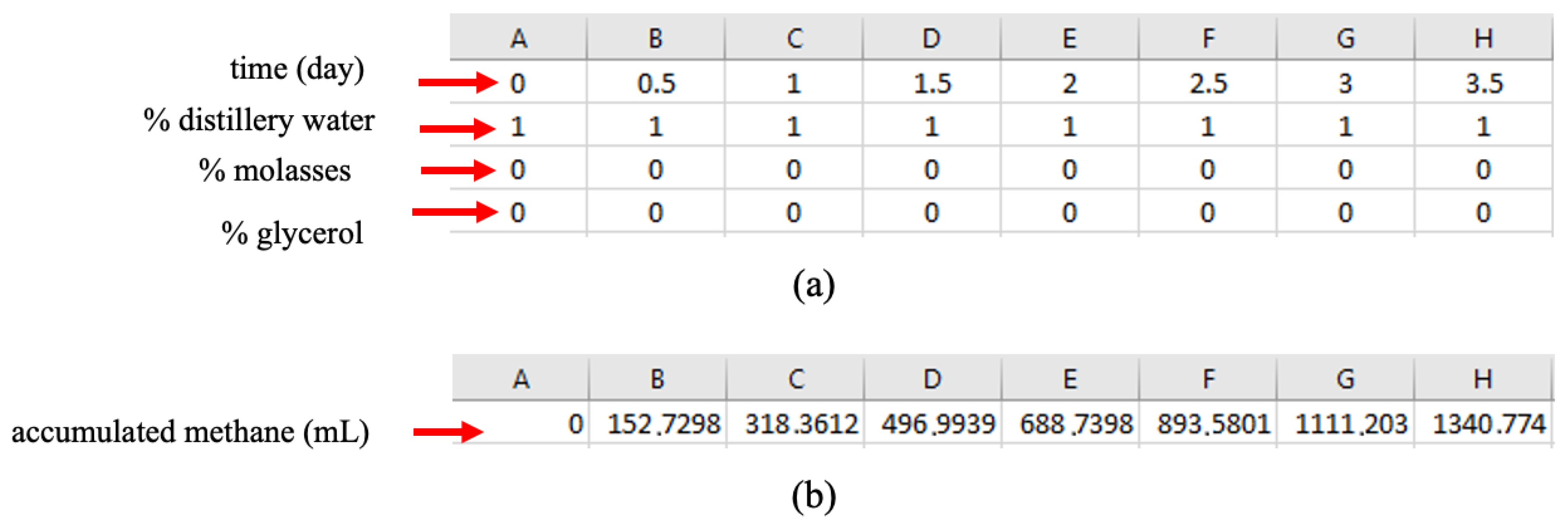

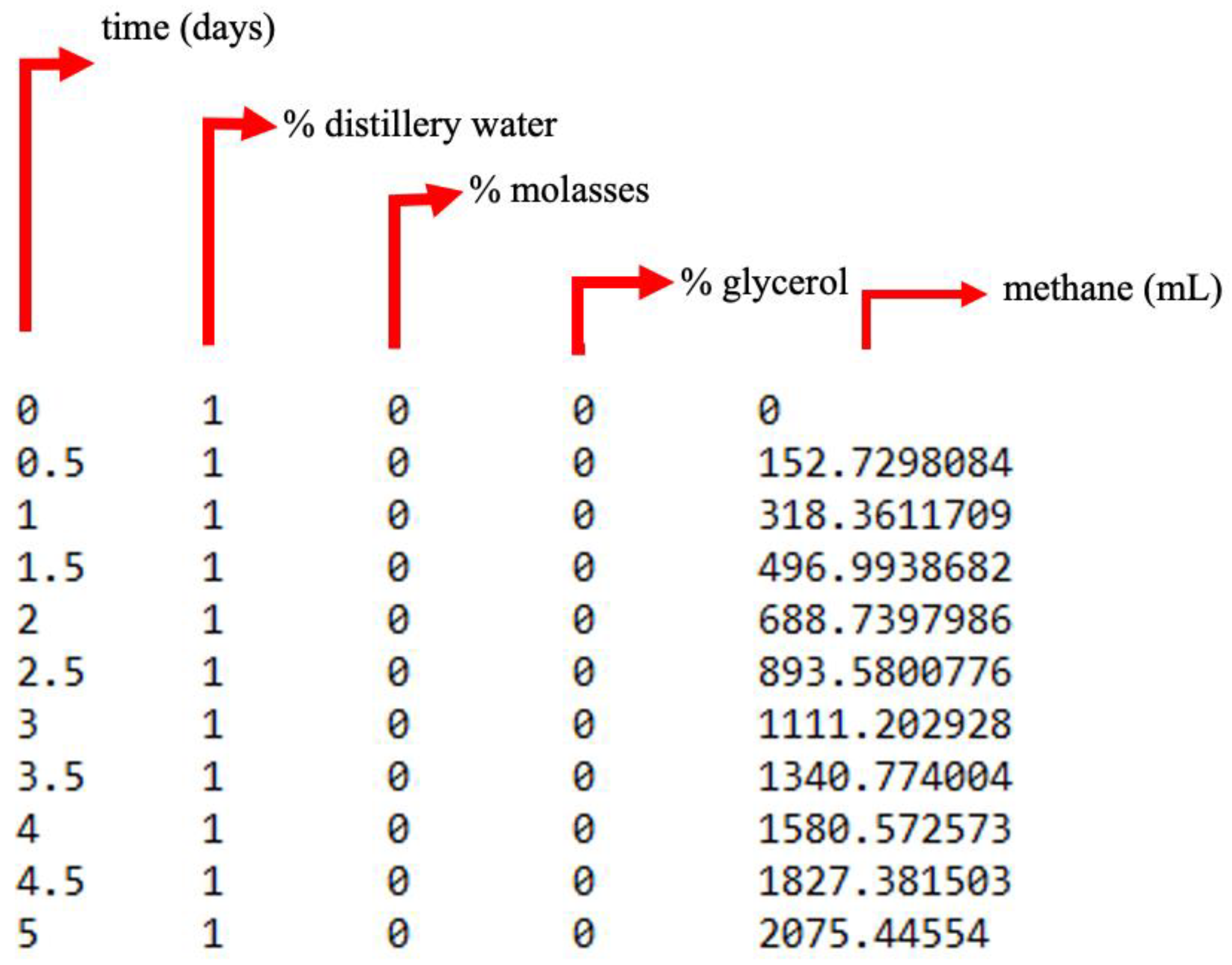

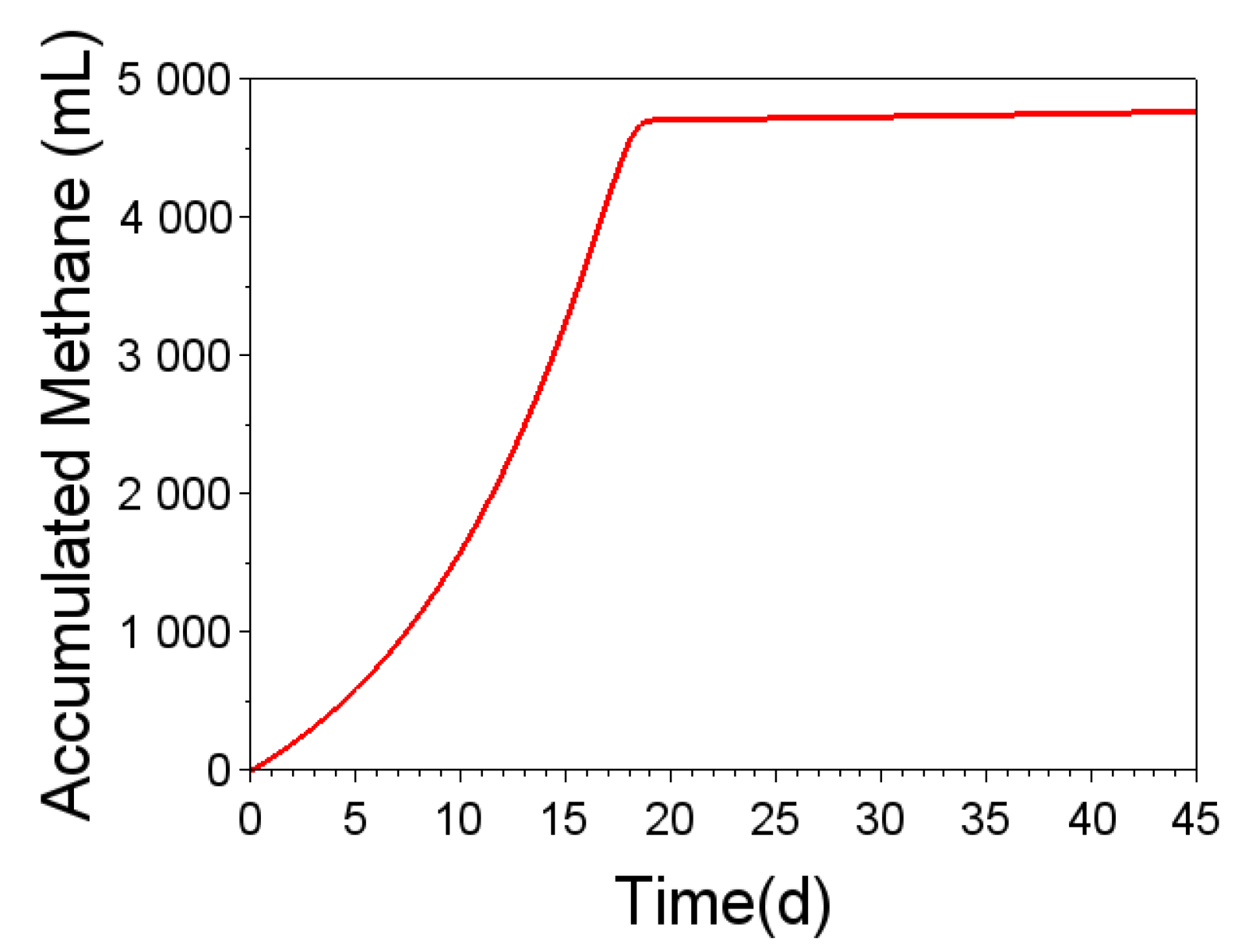

5.1. Biomethane production using monod kinetics

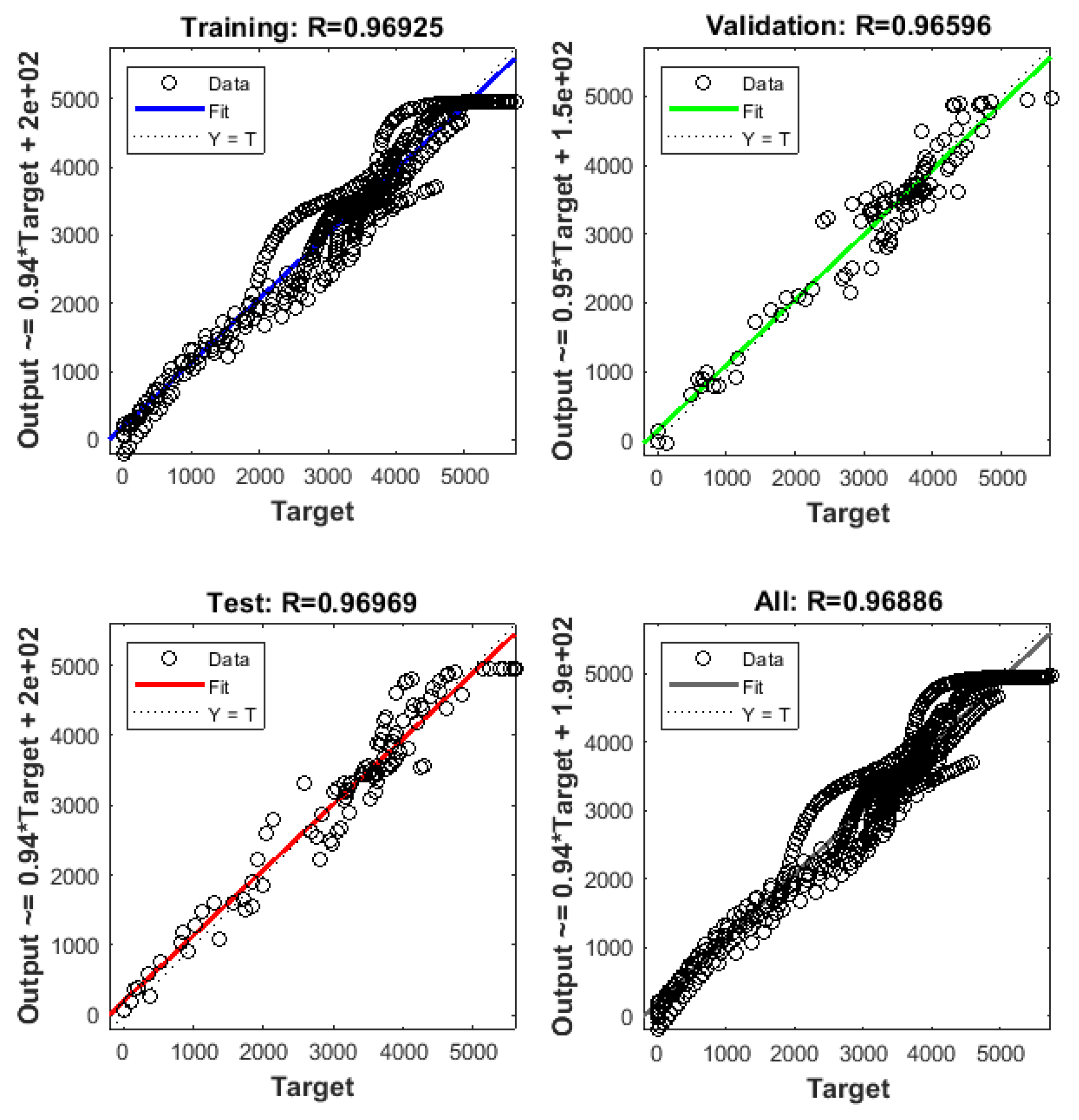

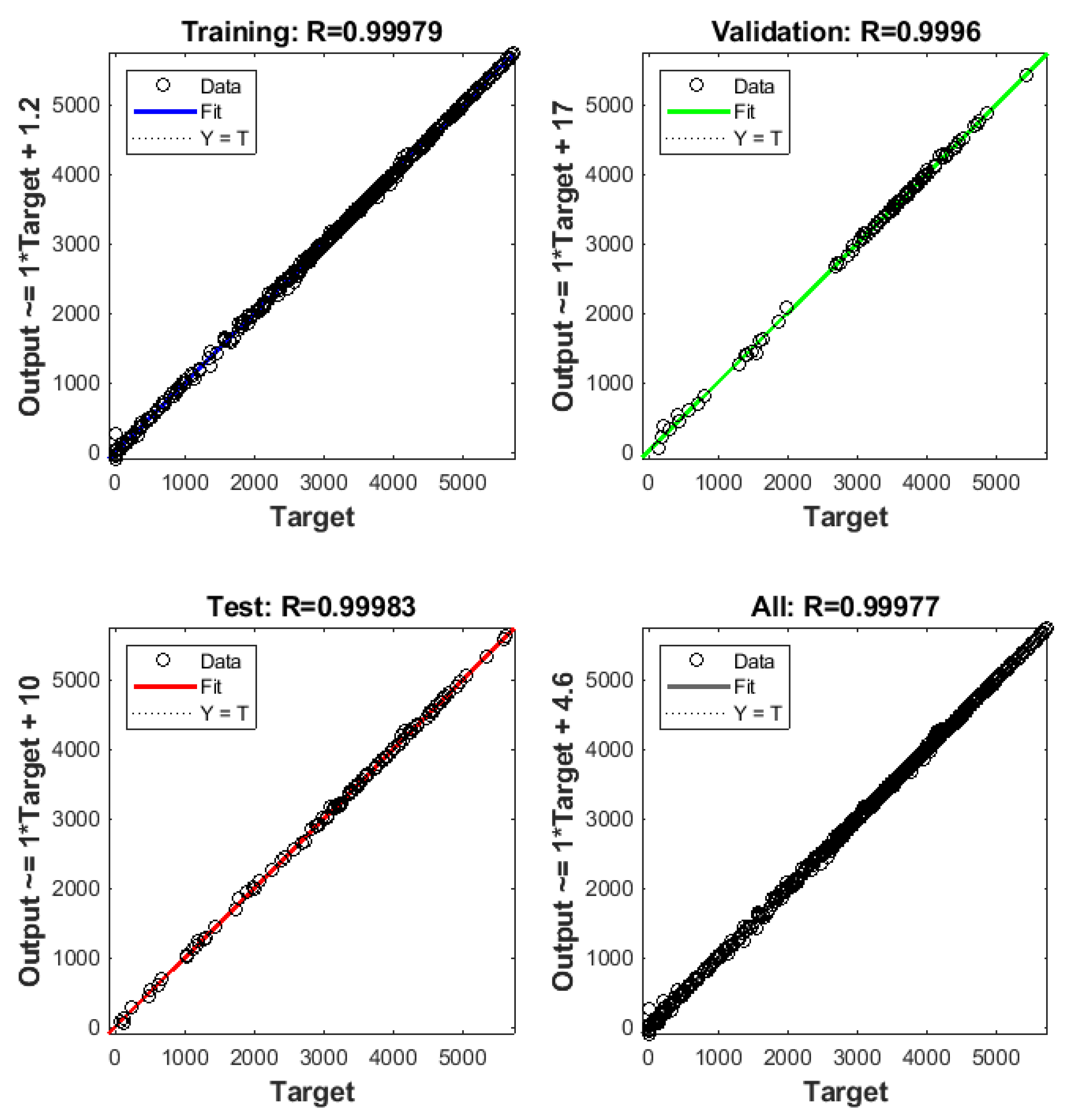

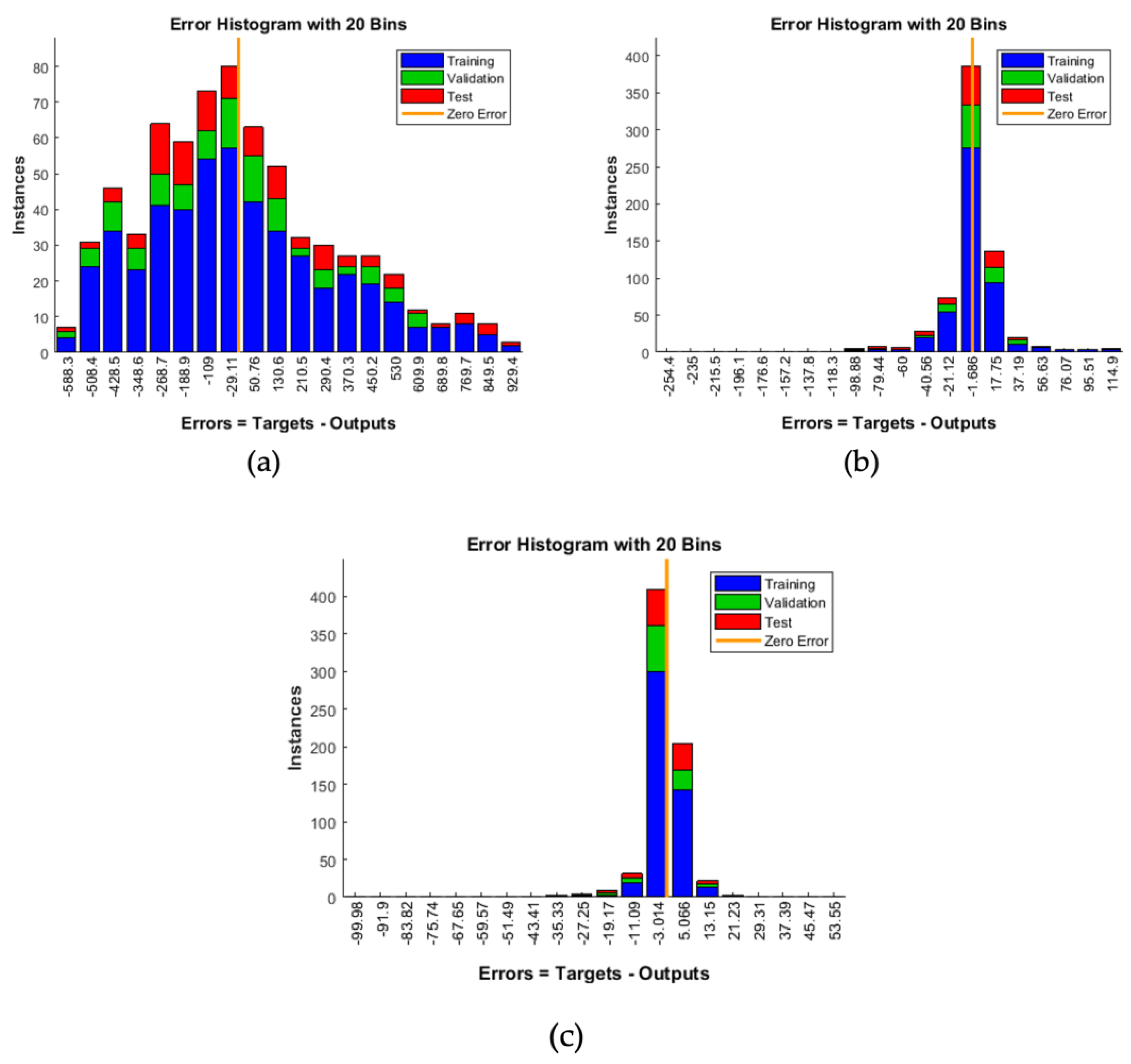

5.2. Training of the neural network for biomethane production

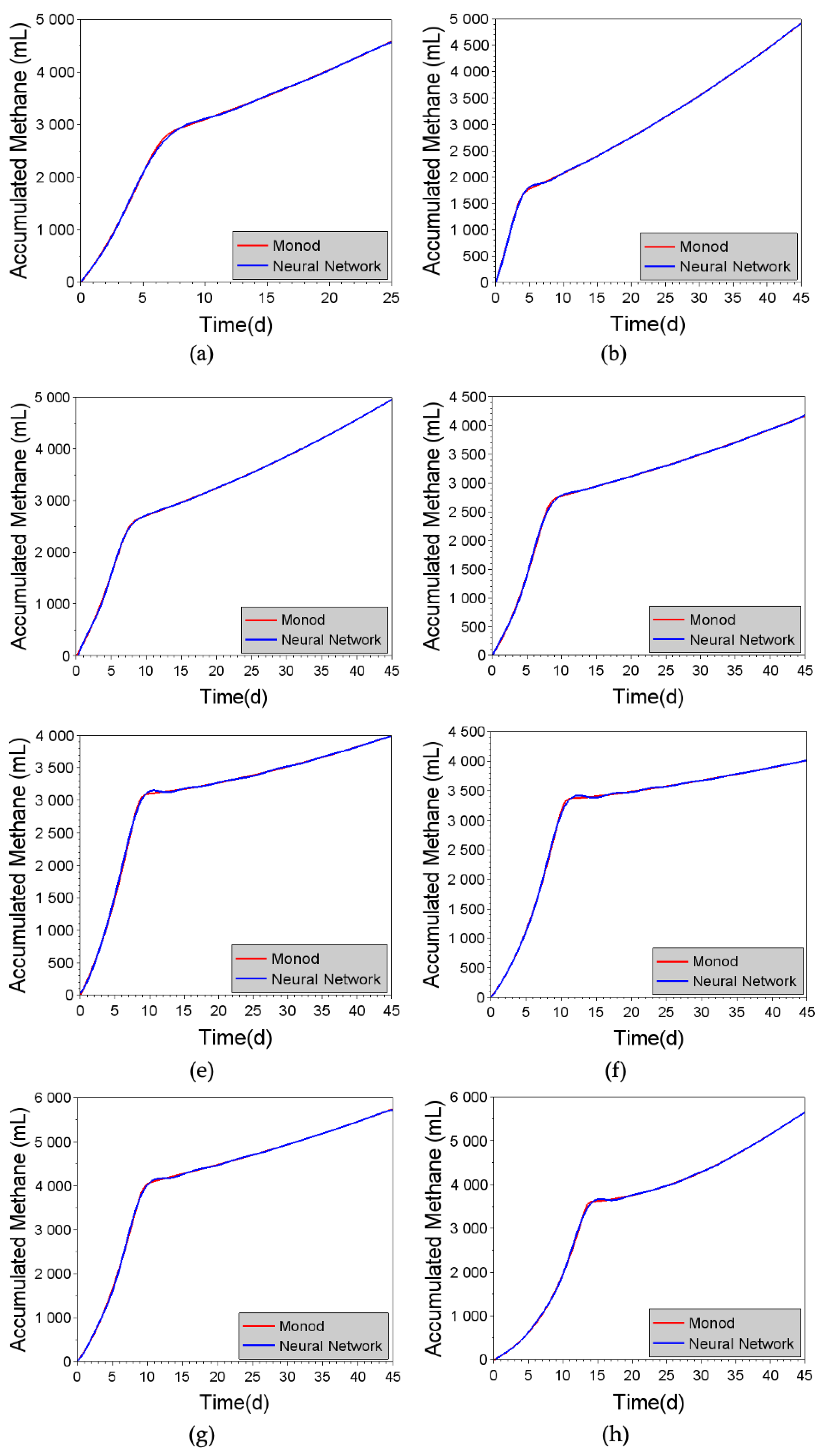

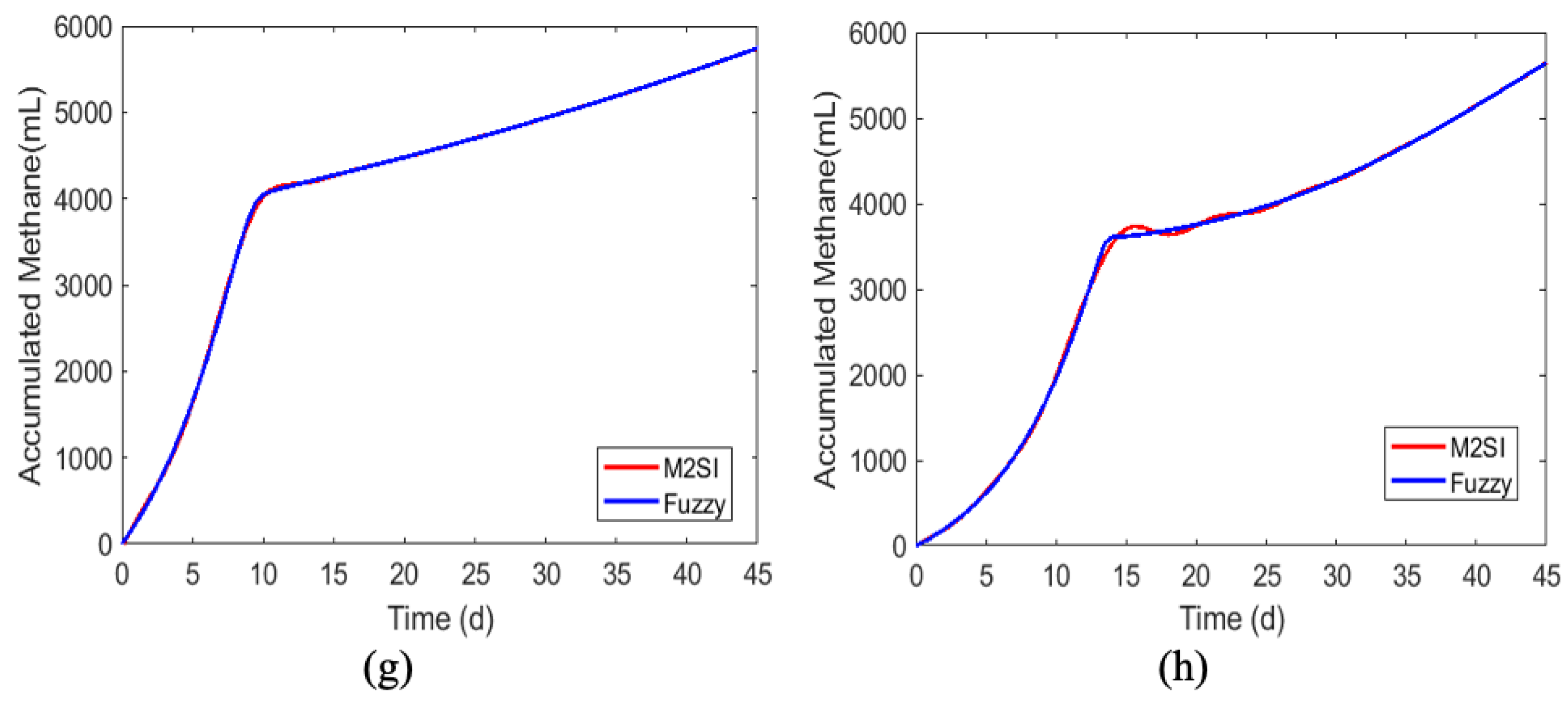

5.3. Comparison of prediction of methane production using the M2SI model and the generic neural network

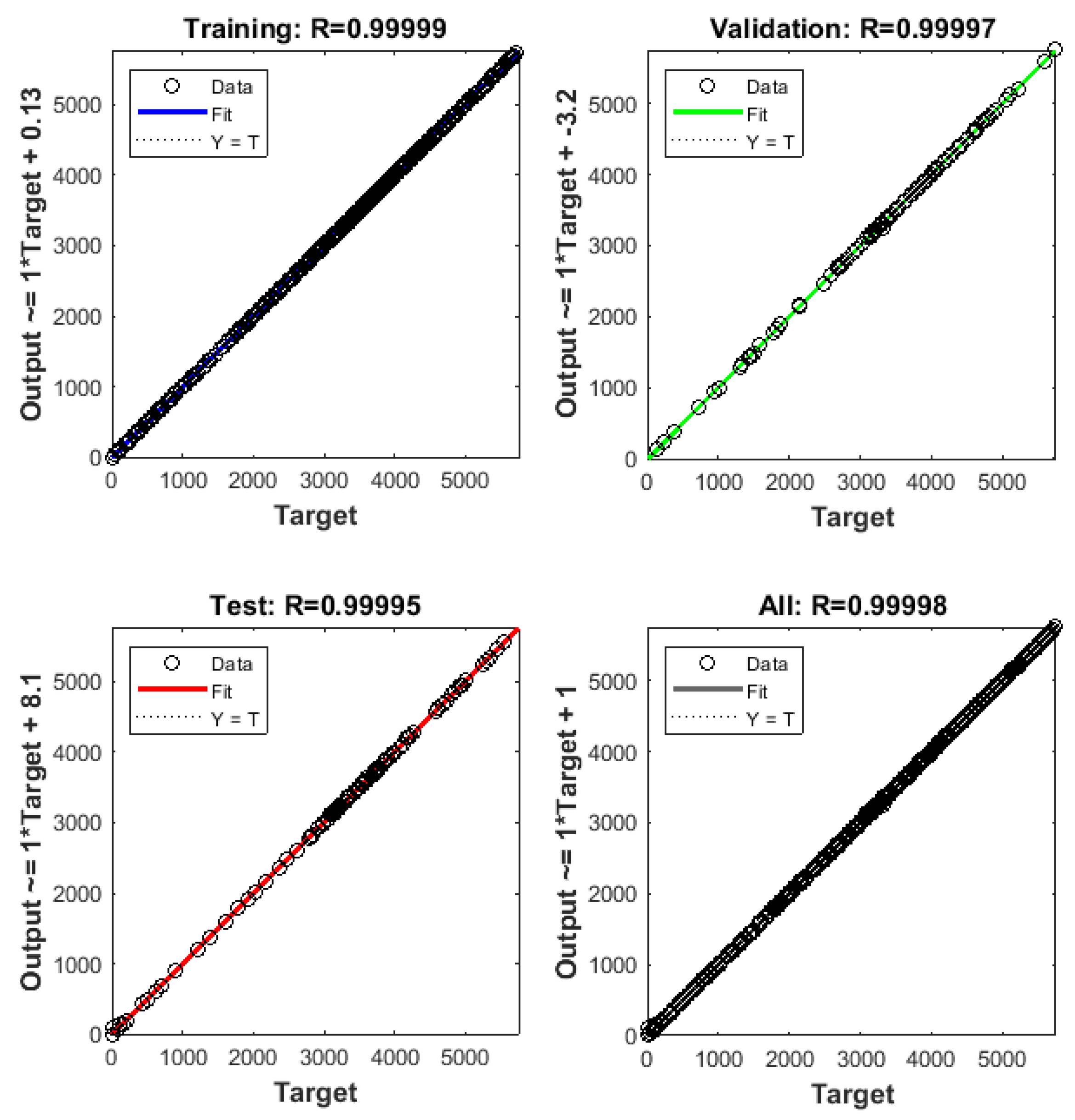

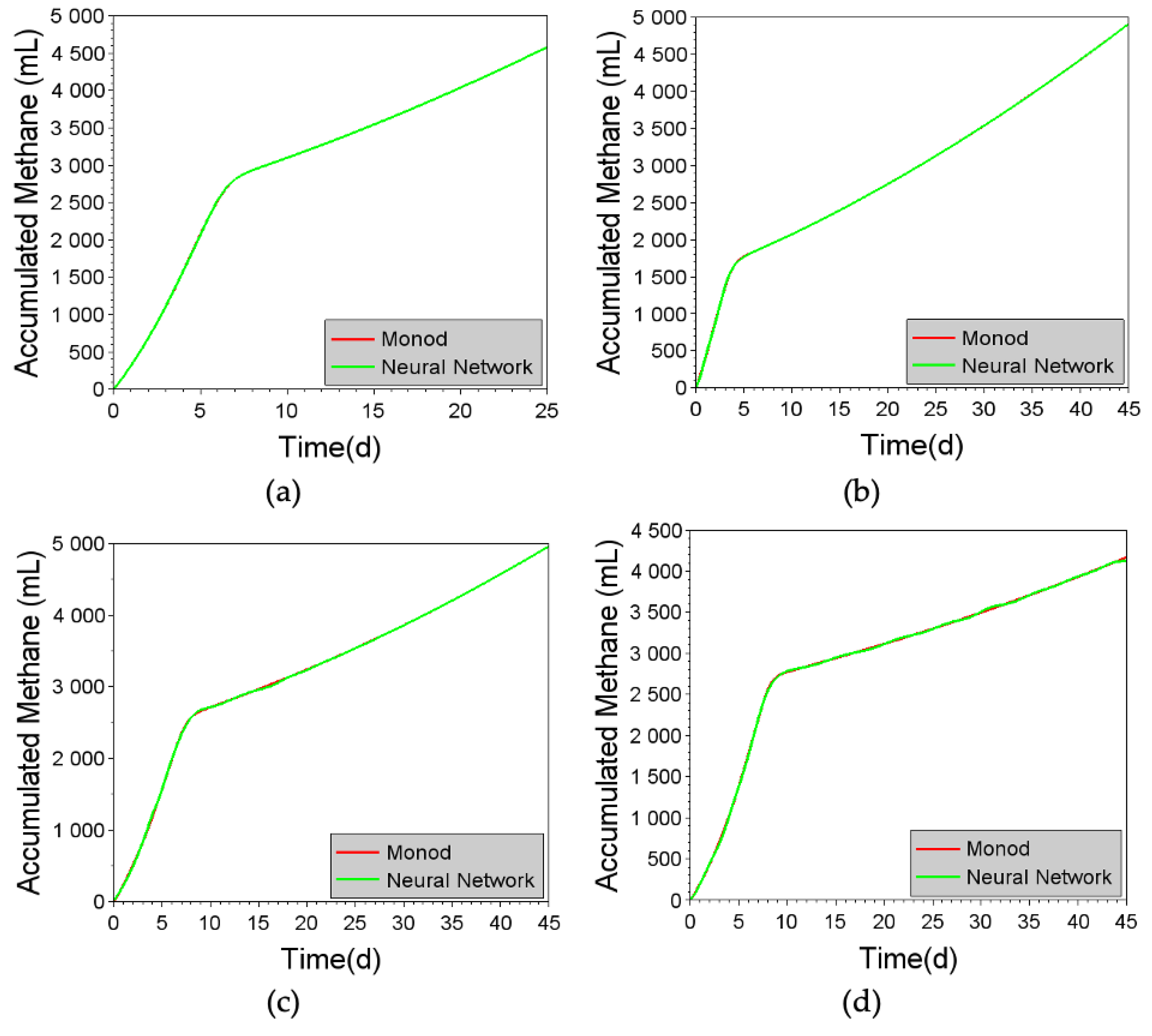

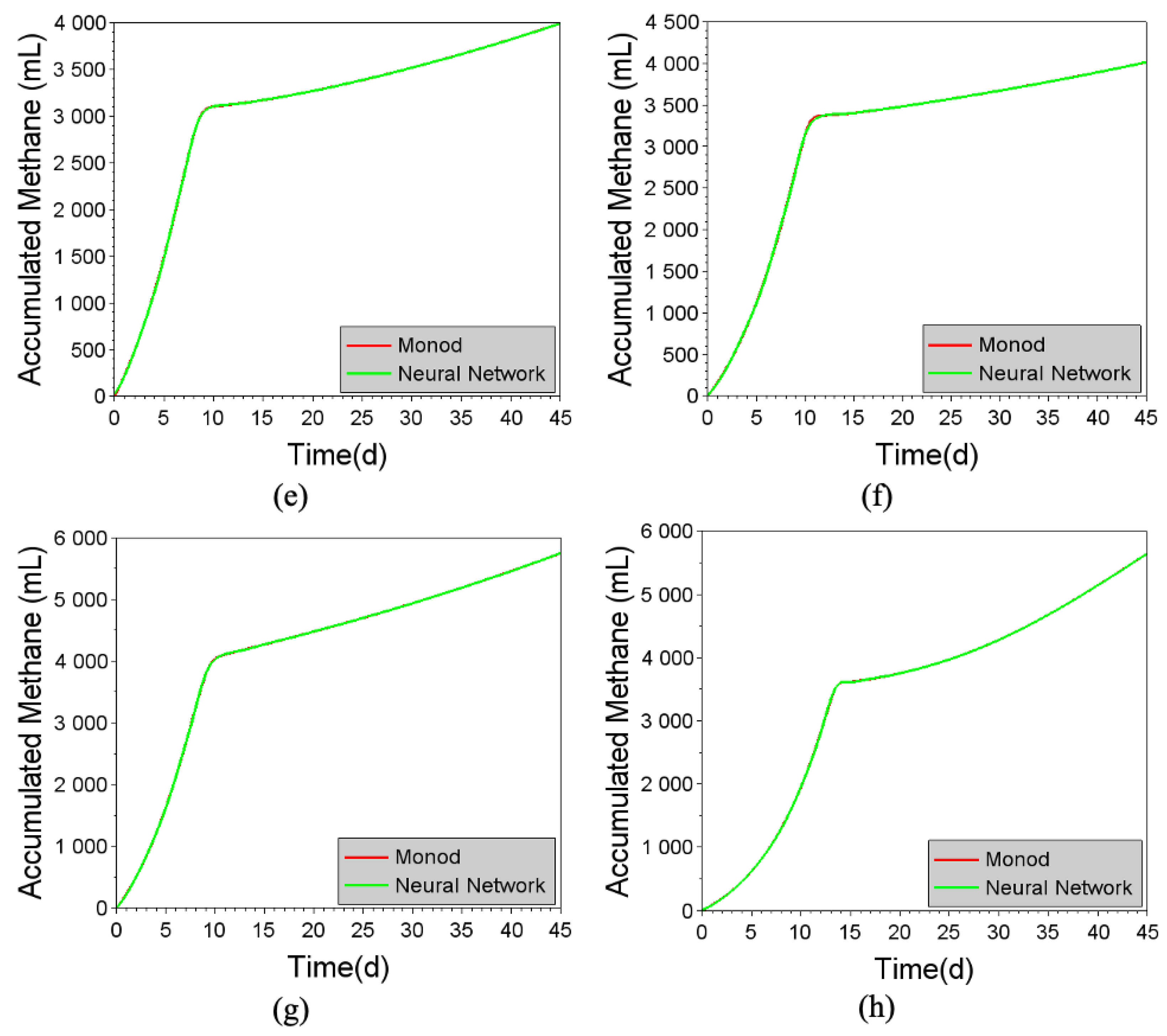

5.4. Prediction of methane production using specific neural networks

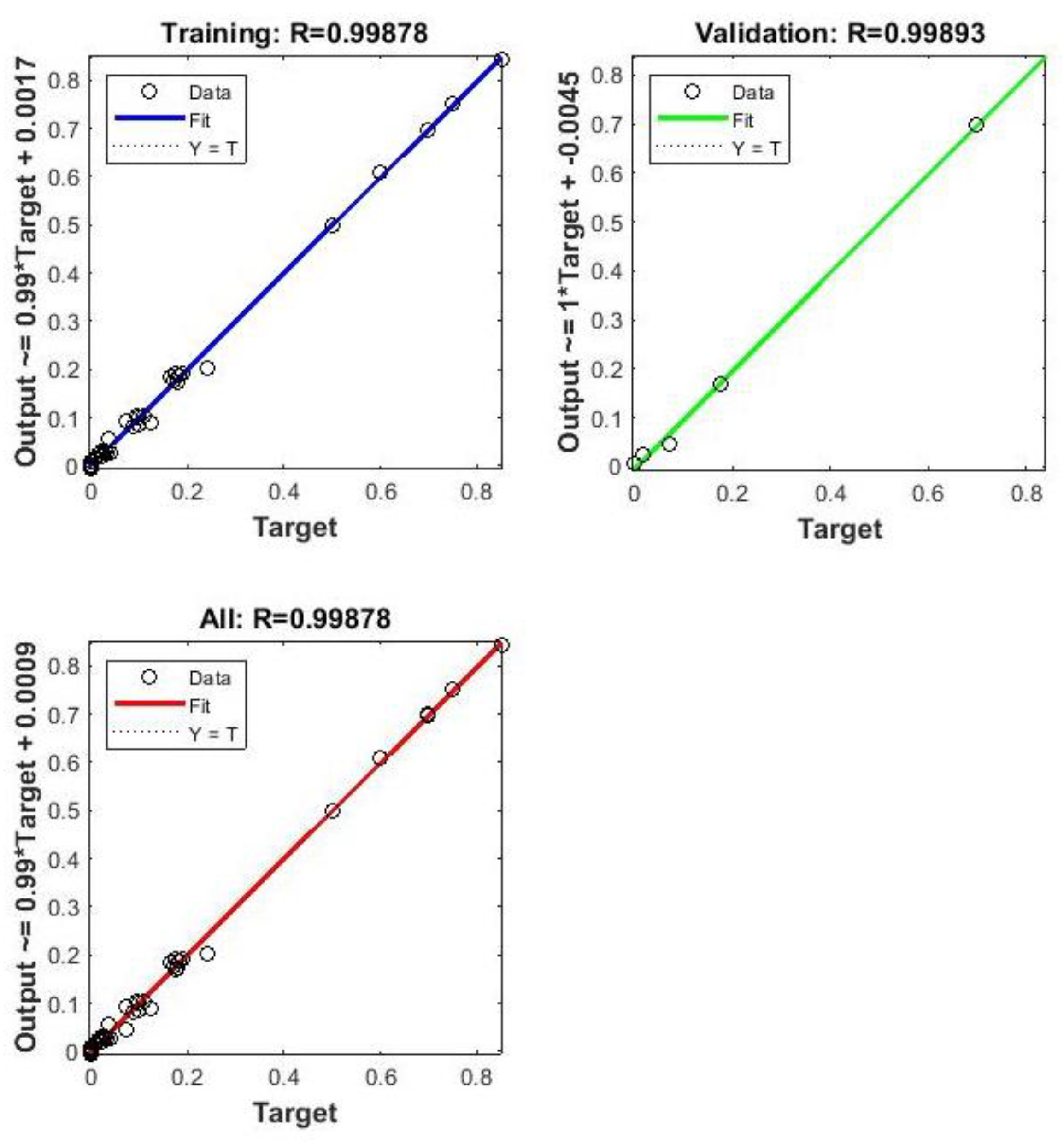

5.5. Neural network training to predict monod kinetic parameters

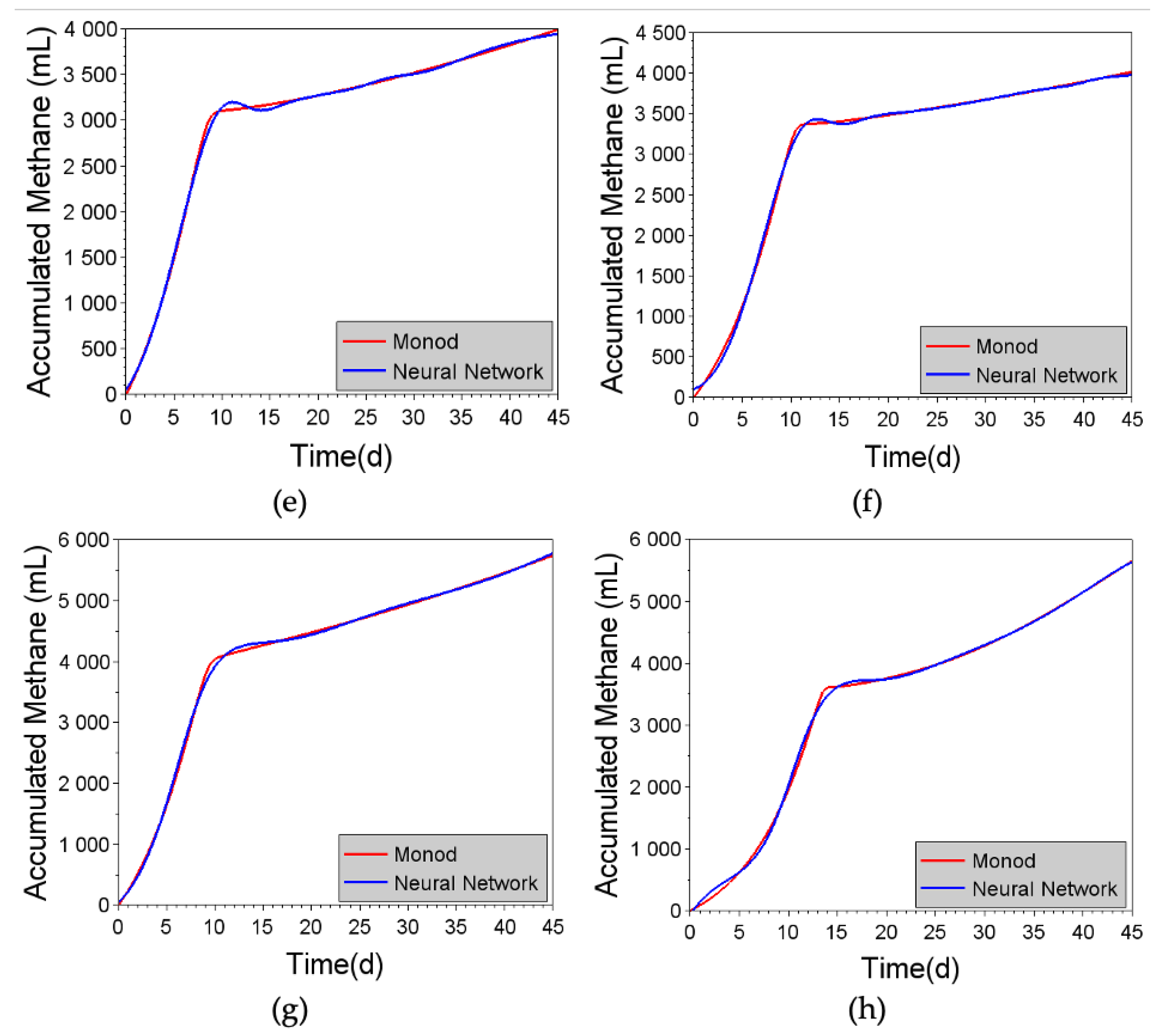

5.5.1. Assessment of the predictive capability of hybrid M2SI-Neural Network approach

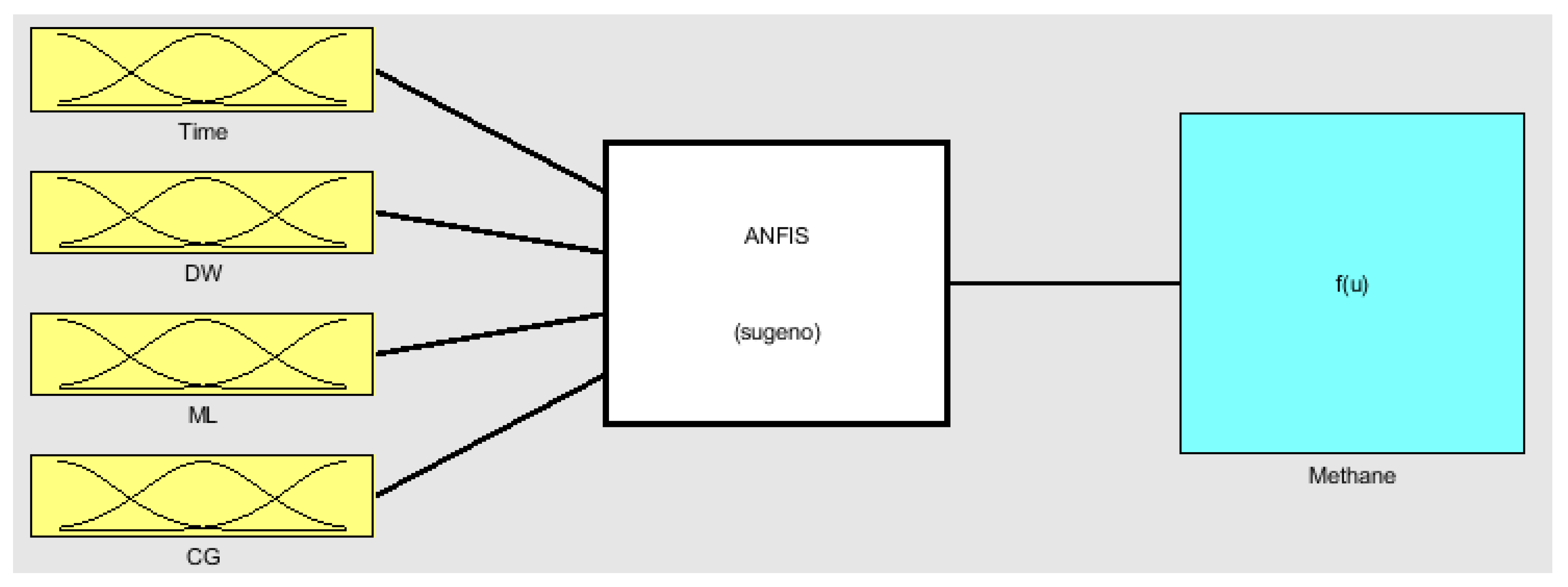

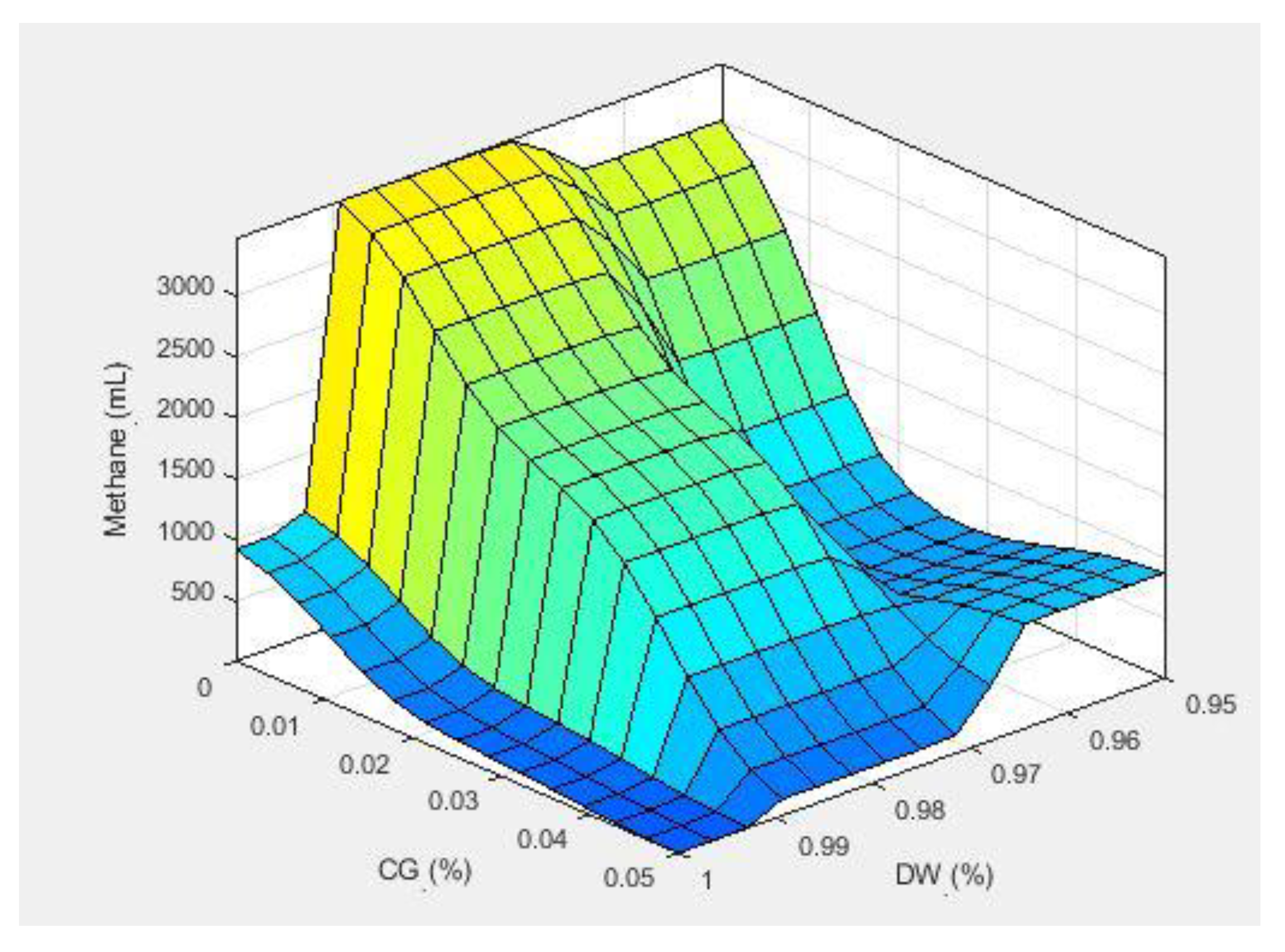

5.6. Application of fuzzy logic

5.6.1. Analysis of the response surface generated by the fuzzy model

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DW | Distillery wastewater |

| ANFIS | Adaptive-Network-Based Fuzzy Inference System |

| ANP | Agência Nacional de Petróleo, Gás Natural e Biocombustíveis |

| CH4 | Methane |

| CH3COOH | Acetate |

| CO2 | Carbon dioxide |

| COD | Chemical oxygen demand |

| FIS | Fuzzy inference system |

| MF | Membership function |

| ML | Molasses |

| CG | Crude glycerol |

| MD | Membership degree |

| H2 | Hydrogen gas |

| H2O | Water |

| M2SI | Monod two-substrate with an intermediate model |

| MLP | Multilayer perceptron |

| pH | Hydrogen ion potential |

| RMSE | Root mean squared error |

| R² | Coefficient of determination |

| SCG | Scaled conjugate gradient |

| UASB | Upflow anaerobic sludge blanket |

References

- UN – United Nations. United Nations Conference in the Human Environment, 5-16 June 1972, Stockholm. Available online: https://www.un.org/en/conferences/environment/stockholm1972 (access on 13 april 2022a).

- ANP – Agência Nacional de Petróleo, Gás Natural e Biocombustíveis. Biodiesel. Available online: https://www.gov.br/anp/pt-br/assuntos/producao-e-fornecimento-de-biocombustiveis/biodiesel (access on 14 april 2022a).

- ANP – Agência Nacional de Petróleo, Gás Natural e Biocombustíveis. Painel Dinâmico de Produtores de Biodiesel. Available online: https://www.gov.br/anp/pt-br/centrais-de-conteudo/paineis-dinamicos-da-anp/paineis-e-mapa-dinamicos-de-produtores-de-combustiveis-e-derivados/painel-dinamico-de-produtores-de-biodiesel (access on 14 april 2022b).

- Leung, D. Y.C.; Wu, X.; Leung, M. K.H. A review on biodiesel production using catalyzed transesterification. Applied Energy, 2010, 87, 1083–1095. [CrossRef]

- ANP – Agência Nacional de Petróleo, Gás Natural e Biocombustíveis. RenovaBio. Available online: https://www.gov.br/anp/pt-br/assuntos/renovabio (access on 14 april 2022c).

- Quispe, C. A.G.; Coronado, C. J.R.; Carvalho, J. A. Glycerol: Production, consumption, prices, characterization and new trends in combustion. Renewable and Sustainable Energy Reviews, 2013, 27, 475–493. [CrossRef]

- Chernicharo, C. A. L. Anaerobic Reactors. Vol 4 - Biological Wastewater Treatment. IWA Publishing: London, UK, 2007.

- Gabra, F. A.; Abd-alla, M. H.; Danial, A. W.; et al. Production of biofuel from sugarcane molasses by diazotrophic Bacillus and recycle of spent bacterial biomass as biofertilizer inoculants for oil crops. Biocatalysis and Agricultural Biotechnology, 2019, 19. [CrossRef]

- UN – United Nations. FAO: América Latina e Caribe vão responder por mais de 25% das exportações agrícolas globais até 2028. Available online: https://brasil.un.org/pt-br/83643-fao-america-latina-e-caribe-vao-responder-por-mais-de-25-das-exportacoes-agricolas-globais (access on 13 april 2022b).

- Costa, T. B. Produção de hidrogênio e metano a partir de glicerol bruto e cultura mista em reatores anaeróbios de leito fluidizado termofílicos; Federal University of São Carlos. Master Thesis, São Carlos, Brazil, 2017.

- Paranhos, A.G.O., Silva, E. L. Optimized 1,3-propanediol production from crude glycerol using mixed cultures in batch and continuous reactors. Bioprocess Biosystems Engineering, 2018, 41, 1807–1816. [CrossRef]

- Freitas, I. B. F. Produção de hidrogênio e metabólitos com valor biotecnológico a partir de melaço da cana-de-açucar utilizando reatores de leito granular expandido mesofílicos. University of São Paulo – São Carlos School of Engineering. Master Thesis, São Carlos, Brazil, 2018.

- Pereyra, D. A. D.; Rueger, I. B.; Barbosa, P. A. M. A.; Peiter, F. S.; Freitas, D. M. S.; Amorim, E. L. C. Co-fermentation of glycerol and molasses for obtaining biofuels and value-added products. Brazilian Journal of Chemical Engineering, 2020, 37, 653-660. [CrossRef]

- Rakmak, N.; Noynoo, L.; Jijai, S.; Siripatana, C. Monod-Type Two-Substrate Models for Batch Anaerobic Co-Digestion. In Lecture Notes in Applied Mathematics and Applied Science in Engineering. Melaka, Malaysia, p. 11–20, 2019.

- Nelles, O. Nonlinear System Identification: from classical approaches to neural networks and fuzzy models. Springer: New York, USA, 2001; 785 p.

- Viana, M B; Freitas, A V; Leitão, R C; Pinto, G. A. S.; Santaella, S. T. Anaerobic digestion of crude glycerol: a review. Environmental Technology Reviews, 2012, 1, 81–92. [CrossRef]

- Ayoub, M.; Abdullah, A. Z. Critical review on the current scenario and significance of crude glycerol resulting from biodiesel industry towards more sustainable renewable energy industry. Renewable and Sustainable Energy Reviews, 2012, 16, 2671–2686. [CrossRef]

- Santibáñez, C.; Vernero, M. T.; Bustamante, M. Residual glycerol from biodiesel manufacturing, waste or potential source of bioenergy: a review. Chilean Journal of Agricultural Research, 2011, 71, 469–475. [CrossRef]

- Rezania, S.; Oryani, B.; Park, J.; Hashemi, B.; Yadav, K. K.; Kwon, E. E.; Hur, J.; Cho, J. Review on transesterification of non-edible sources for biodiesel production with a focus on economic aspects, fuel properties and by-product applications. Energy Conversion and Management, 2019, 201, 112-155. [CrossRef]

- ABIQUIM - ASSOCIAÇÃO BRASILEIRA DA INDÚSTRIA QUÍMICA. Report of Dynamic system of statistical information. São Paulo, Brazil, 2008. 36 p.

- Oliveira, C. A.; Fuess, L. T.; Soares, L. A.; et al. Thermophilic biomethanation of sugarcane molasses comparing single and two-stage systems: Process performance and energetic potential. Bioresource Technology Reports, 2020, 12. [CrossRef]

- Aguilar, F. A.; Nelson, D L.; Pantoja, L. A.; Santos, A. S. Study of anaerobic co-digestion of crude glycerol and swine manure for the production of biogas. Revista Virtual de Quimica, 2017, 9, 2384–2403. [CrossRef]

- Menezes, C. A.; Beike, K. et al. Biohydrogen Production in Fluidized Bed Reactors: An Environmental Approach. In Fluidized Bed Reactors: Principles and Applications. 1st edition; Nova Science Publishers: New York, 2020; pp 1-39.

- Jaroenpoj, S.; Yu, Q. J.; Ness, J. Development of Artificial Neural Network Models for Biogas Production from Co-Digestion of Leachate and Pineapple Peel. The Global Environmental Engineers, 2014, 1, 42-47. [CrossRef]

- Ghatak, M.; Ghatak, A. Artificial neural network model to predict behavior of biogas production curve from mixed lignocellulosic co-substrates. Fuel, 2018, 232, 178–189. [CrossRef]

- Özarslan, S.; Abut, S.; Atelge, M.R.; Kaya, M.; Unalan, S. Modeling and simulation of co-digestion performance with artificial neural network for prediction of methane production from tea factory waste with co-substrate of spent tea waste. Fuel, 2021, 306. [CrossRef]

- Gonçalves Neto, J.; Ozorio, L. V.; Abreu, T. C. C.; Santos, B. F.; Pradelle, F. Modeling of biogas production from food, fruits and vegetables wastes using artificial neural network (ANN). Fuel, 2021, 285. [CrossRef]

- MathWorks. Fuzzy Logic ToolboxTM User’s Guide R2018a. MathWorks: Natick, MA, USA, 2018.

- Khayum, N.; Rout, A.; Deepak, B. B. V. L.; Anbarasu, S.; Murugan, S. Application of Fuzzy Regression Analysis in Predicting the Performance of the Anaerobic Reactor Co-digesting Spent Tea Waste with Cow Manure. Waste And Biomass Valorization, 2019, 11, 5665-5678. [CrossRef]

- Heydari, B.; Sharghi, E. A.; Rafiee, S.; Mohtasebi, S. S. Use of artificial neural network and adaptive neuro-fuzzy inference system for prediction of biogas production from spearmint essential oil wastewater treatment in up-flow anaerobic sludge blanket reactor. Fuel, 2021, 306. [CrossRef]

- Phayungphan, K.; Rakmak, N.; Promraksa, A. Application of monod two-substrate kinetics with an intermediate for anaerobic co-digestion of distillery wastewater and molasses/glycerol waste in batch experiments. Water Practice and Technology, 2020, 15, 1068-1082. [CrossRef]

- Beale, M. H.; Hagan, M. T.; Demuth, H. B. Neural Network Toolbox: user's guide. 7th ed. Natick, MA, USA, 2010.

- Yetilmezsoy, K.; Turkdogan, F. I.; Temizel, I.; Gunay, A. Development of Ann-Based Models to Predict Biogas and Methane Productions in Anaerobic Treatment of Molasses Wastewater. International Journal of Green Energy, 2013, 10, 885-907. [CrossRef]

- Horta, A. C. L.; Zangirolami, T. C.; Nicoletti, M. C.; Montera, L.; Carmo, T. S.; Gonçalves, V. M. An Empirical Investigation of the Use of a Neural Network Committee for Identifying the Streptococcus pneumoniae Growth Phases in Batch Cultivations. Lecture Notes in Computer Science, 2008, 5027, 215-224. [CrossRef]

- Turkdogan-Aydinol, F. I.; Yetilmezsoy, K. A fuzzy-logic-based model to predict biogas and methane production rates in a pilot-scale mesophilic UASB reactor treating molasses wastewater. Journal of Hazardous Materials, 2010; 182, 460-471. [CrossRef]

| Assay | Distillery wastewater (%) | Molasses (%) | Glycerol (%) |

|---|---|---|---|

| 1 | 100 | 0 | 0 |

| 2 | 99 | 1 | 0 |

| 3 | 98 | 2 | 0 |

| 4 | 97 | 3 | 0 |

| 5 | 96 | 4 | 0 |

| 6 | 95 | 5 | 0 |

| 7 | 99 | 0 | 1 |

| 8 | 98 | 0 | 2 |

| 9 | 97 | 0 | 3 |

| 10 | 96 | 0 | 4 |

| 11 | 95 | 0 | 5 |

| Assay1 | Composition (%) | Accumulated Methane (mL) |

|---|---|---|

| 1 | 100 DW | 4580.44 |

| 2 | 99 DW + 1 ML | 4918.50 |

| 3 | 98 DW + 2 ML | 4963.33 |

| 4 | 97 DW + 3 ML | 4168.67 |

| 5 | 96 DW + 4 ML | 3992.97 |

| 6 | 95 DW + 5 ML | 4014.97 |

| 7 | 99 DW + 1 CG | 5744.64 |

| 8 | 95 DW + 5 CG | 5647.33 |

| Linguistic variable | Linguistic value | Standard deviation (σ) | |

|---|---|---|---|

| Time | Initial | 2.731 | 0.00077 |

| Very short | 2.730 | 6.428 | |

| Short | 2.730 | 12.860 | |

| Low medium | 2.731 | 19.280 | |

| Medium | 2.730 | 25.710 | |

| High medium | 2.730 | 32.140 | |

| Long | 2.730 | 38.570 | |

| Very long | 2.730 | 45.000 | |

| DW | Low | 0.0073 | 0.9483 |

| Medium | 0.0034 | 0.9768 | |

| High | 0.0029 | 1.0040 | |

| ML | Low | 0.0091 | -0.0016 |

| Medium | 0.0145 | 0.0250 | |

| High | 0.0163 | 0.0480 | |

| CG | Low | 0.0094 | -0.0013 |

| Medium | 0.0116 | 0.0238 | |

| High | 0.0106 | 0.0500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).