Submitted:

20 June 2023

Posted:

20 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

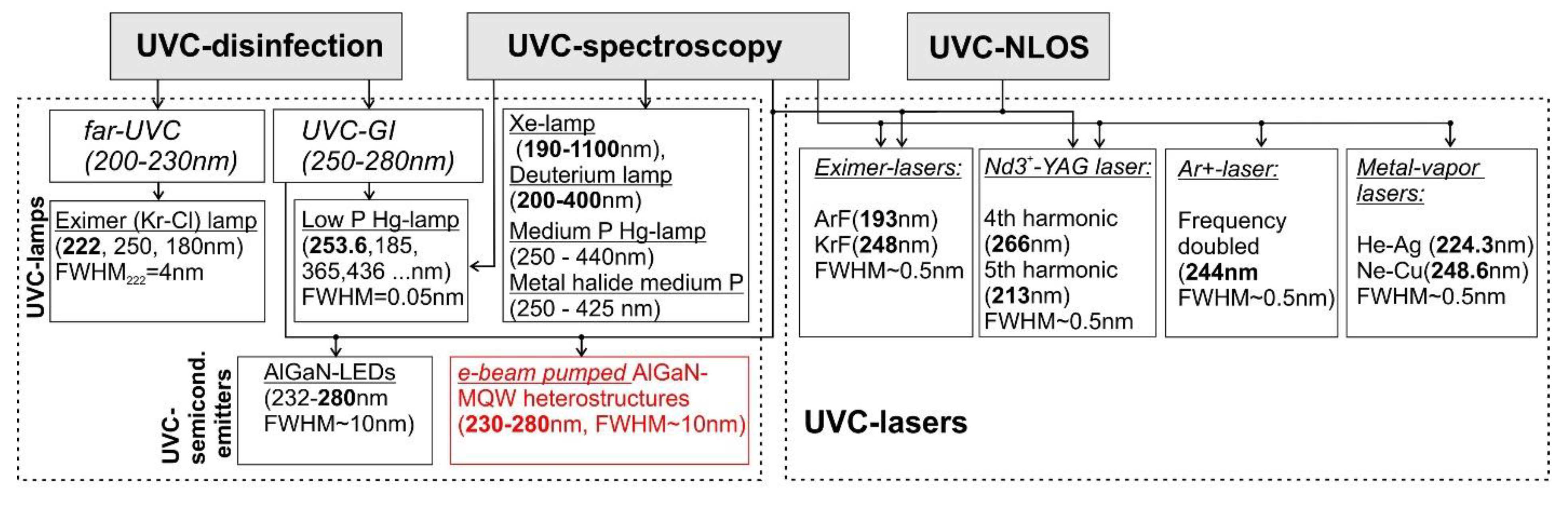

2. Main applications of UVC-emitters

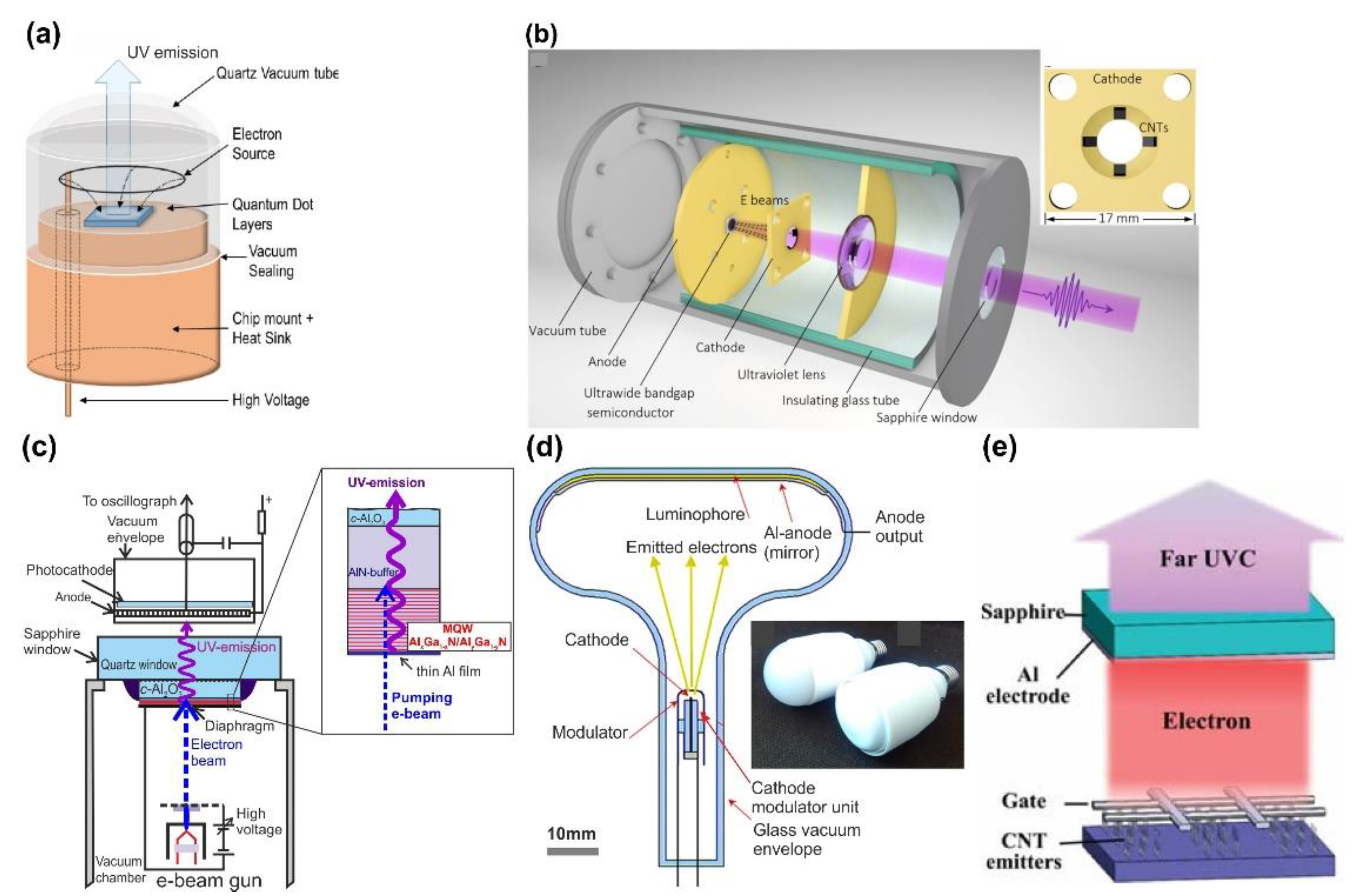

3. General Principles of Electron-Pumped UV-Light Emitters

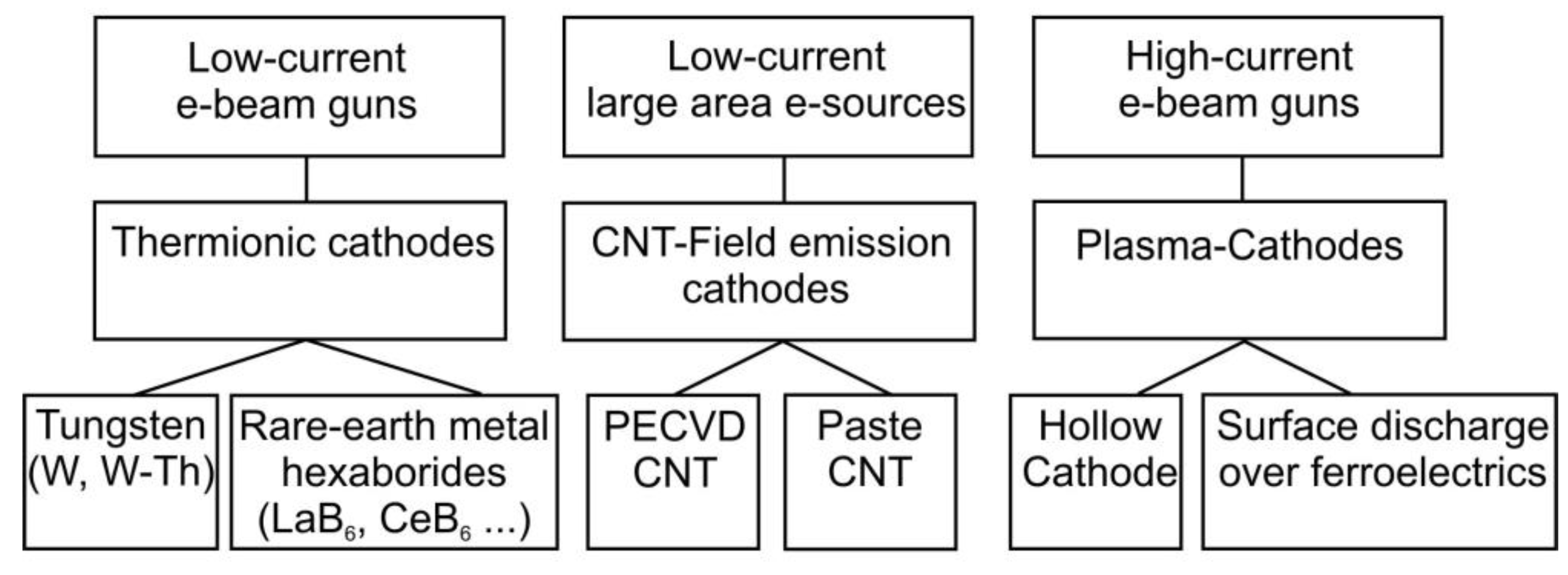

4. The main types of electron guns used to excite UVC radiation

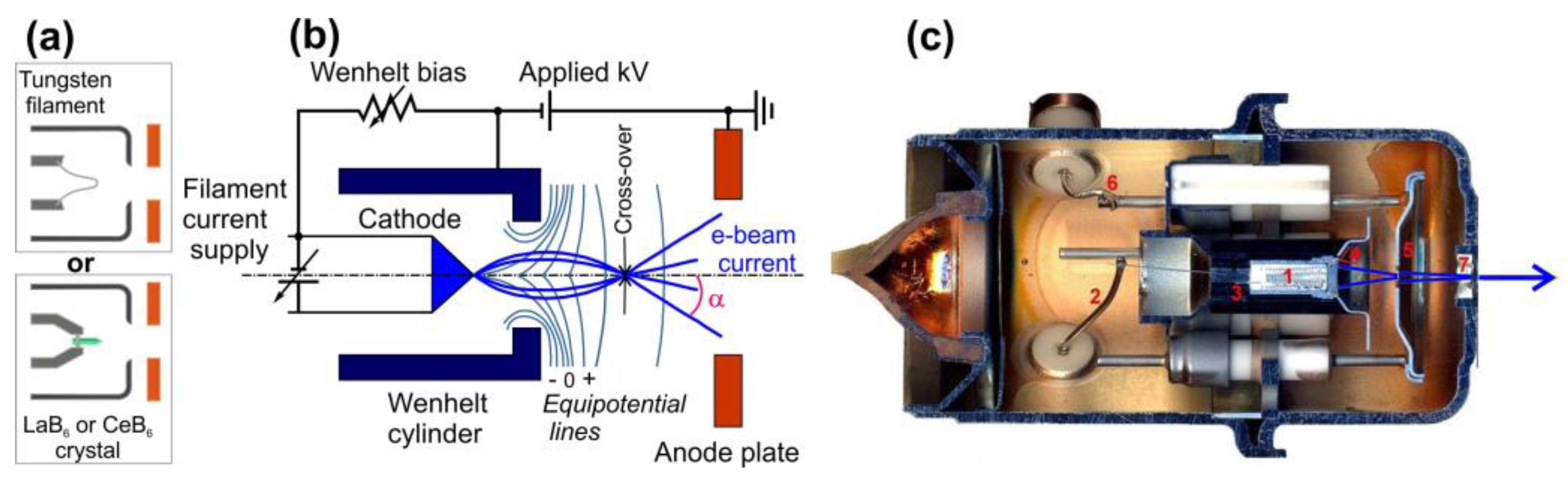

4.1. Thermionic e-beam emission guns

4.2. Field emission (Cold) electron sources

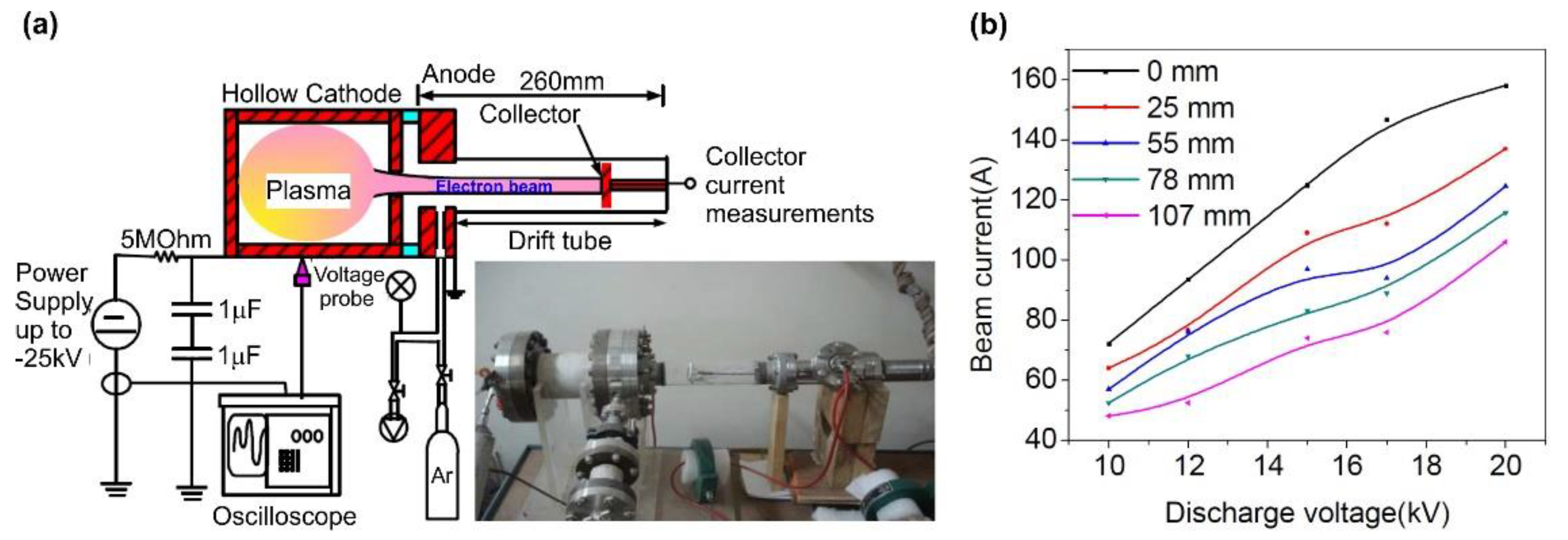

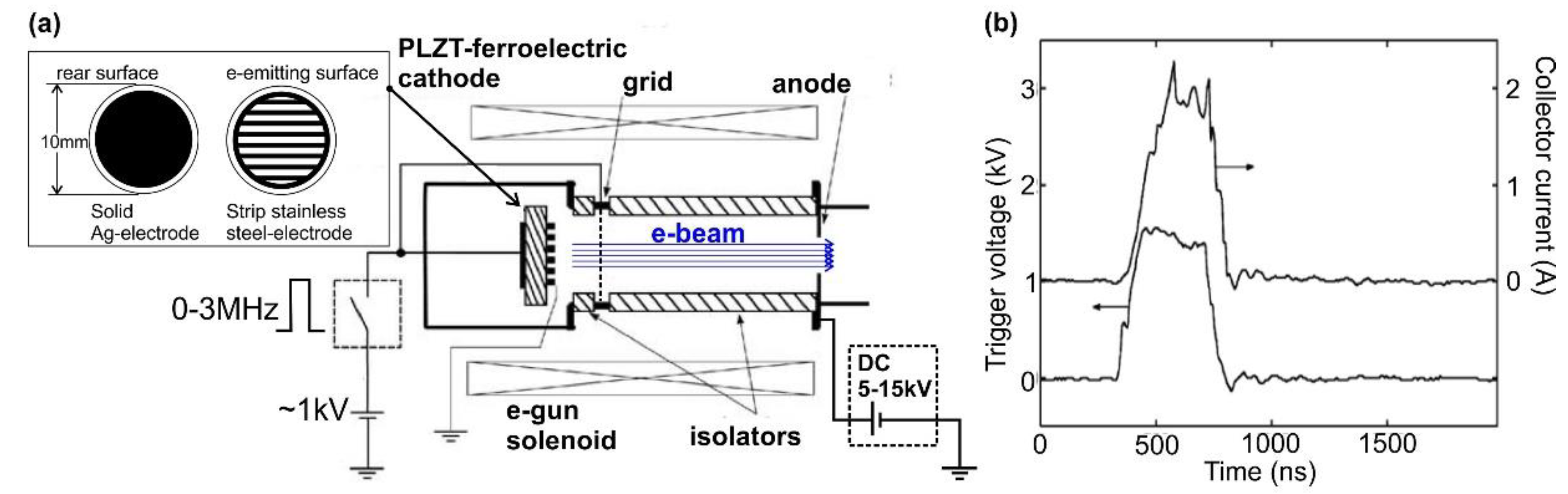

4.3. Electron guns with plasma cahodes

5. Main results on UV-C emitters with Electron Beam Pumping

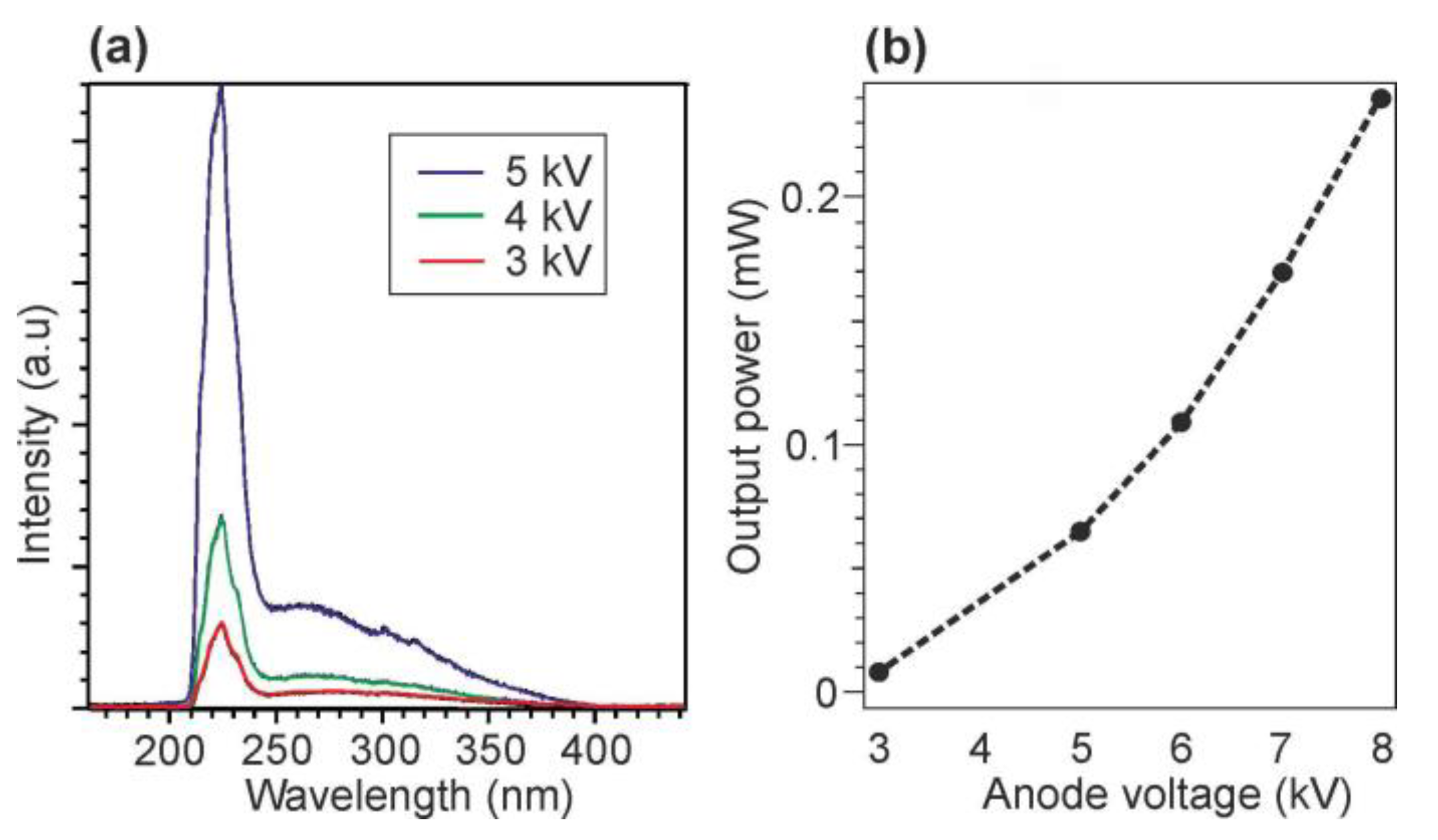

5.1. Low power UVC emitters (<20mW)

5.1.1. Pumping by a focused e-beams from guns with thermoionic cathodes

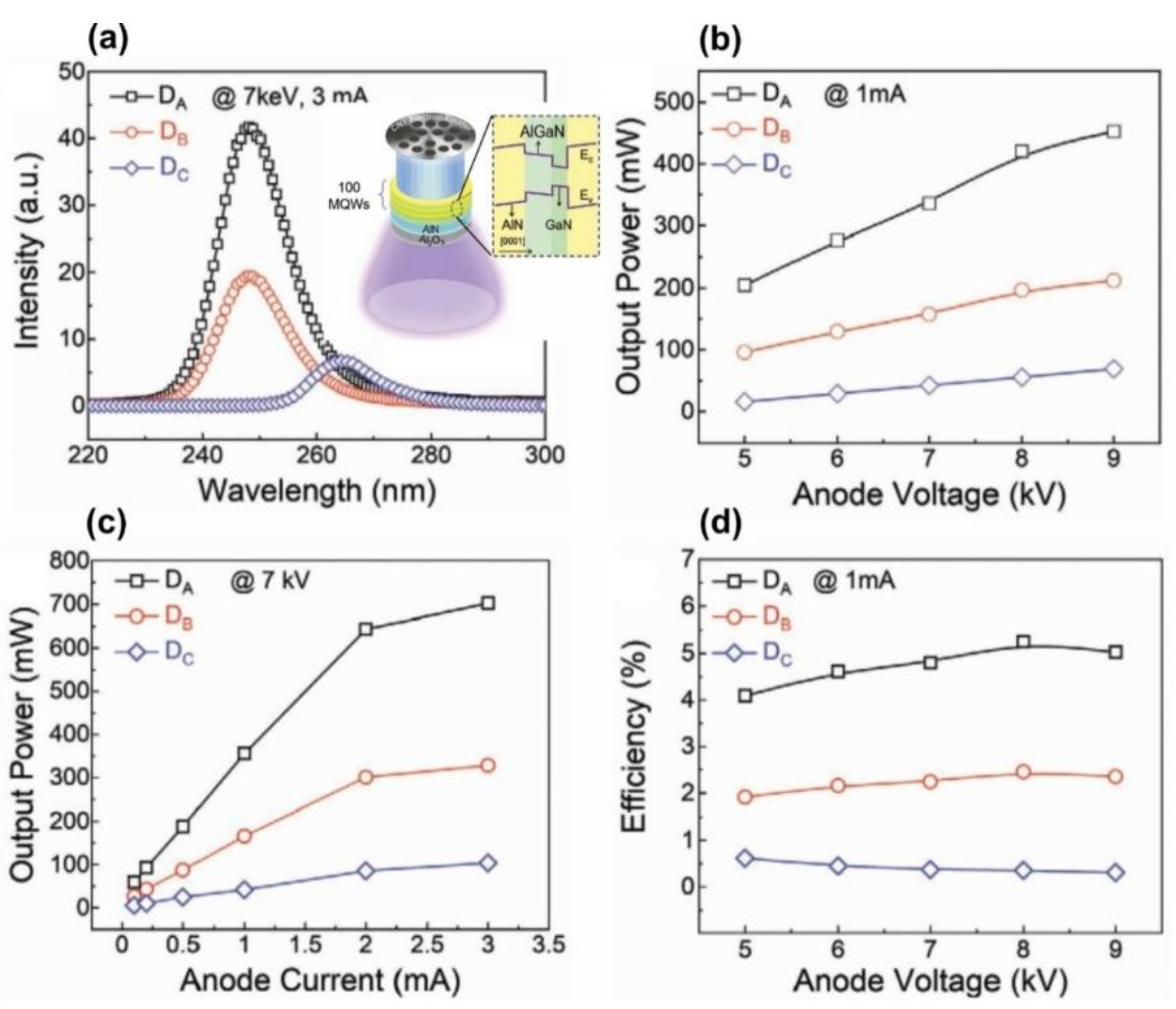

5.1.2. UVC emitters pumped by large-area e-beams generated by CNT-based e-sources

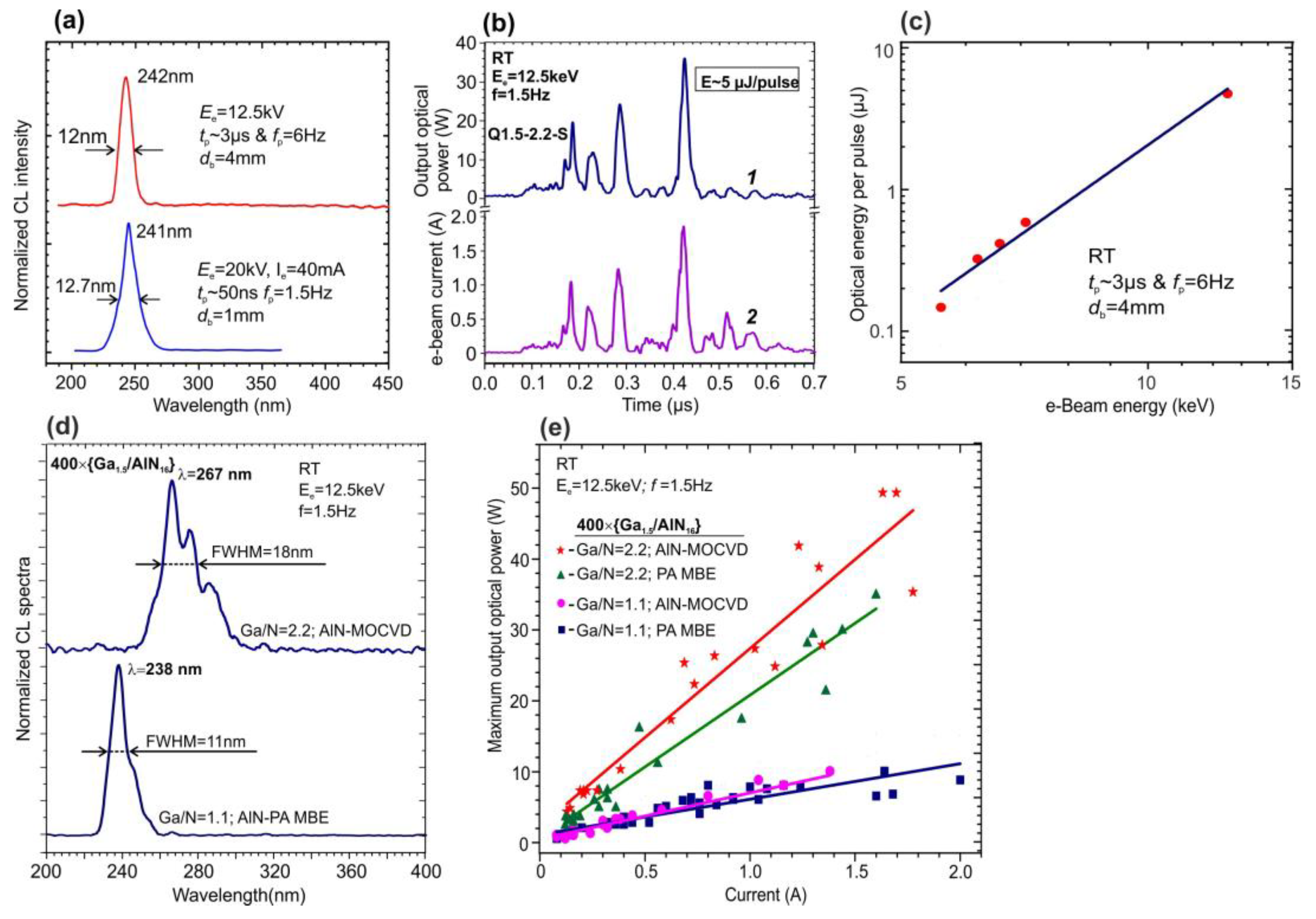

5.2. Medium power UVC emitters (up to 1W)

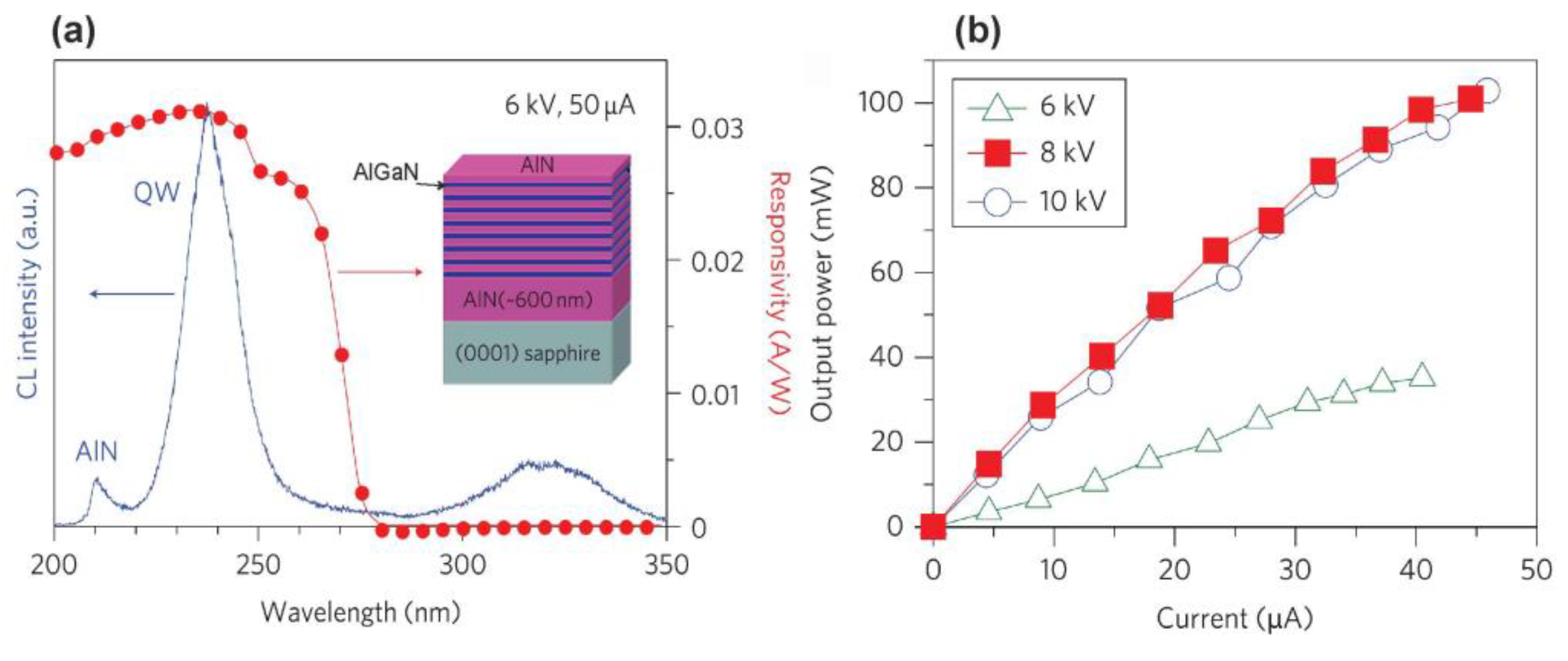

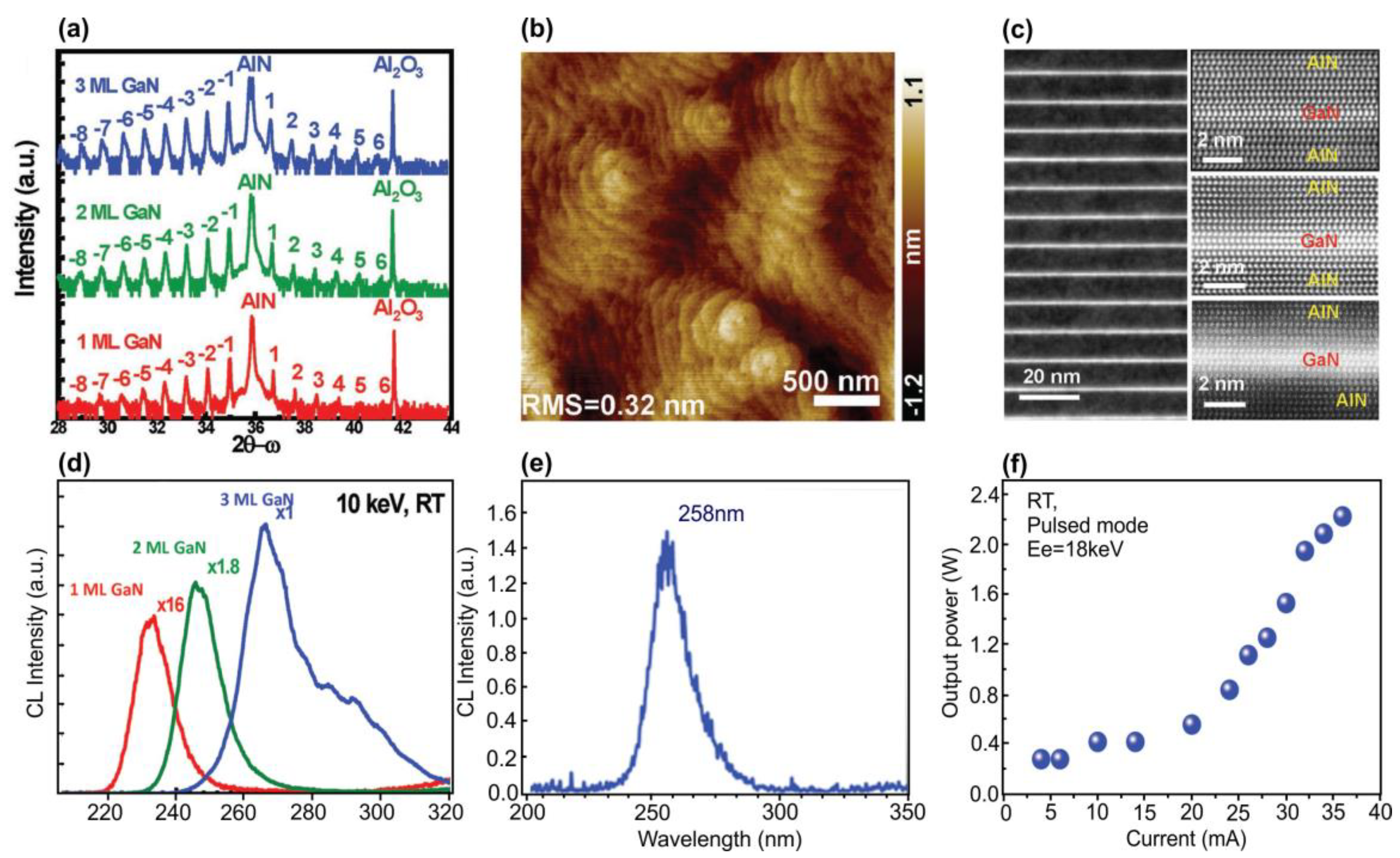

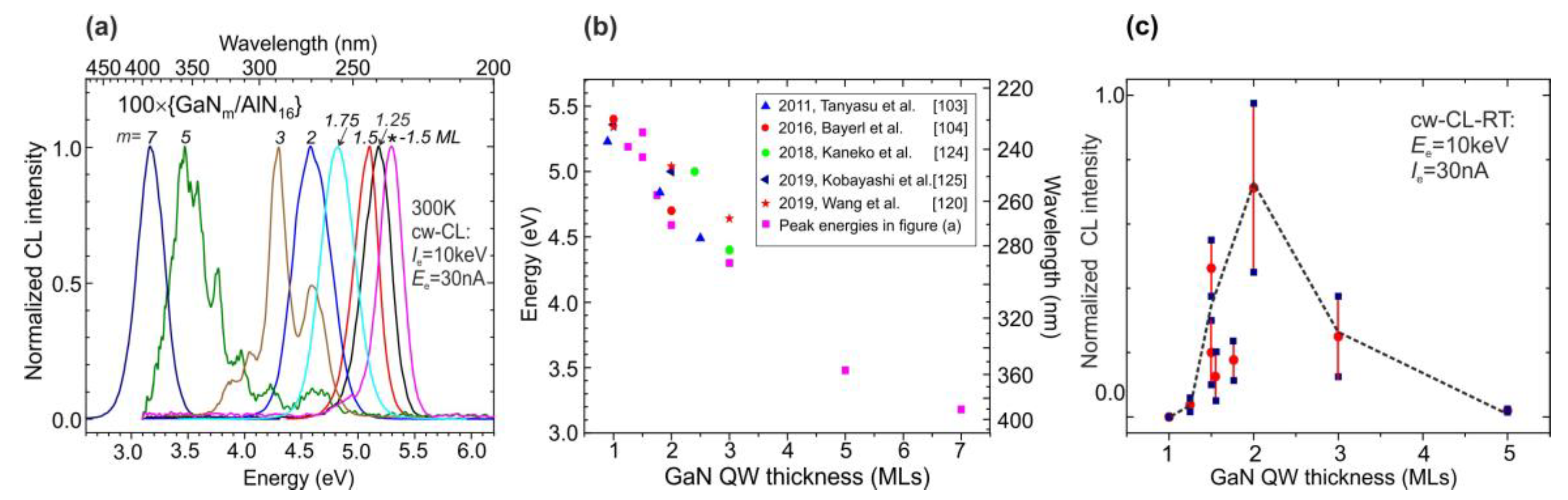

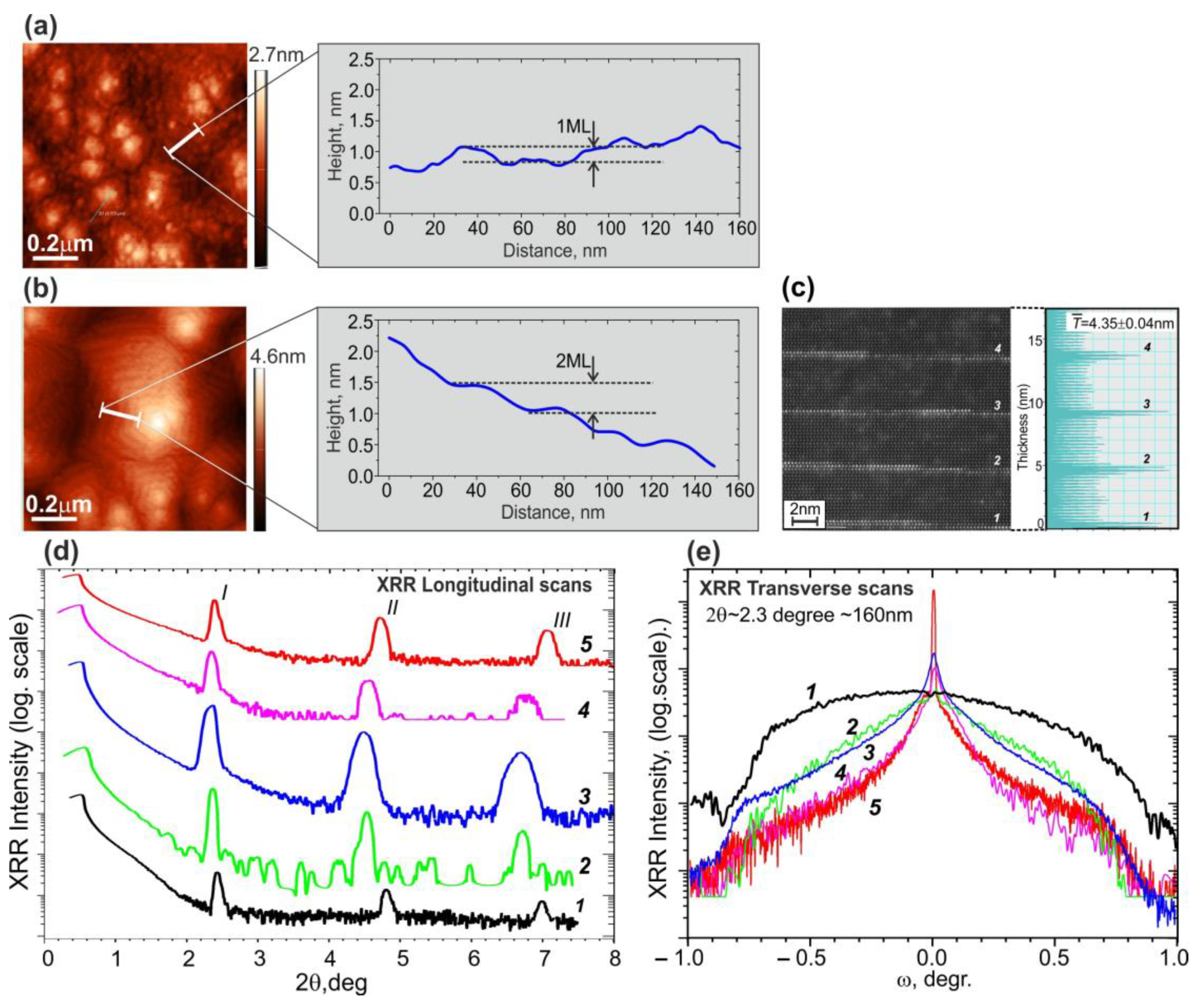

5.2.1. UVC-emitters pumped by thermionic e-guns

5.2.2. Sub-Watt power UV-emitters cw-pumped by large-area CNT-based e-sources

5.3. High power (up to several tens of Watt) pulsed UVC emitters

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kneissl, M. in III-Nitride Ultraviolet Emitters: Technology and Applications, ed. M. Kneissl and J. Rass (Springer, Cham, 2016) Springer Series in Material Science, Vol. 227, Chap. 1.

- Amano, H.; Collazo, R.; Santi, C.D.; Einfeldt, S.; Funato, M.; Glaab, J.; Hagedorn, S.; Hirano, A.; Hirayama, H.; Ishii, R.; Kashima, Y.; Kawakami, Y.; Kirste, R.; Kneissl, M.; Martin, R.; Mehnke, F.; Meneghini, M.; Ougazzaden, A.; Parbrook, P.J.; Rajan, S.; Reddy, P.; Römer, F.; Ruschel, J.; Sarkar, B.; Scholz, F.; Schowalter, L. J.; Shields, P.; Sitar, Z.; Sulmoni, L.; Wang, T.; Wernicke, T.; Weyers, M.; Witzigmann, B.; Wu.; Y.R., Wunderer, T. The 2020 UV emitter roadmap. J. Phys.D: Appl.Phys 2020, 53, 503001. [Google Scholar] [CrossRef]

- Sharma, V.K.; Demir, H.V. Bright Future of Deep-Ultraviolet Photonics: Emerging UVC Chip-Scale Light-Source Technology Platforms, Benchmarking, Challenges, and Outlook for UV Disinfection, ACS Photonics 2022, 9, 1513−1521. 9. [CrossRef]

- Zollner, C. J.; DenBaars, S. P.; Speck, J. S.; Nakamura, S. Germicidal ultraviolet LEDs: a review of applications and semiconductor technologies, Semicond. Sci. Technol. 2021, 36, 123001 (39pp). [CrossRef]

- Hsu, T.C.; Teng, Y.T.; Yeh, Y.W.; Fan, X.; Chu, K. H.; Lin, S.H.; Yeh, K.K.; Lee, P.T.; Lin, Y.; Chen, Z. , Wu, T. ; Kuo H.V. Perspectives on UVC LED: its progress and application, Photonics 2021, 8, 196. [Google Scholar] [CrossRef]

- Chen, Y.; Ben, J.; Xu, F.; Li, J.; Chen, Y.; Sun, X.; Li, D. Review on the Progress of AlGaN-based Ultraviolet Light-Emitting Diodes, Fundamental Research 2021, 1, 717–734. [CrossRef]

- Mondal, R.K.; Adhikari, S.; Chatterjee, V.; Pal, S. Recent advances and challenges in AlGaN-based ultra-violet light emitting diode technologies, Mater. Res. Bull. 2021, 140, 111258. [Google Scholar] [CrossRef]

- Zhao, S.; Lu, J.; Hai, X.; Yin, X. R: Nanowires for Ultraviolet Light-Emitting, 2020; 11. [CrossRef]

- UVC LED Beyond Covid-19: Performance Analysis and Comparison Report 2023, https://www.yolegroup. 2023.

- Kneissl, M.; Seong, T.-Y.; Han, J.; Amano, H. The emergence and prospects of deep-ultraviolet light-emitting diode technologies, Nature Photonics 2019, 13, 233–244. [CrossRef]

- Knauer, A.; Kolbe, T.; Hagedorn, S.; Hoepfner, J.; Guttmann, M.; Cho, H. K.; Rass, J.; Ruschel, J.; Einfeldt, S.; Kneissl, M.; Weyers, M. Strain induced power enhancement of far-UVC LEDs on high temperature annealed AlN templates, Appl. Phys. Lett. 2023, 122, 011102. [Google Scholar] [CrossRef]

- Sarkar, B.; Washiyama, S.; Breckenridg, M. H.; Klump, A.; Baker, J. N.; Reddy, P.; Tweedie, J.; Mitab, S.; Kirste, R.; Irving, D. L.; Collazo, R.; Sitar, Z. N- and P- type Doping in Al-rich AlGaN and AlN, ECS Transactions 2018, 86 (12), 25-30. [CrossRef]

- Wang, J.; Wang, M.; Xu, F.; Liu, B.; Lang, J.; Zhang, N.; Kang, X.; Qin, Z.; Yang, X.; Wang, X.; Ge, W.; Shen, B. Sub-nanometer ultrathin epitaxy of AlGaN and its application in efficient doping, Light: Science & Applications, 2022, 11, 71. [CrossRef]

- Li, D.; Jiang, K.; Sun, X.; Guo, C. AlGaN photonics: recent advances in materials and ultraviolet devices, Adv. Opt. Photonics, 2018, 10, 43–110. [Google Scholar] [CrossRef]

- Li, L. ; Y. Zhang, S. Xu, W. Bi, Z.H. Zhang, H.C. Kuo, On the Hole Injection for III-Nitride Based Deep Ultraviolet Light-Emitting Diodes, Materials 2017, 10, 1221. [Google Scholar] [CrossRef]

- Liang, Y.-H.; Towe, E. Progress in efficient doping of high aluminum-containing group III-nitrides, Appl. Phys. Rev. 2018, 5, 011107. [Google Scholar] [CrossRef]

- Downes, A.; Blunt, T.P. Research on the effect of light upon bacteria and other organisms. Proc. Roy Soc London 1877, 26, 488–500. [Google Scholar] [CrossRef]

- Barnard, J.; Morgan, H. The physical factors in phototherapy, Brit. Med. J. 1903, 2, 1269–1271. [Google Scholar] [CrossRef] [PubMed]

- von Recklinghausen, M. The Ultra-Violet rays and their application for the sterilization of water, J. Franklin Institute, 1914, 1057–1062, 681–704.

- Kowalski, W. Ultraviolet Germicidal Irradiation Handbook UVGI for Air and Surface Disinfection, © Springer-Verlag Berlin Heidelberg 2009, ISBN 978-3-642-01998-2 e-ISBN 978-3-642-01999-9 Springer Heidelberg Dordrecht London New York. [CrossRef]

- Raeiszadeh, M.; Adeli, B. A Critical Review on Ultraviolet Disinfection Systems against COVID-19 Outbreak: Applicability, Validation, and Safety Considerations, ACS Photonics 2020, 7, 2941–2951. [CrossRef]

- de Abajo, F. J. G.; Hernández, R. J. , Kaminer, I.; Meyerhans, A., Rosell-Llompart, J., Eds.; Sanchez-Elsner, T. Back to Normal: An Old Physics Route to Reduce SARS-CoV-2 Transmission in Indoor Spaces, ACS Nano 2020, 14, 7704−7713. [Google Scholar] [CrossRef]

- Blatchley, E. R.; Brenner, D. J.; Claus, H.; Cowan, T. E.; Linden, K. G.; Liu, Y.; Mao, T.; Park, S.-J.; Piper, P. J.; Simons, R. M.; Sliney, D. H. Far UV-C radiation: An emerging tool for pandemic control, Critical Reviews in Environmental Science and Technology 2023, 53(6), 733–753. [CrossRef]

- Epelle, E. I.; Macfarlane, A.; Cusack, M.; Burns, A.; Mackay, W. G.; Rateb, M. E.; Yaseen, M. Application of Ultraviolet-C Radiation and Gaseous Ozone for Microbial Inactivation on Different Materials, ACS Omega 2022, 7, 43006−43021. [CrossRef]

- Singh, H.; Bhardwaj, S. K.; Khatri, M.; Kim, K.-H.; Bhardwaj, N. UVC radiation for food safety: An emerging technology for the microbial disinfection of food products, Chem. Eng. J. 2021, 417, 28084. [Google Scholar] [CrossRef]

- 2010.

- Forbes, P. D.; Cole, C. A.; deGruijl, F. Origins and evolution of photocarcinogenesis action spectra, including germicidal UVC, Photochem. and Photobiol., 2021, 97, 477–484. [Google Scholar] [CrossRef] [PubMed]

- Barnard, I. R.; Eadie, M.; Wood, E.K. Further evidence that far-UVC for disinfection is unlikely to cause erythema or pre-mutagenic DNA lesions in skin, Photodermatol. Photoimmunol. Photomed. 2020, 36, 476–477. [Google Scholar] [CrossRef] [PubMed]

- Buonanno, M.; Ponnaiya, B.; Welch, D.; Stanislauskas, M.; Randers-Pehrson, G.; Smilenov, L.; Lowy, F. D.; Owens, D. M.; Brenner, D. J. Germicidal efficacy and mammalian skin safety of 222-nm UV light, Radiation Research, 2017, 187(4), 483–491. [CrossRef]

- Yamano, N.; Kunisada, M. ; Kaidzu, S; Sugihara, K.; Nishiaki-Sawada, A.; Ohashi, H.; Yoshioka, A.; Igarashi, T.; Ohira, A.; Tanito, M.; Nishigori, C. Long-term effects of 222-nm ultraviolet radiation C sterilizing lamps on mice susceptible to ultraviolet radiation, Photochemistry and Photobiology 2020, 96(4), 853–862. [CrossRef]

- American Conference of Governmental Industrial Hygienists (ACGIH), 2022 TLVs and BEIs: Based on the documentation of the threshold limit values for chemical and physical agents & biological exposure indices. ACGIH 2022, ISBN 9781607261520.

- Graeffe, F.; Luo, Y.; Guo, Y.; Ehn, M. Unwanted Indoor Air Quality Effects from Using Ultraviolet C Lamps for Disinfection, Environ. Sci. Technol. Lett. 2023, 10, 172–178. [Google Scholar] [CrossRef]

- Yoshiyama, K. O.; Okamoto, N. L.; Hidema, J.; Higashitani, A. 222 nm far-UVC efficiently introduces nerve damage in Caenorhabditis elegans, PLoS ONE 2023, 18(1), e0281162. [CrossRef]

- Chitraningruma, N. ; Y. N. Wijayanto, Y. N.; Arisesa, H.; Sakti, I.; Mahmudin, D.; Prawara, B.; Kurniadi, D. P.; Daud, P. The Optical Characteristics of 20 Watt Far-UVC Light and Its Application for Disinfection Chamber, Jurnal Elektronika dan Telekomunikasi (JET) 2022, 22(2), 57-62. [CrossRef]

- Eadie, E.; Hiwar, W.; Fletcher, L.; Tidswell, E.; O’Mahoney, P.; Buonanno, M.; Welch, D.; Adamson, C. S.; Brenner, D. J.; Noakes, C.; Wood, K. Far-UVC (222 nm) efficiently inactivates an airborne pathogen in a room-sized chamber, Sci. Rep. 2022, 12, 4373. [Google Scholar] [CrossRef]

- Joshi, D.; Kumar, D.; Maini, A. K.; Sharma, R. C. Detection of biological warfare agents using ultraviolet-laser induced fluorescence LIDAR, Spectrochim. Acta A Mol. Biomol. Spectrosc. 2013; 112, 446-56. [CrossRef]

- DeFreez, R. LIF Bio-Aerosol Threat Triggers: Then and Now, Optically Based Biological and Chemical Detection for Defence V, ed. by J. C. Carrano, C. J. Collins, Proc. of SPIE 2009, 7484, 74840H. [Google Scholar] [CrossRef]

- Hug, W. F.; Bharti, R.; Sijapati, K.; Beegle, L. W.; Reid, R.D. Improved sensing using simultaneous deep-UV Raman and fluorescence detection – II, Chemical, Biological, Radiological, Nuclear, and Explosives (CBRNE) Sensing XV, edited by A. W. Fountain III, Proc. of SPIE 2014, 9073, 90730I. [Google Scholar] [CrossRef]

- Reismaa, P. S.; Erme, E.; Vaher, M.; Kulp, M.; Kaljurand, M.; Mazina-Šinkar, J. In situ Determination of Illegal Drugs in Oral Fluid by Portable Capillary Electrophoresis with Deep UV Excited Fluorescence Detection, Anal. Chem. 2018, 90, 10–6253. [Google Scholar] [CrossRef]

- D'Elia, V.; Montalvo, G.; García Ruiz, C.; Ermolenkov, V. V.; Ahmed, Y.; Lednev, I. K. Ultraviolet resonance Raman spectroscopy for the detection of cocaine in oral fluid, Spectrochim. Acta A 2018, 188, 338–340. [Google Scholar] [CrossRef]

- Kumar, V.; Holtum, T.; Voskuhl, J.; Giese, M.; Schrader, T.; Schlücker, S. Prospects of ultraviolet resonance Raman spectroscopy in supramolecular chemistry on proteins, Spectrochim. Acta A 2021, 254, 119622. [Google Scholar] [CrossRef]

- Hollis, J.R.; Ireland, S.; Abbey, W. et al., Deep-ultraviolet Raman spectra of Mars-relevant evaporite minerals under 248.6nm excitation, Icarus 2020, 351,113969. [CrossRef]

- Fox, A. C.; Jakubek, R. S.; Eigenbrode, J. L. Changes in the Raman and fluorescence spectroscopic signatures of irradiated organic-mineral mixtures: Implications for molecular biosignature detection on Mars, J. Geophys. Res. Planets 2023, 128, e2022JE007624. [Google Scholar] [CrossRef]

- Nikishin, S.; Bernussi, A.; Karpov, S. Towards Efficient Electrically-Driven Deep UVC Lasing: Challenges and Opportunities, Nanomaterials 2023, 13, 185. 13. [CrossRef]

- Majumdar, A. K. Chapter 5 Non-Line-Of-Sight (NLOS) Ultraviolet and Indoor Free-Space Optical (FSO) Communications, in A. K. Majumdar Advanced Free Space Optics (FSO) A Systems Approach, Springer Series in Optical Sciences, 2015 Volume 186, Springer New York Heidelberg Dordrecht London. [CrossRef]

- Belov, V. V.; Juwiler, I.; Blaunstein, N.; Tarasenkov, M. V.; Poznakharev, E. S. NLOS Communication: Theory and Experiments in the Atmosphere and Underwater, Atmosphere 2020, 11, 1122. 11. [CrossRef]

- Guo, L.; Guo, Y.; Wang, J.; Wei, T. Ultraviolet communication technique and its application, J. Semicond 2021, 42, 081801. [Google Scholar] [CrossRef]

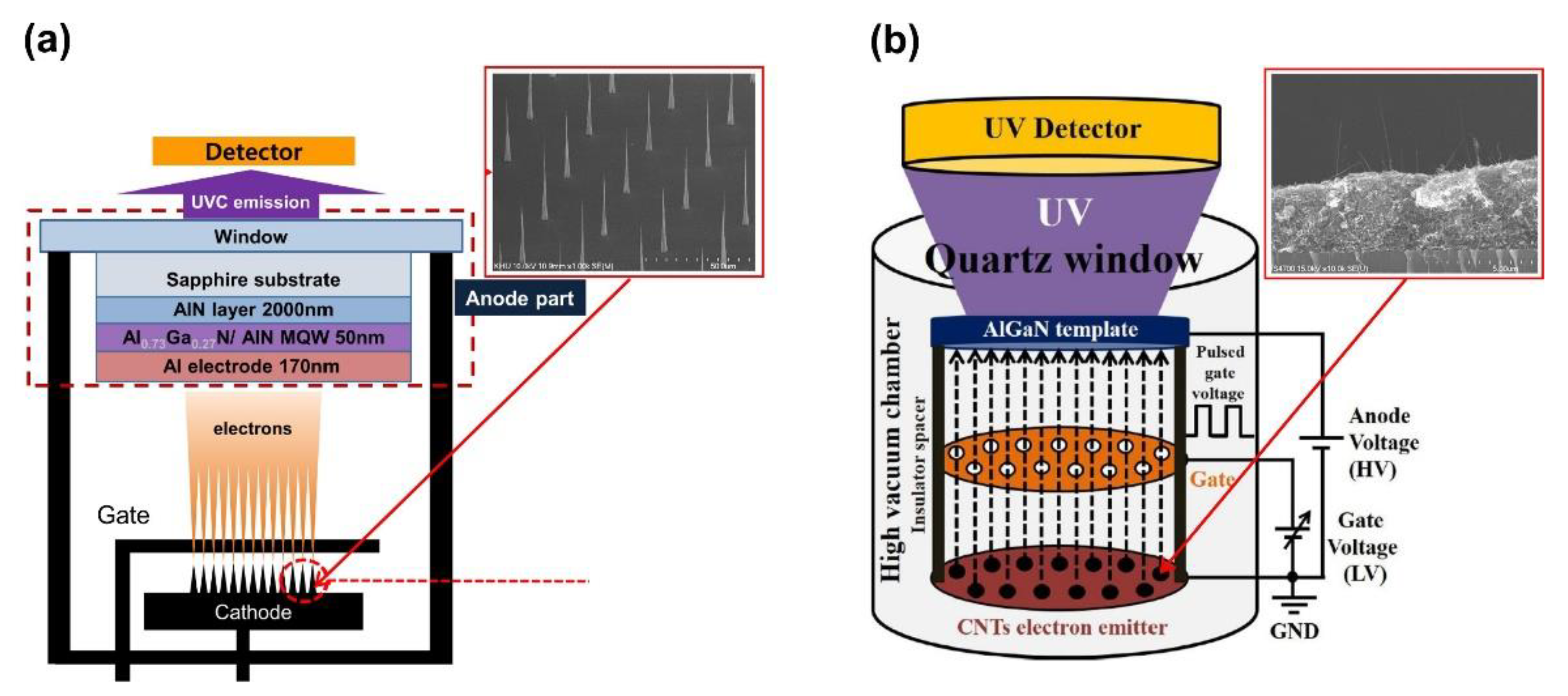

- Yoo, S. T.; Lee, J. Y.; Rodiansyah, A.; Yune, T. Y.; Park, K. C. Far UVC light for E. coli disinfection generated by carbon nanotube cold cathode and sapphire anode, Curr. Appl. Phys. 2021, 28, 93–97. [Google Scholar] [CrossRef]

- DeFreez, R.; Hug, W.; Reid, R.; Bhartia, R. New deep-ultraviolet sources for detecting biological threats, SPIE Newsroom 2010. [CrossRef]

- Kang, Y.; Zhao, J.; Wu, J.; Zhang, L.; Zhao, J. Superior Deep-Ultraviolet Source Pumped by an Electron Beam for NLOS Communication, IEEE Trans. Electron Devices 2020, 67(8), 3391 – 3394. [CrossRef]

- Cuesta, S.; Harikumar, A.; Monroy, E. Electron beam pumped light emitting devices, J. Phys. D: Appl. Phys. 2022, 55, 273003. [Google Scholar] [CrossRef]

- Harikumar, A. Développement de nanostructures à base d’AlGaN pour la fabrication de com- posants émetteurs de lumière UV à pompage électronique. Physique [physics]. Université Grenoble Alpes [2020-..], 2022. Français. NNT : 2022 GRALY039. tel-03813791.

- Yu, Y.; Han, D.; Wei, H.; Tang, Z.; Luo, L.; Hong, T.; Shen, Y.; Zheng, H.; Wang, Y.; Wang, R.; Zhu, H.; Deng, S. Aluminum Nitride Ultraviolet Light-Emitting Device Excited via Carbon Nanotube Field-Emission Electron Beam, Nanomaterials 2023, 13, 1067. 13. [CrossRef]

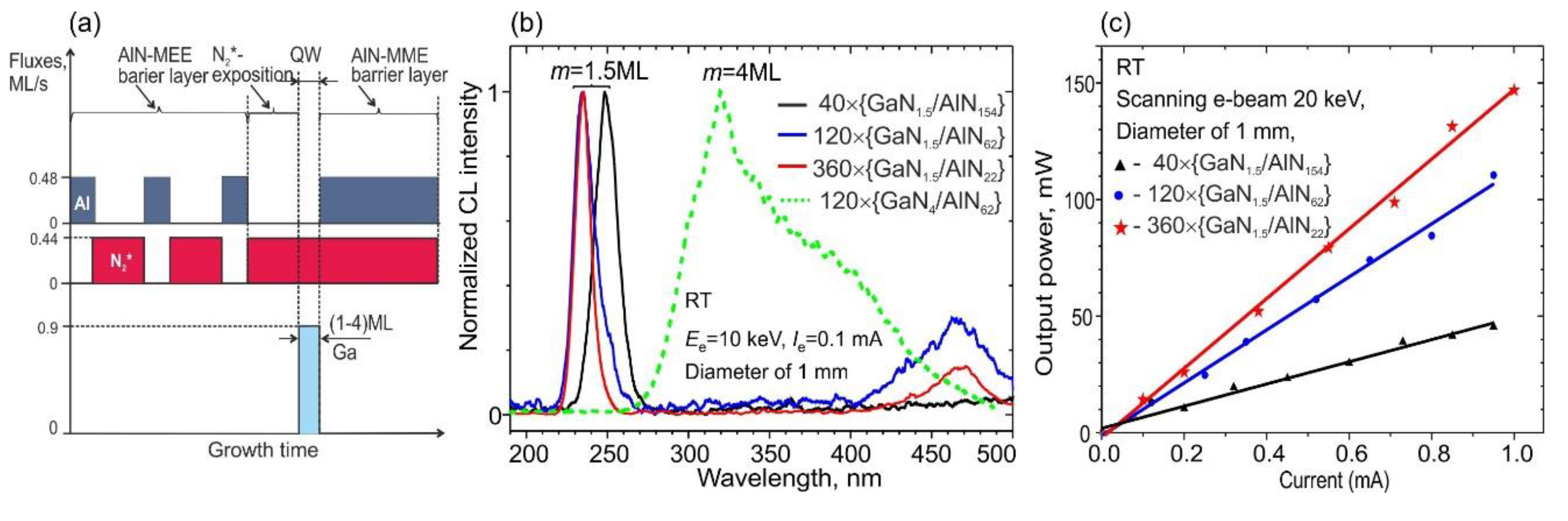

- Jmerik, V.; Toropov, A.; Davydov, V.; Ivanov, S. Monolayer-Thick GaN/AlN Multilayer Heterostructures for Deep-Ultraviolet Optoelectronics, Phys. Status Solidi RRL 2021, 15, 2100242. [Google Scholar] [CrossRef]

- Sheshin, E. P.; Kolodyazhnyj, A. Yu.; Chadaev, N. N.; Getman, A. O.; Danilkin, M. I.; Ozol, D. I. Prototype of cathodoluminescent lamp for general lighting using carbon fiber field emission cathode, J. Vac. Sci. Technol. B 2019, 37, 031213. [Google Scholar] [CrossRef]

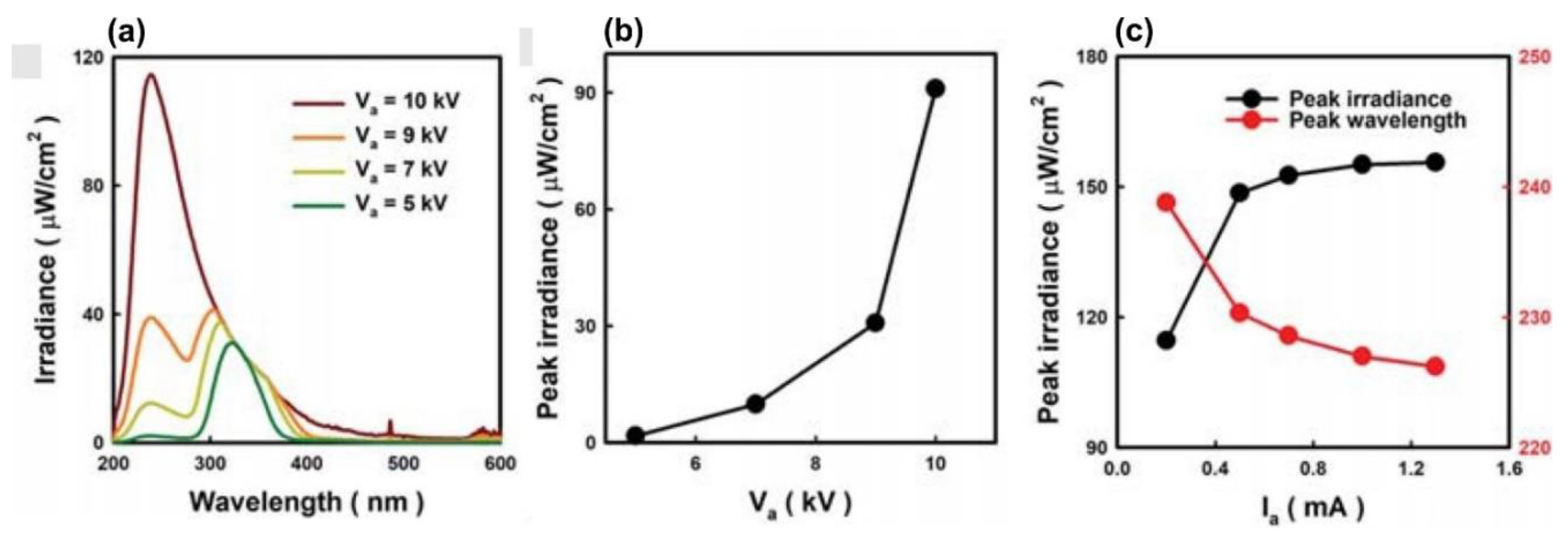

- Yoo, S. T.; Park, K. C. ; Sapphire Wafer for 226 nm Far UVC Generation with Carbon Nanotube-Based Cold Cathode Electron Beam (C-Beam) Irradiation, ACS Omega 2020, 5(25), 15601–15605. [CrossRef]

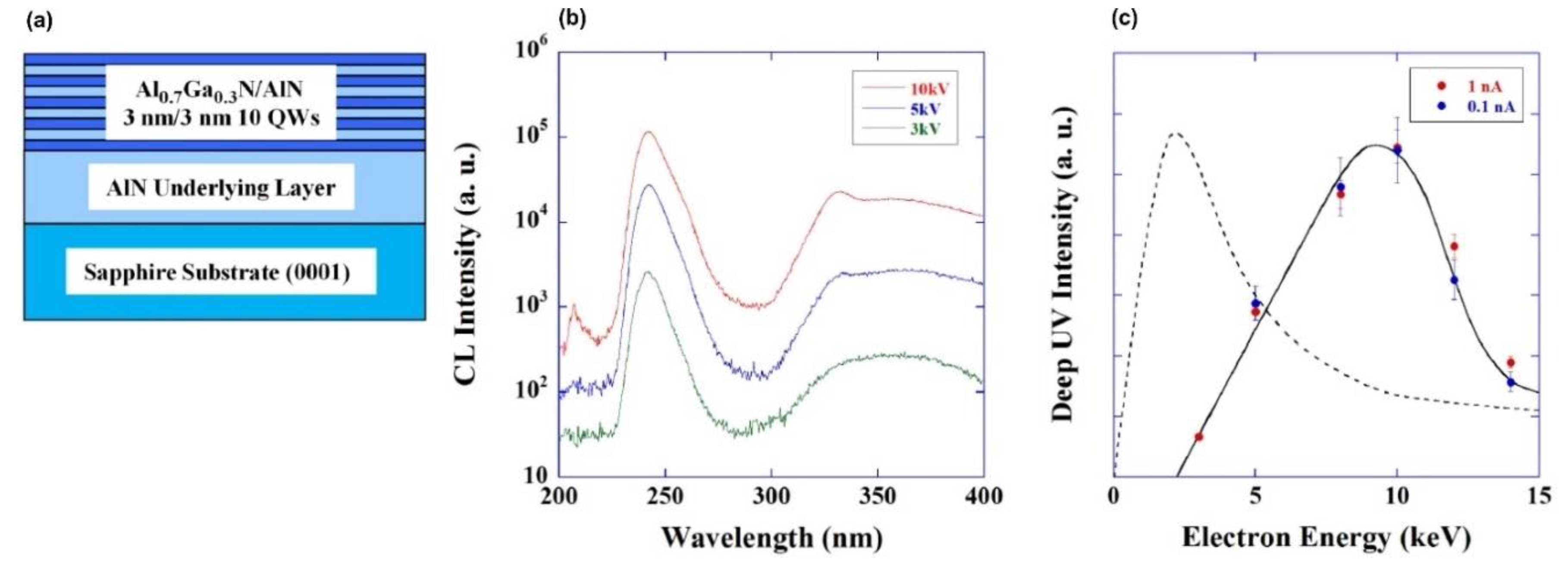

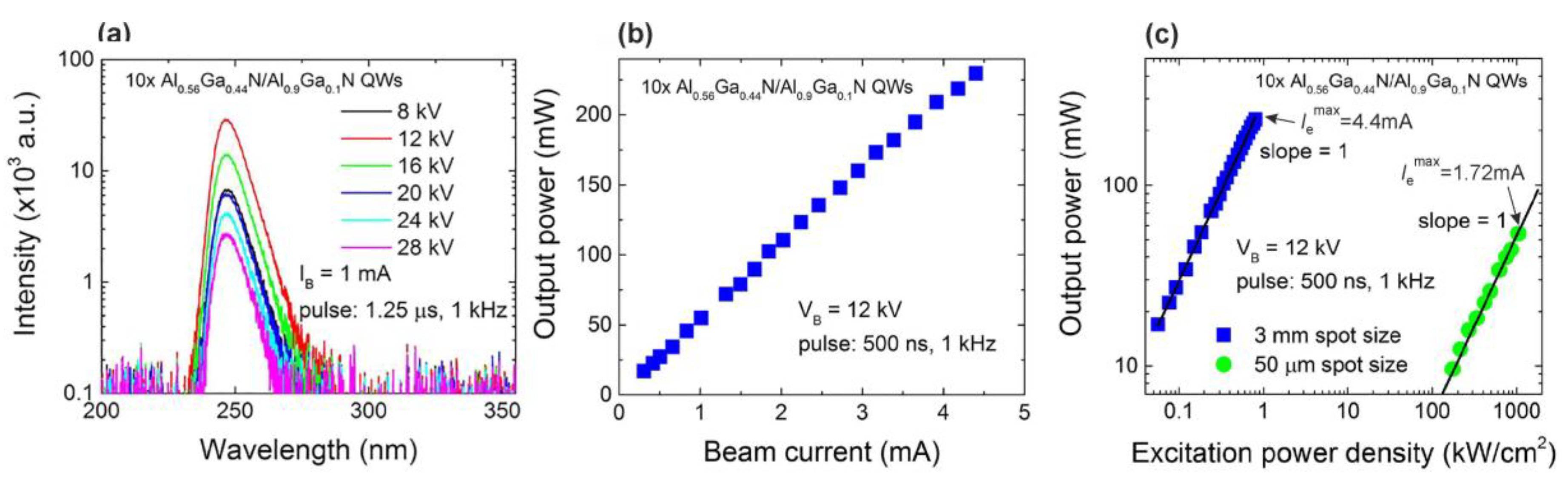

- Tabataba-Vakili, F.; Wunderer, T.; Kneissl, M.; Yang, Z.; Teepe, M.; Batres, M.; Feneberg, M.; Vancil, B.; Johnson, N.M. Dominance of radiative recombination from electron-beam-pumped deep-UV AlGaN multi-quantum-well heterostructures. Appl. Phys. Lett. 2016, 109, 181105. [Google Scholar] [CrossRef]

- Chapter 5 Electron sources in David, B. Williams C. Barry Carter, Transmission Electron Microscopy A Textbook for Materials Science, 2nd edition, Springer ScienceþBusiness Media, LLC 1996, 2009. New York, NY 10013, USA. 73-89.

- Liu, H.; Zhang, X.; Ning, S.; Xiao, Y.; Zhang, J. The electronic structure and work functions of single crystal LaB6 typical crystal surfaces, Vacuum 2017, 143, 245−250. 143. [CrossRef]

- Çetinkaya, H.; Özbey, A.; Yüncü, A. Thermionic Electron Gun Design and Prototyping, Eur. j., eng. sci., tech. 2021, 23, 702–709. [Google Scholar] [CrossRef]

- Schmidt, P. H. , Longinotti, L. D.; Joy, D. C.; Ferris, S. D.; Leamy, H. J.; Fisk, Z. Design and optimization of directly heated LaB6 cathode assemblies for electron beam instruments, J. Vac. Sci. Technol. 1978, 15, 1554. [Google Scholar] [CrossRef]

- Gesley, M.; Hohn, F. Emission distribution, brightness, and mechanical stability of the LaB6 triode electron gun, J. Appl. Phys. 1988, 64, 3380. [Google Scholar] [CrossRef]

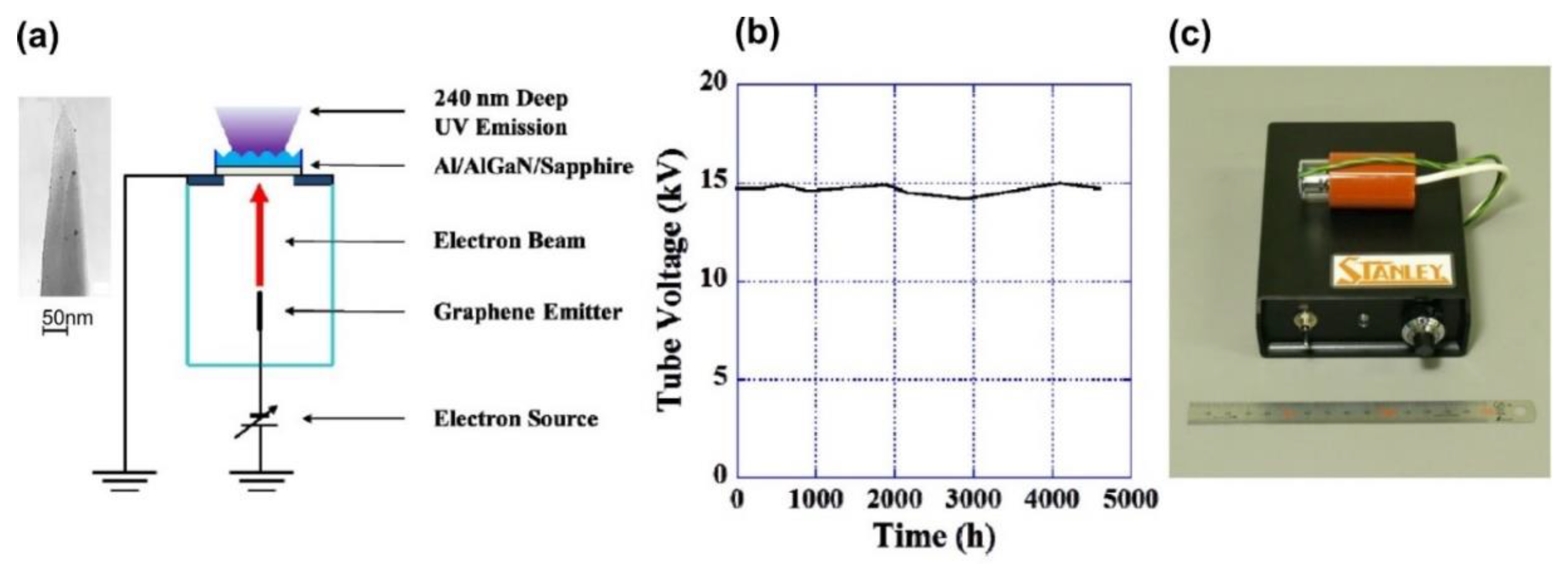

- Matsumoto, T.; Iwayama, S.; Saito, T.; Kawakami, Y.; Kubo, F.; Amano, H. Handheld deep ultraviolet emission device based on AlN QWs and graphene nanoneedle field emitters, Opt. Express 2012, 20, 24320–24329. [Google Scholar] [CrossRef]

- Yoo, S. T.; Hong, J. H.; Kang, J. S.; Park, K. C. Deep-ultraviolet light source with a carbon nanotube cold-cathode electron beam, J. Vac. Sci. Technol B 2018, 36, 02C103. [Google Scholar] [CrossRef]

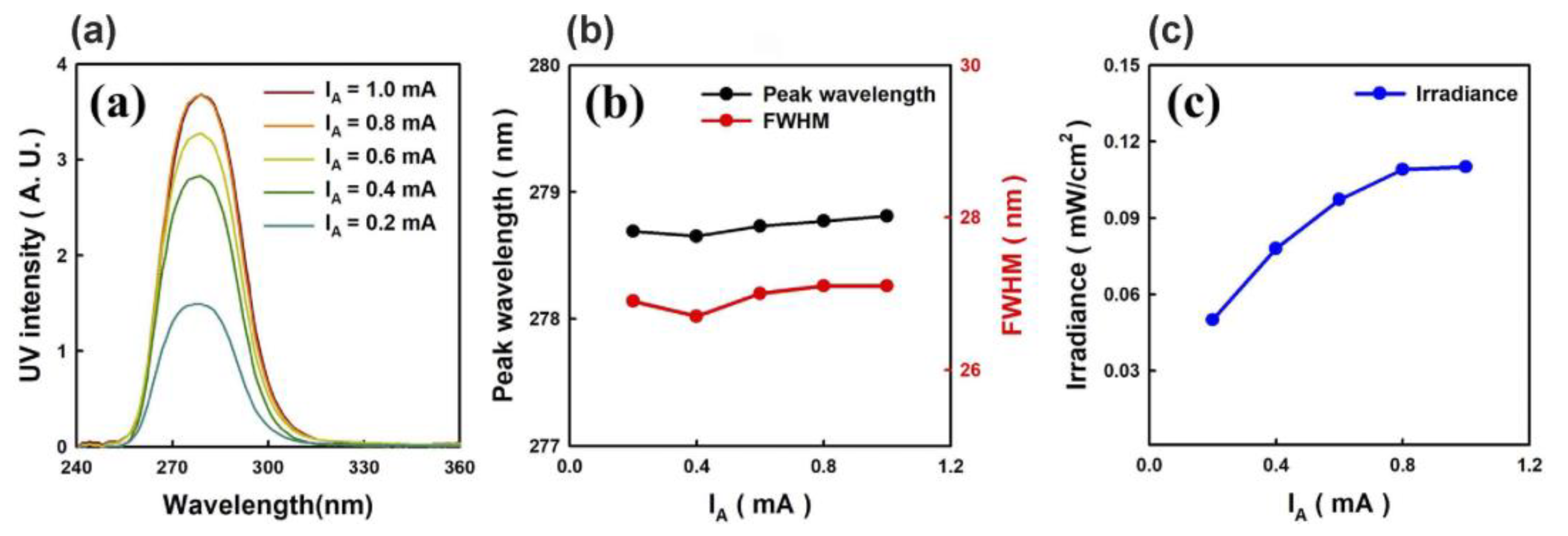

- Yoo, S. T.; So, B.; Lee, H. I.; Nam, O.; Park, K. C. Large area deep ultraviolet light of Al0. 47Ga0.53N/Al0.56Ga0.44N multi quantum well with carbon nanotube electron beam pumping, AIP Advances 2019, 9, 075104. [Google Scholar] [CrossRef]

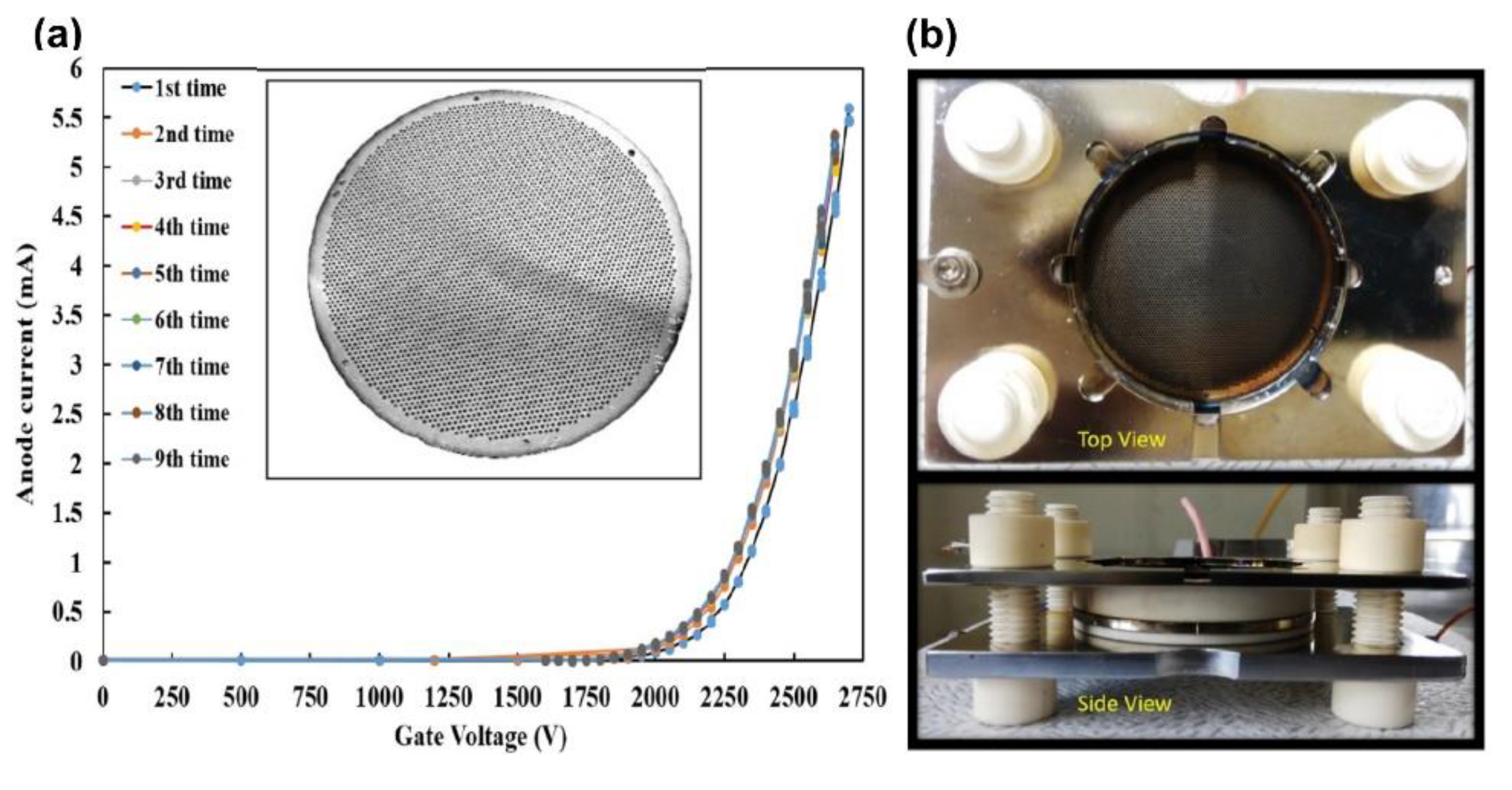

- Tawfik, W. Z.; Kumar, C.M. M.; Park, J.; Shim, S. K.; Lee, H.; Lee, J.; Han, J. H.; Ryu, S.; Lee, N.; Lee, J. K. Cathodoluminescence of 2-inch Ultraviolet-Light-Source Tube Based on the Integration of AlGaN Materials and Carbon Nanotubes Field Emitters, J. Mater. Chem. C Mater. 2019, 7, 11540–11548. [Google Scholar] [CrossRef]

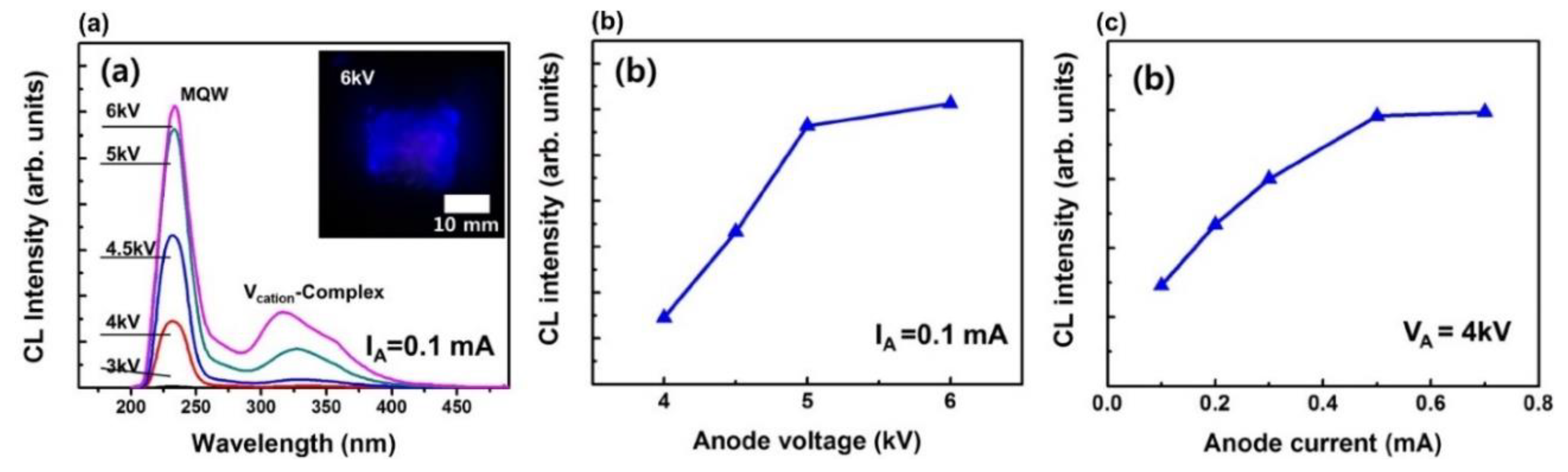

- Lee, J.; Yoo, S. T.; So, B.; Park, K. C.; Nam, O. Large-area far ultraviolet-C emission of Al0. 73Ga0.23N/AlN multiple quantum wells using carbon nanotube based cold cathode electron-beam pumping, Thin Solid Films 2020, 711, 138292. [Google Scholar] [CrossRef]

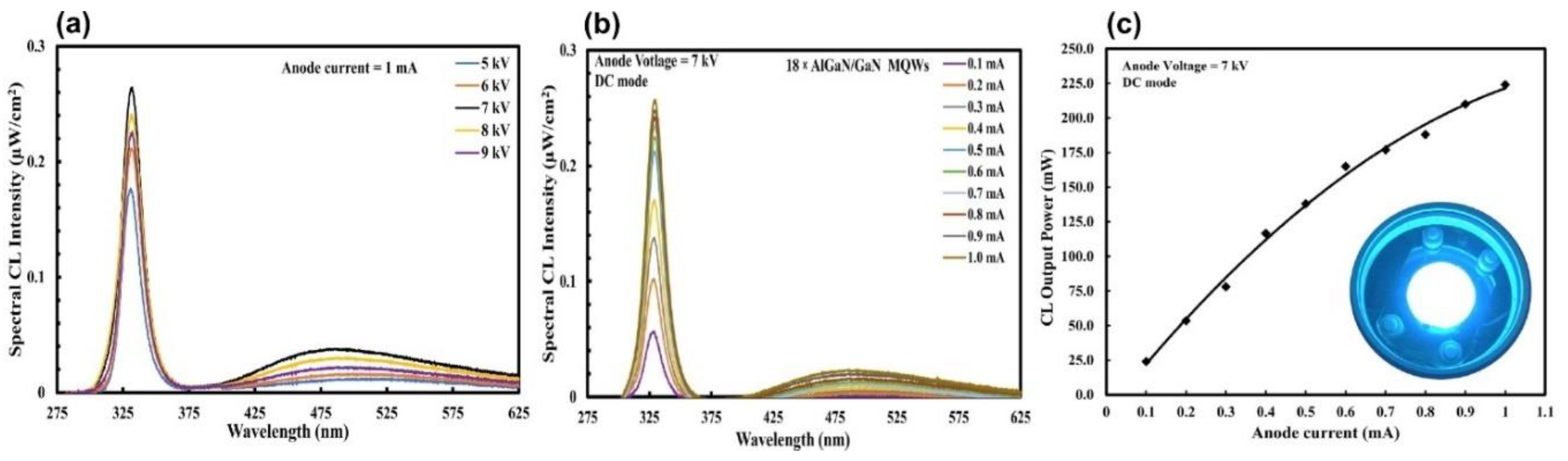

- Mohan, M. K. C.; Shim, S. K.; Cho, M. U.; Kim, T. K.; Kwak, J. S.; Park, J.; Jang, N.; Ryu, S.-W.; Lee, N.; Lee, J. K. Ultraviolet-cathodoluminescent 330 nm light source from a 2-inch wide CNT electron-beam emission under DC electric field, Curr. Appl. Phys. 2021, 28, 72–77. [Google Scholar] [CrossRef]

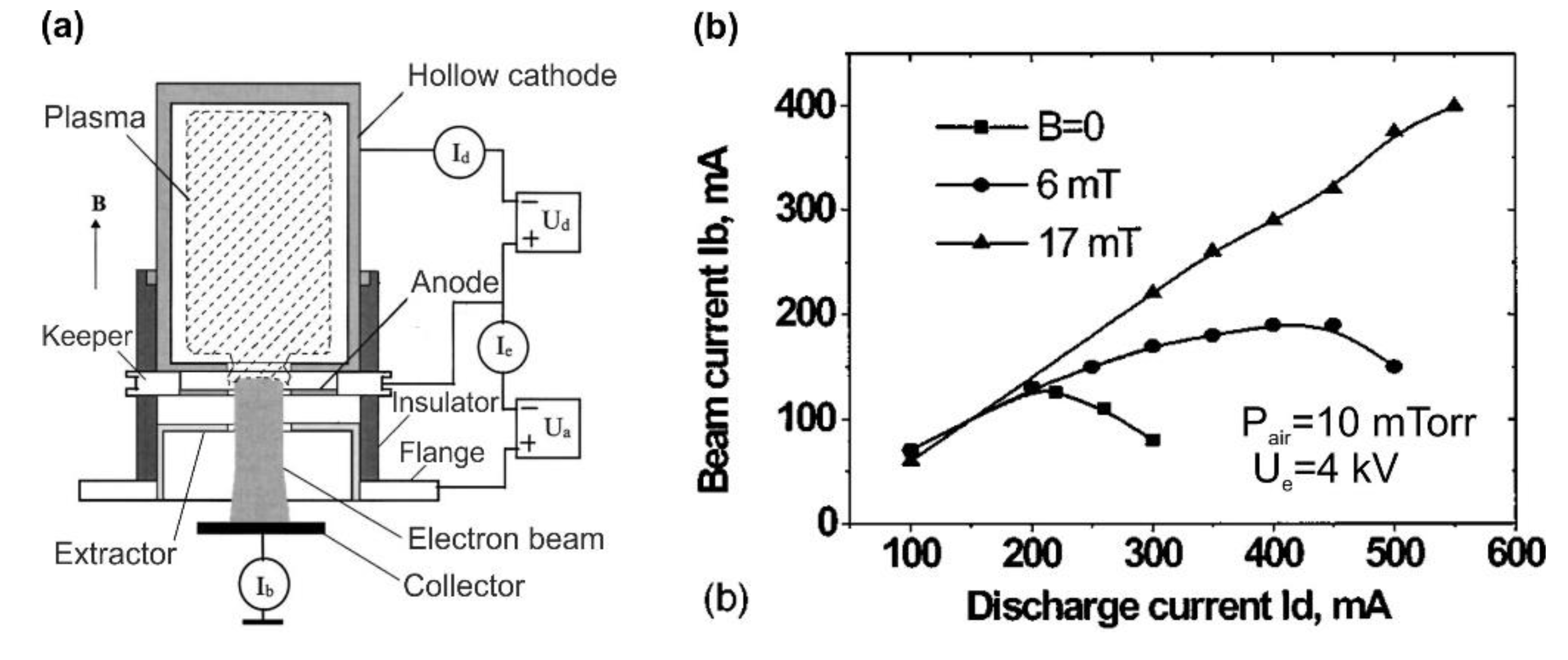

- Burdovitsin, V.; Oks, E. Hollow-cathode plasma electron gun for beam generation at forepump gas pressure, Rev. Sci. Instrum. 1999, 70, 2975. [Google Scholar] [CrossRef]

- Oks, E. M.; Schanin, P. M. Development of plasma cathode electron guns, Phys. Plasmas 1999, 6, 1649. [Google Scholar] [CrossRef]

- Verma, D.K.; Pal, U.N.; Kumar, N.; Prajapati, J.; Kumar, M.; Prakash, R.; Srivastava, V. Investigation of electron beam parameters inside the drift region of plasma cathode electron gun, J. Phys.: Conf. Ser. 2012, 365, 012048. [Google Scholar] [CrossRef]

- Burdovitsin, V. A.; Oks E., M. Discharge systems and plasma-assisted electron emission in forevacuum pressure range, Russ. Phys. J. 2021, 63(10), 1678. [Google Scholar] [CrossRef]

- Rosenblum, B.; Bräunlich, P.; Carrico, J. P. Thermally stimulated field emission from pyroelectric LiNbO3, Appl. Phys. Lett. 1974, 25, 17. [Google Scholar] [CrossRef]

- Rozenman, G. I.; Okhapkin, V. A.; Chepelev, Yu. L.; Shur, V. Ya. Electron emission during the switching of ferroelectric lead germanate, Pis’ma Zh. Eksp. Teor. Fiz. (JETP Letters) 1984, 39(9), 397-399.

- Ivers, J. D.; Schächter, L.; Nation, J. A.; Kerslick, G. S.; Advani, R. Electron beam diodes using ferroelectric cathodes, J. Appl. Phys. 1993, 73, 2667. [Google Scholar] [CrossRef]

- Moorti, A.; Sailaj, S.; Naik, P. A.; Gupta, P. D.; Korobkin, Yu. V.; Romanov, I. V.; Rupasov, A. A.; Shikhanov, A. S. Laser-driven high-current-density pulsed electron emission from lead zirconium titanate ferroelectric ceramic, Appl. Phys. Lett. 2001, 79, 1163. [Google Scholar] [CrossRef]

- Einat, M.; Jerby, E.; Rosenman, G. A ferroelectric electron gun in a free-electron maser experiment, Nucl. Instrum. Methods Phys. Res. A 2002, 483, 326–330. [Google Scholar] [CrossRef]

- Seo, M.; Hong, K. Characteristics of Electron Emission from a (Pb,La)(Zr,Ti)O3 Ferroelectric Cathode, Jap. J. Appl. Phys. 2010, 49, 076001. [Google Scholar] [CrossRef]

- Chen, S.; Zheng, S.; Zhu, Z.; Dong, X.; Tang, C. Electron emission and plasma generation in a modulator electron gun using ferroelectric cathode, Nucl. Instrum. Methods Phys. Res. A 2006, 566, 662–667. [Google Scholar] [CrossRef]

- Schachter, L.; Ivers, J. D.; Nation, J. A.; Kerslick G., S. Analysis of a diode with a ferroelectric cathode, J. Appl. Phys. 1993, 73, 8097. [Google Scholar] [CrossRef]

- Riege, H. Electron emission from ferroelectrics - a review, Nucl. Instrum. Methods Phys. Res. A 1994, 340(1), 80–89. [Google Scholar] [CrossRef]

- Rosenman, G.; Shur, D.; Krasik, Ya. E.; Dunaevsky, A. Electron emission from ferroelectrics, J. Appl. Phys. 2000, 88, 6109. [Google Scholar] [CrossRef]

- Mesyats, G. A. Electron emission from ferroelectric plasma cathodes, Phys. - Uspekhi 2008, 178(1), 85 - 108. [CrossRef]

- Watanabe, K.; Taniguchi, T.; Niiyama, T.; Miya, K.; Taniguchi, M. Far-ultraviolet plane-emission handheld device based on hexagonal boron nitride, Nat. Photon. 2009, 3, 591–594. [Google Scholar] [CrossRef]

- Oto, T.; Banal, R. G.; Kataoka, K.; Funato, M.; Kawakami, Y. 100 mW deep-ultraviolet emission from aluminium-nitride-based quantum wells pumped by an electron beam, Nat. Photon. 2010, 4, 767–771. [Google Scholar] [CrossRef]

- Shimahara, Y. , Miyake, H.; Hiramatsu, K.; Fukuyo, F.; Okada, T.; Takaoka, H.; Yoshida, H. Fabrication of Deep-Ultraviolet-Light-Source Tube Using Si-Doped AlGaN, Appl. Phys. Express 2011, 4, 042103. 4,. [CrossRef]

- Fukuyo, F.; Ochiai, S.; Miyake, H.; Hiramatsu, K.; Yoshida, H.; Kobayashi, Y. Growth and Characterization of AlGaN Multiple Quantum Wells for Electron-Beam Target for Deep-Ultraviolet Light Sources, Jap. J. Appl. Phys. 2013, 52, 01AF03. [Google Scholar] [CrossRef]

- Duboz, J. Y.; Binet, F.; Dolfi, D.; Laurent, N.; Scholz, F.; Off, J.; Sohmer, A.; Briot, O.; Gil, B. Diffusion length of photoexcited carriers in GaN, Mater. Sci. Eng. B 1997, 50, 289. [Google Scholar] [CrossRef]

- Yakimov, E. B. Electron-beam-induced-current study of defects in GaN; experiments and simulation, J. Phys. Condens. Matter. 2002, 14, 13069. [Google Scholar] [CrossRef]

- Lin, Y.; Flitsyian, E.; Chernyak, L.; Malinauskas, T.; Aleksiejunas, R.; Jarašiunas, K.; Lim, W.; Pearton, S. J.; Gartsman, K. Optical and electron beam studies of carrier transport in quasibulk GaN, Appl. Phys. Lett. 2009, 95, 092101. [Google Scholar] [CrossRef]

- Hocker, M.; Maier, P.; Jerg, L.; Tischer, I.; Neusser, G.; Kranz, C.; Pristovsek, M.; Humphreys, C. J.; Leute, R. A. R. , Heinz, D. ; Rettig, O.; Scholz, F.; Thonke, K. Determination of axial and lateral exciton diffusion length in GaN by electron energy dependent cathodoluminescence, J. Appl. Phys. 2016, 120, 085703. [Google Scholar] [CrossRef]

- Brandt, O.; Kaganer, V. M.; Lähnemann, J.; Flissikowski, T.; Pfüller, C.; Sabelfeld, K. K. , Kireeva, A. E., Chèze, C.; Calarco, R.; Grahn, H. T.; Jahn, U. Carrier Diffusion in GaN: A Cathodo-luminescence Study. II. Ambipolar versus Exciton Diffusion, Phys. Rev. Applied 2022, 17, 024018. [Google Scholar] [CrossRef]

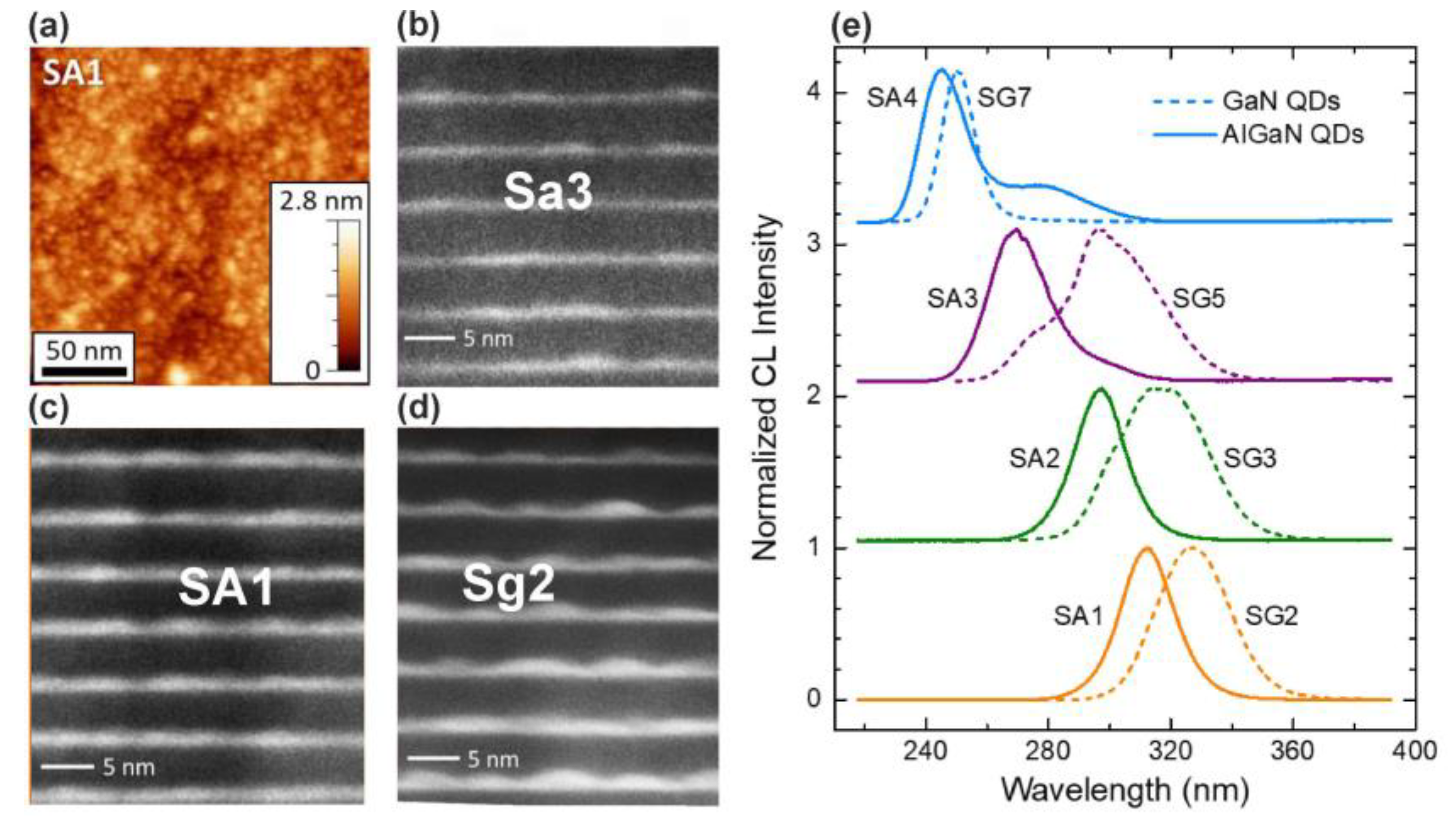

- Zheng, H.; Sharma, V. K.; Tsai, P.; Zhang, Y.; Lu, S.; Zhang, X.; Tan, S. T.; Demir, H. V. Engineered ultraviolet InGaN/AlGaN multiple-quantum-well structures for maximizing cathodoluminescence efficiency, AIP Advances 2022, 12, 015005. 12. [CrossRef]

- Barjon, J.; Brault, J.; Daudin, B.; Jalabert, D.; Sieber, B. Cathodoluminescence study of carrier diffusion in AlGaN, J. Appl. Phys. 2003, 94, 2755. [Google Scholar] [CrossRef]

- Koppe, T.; Hofsäss, H.; Vetter, U. Overview of band-edge and defect related luminescence in aluminum nitride, J. Lumin. 2016, 178, 267–281. [Google Scholar] [CrossRef]

- Liu, J.; Tam, W.S.; Wong, H.; Filip, V. Temperature-dependent light-emitting characteristics InGaN/GaN diodes, Microelectron. Reliab. 2009, 49, 38–41. [Google Scholar] [CrossRef]

- Yasan, A.; McClintock, R.; Mayes, K.; Kim, D.H.; Kung, P. , Razeghi, M. Photoluminescence study of AlGaN-based 280nm ultraviolet light-emitting diodes, Appl. Phys. Lett. 2003, 83, 4083. [Google Scholar] [CrossRef]

- Pinos, A.; Liuolia, V.; Marcinkevičius, S.; Yang, J. , Gaska, R.; Shur, M.S. Localization potentials in AlGaN epitaxial films studied by scanning ear-field optical spectroscopy, J. Appl. Phys. 2011, 109, 113516. 109,. [CrossRef]

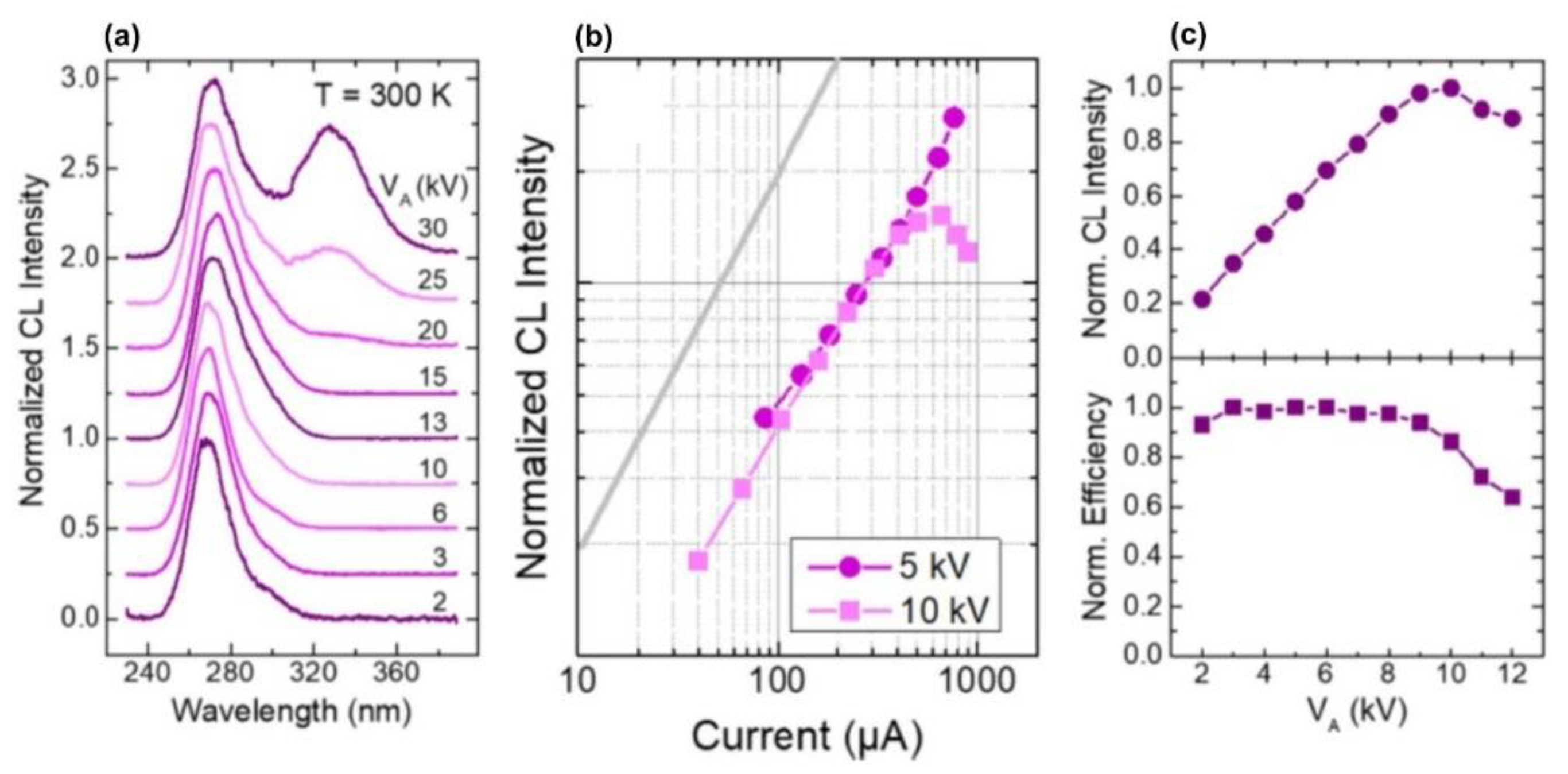

- Ivanov, S. V.; Jmerik, V. N.; Nechaev, D. V.; Kozlovsky, V. I.; Tiberi, M. D. E-beam pumped mid-UV sources based on MBE-grown AlGaN MQW, Phys. Status Solidi A 2015, 212, 1011. [Google Scholar] [CrossRef]

- Jmerik, V.N.; Shubina, T.V.; Mizerov, A.M.; Belyaev, K.G.; Sakharov, A.V.; Zamoryanskaya, M.V.; Sitnikova, A.A.; Davydov, V.Yu.; Kop’ev, P.S.; Lutsenko, E.V.; Rzheutskii, N.V.; Danilchik, A.V.; Yablonskii, G.P.; Ivanov, S.V. AlGaN quantum well structures for deep-UV LEDs grown by plasma-assisted MBE using sub-monolayer digital-alloying technique, J. Crystal Growth 2009, 311, 2080–2083. [Google Scholar] [CrossRef]

- Rong, X.; Wang, X. Q.; Ivanov, S. V.; Jiang, X. H.; Chen, G.; Wang, P.; Wang, W. Y.; He, C. G.; Wang, T.; Schulz, T.; Albrecht, M.; Jmerik, V. N.; Toropov, A. A.; Ratnikov, V. V.; Kozlovsky, V. I.; Martovitsky, V. P.; Jin, P.; Xu, F. J.; Yang, X. L.; Qin, Z. X.; Ge, W. K.; Shi, J. J.; Shen, B. High-output-power ultraviolet light source from quasi-2D GaN quantum structure, Adv. Mater. 2016, 28, 7978–7983. [Google Scholar] [CrossRef]

- Kamiya, K.; Ebihara, Y.; Shiraishi, K.; Kasu, M. Structural design of AlN/GaN superlattices for deep-ultraviolet light-emitting diodes with high emission efficiency, Appl. Phys. Lett. 2011, 99, 151108. [Google Scholar] [CrossRef]

- Taniyasu, Y.; Kasu, M. Polarization property of deep-ultraviolet light emission from c-plane AlN/GaN short-period superlattices, Appl. Phys. Lett. 2011, 99, 251112. [Google Scholar] [CrossRef]

- Bayerl, D.; Islam, S.M.; Jones, C.M.; Protasenko, V.; Jena, D.; Kioupakis, E. Deep ultraviolet emission from ultra-thin GaN/AlN heterostructures, Appl. Phys. Lett. 2016, 109, 241102. [Google Scholar] [CrossRef]

- Liu, C.; Ooi, Y. K.; Islam, S. M.; Xing, H. (Grace), Jena, D. , Zhang, J. 234 nm and 246 nm AlN-Delta-GaN quantum well deep ultraviolet light-emitting diodes, Appl. Phys. Lett. 2018, 112, 011101. [Google Scholar] [CrossRef]

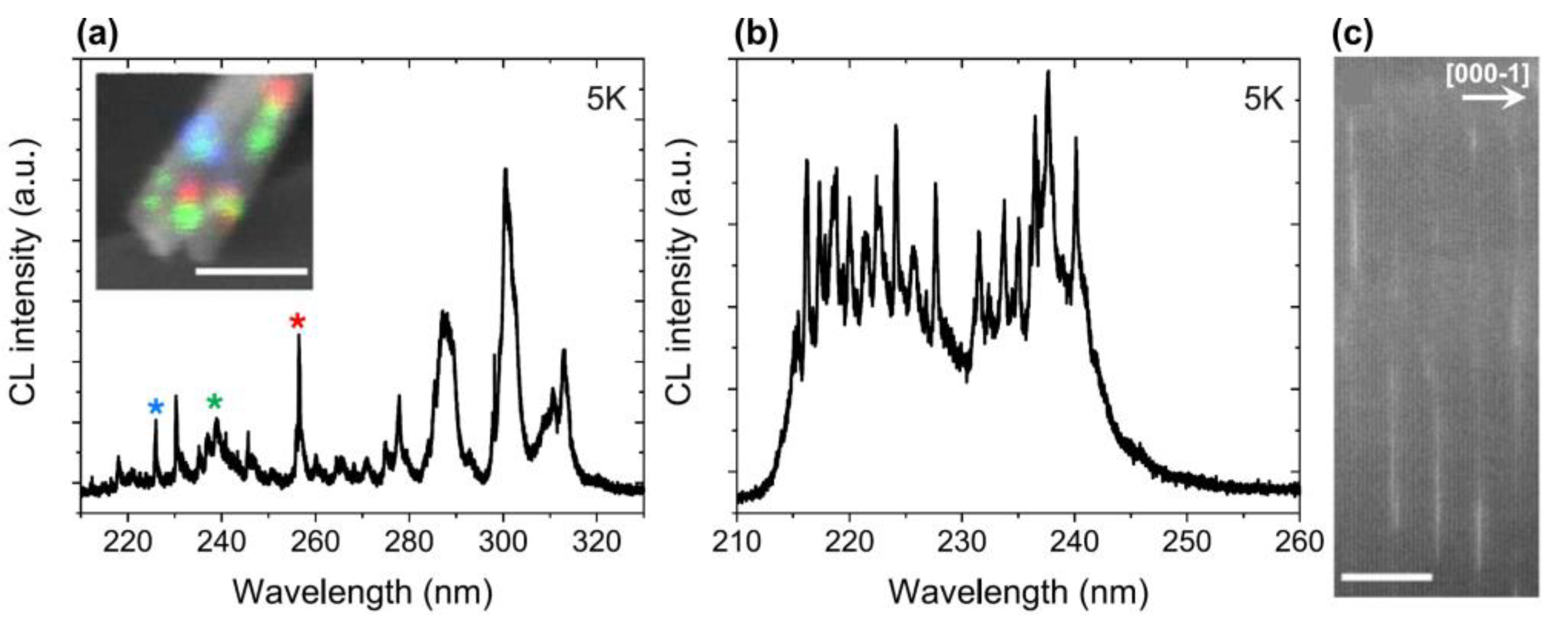

- Jmerik, V.N.; Nechaev, D.V.; Toropov, A.A.; Evropeitsev, E.A.; Kozlovsky, V.I.; Martovitsky, V.P. , Rouvimov, S. ; Ivanov, S.V. High-efficiency electron-beam-pumped sub-240-nm ultraviolet emitters based on ultra-thin GaN/AlN multiple quantum wells grown by plasma-assisted molecular-beam epitaxy on c-Al2O3, Appl. Phys. Express 2018, 11, 091003. [Google Scholar] [CrossRef]

- Jmerik, V.N.; Nechaev, D.V.; Ivanov, S.V. Kinetics of metal-rich PA molecular beam epitaxy of AlGaN heterostructures for mid-UV photonics, in Molecular Beam Epitaxy: from Research to Mass Production, 2nd ed.; Henini, M., Ed.; Elsevier Inc.: Amsterdam, Netherlands, Oxford, UK, Cambridge, USA, 2018; pp. 135–179. [Google Scholar] [CrossRef]

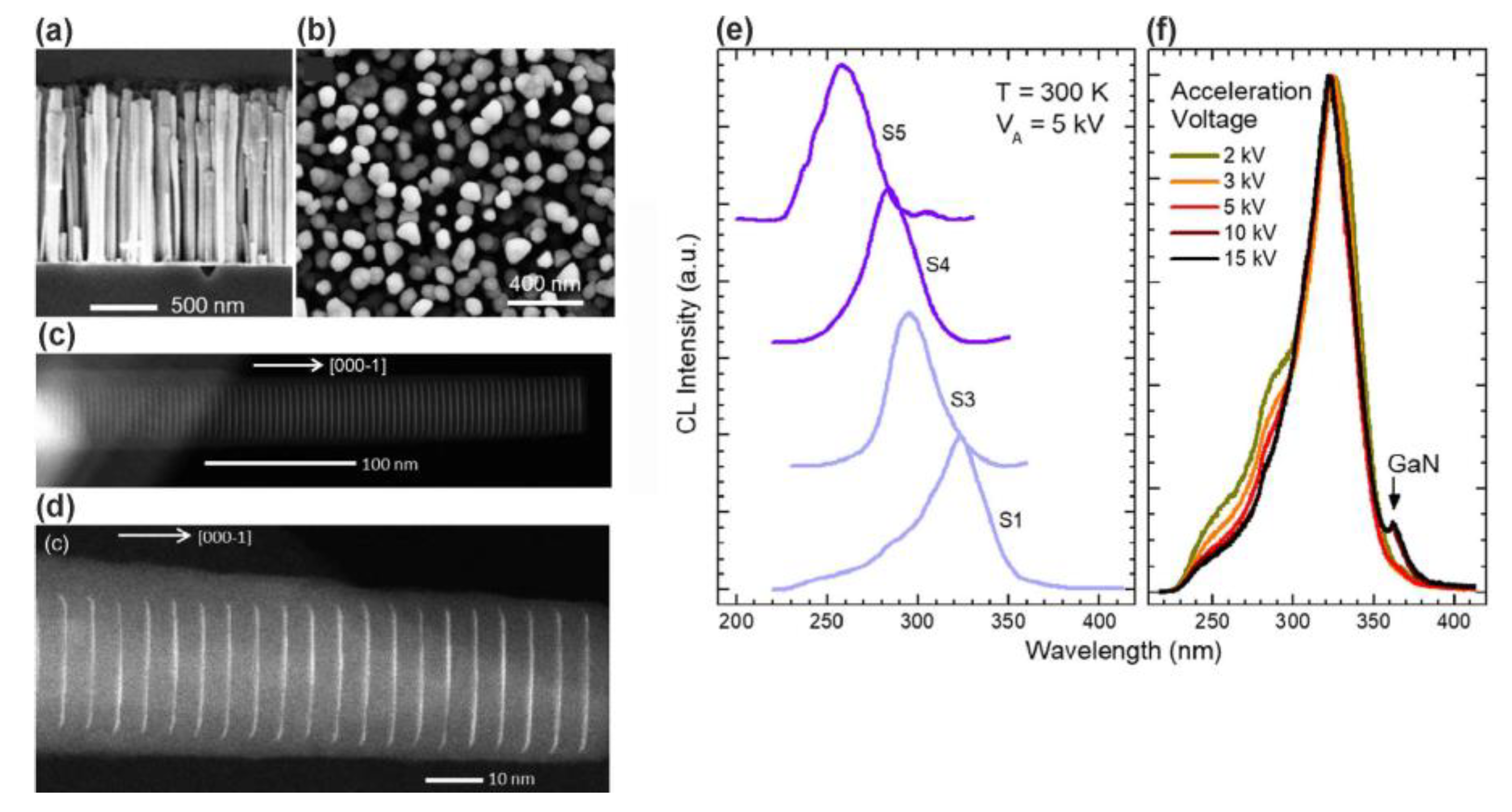

- Dimkou, I.; Harikumar, A.; Ajay, A.; Donatini, F.; Bellet-Amalric, E.; Grenier, A. ; den Hertog, M I.; Purcell, S. T.; Monroy, E. Design of AlGaN/AlN Dot-in-a-Wire Heterostructures for Electron-Pumped UV Emitters, Physica Status Solidi A 2020, 217(7), 1900714. [CrossRef]

- Dimkou, A.; Harikumar, F.; Donatini, J.; Lähnemann, M. I. ; den Hertog, Bougerol, C. ; Bellet-Amalric, E.; Mollard, N.; Ajay, A.; Ledoux, G.; Purcell, S. T.; Monroy, E. Assessment of AlGaN/AlN superlattices on GaN nanowires as active region of electron-pumped ultraviolet sources, Nanotechnology 2020, 31, 204001. [Google Scholar] [CrossRef] [PubMed]

- Harikumar, F. Donatini, C. Bougerol, E. Bellet-Amalric, Q-M. Thai, C. Dujardin, I. Dimkou, S.T. Purcell, E. Monroy, Internal quantum efficiency of AlGaN/AlN quantum dot superlattices for electron-pumped ultraviolet sources, Nanotechnology 2020, 31(50), 505205. [CrossRef]

- Widmann, F.; Daudin, B.; Feuillet, G.; Samson, Y.; Rouvie`re, J. L.; Pelekanos, N. Growth kinetics and optical properties of self-organized GaN quantum dots, J. Appl. Phys. 1998, 83, 7618. [Google Scholar] [CrossRef]

- Mula, G.; Adelmann, C.; Moehl, S.; Oullier, J.; Daudin, B. Surfactant effect of gallium during molecular-beam epitaxy of GaN on AlN(0001), Phys. Rev. B 2001, 64, 195406. [Google Scholar] [CrossRef]

- Adelmann, C.; Daudin, B.; Oliver, R. A. ; D. Briggs, G. A.; Rudd, R. E. Nucleation and growth of GaN/AlN quantum dots, Phys. Rev. B 2004, 70, 125427. [Google Scholar] [CrossRef]

- Gogneau, N.; Jalabert, D.; Monroy, E.; Sarigiannidou, E.; Rouvie`re, J. L.; Shibata, T.; Tanaka, M.; Gerard, J. M.; Daudin, B. Influence of AlN overgrowth on structural properties of GaN quantum wells and quantum dots grown by plasma-assisted molecular beam epitaxy, J. Appl. Phys. 2004, 96, 1104–1110. [Google Scholar] [CrossRef]

- Vermeersch, R.; Jacopin, G.; Castioni, F.; Rouvière, J.-L.; García-Cristóbal, A.; Cros, A.; Pernot, J.; Daudin, B. Ultrathin GaN quantum wells in AlN nanowires for UV-C emission, Nanotechnology 2023, 34, 275603. 34. [CrossRef]

- Mokutani, N.; Deura, M.; Mouri, S.; Shojiki, K.; Xiao, S.; Miyake, H.; Araki, T. Control of Metal-Rich Growth for GaN/AlN Superlattice Fabrication on Face-to-Face-Annealed Sputter-Deposited AlN Templates, Phys. Status Solidi B 2023, 2300061. [Google Scholar] [CrossRef]

- T. Yamaguchi, Y. T. Yamaguchi, Y. Nanishi1, Indium Droplet Elimination by Radical Beam Irradiation for Reproducible and High-Quality Growth of InN by RF Molecular Beam Epitaxy, Applied Physics Express 2 (2009) 051001. [CrossRef]

- Y. Wang, Y. Yuan, R. Tao, S. Liu, T. Wang, S. Sheng, P. Quach, M. Kumar CM, Z. Chen, F. Liu, X. Rong, P. Jin, M. Feng, H. Li, S. Guo, W. Ge, J. K. Lee, B. Shen, X. Wang, High-Efficiency E-Beam Pumped Deep-Ultraviolet Surface Emitter Based on AlGaN Ultra-Thin Staggered Quantum Wells. Adv. Optical Mater 2022, 2200011. [CrossRef]

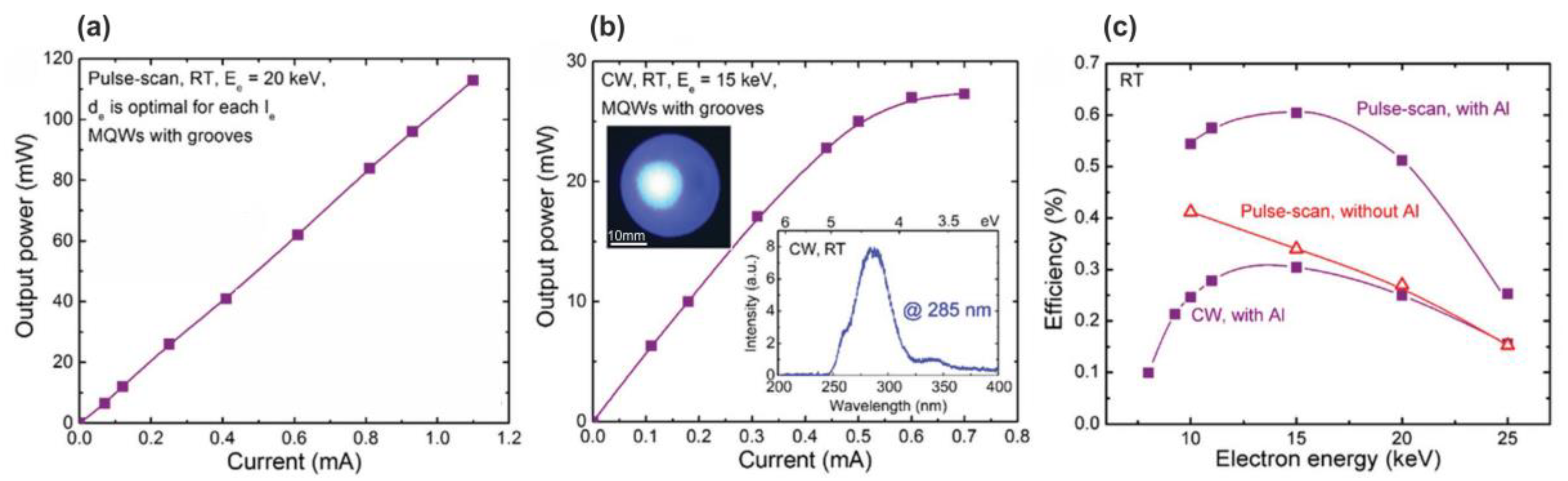

- Wang, Y.; Rong, X.; Ivanov, S.; Jmerik, V.; Chen, Z.; Wang, H.; Wang, T.; Wang, P.; Jin, P.; Chen, Y.; Kozlovsky, V.; Sviridov, D.; Zverev, M.; Zhdanova, E.; Gamov, N.; Studenov, V.; Miyake, H.; Li, H.; Guo, S.; Yang, X.; Xu, F.; Yu, T.; Qin, Z.; Ge, W.; Shen, B.; Wang, X. Deep Ultraviolet Light Source from Ultrathin GaN/AlN MQW Structures with Output Power Over 2 Watt, Adv. Optical Mater. 2019, 1801763. [Google Scholar] [CrossRef]

- Jmerik, V.N.; Nechaev, D.V.; Orekhova, K.N.; Prasolov, N.D.; Kozlovsky, V.I.; Sviridov, D.E.; Zverev, M.M.; Gamov, N.A.; Grieger, L.; Wang, Y.; Wang, T.; Wang, X.; Ivanov, S. Monolayer-Scale GaN/AlN Multiple Quantum Wells for High Power e-Beam Pumped UV-Emitters in the 240–270 nm Spectral Range. Nanomaterials 2021, 11, 2553. [Google Scholar] [CrossRef]

- Nechaev, D.V.; Koshelev, O.A.; Ratnikov, V.V.; Brunkov, P.N.; Myasoedov, A.V.; Sitnikova, A. A.; Ivanov, S.V.; Jmerik, V.N. Effect of stoichiometric conditions and growth mode on threading dislocations filtering in AlN/c-Al2O3 templates grown by PA MBE, Superlattices and Microst. 2020, 138, 106368. [CrossRef]

- Koshelev, O.A.; Nechaev, D.V.; Brunkov, P.N.; Ivanov, S.V.; Jmerik, V.N. Stress control in thick AlN/c-Al2O3 templates grown by plasma-assisted molecular beam epitaxy, Semicond. Sci. Technol. 2021, 36, 035007–13pp. [Google Scholar] [CrossRef]

- Kaneko, M.; Ueta, S.; Horita, M.; Kimoto, T.; Suda, J. Deep-ultraviolet light emission from 4H-AlN/4H-GaN short-period superlattice grown on 4H-SiC(11-20), Appl. Phys. Lett. 2018, 112, 012106. [Google Scholar] [CrossRef]

- Kobayashi, H.; Ichikawa, S.; Funato, M.; Kawakami, Y. Self-Limiting Growth of Ultrathin GaN/AlN Quantum Wells for Highly Efficient Deep Ultraviolet Emitters, Adv. Optical Mater. 2019, 1900860. [Google Scholar] [CrossRef]

- Jmerik, V.; Nechaev, D.; Semenov, A.; Evropeitsev, E.; Shubina, T.; Toropov, A.; Yagovkina, M.; Alexeev, P.; Borodin, B.; Orekhova, K.; Kozlovsky, V.; Zverev, M.; Gamov, N.; Wang, T.; Wang, X.; Pristovsek, M.; Amano, H.; Ivanov, S. 2D-GaN/AlN Multiple Quantum Disks/Quantum Well Heterostructures for High-Power Electron-Beam Pumped UVC Emitters, Nanomaterials 2023, 13, 1077. 13. [CrossRef]

- Toropov, A.A.; Evropeitsev, E.A.; Nestoklon, M.O.; Smirnov, D.S.; Shubina, T.V.; Kaibyshev, V.Kh.; Budkin, G.V.; Jmerik, V.N.; Nechaev, D.V.; Rouvimov, S.; et al. Strongly confined excitons in GaN/AlN Nanostructures with atomically thin GaN Layers for efficient light emission in deep-ultraviolet. Nano Lett. 2020, 20, 158–165. [Google Scholar] [CrossRef] [PubMed]

| Units | Thermionic cathodes |

Carbon-based cold field emitters | Plasma cathodes | |||||

| W | LaB6 | Graphene nanoneedle |

CNT-CVD | CNT-Paste | Hollow cathode |

Ferroelectric cathode | ||

| Work function, (W) | eV | 4.5 | 2.4-2.7 | - | 5 | - | - | - |

| Richardson’s constant, (A) | A·m-2K-2 |

6·109 | 4·109 | - | - | - | - | - |

| Operating temperature, (T) | K | 2700 | 1700 | 300 | 300 | 300 | 300 | 300 |

| Crossover (beam) size | mm | >0.1 | 0.01 | - | - | - | ||

| Brightness | A·m-2sr-1 | 1010 | 5·1011 | 1013 | ||||

| Emission current stability | %·hr-1 | <1 | <1 | good | poor | |||

| Vacuum | Pa | 10-2 | 10-4 | 10-4 | 10-5 | 10-5 | 10-1 | 10-2-10-3 |

| Lifetime | hr | 100 | 1000 | >5000 | >107pulses | |||

| Gate voltage | kV | - | - | - | ~1.5 | 2.7 | 0.8 − 1.5 | |

| Anode voltage | kV | 10 − 20 | 10 − 20 | 3 − 10 | ~5 | 7 | 5 − 15 | |

| Maximum anode (e-beam) current | A | 1 − 5 | 60 | 0.5 | 1.5 | ~5.5 | cw:0.4 peak: 120 |

peak: 2 |

| Technology | H2-plasma etching | PECVD | MOCVD+screen-printing | |||||

| Radius of tip | nm | - | - | 5 | 60 | 5 − 7 | - | - |

| e-emission area | mm2 | ~1 | ~1 | - | ~300 | Up to 2-inch | >250 | ~20 |

| Operation mode | Cw-& Pulsed |

Pulse | Cw-& Pulsed |

Cw-& Pulsed |

Cw-& Pulsed |

Cw-& Pulsed |

Pulsed | |

| № | Emitter (Powder/Layer/ MQW structure) |

Technology | λ | Output optical power | e-beam | WPE (IQE) |

Life time |

Year, Institute |

Ref. | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cathode | Energy | Current | Area | |||||||||||

| Pulse (Scan) |

cw- | |||||||||||||

| nm | mW | mW | keV | mA | cm2 | % | hrs | |||||||

| 1 | Pyro-BN Powder | HP HT |

225 | 0.2 | W-TE | 8 | 0.05 | 0.2 | 0.5 | >150 | 2009, National Institute for Materials Science | [84] | ||

| 2 | 8×{Al0.69Ga0.31N(1nm)}/ AlN(15nm) |

MO CVD |

240 | 100 | W-TE | 8 | 0.05 | 0.002 | 40 | 1 | 2010, Kyoto Univ. |

[85] | ||

| 3 | AlGaN:Si(800nm)/AlN Layer |

MO CVD |

247 | 2.2 | TE | 10 | 0.1 | 0.003 | 0.24 | >2· 103 |

2011, Mie Univ. Hamamatsu |

[86] | ||

| 4 | 10×{Al0.7Ga0.3N(3nm)/ AlN(3нм) |

MO CVD |

240 | 20 | Graphe-ne -FE |

7.5 | 0.08 | 7 | 3−4 | >5·103 | 2012, Stanley Electric corp.& Nagoya Univ. |

[63] | ||

| 5 | 70×Al0.6Ga0.4N:Si(1.5nm)/Al0.75Ga0.25N:Si(7nm) | MO CVD |

256 | 15 | TE | 10 | 0.2 | 0.002 | 0.75 | - | 2013, Mie Univ.& Hamamatsu |

[87] | ||

| 6 | 40×{3×[(GaN)1/(Al0.75Ga0.25N)2]/(Al0.75Ga0.25N)124} | PA MBE | 270 | 60 | 4.7 | W-TE | ps:32p cw:20 |

ps:1.2 cw:0.1 |

0.5 | 0.19 0.24 |

- | 2015, IOFFE |

[99] | |

| 7 | 40×{3×[(GaN)1/(Al0.75Ga0.25N)2]/(Al0.75Ga0.25N)124} | PA MBE | 285 | 160 | 39 | W-TE | ps:20 cw:15 |

ps:1.1 cw:0.7 |

ps:3·10-4 cw:0.8 |

ps:0.86 cw:0.43 |

- | 2016, Peking Univ.&IOFFE |

[101] | |

| 8 | 10×Al0.56Ga0.44N(1.5nm)/Al0.9Ga0.1N(40nm) | MO CVD |

246 | 230 | - | W-TE | p:12 | p:4.4 | p:0.07 | p:0.43 | - | 2016, Palo-Alto & TU-Berlin |

[57] | |

| 9 | 360×{GaN1.5/AlN22} | PA MBE | 235 | 150 | 28 | W-TE | ps:20 cw:15 |

ps:1.0 cw:0.45 |

ps:0.75 cw:0.42 |

2018, IOFFE |

[106] | |||

| 10 |

5×Al0.47Ga0.53N/Al0.56Ga0.44N | MO CVD |

279 | - | 30 | CNT | 3 | 0.8 | 3.03 | 1.25 | 2019, Kying Univ. Korea |

[65] | ||

| 11 |

100×{GaN3/AlN40} 100×{GaN2/AlN40} 100×{GaN1/AlN40} 150×{GaN2/AlN40} |

MO CVD |

265 243 232 258 |

179 123 25 2200 |

53 39 0.8 |

TE TE TE LaB6 |

Ps:20 Ps:20 Ps:20 Ps:18 |

1.2 1.2 1.0 Ps:37 |

0.01 0.01 0.01 0.01 |

0.75 0.51 0.13 0.33 |

2019, Peking Univ.&IOFFE |

[119] | ||

| 12 | Al0.73Ga0.27N/AlN | MOCVD | 233 | - | 6.4 | CNT | 4 | 0.5 | 2.83 | 0.32 | - | 2020, Kying Univ. Korea |

[67] | |

| 13 | NW-88×{(AlxGa1-xN) (0.65-1.5нм) (x=0,0.1)/ AlN (3-4нм) |

PA MBE | 258- 340 |

- | - | W-TE | 2-15 | <120 pA |

- | IQE: 22-63% |

- | 2020, Univ. Grenoble-Alpes |

[109] | |

| 14. | NW-88×{(AlxGa1-xN) (0.65-1.5нм) (0≤x≤0.1)/ AlN (3-4нм) |

PA MBE | 258- 340 |

3-10 | 0.4 | 0.13 (4mmdia) |

IQE: >60% |

2020, Univ. Grenoble-Alpes |

[110] | |||||

| 15 | 100×{QD-QW(AlxGa1-xN) (0.65-1.5нм) (x=0,0.1)/AlN(3-4нм) |

PA MBE | 244- 335 |

- | W-TE | 3-10 | 0.8 | 0.13 (4mm Dia) |

IQE: 33-54% |

2020, Univ. Grenoble-Alpes |

[111] | |||

| 16. | Bulk k-Al2O3 wafer | 226-400 | - | Peak:1.5 | CNT | 10 | 1.3 | 9.6 | Peak: 0.01 |

2020, Kying Univ. Korea |

[66] | |||

| 17. | 18×{GaN(2.1nm)/Al0.36Ga0.64N(9nm)} | MOCVD | 330 | 225 | CNT | 7 | 1 | ~20 | 3.6 | 2021, Chonnam Nat. Univ. |

[68] | |||

| 18 | 400×{GaN1.5/AlN16} | PA MBE | 240 242 |

103 (11.8· 103) 5µJ/ Pulse |

- | LaB6 TE PC |

P:20 P:12.5 |

P:65 P:450 |

0.008 1mm) 0.13 (4mm Dia) |

0.08 0.2 |

2021, IOFFE&Peking Univ. | [120] | ||

| 19 | 100×{GaN1/AlxGa1xN2/AlN40} (x = 0.6) | MO CVD |

248 | 420 702 |

CNT |

8 8 |

1 3 |

2” | 5.25 |

2022 Peking Univ. |

[118] | |||

| 20 | 400×{GaN1.5/AlN16} | PA MBE | 238-265 | 15W 50W |

- - |

TE, PC |

10 12.5 |

30нА 2А |

1µm 4mm |

0.1-0.3 |

2021, IOFFE&Peking Univ. | [121] | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).