Submitted:

11 July 2023

Posted:

12 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

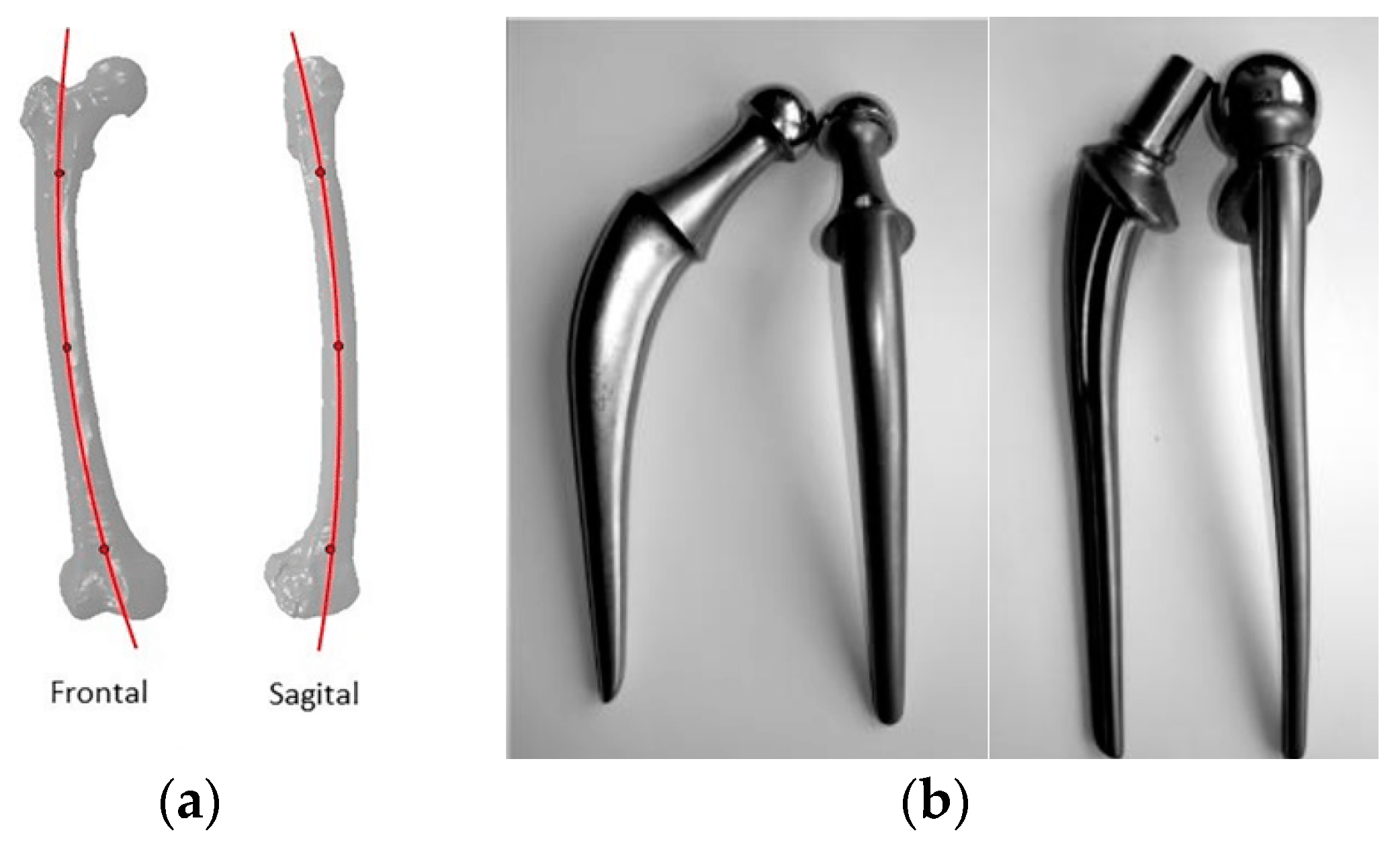

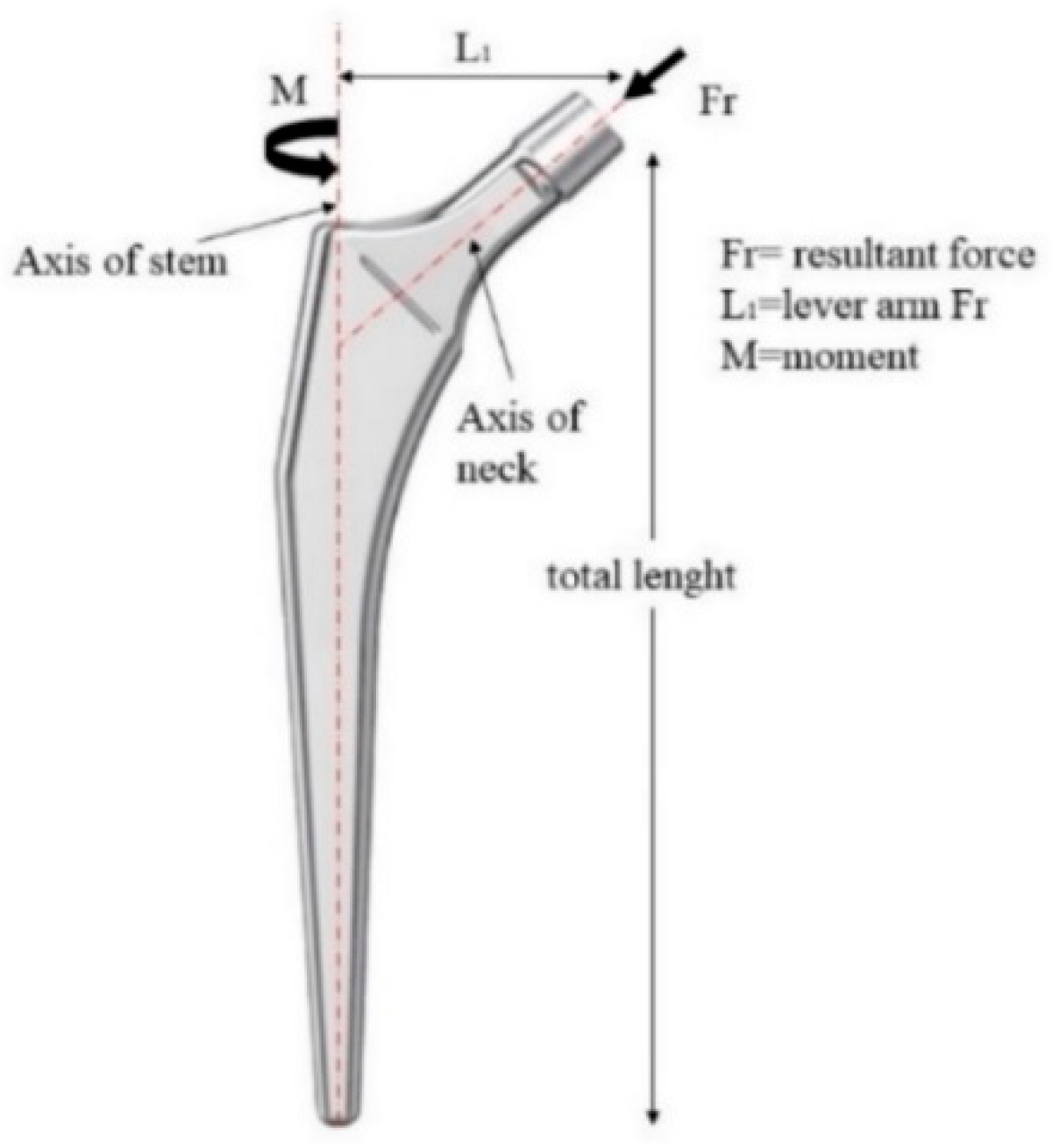

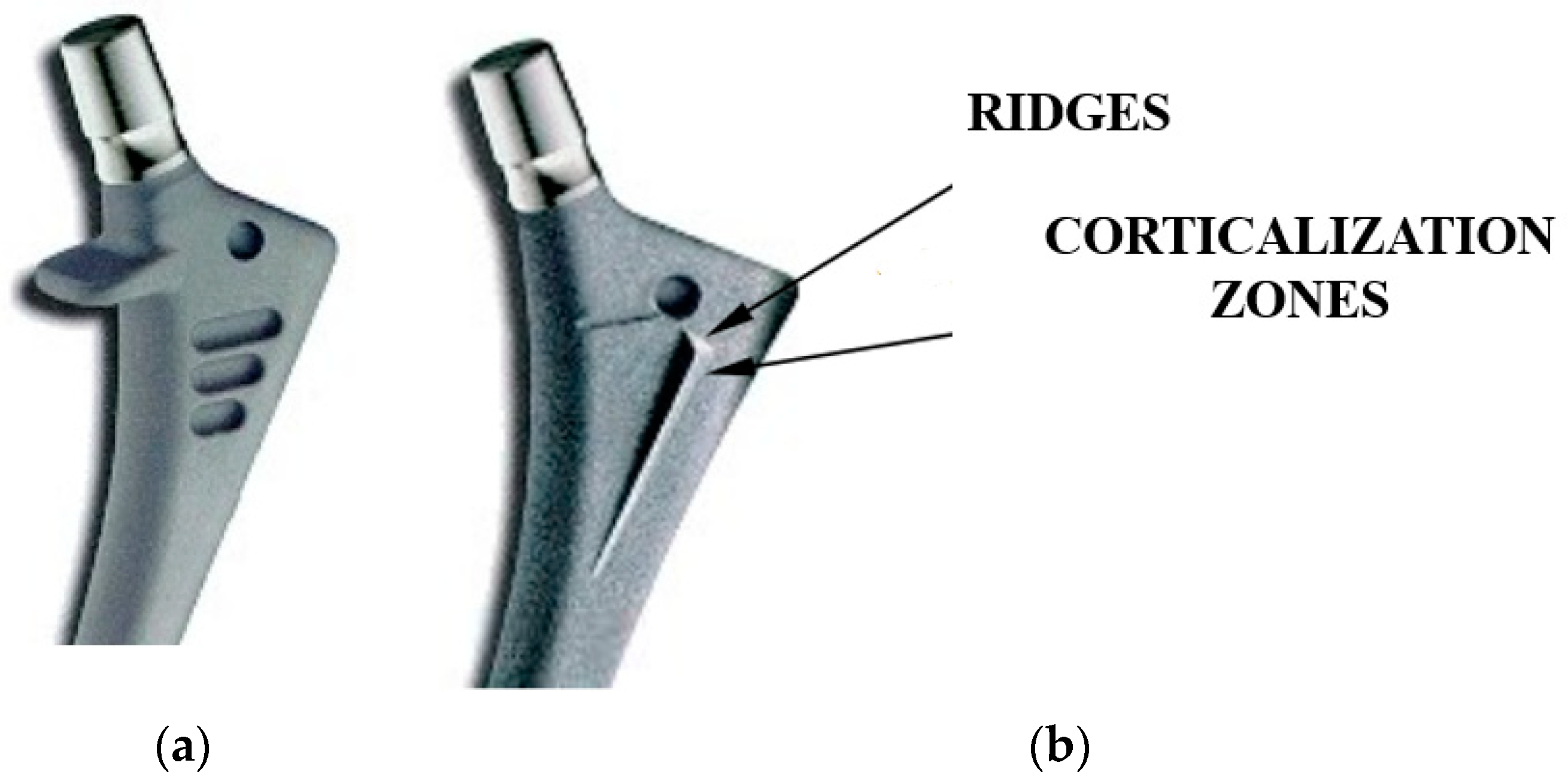

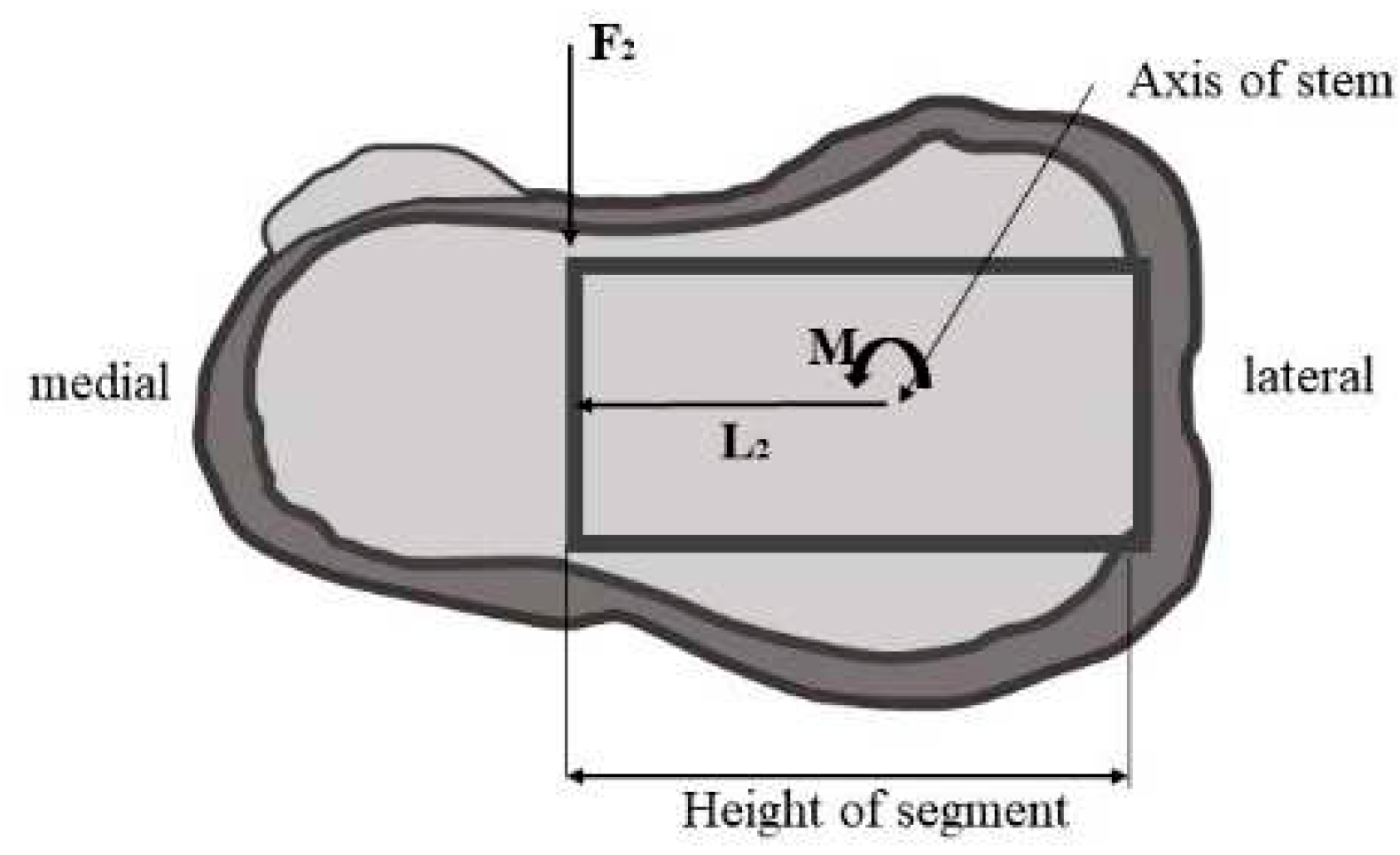

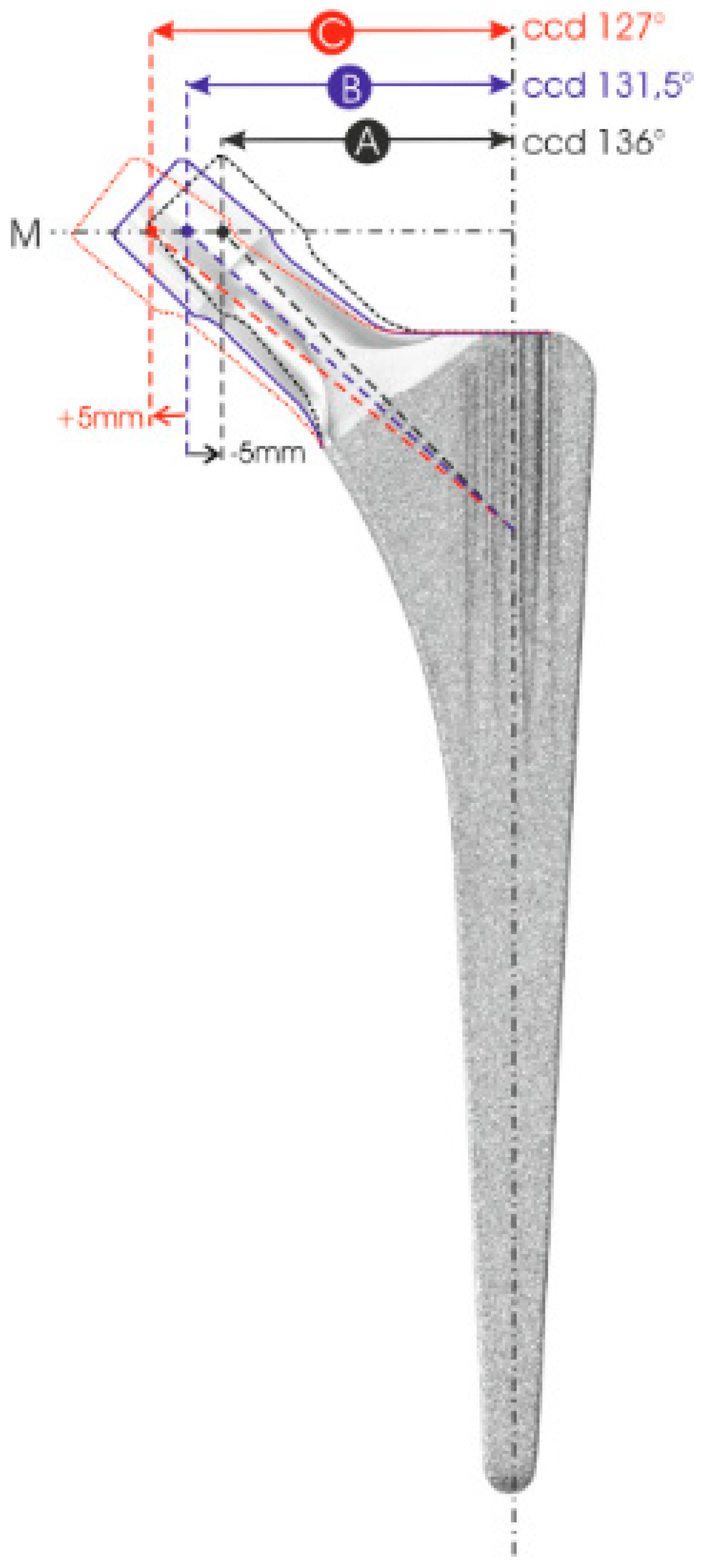

1.1. Rotational instability

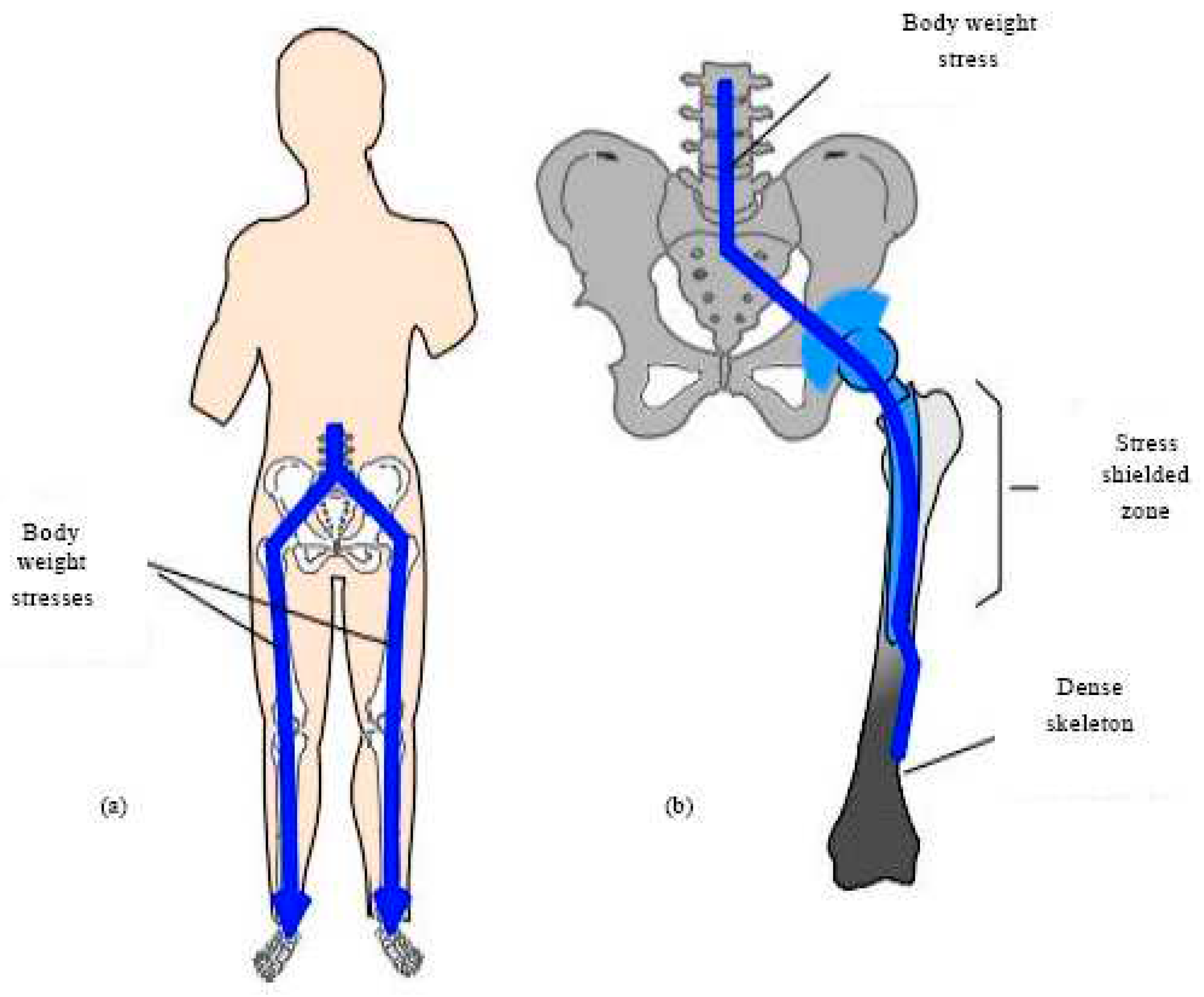

1.2. Stress-shielding

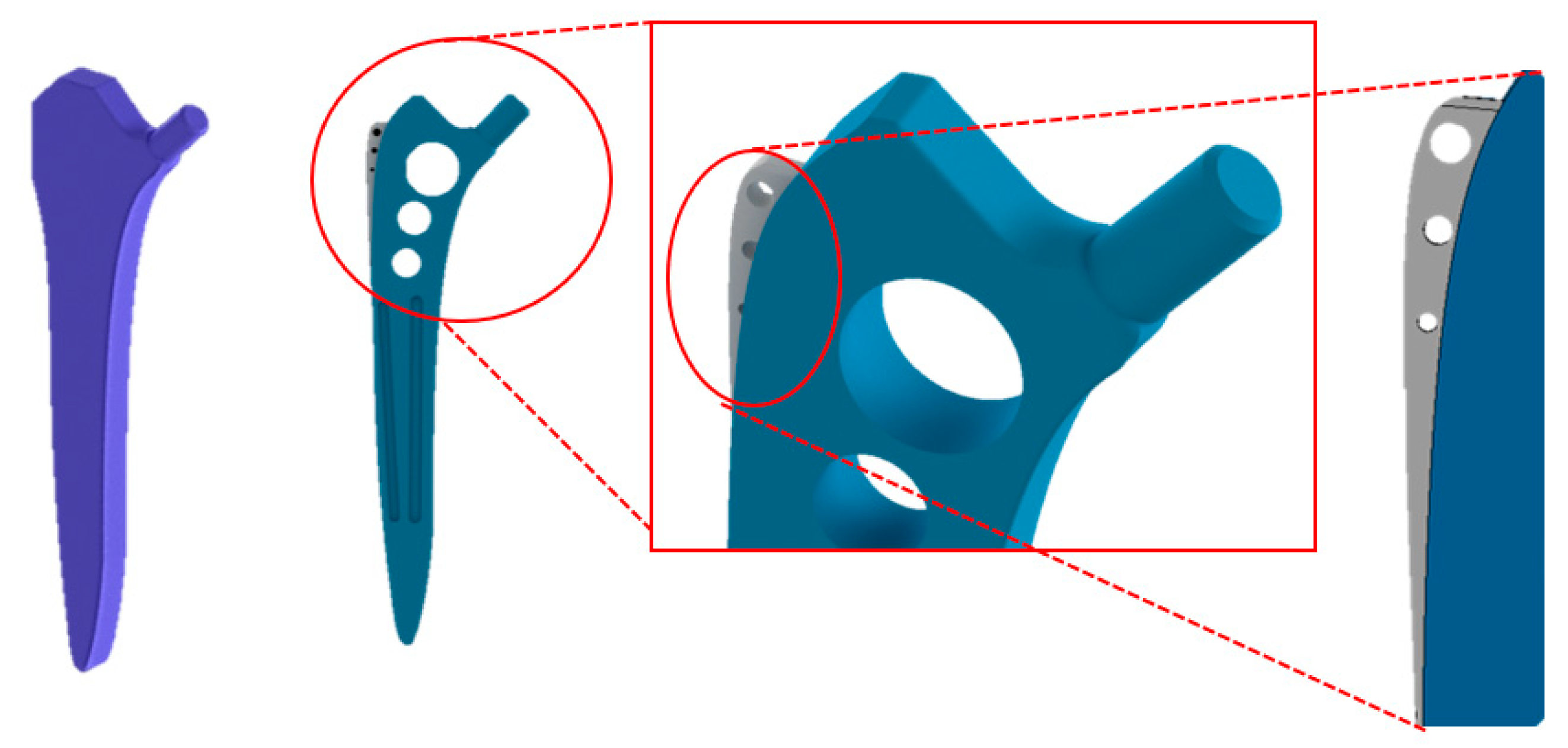

2. Materials and Methods

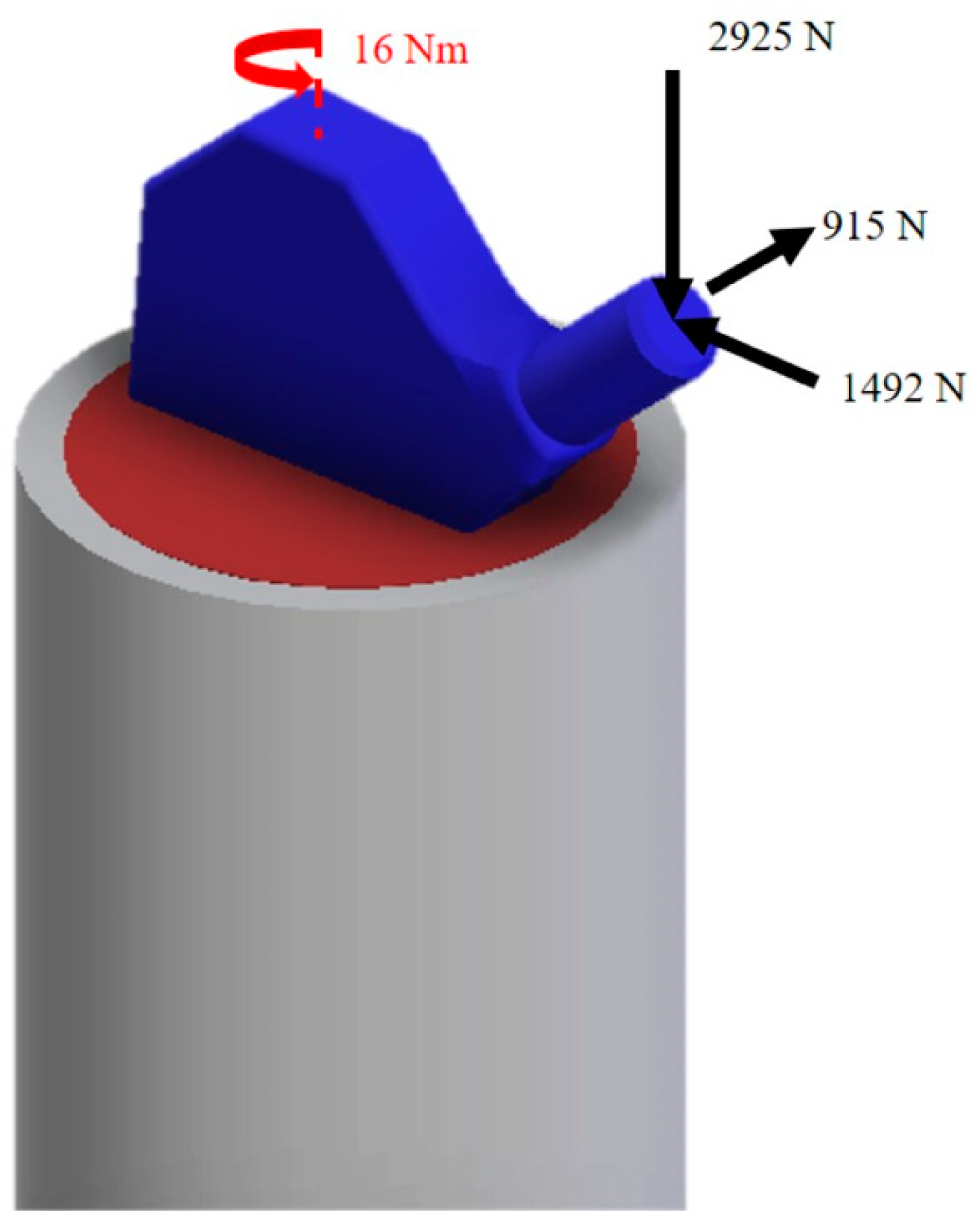

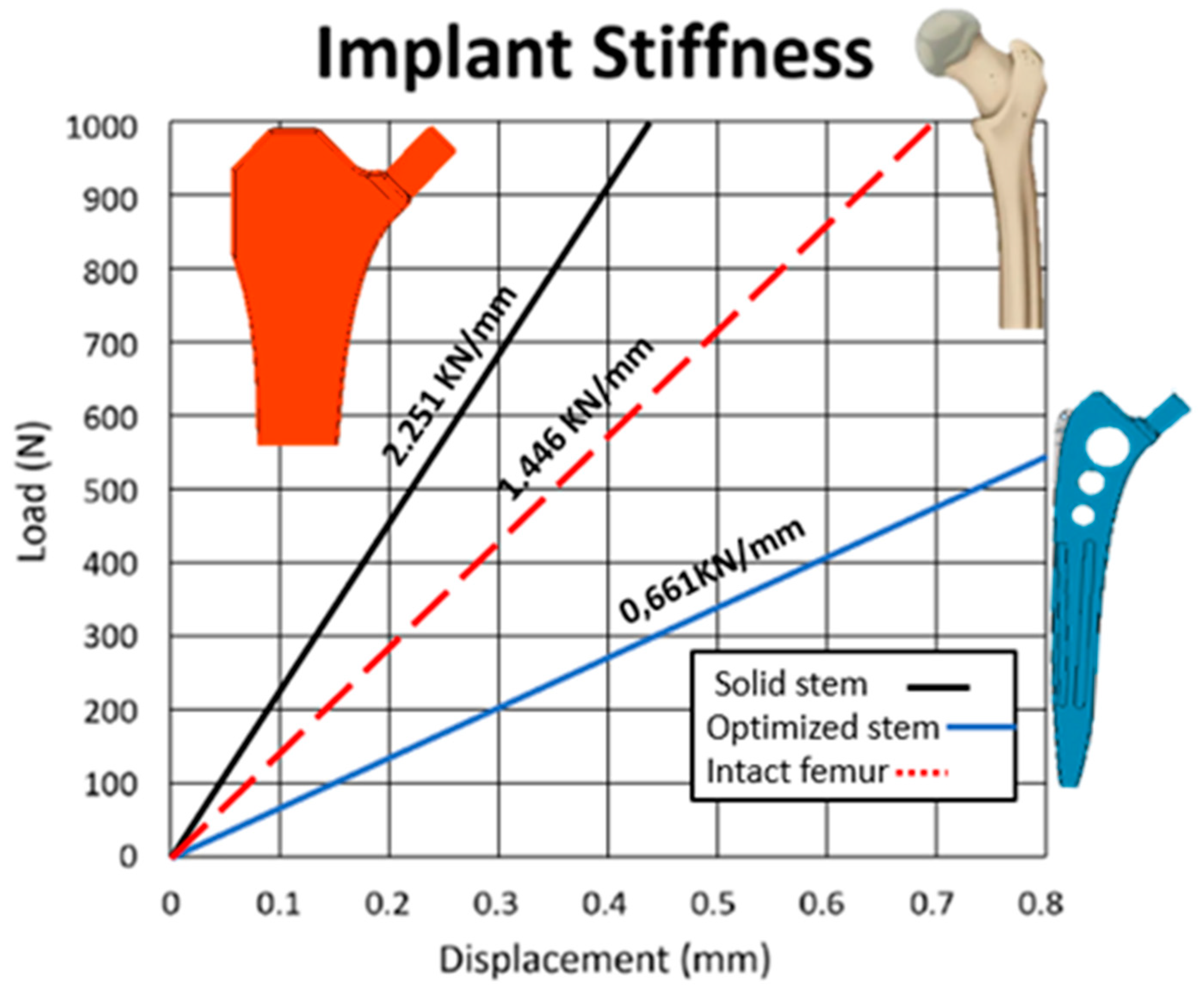

2.1. Evaluation of stem stiffness

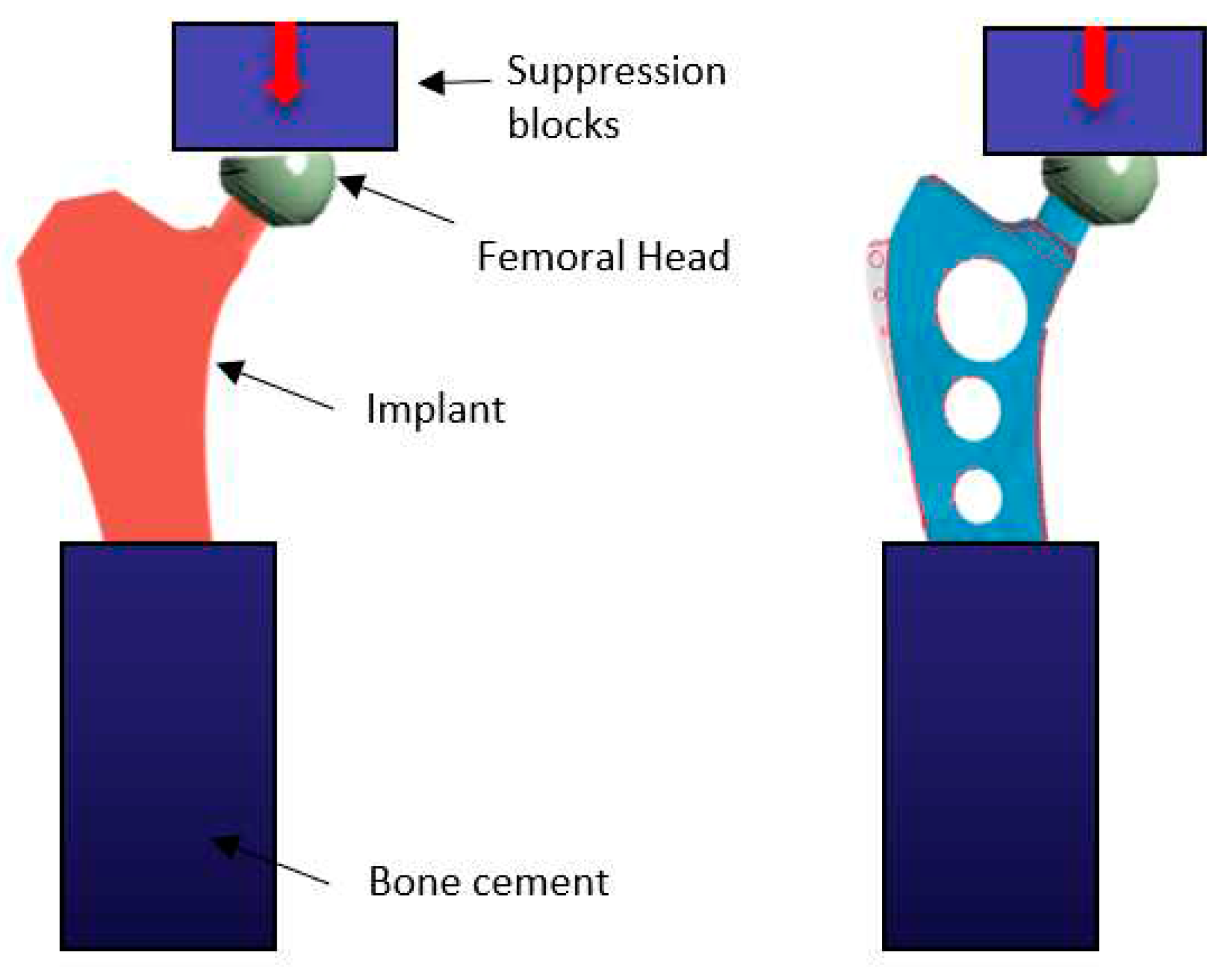

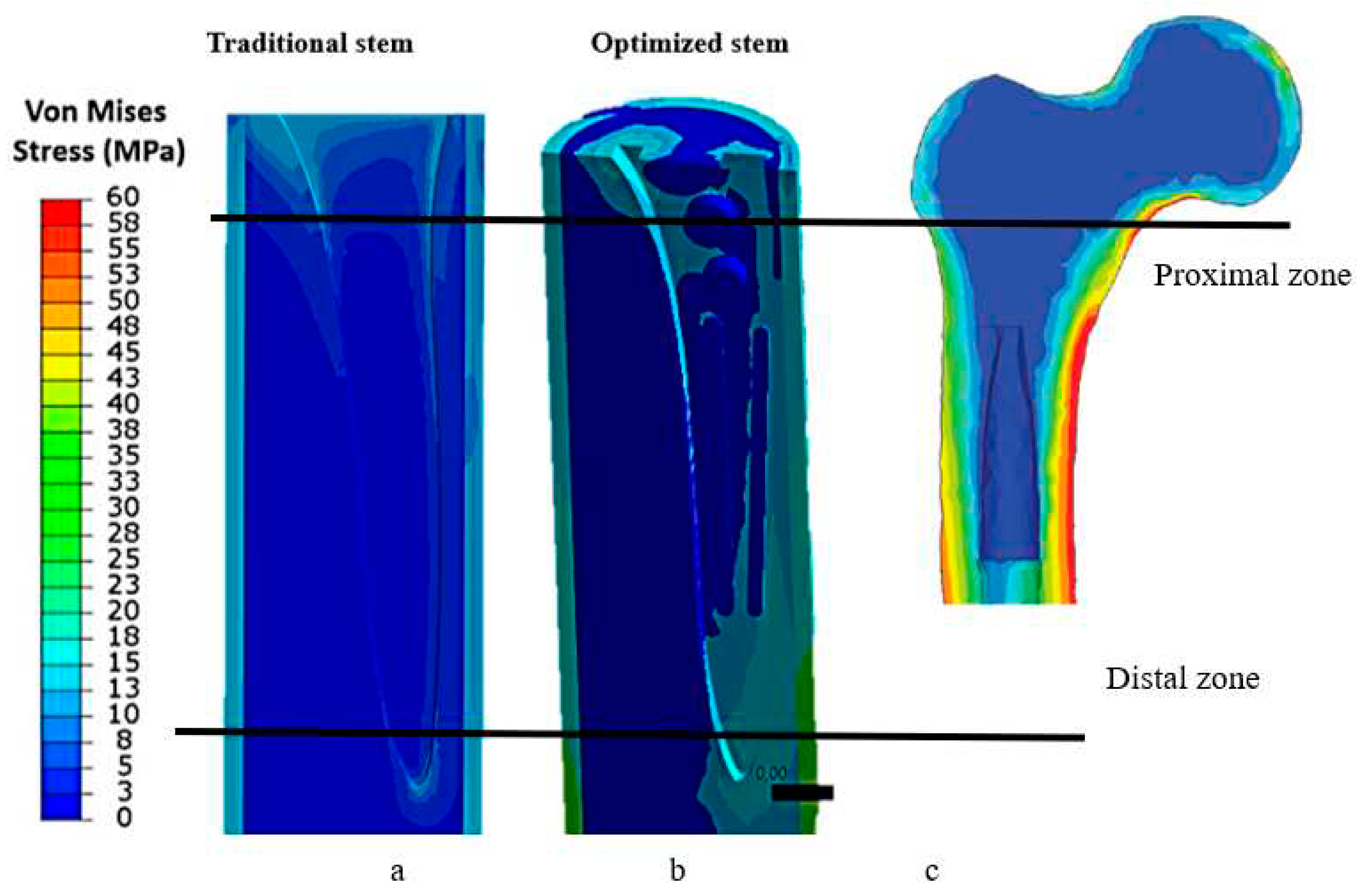

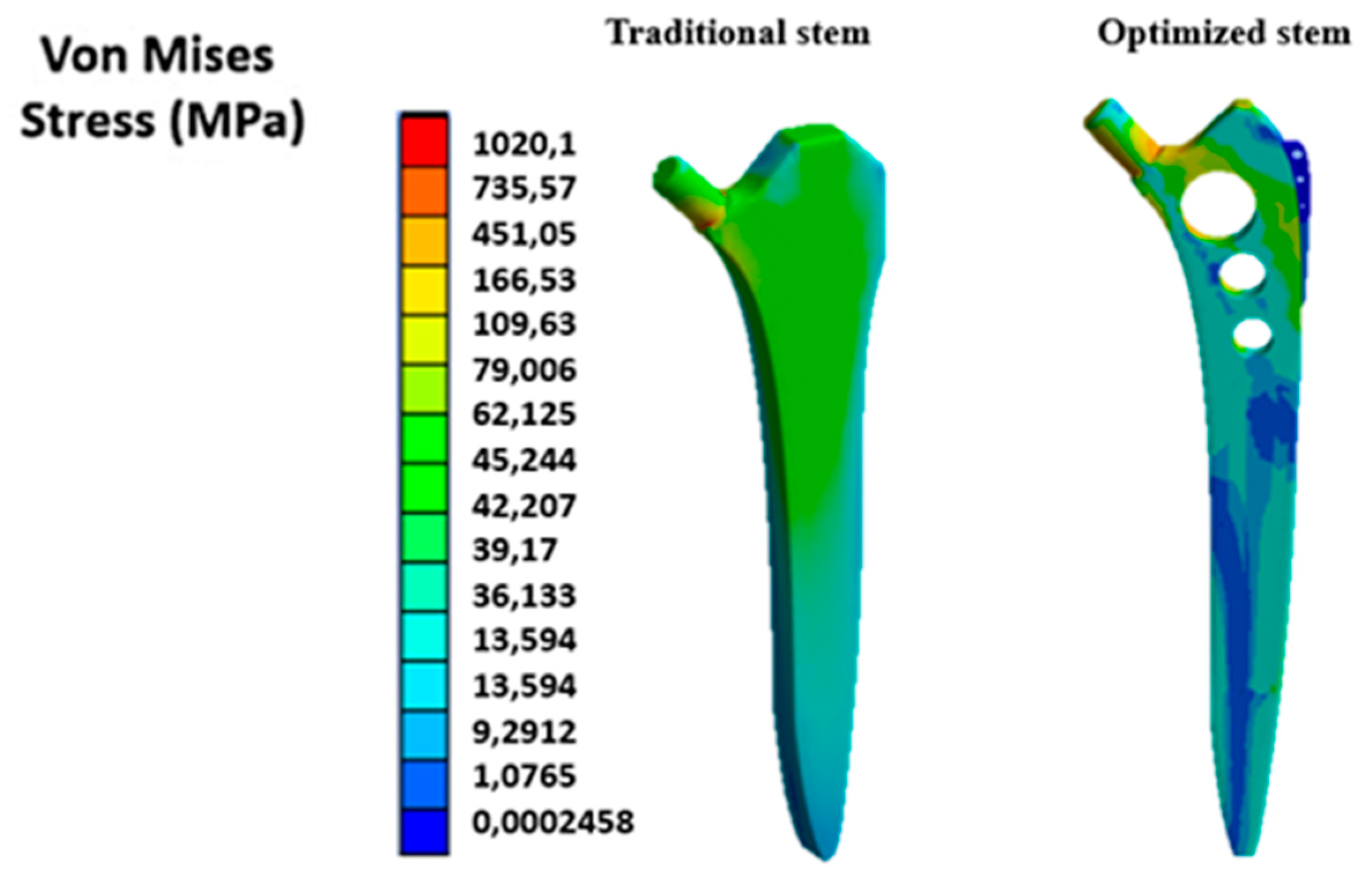

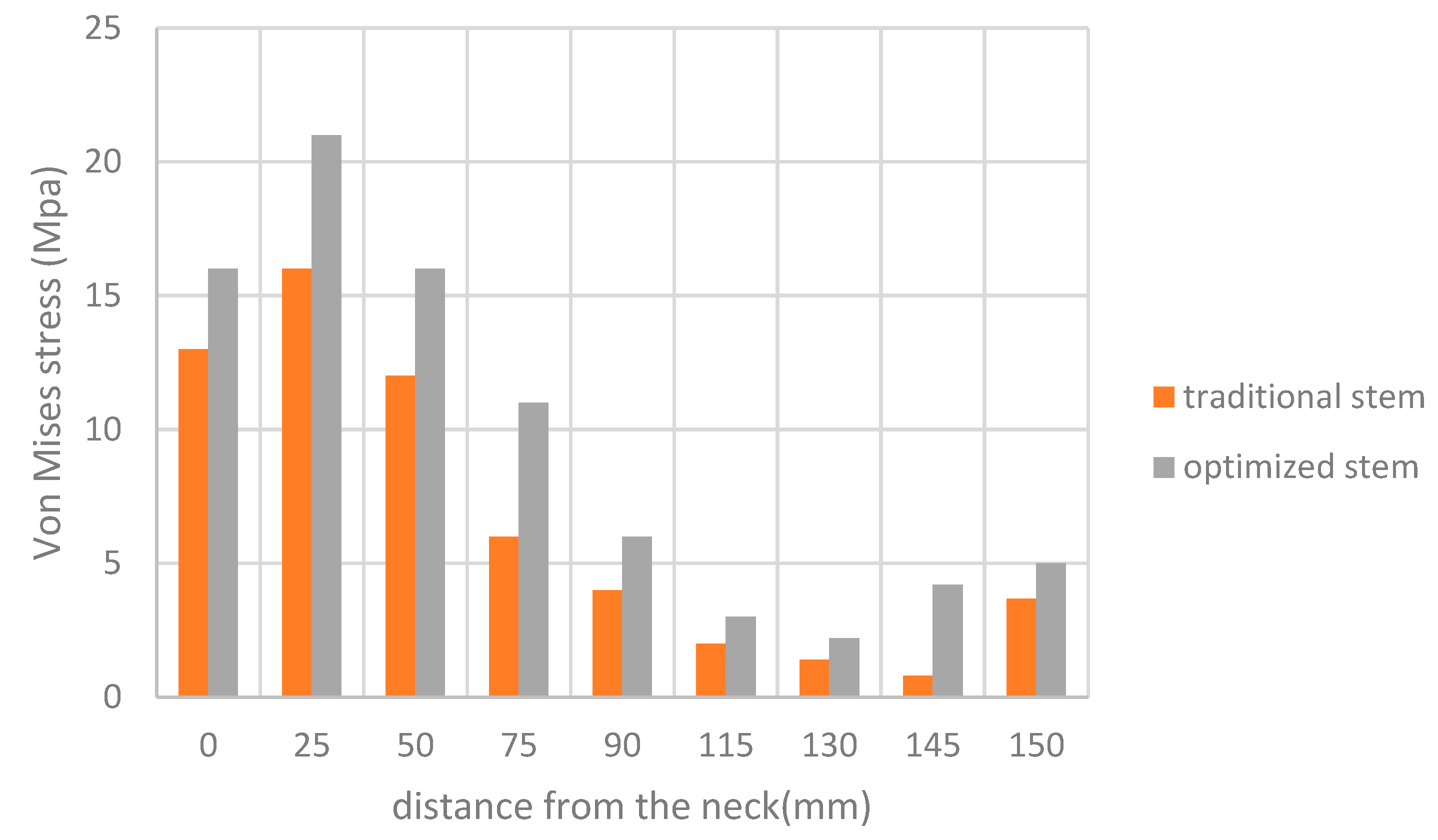

2.2. Bone implant stress assessment

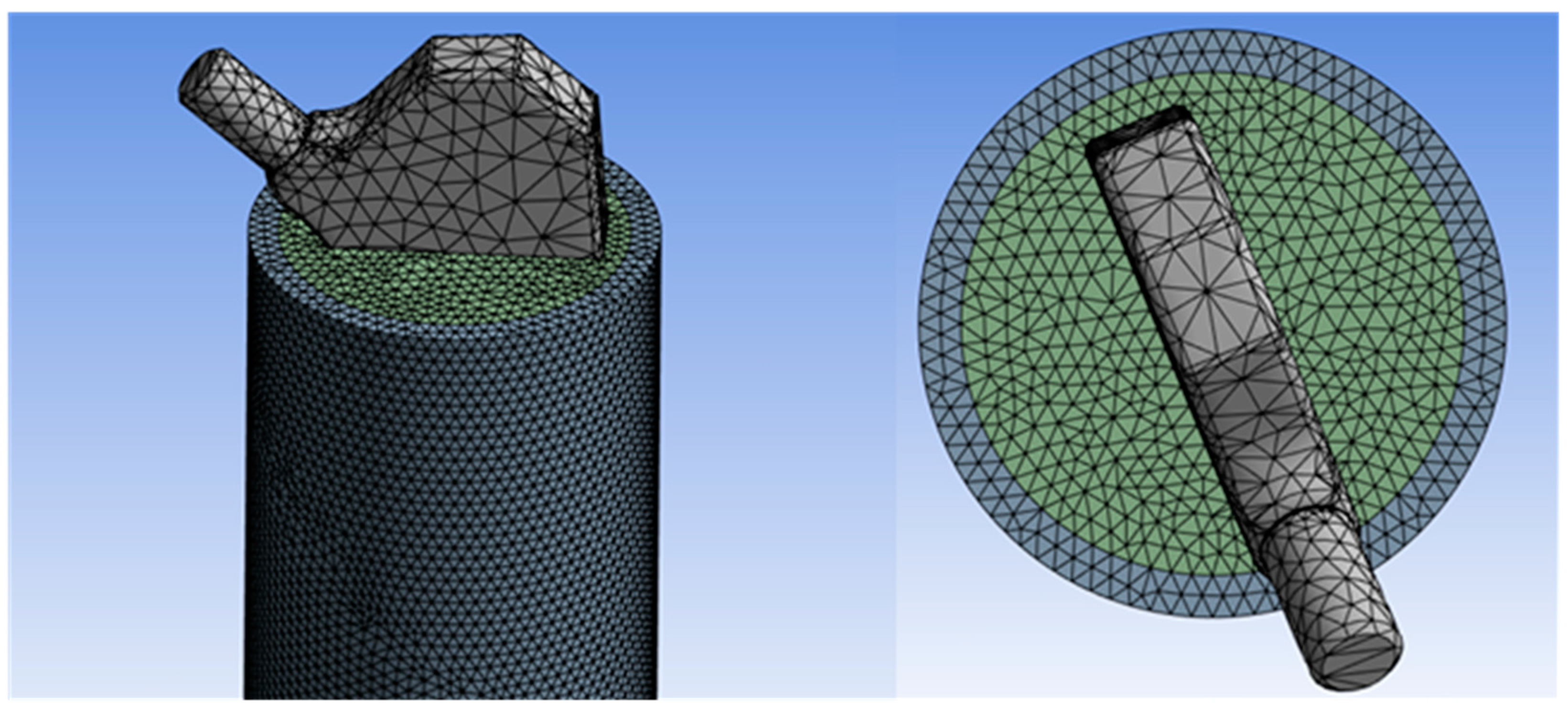

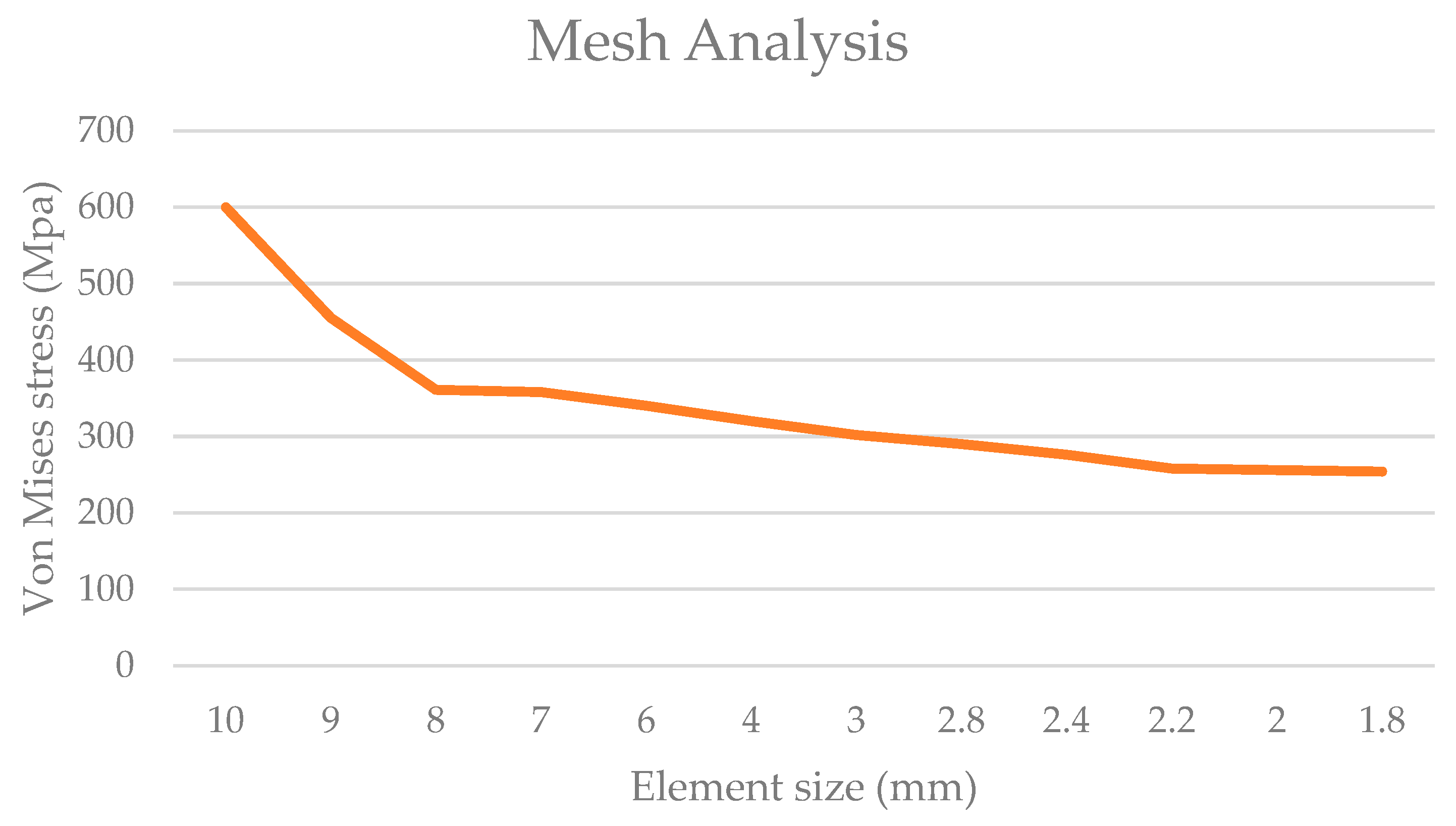

2.3. Meshing.

3. Results

4. Discussion

5. Conclusions

- Stem flexibility: A femoral stem designed with an appropriate degree of flexibility may allow for better load distribution between the implant and the surrounding bone. This helps reduce stress focused on specific regions of the bone and minimize stress shielding.

- Neck geometry: The geometry of the stem neck can affect the distribution of forces and the stress transferred to the bone. A neck with a proper shape and length can contribute to a more even distribution of the load and reduce stress shielding.

- Surface coatings: The use of surface coatings, such as porous coatings or hydroxyapatite coatings, can promote osseointegration of the implant and improve load transmission to the surrounding bone. This helps reduce stress shielding and promote better long-term stability of the implant.

- Selective fixation: Selective fixation refers to the use of different fixation methods in different regions of the femoral stem. For example, cemented fixation or press-fit fixation may be used in regions where greater stability is desired, while in other regions less rigid fixation may be preferable. This strategy helps reduce overall stem stiffness and minimize stress shielding.

- Gradual loading: A gradual post-operative loading and appropriate rehabilitation can contribute to a better adaptation of the bone to the implant and a reduction in stress shielding. A gradual loading process allows the bone to gradually adapt to new mechanical conditions and promotes bone remodeling

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hampton, S.J.; Andriacchi, T.P.; Galante, J.O. Three dimensional stress analysis of the femoral stem of a total hip prosthesis. J. Biomech. 1980, 13, 443–448. [Google Scholar] [CrossRef] [PubMed]

- Joseph, J. Movements at the hip joint, Ann. R. Coll. Surg. Engl. 1975, 56, 192–201. [Google Scholar]

- Joshi, M.G.; Advani, S.G.; Miller, F.; Santare, M.H. Analysis of a femoral hip prosthesis designed to reduce stress shielding. Journal of Biomechanics 2000, 33, 1655–1662. [Google Scholar] [CrossRef] [PubMed]

- Gross, S.; Abel, E.W. A finite element analysis of hollow stemmed hip prostheses as a means of reducing stress shielding of the femur. Journal of Biomechanics 2001, 34, 995–1003. [Google Scholar] [CrossRef]

- Rometsch, E.; Bos, P.K.; Koes, B.W. Survival of short hip stems with a “modern”, trochanter-sparing design - a systematic literature review. Hip Int 2012, 22, 344–354. [Google Scholar] [CrossRef]

- Banerjee, S.; Pivec, R.; Issa, K.; et al. Outcomes of short stems in total hip arthroplasty. Orthopedics 2013, 36, 700–707. [Google Scholar] [CrossRef]

- Moskal, J.T.; Capps, S.G. Is limited incision better than standard total hip arthroplasty? A meta-analysis. Clin Orthop Relat Res 2013, 471, 1283–1294. [Google Scholar] [CrossRef]

- Berstock, J.R.; Blom, A.W.; Beswick, A.D. A systematic review and meta-analysis of the standard versus miniincision posterior approach to total hip arthroplasty. J Arthroplasty 2014, 29, 1970–1982. [Google Scholar] [CrossRef]

- Yue, C.; Kang, P.; Pei, F. Comparison of direct anterior and lateral approaches in total hip arthroplasty: A systematic review and meta-analysis (PRISMA). Medicine (Baltimore) 2015, 94, e2126. [Google Scholar] [CrossRef]

- Feyen, H.; Shimmin, A.J. Is the length of the femoral component important in primary total hip replacement? Bone Joint J 2014, 96-B, 442–448. [Google Scholar] [CrossRef]

- Khanuja, H.S.; Banerjee, S.; Jain, D.; et al. Short bone-conserving stems in cementless hip arthroplasty. J Bone Joint Surg Am 2014, 96, 1742–1752. [Google Scholar] [CrossRef] [PubMed]

- Courpied, J.P.; Caton, J.H. Total hip arthroplasty, state ofthe art for the 21st century. Int Orthop 2011, 35, 149–150. [Google Scholar] [CrossRef] [PubMed]

- Khanuja, H.S.; Vakil, J.J.; Goddard, M.S.; et al. Cementless femoral fixation in total hip arthroplasty. J Bone Joint Surg Am 2011, 93, 500–509. [Google Scholar] [CrossRef] [PubMed]

- Brown, T.E.; Larson, B.; Shen, F.; et al. Thigh pain after cementless total hip arthroplasty: Evaluation and management. J Am Acad Orthop Surg 2002, 10, 385–392. [Google Scholar] [CrossRef] [PubMed]

- Engh, C.A., Jr.; Young, A.M.; Engh, C.A., Sr.; et al. Clinical consequences of stress shielding after porous-coated total hip arthroplasty. Clin Orthop Relat Res 2003, 417, 157–163. [Google Scholar] [CrossRef]

- Wilson, D.A.; Dunbar, M.J.; Amirault, J.D.; Farhat, Z. Early failure of a modular femoral neck total hip arthroplasty component: A case report. J Bone Joint Surg Am 2010, 92, 1514e7. [Google Scholar] [CrossRef] [PubMed]

- Lakstein, D.; Eliaz, N.; Levi, O.; Backstein, D.; Kosashvili, Y.; Safir, O.; et al. Fracture of cementless femoral stems at the mid-stem junction in modular revision hip arthroplasty systems. J Bone Joint Surg Am 2011, 93, 57e65. [Google Scholar] [CrossRef]

- Wright, G.; Sporer, S.; Urban, R.; Jacobs, J. Fracture of a modular femoral neck after total hip arthroplasty: A case report. J Bone Joint Surg Am 2010, 92, 1518e21. [Google Scholar] [CrossRef]

- Quintana, J.M.; Arostegui, I.; Azkarate, J.; Goenaga, J.I.; Elexpe, X.; Letona, J.; Arcelay, A. Evaluation of explicit criteria for total hip joint replacement. J. Clin. Epidemiol. 2000, 53, 1200–1208. [Google Scholar] [CrossRef]

- Gademan, M.G.J.; Hofstede, S.N.; Vlieland, T.P.M.V.; Nelissen, R.G.H.H.; De Mheen, P.J.M.-V. Indication criteria for total hip or knee arthroplasty in osteoarthritis: A state-of-the-science overview. BMC Musculoskelet. Disord. 2016, 17, 463. [Google Scholar] [CrossRef]

- Lucchini, S.; Castagnini, F.; Giardina, F.; Tentoni, F.; Masetti, C.; Tassinari, E.; Bordini, B.; Traina, F. Cementless ceramic-on ceramic total hip arthroplasty in post-traumatic osteoarthritis after acetabular fracture: Long-term results. Arch. Orthop. Trauma. Surg. 2021, 141, 683–691. [Google Scholar] [CrossRef] [PubMed]

- Fokter, S.K.; Levašič, V.; Kovač, S. The Innovation Trap: Modular Neck in Total Hip Arthroplasty. ZdravVestn 2017, 86, 115–126. [Google Scholar]

- Aljenaei, F.; Catelas, I.; Louati, H.; Beaulé, P.E.; Nganbe, M. Effects of hip implant modular neck material and assembly method on fatigue life and distraction force. J. Orthop. Res. 2017, 35, 2023–2030. [Google Scholar] [CrossRef] [PubMed]

- Zajc, J.; Moličnik, A.; Fokter, S. Dual Modular Titanium Alloy Femoral Stem Failure Mechanisms and Suggested Clinical Approaches. Materials 2021, 14, 3078. [Google Scholar] [CrossRef]

- Weiser, M.C.; Chen, D.D. Revision for taper corrosion at the neck-body junction following total hip arthroplasty: Pearls and pitfalls. Curr. Rev. Musculoskelet. Med. 2016, 9, 75–83. [Google Scholar] [CrossRef]

- Wright, C.G.; Sporer, S.; Urban, R.; Jacobs, J. Fracture of a Modular Femoral Neck After Total Hip Arthroplasty: A Case Report. J. Bone Jt. Surg. 2010, 92, 1518–1521. [Google Scholar] [CrossRef]

- Vucajnik, I.; Fokter, S.K. Modular Femoral Neck Fracture After Total Hip Arthroplasty. In Recent Advances in Hip and Knee Arthroplasty; IntechOpen: London, UK, 2012. [Google Scholar]

- Grupp, T.M.; Weik, T.; Bloemer, W.; Knaebel, H.-P. Modular titanium alloy neck adapter failures in hip replacement—Failure mode analysis and influence of implant material. BMC Musculoskelet. Disord. 2010, 11, 3. [Google Scholar] [CrossRef]

- Meftah, M.; Haleem, A.M.; Burn, M.B.; Smith, K.M.; Incavo, S.J. Early Corrosion-Related Failure of the Rejuvenate Modular Total Hip Replacement. J. Bone Jt. Surg. Am. 2014, 96, 481–487. [Google Scholar] [CrossRef]

- Bernstein, D.T.; Meftah, M.; Paranilam, J.; Incavo, S.J. Eighty-six Percent Failure Rate of a Modular-Neck Femoral Stem Design at 3 to 5 Years: Lessons Learned. J. Bone Jt. Surg. 2016, 98, e49. [Google Scholar] [CrossRef]

- Pipino, F. CFP Prosthetic Stem in Mini-Invasive Total Hip Arthroplasty. Journal ofOrthopaedics and Traumatology 2004, 4, 165–171. [Google Scholar] [CrossRef]

- Effenberger, H.; Heiland, A.; Ramsauer, T.; Plitz, W.; Dorn, U. A model for assessing the rotational stability of uncemented femoral implants. Arch Orthop Trauma Surg. 2001, 121, 60–64. [Google Scholar] [CrossRef] [PubMed]

- Wolff, J. Das Gesetz der Transformation der Knochen; Verlag von August Hirschwald: Berlin, Germany, 1892. [Google Scholar]

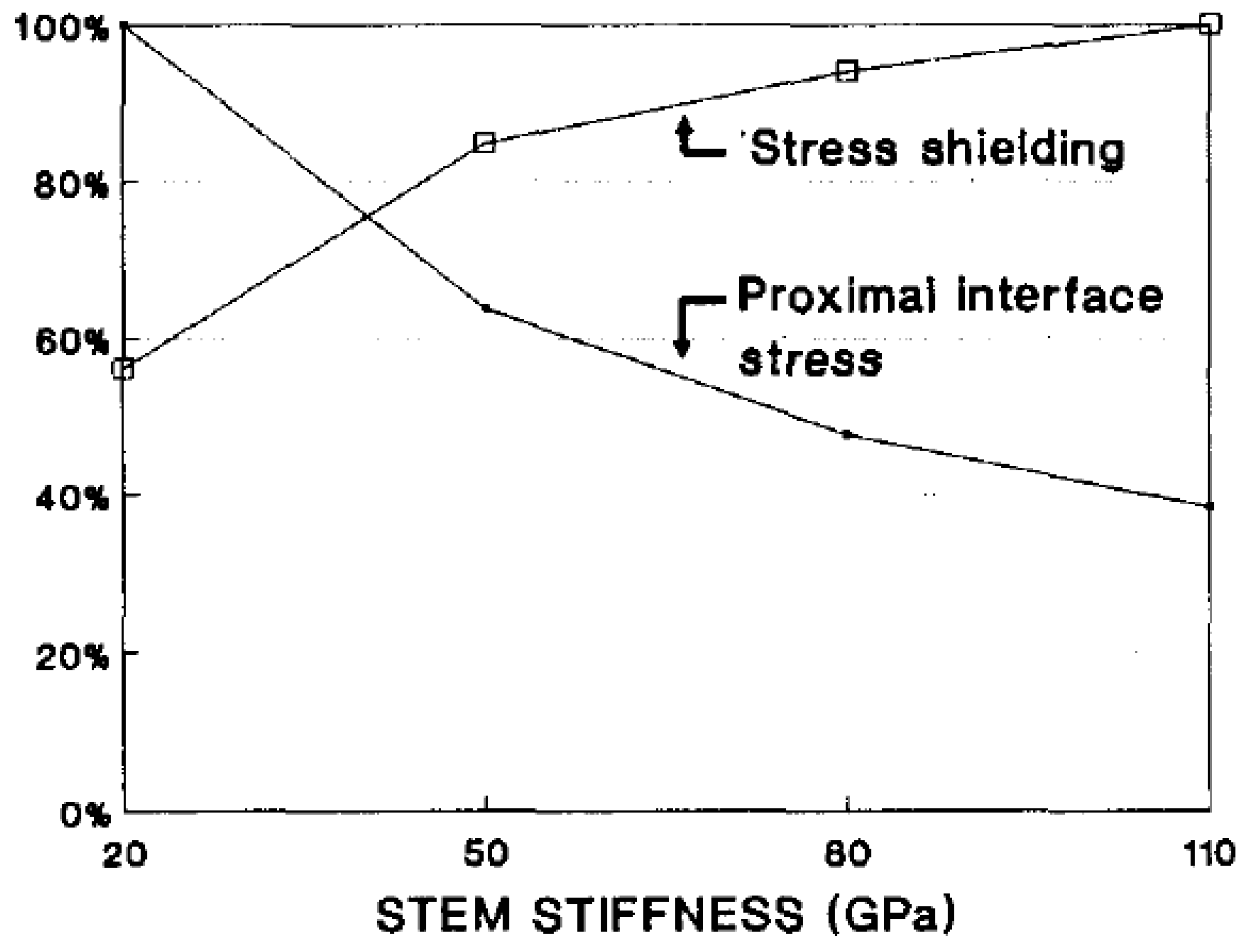

- Huiskes, R.; Weinans, H.; Van Rietbergen, B. The Relationship between Stress Shielding and Bone Resorption around Total Hip Stems and the Effects of Flexible Materials. Clin. Orthop. Relat. Res. 1992, 274, 124–134. [Google Scholar] [CrossRef]

- Wang, X.; Xu, S.; Zhou, S.; Xu, W.; Leary, M.; Choong, P.; Qian, M.; Brandt, M.; Xie, Y.M. Topological Design and Additive Manufacturing of Porous Metals for Bone Scaffolds and Orthopaedic Implants: A Review. Biomaterials 2016, 83, 127–141. [Google Scholar] [CrossRef] [PubMed]

- Diegel, P.D.; Daniels, A.U.; Dunn, H.K. “Initial effect of collarless stem stiffness on femoral bone strain. ” The Journal of arthroplasty 1989, 4, 173–178. [Google Scholar] [CrossRef] [PubMed]

- Fraldi, M.; Esposito, L.; Perrella, G.; Cutolo, A.; Cowin, S.C. Topological Optimization in Hip Prosthesis Design. Biomech. Model. Mechanobiol. 2010, 9, 389–402. [Google Scholar] [CrossRef]

- Kappe, T.; et al. Minimally Invasive Total Hip Arthroplastytrend or State of the Art?: A Meta-analysis. Ortopade Journal, 2011; Epub ahead of print. [Google Scholar]

- Chen, W.C.; Lai, Y.S.; Cheng, C.K.; Chang, T.K. A cementless, proximally fixed anatomic femoral stem induces high micromotion with nontraumatic femoral avascular necrosis: Afinite element study. J. Orthop. Transl. 2014, 2, 149–156. [Google Scholar] [CrossRef]

- Bergmann, G.; et al. Hip contact forces and gait patterns from routine activities. Journal of Biomechanics 2001, 34, 859–871. [Google Scholar] [CrossRef]

- Naghavi, S.; Tamaddon, M.; Hejazi, M.; Moazen, M.; Liu, C. On the Mechanical Aspect of Additive Manufactured Polyether– Ether–Ketone Scaffold for Repair of Large Bone Defects. Biomater. Transl. 2022, 3, 142–151. [Google Scholar]

- Svesnsson, N.L.; Valliappan, S.; Wood, R.D. Stress analysis of human femur with implanted Charnley prosthesis. Journal of Biomechanics 1977, 10, 581–588. [Google Scholar] [CrossRef]

- Papini, M.; Zdero, R.; Schemitsch, E.H.; Zalzal, P. The Biomechanics of Human Femurs in Axial and Torsional Loading: Comparison of Finite Element Analysis, Human Cadaveric Femurs, and Synthetic Femurs. J. Biomech. Eng. 2007, 129, 12–19. [Google Scholar] [CrossRef]

- Tan, N.; van Arkel, R.J. Topology Optimisation for Compliant Hip Implant Design and Reduced Strain Shielding. Materials 2021, 14, 7184. [Google Scholar] [CrossRef] [PubMed]

- Cortis, G.; Mileti, I.; Nalli, F.; Palermo, E.; Cortese, L. Additive Manufacturing Structural Redesign of Hip Prostheses for Stress–Shielding Reduction and Improved Functionality and Safety. Mech. Mater. 2022, 165, 104173. [Google Scholar] [CrossRef]

- Mehboob, H.; Tarlochan, F.; Mehboob, A.; Chang, S.H.; Ramesh, S.; Harun, W.S.W.; Kadirgama, K. A Novel Design, Analysis and 3D Printing of Ti–6Al–4V Alloy Bio–Inspired Porous Femoral Stem. J. Mater. Sci. Mater. Med. 2020, 31, 104173. [Google Scholar] [CrossRef] [PubMed]

- Kladovasilakis, N.; Tsongas, K.; Tzetzis, D. Finite Element Analysis of Orthopedic Hip Implant with Functionally Graded Bioinspired Lattice Structures. Biomimetics 2020, 5, 44. [Google Scholar] [CrossRef]

- Engh, C.A.; Bobyn, J.D.; Glassman, A.H. Porous-coated hip replacement. The factors governing bone ingrowth, stress shielding, and clinical results. J Bone Joint Surg Br 1987, 69, 45. [Google Scholar] [CrossRef]

- Gross, S.; Abel, E.W. A finite element analysis of hollow stemmed hip prostheses as a means of reducing stress shielding of the femur. J Biomech. 2001, 34, 995–1003. [Google Scholar] [CrossRef]

- Effenberger, H.; Heiland, A.; Ramsauer, T.; Plitz, W.; Dorn, U. A model for assessing the rotational stability of uncemented femoral implants. Arch Orthop Trauma Surg. 2001, 121, 60–64. [Google Scholar] [CrossRef]

- Nunn, D.; Freeman, M.A.R.; Tanner, K.E.; Bonfield, W. Torsional stability of the femoral component of hip arthroplasty. Response to an anteriorly applied load. J Bone Joint Surg Br 1989, 71, 452–455. [Google Scholar] [CrossRef]

- Freeman, M.A.R. Why resect the neck? J Bone Joint Surg Br 1986, 68, 346–349. [Google Scholar] [CrossRef]

- Sugiyama, H.; Whiteside, L.A.; Engh, C.A. Torsional fixation of the femoral component in total hip arthroplasty. The effect of surgical press-fit technique. Clin Orthop 1992, 275, 187–193. [Google Scholar] [CrossRef]

- Hanada, S.; Masahashi, N.; Jung, T.K.; Yamada, N.; Yamako, G.; Itoi, E. Fabrication of a High–Performance Hip Prosthetic Stem Using Ti–33.6Nb–4Sn. J. Mech. Behav. Biomed. Mater. 2014, 30, 140–149. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.; Wang, L.; Kang, J.; Li, D.; Jin, Z. Biomechanical Optimization of Elastic Modulus Distribution in Porous Femoral Stem for Artificial Hip Joints. J. Bionic Eng. 2018, 15, 693–702. [Google Scholar] [CrossRef]

- Cortis, G.; Mileti, I.; Nalli, F.; Palermo, E.; Cortese, L. Additive Manufacturing Structural Redesign of Hip Prostheses for Stress–Shielding Reduction and Improved Functionality and Safety. Mech. Mater. 2022, 165, 104173. [Google Scholar] [CrossRef]

- Mehboob, H.; Tarlochan, F.; Mehboob, A.; Chang, S.H.; Ramesh, S.; Harun, W.S.W.; Kadirgama, K. A Novel Design, Analysis and 3D Printing of Ti–6Al–4V Alloy Bio–Inspired Porous Femoral Stem. J. Mater. Sci. Mater. Med. 2020, 31, 104173. [Google Scholar] [CrossRef] [PubMed]

| Material | Modulus of Elasticity | Shear modulus (Gpa) | Poisson’s ratio | Compressive Strength (Mpa) | Yield strength (Mpa) | Density g/cm3 |

|---|---|---|---|---|---|---|

| Cortical bone | Ex=6979 (Mpa) Ey=18132 (Mpa) Ez=6979 (Mpa) |

Gyz=5.6 Gzx=4.5 Gxy=6.2 |

195 | 2.02 | ||

| Cancellous bone | Ex=660 (Mpa) Ey=1740 (Mpa) Ez=660 (Mpa) |

Gyz=0.211 Gzx=0.165 Gxy=0.260 |

16 | 1.37 | ||

| Ti6Al4V | 110 (GPa) | 0.3 | 970 | 930 | 4.42 |

|

| Steel (suppression blocks) | 210 (Gpa) | 0.3 | ||||

| Bone cement | 3.8 (Gpa) | 0.3 | ||||

| Cr-Co (femoral head) | 200 (Gpa) | 0.33 |

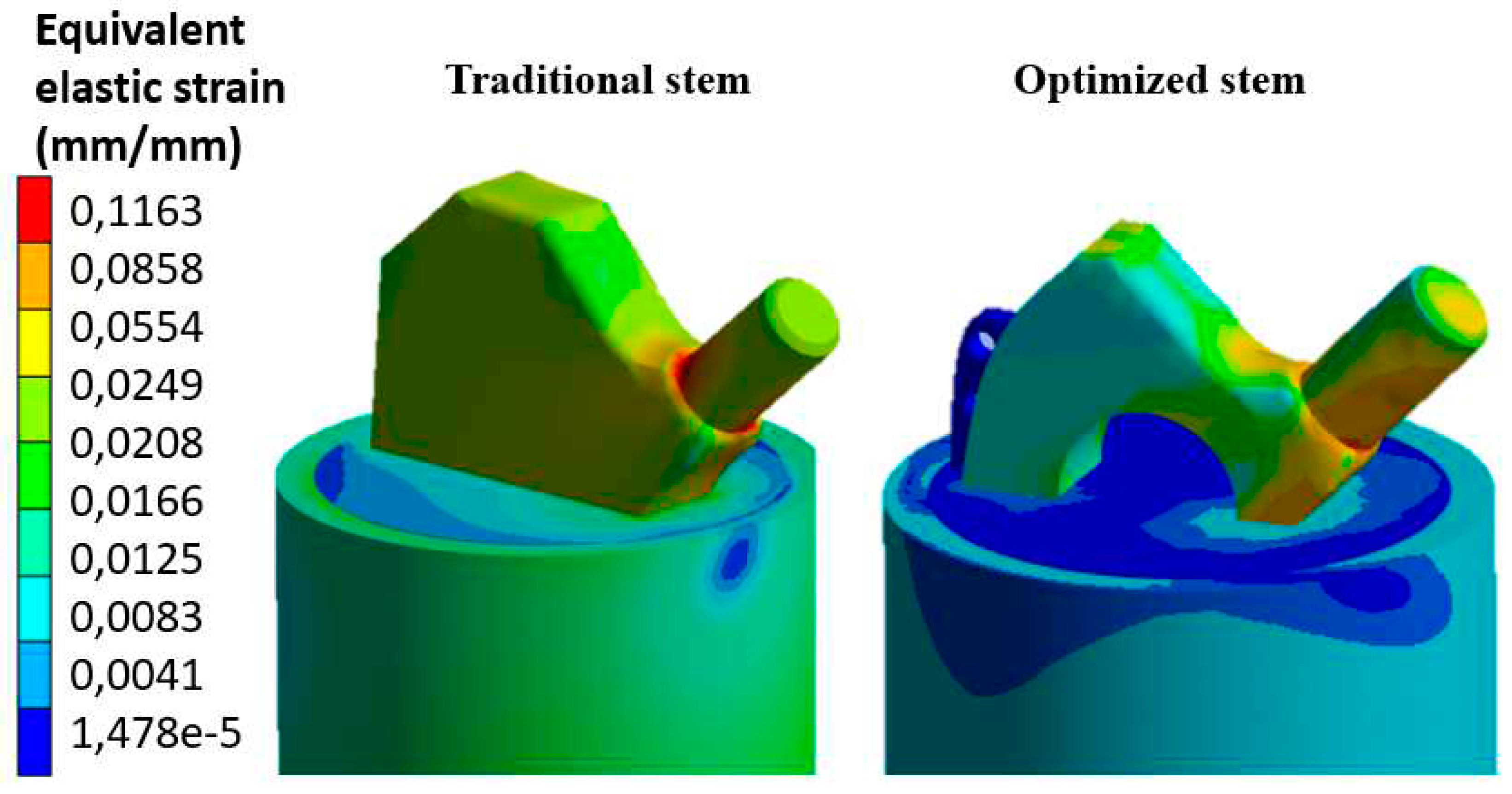

| Von Mises stress bone with traditional stem | Von Mises bone stress with optimized stem | Stress-shielding reduction% | |

|---|---|---|---|

| Traditional stem | optimized stem | ||

| Proximal 13 Mpa | Proximal 17 Mpa | 24.08% | 31.46% |

| Central 3.1 Mpa | Central 4.2 Mpa | 5.54% | 7.5% |

| Distal 4.6 Mpa | Distal 5 Mpa | 9.59% | 10.1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).