1. Introduction

The transportation sector has started to electrify in response to the crises of fossil fuels and global air pollution. Rail transportation has pioneered the popularization of electric drive. The transition from gasoline-powered to electric vehicles has begun in the road transportation sector as a result. Plans to outlaw the selling of fuel-powered vehicles have been put forth by nations all over the world. By the end of 2022, China has already achieved the 20 % penetration of new energy vehicles by 2025 ahead of schedule. While hydrogen fuel cell technology is gaining traction as another new energy supply solution for new energy cars, pure electric vehicles with lithium-ion battery packs and drive motors as the power system are the industry mainstream [

1]. The lithium-ion battery is the essential part of any car's energy supply system, whether it be a fuel cell vehicle or a pure electric vehicle.

New energy vehicles have benefits over conventional internal combustion engine vehicles, such as high efficiency and cleanliness. However, there are also some distinct drawbacks, the most notable of which is the stringent criteria for the usage of environmental temperature. All have specific temperature ranges, whether they are drive motors, fuel cells, or power lithium-ion batteries. The normal operating temperature range for the lithium-ion battery is between -10 °C and +50 °C. Considering their performance and durability, vehicle lithium-ion power batteries are sometimes restricted to a narrower operating temperature range, which is between +20 °C and +40 °C [

2,

3,

4,

5]. Between +45 °C and +60 °C is the ideal operating temperature for fuel cells [

6]. The operating temperature range for the drive motor is greater, with a maximum temperature of +130 °C [

7,

8]. During the charging and discharging process, lithium-ion batteries inevitably produce Joule heat and chemical reaction heat. The battery temperature rise brought on by the accumulation of heat cannot be disregarded because it will negatively impact the battery's energy efficiency, safety, and life [

9]. So. The powertrain of new energy vehicles needs to be developed with a dependable Battery Thermal Management System (BTMS) that can adapt to both cold and hot climates for global adoption.

If we merely take the heat dissipation condition into account, BTMS is essentially a collection of heat transfer devices that, in the event of a battery overheating, allow heat to be transferred from the battery to the outside environment, lowering the temperature of the battery body [

10]. Among them, the method of heat transfer has changed from the conventional air-cooling and liquid-cooling to the new phase change cooling method. Examples include removing heat from the battery through heat pipes [

11,

12], absorbing heat from the cell surface by the refrigerant evaporation process [

13,

14], and using a thermoelectric cooler method of cooling [

15]. Liquid cooling is now the most popular battery thermal management solution, taking into account the technical viability, heat dissipation effect, and economic cost.

Transverse flow and series connection are mostly employed for the heat dissipation of cylindrical battery packs that are either liquid-cooled or air-cooled. Although the design of the flow channel for the transverse flow heat dissipation method is relatively straightforward, the fluid transverse flow channel must pass through the cells, necessitating the maintenance of a specific gap between each cell. This requires additional space to be occupied and is inimical to increasing the energy density of the battery pack. The surface temperatures of each individual cell in a series heat dissipation battery pack are also out of balance due to the large temperature difference along the direction of fluid flow, which reduces capacity and shortens battery pack life [

16]. Individual studies have proposed some forms of longitudinal flow heat dissipation for cylindrical cells, which can improve the uniform temperature performance of the battery pack; however, these solutions still require a certain gap between individual cells and do not effectively improve the space utilization of the battery pack.

The longitudinal flow heat dissipation proposed in this paper refers to a form of convective heat transfer in which the heat transfer fluid flows axially along the cell in the apertures formed by cylindrical cells in a tightly arranged group and forms a convective heat transfer between the cell and the cylindrical surface. The solution has three features: first, the arrangement characteristics of cylindrical lithium-ion batteries can be used as coolant flow channels with the help of their arranged pores, so that the cells can be closely arranged, effectively reducing the size of the battery pack and improving the energy density of the cylindrical battery pack; second, for each cell, the heat transfer area is the same and the inlet temperature of the heat transfer fluid is also the same, so the battery pack has better uniform temperature performance; third, the heat transfer fluid flows along the axial direction of the cell, and the entire side of the cell can be used for heat dissipation, thus obtaining a higher heat transfer efficiency. The research contribution of this program is reflected in two aspects.

- 1)

Improved energy density of cylindrical battery packs

Compared with natural cooling and forced air cooling, the liquid flow cooling method of batteries is widely used because of its high efficiency, reliability and other characteristics [

17]. However, the extra weight of the coolant itself, the coolant flow channels, and the sealing elements used to avoid coolant leakage increase the manufacturing cost of the coolant circulation system, which is a disadvantage of the liquid cooling method [

18]. For liquid cooling of cylindrical cells, all methods proposed or in use today require a certain gap between each individual cell in the diameter direction to allow a coolant flow path to pass through, which undoubtedly increases the size of the battery pack and reduces its volumetric energy density. The longitudinal flow heat dissipation method proposed in this paper aims to eliminate this gap by combining the arrangement characteristics of cylindrical Li-ion cells and using their arrangement pores as coolant flow paths to pass cooling media along the axial direction of the cells for heat dissipation. This approach allows the cylindrical cells to be closely arranged, which not only saves the material and weight of the coolant flow channel, but also increases the volumetric energy density of the whole battery pack.

- 2)

Improved uniform temperature performance of cylindrical battery packs

The conventional cooling method for cylindrical cells is transverse flow series cooling. The cooling medium flows in the direction of the cell's diameter and is in direct or indirect contact with the sides of the individual cells. In the direction of flow of the cooling medium, heat is exchanged with each individual cell in turn. Therefore, the closer to the outlet, the higher the temperature of the cooling medium, the lower the heat exchange rate with the surface of the cell, and the worse the heat dissipation effect, the higher the surface temperature of the cell. This is the biggest disadvantage of the transverse flow cooling method. In contrast, with the longitudinal flow cooling method, each cell can get an even temperature coolant, and there is no such problem.

2. Method and simulation

2.1. Longitudinal flow geometry model

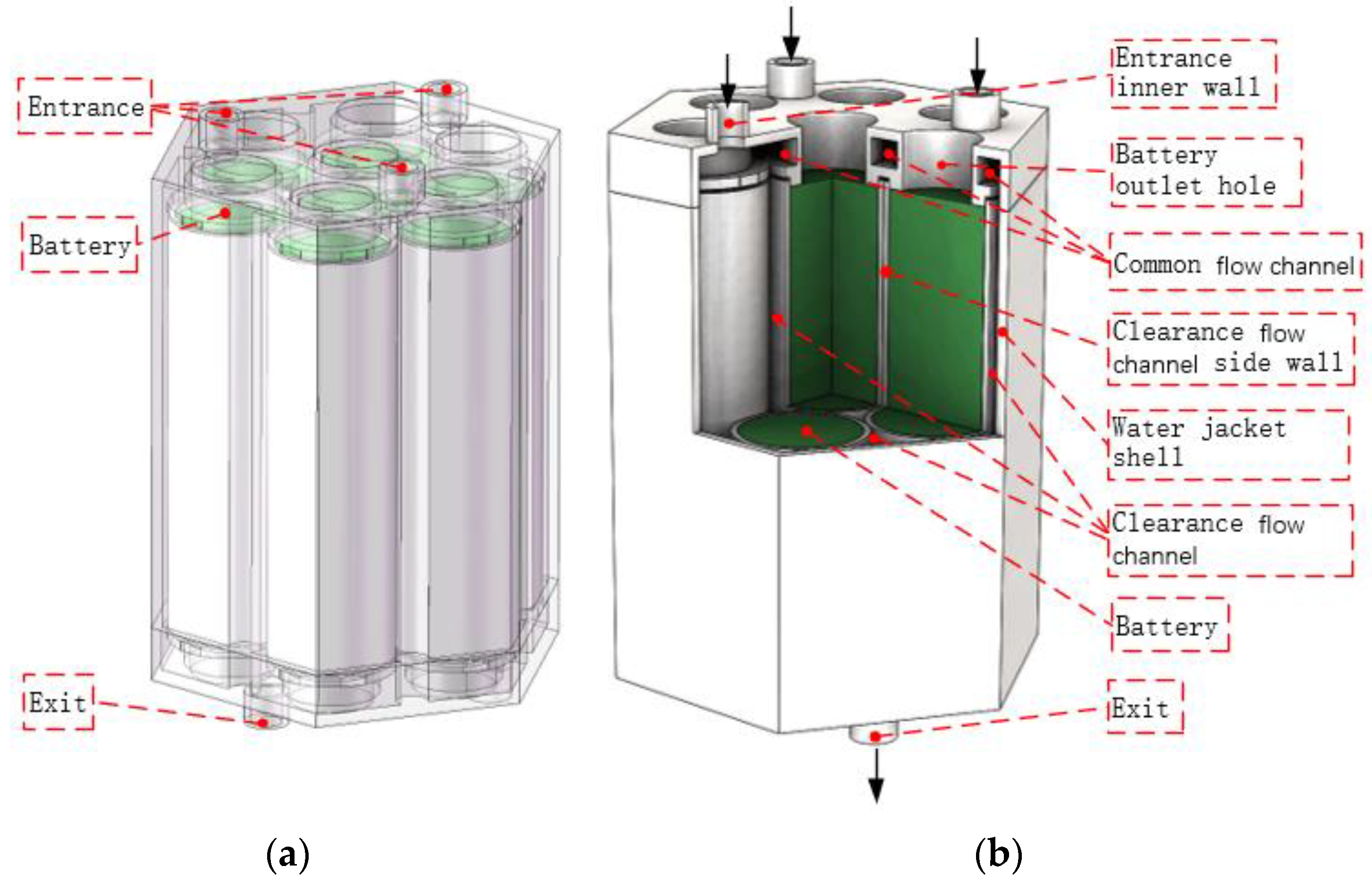

Figure 1 shows the longitudinal flow liquid cooling model, which consists of seven cylindrical cells closely arranged in green as shown in the figure. In the test, in order to prevent the cooling water from contacting with the cells and leakage causing test failures or even safety problems, a layer of sidewalls with a thickness of 0.5 mm was applied to the cells to completely isolate the cell from the cooling liquid. Therefore, the battery is separated in the radial direction by two layers of sidewalls, the thickness of which is 1 mm. In the actual project, insulated coolant should be employed, and the clearance sidewalls can be eliminated. So that, through a more advanced metal welding process, the thickness of the sidewalls can be greatly reduced; or use direct contact.

2.2. Model calculation domain

Based on the above structural design scheme, the geometric model for simulation is established in the multi-physics field simulation software COMSOL based on the three-dimensional model of the battery pack shown in

Figure 1. Three physical fields, solid and fluid heat transfer, turbulent flow and lumped cell, are added to the software and applied to the water jacket shell, coolant and cell, respectively, to verify the thermal characteristics of the battery pack. In addition, two multi-physical field interfaces are coupled through non-isothermal flow and electrochemical heat.

It is worth noting that since the outer sidewalls of the two cells are tangential in the actual model, singularities will occur during COMSOL meshing, resulting in mesh generation failure. To avoid this problem, the diameter of the total cell is set to 17 mm in the simulation model, while the thin layer property is added to its sidewalls, and the thickness of the thin layer is set to 0.5 mm. In addition, an inner wall as shown in

Figure 1 is set between the sidewalls of the simulated cell to isolate the flow between the gap flow channels.

2.3. Control equation and related parameters

2.3.1. Heat generation mechanism of battery

The cell model used in this paper is provided by the lumped cell interface in the simulation software, and its electrochemical heat generation equation is shown in equation (1).

Where,

is the heat generation power of the battery, in W;

is ohmic overvoltage, unit: V,

is the activation over-potential, unit: V,

is the heat of mixing, in W,

is the charge and discharge current of the battery, in A. The third item in the brackets is the product of the open-circuit voltage temperature coefficient of the battery and the average temperature of the battery, indicating the heat of the chemical reaction of the battery, which can be expressed as heat absorption or heat release. In calculation, activation overpotential and mixing heat are often neglected [

19], so electrochemical heat is mainly generated by ohmic overpotential and chemical reaction heat. The simplified heat generation formula is shown in formula (2):

The expression of ohmic overpotential is shown in Formula (3) and (4).

Among them,

is 1C ohmic overvoltage, unit: V;

represents the current of the battery at 1C magnification, unit: A;

is a constant, representing the 1C ohmic overvoltage at the reference temperature, in V;

is a constant, indicating the activation energy of the battery, in J/mol. Tcell is the average temperature of the battery, in K. In the formula, the function Arrh is the Arrhenius equation, which represents the relationship between the chemical reaction rate constant and temperature. The exponential form is used here, and the formula is as follows:

R is the molar gas constant, and its value is 8.314 J/ (mol · K); Ea represents the activation energy of the battery, and the calculation process is substituted into . T0 is the reference temperature, 293.15 K is taken in this paper.

2.3.2. Flow and heat transfer equation

The differential equations for the heat transfer of solids and fluids are shown in Equations (6), (8) and (9).

Equation (6) is the differential equation for the thermal conductivity of the solid cell in the cylindrical coordinate system. Equation (7) is the differential equation for the heat transfer of the fluid. Where is the density, and the monomer is kg/m3; cp is the specific constant pressure heat capacity, in J/ (kg·K); T is the temperature, in K; t is the time, in seconds; u is the vector of fluid velocity, in m/s; q is the heat flux in W/m2; Q is the heat generation power of the heat source, in W; k, kr, kφ, kz is the thermal conductivity, in W/ (m·K).

The temperature and velocity field distributions can be derived from this equation. Where the Q is filled by the battery heat generation power, so as to realize the coupling of electrochemical heat and fluid heat transfer.

The actual Reynolds number of coolant flow in the water jacket of the cell is calculated by the following equation:

Where, Re is the Reynolds number of the actual flow;

is the average flow velocity, in m/s; D is the equivalent diameter, in m; ν is the kinematic viscosity of the fluid, in m

2/s, and the kinematic viscosity of water at normal temperature is 1.006×10

-6 m

2/s. The equivalent diameter D of the gap is calculated by the following formula

Where A is the effective sectional area, unit: m2; χ is the wet circumference, in m.

According to the three-dimensional structure model shown in

Figure 1, the effective sectional areas of the two clearances are calculated to be 15.52 mm

2 and 42.43 mm

2 respectively; Its corresponding wet circumference is 21.43 mm and 40.32 mm. The average velocity is calculated at 4 m/s, and its maximum Reynolds number is 11518 and 16774, which is close to or more than the empirical value of the upper Reynolds number 13800 [

20]. Therefore, K-Ɛ turbulence model is adopted in the simulation mode.

In the COMSOL lumped battery numerical model, there are two important parameters to be configured, one is the open-circuit voltage and state of charge (OCV-SOC) characteristic curve, and the other is the temperature coefficient of the battery open-circuit voltage. These two parameters are measured by specific test aforehand.

2.5. Initial and boundary conditions

The initial and boundary conditions of the model used are shown in

Table 1.

Table 1.

Initial and boundary conditions.

Table 1.

Initial and boundary conditions.

| number |

conditions |

| 1 |

The initial temperature and reference temperature of the model and environment are set as 20 oC |

| 2 |

The outer wall of the water jacket in contact with the air is set as an adiabatic surface |

| 3 |

The heat convection between the two end surfaces of the cell and the heat conduction of the wires are set to a constant heat flux value |

| 4 |

Ignore the contact thermal resistance of the battery sidewalls and coolant water jacket |

| 5 |

The thermal property parameters of the materials used are treated as constant values |

| 6 |

The coolant is set as water, the fluid is considered incompressible, and the gravity of water is ignored |

| 7 |

The fluid inlet is set according to the normal inflow speed, and the outlet is set to zero pressure |

Table 2.

Parameters used in the model.

Table 2.

Parameters used in the model.

| Condition |

Value |

Unit |

| Initial temperature |

20.0 |

oC |

| Equivalent heat flux of battery end face |

247.19 |

K) |

| Radial thermal conductivity of battery |

2.37 |

K) |

| Axial thermal conductivity of battery |

28.27 |

K) |

| Battery capacity |

3.25 |

Ah |

| Specific heat capacity of battery at constant pressure |

2482.3 |

K) |

| Battery density |

2841.60 |

kg/m3

|

2.6. Grid validity verification

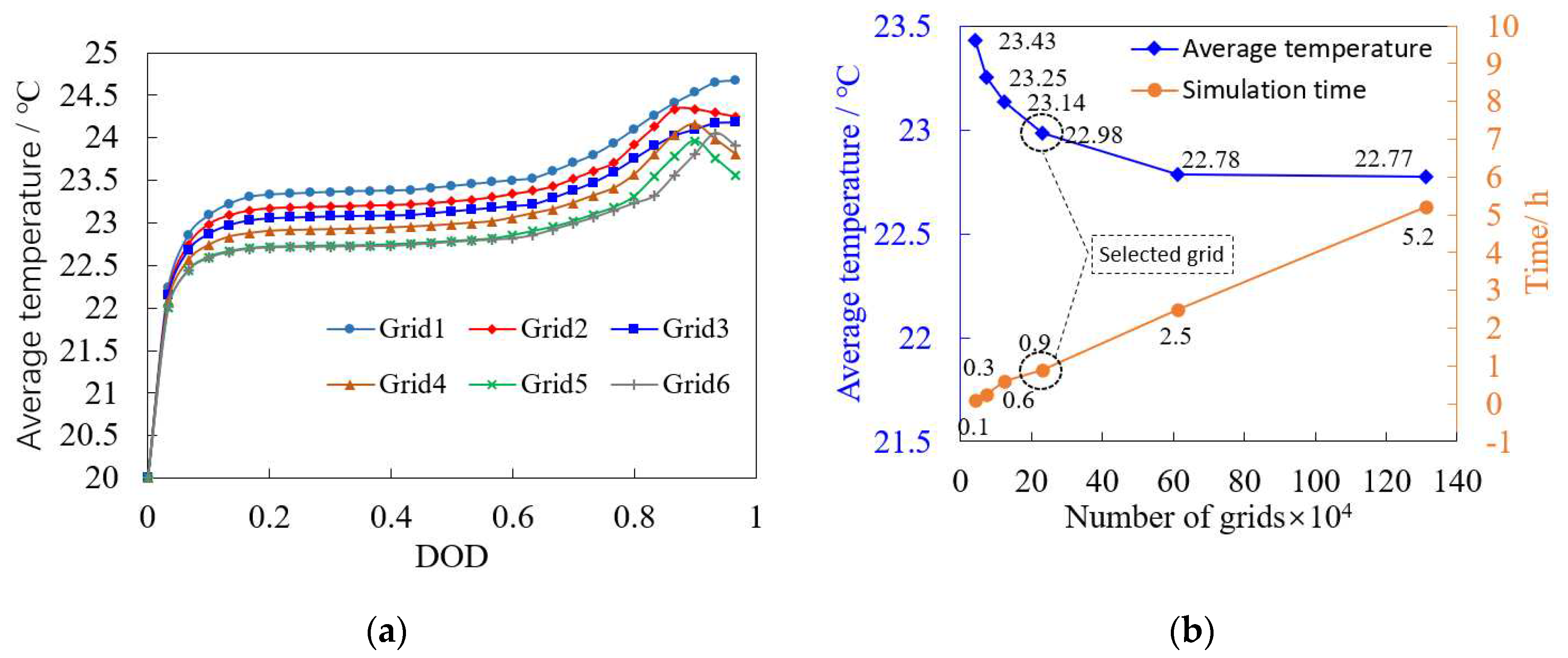

As shown in

Table 3, six cases are selected to verify the effect of meshing on the cell simulation temperature. The meshing strategy is based on five modes predefined by the software, which are super coarsening, relatively coarsening, coarsening, conventional and refinement. All simulation conditions are kept consistent except for the mesh division.

One of the batteries is selected as the research object, and its average temperature is calculated under the above five meshing cases, and the simulation results are obtained as shown in

Figure 2a. It can be seen from the figure that the more the number of grids, the lower the average temperature. The maximum temperature difference of the five cases is within ±0.5 °C. The average temperature shown in the main axis of

Figure 2b is the value when the Depth of Discharge (DOD) in

Figure 2a is 50 %, and the time shown in the secondary axis is the number of hours consumed in the complete discharge simulation of the battery pack. As can be seen from the graph, the time required for the simulation increases proportionally with the number of grids while the difference in the average temperature after the refinement of the grid of 5 is small and can be ignored. In order to balance the simulation accuracy and efficiency, grid 4 is selected for the simulation model used in this paper.

3. Experiment

3.1. TDC-based pack principle

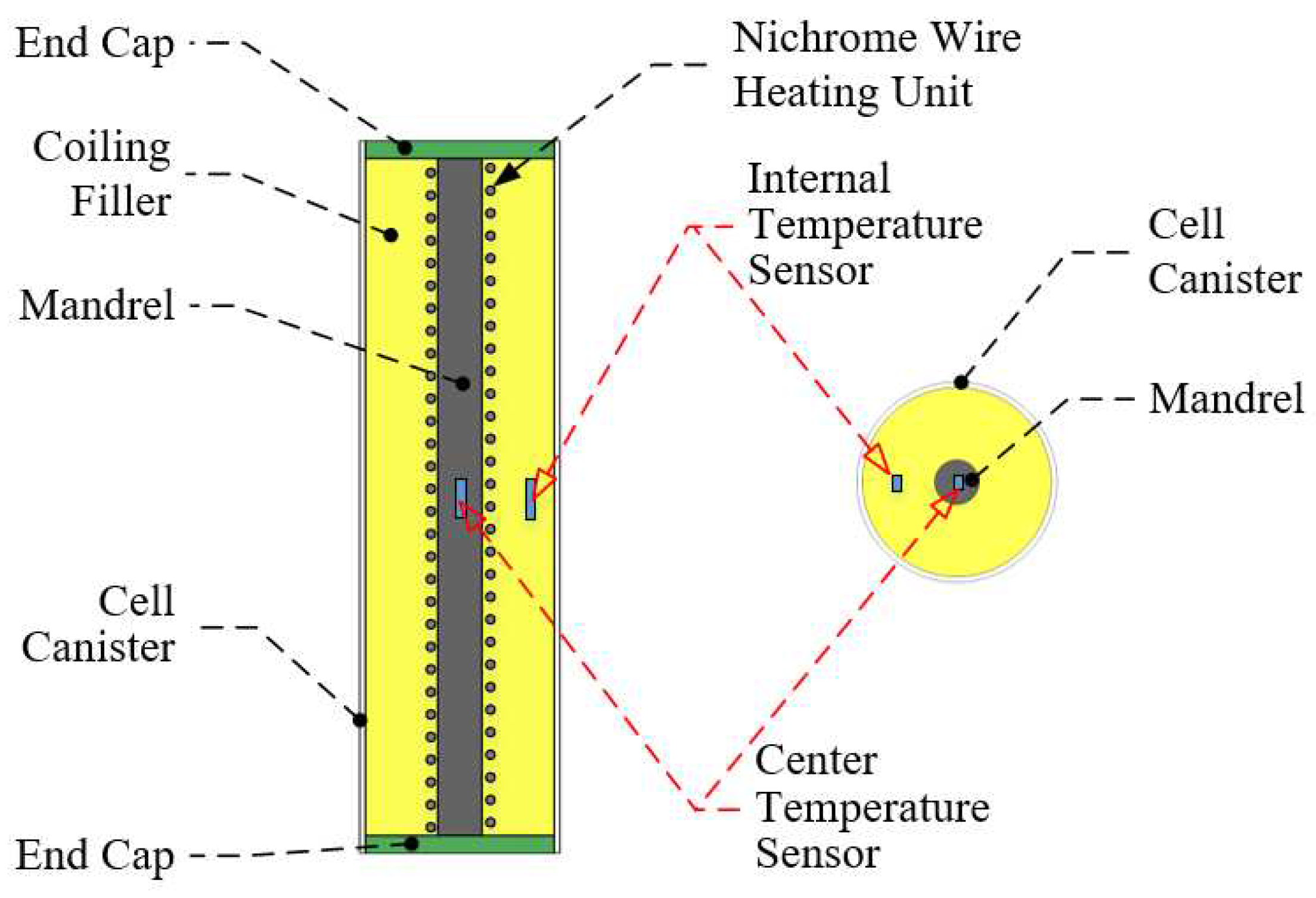

3.1.1. TDC structure

The battery pack used in this experiment consists of seven self-researched thermal dummy cells (TDC), the details of which can be found in my previous publication [

21]. A TDC was used instead of the real cell for thermal power simulation, and both internal and core temperatures were measured to obtain the extremes and variation curves of temperature for different cell operating conditions and coolant flow rates. The internal structure and principle of the used TDC are basically the same as the simulation model, here the core of the TDC is a hollow alumina ceramic rod with 4 mm outer diameter and 2 mm inner diameter to facilitate the arrangement of a temperature sensor in the center.

Two temperature sensors are embedded inside each TDC. One is placed inside the mandrel, called the central temperature sensor, and the other is placed at the axial midpoint inside the winding fill, which is separated from the outer shell by an approximately 3 mm thick thermally conductive silicone fill, called the internal temperature sensor. The TDC is similar to the battery in that the highest temperature of its sidewall is at the midpoint, so the reading of the internal temperature sensor is representative of the average temperature of the actual cell. Since the center temperature sensor is very close to the heating unit, the temperature response at this point is fast and reflects the amount of heating power, representing the maximum temperature inside the TDC.

Due to the production error, there is a certain deviation in the resistance of the heating unit of the 7 TDCs, and their resistance values and average values are shown in

Table 4. It can be seen that the maximum resistance deviation between them is within 3.8 %, and under the same supply voltage, the corresponding heating power will also have a certain deviation, but not too large.

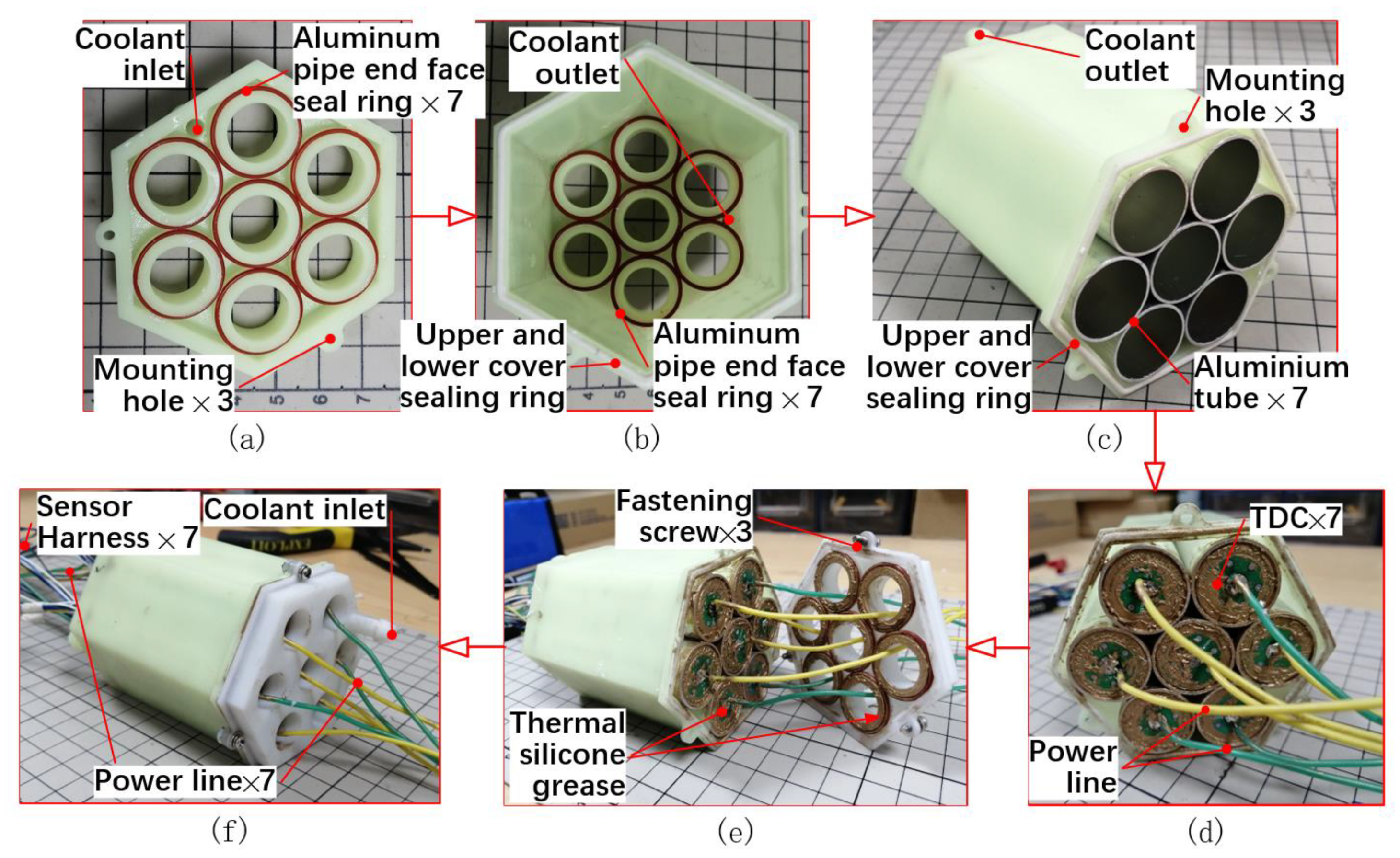

3.1.2. Design of TDC battery pack and liquid-cooled heat exchange structure

According to the structure model in

Figure 1, a set of battery pack cooling water jacket prototypes were made by 3D printing technology. Its real object is shown in

Figure 4 The assembly process and internal structure details of the battery pack prototype are given in the figure.

The prototype has two difficulties: one is sealing and waterproofing, this paper adopts O-type silicone seal with wire diameter 1.2 mm to seal between the aluminum tube and the upper and lower cover, and adopts foam silicone seal with wire diameter 1.0 mm to seal between the upper and lower cover; the second is thermal conductivity, this paper fills thermal conductive silicone grease (QM950; Shanghai Zihong Electronics Co.) between the TDC and the aluminum tube to reduce the contact thermal resistance. The thermal conductivity is greater than 4 W/(m·K) according to the product specification provided by the manufacturer. In particular, the battery pack prototype used in this test was assembled with aluminum tubes with a wall thickness of 0.5 mm, resulting in a radial cell clearance of 1 mm. In practice, this clearance can be reduced to 0.5 mm or less by manufacturing processes such as custom aluminum profiles and brazing. The temperature measurement system used in this experiment can be found in the aforementioned literature [

22].

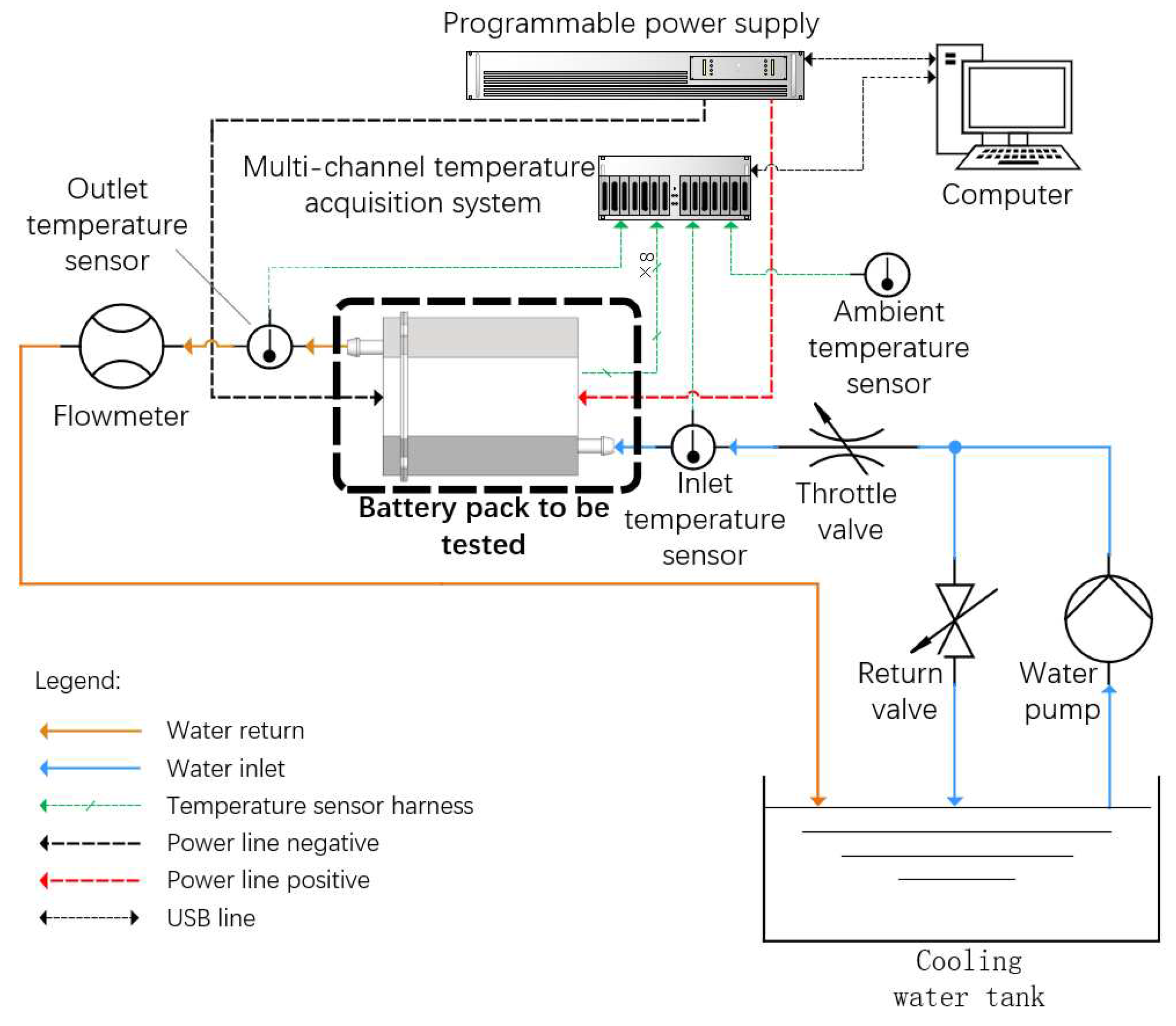

3.2. Test system and method

3.2.1. Test system composition

In order to verify the feasibility of the new liquid cooling scheme based on the above battery pack prototype, a dedicated test bench needs to be built to establish the coolant circulation, signal sampling and power supply [

23]. In this paper, a test bench scheme is designed as shown in

Figure 5.

The test bench consists of a water pump, two regulating valves, a flow meter and a water tank to form a coolant circulation channel. A programmable power supply (IT6516D; Itech Electronics Co, Ltd, China) with an output power of 1.8 kW supplies power to seven parallel TDCs, and a multi-channel temperature acquisition system measures the temperature of each TDC, the coolant inlet and outlet, and the ambient air. The flow meter used for the test was a gear-type liquid flow meter with a range of 0.1-10 L/min and a measurement accuracy of ±0.5 %. The pump used has a head of 2.8 m and a maximum flow rate of 60 L/min. In order to avoid leakage of coolant into the TDC, which may cause temperature measurement errors, industrial deionized distilled water is used as the coolant in this test.

The pump used in the test is a submersible pump, which needs to be submerged in the water tank for use. The battery pack in the test is supported by two bases and placed vertically. Its water inlet is at the bottom and the water outlet is at the top, so that the water jacket of the battery pack can be filled with coolant even under the test conditions of small flow rate. Since the cooling water for the test is recycled and the test bench is not equipped with heat sink, the water tank should be as large as possible to ensure the constant water temperature. The water tank for this experiment is a 50 L plastic tank. In the test, the tank contains 30 L of deionized water. As the water pump used in the test bench is a fixed-speed pump, so in order to achieve the regulation of the cooling water flow, a precision-adjustable throttle valve is employed, also set a return valve, so as to avoid blockage of the water pump in the case of the throttle valve closed, resulting in motor overload failure. In the beginning of the test, keeping the return valve in the fully open state, and then gradually close the return valve when the cooling water flow needs to be further increased.

3.2.2. Test procedure

The experiments described in the following sections of this paper are conducted as follows:

- 1)

Establish cooling water circulation to bring the flow rate up to the predetermined value.

- 2)

Start the temperature acquisition system and observe and wait for the coolant inlet and outlet temperatures to become essentially constant.

- 3)

Import the predefined output voltage sequence into the programmable power supply.

- 4)

Clear the temperature acquisition system's historical data and start a new acquisition while starting the power supply output.

- 5)

Wait for the programmable power supply to complete the voltage sequence output, and then end the temperature sampling and save the data.

4. Result analysis

4.1. Analysis of simulation results

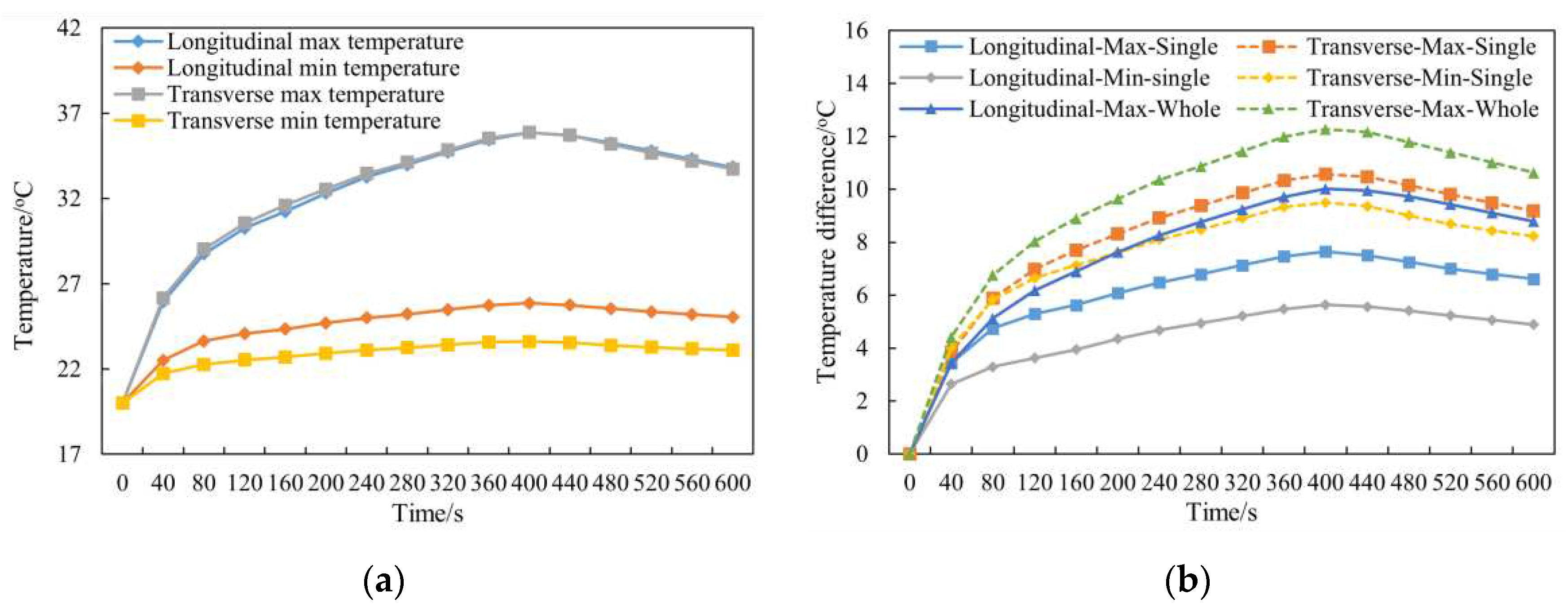

4.1.1. Comparison of cooling performance with transverse flow battery pack

The geometric model of the longitudinal flow is shown in

Figure 1. According to the practical working condition of transverse flow cooling of the battery, on the basis of the longitudinal flow cooling model, the axis distance of the cell is increased to 22 mm and the coolant exposure height is set to 32.5 mm. Orderly transverse flow of coolant is achieved by setting a partition. Keeping the battery heat power, inlet and outlet area, and flow rate constant, the following curves are obtained by simulation:

Figure 6a compares the maximum and minimum temperatures of the battery pack under longitudinal flow and transverse flow cooling conditions.

Figure 6b compares the maximum temperature difference of different cells in the battery pack under different cooling conditions, and the figure specifies the maximum and minimum temperature difference of cells with the maximum temperature difference between longitudinal flow and transverse flow, as well as the overall maximum temperature difference. As can be seen from the figure, the temperature rise of the battery pack after cooling by transverse flow and longitudinal flow is almost the same under the simulation conditions, but the longitudinal flow can play a good role in reducing the temperature difference in both individual cells and the battery pack.

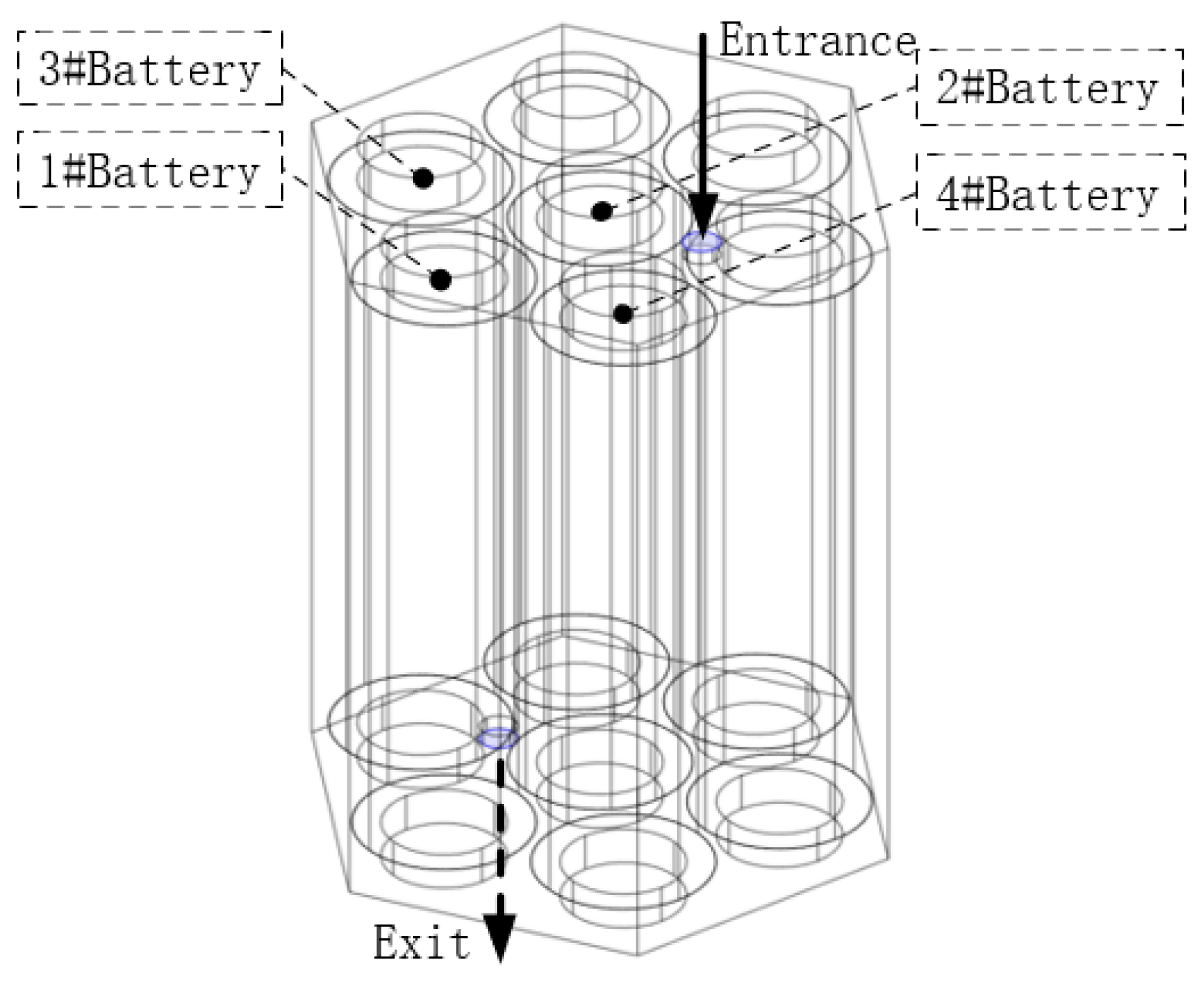

4.1.2. Effect of flow channel parameters on thermal performance of longitudinal flow battery pack

For liquid-cooled battery packs, the design of coolant flow channels largely affects the cooling effect of the battery. By comparing the flow channel alignment/staggered, direction, location, aperture diameter, inlet/outlet location, size, and number, the effect of the proposed gap flow channel coolant inlet/outlet setting scheme on the heat dissipation effect is comprehensively studied, and considering the cooling effect of the battery pack and engineering feasibility, it is concluded that the optimal coolant flow is staggered distribution of one inlet and one outlet from the end direction. The specific location of the flow channel is shown in

Figure 7, and the 4mm inlet and outlet apertures are used.

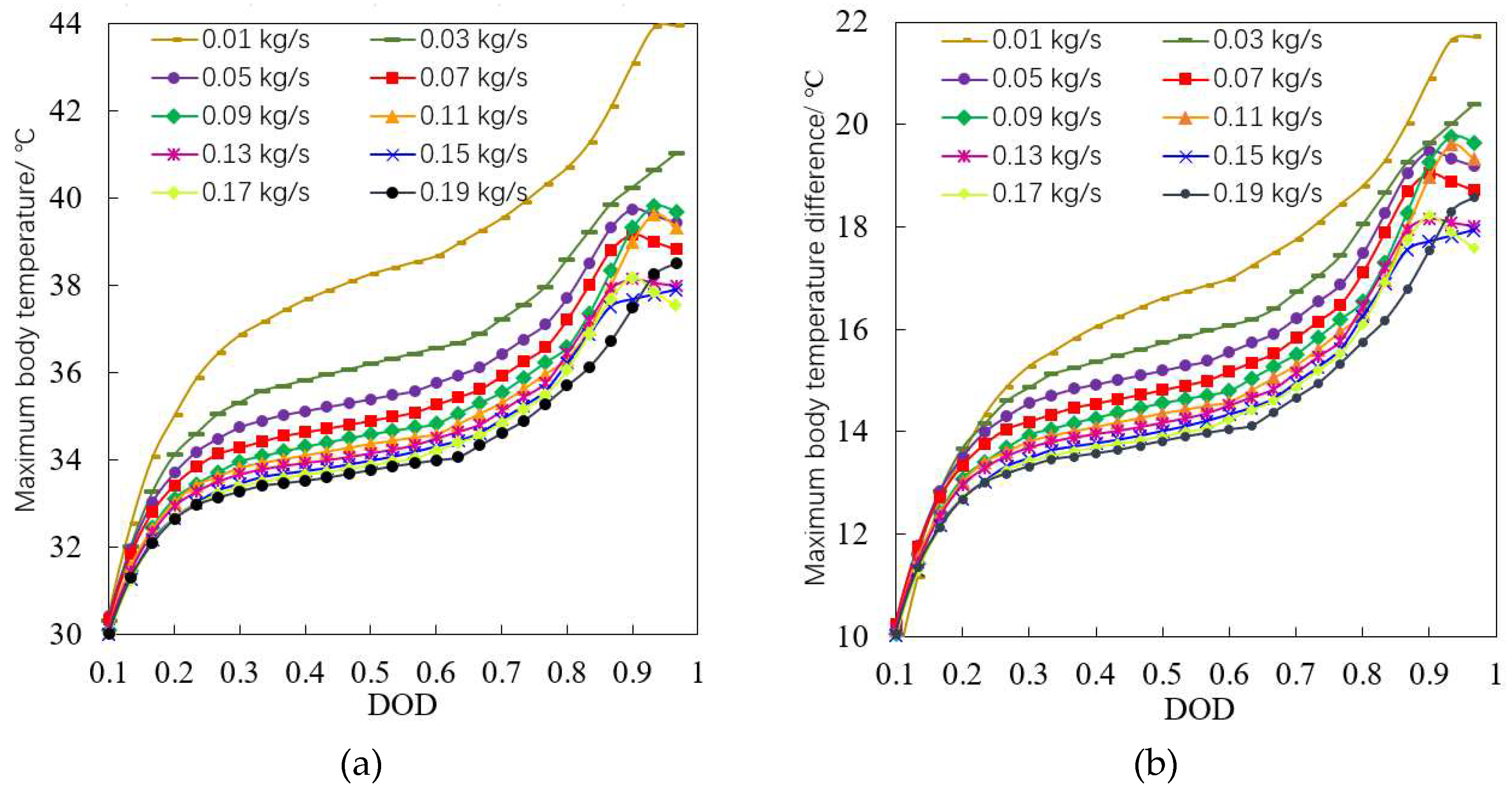

4.1.3. Effect of operating parameters on the thermal performance of longitudinal flow battery packs

In the previous section, the geometric dimensions and location relationships of the coolant inlet and outlet of the battery pack were studied and selected. In this section, based on this, the effect of the liquid cooling method proposed in this paper on the cooling performance of the battery when the flow rate, discharge rate and operating conditions are changed is investigated to further verify its feasibility.

- 1)

Influence of coolant flow change on cooling effect

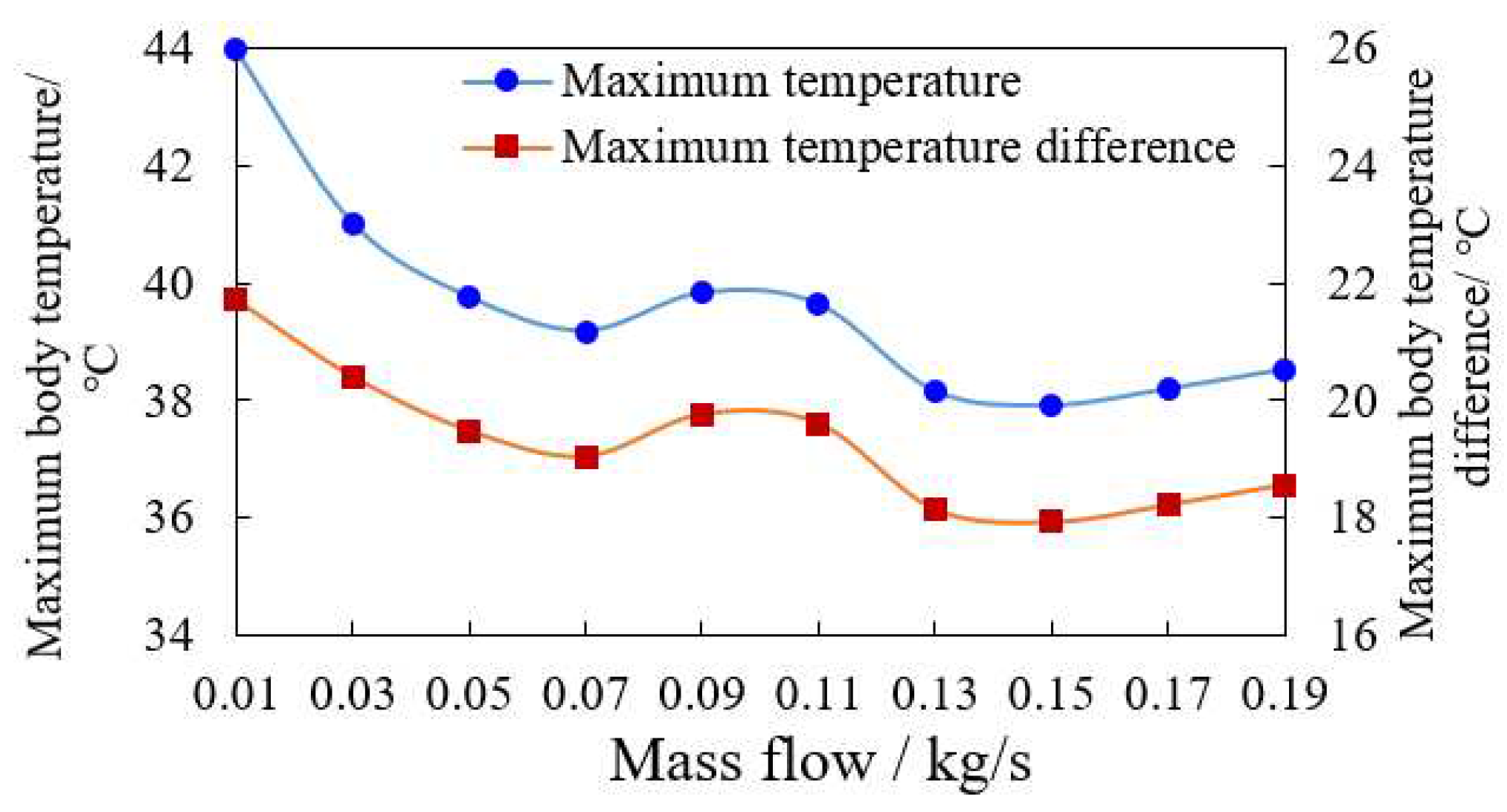

The relationship between flow rate and cell temperature is investigated according to the entrance and exit scheme determined in the previous section. The battery is discharged at 4C condition, the coolant flow rate is gradually increased from 0.01 kg/s to 0.19 kg/s, and the change of the maximum temperature and maximum temperature difference of the battery pack is recorded. The simulation results are shown in

Figure 8.

As can be seen from the figures, the maximum body temperature and maximum body temperature difference of the battery pack have approximately the same trend of change throughout the discharge process. In the stage of DOD of 10 %~85 %, the temperature values shown in both figures decrease with the gradual increase of the flow rate, but the magnitude of the decrease is gradually decreasing. There is no such pattern at the stage of DOD of 85 % to 100 %. During the whole discharge process, the relationship between the extreme value of the maximum body temperature and the maximum body temperature difference and the flow rate is shown in

Figure 9.

It can be seen from

Figure 9 that when the flow rate is 0.01-0.07 kg/s, the maximum body temperature and the maximum body temperature difference of the battery pack decrease rapidly with the increase of the flow rate, and the total decrease can reach 5 °C; In the range of 0.07-0.19 kg/s, the temperature value shows a non-monotonic change with the change of flow rate, which first increases, then decreases, and then increases, and the change range of temperature is only about 1 °C. It can be seen that from 0.07 kg/s, the ability to continuously increase the coolant flow to reduce the maximum temperature and maximum temperature difference of the battery is limited.

- 2)

Influence of discharge rate on cooling effect of battery pack

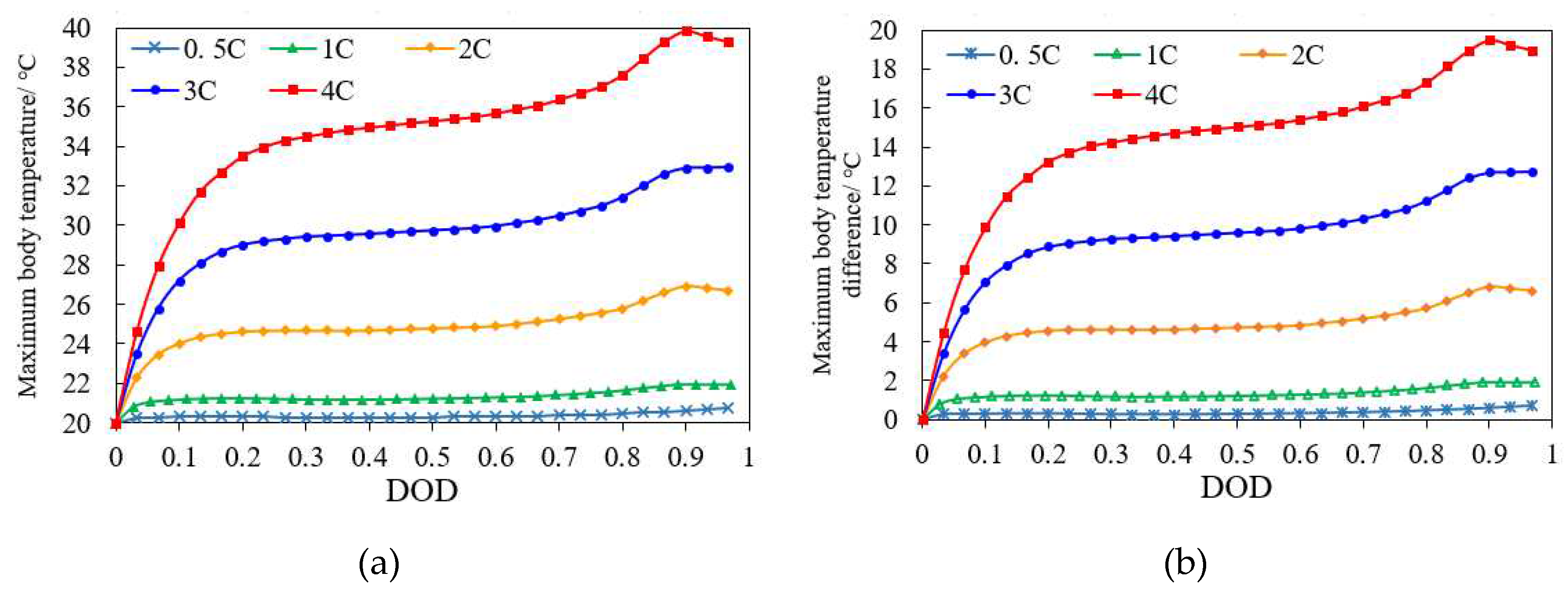

When the flow rate is set to 0.05 kg/s and the discharge rate of the battery is 0.5C, 1C, 2C, 3C and 4C, study the temperature change of the battery pack. The simulation results are shown in

Figure 10.

It can be seen from the graph that the higher the discharge rate is, the higher the temperature of the battery is. When the battery is continuously discharged at 4C multiplier, its maximum temperature does not exceed 40 °C, and the maximum temperature difference is 19 °C; when it is continuously discharged at 3C rate, its maximum temperature does not exceed 33 °C, and the maximum temperature difference is less than 12 °C. Therefore, the coolant flow rate can be dynamically adjusted according to the operating current and temperature feedback of the battery, using a large flow rate when discharging at high temperature and high current, and a small flow rate when discharging at low temperature and low current, in order to reduce the energy consumption of the thermal management system.

4.2. Analysis of experimental results

4.2.1. Test results and analysis under constant condition

- 1)

The average temperature performance of a battery pack at a high discharge rate

According to the lumped parameter cell model described in

Table 2, the simulation is performed under 3C constant current continuous discharge conditions, and the thermal power curve of the cell is recorded as a function of time. This is then converted to the curve of supply voltage versus time for the TDC according to Ohm's law. The average values of the resistance of the seven TDCs given in

Table 4 are taken here for conversion.

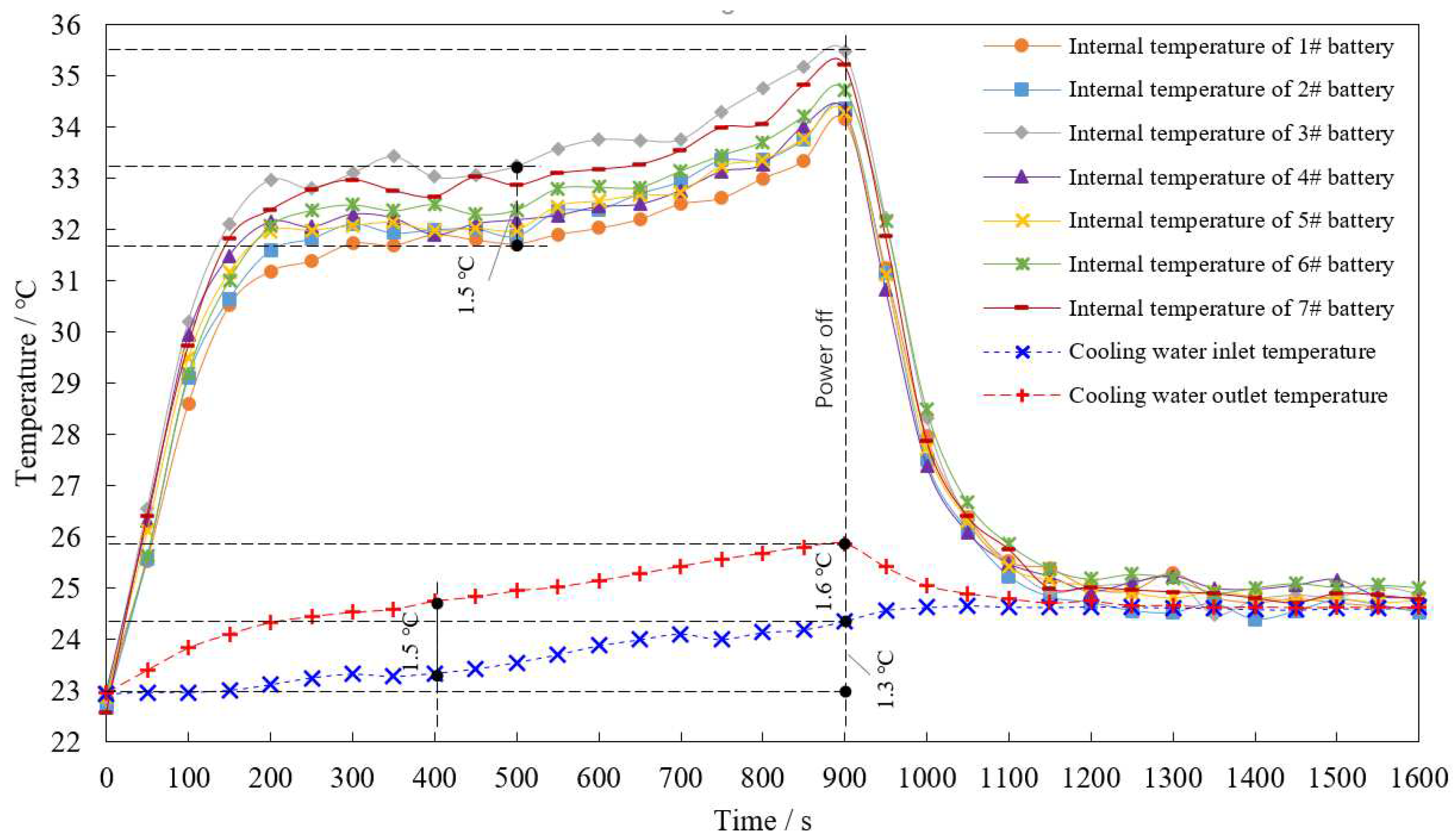

This voltage curve is loaded step by the programmable power supply to the seven parallel TDCs. At the same time, the volume flow of cooling water was adjusted to 0.4 L/min (mass flow was 0.0067 kg/s), and the temperature curve was measured as shown in

Figure 11.

The test was conducted at room temperature of 23 °C. As can be seen from the figure, the internal temperature of all seven TDCs rose rapidly with the power on, reached the first peak after 200 s, then maintained a steady increase until the second peak at 900 s, and then dropped rapidly with the power off immediately. The cooling water outlet temperature rises slowly as the power is turned on and gradually decreases after the power is turned off. The cooling water inlet temperature also increased slightly during the test, and finally the cooling water outlet temperature and the internal temperature of the seven TDCs both returned to the same relatively stable value. Due to the self-heating effect of the pump, the cooling water inlet temperature also gradually increased as the test was carried out, and its maximum temperature rise was 1.3 °C. The maximum temperature rise of the outlet cooling water is 2.9 °C, minus the rise of the inlet water temperature, the maximum value of the temperature difference between the inlet and outlet cooling water is 1.6 °C. It can be converted into heat according to the formula (11).

where, Q is the heat carried away by cooling water, unit: J; c is the specific heat capacities of water, 4.2 × 10

3 J/(kg·K);m is the mass of water, in kg; ΔT is the temperature difference, in K.

For example, at the 400th second, the calculated heat transfer power is 42.21 W, while the heating power of TDC is 47.68 W. Without considering other heat dissipation factors such as surface heat transfer, the heating power is greater than the heat dissipation power, and the temperature of the TDC will continue to rise slowly.

The temperature difference of 7 TDCs in the temperature-holding stage was 1.5 °C. It is observed that the temperature of each TDC has no specific relationship with its distribution in the battery pack. Therefore, the temperature difference should come from two aspects. On the one hand, it comes from the measurement error of the temperature measurement system, including the maximum error of the sensor --about ± 0.5 °C; On the other hand, it comes from the manufacturing process of the TDC and prototype battery pack, including the accuracy of the sensor position inside the TDC, and the uniformity of the thermal conductive silicone grease applied between the TDC and the aluminum tube.

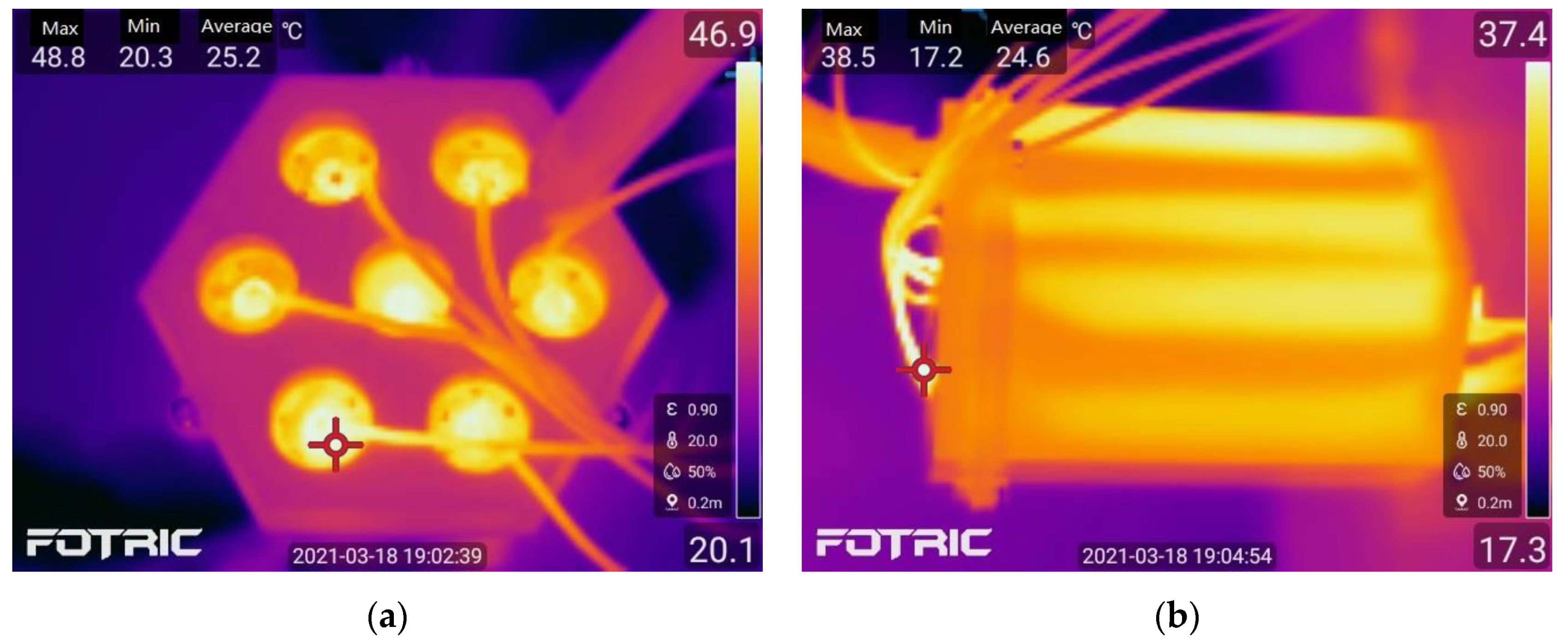

On the whole, under this test condition, the maximum internal temperature rise of the TDC is 12.8 °C. According to the existing conclusions, the temperature of the central end face of the cell is the highest point of the entire surface temperature, and is close to the core temperature of the battery. In order to further observe the temperature distribution of the end face of each TDC, the infrared thermal imager (Fotric 322Pro, Shanghai Thermal Imaging Technology Co, Ltd, China) was used to take photos near the time of highest temperature, as shown in Fig. 15. The resolution of the thermal imager is 320 × 240, temperature measurement accuracy is ± 2 °C, thermal sensitivity is 0.7 °C. Note that the temperature measured by the infrared thermal imager is the surface temperature, which does not represent the real temperature, but only reflects the temperature difference on the surface [

24].

It can be seen from

Figure 12a that there is no obvious distinction between light and dark in the thermal image of the end faces of the seven TDCs, and the temperature is relatively uniform. Consistent with the simulation results, the maximum temperature of the end face of each TDC is located at the center of the end face circle. The highest temperature in this figure reached 48.8 °C. In addition, it can be seen that the wire temperature is quite high, and the closer it is to the TDC, the higher its temperature is. In

Figure 12b, the position of the TDC in the battery pack is clearly visible. The surface temperature near the corner and edge gap channel is significantly lower than that near the TDC. In addition, by comparing

Figure 12a,b, it can be seen that the average temperature at the side of the battery pack is slightly lower than that at the end.

- 2)

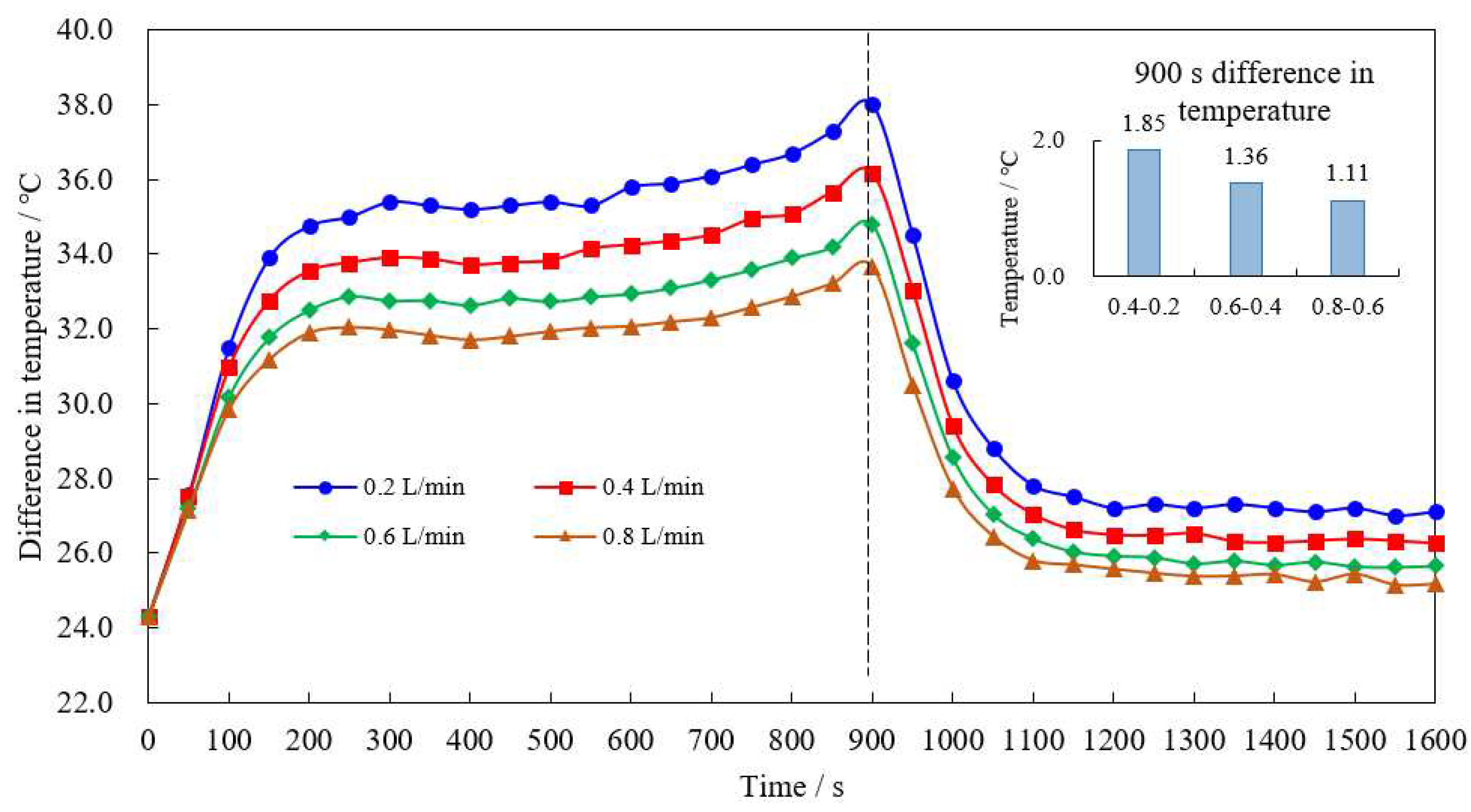

Effect of coolant flow rate on heat dissipation performance of longitudinal flow battery pack

Under the current cooling water flow rate and the thermal power rate of the TDC, the maximum temperature of TDC does not exceed 40 °C, but the maximum end temperature exceeds 40 °C. Therefore, it is necessary to further increase the cooling water flow to reduce the temperature, and study the relationship between temperature and flow. In order to observe the temperature changes of the seven TDCs more clearly, the average temperature was taken as the research object. Under the same heating power and ambient temperature, change the flow of cooling water from 0.2 L/min to 0.2 L/min each time and gradually increase to 0.8 L/min. The relationship between the average temperature and flow of the TDC is shown in

Figure 13.

It can be seen that the average temperature of TDC is closely related to the coolant flow and decreases with the increase of coolant flow. However, when the coolant flow increases in the sequence of equal difference, the temperature drop gradually decreases. Taking the data in the 900th second in

Figure 13 as an example, when the flow rate is gradually increased, the corresponding temperature difference is 1.85 °C, 1.36 °C and 1.11 °C, and the reduction range is gradually reduced. It can be concluded that there is an upper limit to improve the cooling effect by increasing the flow rate, which is consistent with the above simulation results.

To sum up, the liquid cooling scheme can ensure that the temperature uniformity of each cell in the battery pack is within 1.5 °C, and the maximum temperature inside the TDC is within 40 °C when the cooling water flow is 0.4 L/min. Furthermore, the maximum temperature can be further reduced by increasing the cooling water flow.

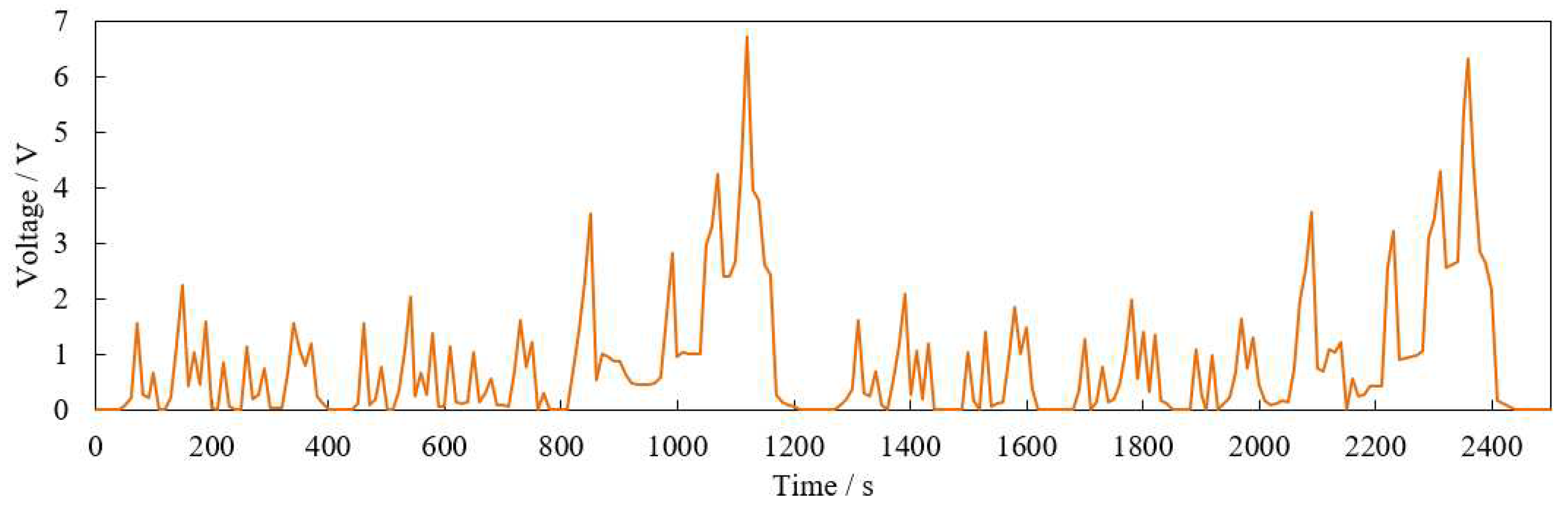

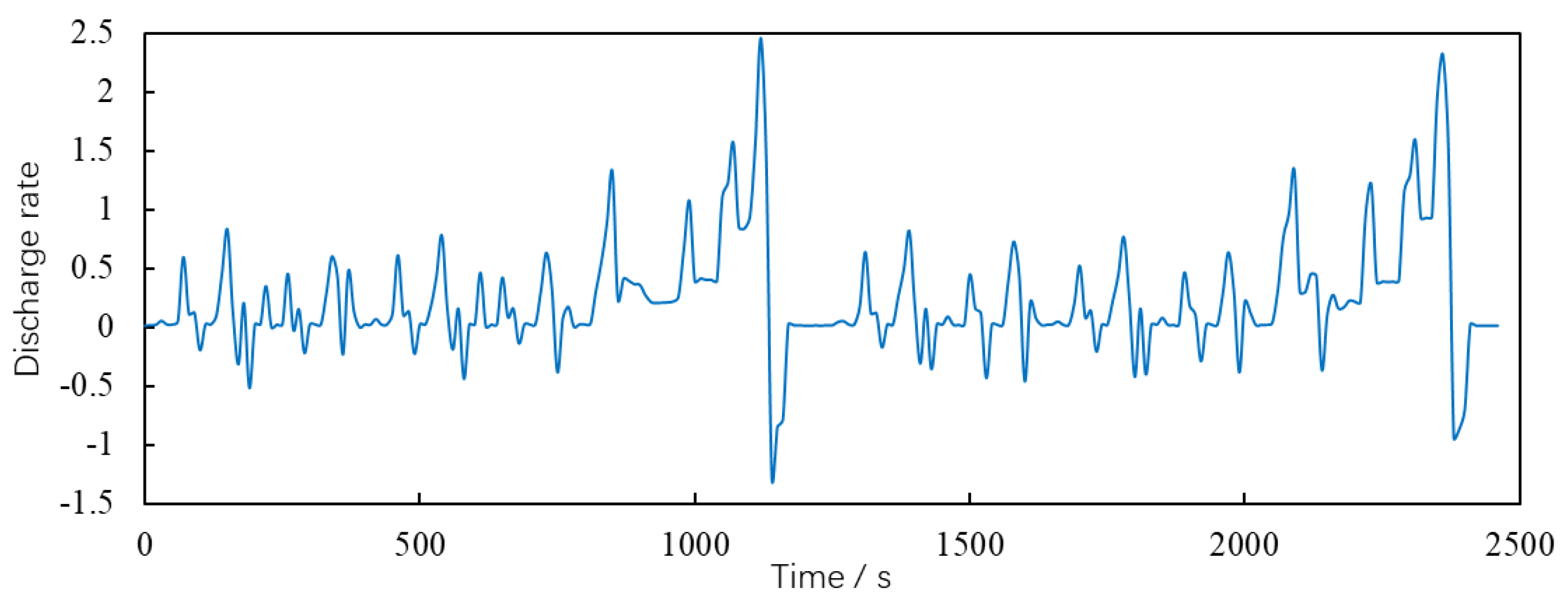

4.2.2. Test results and analysis under NEDC conditions

In order to further verify the feasibility of the liquid cooling method proposed in this paper, the NEDC working condition is used for loading in the test bench of this paper. First, in the lumped parameter battery model, the thermal power of the battery is obtained by numerical simulation according to the discharge rate shown in

Figure 15, and then converted into the curve of the supply voltage of the TDC with time according to Ohm's law, as shown in

Figure 14. The resistance value used for conversion is the average value of seven TDCs given in

Table 4.

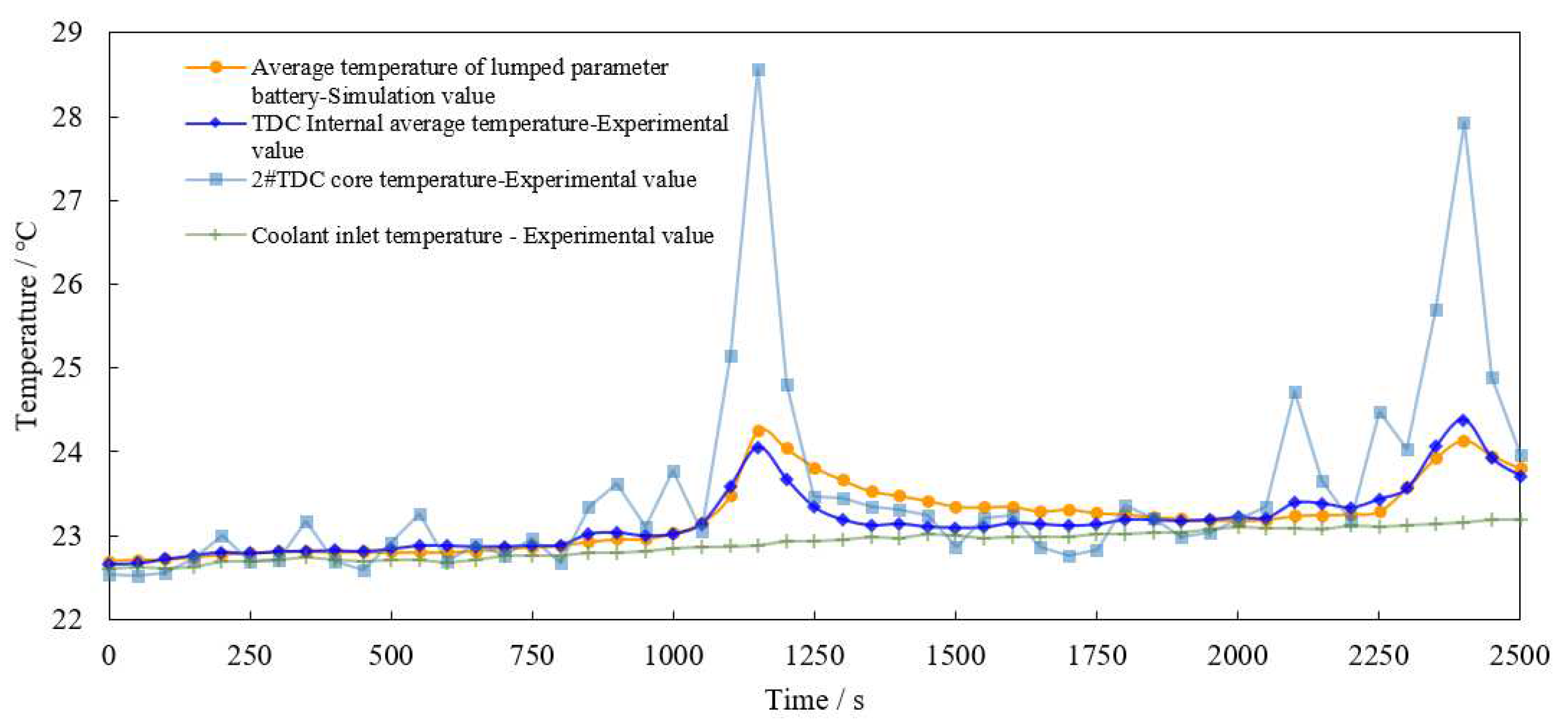

After the curve is discretized in 10 s, it is loaded into the programmable power supply and output to the TDC pack. The total output time is 2500 s, including two NEDC cycle conditions . During the test, the internal temperature of each TDC was measured and its average value was taken. At the same time, the core temperature of No. 2 TDC was measured and plotted together with the simulation results into the curve shown in

Figure 16.

In the simulation model, the coolant inlet flow of the battery pack is set at 0.2 L/min, which is equal to the flow used in the test; The initial temperature is adjusted to the ambient temperature during the test, 22.6 °C. Due to the self-heating effect of the water pump, there is a basic rising process in the measured data, which is also proved by the slow rise of the coolant inlet temperature. In order to compensate for this error in the simulation model, the inlet water temperature measured in the test is compiled into an interpolation function and used as the inlet temperature of the coolant in the simulation.

Figure 16 shows that under the NEDC working condition, the change trends of the test temperature curve and the simulation curve are basically the same, with two obvious peaks at the same time, and the difference between the maximum temperatures of the two is only 0.2 °C. Within 500 s after the end of the first cycle, the simulation value is slightly higher than the test value. The maximum temperature rise point of the test curve appears 100 s before the end of each cycle, and the temperature rise at its peak is about 1.4 °C. The core temperature curve of No. 2 battery is also shown in the figure. It can be seen that its response to voltage input is very sensitive, which basically corresponds to the peak of the input voltage curve shown in

Figure 15, with the highest peak reaching 28.5 °C. After two NEDC cycles, the internal temperature rise of the TDC does not exceed 2 °C, the temperature rise of the core temperature is also less than 6 °C, and the peak value of the second cycle is not higher than that of the first cycle. Therefore, this test shows that the liquid cooling method designed in this paper can effectively cool the battery under NEDC driving conditions.

4.2.3. Discussion of test results

In the simulation process, the battery lumped parameter model was used for simulation, and in the experimental process, the TDC was used for verification. Although there is a certain error compared with the actual battery, it can be shown by the reference [

21] that the TDC battery can meet the needs of this experiment and verify that the longitudinal flow method can perform effective cooling.

The results of above three tests are: 1) The steady-state condition test shows that under the 3 C continuous discharge condition and the cooling water flow rate of 0.4 L/min, the temperature uniformity of each TDC in the battery pack is controlled within 1.5 °C, and its internal maximum temperature rise is below 14 °C, and decreases to 10 °C as the flow rate increases to 0.8 L/min; 2) The self-defined condition test shows that under the battery charging and discharging conditions with great dynamic changes, as long as the cooling water flow is maintained at 0.2 L/min, the internal temperature rise of the battery can be controlled at about 5 °C, and the heat dissipation effect is significantly better than natural cooling under the same thermal power; 3) The NEDC working condition test shows that the maximum internal temperature rise of the TDC is not more than 2 °C and the core temperature rise is only 6 °C under the driving condition close to the actual driving condition.

5. Conclusions

This paper focuses on the longitudinal flow heat dissipation method for cylindrical lithium-ion batteries. The longitudinal flow heat dissipation method is proposed for cylindrical lithium-ion battery packs. Compared to transverse flow, the average temperature of longitudinal flow is higher, but the maximum temperature is almost the same when considering the actual operating conditions, and the longitudinal flow technology can significantly reduce the cells temperature difference and reduce the cells pack size by about 10 %. In order to further verify the feasibility of longitudinal flow heat dissipation, a study of liquid-cooled longitudinal flow heat dissipation is conducted in this paper, and numerical simulations conclude that a one-in-one-out coolant flow scheme is the optimal implementation. Further, a multi-channel temperature measurement system and TDCs built by the previous study are used to conduct validation tests on the liquid cooling method. The simulation and test also proved that the liquid cooling method can control the maximum temperature rise of the battery in the battery pack to less than 20 °C under the static condition of continuous discharge of the battery with high current at 3C rate, and can control the maximum temperature rise to less than 2 °C under the dynamic driving condition of NEDC. The technical solution proposed in this paper not only has sufficient theoretical basis, but also has strong practical significance. The liquid cooling method has certain advantages in application scenarios with strict requirements on the arrangement space of battery packs, such as passenger car power batteries and spacecraft power supplies. In addition, this study proposes for the first time a longitudinal flow heat dissipation method by passing a heat transfer fluid into the gaps formed by the close-packed cylindrical cells.

Author Contributions

Conceptualization, Wei Li.; methodology, Wei Li and Wei Shi; software, Wei Li; validation, Wei Li, Wei Shi, Hai Huang and Guodong Chen; formal analysis, Wei Li, Wei Shi and Hai Huang; investigation, Wei Li and Wei Shi; resources, Wei Li and Wei Shi; data curation, Wei Li and Hai Huang; writing—original draft preparation, Wei Li; writing—review and editing, Wei Li and Hai Huang; visualization, Wei Li and Hai Huang; supervision, Wei Li; project administration, Wei Li; funding acquisition, Shusheng Xiong. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Key Research and Development Program of China, grant number 2022YFB2502403 and Zhejiang Province "Spearhead" and "Leading Goose" Research and Development Key Program, grant number 2023C01239.

Data Availability Statement

Not Availability.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kaya K, Hames Y. Two new control strategies: For hydrogen fuel saving and extend the life cycle in the hydrogen fuel cell vehicles[J]. International Journal of Hydrogen Energy, 2019,44(34):18967-18980. [CrossRef]

- Wang H, Xu W, Ma L. Actively controlled thermal management of prismatic Li-ion cells under elevated temperatures[J]. International Journal of Heat and Mass Transfer, 2016,102:315-322. [CrossRef]

- Karimi G, Li X. Thermal management of lithium-ion batteries for electric vehicles[J]. International journal of energy research, 2013,37(1):13-24. [CrossRef]

- Teng H, Ma Y, Yeow K, et al. An Analysis of a Lithium-ion Battery System with Indirect Air Cooling and Warm-Up[J]. SAE International Journal of Passenger Cars - Mechanical Systems, 2011,4(3):1343-1357. [CrossRef]

- Kang D, Lee P, Yoo K, et al. Internal thermal network model-based inner temperature distribution of high-power lithium-ion battery packs with different shapes for thermal management[J]. Journal of Energy Storage, 2020,27:101017. [CrossRef]

- Asensio F J, San Martín J I, Zamora I, et al. Model for optimal management of the cooling system of a fuel cell-based combined heat and power system for developing optimization control strategies[J]. Applied Energy, 2018,211:413-430. [CrossRef]

- Fang G, Yuan W, Yan Z, et al. Thermal management integrated with three-dimensional heat pipes for air-cooled permanent magnet synchronous motor[J]. Applied Thermal Engineering, 2019,152:594-604. [CrossRef]

- Guo F, Zhang C. Oil-Cooling Method of the Permanent Magnet Synchronous Motor for Electric Vehicle[J]. Energies, 2019,12(15):2984. [CrossRef]

- Hu X, Li S, Peng H. A comparative study of equivalent circuit models for Li-ion batteries[J]. Journal of Power Sources, 2012,198:359-367. [CrossRef]

- Tian Zhen. Experimental study and simulation analysis of electric vehicle thermal management system based on heat pump[D]. Shanghai Jiao Tong University, 2016.

- Gan Y, Wang J, Liang J, et al. Development of thermal equivalent circuit model of heat pipe-based thermal management system for a battery module with cylindrical cells[J]. Applied Thermal Engineering, 2020,164:114523. [CrossRef]

- Behi H, Karimi D, Behi M, et al. A new concept of thermal management system in Li-ion battery using air cooling and heat pipe for electric vehicles[J]. Applied Thermal Engineering, 2020,174:115280. [CrossRef]

- Zhang K, Li M, Yang C, et al. Exergy Analysis of Electric Vehicle Heat Pump Air Conditioning System with Battery Thermal Management System[J]. Journal of Thermal Science, 2020,29(2):408-422. [CrossRef]

- Al-Zareer M, Dincer I, Rosen M A. A thermal performance management system for lithium-ion battery packs[J]. Applied Thermal Engineering, 2020,165:114378. [CrossRef]

- Zhang C, Xia Z, Wang B, et al. A Li-Ion Battery Thermal Management System Combining a Heat Pipe and Thermoelectric Cooler[J]. Energies, 2020,13(4):841. [CrossRef]

- Guohua Wang. Research on Thermal Management System Cooling Modeling and Battery Thermal Control Strategy[D].Jilin University, 2017.

- Chen D, Jiang J, Kim G, et al. Comparison of different cooling methods for lithium ion battery cells[J]. APPLIED THERMAL ENGINEERING, 2016,94:846-854. [CrossRef]

- Zhou H, Zhou F, Xu L, et al. Thermal performance of cylindrical Lithium-ion battery thermal management system based on air distribution pipe[J]. International journal of heat and mass transfer, 2019,131:984-998. [CrossRef]

- ZHAI Wen-bo,SHI Xiao-yan,ZHU Lei. Test and analysis of OCV temperature coefficient of lithium-ion batteries[J]. Power Technology, 2013,37(11):1954-1955, 1968.

- Lan, Yu. Fundamentals of Thermal Engineering and Fluid Mechanics [M]. Beijing:China Electric Power Press, 2014.

- Li W, Xiong S, Zhou X, et al. Design of Cylindrical Thermal Dummy Cell for Development of Lithium-Ion Battery Thermal Management System[J]. Energies, 2021,14(5):1357. [CrossRef]

- Li W, Xiong S, Zhou X, et al. Design of a Multichannel Dynamic Temperature Measurement System for Developing Thermal Management System of New Energy Vehicles[J]. Energy Engineering, 2020,117(5):301-314. [CrossRef]

- Zhoujian, An. Investigation on Flow Boiling-based LiFePO4 Battery Cooling and Thermal Safety[D]. Beijing Jiaotong University, 2019.

- Pinyun Lin. Some Problems about Infrared Thermometer [J]. Science and technology outlook,2015,(10):181.

Figure 1.

Schematic diagram of the battery pack structure: (a) translucent view; (b) 1/8 sectional view.

Figure 1.

Schematic diagram of the battery pack structure: (a) translucent view; (b) 1/8 sectional view.

Figure 2.

Comparison of average temperature and simulation time for five meshing cases: (a) average temperature of the battery during discharge; (b) average temperature and simulation time for cases with different number of meshes.

Figure 2.

Comparison of average temperature and simulation time for five meshing cases: (a) average temperature of the battery during discharge; (b) average temperature and simulation time for cases with different number of meshes.

Figure 3.

Distribution diagram of TDC temperature sensor in the test.

Figure 3.

Distribution diagram of TDC temperature sensor in the test.

Figure 4.

Assembly process and structural principle of battery pack prototype with Gap flow channel: (a) after the upper cover assembles the seal; (b) after the lower cover assembles the seal; (c) after the lower cover is loaded into the aluminum tube; (d) after the lower cover is loaded with the TDC; (e) before the upper and lower covers are combined; (f) after the upper and lower covers are tightened.

Figure 4.

Assembly process and structural principle of battery pack prototype with Gap flow channel: (a) after the upper cover assembles the seal; (b) after the lower cover assembles the seal; (c) after the lower cover is loaded into the aluminum tube; (d) after the lower cover is loaded with the TDC; (e) before the upper and lower covers are combined; (f) after the upper and lower covers are tightened.

Figure 5.

Schematic diagram of test bench.

Figure 5.

Schematic diagram of test bench.

Figure 6.

Comparison of longitudinal flow and transverse flow simulation based on actual working conditions: (a) maximum and minimum temperature profile of the battery pack during discharging; (b) the maximum and minimum curves of the maximum temperature difference between the individual cells of different cells in the battery pack. And the maximum temperature difference curve of the battery pack as a whole.

Figure 6.

Comparison of longitudinal flow and transverse flow simulation based on actual working conditions: (a) maximum and minimum temperature profile of the battery pack during discharging; (b) the maximum and minimum curves of the maximum temperature difference between the individual cells of different cells in the battery pack. And the maximum temperature difference curve of the battery pack as a whole.

Figure 7.

Design of flow channel and inlet and outlet.

Figure 7.

Design of flow channel and inlet and outlet.

Figure 8.

Body maximum temperature and maximum temperature difference of the battery pack at different flow rates: (a) maximum body temperature; (b) maximum body temperature difference.

Figure 8.

Body maximum temperature and maximum temperature difference of the battery pack at different flow rates: (a) maximum body temperature; (b) maximum body temperature difference.

Figure 9.

Relationship between maximum temperature and maximum temperature difference of the body and coolant flow.

Figure 9.

Relationship between maximum temperature and maximum temperature difference of the body and coolant flow.

Figure 10.

The maximum body temperature and maximum temperature difference of the battery pack at different discharge rates: (a) (a) maximum body temperature; (b) maximum body temperature difference.

Figure 10.

The maximum body temperature and maximum temperature difference of the battery pack at different discharge rates: (a) (a) maximum body temperature; (b) maximum body temperature difference.

Figure 11.

Temperature curve of thermal power under 3C discharge condition simulated by TDC with coolant flow of 0.4 L/min.

Figure 11.

Temperature curve of thermal power under 3C discharge condition simulated by TDC with coolant flow of 0.4 L/min.

Figure 12.

Infrared thermal image of the battery pack: (a) End face shooting; (b) Side shot.

Figure 12.

Infrared thermal image of the battery pack: (a) End face shooting; (b) Side shot.

Figure 13.

Average temperature of 7 TDCs under different cooling water flows.

Figure 13.

Average temperature of 7 TDCs under different cooling water flows.

Figure 14.

Voltage calculated according to NEDC working conditions.

Figure 14.

Voltage calculated according to NEDC working conditions.

Figure 15.

Time curve of discharge rate for simulation.

Figure 15.

Time curve of discharge rate for simulation.

Figure 16.

Comparison between the measured average temperature of TDCs and the simulated average temperature of lumped parameter battery under NEDC condition.

Figure 16.

Comparison between the measured average temperature of TDCs and the simulated average temperature of lumped parameter battery under NEDC condition.

Table 3.

Grid division patterns and quantity.

Table 3.

Grid division patterns and quantity.

| Condition |

Grid 1 |

Grid 2 |

Grid 3 |

Grid 4 |

Grid 5 |

Grid 6 |

| Predefined mode |

Super coarsening |

Relatively coarsening |

Coarsening |

Conventional |

Refinement |

Relatively refinement |

| Number of domain units |

42,756 |

73,005 |

123,990 |

229,310 |

612,397 |

1,310,894 |

| Number of boundary elements |

8,025 |

12,066 |

17,408 |

25,652 |

46,129 |

71,452 |

| Number of side cells |

1,314 |

1,663 |

2,081 |

2,532 |

3,673 |

4,598 |

Table 4.

Resistance value and average value of heating unit in each TDC.

Table 4.

Resistance value and average value of heating unit in each TDC.

| TDC No. |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

| Resistance value / Ω |

14.74 |

14.84 |

14.32 |

14.87 |

14.60 |

14.53 |

14.86 |

| Average value of resistance / Ω |

14.68 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).