1. Introduction

The automotive industry has experienced remarkable advancements in recent years, with an increased emphasis on improving vehicle efficiency and reducing environmental impact. One critical aspect that significantly influences both driver comfort and energy consumption is the air conditioning (AC) system. Traditional vapour compression-based AC systems have been the primary choice for automotive applications for decades. However, their reliance on mechanical compression and the use of environmentally harmful refrigerants have spurred the exploration of alternative technologies.

In recent years, thermally driven air conditioning systems have gained considerable attention as a promising solution. These systems leverage waste heat or solar energy to drive the cooling process, presenting a viable and sustainable alternative to conventional AC systems. This review paper aims to provide a comprehensive overview of the advancements in air conditioning systems for automotive applications, with a special focus on adsorption systems [

1].

The primary objective of this review is to analyze the latest developments in adsorption AC technology. These systems utilize low-grade waste heat or renewable energy sources to drive the cooling cycle, reducing the dependency on mechanical compression and offer improved energy efficiency and environmental friendliness.

Throughout this paper, I will discuss the fundamental working principles, key components, and operating characteristics of adsorption AC systems. Additionally, I will delve into recent research studies, technological innovations, and commercialization efforts in this field. Emphasis will be placed on the potential benefits, challenges, and future prospects in the automotive sector.

Moreover, this review will explore the performance comparison between adsorption AC systems and conventional vapour compression-based systems in terms of cooling capacity, energy efficiency, environmental impact, and overall system integration. Special attention will be given to practical considerations, such as system size, weight, cost, and feasibility for mass production and integration into existing vehicle platforms.

By examining the current state-of-the-art for automotive applications, this review aims to provide researchers, engineers, and industry professionals with valuable insights into technological advancements and potential avenues for further research and development. The ultimate goal is to contribute to the ongoing efforts in improving vehicle sustainability, enhancing energy efficiency, and providing occupants with comfortable and environmentally friendly AC solutions.

Indeed, air conditioning in cars plays a crucial role in ensuring passenger comfort and safety. It helps maintain a comfortable temperature inside the vehicle, especially during hot and humid weather conditions. Effective air conditioning promotes driver alertness and concentration, leading to safer driving experiences. It also aids in preventing heat-related illnesses and fatigue among occupants, contributing to their overall well-being. Furthermore, air conditioning helps improve air quality by filtering out pollutants, allergens, and harmful particles, creating a healthier environment inside the car. In summary, air conditioning in cars is not just a luxury but a necessity, providing comfort, safety, and enhanced driving experiences for passengers.

Recently Kwon et al. [

2] offered an interesting overview of the issue. In their study authors emphasized the significance of thermal management in automobiles, particularly in the context of autonomous driving and electric vehicles. It identifies the need for research addressing changing mobility dynamics and proposes basic research directions. The study highlights environmental factors such as vehicle diversification, personalized air conditioning, and dynamic thermal management.

However, compression air conditioning systems dominate automotive applications due to their efficiency and widespread availability. They offer reliable cooling performance, even in extreme temperatures, making them ideal for automotive applications. Additionally, compression air conditioning systems are compatible with various types of vehicles, including hybrid, and electric vehicles. Their dominance in the automotive industry is attributed to their proven effectiveness, durability, and the extensive infrastructure supporting their maintenance and repair. For such a reason a lot of studies on specific technological aspects of these systems are available in the literature. For example, in [

3] the authors investigate the power consumption and energy efficiency issues of scroll compressors of car air conditioners caused by friction and explore the use of coating technology to improve the performance of the scroll compressor.

Indeed, the consumption and environmental impact of compression air conditioners in cars are significant concerns. These systems consume a lot of energy, increase fuel consumption, and contribute to greenhouse gas emissions. In [

4] the authors study the transition to eco-friendly refrigerants by investigating the performance of three refrigerants, R152a, R1234yf, and R134a, in an oil-free vapour compression refrigeration (VCR) system. As well known, the R134a has been commonly used in automotive air conditioning until 2022 when it has been banned due to its high global warming potential. R152a and R1234yf are potential low global warming potential alternatives. Experimental tests were conducted and the R152a exhibited higher volumetric efficiency, adiabatic efficiency, cooling capacity, and COP than R134a. Although R152a's flammability restricts its use in conventional automotive air conditioners, it is considered a more promising alternative for oil-free automotive air conditioning due to its high efficiency, lower cost, and reasonable safety level in the absence of oil lubricants. Also, Meng et al. [

5] studied alternative refrigerants for mobile air-conditioning. In this study, they evaluated the performance of a new refrigerant, R1234yf/R134a mixture (89:11 ratio), as an alternative to R134a in automotive air conditioning systems. The results indicate similar cooling and heating capacities between R1234yf/R134a and R134a. However, the COP of R1234yf/R134a is slightly lower by 4-9% in cooling mode and 4-16% in heating mode compared to R134a. R1234yf/R134a exhibits a significantly lower compressor discharge temperature than R134a. By adding 11% R134a, R1234yf/R134a becomes virtually non-flammable and meets environmental standards. R1234yf/R134a is a viable replacement for R134a in automotive air conditioning systems with minor modifications, even with lower performance.

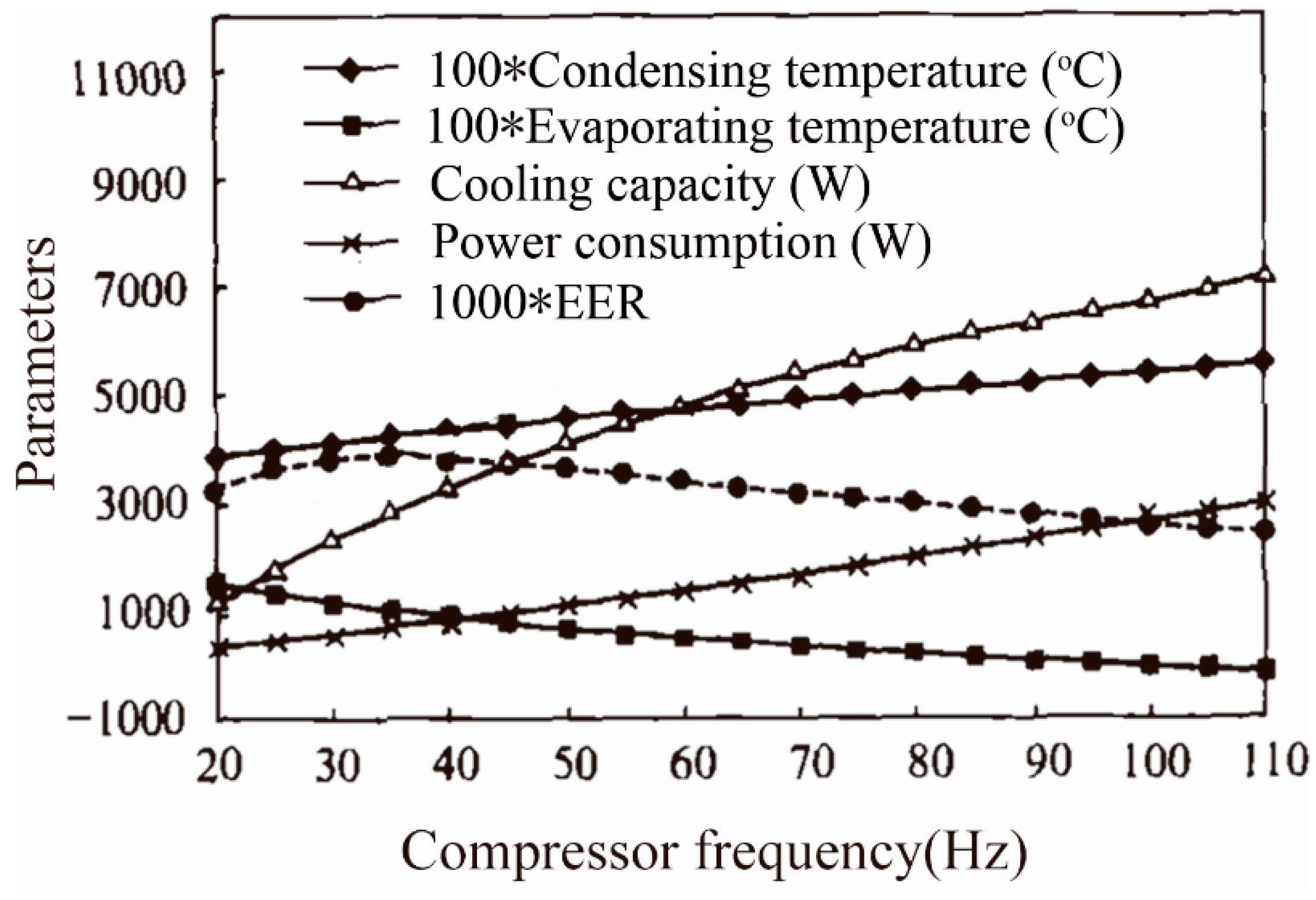

However, also novel technical solutions are investigated. In [

6] author compared the performances of an automotive air conditioning system equipped with a liquid-vapour separation micro-channel condenser and a common parallel flow micro-channel condenser (PFMC). Under normal running conditions, the proposed system exhibited a 5.18% higher cooling capacity and a 3.73% higher EER (Energy Efficiency Ratio) compared to the standard solution. Cola et al. [

7] investigated the factors influencing the length of the stable operating plateau in integrated receivers used in automotive air conditioning systems. They found that the receiver diameter and axial spacing between inlet and outlet holes have the most significant impact on receiver operation. These findings are used to develop a numerical model that accurately estimates the filling efficiency of the integrated receiver. The study highlights the importance of geometrical and thermodynamic conditions in optimizing the performance of the systems.

It is self-evident that a lot of efforts are being made to study, test and realize energy-efficient systems and for the transition to eco-friendly refrigerants. Stricter regulations and incentives drive the industry toward sustainability. The goal is to achieve efficient and environmentally responsible air conditioning in cars. In this direction, adsorption systems have an energetic edge over compression-based systems in automotive air conditioning. By utilizing waste heat from the Internal Combustion Engine (ICE), they dramatically reduce energy consumption and increase overall efficiency. With fewer moving parts and environmentally friendly refrigerants, they offer a sustainable and efficient cooling solution for vehicles. This review paper presents a comprehensive exploration of air conditioning systems for automotive applications, with a specific focus on the advancements and potential of adsorption systems. By examining the latest research, technologies, and future prospects, this review seeks to foster innovation and contribute to the advancement of sustainable and efficient AC solutions in the automotive industry.

2. The Impact of AC Systems on Fuel Consumption and Electric Vehicle Range

Air conditioning (AC) systems in vehicles, whether thermal or electric, have a significant impact on fuel consumption [

8] and the electric vehicle (EV) range [

9]. The operation of AC systems requires energy, which can be supplied by burning fuel in traditional combustion engines or drawing power from the vehicle's battery pack in electric vehicles. In combustion engine vehicles, AC systems are typically driven by the engine's mechanical power and rely on the engine's cooling system. The compressor, condenser, and other components consume additional energy from the engine, resulting in increased fuel consumption. The Society of Automotive Engineers (SAE) has conducted studies to quantify the impact of AC systems on fuel consumption in different driving conditions [

10]. According to SAE J1634 test procedures, AC usage can increase fuel consumption by up to 20% in urban driving and around 5-10% on highways.

Some modern vehicles feature electrically-driven AC systems that reduce the load on the engine and improve efficiency. These systems use electric motors to power the compressor instead of a belt connected to the engine. Electric AC systems can provide more precise control over the cooling process, reducing energy wastage. While exact fuel consumption data for vehicles with electric AC systems is limited, studies suggest potential fuel savings of up to 2-3% compared to traditional mechanical AC systems [

11].

In electric vehicles, the impact of AC systems on the driving range is more pronounced. AC systems draw power from the vehicle's battery, consuming energy that could otherwise be used for propulsion [

12]. Several factors influence the range reduction caused by AC usage, including outside temperature, desired cabin temperature, AC system efficiency, and vehicle speed. Studies conducted by the National Renewable Energy Laboratory (NREL) have evaluated the impact of AC usage on electric vehicle range [

13]. According to NREL's analysis, AC usage can result in a range reduction of approximately 5-20% depending on the aforementioned factors. Higher range reductions are observed in extreme temperatures and aggressive AC settings.

For such reasons, automakers and researchers are continuously working on improving the efficiency of AC systems and developing strategies to mitigate the impact on fuel consumption and electric vehicle range. These efforts include:

Advancements in compressor design and refrigerant technology to reduce energy consumption [

14,

15,

16,

17].

Integration of waste heat recovery systems to utilize excess heat from the AC system and reduce the load on the engine [

18].

Improved insulation and cabin temperature management techniques to minimize the need for extensive cooling or heating [

19,

20,

21].

Smart control algorithms and predictive thermal management systems to optimize AC usage based on driving conditions and driver preferences [

22,

23,

24].

It is worth being reported a 2016 study that analyzed the progresses in the air conditioning sector with a special focus on electrical vehicles. In [

25] the authors provided an extensive literature review of the advances made in heat pump air conditioning systems for electric vehicles. The authors carried out a double review: they started with a review of alternatives to environmentally harmful refrigerants, and then they went on to describe other innovative components such as inverter technology (see

Figure 1). The paper is also interesting because the authors provided a detailed analysis of the system structure of the heat pump air conditioning system. As an outcome, the paper presents the recent development in multiple source heat pump systems which can not only provide sufficient refrigerating capacity for the electric vehicle but also higher climate control system efficiency.

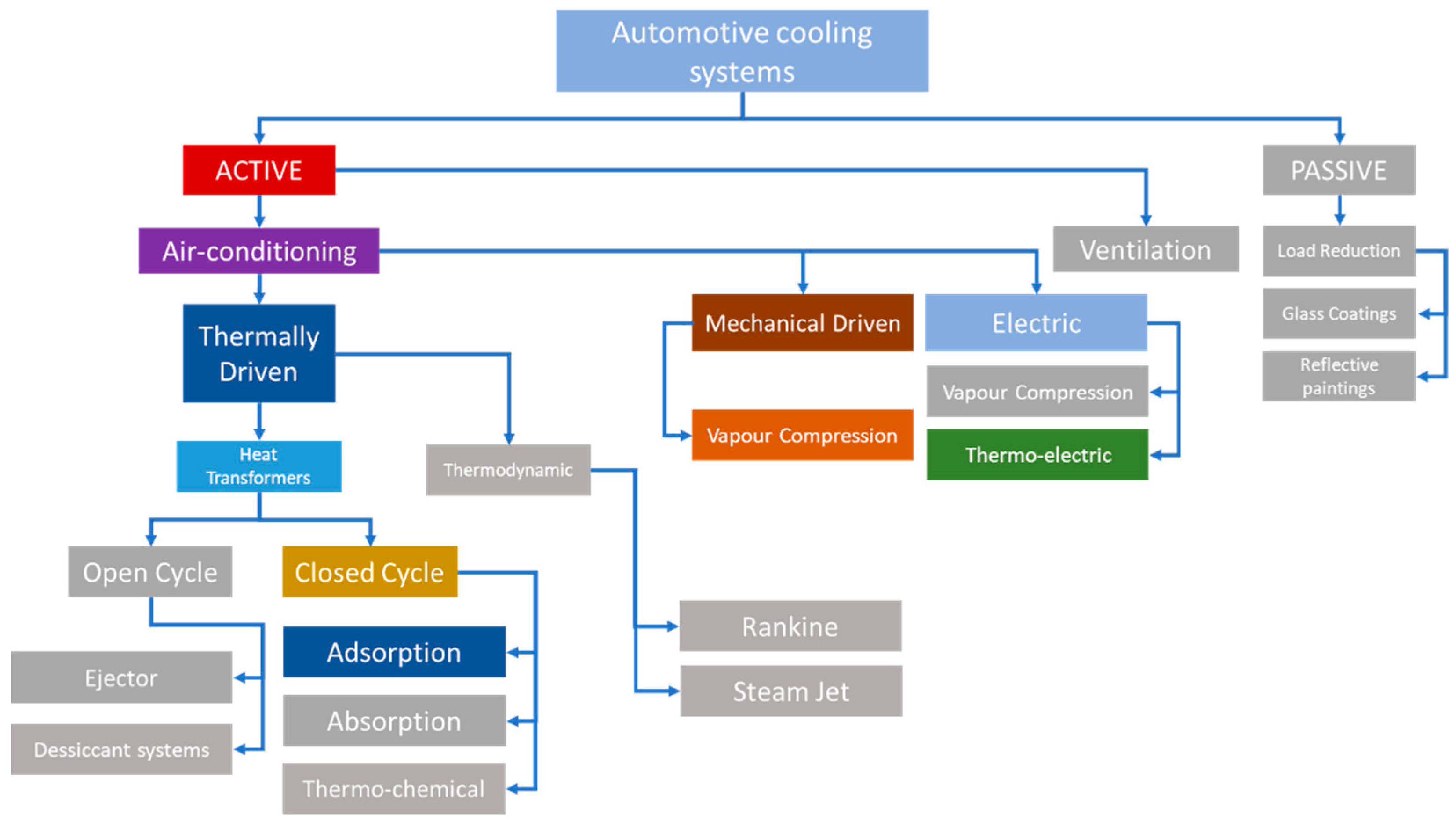

3. Classification of Air Conditioning Systems for Automotive Applications

Air conditioning (AC) systems for automotive applications can be classified based on various factors, including the cooling technology used, the source of energy or power, and the system's overall design and functionality. Here, I present a classification of air conditioning systems commonly employed in automotive applications:

Vapour Compression Systems

Vapour compression-based AC systems have been the traditional choice for automotive applications. These systems utilize a mechanical compressor, condenser, evaporator, and expansion valve to cool the air. They rely on refrigerants such as hydrofluorocarbons (HFCs) or hydrochlorofluorocarbons (HCFCs) for heat transfer.

Thermally driven AC systems utilize waste heat to drive the cooling process. They can be further categorized into:

Absorption Systems.

Adsorption Systems

Thermochemical Systems

Ejector systems.

Electric-Driven Systems

Electric-driven AC systems rely on electric power to operate the cooling cycle. These systems typically incorporate an electric compressor and refrigerant-based heat exchange components, similar to vapour compression systems. Electric-driven AC systems are commonly found in electric and hybrid vehicles where high-voltage electrical systems are available.

Hybrid AC systems combine different cooling technologies to optimize performance and efficiency. These systems often integrate vapour compression with thermally driven components to utilize waste heat, solar energy, or other renewable energy sources, while maintaining the benefits of mechanical compression when required.

Climate control systems are a passive (concerning the classification of

Figure 1) approach to provide more advanced functionalities, allowing precise temperature control, air distribution, and individual passenger comfort settings. These systems often incorporate multiple sensors, actuators, and control algorithms to optimize cabin comfort while minimizing energy consumption.

It's important to note that advancements and ongoing research in the field of automotive air conditioning continually introduce new technologies and variations. Therefore, this classification serves as a general framework to understand the different types of air conditioning systems commonly used in automotive applications.

4. Vapour compression systems

It is important to discuss the concept of vapour compression air conditioning before delving into adsorption units for mobile applications because it serves as the most traditional technique in automotive air conditioning technology. Moreover, understanding the concept of vapour compression air conditioning is essential before exploring newer and less proven technologies like the adsorption unit.

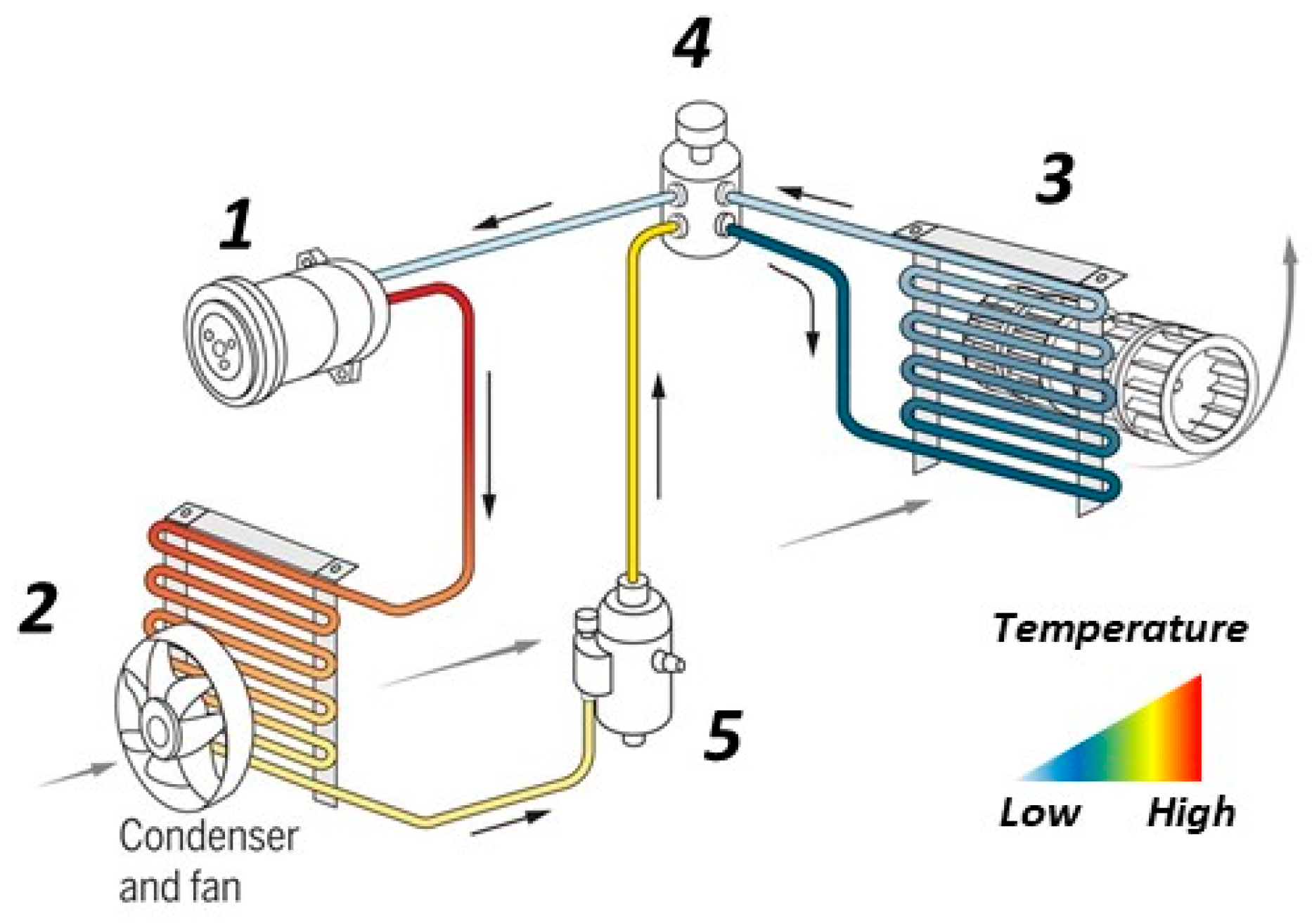

Vapour compression systems have long been the dominant choice for air conditioning in automotive applications due to their high cooling capacity and efficiency. Here are more details about vapour compression systems specifically designed for automotive use. Vapour compression systems for automotive applications consist of several key components (see

Figure 1)

Figure 3.

Vapour compression system key components: 1 - Compressor: The compressor is the heart of the system and is responsible for compressing the refrigerant vapour, increasing its pressure and temperature. 2 - Condenser: The condenser facilitates the transfer of heat from the refrigerant to the ambient air, resulting in the condensation of the refrigerant vapour into a liquid state.3 - Evaporator: The evaporator is located inside the vehicle cabin and allows the refrigerant to absorb heat from the air, thereby cooling the cabin. As the refrigerant evaporates, it transforms from a liquid to a vapour state. 4 Expansion Valve: The expansion valve regulates the flow of refrigerant from the high-pressure side to the low-pressure side, causing a drop-in pressure and temperature before entering the evaporator. 5 – Accumulator: refrigerant reservoir and dryer.

Figure 3.

Vapour compression system key components: 1 - Compressor: The compressor is the heart of the system and is responsible for compressing the refrigerant vapour, increasing its pressure and temperature. 2 - Condenser: The condenser facilitates the transfer of heat from the refrigerant to the ambient air, resulting in the condensation of the refrigerant vapour into a liquid state.3 - Evaporator: The evaporator is located inside the vehicle cabin and allows the refrigerant to absorb heat from the air, thereby cooling the cabin. As the refrigerant evaporates, it transforms from a liquid to a vapour state. 4 Expansion Valve: The expansion valve regulates the flow of refrigerant from the high-pressure side to the low-pressure side, causing a drop-in pressure and temperature before entering the evaporator. 5 – Accumulator: refrigerant reservoir and dryer.

The history of vapour compression air conditioning units for automobile applications dates back to the early 1900s. The first automobile air conditioning system was developed in 1930 by Packard, a luxury car manufacturer in the United States. The system was designed to cool the passenger compartment of the car by using a complex network of tubes and a compressor that operated on a refrigerant, which was circulated through the system.

Over the next several decades, automobile manufacturers continued to refine and improve air conditioning systems, making them more efficient and reliable. By the 1960s, air conditioning had become a standard feature in many cars, especially in the United States where hot summers make air conditioning a necessity.

The first modern air conditioning system for automobiles was introduced by General Motors in 1953. The system used a compressor, condenser, evapourator, and expansion valve to cool the passenger compartment. This was the first air conditioning system to use a refrigerant known as R-12, which was later replaced with R-134a due to environmental concerns [

26].

In the 1980s, automobile manufacturers began to introduce digital climate control systems, which allowed drivers to set the temperature and other settings with the push of a button. This technology became more advanced over time and is now standard in most new cars.

In recent years, there has been a renewed focus on improving the efficiency of automobile air conditioning systems due to concerns over global warming and rising fuel costs. Manufacturers have introduced systems that use less energy and refrigerants that have a lower impact on the environment.

Today, automobile air conditioning systems are an essential feature that has transformed the driving experience for millions of people around the world. Advances in technology continue to make these systems more efficient, reliable, and affordable, ensuring that they will remain a standard feature of automobiles for years to come.

Vapour compression systems for automotive applications historically used hydrofluorocarbons (HFCs) or hydrochlorofluorocarbons (HCFCs) as refrigerants. However, due to their high global warming potential (GWP), there has been a transition towards more environmentally friendly refrigerants. Common refrigerants used in automotive AC systems today include hydrofluoroolefins (HFOs) such as R1234yf, which have significantly lower GWPs compared to their predecessors.

Table 1 reports a comprehensive list of refrigerants widely used in automotive applications (1-5) as well as new refrigerants (6-9).

Increasing energy efficiency is a major focus in the development of automotive vapour compression systems. Efforts are made to optimize system design, improve component efficiency, and reduce power consumption. Variable displacement compressors, for example, adjust their capacity based on cooling demand, minimizing energy wastage during part-load conditions. Additionally, advancements in heat exchanger designs and refrigerant flow control contribute to enhanced system performance.

Modern vapour compression systems are integrated into the vehicle's control system, allowing for intelligent operation and precise temperature control. Temperature sensors strategically placed inside the cabin provide feedback to the system, enabling automatic adjustment of compressor speed, air distribution, and fan operation to maintain desired cabin temperature levels. These integrated controls optimize comfort while minimizing energy consumption.

In response to environmental concerns, efforts have been made to phase out or minimize the use of high-GWP refrigerants in vapour compression systems. Regulations such as the European Union's Mobile Air Conditioning (MAC) Directive and the United States' Significant New Alternatives Policy (SNAP) program have driven the adoption of low-GWP refrigerants. Automakers and AC system suppliers are actively working to ensure compliance with these regulations and promote sustainability.

Future developments in vapour compression systems for automotive applications are focused on improving overall system efficiency, reducing refrigerant charge, and advancing leak detection and mitigation technologies. Additionally, there is ongoing research into advanced heat exchanger designs, such as microchannel and parallel flow condensers and evaporators, which offer increased heat transfer efficiency and compactness.

By continuously improving vapour compression systems for automotive applications, manufacturers are striving to enhance passenger comfort, reduce energy consumption, and minimize environmental impact. These systems remain a crucial component in ensuring a comfortable and pleasant driving experience, particularly in conventional internal combustion engine vehicles.

5. Thermally Driven automotive air-conditioning systems

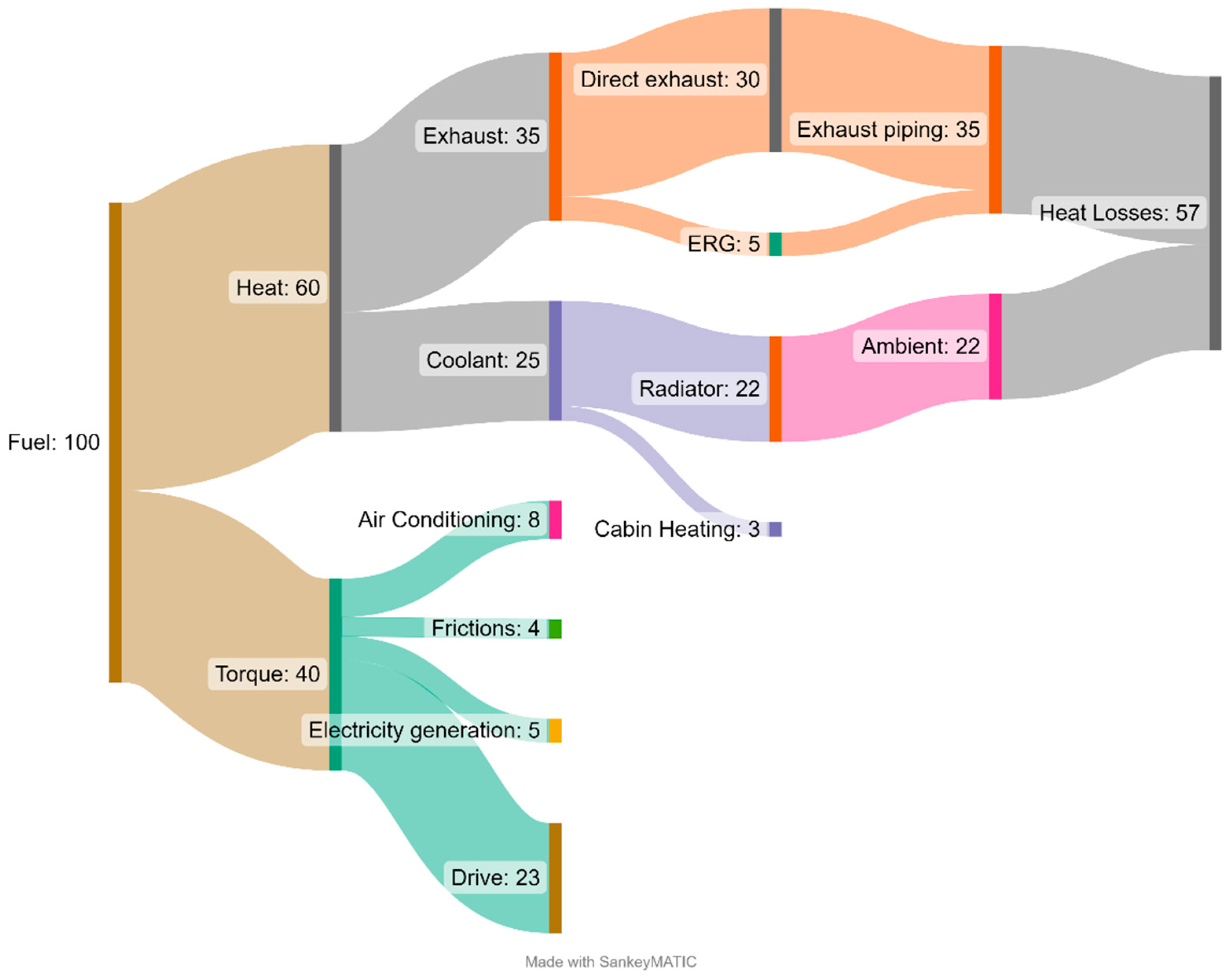

A significant amount of energy is lost in the internal combustion engines of automobiles. Most vehicles have an efficiency of 20-25%, with the highest recorded thermal efficiency being around 44% for a heavy-duty diesel engine [

37]. When accounting for drive, friction, and electronic parts, the total available heat loss is approximately 60-70% of the chemical energy of the fuel. Recovering waste heat from the combustion process can improve energy utilization [

38]. The immediate application of this waste heat recovery is in cabin climate control, which currently consumes a large amount of energy. Some heat-activated cooling processes that have been explored include thermoelectric systems, absorption cycles, and adsorption cycles. Different technologies have been developed for the recovery of exhaust gas waste heat, including organic Rankine cycles, turbocharger technology, etc. Waste heat from automobile engines can be recovered from two sources: waste heat from the engine coolant circuit and the thermal energy from the exhaust stream.

Figure 4.

Energy flow Sankey Diagram for an average car engine.

Figure 4.

Energy flow Sankey Diagram for an average car engine.

Maeda et al. [

39] reported the advantages and disadvantages of recovering the heat from the exhaust or coolant. They are summarized in the table below (

Table 2):

Then, while there are several advantages to recovering heat, there are also some disadvantages to consider. Other than the ones listed in

Table 1 the following additional have to be considered:

Energy Efficiency: Recovering waste heat from the coolant loop and exhaust gases provides an opportunity to utilize otherwise wasted energy. By using this heat to drive the air conditioning system, the overall energy efficiency of the vehicle can be significantly improved. This results in reduced fuel consumption and lower greenhouse gas emissions, making it an environmentally friendly solution.

Reduced Load on the Engine: Conventional air conditioning systems in vehicles are typically powered by the engine, which increases the load and decreases fuel efficiency. By recovering waste heat, the thermally driven air conditioning system lightens the load on the engine, allowing it to operate more efficiently. This can lead to improved overall vehicle performance and fuel economy.

Lower Operating Costs: Since thermally driven air conditioning systems utilize waste heat, they can potentially reduce the reliance on the vehicle's electrical system. This can result in lower operating costs, as the system does not draw power from the engine or the battery. Additionally, it reduces the strain on the vehicle's electrical system, potentially prolonging its lifespan.

Simplicity and Reliability: Thermally driven air conditioning systems are generally simpler in design compared to conventional air conditioning systems, as they do not require a compressor or refrigerant. This simplicity can lead to improved reliability, with fewer components that could potentially fail or require maintenance. It also simplifies the overall vehicle design and can result in weight reduction.

Limited Cooling Capacity: One of the main drawbacks of thermally driven air conditioning systems is their limited cooling capacity. The waste heat recovered from the coolant loop may not be sufficient to provide cooling in extreme conditions or larger vehicles. This can lead to reduced cooling performance, especially in hot climates, and may require additional cooling sources to supplement the system.

Heat Availability: The effectiveness of a thermally driven air conditioning system relies heavily on the availability and consistency of waste heat. In situations where the engine is not running, such as during idling or short stops, there may be insufficient heat available to drive the system. This can result in reduced or no cooling capabilities during these periods, which can be inconvenient for occupants.

Integration Challenges: Retrofitting existing vehicles with thermally driven air conditioning systems can be challenging due to the need for integration with the existing coolant loop and exhaust system. It may require modifications to the vehicle's design and infrastructure, potentially increasing the cost and complexity of implementation. However, in newly designed vehicles, these challenges can be addressed more effectively.

Limited Applicability: Thermally driven air conditioning systems are most effective in applications where waste heat is abundant and easily accessible, such as in long-haul trucks or heavy-duty vehicles. In smaller or more fuel-efficient vehicles, the amount of waste heat generated may be insufficient to provide significant cooling. Thus, the applicability of such systems may vary depending on the vehicle type and usage.

It is evident that recovering waste heat for driving thermally driven air conditioning systems in automotive applications offers several advantages. However, there are limitations and challenges to be explored. Careful consideration of these advantages and disadvantages is necessary to determine the feasibility

6. Adsorption air-conditioners.

As seen in the previous sections, adsorption air-conditioners (AAC), being a thermally-driven technology, have the potential to substitute vapour compression ones, where adsorber beds take the place of compressors. The operating principle of AAC centres around the phenomenon of sorption, in which a permeable solid material (adsorbent) traps a fluid (adsorbate) on its surface. Zeolite-water, silica gel-water, and activated carbon-methanol [

40] are some of the popular adsorption pairs employed in AAC [

41]. These materials have the added advantage of being cost-effective, eco-friendly, non-toxic, and non-corrosive.

Adsorbents are materials that contain tiny pores that can be as small as nanometers. while the substance that accumulates on its surface is called the adsorbate

Adsorption mechanisms are classified into physical and chemical types. Physical adsorption involves the use of intermolecular forces or Van der Waals forces, whereas chemical adsorption involves covalent or ionic forces between the adsorbent and the molecules. Chemical adsorption produces more heat as covalent or ionic bonding is typically stronger than Van der Waals bonding. Physical adsorption is reversible, while chemical adsorption is permanent [

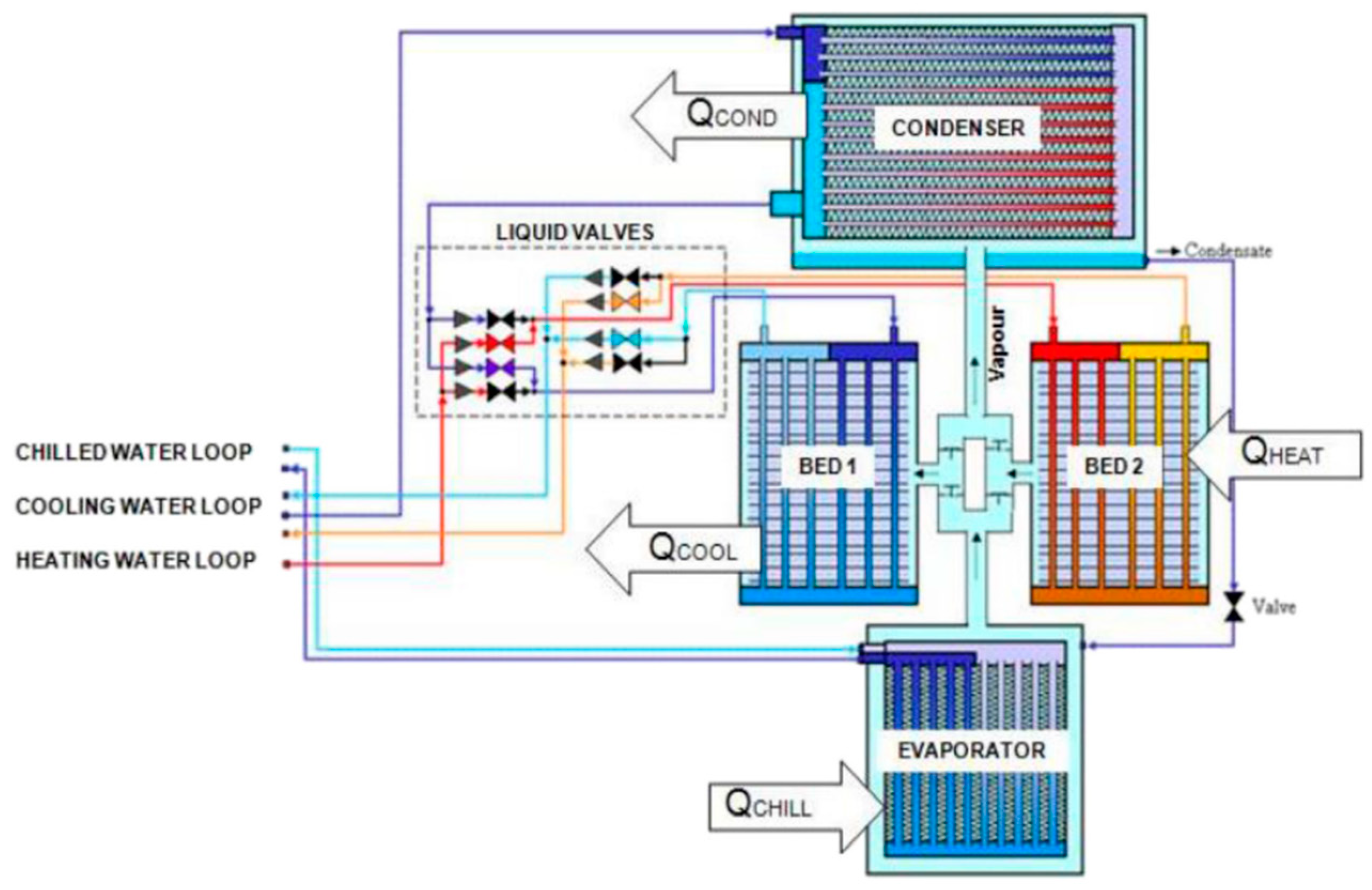

42]. A refrigeration or air conditioning adsorption cycle does not require mechanical energy but instead uses heat energy from a waste heat source, solar energy, or other heat sources. The cycle includes one or more adsorbers, a condenser, an evaporator and a heat source. This cycle is intermittent, but if more than one adsorber is utilized, it can be operated out of phase to produce a nearly continuous cooling effect [

43].

Various types of adsorption systems for different applications have been studied and experimented with over the last decades [

41,

44,

45,

46,

47] also focusing on specific mobile applications, such as trucks and vessels [

48,

49]. The adsorption cycle typically consists of the following steps:

Adsorption: The cycle begins with an adsorber, which contains a solid adsorbent material, often activated carbon, zeolite, or silica gel. The adsorbent has a high affinity for the refrigerant vapour. At low temperatures, the adsorbent attracts and retains the refrigerant vapour molecules on its surface, effectively adsorbing the vapour and releasing heat.

Desorption: The adsorbed vapour is then desorbed from the adsorbent material by raising its temperature. This is achieved by supplying heat from an external source, such as hot water or gas. The refrigerant vapour is released from the adsorbent surface, and the adsorbent material is regenerated.

Condensation: The desorbed refrigerant vapour is then condensed into a liquid state by transferring heat to a cooling medium, such as air or water. This process releases additional heat, which has to be dissipated in the ambient.

Expansion: The high-pressure liquid refrigerant is throttled through a valve, reducing its pressure, and transferred to the evaporator. This expansion process is different to the expansion valve in traditional refrigeration cycles.

Evaporation: The low-pressure, low-temperature refrigerant liquid absorbs heat from the surrounding environment (such as air or water) and evaporates, turning into a vapour. This heat absorption cools down the environment, making it suitable for air-conditioning in vehicles or other applications.

Adsorbent Regeneration: After the evaporation, the low-pressure refrigerant vapour returns to the adsorber where it is adsorbed again by the adsorbent material. The adsorption process generates heat which has to be dissipated (usually at the same temperature as the condensation heat) in the ambient. The cycle repeats as the adsorbent is regenerated and used for adsorption again.

Figure 5 reports the above-mentioned working phases of a closed adsorption thermodynamic cycle drawn on a Clapeyron diagram [

50]. During the desorption stage the adsorber or reactor, in which the adsorbent material is saturated with adsorbate, is regenerated by exploiting the waste heat coming from the engine, Q

1 + Q

2 (lines 1-2-3,

Figure 5). The desorbed vapour is then condensed in the condenser, and the heat of condensation, Q

c, is dissipated in the ambient, at the temperature of point E, through a radiator or an air-mass-cooled by a fan or direct air. Once the desorption process is completed and the adsorbent material is dry, the connection between the condenser and adsorber is closed. Afterwards, the connection between the evaporator and the adsorber is opened. During this phase, the refrigerant is evaporated adsorbing heat from the vehicle passenger compartment, Q

ev, or providing cooling to a specific on-board process (batteries’ cooling) at the temperature of point F in

Figure 5. Then, the vapour fluxes to the adsorber and, since the adsorption process is exothermic, the heat of adsorption is released, Q

3 + Q

4 (3-4-1). It is self-evident that in a double reactor system, working in counter-phase, the refrigerant is almost continuously condensed/evaporated in a closed system without any mass exchange with the ambient, thus ensuring a proper and reliable operation.

Considering the technical featured and the thermodynamic process involved and presented above, in the pursuit of more sustainable and energy-efficient cooling solutions for automotive applications, more researchers have turned their attention to adsorption technology for air-conditioning. However, the literature analysis here reported, and aimed to explore the potential of adsorption air-conditioning technology specifically for automotive use, highlighted a limited number of studies if compared to vapour compression technology. By analyzing existing research, identifying advancements, and highlighting challenges, this analysis seeks to evaluate the feasibility of employing adsorption air-conditioning as an efficient and eco-friendly cooling solution for automobiles.

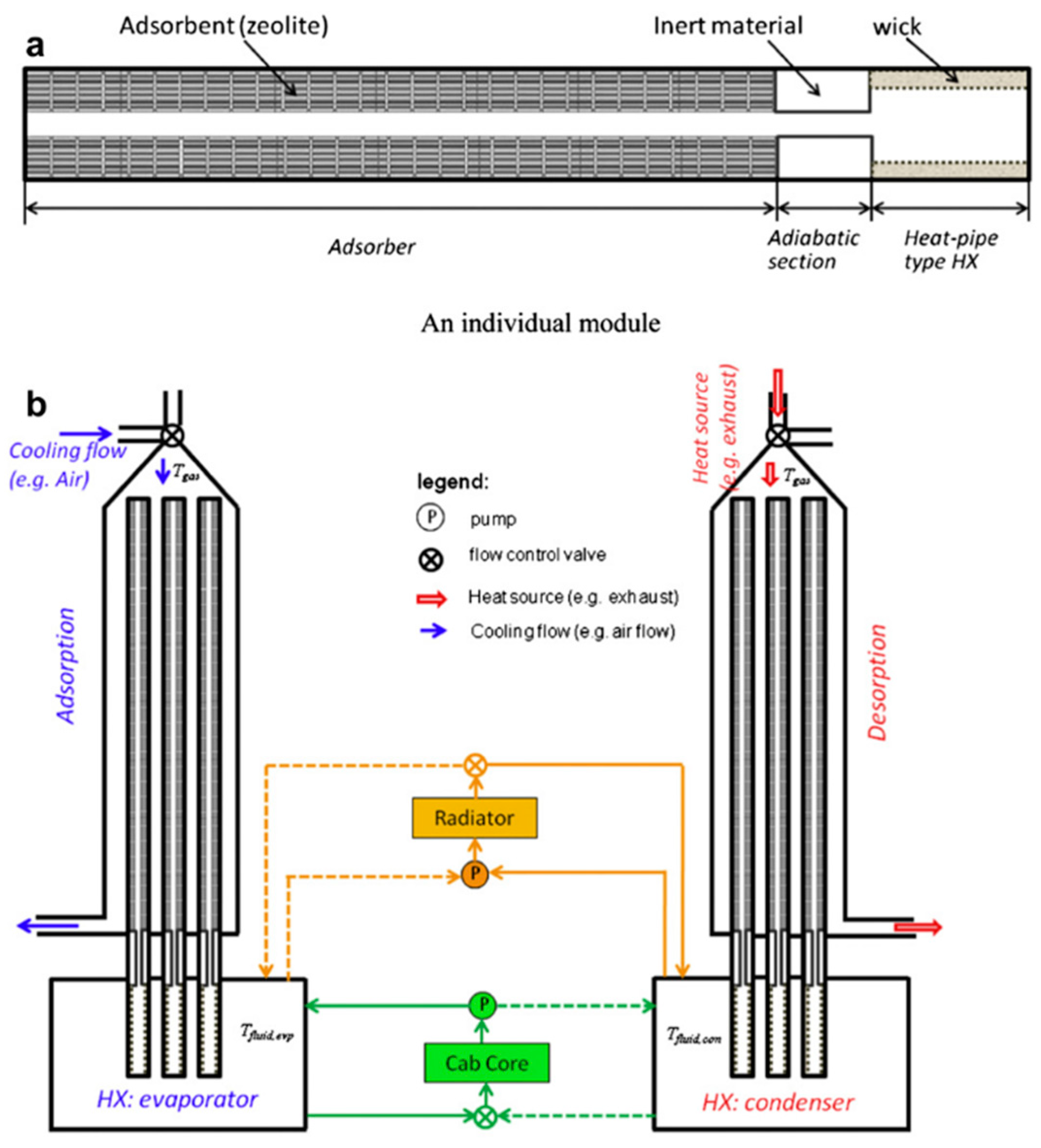

With this aim, in [

51] the authors present a proposal for an integration of an adsorption air-conditioning system into recent emission control devices for heavy-duty truck applications. As emission standards continue to evolve, there are additional heat sources available to drive cooling systems. Thus, Zhong at al. proposed an adsorption system (see

Figure 7) to both reduce engine emissions and improve overall energy efficiency, with the added benefit of reducing engine idle for long-haul vehicles. They reviewed the emission control components applicable to the adsorption system, presented a modular design of the system, and develops a model using zeolite and water as its working pair to study its dynamic performance and parametric effects. The results show that the cooling rate is greatly impacted by the mass transfer within the adsorber and increases as the adsorption rate increases. Additionally, there is a temperature transition during the transition between the adsorption and desorption phases. The heat transfer rate into or out of the adsorber reaches the maximum during this transition and then decreases as the process continues.

Moreover, they examined the system's adsorbent properties, operating temperatures, and cycle periods finding out that they can provide valuable design guidance. Interestingly, a shorter cycle period may result in low COP but provide a larger total cooling capacity for the vehicle. To minimize the required number of modules for a given cooling load, an optimal cycle period must be determined due to the system's performance decay.

However, also the mass of the adsorbent embedded in the reactor can heavily affect the overall performance. Indeed, in [

52] the authors a specific study on this issue. Indeed, in the field of vehicle air conditioning, the adsorption air-conditioners (ACS) weight and bulkiness prove significant challenges for their commercialization as eco-friendly alternatives to standard units. To try to answer this, Sharafian et al. assessed the impact of adsorbent mass and the number of adsorber beds on the performance of a FAM-Z02/water ACS under various operational conditions. Their experiments indicated that reducing FAM-Z02 mass from 1.9 to 0.5 kg significantly increases specific cooling power (SCP) by 82% from 65.8 to 119.4 W/kg at a 20-minute cycle time, but comes at the expense of a 37% decrease in coefficient of performance (COP) due to the rise in adsorber bed to adsorbent mass ratio. Moreover, findings demonstrate that the ACS's thermal mass limits its overall efficiency, particularly under shorter cycle times (i.e., 8-20 minutes). To ensure continuous cooling in the evaporator, a second adsorber bed is integrated into the initial ACS test bed containing one adsorber bed, and the results reveal an increase in SCP and COP by 28% and 47%, respectively, when comparing one and two-adsorber bed ACS packed with 0.5 kg of FAM-Z02 particles and a cycle time of 20 minutes.

Also, other technological aspects are of interest and have been investigated over the years. In this direction, for example, Sharafian et al [

53] investigated how the spacing of fins affects the distribution of temperature within a finned tube adsorber bed. The goal of their work was to minimize the adsorber bed to adsorbent mass ratio (AAMR) and reduce the temperature gradient within the adsorber bed for use in vehicle air conditioning applications. Finned tube adsorber beds offer superior specific cooling power, coefficient of performance, and low AAMR compared to other types of adsorber beds. To conduct the study, a single-adsorber bed ACS with interchangeable heat exchangers was built and fitted with hermetic-type T thermocouples. Two copper heat exchangers with custom-built fin spacing were packed with silica gel grains. Results of the study showed that decreasing fin spacing from 9.5 mm to 6.35mm resulted in a reduction of 4.6°C in the temperature difference between the fin and adsorbent during a cycle time of 600 s and adsorption to desorption time ratio (ADTR) of one. Shorter cycle times (600 s) showed a greater reduction in temperature gradient within the adsorber bed than longer cycle times (1400 s). The optimum fin spacing for a finned tube heat exchanger packed with silica gel grains was found to be approximately 6 mm based on a simultaneous comparison of the temperature gradient between the fins and AAMR against fin spacing.

Also, other studies proved that the design of the adsorber bed has a significant impact on the functioning of waste-heat-driven adsorption cooling systems for vehicle air conditioning. Indeed, it is necessary to size the adsorber beds specifically for vehicles taking into account the limitations of mobile applications. To this aim, the same research group also investigated the influence of the reactor design on the performance of an adsorption air-conditioner [

54]., They used some selected KPIs, such as specific cooling power, adsorber bed to adsorbent mass ratio, and coefficient of performance to evaluate the performance of ACS. The study was carried out through a review of existing literature. The analysis showed that a desired specific cooling power of 350 W/kg dry adsorbent and adsorber bed to adsorbent mass ratio of under one is necessary. They also highlighted how systems having a 2-adsorber bed and silica gel-water as working pair were common for ACS. The various adsorber bed designs examined were summarized into nine groups, with the finned tube adsorber bed design ultimately being selected. Practical solutions, such as optimizing fin spacing and height, and adding metal wool to enhance the thermal conductivity of the adsorbent material within the finned tube adsorber bed, are suggested to improve heat and mass transfer rates within the adsorber bed.

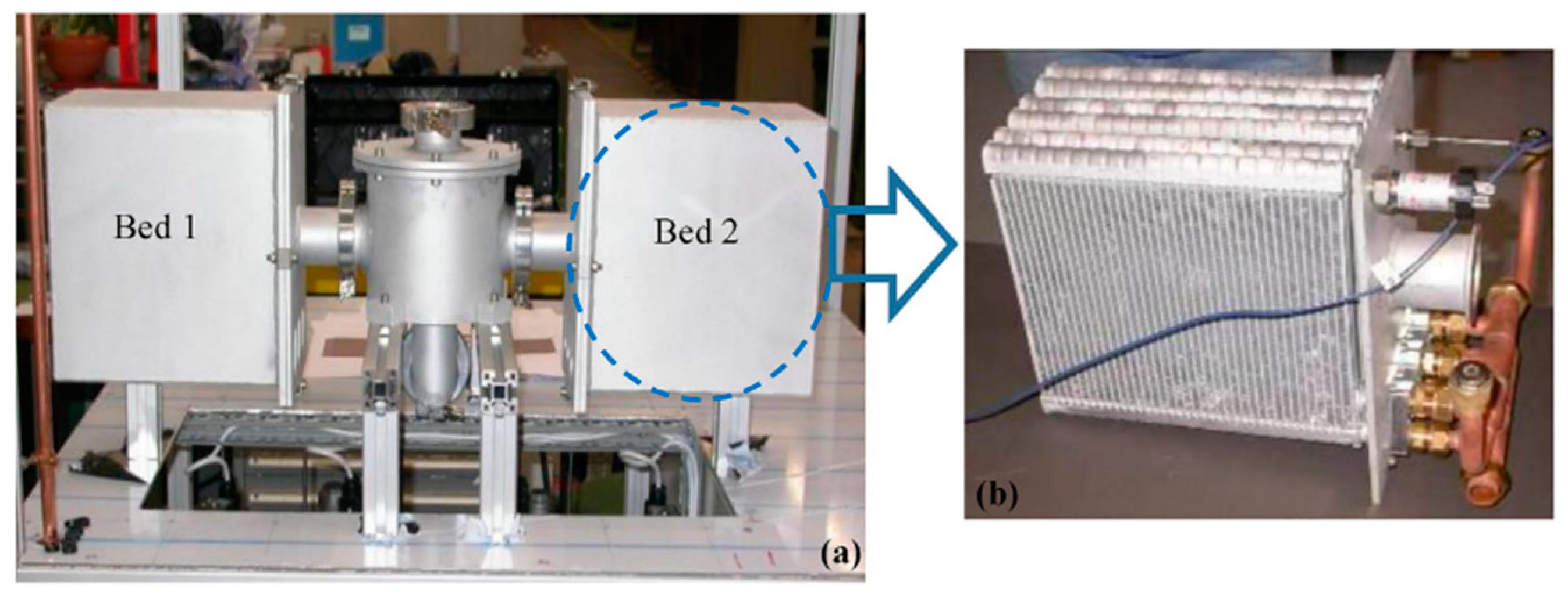

One of the most complete studies on ACS for automotive applications is the one presented by Verde et al. [

55]. The authors presented a two-part investigation. The first part involved both theoretical and experimental examinations of a two-bed, automotive-based silica gel adsorption chiller. A prototype adsorption system weighing around 86 kg was created and tested with low-grade waste heat. The single adsorbent bed had three plate-fin heat exchangers linked in parallel (

Figure 9).

Moreover, the authors developed a fully dynamic, non-equilibrium lumped parameter model to predict the system's transient performance while accounting for the mass transfer resistance and pressure drop for each system component (

Figure 8). The outcomes showed that the model could precisely forecast the system's dynamic performance under various operating conditions and setup modes while having a short calculation time. The tested chiller (see

Figure 9) was capable of generating an average cooling power of roughly 2.1 kW with a COP of 0.35 at the rated operating conditions. The heat recovery system caused a 43% increase in COP and a 4% increase in cooling power.

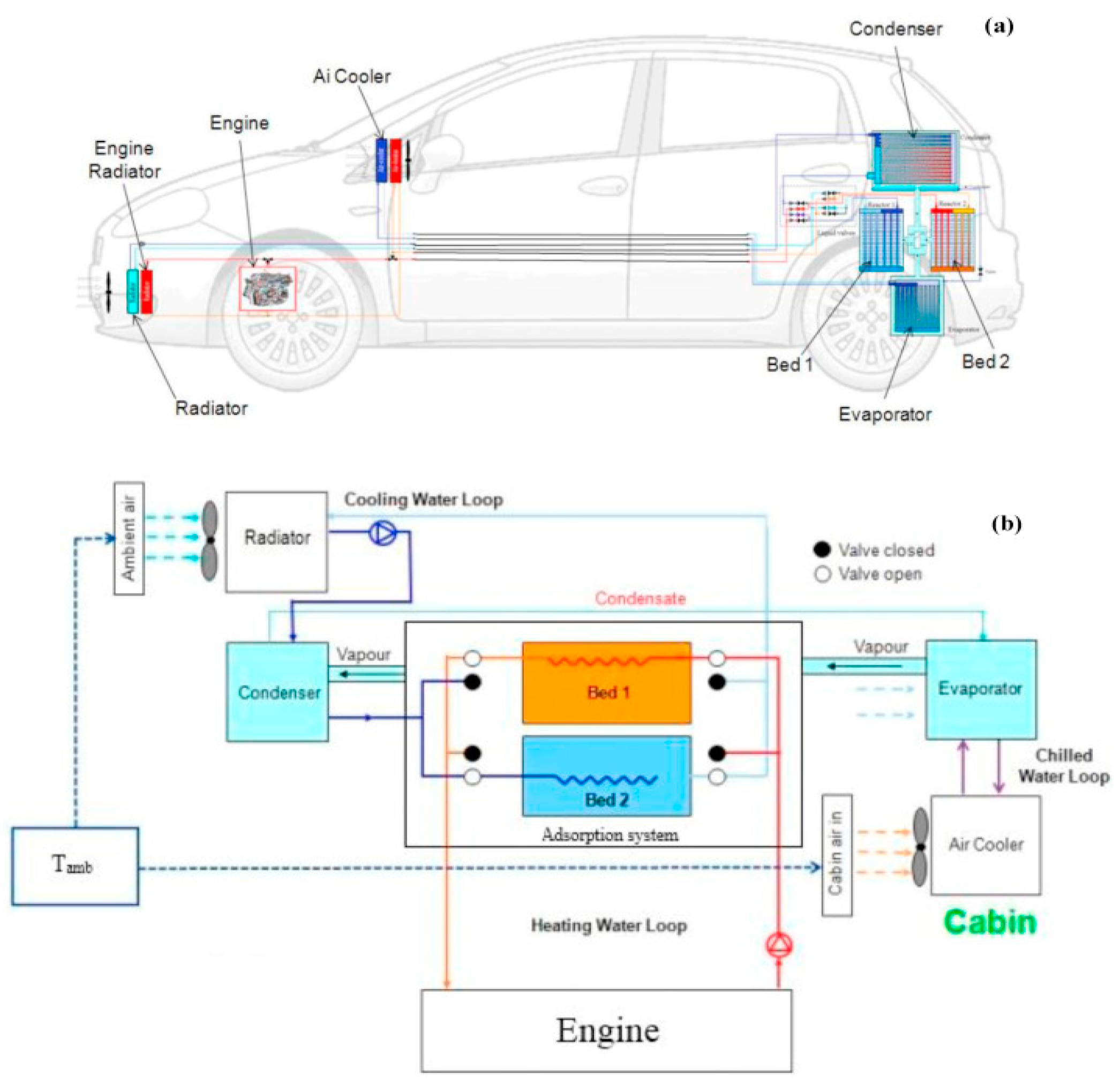

In the second part of their study [

56] Verde et al. validated the model from Part I and integrated it into a comprehensive vehicle model to anticipate the system's efficiency during actual driving situations. The overall model considered all system elements to simulate the dynamic system performance and predict the available waste heat for regulating cabin temperature. Experimental tests on the Fiat Grande Punto vehicle were conducted at the Centro Ricerche Fiat (CRF), Italy labs, exploring different design configurations for improved performance.

Figure 10 shows a scheme of the system installed into the car and the general lay-out of the adsorption unit tested. Results showed that the model accurately predicted the system's transient performance in various start-up and ambient conditions, as well as normal operating conditions. Installing two radiators instead of one increased cooling capacity by 7.0% and decreased cabin temperature by 9.1%. However, the adsorption system faced difficulties producing cooling during the warming-up period. The research confirmed that there is adequate engine waste heat available to provide sufficient cooling for reasonably comfortable cabin temperatures.

This last study was supported by an intense models activity, reported in [

57]. The research aimed to determine the ideal geometrical and thermal parameters of a flat tube-fin adsorbent bed through an analytical model to achieve optimal performance: indeed, the design and performance of an adsorbent bed have a significant impact on the overall efficiency of adsorption systems. Flat tube-fin heat exchangers have advantages such as decreased weight, cost, volume, and thermal conductivity, which make them a suitable choice for automobile adsorbent bed applications. The study found that reducing the flat tube thickness and fin pitch, along with increasing fin and water channel wall thickness, improved both the overall thermal conductance of the bed and the maximum practical specific cooling capacity. Furthermore, decreasing the channel pitch enhanced the specific thermal conductance. Of all the thermal parameters examined, adsorbent thermal conductivity was found to be the most sensitive factor affecting the specific thermal conductance of beds. The system's performance improved significantly when reducing the mass of the metal bed and heat transfer fluids, as well as the desorption heat of the selected working pair.

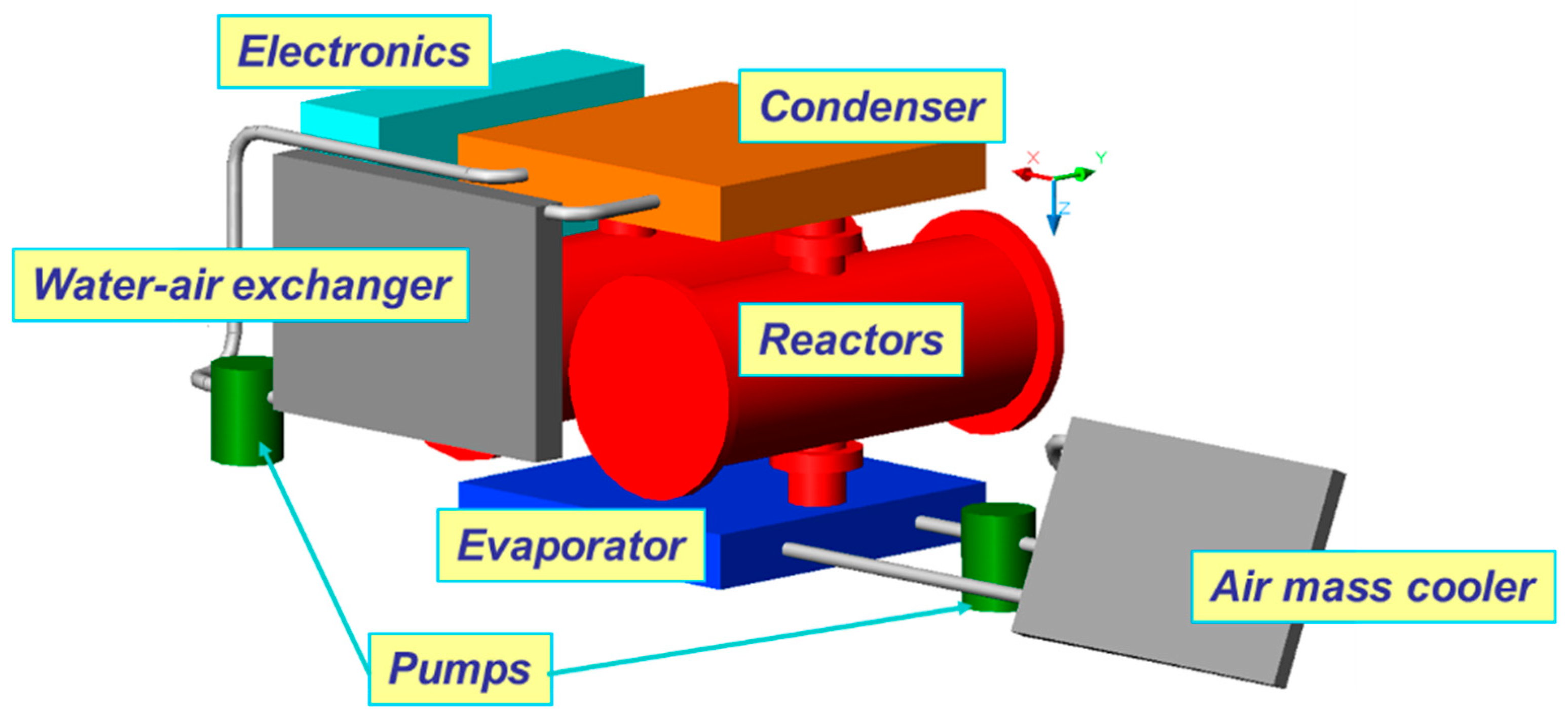

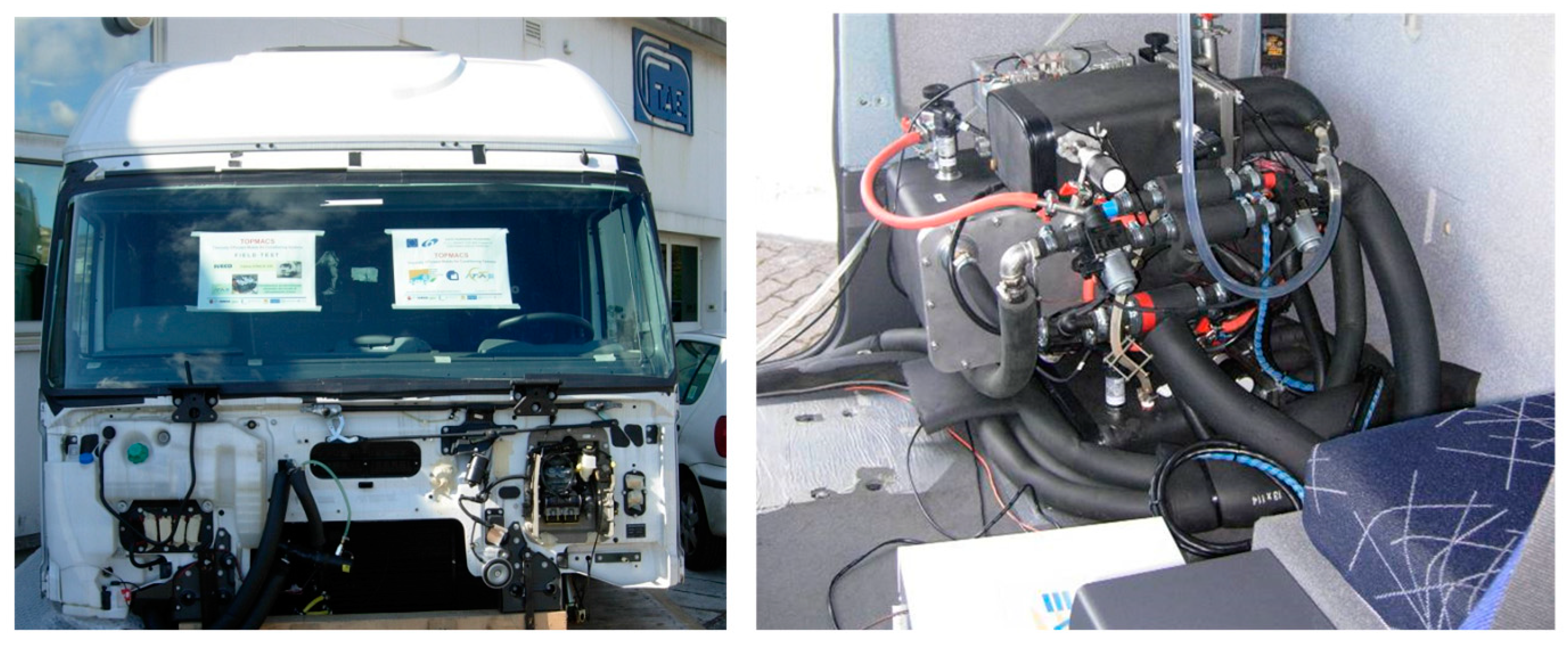

Within the same project, another research group developed and tested a compact adsorption unit designed for the installation of large trucks [

58]. In the paper, the authors examined a mobile adsorption chiller as a cooling solution for truck cabins, with a focus on its experimental performance. The unit was developed by CNR – ITAE and featured a double-bed adsorber linked to an evaporator and condenser, which utilizes the low-grade thermal energy generated by the engine coolant loop. The machine had an overall volume of 170 dm3 and a weight of 60 kg. Initial testing of the chiller's performance was conducted under typical EU car air conditioning conditions, determining an Average Cooling Power ACP of 1–2.3 kW and Cooling COP of 0.25–0.45 at a desorption temperature of approx. 90°C (Tev ∼ 8–14°C and Tcon ∼ 28–35°C). The chiller was then integrated into an IVECO STRALIS truck cabin and tested in a laboratory setting, demonstrating its ability to provide cooling comfort to passengers (see

Figure 11). This was achieved by simulating the engine cooling loop through an ideal heat source.

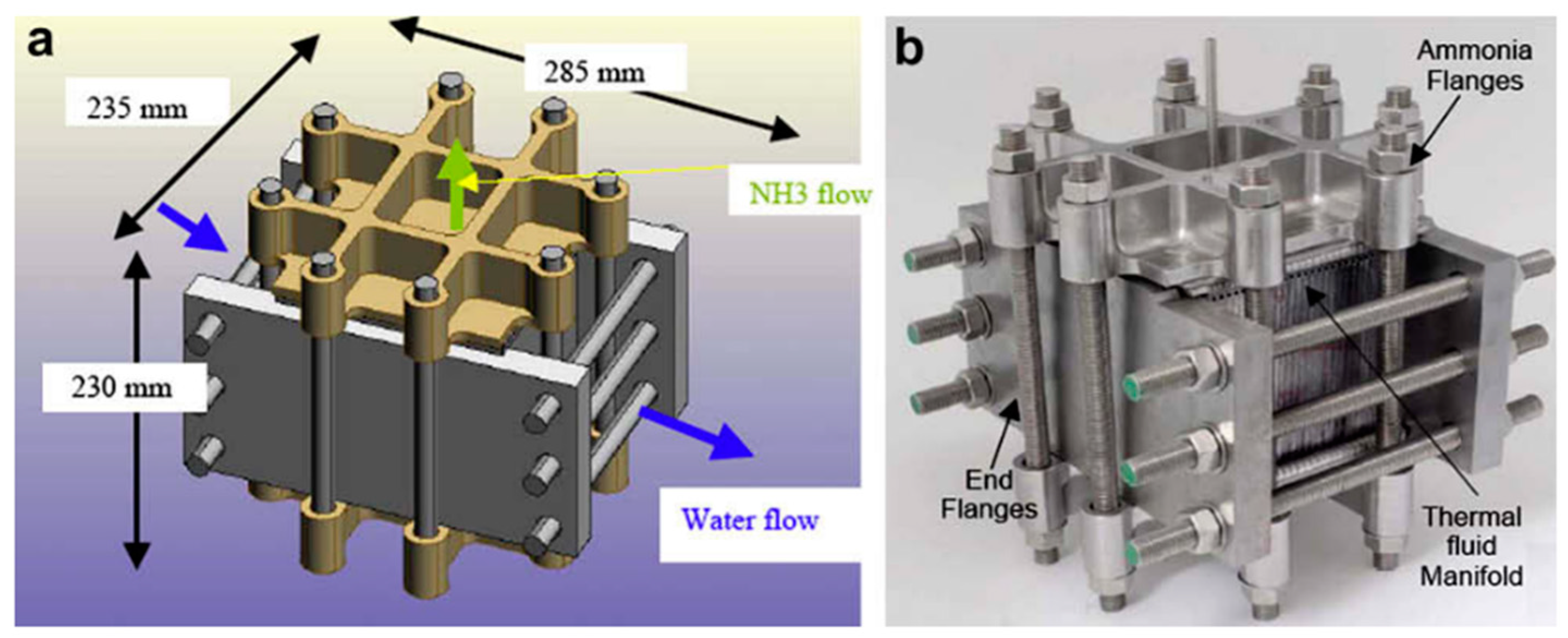

Also, Tamainot-Telto et al. proposed a novel compact adsorption unit for automotive air-conditioning [

59]. The authors developed a compact generator prototype that utilizes activated carbon and ammonia as working pair and is based on the plate heat exchanger concept (see

Figure 12). This innovative generator boasts a low thermal mass and effective heat transfer capabilities. The heat exchanger consists of nickel-brazed shims and spacers, which create thin adsorbent layers (measuring only 4 mm) between pairs of liquid flow channels with minimal thermal mass. The sorption generator prototype was evaluated under EU car air conditioning test conditions: when powered by waste heat from engine coolant water at 90 °C, two of the current prototype generators (loaded with approximately 1 kg of activated carbon) operating out of phase produced an average cooling power of 1.6 kW with 2 kW peaks. The typical average coefficient of performance (COP) obtained is 0.22.

The four above-mentioned studies belong to the same EU-funded project [

60] whose main results have been summarized in [

38].

Another study focused on the impact of fin spacing on the performance of gas-driven adsorption units for heavy trucks. Golparvar et al, [

61] demonstrated how the performance of ACS heavily relies on the design of the adsorber bed heat exchangers (ABHEx). Indeed, according to the authors’ findings, the dynamic behaviour of ACS is directly influenced by the response time of ABHEx, as they undergo significant temperature swings to derive refrigerant. The authors developed a detailed three-dimensional non-equilibrium model to investigate the heat and mass transfer effects in zeolite-13x particle-filled annular and longitudinal finned tube adsorber beds.

The study focused on studying the impact of fin height and spacing on the operating parameters of the system to identify an optimal fin geometry. Simulation results indicate that decreasing fin spacing leads to a decrease in the coefficient of performance (COP) and an increase in the specific cooling power (SCP). The results revealed that, under similar dimensions and operating conditions, ACS employing annular finned tube ABHEx provides a 10% higher total cooling power than ACS with longitudinal finned tube ABHEx at the optimum fin spacing. It is worth highlighting that Golparvar et al. found that implementing ACS with optimized ABHEx in trucks has the potential to save approximately 370 L of fuel consumption annually and reduce greenhouse gas emissions by up to 738 kg CO2e. These findings emphasize the significance of ABHEx design in enhancing the performance and energy efficiency of ACS, thereby contributing to fuel savings and environmental sustainability in heavy-duty vehicle air conditioning systems.

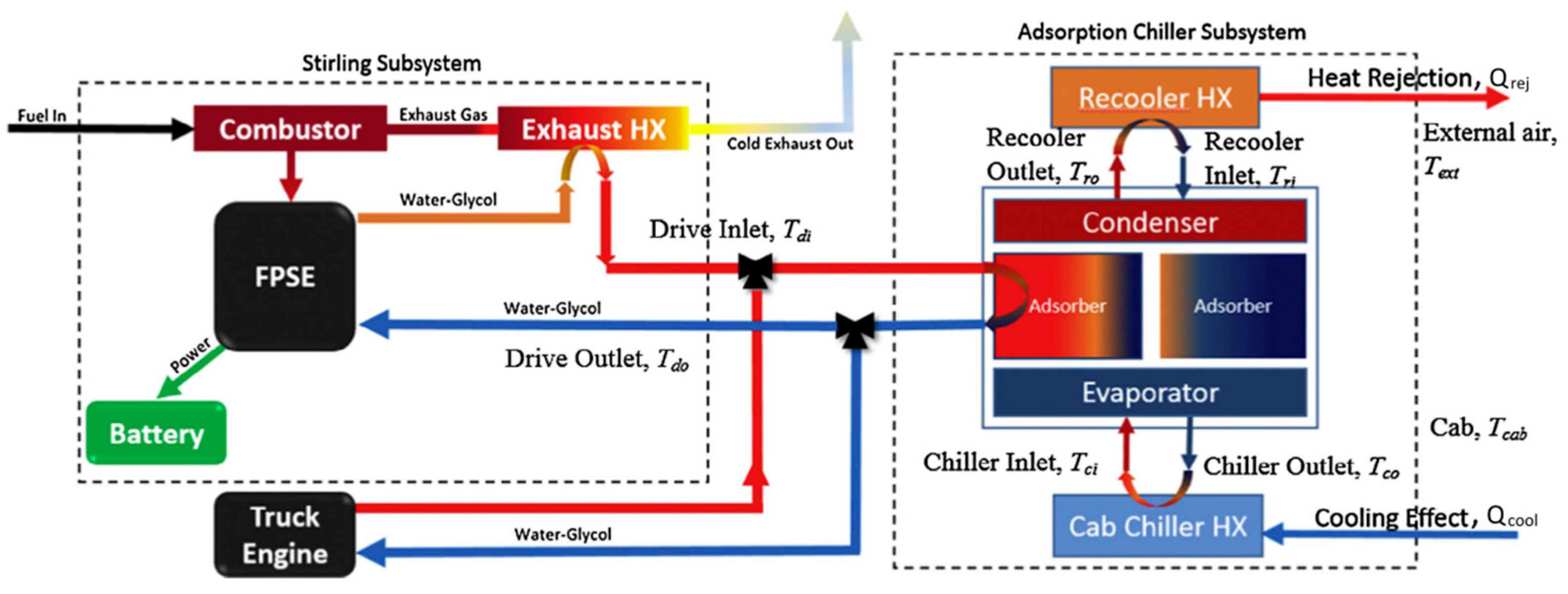

It is worth noticing that research has been sometime addressed also in solving different “on-board” issues for trucks and other heavy-duty transport units. For example, in [

62,

63], the authors firstly identified the key technical requirements of a heavy truck auxiliary power unit (APU) and then explored a potential new technology to replace the current diesel engine-vapour compression APUs, which are known to cause issues related to emissions, noise, and maintenance. They investigated the potential performance of a novel hybrid Stirling engine-adsorption chiller system and compared it to the current technology using experimental data. The

Figure 13 shows a scheme of the proposed concept. The results of a prototype SAS test rig demonstrated that the system was capable of an average COP of 0.42 ± 0.06 and 2.3 ± 0.1 kWt of cooling capacity. The study also demonstrated that there are no significant technological barriers preventing the adoption of the proposed concept, which could offer reduced emissions, noise, maintenance, and fuel flexibility with increased reliability. Preliminary modelling results indicate that the proposed system could offer superior overall electrical and cooling efficiencies compared to incumbent APUs, with a payback period lower than 5 years.

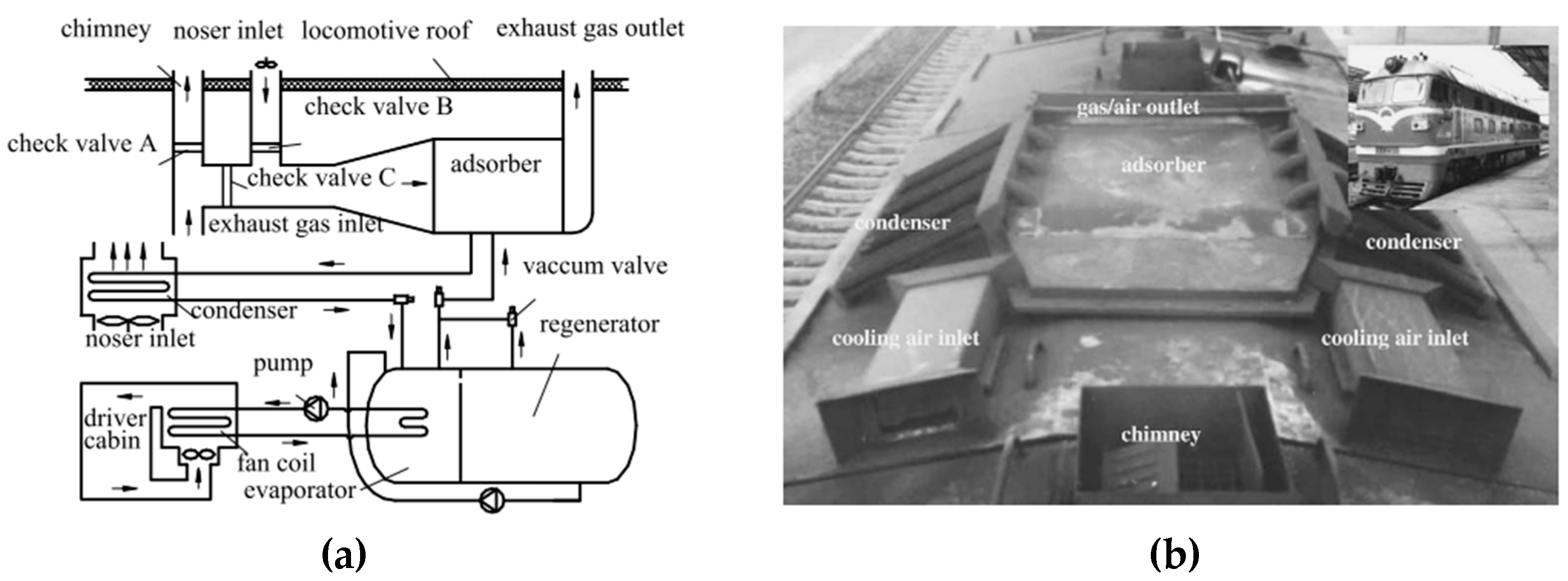

In 2001, Jiangzhou, Wang et al. [

64] developed and tested an adsorber air-conditioning system for a locomotive driver-cabin. The prototype developed is shown in

Figure 14. They proved that the system can provide a constant refrigeration capacity during the desorption stage, which simplifies the entire system. Therefore, this system can be practically applied to cool the driver-cabin. The desorption period can be optimized to improve system performance, especially by increasing the adsorption time over the desorption time. The study provided the following interesting evidence:

The adsorption and desorption temperatures affect the COP significantly.

The condensing temperature is less sensitive to the COP of a zeolite-water adsorption system than an activated carbon-methanol adsorption system.

The system's performance can be enhanced by optimizing mass transfer within the adsorber, and an air-cooled condenser may be used.

A well-designed evaporator can fuel refrigeration capacity output.

The use of adiabatic and cooling adsorption processes can provide additional refrigeration capacity for immediate space cooling,

The adsorber can function as another regenerator if there is a refrigeration capacity deficit.

Finally, their tests highlighted that at actual operating conditions, the heating power and flow rates of cooling air are significantly higher than experimental conditions, making heating and cooling adsorber processes more efficient and decreasing the total circulation period, thus increasing refrigeration capacity.

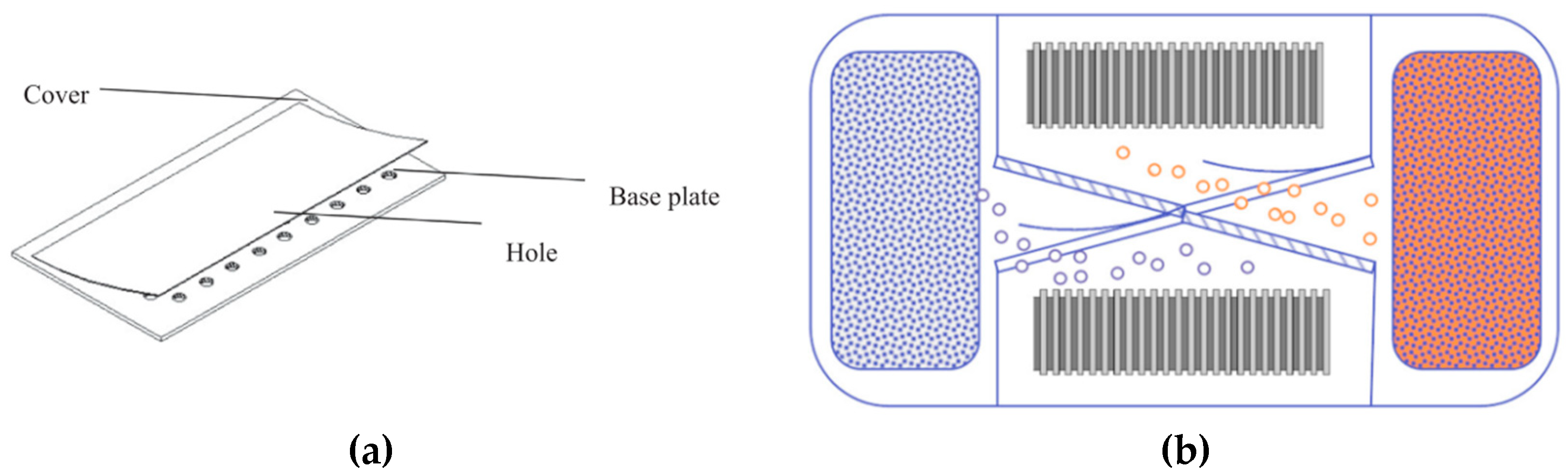

However, while installation on heavy goods transport vehicles does not pose particular size and weight limits, installation inside passenger transport vehicles, even small ones, poses new challenges as the size of most adsorption chillers can limit their application in the automotive industry. To overcome this issue, in [

65] the authors presented a compact adsorption chiller that meets the specific requirements of automobile installation and has a volume of approximately 40 L. Authors highlighted how the size of the adsorption chiller is often significantly increased by the use of off-the-shelf vacuum valves, resulting in four high vacuum valves for the two adsorbers, evapourator, and condenser. For such a reason they developed an innovative flap-based valve regulated by the difference in pressure at both ends (see

Figure 15 a). Cooling power and coefficient of performance were evaluated by analyzing the inlet and outlet temperatures of the evapourator, as well as the flow rate of chilled water and cycled time. The prototype adsorption chiller had a maximum cooling power output of around 1.5 kW at a driving temperature of 368 K and a cycle time of 90 seconds.

Also, Sharafian et al. proposed an innovative design both for the expansion valve and the control valve of an automotive adsorption air-conditioner [

66]. Their idea was to reduce the weight and parasitic power consumption of an adsorption cooling system (ACS) for vehicle air conditioning by implementing two new expansion valve and control valves. These ideas include a check valve for the expansion valve with a cracking pressure of 3.5-7 kPa and a combination of low cracking pressure check valves and solenoid valves for the control valves. These designs were tested on a two-adsorber bed silica gel/CaCl2-water ACS under various operating conditions, resulting in a 10.5 kg reduction in total mass and a 50% decrease in parasitic power consumption of the control valves. Their tests proved that the expansion valve and control valves functioned effectively under specific temperature ranges for the heating and cooling fluid inlet, coolant water inlet, and chilled water inlet. Additionally, they developed a numerical model of the ACS thermodynamic cycle showing that increasing the adsorber bed heat transfer coefficient and surface area can increase the specific cooling power of the system up to six times.

However, also the performance of the adsorbent material used in an adsorption air-conditioner, especially if designed for mobile applications, plays a crucial role in determining the overall efficiency and effectiveness of the system. The adsorbent material serves as the key component responsible for adsorbing and desorbing the refrigerant, thus facilitating the heat transfer process and achieving cooling. Some key features affect the performance of the adsorption units:

Adsorption Capacity: A high adsorption capacity allows for a greater amount of refrigerant to be adsorbed onto the material's surface, resulting in improved cooling performance. Adsorbents with a higher adsorption capacity can achieve higher cooling capacities and better overall efficiency.

Desorption Temperature: An ideal adsorbent material should have a desorption temperature that matches well with the available heat source.

Thermal Conductivity: A higher thermal conductivity allows for better heat transfer between the refrigerant and the adsorbent, leading to faster adsorption and desorption rates. Improved heat transfer enhances the chiller's overall efficiency and performance.

Stability and Durability: Adsorption chillers operate through repeated cycles of adsorption and desorption, subjecting the material to temperature and pressure variations. An adsorbent material with excellent stability and durability can maintain its performance over an extended period, minimizing degradation and ensuring consistent efficiency.

It’s self-evident that the performance characteristics of the adsorbent material directly influence the overall efficiency and effectiveness of an adsorption chiller. That’s why the ongoing research and development efforts focus on optimizing adsorbent materials to further improve the performance and efficiency of adsorption air-conditioners.

To accomplish this task, the researchers at the Laboratory for Alternative Energy Conversion (LAEC), of the School of Mechatronic Systems Engineering at Simon Fraser University, studied the impact of the reactor design on the water uptake of a zeolitic material for an adsorption air-conditioner for vehicles [

67]. In their study, they highlighted how the performance of an ACS can be significantly influenced by the design of the adsorber bed by focusing on measuring the water uptake rate of AQSOA FAM-Z02 zeolite, packed in two different adsorber beds, under adsorption and desorption temperatures of 30 and 90 °C, with water vapour supplied at 20 °C. They found that various parameters (heat transfer, fluid density changes, the flexibility of the hosing connected to the adsorber bed, etc.) have a notable impact on adsorbate uptake measurements. To mitigate these undesired effects, they employed a two-step mass measurement method to accurately determine the adsorbate uptake rate and validated it by comparing the equilibrium water uptake of AQSOA FAM-Z02 zeolite with available literature data obtained from the thermogravimetric analysis. The water uptake of zeolitic material was measured for different cycle times to calculate the specific cooling power (SCP) and coefficient of performance (COP). The results demonstrate that a well-designed adsorber bed for automotive applications should have a high heat transfer surface area and small fin spacing.

Another study [

68] investigated the potentialities of Metal-organic frameworks (MOFs). These materials represent a new class of adsorbent materials that exhibit remarkable properties such as a substantial surface area, a significant pore volume, a uniform pore size, and highly adjustable structural characteristics. While numerous MOFs have been developed primarily for gas storage applications, only a limited number have been explored for their potential in water adsorption heat pumping applications. In this study, the authors focused on investigating the viability of utilizing a commercially available MOF known as CPO-27(Ni) for automotive adsorption air conditioning. The investigation involves dynamic modelling and experimental testing to assess the performance of this MOF. To evaluate the performance of CPO-27(Ni) under different operating conditions, Shi et al. developed a single-bed adsorption system and a Simulink model to simulate the operation of a two-bed adsorption system with a cooling capacity of 2.4 kW, specifically designed for automotive air conditioning. The results obtained from the study indicate that the adsorption air conditioning system utilizing CPO-27(Ni) achieves a specific cooling power (SCP) of 440 W/kg and a coefficient of performance (COP) of 0.456 when the desorption temperature reaches 130°C, which can be obtained through the utilization of the engine's exhaust gas. Furthermore, they conducted a comparison between the performance of CPO-27(Ni) and the ones achieved by using the advanced zeolite SAPO-34. The comparison demonstrated that CPO-27(Ni) outperformed SAPO-34, delivering a 42% higher SCP value, thus leading to a more compact air conditioning system. The research emphasized the potential application of MOF materials in automotive air conditioning systems, showcasing their capacity to enhance performance and efficiency in this context.

In [

69] Wang et al. analysed different pairs adsorbent/refrigerant for adsorption air conditioners for electric vehicles. Indeed, authors highlihghted how the use of traditional compression air conditioners on electric vehicles leads to a significant drain on the battery's power, resulting in reduced range, while intermittent sorption and resorption cycle energy storage phases could be employed to fix the issue. These cycles have a simpler design, requiring only two heat exchangers compared to conventional ACs. Equilibrium performance analysis revealed that resorption cycles have higher energy density and coefficient of performance (COP) than sorption cycles, given both have the same high temperature salt for resorption and halide for sorption. CaCl2-NH4Cl-NH3 performed the best compared to MnCl2-CaCl2-NH3 and MnCl2-NH4Cl-NH3, demonstrating a 160% energy density improvement and a minimum COP increase of 35%. Comparing CaCl2-NH4Cl-NH3 with CaCl2-NH3 revealed similar minimum energy density, but CaCl2-NH4Cl-NH3 performed better in terms of COP considering year-round working conditions. The energy requirements for electric cars with resorption ACs ranged from 0.23-0.265 kWh/km, which is an acceptable level compared to conventional ACs.

Finally, hybrid air-conditioning systems are becoming increasingly popular within the scientific community [

70,

71,

72,

73,

74], and they possess great potential for automotive applications due to their energy efficiency and reliability. These systems use a combination of adsorption and compression to create a cooling effect, making them ideal for use in small or confined spaces. When used together, the adsorption and compression elements of a hybrid air-conditioning system create a highly efficient cooling system that is ideal for mobile applications. These systems are suitable for commercial trucks, RVs, and boats, where space is limited and energy efficiency is crucial. As already proved in the previous sections, the thermal management system is an essential aspect of vehicles, primarily relying on a vapour compression refrigeration system. However, an adsorption air-conditioning system which possesses the ability to recover battery waste heat is limited in its continuous operation. To bridge this gap, the authors in [

75] tried to merge the benefits of both vapour compression and adsorption technology: they proposed a vapour compression-adsorption thermal management system (VCATMS) to tackle the cooling/preheating load and reduce electricity consumption. Their system provides waste heat recovery for battery cooling in summer and preheating in winter, plucking from a variety of working fluid pairs. They proved that the best performance is achieved with the activated carbon (AC)-R410A working fluid pair, given its exceptional equilibrium adsorption characteristics. With this system, up to 31.3 kJ and 67 kJ of electricity can be saved in recovery mode during summer and preheating mode in winter, respectively. Additionally, the battery can be preheated to 30°C in extreme sub-zero temperatures of around without consuming any electricity.

7. Limitations of adsorption air-conditioners.

As seen in the previous sections, adsorption air conditioners offer a unique alternative to standard air conditioning systems in automotive applications. While these systems have several advantages, they also come with certain limitations that need to be considered.

Moreover, it is a well-known fact that adsorption systems or chillers have existed for many decades, even predating mechanical vapour compression (MVC) systems. However, they have not been able to replace MVC systems. The use of adsorption systems in automotive air conditioning benefits from the availability of waste heat, but this advantage will be significantly impacted by the rise of electric vehicles. On the other hand, internal combustion engine-driven vehicles are expected to remain in use for the foreseeable future, and the potential success of adsorption cooling systems in automotive air conditioning could breathe new life into the industry by offering improved fuel efficiency and environmental benefits. However, the study presented above highlighted how it is essential to consider vehicle adsorption systems separately from stationary chillers, as they operate in different domains and are subject to space and weight constraints. Following, I will highlights the limitations of adsorption air conditioners for automotive applications in comparison to standard systems that emerged in this study:

Capacity density: One of the primary limitations of adsorption air conditioners is their lower cooling capacity density compared to standard systems. Adsorption technology relies on the desorption of water vapour from a solid material and this process is slower and less efficient than the compression and expansion of refrigerant gases used in standard air conditioners. As a result, adsorption systems may struggle to provide adequate cooling performance, especially in extremely hot climates or under heavy load conditions or they may rusult in bulk and heavy systems that could impact with integration process in small vehicles, even though the industry has made significant advancements to address this issue: compact and efficient evapourator designs [

76], compact or innovative adsorber heat exchangers [

77,

78], the introduction of composite adsorbents [

79,

80], etc. Reported capacity density values for adsorption systems range from 70 to 110 W/kg (based on different studies [

81,

82,

83]), while a typical VC system has an energy higher than 520 W/kg [

82]. In terms of volumetric energy density, reported values are lower than 27 W/m3 [

83]. Also, external piping and valves, which size and weight increase with the capacity, contribute to reducing the capacity density. A solutions for such a issue may be represented by the integration of the heat pipe technology for heat exchange into high power air conditioners [

84]. However, there is a need for further improvement in the capacity density of adsorption systems. It is important to note that conventional terminologies, for example the specific cooling power (SCP) based on dry mass, can be misleading. Instead, specific energy density based on the total mass or volume of the system should be used, and a fair comparison with conventional VC systems should be made when appropriate.

Size and Weight: when comparing the size and weight of adsorption systems to compression-based systems for automotive applications, there are notable differences to consider. Adsorption systems tend to be bulkier and heavier than their compression counterparts. This is primarily due to the adsorbent material used in adsorption systems, which requires a larger exchanger surface area for efficient cooling [

85]. As a result, adsorption systems often require larger components and additional space for the adsorption and desorption processes to take place effectively. This increased size and weight can pose challenges in automotive applications, where space and weight constraints are crucial considerations for vehicle design and performance. On the other hand, compression-based systems, such as mechanical vapour compression (MVC) systems, have undergone significant miniaturization and optimization over the years [

86]. They have been engineered to be more compact and lightweight, making them a preferred choice for automotive air conditioning applications. These systems leverage the efficiency of compression and expansion cycles, which can be achieved with smaller components and less material. The size and weight limitations of adsorption systems can impact the overall design and performance of vehicles. They may require more space for installation and could add extra weight, potentially affecting fuel efficiency and vehicle handling. In contrast, compression systems offer more flexibility in terms of integration and can be designed to fit within the available space and weight restrictions of a vehicle. While efforts have been made to reduce the size and weight of adsorption systems through advancements in technology, they still tend to lag behind compression-based systems in this aspect. As a result, the size and weight considerations remain a significant limitation for adsorption systems in automotive applications, where compactness and lightweight solutions are highly valued.

Response Time: Adsorption air conditioners typically have a longer response time compared to standard systems. Adsorption and desorption processes take time to occur, resulting in slower cooling performance when the system is first activated. This delay can be problematic in situations where quick cooling is necessary, such as when entering a hot vehicle or during short stops. Moreover, another property of the adsorbent materials affects the response time: adsorption kinetic. The adsorption kinetic in adsorption air-conditioners is primarily determined by the properties of the adsorbent material, its shape and its physical status. The adsorbent should have a large surface area and strong adsorption affinity for the refrigerant being targeted. Additionally, the adsorbent should be able to maintain its structural integrity over many adsorption-desorption cycles to ensure that it provides long-term performance. In terms of adsorption kinetics, the rate at which the refrigerant (usually water) molecules are adsorbed onto the adsorbent material is a key factor in determining the overall efficiency, the cycle time and the specific cooling capacity of the adsorption air conditioners [

87,

88].

Limited Operating Conditions: in automotive applications, closed-cycle adsorption systems face certain limitations in terms of their operating conditions when compared to vapour compression systems. These limitations arise from the fundamental differences in the underlying principles of these two cooling technologies. Vapour compression systems, allow for a wide range of operating conditions, including varying temperatures, making them adaptable to different environmental conditions and user preferences. The compressors in these systems can adjust their speed and capacity, providing precise control over cooling output. On the other hand, adsorption systems utilize the adsorption and desorption of a working substance that selectively adsorbs the adsorbate (water vapour) at low temperatures and desorbs it at higher temperatures: this process drives the cooling effect in the system. One of the limitations of adsorption systems in automotive applications is their dependence on specific operating conditions for efficient performance[

89], [

90]. The adsorbent material used in the system has a limited range of temperatures at which it can effectively adsorb and desorb the adsorbate[

91]. This restricts the operating temperature range of the system, limiting its adaptability to varying ambient temperatures and user preferences. Moreover, efficient adsorption systems often require high desorption temperatures to release the adsorbed refrigerant effectively. Achieving these high temperatures can be challenging in automotive applications, especially considering the limited temperature of waste heat sources available in some conditions such as start-up and idle operations.

Reliability: when evaluating reliability, it has been reported that adsorption systems can effectively function for many years [

92], while adsorbent materials are capable of thousand of cycles [

93]. It is important to note, however, that the systems presented in the last references are not suitable for automobile air conditioning due to the harsh operational environment. Vibrations, sudden impacts, and high temperatures can all potentially damage the adsorber heat exchanger. Therefore, sintered or firmly coated adsorber heat exchangers may be preferable to the conventional wire-mesh packing method [

94,

95,

96]. Also, exchangers realised of plastic material, if well-engineered, can represent an effective breakthrough for reliability and lifetime increase [

97]. In addition, the high-temperature environment can negatively impact the adsorption process which is highly dependent on the coolant temperature.

Economic aspects: The production cost of adsorption air-conditioners for automotive applications can vary depending on various factors, and it is generally higher than conventional systems. Recently, Al Hasni and Santori provided the average cost breakdown for an adsorption chiller [

98]. They showed that, Although adsorption chillers are more environmentally sustainable than other types of chillers, their price-performance trade-off makes it difficult for them to capture a significant share of the air-conditioner system. The authors also highlighted that the emphasis in research so far has been on improving performance, without adequately considering whether this would lead to reduced manufacturing costs. To address this gap, they estimated the manufacturing cost and end-user price of Silica gel adsorption chillers. The analysis is extended across different COP and SCP combinations and identifies a minimum annual selling volume of 14 units. The particular manufacturing process used for the production of adsorption air conditioners also plays a role in determining the cost. The cost of a particular manufacturing process, such as batch production or continuous production, depends on the equipment needed, the level of automation, and the time it takes to complete the process. Also, Their results assessed the economic viability of adsorption chillers with advanced adsorption materials, such as Metal-Organic Frameworks (MOFs) and advanced zeolites, which do not compete, for the moment, with Silica gel chillers in cost thus future innovative adsorption materials should be compared to Silica gel using the correlations they presented in their study.

Non-technical aspects: current development of adsorption systems for automobile air-conditioning is predominantly conducted through laboratory or project-based research. However, for this technology to progress and gain acceptance on a wider scale, active involvement and support from the car manufacturing industry are crucial. In addition, it is important for authorities to provide support and incentives to push forward new technologies. For instance, renewable energy technologies like solar PV and hybrid vehicles gained widespread acceptance through government incentives during their early introduction. Similarly, adsorption systems for automobile air-conditioning could benefit from similar support from authorities.

In summary, while adsorption air conditioners offer some advantages, such as their environmentally friendly operation and potential energy savings during the adsorption process, they also have significant limitations. These limitations include lower cooling capacity, larger size and weight, longer response time, sensitivity to operating conditions, potentially lower overall energy efficiency, and higher maintenance and cost requirements.

In a direct comparison of adsorption systems and conventional vapour compression systems for automobile air conditioning, adsorption units appear to be inferior to conventional systems in numerous aspects. Despite this, the adsorption system's potential to enhance fuel economy and environmental friendliness are its vital features. However, these potentials cannot be realized without facing negative aspects such as the need for improved capacity density and reduced cost. In addition, while electric vehicle numbers increase, they no longer have waste heat as traditional engines do, and energy rejection by battery packs may not be sufficient to drive a thermal system: the extensive use of adsorption systems in vehicles may be further impeded.

These factors need to be carefully considered when evaluating the suitability of adsorption air conditioners for automotive applications, especially in comparison to standard air conditioning systems.

8. The issue of electric vehicles: other active Air Conditioning technologies.

As electric vehicles (EVs) gain prominence in the automotive industry, the need for efficient and effective air conditioning (AC) technologies specifically designed for these vehicles becomes increasingly important. Active air conditioning technologies play a crucial role in providing cabin comfort, optimizing energy consumption, and extending the range of electric vehicles. Active AC technologies tailored for EVs are:

Electric compressor systems are widely used in EVs and work similarly to their counterparts in conventional vehicles. They consist of an electric compressor, condenser, evapourator, and expansion valve. The electric compressor is driven by the vehicle's high-voltage electrical system, enabling independent operation from the internal combustion engine. This allows for efficient cooling even when the vehicle is stationary or during low-speed operation. Similarly, heat pump systems are designed to provide both heating and cooling capabilities for EVs. These systems utilize the principles of refrigeration in reverse, extracting heat from the ambient air or waste heat sources and transferring it to the cabin during cold weather conditions. Heat pumps improve energy efficiency by utilizing the heat already available rather than relying solely on electrical energy for heating.

Thermal storage systems employ phase-change materials (PCMs) to store and release thermal energy [

99]. These systems can pre-condition the vehicle's cabin by absorbing excess heat during charging or discharging cycles. PCMs can store and release heat efficiently, reducing the need for continuous energy consumption during driving, thereby extending the vehicle's range. Also, adsorption-base cold storage devices have high energy density and can be used for both heat and cold release in the automotive sector. However, there have been only a few studies on small and compact systems for mobile applications using low-temperature sources [

100].

Solar-powered ventilation systems utilize photovoltaic (PV) cells installed on the vehicle's roof or windows to convert solar energy into electrical energy. This energy is used to power ventilation fans that extract hot air from the cabin, thereby reducing the temperature buildup while the vehicle is parked. Solar-powered ventilation enhances passenger comfort upon entry and reduces the need for excessive energy consumption from the vehicle's battery for cooling [

101,

102].

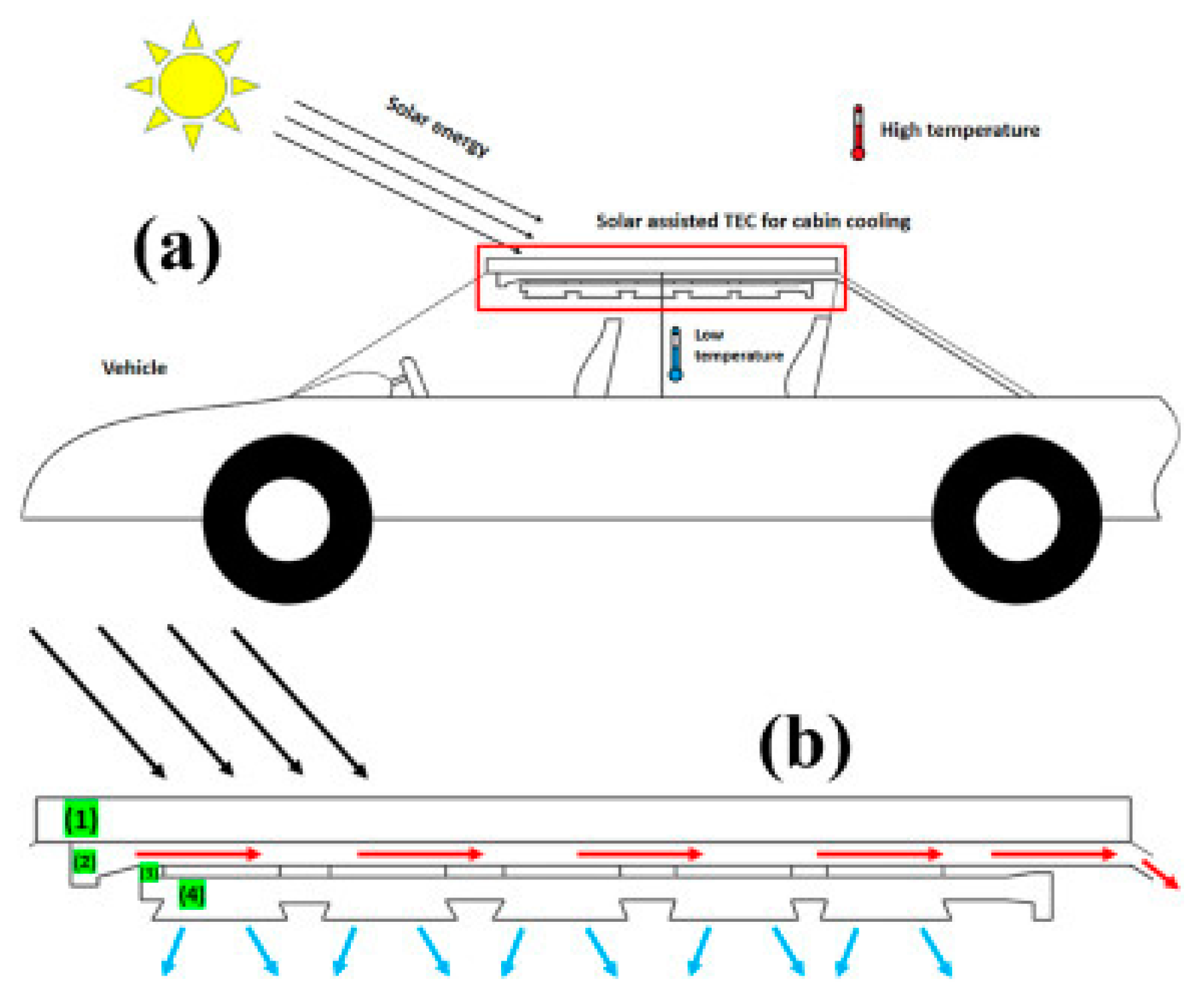

Thermoelectric systems deserve a separate paragraph as I believe they have enormous potential in the field of air conditioning for motor vehicles. Furthermore, technological progress is closely linked to the progress of semiconductor technology, and this bodes well. Thermoelectric technology is a promising approach for automotive air conditioning (AC) applications that offers unique advantages and opportunities for improved energy efficiency and passenger comfort. This technology utilizes the thermoelectric effect to directly convert electrical energy into a temperature gradient and vice versa. Here are some key details about thermoelectric technology for automotive AC applications:

Thermoelectric devices, known as thermoelectric coolers or Peltier devices, consist of semiconductor materials that exhibit the thermoelectric effect. When a direct current (DC) is applied to the device, one side becomes hot while the other side becomes cold, creating a temperature gradient across the device. This effect is based on the Seebeck effect, where a temperature difference generates an electric potential difference (voltage) across a junction of dissimilar materials. By reversing the current flow, the temperature gradient can be reversed, allowing the device to function as a heater.

Figure 16.

An example of thermoelectric technology study carried out for automotive applications [

103].

Figure 16.

An example of thermoelectric technology study carried out for automotive applications [

103].

Advantages of Thermoelectric Technology for Automotive AC:

Compact Size: Thermoelectric devices are compact and have a low-profile design, making them suitable for integration into automotive AC systems without requiring significant space.

Solid-State Operation: Thermoelectric devices have no moving parts, making them reliable, vibration-resistant, and maintenance-free.

Rapid Response: Thermoelectric devices can quickly adjust the cooling or heating output, providing immediate comfort to the passengers.

Zonal Control: Thermoelectric technology enables zonal control, allowing different areas or seats within the vehicle to be cooled or heated individually based on passenger preferences.

Environmentally Friendly: Thermoelectric technology does not use refrigerants or harmful gases, eliminating the environmental concerns associated with traditional vapour compression systems.