Submitted:

25 June 2023

Posted:

26 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Literature review

2. Materials and Methods

3. Results and discusion

3.1. Lend use

- Land use conflicts: ground-mounted PV plants may compete with other land uses, such as agriculture, forestry, conservation, or urban development. This can lead to trade-offs between different environmental, economic, and social goals, such as food security, biodiversity protection, or local employment. Therefore, careful site selection and land use planning is essential to avoid or minimize negative impacts and maximize positive synergies.

- Environmental impacts: Both rooftop and ground-mounted PV systems can have direct or indirect impacts on the environment, such as habitat loss or fragmentation, soil erosion or pollution, water use and pollution, visual impacts, or glare. Therefore, environmental impact assessments and mitigation measures are required to ensure compliance with relevant standards and regulations and to improve environmental sustainability.

3.2. Greenhouse gas emissions

| PV system part | Min. | Max. | Median |

|---|---|---|---|

| PV module | 9.13 | 14.4 | 11.6 |

| Mounting structure | 1.49 | 7.66 | 1.71 |

| Inverter | 0.39 | 1.11 | 0.69 |

| Cabling | 0.04 | 0.05 | 0.04 |

| Total | 11.1 | 23.3 | 14.0 |

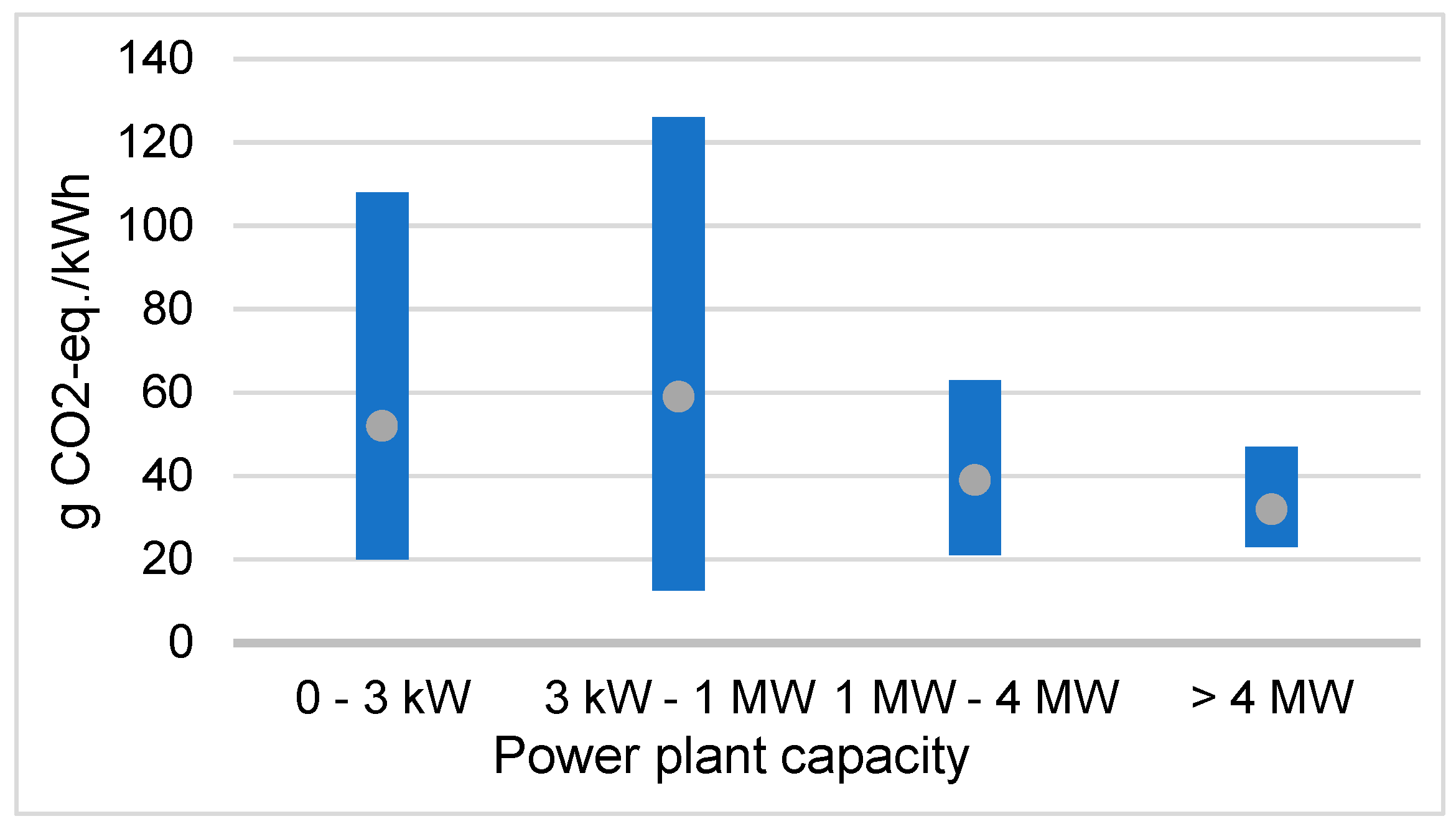

- GHG emissions for PV power plant production are much lower than fossil fuel power plants, which emit several hundred grams of CO2 equivalent per kWh [63].

- the largest share of emissions comes from the manufacturing phase of the PV system components (80% to 95%), followed by the end-of-life disposal phase (5% to 20%), and negligible amounts of GHGs are emitted during the operation of the PV power plant (0.3% to 1%). For comparison, most GHG emissions from non-renewable energy sources occur during the operation phase of the power plant (about 98%), with the remainder occurring during the construction and decommissioning phases of the power plant. (Author's estimation).

- GHG emissions for the production of PV power plants decrease over time as PV modules become more efficient, the production of solar cells is less energy intensive, and the share of renewable energy in the power grid increases [64].

3.2.1. The energy payback time (EPBT)

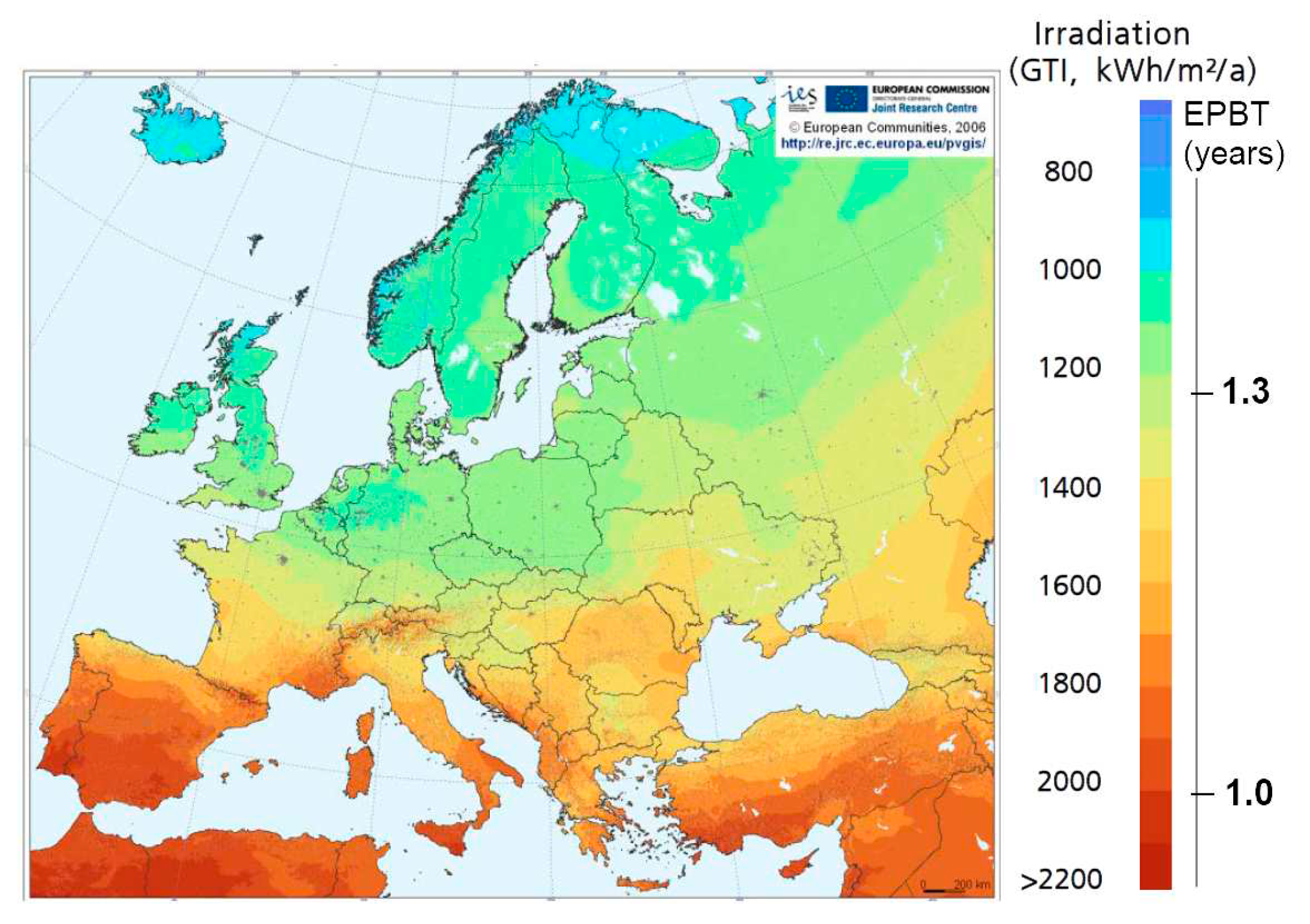

- The materials used to manufacture the PV system and the technology used

- The efficiency of the solar cells

- The irradiation related to the location of the PV solar system

3.2.2. Other pollutant emissions

3.3. Hazardous materials

3.4. Water use

3.5. The impact on biodiversity

3.6. Noise

3.7. End of life

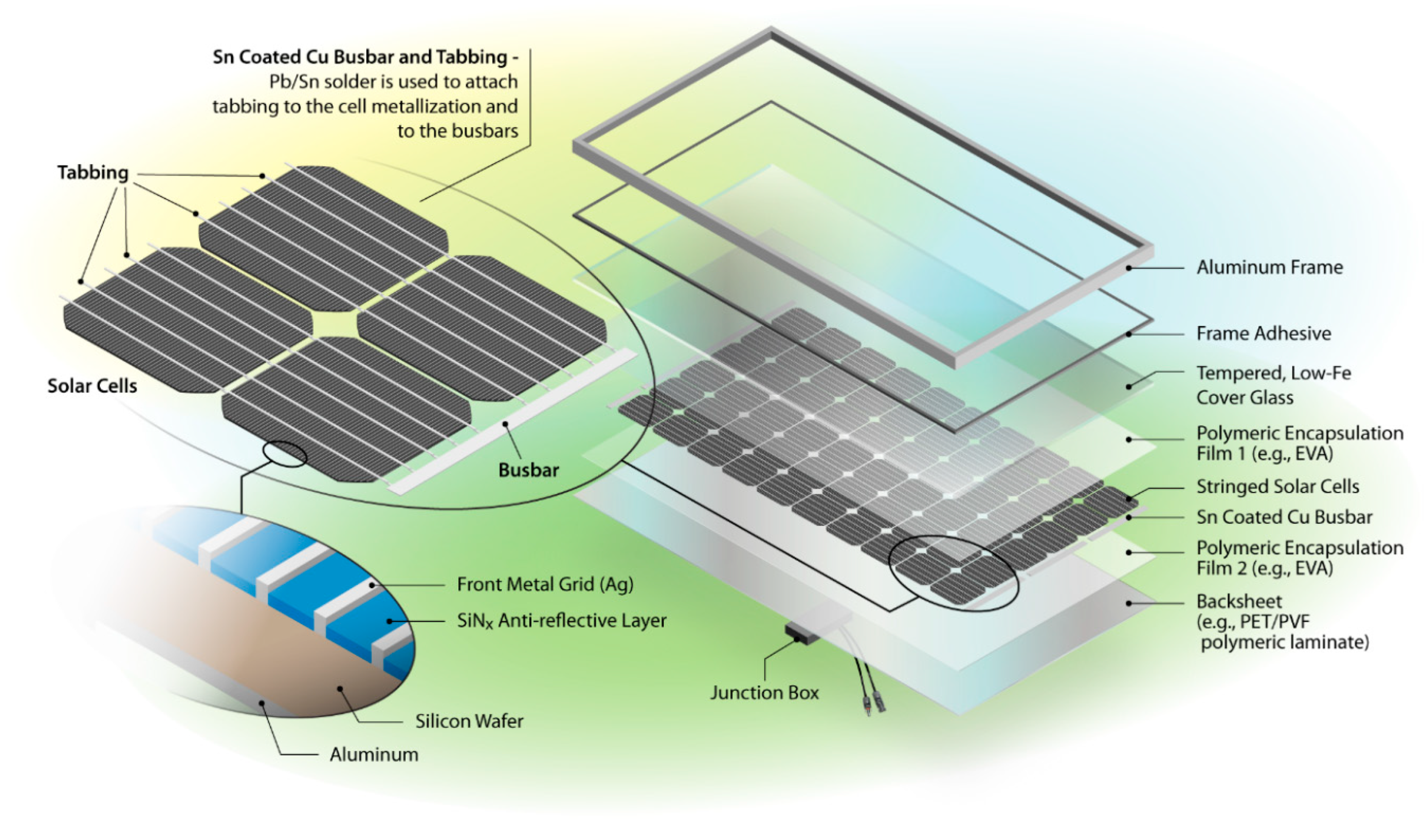

| Component / material | Content (kg/kWp) | Share in panel (%) | Remark |

|---|---|---|---|

| Frame - Al | 12.771 | 18 | Al scrap suitable for producing secondary Al |

| Polycrystalline silicon chips - Si | 3.101 | 4 | Recovery rate of silicon ~95% |

| Silver bar line - Ag | 0.03 | 0.05 | Recovered through electrolysis or precipitation in leaching solution |

| Cu Bushbar and tabbing | 0.451 | 2 | Recovery from cable scrap (~97%) |

| Top surface - tempered glass | 54.721 | 70 | Glass cullet for glass production |

| Back-sheet layer - Polyvinyl fluoride | 17.091 | 1.5 | Energy recovery from incineration process |

| Encapsulation layer - EVA | (10%??) | 5 | Energy recovery from incineration process |

- Removal of the frame and junction box;

- Removing the encapsulant from the laminated structure

- Separation of the glass and silicon wafer by thermal, mechanical or chemical processes;

- Separation and purification of silicon cells and special metals (e.g. silver, tin, lead, copper, Al) by chemical and electrical processes.

3.7.1. Land use

3.7.2. Water use

3.7.3. Gass emmisions

3.7.4. Solid wastes

3.7.5. Hazardous materials

3.7.6. Noise pollution

3.7.7. Challenges and barriers in PV recycling

- The lack of a standardized and efficient collection system for PV modules. There is no global regulation or incentive for the owners of PV modules to return them to the recyclers. This leads to a low recycling rate and a high risk of illegal landfilling of PV modules.

- Lack of recycling facilities and technologies

- Lack of market demand for recycled or reused PV modules

- Lack of awareness and education among stakeholders and consumers

- The complexity and diversity of PV module materials and designs. Each material has different properties and requires different recycling methods. This makes it difficult to separate and recover the valuable materials from the PV modules.

- The high cost and low profitability of PV module recycling. The recycling process of PV modules is often labor-intensive, energy-consuming, and technically demanding. The cost of recycling may exceed the value of the recovered materials.

- Develop and harmonize regulations and standards for the EOL treatment of PV modules

- Establish extended producer responsibility (EPR) systems that hold manufacturers accountable for the EOL management of their products

- Support research and development of innovative recycling and reuse technologies and methods

- Promote market development and value creation for recycled or reused PV modules

- Raise public awareness of the benefits and opportunities of EOL management of PV modules

- Develop better technologies to improve PV panel recycling. Designing for Recycling, for example, is one such technology.

4. Conclusion

- an average area of 4.53 km2/GW is required for the installation of rooftop PV power plants, and 19 km2/GW for large-scale power plants (Table 1 and Table 2). Based on the planned capacities for 2030 and the assumed share of rooftop PV power plants in these capacities, the required area in Europe and worldwide was calculated (Table 3).

- based on the data on available area (rooftops and vacant land), it can be concluded that this area is much larger than needed and that there should be no problem to reach the planned PV power plant capacities.

- possible land use conflicts, e.g. with agriculture and forestry, should be considered.

- there are large differences in the amount of CO2 emissions depending on where the PV system components are manufactured (greedy energy mix), the type of modules (Table 4), and the lifetime of the PV power components. In general, emissions range from 12.5 to 126 CO2 eq./kWh, which is on the order of CSP and far below fossil fuel power plant emissions.

- most of the CO2 emissions come from the production phase of the PV system components, as this is an energy-intensive process. The energy payback time for Europe is between 1 and 2.5 years (Figure 2).

- hazardous substances (heavy metals) are also used in the production of PV system components. They can only pose a significant environmental problem if the modules are not recycled at the end of the power plant's life, but are landfilled, and in this way can significantly pollute the soil and drinking water.

- water consumption in the life cycle of the PV power plant is not large and does not represent a significant problem, the same applies to noise emission.

- At the end of the life cycle, recycling can reduce the need for new materials and the associated energy consumption and emissions. This is particularly important given concerns about potential material shortages to achieve decarbonization and electrification on a global scale.

- The recycling process requires the use of a certain amount of mechanical, thermal or electrical energy to separate the components of the module, and that certain chemicals and water must be used, resulting in certain gas emissions

- The forecast for 2050 assumes a recyclable value of 630 GW of modules, which corresponds to a mass of 32.1 million tonnes of waste.

- The recycling processes for the various PV technologies are not yet fully developed

- After disassembly and extraction, the mass fraction of the various resources in a typical solar module breaks down as follows: Glass 54.7%, aluminium 12.7%, adhesive 10%, silicon 3.1% and others 19.5%

- The main problems in recycling modules are the removal of ethylene vinyl acetate and extraction of metals with minimal development of toxic gases and effluents.

- Globally, there are no regulations or incentives for owners of PV modules to return them to recyclers. This results in a low recycling rate and a high risk of illegal disposal of PV modules.

- The big problem is the high cost and low profitability of recycling PV modules

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Hemeida, M.G.; Hemeida, A.M.; Senjyu, T.; Osheba, D. Renewable Energy Resources Technologies and Life Cycle Assessment: Review. Energies 2022, 15, 1–36. [Google Scholar] [CrossRef]

- Bošnjaković, M.; Tadijanović, V. Environment Impact of a Concentrated Solar Power Plant. Teh. Glas. 2019, 13, 68–74. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Al-Othman, A.; Kafiah, F.; Abdelsalam, E.; Almomani, F.; Alkasrawi, M. Environmental Impacts of Solar Photovoltaic Systems: A Critical Review of Recent Progress and Future Outlook. Sci. Total Environ. 2021, 759, 143528. [Google Scholar] [CrossRef]

- Louwen, A.; Van Sark, W.G.J.H.M.; Faaij, A.P.C.; Schropp, R.E.I. Re-Assessment of Net Energy Production and Greenhouse Gas Emissions Avoidance after 40 Years of Photovoltaics Development. Nat. Commun. 2016, 7, 1–9. [Google Scholar] [CrossRef] [PubMed]

- C. Reichel, A. Müller, L. Friedrich, S. Herceg, M. Mittag, A. Protti, D.H.N. CO2 Emissions of Silicon Photovoltaic Modules – Impact of Module Design and Production Location. In Proceedings of the 8th World Conference on Photovoltaic Energy Conversion; EU PVSEC: Milano, 2022; pp. 1617–1619.

- Liu, F.; van den Bergh, J.C.J.M. Differences in CO2 Emissions of Solar PV Production among Technologies and Regions: Application to China, EU and USA. Energy Policy 2020, 138, 111234. [Google Scholar] [CrossRef]

- Biswas, A.; Husain, D.; Prakash, R. Life-Cycle Ecological Footprint Assessment of Grid-Connected Rooftop Solar PV System. Int. J. Sustain. Eng. 2021, 14, 529–538. [Google Scholar] [CrossRef]

- van de Ven, D.J.; Capellan-Peréz, I.; Arto, I.; Cazcarro, I.; de Castro, C.; Patel, P.; Gonzalez-Eguino, M. The Potential Land Requirements and Related Land Use Change Emissions of Solar Energy. Sci. Rep. 2021, 11, 1–12. [Google Scholar] [CrossRef]

- Vyas, M.; Chowdhury, S.; Verma, A.; Jain, V.K. Solar Photovoltaic Tree: Urban PV Power Plants to Increase Power to Land Occupancy Ratio. Renew. Energy 2022, 190, 283–293. [Google Scholar] [CrossRef]

- Bolinger, M.; Bolinger, G. Land Requirements for Utility-Scale PV: An Empirical Update on Power and Energy Density. IEEE J. Photovolt. 2022, 12, 589–594. [Google Scholar] [CrossRef]

- Shum, R.Y. A Comparison of Land-Use Requirements in Solar-Based Decarbonization Scenarios. Energy Policy 2017, 109, 460–462. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, S.; Pu, Y.; Cao, S.; Zhang, Y. Estimation of Photovoltaic Power Generation Potential in 2020 and 2030 Using Land Resource Changes: An Empirical Study from China. Energy 2021, 219, 119611. [Google Scholar] [CrossRef]

- Trondle, T. Supply-Side Options to Reduce Land Requirements of Fully Renewable Electricity in Europe. PLoS ONE 2020, 15, 1–19. [Google Scholar] [CrossRef]

- Sukumaran, S.; Sudhakar, K.; Yusop, A.F.; Kirpichnikova, I.; Cuce, E. Solar Farm: Siting, Design and Land Footprint Analysis; 2022; Vol. 17.

- Giri, N.C.; Mohanty, R.C.; Mishra, S.P. Smart Shift from Photovoltaic to Agrivoltaic System for Land-Use Footprint. Ambient Sci. 2021, 8, 12–18. [Google Scholar] [CrossRef]

- Zhang, H.; Yu, Z.; Zhu, C.; Yang, R.; Yan, B.; Jiang, G. Green or Not? Environmental Challenges from Photovoltaic Technology. Environmental pollution 2023, 320, 121066. [Google Scholar] [CrossRef] [PubMed]

- Nain, P.; Kumar, A. Metal Dissolution from End-of-Life Solar Photovoltaics in Real Landfill Leachate versus Synthetic Solutions: One-Year Study. Waste Manag. 2020, 114, 351–361. [Google Scholar] [CrossRef] [PubMed]

- Kwak, J.I.; Nam, S.H.; Kim, L.; An, Y.J. Potential Environmental Risk of Solar Cells: Current Knowledge and Future Challenges. J. Hazard. Mater. 2020, 392, 122297. [Google Scholar] [CrossRef]

- Bakhiyi, B.; Labrèche, F.; Zayed, J. The Photovoltaic Industry on the Path to a Sustainable Future — Environmental and Occupational Health Issues. Environ. Int. 2014, 73, 224–234. [Google Scholar] [CrossRef]

- Power, P.; Piasecka, I.; Bałdowska-witos, P.; Piotrowska, K. Eco-Energetical Life Cycle Assessment of Materials. Energies 2020, 1–24. [Google Scholar]

- Stamford, L.; Azapagic, A. Environmental Impacts of Photovoltaics: The Effects of Technological Improvements and Transfer of Manufacturing from Europe to China. Energy Technol. 2018, 6, 1148–1160. [Google Scholar] [CrossRef]

- Roy, S.; Ghosh, B. Land Utilization Performance of Ground Mounted Photovoltaic Power Plants: A Case Study. Renew. Energy 2017, 114, 1238–1246. [Google Scholar] [CrossRef]

- Farrell, C.C.; Osman, A.I.; Doherty, R.; Saad, M.; Zhang, X.; Murphy, A.; Harrison, J.; Vennard, A.S.M.; Kumaravel, V.; Al-Muhtaseb, A.H.; et al. Technical Challenges and Opportunities in Realising a Circular Economy for Waste Photovoltaic Modules. Renew. Sustain. Energy Rev. 2020, 128. [Google Scholar] [CrossRef]

- Sica, D.; Malandrino, O.; Supino, S.; Testa, M.; Lucchetti, M.C. Management of End-of-Life Photovoltaic Panels as a Step towards a Circular Economy. Renew. Sustain. Energy Rev. 2018, 82, 2934–2945. [Google Scholar] [CrossRef]

- Tao, J.; Yu, S. Review on Feasible Recycling Pathways and Technologies of Solar Photovoltaic Modules. Sol. Energy Mater. Sol. Cells 2015, 141, 108–124. [Google Scholar] [CrossRef]

- Teknetzi, I.; Holgersson, S.; Ebin, B. Valuable Metal Recycling from Thin Film CIGS Solar Cells by Leaching under Mild Conditions. Sol. Energy Mater. Sol. Cells 2023, 252, 112178. [Google Scholar] [CrossRef]

- Gahlot, R.; Mir, S.; Dhawan, N. Recycling of Discarded Photovoltaic Solar Modules for Metal Recovery: A Review and Outlook for the Future. Energy \& Fuels 2022, 36, 14554–14572. [Google Scholar] [CrossRef]

- Peplow, M. Solar Panels Face Recycling Challenge. ACS Cent. Sci. 2022, 8, 299–302. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.-Y. Recycling of Solar Cell Materials at the End of Life. In Advances in Solar Photovoltaic Power Plants; Islam, M.R., Rahman, F., Xu, W., Eds.; Springer: Berlin, Heidelberg, 2016; ISBN 978-3-662-50521-2. [Google Scholar]

- Dias, P.; Veit, H. Recycling Crystalline Silicon Photovoltaic Modules. Emerging photovoltaic materials 2018, 61–102. [Google Scholar]

- Dias, P.R.; Schmidt, L.; Chang, N.L.; Monteiro Lunardi, M.; Deng, R.; Trigger, B.; Bonan Gomes, L.; Egan, R.; Veit, H. High Yield, Low Cost, Environmentally Friendly Process to Recycle Silicon Solar Panels: Technical, Economic and Environmental Feasibility Assessment. Renew. Sustain. Energy Rev. 2022, 169, 112900. [Google Scholar] [CrossRef]

- D’Adamo, I.; Ferella, F.; Gastaldi, M.; Ippolito, N.M.; Rosa, P. Circular Solar: Evaluating the Profitability of a Photovoltaic Panel Recycling Plant. Waste Manag. Res. : J. Int. Solid Wastes Public Clean. Assoc. ISWA 2023, 41, 1144–1154. [Google Scholar] [CrossRef]

- Isherwood, P.J.M. Reshaping the Module: The Path to Comprehensive Photovoltaic Panel Recycling. Sustainability 2022, 14. [Google Scholar] [CrossRef]

- Brunet, C.; Savadogo, O.; Baptiste, P.; Bouchard, M.A.; Rakotoary, J.C.; Ravoninjatovo, A.; Cholez, C.; Gendron, C.; Merveille, N. Impacts Generated by a Large-Scale Solar Photovoltaic Power Plant Can Lead to Conflicts between Sustainable Development Goals: A Review of Key Lessons Learned in Madagascar. Sustainability 2020, 12. [Google Scholar] [CrossRef]

- Bala Subramaniyan, A.; Pan, R.; Kuitche, J.; TamizhMani, G. Quantification of Environmental Effects on PV Module Degradation: A Physics-Based Data-Driven Modeling Method. IEEE J. Photovolt. 2018, 8, 1289–1296. [Google Scholar] [CrossRef]

- Jathar, L.D.; Ganesan, S.; Awasarmol, U.; Nikam, K.; Shahapurkar, K.; Soudagar, M.E.M.; Fayaz, H.; El-Shafay, A.S.; Kalam, M.A.; Bouadila, S.; et al. Comprehensive Review of Environmental Factors Influencing the Performance of Photovoltaic Panels: Concern over Emissions at Various Phases throughout the Lifecycle. Environ. Pollut. 2023, 326, 121474. [Google Scholar] [CrossRef] [PubMed]

- Pouran, H.M.; Padilha Campos Lopes, M.; Nogueira, T.; Alves Castelo Branco, D.; Sheng, Y. Environmental and Technical Impacts of Floating Photovoltaic Plants as an Emerging Clean Energy Technology. iScience 2022, 25, 105253. [Google Scholar] [CrossRef]

- Haas, J.; Khalighi, J.; de la Fuente, A.; Gerbersdorf, S.U.; Nowak, W.; Chen, P.-J. Floating Photovoltaic Plants: Ecological Impacts versus Hydropower Operation Flexibility. Energy Convers. Manag. 2020, 206, 112414. [Google Scholar] [CrossRef]

- Allouhi, A.; Rehman, S.; Buker, M.S.; Said, Z. Up-to-Date Literature Review on Solar PV Systems: Technology Progress, Market Status and R&D. J. Clean. Prod. 2022, 362, 132339. [Google Scholar] [CrossRef]

- Hou, G.; Sun, H.; Jiang, Z.; Pan, Z.; Wang, Y.; Zhang, X.; Zhao, Y.; Yao, Q. Life Cycle Assessment of Grid-Connected Photovoltaic Power Generation from Crystalline Silicon Solar Modules in China. Appl. Energy 2016, 164, 882–890. [Google Scholar] [CrossRef]

- ITRPV. International Technology Roadmap for Photovoltaic; 2022; Vol. 14th Ed.

- International Energy Agency (IEA) Net Zero by 2050: A Roadmap for the Global Energy Sector. Int. Energy Agency 2021, 224.

- European Commission EU Solar Energy Strategy. COM(2022) 221 final 2022, 1–21.

- Yasmina, Abdelilah; Heymi, Bahar; Trevor, Criswell; Piotr Bojek, Feuvre; François, Briens; Pharoah, L.F. Renewables 2020 - Analysis and Forecast to 2025. International Energy Agency 2020.

- IFC. A Project Developer’s Guide to Utility-Scale Solar Photovoltaic Power Plants; Lumby, B., Ed.; International Finance Corporation: Washington, 2015.

- HEP Group Unintegrated Solar Power Plants. Available online: https://www.hep.hr/projects/renewable-energy-sources/unintegrated-solar-power-plants/3423 (accessed on 13 June 2023).

- Power-technology.com Nunez de Balboa Solar Project, Badajoz. Available online: https://www.power-technology.com/projects/nunez-de-balboa-solar-project-badajoz/ (accessed on 15 June 2023).

- Chatzipanagi, A., Jaeger-Waldau, A., Cleret de Langavant, C., Letout, S., Latunussa, C., Mountraki, A., Georgakaki, A., Ince, E., Kuokkanen, A. and Shtjefni, D. Photovoltaics in the European Union – 2022 Status Report on Technology Development, Trends, Value Chains and Markets. Final report 2022, 1–89.

- Bódis, K.; Kougias, I.; Jäger-Waldau, A.; Taylor, N.; Szabó, S. A High-Resolution Geospatial Assessment of the Rooftop Solar Photovoltaic Potential in the European Union. Renew. Sustain. Energy Rev. 2019, 114, 109309. [Google Scholar] [CrossRef]

- Kumar, A.; Joshi, J.B.; Nayak, A.K.; Vijayan, P.K. A Review on the Thermal Hydraulic Characteristics of the Air-Cooled Heat Exchangers in Forced Convection. Sadhana - Acad. Proc. Eng. Sci. 2015, 40, 673–755. [Google Scholar] [CrossRef]

- RICS Energy Efficiency of the Building Stock in the EU. Available online: https://www.rics.org/news-insights/energy-efficiency-of-the-building-stock-in-the-eu (accessed on 20 June 2023).

- Bošnjaković, M.; Katinić, M.; Čikić, A.; Muhič, S. Building Integrated Photovoltaics: Overview of Barriers and Opportunities. Therm. Sci. 2023, 27, 1433–1451. [Google Scholar] [CrossRef]

- Abuzaid, H. Environmental and Economic Impact Assessments of a Photovoltaic Rooftop System in the United Arab Emirates. 2022.

- Silva, M.; Raadal, H.L. Life Cycle GHG Emissions of Renewable and Non-Renewable Electricity Generation Technologies Part of the RE-Invest Project; 2019; ISBN 978-82-7520-806-2.

- Fthenakis, V.M.; Kim, H.C.; Alsema, E. Emissions from Photovoltaic Life Cycles. Environ. Sci. Technol. 2008, 42, 2168–2174. [Google Scholar] [CrossRef] [PubMed]

- Sherwani, A.F.; Usmani, J.A. ; Varun Life Cycle Assessment of Solar PV Based Electricity Generation Systems: A Review. Renew. Sustain. Energy Rev. 2010, 14, 540–544. [Google Scholar] [CrossRef]

- IEA -Lead author Piotr Bojek Solar PV - Tracking Report - September 2022; Paris, 2022.

- Fraunhofer Institute for Solar Energy Systems, I. Photovoltaics Report. 2023, 1–53.

- Chen, W.; Hong, J.; Yuan, X.; Liu, J. Environmental Impact Assessment of Monocrystalline Silicon Solar Photovoltaic Cell Production: A Case Study in China. J. Clean. Prod. 2016, 112, 1025–1032. [Google Scholar] [CrossRef]

- Fthenakis, V.M.; Kim, H.C. Photovoltaics: Life-Cycle Analyses. Sol. Energy 2011, 85, 1609–1628. [Google Scholar] [CrossRef]

- Polverini, D.; Espinosa, N.; Eynard, U.; Leccisi, E.; Ardente, F.; Mathieux, F. Assessing the Carbon Footprint of Photovoltaic Modules through the EU Ecodesign Directive. Sol. Energy 2023, 257, 1–9. [Google Scholar] [CrossRef]

- Brüstle, F. Carbon Footprint Optimization for a Large-Scale PV on-Grid System in Borlänge, Sweden, Dalarna University, 2022.

- International Energy Agency. Global Energy Review: CO2 Emissions in 2021; 2021.

- International Energy Agency CO2 Emissions in 2022; 2022.

- Philipps, S.; Warmuth, W. Photovoltaics Report (Updated 24 February 2022); Freiburg, 2022.

- Norgren, A.; Carpenter, A.; Heath, G. Design for Recycling Principles Applicable to Selected Clean Energy Technologies: Crystalline-Silicon Photovoltaic Modules, Electric Vehicle Batteries, and Wind Turbine Blades. J. Sustain. Metall. 2020, 6, 761–774. [Google Scholar] [CrossRef]

- ITRPV. International Technology Roadmap for Photovoltaic (ITRPV) - Results 2018; 2019.

- Bošnjaković, M.; Stojkov, M.; Zlatunić, B. Experimental Testing of PV Module Performance. Teh. Glas. 2021, 15, 127–132. [Google Scholar] [CrossRef]

- Hossain, M.I.; Ali, A.; Bermudez Benito, V.; Figgis, B.; Aïssa, B. Anti-Soiling Coatings for Enhancement of PV Panel Performance in Desert Environment: A Critical Review and Market Overview. Materials 2022, 15. [Google Scholar] [CrossRef]

- Stolz, P.; Frischknecht, R.; Heath, G.; Komoto, K.; Macknick, J.; Sinha, P.; Wade, A. Water Footprint of European Rooftop Photovoltaic Electricity Based on Regionalised Life Cycle Inventories; 2017.

- Montag, Hannah; Parker, Guy; Clarkson, T. The Effects of Solar Farms on Local Biodiversity: A Comparative Study; Clarkson and Woods and Wychwood Biodiversity, 2016; ISBN 9781526202239.

- Heidari, S.M.; Anctil, A. Material Requirement and Resource Availability for Silicon Photovoltaic Laminate Manufacturing in the Next 10 Years. In Proceedings of the 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC); 2021; pp. 1768–1772.

- Gervais, E.; Shammugam, S.; Friedrich, L.; Schlegl, T. Raw Material Needs for the Large-Scale Deployment of Photovoltaics – Effects of Innovation-Driven Roadmaps on Material Constraints until 2050. Renew. Sustain. Energy Rev. 2021, 137, 110589. [Google Scholar] [CrossRef]

- IEA. The Role of Critical Minerals in Clean Energy Transitions; 2021.

- Burrows, K.; Fthenakis, V. Glass Needs for a Growing Photovoltaics Industry. Sol. Energy Mater. Sol. Cells 2015, 132, 455–459. [Google Scholar] [CrossRef]

- Mirletz, H.; Ovaitt, S.; Sridhar, S.; Barnes, T.M. Circular Economy Priorities for Photovoltaics in the Energy Transition. PLoS ONE 2022, 17, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Lunardi, M.M.; Alvarez-Gaitan, J.P.; Bilbao, J.I.; Corkish, R. A Review of Recycling Processes for Photovoltaic Modules. In Solar Panels and Photovoltaic Materials; Zaidi, B., Ed.; IntechOpen: Rijeka, 2018. [Google Scholar]

- Tao, M.; Fthenakis, V.; Ebin, B.; Steenari, B.-M.; Butler, E.; Sinha, P.; Corkish, R.; Wambach, K.; Simon, E.S. Major Challenges and Opportunities in Silicon Solar Module Recycling. Prog. Photovolt. : Res. Appl. 2020, 28, 1077–1088. [Google Scholar] [CrossRef]

- Weckend, S.; Wade, Andreas; Heath, G. End-Of-Life Management: Solar Photovoltaic Panels; IRENA and IEA-PVPS, 2016.

- Bustamante, M.L.; Gaustad, G. Challenges in Assessment of Clean Energy Supply-Chains Based on Byproduct Minerals: A Case Study of Tellurium Use in Thin Film Photovoltaics. Appl. Energy 2014, 123, 397–414. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency (EPA). Solar Panel Recycling. Available online: https://www.epa.gov/hw/solar-panel-recycling (accessed on 12 June 2023).

- Xu, Y.; Li, J.; Tan, Q.; Peters, A.L.; Yang, C. Global Status of Recycling Waste Solar Panels: A Review. Waste Manag. 2018, 75, 450–458. [Google Scholar] [CrossRef]

- Ziemińska-stolarska, A.; Pietrzak, M.; Zbiciński, I. Application of LCA to Determine Environmental Impact of Concentrated Photovoltaic Solar Panels—State-of-the-Art. Energies 2021, 14, 1–20. [Google Scholar] [CrossRef]

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Tiong, S.K.; Sopian, K.; Amin, N. An Overview of Solar Photovoltaic Panels’ End-of-Life Material Recycling. Energy Strategy Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- Trivedi, H.; Meshram, A.; Gupta, R. Recycling of Photovoltaic Modules for Recovery and Repurposing of Materials. J. Environ. Chem. Eng. 2023, 11, 109501. [Google Scholar] [CrossRef]

- Divya, A.; Adish, T.; Kaustubh, P.; Zade, P.S. Review on Recycling of Solar Modules/Panels. Sol. Energy Mater. Sol. Cells 2023, 253, 112151. [Google Scholar] [CrossRef]

- HUAWEI TECHNOLOGIES Co, lTD. Solar Inverter - Product Carbon Footprint Report. Available online: https://ske-solar.com/wp-content/uploads/2021/01/Zertifikat-Product-Carbon-Footprint-Report-für-Huawei-SUN2000-12KTL-M0-Wechselrichter.pdf (accessed on 15 June 2023).

| Company | Solar panel model | Power (W) | Hight (m) |

Width (m) |

Area (m2) | Area (m2/kW) | Weight (kg/kW) |

|---|---|---|---|---|---|---|---|

| Jinko | Tiger Neo N-type 72HL4 | 575 | 2.278 | 1.134 | 2.58 | 4.49 | 48.7 |

| Longi | HI-MO-5 | 550 | 2.256 | 1.133 | 2.56 | 4.65 | 58.7 |

| Q Cells | Q.tron G1+ Series | 395 | 1.717 | 1.045 | 1.79 | 4.54 | 50.4 |

| JA Solar | 72-cell MBB Half-cell Module | 565 | 2.278 | 1.134 | 2.58 | 4.57 | 55,9 |

| AIKO | AIKO-A-MAH72Mb | 615 | 2.278 | 1.134 | 2.58 | 4.20 | 45.9 |

| SOLVIS | SV144 E HC9B | 455 | 2.094 | 1.038 | 2.62 | 4.63 | 54.9 |

| Project Solar | Evolution Titan 445 | 415 | 1.724 | 1.134 | 1.96 | 4.71 | 48.2 |

| RISEN | RSM108-9-415N-440N | 440 | 1.722 | 1.134 | 1.95 | 4.44 | 50.0 |

| REC Solar | Alpha Pure-R | 420 | 1.729 | 1.118 | 1.93 | 4.60 | 51.2 |

| Sunpower | MAXEON 6 AC | 435 | 1.872 | 1.032 | 1.93 | 4.44 | 50.1 |

| Average | 492 | 2.008 | 1.112 | 2.26 | 4.53 | 51.0 |

| PV power plant capacity, year of start of work |

Required land area (km2/GW) | Source |

|---|---|---|

| PV < 10 kW | 13 | Tawalbeth [3] |

| PV < 10 MW | 22 | Tawalbeth [3] |

| PV >100 MW | 25 – 32 | Tawalbeth [3] |

| 1 MW | 10 – 20 | IFC [45] |

| Examples of installed utility-scale PV power plants | ||

| PV power plant Kaštelir 2, Croatia, 2 MW, 2021 | 20 | HEP Group [46] |

| PV power plant Marići, Croaria, 1 MW, 2021 | 18 | HEP Group [46] |

| PV power plant Stankovci, Croatia, 2.5 MW, 2022 | 26 | HEP Group [46] |

| PV power plant Obrovac, Croatia, 8.7 MW, 2022 | 13 | HEP Group [46] |

| PV power plant Nunez de Balboa, Spain, 2020 | 20 | Iberdrola [47] |

| Europe | Global | |||||

|---|---|---|---|---|---|---|

| Total | Rooftop | Utility scale | Total | Rooftop | Utility scale | |

| Planned capacity (GW) | 600 | 282 | 318 | 4400 | 1804 | 2596 |

| Share (%) | 100% | 47% | 53% | 100% | 41% | 59% |

| Area (km2/GW) | 4.53 | 19 | 4.53 | 19 | ||

| Required area (km2) | 7319 | 1277 | 6042 | 57496 | 8172 | 49324 |

| PV technologies | Life cycle excl. use stage | Use stage | SUM |

|---|---|---|---|

| (gCO2 eq/kWh) | (gCO2 eq/kWh) | (gCO2 eq/kWh) | |

| Micromorphous silicon | 43.0 | 0.015 | 43.02 |

| Multicrystalline silicon | 48.8 | 0.010 | 48.81 |

| Monocrystalline silicon | 80.4 | 0.010 | 80.41 |

| CdTe | 19.9 | 0.011 | 19.91 |

| CIGS | 35.9 | 0.014 | 35.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).