1. Introduction

In recent years, the proportion of photovoltaic (PV) generation, wind power generation, and other renewable energy sources in the grid has been increasing, and the planning and construction of future renewable-dominated power systems have become the key to building a modern energy system [

1]. Although renewable generation has the advantages of environmental protection, energy saving, and emission reduction, it relies on external environmental conditions and shows the characteristics of uncertainties in power output [

2]. Large-scale grid integration of renewable generation will cause many adverse effects on the normal operation of traditional power systems [

3]. Microgrid, as a combination of distributed renewable generation, energy storage devices, and various types of loads into a small power network, provides a promising tool for renewable accommodation. Microgrids not only serve as a bridge for energy exchange between distributed power sources and distribution grids, but also plays a positive role in load redistribution [

4,

5]. Optimal planning of microgrids coordinating resources and loads is an important issue.

As electric vehicles (EVs) gain popularity and the share of EV charging load is continuously increasing, characteristics of loads in microgrids show diversity [

6]. Compared with conventional electricity load, EV charging load shows significant randomness and fluctuation in spatial and temporal distribution, and EV charging decision is susceptible to real-time electricity price, weather, road conditions, battery state of charge, and other factors [

7,

8]. Users' travel habits and usage habits also make EV charging load present a certain dispersion, and the operation and charging characteristics of different types of EVs also differ greatly, thus bringing more uncertainty to microgrid operation [

9]. Microgrids with only conventional loads considered in the planning stage might fail to accommodate the massive access of EVs, and the electricity quality and economic performance of microgrids will be significantly impacted by EV loads [

10]. The large-scale access of EVs to the microgrid system will lead to load growth and affect the microgrid load architecture and characteristics, and the simultaneous access of a large number of EVs will also lead to a surge in the microgrid power supply pressure and deterioration of power quality [

11,

12], which will affect operation stability and economy of the microgrid. In this context, the necessity of taking into account EV charging loads in microgrid planning is enhanced.

The problem of optimal planning of microgrids has been widely studied. In the literature [

13], the objective function of minimizing active power fluctuation is established to derive the optimal configuration of microgrid energy storage capacity with minimum active power fluctuation. In the literature [

14], an off-grid microgrid economic optimization model was established, mainly considering the effects of battery capacity decay and temperature. The results showed that the overall economy of the microgrid system was effectively improved. In literature [

15], the optimal allocation of PV and energy storage in rural microgrids is achieved based on the second-generation non-dominated ranking genetic algorithm with the optimization objectives of maximum PV utilization and optimal economy, considering the load characteristics of rural areas, local environmental factors and various economic factors. In literature [

16], the optimal planning of isolated hybrid systems is derived with total NPV minimization as the optimization objective and based on an improved genetic algorithm. However, these studies mainly focused on economic factors and did not adequately consider other important indicators such as renewable energy resource utilization and carbon emissions. In literature [

17], a microgrid system with renewable resources and batteries is constructed, and the electric vehicle load is generated based on Monte Carlo algorithm, with the lowest probability of power loss and the lowest life cycle cost as the optimization objectives, and finally the optimal configuration of the system is derived based on particle swarm optimization algorithm. The aforementioned literature conducts studies by establishing optimization models and seeking solution algorithms. In addition, HOMER as one of the commercial software, provides an efficient platform for tailored microgrid planning. In literature [

18], HOMER software was employed to perform the technical-economic assessment of hybrid renewable energy systems to electrify three off-grid remote villages in Columbia. And the most economical system was proposed for each village based on net present cost (NPC), levelized cost of electricity (LCOE), and initial capital cost. In literature [

19], Rahman used the Canadian Ontario region as a study, set up seven generation scenarios based on the percentage of renewable energy and applied HOMER for a hybrid energy generation design that can meet a peak load of 772 kW and an average load of 4.4 kWh/day. In addition, the carbon dioxide penalty cost is also considered in the total cost components and solar surface radiation, wind speed, diesel price and carbon dioxide penalty cost are analyzed as sensitive variables.The simulation results show that the percentage of renewable energy is 100%, 80%, 65%, 50%, 35%, 21%, and 0%, and the corresponding electricity costs are

$1.48/kWh,

$0.62/kWh,

$0.54/kWh,

$0.42/kWh,

$0.39/kWh,

$0.37/kWh, and

$0.36/kWh, respectively. In literature [

20], based on HOMER software, an optimal configuration of a diesel-battery-wind-PV hybrid system was proposed considering NPC and LCOE. In literature [

21], HOMER Pro software was used to develop a stand-alone microgrid system with a mixture of wind power, PV power, diesel generators, and batteries to meet the agricultural load requirements using minimized NPC as the objective function and resources, technology, reliability, and emissions as constraints. Overall, the effectiveness of HOMER software is verified in several scenarios. However, existing studies using HOMER did not comprehensively consider the technical, economic, and environmental-friendly performance of different components in microgrids, especially with multiple operating scenarios with EVs.

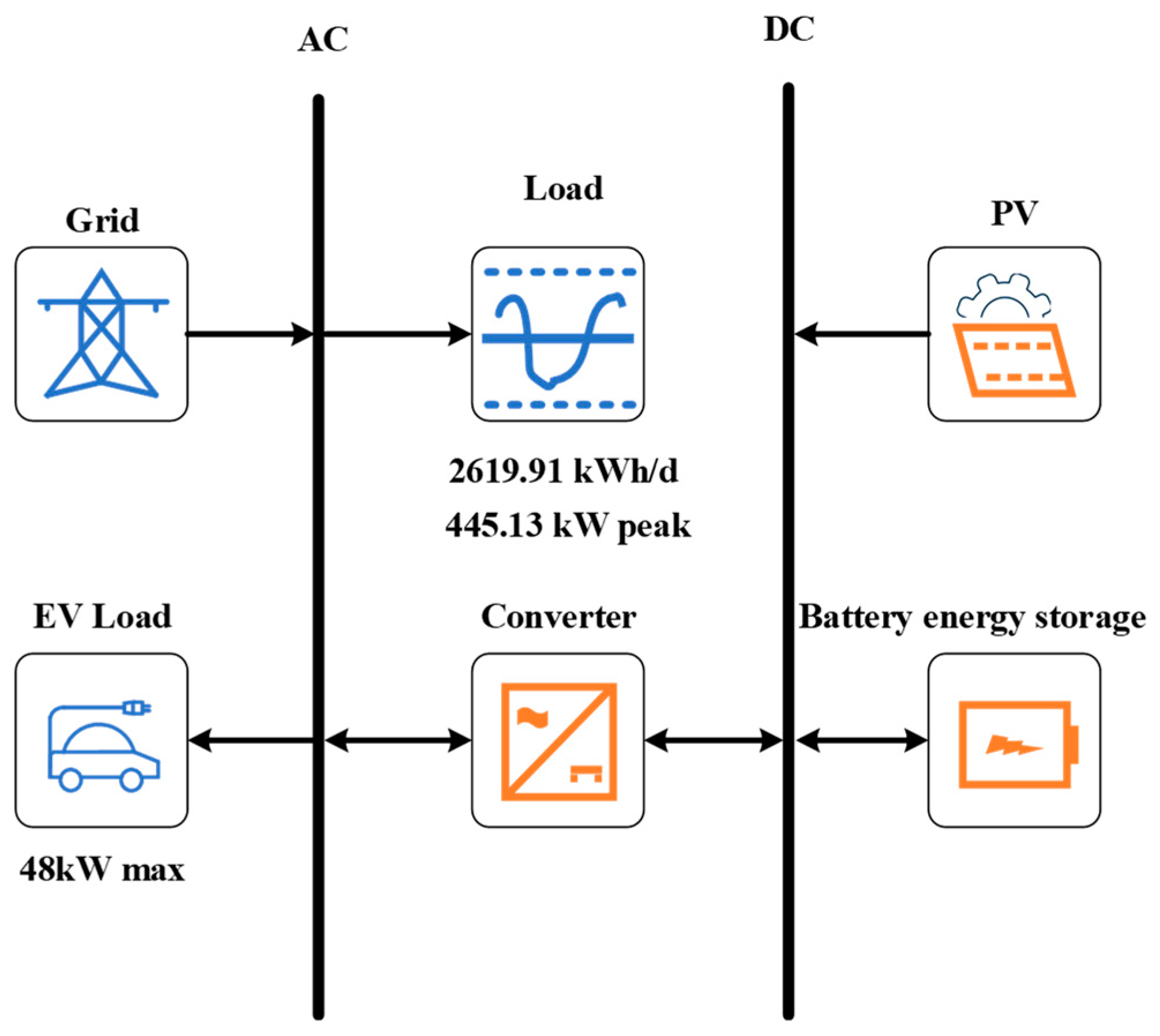

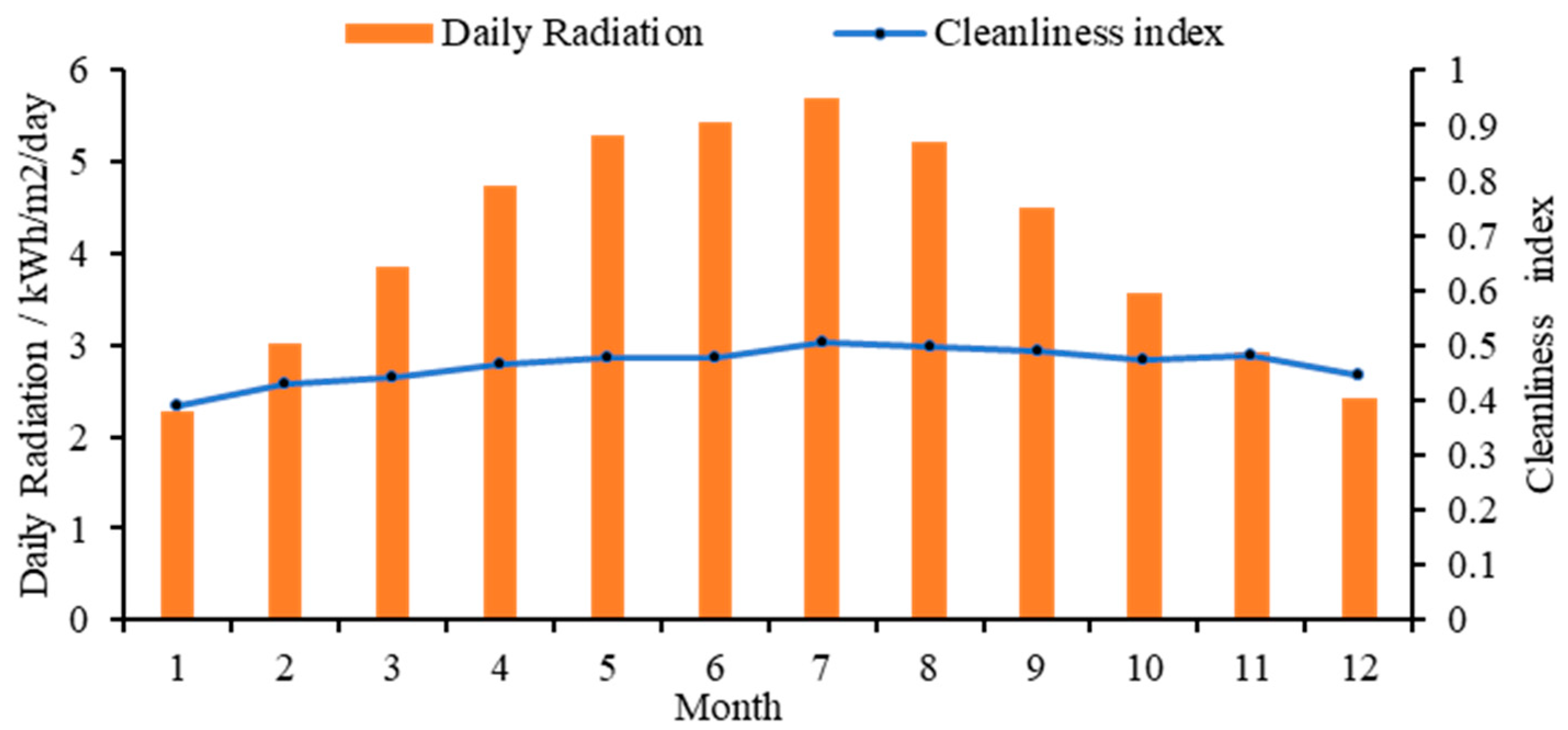

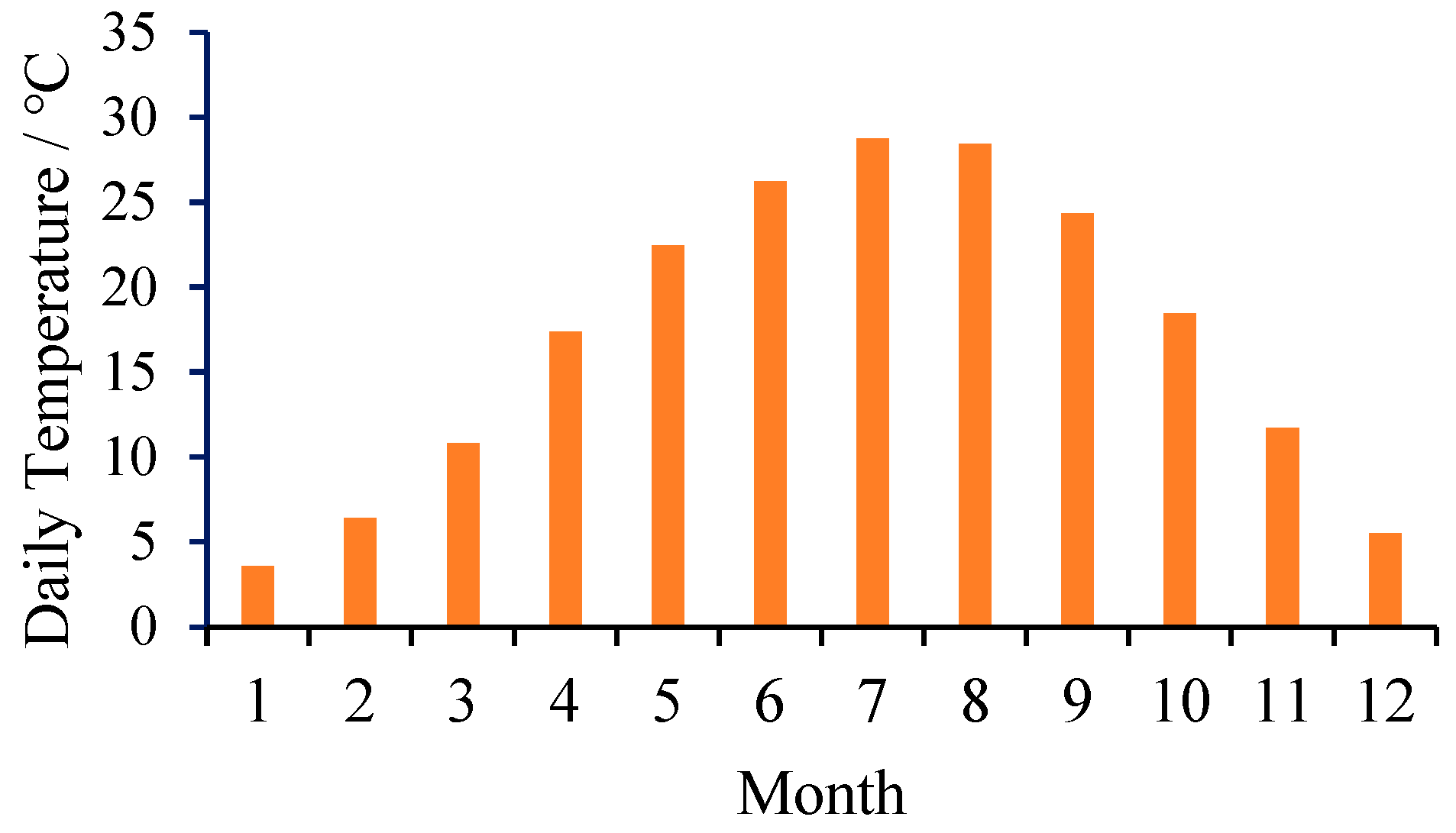

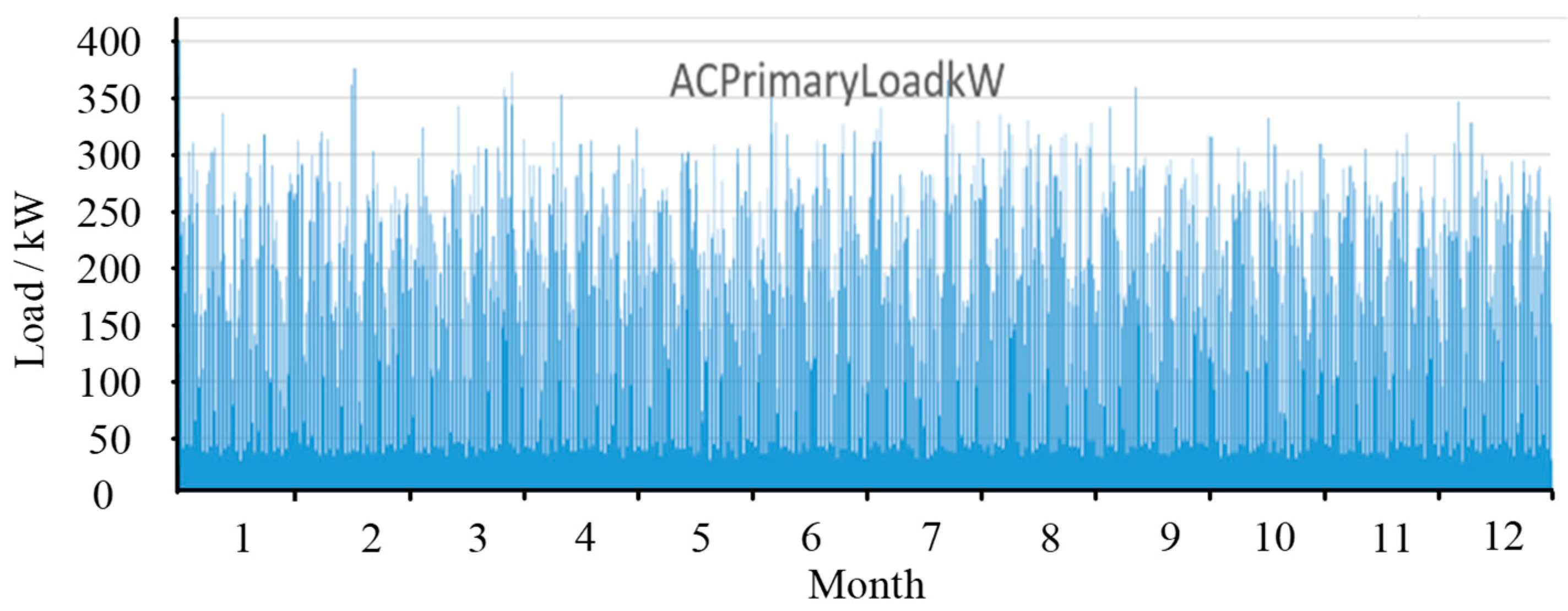

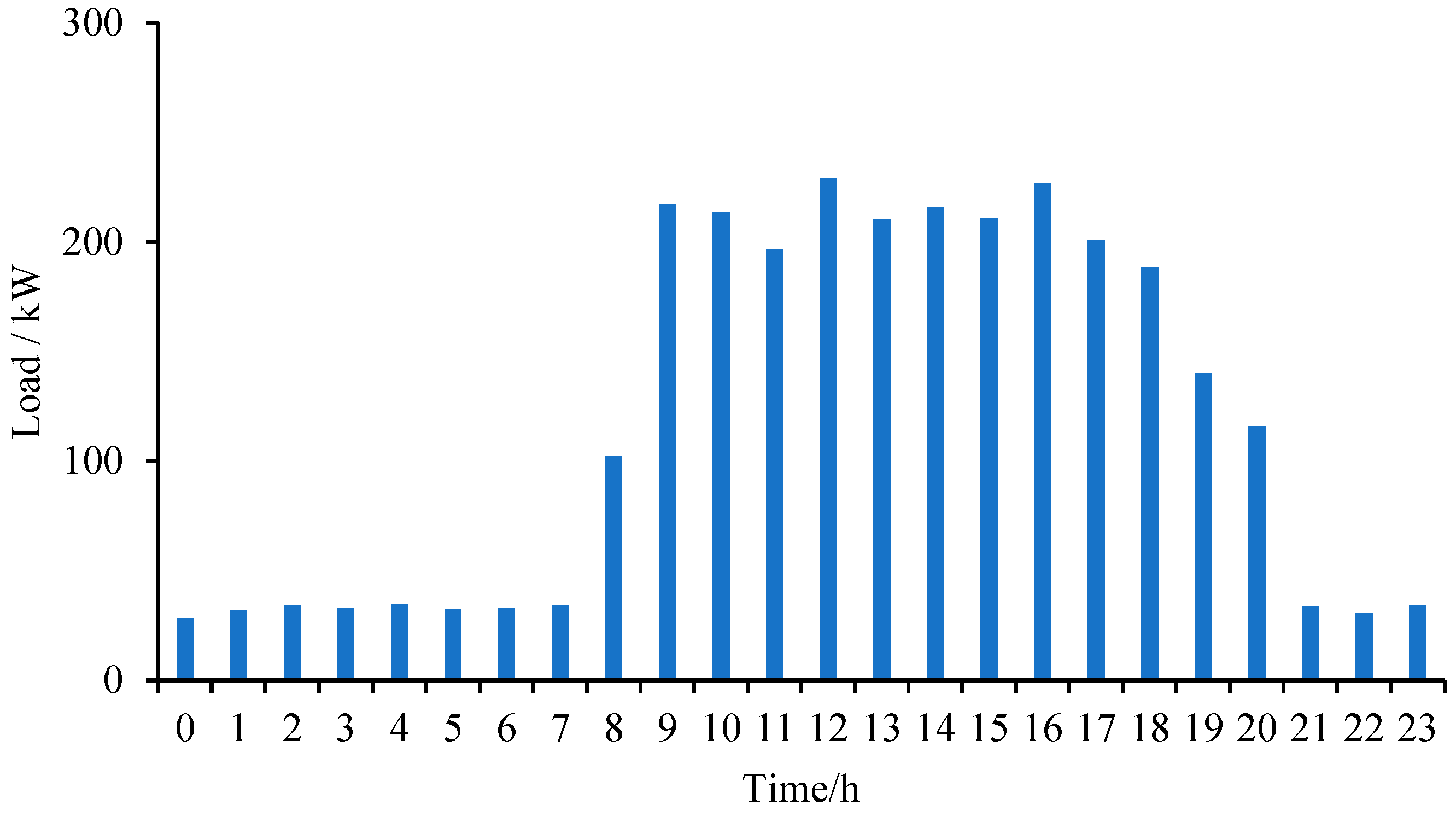

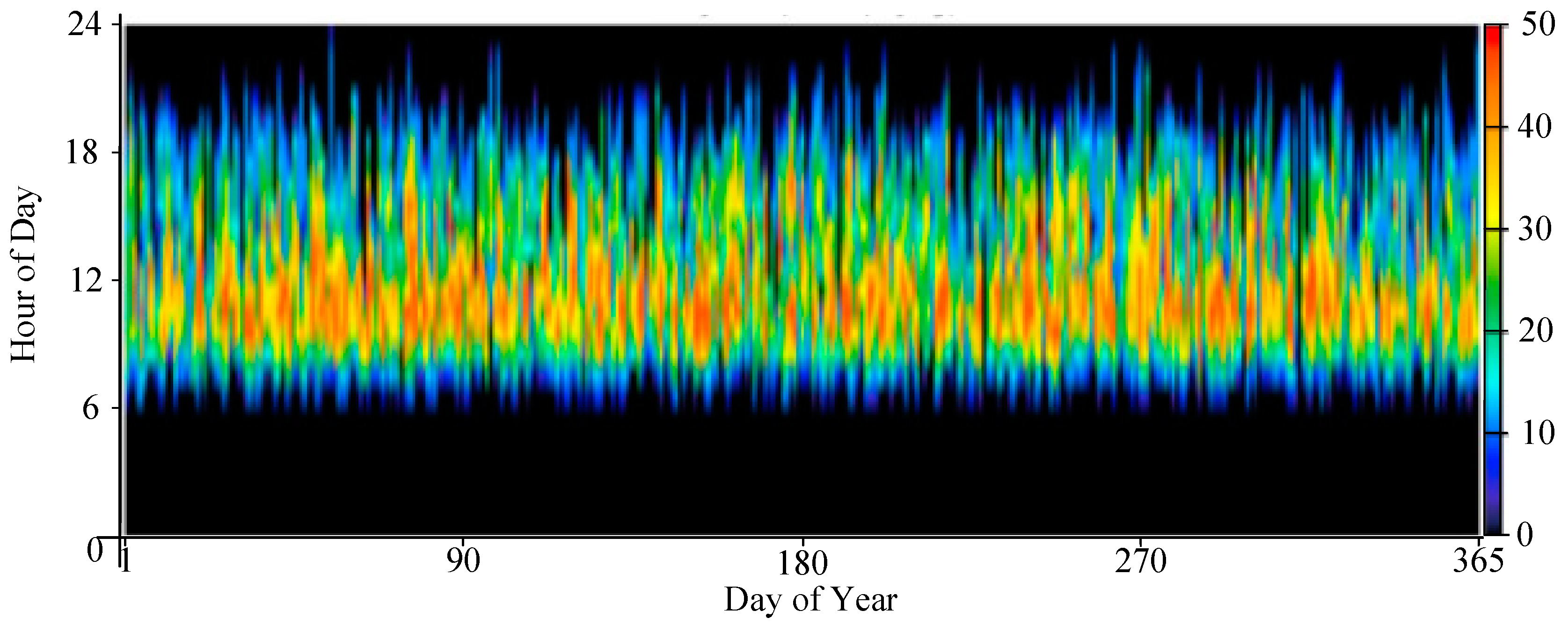

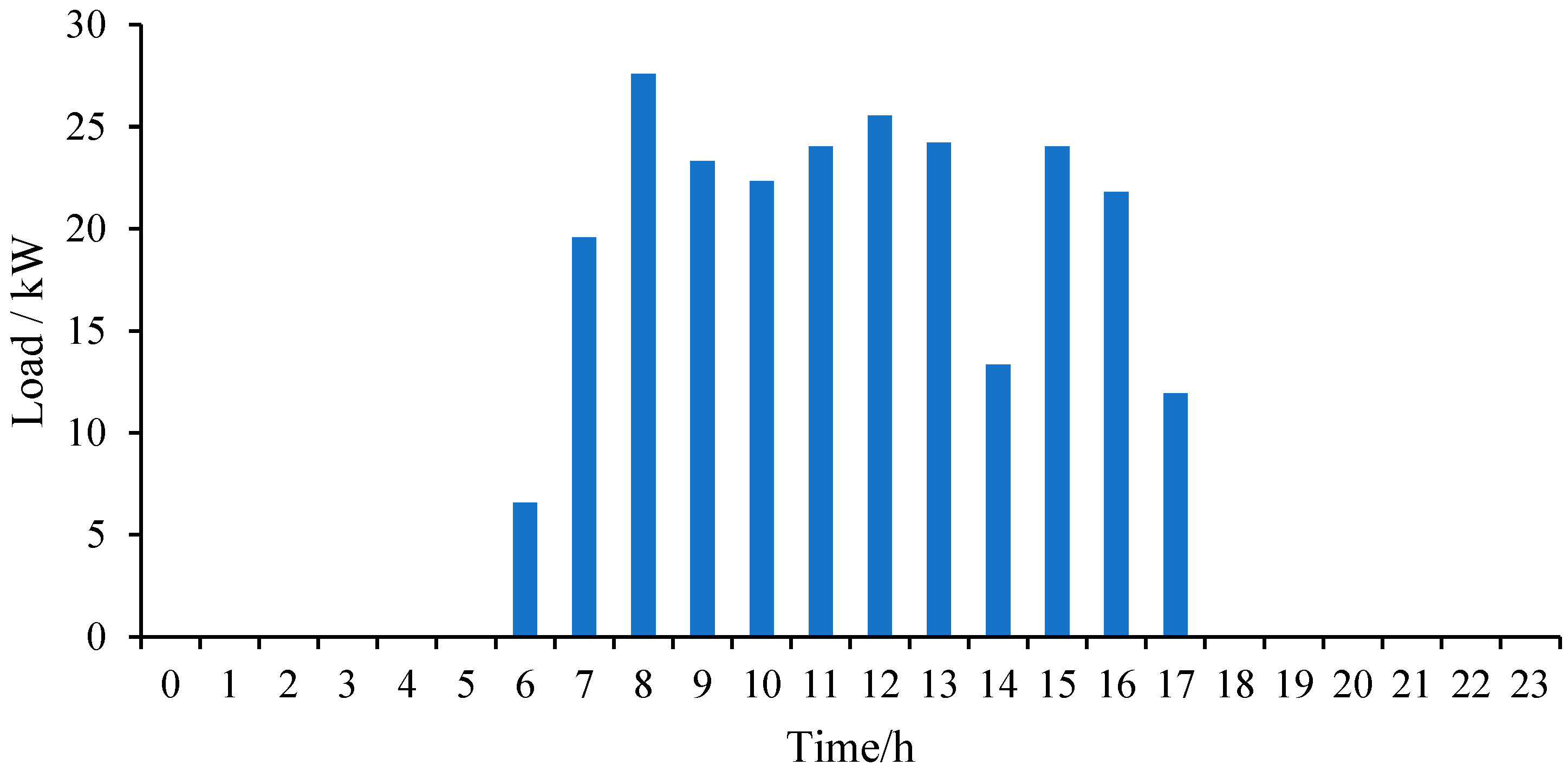

In this paper, we use HOMER software to carry out multi-scenario collaborative planning for grid-connected PV-storage microgrids with EVs. Specifically, we build a multi-scenario optimization model considering both the economic and cleanliness performance of EV-connected microgrids. Based on HOMER software, we build multi-type EV charging load and consider the stochasticity of multi-type EV charging load. The performance is quantified using indices such as NPC, LCOE, and carbon dioxide emission under multiple scenarios. Extensive case studies on a business park in Wuhan, China, are conducted to compare and discuss the planning performance under multiple scenarios, as well as sensitivity analysis with specific cases.

The remainder of this paper is structured as follows.

Section 2 presents the modelling of each component of the grid-connected PV-storage microgrid based on HOMER.

Section 3 presents the multi-scenario collaborative planning model.

Section 4 conducts an extensive case analysis based on a business park in China.

Section 5 concludes this paper.

5. Conclusions

This paper uses HOMER software to carry out the collaborative planning of a PV-storage microgrid with EVs. Multiple scenarios comprising different performances, e.g., economic and cleanliness performance of the microgrid, are incorporated into the collaborative planning. A case study on a business park in Wuhan, China, is implemented to compare and analyze the optimal PV-storage configuration of the microgrid. The economic and cleanliness performance under different scenarios are discussed, and sensitivity analysis is conducted. Through case studies, the following conclusions can be drawn.

1) Based on the proposed economic and cleanliness indices, the optimal planning scheme of grid-connected PV-storage microgrids under three different scenarios is obtained. The comparison of the planning results shows that, when only the economic index is considered (Scenario I), the configured microgrid contains a lower percentage of renewable energy and is less clean, but shows the best economic performance. When only the cleanliness index is considered (Scenario II), the economic performance of the microgrid is poor, and the LCOE reaches 1.893 Yuan/kWh, which is 28.69% higher than the LCOE in Scenario I, but the cleanliness index is the highest. When both the economic and cleanliness indices are considered (Scenario III), the obtained optimal planning scheme balances the economic and cleanliness performance.

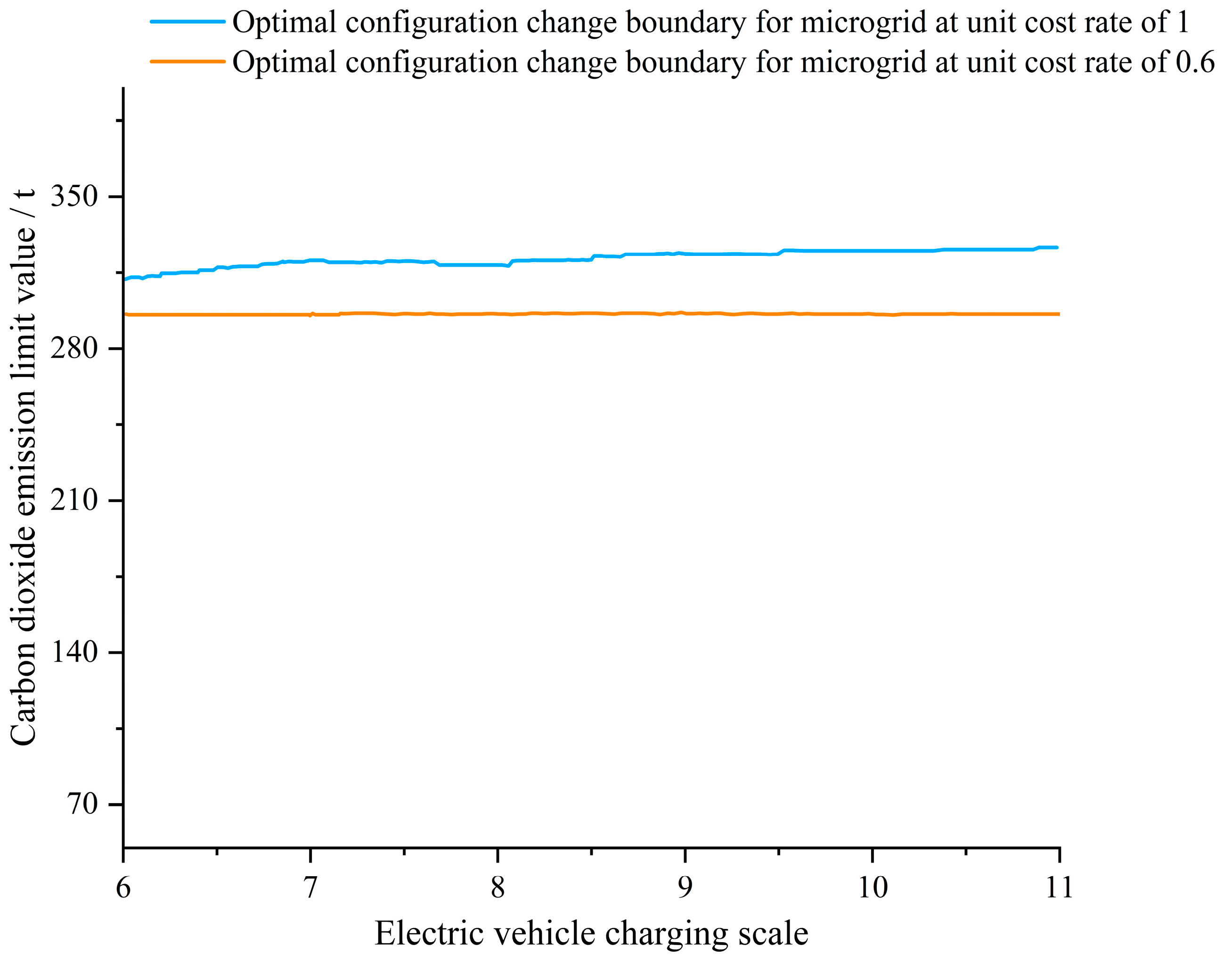

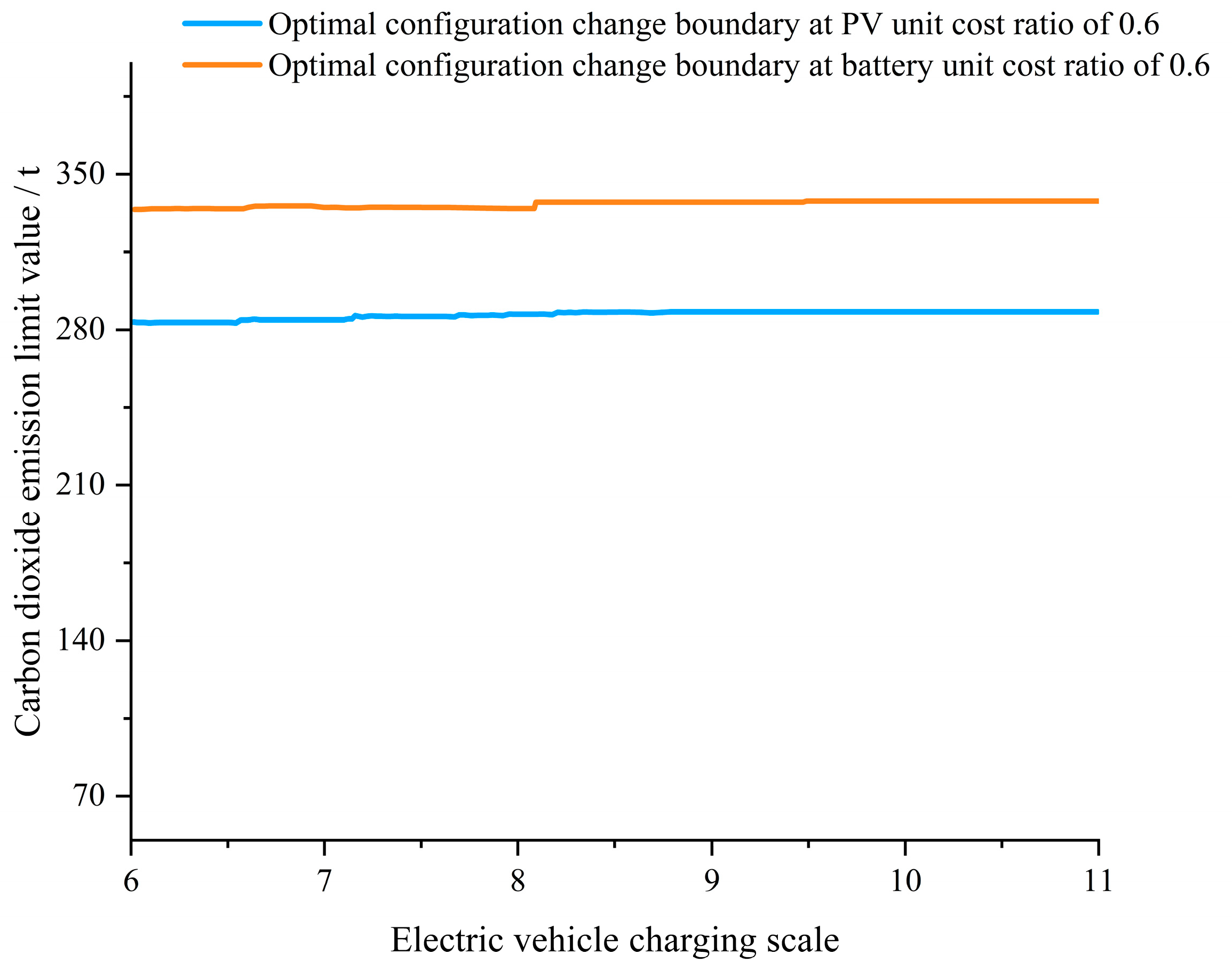

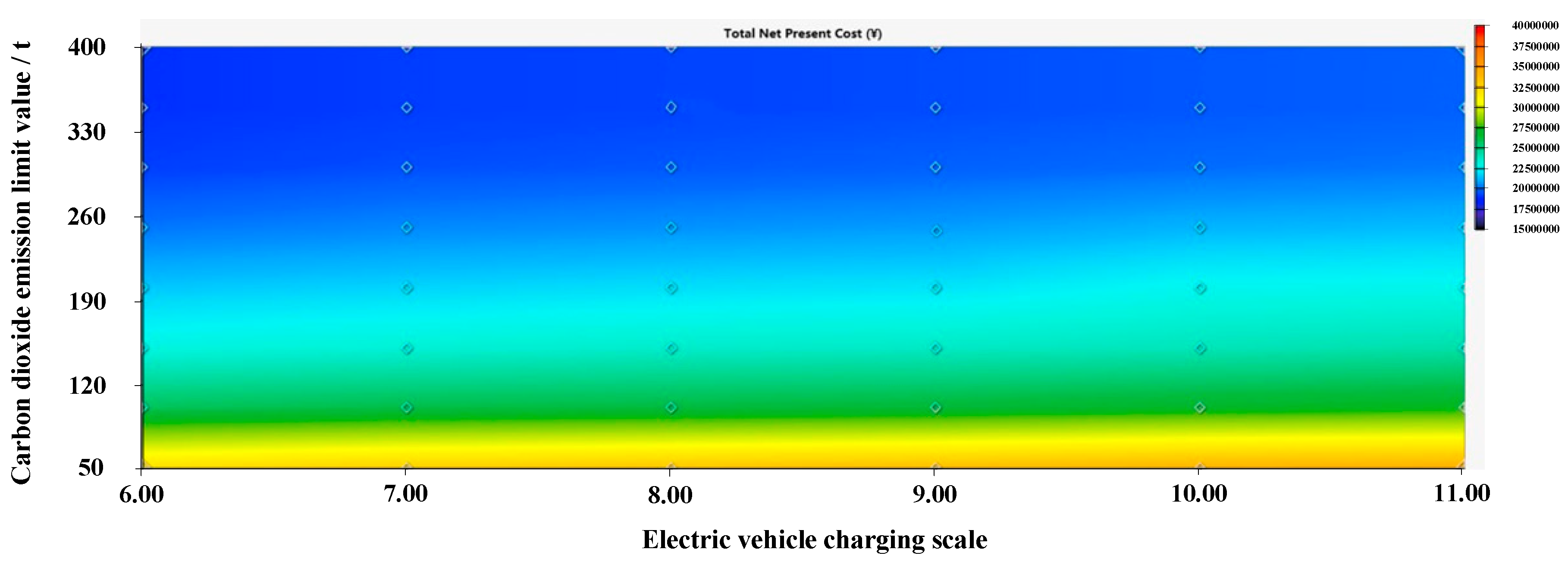

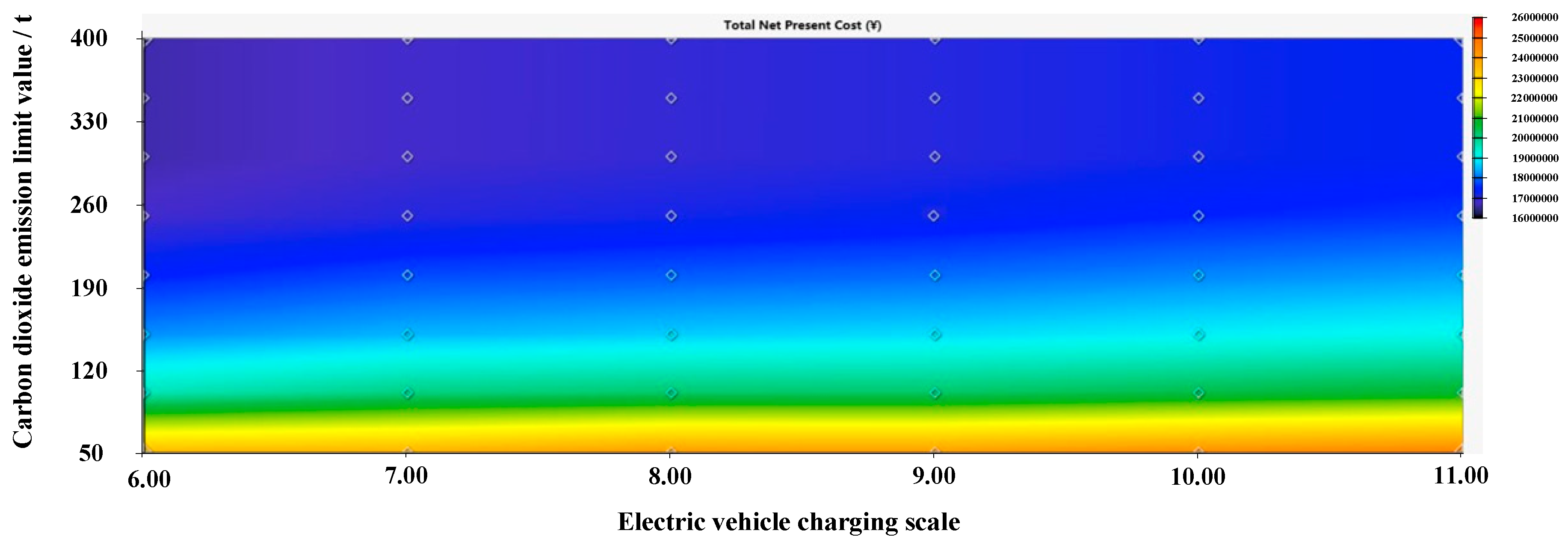

2) Sensitivity analysis demonstrates that, the NPC of the microgrid is jointly determined by the unit investment of equipment, EV charging demand, and carbon emission limits. The NPC gradually increases as the EV charging demand increases and the allowed carbon dioxide emission limits decrease. As the EV charging demand increases, the energy storage capacity required in the microgrid gradually increases, while the carbon dioxide emission limit is negatively correlated with the energy storage capacity demand. In addition, the unit investment cost of PV and battery modules can significantly affect the optimal configuration of the microgrid. A lower unit investment cost of battery energy storage leads to a larger energy storage capacity in the planning schemes, while a lower unit investment cost of PV modules results in lower demand for energy storage in microgrids. The unit investment cost of PV module units has a greater impact on the optimal system configuration than the cost of batteries. The optimal planning scheme of the microgrid under 60% unit investment cost is stable and less affected by EV charging scale, while the optimal planning scheme of the microgrid under unit investment cost is more affected by EV charging scale. The increase in the scale of EV charging at unit investment cost will increase the reliance of the microgrid on energy storage.