Submitted:

07 July 2023

Posted:

10 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methods

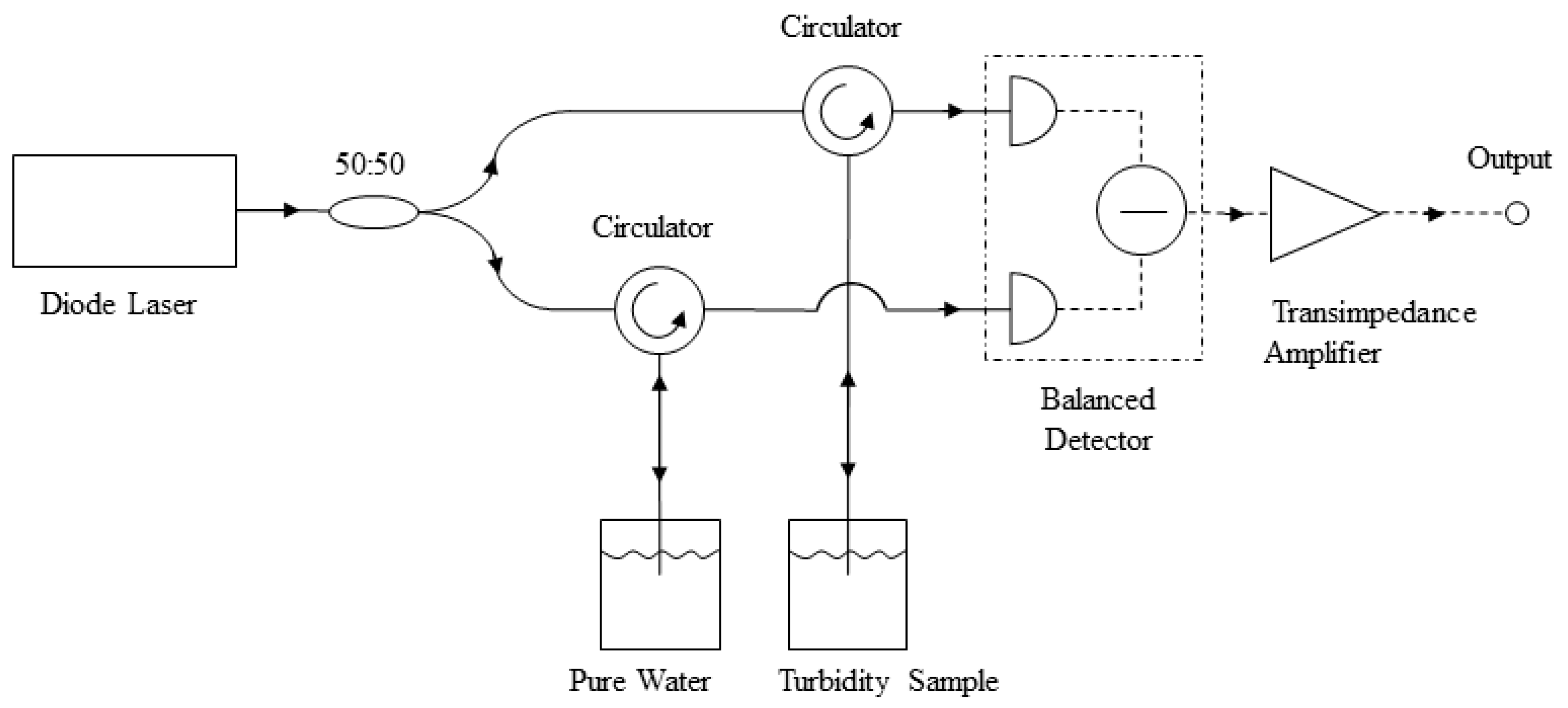

2.1. Design and Measurement Principle

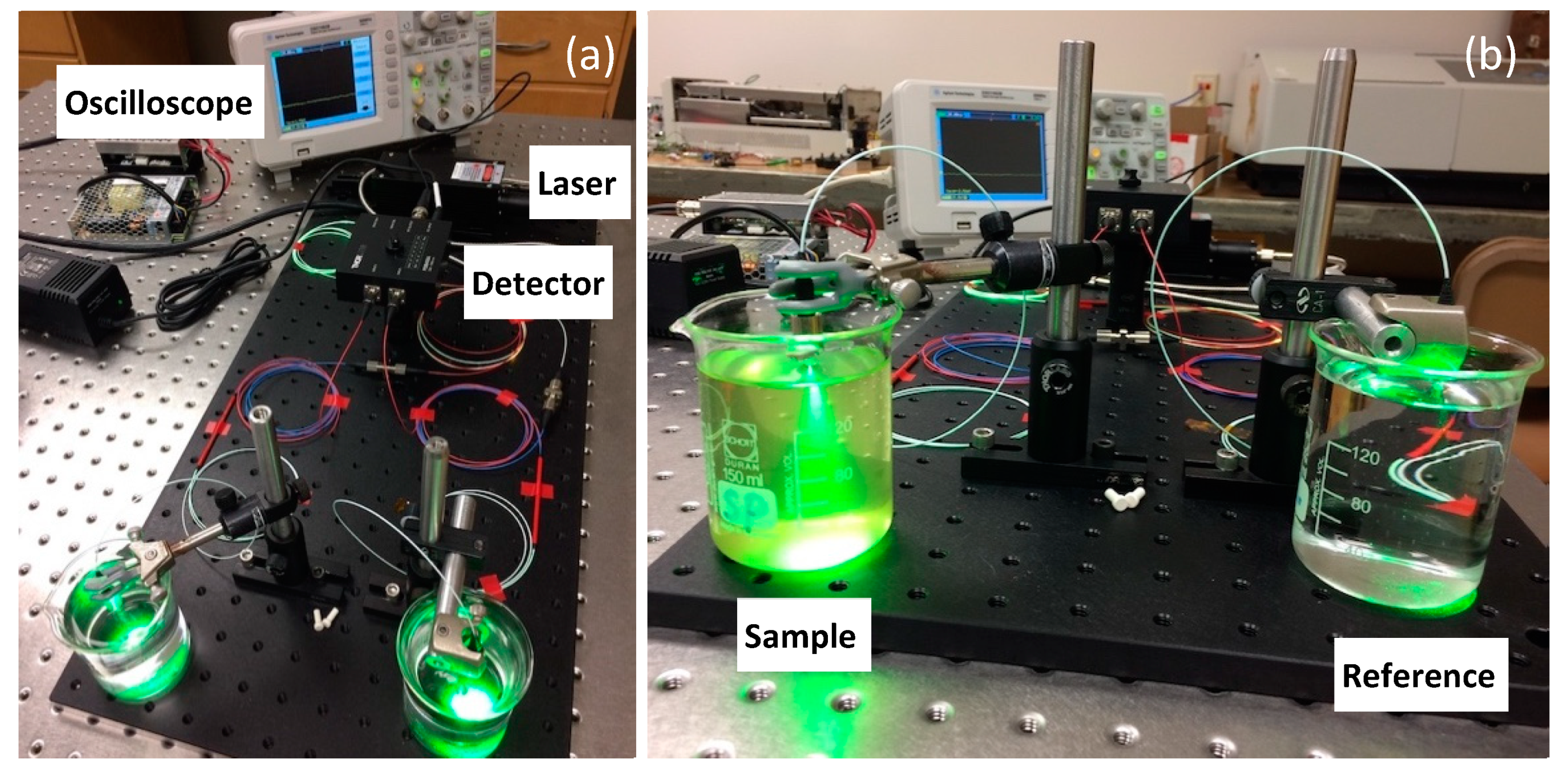

2.2. Experimental System, Materials and Equipment

3. Results and Discussions

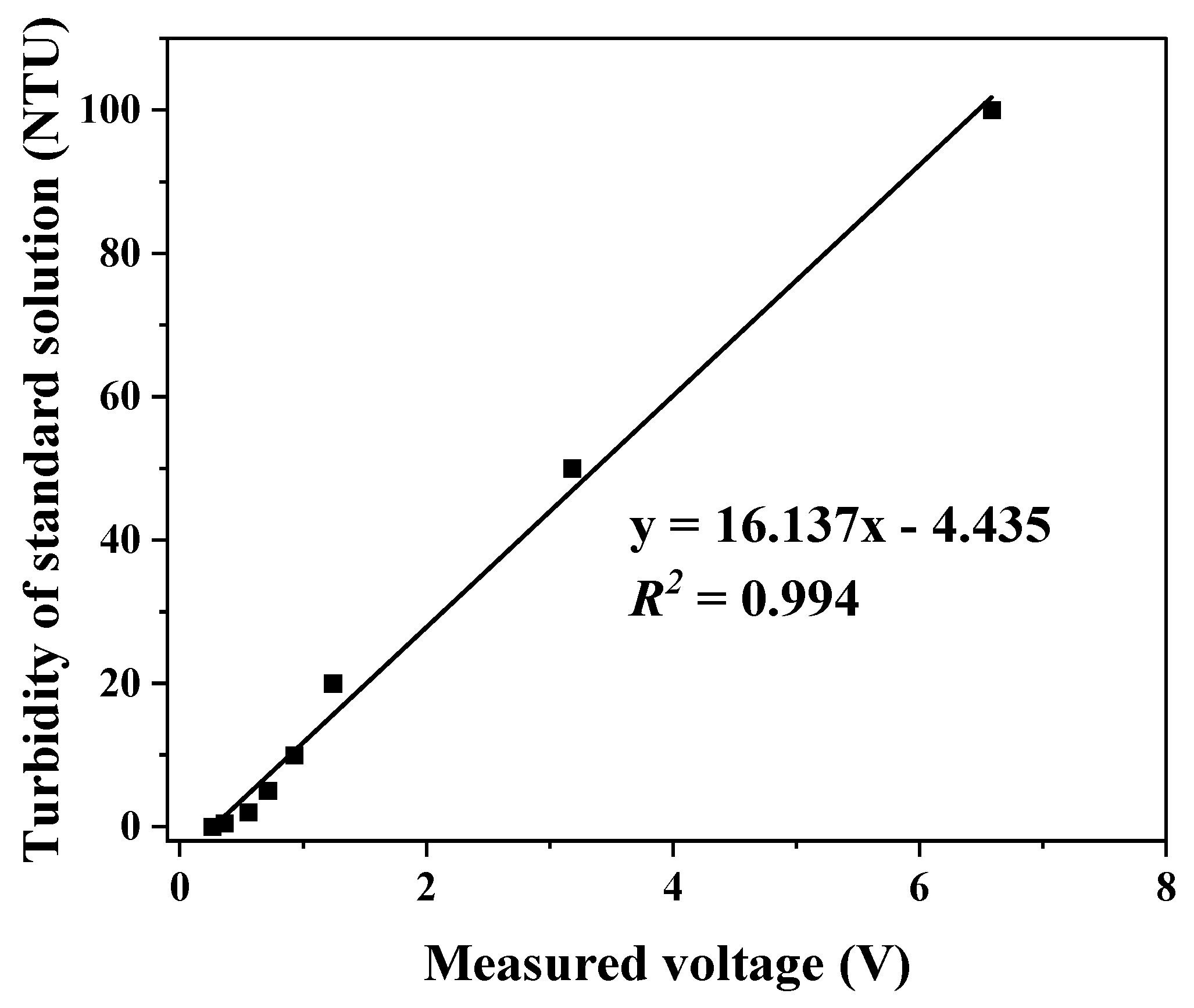

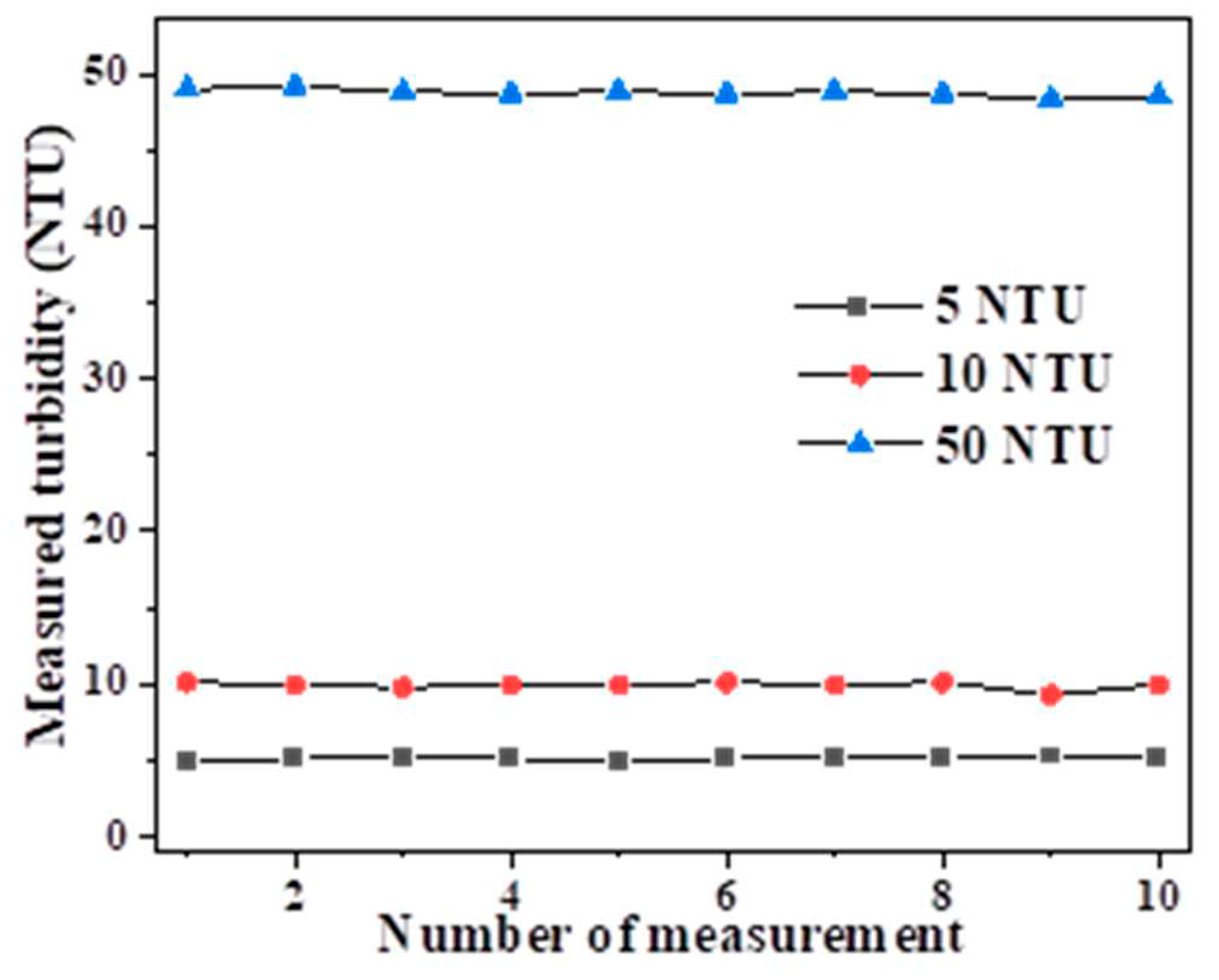

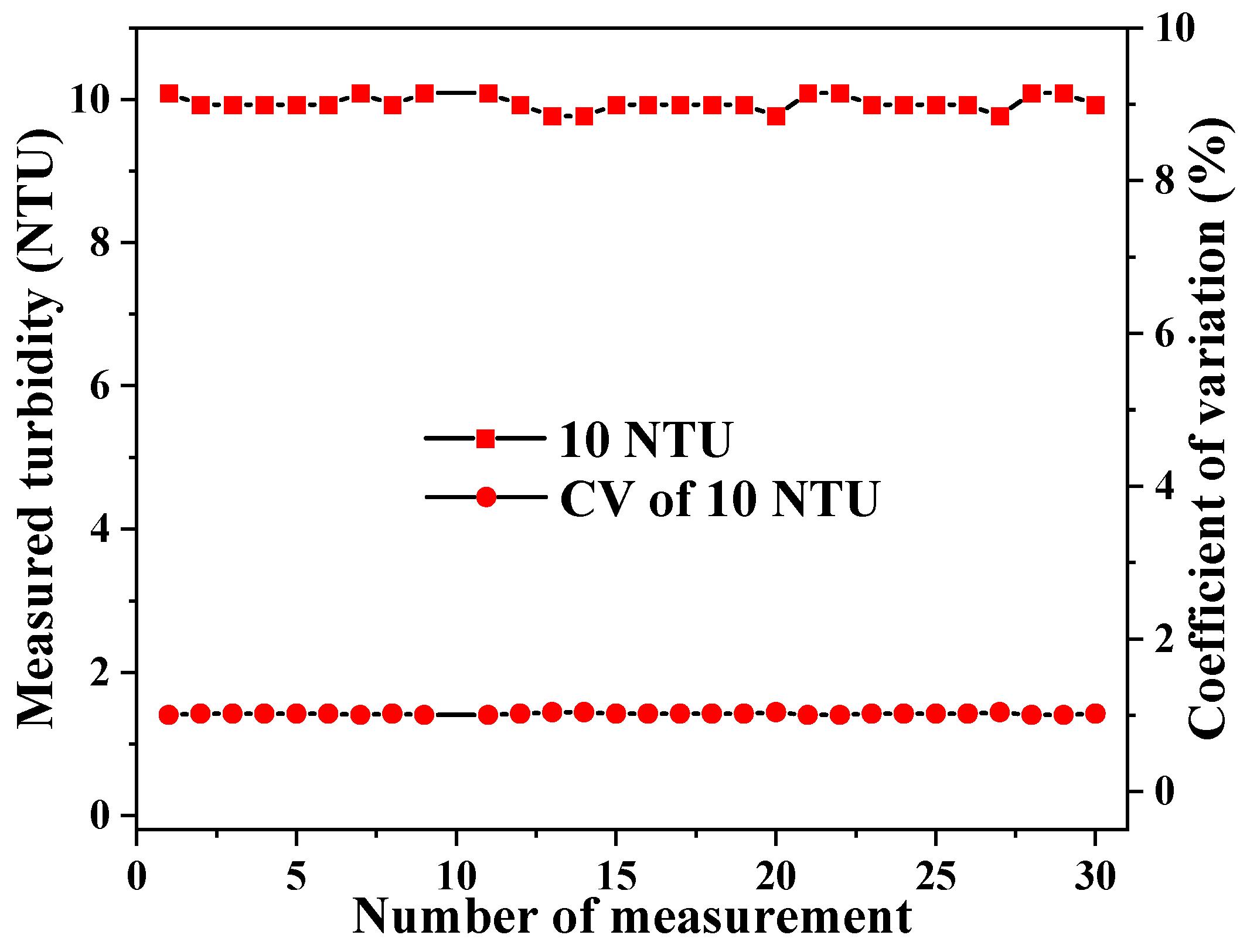

3.1. Sensor Characterization

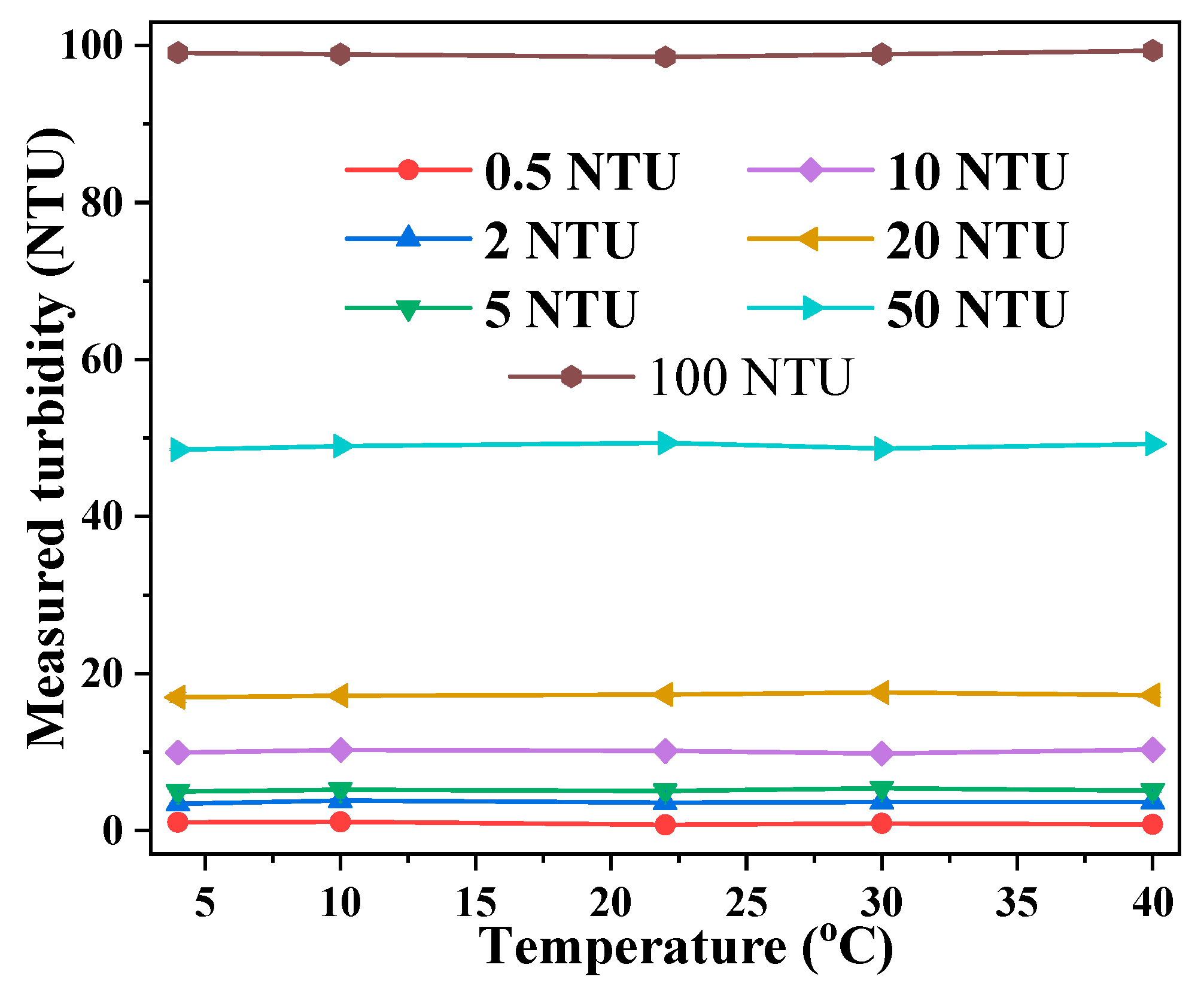

3.2. Effects of Temperature

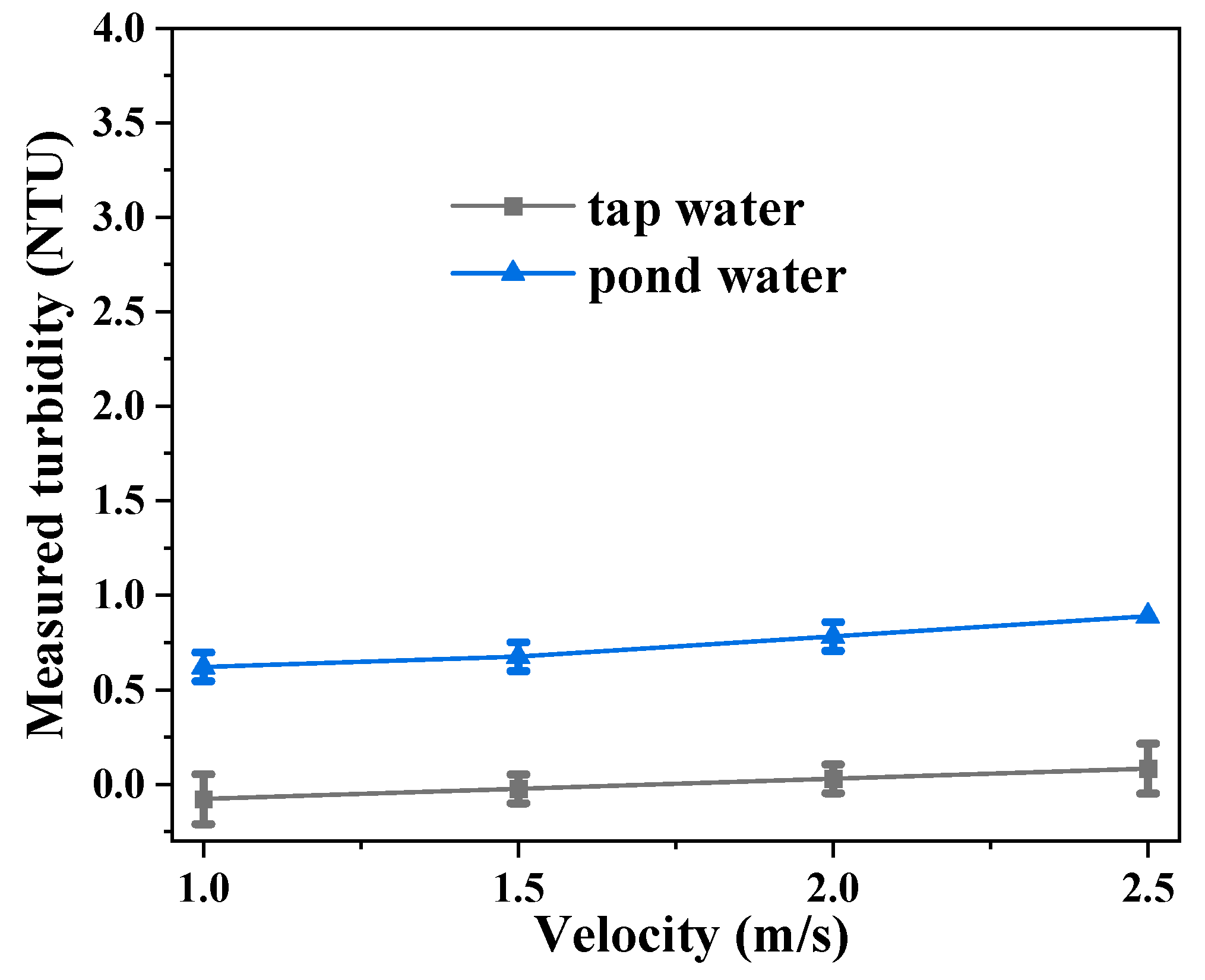

3.3. Demonstration in Real Environmental Matrices

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Parra, L.; Rocher, J.; Escrivá, J.; Lloret, J. Design and Development of Low Cost Smart Turbidity Sensor for Water Quality Monitoring in Fish Farms. Aquac. Eng. 2018, 81, 10–18. [Google Scholar] [CrossRef]

- Fleet, C.F.; Siebert, K.J. Effect of Illumination Intensity on Visual Perception of Turbidity. Food Qual. Prefer. 2005, 16, 536–544. [Google Scholar] [CrossRef]

- Gaiani, C.; Scher, J.; Schuck, P.; Desobry, S.; Banon, S. Use of a Turbidity Sensor to Determine Dairy Powder Rehydration Properties. Powder Technol. 2009, 190, 2–5. [Google Scholar] [CrossRef]

- Świetlik, J.; Raczyk-Stanisławiak, U.; Piszora, P.; Nawrocki, J. Corrosion in Drinking Water Pipes: The Importance of Green Rusts. Water Res. 2012, 46, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Shi, B.; Gu, J.; Wang, D.; Yang, M. Morphological and Physicochemical Characteristics of Iron Corrosion Scales Formed under Different Water Source Histories in a Drinking Water Distribution System. Water Res. 2012, 46, 5423–5433. [Google Scholar] [CrossRef]

- Tang, Z.; Hong, S.; Xiao, W.; Taylor, J. Characteristics of Iron Corrosion Scales Established under Blending of Ground, Surface, and Saline Waters and Their Impacts on Iron Release in the Pipe Distribution System. Corros. Sci. 2006, 48, 322–342. [Google Scholar] [CrossRef]

- Brodeur, T.; Davis, F.S.; Florence, R.; Kim, M.; Craig, M.; Gianatasio, J.; Sharp, D.; Lowe, P. From Red Water to Pump Failures Corrosion Control Activities Related Studies. 2005 Distrib. Syst. Symp. Proceedings, DSS 2005 2005, 42–48. [Google Scholar]

- Husband, P.S.; Boxall, J.B. Asset Deterioration and Discolouration in Water Distribution Systems. Water Res. 2011, 45, 113–124. [Google Scholar] [CrossRef]

- Vreeburg, J.H.G.; Schippers, D.; Verberk, J.Q.J.C.; van Dijk, J.C. Impact of Particles on Sediment Accumulation in a Drinking Water Distribution System. Water Res. 2008, 42, 4233–4242. [Google Scholar] [CrossRef]

- Vreeburg, I.J.H.G.; Boxall, D.J.B. Discolouration in Potable Water Distribution Systems: A Review. Water Res. 2007, 41, 519–529. [Google Scholar] [CrossRef]

- LeChevallier, Mark W., William D. Norton, and R.G.L. Occurrence of Giardia and Cryptosporidium Spp. in Surface Water Supplies. Appl. Environ. Microbiol. 1991, 57, 2610–2616. [CrossRef]

- R D Morris, E N Naumova, R Levin, and R.L.M. Temporal Variation in Drinking Water Turbidity and Diagnosed Gastroenteritis in Milwaukee. Am. J. Public Health 1996, 86, 237–239. [CrossRef]

- Kitchener, Ben GB, John Wainwright, and A.J.P. A Review of the Principles of Turbidity Measurement. Prog. Phys. Geogr. 2017, 41, 620–624. [CrossRef]

- US EPA Method 180.1: Determination of Turbidity by Nephelometry. Available online: https://www.epa.gov/sites/production/files/2015-08/documents/method_180-1_1993.pdf (accessed on 25 May 2023).

- ISO 7027-1:2016 Water Quality —Determination of Turbidity — Part 1: Quantitative Methods. Available online: https://www.iso.org/standard/62801.html (accessed on 6 May 2023).

- Analytical Method for Turbidity Measurement: GLI Method 2. Available online: https://www.esonetyellowpages.com/manuals/4beam_1254491289.pdf (accessed on 5 April 2023).

- Storey, M. V.; van der Gaag, B.; Burns, B.P. Advances in On-Line Drinking Water Quality Monitoring and Early Warning Systems. Water Res. 2011, 45, 741–747. [Google Scholar] [CrossRef] [PubMed]

- Lambrou, T.P.; Anastasiou, C.C.; Panayiotou, C.G.; Polycarpou, M.M. A Low-Cost Sensor Network for Real-Time Monitoring and Contamination Detection in Drinking Water Distribution Systems. IEEE Sens. J. 2014, 14, 2765–2772. [Google Scholar] [CrossRef]

- Zhuiykov, S. Solid-State Sensors Monitoring Parameters of Water Quality for the next Generation of Wireless Sensor Networks. Sensors Actuators, B Chem. 2012, 161, 1–20. [Google Scholar] [CrossRef]

- Kavi Priya, S.; Shenbagalakshmi, G.; Revathi, T. Design of Smart Sensors for Real Time Drinking Water Quality and Contamination Detection in Water Distributed Mains. Rom. J. Inf. Sci. Technol. 2018, 7, 47–51. [Google Scholar] [CrossRef]

- Lambrou, T.P.; Panayiotou, C.G.; Polycarpou, M.M. Contamination Detection in Drinking Water Distribution Systems Using Sensor Networks. 2015 Eur. Control Conf. ECC 2015 2015, 3298–3303. [Google Scholar] [CrossRef]

- Tai, H.; Li, D.; Wang, C.; Ding, Q.; Wang, C.; Liu, S. Design and Characterization of a Smart Turbidity Transducer for Distributed Measurement System. Sensors Actuators, A Phys. 2012, 175, 1–8. [Google Scholar] [CrossRef]

- Keizer, J. Jacob, M. A. S. Martins, S. A. Prats, L. F. Santos, D. C. S. Vieira, R. Nogueira, and L.B. Assessing the Performance of a Plastic Optical Fibre Turbidity Sensor for Measuring Post-Fire Erosion from Plot to Catchment Scale. Soil 2015, 1, 641–650. [CrossRef]

- Aiestaran, P.; Arrue, J.; Zubia, J. Design of a Sensor Based on Plastic Optical Fibre (POF) to Measure Fluid Flow and Turbidity. Sensors 2009, 9, 3790–3800. [Google Scholar] [CrossRef] [PubMed]

- Omar, A.F. Bin; MatJafri, M.Z. Bin Turbidimeter Design and Analysis: A Review on Optical Fiber Sensors for the Measurement of Water Turbidity. Sensors 2009, 9, 8311–8335. [Google Scholar] [CrossRef] [PubMed]

- Prerana, D.; Shenoy, M.R.; Pal, B.P.; Gupta, B.D. Design, Analysis, and Realization of a Turbidity Sensor Based on Collection of Scattered Light by a Fiber-Optic Probe. IEEE Sens. J. 2012, 12, 44–50. [Google Scholar] [CrossRef]

- García, A.; Pérez, M.A.; Ortega, G.J.G.; Dizy, J.T. A New Design of Low-Cost Four-Beam Turbidimeter by Using Optical Fibers. IEEE Trans. Instrum. Meas. 2007, 56, 907–912. [Google Scholar] [CrossRef]

- Bilro, L.; Prats, S.A.; Pinto, J.L.; Keizer, J.J.; Nogueira, R.N. Design and Performance Assessment of a Plastic Optical Fibre-Based Sensor for Measuring Water Turbidity. Meas. Sci. Technol. 2010, 21. [Google Scholar] [CrossRef]

- Mohd Khairi, M.T.; Ibrahim, S.; Md Yunus, M.A.; Faramarzi, M. A Review on the Design and Development of Turbidimeter. Sens. Rev. 2015, 35, 98–105. [Google Scholar] [CrossRef]

| Tap Water | Pond Water | |||

|---|---|---|---|---|

| Mean | STD | Mean | STD | |

| Cl- (mg L-1) | 9.59 | 0.16 | 4.33 | 0.035 |

| NO3- (mg L-1) | 1.05 | 0.005 | 3.95 | 0.025 |

| SO42- (mg L-1) | 27.1 | 0.025 | 6.26 | 0.035 |

| HCO3- (mg L-1) | 74.4 | 1.2 | 184.2 | 1.2 |

| PO43- (mg L-1) | 0.44 | 0.015 | 0.16 | 0.005 |

| TDS (mg L-1) | 113.9 | 0.1 | 159.2 | 0.8 |

| Conductivity (mS cm-1) | 0.26 | 0.037 | 0.32 | 0.0005 |

| DO (mg L-1) | 6.08 | 0.015 | 6.17 | 0.005 |

| pH | 7.32 | 0.015 | 8.21 | 0.01 |

| TOC (mg L-1) | 3.20 | 0.1535 | 1.63 | 0.376 |

| Turbidity (NTU) | 0.073 | 0.0047 | 0.63 | 0.014 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).