Submitted:

21 June 2023

Posted:

22 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Experiment matrix

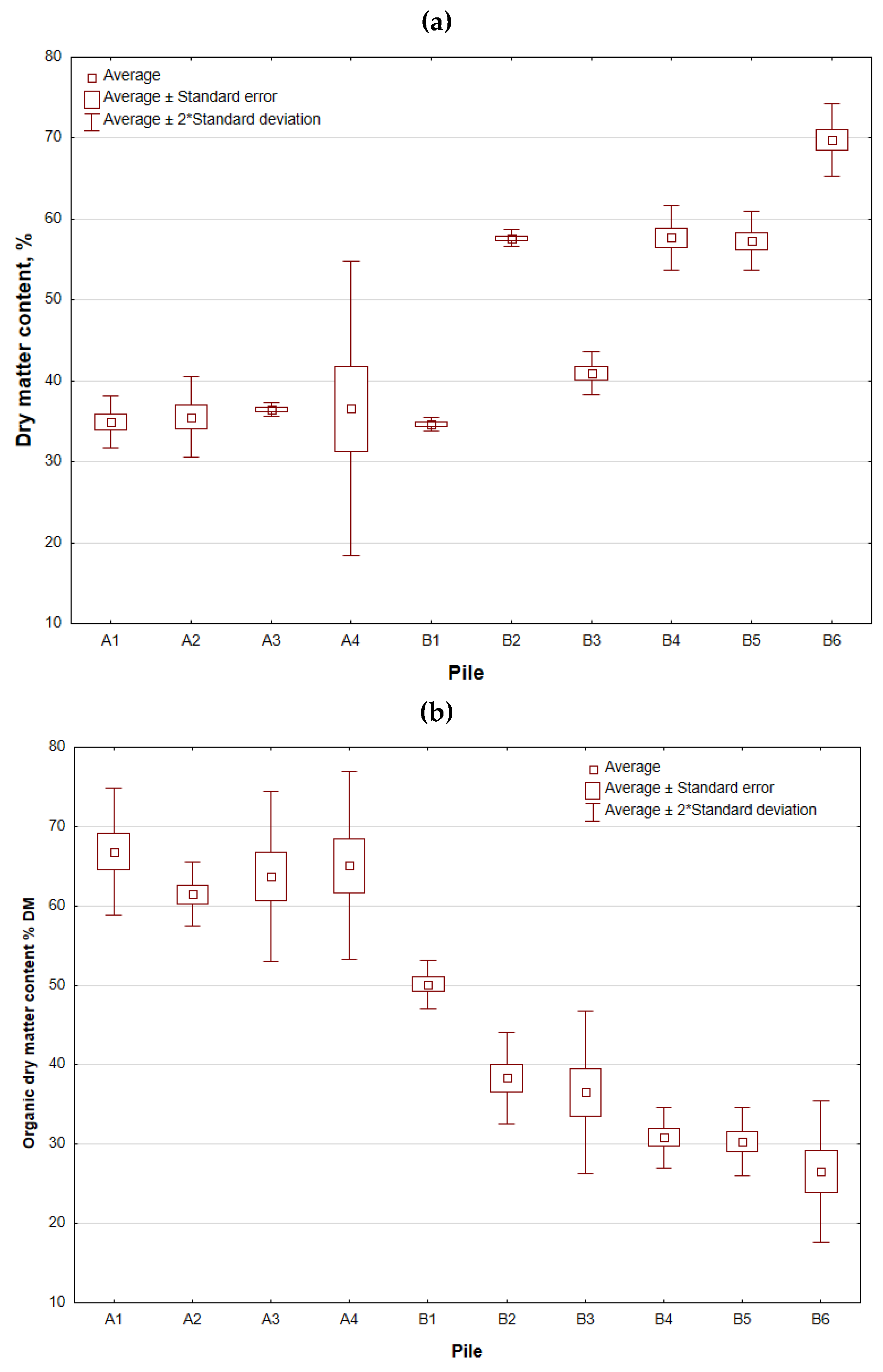

2.2. Biowaste characterization

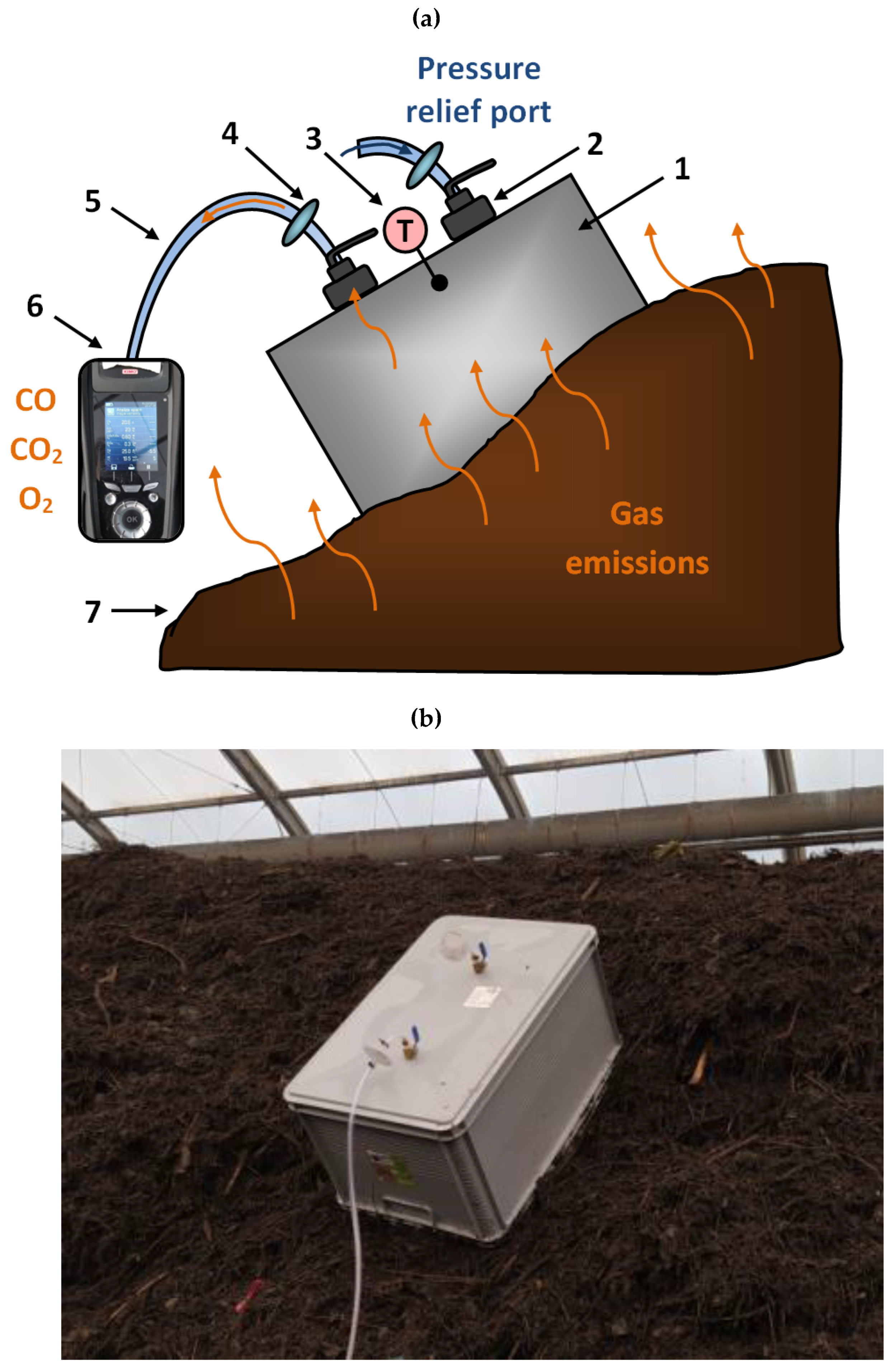

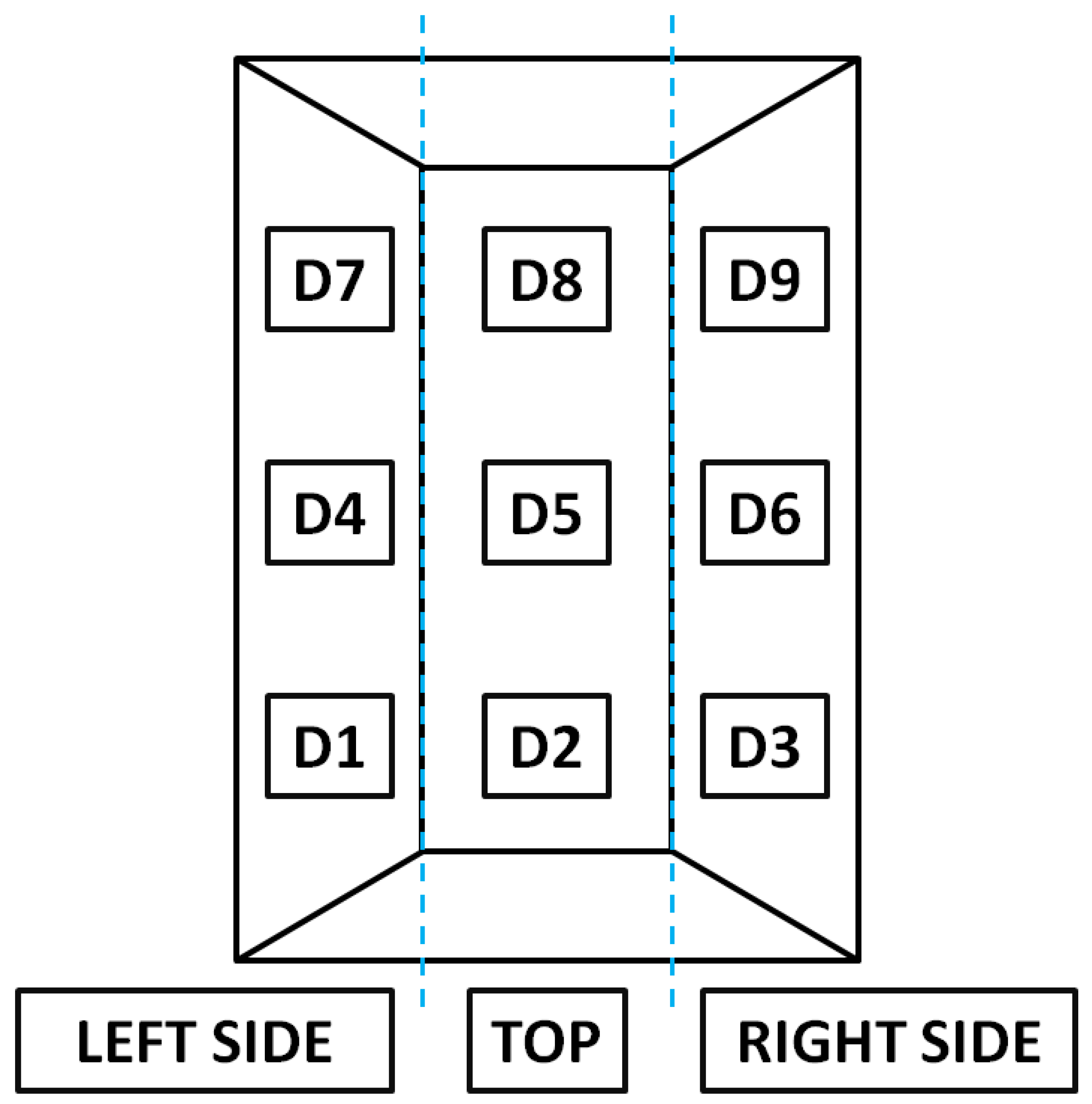

2.3. Analysis of process gas emissions from compost piles

2.4. Estimating CO emissions

- cm – CO concentration, mg‧m-3,

- cv – CO concentration, ppmv,

- MCO – molecular weight of CO, MCO = 28×103 mg‧mol-1,

- VCO – molecular volume of CO at standard conditions, VCO = 0.0224 m3‧mol-1,

- T – analysed gas temperature during measurement.

- Q – CO flux, mg‧m-2‧s-1,

- V – volume of the flux chamber, V = 0.071 m3,

- A – emitting surface area of compost pile enclosed by the flux chamber (flux chamber footprint), A = 0.23 m2,

- dc/dt – rate of change of measured CO concentration in the flux chamber with time, determined by plotting CO concentrations on chart with the x-axis representing time (s) and the y-axis representing the mass concentrations (mg‧m-3), mg‧m-3‧s-1.

2.5. Modelling of CO emissions in the composting plant

- mCO – mass of the emitted CO during t = 1 h for both before and after compost turning, mg,

- Qa – averaged flux of CO from measurement locations D1-D9 on compost pile, mg‧m-2‧s-1,

- Ap – surface of n=1 compost pile, Ap = 300 m2,

- t – time, t = 3600 s,

- n – number of piles inside hermetised composting hall, n = 4.

- CCO – CO concentration in the headspace of the composting hall after accumulation for t = 1 h for both before & after compost turning, mg‧m-3,

- Vhall – volume of the headspace of the airtight composting hall, Vhall = 1,000 m3.

- CCO v – CO concentration in the headspace of the composting hall after accumulation for t = 1 h for both before/after compost turning, ppm.

2.6. Statistical Analyses

3. Results

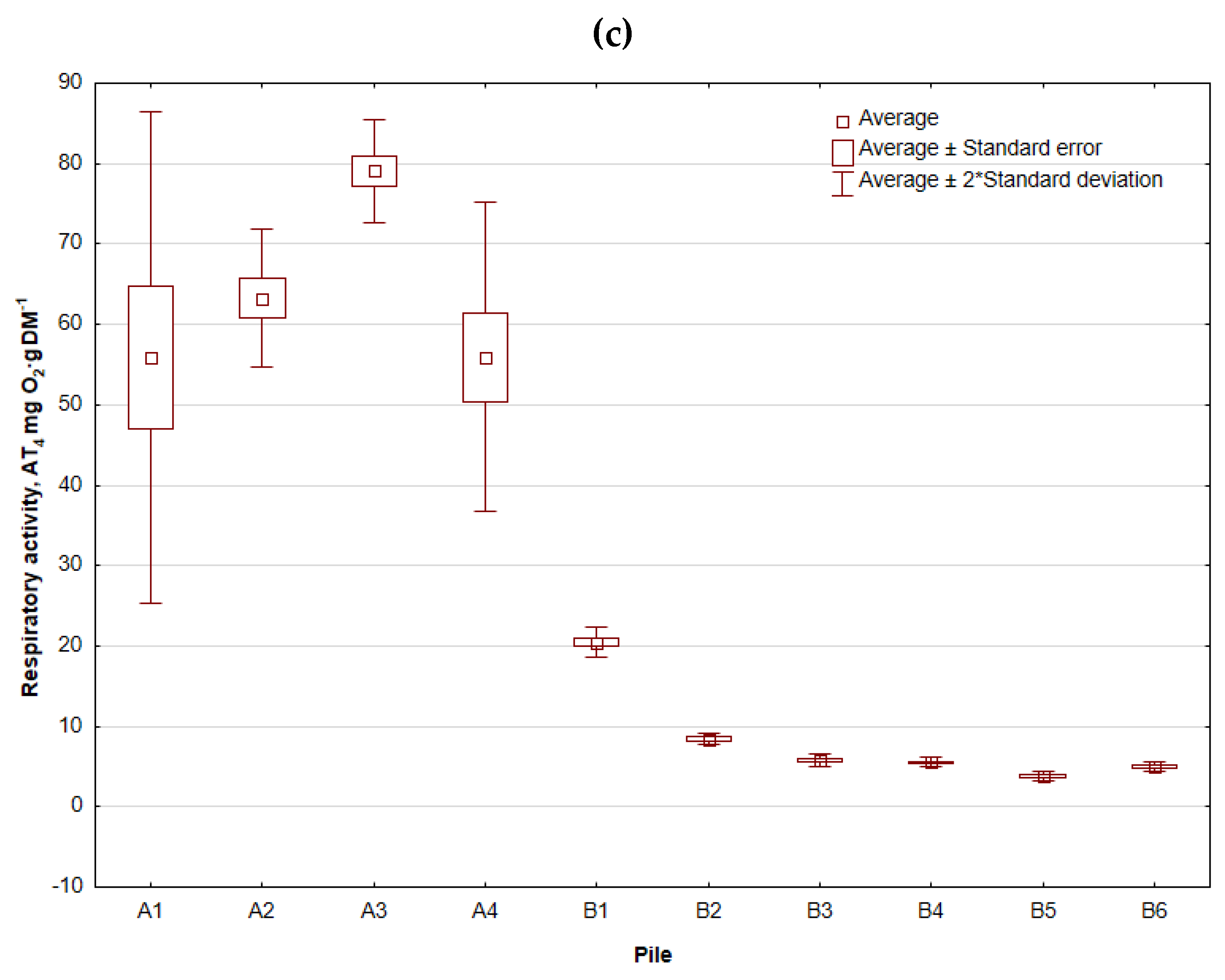

3.1. Compost biowaste characterization

3.2. CO fluxes from composting piles

3.3. CO concentration accumulation in the hermetised composting plant

3.4. Relationship between CO and other process gases and temperature

4. Discussion

5. Conclusions and recommendations

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Körner, I.; Visvanathan, C. Perspectives of Composting and Anaerobic Digestion Technologies for the Treatment of Organic Fraction of Municipal Solid Waste in Europe and Asia. International Journal of Environment and Waste Management 2013, 11, 193–212. [Google Scholar] [CrossRef]

- Slater, R.A.; Frederickson, J. Composting Municipal Waste in the UK: Some Lessons from Europe. Resources, Conservation and Recycling 2001, 32, 359–374. [Google Scholar] [CrossRef]

- European Compost Network e.V. ECN Status Report 2019 – European Bio-Waste Management. Overview of Bio-Waste Collection, Treatment & Markets Across Europe; 2019.

- Pinasseau, A.; Zerger, B.; Roth, J.; Canova, M.; Roudier, S. Best Available Techniques (BAT) Reference Document for Waste Treatment Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control) 2018.

- Tolvanen, O.; Nykänen, J.; Nivukoski, U.; Himanen, M.; Veijanen, A.; Hänninen, K. Occupational Hygiene in a Finnish Drum Composting Plant. Waste Manag 2005, 25, 427–433. [Google Scholar] [CrossRef]

- Taha, M.; Drew, G.; Longhurst, P.; Smith, R.; Pollard, S. Bioaerosol Releases from Compost Facilities: Evaluating Passive and Active Source Terms at a Green Waste Facility for Improved Risk Assessments. Atmospheric Environment 2006, 40, 1159–1169. [Google Scholar] [CrossRef]

- Stegenta, S.; Dębowski, M.; Bukowski, P.; Randerson, P.F.; Białowiec, A. The Influence of Perforation of Foil Reactors on Greenhouse Gas Emission Rates during Aerobic Biostabilization of the Undersize Fraction of Municipal Wastes. Journal of Environmental Management 2018, 207, 355–365. [Google Scholar] [CrossRef]

- Stegenta, S.; Sobieraj, K.; Pilarski, G.; Koziel, J.A.; Białowiec, A. Analysis of the Spatial and Temporal Distribution of Process Gases within Municipal Biowaste Compost. Sustainability 2019, 11, 2340. [Google Scholar] [CrossRef]

- Stegenta-Dąbrowska, S.; Drabczyński, G.; Sobieraj, K.; Koziel, J.A.; Białowiec, A. The Biotic and Abiotic Carbon Monoxide Formation During Aerobic Co-Digestion of Dairy Cattle Manure With Green Waste and Sawdust. Front. Bioeng. Biotechnol. 2019, 7. [Google Scholar] [CrossRef]

- Phillip, E.A.; Clark, O.G.; Londry, K.; Yu, S.; Leonard, J. Emission of Carbon Monoxide During Composting of Municipal Solid Waste. Compost Science & Utilization 2011, 19, 170–177. [Google Scholar] [CrossRef]

- Hellebrand, H.J.; Kalk, W.-D. Emission of Carbon Monoxide during Composting of Dung and Green Waste. Nutrient Cycling in Agroecosystems 2001, 60, 79–82. [Google Scholar] [CrossRef]

- Haarstad, K.; Bergersen, O.; Sorheim, R. Occurrence of Carbon Monoxide during Organic Waste Degradation. Journal of the Air & Waste Management Association 2006, 56, 575–581. [Google Scholar] [CrossRef]

- Stegenta, S.; Sobieraj, K.; Pilarski, G.; Koziel, J.A.; Białowiec, A. The Spatial and Temporal Distribution of Process Gases within the Biowaste Compost. Data 2019, 4, 37. [Google Scholar] [CrossRef]

- Sobieraj, K.; Stegenta-Dąbrowska, S.; Koziel, J.A.; Białowiec, A. Modeling of CO Accumulation in the Headspace of the Bioreactor during Organic Waste Composting. Energies 2021, 14, 1367. [Google Scholar] [CrossRef]

- Who Guidelines for Indoor Air Quality: Selected Pollutants; World Health Organization, Ed.; WHO: Copenhagen, 2010; ISBN 978-92-890-0213-4.

- Ernst, A.; Zibrak, J.D. Carbon Monoxide Poisoning. N. Engl. J. Med. 1998, 339, 1603–1608. [Google Scholar] [CrossRef]

- Van Meter, K.W.; Weiss, L.; Harch, P.G.; Andrews, L.C.; Simanonok, J.P.; Staab, P.K.; Gottlieb, S.F. Should the Pressure Be off or on in the Use of Oxygen in the Treatment of Carbon Monoxide-Poisoned Patients? Ann Emerg Med 1994, 24, 283–288. [Google Scholar] [CrossRef]

- Townsend, C.L.; Maynard, R.L. Effects on Health of Prolonged Exposure to Low Concentrations of Carbon Monoxide. Occup Environ Med 2002, 59, 708–711. [Google Scholar] [CrossRef]

- Rolston, D.E. Gas Flux. In Methods of Soil Analysis; John Wiley & Sons, Ltd., 1986; pp. 1103–1119 ISBN 978-0-89118-864-3.

- Collier, S.M.; Ruark, M.D.; Oates, L.G.; Jokela, W.E.; Dell, C.J. Measurement of Greenhouse Gas Flux from Agricultural Soils Using Static Chambers. J Vis Exp 2014, 52110. [Google Scholar] [CrossRef]

- Maurer, D.L.; Koziel, J.A.; Bruning, K. Field Scale Measurement of Greenhouse Gas Emissions from Land Applied Swine Manure. Front. Environ. Sci. Eng. 2017, 11, 1. [Google Scholar] [CrossRef]

- Polish Committee for Standardization PN-EN 14346:2011 - Characterization of Waste - Calculation of the Dry Matter from the Determination of the Dry Residue or the Water Content 2011.

- Polish Committee for Standardization PN-EN 15169:2011 - Characterization of Waste - Determination of Loss on Ignition of Waste and Sludge 2011.

- Binner, E.; Böhm, K.; Lechner, P. Large Scale Study on Measurement of Respiration Activity (AT(4)) by Sapromat and OxiTop. Waste Manag 2012, 32, 1752–1759. [Google Scholar] [CrossRef]

- Environment Agency Wales LFTGN07: Guidance on Monitoring Landfill Gas Surface Emissions 2010.

- Ministry of Environment Regulation of the Minister of the Environment of September 11, 2012 on the Mechanical and Biological Treatment of Unsorted Municipal Waste 2012.

- Andersen, J.K.; Boldrin, A.; Samuelsson, J.; Christensen, T.H.; Scheutz, C. Quantification of Greenhouse Gas Emissions from Windrow Composting of Garden Waste. J. Environ. Qual. 2010, 39, 713–724. [Google Scholar] [CrossRef]

- Whittle, C.P.; Waterford, C.J.; Annis, P.C.; Banks, H.J. The Production and Accumulation of Carbon Monoxide in Stored Dry Grain. Journal of Stored Products Research 1994, 30, 23–26. [Google Scholar] [CrossRef]

- Reuss, R.; Pratt, S. Accumulation of Carbon Monoxide and Carbon Dioxide in Stored Canola. J Stored Prod Res 2000, 37, 23–34. [Google Scholar] [CrossRef]

- Svedberg, U.; Högberg, H.-E.; Högberg, J.; Galle, B. Emission of Hexanal and Carbon Monoxide from Storage of Wood Pellets, a Potential Occupational and Domestic Health Hazard. Annals of Occupational Hygiene 2004, 48, 339–349. [Google Scholar] [CrossRef]

- World Health Organization Air Quality Guidelines for Europe; WHO Regional Publications: Copenhagen, Denmark, 2000; Vol. Second edition; ISBN 92 890 1358 3.

- Peterson, J.E. Postexposure Relationship of Carbon Monoxide in Blood and Expired Air. Arch Environ Health 1970, 21, 172–173. [Google Scholar] [CrossRef]

- Büyüksönmez, F. Full-Scale VOC Emissions from Green And Food Waste Windrow Composting. Compost Science & Utilization 2012, 20, 57–62. [Google Scholar] [CrossRef]

- Hellmann, B.; Zelles, L.; Palojarvi, A.; Bai, Q. Emission of Climate-Relevant Trace Gases and Succession of Microbial Communities during Open-Windrow Composting. Appl Environ Microbiol 1997, 63, 1011–1018. [Google Scholar] [CrossRef]

- Sommer, S.G.; McGinn, S.M.; Hao, X.; Larney, F.J. Techniques for Measuring Gas Emissions from a Composting Stockpile of Cattle Manure. Atmospheric Environment 2004, 38, 4643–4652. [Google Scholar] [CrossRef]

- Sobieraj, K.; Stegenta-Dąbrowska, S.; Luo, G.; Koziel, J.A.; Białowiec, A. Carbon Monoxide Fate in the Environment as an Inspiration For Biorefinery Industry: A Review. Frontiers in Environmental Science 2022, 10. [Google Scholar] [CrossRef]

- Seiler, W. The Influence of the Biosphere on the Atmospheric CO and H2 Cycles. In Environmental biogeochemistry and geomicrobiology. Methods, metals and assessment.; Ann Arbor Scientific Publishers, 1978; Vol. 3, pp. 773–810.

- Conrad, R.; Seiler, W. Role of Microorganisms in the Consumption and Production of Atmospheric Carbon Monoxide by Soil. Appl. Environ. Microbiol. 1980, 40, 437–445. [Google Scholar] [CrossRef]

- Whalen, S.C.; Reeburgh, W.S. Carbon Monoxide Consumption in Upland Boreal Forest Soils. Soil Biology and Biochemistry 2001, 33, 1329–1338. [Google Scholar] [CrossRef]

- King, G.M.; Weber, C.F. Distribution, Diversity and Ecology of Aerobic CO-Oxidizing Bacteria. Nat. Rev. Microbiol. 2007, 5, 107–118. [Google Scholar] [CrossRef]

| Pile # | Age of the pile (weeks) | Compost Substrates | Emissions measurements series (per pile) | Season | Location (indoors/outdoors) |

|---|---|---|---|---|---|

| Plant A | |||||

| 1 | 2 | Grass (80%), branches and wood (5%), sewage sludge (15%) |

2 | Autumn (Sep-Oct, 2021) | Enclosed hall (hermetised) |

| 2 | 2 | 3 | |||

| 3 | 3 | 3 | |||

| 4 | 4 | 2 | |||

| Plant B | |||||

| 1 | 8 | Green waste from backyards and parks | 1 | Winter (Feb, 2022) |

Open yard |

| 2 | 8 | 1 | |||

| 3 | 6 | 1 | |||

| 4 | 4 | 1 | |||

| 5 | 3 | 1 | |||

| 6 | 3 | Undersize fraction of municipal waste (<80 mm) |

1 | ||

| Pile # | Measurement series | Turning | CO flux from measurement locations D1-D9 on compost pile (Q), mg‧m-2‧h-1 |

Avg. CO flux, mg‧m-2‧h-1 |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LEFT SIDE | TOP | RIGHT SIDE | ||||||||||

| D1 | D4 | D7 | D2 | D5 | D8 | D3 | D6 | D9 | ||||

| 1 | 1 | Before | 13.22 | -5.22 | -0.78 | 12.34 | 7.67 | 9.22 | 10.89 | 11.78 | 3.22 | 6.93 ± 6.47 |

| After | 135.13 | 2.33 | -5.33 | 194.92 | -2.11 | -4.89 | 136.80 | 1.78 | 1.78 | 51.16 ± 80.22 | ||

| 2 | Before | 33.34 | 20.67 | 19.23 | 12.34 | 26.23 | 16.00 | 28.56 | 15.34 | 19.00 | 21.19 ± 6.85 | |

| After | 75.35 | 68.12 | 37.45 | 59.12 | 33.34 | 38.12 | 59.12 | 67.57 | 31.45 | 52.18 ± 17.04 | ||

| 2 | 1 | Before | 9.89 | 9.56 | 0.33 | 20.67 | 37.12 | 6.33 | 11.00 | 6.78 | 0.11 | 11.31 ± 11.46 |

| After | 142.47 | -1.78 | -3.78 | 350.28 | 86.46 | 1.00 | 188.37 | 3.00 | -2.00 | 84.89 ± 123.05 | ||

| 2 | Before | 10.45 | 10.56 | 9.67 | 53.56 | 27.56 | 15.11 | 13.89 | 16.67 | 17.67 | 19.46 ± 13.90 | |

| After | 17.89 | 44.01 | 12.67 | 90.57 | 15.67 | 28.78 | 26.89 | 41.34 | 20.56 | 33.15 ± 24.13 | ||

| 3 | Before | 50.45 | 37.56 | 22.11 | 59.68 | 77.35 | 15.11 | 54.23 | 38.90 | 17.56 | 41.44 ± 20.99 | |

| After | 87.57 | 100.46 | 37.12 | 79.24 | 72.68 | 48.56 | 75.79 | 78.24 | 38.90 | 68.73 ± 22.15 | ||

| 3 | 1 | Before | 27.89 | 43.12 | 74.24 | 33.23 | 37.01 | 39.01 | 41.90 | 31.67 | 49.90 | 42.00 ± 13.78 |

| After | 110.35 | 99.69 | 120.13 | 160.81 | 47.34 | 55.79 | 108.35 | 86.24 | 79.79 | 96.50 ± 34.45 | ||

| 2 | Before | 11.34 | 19.67 | 28.00 | 18.00 | 33.01 | 22.78 | -1.00 | 11.34 | 25.34 | 18.72 ± 10.31 | |

| After | 43.79 | 61.57 | 83.90 | 36.78 | 84.79 | 91.13 | 44.79 | 66.90 | 69.01 | 64.74 ± 19.74 | ||

| 3 | Before | 5.56 | 18.56 | 15.89 | 8.45 | 0.04 | 24.56 | 15.89 | 13.67 | 15.00 | 13.07 ± 7.33 | |

| After | 15.34 | 48.79 | 78.12 | 13.22 | 72.68 | 158.81 | 16.34 | 54.68 | 76.68 | 59.41 ± 45.79 | ||

| 4 | 1 | Before | 35.67 | 20.67 | 26.67 | 35.12 | 20.61 | 25.23 | 46.34 | 14.56 | 23.67 | 27.62 ± 9.76 |

| After | 59.57 | 127.80 | 92.46 | 61.68 | 129.47 | 81.57 | 55.90 | 110.69 | 108.13 | 91.92 ± 28.89 | ||

| 2 | Before | 1.78 | 24.00 | 61.23 | 77.68 | 19.03 | 11.34 | 5.89 | 20.89 | 55.23 | 30.79 ± 27.03 | |

| After | 68.01 | 76.12 | 93.79 | 109.02 | 102.13 | 106.80 | 78.24 | 84.35 | 101.91 | 91.15 ± 14.92 | ||

| Avg. CO flux, mg‧m-2‧h-1 |

Before | 21.05 ± 18.16 | 26.71 ± 19.37 | 21.20 ± 15.58 | ||||||||

| After | 64.30 ± 42.95 | 80.13 ± 70.60 | 63.72 ± 43.28 | |||||||||

| Pile # | Turning | CO flux from measurement locations D1-D9 on compost pile (Q), mg‧m-2‧h-1 |

Avg. CO flux, mg‧m-2‧h-1 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LEFT SIDE | TOP | RIGHT SIDE | |||||||||

| D1 | D4 | D7 | D2 | D5 | D8 | D3 | D6 | D9 | |||

| 1 | Before | 1.56 | 0.44 | 2.22 | 0.78 | 0.44 | 1.56 | 0.44 | 0.33 | 0.78 | 0.95 ± 0.67 |

| After | 3.78 | 1.56 | 2.22 | 6.89 | 3.11 | 1.56 | 8.00 | 1.89 | 0.78 | 3.31 ± 2.52 | |

| 2 | Before | 0.44 | 0.44 | 0.33 | 0.44 | 0.33 | 0.44 | 0.78 | 0.44 | 0.44 | 0.45 ± 0.13 |

| After | 4.56 | 4.56 | 1.89 | 5.78 | 1.89 | 3.45 | 4.11 | 1.22 | 3.11 | 3.40 ± 1.51 | |

| 3 | Before | 0.33 | 0.44 | 0.44 | 0.33 | 1.22 | 1.22 | 0.33 | 0.44 | 0.44 | 0.58 ± 0.37 |

| After | 12.78 | 6.67 | 8.89 | 4.22 | 11.0 | 6.33 | 11.22 | 7.22 | 2.89 | 7.91 ± 3.33 | |

| 4 | Before | 0.44 | 0.44 | 0.44 | 0.44 | 0.22 | 0.33 | 0.33 | 0.44 | 0.44 | 0.39 ± 0.08 |

| After | 4.67 | 7.45 | 4.22 | 2.89 | 4.00 | 3.45 | 3.78 | 2.22 | 6.78 | 4.38 ± 1.72 | |

| 5 | Before | 0.44 | 0.33 | 0.44 | 0.44 | 1.00 | 0.33 | 0.33 | 0.44 | 0.44 | 0.47 ± 0.21 |

| After | 4.56 | 6.56 | 3.45 | 3.78 | 4.67 | 7.00 | 8.11 | 3.45 | 3.22 | 4.98 ± 1.80 | |

| 6 | Before | 1.56 | - | - | 0.44 | - | - | 1.22 | - | - | 1.07 ± 0.57 |

| After | 10.00 | - | - | 6.45 | - | - | 12.89 | - | - | 9.78 ± 3.23 | |

| Avg. CO flux, mg‧m-2‧h-1 |

Before | 0.67 ± 0.57 | 0.62 ± 0.41 | 0.50 ± 0.23 | |||||||

| After | 5.49 ± 3.08 | 4.78 ± 2.38 | 5.06 ± 3.59 | ||||||||

| Average CO flux (Q), mg‧m-2‧h-1 | ||

|---|---|---|

| Plant A (hermetised) | Plant B (open) | |

| Before | 23.25 ± 17.75 | 0.60 ± 0.42 |

| After | 69.38 ± 53.79 | 5.11 ± 3.01 |

| Before/after ratio | 0.34 | 0.12 |

| Before/after ratio range (min. – max) | -5.37 – 6.62 | 0.03 – 1.00 |

| Pile # | Measurements series | Concentration of accumulated CO in the hall headspace during 1 h | |||

| Before turning | After turning | ||||

| mg‧m-3 | ppm | mg‧m-3 | ppm | ||

| 1 | 1 | 8.31 | 9.68 | 61.39 | 71.50 |

| 2 | 25.43 | 29.61 | 62.62 | 72.93 | |

| 2 | 1 | 13.57 | 15.81 | 101.87 | 118.65 |

| 2 | 23.35 | 27.20 | 39.78 | 46.34 | |

| 3 | 49.73 | 57.92 | 82.47 | 96.06 | |

| 3 | 1 | 50.39 | 58.69 | 115.80 | 134.87 |

| 2 | 22.46 | 26.16 | 77.69 | 90.48 | |

| 3 | 15.68 | 18.27 | 71.29 | 83.03 | |

| 4 | 1 | 33.14 | 38.60 | 110.30 | 128.46 |

| 2 | 36.94 | 43.03 | 109.38 | 127.39 | |

| Average ± standard deviation | 27.90 ± 14.48 | 32.50 ± 16.86 | 83.26 ± 25.36 | 96.97 ± 29.53 | |

| CO | ||||||

| Pile 1 | Pile 2 | Pile 3 | Pile 4 | |||

| Before turning | CO2, % | r | 0.18 | 0.55 | 0.64 | 0.86 |

| p value | 0.463 | 0.003 | 0.000 | 0.000 | ||

| O2, % | r | -0.071 | 0.15 | -0.78 | -0.87 | |

| p value | 0.778 | 0.468 | 0.000 | 0.000 | ||

| Temperature, °C | r | -0.03 | -0.4 | 0.85 | -0.17 | |

| p value | 0.282 | 0.031 | 0.000 | 0.510 | ||

| After turning | CO2, % | r | 0.91 | 0.64 | 0.85 | 0.37 |

| p value | 0.000 | 0.000 | 0.000 | 0.136 | ||

| O2, % | r | -0.91 | -0.82 | -0.78 | -0.35 | |

| p value | 0.000 | 0.000 | 0.000 | 0.159 | ||

| Temperature, °C | r | 0.09 | 0.35 | 0.56 | 0.41 | |

| p value | 0.720 | 0.075 | 0.002 | 0.091 | ||

| CO | ||||||||

| Pile 1 | Pile 2 | Pile 3 | Pile 4 | Pile 5 | Pile 6 | |||

| Before turning | CO2, % | nd | ||||||

| O2, % | ||||||||

| Temperature, °C | ||||||||

| After turning | CO2, % | r | -0.05 | -0.10 | -0.12 | -0.01 | 0.03 | nd |

| p value | 0.905 | 0.804 | 0.751 | 0.989 | 0.946 | |||

| O2, % | r | 0.43 | nd | -0.25 | -0.44 | -0.56 | ||

| p value | 0.244 | 0.520 | 0.233 | 0.113 | ||||

| Temperature, °C | r | -0.73 | -0.08 | 0.53 | -0.10 | -0.20 | 0.71 | |

| p value | 0.027 | 0.838 | 0.143 | 0.808 | 0.610 | 0.499 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).