Submitted:

10 July 2023

Posted:

11 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methodology

2.1. Location survey

2.2. Energy storage capacity

2.3. Required site in Jordan

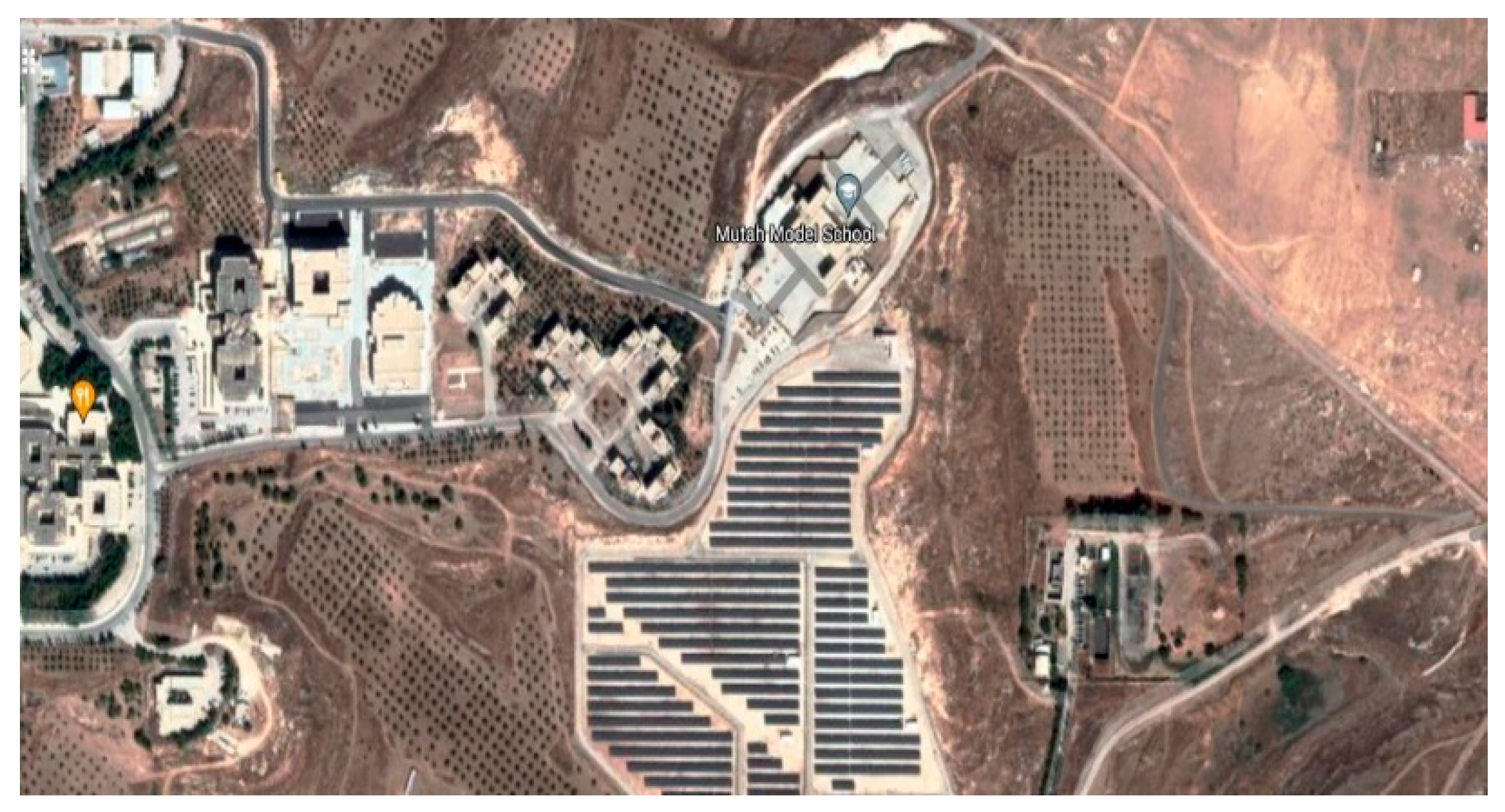

2.3.1. Mutah university

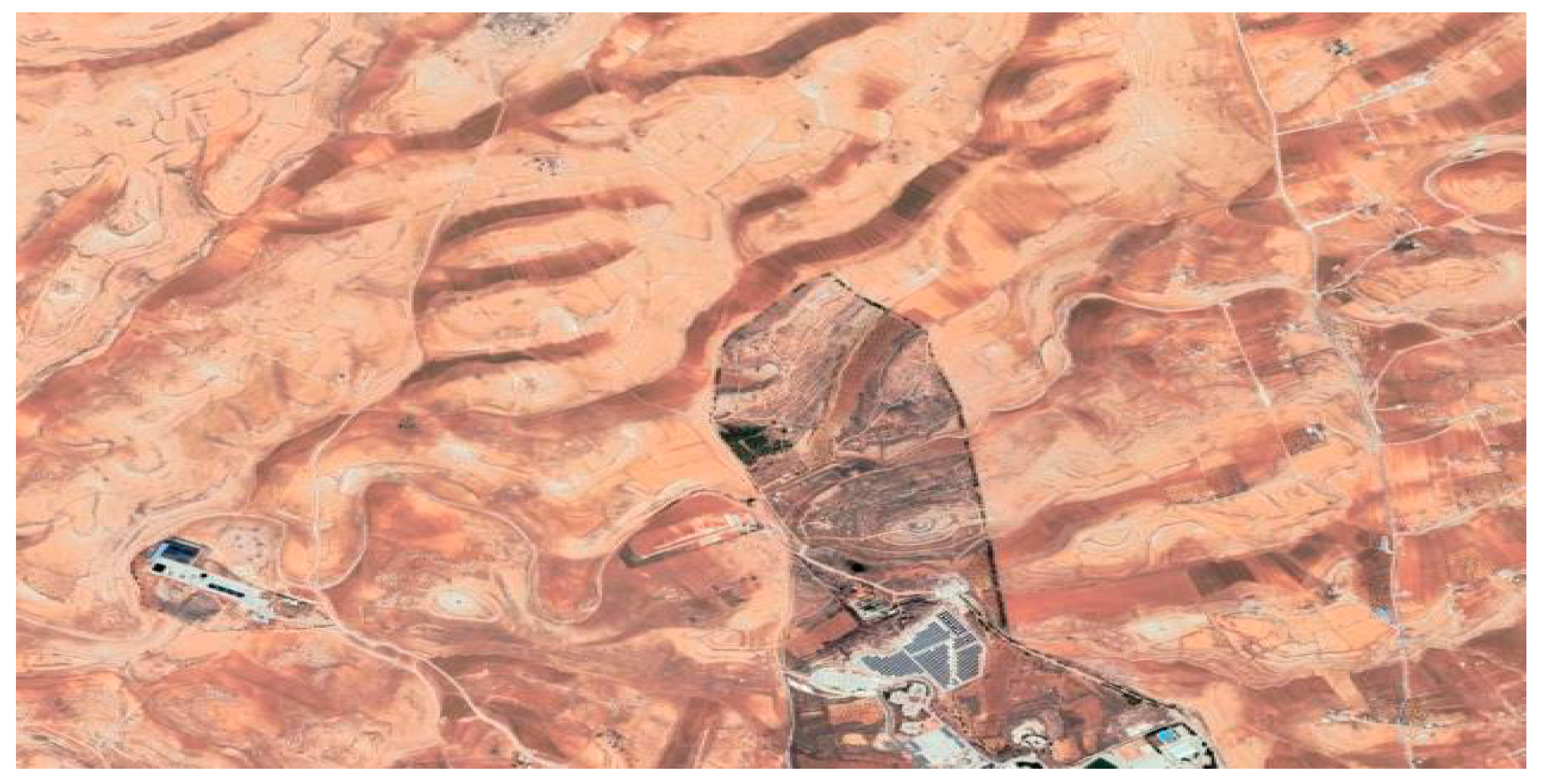

2.3.2. Candidate Reservoir Locations

2.4. Design of PHES

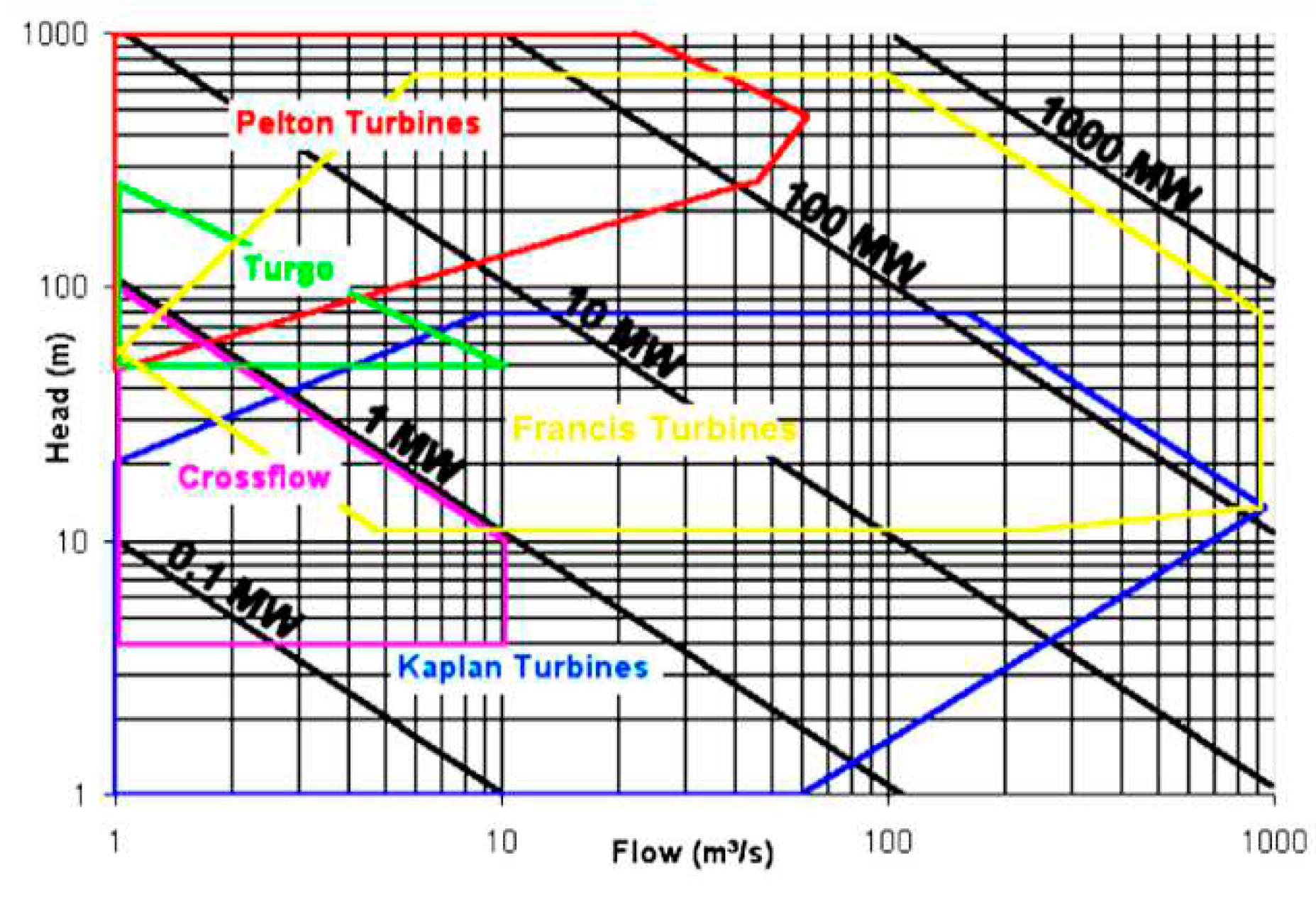

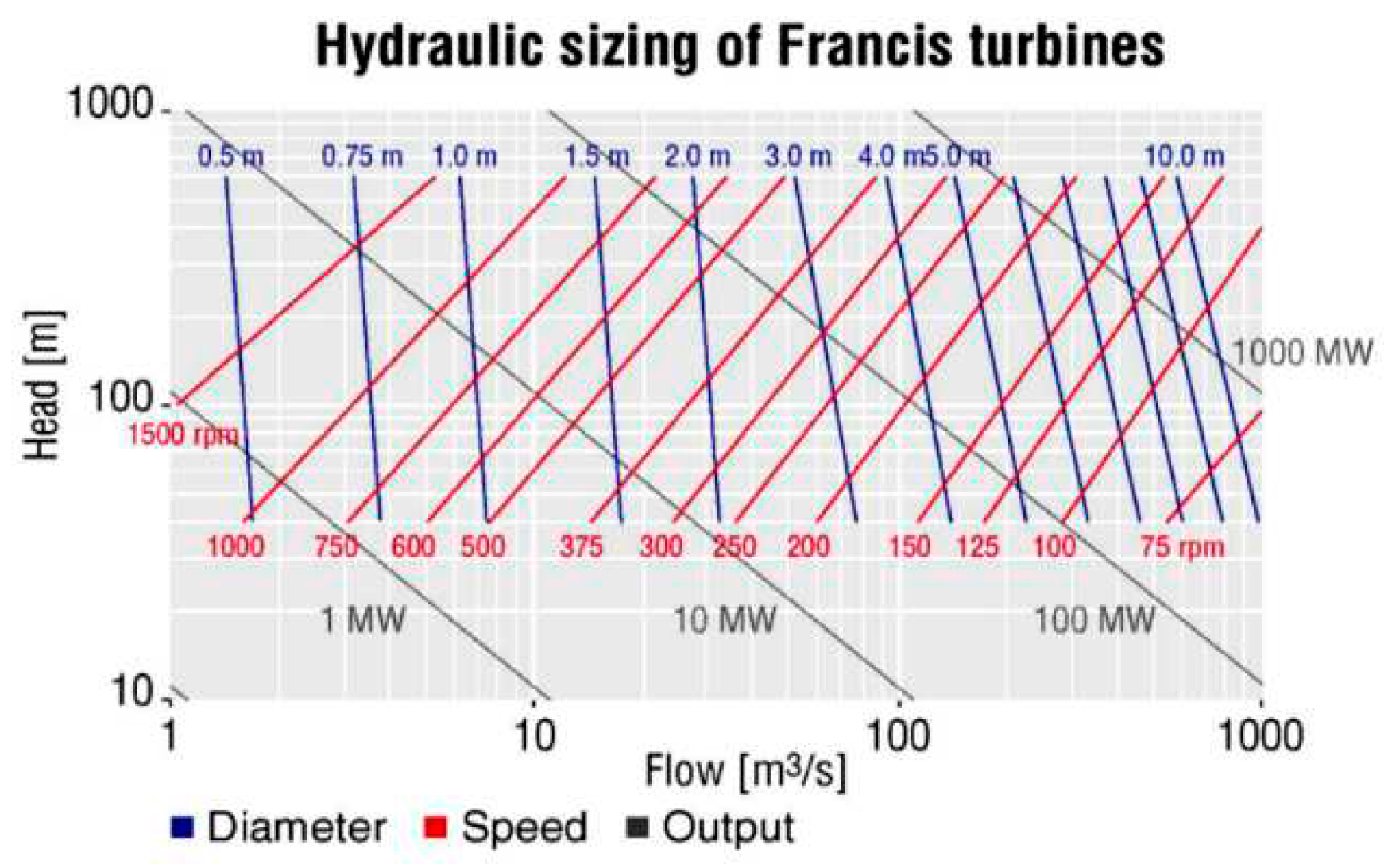

2.4.1. Turbine selection for case study

2.4.2. Identification of PHES site for the case study in Jordan

2.5. Specifications of storage system’s components

2.5.1. Upper reservoir

2.5.2. Lower reservoir

2.5.3. Powerhouse

2.5.4. Conduit

2.6. Piping design

2.6.1. Pipe diameter calculation

3. Power System Modelling

3.1. Power system characteristics

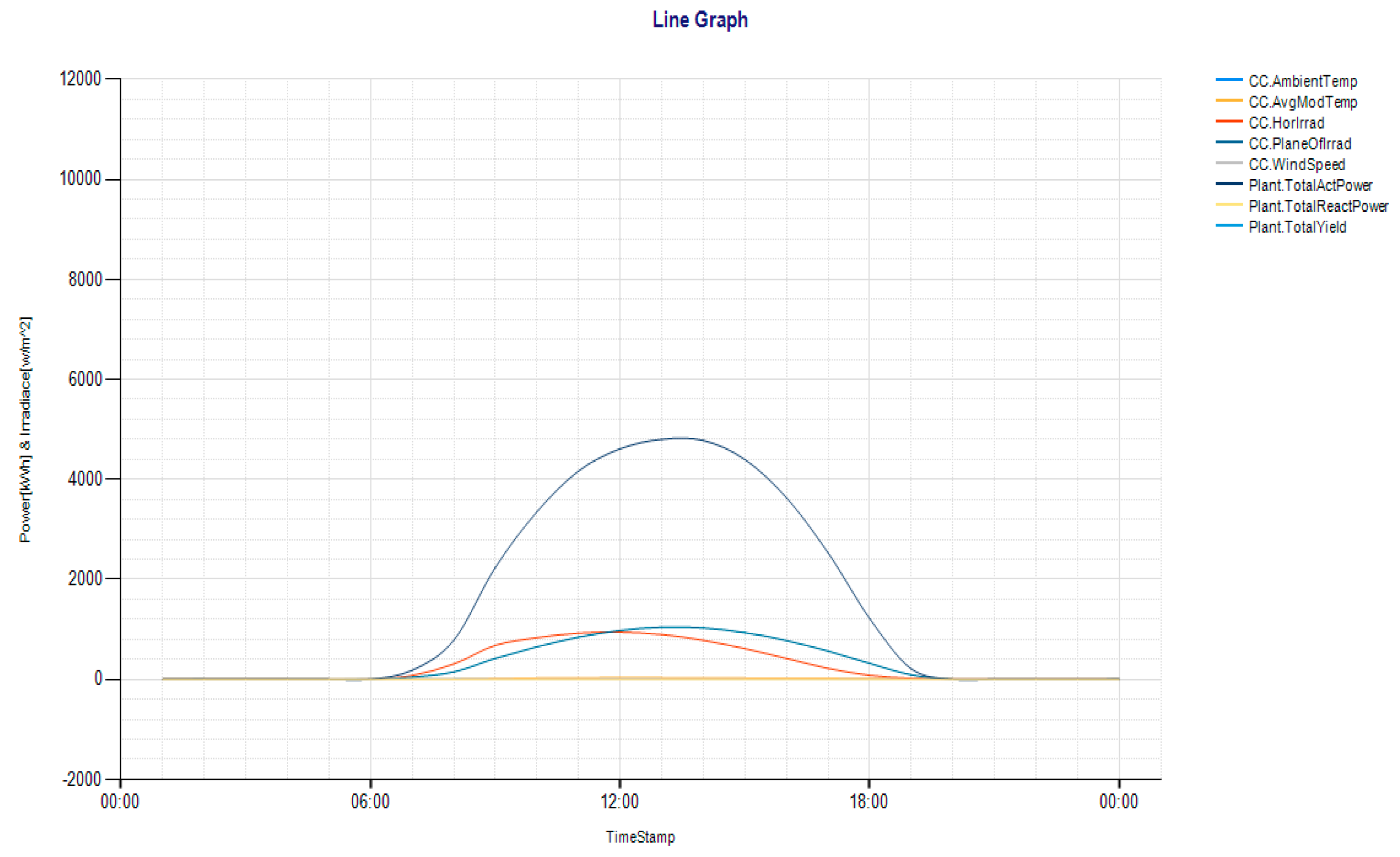

3.1.1. PV solar power plant at Mutah University

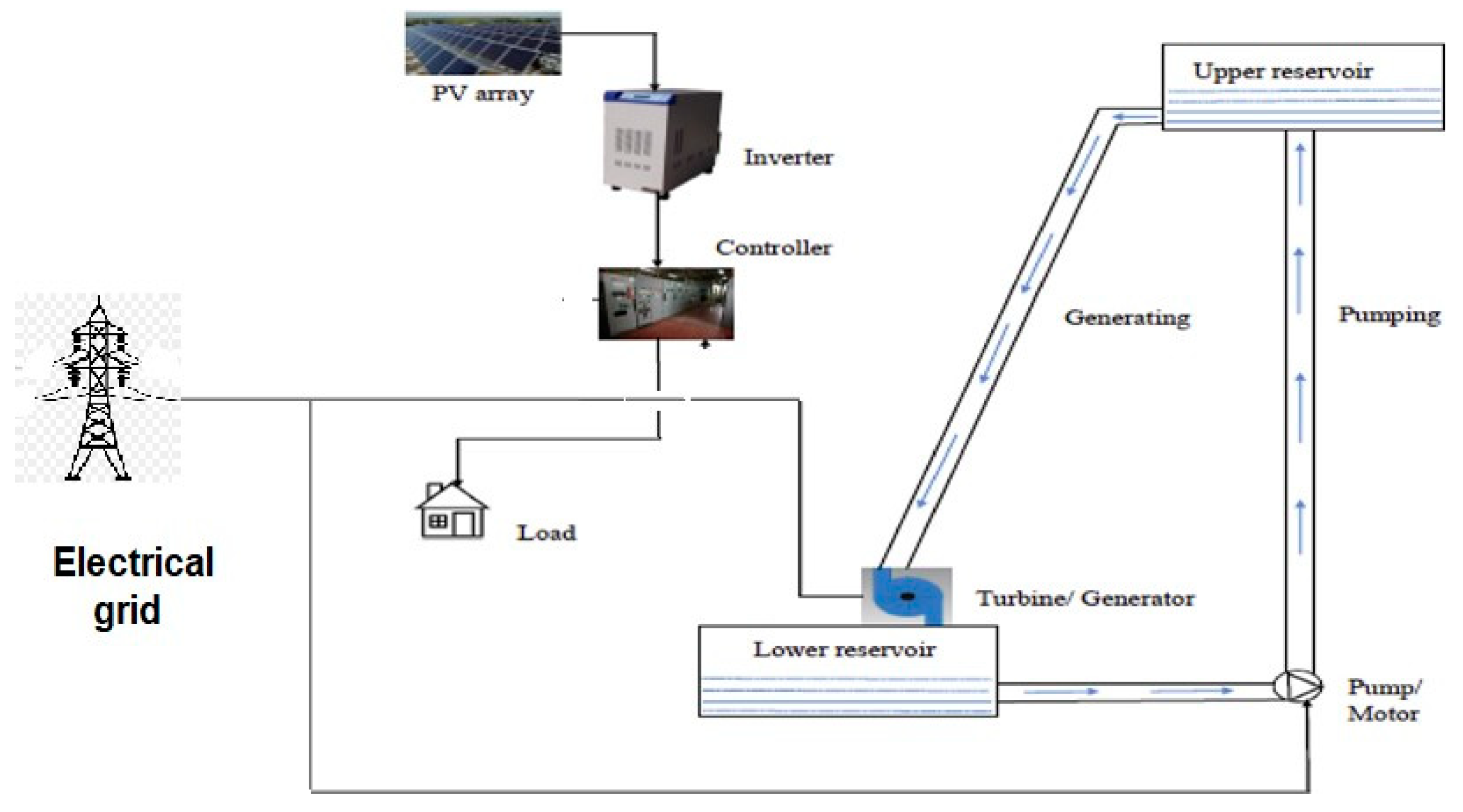

3.2.2. Defining PHES

- -

- If 𝑃𝐷𝑒𝑚(𝑡) > 𝑃𝐺𝑒𝑛(𝑡), the extra power from the hydro-turbine, 𝑃𝑃𝐻𝐸𝑆(𝑡) > 0, and makes up the shortfall in the power generated from the 𝑃𝑃𝑉(𝑡).

- -

- If 𝑃𝐷𝑒𝑚(𝑡) = 𝑃𝐺𝑒𝑛(𝑡), 𝑃𝑃𝐻𝐸𝑆(𝑡) = 0; the power generated by the 𝑃𝑃𝑉(𝑡) is just sufficient to supply the demand.

- -

- If 𝑃𝐷𝑒𝑚(𝑡) < 𝑃𝐺𝑒𝑛(𝑡), PHES 𝑃𝑃𝐻𝐸𝑆(𝑡) < 0; and the excess power generated is stored by the PHES.

3.2.3. Defining the electrical load data

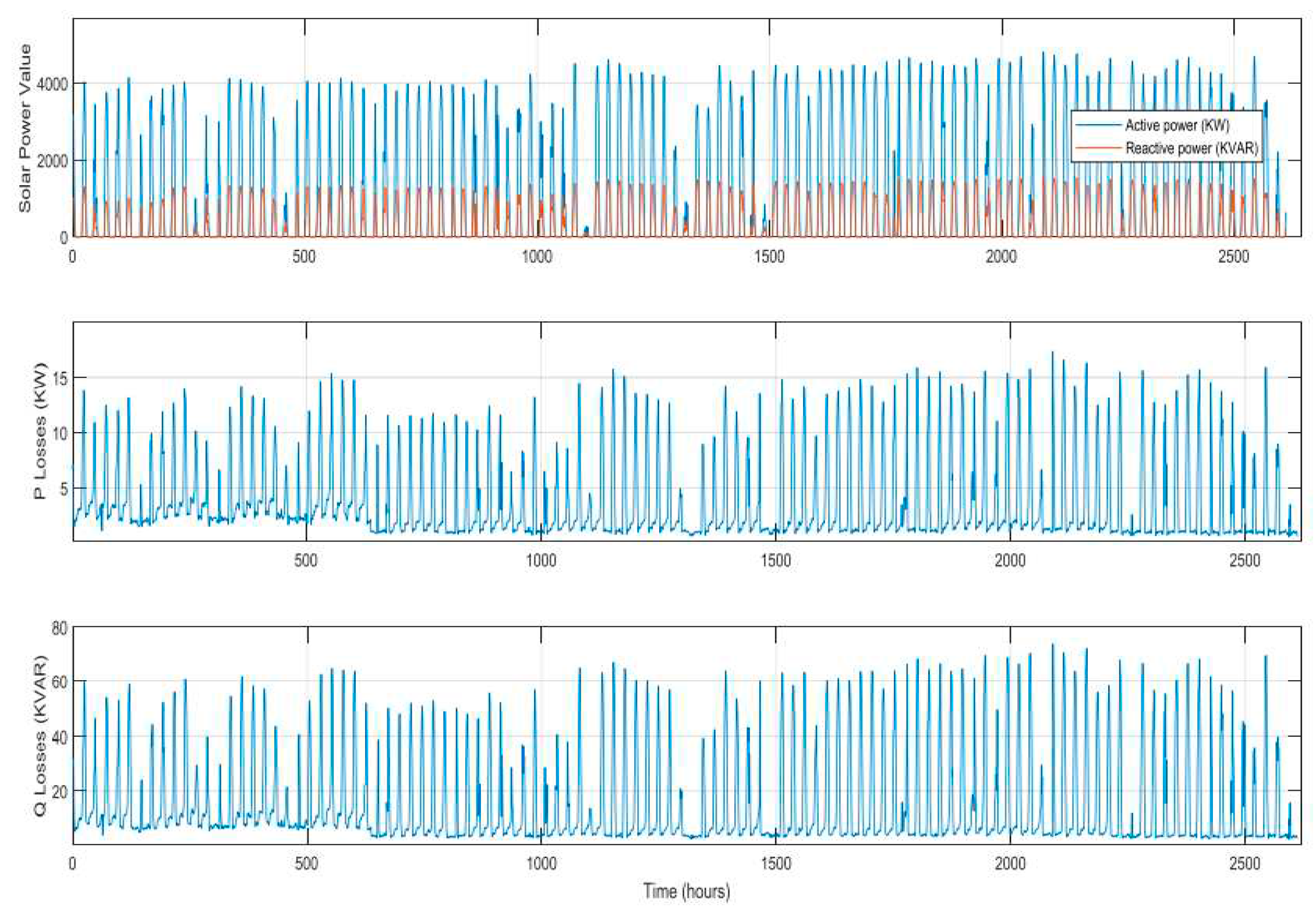

3.2.4. Electrical power losses in distribution lines

3.3. Load flow

4. Results and Discussions

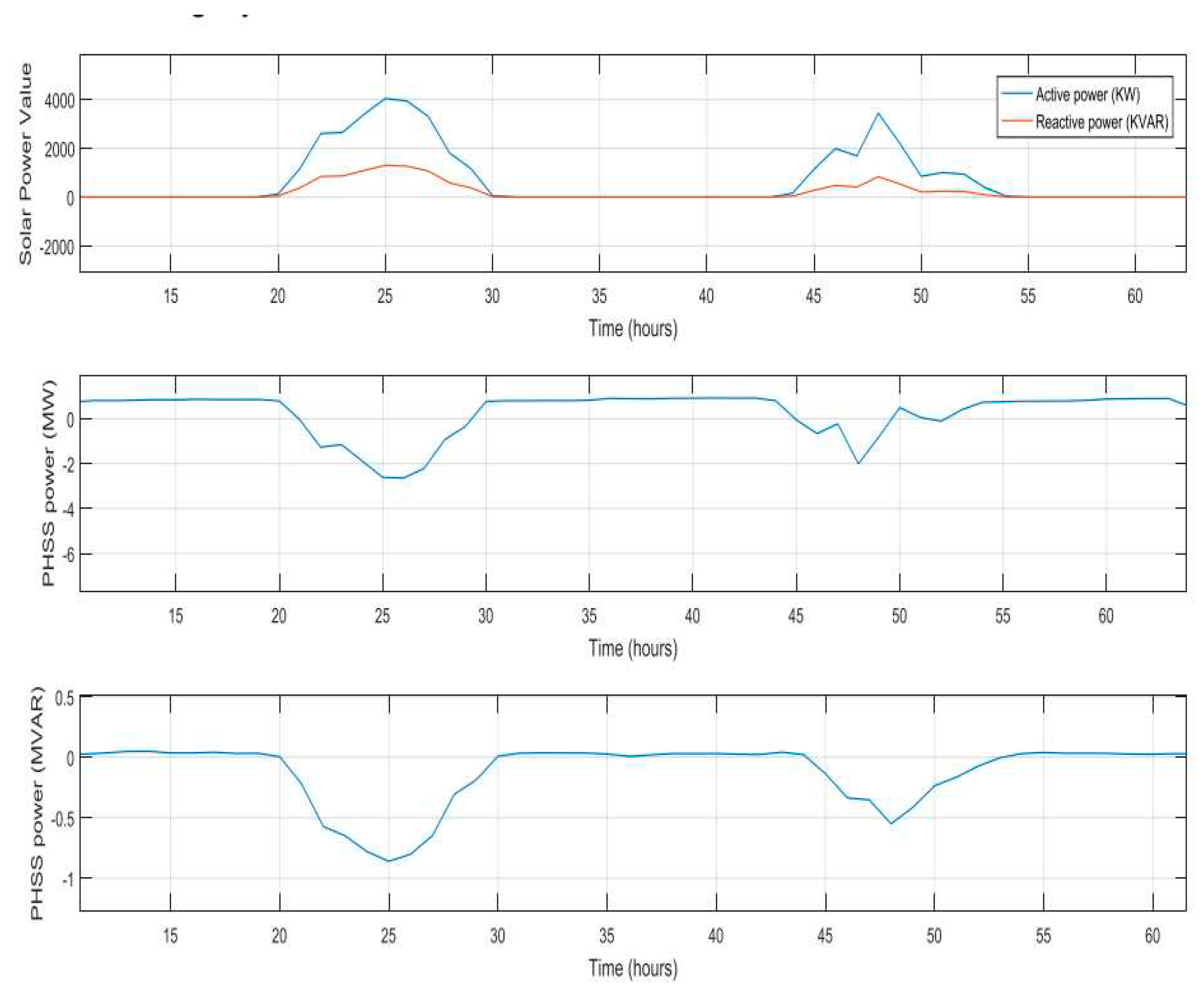

4.1. PV Solar power results

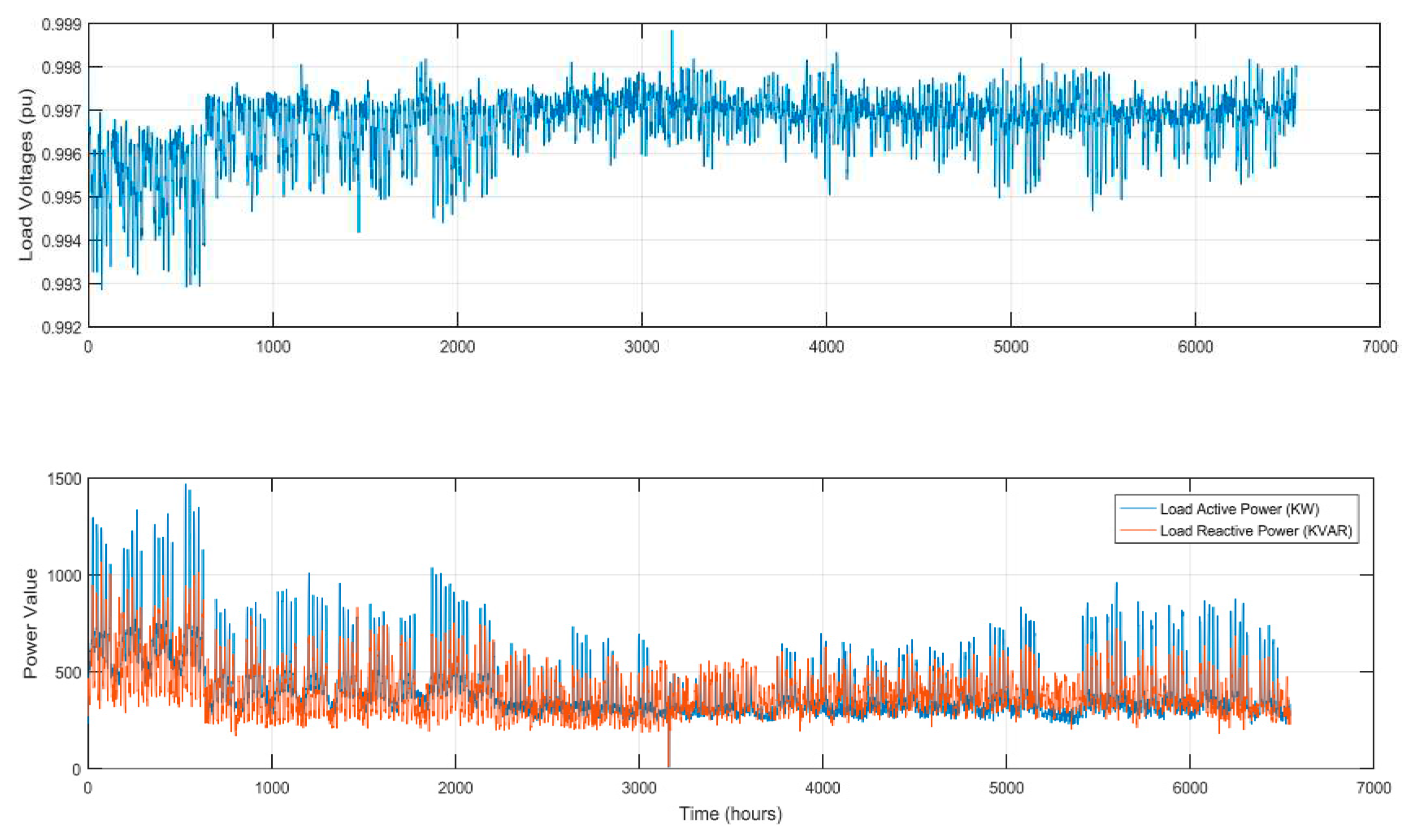

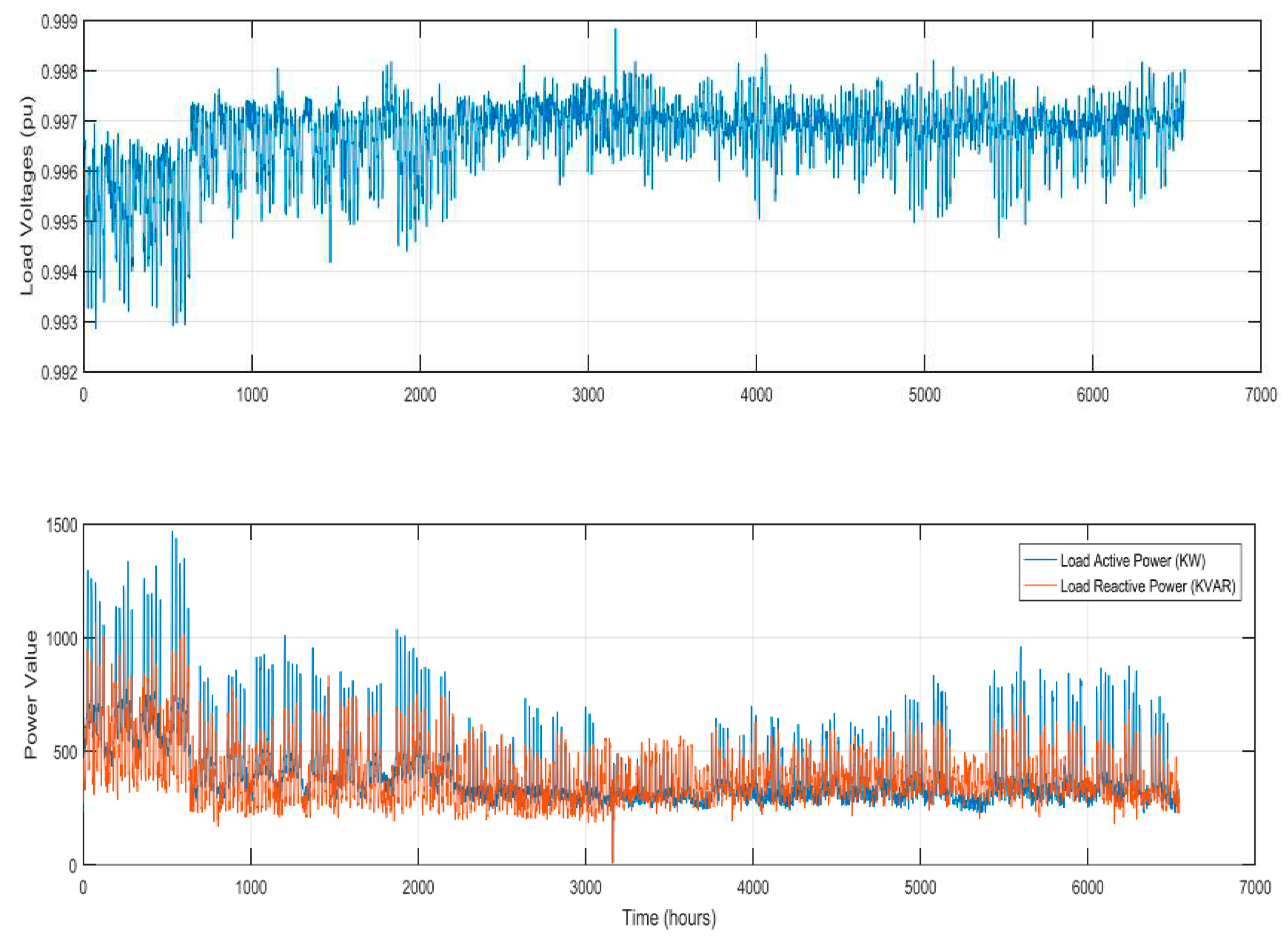

4.2. Load profile results

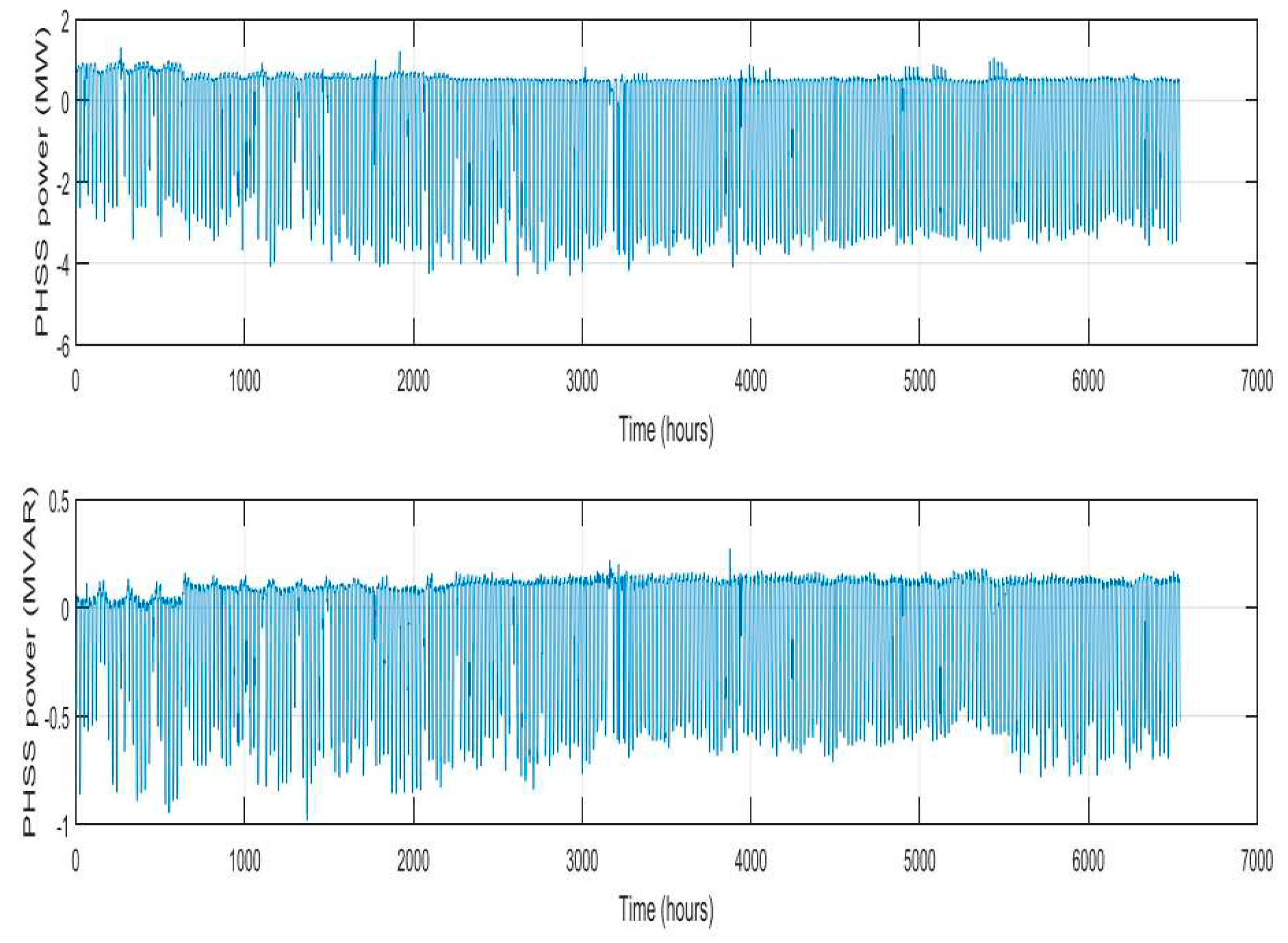

4.3. PHES results

5. Conclusions

- Jordan has a significantly higher chance of installing PHES because all necessary prerequisites have been met.

- The system will run efficiently and independently of the national electric network, reducing the university’ transit costs to the electrical distribution company.

- The system renders an annual energy production of 9230.89 MWh/year, an annual load yield of 4430 MWh/year., which cover the Mutah university demand with an estimate saving of 2039773 JD.

References

- Alrwashdeh, S.S.; Alsaraireh, F.M.; Saraireh, M.A. Solar radiation map of Jordan governorates. Int. J. Eng. Technol. 2018, 7, 1664–1667. [Google Scholar] [CrossRef]

- Aboushi, A.; Hamdan, M.; Abdelhafez, E.; Turk, E.; Lbbini, J.; Abu Shaban, N. Water disinfection by solar energy. Energy Sources A: Recovery Util. Environ. Eff. 2021, 43, 2088–2098. [Google Scholar] [CrossRef]

- Hrayshat, E.S. , Al-Soud, M.S. Potential of solar energy development for water pumping in Jordan. Renew. Energ. 2004, 29, 1393–1399. [Google Scholar] [CrossRef]

- Al-Qawabah, S.; Al-Soud, M.; Althneibat, A. Assessment of hybrid renewable energy systems to drive water desalination plant in an arid remote area in Jordan. Int. J. Green Energy 2021, 18, 503–511. [Google Scholar] [CrossRef]

- Baniyounes, A.M. Renewable Energy Potential in Jordan. Int. J. Appl. Eng. Res., 2017, 12, 8323–8331. [Google Scholar]

- Hrayshat, E.S.; Al-Soud, M.S. Solar energy in Jordan: current state and prospects. Renewable Sustainable Energy Rev 2004, 8, 193–200. [Google Scholar] [CrossRef]

- Abu-Rumman, G.; Khdair, A.I.; Khdair, S.I. 2020. Current status and future investment potential in renewable energy in Jordan: An overview. Heliyon 2020, 6, 3346. [Google Scholar] [CrossRef] [PubMed]

- Hossain, E.; Faruque, H.M.; Sunny, M.S.; Mohammad, N.; Nawar, N. A Comprehensive Review on Energy Storage Systems: Types, Comparison, Current Scenario, Applications, Barriers, and Potential Solutions, Policies, and Future Prospects. Energies 2020, 13. [Google Scholar] [CrossRef]

- Thapar, O.D. Characteristics of large hydro generators of Dehar Power Plant. Proceedings 2nd world congress International Water Resources Association, New Delhi, India, December,1975, 17-24.

- Morley, J.; Widdicksb, K.; Hazas, M. Digitalization, energy and data demand: The impact of Internet traffic on overall and peak electricity consumption. Energy Res. Soc. Sci. 2018, 38, 128–137. [Google Scholar] [CrossRef]

- Sandri, S.; Hussein, H.; Alshyab, N. 2020. Sustainability of the Energy Sector in Jordan: Challenges and Opportunities. Sustainability, 2020; 12, 1–25. [Google Scholar] [CrossRef]

- Kabo-Bah, A.T.; Diawuo, F.A.; Antwi, E.O. Comprehensive Energy Systems, Pumped Hydro-Energy Storage System. 2023 Elsevier Inc.

- National Hydropower Association, Pumped Storage Report| National Hydropower Association. NHA. 2018.

- Dixon, S.L.; Hall, C.A. Fluid Mechanics and Thermodynamics of Turbomachinery, Hydraulic Turbines, CH9. 6th, 2010, pp. 303–355.

- Hatataab, A.Y.; El-Saadawia, M.M.; Saada, S. A feasibility study of small hydropower for selected locations in Egypt. Energy Strategy Rev. 2019, 24, 300–313. [Google Scholar] [CrossRef]

- Borges, C.L.T.; Pinto, R.J. Small Hydro Power Plants Energy Availability Modelling for Generation Reliability Evaluation. IEEE Trans. Power Appar. Syst. 2008, 23, 1125–1135. [Google Scholar] [CrossRef]

- Kolmetz, K. Piping hydraulics fluid flow line sizing and material selection. Kolmetz Handbook of Process Equipment Design, KLM Technology Group. 2018. [Google Scholar]

- Babajimopoulos, C.; Terzidis, G. Accurate explicit equations for the determination of pipe diameter. J Hydraul Eng 2013, 2, 115–120. [Google Scholar] [CrossRef]

- Nyeche, E.N.; Diemuodeke, E.O. Modelling and optimisation of a hybrid PV wind turbine-Pumped Hydro Storage Energy System for Mini-Grid Application in Coastline Communities, J. Clean. Prod. 2019, 250. [Google Scholar] [CrossRef]

- Afolabi, O.A.; Warsame, H.A.; Cofie, P.; Fuller, J.; Obiomon, P.; Kolawole, E.S. Analysis of the load flow problem in power system planning studies. J. energy power eng 2015, 7. [Google Scholar] [CrossRef]

| Type of machine | Reversible pump-turbine unit (Francis) |

| Overall capacity | 5 MW |

| Unit capacity | 1 MW |

| Number of units | 5 units |

| Rated head | 85 m |

| Efficiency of generator | 90% |

| Efficiency of pump | 90% |

| Total Efficiency | 81% |

| Rated discharge of generator mode | 1.33 ( 𝑚3⁄𝑠) For each unit |

| Rated discharge of pump mode | 1.079 (𝑚3⁄𝑠) For each unit |

| Type | JAM72S01-340/SC |

| Peak power (PMAX) | 340 W |

| Open circuit voltage(Voc) | 46.32V |

| Max. power voltage (Vmp) | 37.87 V |

| Short circuit current (Isc) | 9.60 A |

| Max power current (Imp) | 8.98 A |

| Power selection | 0--+5W |

| PV input | 565 Vdc-1000Vdc 110 A/150A max. rated current/Isc |

| Output | 3P+PE,380/400 Vac delta 352-440 Vac @400 Vac, 87.0 A Cos(Phi):0.8…1 ..0.8 over/underexc. Max. output fault current:49.8 over ms |

| Power | 60 Kva@400 Vac, 45ºC/113ºF, Cos(Phi=1 |

| Freq. | 50/60 Hz(45-65) |

| Chassis | Outdoor IP65, Protective class I Temp. -25 ºC to 60 ºC/ -13 ºFto 140 ºF |

| Average active losses (P) | 3.6062 kW |

| Maximum active losses (P) | 17.2833 kW |

| Average reactive losses (Q) | 14.4996 kVAR |

| Maximum reactive losses (Q) | 73.7099 kVAR |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).