Submitted:

08 July 2023

Posted:

11 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

- Recovering sensors data not provided by the engine model, due to convergence difficulties. Also, recovering data at places in the engine not accessible to sensor measurements.

- Correcting wrong sensors data due to ill-functioning of the sensors themselves or the engine instrumentation, which may produce large errors.

- The condition monitoring tool 1 is based on a linear approximation and thus requires small degradations around a baseline state, which are expected in each individual flight. Its online operation is extremely fast, namely it can operate in continuous real-time. It precisely computes the turbine inlet temperature and gives a first approximation of the engine degradation. This tool has been obtained as an unexpected byproduct, when checking the importance of nonlinear effects.

- The condition monitoring tool 2 is the counterpart, using the ROM surrogate, of a very efficient tool developed in [19] for the full engine model. This tool operates in in-flight real-time and is designed for non-small degradations (up to %), for which nonlinear effects must be accounted for. Let us mention here that degradations of 2% are fairly high and usually require performing maintenance tasks on the degraded engine component [28,29,30] to avoid future dangerous events. On the other hand, the very small degradations that are expected during each flight accumulate in subsequent flights. In this sense, if an accumulated degradation becomes larger than 2 %, then it must be monitored since it could reach dangerous values as time proceeds. Such monitoring can be performed using the method developed in [19], which accurately performs diagnosis for very large degradations. In this sense, the tool 2 developed in this paper is complementary to the methodology presented in [19].

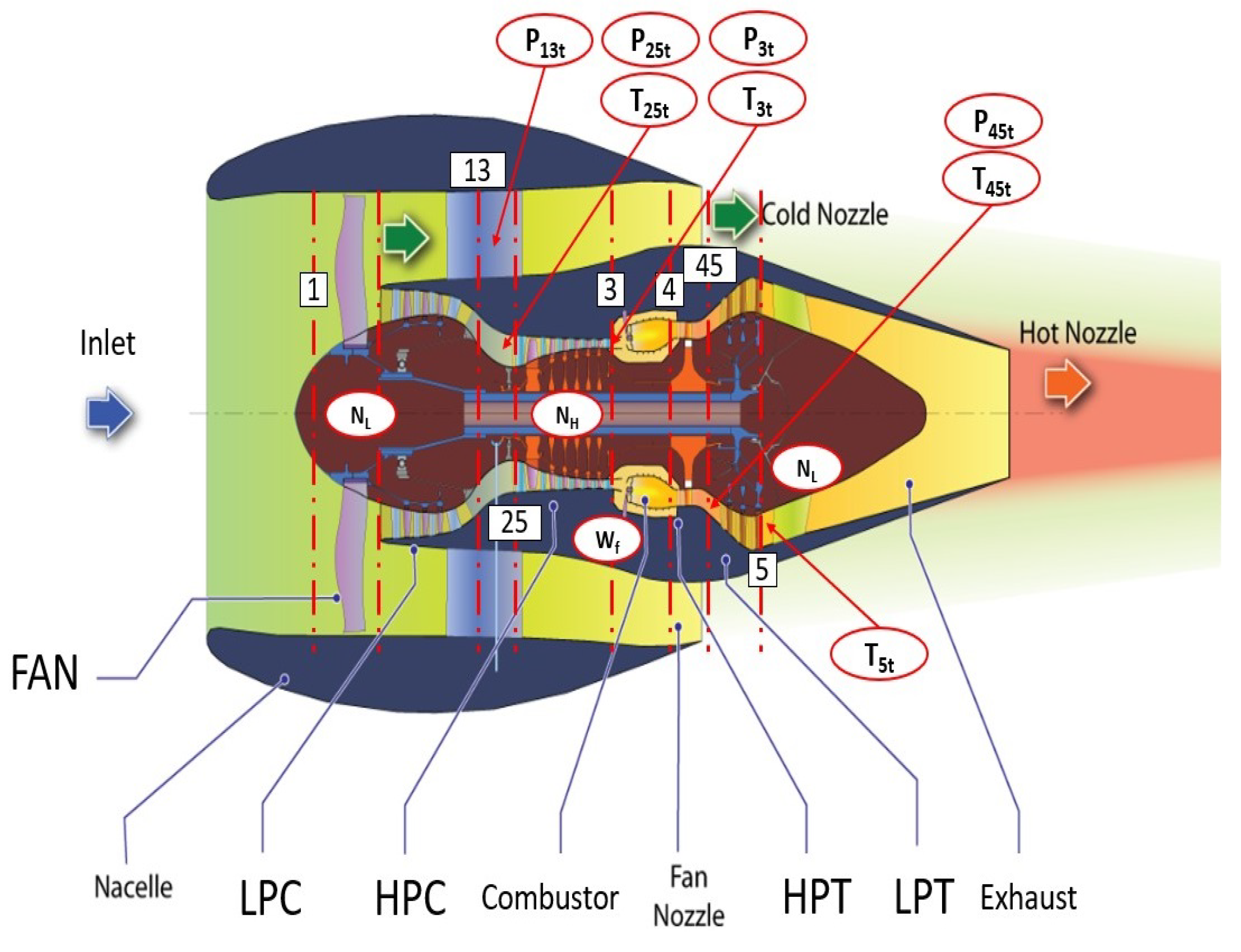

2. Test case to evaluate the performance of the methodology: the CFM56 aeroengine.

3. Methods and tools

3.1. Standard SVD and HOSVD

3.2. Construction of the HOSVD-based surrogate engine model

- For , the first index indicates the eleven sensors.

- For , the second index corresponds to the three flight altitudes displayed in (3).

- For , the third index is associated with the three Mach numbers appearing in (4).

- For , the fourth index indicates the five values of the turbine inlet temperature displayed in (5).

- The remaining ten indexes, , correspond to the ten degradations denoted as x and are allowed to take the following three values

3.3. Condition monitoring tool 1: a purely linear method

3.4. Condition monitoring tool 2: a global, constraint Newton-based method

4. Representative condition monitoring results

4.1. Results using the condition monitoring tool 1

- The linear tool is robust in connection with random noise added to the clean sensors data.

- Nonlinear effects cannot be ignored in the considered range of degradations.

- In spite of that, the tool is able to compute the temperature very fast and very accurately. Thus, this tool can be used to obtain this temperature in continuous real-time, continuously showing its value in a monitor installed in the aircraft cockpit, as anticipated.

4.2. Results using the condition monitoring tool 2

- The global, constraint Newton-based method is robust in connection with random noise added to the clean data.

- This tool takes nonlinear effects into account and, thus, it gives precise results for both the turbine inlet temperature and the degradation parameters.

- The tool gives results in in-flight real-time, meaning that it can be applied several times in each flight. This permits recalculating the engine condition when some degradations are not small enough.

5. Concluding remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Knotts, R.M.H. Civil aircraft maintenance and support fault diagnosis from a business perspective. SIAM J. Qual. Maiten. Eng. 1999, 5, 335–348. [Google Scholar] [CrossRef]

- He, Q.; Zhang, W.; Lu, P.; Liu, J. Performance comparison of representative model-based fault reconstruction algorithms for aircraft sensor fault detection and diagnosis. Aerosp. Sci. Technol. 2020, 98, 105649. [Google Scholar] [CrossRef]

- Jin, P.; Lu, F.; Huang, J.; Kong, X.; Fan, M. Life cycle gas path performance monitoring with control loop parameters uncertainty for aeroengine. Aerosp. Sci. Technol. 2021, 115, 106775. [Google Scholar] [CrossRef]

- Ewald, V.; Sridaran Venkat, R; Asokkumar, A.; Benedictus, R.; Boller, C; Groves, R.M. Perception modelling by invariant representation of deep learning for automated structural diagnostic in aircraft maintenance: A case study using DeepSHM. Mech. Syst. Signal Process. 2022, 165, 108153. [Google Scholar] [CrossRef]

- International Air Transport Association, Airline Maintenance Cost Executive Commentary (FY2018 Data). Available online: https://www.iata.org/ (accessed on December 12, 2021).

- Mobley, R.K. An introduction to predictive maintenance (2nd ed.); Butterworth-Heinemann, 2002.

- Zonta, T.; da Costa, C.A.; da Rosa Righi, R.; de Lima, M.J.; Silveira da Trindade, E.; Li, G.P. Predictive maintenance in the Industry 4.0: A systematic literature review. Computers & Ind. Engineering 2020, 150, 106889. [Google Scholar]

- Dolatabadi, S.H.; Budinska, I. Systematic literature review predictive maintenance solutions for SMEs from the last decade. Machines 2021, 9, 191. [Google Scholar] [CrossRef]

- Jardine, A.K.S.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Li, R.; Verhagen, W.J.C.; Curran, R. Toward a methology of requirements definition for prognostics and health management system to support aircraft predictive maintenance. Aerosp. Sci. Technol. 2020, 102, 105887. [Google Scholar] [CrossRef]

- Li, Z.; Y. Wang, Y.; Wang, K. Intelligent predictive maintenance for fault diagnosis and prognosis in machine centers: Industry 4.0 scenario. Adv. Manuf. 2017, 5, 377–387. [Google Scholar] [CrossRef]

- Davari, N.D.; Veloso, B.; de Assis Costa, G.; Mota Pereira, P.; Ribeiro, R.P.; Gamma, J. A survey on data-driven predictive maintenance for the Railway industry. Sensors 2021, 21, 5739. [Google Scholar] [CrossRef]

- Marinai, L.; Probert, D.; Singh, R. Prospects for aero gas-turbine diagnostics: a review. Applied Energy 2004, 79, 109–126. [Google Scholar] [CrossRef]

- Skliros, Ch.; Esperon Miguez, M.; Fakhre, A.; Jennions, I.K. A review of model based and data driven targeting hardware systems diagnostics. Diagnostyka 2019, 20, 3–21. [Google Scholar] [CrossRef]

- Raissi, M.; Perdicaris, P.; Karniadakis, G.E. Physics-informed neural networks: A deep learning framework for solving forward and inverse problems involving nonlinear partial differential equations. J. Comput. Phys. 2019, 378, 686–707. [Google Scholar] [CrossRef]

- Basora, L.; Olive, X.; Dubot, T. Recent advances in anomaly detection methods applied to aviation. Aerospace 2019, 6, 117. [Google Scholar] [CrossRef]

- Stamatis, A.; Mathioudakis, K.; Papailiou, K. Optimal measurement and health index selection for gas turbine performance status and fault diagnosis. J. Eng. Gas Turb. Power 1992, 114, 209–216. [Google Scholar] [CrossRef]

- EcosimPro, PROOSIS - Modelling and Simulation Toolkits and Services. Available online: https://www.ecosimpro.com/ (accessed on June 4, 2023).

- Rodrigo, J.; Sanchez de Leon, L.; Montañes, J.L.; Vega, J.M. Aeroengine diagnosis using a new robust gradient-like methodology. Aerospace 2023, 10, 355. [Google Scholar] [CrossRef]

- Bui-Thanh, T. Proper Orthogonal Decomposition Extensions and their Applications in Steady Aerodynamics; Master Thesis: Singapore-MIT Alliance, 2003. [Google Scholar]

- Bui-Thanh, T.; Damodaran, M.; Willcox, K. Aerodynamic data reconstruction and inverse design using Proper Orthogonal Decomposition. AIAA Journal 2004, 42, 1505–1516. [Google Scholar] [CrossRef]

- Lorente, L.S.; Vega, J.M.; Velazquez, A. Generation of aerodynamic databases using high order singular value decomposition. J. Aircraft 2008, 45, 1779–1788. [Google Scholar] [CrossRef]

- Benito, N.; Arias, J.R.; Velazquez, A.; Vega, J.M. Real time performance improvement of engineering control units via high order singular value decomposition: application to a SI engine. Control Eng. Practice 2011, 19, 1315–1327. [Google Scholar] [CrossRef]

- de Lucas, S.; Vega, J.M.; Velazquez, A. Aeronautic conceptual design optimization method based on high order singular value decomposition. AIAA Journal 2011, 49, 2713–2725. [Google Scholar] [CrossRef]

- de Lucas, S.; Vega, J.M.; Velazquez, A. Surrogate model for viscous drag in aircraft empennage conceptual design. Aerosp. Sci. Technol. 2013, 31, 99–107. [Google Scholar] [CrossRef]

- Moreno, A.; Jarzabek, A.; Perales, J.M.; Vega, J.M. Aerodynamic database reconstruction via gappy high order singular value decomposition. Aerosp. Sci. Technol. 2016, 52, 115–128. [Google Scholar] [CrossRef]

- Jarzabek, A.; Moreno, A.; Perales, J.M.; Vega, J.M. Aerodynamic database error filtering via SVD-like methods. Aerosp. Sci. Technol. 2017, 65, 62–77. [Google Scholar] [CrossRef]

- Olsson, W.J.; Stromberg, W.J. JT9D jet engine diagnostics program; Technical Report No. 1981-0022657, January 1981, pp. 43–61. National Aeronautics and Space Administration: Cleveland, OH, USA, 1981. [Google Scholar]

- James, A.D.; Weisel, D.R. JT8D engine performance retention; Technical Report No. 1981-0022658, January 1981, pp. 63–81. National Aeronautics and Space Administration: Cleveland, OH, USA, 1981. [Google Scholar]

- Astridge, B.L.; Pinder, J.T. Performance Retention of the RB211 Powerplant in Service; Technical Report No. 1981-0022659, January 1981, pp. 83–102; National Aeronautics and Space Administration: Cleveland, OH, USA, 1981. [Google Scholar]

- Daly, M. IHS Jane’s Aero Engines, (2016/2017); IHS Global Limited: London, UK, 2016. [Google Scholar]

- Kashkhan, Turbofan schematic. 2009. Available online: https://en.wikipedia.org/wiki/File:Tfan-schematic-kk-20090106.png (accessed on 27 March 2023).

- Stewart, G.W. On the early history of the Singular Value Decomposition. SIAM Review 1993, 35, 551–566. [Google Scholar] [CrossRef]

- Eckart, C.; Young, G. The approximation of one matrix by another of lower rank. Psychometrika 1936, 1, 211–218. [Google Scholar] [CrossRef]

- Golub, G.H.; van Loan, G.T. Matrix Computations; John Hopkins University Press: Baltimore, MD, USA, 1996. [Google Scholar]

- Trefethen, L.N.; Bau, D. Numerical Linear Algebra; Society for Industrial and Applied Mathematics, 1997.

- Kolda, T.G.; Bader, B.W. Tensor decompositions and applications. SIAM Review 2009, 51, 455–500. [Google Scholar] [CrossRef]

- da Silva, V.; Lim, L.H. Tensor rank and the ill-posedness of the best low-rank approximation problem. SIAM J. Matrix Anal. Appl. 2008, 30, 1084–1127. [Google Scholar] [CrossRef]

- Tucker, L.R. Some mathematical notes on three-mode factor analysis. Psychometrika 1966, 31, 279–311. [Google Scholar] [CrossRef]

- de Lathauwer, L.; de Moor, B.; Vandewalle, J. A multilinear singular value decomposition. SIAM J. Matrix Anal. Appl. 2000, 21, 1253–1278. [Google Scholar] [CrossRef]

- de Lathauwer, L.; de Moor, B.; Vandewalle, J. On the best rank-one and rank-(R1,R2,...,RN) approximation of higher order tensors. SIAM J. Matrix Anal. Appl. 2000, 21, 1324–1342. [Google Scholar] [CrossRef]

- https://es.mathworks.com/matlabcentral/fileexchange/25514-tp-tool (accessed on June 4, 2023).

- Meseguer, A. Fundamentals of Numerical Mathematics for Physicists and Engineers; Wiley, 2020.

| Degradation # | Degradation description |

|---|---|

| 1 | : FAN efficiency |

| 2 | : FAN flow capacity |

| 3 | : LPC efficiency |

| 4 | : LPC flow capacity |

| 5 | : HPC efficiency |

| 6 | : HPC flow capacity |

| 7 | : HPT efficiency |

| 8 | : HPT flow capacity |

| 9 | : LPT efficiency |

| 10 | : LPT flow capacity |

| Sensor # | description | average value | standard deviation |

|---|---|---|---|

| 1 | Pa | 0.15 | |

| 2 | Pa | 0.15 | |

| 3 | Pa | 0.15 | |

| 4 | Pa | 0.15 | |

| 5 | K | 0.025 | |

| 6 | K | 0.034 | |

| 7 | K | 0.050 | |

| 8 | K | 0.054 | |

| 9 | rpm | 0.035 | |

| 10 | rpm | 0.029 | |

| 11 | kg/s | 0.18 |

| -0.0666 | -0.0665 | -0.0666 | -0.0665 | |||

| 0.3389 | 0.0849 | 0.8688 | 0.5538 | |||

| 0.0982 | 0.0934 | 0 | 0.0923 | |||

| 0.2450 | 0.0679 | 1.7819 | 0.1943 | |||

| 0 | 0.0758 | 2 | 1.6469 | |||

| 0 | 0.0743 | 1.0834 | 1.3897 | |||

| 0 | 0.0392 | 0.1105 | 0.6342 | |||

| 0.0876 | 0.0655 | 1.9593 | 1.9004 | |||

| 0.2385 | 0.0171 | 0.3016 | 0.0689 | |||

| 0 | 0.0706 | 0.8167 | 0.8775 | |||

| 0.2357 | 0.0032 | 0.9587 | 0.7631 |

| -0.0666 | -0.0665 | -0.0666 | -0.0665 | |||

| 0.2828 | 0.0849 | 0.8747 | 0.5538 | |||

| 0.0692 | 0.0934 | 0.0271 | 0.0923 | |||

| 0.2596 | 0.0679 | 1.7709 | 0.1943 | |||

| 0.0208 | 0.0758 | 1.9969 | 1.6469 | |||

| 0.0121 | 0.0743 | 1.0898 | 1.3897 | |||

| 0 | 0.0392 | 0.1430 | 0.6342 | |||

| 0.0863 | 0.0655 | 1.9509 | 1.9004 | |||

| 0.2201 | 0.0171 | 0.2896 | 0.0689 | |||

| 0.0077 | 0.0706 | 0.8290 | 0.8775 | |||

| 0.2061 | 0.0032 | 0.9365 | 0.7631 |

| -0.0338 | -0.0665 | -0.0665 | -0.0293 | -0.0665 | -0.0665 | |||

| 0.4481 | 0.0849 | 0.0849 | 0.1822 | 0.5538 | 0.5538 | |||

| 1.3357 | 0.0934 | 0.0934 | 1.1524 | 0.0923 | 0.0923 | |||

| 1.6888 | 0.0679 | 0.0679 | 1.3667 | 1.1943 | 0.1943 | |||

| 0.6889 | 0.0758 | 0.0758 | 1.0932 | 1.6469 | 1.6469 | |||

| 1.5610 | 0.0743 | 0.0743 | 0.8515 | 1.3897 | 1.3897 | |||

| 1.3507 | 0.0392 | 0.0392 | 1.2889 | 0.6342 | 0.6342 | |||

| 0.0134 | 0.0655 | 0.0655 | 1.2952 | 1.9004 | 1.9004 | |||

| 1.2043 | 0.0171 | 0.0171 | 1.3580 | 0.0689 | 0.0689 | |||

| 0.7735 | 0.0706 | 0.0706 | 1.2716 | 0.8775 | 0.8775 | |||

| 1.8320 | 0.0032 | 0.0032 | 1.8903 | 0.7631 | 0.7631 |

| -0.0666 | -0.0665 | -0.0665 | -0.0666 | -0.0665 | -0.0665 | |||

| 0.2828 | 0.1456 | 0.0849 | 0.8747 | 0.5304 | 0.5538 | |||

| 0.0692 | 0.1177 | 0.0934 | 0.0271 | 0.0754 | 0.0923 | |||

| 0.2596 | 0.0821 | 0.0679 | 1.7709 | 0.2140 | 0.1943 | |||

| 0.0208 | 0.0817 | 0.0758 | 1.9969 | 1.6630 | 1.6469 | |||

| 0.0121 | 0.0855 | 0.0743 | 1.0898 | 1.3878 | 1.3897 | |||

| 0 | 0.0591 | 0.0392 | 0.1430 | 0.6526 | 0.6342 | |||

| 0.0863 | 0.0653 | 0.0655 | 1.9509 | 1.9015 | 1.9004 | |||

| 0.2201 | 0.0293 | 0.0171 | 0.2896 | 0.0661 | 0.0689 | |||

| 0.0077 | 0.0771 | 0.0706 | 0.8290 | 0.8879 | 0.8775 | |||

| 0.2061 | 0.0351 | 0.0032 | 0.9365 | 0.7324 | 0.7631 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).