1. Introduction

Highways are important components of a nation’s infrastructure, which play an indispensable role in stimulating economic growth, enhancing connectivity, encouraging regional development, and improving the quality of life [

1,

2,

3,

4]. The construction of pavements involves a series of layered components such as a subbase, base, and surface course, each with a specific role. The subbase, which sits directly atop the prepared natural ground level or subgrade, is usually composed of locally sourced materials or stabilized soil. It is designed to evenly distribute the load from the base to the subgrade, effectively safeguarding the impact of aggressive moisture. The base layer above the subbase often consists of crushed aggregate designed to further distribute the load, thereby providing a stable surface for the subsequent pavement layer and protecting the underlying subbase from detrimental environmental effects. The surface course is constructed using high-quality materials like asphalt or concrete, ensuring its ability to resist traffic loads and provide a durable and skid-resistant surface, making it critical for safety and efficiency in transportation. Based on the type of surface course, the pavement can be classified into the flexible pavement (asphalt surface layer) and rigid pavement (concrete surface layer). Because of the rigidity behavior, the load in rigid pavements is distributed over a wide area of the subgrade. This reduces the stress on the subgrade and makes the pavement more tolerant to weaker or less uniformly compacted subgrades when compared with the flexible pavement. In addition, rigid pavements are resistant to rutting and weathering and require less maintenance over time [

5,

6,

7].

Rigid pavements are primarily made from a mixture of Portland cement, coarse and fine aggregates, and water. In addition, the admixture is added to the mix to modify concrete properties. Portland cement is the binding agent in the concrete mix. When mixed with water, it reacts chemically to form a hard, strong, and durable matrix, which binds the aggregate particle together. In concrete paving materials, a significant source of greenhouse gas emissions is the cement manufacturing process [

8,

9]. The production of Portland cement is an energy-intensive process that typically relies on the burning of fossil fuels. In a cement kiln, limestone (calcium carbonate) and clays are heated to very high temperatures (about 1400-1450

oC) to produce clinker, the main component in Portland cement. Throughout the manufacturing calcination process can generate approximately 7% of CO

2 [

10]. This has led to increasing interest in developing alternative, more sustainable cementitious materials and production methods that can reduce the industry’s carbon footprint. Because of the low-temperature production methods, hydraulic cement is reported to produce less carbon footprint than conventional Portland cement [

11].

Coarse and fine aggregates are crucial components in the concrete mix. The coarse aggregate provides bulk, strength, and wear resistance to the pavement, while fine aggregate (typically sand) fills the spaces between the coarse aggregate and makes more cohesive, and prevents the concrete from shrinking and cracking. In recent years, environmental and sustainable considerations have led to the inclusion of recycled materials and additives in the concrete layer to improve performance and reduce the environmental impact. The environmental issues associated with the disposal of used tires and PET plastic are on the other had substantial, which cause negative impacts on the environment and may result from improper management of these materials. Millions of tons of waste plastic are produced each year [

12]. Due to their slow decomposition and incorrect disposal, PET plastic bottles add to the rising problem of plastic waste by taking up landfill space and increasing the risk of microplastic pollution [

13,

14]. Similarly, millions of tons of waste tires are produced globally every year and poses long-term environmental risks since it takes up valuable landfill space and does not biodegrade [

15,

16,

17]. Poorly managed waste tires can pose safety issues, attract bugs, and discharge harmful materials into the ground and water [

18,

19,

20].

In recent years, there have been significant developments in the field of sustainable construction materials, such as innovation involving the incorporation of PET plastics and waste tires in concrete pavement [

21,

22]. Waste tries can be made into crumb rubber particles and used in the concrete mix as a sand replacement [

23]. Utilizing crumb rubber reduces the need for sand mining, protecting natural resources and lessening its negative effects on the environment. PET plastic bottles can also be broken down into small particles and used as a coarse aggregate replacement in the concrete mix [

24]. However, the utilization of PET and waste tires in concrete mix resulted in the reduction of flexural strength (modulus of rupture) of concrete, which is an important property for concrete pavement. Therefore, additional additives might enhance the properties of concrete in rigid pavement applications. In terms of sustainable road construction, Yaowarat et al. proposed an innovative idea of value-added natural rubber latex (NRL) as a natural additive and studied the influence of various rubber-to-cement (r/c) ratios on the strength development of normal concrete [

25]. It was indicated that the optimum r/c ratio could improve the flexural strength of the concrete, resulting in the long service life of the rigid pavement.

To the authors’ best knowledge, the study on using NRL to improve the mechanical properties of concrete with PET and crumb rubber as aggregates replacement is still limited; hence it is the aim of this research work. The compressive and flexural strength tests were conducted to investigate the mechanical strength development of concretes with various PET and crumb rubber replacement ratios and optimum r/c ratio. The role of these two influence factors on the toughness and resilient modulus, which can store elastic energy or energy absorption without permanent deformation and prevent fracture propagation of concrete pavement, was also evaluated. Scanning electron microscopy (SEM) were used to examine the microstructure and evaluate the strength development of the studied mixtures. It used to investigate the particles interaction within the concrete matrix in order to gain knowledge about the composite's overall efficacy and pinpoint areas for development.

The outcome of this research will advance understanding of the mechanical characteristics of concretes containing PET plastic and crumb rubber. It will offer useful knowledge for the development of sustainable construction methods and the use of waste materials in the production of concrete. The study's ultimate goals are to encourage recycling, lessen trash production, and propose a more circular and environmentally friendly method of designing and building rigid pavements.

2. Materials and Methods

2.1. Materials

Table 1 summarizes the chemical composition of hydraulic cement, following

ASTM C114 [26]. The cement has a specific gravity of 3.15. The properties of natural rubber latex are shown in

Table 2. It was obtained from the Rubber Authority of Thailand and contained 52% dry rubber and 48% water and water-soluble components. The pH was tested to ensure the acidity content in the rubber controlled the property for the other tests, which equaled 10.4.

Table 3 summarizes the properties of crushed rock and natural river sand, which were used as coarse and fine aggregates, respectively. The preparation of the concrete specimens was followed by ASTM C127 and ASTM C128 [

27,

28]. The fine aggregate had a specific gravity (in a saturated surface dry state) of 2.66, a fineness modulus of 2.70, a percent of voids of 38.24, and water absorption of 0.74%. The coarse aggregate had a nominal maximum size of 19 mm, a specific gravity of 2.70, a water absorption of 1.85%, a Los Angeles abrasion loss of 22.2%, a flakiness index of 27.69%, and an elongation index of 22.35%. The waste tires were crushed by a tire granulator crusher machine, resulting in a granular size between 2 and 3 mm to replace the sand with a specific gravity of 1.02. While PET bottles were collected, pre-washed, and shredded by a plastic shredder machine into granules with an average size of 10 mm to replace the crushed stone; the specific gravity was 1.20 [

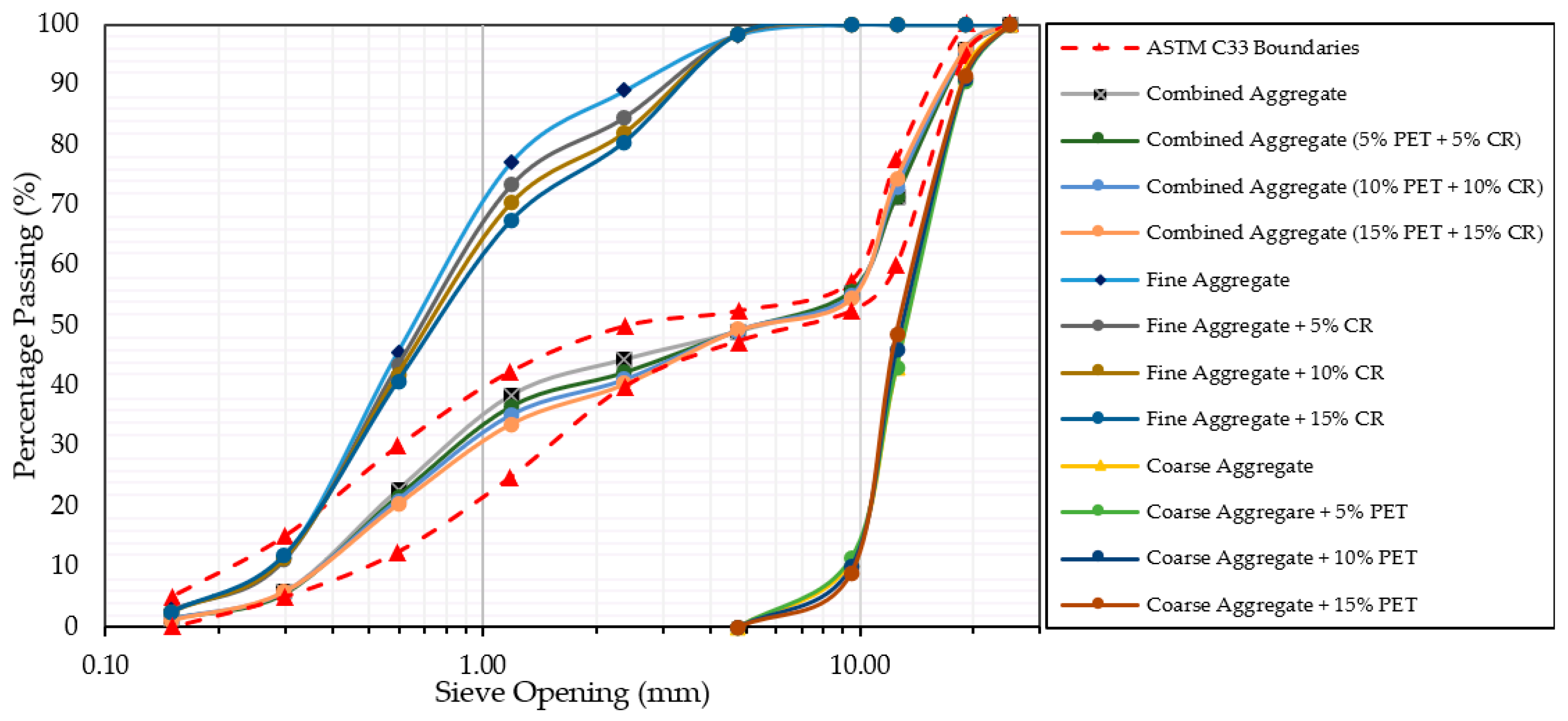

29]. Thus, there was a mixture between the crumb rubber and PET in concrete proportions to reduce the fine and coarse aggregates. The particle sizes were sieved and controlled by

ASTM C33 and ASTM C136 [

30,

31], which limited the lower and upper boundaries in

Figure 1. The figure showed the mixture between sand and crushed stone and the combination between PET and crumb rubber in various percentage mixtures.

2.2. Concrete Mix Design

The water-to-cement (w/c) ratio was fixed at 0.5 for all studied samples, whereas the rubber-to-cement (r/c) ratio was fixed at 0.58 for NRL-modified concrete and NRL-modified concrete with PET and crumb rubber replacements. These ratios were selected to study based on previous research and practical work, which were reported to be the optimum ratios for producing concrete pavement, which meets the minimum required compressive and flexural strengths specified by the Department of Highways, Thailand [

32]. The amount of NRL can be determined following

equations 1, 2, and 3, which relate to a water content of 48% in total natural rubber latex, according to Yaowarat et al. [

25].

where

r/c = rubber to cement ratio (%),

C = cement (kg),

WNRL (kg), and

Wt (kg).

In this study, the slump of the studied concrete mixtures was in control at 75 mm ± 25 mm for the concrete pavement application. The combination of PET and crumb rubber was designed to replace coarse and fine aggregates, respectively, in percentages of 5%, 10%, and 15%. Therefore, a total of 4 mixes, as shown in

Table 4, were studied in this research (i.e., normal concrete, NRL-modified concrete, NRL10WP = a combination of 5% crumb rubber and 5% PET, NRL20WP = a combination of 10% crumb rubber and 10% PET, and NRL30WP = a combination of 15% crumb rubber and 15% PET).

2.3. Experimental Testing Program

2.3.1. Compressive and flexural strengths

The fresh concrete was prepared using a rotary drum mixer following ASTM C192 [

33] and placed in the cylindrical (150 mm × 300 mm) and prismatic (150 mm × 150 mm × 600 mm) molds for the compressive and flexural strength tests as per ASTM C39 [

34] and AASHTO T97 [

35], respectively. The concrete was poured in three separate stages, and each layer was compacted using a standard tamping rod with 25 strikes. After being cured at room temperature for a day, the samples were then removed from their molds and placed in water at a temperature of 27°C ± 2°C. They were kept submerged for periods of 7, 14, and 28 days prior to the compressive and flexural tests. The procedure for the compressive strength test was implemented according to the ASTM C39 standard, while the flexural strength test adhered to the AASHTO T97, employing the third-point loading technique. The flexural strength (

ff) was computed using the following expression:

where

P is the maximum applied load;

L is a support length;

b is the average width of beam specimen, and

d is the average depth of the sample.

The tested data were analyzed in the mean value of test specimens within the same testing condition in compression and flexural strengths to secure the data consistency followed by low mean standard deviation, SD (SD/ < 10 %, where is the mean strength value).

2.3.3. Scanning Electron Microscopy (SEM)

The influence of various replacement materials such as NRL, PET, and crumb rubber on compressive strength and flexural strength development was investigated using SEM analysis. Fragments from the specimen tested for both compressive and flexural strength after 28 days were collected for SEM analysis. In order to prevent the hydration of the concrete specimens, the freezing and drying process was conducted and then coated with gold prior to SEM analysis. SEM morphological detection at 1,000 and 5,000 times magnification was performed.

3. Results

3.1. Compressive Strength

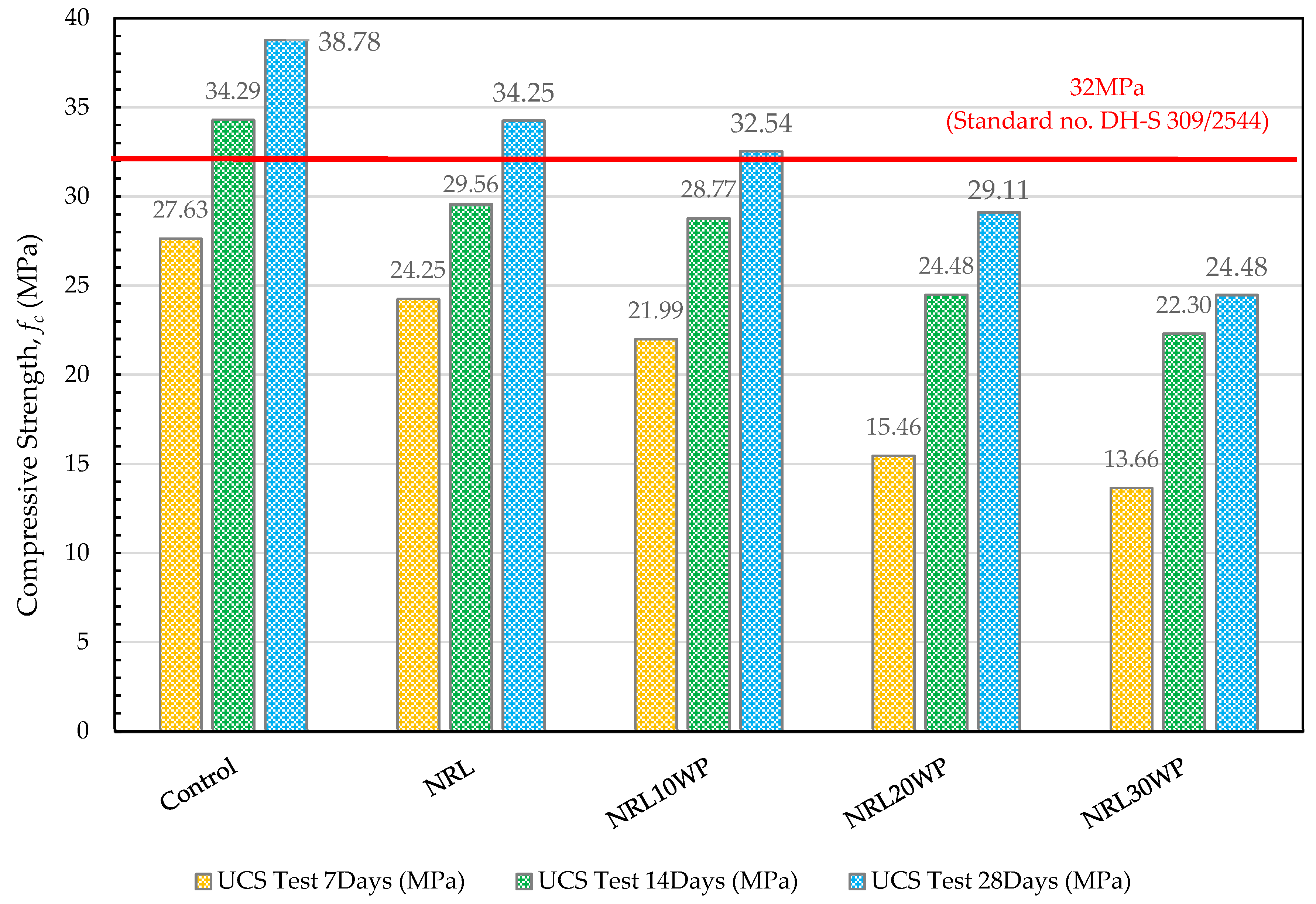

The compressive strengths of the studied samples cured at 7, 14, and 28 days are shown in

Figure 2. The solid red line demonstrates the minimum 28-day compressive strength requirement (

fc 32 MPa) for concrete pavement specified by the Department of Highways (DOH), Thailand [

29]. For normal concrete (controlled sample), its compressive strength increased with curing time (compressive strength of 27.6, 34.3, and 38.8 MPa at 7, 14, and 28 days, respectively). As expected, when NRL additive was added to the concrete, the NRL-modified concrete had lower compressive strength than the normal concrete, which was similar to the previous research [

25,

32]. The NRL-modified concrete had a compressive strength of 24.6, 29.6, and 34.3 MPa at 7, 14, and 28 days. The compressive strength of the NRL-modified concrete with waste aggregate replacements decreased with increasing aggregate replacement ratios and was lower than the normal concrete and NRL-modified concrete, respectively. This finding was similar to the previous research studies on the effects of waste PET bottles and crumb rubber aggregates on the hardened properties of concrete [

24,

36,

37]. However, the 28-day compressive strength of NRL10WP (NRL-modified concrete with 5% PET + 5% crumb rubber aggregate) met the minimum strength requirement for a rigid pavement designated by DOHs, Thailand. The compressive strength of NRL10WP was 21.9 MPa, 28.77 MPa, and 32.5 MPa at 7, 14, and 28 days, respectively. In other words, the compressive strength was found to reduce by 8.3% compared to that of the NRL-modified concrete. The compressive strength of NRL20WP was 15.46, 24.48, and 29.11 MPa at 7, 14, and 28 days, respectively, which was approximately 15% in strength reduction when compared to the NRL-modified concrete. The compressive strength was found to be remarkably reduced when the waste aggregate replacement in the NRL-modified concrete was 30%. The compressive strength of NRL30WP was 13.6, 22.3, and 24.5 MPa at 7, 14, and 28 days, respectively. The 28-day compressive strength of NRL30WP indicated 28.5% and 36.9% in strength reduction when compared to the NRL-modified concrete and normal concrete, respectively.

3.2. Flexural Strength

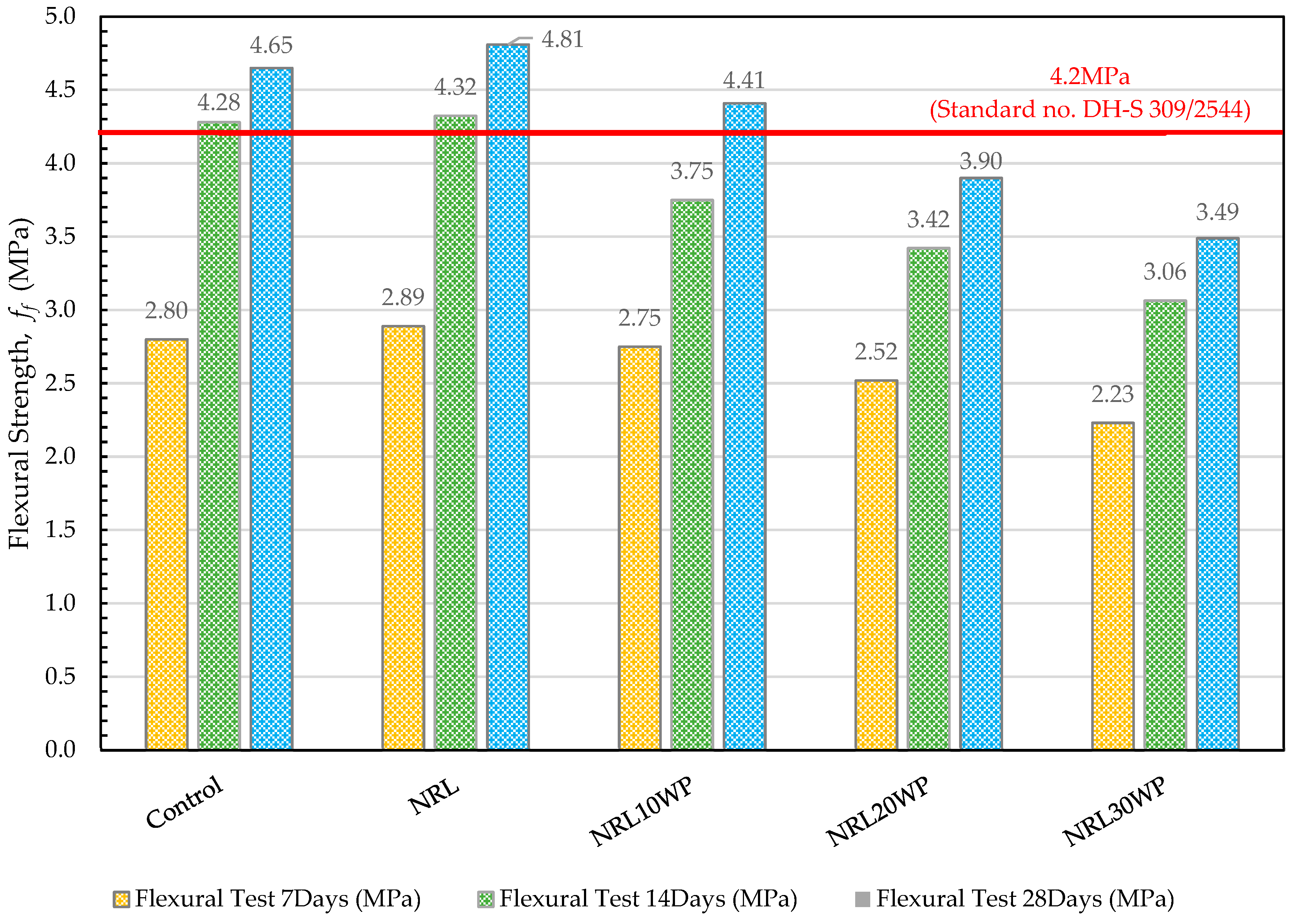

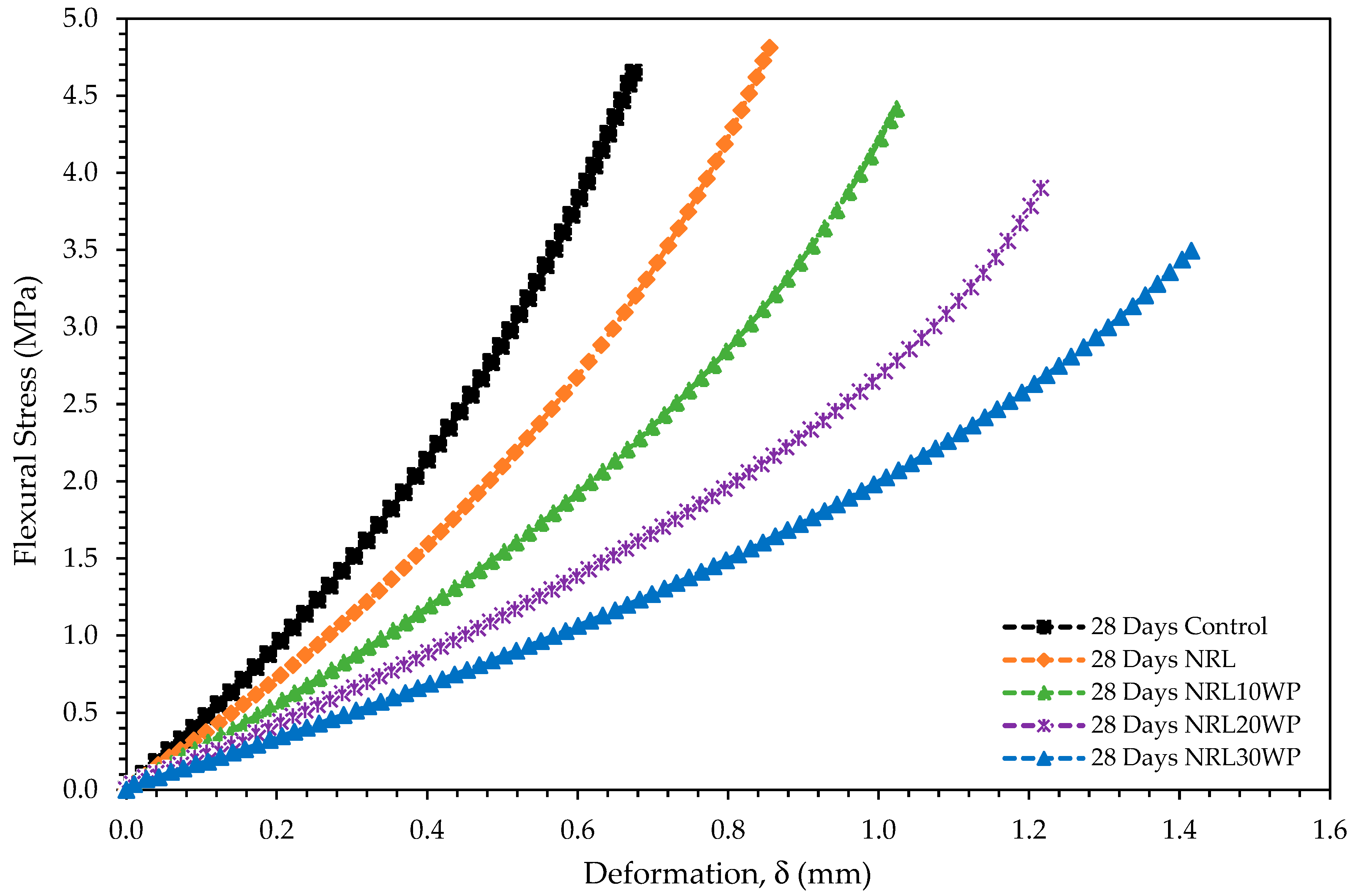

The flexural strengths of normal concrete, NRL-modified concrete, and NRL-modified waste polymer concrete samples cured at 7, 14, and 28 days are shown in

Figure 3. The solid line represents the minimum 28-day flexural strength requirement (

ff 4.2 MPa) for concrete pavement specified by DOH, Thailand [

38]. For normal concrete, the flexural strength increased with curing time as expected; flexural strength initially was 2.8 MPa, 4.3 MPa, and 4,7 MPa at 7, 14, and 28 days, respectively, which met the specification.

Figure 3 indicates that the NRL additive can improve the flexural strength of NRL-modified concrete, and its flexural strength was about 3.3% higher than that of normal concrete cured at 28 days. The flexural strength of NRL-modified concrete was 2.9, 4.3, and 4.86 MPa at 7, 14, and 28 days, respectively. This is because the NRL modifies the microstructure of the concrete, making it denser and reducing the gaps between particles, which prevents water alteration in the matrix and modifies the chemical reaction phases [

25,

32]. The effect of the PET and crumb rubber aggregate replacement was found to reduce the flexural strength when compared with the normal concrete. The flexural strength of concrete with PET and crumb rubber aggregate replacement decreased with increasing the replacement ratios. Although the flexural strength was reduced, the 28-day flexural strength of NRL10WP was 4.4 MPa, which met the minimum requirement of 4.2 MPa. Furthermore, at the age of 28 days, the flexural strength of NRL10WP, NRL20WP, and NRL30WP concretes was respectively 5.2%, 24.9%, and 36.9% lower than that of normal concrete. The percentage reduction in flexural strength of NRL10WP was lower than that of concrete using PET or crumb rubber aggregate as a rigid pavement previously reported [

22]. This implies that NRL additive can improve the flexural strength development of NRL-modified concrete with PET and crumb rubber aggregate replacement.

3.3. Mechanical Properties

Table 5 demonstrates the mechanical properties, including density, modulus of elasticity, compressive and flexural toughness, or modulus of resilience of the studied concrete samples. As per the mix design, the control concrete sample had a density of 2386.4 kg/m

3, which is within the common density of normal concrete between 2350 and 2400 kg/m

3. The NRL-modified concrete had a density of 2385.2 kg/m

3, which indicated that the NRL additive had less effect on the density. Identically, the PET and crumb rubber aggregate replacement resulted in reducing the density of the concrete samples. The NRL10WP, NRL20WP, and NRL30WP had densities of 2342.3, 2325.6, and 2305.4 kg/m

3, respectively, in which they were reduced about 1.9%, 2.6% and 3.4% compared to normal concrete.

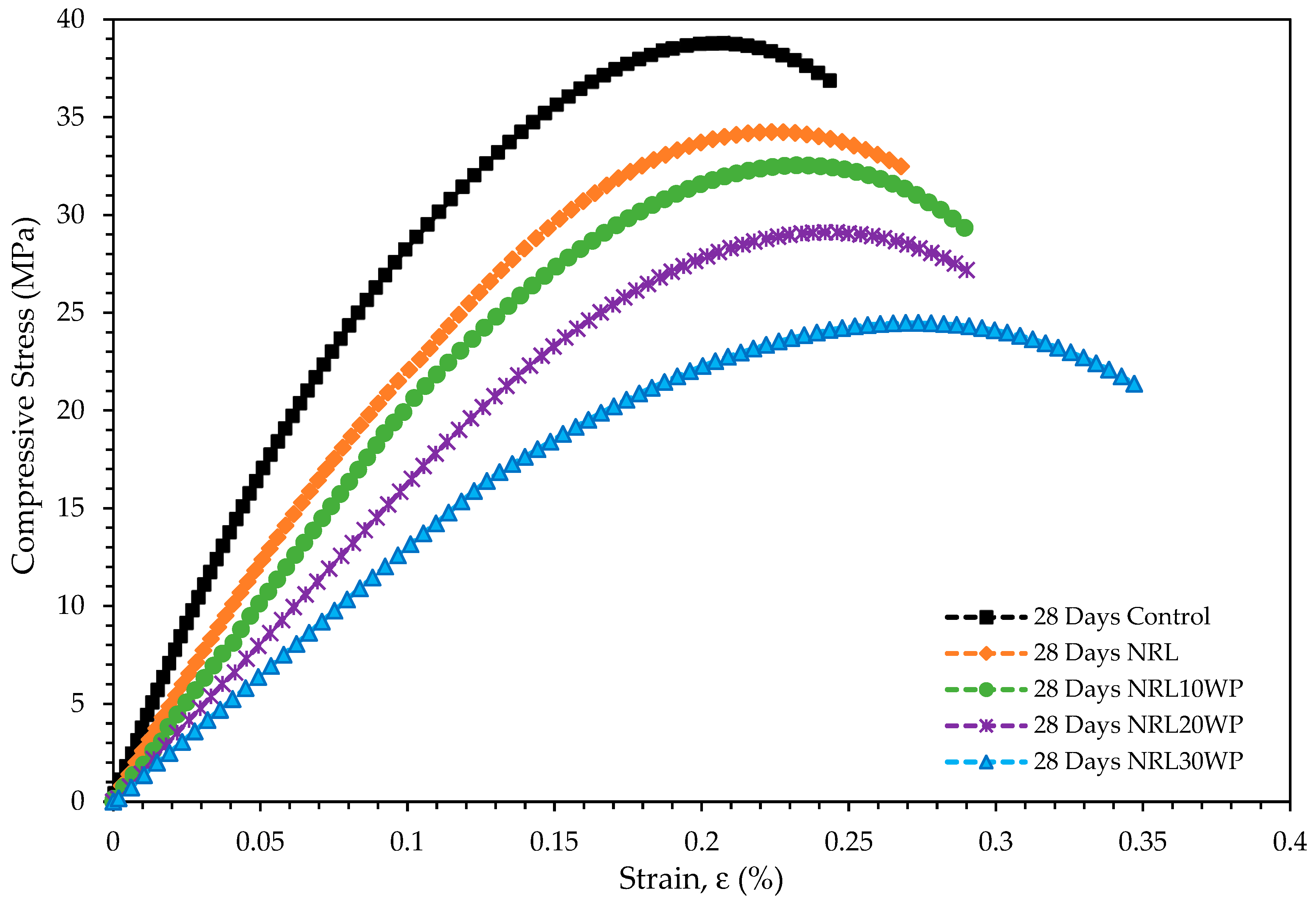

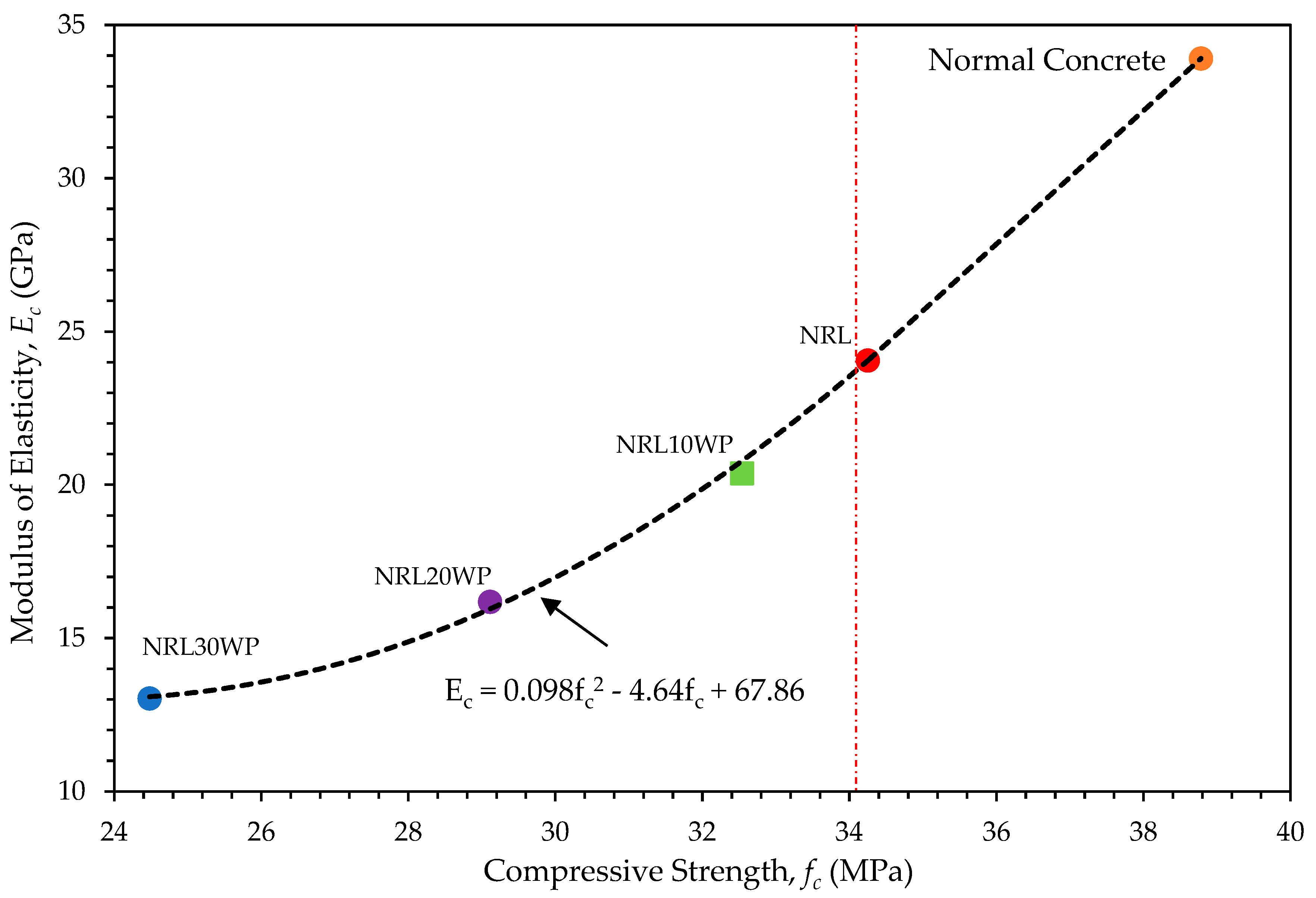

The modulus of elasticity (Young’s modulus) values of the studied samples in

Table 5 were obtained from the compressive stress-strain curve at 28 days as shown in

Figure 4. In general, the modulus of elasticity of the normal concrete was in the range of 30 and 50 GPa, and the modulus of elasticity of the studied control concrete sample was 33.91 GPa. The modulus of elasticity of NRL-modified concrete was about 28.4% lower than the control sample. While the modulus of elasticity of NRL-modified concretes with PET and crumb rubber aggregate replacement remarkably decreased with the increase of replacement ratios. The modulus of elasticity of NRL10WP, NRL20WP, and NRL30WP was 20.4, 16.2, and 13.04 GPa, respectively.

The compressive toughness was used to demonstrate the energy absorption under the compressive mode. The compressive toughness (measured in MJ/m

3) of the studied samples can be determined from their compressive stress-strain curve depicted in

Figure 4. The control sample had a compressive toughness of 5.35 MJ/m

3 while the NRL-modified had compressive toughness 4.89 MJ/m

3, or was about 8.6% lower than the normal concrete. The compressive toughness of NRL10WP, NRL20WP, and NRL30WP was 4.74, 4.30, and 4.22 MJ/m3, respectively. In other words, the compressive toughness of the NRL-modified concrete was reduced by about 11.4%, 19.6%, and 21.1% with 10%, 20%, and 30% of PET and crumb rubber aggregate replacement, respectively, when compared with the control sample.

On the other hand, the flexural toughness characteristics of NRL-modified concrete with and without PET and crumb rubber replacement were found to be different from their compressive toughness. The flexural toughness is used to indicate the energy absorption of the studied concrete when subjected to bending stress, such as the traffic loading on the concrete slab. The bending stress generated by repeated traffic loading can cause distress in the rigid pavement, which is considered the major mode of failure of concrete pavement. Therefore, the concrete’s ability to absorb energy (fracture energy), or known as flexural toughness, can positively impact the service life of a rigid pavement. This characteristic allows the pavement to resist crack propagation better, which is particularly important considering the dynamic loads and environmental impacts pavements are subjected to [

39].

When the concrete has a higher energy absorption capacity, it can deform more before fracturing. This deformation distributes stresses over a large volume of the material, which can prevent or delay the initiation of cracks. Furthermore, even when cracks do start, the higher energy absorption capacity can help prevent the rapid growth of these cracks [

40]. As such, it increases the pavement’s durability and resilience against various forms of distress, potentially extending its service life.

The flexural toughness values of the studied concrete samples shown in

Table 5 were determined in MPa.m and obtained from their flexural stress-strain curves, as shown in

Figure 5. It clearly indicated that the energy absorption of the NRL-modified concrete (1.65 MPa.m) was higher than that of normal concrete (1.29 MPa.m). This confirms that the addition of NRL additive can improve the flexural strength and energy absorption capacity of normal concrete. It is interesting to note that even though the flexural strength values of the NRL-modified concrete with PET and crumb rubber aggregate replacement were lower than the normal concrete, their flexural toughness values were higher than that of normal concrete. In addition, the energy absorption capacity of the NRL-modified concrete with waste aggregate replacement increased with the increase of replacement ratios. It implies that the NRL-modified concrete with PET and crumb rubber aggregate replacement had better ductility behavior than that of the normal concrete.

The flexural and compressive strengths are crucial parameters in concrete material selection for rigid pavement application, because they determine how much load a material or pavement structural layers can withstand without deforming or failing in both compressive and tensile modes. The relationship between the two is important because it helps the pavement engineers or designers to predict how a material will behave under different types of stress. In other words, a normal concrete material may have high compressive strength but low flexural strength, meaning it can withstand being compressed but may easily fracture when subjected to tensile stress. This is significant in applications such as rigid pavement where both compression and bending forces are present, hence the relationship between the flexural and compressive strength of the normal concrete is general plotted.

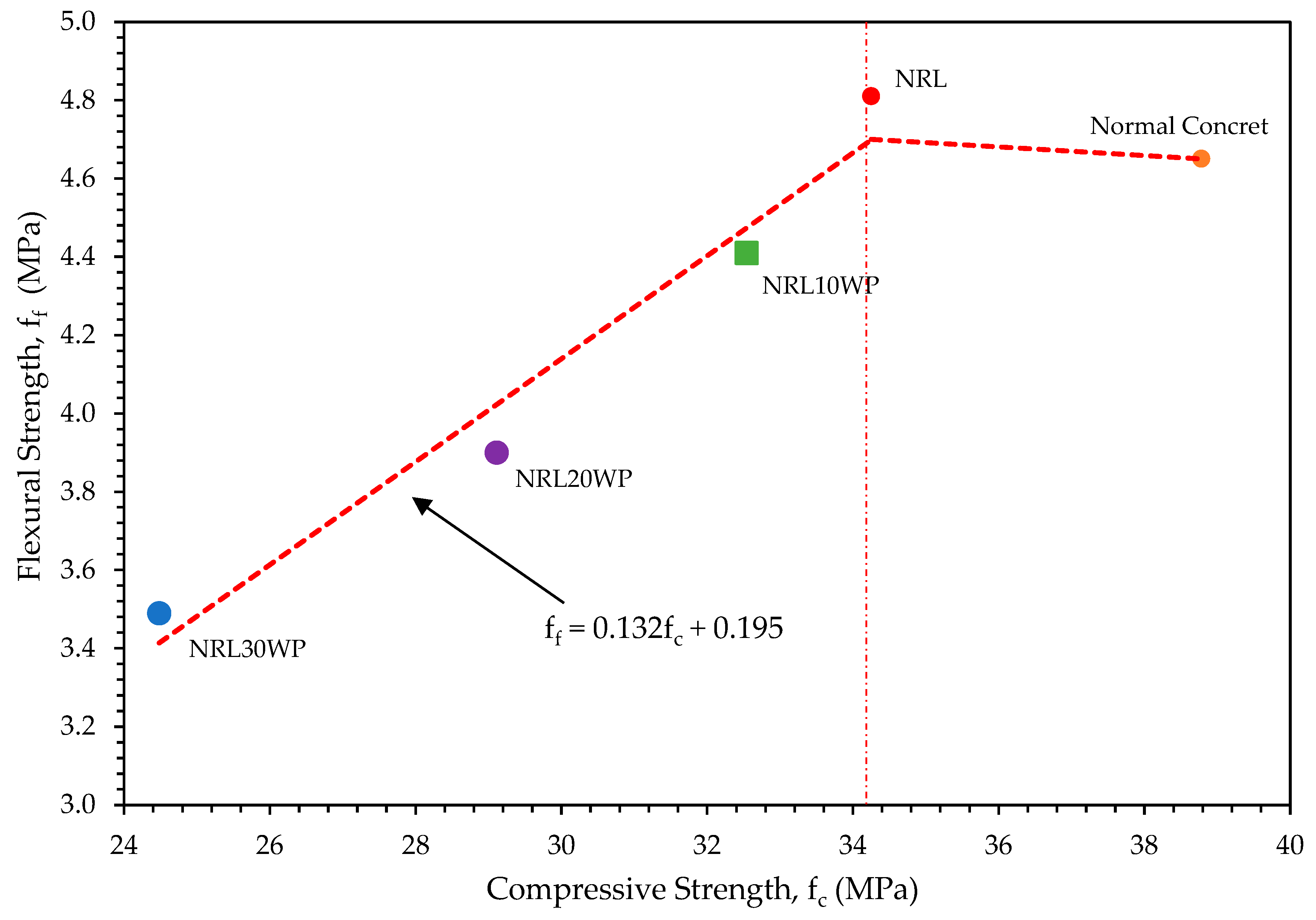

The relationship between the flexural strength (

ff) and compressive strength (

fc) of the NRL-modified concrete with PET and crumb rubber aggregates replacement was plotted in

Figure 6. This relationship can help pavement engineers or designers as a guideline to choose the waste materials such as PET and crumb rubber for a specific application and designer safer, more efficient structures. It can also be used in quality control, failure analysis, and the development of newly waste materials.

In addition, a common assumption in concrete pavement design is that the modulus of elasticity of concrete is directly related to its compressive strength. This implies that as the compressive strength of the concrete increases, so does its stiffness. Therefore, the relationship between the modulus of elasticity and the compressive strength can be used to predict the performance of concrete under various load conditions. This relationship is not always linear or direct, and it can be influenced by several factors such as type and quantity of aggregate used in the mix. As such, the actual tests on the concrete are required to determine these properties accurately for pavement structural design applications.

Figure 7 shows the relationship between modulus of elasticity (

Ec) and 28-day compressive strength (

fc) of NRL-modified concrete with PET and crumb rubber aggregates replacement. The relationship between these two properties can help in optimizing the NRL-modified concrete mix design when used waste PET and crumb rubber as aggregate replacement. By adjusting the ingredients and proportions in the mix, one can control both compressive strength and the modulus of elasticity to meet the specific requirements of a rigid pavement design.

3.4. Microstructural Analysis

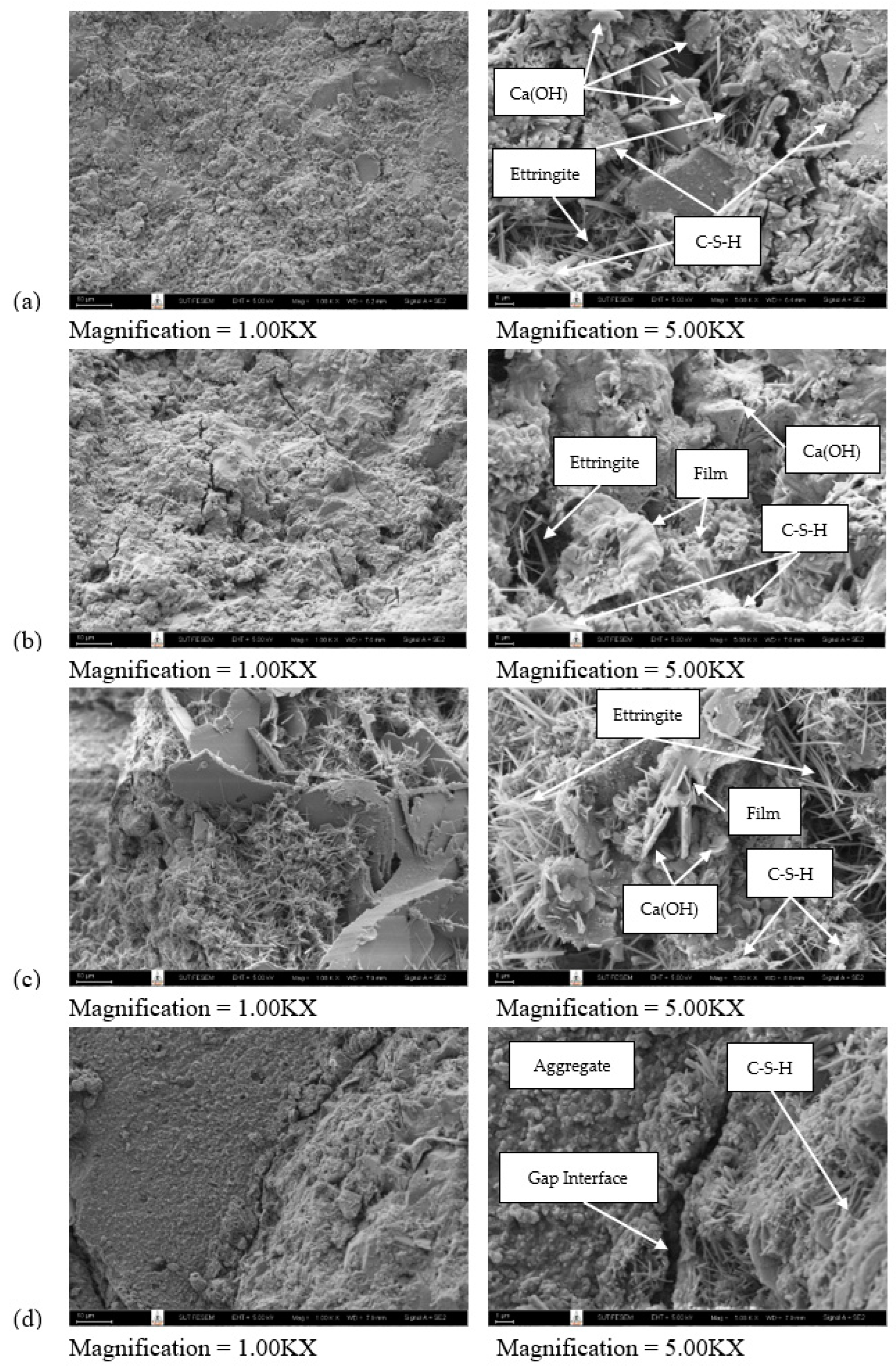

Figure 8 illustrates the SEM images of normal concrete, NRL-modified concrete, NRL10WP, and NRL30WP, which were cured at 28 days at magnifications of 1,000 and 5,000 times, respectively.

Figure 8a, plenty of calcium silicate hydrate (C-S-H) gel, Ca(OH)

2, and ettringite were clearly detected in the normal concrete mix (without NRL and waste aggregates). This confirmed that the strength of the concrete was theoretically developed in accordance with the production of hydration products.

Figure 8b shows the SEM images of NRL-modified concrete, which demonstrated that its matrix became slightly loose compared to the normal concrete. This might be due to the effect of NRL additive generated film network blocking the growth of hydration products, which resulted in lower compressive strength. However, the film network was detected to covering and bridging the C-S-H gels and aggregates. Furthermore, less ettringite was detected and resulted in enhanced adhesion or bonding between the aggregates by film network. Therefore, the flexural strength of the NRL-modified concrete was gained [

25,

32]. In addition, the NRL film network can absorb energy and helps mitigate crack propagation in the concrete, which reduces the likelihood of a brittle failure. This confirmed the improvement of concrete’s toughness and ductility as demonstrated in

Figure 5.

Figure 8c illustrates the SEM images of NRL-modified concrete with 10% of PET and crumb rubber aggregate replacement (NRL10WP). It clearly indicated the connection between the waste aggregates and hydration products resulted in several pores and loose matrix. This led to the reduction of its compressive and flexural strengths. SEM image of NRL-modified concrete with 30% of PET and crumb rubber aggregate replacement (NRL30WP) was demonstrated in

Figure 8d. It was evident that the higher rate of PET and crumb rubber aggregate replacement affect the microstructure by creating a weaker interface between the aggregate and the cement paste. PET and crumb rubber are hydrophobic and non-polar materials, which make them difficult for the cement paste to bond with. Subsequently, this can lead to a remarkably decrease in compressive strength. However, the inclusion of PET and crumb rubber can increase the concrete’s ability to absorb energy, improving its toughness and resistance to impact and dynamic loads due to its plastic deformation characteristics [

41].

The use of waste PET and crumb rubber in NRL-modified concrete is a sustainable practice that can alter the microstructure and mechanical properties of the concrete when used in rigid pavement applications. However, it is crucial to consider the specific requirements of the concrete and adjust the mix design accordingly to attest the best possibility of using these waste aggregates in the concrete pavement applications.

4. Conclusions

This research investigates the influence of waste PET and crumb rubber aggregate replacement on the microstructure and mechanical strength properties of NRL-modified concrete. The combination of PET and crumb rubber in percentages of 10%, 20%, and 30% aggregate replacement ratios were studied. In order to investigate the effect of waste aggregates and NRL additive on the strength development of concrete, 4 mixtures were prepared, such as normal concrete, NRL-modified concrete, NRL-modified concrete with 10%, 20%, and 30% of PET and crumb rubber replacements, namely NRL10WP, NRL20WP, and NRL30WP. The significant finding from this research work can be summarized as follows

With the addition of NRL additive, the compressive strength of the NRL-modified concrete was lower than that of the normal concrete. At the age of 28 days, the compressive strength of NRL10WP, NRL20WP, and NRL30WP was about 8.3%, 15%, and 28.5% lower than that of NRL-modified concrete. However, the 28-day compressive strength of NRL-modified concrete and NRL10WP was 34.25 MPa and 32.54 MPa and met the minimum compressive requirement (fc 32 MPa) for concrete pavement specified by DOH, Thailand. On the other hand, the flexural strength of NRL-modified concrete was approximately 3.3% higher than normal concrete. Similar to the compressive strength behavior, the flexural strength of NRL-modified concrete with PET and crumb rubber aggregate replacement decreased with the increased replacement ratio. However, the flexural strength of NRL10WP was found to meet the minimum flexural strength requirement (ff 4.2 MPa), for rigid pavement specified by DOH, Thailand. In terms of mechanical strength properties, it is confirmed that 10% of waste PET and crumb rubber aggregate replacement can be used in concrete mix for rigid pavement design.

Microstructural analysis indicated that the addition of NRL additive generated the film network to prevent the development of hydration products and resulted in compressive strength reduction. However, this film network acts as a bridge mechanism to enhance the adhesion or bonding between the aggregates in the concrete matrix, leading to the improved flexural strength. PET and crumb rubber are hydrophobic and non-polar materials, hence increasing the amount of these materials in the concrete mix can affect their microstructure by creating weaker interfaces between aggregates and cement paste. As such, the mechanical strength dropped. However, the PET and crumb rubber aggregate replacement can improve the ability to absorb energy of NRL-modified concrete and hence improve its toughness and resistance to impact and dynamic loads.

The research demonstrates that integrating waste PET and crumb rubber in concrete mix is a sustainable practice. The output of this research can be used as a guideline for pavement researchers, engineers, designers, and end-users understanding the crucial microstructural and macro-characteristics of NRL-modified concrete with waste aggregates and can adjust the mix design to meet the specification requirements of the concrete for rigid pavement applications.

Author Contributions

Conceptualization, M.H., B.R, and S.H.; methodology, T.Y.; software, B.R.; validation, A.A., A.S. and A.B.; formal analysis, M.H.; investigation, T.Y; resources, B.R.; data curation, T.Y.; writing—original draft preparation, B.R.; writing—review and editing, M.H., and S.H; visualization, A.S.; supervision, M.H. and S.H.,; project administration, M.H. and S.H.; funding acquisition, M.H. and S.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Research Council of Thailand (NRCT) under Young Researcher Genius program [grant No. N42A650210] and “Thailand Science Research and Innovation (TSRI) and the National Science, Research, and Innovation (NSRF) [grant No. 160338], and the National Science and Technology Development Agency under the Chair Professor program [grant No. P-19-52303].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Acknowledgments

This work was financially supported by Suranaree University of Technology, National Research Council of Thailand (NRCT), under Young Researcher Genius program [grant No. N42A650210], and Thailand Science Research and Innovation (TSRI), the National Science, Research, and Innovation Fund (NSRF) [grant No. 160338], and the National Science and Technology Development Agency under the Chair Professor program [grant No. P-19-52303].

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ng, C., et al. Road infrastructure development and economic growth. in IOP Conference Series: Materials Science and Engineering. 2019. IOP Publishing.

- Weizheng, Y. Research about the impact of transportation infrastructure on economic growth in a transportation power. E3S Web Conf. 2021, 253, 01037. [Google Scholar] [CrossRef]

- Yu, N.; De Jong, M.; Storm, S.; Mi, J. The growth impact of transport infrastructure investment: A regional analysis for China (1978–2008). Policy Soc. 2012, 31, 25–38. [Google Scholar] [CrossRef]

- Zhang, M.; Li, Z.; Wang, X.; Li, J.; Liu, H.; Zhang, Y. The Mechanisms of the Transportation Land Transfer Impact on Economic Growth: Evidence from China. Land 2021, 11, 30. [Google Scholar] [CrossRef]

- Hrapović, K. Paving of concrete carriageway Case study Tauern motorway at the Wengen-Pongau junction. Journal of Road and Traffic Engineering 2023, 69, 1–12. [Google Scholar] [CrossRef]

- Nosov, V.P.; Ushakov, V.V.; A Fotiadi, A.; Stepush, A.P. Improving the regulatory framework for the design of rigid pavements. IOP Conf. Series: Mater. Sci. Eng. 2020. [Google Scholar] [CrossRef]

- Peng, X. Recycling technology of old cement concrete pavement in highways. Vibroengineering PROCEDIA 2022, 46, 86–91. [Google Scholar] [CrossRef]

- Ma, F.; Sha, A.; Yang, P.; Huang, Y. The Greenhouse Gas Emission from Portland Cement Concrete Pavement Construction in China. Int. J. Environ. Res. Public Heal. 2016, 13, 632. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V.; Alcalá, J. Life cycle greenhouse gas emissions of blended cement concrete including carbonation and durability. Int. J. Life Cycle Assess. 2014, 19, 3–12. [Google Scholar] [CrossRef]

- Deja, J., A. Uliasz-Bochenczyk, and E. Mokrzycki, CO2 emissions from Polish cement industry. International Journal of Greenhouse Gas Control 2010, 4, 583–588. [CrossRef]

- Pheeraphan, T. Comparative study of properties of concrete made of hydraulic cement (TIS 2594) and ordinary Portland cement (TIS 15). Journal of Thailand Concrete Association 2021, 9, 1–6. [Google Scholar]

- Adrados, A.; de Marco, I.; Caballero, B.; López, A.; Laresgoiti, M.; Torres, A. Pyrolysis of plastic packaging waste: A comparison of plastic residuals from material recovery facilities with simulated plastic waste. Waste Manag. 2012, 32, 826–832. [Google Scholar] [CrossRef] [PubMed]

- Duncan, E.M.; Arrowsmith, J.; Bain, C.; Broderick, A.C.; Lee, J.; Metcalfe, K.; Pikesley, S.K.; Snape, R.T.; van Sebille, E.; Godley, B.J. The true depth of the Mediterranean plastic problem: Extreme microplastic pollution on marine turtle nesting beaches in Cyprus. Mar. Pollut. Bull. 2018, 136, 334–340. [Google Scholar] [CrossRef]

- Crawford, C.B. and B. Quinn, Microplastic pollutants. 2016: Elsevier Limited.

- Barbooti, M.M.; Mohamed, T.J.; Hussain, A.A.; Abas, F.O. Optimization of pyrolysis conditions of scrap tires under inert gas atmosphere. J. Anal. Appl. Pyrolysis 2004, 72, 165–170. [Google Scholar] [CrossRef]

- Fernández, A., et al. Pyrolysis of tyre wastes. In 1st Spanish National Conference on Advances in Materials Recycling and Eco-Energy. 2009.

- López, F.A.; Centeno, T.A.; Alguacil, F.J.; Lobato, B.; López-Delgado, A.; Fermoso, J. Gasification of the char derived from distillation of granulated scrap tyres. Waste Manag. 2012, 32, 743–752. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.R., et al., Innovation in pyrolysis technology for management of scrap tire: a solution of energy and environment. International Journal of Environmental Science and Development 2010, 1, 89.

- Kuncser, R.; Paraschiv, M.; Tazerout, M.; Bellettre, J. Liquid fuel recovery through pyrolysis of polyethylene waste. Environ. Eng. Manag. J. 2010, 9, 1371–1374. [Google Scholar] [CrossRef]

- Wójtowicz, M.A. and M.A. Serio, Pyrolysis of scrap tires: Can it be profitable? Chemtech 1996, 26, 48–53.

- Saikia, N.; de Brito, J. Use of plastic waste as aggregate in cement mortar and concrete preparation: A review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Youssf, O.; Mills, J.E.; Hassanli, R. Assessment of the mechanical performance of crumb rubber concrete. Constr. Build. Mater. 2016, 125, 175–183. [Google Scholar] [CrossRef]

- Park, Y.; Abolmaali, A.; Kim, Y.H.; Ghahremannejad, M. Compressive strength of fly ash-based geopolymer concrete with crumb rubber partially replacing sand. Constr. Build. Mater. 2016, 118, 43–51. [Google Scholar] [CrossRef]

- Islam, M.J., M.S. Meherier, and A.R. Islam, Effects of waste PET as coarse aggregate on the fresh and harden properties of concrete. Construction and Building materials 2016, 125, 946–951. [CrossRef]

- Yaowarat, T.; Suddeepong, A.; Hoy, M.; Horpibulsuk, S.; Takaikaew, T.; Vichitcholchai, N.; Arulrajah, A.; Chinkulkijniwat, A. Improvement of flexural strength of concrete pavements using natural rubber latex. Constr. Build. Mater. 2021, 282, 122704. [Google Scholar] [CrossRef]

- ASTM, Standard Test Methods for Chemical Analysis of Hydraulic Cement. ASTM C114-04. 2004, ASTM International, West Conshohocken, PA, 2004.

- ASTM, Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Fine Aggregate. ASTM C128-01. 2001, ASTM International, West Conshohocken, PA, 2001.

- ASTM, Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate. ASTM C127-01. 2001, ASTM International, West Conshohocken, PA, 2001.

- Al-Manaseer, A. and T. Dalal, Concrete containing plastic aggregates. Concrete international 1997, 19, 47–52.

- ASTM, Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM C136-01. 2001, ASTM International, West Conshohocken, PA, 2001.

- ASTM, Standard specification for concrete aggregates. ASTM C33. 2016, West Conshohocken, PA, 2016.

- Suddeepong, A.; Buritatum, A.; Hoy, M.; Horpibulsuk, S.; Takaikaew, T.; Horpibulsuk, J.; Arulrajah, A. Natural Rubber Latex–Modified Concrete Pavements: Evaluation and Design Approach. J. Mater. Civ. Eng. 2022, 34, 04022215. [Google Scholar] [CrossRef]

- ASTM, Standard practice for making and curing concrete test specimens in the laboratory. ASTM C192. 2016: West Conshohocken, PA, 2016.

- ASTM, Standard test method for compressive strength of cylindrical concrete specimens. ASTM C39. 2016, West Conshohocken, PA, 2016.

- AASHTO, Standard Method of Test for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading), AASHTO T97. 2002, American Association of Sate Highway and Transportation Officials, Washington, DC, 2002.

- Frigione, M. Recycling of PET bottles as fine aggregate in concrete. Waste Manag. 2010, 30, 1101–1106. [Google Scholar] [CrossRef]

- Guo, S.; Dai, Q.; Si, R.; Sun, X.; Lu, C. Evaluation of properties and performance of rubber-modified concrete for recycling of waste scrap tire. J. Clean. Prod. 2017, 148, 681–689. [Google Scholar] [CrossRef]

- DOH, Standards for highway construction, DH-S309/2544. 1996, Thailand Department of Highways, Bangkok, Thailand, 1996.

- Lohaus, L. and S. Anders, Ductility and Fatigue Behaviour of Polymer-Modified and Fibre-Reinforced High-Performance Concrete. In Advances in Construction Materials 2007. 2007, Springer. pp. 165-172. [CrossRef]

- Wille, K.; El-Tawil, S.; Naaman, A. Properties of strain hardening ultra high performance fiber reinforced concrete (UHP-FRC) under direct tensile loading. Cem. Concr. Compos. 2014, 48, 53–66. [Google Scholar] [CrossRef]

- Atahan, A.O.; Yücel, A. Crumb rubber in concrete: Static and dynamic evaluation. Constr. Build. Mater. 2012, 36, 617–622. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).