1. Introduction

The development of a new product usually starts with an idea, which is followed by a whole sequence of processes that will give rise to an invention. To protect it from possible copies, it is normal to register a patent. A new product is created, which is placed on the market. If it has acceptance by potential customers, this makes innovation happen [

1]. Later, new improved versions of the new product appear at the market. We call this process technological development [

2], as new versions of the developed product that appear on the market. During the product development process, the selection of materials is of fundamental importance, on the one hand to avoid possible accidents, and on the other hand, to prolong the life cycle of the product, thus protecting the environment [

3], guaranteeing its quality and, therefore, its good performance [

4]. Creating and developing new products through technological development become a crucial survival factor for companies. All of them seek to create wealth for them and for the countries where they operate, in ever-shorter periods. Therefore, product development times tend to become shorter. The price tends to go down and the quality of the products to go up. This is the great business challenge for today's companies [

5], which must be carried out by engineers, designers and business managers.

Invention is often born out of a need, or just the desire to improve something. This indication is the driving force for the development of society [

6]. For this, highly qualified professionals are needed, namely design engineers, who need to select materials capable of specifying the quality of the product. In addition, they will have to take into account the environmental benefits, selecting environmentally friendly materials, as well as the possibility of reusing materials, always considering sustainability, thus promoting the designer's green self-identity [

7]. Designers of these products, when selecting materials, must take into account their properties, shape and density, as well as surface finishes [

8] that influence consumer choice, and therefore the final value of the product [

9].

To materialize their products, engineers and designers use the most diverse materials, such as metals, ceramics, glass, wood, plastics and composites, among others [

10]. In recent years, the use of smart materials has grown. Smart materials are conceived to have more properties that can be changed in a controlled situation by some external stimuli, of which we can highlight, among others, temperature, electrical field, pH, magnetic field, stress and moisture [

11]. The technicians have at their disposal all possible information about the properties and characteristics of these materials where Construction industry, among others, is one of the most energy consuming sections of all the countries' economy [

12]. To select materials for their projects, they use the most diverse technical manuals, magazines, computer programs, etc. However, the problems related to the selection of materials, although they are minimized, we know that they persist due to the gaps that exist in the selection methods that are made available. Therefore, it is necessary to overcome, or at least minimize, these gaps. For this, additional information is required.

Most of the time, the manuals that support the various technicians are developed by engineering specialists. The technical language used by engineers in these manuals is not well interpreted by designers, who come from the arts, but who shape the product. The designer, who comes from the arts and often gives an aesthetic form to the product, has difficulty understanding all the concepts and characteristics of the materials that will be applied to the products. However, designers must better understand the mechanical properties of materials, as well as learn the fundamentals of graphic data, as presented in the CES program [

13], material selection, designed and developed by Professor Mike Asbhy [

14], with assistance from his collaborators at the University of Cambridge. This program validates very important positive results. However, it adds more value to the engineering area of the product than, properly, to the aesthetic way in which the product was conceived.

Interviews were conducted and a questionnaire was sent to product designers and engineers who work in the current market and also, former product design students, with the aim of surveying the difficulties they encountered in selecting the respective materials and the way they overcame their difficulties, according to section 3 of this work.

The research gap made led the authors to identify the following research questions (RQ):

RQ1: As a product designer or an engineer, do you need to use materials selection tools, as well as, methodologies in your daily work?

RQ2: What are the main criteria for selecting materials that you use in your daily life? What tools and methodologies do you use?

RQ3: What are the main difficulties you feel in the creative process phase? Do you have any suggestions for improvement?

After literature review about main methods of selection of materials, presented in section 2, as well as, Materials and Methods presented in section 3, in section 4, we present the main results, namely, a critical analysis of some educational materials as well as, a new wider and more comprehensive model for materials selection. The final section of this work present the discussion, as well as the main conclusions.

2. Literature review

With the advance of industrialization, it became necessary to search for initiatives to minimize the negative impacts generated by man and his way of life on the environment, such as pollution in large urban centers, mass consumption, waste generation and the disorderly extraction of non-renewable natural resources. In the binomial “product design and materials” it has been observed the emergence of multiple approaches aimed at this context, with emphasis on the correct selection of materials. The project of a new product can be considered in several contexts. First, it can mean designing with new materials that have unique combinations of their properties. In another aspect, design may involve selecting a new material that has a better combination of characteristics for a specific application [

2,

8,

11].

To implement product innovation in a conscious and sustainable way, the environmental impact of products needs to be taken into account already in the early stages of design. A product life cycle perspective based on the correct selection of materials in the design process can guide the implementation of important eco-design measures. However, there is not much literature available neither appropriate tools to empower designer in making sustainable design decisions [

15]. Engineers and Designers are professionals who, in their daily lives, are used to solving problems for the benefit of humanity. They are looking for the easiest, fastest and most economical way to use materials and the forces of nature to overcome the most difficult challenges. It has been like this over the centuries until today. These professionals have been at the forefront of the progress of human civilization [

16,

17]. For this, it is necessary to select good materials so that the products they conceive/design are quality products [

18,

19,

20].

Therefore, materials play a very critical role in the entire manufacturing process. The existence of various ways of selecting materials is a sign of the importance of this issue. However, the proper selection of materials is a very important and challenging task for many applications in product design [

21]. There are over one hundred thousand different materials in our world and several factors must be taken into account to evaluate alternative materials [

2] towards sustainability [

22,

23,

24].

The first step in the material selection process is to specify the product's performance requirements, which should be related to the material's key properties [

2]. Processing requirements are important, but they are of second order [

25], because one of the most important issues in material selection is their properties, with some being more important than others are. For example, the mechanical properties of a material, namely the mechanical resistance (strength/stess), that is, the ability of that material to withstand certain stresses without breaking, is a matter of first order. There are other important mechanical properties, such as, toughness, hardness, ductility and resilience, among others [

26].The selection of suitable materials for sustainable development is an increasingly important process [

2]. It is in selection of materials, still in the product design phase, that the designer's green self-identity must be manifested, selecting materials compatible with sustainable development. When the designer has a green self-identity, nature gains a lot from it [

27]. Moreover, all the inhabitants of the planet win.

The selection of materials is of fundamental importance, both in the design phase of the product when it is conceived, and in the development phase when the product begins to be improved, and during the product production phase. An incorrectly selected material can lead to premature product failure. This could mean some disaster, as well as loss of revenue and reputation for the respective company. When selecting the most suitable material for a specific application in a product, the designer usually needs a solid and systematic methodology because he has several alternative options and conflicting objectives [

8] and, even with a lot of practical experience and many years of service, it is not easy to decide. However, the good selection of materials is multidisciplinary. Its practice involves joint work between the materials engineer, the design engineer and the salesperson. However, for a student a discipline of selection of materials unites the notions of material resistance with their remaining properties and the different ways of processing products [

28].

In today's manufacturing environment, designers of new products have a large number of engineering materials [

29,

30] and manufacturing processes available for selection[

28,

31]. Choice decisions are difficult due to the high number of materials available and need to be taken during the design phase, where the selection of a material for a specific application is made. Designers of new products always must take into account a large number of factors. Among the most important, we highlight the physical and mechanical properties of materials. In addition, other factors must be considered, such as corrosion resistance, thus promoting the longevity of the products. Economic considerations are always important, as it is critical to design quality products at low cost. The possibility of recycling materials must always be taken into account. There are very complex interrelationships between the various material selection criteria. Hence, the correct material selection process is a challenging task, but also more time-consuming for designers [

8,

32].

With regard to the effective compliance with the properties of the materials, many of them are being excluded during the selection process, leaving only a few of them, which can be selected, as likely candidates to materialize the designed objects. In order to achieve a sustainable society, it is necessary for design professionals to be competent and concerned with the selection of materials that are more suitable for the purposes for which they are intended, but materials that are environmentally friendly, the so-called green materials. We know that material selection resources are constantly evolving, including databases, libraries of physical materials, dedicated software programs and tools that help designers who conceive products. The selection of materials for product design needs to consider a broader material system, reflecting industry behavior, stakeholders, legislation, access to knowledge, networks, among other issues [

23]. Therefore, engineers and designers of new products must be aware of all possible issues and select the material that can perform well during the useful life of the product, seeking to reduce its costs in the face of the most varied situations and requests for performance [

29,

33]. All these needs must be considered, which makes the material selection process a difficult multicriterion decision making (MCDM) problem [

29]. Hence, the selection of the appropriate materials for the most diversified products presents itself as one of the most difficult tasks in the design of new products and in the improvement of existing products in several industrial applications. Improper selection of materials can result in damage or failure of an assembly and significantly decreases performance [

34], and sometimes ends in disaster.

There are many ways to innovate, but the main one is exactly through materials. Let's look at the case of semiconductor materials and the innovation they have provided. Engineers and designers must embrace this form of innovation. Therefore, at the beginning of the project, the greatest possible number of materials should be considered, which will be reduced as the design process progresses. From then on, options regarding function and form emerge, reducing the number of possible materials to be selected. In the final phase, selection possibilities are reduced to a few materials and the necessary information becomes increasingly detailed [

35]. Thus, models that assist in material selection, as well as the various traditional and non-traditional methods of material selection, are important tools for optimizing material selection for an important work. It is difficult to satisfy simultaneous requirements of selected materials, when sometimes they are conflicting [

36], at a time when customers are very enlightened and demanding [

9], when we know that the green self-identity has been asserting itself among consumers [

37,

38]. This is a path capable of shaping a green self-awareness for the designer, which also leads us, the consumers, to a green self-identity.

There is no information without support; there is no information technology without monocrystalline silicon (or other materials in the future). Extremely complex and integrated objects could not exist without materials that provide a correct performance [

17]. New materials are constantly appearing and the product designer has to be up to date and know how to make a correct selection of materials.

Table 1 represents the main traditional methods of material selection used in different contexts, according to their own authors [

10,

30,

31,

32,

39]. These authors address different requirements for the selection of materials, most of which are common to all authors, such as technical properties. However, some authors are more careful and add unique specificities, such as material availability, reliability, product lifecycle and environmental properties for instance.

When selecting materials, product designers must consider many functional characteristics, namely, technical properties, manufacturing requirements and economy. They also can consider some intangible aspects in order to express their intentions in the new product design. A few years ago, there has been a need to integrate the intangible characteristics of materials in the selection process, namely, the emotions provoked by the materials [

17,

33,

40].

The material selection process represents a problem when it comes to decision making. It is necessary to reach a compromise with conflicting objectives – cost, production, sizing, quantitative and qualitative properties, performances, availability, reliability and environmental issues, among others.

If on the one hand we have traditional methods of selection of material (

Table 1) developed essentially for engineers. On the other hand we have, non-traditional methods (

Table 2) developed for designers, namely those professionals who often come from the arts and give products beautiful and interesting shapes, which are capable of provoking feelings of pleasure and emotions in their consumers.

Hence, product designers carry out the selection of materials combining functional properties with intangible aspects in order to express their intentions in the projects.

As such, there is no model that aggregates all the requirements of all authors. Hence, the first objective of this study is to analyze the contribution of different authors to the material selection process for a new product, towards sustained development and to guarantee its quality.

With the review of the state of the art, the new designed model intends to provide professionals who need to select materials, some improvement of current methods, with the help of responses from professionals in the sector, who daily seek answers to these problems, identified with green self-awareness from the designer.

Finally, bringing together the contributions of several authors, as well as the concerns of many product designers, inspired by the "Canvas" model, that aggregates the concerns of the most different stakeholders, a new business model based on the basic modular methodology for a project of new product to market is presented. It intends to answer the concerns of the surveyed professionals in the product design sector. Hence, it can help the product designer to conceive products paying attention to all specificities, looking to reduce problems and costs.

Our study focuses on the selection of materials, since this aspect is one of the most relevant steps in the prototyping phase of new products.

3. Materials and Methods

The questionnaire was put online and mailed to around 122 professional designers and engineers. Of the respondents, 38 responses were considered valid, thus constituting the sample of this work. The participants, aged between 18 and 60, were mostly Portuguese and only a few from other countries, working in multinational companies that do business with Portugal. According to

Table 3, the percentage of gender of the participants was 60.52% male and 39.47% female, product design professionals, industrial design and engineers. Some design students were also involved in this research.

Many questions were asked in the questionnaire, of which we can highlight, among others: as a product designer or engineer, do you think it is necessary to use materials selection tools and methodologies in the day-to-day work? What are the main criteria for selecting materials that you use in your daily life? What tools and methodologies do you use? Do you think it will be important to conceive a new methodology or new tool or a model for selecting materials that can satisfy the needs of the design engineer or the product designer? What are the main difficulties do you feel in the creative process phase? Do you have any suggestions for improvement?

According to Kothari & Garg [

41] this work can be considered a qualitative investigation. Therefore, this type of research, usually, is considered applied research, as it aims to generate knowledge that responds to practical problems. Hence, it seeks to solve problems that product designers face, namely when they encounter difficulties in the selection of materials related to their profession. A qualitative investigation aims to interpret difficulties and find answers for solving problems in the daily lives of many professionals and does not necessarily require the use of statistical methods and techniques.

4. Results

It is necessary that the designers of new products give the true importance to the selection of materials for the development of a new product, in order to validate their choices and design quality products that are friendly to the environment.

72% of respondents felt the need of more information on material selection methodologies and tools. Materials are constantly evolving, and as such, it is important to update knowledge, namely through a knowledge refresher course every two years, due to the emergence of new materials, of which we can highlight “high resistance composite materials”. A correct selection of materials for the new product is indispensable in the development of a new product. The tools used by professionals who design new products help them to understand the limits to which materials can be exposed, as well as in the respective production process. These material selection tools are important in helping to develop new products as well as in potentially improving existing products.

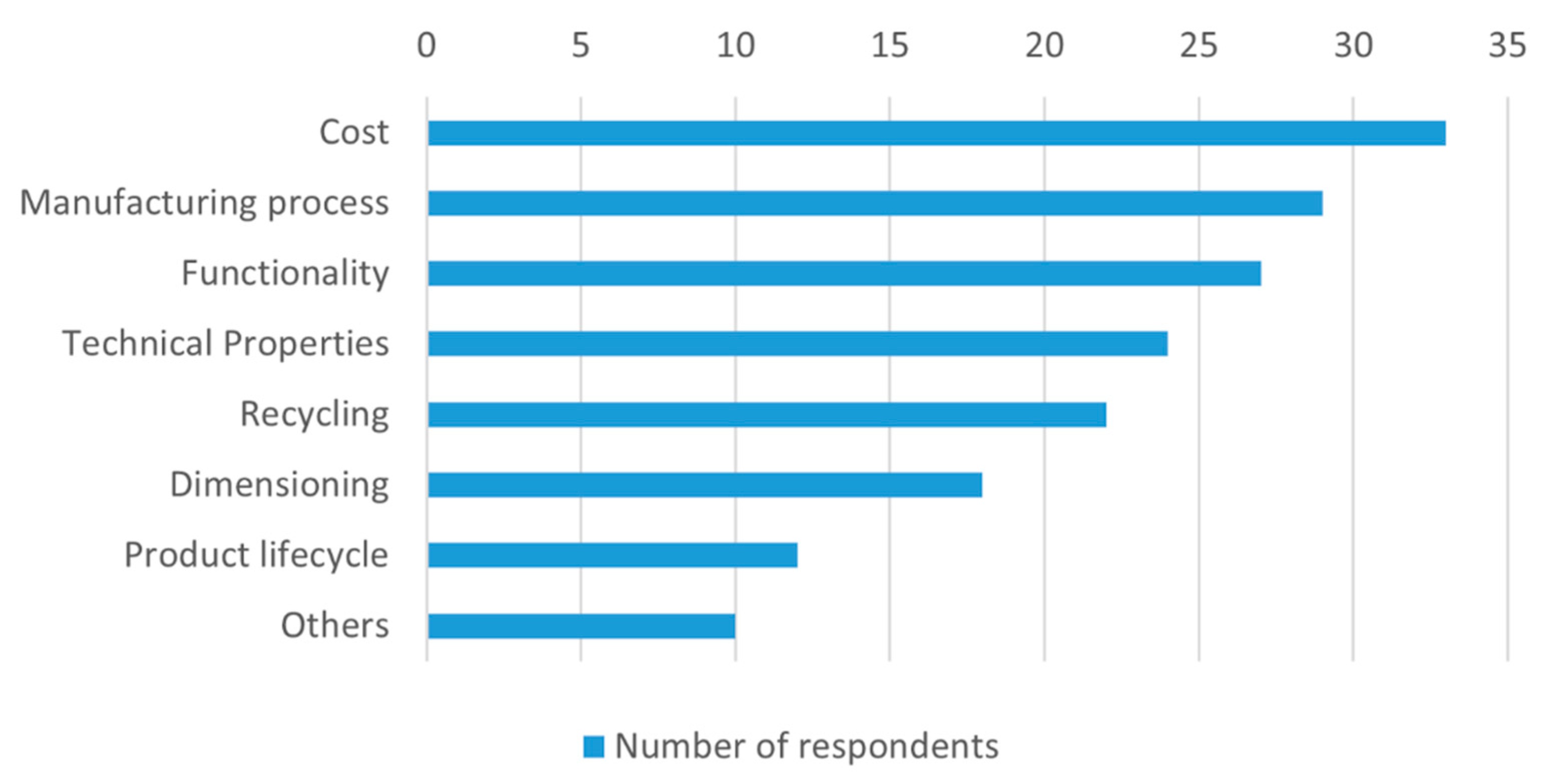

The main material selection criteria that the surveyed professionals responded to are shown in

Figure 1. Cost, manufacturing processes and functionality represent the three main criteria. They confirm that for products produced in mass production, cost comes first. For functionality, we can consider the purposes for which the product is intended. Questions related to the technical properties of materials are also very important. Respondents also gave importance to the issue of recycling, as well as the duration of the product's life cycle. It is in this type of approach that the green self-identity of the designer of new products is modeled, namely, designing quality products, increasing the life cycle of the products, taking into account the recycling of materials at the end of the product's life cycle. Thus, consumers who are concerned about the environment will be able to purchase these new products, knowing that the issue of sustainability was taken into account in their project. This is the way forward for new product designers towards a sustainable society.

We know that chances are occasional, but facts and theories are constant and must be analyzed, making the problem less complex.

With this, we try to show that the existing methods and materials selection tools are not so available for those who need them. It is known that are some gaps in the use of material`s selection tools by design engineers and product designers. Sometimes the existing material selection tools are not obvious to the product designer or design engineer, and they find it difficult to interpret the data. Current tools use a specific technical language, with which some designers are not very familiar, namely those with training in the arts, who develop more aesthetic concepts. It is necessary to improve the language in order to be understood by professionals who need to use it, using explanatory concepts, which can be understood and assimilated, namely by those who have their training in arts, but are very important, to give aesthetic form to new products, or to the improvement of products existing.

Before the age of information technologies, conceiving and sizing new products was the most common way of doing new product designs. However, with the advent of computers, the CES (Cambridge Engineering Selector) program, which is a software package, helps answer many questions.

According to

Figure 2, it is one of many used by professionals, such as engineers, designers, engineering students and others. They have the difficult task of correctly selecting the materials for the designs of the products they develop and which we all use.

It is fundamental to understand the technical characteristics of the materials, in order to design quality products, thus contributing to the happiness of the user. It is also very important to verify that the material selection process is part of the complex creation process in product design. Hence, it is necessary to adopt a method, or tools that help the product designer in the initial phase of the new project, or in the development of the proposal for the creative process of the new product.

According to

Figure 3, Michael Asbhy's methodologies are the most used by the surveyed professionals, followed by the MSA method (Material Selection Activities).

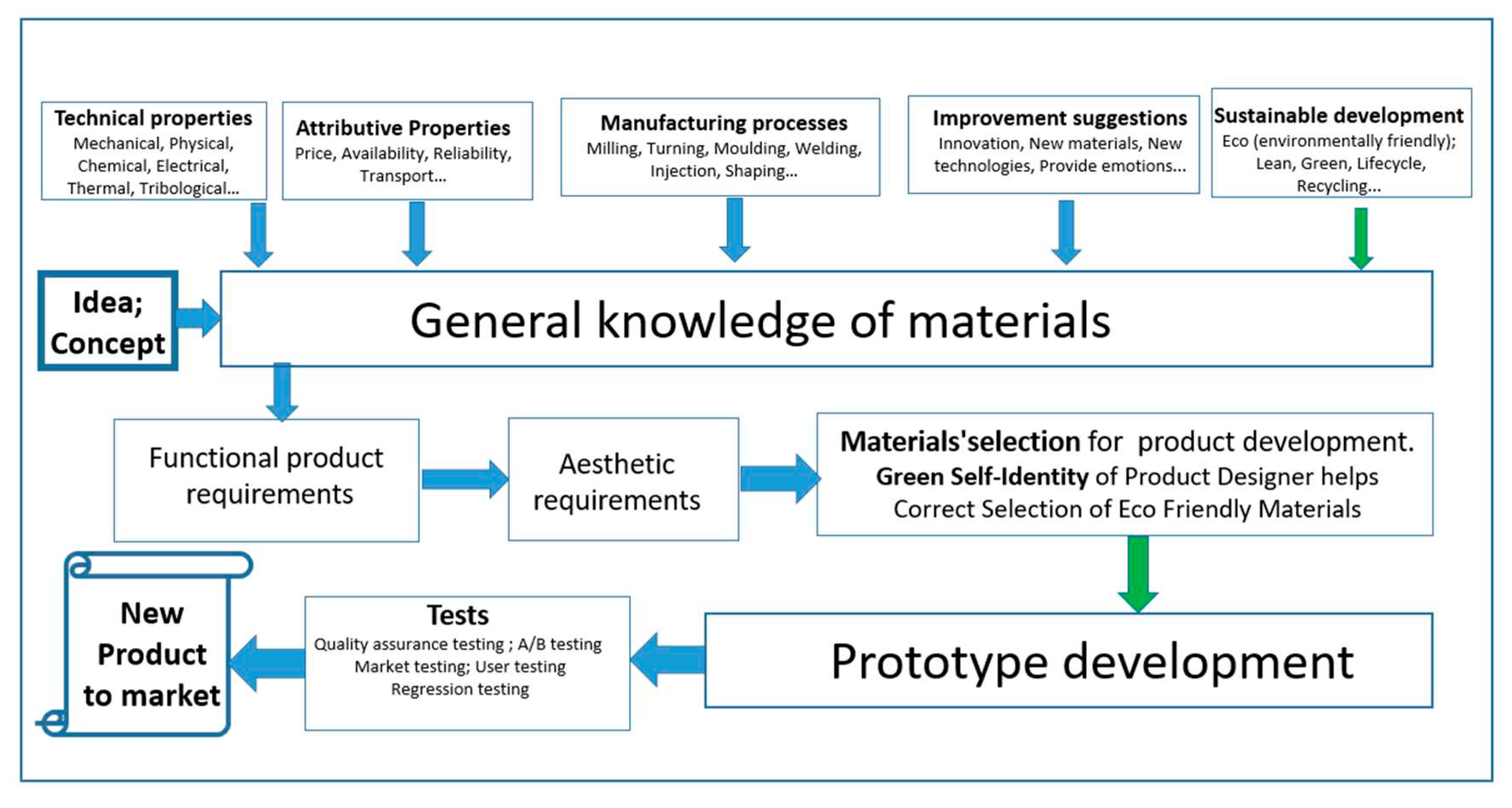

After analyzing the answers given through the questionnaire by product designers, who work in the market, students who are graduating in product design and with some engineers, a new model according to the “Canvas” model was developed. The referred model, which fulfills a whole set of important requirements demanded during the material selection process, helps professionals in the selection of materials for the products they conceive. The new model shown in

Figure 4 is intended to be a tool to help the product designer in the selection of materials for the development of a prototype of a new product for the market. The presented model is based on the basic modular methodology for a project of new products to be implemented and developed in the industry. The application of the modular methodology, presented in

Figure 4, helps the product designer to find the best solutions for the selection of materials for the products he conceives.

It all starts with an idea or concept. Then, sketches are executed and the properties, namely technical properties, of the materials available on the international market are analyzed. The functional and aesthetic requirements of the new product are also analyzed. In the next phase, specific materials are selected for the development of the product, namely, environmentally friendly materials, as well as the manufacturing process. The prototype is designed. Tests are carried out, the prototype is improved and optimized. Finally, a new product is put on the market.

About the question surveyed: “state the main difficulties faced during the creative process phase”, it can be concluded that selection of materials is a difficult issue for all research participants. Some of them, due to the lack of knowledge of some of the most diverse properties of the materials and others due to the diverse complexity in the choice of materials.

There are many thousands of materials, with the most diverse characteristics and properties and the respective selection for the final product depends on the intended use of the designed product. A simple cup can be made of metal, ceramic or even plastic, depending on its intended purpose.

4.1. The contribution of green materials to the designer's green self-identity towards sustainability.

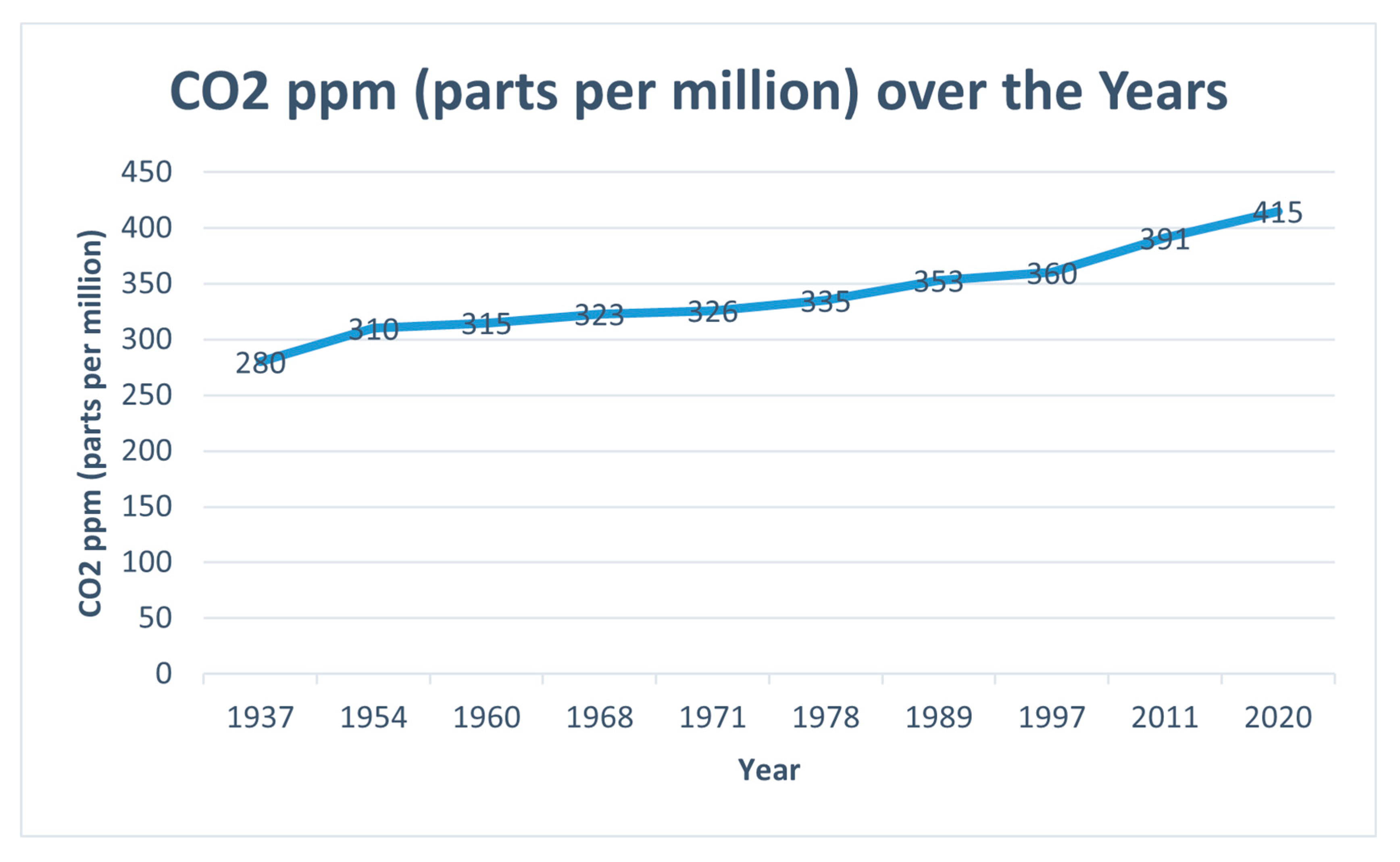

To contribute to a better world, products that become technological innovations must be able to respond, namely, to economic and, simultaneously, demographic problems. In a world with more inhabitants, with a constantly growing middle class, the demand for essential goods has increased, contributing to a greater carbon footprint as shown in

Figure 5, where over the years we will have increasingly polluted air with more and more parts of CO₂ in the air that we all breathe. There is no planet B. It is essential to use green, environmentally friendly materials that produce less carbon into the atmosphere towards sustainability. In manufacturing new products, economies of scale are essential for delivering goods at low cost. As we produce optimally using less material, as such we release less carbon into the atmosphere.

To implement product innovation in a conscious and sustainable way, the environmental impact of products needs attention, in the early stages of design as shown in

Figure 4, thus contributing to the reduction of the ecological footprint.

5. Discussion

Of course, during the material selection process, the most diverse variables are taken into account. Mechanical properties are sometimes, common to the family of materials. Attributive properties and manufacturing processes are, also, common to different materials. The cost is of great importance for all products. It is worth highlighting the importance of quality in the selection of materials for product design, as well as a green self-identity for the designer, who seeks to select environmentally friendly materials, towards sustainability.

5.1. Mechanical and Physical properties.

Mechanical and physical properties are sometimes common to a wide variety of materials. The model was developed focusing on responses to the needs of professionals who develop and materialize new products. Thus, the main materials are divided into large families, according to the best existing literature. The main common properties of these materials must be characterized and presented. What is new in this model is that all the needs of the newly designed product, such as technical, aesthetic, production, environmental and others, are all grouped in a model, which serves as an innovative support - the common analysis of all the main properties and characteristics of materials. Hence, the product designer has at his disposal a range of intrinsic and extrinsic characteristics, which can help him in selecting the best material for the objects he idealizes, designs and materializes.

Besides being necessary to make a correct selection of materials, it is also necessary to integrate quality concepts in the design phase of the product development process. Thus, design errors and late changes in the product development process can be avoided, thus allowing shorter time to market, cheaper and higher quality products [

43,

44]. Issues related to the environment are also important, seeking to reduce the ecological footprint and waste [

45,

46]. Finally, it has to be taken into account that the selected material is available and production is feasible [

45,

46,

47,

48].

5.2. Attributive and other properties

Attributive properties are very important but they are difficult to categorize, in face of constant changes in the market, prices are constantly changing, the place of purchase is sometimes very far from the designer's workplace, and transportation is sometimes uncertain, with unforeseen delays. This is constantly changing and sometimes unpredictable. Each company has its own databases and its suppliers that it works with. It is not always easy to have the materials available to select and apply in the designed products. At this stage of the creative process, it should be noted that the selection of materials that enable the materialization of the product is one of the most relevant issues in the creative process. We can consider the selection of materials as a fundamental interface link with the future product that is being designed. It is at this stage of product design that important aspects of the materials must be taken into account, of which we highlight in the first place the technical aspects that promote the good performance of the product and the consequent reduction of risks. All this should promote the lowest possible cost [

8,

17,

50].

5.3. Aesthetic and emotional aspects of product design

It is also important to take into account the aesthetic aspects that promote a good vision of the product and sometimes contribute to reinforce the emotional aspects. After resolving the technical issues, priority was given to the requirements of an emotional design, which culminated in a surface design, and recently three levels of design were considered: visceral, behavioral and reflective [

51]. Each of these three levels has its role of importance, being that, the visceral design is related to the immediate impact associated with the appearance of the products, the behavioral design consists of the pleasure of the use that is given to the products and finally, the reflective design relates to meaning, recall and satisfaction with the product.

Emotional design is part of an area arising from the union between psychology and design, which seeks answers between the emotional and subjective association that exists between product design and people, leading to the understanding that emotions can be evoked in the interaction with objects. Surface design is part of a specialty within design, having its own visual and technical language. Surface Design is a creative and technical activity that develops both, technical and subjective aspects. It adapt to different sociocultural contexts and different needs.

5.4. Manufacturing processes for the materialization of the new product

To work with the different materials selected to materialize the product we want to produce, there are manufacturing processes, which are common to different materials. Every engineer, like every product designer, can also select the manufacturing processes that he considers essential for the realization of his project [

52].There are common manufacturing processes to work with, for example, metals and technical plastics. The selection of common manufacturing processes for different materials and for different components, contributes to the reduction of costs of the final product.

5.5. The importance of quality management in the material`s selection for a new product

For a product to be competitive, it must have the best performance at the lowest cost. For this, it is very important to respect all aspects related to quality control [

53]. Consumers in the global market currently have complete information, where they can verify the quality of products. When consumers have all the information related to the product they intend to purchase, they can make a more correct decision about purchasing the product they want. Hence, several studies [

54,

55,

56] demonstrate that Quality Management (QM) has been a widespread management approaches worldwide during the last decades.

For the designer, lean thinking is also very important to identify and minimize possible waste. Lean philosophy, as well as Lean tools, guide designers towards continuous improvement in a wide range of industrial activities, which cover areas such as planning, production, quality, maintenance and logistics, among others [

57]. Therefore, designers of new products must have solid knowledge in the area of materials and, in addition, good training, namely in the area of production, in particular, with regard to product quality management. So that they can make their country's economy converge with the economy of the more developed countries [

58].

5.6. Green self-identity in early stage design towards sustainability.

It is important for product designers and engineers to have a green self-identity to design sustainability-oriented products, namely in the early stage of project, thus helping to protect our planet. The green self-identity, necessary to implement product innovation in a conscious and sustainable way, needs to be given importance, preferably, in the initial stages of product design, when materials are selected. However, for this and other aspects, namely from a perspective of the life cycle of products, as well as eco-design, there is little literature available to enable designers to make decisions regarding sustainable design [

15]. We must learn to value more ecologically correct materials, the so-called green materials. Consumers' green self-identity leads them to consume ecologically correct products, because these items satisfy their self-definition needs and they obtain personal satisfaction [

7].

It should also establish an organization with environmental care, free of waste towards sustainability [

59,

60,

61]. Therefore, the sustainable management of the product lifecycle requires important improvements in the conception and product design processes, where the designer's green self-identity is very important. Achieving these improvements requires the use of important tools for improvement of the product, namely environmental and quality tools [

62,

63,

64].

Improvements in production processes lead to fewer variations. This leads to the elimination of defects and better product quality. This is directly related to customer satisfaction [

65]. Thus, they reduce the production costs of the product and increase the profit margin of the producers. What has been said above promotes a more sustainable product life cycle [

66,

67,

68], where computational tools can give a precious help [

69].

The world changes every day. One of the most significant contributions to climate change comes from the garment industry. Estimates indicate that this type of industry is responsible for about 8 percent of carbon emissions. This value is higher than that of international flights and maritime navigation, that is, all planes and ships on the planet together. The emergence of new materials, namely, the new field of nanotechnology, could significantly reduce the dependence on synthetic fibers manufactured with fossil fuels [

70]. The world needs new environmentally friendly materials and product designers need to assume their green self-identity the early phase of material selection [

71]. This concern has been reinforced in recent years [

72,

73,

74].

6. Conclusions

This work aims, above all, to draw attention to the responsibility of the engineer or product designer when selecting the main properties of materials, namely technical properties, and consequently, when he/she select the final material. In order to have an idea of the enormous importance of material selection, we can point out that an incorrect selection of materials can lead to disaster and, consequently, to high economic losses, as well as, in certain circumstances, to the loss of human life.

All customers hope that the designed product has a good performance and does not present weaknesses that can lead to serious risks and even failures that lead to disaster.

From the analysis carried out in the literature review, namely, traditional and non-traditional methods of material selection, as well as the answers given by professionals and students regarding the difficulties encountered in the correct selection of materials, it is possible to answer and conclude the proposed research questions:

RQ1: As a product designer or an engineer, do you need to use materials selection tools, as well as, methodologies in your daily work?

The existing tools are very important help for a correct selection of materials.

The most important material selection criteria are several, as there are many variables, but the most important, for mass production of products, is certainly the cost. Manufacturing processes and product functionality are also very important. The technical properties are too important, namely the mechanical resistance which, if well selected, avoids many disasters. There are other issues, also important, such as the possibility of recycling and the life cycle of the product. The CES (Cambridge Engineering Selector) is the most used tool as well as Michael Ashby's methodologies.

The material can condition the imagined piece, as well as it can also help in its conception. There is difficulty in correlating all the characteristics of the materials with the production processes that will materialize the product. When moving to a prototype/final product development phase, all material`s selection issues are directly linked and they all interfere with each other causing constraints throughout the creative process until you get a final product. It is difficult to determine what are the limits / restrictions for the final choice of material. The time factor is always a problem – it is difficult to define the time for the creative process, the market requires deadlines, which sometimes complicates the creative process because creativity does not have a defined recipe or method, it varies from project to project. As a suggestion, it would be good to design a model that covers as many variants of the creative process as possible. The issue of eco-design and sustainability need to be taken into account in the initial phase of the design of new products, exactly, when the materials are selected.

The methodologies of material selection presented in this work, as well as the new model conceived, which is based on the "Canvas" modular methodology, can help the designer of new products to select the materials, correctly, so that the products have a good performance and a long lifecycle. Special attention should be given to environmentally friendly materials, as well as recycling. The designer can take this concern during the creative process. It reinforces the designer's green self-identity, which is very important for the sustainability of the products. This is certainly the desire of all companies and of all consumers.

7. Limitations of This Work and Future Research

Although this work has achieved its objectives, seeking to find answers to important questions, it has limitations. More questions and a larger sample would certainly give more consistency to our work.

Future research with more questions may reinforce the methodology based on the new conceptual model. It would also be important, in future work, to test the model and apply new technologies such as 3D printing.

Author Contributions

The authors made the following contributions to this work: concept about the idea, Z.S. (Zhonghua Sun) and G.S. (Gilberto Santos); Data Curation, G.S. (Gilberto Santos) and M.D. (Manuel Doiro); Problem analysis Z.S. (Zhonghua Sun) and J.C.S (José Carlos Sá); Investigation (José Carlos Sá) and M.D. (Manuel Doiro); Methods, G.S. (Gilberto Santos) and J.C.S. (José Carlos Sá); Writing - original draft, Z.S. (Zhonghua Sun) and G.S. (Gilberto Santos); Writing - proofreading improvement and editing, Z.S. (Zhonghua Sun), G.S. (Gilberto Santos), M.D. (Manuel Doiro) and J.C.S. (Jose Carlos Sá). All authors read and agreed with the published version of the manuscript.

Funding

This research does not received external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are available on request.

Conflicts of Interest

The authors declare no conflict of interest.

Ethical statement

The study was conducted according to the guidelines of the Declaration of Helsinki. According Portuguese legislation does not require a pre-approval of Ethical Committee.

References

- Santos, G.; Gomes, S.; Braga, V.; Braga, A.; Lima, V.; Teixeira, P.; Sá, J. C. Value creation through quality and innovation – a case study on Portugal. TQM Journal 2019, 31(6), 928–947. [CrossRef]

- Ljungberg, L. Y. Materials selection and design for development of sustainable products. Materials and Design, 2007, 28(2), 466-479. [CrossRef]

- Santos G.; Rebelo, M.; Ramos S.; Silva, R.; Pereira M.; Ramos, G. N. L. Developments regarding the integration of the occupational safety and health with quality and environment management systems. In Ilias G. Kavouras & Marie-Cecile G. Chalbot. (Ed.), Developments Regarding the Integration of the Occupational Safety and Health with Quality and Environment Management Systems, 2014, 113-146. New York: Nova Publishers New York.

- Sá, J.C.; Vaz, S.; Carvalho, O.; Lima, V.; Morgado, L.; Fonseca, L.; Doiro, M.; Santos, G. A model of integration ISO 9001 with Lean six sigma and main benefits achieved. Total Quality Management & Business Excellence, 2022, 33 (1-2), 218-242. [CrossRef]

- Santos. G.; Murmura, F.; Bravi, L. Developing a model of vendor rating to manage quality in the supply chain. International Journal of Quality and Service Sciences, 2019, 11(1), 34-52. [CrossRef]

- Zgodavova, K.; Bober, P.; Majstorovic, V.; Monkova, K.; Santos, G.; Juhaszova, D. Innovative methods for small mixed batches production system improvement: The case of a bakery machine manufacturer. Sustainability (Switzerland), 2020, 12, 6266. 10.3390/su12156266.

- Barbarossa, C.; De Pelsmacker, P.; Moons, I. Personal values, green self-identity and electric car adoption. Ecological Economics 2017, 140, 190-200. [CrossRef]

- Prasad, K.; Chakraborty, S. A quality function deployment-based model for materials selection. Materials and Design 2013, 49, 525–535. [CrossRef]

- Bravi, L; Murmura, F.; Santos, G. Attitudes and behaviours of Italian 3D prosumer in the Era of Additive Manufacturing. Procedia Manufacturing 2017, 13, 980–986. [CrossRef]

- Patton, W. J. Materials in industry. Prentice-Hall New Jersey, 1968.

- Jain, N., Ovhal, S.N., Patil, V., Kartik, K.N. Smart materials – A state-of-the-art-review. Materials Today: Proceedings. Materials Today: Proceedings 2023, 82, 381–389. [CrossRef]

- Balali, A., Valipour, A. Identification and selection of building façade's smart materials according to sustainable development goals. Sustainable Materials and Technologies 2020, 26, e00213. [CrossRef]

- Ashby, M. F.; Cebon, D. Teaching Engineering Materials : the CES EduPack, 2007, Cambridge University.

- Ashby, M. F.; Johnson, K. Materials and Design: The Art and Science of Material Selection in Product Design: Third Edition, 2014. [CrossRef]

- Velden, N.M., Kuusk, K., Köhler, A.R. Life cycle assessment and eco-design of smart textiles: The importance of material selection demonstrated through e-textile product redesign. Materials and Design 2015, 84, 313–324. [CrossRef]

- Conner, M.; Armitage, C. J. Extending the theory of planned behavior: A review and avenues for further research. Journal of Applied Social Psychology 1998, 28(15), 1429-1464. [CrossRef]

- Manzini, E. The Material of Invention: Materials and Design. Arcadia Edizioni Milano, 1986.

- Sá, C., Amaral, A., Barreto, L., Carvalho, F., Santos, G. Perception of the importance to implement ISO 9001 in organizations related to people linked to quality – an empirical study. International Journal for Quality Research 2019, 13(4) 1055–1070. [CrossRef]

- Bravi, L.; Murmura, F.; Santos, G. The ISO 9001:2015 quality management system standard: Companies’ drivers, benefits and barriers to its implementation. Quality Innovation Prosperity Journal 2019, 23(2), 64-82. [CrossRef]

- Jahanzaib, M.; Masood, S. A.; Jamil, U. Akhtar, K. Product design variables optimization using design for six sigma (DFSS) approach. Life Science Journal, 2013, 10, 57-63.

- Mousavi-Nasab, S. H.; Sotoudeh-Anvari, A. A new multi-criteria decision making approach for sustainable material selection problem: A critical study on rank reversal problem. Journal of Cleaner Production 2018, 182, 466-484. [CrossRef]

- Teixeira, P.; Coelho, A.; Fontoura, P.; Sá, J.C.; Silva, F.J.G.; Santos, G.; Ferreira, L.P. Connecting lean and green practices to achieve a superior performance: The contribution for a sustainable development and competitiveness—An empirical study on the Portuguese context. Corp Soc Responsib Environ Manag. 2022, 29, 887–903. [CrossRef]

- Prendeville, S.; O’Connor, F.; Palmer, L. Material selection for eco-innovation: SPICE model. Journal of Cleaner Production 2014, 85, 31-40. [CrossRef]

- Barbosa, L. C. F.; Oliveira, O. J.; Santos, G. Proposition for the alignment of the integrated management system (quality, environmental and safety) with the business strategy. International Journal for Quality Research 2018, 12(4), 925–940.

- Doiro, M.; Fernández, J.F.; Félix, M.J.; Santos, G. ERP - machining centre integration: a modular kitchen production case study. Procédia Manufacturing, 2017, 13, 1159-1166. [CrossRef]

- van Kesteren, I. E. H. Product designers’information needs in materials selection. Materials and Design 2008, 29, 133-145. [CrossRef]

- Patel, J. D.; Trivedi, R. H.; Yagnik, A. Self-identity and internal environmental locus of control: Comparing their influences on green purchase intentions in high-context versus low-context cultures. Journal of Retailing and Consumer Services 2020, 53, 102003. [CrossRef]

- Ferrante, M. Seleção de Materiais. 2 ed. São Carlos, EdUFSCar, 2002, S. Paulo, Brazil.

- Edwards, K. L. Selecting materials for optimum use in engineering components. Materials and Design 2005, 26, 469–472. [CrossRef]

- Budinski, K. G. Engineering Materials: Properties and Selection. Prentice-Hall New Jersey, 1996.

- Lindbeck, J. R. Product Design and Manufacture. Simon & Schuster Company, New Jersey, 1995.

- Ashby, M. F. Material’s selection in Mechanical Design. Butterworth-Heinemann Oxford, 1992.

- Ashby, M. F., Johnson, K. W. Materials and design: the art and science of material selection in product design. Butterworth-Heinemann Oxford, 2002.

- Jahan, A.; Mustapha, F.; Ismail, M. Y.; Sapuan, S. M.; Bahraminasab, M. A. comprehensive VIKOR method for material selection. Materials and Design 2011, 32, 1215–1221. [CrossRef]

- Ramalhete, P. S.; Senos, A. M. R.; Aguiar, C. Digital tools for material selection in product design. Materials and Design 2010, 31, 2275–228. [CrossRef]

- Vitorino, N.; Abrantes, J. C. C.; Frade, J. R. Quality criteria for phase change materials selection. Energy Conversion and Management 2016, 124, 598–606. [CrossRef]

- Teixeira, P.; Sá, J.C.; Silva, F.J.G.; Santos, G.; Ferreira, L.P.; Fontoura, P. Connecting lean and green with sustainability towards a conceptual model. Journal Cleaner production 2021, 322, 129047. [CrossRef]

- Thoits, P. A.; Virshup, L. K. Me’s and we’s. Self and identity: Fundamental issues 1997, 106-133.

- Farag, M. M. Quantitative methods of materials substitution: application to automotive components. Materials and Design 2008, 29, 374–380. [CrossRef]

- Karana, E., Hekkert, P., Kandachar, P. Material Considerations in Product Design: A survey on crucial material aspects used by product designers. Materials and Design 2008, 29, 1081–1089. [CrossRef]

- Kothari, C. R. Research methodology methods and techniques. New Age International (P) Ltd., Publishers. Daryaganj, New Delhi, 2004.

- Attenborough, D. (2020). A life on Our Planet –My Witness Statement and a Vision for the Future. David Attenborough (Productions), Lda. Great Britain.

- Santos, G.; Barbosa, J. QUALIFOUND - a modular tool developed for Quality Improvement in Foundries. Journal of Manufacturing Technology Management 2006, 17(3), 351-362. [CrossRef]

- Bravi, L.; Murmura, F.; Santos, G. Manufacturing labs: Where new digital technologies help improve life quality. International Journal for Quality Research 2018, 12(4), 957–974. [CrossRef]

- Carvalho, F.; Santos, G.; Gonçalves, J. The disclosure of information on Sustainable Development on the corporate website of the certified Portuguese organizations. International Journal of Quality Research 2018, 12(1), 253-276. [CrossRef]

- Talaprata, S.; Santos, G.; Uddin, K.; Carvalho, F. Main Benefits of Integrated Management Systems Through Literature Review. International Journal for Quality Research 2019, 13(4), 1037–1054. [CrossRef]

- Carqueijó, S.; Ramos, D.; Gonçalves, J.; Carvalho, S.; Murmura, F.; Bravi, L.; Santos, G. The Importance of Fab Labs in the Development of New Products toward Mass Customization. Sustainability (Switzerland), 2022, 14, 8671. [CrossRef]

- Francisco, M.G.; Junior, O.C.; Sant’Anna, A.M. O. Design for six sigma integrated product development reference model through systematic review. International Journal of Lean Six Sigma, 2020, Vol. ahead-of-print No. ahead-of-print. [CrossRef]

- Ipek, M.; Selvi, I. H.; Findik, F.; Torkul, O.; Cedimoĝlu, I. H. An expert system based material selection approach to manufacturing. Materials and Design 2013, 7, 331–340. [CrossRef]

- Sánchez, J.M. and Priest, J.W., Product Development and Design for Manufacturing, 2st ed. 2001, Marcel Dekker, New York, NY.

- Norman, D.A. Emotional Design - Why we love (or Hate) everyday things. Basic Books publisher, New York, 2004.

- Lefteri, C. Making It: Manufacturing Techniques for Product Design. 2007, Continuum.

- Araújo, R.; Santos, G.; Costa, J.; Sá, J. C. The quality management system as a driver of organizational culture: An empirical study in the Portuguese textile industry. Quality Innovation Prosperity Journal, 2019, 23(1), 1-24. [CrossRef]

- Costa, A. R.; Barbosa, C.; Santos, G.; Alves, M. R. Six sigma: Main metrics and R based software for training purposes and practical industrial quality control. Quality Innovation Prosperity Journal 2019, 23(2), 83-99. [CrossRef]

- Jimenez, G.; Santos, G.; Sá. J.C.; Ricardo, S.; Pulido, J.; Pizarro, A.; Hernandez, H. Improvement of Productivity and Quality in the Value Chain through Lean Manufacturing – a case study. Procedia Manufacturing 2019, 41, 882- 889. [CrossRef]

- Sá, J.C.; Amaral, A.; Barreto, L.; Carvalho, F.; Santos, G. Perception of the importance to implemente ISO 9001 in organizations related to people linked to quality – an empirical study. International Journal for Quality Research 2019, 13(4), 1055–1070. [CrossRef]

- Pombal, T.; Ferreira, L.P.; Sá, J.C.; Pereira, M.T.; Silva, F.J.G. Implementation of Lean Methodologies in the Management of Consumable Materials in the Maintenance Workshops of an Industrial Company. Procedia Manufacturing 2019, 38, 975–982. [CrossRef]

- Yülek, M.A.; Santos, G. Why Income Gaps Persist: Productivity Gaps, (No-) Catch-up and Industrial Policies in Developing Countries. Journal of Economic Issues, 2022, 56, 158-183. [CrossRef]

- Santos, D.; Rebelo, M.; Santos, G. The Integration of certified Management Systems. Case Study – Organizations located at the district of Braga, Portugal. Procedia Manufacturing, 2017, 13, 964-971. [CrossRef]

- Rodrigues, J.; Sá, J.C.; Silva, F.; Ferreira, L.; Santos, G. Implementation Lean Management "Quick-Wins" – A Portuguese case study. Quality Innovation Prosperity Journal 2019, 23, 3-21.

- Santos, G.; Mendes, F.; Barbosa, J. Certification and integration of management systems: the experience of Portuguese small and medium enterprises. Journal of Cleaner Production 2011, 19(17-18), 1965-1974. [CrossRef]

- Carvalho, M.; Sá, J.C.; Marques, P.A., Santos, G., Pereira, A.M. Development of a conceptual model integrating management systems and the Shingo Model towards operational excellence. Total Quality Management & Business Excellence 2023, 34, 397–420. [CrossRef]

- Ribeiro, P.; Sá, J.C.; Ferreira, L.P.; Silva, F.J.G.; Pereira, M.T.; Santos, G. The Impact of the Application of Lean Tools for Improvement of Process in a Plastic Company: a case study. Procedia Manufacturing 2019, 38, 765–775. [CrossRef]

- Santos, G.; Afonseca, J.; Murmura, F.; Félix, M. J.; Lopes, N. Critical success factors in the management of ideas as an essential component of innovation and business excellence. International Journal of Quality and Service Sciences, 2018, 3(3), 214-232. [CrossRef]

- Jimenez, G.; Santos, G.; Sá, J.C.; Ricardo, S.; Pulido, J.; Pizarro, A.; Hernández, H. Improvement of Productivity and Quality in the Value Chain through Lean Manufacturing – a case study. Procedia Manufacturing 2019, 41, 882-889. [CrossRef]

- Santos, G.; Félix, M.J.; Doiro, M., Mandado, E.; Sá, J.C.; Gonçalves, J.; Teixeira, P. On the concept of an integrated and lean model of product development proposed for intellectual property creation and competitive economies. International Journal of Intellectual Property Management 2020, 10, 409 – 43. [CrossRef]

- Carvalho F.; Santos G.; Gonçalves J. Critical analysis of information about integrated management systems and environmental policy on the Portuguese firms' website, towards sustainable development. Corporate Social Responsibility Environmental Management 2019, 27(2), 1069-108. [CrossRef]

- Vieira, T.; Sá, J.C.; Lopes, M.P.; Santos, G.; Félix, M.J.; Ferreira, L.P.; Silva, F. J. G.; M. T. Pereira, M.P. Optimization of the cold profiling process through SMED. Procedia Manufacturing 2019, 38, 892–899. [CrossRef]

- Santos, G.; Doiro, M.; Mandado, E.; Silva, R. Engineering learning objectives and computer-assisted tools. European Journal of Engineering Education 2019, 44(4), 616-628. [CrossRef]

- Guillén, M.F. 2030, Major global trends. A shock that will change the future of everything, 2020. St. Martin Publishing Group, USA.

- Pollini, B., Rognoli, V., Early-stage material selection based on life cycle approach: tools, obstacles and opportunities for design. Sustainable Production and Consumption 2021, 28, 1130–1139. [CrossRef]

- Omrany,H., Ghaffarianhoseini, A., Chang,R., Ghaffarianhoseini, A., Rahimian, F.P. Applications of Building information modelling in the early design stage of high-rise buildings. Automation in Construction 2023, 152, 104934.

- Subramanian, V.,Peijnenburg, W.J.G.M., Vijver, M.G., Blanco, C.B., Cucurachi, S., Guinée, J.B. Approaches to implement safe by design in early product design through combining risk assessment and Life Cycle Assessment. Chemosphere 2023, 311, 137080. [CrossRef]

- Badawy, M., Alqahtani, F., Hafez, H. Identifying the risk factors affecting the overall cost risk in residential projects at the early stage. Ain Shams Engineering Journal 2022, 13, 101586. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).