1. Introduction

Preservation of the structural integrity of aging and historic buildings is a crucial step towards ensuring their lasting conservation [

1]. To this end, temporal destructive and non-destructive testing is performed to predict the material properties of structural components and determine the structural response and consequentially their effective life cycle [

2,

3]. At the extreme cases, a complete demolition of the structural systems, followed by a preservation of the envelop (and interior architectural components) may be the only possible option. The environmental impact of construction and demolition waste (CDW) is, however, significant. In the European Union, the construction sector produces 839 million tons of waste annually, with 281 million tons of Construction and Demolition waste (CDW), contributing to 33% of the total waste from all sectors [

4]. In addition, CDW contributes to 10–30% of all landfilled waste [

5]. As a result, in recent years, more attention has been focused on reusing and recycling strategies to manage CDW and reduce machine demolition and landfill. A study conducted by Marzouk and Azab [

6] shows that recycling CDW reduces emissions, energy use, and global warming potential (GWP) significantly, while preserving landfill space. In addition, increasing prices and shortage of building materials compel the construction industry to find new, affordable, and sustainable material sources. In this case, the considerable amount of CDW allows them to obtain building materials.

As such, this study aims to evaluate the environmental impact of two different development strategies for existing aging buildings (i.e., older than 60 years), namely, (i) deconstructing or demolishing (both separately) the existing building and erecting a new building with optimized and up-to-date properties; and (ii) renovating the existing building twice during its lifespan. In the former case, the considerable amount of CDW can be repurposed to allow reuse of the existing building materials that still comply with local code standards. In the latter strategy, the building was planned for renovation every thirty years (twice in a 60 year lifespan). The total cost, energy consumption, and carbon emission generated in the considered scenarios were compared to choose the best option for the existing building.

To achieve the goals of this manuscript, the remainder of this section provides an overview of the state-of-the-art for challenges in BIM-based sustainability assessment of existing buildings; and state of design optimization for sustainability.

1.1. Challenges in BIM-based Sustainability Assessment of Existing Buildings

Typical metrics to quantify sustainability aspects, such as embodied energy and carbon, report the cradle-to-gate or cradle-to-grave values in unit weight of material consumed (e.g., the Inventory of Carbon and Energy (ICE) [

7,

8]). As such, once the inventory of material consumed in a building is determined (through quantity-surveying), the embodied energy and Carbon of the whole building can be determined. Given that BIM is the process of modeling intelligent graphical and non-graphical data related to building construction projects within a unified model [

9,

10,

11], the quantity of material can be automatically extracted from the BIM. In fact, most BIM software platforms, such as Revit [

12], provide this opportunity. For instance, the effectiveness of a BIM-based system for estimating and planning demolition and renovation wastes was evaluated in [

13]. The study extracted material and corresponding volume information from the BIM model, which was then used to predict the required dump truck capacities, including number of rounds for off-loading, and total costs for waste disposal.

However, a BIM model is not always available, especially for historic and aging buildings. The geometry of the visible structural elements of a building can be determined using optical metrology tools, such as laser scanners and cameras. To generate a semantic BIM from the acquired point clouds, the Field Information Modeling (FIM)® framework [

14] can be utilized, which has shown effective in automatic semantic BIM generation of oil and gas pipes [

15], mechanical residential pipes [

16,

17], reinforced concrete structures [

18], and cultural heritage domes [

1]. The BIM model generated using only visual digital information, such as point clouds, will contain information about building construction, boundaries and relationship between elements (e.g., partition walls, beams and building envelopes), and the quantities and types of building materials. This is a precondition for producing a material inventory.

However, in order to create a detailed material inventory for lifecycle analysis, the FIM® framework requires additional information regarding the inherent and hidden material within the visible elements of the building. These include, concrete reinforcement steel, exact concrete composition, types and thickness of insulations, and many more. Some inherent mechanical and material properties can be identified automatically using non-destructive testing methods, such as ultrasonic pulse velocity test [

19], concrete tomography [

20] and ferro-scanning [

21]. Others can be determined through available textual documents, such as building permits and technical specifications, and automatically determined using natural language processing [

22,

23]. Despite such advancements and developments, many old buildings lack up-to-date and accurate information. As such, in this study an informed assumption about the unknown internal characteristics of the building, such as weight of steel and concrete volume ratio was made (see

Table 1; adopted from [

24]).

In terms of material classification, two systems were utilized, namely, the directive 2008/98/EC of the European Parliament, and the ASTM Uniformat II [

25]. The former provided relevant information regarding common material types and their characteristics (e.g., hazardous vs. non-hazardous) [

24], whereas the latter provided a hierarchical classification of different element groups [

26] (recommended in quantity surveying and sustainability evaluation [

27]).

Finally, it is worth noting that many factors influence the embodied energy and Carbon depending on the type of analysis (e.g., 50-50 [

7,

8]), even for the same material type. For example, embodied energy and Carbon of sand imported from abroad greatly differs from that obtained through domestic sources. This study refers to the ICE database [

7,

8], which adopts the EU-wide standard 15804 EPDs (i.e., Environmental Product Declarations), for embodied energy calculations and the possible effect of idealizations have been disregarded.

1.2. Design Optimization for Sustainability

Generative design (GD) [

28,

29,

30,

31] is the process of utilizing artificial intelligence (AI) to generate meaningful heuristic results when either traditional methods fail, or a single solution cannot be obtained (e.g., no single solution exists that satisfies all objectives simultaneously). In such cases, many good solutions (in the case of multi-objective optimization, Pareto front) are generated to solve the optimization problem [

32,

33]. In terms of building design, the integration of visual programming [

34], BIM and GD has shown effective, particularly to enhance lifecycle sustainability. Some examples of successful BIM and GD integration with sustainability considerations, include construction feasibility of underground infrastructures [

35]; drywall installation planning in prefabricated construction [

36]; design of connections to code regulatory standards [

37]; cloud-based solution for energy performance simulation, such as daylight analysis [

38]; lay-out of steel frame components [

39,

40]; spatial planning for residential blocks [

41]; and topology optimization [

42,

43].

Despite considerable efforts by the academic community in the area of GD for building and process optimization, a considerable gap between academic research and industry in structural optimization exists. This discrepancy is attributed to the absence of robust intermediary frameworks that effectively integrate with the BIM software. To address this issue, a workflow for automated structural design optimization using architectural designs generate through BIM-based software was proposed [

44]. This approach uses a BIM software package, including Revit, the Dynamo plugin [

34], and Robot Structural Analysis (RSA), to merge the architectural design and structural design phases. In this study, this framework together with genetic algorithm [

45] will be utilized to optimally design new structures.

2. Materials and Methods

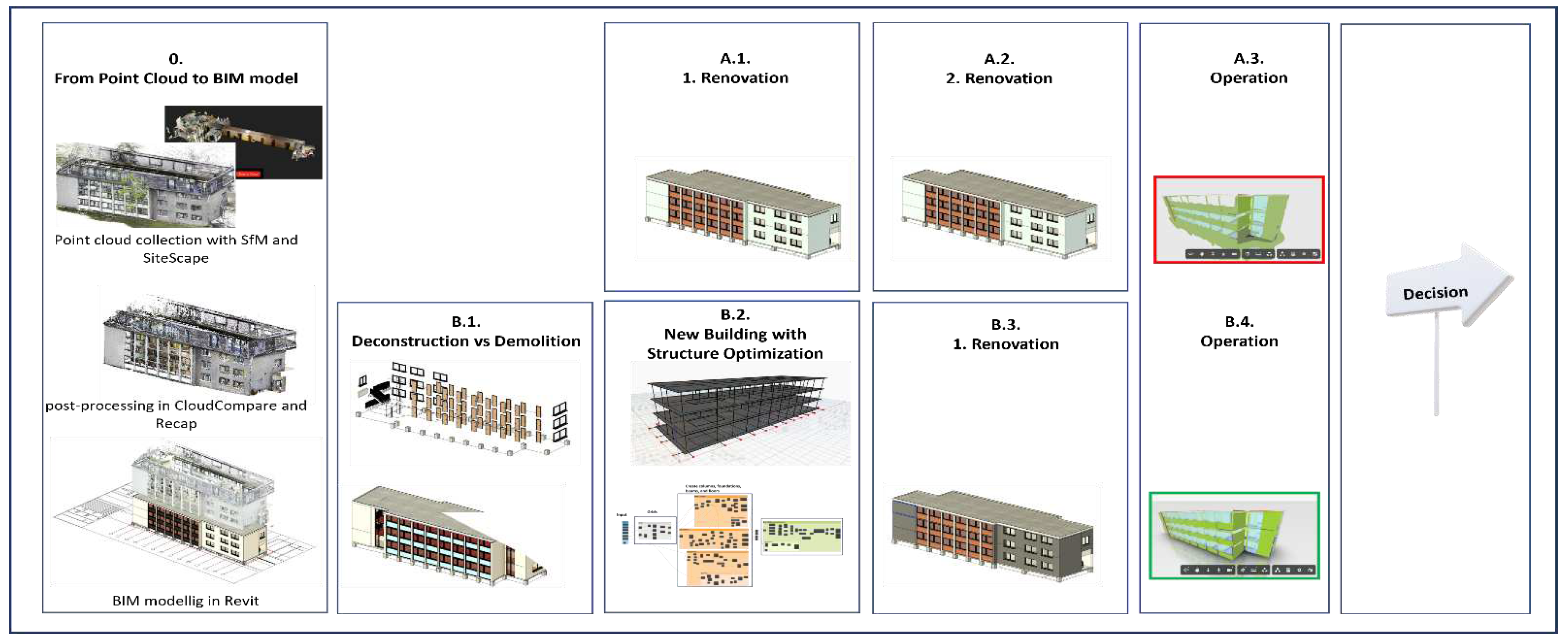

The methodology consists of the following steps (summarized in

Figure 1):

Point cloud collection: collection of point clouds through Structure-from-Motion (SfM) and Laser Scanner using smartphones from an existing building;

BIM generation: creating BIM model of the point cloud;

-

Lifecycle assessment: calculate the embodied energy and carbon for the material and construction processes, along with energy demand during operation.

Decision-support: provide systematic recommendations and strategies for the reduction in the environmental footprint of the project.

2.1. Point Cloud Collection

The process of generating a complete point cloud model for a building involved three steps:

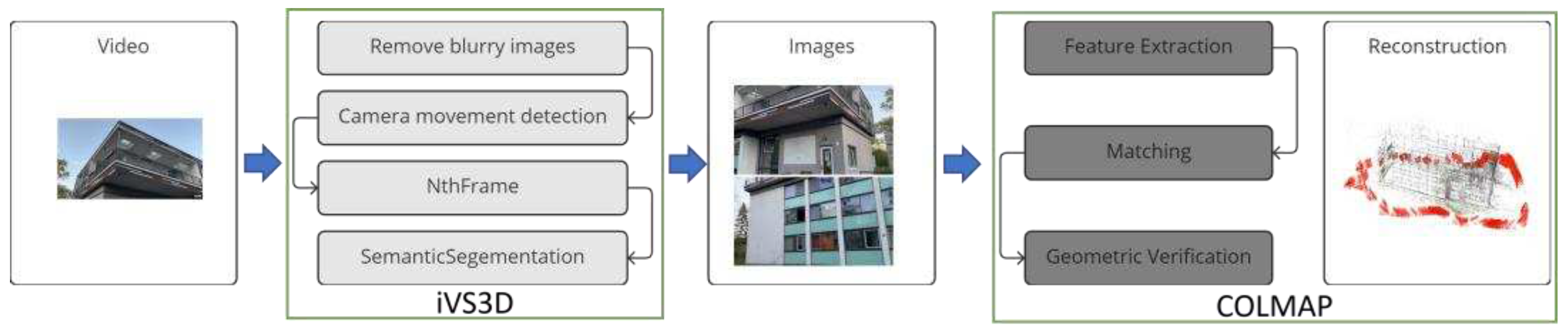

SfM façade monitoring: create a point cloud of the facades using smartphone videos and the Structure-from-Motion process (SfM) [

16] with COLMAP [

46,

47]. Due to the requirement for convergence imagery [

48] and high network overlap [

16], prior to data collection a path was designed using Google Maps. iPhone 13 mini was used for video recording, which can acquire 4k video recording at 30 and 60 frames-per-second (fps). To maintain high image overlap and quality, the iVS3D method was utilized to sample and pre-process videos to increase 3D reconstruction speed and quality by eliminating images with low content [

49]. Summary of the SfM is shown in

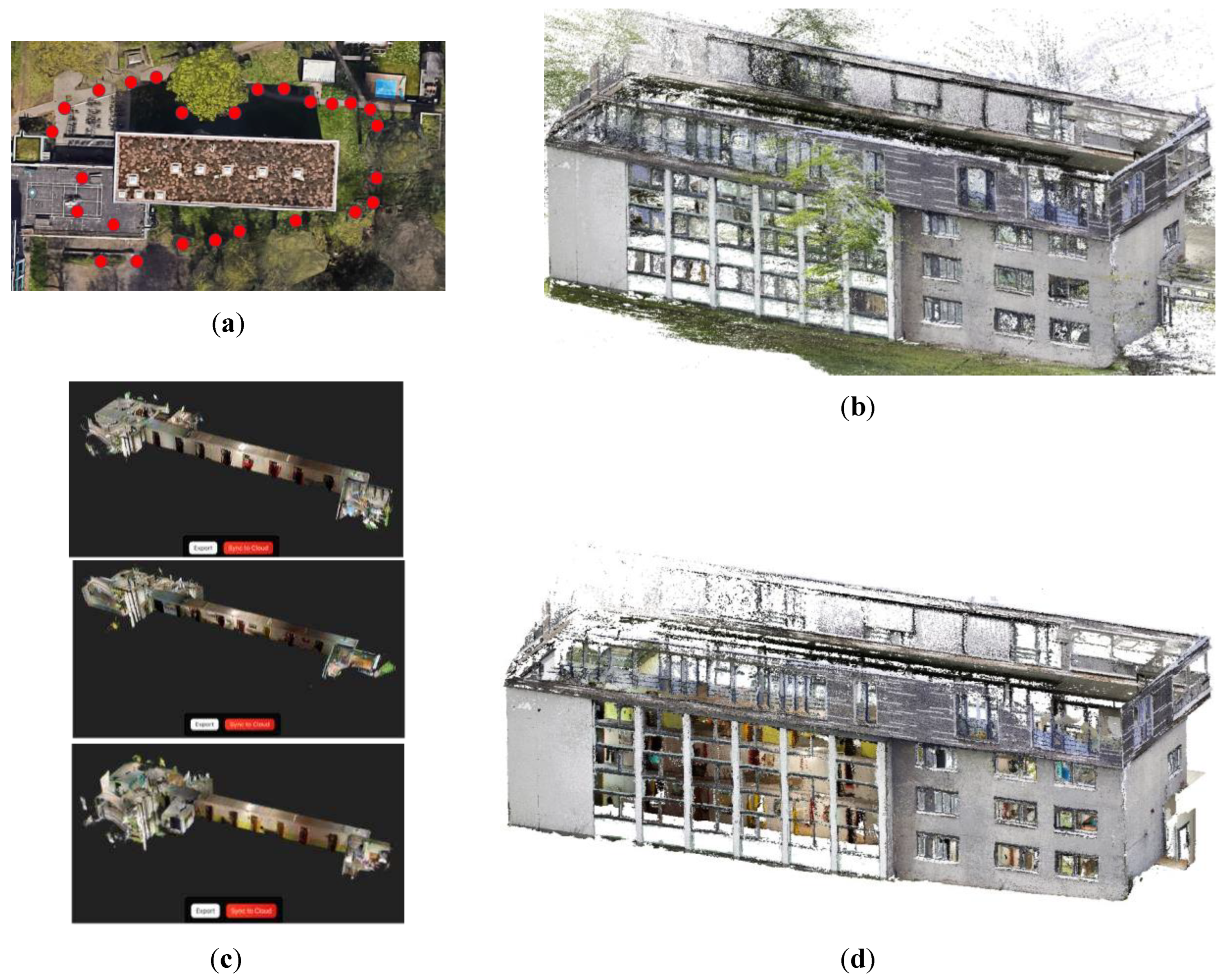

Figure 2.

LiDAR interior scanning: scan of the interior of the building with the light detection and ranging (LiDAR) scanning smartphone app, SiteScape. The LiDAR data was collected using the iPad Pro. Point density and point sizes in the app were set to medium with slow movement during scanning (i.e., left-to-right rotations of more than around 15° were avoided). To ensure consistent data quality, all data was collected while maintaining at least 50% of battery and cooled down to room temperature before starting the next scanning.

Registration: registration of the collected point clouds in the opensource point cloud processing software, CloudCompare [

50]. After scaling of the SfM point cloud, both were taken to CloudCompare where floor detection using the method of [

51] was used to orient both point clouds such that the z-axis was parallel to the plane normal. A translation is used to level the two planes of the floors. Using this, the problem of 3D registration was reduced to 2D alignment of the exterior and interior walls in the x-y plane.

Scan vs. BIM: alignment and point cloud object detection using the scan vs. BIM framework [

14,

52]. Using the blueprints, a BIM model was generates (manually), and aligned to the registered point cloud. Iterative closest point (ICP) registration between the point cloud and model was performed to determine compliance with the generated model and to correct the model if required.

2.2. BIM from Point Cloud

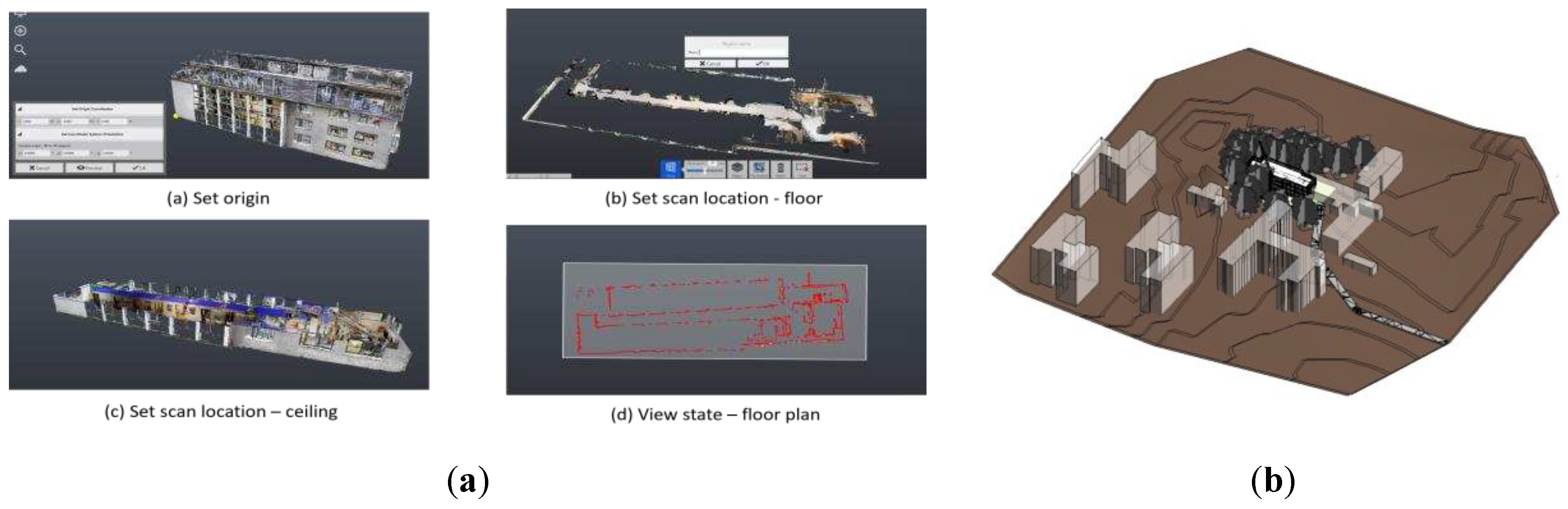

The point cloud must be converted into Recap (.rcp) file in Recap Pro and imported into Revit. To this end, a workflow was organized (shown in

Figure 3a) as follows: (i) set a new origin for the point cloud; (ii) set the scan location for the ceiling; (iii) set the scan location for the floor; and (iv) create a view state for the floor plan. The marked floor and ceiling panels were used in Revit to define levels. Finally, a view state of the floor plan is created using a bounding box with highlighting edges.

Next, a new metric architectural project with defined units was created in Revit. The levels were defined using the point cloud floors, and the main grids were drawn (centre-on-centre) according to the positions of the columns and walls. In level 1, the view range is defined to provide a clear floor plan. Exterior and interior walls are drawn based on this floor plan, slab, and foundations, followed by drawing windows, doors, and curtain walls. All objects are then selected and copied to levels 2 and 3. Stairs and railings are added. Finally, the functions of all rooms are defined, and their areas were calculated. The BIM model consists of 3D parametric objects, allowing for the modification of the dimensions and positions of these objects.

The CADMapper website was then utilized to generate a 3D site plan in Revit for the generate building. This map enabled the generation of realistic scenarios for the calculation of embodied energy and Carbon within the case studies (

Figure 3b).

2.3. Embodied Energy and Carbon Calculation

The object-oriented building information was classified into four hierarchical levels: (i) the top level representing the entire building; (ii) the second level comprising of groups of structural and non-structural components; (iii) the third level denoting individual building elements, such as walls and floors; (iv) and the lowest level encompassing materials and products. The quantity of materials, such as densities, volume, length, and weight, were extracted from the BIM model, and subsequently listed in the material inventory.

The embodied energy and carbon of the study building were calculated based on this inventory through the following idealizations:

The primary building components, excluding finishing materials, furniture, and services (e.g., steel, timber, concrete, and glass) were extracted.

The materials' type, volume information, density, and quantity were extracted.

The ICE database [

7,

8] was then adopted to calculate embodied energy and carbon.

The embodied energy and carbon are calculated by multiplying material weight with ICE coefficients

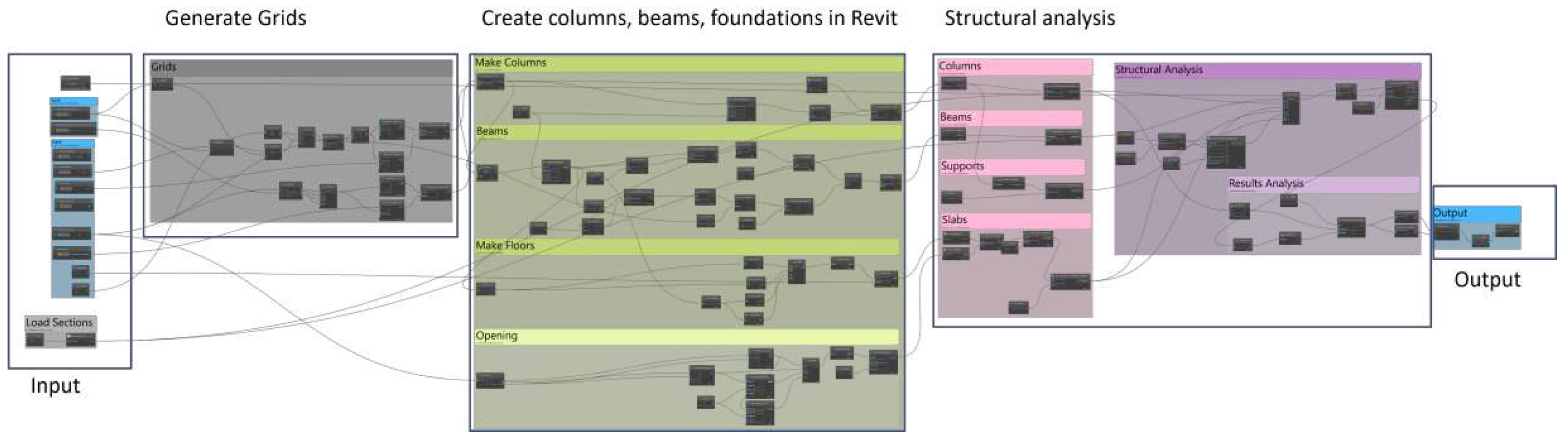

2.4. Design Optimization Framework

Structural optimization was performed to evaluate the true benefits of a new design with similar properties as the existing building (e.g., floor plan area, and number of rooms). Here, the decision variables were the location, and number of columns, and beams, along with the thickness of the slab. The structural loadings were prepared based on the relevant DIN standard and the finite element analysis was carried out using RSA, structural analysis integration with Dynamo visual programming. The Dynamo script was generated and integrated with RSA using the genetic algorithm framework presented in [

53]. The general steps of the newly generated Dynamo script is shown in

Figure 4. The combination receiving the least weight, while satisfying code specific standards on slenderness, displacement, and stress was considered as the optimal structure.

2.5. Deconstruction vs, Demolition

The energy consumption for the deconstruction and demolition are calculated using the following formula:

where

,

,

,

,

are the energy consumption in the deconstruction, transportation, recycling, recovered energy during recycling, and demolition processes, respectively. The workflow for deconstruction and demolition can be summarized as follows:

-

Plan deconstruction/demolition work:

Define deconstruction groups.

Plan the sequence of deconstruction work.

Calculate the duration for each deconstruction task.

Analyze each deconstruction work: choosing the proper tools and machines for each group.

-

Plan recycling workflow and transportation:

Quantify the deconstructed building material.

Reuse building materials.

Recycle building materials.

Dispose of non-recyclable materials.

-

Conduct quantitative evaluation:

Estimate duration and cost for deconstruction and demolition.

Calculate energy costs and carbon emissions caused during demolition or deconstruction work.

Calculate energy cost and carbon emission in transportation.

Calculate recovered energy and saved carbon emissions from recycled and 311 reused building materials and products.

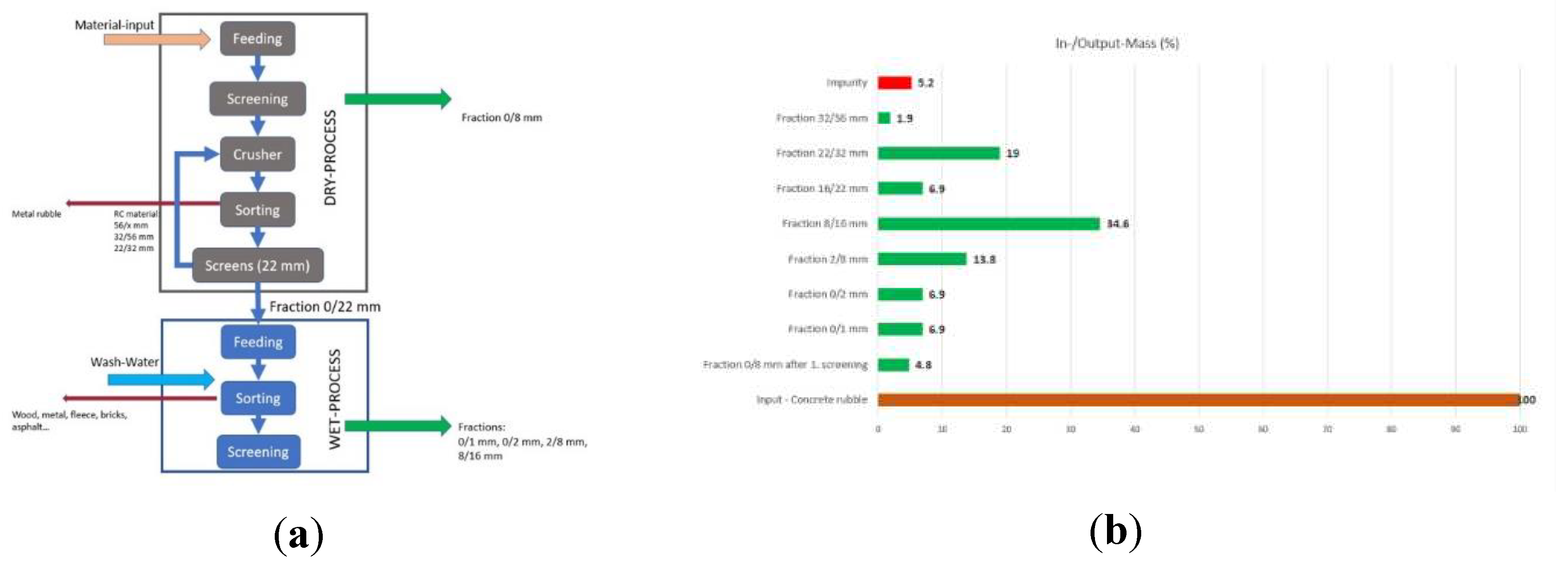

2.5.1. Recycling Workflow

An advanced recycling workflow for concrete rubble was adopted here. The workflow can be divided into two stages (i.e., dry-process and wet-process). In the dry process, the concrete rubble is crushed in a jaw crusher, sorted, and screened in a dry process. The crushed materials are sieved through a 22 mm sieve to obtain a fraction of 0/22 in size. The fractions of > 22 mm are collected and placed in the jaw crusher again. Meanwhile, the metal rubble is separated in this process. Afterward, the fraction of 0/22 will be transported to the next stage - the wet process. In this stage, further sorting and screening processes occur, and the aggregates are divided into fractions of 0/2 mm, 0/1 mm, 2/8 mm, and 8/16 mm [

54]. The process is summarized in

Figure 5a.

Figure 5b shows the mass balance of recycled materials adopted from [

54]. Their study extracted the concrete rubble from a reinforced concrete assembly construction. After removing harmful materials and impurities, 83% of demolition waste is concrete rubble, 9% is mortar, and the rest is impurity (i.e., plastics, glass, wood). The production efficiency from this study is adopted in the analysis of the deconstruction scenario (

Figure 5a). Other than proportions of materials, the energy cost of recycling [

54], shown in

Table 2 is utilized.

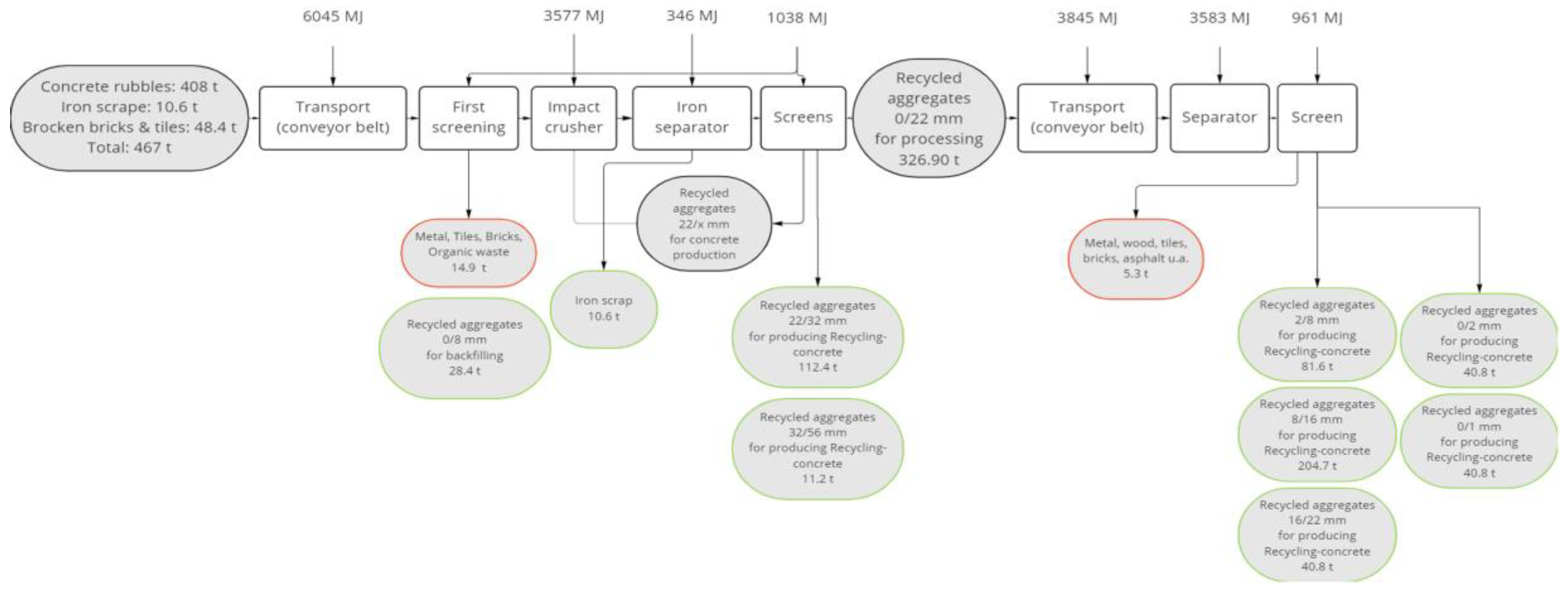

Finally, using the proposed recycling process, a material and energy flow diagram was generated.

Figure 6 shows the material and energy flow diagram for the case study used in this manuscript. The input included 408 tons of concrete rubble, 48.4 tons of mixed broken bricks and tiles, and 10.6 tons of steel in concrete.

2.5.2. Criteria for Evaluation

Finally, a set of relevant criteria is devised to evaluate the advantages and disadvantages of utilizing demolition vs. deconstruction.

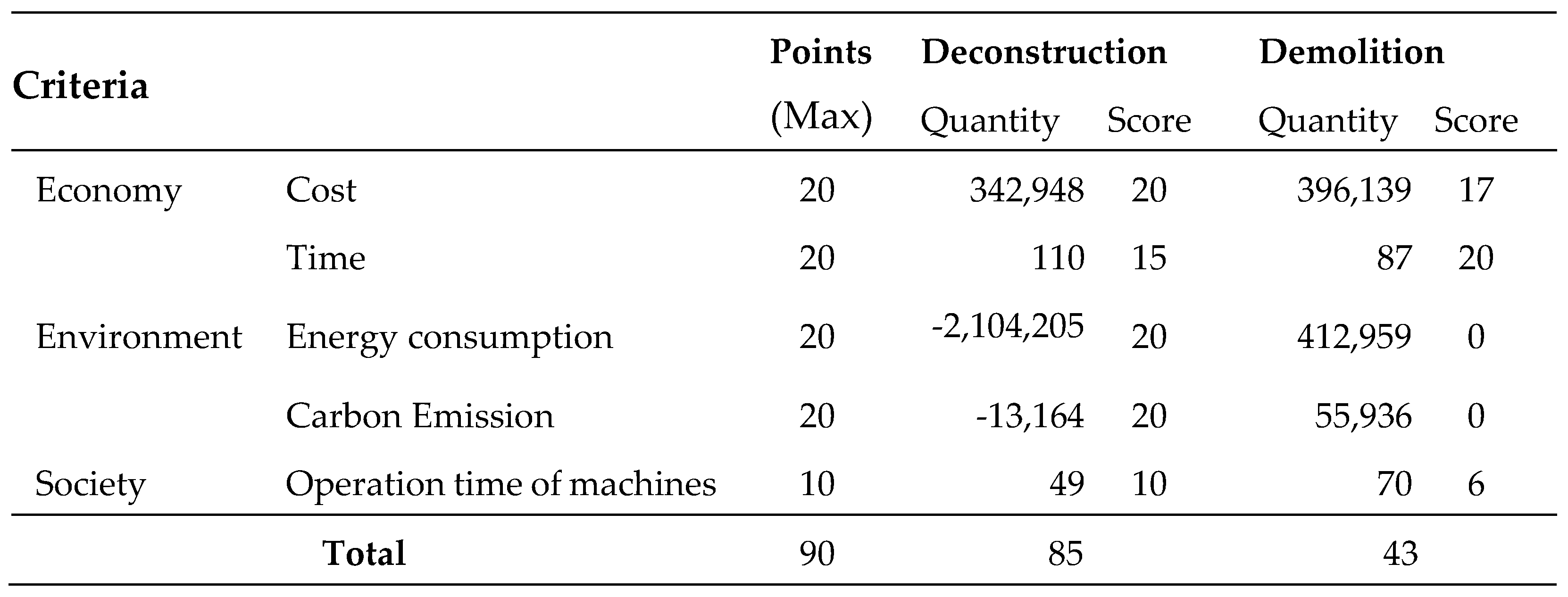

Table 3 shows the criteria and the corresponding points associated with each factor. These factors include economics (e.g., cost), environmental (e.g., embodied Carbon), and social (e.g., noise and disruption to the neighbors).

2.6. Renovation

The computation of embodied energy and Carbon for renovation is similar to that presented in section 2.3. Here, it is important to describe the process in which the cost of renovation was calculated. The present value of future renovation was determined using the construction price escalation index, along with the cost of restoration, obtained from the official German statistics office [

55].

The final energy consumption is calculated by incorporating the ratio of usable area with the electricity price, which employs an electricity price of 0.38 €/kWh for 2022. Additionally, several assumptions were made to approximate the operation cost, energy consumption, and carbon emissions, outlined as follows:

energy consumption amounted to 88 kWhm−2 year−1 (the model also accommodated for improved energy efficiency of around 25% after each renovation to account for required energy consumption reduction in the EU [

56]);

a new building energy consumption is set to 62 kWhm−2 year−1;

electricity price escalation was assumed at 0.38%;

electricity was the only form of energy utilized, with 1 MJ of energy from electricity resulting in 177 g of CO2e emissions according to [

7,

8]; and

the renovation period was considered every 30 years;

3. Results and Discussions

3.1. Case Study

A 3-story residential building was selected as the subject of this investigation. The original plans and other documents related to the renovation conducted in 2011, along with the site plan and floor plans were available and utilized for this study. The main features of the study building are presented in

Table 4.

3.2. Point Cloud Collection and Processing

The walking path shown in

Figure 7a was planned for data collection using the iPhone 13 with 4K video resolution at 60fps. Using the iVS3D [

49] framework, 248 images were generated and selected for SfM using COLMAP (

Figure 7b). Finally, the iPad Pro together with the SiteScape app were utilized for data collection of the interior of the building (

Figure 7c; each floor was scanned separately). The final point cloud of the registered interior and exterior using CloudCompare is shown in

Figure 7d.

3.3. BIM-based Bill of Quantities and Sustainability Evaluation

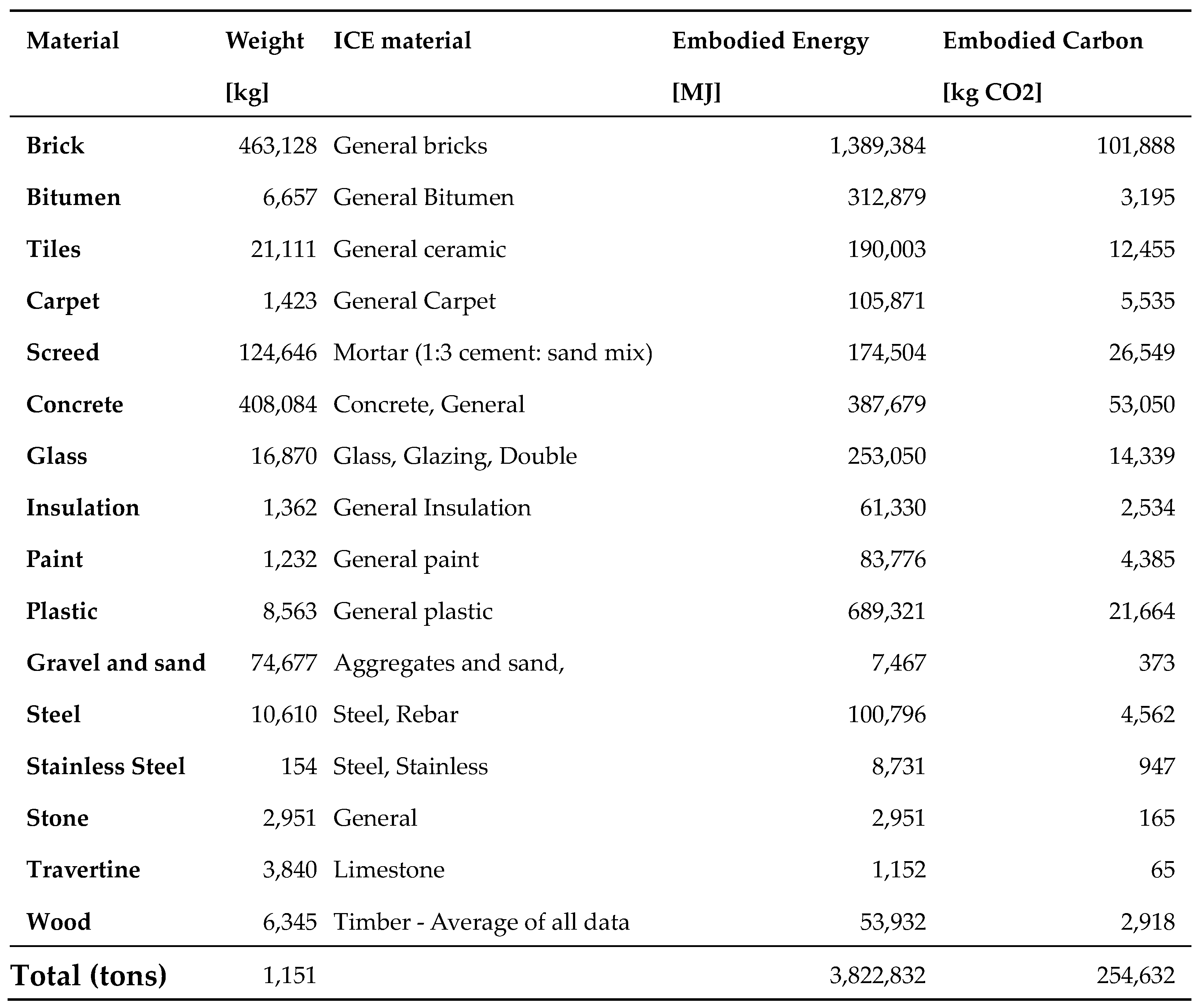

Based on the generated BIM model from the point cloud, the bill of quantities were determined and utilized to determine the environmental impact of the project material, which will then be used to determine the environmental impact in case of demolition and deconstruction. The results of the BIM-based analysis is provided in

Table 5. It was observed that bricks and concrete as main construction materials contributed to around 46% embodied energy and over 60% of Carbon emission. Furthermore, 8.5 tons of plastic contributed to 18% embodied energy and 8% of Carbon emissions. It can be inferred that reducing weight of main structural materials (e.g., concrete and brick) by design (e.g., through effective optimization strategies) together with utilization of sustainable circular materials to replace plastic waste were crucial for decreasing embodied energy and carbon in buildings, particularly when demolished.

3.3. Deconstruction vs. Demolition

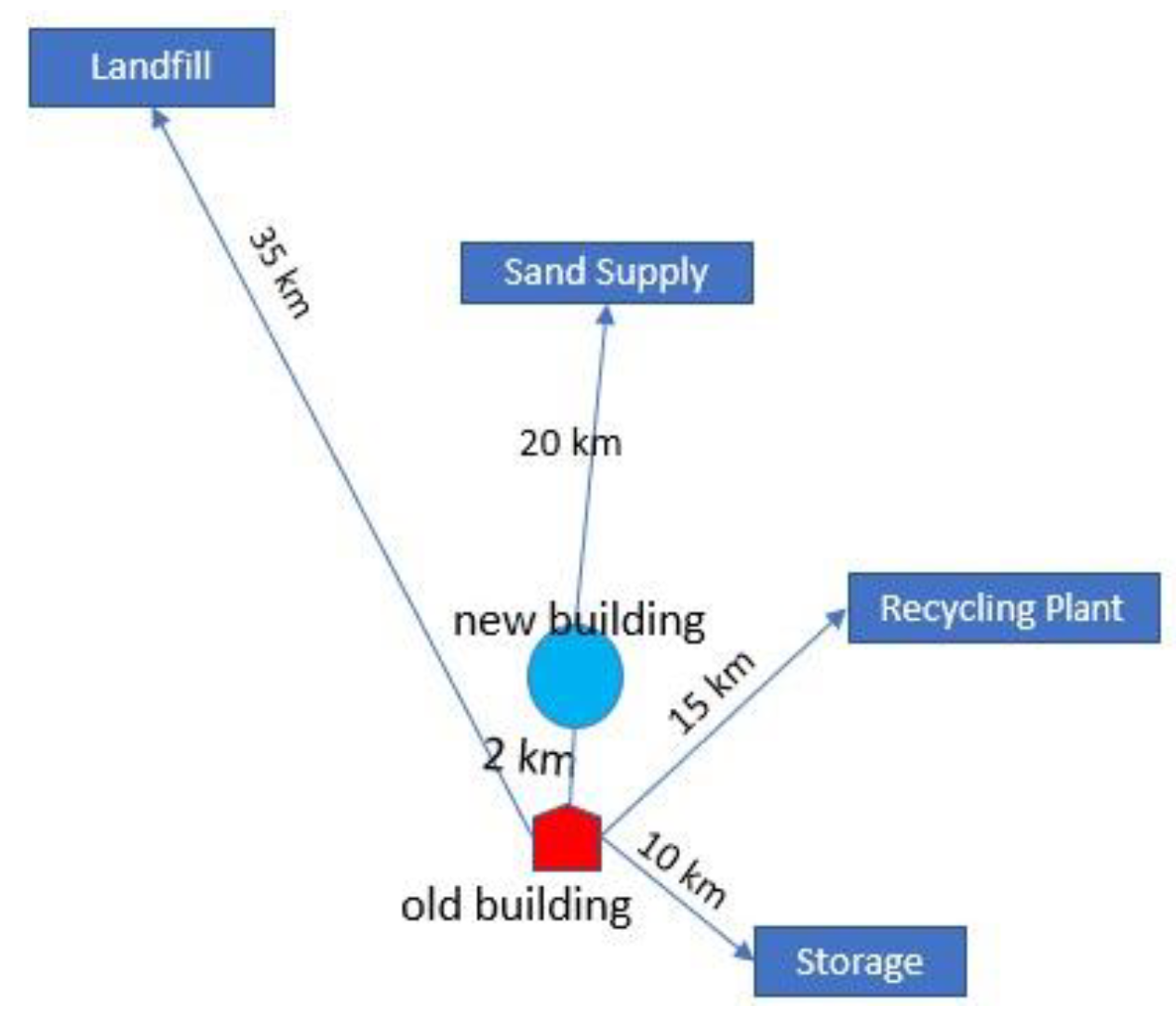

A logistical assumption regarding the distance between the old building, new building development, landfill, recycling plant, storage and sand supply was made (

Figure 8). As shown, the distance between the old and new buildings was assumed to be 2 km. It was assumed that 85% of bricks were preserved and reused, and the rest were mixed with concrete rubble. The reusable bricks were transported to the storage facility with the transport distance 10 km. Concrete, bitumen, and insulation were delivered to the recycling plant, which was considered 15 km from the deconstruction site. Carpet and frames were disposed of in a landfill place. The distance to the landfill was assumed to be 35 km. In the demolition scenario, after removing bitumen, insulation, carpet, windows, and doors, the whole building was demolished, and all construction wastes were disposed of.

Based on the provided assumptions and with due consideration of equation (1), the results of the choice between deconstruction and demolition (as proposed in section 2.5.2), are presented in

Table 6. It was observed that the deconstruction, due to possible repurposing of more material achieved a better overall score of 85 compared to the score of 43 received using demolition. The deconstruction together with optimized structural design for new building will be adopted for comparison with the renovation.

3.3. Comparison of Results with Renovation

The selected strategy of deconstruction together with optimized design of new building was compared to the renovation of the existing facility. In the case of the present study, cost, total energy consumption and Carbon footprint are used for comparison. The results are shown in

Table 7. It was observed that the deconstruction and new development exceeded the cost and embodied energy consumption for two renovations by around 10.5%, and 7.8%, while improving embodied Carbon by roughly 9.6%. At this stage, the project team must decide on the relative importance between different criteria to make a final decision. For instance, if cost and embodied energy are deemed more important by the project team, renovation will be considered the better solution. The results of this case study reveal the need for such lifecycle analysis in decisions pertaining to deep renovations or deconstruction.

5. Conclusions

This study investigated the environmental impact of two distinct scenarios in building rehabilitation work, namely, renovation of an existing building; and deconstruction or demolition, followed by construction of a newly optimized building. The analysis is conducted through developing a digital model of the existing building and converting it to a semantic BIM, which can then be utilized as a valuable tool to assess the environmental aspects of a building. Although BIM offers significant advantages in data management and visualization, it is important to note that substantial manual efforts remain necessary for accurate calculations and the overall assessment process.

This research investigates various aspects of the building development process, including integrating BIM with reliable databases for material quantity-takeoff, applying generative design techniques, incorporating parametric design methodologies, and assessing the long-term energy performance of buildings. These components are crucial for a comprehensive understanding of the environmental impact of aging buildings in need of rehabilitation. To this end, the study proposed a formal framework to assess the environmental impact of the two possible separate scenarios of renovation and deconstruction/demolition. The framework encompasses several stages, including FIM® inspired digital documentation, BIM model recreation, deconstruction and demolition planning, material recycling, building material weight optimization, cost estimation, and energy performance analysis. A real-world case study was used to evaluate the framework's effectiveness and applicability.

In the present study, it was observed that deconstruction was more environmentally friendly and economical than demolition. However, despite generative design optimization efforts to minimize weight of a new building, the cost and embodied energy was found to be 10.5% and 7.8% worse than renovation, respectively. The deconstruction with new development, on the other hand, gained 9.6% in embodied Carbon compared to renovation. Considering all three criteria with equal weight, the renovation scenario was found more favorable, as it offered a more cost-effective solution with a lower embodied energy. These results suggest that a formal lifecycle analysis that incorporates all aspects of sustainability, digitization, optimization and rehabilitation can provide valuable decision-support information.

Author Contributions

Conceptualization, R.M.; methodology, R.M. and B.W.; software, B.W.; validation, B.W.; formal analysis, B.W.; investigation, B.W. and R.M.; resources, R.M.; data curation, B.W.; writing—original draft preparation, B.W.; writing—review and editing, R.M.; visualization, B.W.; supervision, R.M.; project administration, R.M.; funding acquisition, R.M. All authors have read and agreed to the published version of the manuscript.

Funding

The study was funded through the personal research fund of Jun.-Prof. Dr. Reza Maalek, at the Department of Digital Engineering and Construction, partially endowed by GOLDBECK GmbH. The authors wish to acknowledge the support provided by the KIT Publication Fund of the Karlsruhe Institute of Technology in supplying the APC.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Maalek, R.; Maalek, S. Automatic Recognition and Digital Documentation of Cultural Heritage Hemispherical Domes using Images. J. Comput. Cult. Herit. 2023, 16, 1–21. [Google Scholar] [CrossRef]

- Akbari, R.; Maalek, S.; Ashayeri, H. Modal analysis and step-by-step repair operation of a two span concrete skew bridge to replacement of its elastomeric bearings. In Proceedings of the Bridge Maintenance, Safety, Management, Health Monitoring and Informatics - Proceedings of the 4th International Conference on Bridge Maintenance, Safety and Management; p. 2008.

- Maalek, S.; Akbari, R. Distribution of demand in single-column-bent viaducts with irregular configuration in longitudinal direction. In Bridge Maintenance, Safety Management, Health Monitoring and Informatics - IABMAS ’08; 2008.

- Eurostat Generation of waste by waste category, hazardousness and NACE Rev. 2 activity. 2023.

- Agamuthu, P. Challenges in sustainable management of construction and demolition waste. Waste Manag. Res. 2008, 26. [Google Scholar] [CrossRef] [PubMed]

- Marzouk, M.; Azab, S. Environmental and economic impact assessment of construction and demolition waste disposal using system dynamics. Resour. Conserv. Recycl. 2014, 82. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C. Embodied Carbon: The Inventory of Carbon and Energy (ICE). A BSRIA Guid. 2011. [Google Scholar]

- Jones, C.; Hammond, G. Inventory of Carbon and Energy (ICE database). 2019 2019.

- Jung, Y.; Joo, M. Building information modelling (BIM) framework for practical implementation. Autom. Constr. 2011. [Google Scholar] [CrossRef]

- Eastman, C. , Teicholz, P. Sacks, R. and G.L. BIM Handbook - A Guide to Building Information Modelling for Owners, Designers, Engineers, Contractors, and Facility Managers, 2018. [Google Scholar]

- AGC The Contractors’ Guide to BIM. Assoc. Gen. Contract. Am. 2013.

- AUTODESK Revit IFC Manual: Detailed instructions for handling IFC files.

- Cheng, J.C.P.; Ma, L.Y.H. A BIM-based system for demolition and renovation waste estimation and planning. Waste Manag. 2013, 33. [Google Scholar] [CrossRef]

- Maalek, R. Field Information Modeling (FIM)TM: Best Practices Using Point Clouds. Remote Sens. 2021, 13, 967. [Google Scholar] [CrossRef]

- Maalek, R.; Lichti, D.D.; Walker, R.; Bhavnani, A.; Ruwanpura, J.Y. Extraction of pipes and flanges from point clouds for automated verification of pre-fabricated modules in oil and gas refinery projects. Autom. Constr. 2019, 103. [Google Scholar] [CrossRef]

- Maalek, R.; Lichti, D.D.; Maalek, S. Towards automatic digital documentation and progress reporting of mechanical construction pipes using smartphones. Autom. Constr. 2021, 127, 103735. [Google Scholar] [CrossRef]

- Maalek, R.; Lichti, D.D. Robust detection of non-overlapping ellipses from points with applications to circular target extraction in images and cylinder detection in point clouds. ISPRS J. Photogramm. Remote Sens. 2021, 176, 83–108. [Google Scholar] [CrossRef]

- Maalek, R.; Lichti, D.D.; Ruwanpura, J.Y. Automatic recognition of common structural elements from point clouds for automated progress monitoring and dimensional quality control in reinforced concrete construction. Remote Sens. 2019, 11. [Google Scholar] [CrossRef]

- Hong, S.; Yoon, S.; Kim, J.; Lee, C.; Kim, S.; Lee, Y. Evaluation of condition of concrete structures using ultrasonic pulse velocity method. Appl. Sci. 2020, 10. [Google Scholar] [CrossRef]

- Słoński, M.; Schabowicz, K.; Krawczyk, E. Detection of flaws in concrete using ultrasonic tomography and convolutional neural networks. Materials (Basel). 2020, 13. [Google Scholar] [CrossRef]

- Korl, S.; Wuersch, C.; Zanona, J. Innovative sensor technologies for nondestructive imaging of concrete structures: Novel tools utilising radar and induction technologies. RILEM Bookseries 2012, 6. [Google Scholar] [CrossRef]

- Amer, F.; Golparvar-Fard, M. Modeling dynamic construction work template from existing scheduling records via sequential machine learning. Adv. Eng. Informatics 2021, 47, 101198. [Google Scholar] [CrossRef]

- Khurana, D.; Koli, A.; Khatter, K.; Singh, S. Natural language processing: state of the art, current trends and challenges. Multimed. Tools Appl. 2023, 82. [Google Scholar] [CrossRef]

-

Bauablaufplanung und Logistik im Baubetrieb, 2007.

- ASTM ASTM E1557-09(2020)e1: Standard Classification for Building Elements and Related Sitework-UNIFORMAT II; 2020. S.

- Huxley, A.L. The philosophy and logic within UNIFORMAT II classifications. In Proceedings of the ASTM Special Technical Publication; 2014; Vol. STP 1586. [Google Scholar]

- Lippiatt, B.C. Evaluating sustainability using standard approaches: The BEES tool. In Proceedings of the ASTM Special Technical Publication; 2009; Vol. 1503 STP. [Google Scholar]

- Ramu, P.; Thananjayan, P.; Acar, E.; Bayrak, G.; Park, J.W.; Lee, I. A survey of machine learning techniques in structural and multidisciplinary optimization; Springer Berlin Heidelberg, 2022; Vol. 65; ISBN 0123456789.

- Watson, M.; Leary, M.; Brandt, M. Generative design of truss systems by the integration of topology and shape optimisation. Int. J. Adv. Manuf. Technol. 2022, 118, 1165–1182. [Google Scholar] [CrossRef]

- Du, W.F.; Wang, Y.Q.; Wang, H.; Zhao, Y.N. Intelligent generation method for innovative structures of the main truss in a steel bridge. Soft Comput. 2023, 0123456789. [Google Scholar] [CrossRef]

- Peng, J.; Feng, Y.; Zhang, Q.; Liu, X. Multi-objective integrated optimization study of prefabricated building projects introducing sustainable levels. Sci. Rep. 2023, 13, 2821. [Google Scholar] [CrossRef]

- Mccormack, J.; Dorin, A.; Innocent, T. Generative design : a paradigm for design research. In Proceedings of the Proceedings of Futureground; p. 2004.

- Oxman, R. Thinking difference: Theories and models of parametric design thinking. Des. Stud. 2017, 52. [Google Scholar] [CrossRef]

- Ravshanovich, K.S. REVIT+DYNAMO. Pindus J. Cult. Lit. ELT 2022, 2. [Google Scholar]

- Huang, M.Q.; Chen, X.L.; Ninić, J.; Bai, Y.; Zhang, Q.B. A framework for integrating embodied carbon assessment and construction feasibility in prefabricated stations. Tunn. Undergr. Sp. Technol. 2023, 132. [Google Scholar] [CrossRef]

- Cuellar Lobo, J.D.; Lei, Z.; Liu, H.; Li, H.X.; Han, S. Building Information Modelling- (BIM-) Based Generative Design for Drywall Installation Planning in Prefabricated Construction. Adv. Civ. Eng. 2021, 2021. [Google Scholar] [CrossRef]

- Henríquez, D.; Herrera, R.F.; Vielma, J.C. Method for Designing Prequalified Connections Using Generative Design. Buildings 2022, 12. [Google Scholar] [CrossRef]

- Asl, M.R.; Bergin, M.; Menter, A.; Yan, W. BIM-based Parametric Building Energy Performance Multi-Objective Optimization. In Proceedings of the Proceedings of the International Conference on Education and Research in Computer Aided Architectural Design in Europe; p. 20142.

- Fu, B.; Gao, Y.; Wang, W. Dual generative adversarial networks for automated component layout design of steel frame-brace structures. Autom. Constr. 2023, 146. [Google Scholar] [CrossRef]

- Elsayed, A.M.; Elanwar, H.H.; Marzouk, M.; Safar, S.S. Sustainable layout design of steel buildings through embodied energy and costs optimization. Clean. Eng. Technol. 2021, 5. [Google Scholar] [CrossRef]

- Mukkavaara, J.; Sandberg, M. Architectural design exploration using generative design: Framework development and case study of a residential block. Buildings 2020, 10. [Google Scholar] [CrossRef]

- Rong, Y.; Zhao, Z.L.; Feng, X.Q.; Xie, Y.M. Structural topology optimization with an adaptive design domain. Comput. Methods Appl. Mech. Eng. 2022, 389. [Google Scholar] [CrossRef]

- Ching, E.; Carstensen, J. V. Truss topology optimization of timber–steel structures for reduced embodied carbon design. Eng. Struct. 2022, 252. [Google Scholar] [CrossRef]

- Hamidavi, T.; Abrishami, S.; Hosseini, M.R. Towards intelligent structural design of buildings: A BIM-based solution. J. Build. Eng. 2020, 32. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6. [Google Scholar] [CrossRef]

- Schönberger, J.L. Robust Methods for Accurate and Efficient 3D Modeling from Unstructured Imagery, ETH Zurich, 2018.

- Schonberger, J.L.; Frahm, J.M. Structure-from-Motion Revisited. In Proceedings of the Proceedings of the IEEE Computer Society Conference on Computer Vision and Pattern Recognition; p. 20162016.

- Maalek, R.; Lichti, D.D. Automated calibration of smartphone cameras for 3D reconstruction of mechanical pipes. Photogramm. Rec. 2021, 36. [Google Scholar] [CrossRef]

- Hermann, M.; Pollok, T.; Brommer, D.; Zahn, D. IVS3D: An Open Source Framework for Intelligent Video Sampling and Preprocessing to Facilitate 3D Reconstruction. In Proceedings of the Lecture Notes in Computer Science (including subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); 2021; Vol. 13017 LNCS. [Google Scholar]

- Girardeau-Montaut, D. CloudCompare - User manual. Webpage: http://www.cloudcompare.org 2015.

- Maalek, R.; Lichti, D.D.; Ruwanpura, J.Y. Robust segmentation of planar and linear features of terrestrial laser scanner point clouds acquired from construction sites. Sensors (Switzerland) 2018, 18. [Google Scholar] [CrossRef] [PubMed]

- Bosché, F. Automated recognition of 3D CAD model objects in laser scans and calculation of as-built dimensions for dimensional compliance control in construction. Adv. Eng. Informatics 2010, 24, 107–118. [Google Scholar] [CrossRef]

- Vermeulen, D. Structural Dynam(o)ite: Optimized Design and Fabrication Workflows with Dynamo 2018.

- Heyn, S.; Mettke, A. Ökologische Prozessbetrachtungen - RC-Beton (Stofffluss, Energieaufwand, Emissionen); 2010.

- DeStatis- Price Indices and Restoration Costs.

- COM/2020/662 final A Renovation Wave for Europe - greening our buildings, creating jobs, improving lives; Brussels. 2020.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).