Submitted:

05 July 2023

Posted:

06 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Literature review

2.1. Urban freight transport

2.2. Fleet replacement problem

3. Problem description

3.1. Problem setting

3.2. Formulation of the problem

- : number of vehicles of type k and age i used in zone z during year t;

- : number of salvaged vehicles of type k and age i at the end of year t;

- : number of vehicles of type k purchased at the beginning of year t;

4. Data sources and assumptions

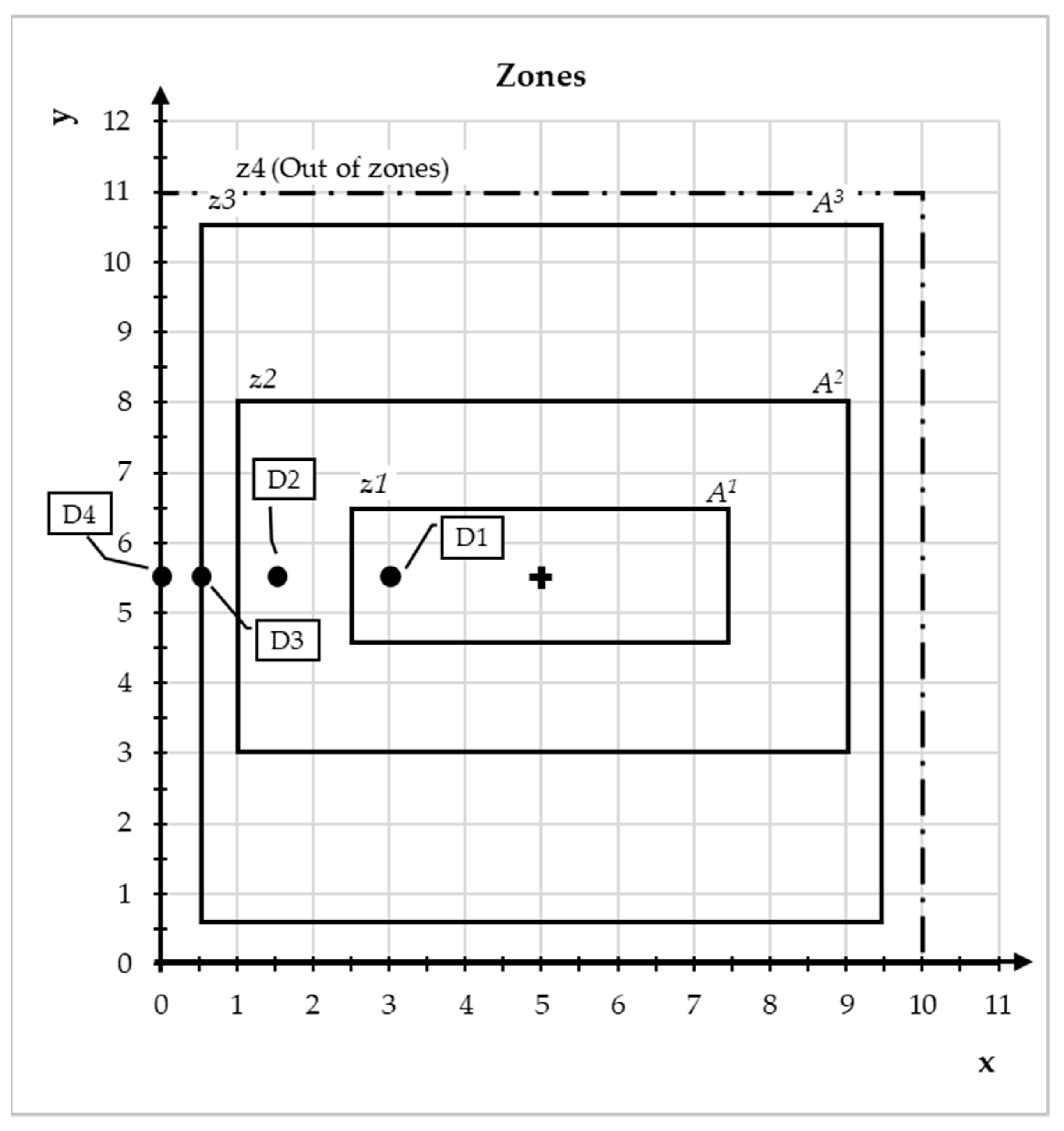

4.1. Zones characterization

- S1: each zone has its own depot points (D1, D2 and D3);

- S2: depot points are located only in zone 2 and zone3 (D2 and D3);

- S3: depot point is located only in zone 3 (D3);

- S4: depot point is out of all zones and in the suburb of the city (D4);

- S5: all vehicle types can access all zones, each with its own depot points (D1, D2, and D3).

4.2. Vehicle characterization

4.3. Demand and fleet composition

- Light-size vehicles can serve c1 = 6 customers;

- Medium-size vehicles can serve c2 = 12 customers;

- Heavy vehicles can serve c3 = 36 customers.

5. Results and discussion

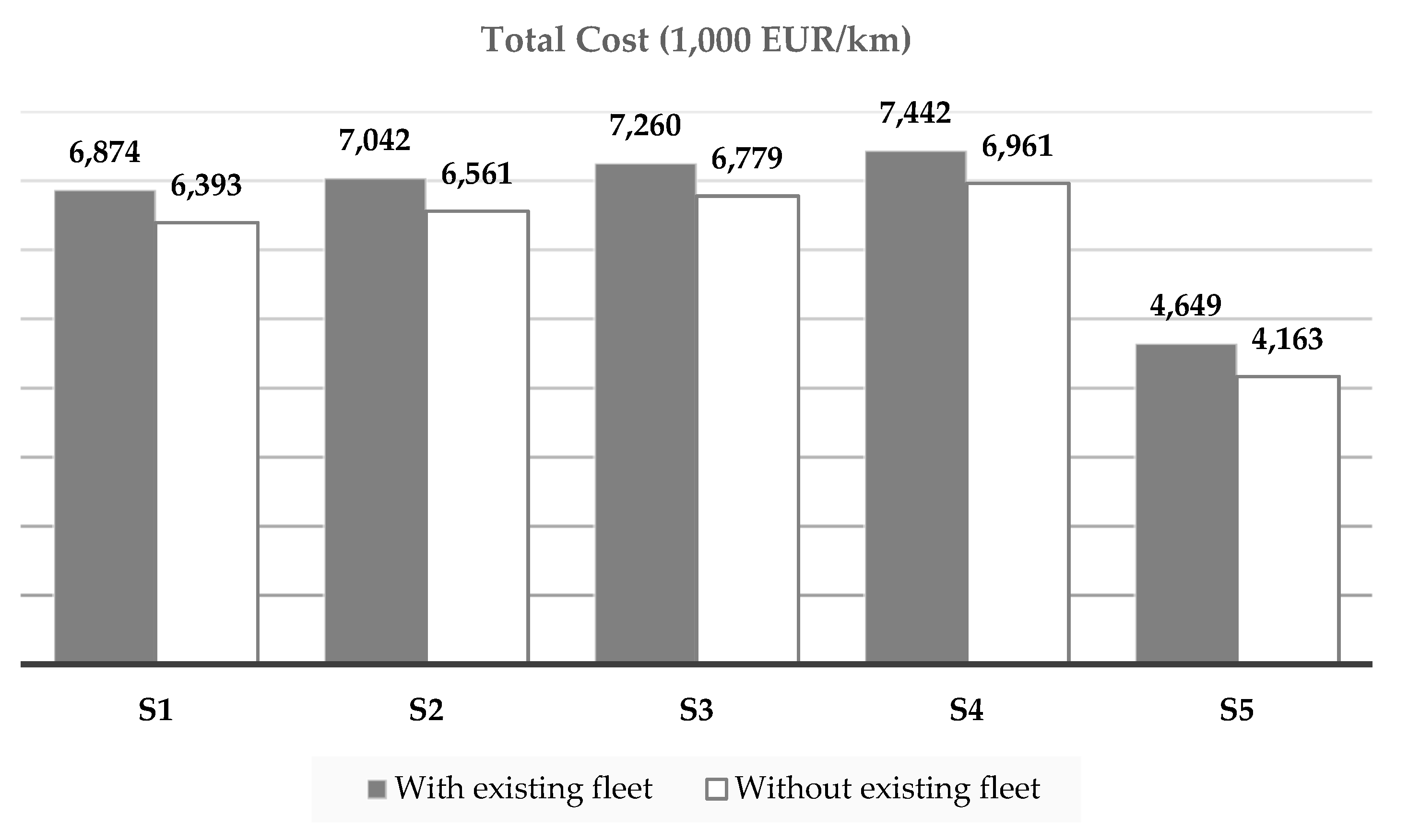

5.1. Total cost

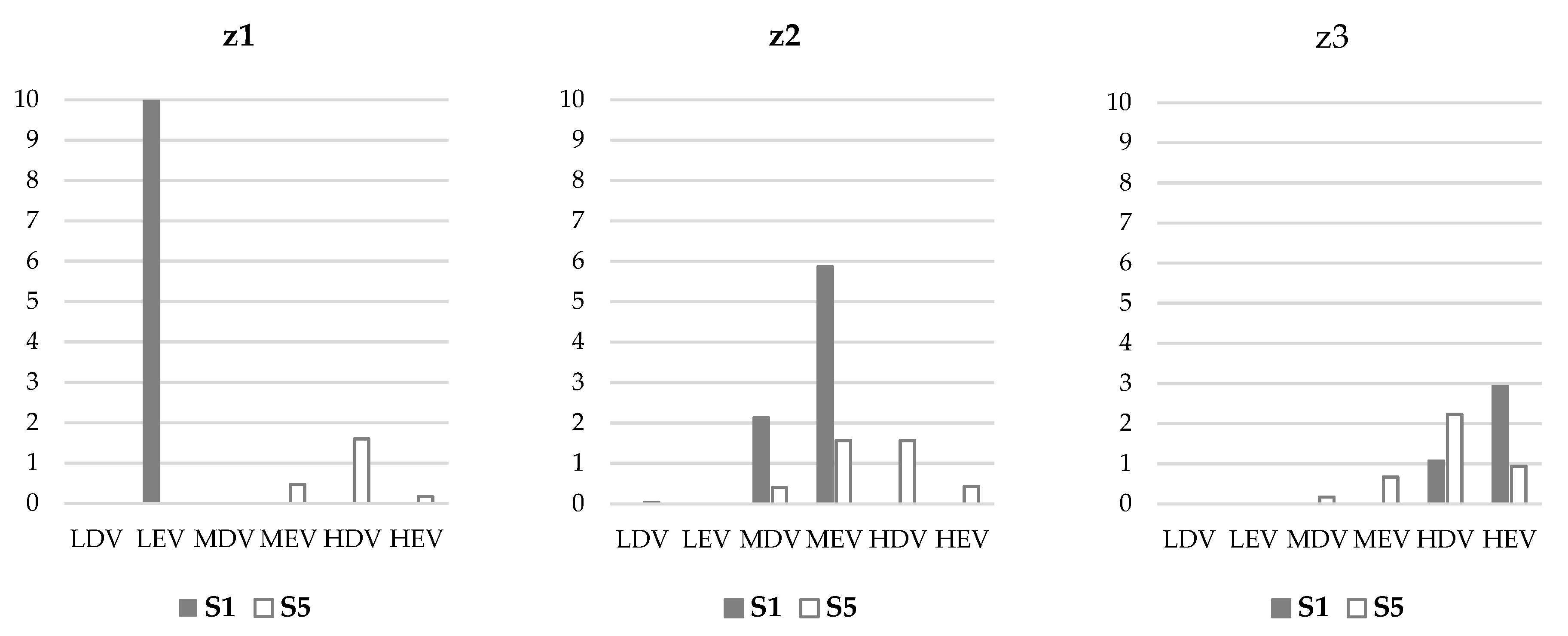

5.2. Fleet composition

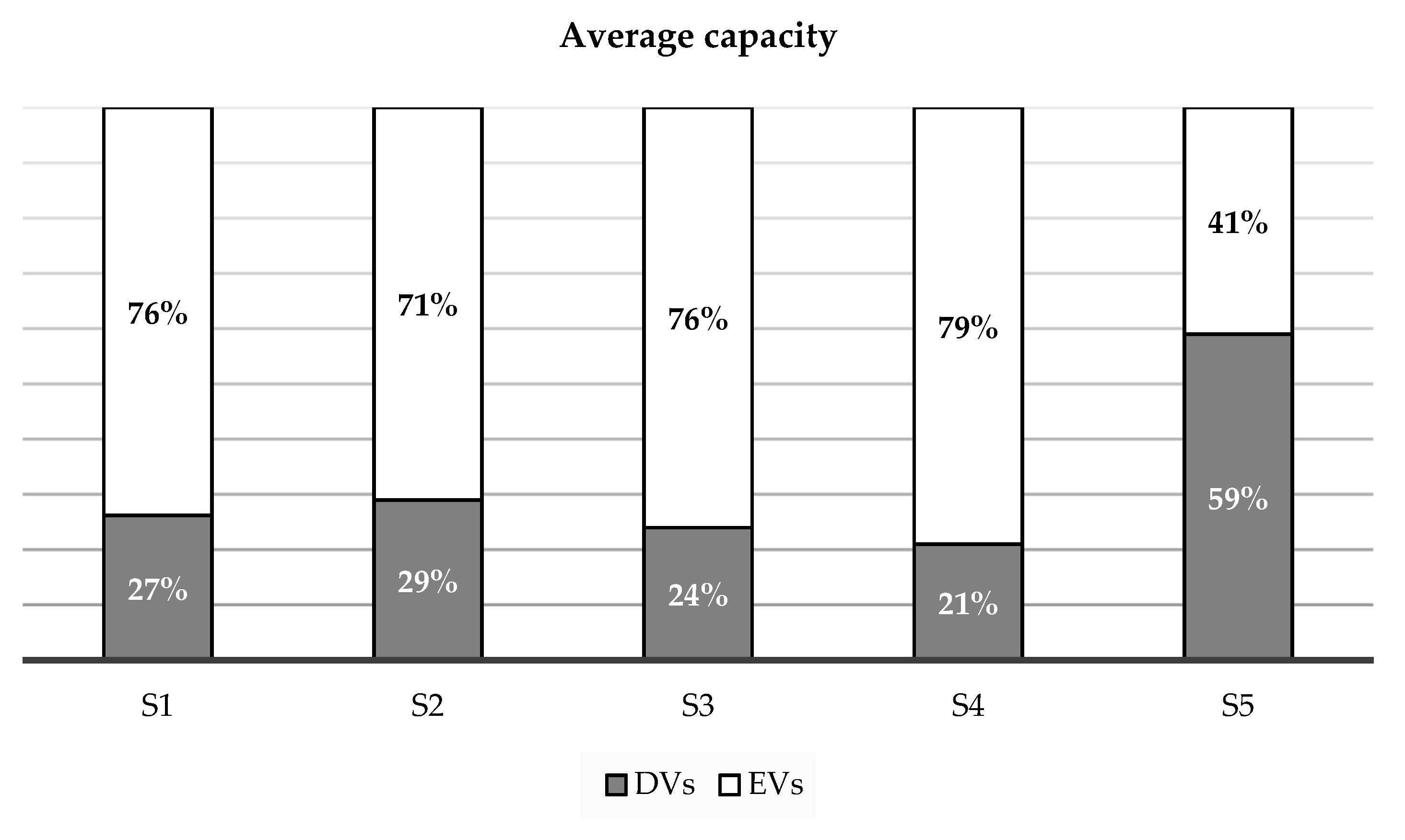

5.3. Capacity analysis

5.4. Elasticity analysis

6. Conclusions

Author Contributions

Data Availability Statement

Conflicts of Interest

References

- European Commission Urbanisation Worldwide. Available online: https://knowledge4policy.ec.europa.eu/foresight/topic/continuing-urbanisation/urbanisation-worldwide_en (accessed on 9 June 2020).

- Sheth, M.; Butrina, P.; Goodchild, A.; McCormack, E. Measuring Delivery Route Cost Trade-Offs between Electric-Assist Cargo Bicycles and Delivery Trucks in Dense Urban Areas. Eur. Transp. Res. Rev. 2019, 11, 12. [Google Scholar] [CrossRef]

- Bosona, T. Urban Freight Last Mile Logistics—Challenges and Opportunities to Improve Sustainability: A Literature Review. Sustain. 2020, 12, 8769. [Google Scholar] [CrossRef]

- Cardenas, I.; Borbon-Galvez, Y.; Verlinden, T.; Voorde, E. Van De; Vanelslander, T.; Dewulf, W. City Logistics, Urban Goods Distribution and Last Mile Delivery and Collection. Compet. Regul. Netw. Ind. 2017, 18. [Google Scholar] [CrossRef]

- Melacini, M.; Perotti, S.; Rasini, M.; Tappia, E. E-Fulfilment and Distribution in Omni-Channel Retailing: A Systematic Literature Review. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 391–414. [Google Scholar] [CrossRef]

- Macharis, C.; Kin, B. The 4 A’s of Sustainable City Distribution: Innovative Solutions and Challenges Ahead. Int. J. Sustain. Transp. 2017, 11, 59–71. [Google Scholar] [CrossRef]

- Letnik, T.; Hanžič, K.; Luppino, G.; Mencinger, M. Impact of Logistics Trends on Freight Transport Development in Urban Areas. Sustain. 2022, 14, 16551. [Google Scholar] [CrossRef]

- Riccardi, M.R.; Mauriello, F.; Sarkar, S.; Galante, F.; Scarano, A.; Montella, A. Parametric and Non-Parametric Analyses for Pedestrian Crash Severity Prediction in Great Britain. Sustainability 2022, 14, 3188. [Google Scholar] [CrossRef]

- Montella, A.; Marzano, V.; Mauriello, F.; Vitillo, R.; Fasanelli, R.; Pernetti, M.; Galante, F. Development of Macro-Level Safety Performance Functions in the City of Naples. Sustainability 2019, 11, 1871. [Google Scholar] [CrossRef]

- Ville, S.; Gonzalez-Feliu, J.; Dablanc, L. The Limits of Public Policy Intervention in Urban Logistics: Lessons from Vicenza (Italy). Eur. Plan. Stud. 2013, 21, 1528–1541. [Google Scholar] [CrossRef]

- Lindholm, M. Urban Freight Transport from a Local Authority Perspective-A Literature Review. Eur. Transp. - Trasp. Eur. 2013, 1–37. [Google Scholar]

- Nuzzolo, A.; Comi, A. Urban Freight Transport Policies in Rome: Lessons Learned and the Road Ahead. J. Urban. 2015, 8, 133–147. [Google Scholar] [CrossRef]

- Maxner, T.; Chiara, G.D.; Goodchild, A. Identifying the Challenges to Sustainable Urban Last-Mile Deliveries: Perspectives from Public and Private Stakeholders. Sustain. 2022, 14, 4701. [Google Scholar] [CrossRef]

- Masłowski, D.; Kulińska, E.; Komada, G. Impact of Alternative Forms of Transport on Urban Freight Congestion. Sustain. 2022, 14, 10972. [Google Scholar] [CrossRef]

- Anderson, S.; Allen, J.; Browne, M. Urban Logistics––How Can It Meet Policy Makers’ Sustainability Objectives? J. Transp. Geogr. 2005, 13, 71–81. [Google Scholar] [CrossRef]

- Browne, M.; Allen, J. Enhancing the Sustainability of Urban Freight Transport and Logistics. Transp. Commun. Bull. Asia Pacific 2011, 44, 1–19. [Google Scholar]

- Axelsson, J.; Jensen, C.; Johansson, H.; Lagercrantz, J.; Larsson, M.-O.; Lindman, K.; Ottosson, M.; Siira, J.; Stenström, M.; Vennersten, S.; et al. Final Evaluation Report Göteborg (TELLUS Project); 2005.

- Comi, A.; Site, P.D.; Filippi, F.; Marcucci, E.; Nuzzolo, A. Differentiated Regulation of Urban Freight Traffic: Conceptual Framework and Examples from Italy. In Proceedings of the 13th International Conference of Hong Kong Society for Transportation Studies: Transportation and Management; 2008; pp. 815–824.

- Barter, G.E.; Reichmuth, D.; Westbrook, J.; Malczynski, L.A.; West, T.H.; Manley, D.K.; Guzman, K.D.; Edwards, D.M. Parametric Analysis of Technology and Policy Tradeoffs for Conventional and Electric Light-Duty Vehicles. Energy Policy 2012, 46, 473–488. [Google Scholar] [CrossRef]

- Lebeau, P.; Macharis, C.; Van Mierlo, J.; Lebeau, K. Electrifying Light Commercial Vehicles for City Logistics? A Total Cost of Ownership Analysis. Eur. J. Transp. Infrastruct. Res. 2015, 15, 551–569. [Google Scholar] [CrossRef]

- Crist, P. Elecric Vehicles Revisited - Costs, Subsidies and Prospects; OECD Publishing: Paris, 2012. [Google Scholar]

- Tipagornwong, C.; Figliozzi, M. Analysis of Competitiveness of Freight Tricycle Delivery Services in Urban Areas. Transp. Res. Rec. 2014, 2410, 76–84. [Google Scholar] [CrossRef]

- Feng, W.; Figliozzi, M. An Economic and Technological Analysis of the Key Factors Affecting the Competitiveness of Electric Commercial Vehicles: A Case Study from the USA Market. Transp. Res. Part C Emerg. Technol. 2013, 26, 135–145. [Google Scholar] [CrossRef]

- Taefi, T.T.; Kreutzfeldt, J.; Held, T.; Konings, R.; Kotter, R.; Lilley, S.; Baster, H.; Green, N.; Laugesen, M.S.; Jacobsson, S.; et al. Comparative Analysis of European Examples of Freight Electric Vehicles Schemes—A Systematic Case Study Approach with Examples from Denmark, Germany, the Netherlands, Sweden and the UK. In Dynamics in Logistics - Proceedings of the 4th International Conference LDIC, 2014 Bremen, Germany; Kotzab, H., Pannek, J., Thoben, K.D., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 495–504. ISBN 9783319235127. [Google Scholar]

- Dablanc, L. Goods Transport in Large European Cities: Difficult to Organize, Difficult to Modernize. Transp. Res. Part A Policy Pract. 2007, 41, 280–285. [Google Scholar] [CrossRef]

- Behiri, W.; Belmokhtar-Berraf, S.; Chu, C. Urban Freight Transport Using Passenger Rail Network: Scientific Issues and Quantitative Analysis. Transp. Res. Part E Logist. Transp. Rev. 2018, 115, 227–245. [Google Scholar] [CrossRef]

- Pelletier, S.; Viswanath, P.; Mathew, M. Goods Distribution with Electric Vehicles : Review and Research Perspectives Goods; 2014.

- Nina, M. Introduction of Electric Vehicles in Portugal - A Cost-Benefit Analysis, Instituto Superior Técnico, Universidade de Lisboa, 2010.

- Eilon, S.; King, J.R.; Hutchinson, D.E. A Study in Equipment Replacement. J. Oper. Res. Soc. 1966, 17, 59–71. [Google Scholar] [CrossRef]

- Christer, A.H.; Goodbody, W. Equipment Replacement in an Unsteady Economy. J. Oper. Res. Soc. 1980, 31, 497–506. [Google Scholar] [CrossRef]

- Scarf, P.A.; Bouamra, O. Capital Equipment Replacement Model for a Fleet with Variable Size. J. Qual. Maint. Eng. 1999, 5, 40–49. [Google Scholar] [CrossRef]

- Redmer, A. Optimisation of the Exploitation Period of Individual Vehicles in Freight Transportation Companies. Transp. Res. Part E Logist. Transp. Rev. 2009, 45, 978–987. [Google Scholar] [CrossRef]

- Rees, L.P.; Clayton, E.R.; Taylor, B.W. A Network Simulation Model for Police Patrol Vehicle Maintenance and Replacement Analysis. Comput. Environ. Urban Syst. 1982, 7, 191–196. [Google Scholar] [CrossRef]

- Suzuki, Y.; Pautsch, G.R. A Vehicle Replacement Policy for Motor Carriers in an Unsteady Economy. Transp. Res. Part A Policy Pract. 2005, 39, 463–480. [Google Scholar] [CrossRef]

- Kim, H.C.; Keoleian, G.A.; Grande, D.E.; Bean, J.C. Life Cycle Optimization of Automobile Replacement: Model and Application. Environ. Sci. Technol. 2003, 37, 5407–5413. [Google Scholar] [CrossRef]

- Emiliano, W.; Alvelos, F.; Telhada, J.; Lanzer, E.A. An Optimization Model for Bus Fleet Replacement with Budgetary and Environmental Constraints. Transp. Plan. Technol. 2020, 43, 488–502. [Google Scholar] [CrossRef]

- Beaujon, G.J.; Turnquist, M.A. A Model for Fleet Sizing and Vehicle Allocation. Transp. Sci. 1991, 25, 17–45. [Google Scholar] [CrossRef]

- Li, L.; Lo, H.K.; Xiao, F.; Cen, X. Mixed Bus Fleet Management Strategy for Minimizing Overall and Emissions External Costs. Transp. Res. Part D Transp. Environ. 2018, 60, 104–118. [Google Scholar] [CrossRef]

- Redmer, A. Strategic Vehicle Fleet Management–a Joint Solution of Make-or-Buy, Composition and Replacement Problems. J. Qual. Maint. Eng. 2022, 28, 327–349. [Google Scholar] [CrossRef]

- Wu, P.; Hartman, J.C.; Wilson, G.R. An Integrated Model and Solution Approach for Fleet Sizing with Heterogeneous Assets. Transp. Sci. 2005, 39, 87–103. [Google Scholar] [CrossRef]

- Zheng, S.; Chen, S. Fleet Replacement Decisions under Demand and Fuel Price Uncertainties. Transp. Res. Part D Transp. Environ. 2018, 60, 153–173. [Google Scholar] [CrossRef]

- Raposo, H.; Farinha, J.T.; Ferreira, L.; Galar, D. An Integrated Econometric Model for Bus Replacement and Determination of Reserve Fleet Size Based on Predictive Maintenance. Eksploat. i Niezawodn. 2017, 19, 358–368. [Google Scholar] [CrossRef]

- Koç, Ç.; Bektaş, T.; Jabali, O.; Laporte, G. The Impact of Depot Location, Fleet Composition and Routing on Emissions in City Logistics. Transp. Res. Part B Methodol. 2016, 84, 81–102. [Google Scholar] [CrossRef]

- Daganzo, C.F. Modeling Distribution Problems with Time Windows: Part I. Transp. Sci. 1987, 21, 171–179. [Google Scholar] [CrossRef]

- Ghiani, G.; Laporte, G.; Musmanno, R. Introduction to Logistics Systems Management; 3rd ed.; John Wiley and Sons Ltd, 2022; ISBN 9781119789390.

- Meusalario.pt Compare Seu Salário. Available online: https://meusalario.pt/salario/compare-seu-salario?job-id=8322020000000/%5C#/ (accessed on 6 July 2020).

- NISSAN NISSAN E-NV200. Available online: https://www.nissan.pt/veiculos/novos-veiculos/e-nv200/preco-e-versoes.html (accessed on 6 May 2020).

- ACEA Average Age of the EU Vehicle Fleet, by Country. Available online: https://www.acea.auto/figure/average-age-of-eu-vehicle-fleet-by-country/ (accessed on 22 July 2020).

- Ahani, P.; Arantes, A.; Melo, S. A Portfolio Approach for Optimal Fleet Replacement toward Sustainable Urban Freight Transportation. Transp. Res. Part D Transp. Environ. 2016, 48, 357–368. [Google Scholar] [CrossRef]

- PORDATA Consumo de Energia Elétrica: Total e Por Setor de Atividade Económica. Available online: https://www.pordata.pt/Portugal (accessed on 22 July 2020).

- Zhang, J.; Wang, Z.; Liu, P.; Cui, D.; Li, X. Analysis on Influence Factors of Energy Consumption of Electric Vehicles Based on Real-World Driving Data. In Proceedings of the International Conference on Applied Energy 2019; Västerås, Sweden, 2019; pp. 12–15.

- Lois, D.; Wang, Y.; Boggio-Marzet, A.; Monzon, A. Multivariate Analysis of Fuel Consumption Related to Eco-Driving: Interaction of Driving Patterns and External Factors. Transp. Res. Part D Transp. Environ. 2019, 72, 232–242. [Google Scholar] [CrossRef]

- Adeniran, I.O. The Impacts of Sustainable Concepts in Urban Freight Distribution - A Courier, Express and Parcel Case Study, TUM - Technische Universität München, 2020.

- Gerlagh, R.; Heijmans, R.J.R.K.; Rosendahl, K.E. COVID-19 Tests the Market Stability Reserve. Environ. Resour. Econ. 2020, 76, 855–865. [Google Scholar] [CrossRef]

- Lee, D.Y.; Thomas, V.M.; Brown, M.A. Electric Urban Delivery Trucks: Energy Use, Greenhouse Gas Emissions, and Cost-Effectiveness. Environ. Sci. Technol. 2013, 47, 8022–8030. [Google Scholar] [CrossRef] [PubMed]

- City of Toronto - Fleet Services 2017 Performance Measurement & Benchmarking Report; Canada, 2019.

- Electrification Coalition Fleet Electrification Roadmap: Revolutionizing Transportation and Achieving Energy Security; Washington, D.C., 2010.

- Allen, R.G.D. The Concept of Arc Elasticity of Demand: I. Rev. Econ. Stud. 1934, 1, 226–229. [Google Scholar] [CrossRef]

| Zone | Coordinates (x, y) of the left-down corner of each zone (km, km) |

Outer dimensions of each zone (km x km) |

) (km2) |

Coordinates (x, y) of each depot (km, km) |

(km) |

|---|---|---|---|---|---|

| z1 | 2.5, 4.5 | 5 x 2 | 10 | 3.0, 5.5 | 2.0 |

| z2 | 1.0, 3.0 | 8 x 5 | 30 | 1.5, 5.5 | 3.5 |

| z3 | 0.5, 0.5 | 9 x 10 | 50 | 0.5, 5.5 | 4.5 |

| Suburban zone (Out of zones) | 0.0, 0.0 | 10 x 11 | 20 | 0.0, 5.5 | 5.0 |

| k | Vehicle Model | Motor type | Size type | Capacity (m3) | Price (euro) | Driver salary (EUR/month) [46] | Energy consumption |

|---|---|---|---|---|---|---|---|

| 1 | Renault New Kangoo Express [20] | Diesel | Light | 2 | 13,600 | 750 | 5.2 l/100 km |

| 2 | Renault Kangoo ZE [20] | Electric | Light | 2 | 21,150 | 750 | 15.5 kWh:100 km |

| 3 | Nissan NV200 [20] | Diesel | Medium | 4 | 15,400 | 932 | 5.7 l/100 km |

| 4 | Nissan e-NV200 [47] | Electric | Medium | 4 | 25,652 | 932 | 16.5 k Wh:100 km |

| 5 | Isuzu N-Series [23] | Diesel | Heavy | 12 | 48,450 | 1068 | 17.47 l/100km |

| 6 | eStar (Navistar) [23] | Electric | Heavy | 12 | 133,369 | 1068 | 50 kWh:100km |

| Parameter | Diesel vehicle | Electric vehicle |

|---|---|---|

| Maximum age (Ak) [23,48] | 15 | |

| Discount rate(dr) [23] | 6.50% | |

| Working days in a year (Wd) | 251 | |

| Planning time horizon(year) (t) [23] | 30 | |

| Depreciation rate (θk) [23,49] | 0.15 | 0.198 |

| Energy cost growth rate (fd, fe) [50] | 0.0582 | 0.0289 |

| Energy consumption (Rk, Qk) [51,52] | 0.062 l/km | 0.145 kWh/km |

| Energy cost [50] | 1.167 EUR/l | 0.167 EUR/kWh |

| CO2 emissions (Well-to-Wheel) [53] | 2.63 kg/l | 0.47 kg/kWh |

| Zone | Demand (customer/day) |

LDV | MDV | HDV |

|---|---|---|---|---|

| z1 | n1 = 60 | 10 | - | - |

| z2 | n2 = 90 | 5 | 5 | - |

| z3 | n3 = 120 | 4 | 2 | 2 |

| Total | 270 | 19 1 | 7 | 2 |

| Scenario | Vehicle type | Average usage | Initial usage | Final usage | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| z1 | z2 | z3 | z1 | z2 | z3 | z1 | z2 | z3 | ||

| S1 | LDV | 0.033 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| LEV | 9.967 | 0 | 0 | 9 | 0 | 0 | 10 | 0 | 0 | |

| MDV | 0 | 2.133 | 0 | 0 | 8 | 0 | 0 | 0 | 0 | |

| MEV | 0 | 5.867 | 0 | 0 | 0 | 0 | 0 | 8 | 0 | |

| HDV | 0 | 0 | 1.067 | 0 | 0 | 4 | 0 | 0 | 0 | |

| HEV | 0 | 0 | 2.933 | 0 | 0 | 0 | 0 | 0 | 4 | |

| S2 | LDV | 1.267 | 0 | 0 | 10 | 0 | 0 | 0 | 0 | 0 |

| LEV | 8.733 | 0 | 0 | 0 | 0 | 0 | 10 | 0 | 0 | |

| MDV | 0 | 2.133 | 0 | 0 | 8 | 0 | 0 | 0 | 0 | |

| MEV | 0 | 5.867 | 0 | 0 | 0 | 0 | 0 | 8 | 0 | |

| HDV | 0 | 0 | 1.067 | 0 | 0 | 4 | 0 | 0 | 0 | |

| HEV | 0 | 0 | 2.933 | 0 | 0 | 0 | 0 | 0 | 4 | |

| S3 | LDV | 0.7 | 0 | 0 | 10 | 0 | 0 | 0 | 0 | 0 |

| LEV | 9.3 | 0 | 0 | 0 | 0 | 0 | 10 | 0 | 0 | |

| MDV | 0 | 1.6 | 0 | 0 | 8 | 0 | 0 | 0 | 0 | |

| MEV | 0 | 6.4 | 0 | 0 | 0 | 0 | 0 | 8 | 0 | |

| HDV | 0 | 0 | 1.067 | 0 | 0 | 4 | 0 | 0 | 0 | |

| HEV | 0 | 0 | 2.933 | 0 | 0 | 0 | 0 | 0 | 4 | |

| S4 | LDV | 0.933 | 0 | 0 | 10 | 0 | 0 | 0 | 0 | 0 |

| LEV | 9.067 | 0 | 0 | 0 | 0 | 0 | 10 | 0 | 0 | |

| MDV | 0 | 1.067 | 0 | 0 | 8 | 0 | 0 | 0 | 0 | |

| MEV | 0 | 6.933 | 0 | 0 | 0 | 0 | 0 | 8 | 0 | |

| HDV | 0 | 0 | 1.3 | 0 | 0 | 4 | 0 | 0 | 0 | |

| HEV | 0 | 0 | 2.7 | 0 | 0 | 0 | 0 | 0 | 4 | |

| S5 | LDV | 0 | 0.033 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| LEV | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| MDV | 0 | 0.4 | 0.167 | 0 | 1 | 1 | 0 | 0 | 0 | |

| MEV | 0.467 | 1.567 | 0.667 | 0 | 0 | 0 | 2 | 2 | 1 | |

| HDV | 1.6 | 1.567 | 2.233 | 2 | 2 | 3 | 0 | 0 | 0 | |

| HEV | 0.167 | 0.433 | 0.933 | 0 | 0 | 0 | 1 | 2 | 3 | |

| Scenario | Vehicle type | Average usage | Initial usage | Final usage | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| z1 | z2 | z3 | z1 | z2 | z1 | z2 | z3 | z3 | ||

| S1 | LDV | 0.133 | 0 | 0 | 4 | 0 | 0 | 0 | 0 | 0 |

| LEV | 9.867 | 0 | 0 | 6 | 0 | 0 | 10 | 0 | 0 | |

| MDV | 0 | 2.133 | 0 | 0 | 8 | 0 | 0 | 0 | 0 | |

| MEV | 0 | 5.867 | 0 | 0 | 0 | 0 | 0 | 8 | 0 | |

| HDV | 0 | 0 | 1.067 | 0 | 0 | 4 | 0 | 0 | 0 | |

| HEV | 0 | 0 | 2.933 | 0 | 0 | 0 | 0 | 0 | 4 | |

| S2 | LDV | 1.267 | 0 | 0 | 10 | 0 | 0 | 0 | 0 | 0 |

| LEV | 8.733 | 0 | 0 | 0 | 0 | 0 | 10 | 0 | 0 | |

| MDV | 0 | 2.133 | 0 | 0 | 8 | 0 | 0 | 0 | 0 | |

| MEV | 0 | 5.867 | 0 | 0 | 0 | 0 | 0 | 8 | 0 | |

| HDV | 0 | 0 | 1.067 | 0 | 0 | 4 | 0 | 0 | 0 | |

| HEV | 0 | 0 | 2.933 | 0 | 0 | 0 | 0 | 0 | 4 | |

| S3 | LDV | 0.7 | 0 | 0 | 10 | 0 | 0 | 0 | 0 | 0 |

| LEV | 9.3 | 0 | 0 | 0 | 0 | 0 | 10 | 0 | 0 | |

| MDV | 0 | 1.6 | 0 | 0 | 8 | 0 | 0 | 0 | 0 | |

| MEV | 0 | 6.4 | 0 | 0 | 0 | 0 | 0 | 8 | 0 | |

| HDV | 0 | 0 | 1.067 | 0 | 0 | 4 | 0 | 0 | 0 | |

| HEV | 0 | 0 | 2.933 | 0 | 0 | 0 | 0 | 0 | 4 | |

| S4 | LDV | 0.933 | 0 | 0 | 10 | 0 | 0 | 0 | 0 | 0 |

| LEV | 9.067 | 0 | 0 | 0 | 0 | 0 | 10 | 0 | 0 | |

| MDV | 0 | 1.067 | 0 | 0 | 8 | 0 | 0 | 0 | 0 | |

| MEV | 0 | 6.933 | 0 | 0 | 0 | 0 | 0 | 8 | 0 | |

| HDV | 0 | 0 | 1.3 | 0 | 0 | 4 | 0 | 0 | 0 | |

| HEV | 0 | 0 | 2.7 | 0 | 0 | 0 | 0 | 0 | 4 | |

| S5 | LDV | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| LEV | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| MDV | 0 | 0.433 | 0.167 | 0 | 2 | 1 | 0 | 0 | 0 | |

| MEV | 0.467 | 1.567 | 0.667 | 0 | 0 | 0 | 2 | 2 | 1 | |

| HDV | 1.6 | 1.567 | 2.333 | 2 | 2 | 3 | 0 | 0 | 0 | |

| HEV | 0.167 | 0.433 | 0.933 | 0 | 0 | 0 | 1 | 2 | 3 | |

| Parameter | Interval (%) | Baseline value (%) | S1 | S2 | S3 | S4 | S5 | |

|---|---|---|---|---|---|---|---|---|

| With an existing fleet with | EVs depreciation rate | 10 to 20 | 15 | 0.055 | 0.132 | 0.193 | 0.055 | 0.055 |

| EVs depreciation rate | 14 to 24 | 19.8 | 0.015 | 0.135 | 0.095 | 0.015 | 0.015 | |

| EVs depreciation rate | 18 to 28 | 23 | 0.025 | 0.130 | 0.048 | 0.025 | 0.025 | |

| DVs energy price growth rate | 2.91 to 8.73 | 5.82 | 0.069 | 0.005 | 0.004 | 0.069 | 0.069 | |

| EVs energy price growth rate | 1.44 to 4.33 | 2.89 | 0.016 | 0.016 | 0.026 | 0.016 | 0.016 | |

| Without an existing fleet | EVs depreciation rate | 10 to 20 | 15 | 0.091 | 0.098 | 0.118 | 0.129 | 0.055 |

| EVs depreciation rate | 14 to 24 | 19.8 | 0.052 | 0.054 | 0.079 | 0.095 | 0.015 | |

| EVs depreciation rate | 18 to 28 | 23 | 0.026 | 0.026 | 0.04 | 0.052 | 0.025 | |

| DVs energy price growth rate | 2.91 to 8.73 | 5.82 | 0.069 | 0.068 | 0.063 | 0.061 | 0.132 | |

| EVs energy price growth rate | 1.44 to 4.33 | 2.89 | 0.016 | 0.018 | 0.021 | 0.024 | 0.014 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).