Submitted:

26 June 2023

Posted:

27 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. The three main SBE methodologies revisited

- Physics-based model improvement. This approach consists of refining the modelling, by enriching the model itself, , such that its solution exhibits a smaller error, i.e. .

-

Fully data-driven description. The data-driven route consists of making a large sampling of the space , , with large enough, and with the points location , , maximizing the domain coverage. These points are grouped into the set .The coverage is defined by the convex hull of the set , ensuring interpolation for , limiting the risky extrapolation to the region of outside the convex hull .Factorial samplings try to maximize the coverage, however factorial samplings, or the ones based on the use of Gauss-Lobatto quadratures, related to approximations making use of orthogonal polynomials [3], fail when the dimensionality of the space increases.When , sparse sampling is preferred, LHP (Latin hyper cube) for instance. Samplings based on gaussian processes –GP– aim at distributing the points in locations where the uncertainty is maximum (with respect to the predictions inferred from the previously collected data).Finally, the so-called active learning techniques drive the sampling aiming at maximizing the representation of a certain goal oriented quantity of interest [32].In what follows, we assume a generic sampling to access to the reference solution , , assuming a perfect measurability.Now, to infer the solution at , it suffices constructing an interpolation or approximation, more generally, an adequate regression :with .Different possibilities exist, among them: regularized polynomial regressions Please rearrange all the references to appear in numerical order. [29], neural networks –NN– [16,31], support vector regression –SVR– [9], decision trees and their random forest counterparts [4,23], ... to name few.The trickiest issue concerns the error evaluation, that is quantified from a part of the data kept outside the training-set, the so-called test-set, used to quantify the performances of the trained regression.The main drawbacks of such a general procedure, particularly exacerbated in the multi-dimensional case (), are the following:

- –

- Ability to explain the regression .

- –

- The size of the data-set (), scaling with the problem dimensionality .

- –

- The optimal sampling to cover while guaranteeing the accuracy of , or the one of the goal oriented quantities of interest.

- Hybrid approach. It proceeds by embracing the physics-based and data-driven approaches, that as described in the next section, will improve the physics-based accuracy (while profiting of the physics-based explanatory capabilities) from the use of a data-driven enrichment, that at its turn, and under certain conditions, needs less amount of data than the fully data-driven approach just discussed [6].

2. Illustrating the hybrid approach

2.1. A simple linear regression reasoning

2.2. General remarks

2.3. On the domain of application of the hybrid modeling approach

- Sometimes, the physics-based model operates very accurately in a part of the domain, whereas strong nonlinearities localize in a small region that can, in that case, be captured by a data-driven learned model, as considered in [26] for addressing the inelastic behavior of spot-welds.

- When considering the constitutive modeling of materials, the augmented rationale (or hybrid paradigm) expresses the real behavior from a first order behavior (calibrated from the available data) complemented by an enrichment (or correction) filling the gap between the collected data and the predictions obtained from the assumed model [15].

- When addressing plates (or shells) which noticeable 3D behaviors (deviating from the usual shell theory) a valuable solution consists of using an enriched kinematics consisting of two contributions: the first order one (usual shell kinematics) enriched with a second order contribution [25], that can be learned from data.

- The hybrid modeling can also transfer the existing knowledge slightly outside its domain of applicability with small amount of collected data, as performed in [24] for correcting state-of-the-art structural beam models.

- Sometimes the discrepancy concerns an imperfect alignment of the solution between the prediction and the measures. That discrepancy seems very high when evaluating it at each location, however, a small transport allows aligning both solutions. Optimal transport is very suitable in these situations, where the hybrid model consists of the usual nominal model enriched from a parametric correction formulated in an optimal transport setting as described in [34,35].

- In [20] a correction of a Mises yield function was performed from the deviation between the results predicted by using it, and the measures obtained at the structure level.

3. Methods

3.1. On the integration stability

3.2. Learning integrators

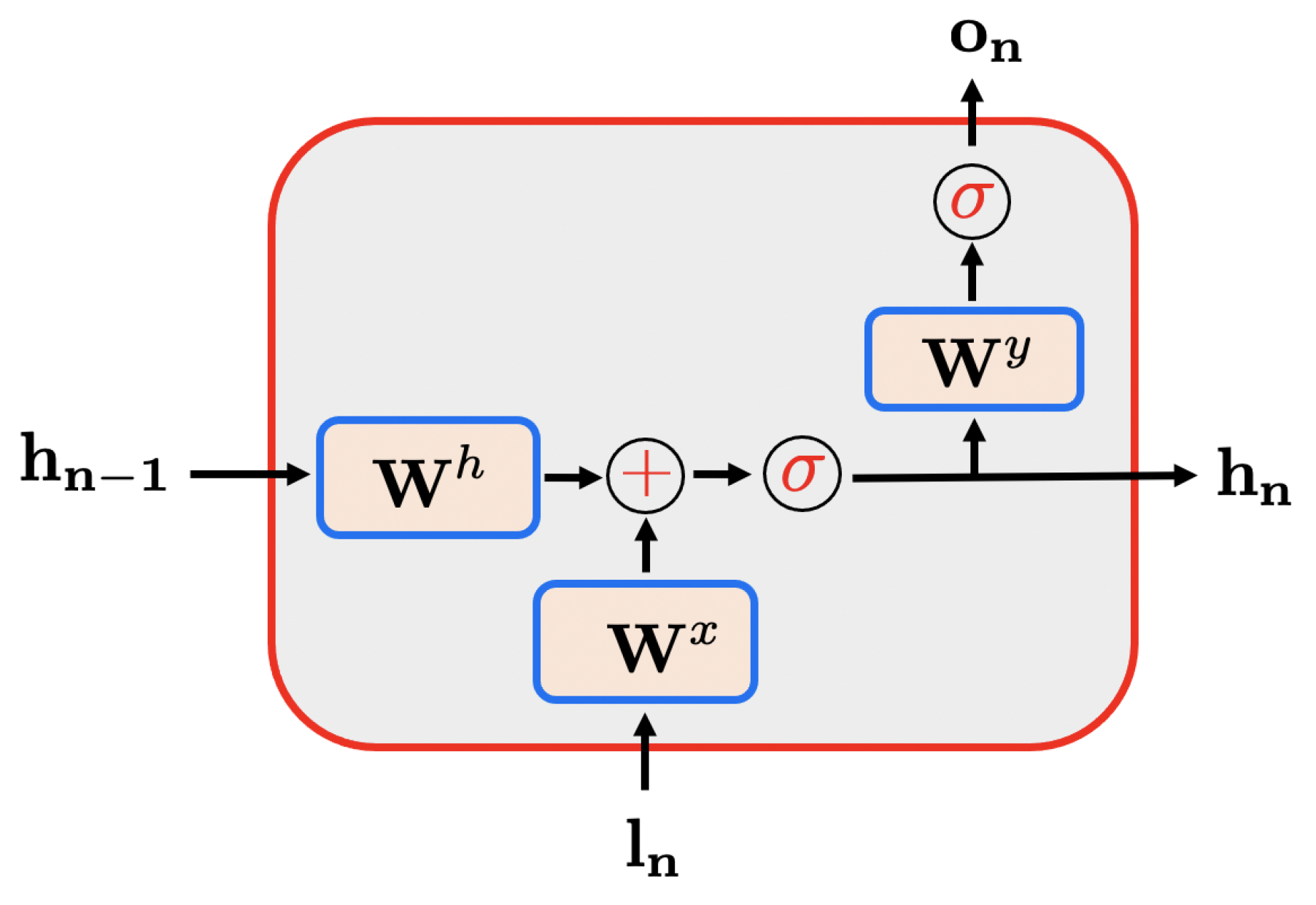

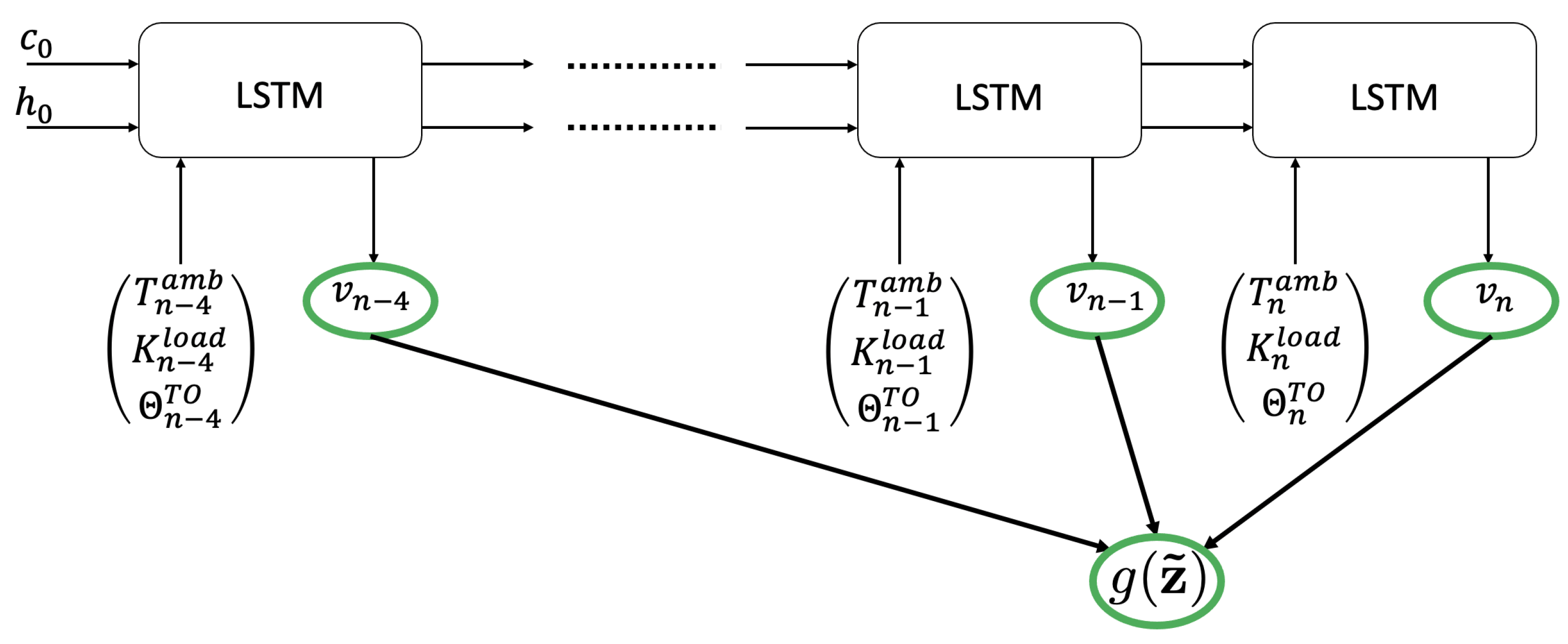

3.2.1. Recurrent Neural Network

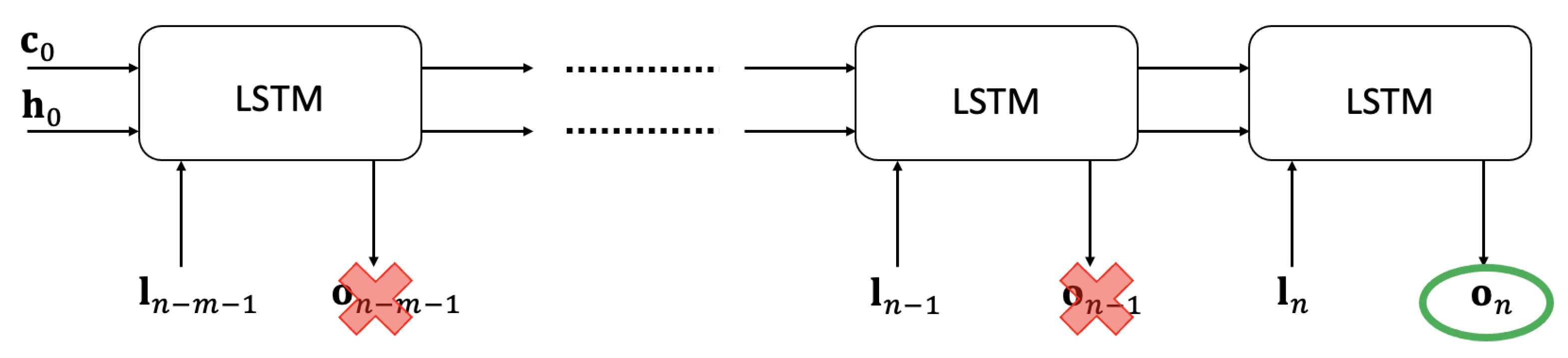

3.2.2. On the model memory

3.2.3. Learners with larger memory

3.2.4. Residual Nets

4. Simple procedures for stabilizing ResNets-based integration

4.1. Learning stable linear dynamical systems

4.2. Learning stable nonlinear dynamical systems

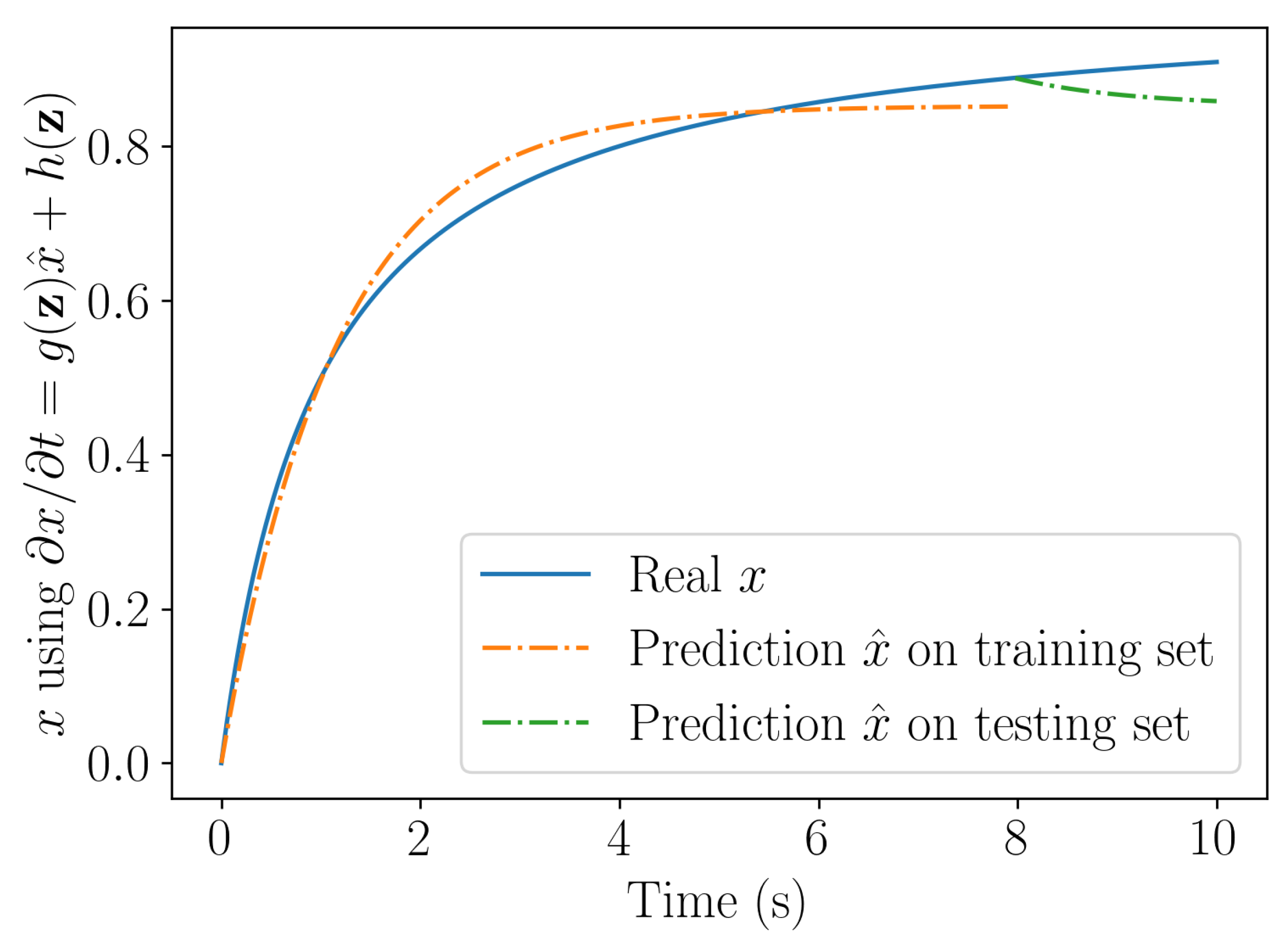

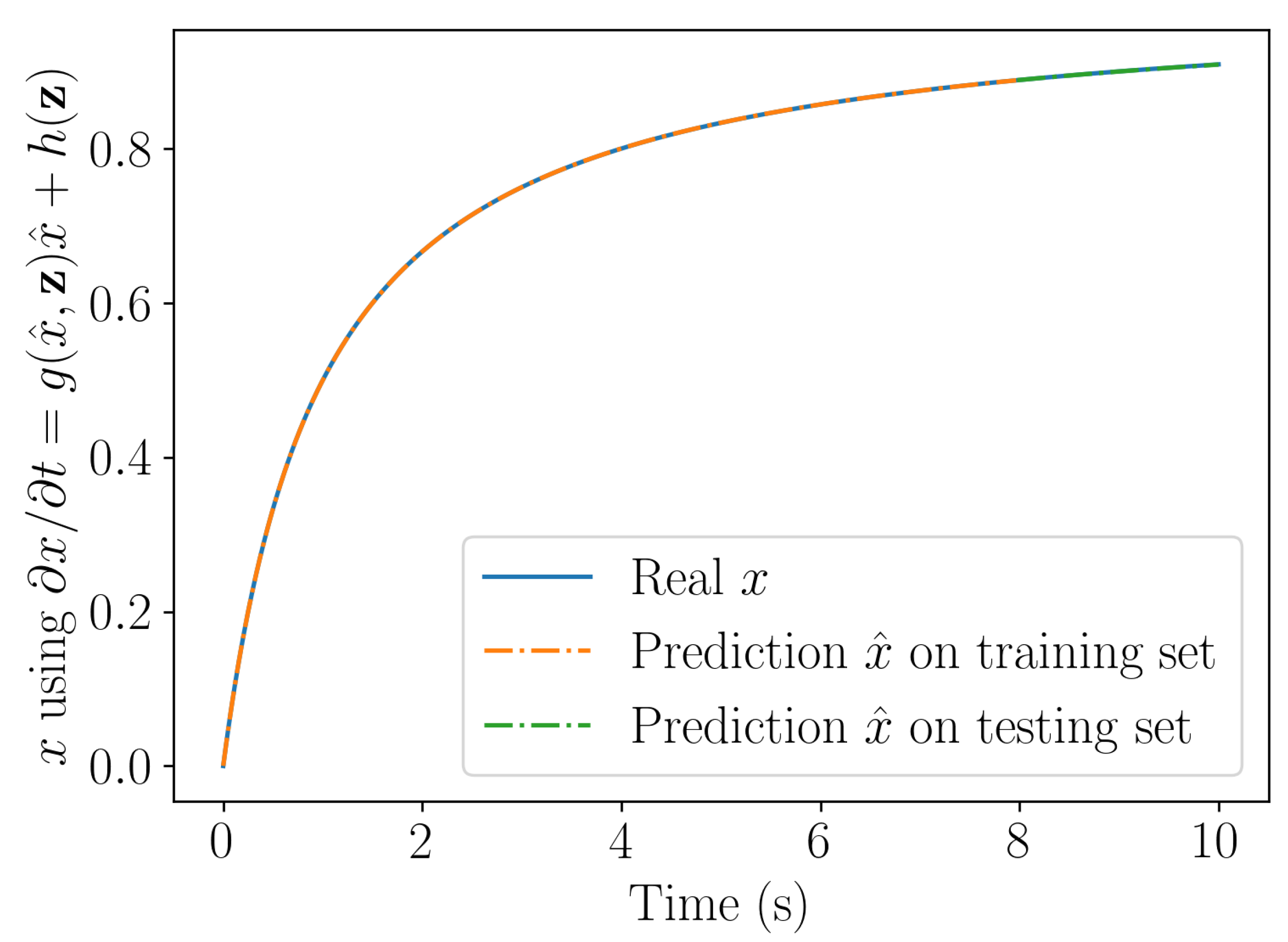

4.3. Numerical examples and discussion

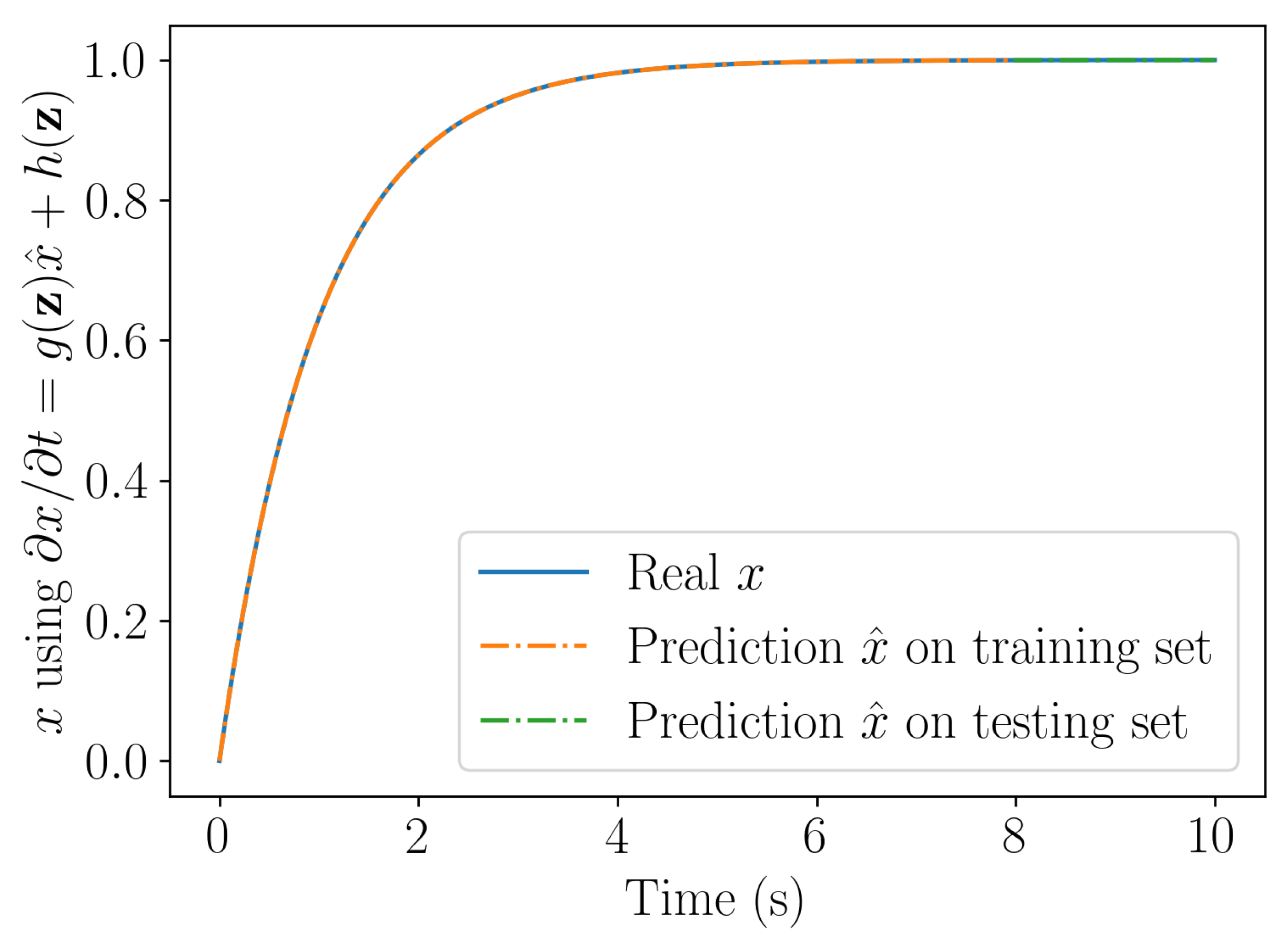

4.3.1. Linear dynamical system

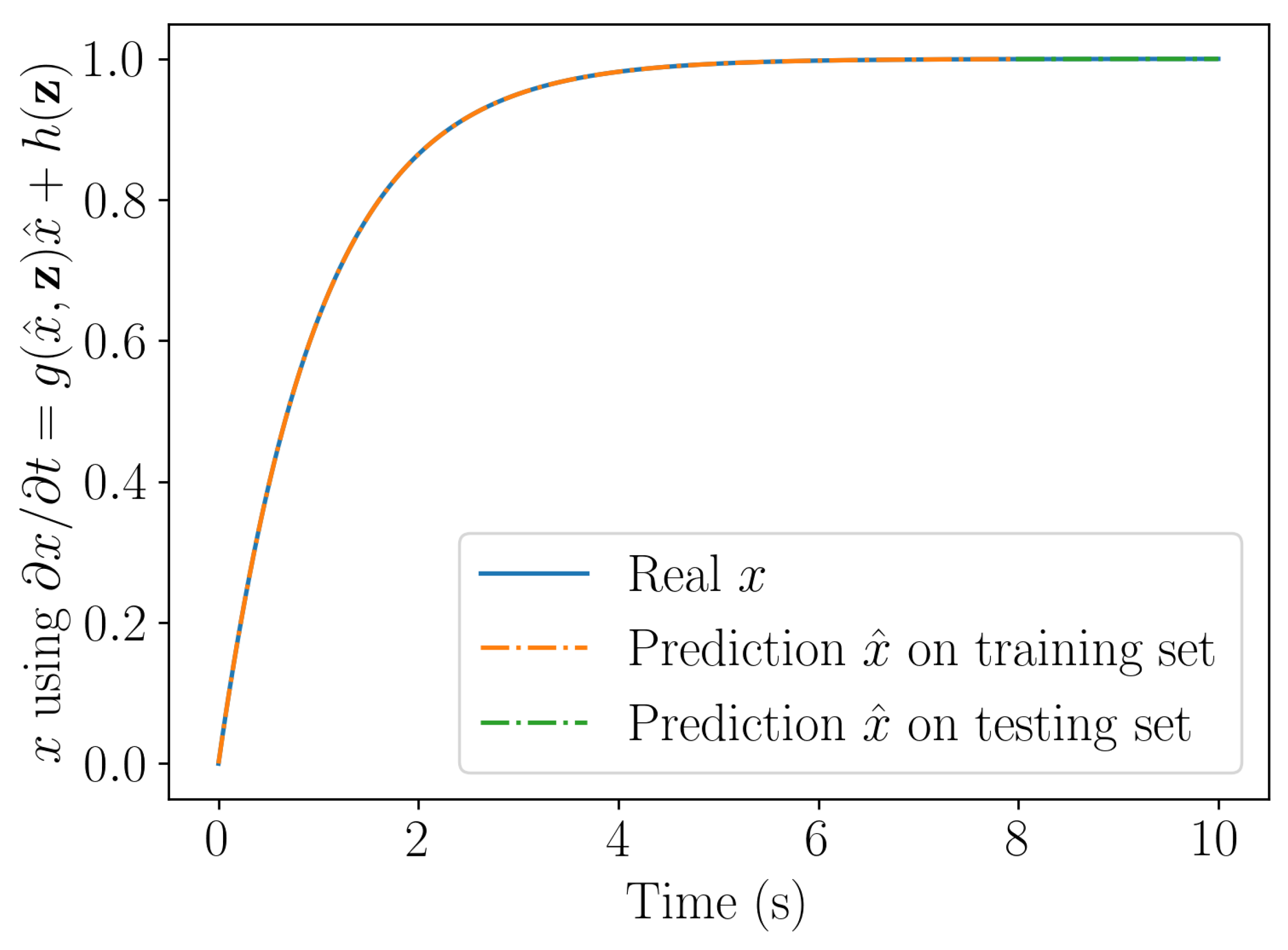

4.3.2. Nonlinear dynamical system

4.4. Final remarks

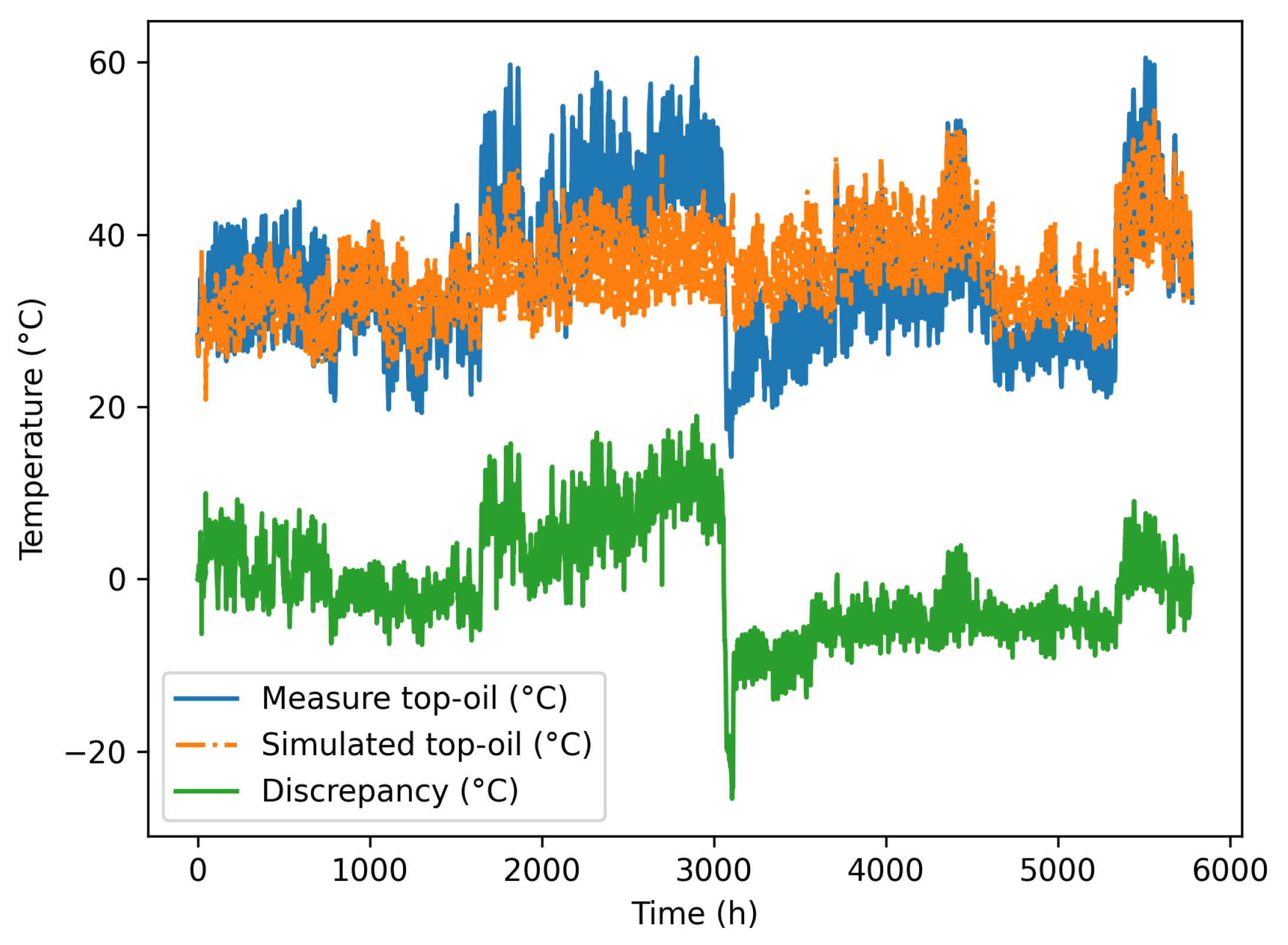

5. Application to the evaluation of the top-oil temperature of an electric power transformer

- : The position of the tap-changer;

- : the load factor, a ratio between the nominal load current and the actual current;

- P: represents the iron, copper and supplementary losses. The power that heats the oil is composed of the losses that do not depend on the transformer load (iron losses, supposed constant) and the losses that depend on the transformer load (copper and supplementary losses) that depend on the average windings temperature and the load factor, according to: , with and (k being a correction factor related to the material resistivity);

- : The ambient temperature;

- : The simulated top oil temperature

- : The temperature difference between the simulated top oil temperature and the ambient temperature;

- and : thermal resistance and thermal capacitance of the equivalent transformer thermal circuit;

- : The average winding temperature;

- : The difference between the average winding temperature and the simulated oil temperature . It is supposed constant and found during the commissioning test (standards)

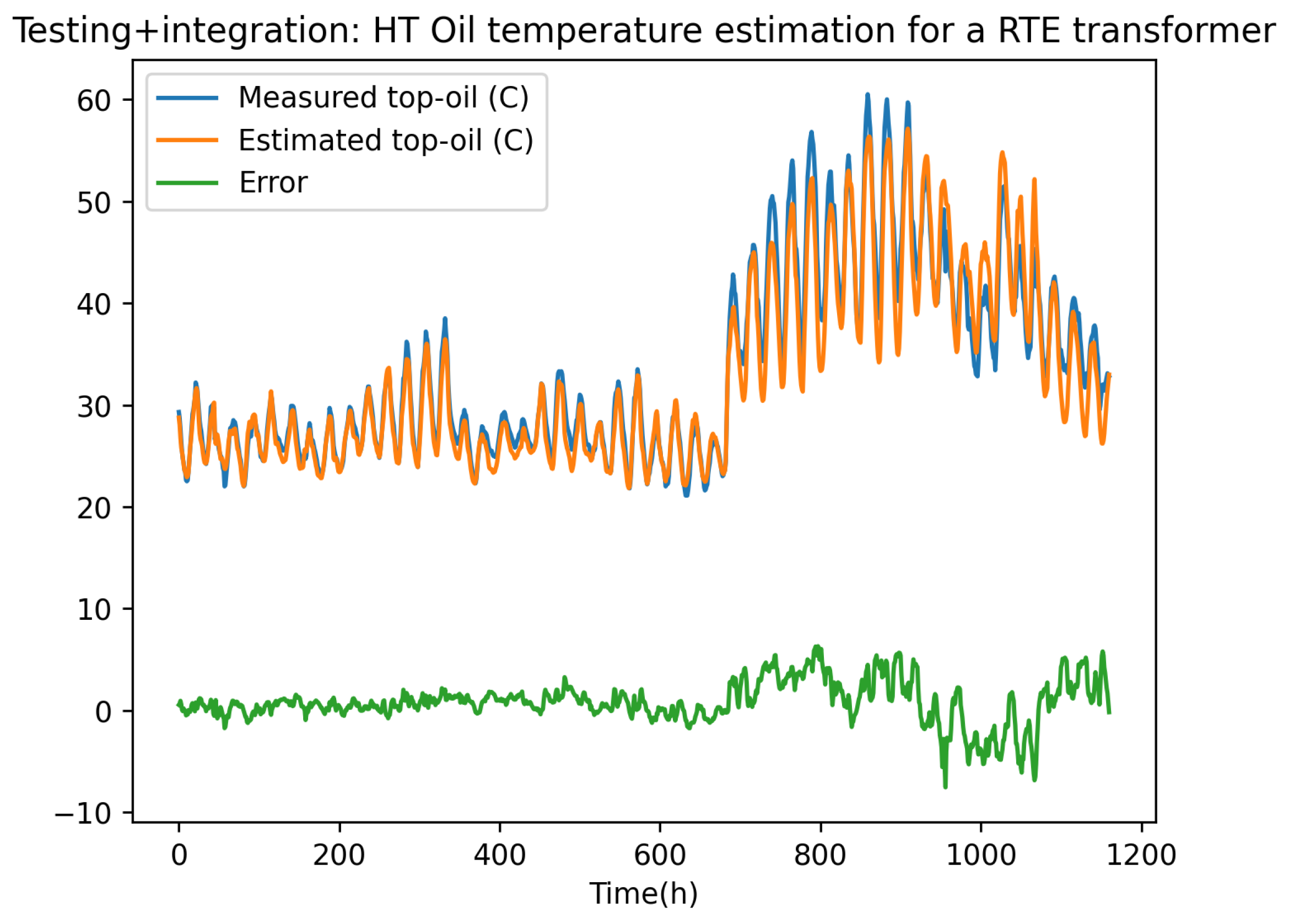

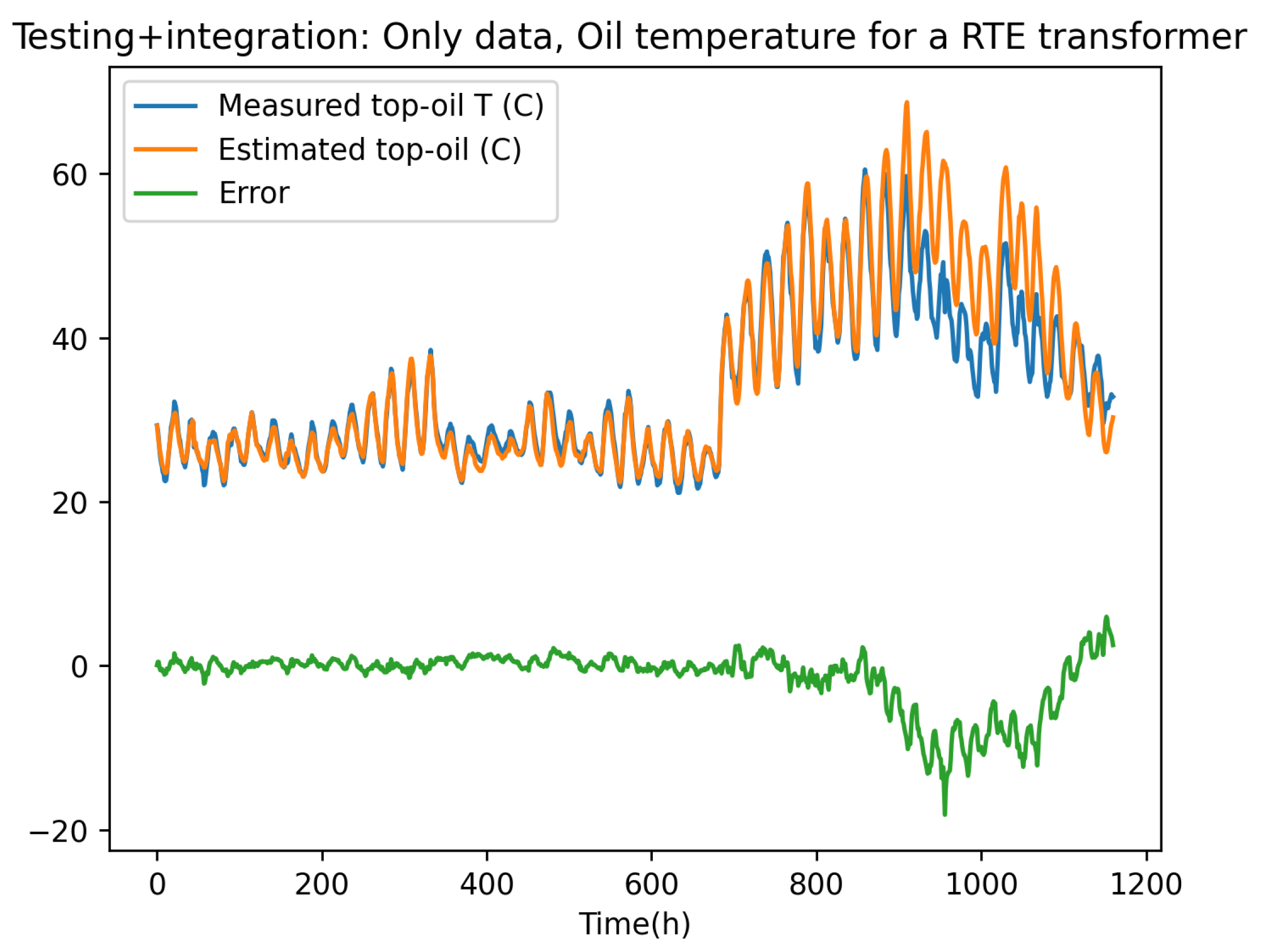

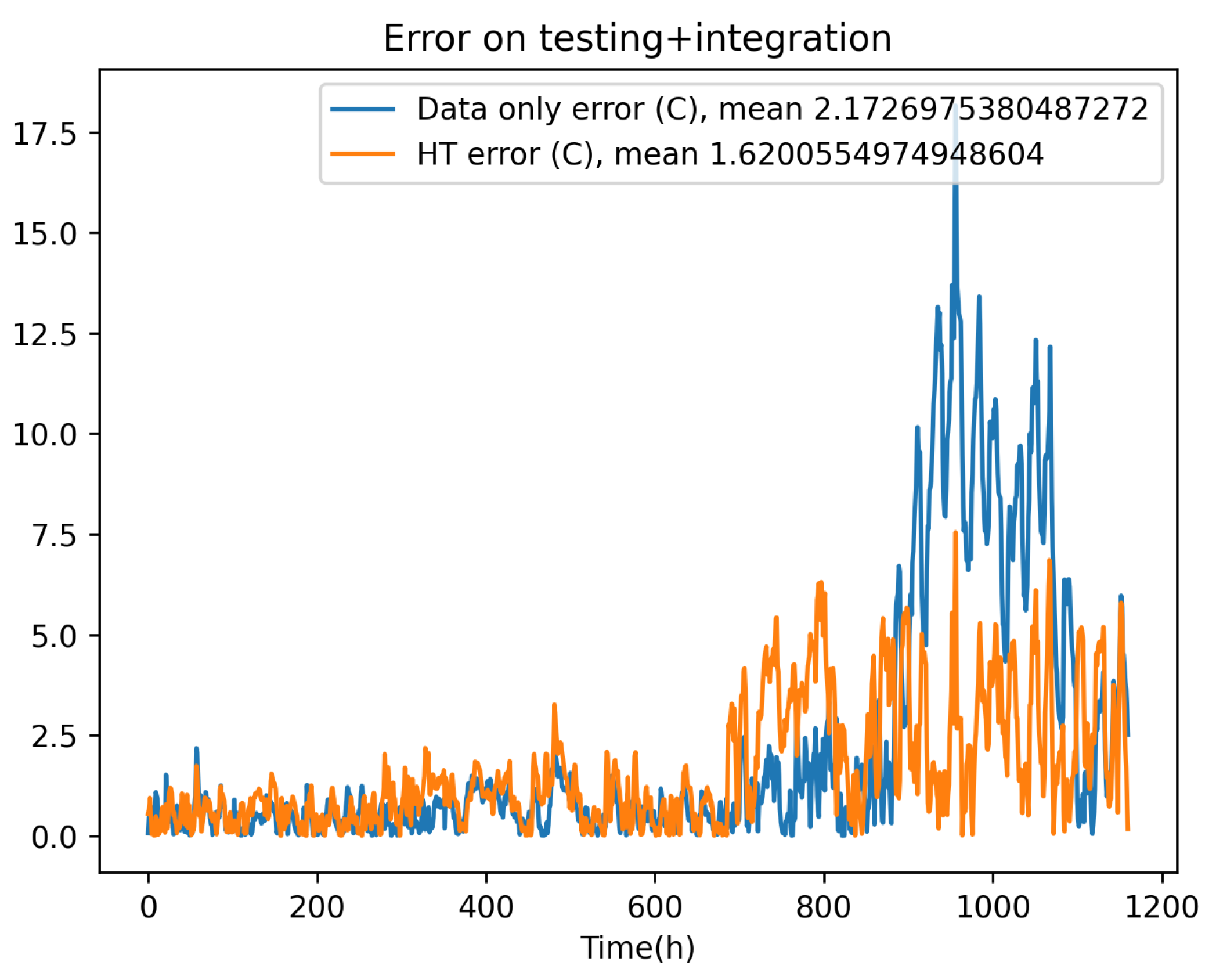

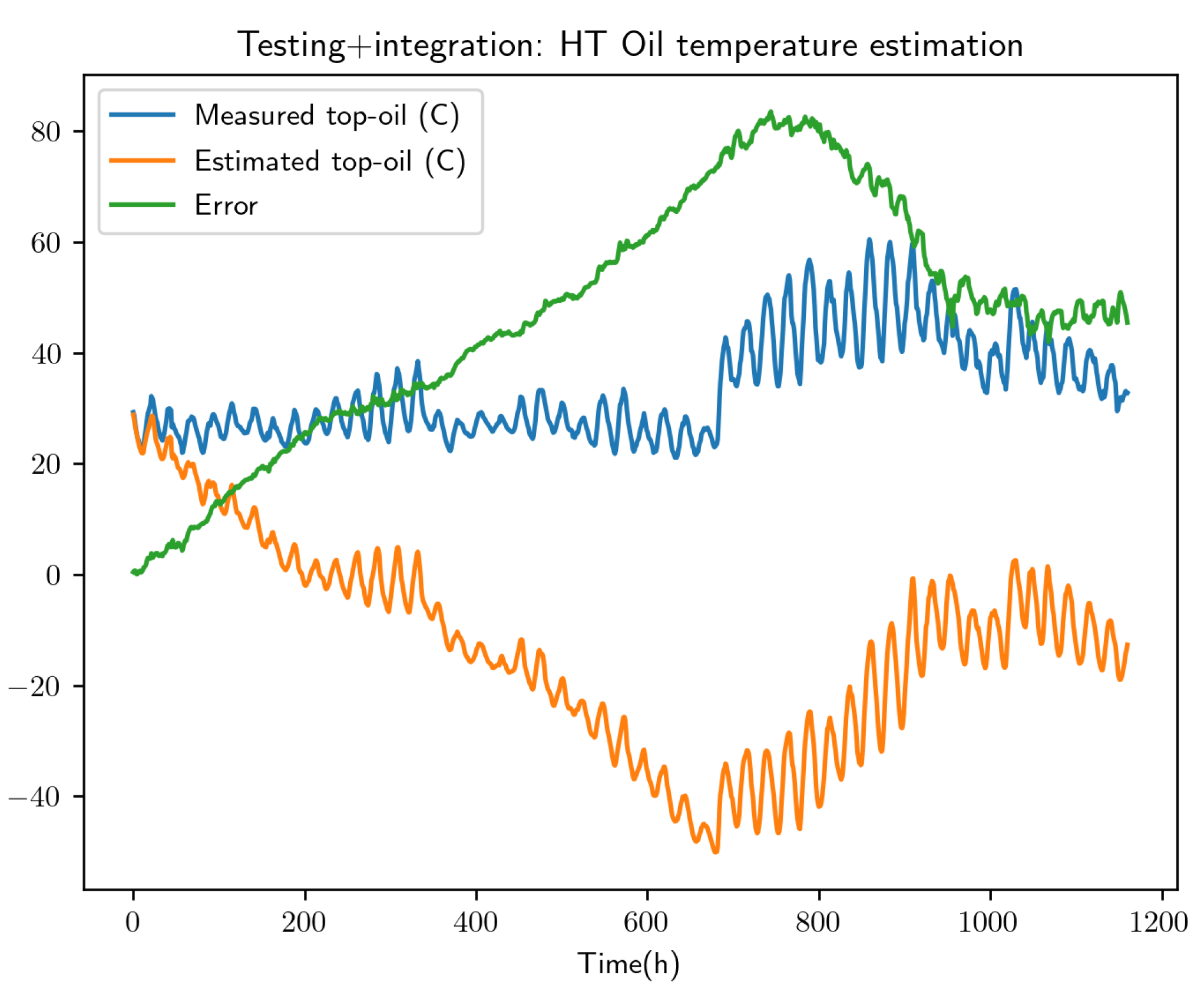

- The hybrid approach improves the physics-based model performances.

- Enriching a richer nonlinear physics-based model outperform with respect to enriching the linear counterpart of the simplified physics-based model.

- When the considered physics-based models are too far from the reference solution (experimental data) the data-driven model can outperform the hybrid modeling.

| ResNet | Fully | HT from a linear | HT from a nonlinear |

|---|---|---|---|

| data-driven | physical model | physical model | |

| Linear stabilized | 2.173 | 3.143 | 1.620 |

| Nonlinear stabilized | 1.716 | 1.516 | 1.439 |

6. Conclusion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- C. Argerich, A. Carazo, O. Sainges, E. Petiot, A. Barasinski, M. Piana, L. Ratier, F. Chinesta. Empowering Design Based on Hybrid Twin: Application to Acoustic Resonators. Designs, 4, 44, 2020. [CrossRef]

- P.C. Blaud, P. Chevrel, F. Claveau, P. Haurant, A. Mouraud. Resnet and polynet based identification and (mpc) control of dynamical systems: a promising way. IEEE Access, 11, 20657-20672, 2022.

- D. Borzacchiello, J.V. Aguado, F. Chinesta. Non-intrusive sparse subspace learning for parametrized problems. Archives of Computational Methods in Engineering, 26, 303-326, 2019.

- L. Breiman. Random Forests. Machine Learning 45, 5-32, 2001.

- F. Casteran, K. Delage, P. Cassagnau, R. Ibanez, C. Argerich, F. Chinesta. Application of Machine Learning tools for the improvement of reactive extrusion simulation. 2020. [CrossRef]

- F. Chinesta, E. Cueto, E. Abisset-Chavanne, J.L. Duval, F. El Khaldi, Virtual, Digital and Hybrid Twins: A New Paradigm in Data-Based Engineering and Engineered Data, Archives of Computational Methods in Engineering, 27, 105-134, 2020.

- R.T.Q. Chen, Y. Rubanova, J. Bettencourt, D. Duvenaud. Neural ordinary differential equations. Conference on Neural Information Processing Systems (NeurIPS 2018), Vol. 32, Montreal, Canada, 1-18, 2018.

- R.T.Q. Chen, B. Amos, M. Nickel. Learning Neural Event Functions for Ordinary Differential Equations, 2020 https://arxiv.org/abs/2011.03902.

- N. Cristianini, J. Shawe-Taylor. An introduction to support vector machines and other kernel-based learning methods. Cambridge University Press, New York, 2000.

- S.H. Dar, W. Chen, F. Zheng, S. Gao, K. Hu. An LSTM with Differential Structure and Its Application in Action Recognition, Mathematical Problems in Engineering, 2022, 7316396, 2022.

- G.P. Distefano. Stability of numerical integration techniques. AIChE Journal, 14(6), 946-955, 1968.

- L. Enciso-Salas, G. Perez-Zuniga, J. Sotomayor-Moriano. Fault Detection and Isolation for UAVs using Neural Ordinary Differential Equations. IFAC-PapersOnLine, 55(6), 643-648, 2022.

- R. Ghanem, C. Soize, L. Mehrez, V. Aitharaju. Probabilistic learning and updating of a digital twin for composite material systems, IJNME, 2020. [CrossRef]

- C. Ghnatios, P. Gérard, A. Barasinski. An advanced resin reaction modeling using data-driven and digital twin techniques. International Journal of Material Forming, 16, 5, 2023.

- D. Gonzalez, F. Chinesta, E. Cueto. Learning corrections for hyper-elastic models from data. Frontiers in Materials - section Computational Materials Science, 6, 2019.

- I. Goodfellow, Y. Bengio, A. Courville. Deep learning. MIT Press, Cambridge, 2016.

- K. He, X. Zhang, S. Ren, J. Sun. Deep residual learning for image recognition. IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 770-778, 2016.

- K. He, X. Zhang, S. Ren, J. Sun. Identity Mappings in Deep Residual Networks. In: Leibe, B., Matas, J., Sebe, N., Welling, M. (eds) Computer Vision - ECCV 2016. ECCV 2016. Lecture Notes in Computer Science, Vol 9908. Springer, Cham, 2016.

- S. Hochreiter, J. Schmidhuber. Long Short-Term Memory. Neural Computation 9(8), 1735-1780, 1997.

- R. Ibanez, E. Abisset-Chavanne, D. Gonzalez, J.L. Duval, E. Cueto, F. Chinesta. Hybrid Constitutive Modeling: Data-driven learning of corrections to plasticity models. International Journal of Material Forming, 12, 717-725, 2019.

- M.G. Kapteyn, K.E. Willcox. From Physics-Based Models to Predictive Digital Twins via Interpretable Machine Learning, 2020 arXiv:2004.11356v3.

- X. Kestelyn, G. Denis, V. Champaney, N. Hascoet, C. Ghnatios, F. Chinesta. Towards a hybrid twin for infrastructure asset management: Investigation on power transformer asset maintenance management. 7th International Advanced Research Workshop on Transformers (ARWtr), 109-114, 2022.

- C.W. Kirkwood. Decision Tree primer, 2002, http://creativecommons.org/licenses/by-nc/3.

- B. Moya, A. Badias, I. Alfaro, F. Chinesta, E. Cueto. Digital twins that learn and correct themselves. International Journal for Numerical Methods in Engineering. [CrossRef]

- G. Quaranta, M. Ziane, E. Haug, J.L. Duval, F. Chinesta. A minimally-intrusive fully 3D separated plate formulation in computational structural mechanics. Advanced Modelling and Simulation in Engineering Sciences, 6, Article number 11, 2019.

- A. Reille, V. Champaney, F. Daim, Y. Tourbier, N. Hascoet, D. Gonzalez, E. Cueto, J.L. Duval, F. Chinesta. Learning data-driven reduced elastic and inelastic models of spot-welded patches. Mechanics & Industry, 22, 32, 2021.

- A. Sancarlos, M. Cameron, A. Abel, E. Cueto, J.L. Duval, F. Chinesta. From ROM of electrochemistry to AI-based battery digital and hybrid twin. Archives of Computational Methods in Engineering, 28, 979-1015, 2021.

- A. Sancarlos, J.M. Le Peuvedic, J. Groulier, J.L. Duval, E. Cueto, F. Chinesta. Learning stable reduced-order models for hybrid twins. A. Sancarlos, M. Cameron. Data Centric Engineering, 2, e10, 2021.

- A. Sancarlos, V. Champaney, E. Cueto, F. Chinesta. Regularized regressions for parametric models based on separated representations. Advanced Modeling and Simulation in Engineering Sciences, 10:4, 2023. [CrossRef]

- P.J. Schmid. Dynamic mode decomposition of numerical and experimental data. J Fluid Mech., 656, 528, 2010.

- J. Schmidhuber. Deep learning in neural networks: An overview. Neural Networks. 61, 85-117, 2015.

- B. Settles, Active Learning Literature Survey. Computer Sciences Technical Report 1648. University of Wisconsin-Madison, 2009.

- Standard. Loading guide for mineral-oil-immersed power transformers. International electrotechnical commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland, 1, 2018.

- S. Torregrosa, V. Champaney, A. Ammar, V. Hebert, F. Chinesta. Surrogate Parametric Metamodel based on Optimal Transport. Mathematics and Computers in Simulation, 194, 36-63, 2022.

- S. Torregrosa, V. Champaney, A. Ammar, V. Herbert, F. Chinesta. Hybrid Twins based on Optimal Transport. Computers and Mathematics with Applications, 127, 12-24, 2022.

- E.J. Tuegel, A.R. Ingraffea, T.G. Eason, S.M. Spottswood. Reengineering Aircraft Structural Life Prediction Using a Digital Twin. International Journal of Aerospace Engineering, 154798, 2011.

- G.B. Zhou, J. Wu, C.L. Zhang, Z.H. Zhou. Minimal gated unit for recurrent neural networks. International journal Automation and Computing, 13, 226-234, 2016.

| Layer | Building block | Activation |

|---|---|---|

| 1 | LSTM layer with 5 outputs, return sequence true | + |

| 2 | Flatten | No activation |

| 3 | Dense connection with 1 output | |

| 4 | Lambda layer returning | No activation |

| Layer | Building block | Activation |

|---|---|---|

| 1 | LSTM layer with 5 outputs, return sequence true | + |

| 2 | Flatten | No activation |

| 3 | Dense connection with 1 output |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).