1. Introduction

The ability of vortex-induced vibration (VIV) to increase the strength of vortices shed through the vibration (e.g. see [

1,

2,

3]) could promote the turbulence generated by flexible protruding surface. Vortex shedding (typically Kármán vortex) happens when flow past a bluff body. Under condition where the structure is rigid enough (high stiffness) to resist the different pressure distribution on the structure caused by the unsymmetrical vortices, it experiences little to negligible motion (oscillation or vibration as their meaning are interchangeable in this context). As is the same with rigid protruding surface, some portion of the oncoming fluid loses kinetic energy as it meets the rigid protruding surface. Given a flexible body with low Young modulus properties and a geometry with low second moment of area, the bending stiffness will inherently be lower. Therefore, smaller fluid force is needed to drive the vibration in order for the VIV to happen.

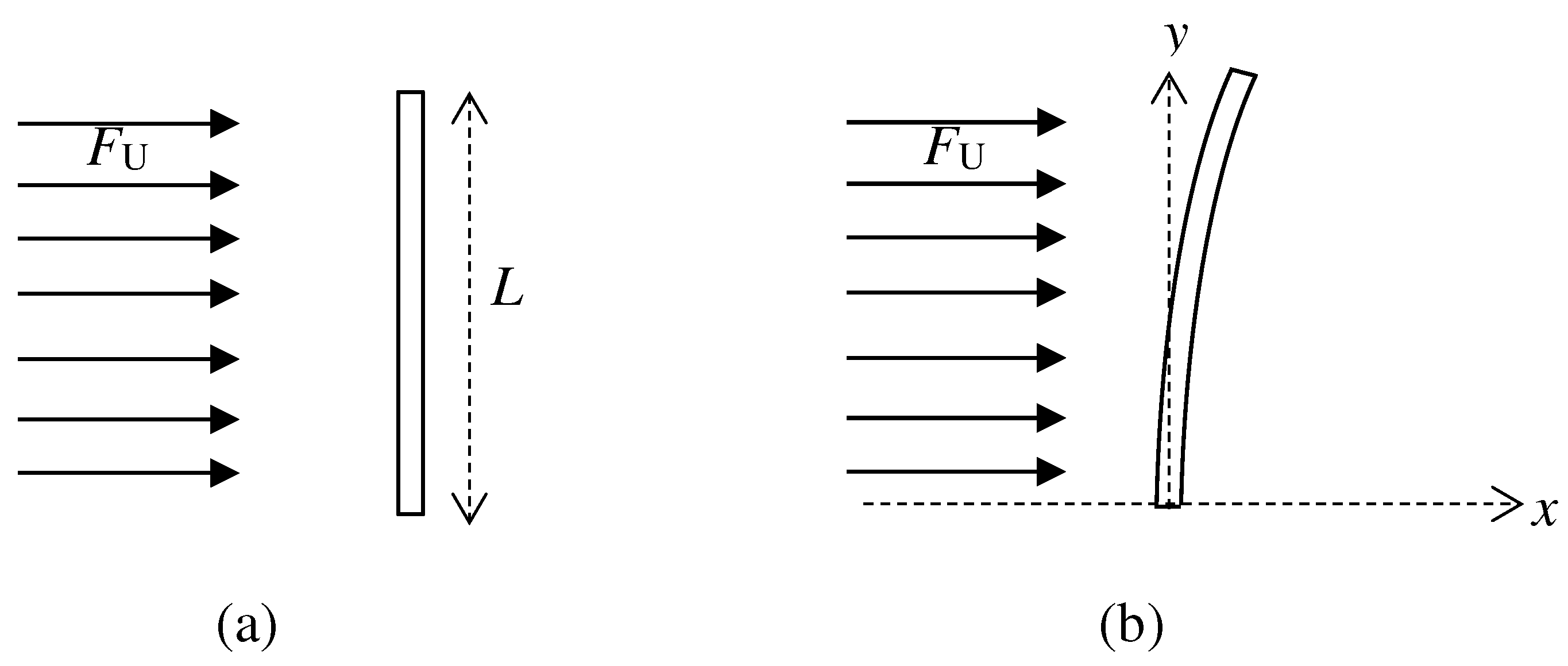

The main component that determines the flexibility or elasticity of the flexible cylinder is the structural stiffness, as shown in

Figure 1. Stiffness relies on material properties and geometry. Therefore, it is the combination of the material’s Young’s modulus,

E and the element’s second moment of inertia,

I.

Under general situations, there are two types of vortex shedding that can affect the oscillation mode of the VIV and one of which is perhaps more commonly known than the other – the Kármán vortex shedding. The Kármán vortex street consists of the alternately shed vortices due to the asymmetric vortex shedding behaviour. It is the asymmetric vortex shedding behaviour that alters the pressure distribution on the surface of each side of the cylinder, thus, leading to the vibration of the cylinder in transverse direction to the flow. This type of vibration is also widely known as cross-flow motion. The second type of vortex shedding is the symmetric vortex shedding. As the name suggests, it consists of a pair of symmetrical vortices when shed in one cycle. The vibration mode of this shedding is in-line or parallel to the flow, hence the name of in-line VIV. Under certain conditions, in-line VIV accompanied by symmetric vortex shedding may occur at lower flow velocities than the Kármán vortex shedding [

4]. Another type of shedding that would happen in addition to either the Kármán vortex shedding or symmetric vortex shedding, is the tip vortex shedding. It happens whenever the free end of the cylinder is exposed to the flow. These tip vortices are generally shed at a frequency one-third the Kármán vortex shedding and may cause large amplitude vibrations.

The back and forth motion, which are lift and drag, is due to vortex shedding at which the vortex shedding frequency,

fs was close to the cylinder natural frequency,

fn at the velocity. The Strouhal number,

St is the frequency of the excitation force in the lift direction whereas the frequency of the excitation force in the drag direction is normally two times the lift direction. The lift force can be explained as a group of vortices shed to one side of the cylinder once per cycle and the other side. The lift force, which appears when the vortex shedding starts to occur, causes the cross-flow motion (perpendicular to the fluid flow direction). Similarly, the drag force appears as a result of vortex shedding but with all vortices shed downstream. In-line motion (in the same direction as the fluid flow) of the cylinder is caused by drag force. Since all the vortices are shed downstream of the cylinder in the drag direction, the drag force associated with vortex shedding occurs at twice the frequency of the lift force, as explained by [

5].

Higher amplitudes of vibration in cross-flow direction have been documented by various experimental results in [

5,

6]. When the amplitude reaches its maximum, lock-in is said to happen. Lock-in occurs when the natural frequency of the structure,

fn is in proximity with the vortex shedding,

fv, or in mathematical expression,

= 1. Both frequencies synchronise and large amplitude vortex induced structural vibration can occur. The vortices in lock-in condition can pack a colossal amount of energy. Besides the increase in vortex strength, consequences of lock-in also increase correlation length, in-line drag force, and lock-in bandwidth; all of which result in the increase of maximum amplitude. The lock-in bandwith was found to increase with increasing response amplitude [

7]. It is easy to see that the lower mass ratio cylinders, require lesser energy to make vibration of the cylinder because it is lighter compared to higher mass ratio cylinders. Thus, it is able to achieve the maximum amplitude (lock-in) more effortlessly at a wider range of reduced velocity, as opposed to the higher mass ratio cylinders.

The wake structure differs according to below and above the critical aspect ratio. The

AR of the cylinder is defined by its length over diameter ratio,

AR =

L/

D. From the various studies by several authors, the value of critical aspect ratio seems to be sensitive to experimental conditions, especially the relative thickness of the boundary layer [

8,

9]. The critical aspect ratio varied from

AR = 1-7 in many literatures, which is a wide range. When a cylinder at a very low

AR is immersed in an atmospheric boundary layer, the vortex formation length, the width of the near wake and the value of Strouhal number at mid-height are reduced, comparable to the case of small relative thickness of the boundary layer [

10,

11]. Liu et al. [

12] supported that a two-dimensional region exists when the

AR is greater than the critical aspect ratio but the area of the two-dimensional region decreases when the

Re increases. It should however be noted that the range of critical aspect ratio is only loosely defined based on the observation of the wake structure. It can be seen that the critical aspect ratio is sensitive and scales with the boundary layer thickness and

Re because the

AR has to be large enough in order to sustain the two-dimensional region. A lower

AR or

AR lower than the critical aspect ratio that is put in a higher

Re and a thicker boundary layer signify that the region of free end effects will engulf the whole span of the cylinder, supressing the two-dimensional region.

Tip vortices are known to have more turbulent energy than the regular Kármán vortices. The turbulence intensity has also been reported to increase considerably at the free end of the cylinder. In the recent work of [

13], they demonstrated that the streamwise turbulence intensity (

u’/U) and wall-normal turbulence intensity (

w’/U) are indeed higher at the free end and within the recirculation region on the wake centreline (

y/

D = 0). On the other hand, Park and Lee [

14] also showed in their results, that the turbulent kinetic energy is at its highest level at the free end for cylinder of

AR = 6 at

ReD = 7,500. Rostamy

et al. [

13] noticed that the elevated turbulence intensity extends into the downwash region. One noticeable distinct pattern that separates the cylinder of

AR = 3 from the rest is that the location of the highest wall-normal turbulence intensity moves downward and further away to a distance of

x/

D = 2. The location of the highest wall-normal turbulence intensity appears to remain at

x/

D < 2 as the

AR of the cylinder increases.

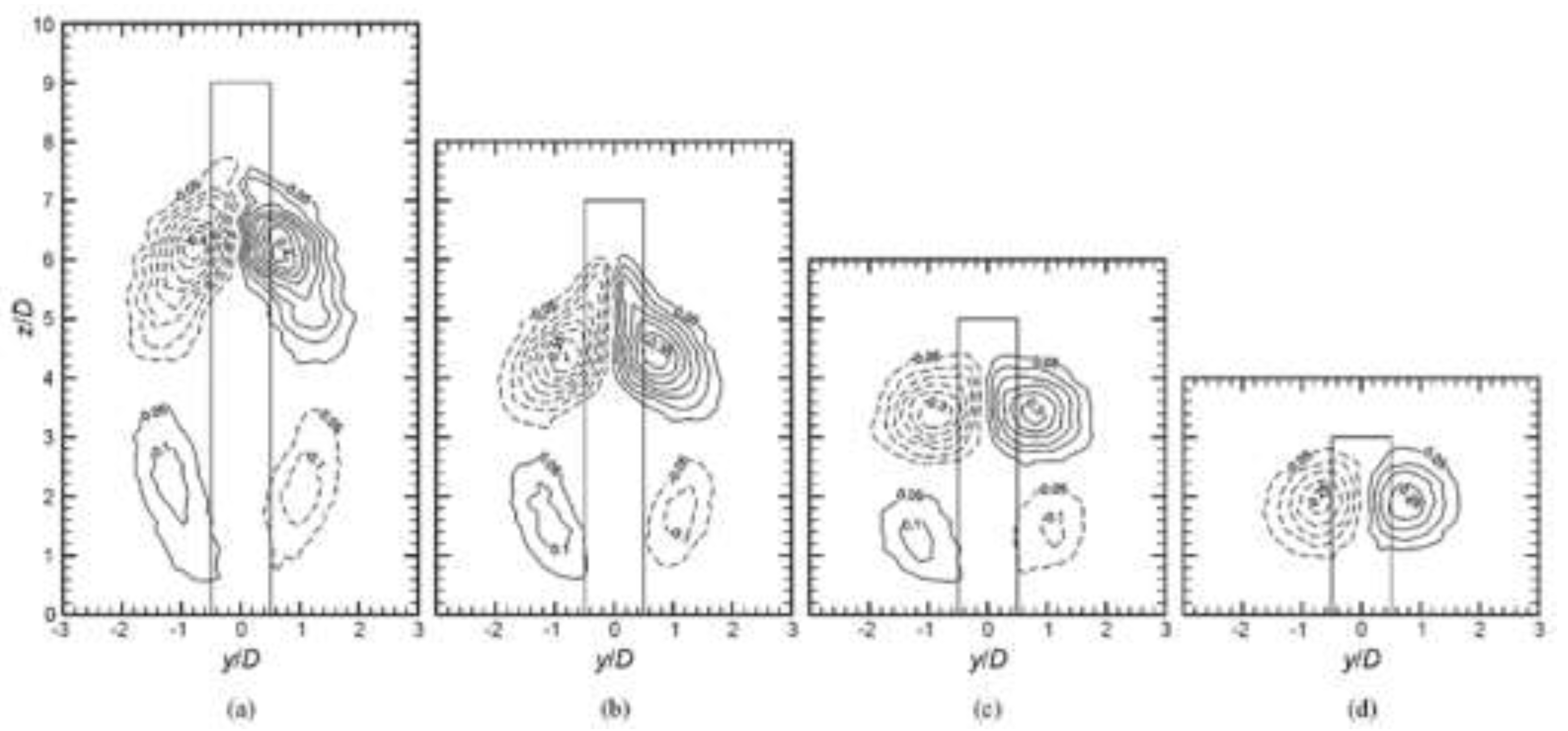

Similarly, the Reynolds shear stress (-

) are also reported to be at a higher value in the experimental work from [

13]. They noticed a region of positive shear stress and a region of negative shear stress at an evaluated value near the wake region. However, the region of positive shear stress is absent below the free end, leaving only the region of negative shear stress for cylinder of

AR = 3. On the contrary, the positive shear stress is dominating the region just below the free end for

AR = 9 but slowly decreasing in size and level as the

AR decreases until it disappears at

AR = 3. In their results, the Reynolds shear stress are found be at highest for cylinder of

AR = 9 with the peak at 0.018. However, the Reynolds shear stress decreases as

AR decreases. Besides, according to

Figure 2, [

8] also showed in their experimental results that the vorticity contour is immensely elevated near the free end. Thus, the tip vortices can greatly improve the quality of mixing. However, due to the downwash phenomenon that is always present at the free end, the tip vortices are always brought downwards to the ground plane. Therefore, its influence could only impinge on fluid in the very near wake. The mean velocity, turbulence intensity and Reynolds shear stress distributions are similar for cylinders above the critical aspect ratio but dissimilar for cylinders below the critical aspect ratio [

15].

The Reynolds normal (

) and shear (

) stress of a flexible cylinder has also been reported by [

16] to increase significantly compared to that of rigid cylinder. They first investigated the Reynolds shear stress of a rigid cylinder and compared with the results from [

17]. The periodic part of Reynolds normal and shear stress of both authors are a near match though the experiment conducted by [

17] was much higher at

Re = 140,000. The peak total Reynolds stress is however much higher for the higher

Re experiments. Govardhan and Williamson [

16] therefore concluded that the periodic part of Reynolds stress, which is generated from the repeatable large-scale coherent structures, holds true over the range of

Re = 3,900 to 140,000. As the other component of total Reynolds stress – random part of Reynolds stress, gain strength from the increasing strength of the Kelvin-Helmholtz instability of the separating shear layer as

Re increases, the total Reynolds stress value increases. They also compared the Reynolds normal and shear stress value of vibrating cylinder to that of rigid cylinder and found that the largest increase in periodic part of Reynolds stress (

)

max increases by 485%, (

)

max increases by 100% and (

)

max increases by 125% in the lower branch.

It was shown in the previous work [

6,

18,

19] that the flexible cylinders bring significant changes to the turbulence in the near wake – the

x-deflection of the flexible cylinders increases the turbulence wake region, which effectively increase the region of turbulent activities; and the aspects of the structural motion such as oscillating amplitude, oscillating frequency and the oscillating motion are able to enhance the turbulence energy production as demonstrated by the production term (in the kinetic energy budget) and the Reynolds stresses. Despite the remarkable findings, it is unable to confirm which parameter(s) of the structural motion could bring effects to the enhancement of turbulence energy in the near wake. It is therefore, this work mainly investigates the influence of different properties of the flexible cylinders to bridge the gap. As an effort to encourage an organized oscillating motion, material properties such as aluminium and carbon steel with moderately high stiffness and low damping coefficient are employed in this studies. The metal group flexible cylinders are performed at Reynolds number of 2,500 due to the limitation of the highest possible freestream velocity the water tunnel could provide. Apart from that,

AR = 12 and 14 of polymer based EVA flexible cylinders at Reynolds number of 4,000, 6,000 and 8,000 will also be investigated in this work.

2. Materials and Methods

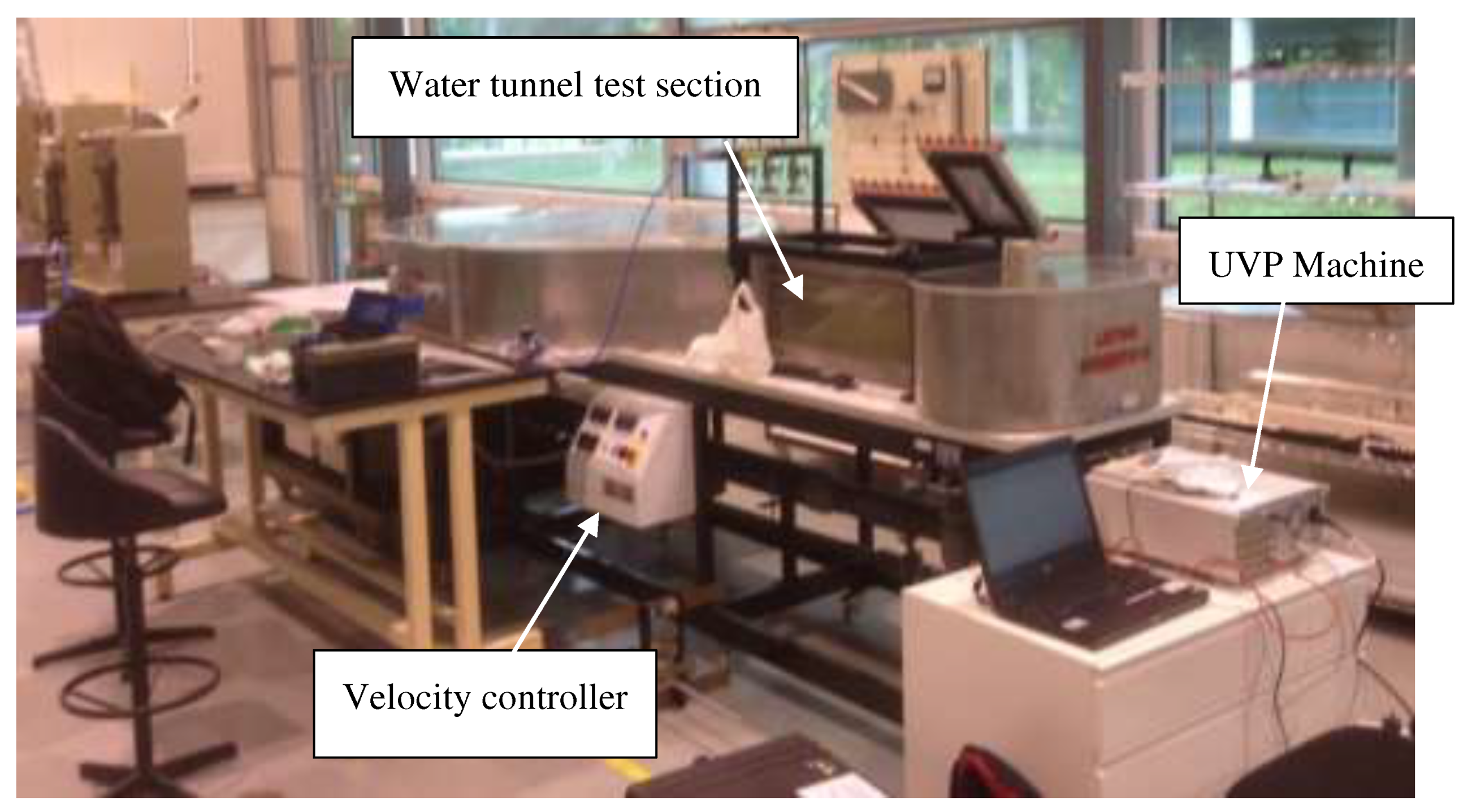

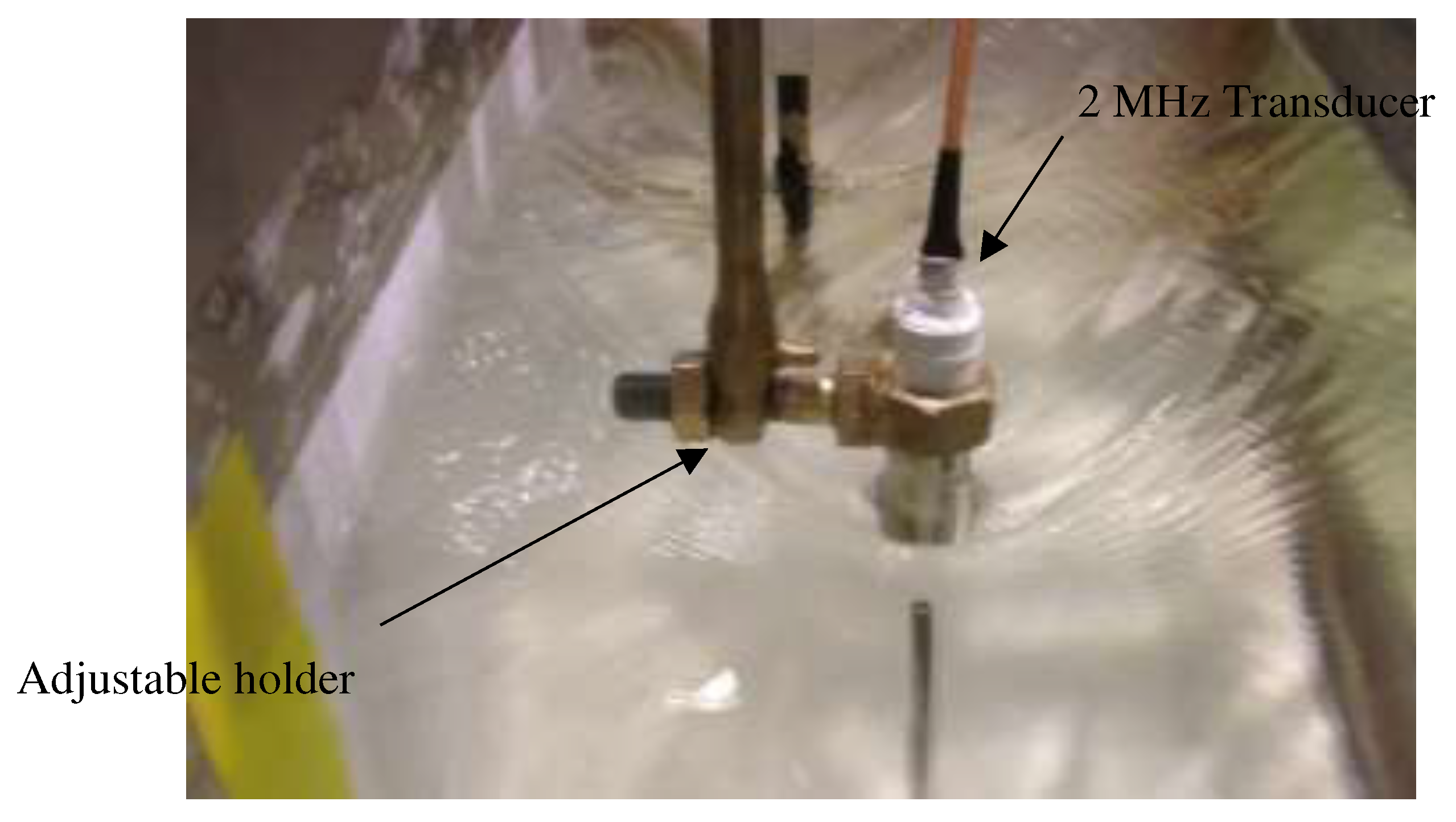

These objectives are achieved by conducting experimentally in an open channel water tunnel, as shown in

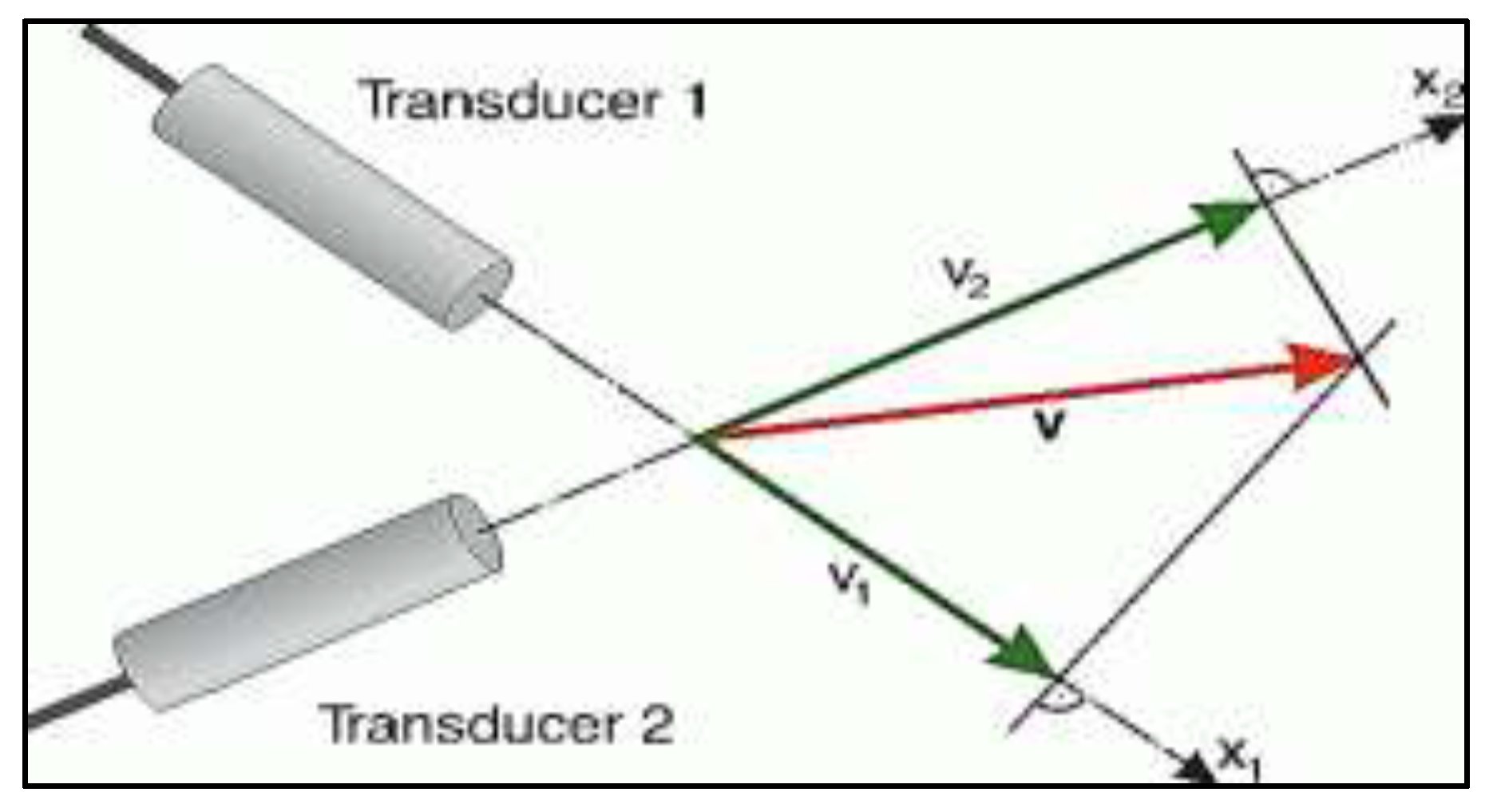

Figure 3. In order to gain insights of the flow behaviour, Ultrasonic Velocity Profiler (UVP), capable of measuring velocity vector as a function of both space and time in an unidimensional Eulerian frame, was used to obtain the velocity vectors. The calibration of the 2 MHz transducer was carried by positioning it at a trajectory angle that has the minimum Doppler angle error possible which is used in speed calculations. As stated by Yokoyama

et al. [

20], at least two transducers are needed in measuring two-dimensional flow and three transducers for three-dimensional flow. This is because each transducer is needed to measure each velocity component at one spatial point in order to form a vector. The vector is therefore obtained from any two non-parallel measured components. As the vector component is an orthogonal projection of a true vector into a measuring line (

Figure 4), therefore, a large projection angle in between the two transducers is encouraged to avoid large inaccuracy in direction estimation. In other words, a two-dimensional flow or three-dimensional flow measurements, unlike the technique of one-dimensional flow measurements, relies solely on the orthogonal composition technique which in turn can only be achieved at their respective intersection points. Further details on the experimental set-up and UVP description can be referred in [

19,

21].

With that in mind, the projection angle between two transducers is orthogonal (90° in between the two transducers) when measuring the

u and

w velocity components behind the finite cylinder. For each of the measurements, 4069 samples were taken at a sampling rate of 100 Hz. Though proven mathematically that the sampling rate must be twice the highest frequency contained in the analogue signal, researchers normally would opt for a sampling rate more than twice the highest frequency contained in the analogue signal if plausible, to be safer, the 100 Hz sampling rate chosen in this experimental work was the highest sampling rate that could be selected after sacrificing the repetition to only 64 pulse. When considering the

St for a cantilever, the

St is approximately 0.14 ~ 0.18 [

8]. Based on the Strouhal number equation,

, selecting the maximum

St, freestream velocity and the minimum diameter give the opportunity in accounting for the maximum vortex shedding frequency available in this work. Taking into consideration, the sampling rate chosen is twice as big than the maximum vortex shedding frequency calculated ~ 40 Hz.

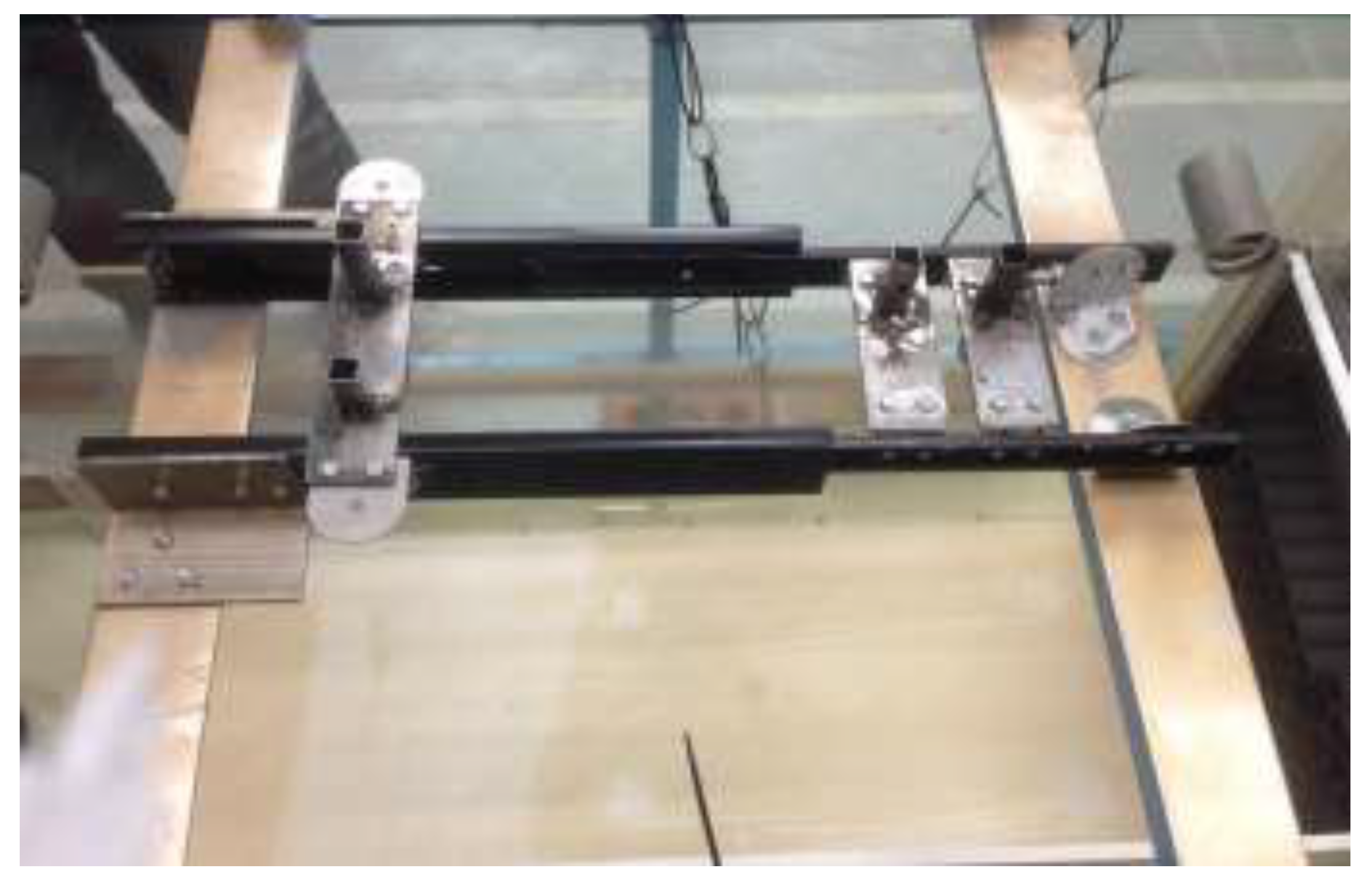

A traverse is important as it guides the UVP accurately. The basic design of traverse can be seen in

Figure 5 and

Figure 6. It can be extended in

x and

z directions. The main body of the traverse was taken from a drawer slides as it can be extended with minimum friction and the extension was perfectly guided so it could travel in a straight line. The extension can be made up to 25 cm long. The extension had a resolution of a ruler, which is 1 mm, as a 50 cm long ruler was fitter on the guiding rail. The drawer slides were made to sit on a steel frame that provide stability to the traverse. All the joints were bolted using hexagonal nuts and bolts to ensure the sturdiness of the structure. In order to account for the ability to move in the

z direction, 4 hollow bars were welded onto the 2 inch flat bars. The UVP transducer was attached to the holder that were moved and guided by the square hollow bar. When the transducer reaches a desired location, the holder was jammed by the bolts so that it would stay in place. The UVP probe emits sound waves in

z direction (top to bottom) and

x-direction (streamwise). They are free to move in

x and

z direction to collect the velocity around the cylinder upstream and downstream.

A set of experiments was performed to investigate the boundary layer and properties of the flow prior to the finite and flexible cylinder experiments. The boundary layer thickness, δ was defined as the point where the local mean velocity was 99% of the freestream velocity while the displacement thickness,

δ* was defined as the boundary layer displacement thickness. The momentum thickness,

δθ on the other hand, was defined as the distance by which the boundary should be displaced to compensate for the reduction in momentum of the flowing fluid on account of boundary layer formation. The shape factor,

Hδ which is the ratio of the displacement thickness over the momentum thickness provides information on the nature of the flow. Tables below show a summary of the boundary layer measurements on the ground plane at different freestream velocity.

x/

D = 0 (350 mm from the leading edge of the flat plate) indicates the location of the cylinder. The

ReL is based on the distance across the leading edge to the location of interest. The specifications of the boundary layer of

U = 0.33 m/s, 0.49 m/s and 0.65 m/s are shown in

Table 1 to

Table 3. The cylinders were partially immersed in the boundary layer (

δ/

H ranged from 0.3 to 0.5) for both rigid and flexible cylinder under all

Re. As previously mentioned,

/

H would greatly alter the critical aspect ratio where the vortex shedding at the free end is suppressed. Therefore, it is with great care in making sure the boundary layer is small enough such that the free end of the cylinder does not submerge in the boundary layer.

To ensure success of the present study, the investigations were conducted in a systematic and organized manner. The tests were divided into two categories: rigid cylinder cantilever and flexible cylinder cantilever. Flow in the lower subcritical Reynolds number regime ~ x10

3 is selected as the regime of interest as it is more compatible in most of the engineering applications. Given the height of the test section is only 20 cm, overall length of the structure to be less than 18 cm were conducted. Firstly, a series of tests was performed on a rigid cantilever in fluid. It served as an insight of flow behaviour influenced by the free end and can later be used to justify the change in flow behaviour caused by flexible cantilevers. Secondly, a series of tests was performed on a flexible cantilever in fluid where it provided a picture of the flow behaviour of the complex problems. The movement of the flexible cantilever was not limited by any means and was intended to vibrate freely as the flow past through it. Two governing parameters, namely Reynolds numbers (based on cylinder diameter), and structural stiffness were varied throughout the tests. The variation of structural stiffness could be achieved by different material selections of different Young Modulus and also the geometry. Since the geometry was fixed in this research, different

AR will be manipulated to achieve different stiffness for the same material. Full details on the finite rigid and flexible cylinders specifications can be found in [

6].

Table 4-5 show the specifications of the models used in the experiments.

The stiffness rating and the deflection is seen to be governed by the Young Modulus, E, second moment of inertia, I, overall length of the cantilever, L, and also the spanwise location of the cantilever, y. It is collectively a function of material properties. In order to vary the Young Modulus, different materials of cantilever cylinder are adopted in this research – aluminium, carbon steel and Ethylene vinyl acetate (EVA). The variation of the geometry can be achieved by changing the length or shape of the object as it affects the second moment of inertia. To increase the flexibility of the cylinders, one could replace the material with high Young Modulus value with a lower Young Modulus value – EVA. Other method is to adopt a very large length to diameter ratio (lower I and longer L) in order to compensate for the materials (aluminium and carbon steel) that have high Young Modulus value.

The behavior of fluctuation quantities can be described by applying the Reynolds decomposition method to the Navier–Stokes equations and after a series of simplifications [

22] the kinetic energy budget which describes the energy of turbulence is formed. Since the kinetic energy budget provides insight on how the turbulence is distributed after being produced from the mean flow, there exists the kinetic energy budget for the mean flow and the kinetic energy budget for the turbulent flow, both of which compliment each other in the process of examining the transfer of turbulence energy. The kinetic energy budget of mean flow is given by:

whilst the kinetic energy budget of turbulent flow is given by the following equation:

The production term is generally positive in the kinetic energy budget of turbulent flow, signifying an energy supply from the mean flow to the turbulent flow. When comparing the Equations (1) and (2), it can be understood that the transfer of energy between the mean and turbulent flow can only be done through the fifth term on the RHS, and therefore is often labelled as the production term. The kinetic energy budget equations are useful in ‘visualizing’ the nature of turbulence and are especially useful in examining the level of turbulence energy produced by the rigid and flexible cylinders through evaluating the production term. In the current work, attention is given to the production term to understand the distribution of the energy by the rigid and flexible cylinders.

In order to examine the strength of the turbulence, the Reynolds averaged statistics, which is important as it gives insight on the transport of momentum within the flow because velocity fluctuations give turbulent flow extra kinetic energy and hence generate extra momentum transfer. Reynolds stress is used to account for turbulent fluctuations in fluid momentum. Hence, the fluctuating components of the instantaneous flow was determined from each velocity field in the

x–

z plane. Since the Reynolds stress is the component of the total stress tensor in a fluid obtained from the averaging operation over the Navier-Stokes equations, the Reynolds averaged Navier-Stokes equation can be written as:

where

is the Reynolds stress tensor. The instantaneous and mean velocity can be extracted directly from the Met-Flow Software Version 3 except the fluctuation velocity, so the fluctuation velocities of 4096 data points at one location were calculated by subtracting the mean from instantaneous. The u component fluctuation velocities were then multiplied by each other before averaging was performed in order to calculate the normal stress,

contributed by u component. The same procedure is valid for w component. To calculate the Reynolds shear stress,

, the u fluctuation velocities were multiplied with the w component before averaging. The uncertainty analysis has been discussed in [

19].

As this project is fully based on experimental work, the results have to be assured to be of high integrity. The uncertainty analysis is performed to give a quantitative estimation of the reliability of the measured value generated from a series of experiments. The uncertainty estimation for the different parameters are calculated based on the Coleman and Steele [

23] approach at a 90 % confidence level.

Figure 1.

(a) A rigid cantilever cylinder subject to fluid force, FU (b) A flexible cantilever cylinder subject to fluid force, FU.

Figure 1.

(a) A rigid cantilever cylinder subject to fluid force, FU (b) A flexible cantilever cylinder subject to fluid force, FU.

Figure 2.

The non-dimensional, time-averaged, streamwise vorticity field at

x/D = 6 (a)

AR = 9, (b)

AR = 7, (c)

AR = 5 and (d)

AR = 3. Vorticity contour increment is 0.05 and minimum vorticity contour is ± 0.05, solid lines represent positive counter-clockwise [

15].

Figure 2.

The non-dimensional, time-averaged, streamwise vorticity field at

x/D = 6 (a)

AR = 9, (b)

AR = 7, (c)

AR = 5 and (d)

AR = 3. Vorticity contour increment is 0.05 and minimum vorticity contour is ± 0.05, solid lines represent positive counter-clockwise [

15].

Figure 3.

The water tunnel with the test section made of Plexiglas for visualization purpose.

Figure 3.

The water tunnel with the test section made of Plexiglas for visualization purpose.

Figure 4.

Vector orthogonal composition technique.

Figure 4.

Vector orthogonal composition technique.

Figure 5.

UVP traverse system.

Figure 5.

UVP traverse system.

Figure 6.

UVP traverse and transducer.

Figure 6.

UVP traverse and transducer.

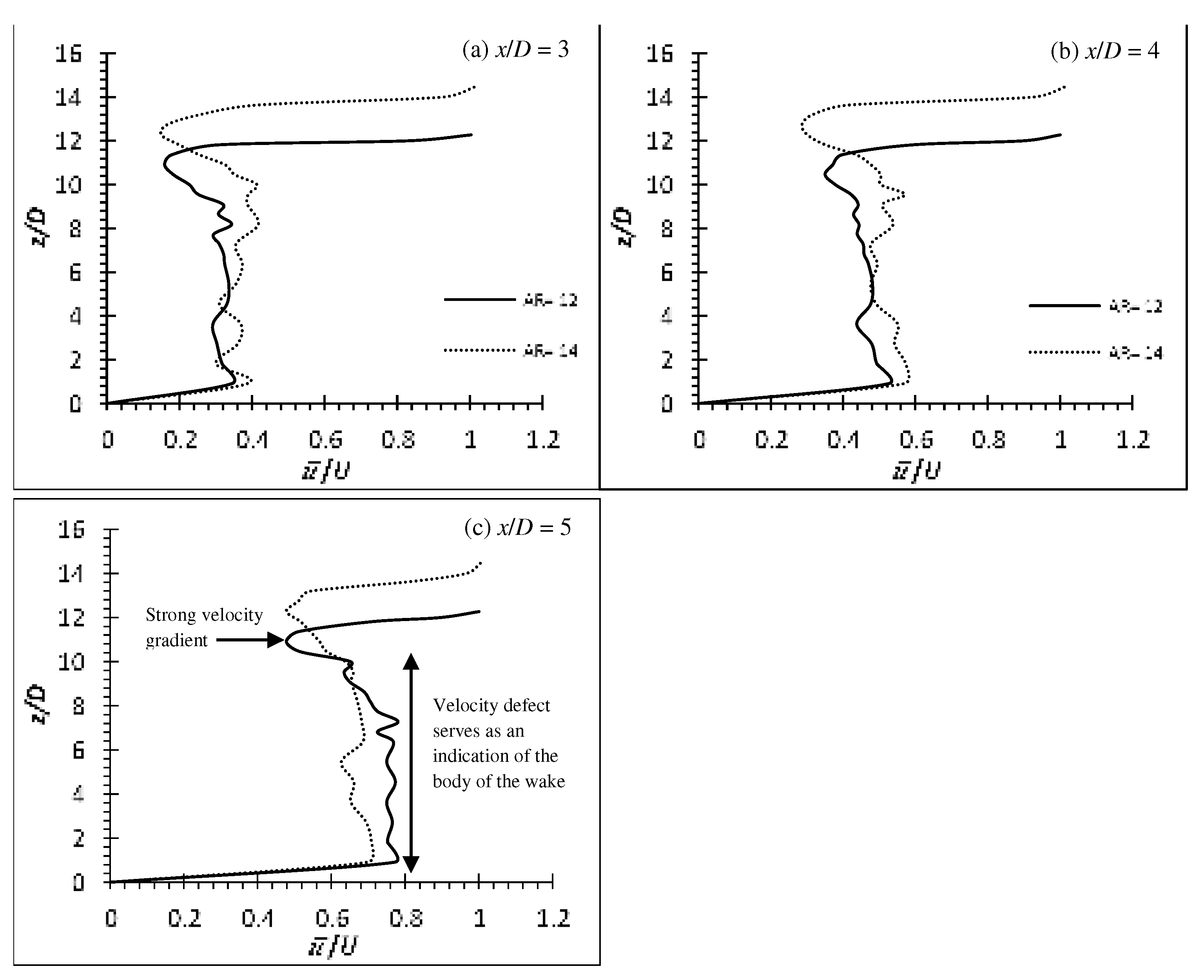

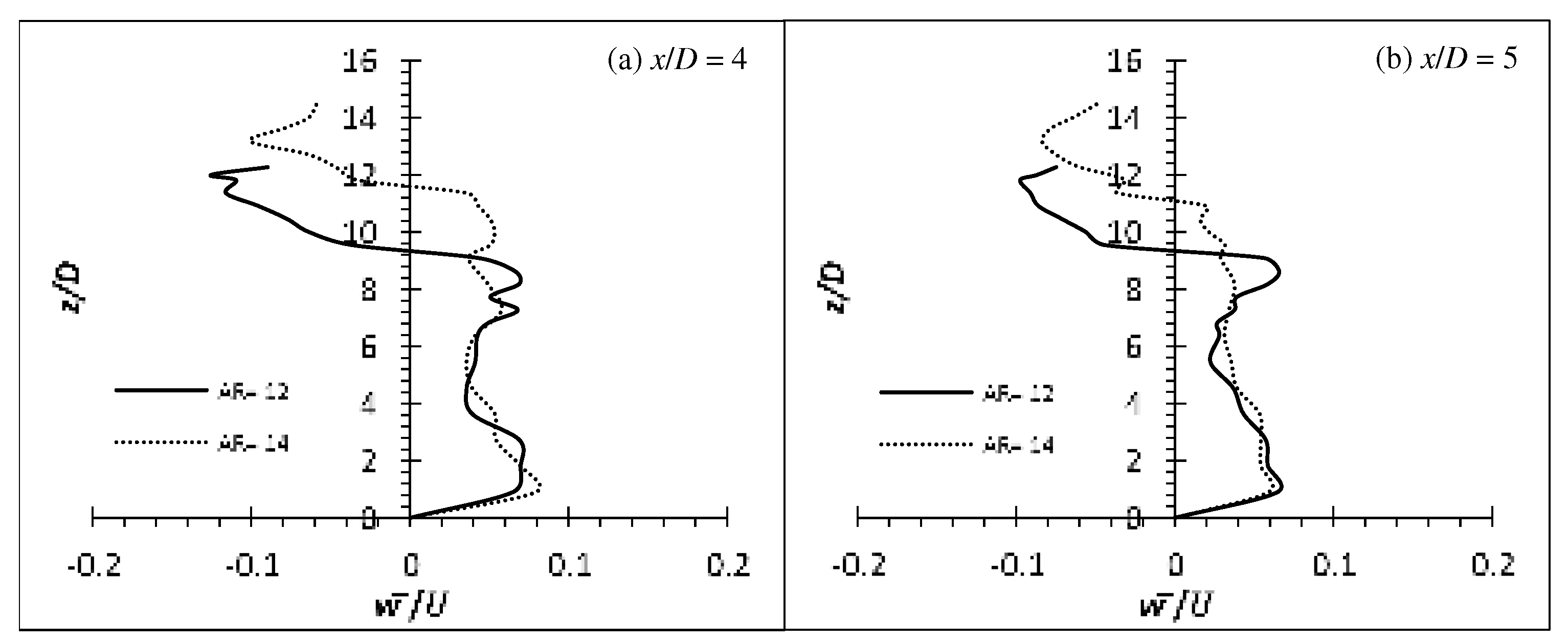

Figure 7.

Time-average streamwise velocity profile of flexible finite cylinder of AR = 12 and 14 at wake centreline (y/D = 0) for Re = 4,000.

Figure 7.

Time-average streamwise velocity profile of flexible finite cylinder of AR = 12 and 14 at wake centreline (y/D = 0) for Re = 4,000.

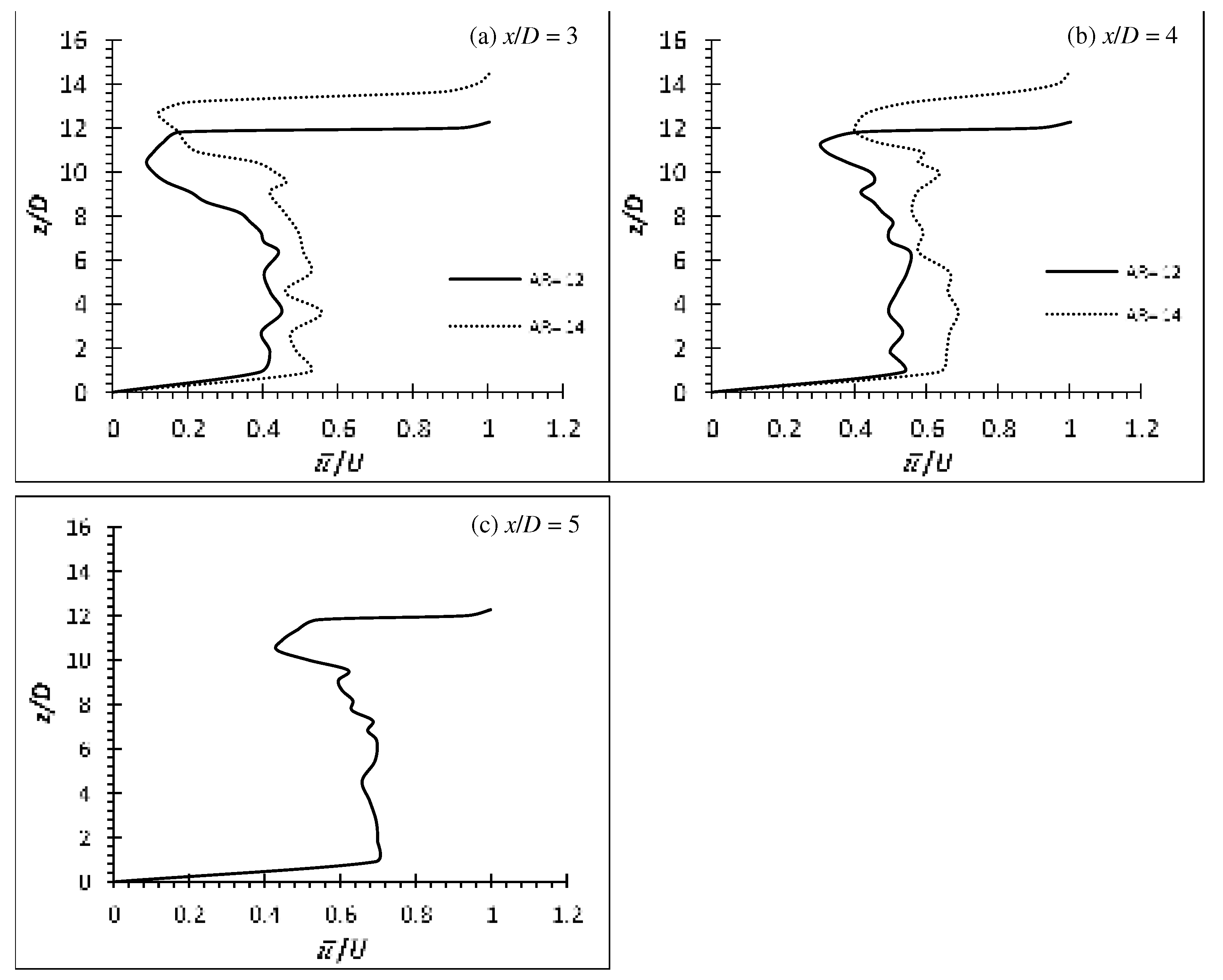

Figure 8.

Time-average streamwise velocity profile of flexible finite cylinder of AR = 12 and 14 at wake centreline (y/D = 0) for Re = 6,000.

Figure 8.

Time-average streamwise velocity profile of flexible finite cylinder of AR = 12 and 14 at wake centreline (y/D = 0) for Re = 6,000.

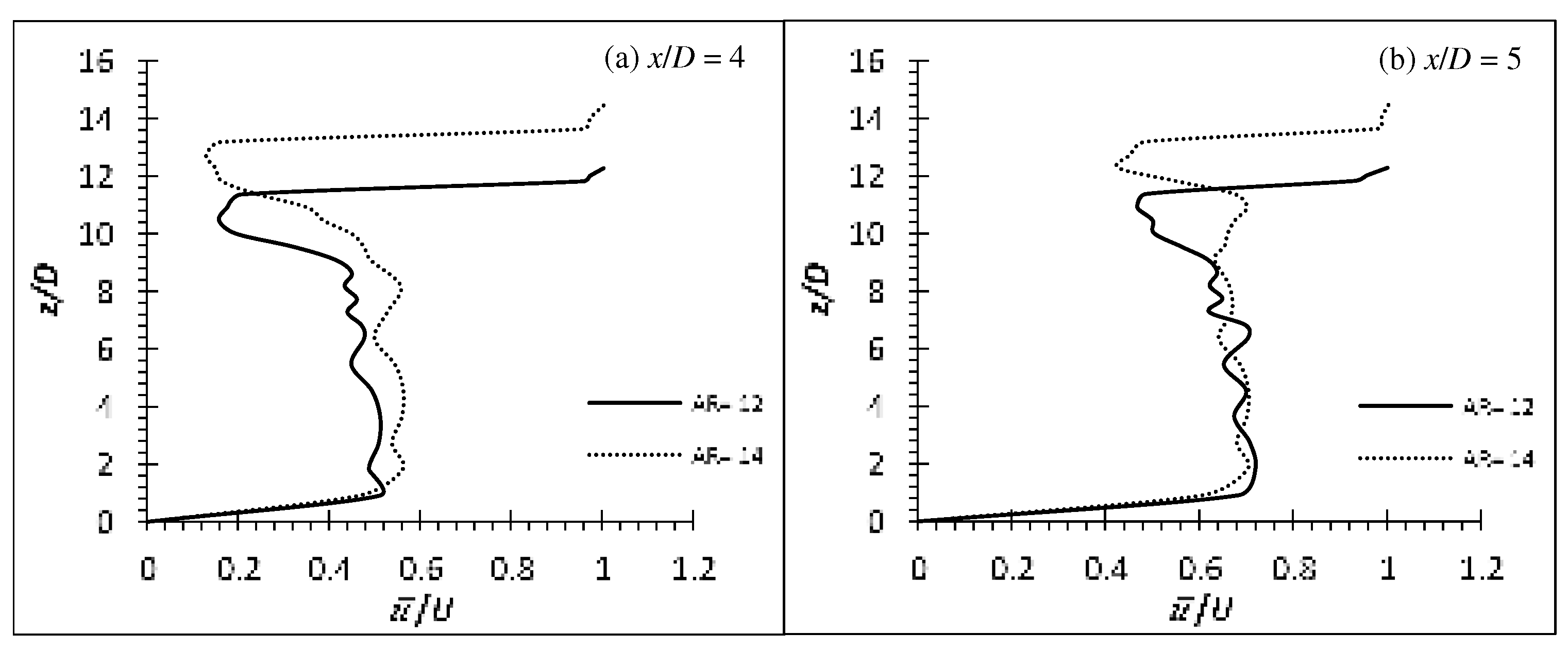

Figure 9.

Time-average streamwise velocity profile of flexible finite cylinder of AR = 12 and 14 at wake centreline (y/D = 0) for Re = 8,000.

Figure 9.

Time-average streamwise velocity profile of flexible finite cylinder of AR = 12 and 14 at wake centreline (y/D = 0) for Re = 8,000.

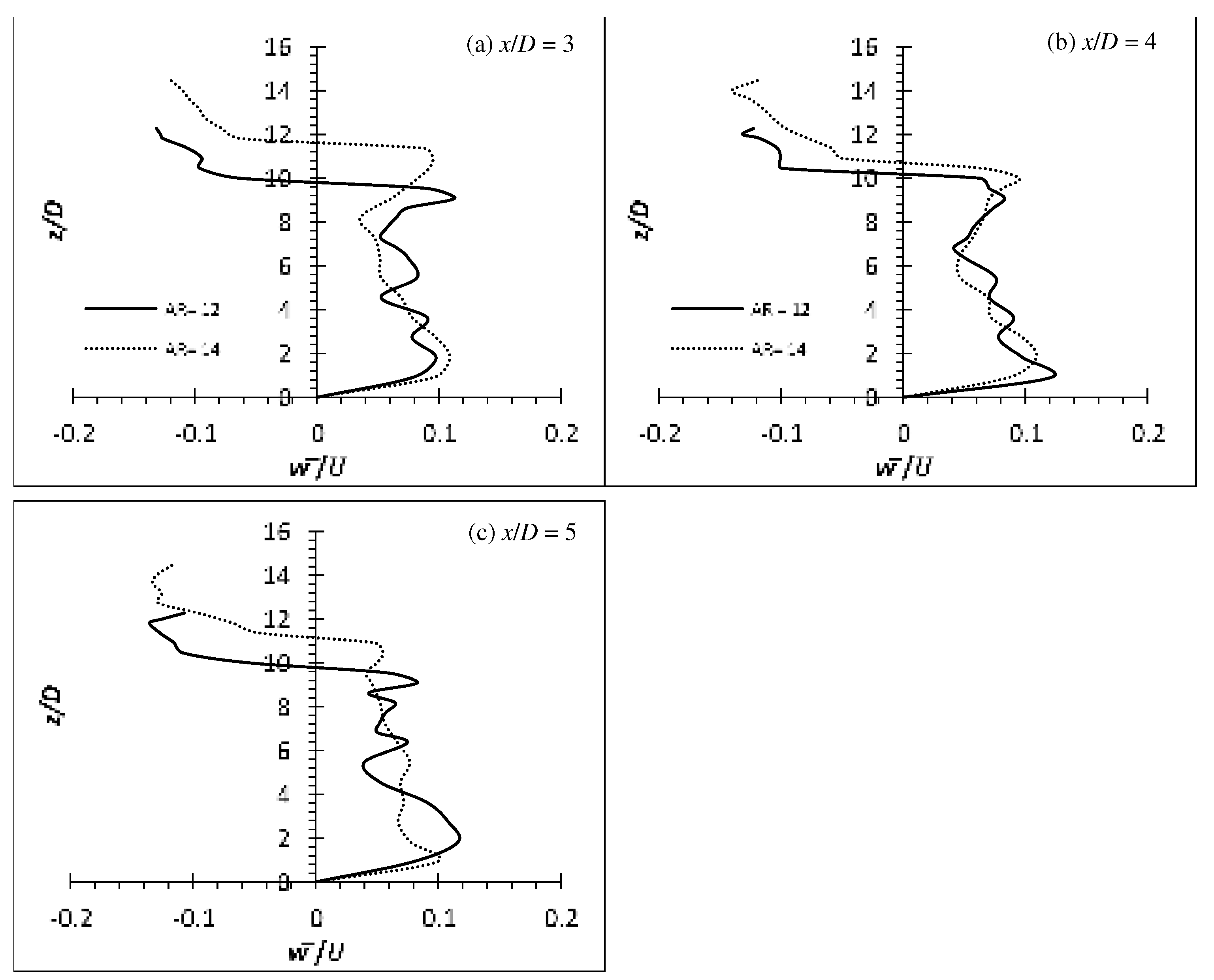

Figure 10.

Time-average wall-normal velocity profile of flexible finite cylinder of AR = 12 and 14 at wake centreline (y/D = 0) for Re = 4,000.

Figure 10.

Time-average wall-normal velocity profile of flexible finite cylinder of AR = 12 and 14 at wake centreline (y/D = 0) for Re = 4,000.

Figure 11.

Time-average wall-normal velocity profile of flexible finite cylinder of AR = 12 and 14 at wake centreline (y/D = 0) for Re = 6,000.

Figure 11.

Time-average wall-normal velocity profile of flexible finite cylinder of AR = 12 and 14 at wake centreline (y/D = 0) for Re = 6,000.

Figure 12.

Time-average wall-normal velocity profile of flexible finite cylinder of AR = 12 and 14 at wake centreline (y/D = 0) for Re = 8,000.

Figure 12.

Time-average wall-normal velocity profile of flexible finite cylinder of AR = 12 and 14 at wake centreline (y/D = 0) for Re = 8,000.

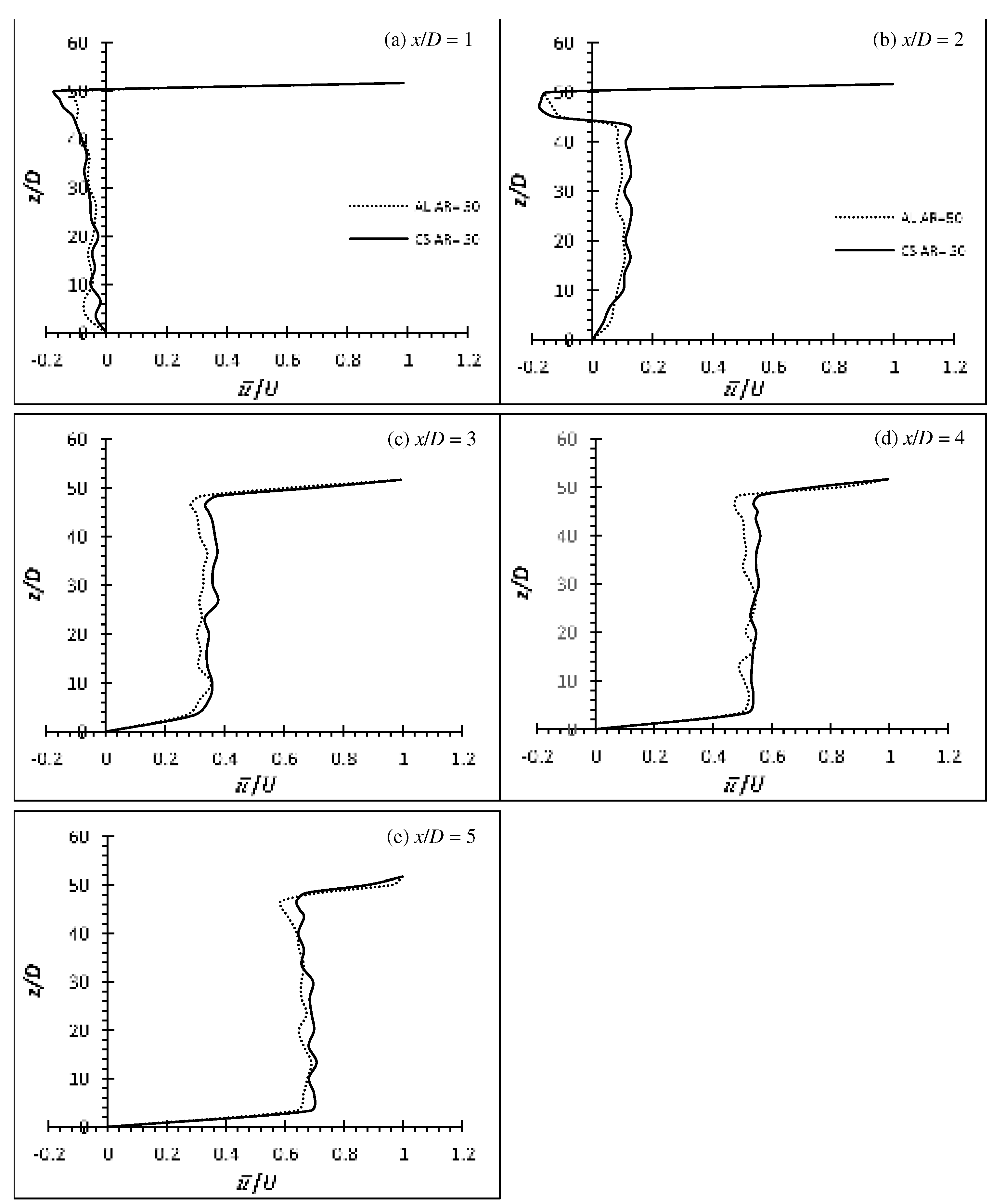

Figure 13.

Time-average streamwise velocity profile of flexible finite cylinder (Aluminium and Carbon Steel) of AR = 50 at wake centreline (y/D = 0) for Re = 2,500. Aluminium denotes Al while Carbon Steel denotes CS.

Figure 13.

Time-average streamwise velocity profile of flexible finite cylinder (Aluminium and Carbon Steel) of AR = 50 at wake centreline (y/D = 0) for Re = 2,500. Aluminium denotes Al while Carbon Steel denotes CS.

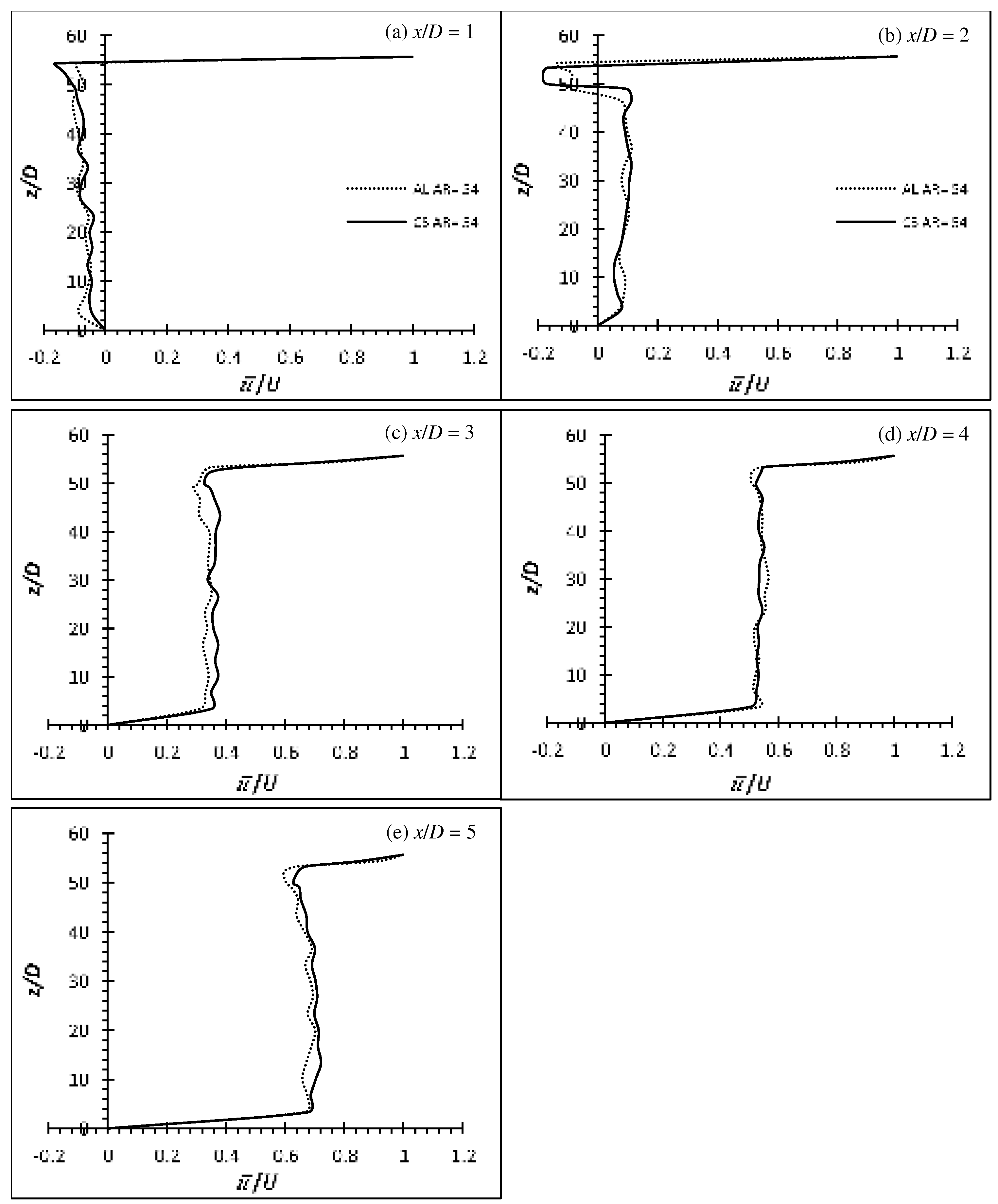

Figure 14.

Time-average streamwise velocity profile of flexible finite cylinder (Aluminium and Carbon Steel) of AR = 54 at wake centreline (y/D = 0) for Re = 2,500. Aluminium denotes Al while Carbon Steel denotes CS.

Figure 14.

Time-average streamwise velocity profile of flexible finite cylinder (Aluminium and Carbon Steel) of AR = 54 at wake centreline (y/D = 0) for Re = 2,500. Aluminium denotes Al while Carbon Steel denotes CS.

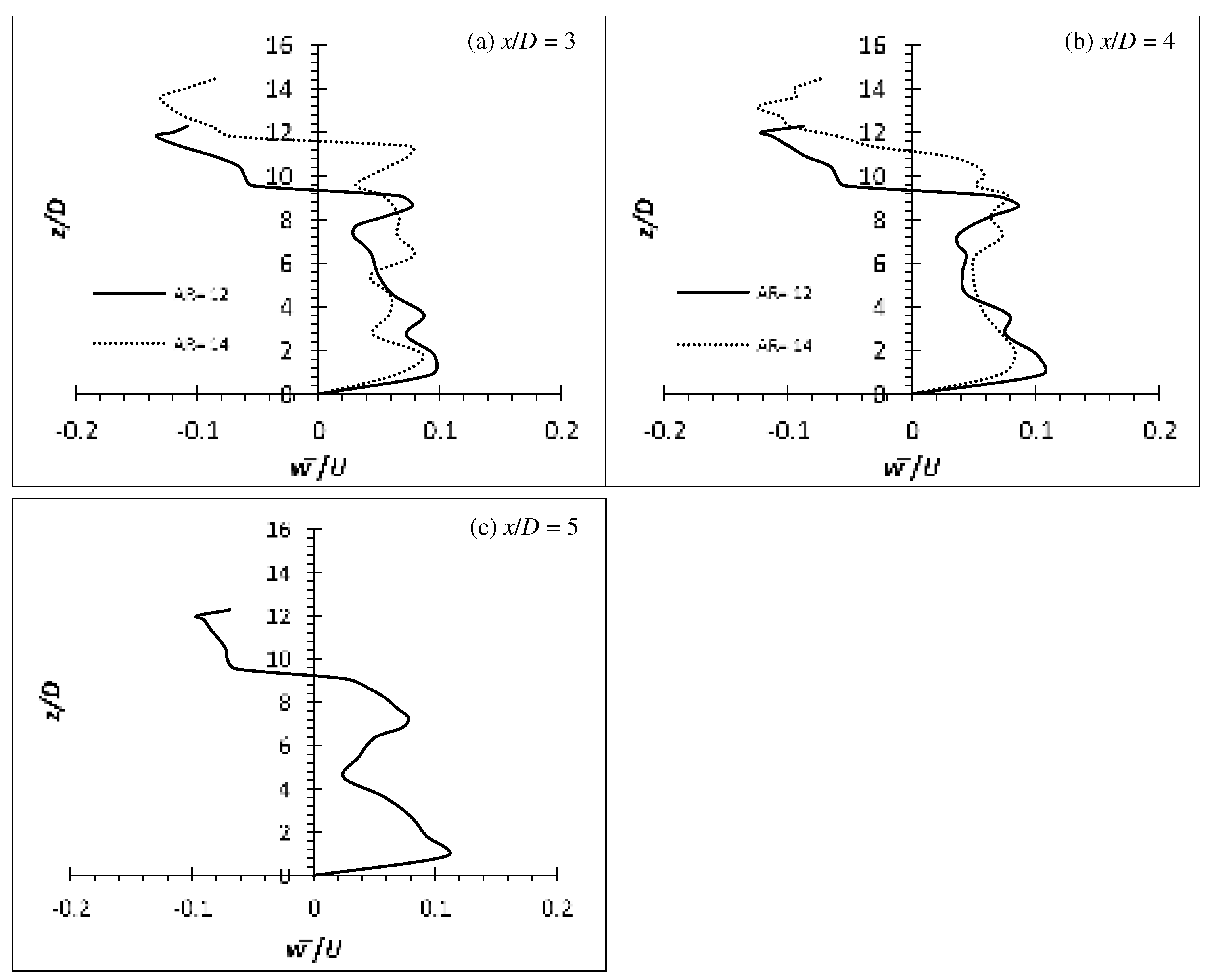

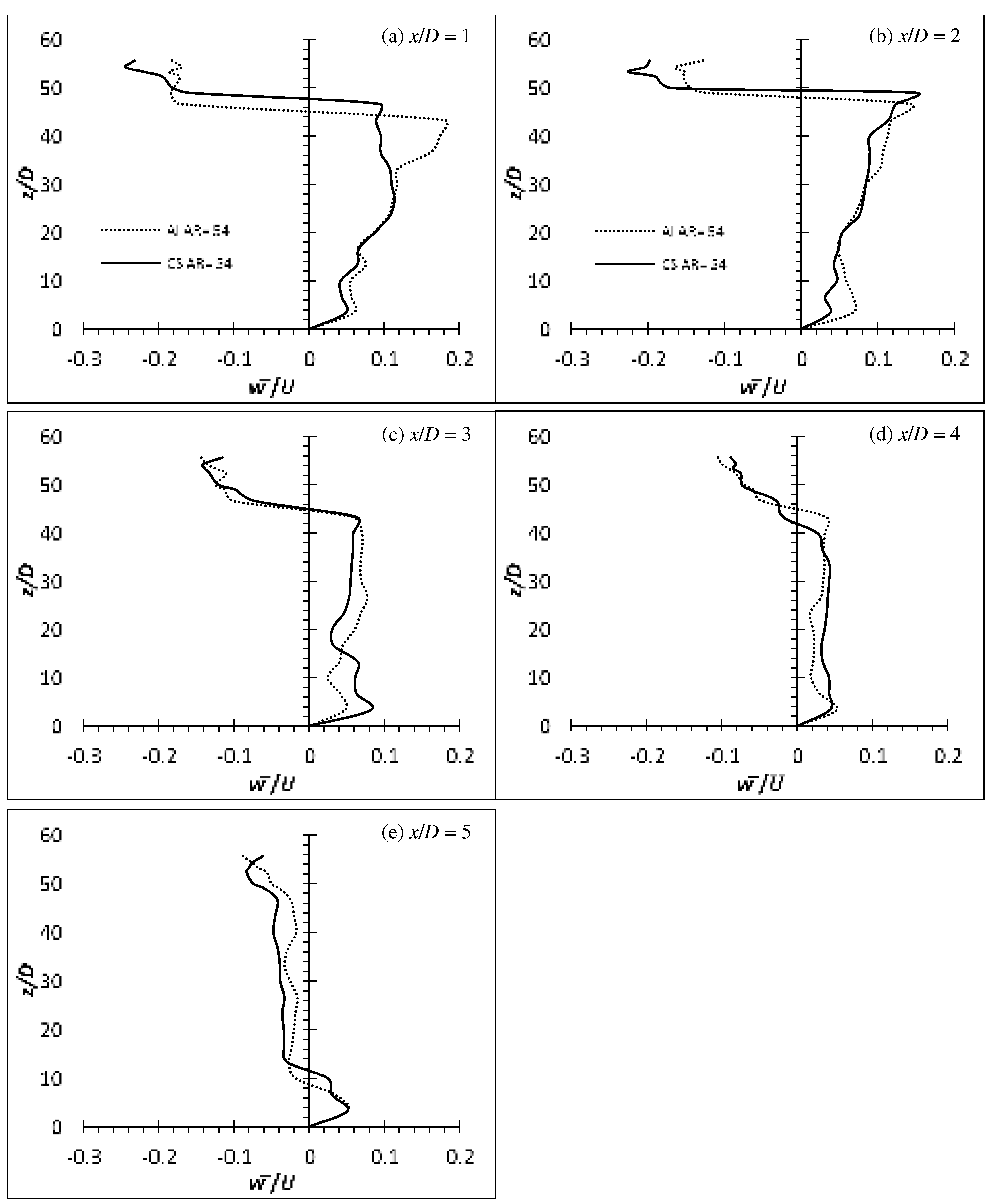

Figure 15.

Time-average wall-normal velocity profile of flexible finite cylinder (Aluminium and Carbon Steel) of AR = 50 at wake centreline (y/D = 0) for Re = 2,500. Aluminium denotes Al while Carbon Steel denotes CS.

Figure 15.

Time-average wall-normal velocity profile of flexible finite cylinder (Aluminium and Carbon Steel) of AR = 50 at wake centreline (y/D = 0) for Re = 2,500. Aluminium denotes Al while Carbon Steel denotes CS.

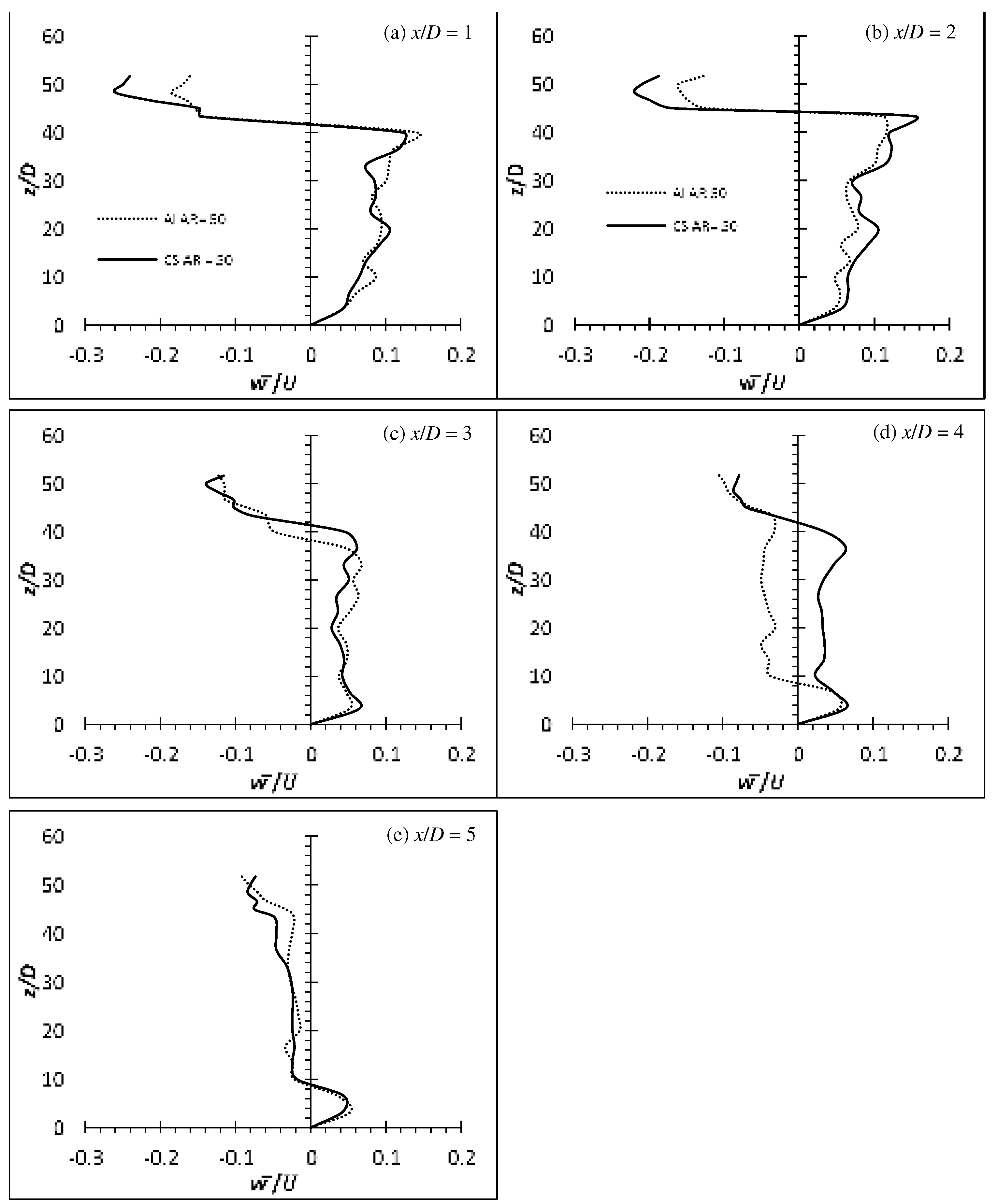

Figure 16.

Time-average wall-normal velocity profile of flexible finite cylinder (Aluminium and Carbon Steel) of AR = 54 at wake centreline (y/D = 0) for Re = 2,500. Aluminium denotes Al while Carbon Steel denotes CS.

Figure 16.

Time-average wall-normal velocity profile of flexible finite cylinder (Aluminium and Carbon Steel) of AR = 54 at wake centreline (y/D = 0) for Re = 2,500. Aluminium denotes Al while Carbon Steel denotes CS.

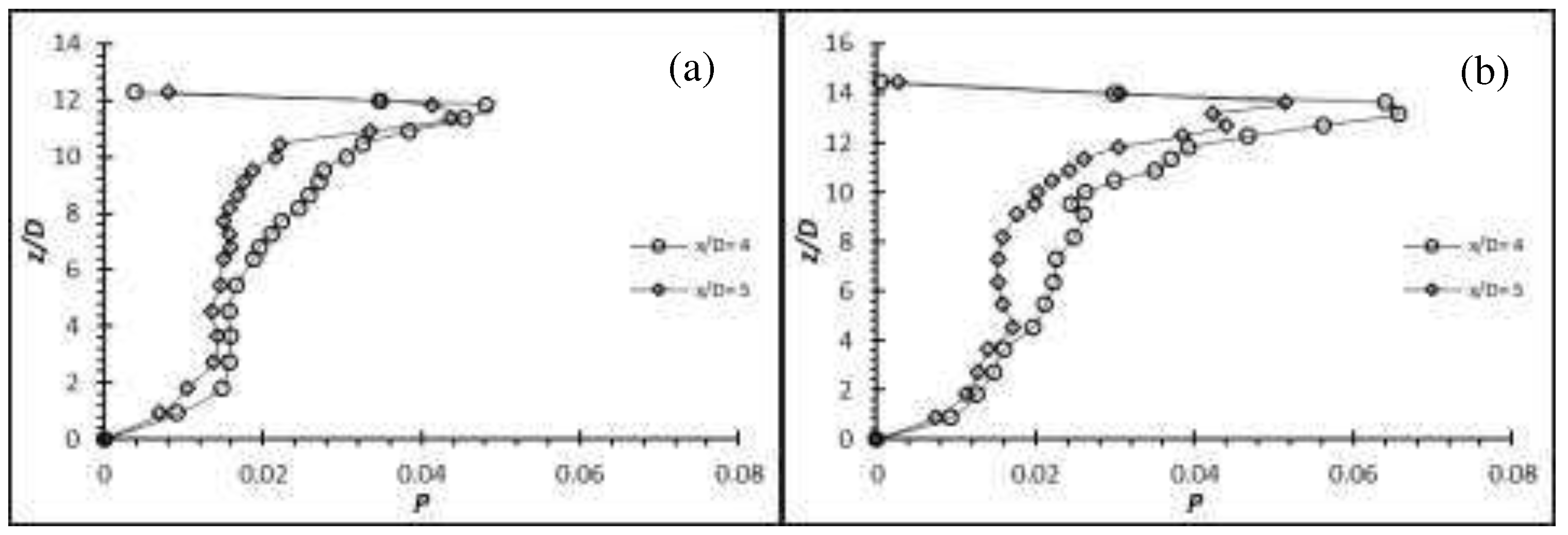

Figure 17.

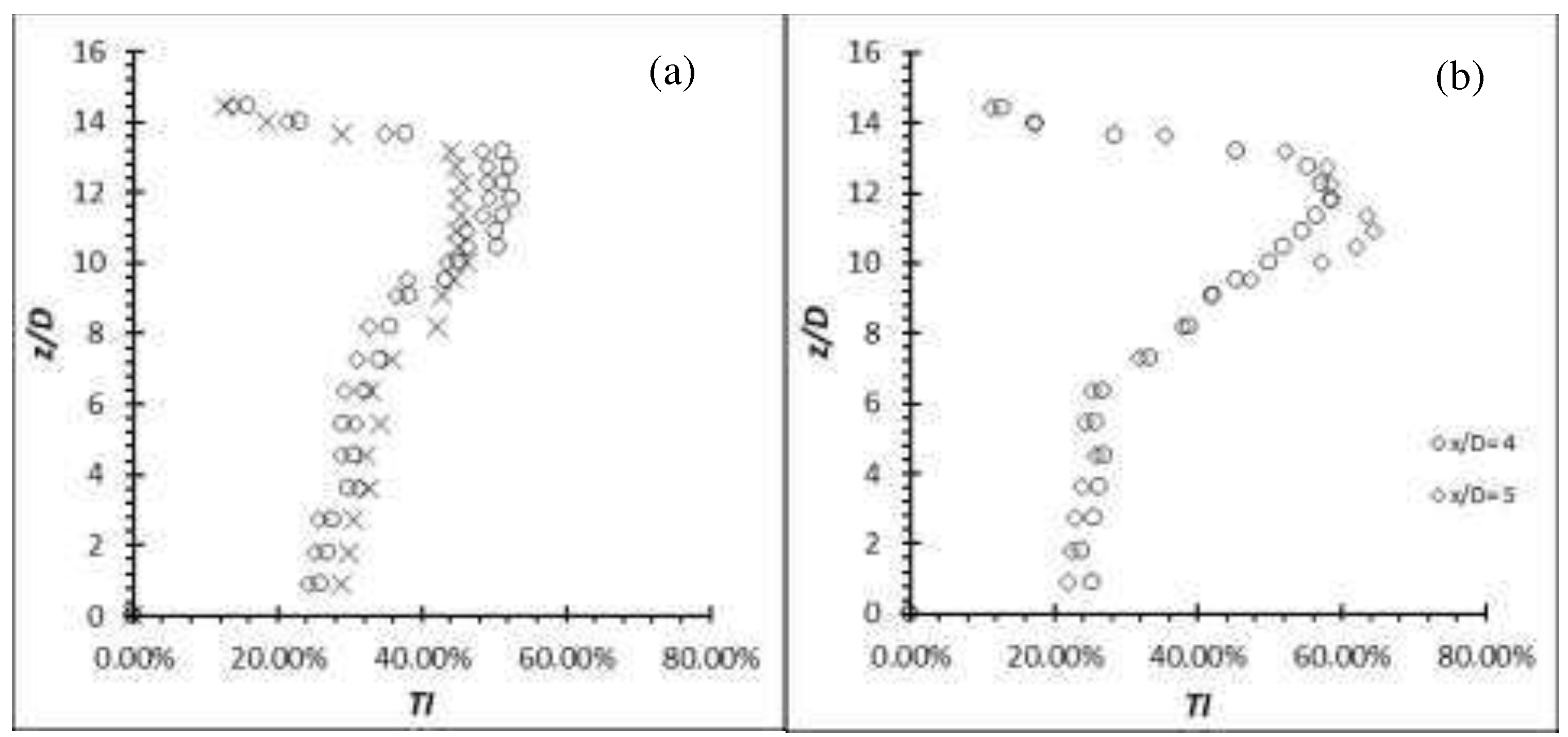

Turbulence intensity distribution for AR = 12 at (a) Re = 4,000; (b) Re = 6,000.

Figure 17.

Turbulence intensity distribution for AR = 12 at (a) Re = 4,000; (b) Re = 6,000.

Figure 18.

Turbulence intensity distribution for AR = 14 at (a) Re = 4,000; (b) Re = 6,000.

Figure 18.

Turbulence intensity distribution for AR = 14 at (a) Re = 4,000; (b) Re = 6,000.

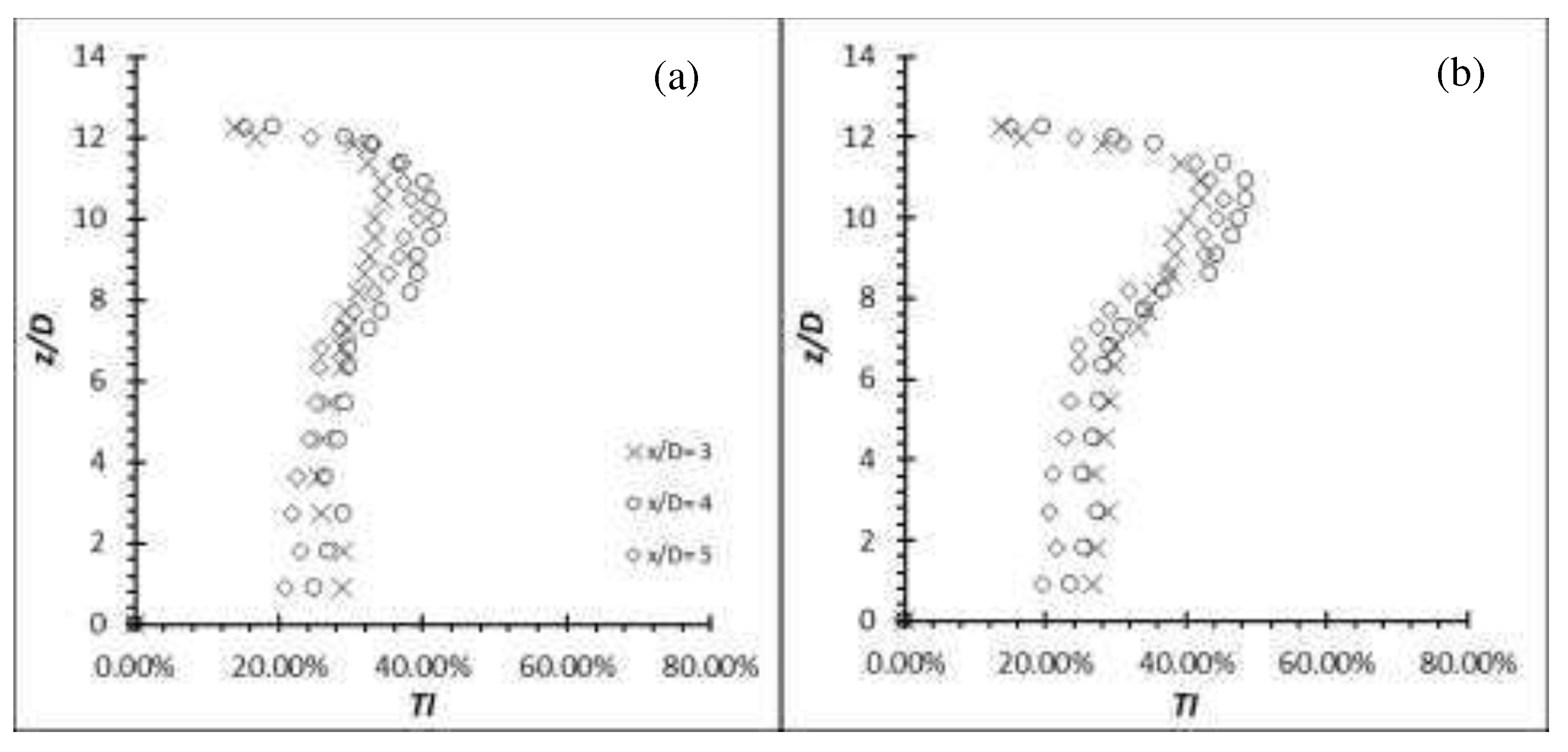

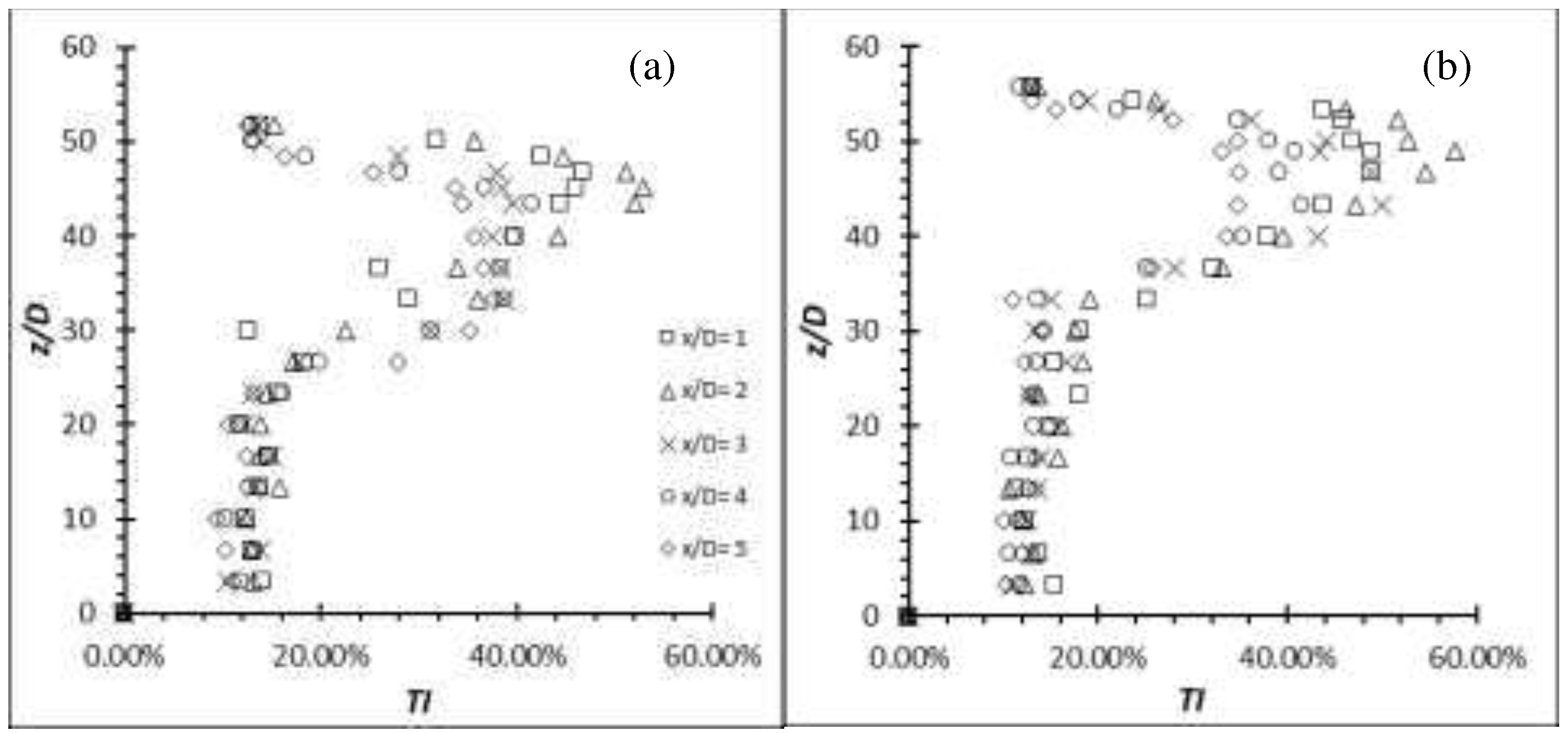

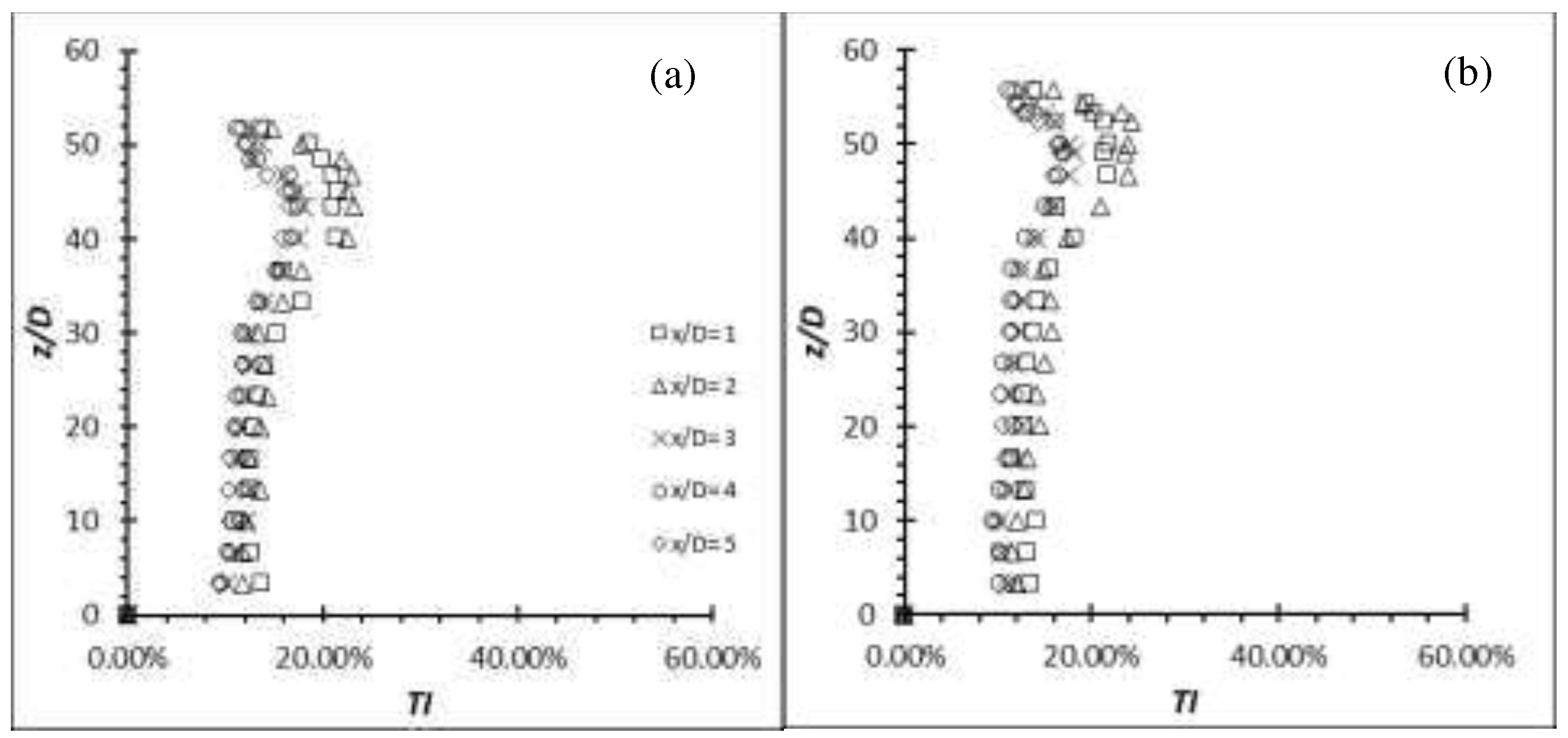

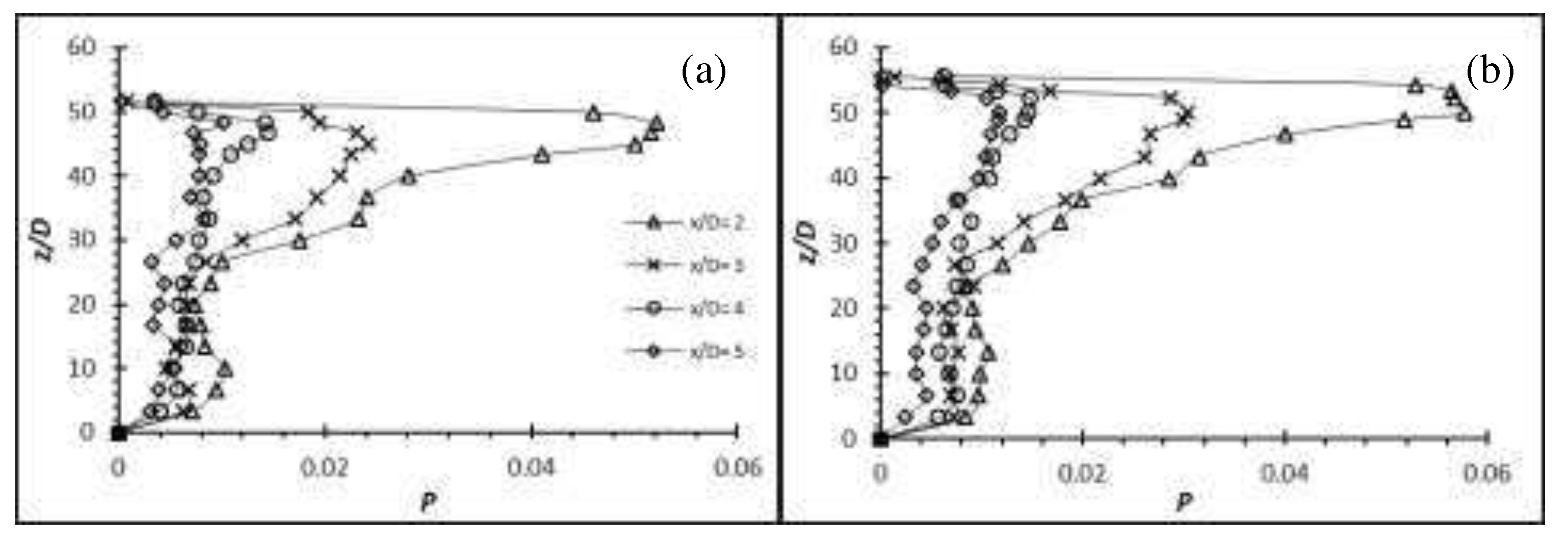

Figure 19.

Turbulence intensity distribution for aluminium cylinder at Re = 2,500 (a) AR = 50; (b) AR = 54.

Figure 19.

Turbulence intensity distribution for aluminium cylinder at Re = 2,500 (a) AR = 50; (b) AR = 54.

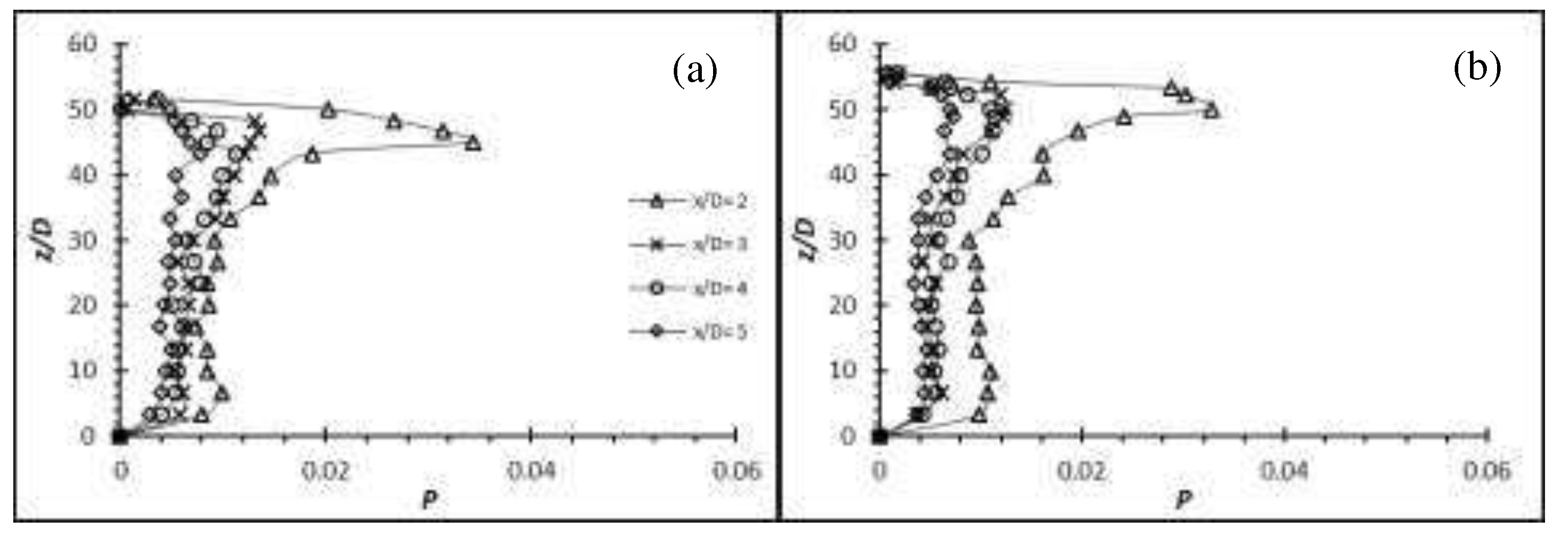

Figure 20.

Turbulence intensity distribution for carbon steel cylinder at Re = 2,500 (a) AR = 50; (b) AR = 54.

Figure 20.

Turbulence intensity distribution for carbon steel cylinder at Re = 2,500 (a) AR = 50; (b) AR = 54.

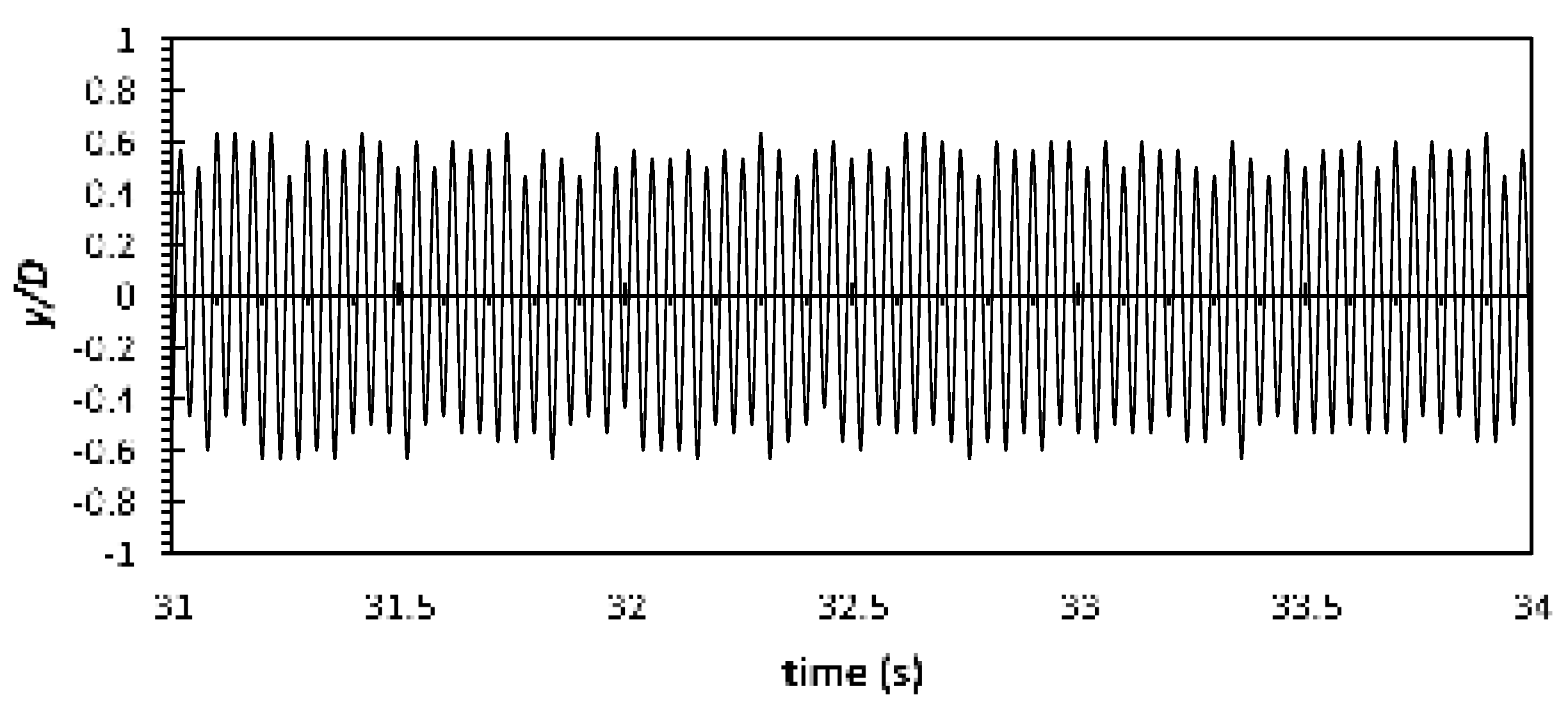

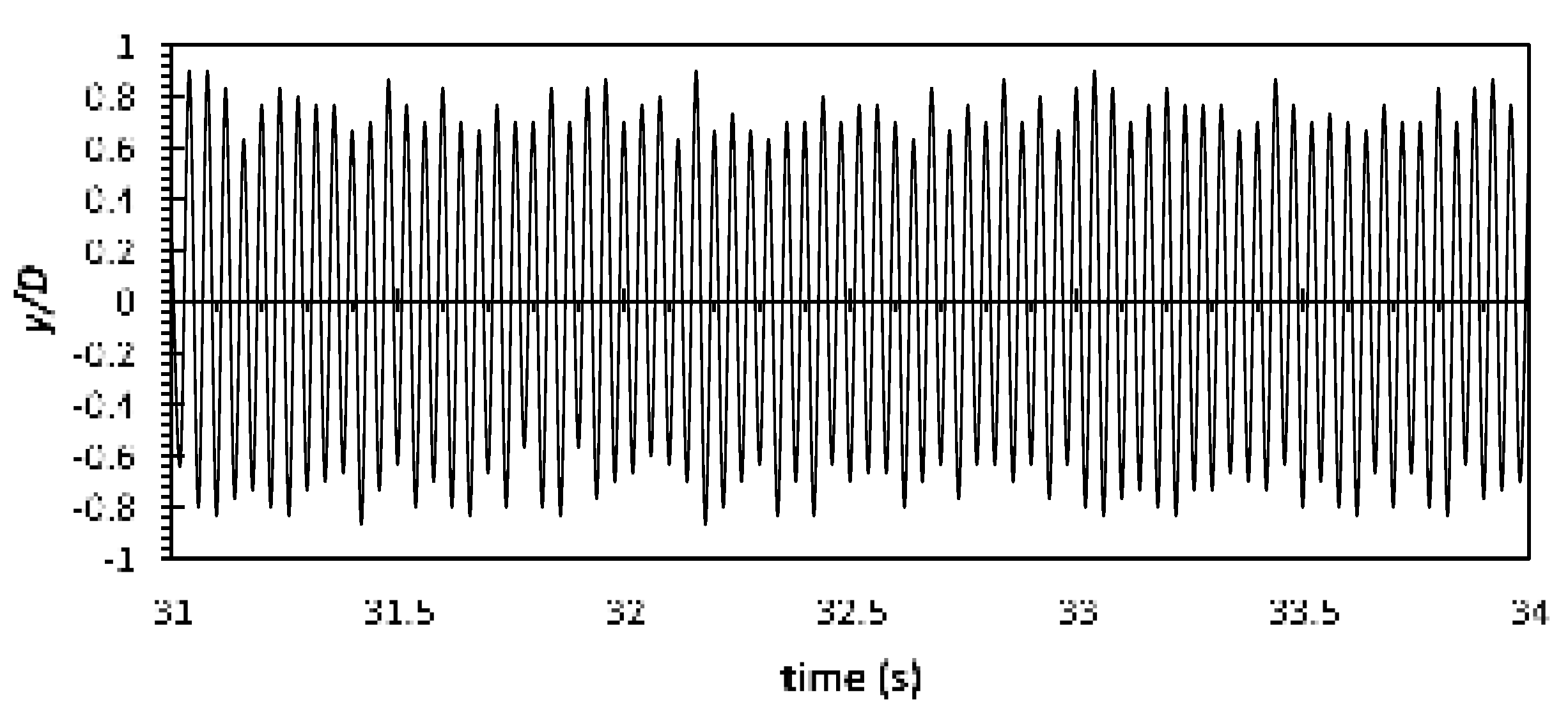

Figure 21.

Oscillation of aluminium flexible cylinder of AR = 50 at Re = 2,500.

Figure 21.

Oscillation of aluminium flexible cylinder of AR = 50 at Re = 2,500.

Figure 22.

Oscillation of aluminium flexible cylinder of AR = 54 at Re = 2,500.

Figure 22.

Oscillation of aluminium flexible cylinder of AR = 54 at Re = 2,500.

Figure 23.

Production term, for flexible cylinder at Re = 4,000 for (a)AR = 12; (b)AR = 14.

Figure 23.

Production term, for flexible cylinder at Re = 4,000 for (a)AR = 12; (b)AR = 14.

Figure 24.

Production term, for flexible aluminium cylinder of (a) AR = 50 and (b) AR = 54 at Re = 2,500.

Figure 24.

Production term, for flexible aluminium cylinder of (a) AR = 50 and (b) AR = 54 at Re = 2,500.

Figure 25.

Production term, for flexible carbon steel cylinder of (a) AR = 50 and (b) AR = 54 at Re = 2,500.

Figure 25.

Production term, for flexible carbon steel cylinder of (a) AR = 50 and (b) AR = 54 at Re = 2,500.

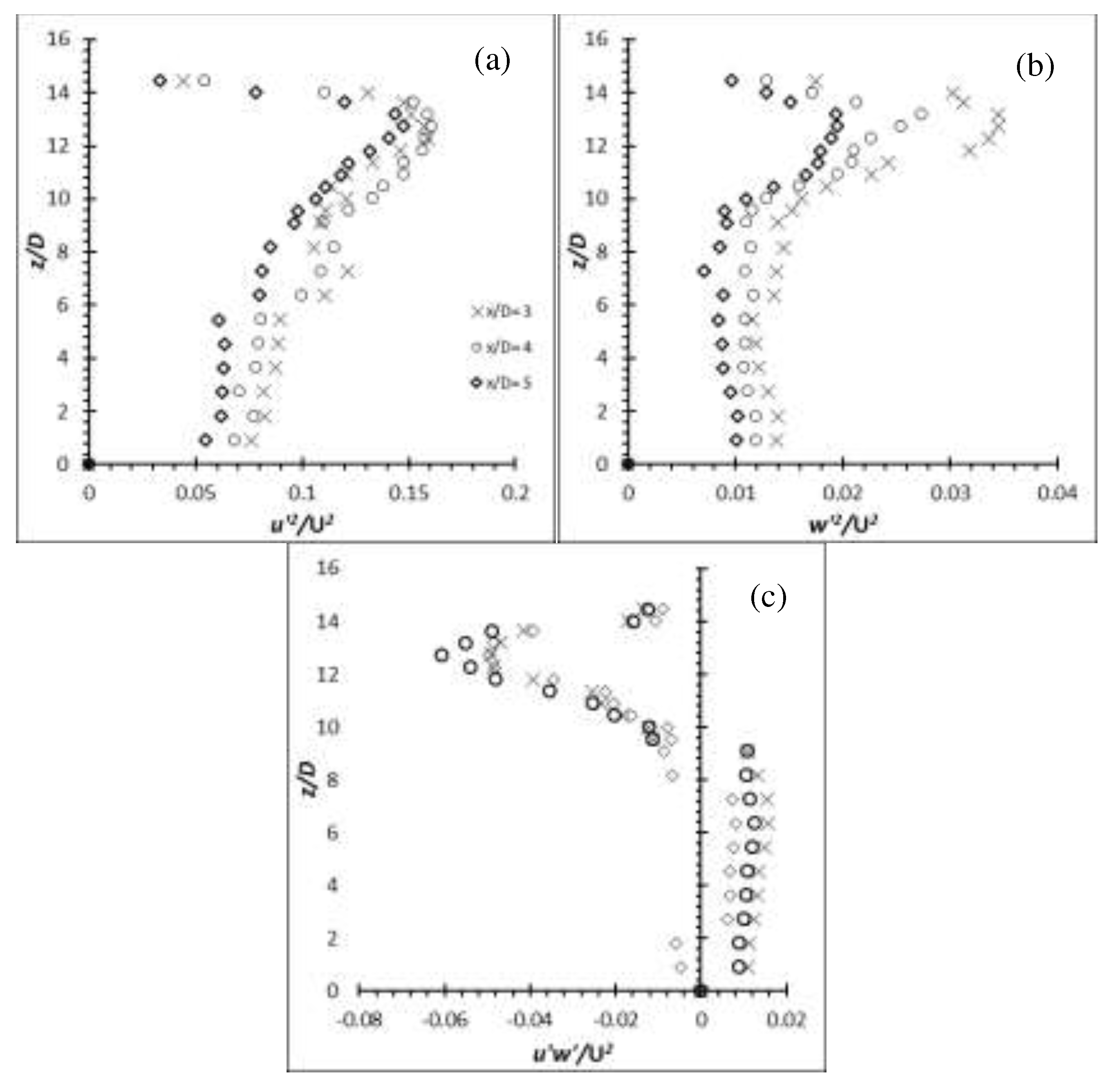

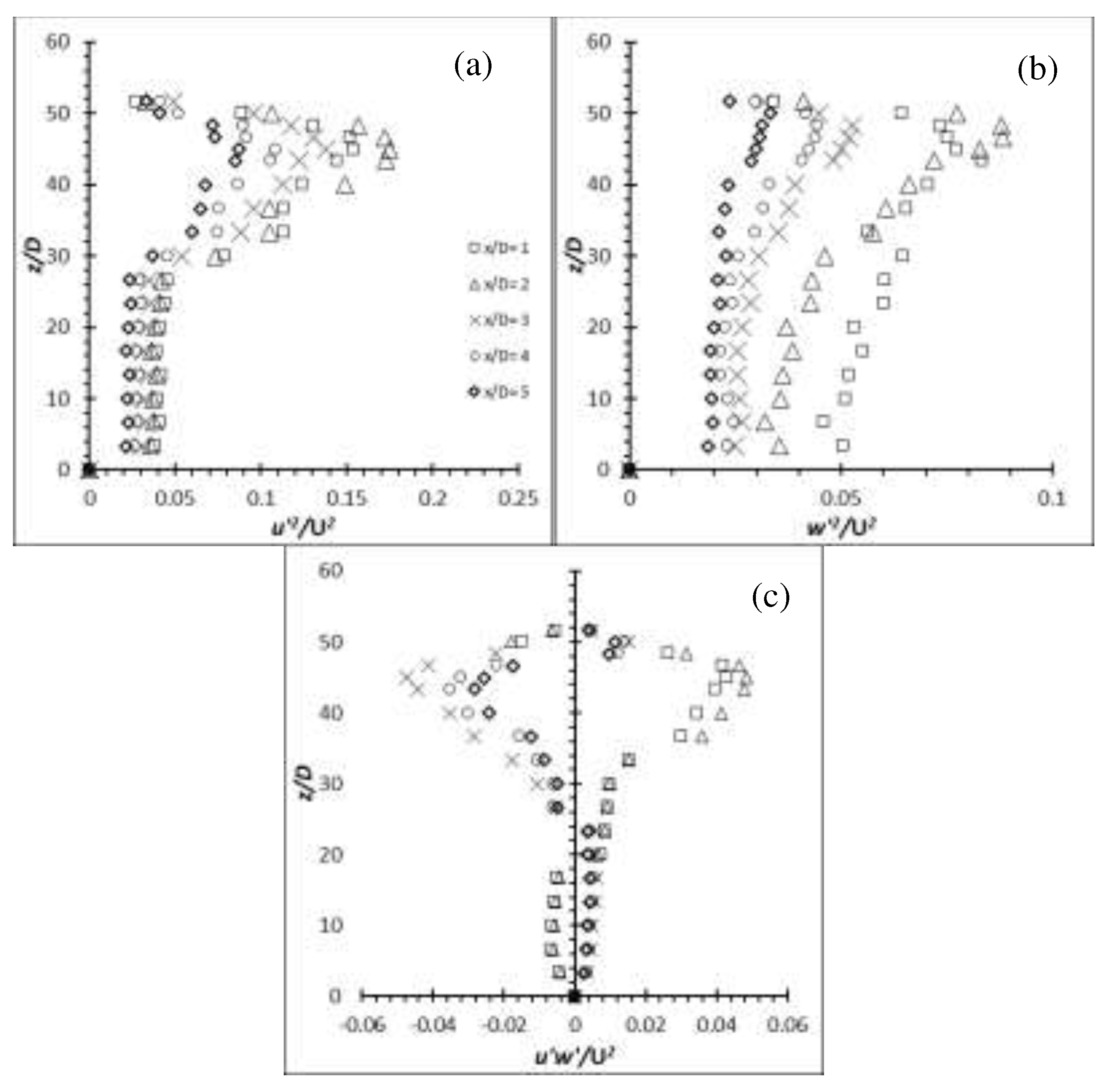

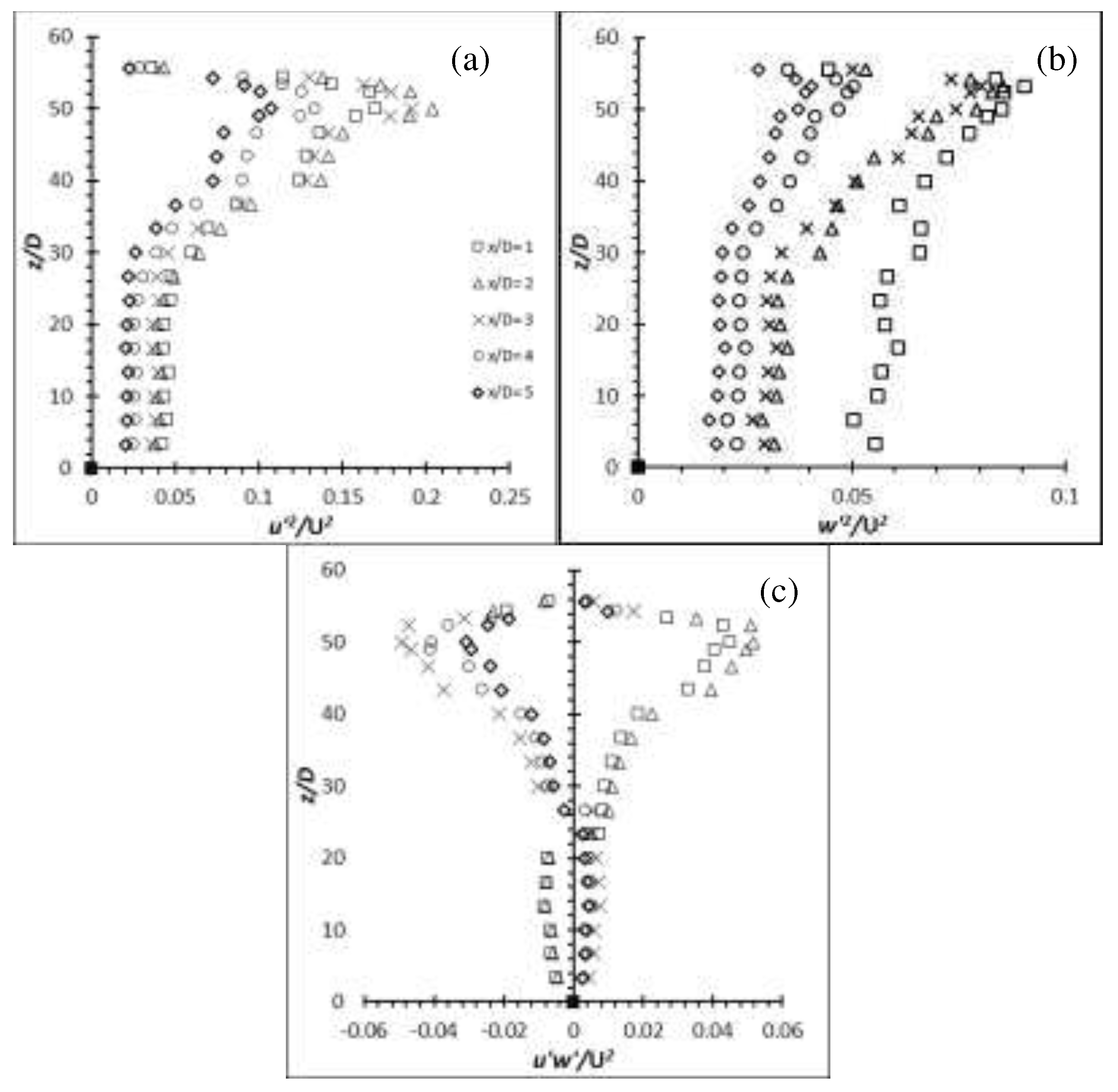

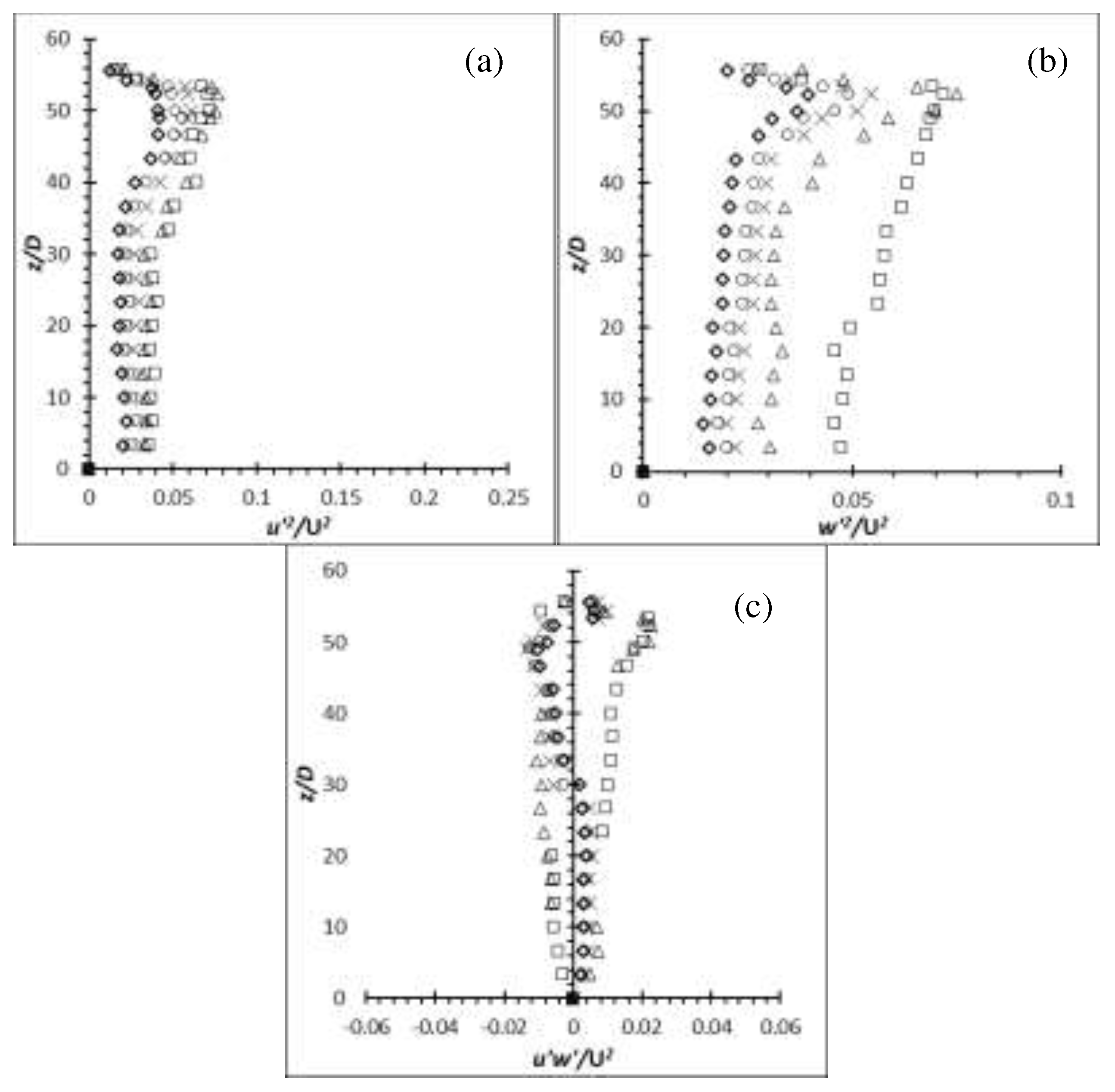

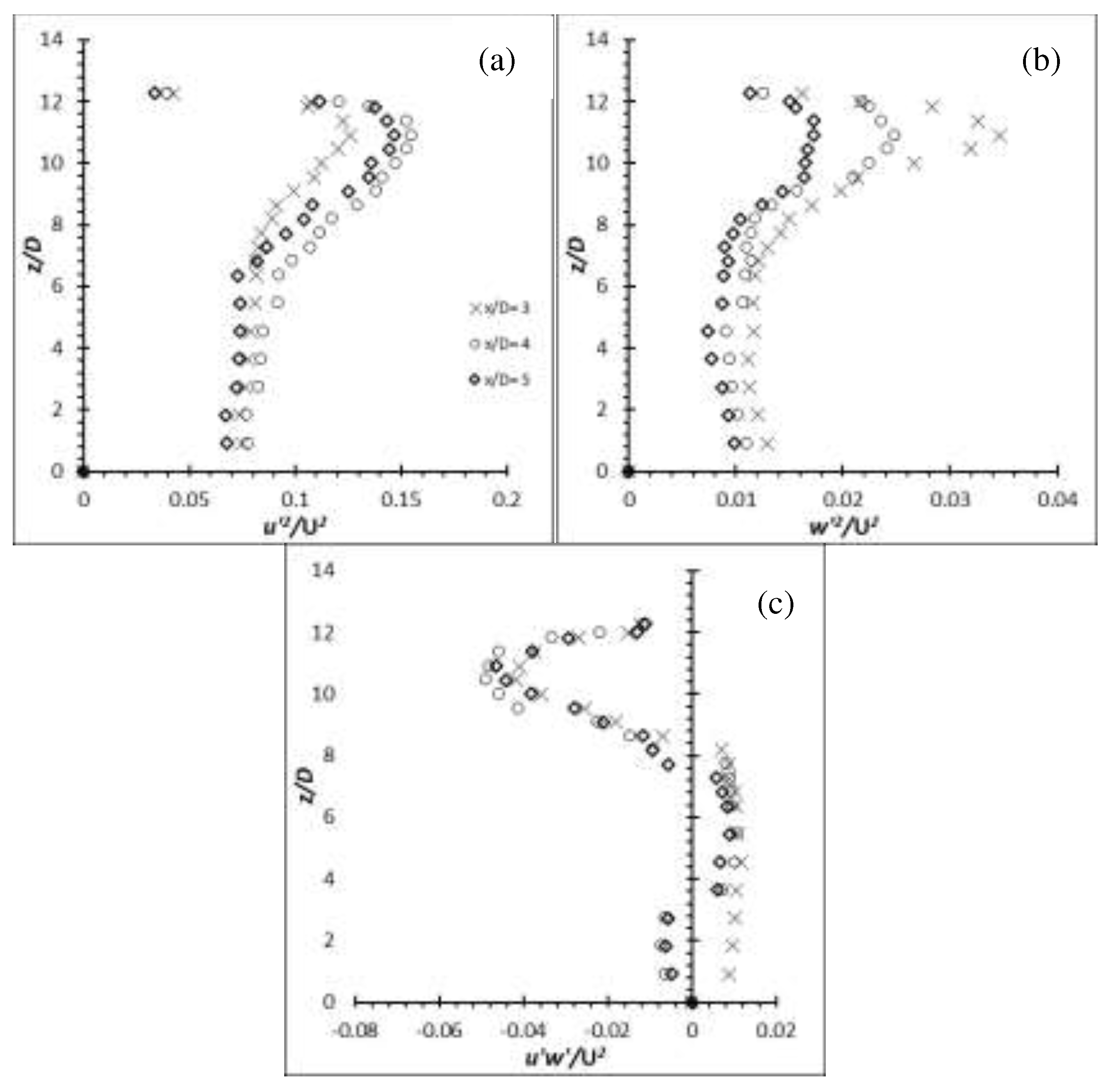

Figure 26.

Reynolds stress profiles for cylinder of AR = 12 at Re = 4,000: (a) . (b) (c) .

Figure 26.

Reynolds stress profiles for cylinder of AR = 12 at Re = 4,000: (a) . (b) (c) .

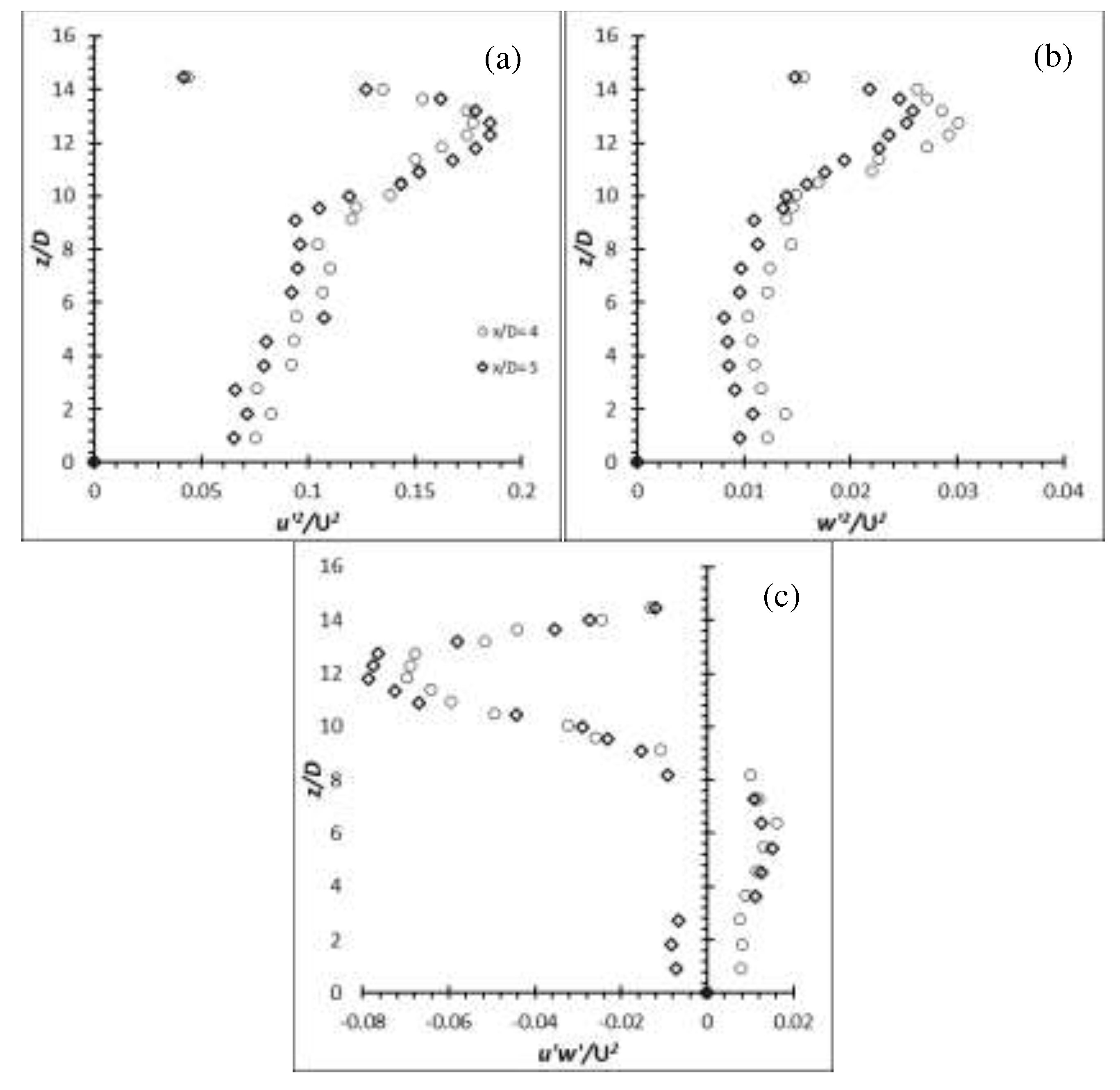

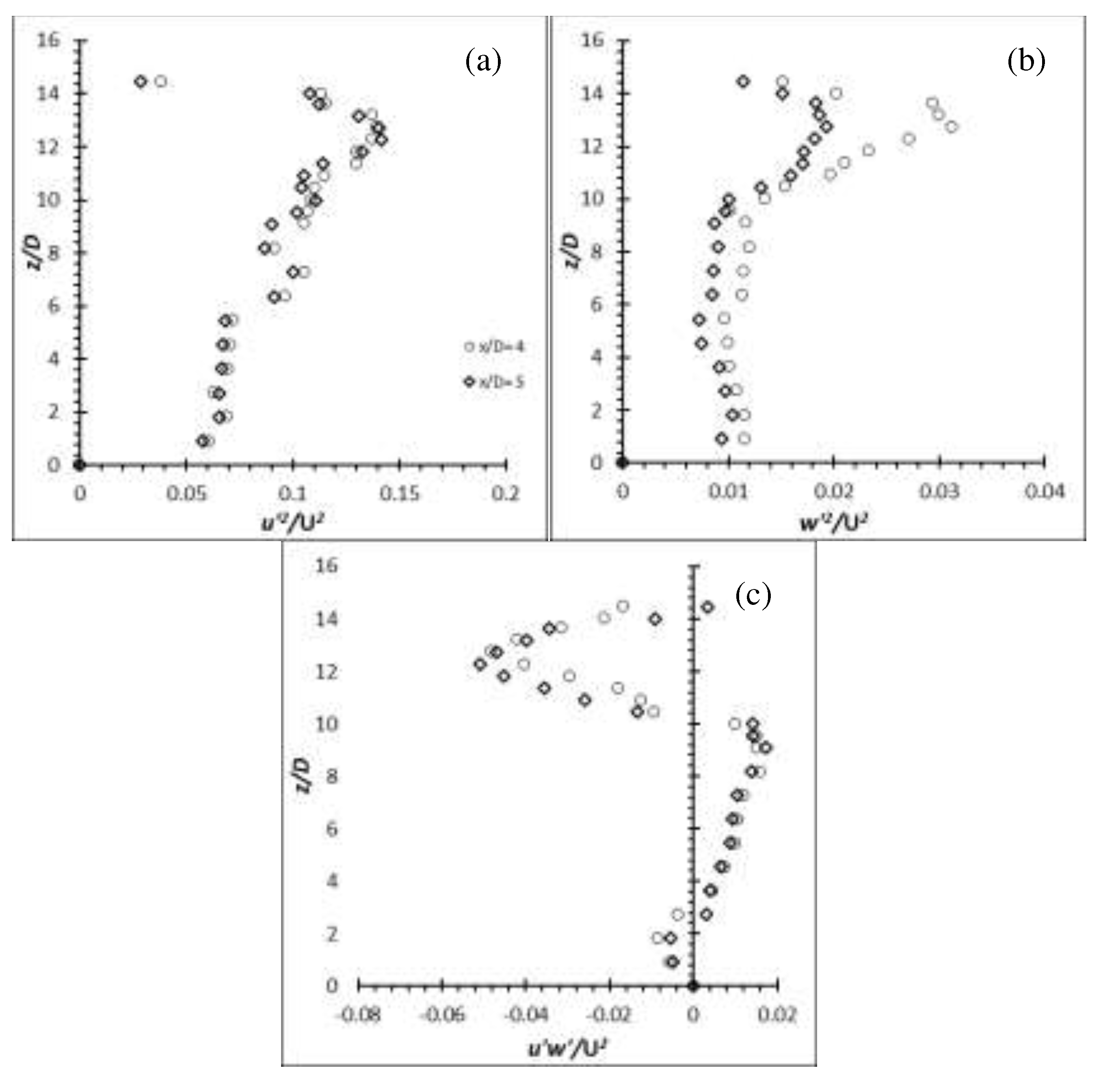

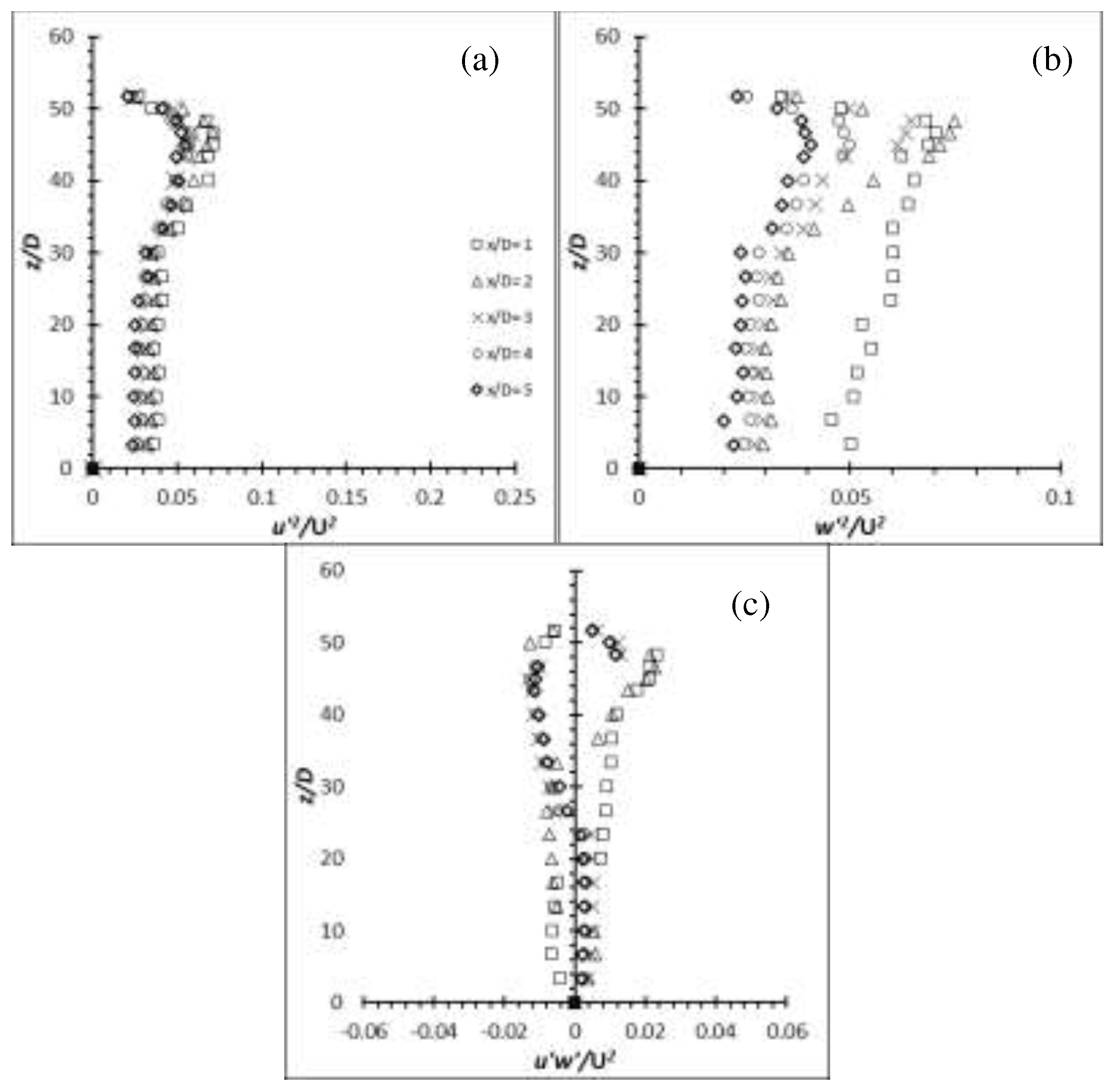

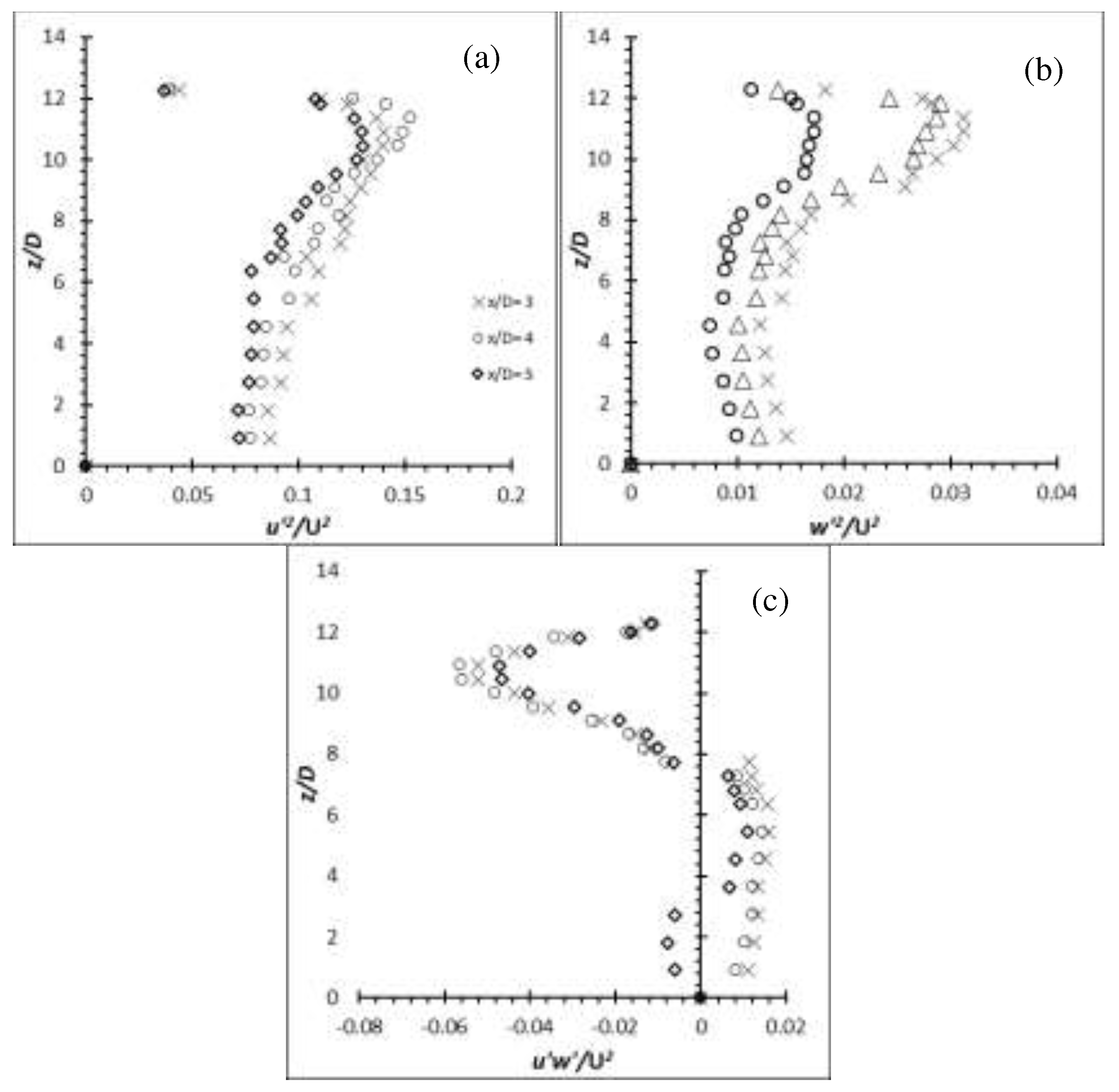

Figure 27.

Reynolds stress profiles for cylinder of AR = 12 at Re = 6,000: (a) (b) (c) .

Figure 27.

Reynolds stress profiles for cylinder of AR = 12 at Re = 6,000: (a) (b) (c) .

Table 1.

Boundary layer measurements on the ground plane at U = 0.33 m/s.

Table 1.

Boundary layer measurements on the ground plane at U = 0.33 m/s.

| Location x/D

|

δ (mm) |

δ* (mm) |

δθ (mm) |

Hδ

|

ReL x 105

|

| -10 |

50 |

11.6 |

8.9 |

1.30 |

0.80 |

| 0 |

54 |

11.9 |

9.9 |

1.20 |

1.28 |

| +10 |

61 |

12.0 |

10.0 |

1.20 |

1.76 |

Table 2.

Boundary layer measurements on the ground plane at U = 0.49 m/s.

Table 2.

Boundary layer measurements on the ground plane at U = 0.49 m/s.

| Location x/D

|

δ (mm) |

δ* (mm) |

δθ (mm) |

Hδ

|

ReL x 105

|

| -10 |

52 |

11.7 |

10.1 |

1.15 |

1.19 |

| 0 |

58 |

11.9 |

9.9 |

1.20 |

1.90 |

| +10 |

67 |

12.3 |

10.2 |

1.20 |

2.61 |

Table 3.

Boundary layer measurements on the ground plane at U = 0.65 m/s.

Table 3.

Boundary layer measurements on the ground plane at U = 0.65 m/s.

| Location x/D

|

δ (mm) |

δ* (mm) |

δθ (mm) |

Hδ

|

ReL x 105

|

| -10 |

54 |

11.9 |

9.0 |

1.30 |

1.58 |

| 0 |

56 |

11.9 |

9.3 |

1.30 |

2.52 |

| +10 |

60 |

12.0 |

9.4 |

1.30 |

3.45 |

Table 4.

Summary of the specifications of finite rigid circular models.

Table 4.

Summary of the specifications of finite rigid circular models.

| AR |

10 |

16 |

| D (mm) |

13.0 ± 0.5 |

11.0 ± 0.5 |

| L (mm) |

130.0 ± 1 |

176.0 ± 1 |

| δ/D |

4.15, 4.46, 4.30 |

4.90, 5.27, 5.09 |

| δ/H |

0.41, 0.44, 0.43 |

0.30, 0.32, 0.31 |

| Blockage ratio (%) |

4.2 |

4.8 |

| ReD

|

4 x103, 6 x103, 8 x103

|

4 x103, 6 x103, 8 x103

|

| Material |

Aluminium |

Aluminium |

| Young Modulus (GPa) |

65 |

65 |

Table 5.

Summary of the specifications of finite flexible circular models.

Table 5.

Summary of the specifications of finite flexible circular models.

| Group |

Metal |

Polymer |

| AR |

50 and 54 |

10, 12, 14 and16 |

|

D (mm) |

3.0 ± 0.5 |

11.0 ± 0.5 |

|

L (mm) |

150.0 ± 1, 160.2 ± 1 |

110.0 ± 1, 132.0 ± 1, 154.0 ± 1, 176.0 ± 1 |

| δ/D

|

25.0, 26.0 |

4.90, 5.27, 5.09 |

| δ/H

|

0.46 – 0.52 |

0.30 – 0.52 |

| Blockage ratio (%) |

1.1 and 1.2 |

3.0, 3.6, 4.2, 4.8 |

| ReD

|

2.5 x103

|

4 x103, 6 x103, 8 x103

|

| Material |

Aluminium and AISI 12L14 carbon steel |

EVA |

| Young Modulus (GPa) |

65 and 200 |

0.0015 |

Table 6.

The average wake region (in approximation) behind the rigid and flexible cylinders at different conditions.

Table 6.

The average wake region (in approximation) behind the rigid and flexible cylinders at different conditions.

| Average wake region |

|---|

| Material |

AR |

Re |

Average Wake Region |

| EVA |

12 |

4,000 |

~10.45 D

|

| 6,000 |

~11.30 D

|

| 8,000 |

~10.90 D

|

| 14 |

4,000 |

~12.27 D

|

| 6,000 |

~12.27 D

|

| 8,000 |

~12.72 D

|

| Aluminium |

50 |

2,500 |

~46.67 D

|

| 54 |

~51.30 D

|

| Carbon Steel |

50 |

~46.67 D

|

| 54 |

~50.00 D |