1. Introduction

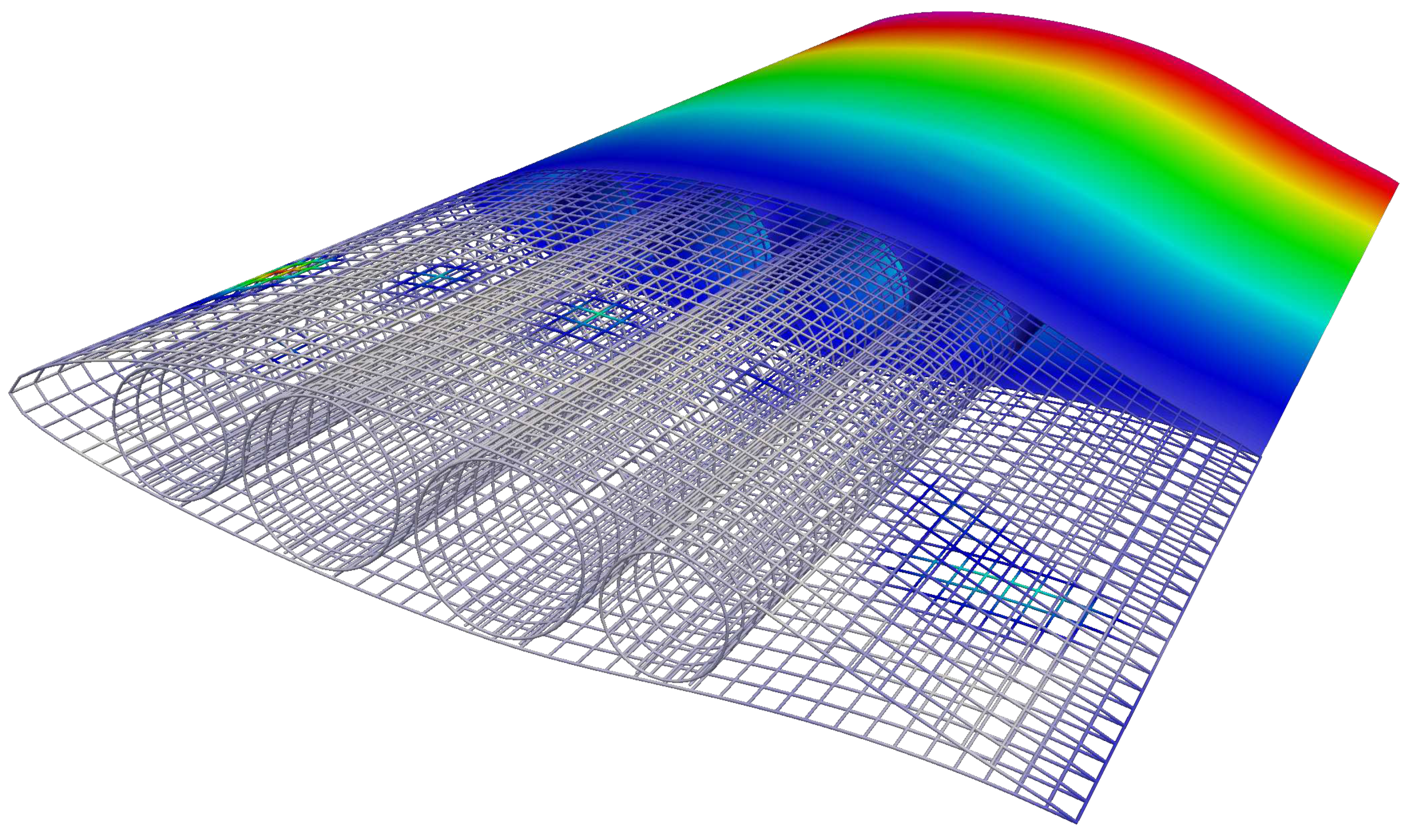

The aerospace industry continually seeks innovations to improve fuel efficiency, reduce aircraft weight, and enhance overall performance. One such development is the concept of

Wing-

Structure-

Integrated high-pressure

Hydrogen

Tanks (SWITHs), pronounced

sweets, that are embedded within an aircraft’s wing structure. An illustrative depiction of a SWITH is provided in

Figure 1. The main difference between integrated and external stored fuel tanks is that integrated tanks are intended to carry external loads and support the airplane’s load bearing components.

External tanks on the other hand are only entrained in aircraft for fuel storage and supply. They are not an integral part of the structure, thus they are not designed to support the load carrying structure by absorbing the loads. The primary advantage of integral tanks is that the substantial space, which would have otherwise been reserved for fuel, is available for other objectives. The same configuration can now be equipped with seats for transporting a larger number of people. Alternatively, it could carry more cargo or large, cumbersome items that do not exceed the size of the original tanks. Despite the potential benefits of SWITHs, the relatively new concept faces challenges among others in terms of manufacturing, safety and unkown regulations.

Given the complexity and innovation of SWITHs, it is essential to initiate a collaborative effort across researchers to tackle each individual hurdle. Each of the mentioned points can be expected to require many scientific groups to explore and find possible solutions. At the moment of writing this paper, there are no known norms and regulations, which could be applied for obtaining a certification. Without a certification that is recognized by local and global authorities, industrial and scientific employment of SWITHs is severely limited. Thus, there is an obvious demand for proper norms which industry and science institutions can rely on. The latter not only serves for obtaining a certification, but can also assist designers in their developmental processes. Aircraft design and production represent a highly complex and multidisciplinary endeavor. As a consequence, the associated certification guidelines are intricate and encompassing. Moreover, due to the exacting quality standards in aviation, even minor modifications can necessitate exhaustive investigations, before an approval for certification is granted. While the latter is insightful for enabling secure personal air transportation, the consequence for SWITHs are significant. Firstly, it is important to note that hydrogen, due to its highly reactive nature, possesses a combustibility range that extends to explosiveness. Secondly, the typically sparse structure of many systems is supplanted by a cylindrical configuration. When these two aspects are combined, we see the implementation of tube spars filled with pressurized hydrogen. These serve as the primary load-bearing structure, signifying a novel approach in structural design.

This latter development constitutes a significant deviation from conventional airplane designs, thereby demands extensive work before certification can be granted. Thus, the objective of this paper is to pave the way for this novel design by providing a review of the current state of the art in standards and regulations that pertinent to structural tests of SWITHs. In this context, we scrutinize norms that are applicable for various types of tanks, norms from diverse areas of mobility that rely on a pressurized cylinder, and hydrogen-specific regulations. We subsequently formulate evaluation criteria, implement them, and present our top choices. These selections might provide the fundamental basis for developing SIT-specific, certification-ready standards.

2. Higher-Level Norms

Standards for Wing- Structure- Integrated high-pressure Hydrogen Tanks (SWITHs) play a vital role in establishing a basis for both design and experimental structural investigation. Particularly when dealing with innovative concepts, fraught with potential risks and uncertainties. Recognizing standards as guidelines allows engineers and specialists to follow a safe, clear, and systematic process. The contribution of experts to the composition and revision of these standards ensures consideration of aspects that an individual might not think of, thereby enhancing the safety and reliability of products and systems. However, the absence of a comprehensive standard that addresses the design and physical structural testing of SWITHs indicates the necessity of choosing a different approach. This entails subdividing SWITHs into two significant sub-categories: aviation and pressure tank standards.

The aviation standards revolve around three main elements: certification space, maximum takeoff mass (MTOW), and the general type of flying object. Certification space encompasses the designated region for the aircraft’s certification and operation, regulated by specific authorities. MTOW refers to the maximum weight an aircraft can safely carry for takeoff and flight, with distinct MTOW classes defined within the standards based on the aircraft’s size and performance. The general type of flying object classifies the aircraft, including commercial large aircraft, helicopters, small aircraft, and military aircraft. General aviation standards in the EU are denoted as Certification Specification (CS). The norms among these which might be classified as relevant to SWITHs are CS-23, CS-25, CS-27, and CS-29. The CS-23, for instance, can be applied for the certification of a small aircraft that falls within specific criteria regarding its category, maximum take-off mass, and passenger capacity.

However, exceeding these criteria may require the application of CS-25, which necessitates a more detailed examination of various aircraft systems due to increased performance demands and complexities. The intent of this paper is not to delve into a comprehensive explanation of the CS norms, as such an exhaustive discussion would exceed the scope of this document. Instead,

Table 1, which enumerates SWITH-relevant and several additional CS standards alongside their respective application fields, should suffice as a suitable reference. The reason why the counterparts on the US side are not mentioned is that both are very similar in scope. This similarity stretches to the extent that even the numbering of the documents and their respective paragraphs align.

The other sub-category revolves around pressure tank standards, applicable to tanks holding high-pressure compressed gas. The selection of a specific standard is influenced by several variables, including the pressure range, the selected gas, the type of storage, the material of the tank, and its application. Given the complexity of SWITHs, reliance on a single standard at the moment of writing this paper is impractical. Therefore, identifying relevant pre-existing standards provides a critical foundation for designing and conducting certification-pertinent experimental tests.

3. Future Potential Aerospace Standards for SWITHs

In the quest for standards applicable to SWITHs, it is crucial to note that, as of the time of this study, no single standard exists that universally governs the approval of SWITHs. This gap necessitates referencing standards applicable to similar domains or sub-areas of SWITHs. Starting with small aircraft, the absence of explicit guidelines for high-pressure hydrogen containers in the commonly used small aircraft certification standard, CS-23, warrants consideration of the other potential standards.

One such standard is found in CS-25 Amendment 27 (CS 25.1453), which contains guidelines to protect oxygen equipment from rupture. Here, it is stipulated that the working pressure of the oxygen cylinders must be sustained by the cylinder, accounting for maximum working pressure, transient pressures, pressure surges, pressure relief device tolerances, and possible pressure fluctuations during normal operating conditions. CS 25.1453 provides additional details. Among these is a list of proof and burst factors for pressurized vessels intended for structural testing. The latter can be found in

Table 2. For the complete description of CS 25.1453 the reader is referred to the original source. Notably, the point

other components in

Table 2 may offer requirements for strength verification, which could be adapted for SWITHs. Nevertheless, the regulators might not readily accept these guidelines due to the substantially different nature of hydrogen tanks in terms of their larger dimensions and higher internal pressure.

One of the other norms which at first glance might be considered to offer some guidance for SWITHs is the ANSI/AIAA S-081B-2018 Space Systems-Composite Overwrapped Pressure Vessels standard. It is primarily applicable in the United States. Other regions have been known to reference established standards to develop their own, although there is no assurance of universal acceptance. The applicability of foreign standards typically depends on the adopting location, with international standards gaining global recognition, followed by continental and national standards. It’s noteworthy that individual countries may impose additional requirements, significantly impacting novel projects. Two other two prominent examples for SWITHs are given by

Society of

Automotive

Engineers (SAE) International and listed in

Table 3. They announced preliminary drafts of standards related to liquid and gaseous hydrogen-powered aircraft in November 2019 and June 2021.

It should be explicitly noted that these standards have solely been announced and are not yet available for purchase as of writing this article in April 2023. With the legitimate assumption that an institution such as SAE International is aware of the standard being published in 2018 (ANSI/AIAA S-081B-2018), the following assumption should be discussed. SAE had approximately two years to draft the general aviation standard for liquid hydrogen. If we consider that these two years were not sufficient, it suggests that the ANSI/AIAA S-081B-2018 Space Systems may not be directly applicable to general aviation. Still, although these standards are yet to be released, they could offer substantial insights for the development of SWITHs once completed. On the other hand, it is critical to realize that these upcoming standards may not cover the external loading of hydrogen tanks. Hence, their applicability to structurally integral hydrogen tanks is uncertain.

In summary, while certain aerospace standards could provide useful insights for SWITHs, their applicability remains uncertain due to geographic and technical constraints. Current standards may not be entirely suitable for SWITHs, necessitating the development of a unique standard that encompasses the specific requirements of this niche area. Announced standards could partially support the certification of SWITHs. However, up to now it is unclear, whether these standards are incorporating the idea of externally loaded hydrogen tanks or not.

4. Examination of Standards Across Diverse Sectors

Acknowledging the advanced state of the automotive industry with respect to high-pressure propulsion systems, a comprehensive examination of relevant standards across various sectors has been undertaken. This survey extends beyond aviation to sectors utilizing high-pressure tanks for propulsion and independent mobile applications. Particular attention is given to International Organization for Standardization (ISO) standards concerning hydrogen applications, given their broad acceptance and relevance.

Key sectors under consideration range from automobiles, buses, and heavy-duty trucks to industries where hydrogen-powered propulsion is either a concept or already a reality. It is critical to note that these sectors share common environmental motivations, aiming to reduce emissions attributed to transportation and mobility applications that contribute significantly to environmental degradation. However, each industry presents unique challenges and design requirements, influencing the applicability of available standards. Aerospace, automotive, and motorcycle industries, for example, differ significantly in pressure vessel positioning and operating conditions. Ground-level vehicles experience minimal pressure variation compared to aircraft designed for variable flight altitudes and associated pressure differences. This discrepancy results in elevated structural design stress in aviation. While rail vehicles are also expected to undergo minor pressure variations, they typically are expected to offer more available space for tank storage compared to aircraft. In aviation, it is known that optimizing weight and space is crucial for maximizing passenger and cargo capacity for economic efficiency.

Another important categorization for mobile hydrogen-powered transportation is distinguishing between light and heavy mobility solutions. Various standards and projects have been identified that address compressed hydrogen as a fuel for light mobility, as enumerated in

Table 4. Comparable standards for heavy-duty mobility, general pressurized cylinders without a clearly defined mobile application case, and ground-level static pressurized storage standards are outlined in

Table 5,

Table 6 and

Table 7, respectively. To enhance the reader’s experience and provide a comprehensive overview, the previously mentioned aerospace standards are consolidated in

Table 8. This arrangement allows for all relevant information to be conveniently accessed in one location.

The ISO, boasts a sterling reputation globally, significantly enhancing the prospects for either partial or potentially complete international recognition. ISO standards pertaining to compressed hydrogen are numerous and comprehensive. The ISO standards dealing exclusively with hydrogen have been compiled in

Table 9. While each of these ISO standards provides valuable insights for their own hydrogen application domain, not each individual standard shall be explored in detail here. Such an exhaustive review of all standards would lead to inefficiency due to a disproportionate time investment for a comparatively minor increase in informational value. Instead, the following

Section 5 will propose a more focused approach. The suggested strategy consists of distilling the multitude of existing standards down to a select few that are most critical and relevant to our SWITH context. Such a method can provide an efficient pathway to comprehend and apply these standards without being overwhelmed by their sheer volume.

In summary, the landscape of hydrogen utilization spans a broad range of sectors, from conceptual stages to established, commercially available technologies. While some sectors have made significant advances, unique industry requirements often limit the direct transferability of their existing concepts and standards to other areas, such as aviation.

5. Results: Identification of Key Standards

Following an extensive survey of standards for compressed hydrogen applications across multiple sectors, this section assesses their applicability to SWITHs. Subsequently, the criteria necessary for isolating pertinent standards from the vast pool available are defined. The insights derived from this process form the bedrock of this work. In the light of structural tests, this section also highlights the safety factors for burst tests and maximal feasible nominal pressures. Since expensive experimental tests are commonly conducted in advance by simulations, the latter data are valuable for experimental and simulation studies.

Table 10 presents three primary categories that should enable proficient standard users to promptly assess their applicability. Here, the categories can be mixed among each other. Examples for the latter could be mobile, type IV, ground or static, type IV and ground. Both combinations are conceivable for use in practice. Considering the variety of potential combinations, standard selection must be scrupulous to best meet the requirement profile. In the current framework, the selection is mobile, Type IV, and air - a choice expected to be suitable for small and larger aircraft.

The constants for general aviation are mobile and air. While the term air is self-explanatory, mobile is used for pressure vessels that feel force through acceleration. Static on the other hand refers to pressure vessels that are subjected to force only through their own weight. In static, no additional acceleration is experienced, caused by movements such as a flying airplane or a moving car. Regarding the tank Type, the Type IV is notably lighter than the Types I, II, and III. The reservation against Type V tanks pertains to their current prohibitive cost and limited availability.

Table 11 presents the criteria essential for determining the key standards. Notably, the order doesn’t imply any hierarchical precedence. The first two demands are obvious prerequisites to pass the initial stage of filtering. Failure to comply with these two requirements is equivalent to the complete dismissal of the respective standards. The notion of

Up to date stems from the understanding that recent publications potentially integrate more updated knowledge by expert teams, reflecting potentially novel requirements. The principal objective of standard issuers is to ensure safety and functionality for people and the environment while bridging any existing knowledge gaps. This dynamic leads to the item of

Active further development, which underscores the need for standard publishers to continuously adapt their standards in alignment with technological progress and changing environmental conditions.

Accessibility, the fifth point in

Table 11, is a paramount criterion, since even excellent standards are meaningless for research and industry if inaccessible. Items 6-8 relate to experience and successful implementation; the more frequently a standard is employed and functioning vehicles are designed and approved, the more credible the standard becomes. Costs become particularly critical for start-ups as well as small and medium-sized research and industrial institutes. Two standards meeting all the criteria and complementing each other were identified in

Table 12.

The selected standard EC 406/2010 is an established regulation for the automotive industry. However, direct application to aviation brings forth some reservations. First, the English title for EC 406/2010 seemingly allows for its application to aircraft, while its German translation restricts it to motor vehicles. The ISO 19881:2018, which has similar purposes as the EC 406/2010 , explicitly limits its scope to land vehicles and permanently attached tanks through its document’s title. The words Land vehicles make it clear that an application for aircraft is not permitted. Besides the language aspect, studying the EC 406/2010, reveals that it has no direct reference to aircraft usages. Other potential limitations of the EC 406/2010 include testing requirements that might exceed available economic resources, i.e., multiple SWITH specimens are required to undergo one test. The demand for multiple SWITH specimens is also found in the ISO 11119-3:2020. The main reason why multiple SWITH samples are highly undesired is the cost and time intensive manufacturing. To make it even more evident for the reader, let us imagine composite tubes with a length between 8 and 15 meters for small aircraft and up to around 80 meters for large aircraft. Recall, a SWITH is a wing with multiple structure integrated tubes. The rationale why multiple tubes are integrated instead of one, is simply to optimally utilize all free space inside the wing. Employing tube shaped tanks, one single tube would only fit at the location of the maximum thickness. Consequently, most of the surrounding space would remain unoccupied. While in far future it might be possible to have airfoil shaped high pressure hydrogen tanks, for this work regular shaped tanks, namely cylinders and rectangular prism, shall be considered.

Having reiterated how to think of SWITHs for the moment and illustrated how long integrated composite tubes might become, it should be obvious why multiple SWITHs for experimental tests are regarded as prohibitively expensive. Another obstacle for why the EC 406/2010 might not be directly applicable to SWITHs arises through some prescribed demands, which may be deemed overly stringent. These demands are found identically in EC 406/2010 and ISO 19881:2018, pertain to the gaseous hydrogen burst ratio criterias. The latter are specified in 3.6 of EC 406/2010 and 7.3.2 of ISO 19881:2018. It requires Equation (

1) to be fulfilled. The variables

and

are denoted as the minimal burst pressure, a factor depending on over-wrap material and the nominal working pressure, respectively.

For glass, aramid and carbon the factors are

and

, respectively. Putting these in words, if glass is deployed as the wrap material, the hydrogen tank must be able to withstand three times of its nominal pressure. Consequently, if the nominal pressure for a tank were set at 300 bar, the tank must be able to cope with at least 900 bar, without showing any sign of bursting. Thus, the high safety factors defined in EC 406/2010 and ISO 19881:2018 can be regarded as severe limiters. The higher the safety factors are, the more material will be required to meet these demands. More materials result in more weight or mass, which is highly undesired in the field of aircraft. Moreover, the high-pressure gas tank testing facility of the European (GasTeF) states in [

7] of being able to test with a maximal internal pressure of 1050 bar. Depending on the wrapping material, maximal working nominal pressures

between 300 and 465 bar can be achieved. However, if the factors of the ISO 11119-3:2020 are followed, maximal working nominal pressures

between 437.5 and 525 bar can be expected. The comprehensive summary of this passage is consolidated in

Table 13. Note, the safety factors can be found in the denominators of the fractions.

Nevertheless, despite its limitations, the EC 406/2010 can still be retained in the winning list of standards. The observations that lead to disqualify the mentioned ISO 19881:2018 are some difficulties in proper understanding the instructions. Due to copyright concerns, no copy of the original document will not be copied here. Instead, a description of the problem shall be provided. In Table 1 - Material tests of the ISO 19881:2018, material test, clause, material type and four fields for the 4 possible tank or container types are selected as the table headers. For material type, multiple metal material types are given, for which each associated field of tank Type IV checked. To the best understanding of the author, this suggests that these tests are not only mandatory for metal tanks, but also for composite (Type IV) tanks. However, when reading the description to the tests, no reference to composite material is made. Given the significant differences between metal and plastic liners, some variations in the testing protocols should be expected. If no distinction is to be made, there should be an explicit one-liner to that effect. Thus, the confusion arises: should composite tanks be tested in the same manner as metallic tanks, or are these tests specific to metallic tanks only? Since these question could not be resolved within a reasonable amount of effort, the ISO 19881:2018 is removed from the list of the winning standards.

Essential aspects of the selected standards include mandatory and optional tests from ISO 11119-3:2020, illustrated in

Table 14 and

Table 15. The reason, why these tables are provided in this manner without copyright worries is that the tables mainly provide the names of the tests. Having compared different standard with each other, it was noted that similar test names would sometimes have very different test descriptions. In conclusive words, the name does not reveal much about the actual testing process. However, still the tables provide an approximate image about which tests might be required. Nonetheless, these tables still offer an approximate impression of the required tests. Note that some of the optional tests may become mandatory, depending on the specific circumstances of the project at hand.

Conclusively, two key standards were identified as the most promising alternative to the all-encompassing SWITH standard. These standards as a collective offer significant insights, despite their non-direct applicability to SWITHs. Furthermore, it was demonstrated that the nominal working pressure can be selected up to a maximum of , depending on the considered standard. This limitation is due to the fact that existing test facilities are unable to generate arbitrarily high pressures for experimental verification.

6. Discussion

In summary, while certain aerospace standards could provide useful insights for Wing- Structure- Integrated high-pressure Hydrogen Tanks (SWITHs), their applicability remains uncertain due to geographic and technical constraints. Current standards may not be entirely suitable for SWITHs, necessitating the development of a unique standard that encompasses the specific requirements of this niche area. Announced standards could partially support the certification of SWITHs. However, up to now it is unclear, whether these standards are incorporating the idea of externally loaded hydrogen tanks or not. The landscape of hydrogen utilization spans a broad range of sectors, from conceptual stages to established, commercially available technologies. Although some sectors have made significant advances, unique industry requirements often limit the direct transferability of their existing concepts and standards to other areas, such as aviation.

Two key standards were identified as the most promising alternative to the all-encompassing SWITH standard. These standards as a collective offer significant insights, despite their non-direct applicability to SWITHs. Furthermore, it was demonstrated that the nominal working pressure can be selected up to a maximum of , depending on the considered standard. This limitation is due to the fact that existing test facilities are unable to generate arbitrarily high pressures for experimental verification. Finally, it shall be reiterated that the standards are intended to serve as guidance, hinting towards a framework or reference point, rather than dictating exact protocols and thus providing a ready-to-use SWITHs-pertained standard.

Funding

This research was funded by Federal Ministry for Economic Affairs and Climate Action with the grant number 20M2117B. We acknowledge the financial support that made this research possible.

Acknowledgments

Purely for my personal satisfaction, I thank the ONE, who is free of the need of my or anybody else’s acknowledgement, appreciation and gratitude.

Conflicts of Interest

The funding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| ASME |

American

Society of

Mechanical

Engineers |

| CS |

Certification

Specification |

| DOT |

Department of

Transportation |

| EC |

European

Commission |

| EIHP |

European

Integrated

Hydrogen

Project |

| ISO |

International

Organization for

Standardization |

| PED |

Pressure

Equipment

Directive |

| SAE |

Society of

Automotive

Engineers |

| SWITH |

Wing-

Structure-

Integrated high-pressure

Hydrogen

Tank

(pronounced sweet) |

| TPED |

Transportable

Pressure

Equipment |

References

- APUS. Homepage of APUS. Available online: https://group.apus-aero.com/.

- Halstead, D. Image, Toyota hydrogen model car. Available online: https://unsplash.com/photos/yhXcqS-f-X4 (accessed on 18 August 2022).

- Brandsma, S. Image, truck. Available online: https://unsplash.com/photos/YnSWpIPX3pE (accessed on 18 August 2022).

- Dittrich, B. Image, shall represent transportation. Available online: https://unsplash.com/photos/eCc7FjMoR74 (accessed on 18 August 2022).

- Coleman, J. Image, ground storage. Available online: https://unsplash.com/photos/ZVkDLrXGMdw (accessed on 18 August 2022).

- BernhardJaeck. Image, Flying bird. Available online: https://pixabay.com/photos/crows-birds-animals-nature-7381423/ (accessed on 21 August 2022).

- Cebolla, R.O.; Acosta, B.; Moretto, P.; de Miguel, N. GASTEF: The high pressure gas tank testing facility of the European commission joint research centre. 2019, 44, 8601–8614. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).