1. Introduction

Oilseed rape is the number one oilseed crop in China, providing more than 50% of the country's edible vegetable oil. About 100 million acres are under permanent cultivation nationwide of oilseed rape, 90% of which are in the Yangtze River basin [

1,

2,

3]. However, the mechanized production level of rape in China is low, with the national level of rape machine harvesting at only 50.97% in 2021, and growing slowly. High rape machine harvesting losses are one of the main reasons limiting the healthy and rapid development of China's rape industry [

4,

5]. According to statistics, the losses of the cutting table during rape harvesting are relatively large and can reach 40% of the total harvesting losses on average [

6,

7]. The reel is an important working part of the rape combine harvesting cutter [

8,

9,

10,

11], its role is to guide the rape to be cut to the cutter or to support the fallen rape in the guidance process, to support the stalks and push the cut stalks backwards during cutting, to prevent the cut stalks from piling up on the cutter causing knife blockage and congestion [

12,

13,

14,

15].

At present, the cam-action reel of the rape combine harvester developed in China generally adopts the reel, which is conducive to holding up the fallen crop [

16,

17,

18]. But because the reel teeth move downwards throughout the whole process and keep the angle unchanged, the rape branches grow around the main branch and the height is uneven, and the plants fork and stagger between different plants and pull each other, the reel tangles, hangs and brings back problems during the paddle operation, which affects both the harvesting. This not only affects the efficiency of the harvesting operation, but also causes the angle fruit of rape to be blown up when the teeth of the reel act directly on it, resulting in a loss of grain [

19].

In order to reduce the problems of winding, picking and hanging of reels during harvesting, some foreign rape harvesters use large-diameter flip-type wheels [

20], which can significantly reduce the winding and hanging of rape as the teeth of the wheel flip during the return journey and the teeth have a large radius of rotation. It also has a complex structure and high cost, and is currently mainly used on large rape harvesting equipment. Therefore, there is an urgent need to develop a new type of reel with a simple structure, which can realize the turning of the reel teeth, a large turning radius and can adapt to the tall and branched rape, and a low speed when paddling into the sheaves, in order to improve the efficiency of rape harvesting operations and reduce paddling losses.

In this paper, the constraints on the trajectory and angle of the reel for weak strike, low winding and fast paddling are constructed based on the analysis of the winding of the reel. Based on the kinematics of the double crank plane five-bar mechanism, a variable speed anti-tangle reel mechanism is designed, and its kinematics and parameters are optimized. This study can provide a reference for the design of low loss and tangle reduction wheels for oilseed rape harvesting.

2. Materials and Methods

2.1. Variable speed reel structure and working principle

According to the biological characteristics of rape and the law of rape plant transport in the process of tilting the tines, the tines should be inserted diagonally into the branch gap from above the plant at an angle that fits the rape branches to reduce the number of collisions with the angular fruits of the rape, and the tines should rise quickly along the tilted angle of the rape at an angle close to the vertical and break away from the plant to avoid tangling and hanging of the tines, and finally gradually accelerate to complete the forward turning of the tines.

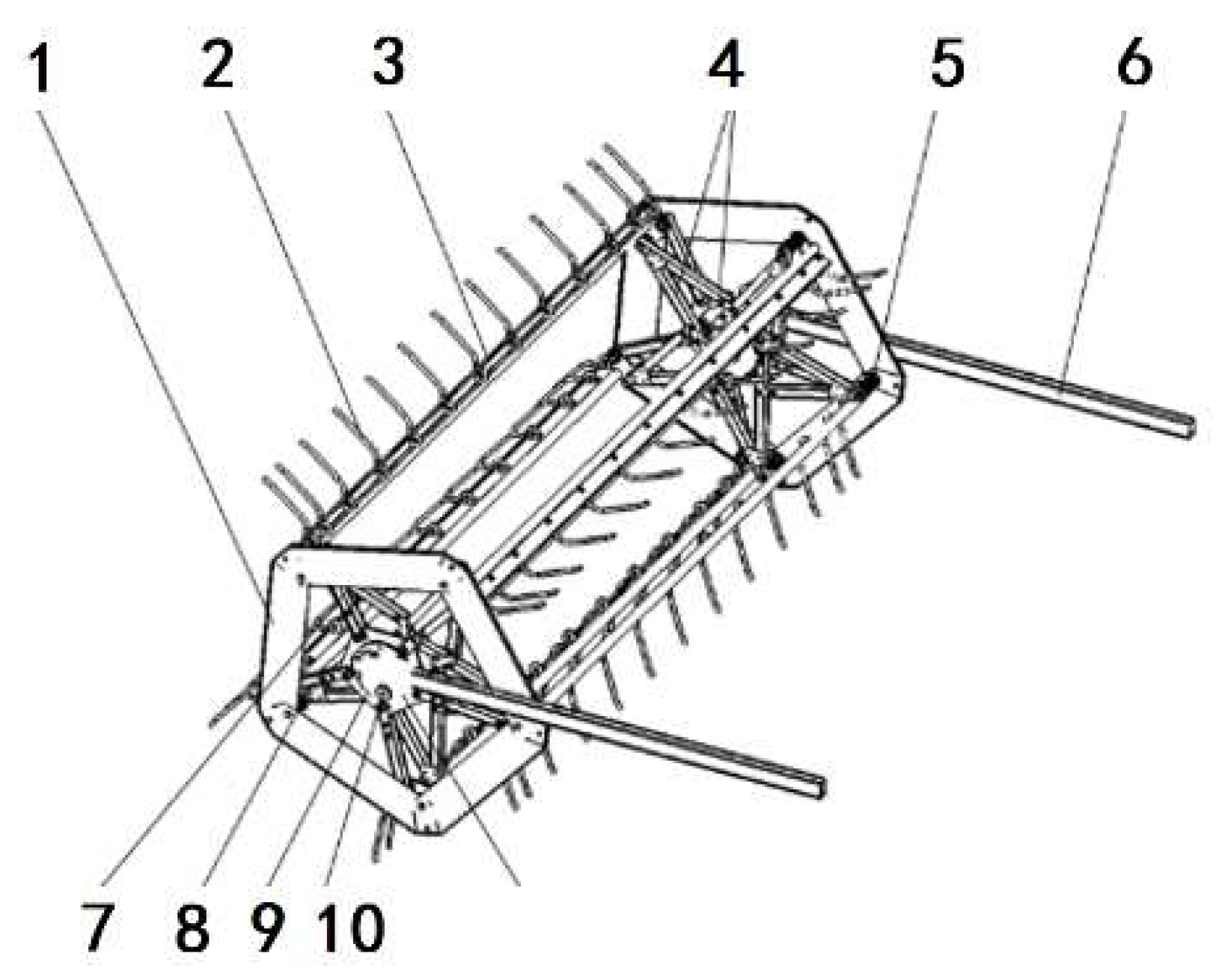

In order to realize the requirements for the trajectory and attitude of the paddle teeth in the rape paddling process, a variable speed reel mechanism is designed in this paper, the structure of which is shown in Fig. 1.

Figure 1.

Structure diagram of variable speed reel.(1)Side plate, (2) Paddle teeth,(3) Paddle plate,(4) Spindle connecting rod, (5) Crank connecting rod, (6) Cutting table support rod,(7) Eccentric disc welding rod,(8) Eccentric disc connecting rod.(9) Pentagonal plate,(10) Reel spindle,(11) Eccentric disc.

Figure 1.

Structure diagram of variable speed reel.(1)Side plate, (2) Paddle teeth,(3) Paddle plate,(4) Spindle connecting rod, (5) Crank connecting rod, (6) Cutting table support rod,(7) Eccentric disc welding rod,(8) Eccentric disc connecting rod.(9) Pentagonal plate,(10) Reel spindle,(11) Eccentric disc.

The main components are the paddle teeth, the paddle plate, the reel spindle, the spindle connecting rod, the crank connecting rod, the eccentric disc connecting rod, the pentagonal plate and the eccentric disc. In particular, the spindle connecting rod 4 is fixedly connected to the reel spindle 10, the eccentric disc welding rod 7 is fixedly connected to the eccentric disc 11 and the remaining four eccentric disc connecting rods 8 are hinged to the eccentric disc 11. The belt pulley rotates to deliver power to the spindle linkage 4, which drives the crank linkage 5 and the eccentric disc welding rod 7. The power is transferred to the eccentric disc 11, which starts to rotate, and the eccentric disc starts to drive the four eccentric disc linkages 8, which are hinged to it.

2.2. Kinematic analysis of the variable speed reel mechanism

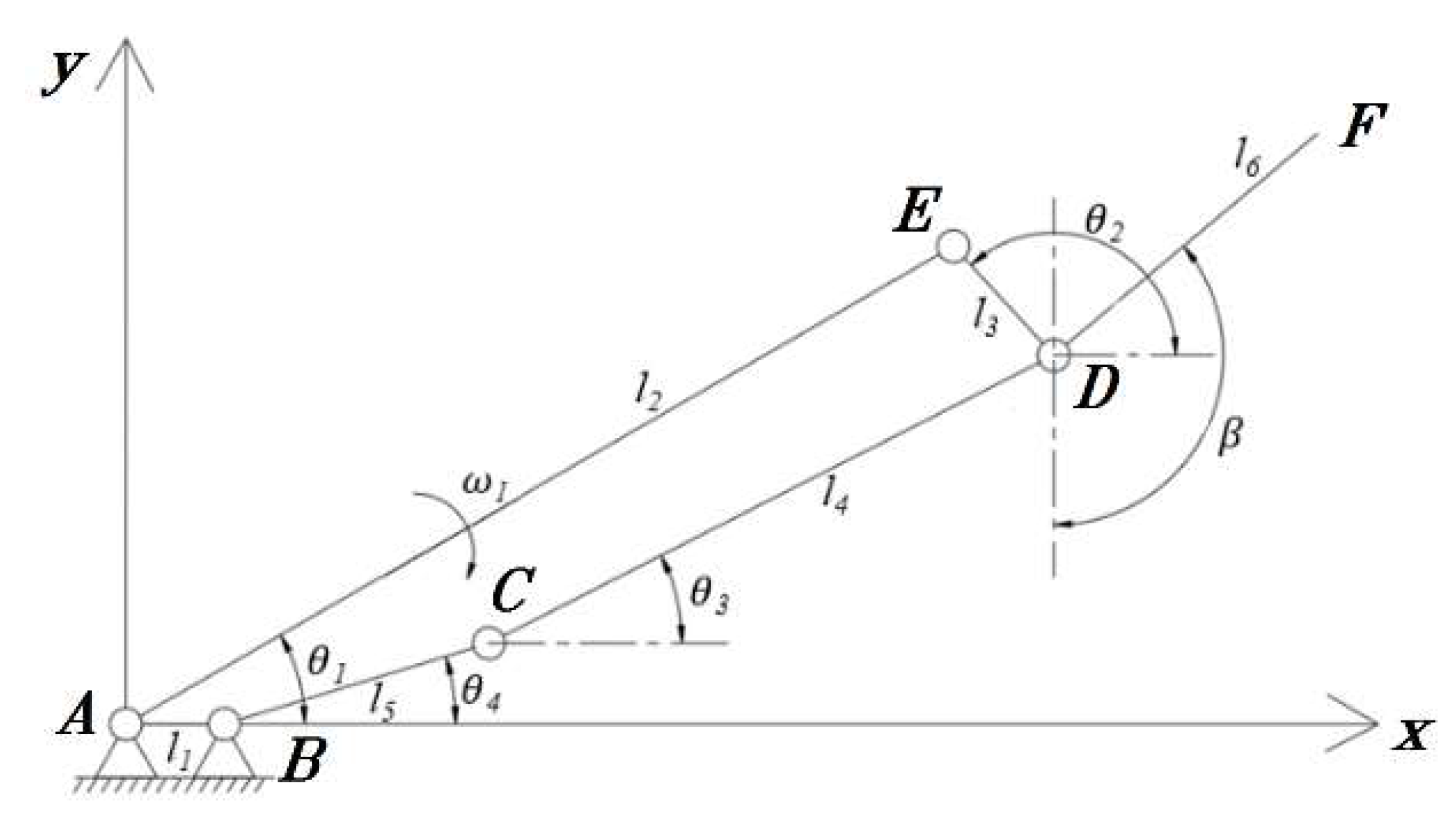

The variable speed reel mechanism is composed of a plane four-bar mechanism and four double crank plane five-bar mechanisms. [

21,

22,

23] Taking one of the paddle teeth as the object of study, the motion model of the reel mechanism is shown in

Figure 2.

Note: are the lengths of the frame, spindle connecting rod, crank connecting rod, eccentric disc welding rod/eccentric disc connecting rod, short crank and toggle teeth in mm, respectively; are the angle of each rod with the x-axis, (°), respectively, and the angle of positive counterclockwise rotation along the x-axis; are the angle of the paddle teeth with the crank connecting rod and the paddle teeth with the y-axis in the negative direction, respectively.

According to

Figure 2, the closed-loop vector equation for the teeth of the variable speed reel mechanism is established as

Decomposition of the closed-loop vector equation of equation (1) along the

x- and

y-axes

tip F of the double crank plane five-bar mechanism is related to the law of motion of the

AE rod, the

DE rod or the

BC and

CD rods. The

AE and

BC rods are the two cranks of the mechanism, doing the same direction of equal velocity rotary motion, the angle

between the paddle teeth

DE and the rod

DF is a constant value, so only need to get the angle under the

,

, at that moment, the equation of the trajectory of the paddle tooth tip F can be found. As the five rods form a closed vector ring

ABCDEA, the following conditions must be satisfied at any moment

,

:

Then the equation of the static trajectory of the point F of the paddle teeth tip can be solved according to the law of motion of the

AE and

DE rods as

Derivation of equation (4) gives the equation for the static trajectory velocity at the point of the paddle tooth tip

F as

Assuming that the harvester travels at a speed

, the dynamic trajectory equation for the point

F of the paddle tooth tip is

Derivation of equation (6) gives the velocity equation for the dynamic condition at the point

F of the paddle tooth tip, as

2.3. Variable speed reel construction parameters

The variable speed reel designed in this paper is mounted on a Ward 4LZ-6.0 full-feed tracked self-propelled rape combine harvester with a 2.2m wide cutting deck. According to preliminary field research, the average angle between the rape branches and the main inflorescence is 25°~40°, so the angle between the reel teeth and the crank connecting rod is set at 40°. Based on the kinematic analysis and the rod length constraint of the double crank plane five-rod mechanism [

24,

25], the structural parameters of the variable speed reel mechanism were determined as shown in

Table 1.

2.4. Test material

The oilseed rape harvest trial was conducted from June 6 to June 8, 2022 in Daitou Town, Liyang City, Changzhou City, Jiangsu Province. The oilseed rape was planted by mechanical direct seeding, and the variety was Ningxia 1818. The average height of the plants in the field was 1.40m, and the row spacing was 0.32m. The diameter of the angular fruit layer was 0.71m. The thickness of the angular fruit layer was 0.56m. The average diameter of the main stalk was 7.6mm, and the height of the low pod was 0.73m. The oilseed rape plant had an average of 5 branches, a branch height of 0.33m, a single plant weight of 120.67g, a rapeseed moisture content of 21.47% at harvest test and a thousand grain weight of 3.96g.

The designed variable speed reel was mounted on a Ward 4LZ-6.0 full-feed tracked self-propelled rape combine harvester cutting table, and the test platform and test site are shown in

Figure 3.

2.5. Evaluation indicators and measurement methods for reels

According to GB/T 8097-2008 "Harvesting Machinery Combine Harvester Test Methods", a planting area with even growth of rape, flat terrain and no pests and diseases was selected as the test field, and rape harvesting operations were carried out under wind speed not greater than 3m/s. Each group was operated with a stroke of 30m and a preparation area of 5m in length, and samples were taken after the rape combine harvester had run steadily. Sampling zones were set up at 8m intervals, making a total of 3 sampling zones. Rapeseed from the sampling zones was collected separately for each group of tests, taken 3 times and averaged.

It is difficult to evaluate the rape paddle loss separately. In this paper, the cutting table loss rate is used as an index to evaluate the quality of variable speed reel operation, and the rape cutting table loss rate is the evaluation index, and the determination method refers to NY/T1231-2006 Technical Specification for Quality Evaluation of Rapeseed Combine Harvesters. The total mass of rapeseed per square meter was obtained according to the mass of kernels harvested at the pick-up point and the corresponding harvested area. The cutting table loss rate is calculated using the following formula:

Where: is the cutting table loss rate, %; is the actual loss per unit area in each group of tests, g/m2; is the harvested mass of rapeseed per square metre, g/m2.

3. Test results and discussion

3.1. One-factor tests and analysis

After several pre-tests, key parameters such as the speed of the reel, the forward speed of the implement and the angle between the reel frame and the ground were selected as the test factors for the single-factor test.

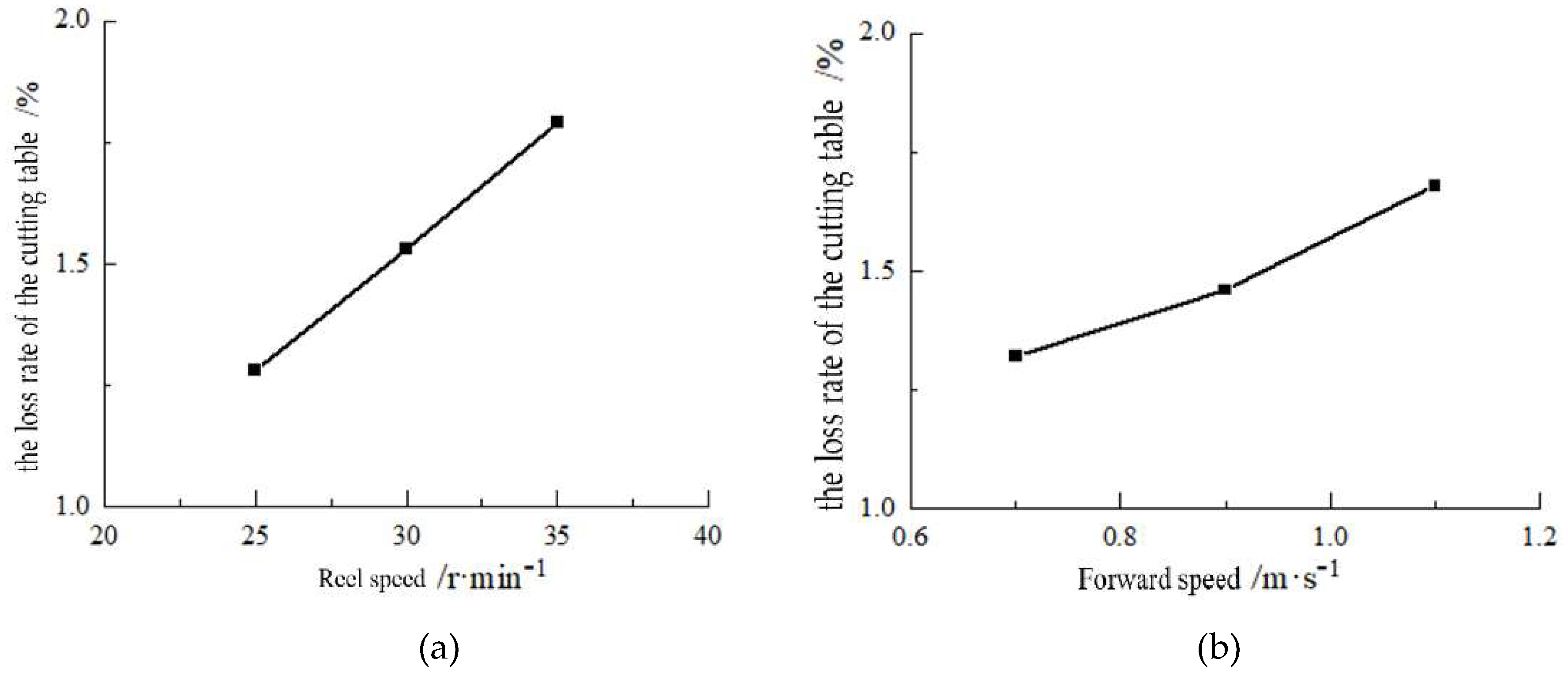

For the single-factor test, the speed of the variable-speed reel was divided into three levels: 25r/min, 30r/min and 35r/min. The speed of the combine harvester was controlled to be 0.9m/s and the reel frame was parallel to the ground, i.e. the angle was zero. In the single-factor test, the forward speed was divided into three levels: 0.7m/s, 0.9m/s and 1.1m/s, at which time the reel paddle speed ratios were 2.07, 1.61 and 1.32 respectively, and the angle between the reel frame and the ground was zero. In this paper, the angle between the frame of the variable speed reel and the ground ranges from -20° to 20°, which is positive if the frame rotates counterclockwise around the rotation axis and negative otherwise, and is divided into -20°, 0° and 20° levels for the paddle test, in which the speed of the reel is 30r/min and the forward speed of the implement is 0.9m/s. Each set of tests is repeated three times and the average value is taken, and the effects of the three factors obtained, namely the speed of the reel, the forward speed of the implement and the angle between the reel frame and the ground, on the loss of the cutting table are shown in

Figure 4.

As can be seen from

Figure 4(a), the loss rate of the cutting table increases significantly with the increase of the speed of the variable speed reel, mainly due to the increase of the speed of the reel, the impact force of the paddle teeth on the rape kernels increases, the number of impacts per unit time becomes more, the rate of kernels blowing up increases, and the loss of seeds increases. From

Figure 4(b), it can be seen that the loss rate of the cutting table gradually increases with the increase of the forward speed of the harvester, which is mainly due to the fact that when the forward speed of the machine increases, the speed ratio of the reel decreases, the feeding volume of the cutting table becomes more per unit time, and the paddle teeth collide with more angular fruits in the process of paddling, and the loss of seeds also increases. As can be seen from

Figure 4(c), as the angle between the frame of the reel and the ground increases, the loss of the cutting table is the first to decrease and then to increase, and when the frame is parallel to the ground, the rate of paddle loss is the smallest, and its value is 1.46%. When the frame of the variable speed reel is parallel to the ground, the attitude angle of the paddle teeth is more in line with the trajectory and attitude of the paddle stage, and the rate of cutting table loss is lowest at this time.

3.2. Box-Behnken centre combination test and analysis

The single-factor test showed that the variable-speed flexible reel speed, the travel speed of the implement and the angle between the frame and the ground all had a significant effect on cutting table losses. According to the Box-Behnken central combination test protocol [

26], the variable speed reel cutting table loss test was carried out using the cutting table loss rate as the response index and the reel speed A, frame and ground angle B and combine harvester forward speed C as the influencing factors. The coding table for the test factor levels is shown in

Table 2.

The test method for the loss of the cutting table of the variable speed reel was the same as the single factor test method, each group of tests was tested three times and the average value was taken.The cutting table losses measured by the different test factors are shown in

Table 3.

Analysis of variance (ANOVA) was performed on the test results in

Table 3 and the results are shown in

Table 4.

From the ANOVA results in

Table 4, the cutting table loss rate model P < 0.01 indicates that the regression model generated was extremely significant with a coefficient of determination R

2 = 0.9918. The regression model misfit term P value of 0.3810 is greater than 0.05, indicating that the error is small and the regression model can be used to predict the cutting table loss rate. The P-values for A, B, C and B

2 are less than 0.05, indicating a significant effect on the model within the 95% confidence interval, while the P-values for AB, AC, BC, A

2 and C

2 are greater than 0.05, indicating a non-significant effect on the model. Based on the P-values, it can be seen that the influence of each influence factor on the loss of the cutting table is in the order of A>C>B, i.e. reel speed, forward speed and angle between the frame and the ground, from largest to smallest. The ternary quadratic regression equation of the loss rate of the cutting table with the speed of the reel, the forward speed and the angle between the frame and the ground was obtained by excluding the non-significant term:

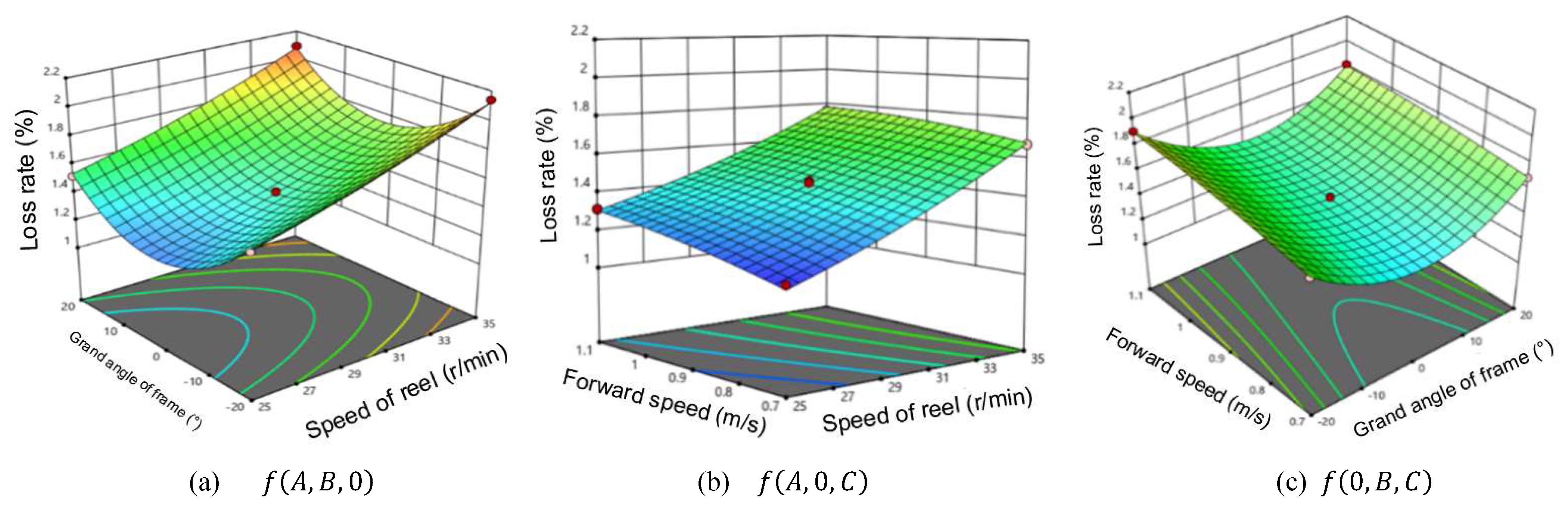

The response surface curves were generated by Design-Expert software as shown in Fig. 5. The effect of any two of the three factors, namely, reel speed, frame to ground angle and implement forward speed, on the loss rate of the cutting table was obtained by placing one of the test factors A, B and C at the 0 level. From

Figure 5(a), when the rotation speed of the reel is fixed at a certain level, the loss rate of the cutting table decreases firstly and then increases with the increase of the angle between the frame and the ground, and the optimal range of the angle between the frame and the ground is -10°~10°; when the angle between the frame and the ground is fixed at a certain level, the loss rate of the cutting table shows an increasing trend with the increase of the rotation speed of the reel. From

Figure 5(b), when the speed of the reel is fixed at a certain level, the loss rate of the cutting table increases with the increase of the forward speed of the implement, but the increase is more gentle, and the optimal range of the forward speed of the implement is 0.8m/s~1m/s; when the forward speed of the implement is fixed at a certain level, the loss rate of the cutting table shows a fast increasing trend with the increase of the speed of the reel, so the optimal range of the speed of the reel is 25 r /min~31r/min. From

Figure 5(c), when the angle between the frame and the ground is fixed at a certain level, the loss rate of the cutting table increases with the increase of the forward speed of the implement, but the rise is more gentle, and the optimal range of the forward speed of the implement is 0.7m/s~1m/s. When the forward speed of the machine is fixed at a certain level, the loss rate of the cutting table tends to fall first and then rise when the angle between the rack and the ground increases, and the rate of fall and rise is faster, so the optimal range of the rack level angle is -10°~10°.

3.3. Parameter optimisation

In order to find the best combination of operating parameters for the variable speed reel, the Optimization module of the Design-Expert software was used to optimize the experimental results of the variable speed reel cutting table. With the lowest cutting table loss as the optimization objective, the constraints of equation (10) were established.

The software analysis resulted in the optimum combination of operating parameters for the variable speed reel: 25r/min reel speed, zero angle between the frame and the ground and a forward speed of 0.7m/s for a loss rate of 1.12% on the cutting table.

3.4. Field tests and discussion

The test was conducted three times with the optimum working parameters, and the average value was taken. The variable speed reel did not show any hanging or winding of the paddle teeth during the whole test. The mean value of cutting table loss rate measured in the field was 1.18%, and the relative error between the test value and the optimised value of the regression equation was 5.36%, which is in good agreement with the results, indicating that the ternary quadratic regression equation established for the cutting table loss rate and the speed of the reel, the forward speed and the angle between the frame and the ground is accurate and reliable.

In order to further verify the advantages of the variable speed reel mechanism over the traditional cam-action reel in terms of tangle reduction and loss reduction, the rape combine harvester with an cam-action reel was subjected to a cutting table loss test in the same test field, with the harvester operating at 30m, and the test was repeated three times and averaged. The 2 types of reel cutting tables are shown in

Figure 6.

Both the variable speed and cam-action reels had a width of 2.2m and a stubble height of 30cm. A comparative test was carried out at the same machine speed and with both wheels having a paddle speed ratio of 1.61. In the field test, the average loss rate was 1.37% at 25r/min of the cam-action reel, which was 13.9% higher than the loss rate of the variable speed reel. During the field tests the cam-action reel became entangled, and the plants and branches were thrown out by the reels.

4. Conclusions

(1) By analyzing the biological characteristics of oilseed rape plants and the transport pattern of oilseed rape plants in the process of paddling, a variable speed anti-tangle reel mechanism was designed based on the kinematic principle of double crank plane five-bar mechanism, and a single-factor test and a multi-factor regression orthogonal combination test were conducted to evaluate the loss rate of rape harvesting cutting table. The main and secondary factors affecting the loss of the cutting table of the variable speed reel were found to be the reel speed, the machine travel speed and the ground angle of the frame.

(2) The optimal combination of parameters for the variable speed reel is 25r/min, the frame is parallel to the ground and the machine travel speed is 0.7m/s. The regression model calculates the loss rate of 1.12%. The mean value of cutting table loss rate measured in the field was 1.18%, and the relative error between the experimental value and the theoretically optimized value was 5.36%, which is a high accuracy of the model.

(3) Comparative tests of variable speed and cam-action reels for cutting table loss rate and reel winding were carried out. The test results showed that the average loss rate of the cam-action reel was 1.37%, which was 13.9% higher than the loss rate of the variable speed reel. During the field tests, the cam-action reels were tangled, the plants and branches were thrown out by the reels, while the variable speed reels did not show winding and tangling.

Author Contributions

Conceptualization, methodology, data curation, formal analysis, writing—original draft, writing—review and editing, M.Z. and G.L.; investigation, Y.Y.; data curation, M.J. and Y.Y.; funding acquisition, M.Z.; validation, G.L.; supervision, T.J. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by Jiangsu Agricultural Science and Technology Innovation Fund (SCX(22)2103), The Foundation Research Project of Jiangsu Province the Natural Science Fund (BK20211022), Funds for Modern Agricultural Industry Technology System Construction of China (CARS-12) and Key Research Program & Technology Innovation Program of Chinese Academy of Agricultural Sciences(CAAS-ZDRW202204).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the authors.

Acknowledgments

The authors thank the editor and anonymous reviewers for providing helpful suggestions for improving the quality of this manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, H. New-demand oriented oilseed rape industry developing strategy. Chinese Journal of Oil Crop Sciences. 2018, 40, 613–617. [Google Scholar]

- Wu, C.; Wang, J.; Liao, Q.; Wang, Z.; Wu, W. Current status and problems of rapeseed production. Journal of Chinese Agricultural Mechanization. 2017, 38, 124–131. [Google Scholar]

- Zhang, M.; Wu, C.; Jin, M.; Mu, S.; Liang, S.; Tang, Q. Effects of harvesting method and date on yield loss and seed quality of rapeseed. Oil Crop Sci. 2019, 4, 166–174. [Google Scholar]

- Zhang, M.; Jin, C.; Liang, S.; Tang, Q.; Wu, C. Parameter optimization and experiment on air-screen cleaning device of rapeseed combine harvester. Trans. Chin. Soc. Agric. Eng. 2015, 31, 8–15. [Google Scholar]

- Ma, N.; Zhang, C.; Li, J.; Zhang, M.; Cheng, Y.; Li, G.; Zhang, S. Mechanical harvesting effects on seed yield loss, quality traits and profitability of winter oilseed rape (Brassicanapus, L.). Journal of Integrative Agriculture 2012, 11, 1297–1304. [Google Scholar]

- Guan, Z.; Jiang, T.; Li, H.; Wu, C.; Zhang, M.; Wang, G.; Mu, S. Analysis and test of the laying quality of inclined transportation rape windrower. Trans. Chin. Soc. Agric. Eng. 2021, 37, 59–68. [Google Scholar]

- Guan, Z.; Wu, C.; Wang, G.; Li, H.; Mu, S. Design of bidirectional electric driven side vertical cutter for rape combine harvester. Trans. Chin. Soc. Agric. Eng. 2019, 35, 1–8. [Google Scholar]

- Yang, Y.; Li, Y.; Qing, Y. Insertion trajectory analysis and experiment of rape combine harvester reel. Journal of Agricultural Mechanization Research. 2020, 10, 189–194. [Google Scholar]

- Xu, L.; Li, Y.; Ma, C.; He, Z.; Lu, F. Design of main working parts of 4LYB1-2.0 rape combine harvester. Trans. Chin. Soc. Agric. Mach. 2008, 39, 54–57. [Google Scholar]

- Li, Y. Design and Analysis of Grain Combine Harvester; China Machine Press: Beijing, China, 2014. [Google Scholar]

- Xu, L.; Li, Y. Modeling and experiment to threshing unit of stripper combine. African Journal of Biotechnology. 2011, 10, 4106–4113. [Google Scholar]

- Jin, M.; Zhang, M.; Wang, G.; Liang, S.; Wu, C.; He, R. Analysis and simulation of wheel-track high clearance chassis of rape windrower. Agricultrue 2022, 12, 1150. [Google Scholar] [CrossRef]

- Li, H.; Wu, C.; Mu, S.; Guan, Z.; Jiang, T. Formation mechanism of laying angle of vertical rape windrower based on ANSYS-ADAMS. Trans. Chin. Soc. Agric. Eng. 2020, 36, 96–105. [Google Scholar]

- Li, P.; Liao, Q.; Li, L.; Han, C.; Huang, P.; Li, H. Design and experiment of the main device of 4SY-1.8 modified rape windrower. Trans. Chin. Soc. Agric. Eng. 2014, 45, 53–58. [Google Scholar]

- Jin, C.; Wu, C.; Jin, M.; Lu, Y.; Yuan, W.; Tang, Z. Design and experiment of 4SY-2 rape windrower. Trans. Chin. Soc. Agric. Mach. 2010, 41, 76–79. [Google Scholar]

- Ren, W.; Wang, H.; Cui, H.; Zhang, Z.; Li, Z. Simulating analysis of plant rebounding in conbine harvesting. Journal of Shenyang Agricultural University. 2003, 34, 121–123. [Google Scholar]

- Liao, Q. Mechanization Technology of Rape Production; Since Press: Beijing, China, 2018. [Google Scholar]

- Lu, T.; Li, B.; Zhou, C.; Chen, D. New type of gear-cam modular reel. Journal of Mechanical Transmission. 2015, 39, 133–137. [Google Scholar]

- Qing, Y.; Li, Y.; Ma, Z.; Xu, L.; Yang, Y. Technology of 2-DOF collision testing for rape pod shatter resistance. Trans. Chin. Soc. Agric. Eng. 2019, 35, 33–40. [Google Scholar]

- Zhang, M.; Jin, M.; Wang, G.; Liang, S.; Wu, C. Design and test of double crank planar five-bar reel in rape windrower. Trans. Chin. Soc. Agric. Mach. 2022, 53, 44–51. [Google Scholar]

- Liao, Q.; Liu, M.; Zhang, Z.; Hu, X. Multi-objective optimization design of double five-bar transplanting mechanism for rape pot seedling. Trans. Chin. Soc. Agric. Mach. 2015, 46, 49–55. [Google Scholar]

- Gardner, J.F. Simulations of Machines Using MATLAB and SIMULINK; Xian Jiaotong University Press: Xian, China, 2002. [Google Scholar]

- Yu, H.; Tang, D.; Wang, J. Analysis of the kinematic and dynamic characteristics of a planar five-bar mechanism. Journal of Harbin Institute of Technology 2007, 39, 940–943. [Google Scholar]

- Wang, X.; Yan, R.; Li, J.; Xu, W. Kinematic analysis of planar five-bar mechanism based on MATLAB. Journal of Changchun University of Technology 2011, 32, 273–277. [Google Scholar]

- Qu, X. Dynamic Simulation of Planar Linkage Based on MATLAB/Simulink; Harbin Institute of Technology Press, 2007. [Google Scholar]

- Xu, X.; He, M. Experiment design and application of design-expert and SPSS; Since Press: Beijing, China, 2010. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).