Submitted:

12 July 2023

Posted:

13 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials

2.1. Materials

2.2. Methods

2.2.1. Fatty Acid Composition

2.2.2. Chemical Analyses Oxidative Stability of Fresh and Stored Flaxseed Oil

2.2.3. Melting Phase Transition Analysis by Differential Scanning Calorimetry (DSC) of Flaxseed Oil during Storage

2.2.4. Statistical Analysis

3. Results

3.1. Physicochemical Characteristics of Fresh and Stored Flaxseed Oils

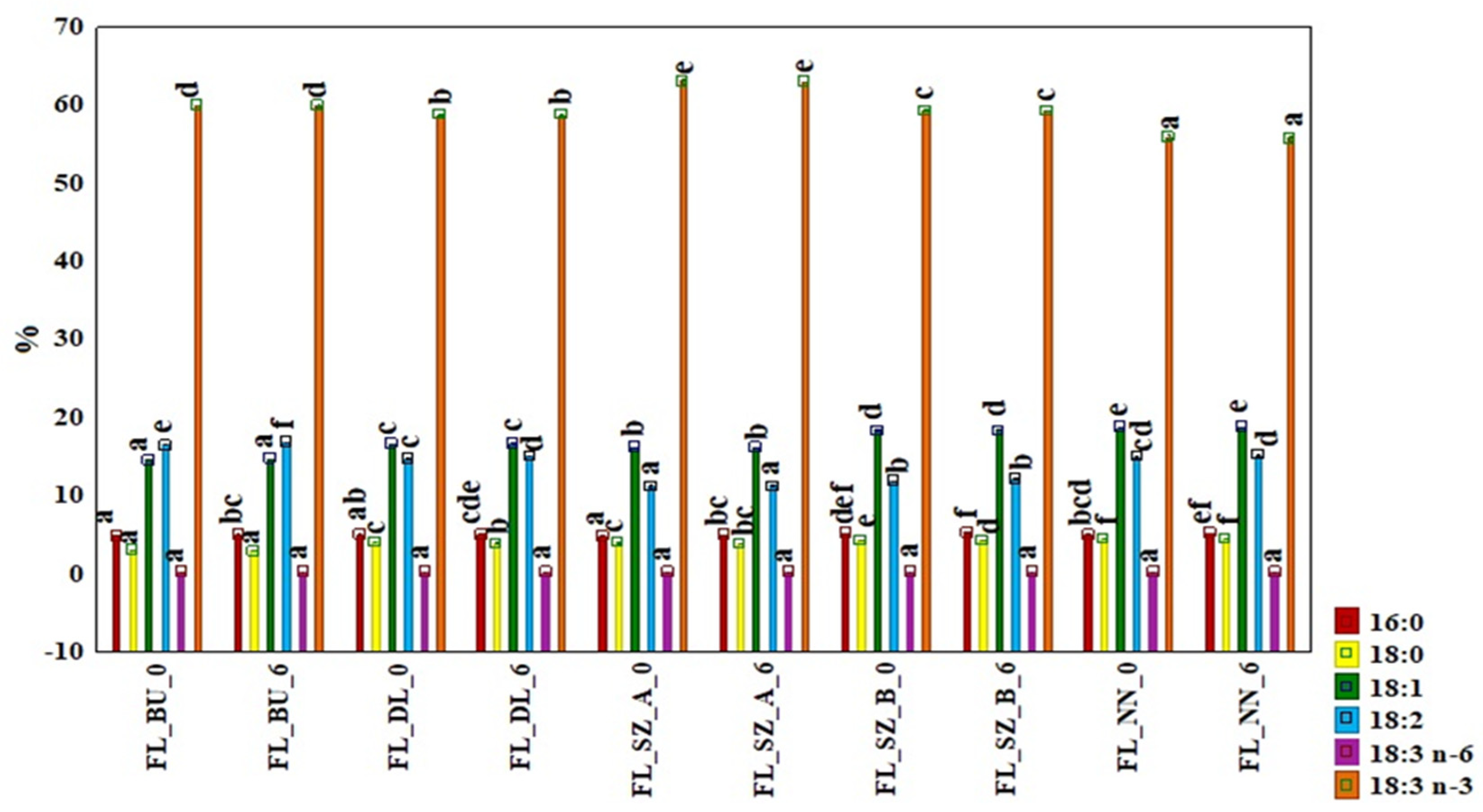

3.1.1. Fatty Acid Content

3.1.2. Oxidative Stability Analysis of Flaxseed Oil

3.2. Analysis of the DSC Melting Profiles of Flaxseed Oils during Shelf Life

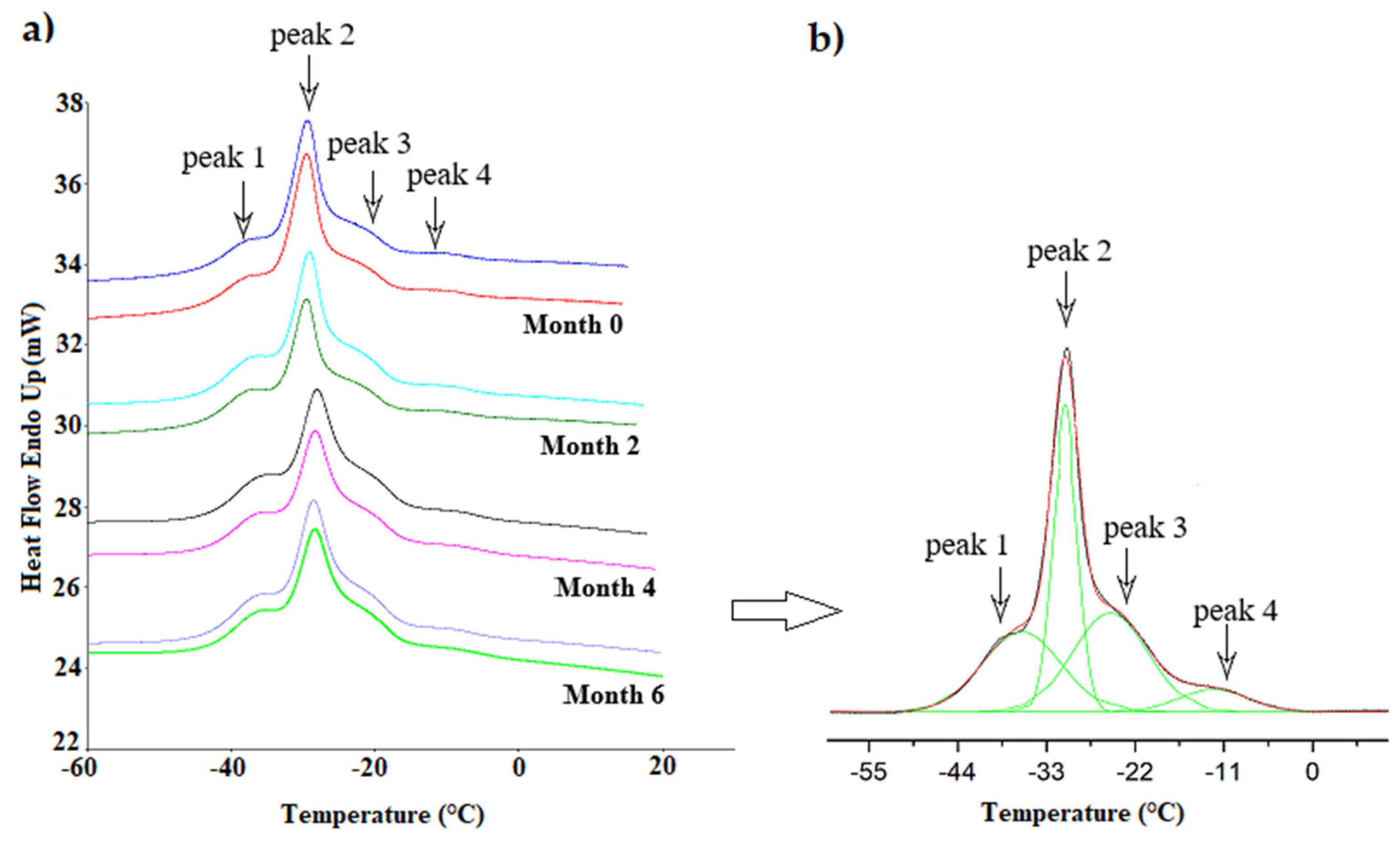

3.2.1. DSC Melting Profile Changes during Storage of Flaxseed Oil

4. Discussion

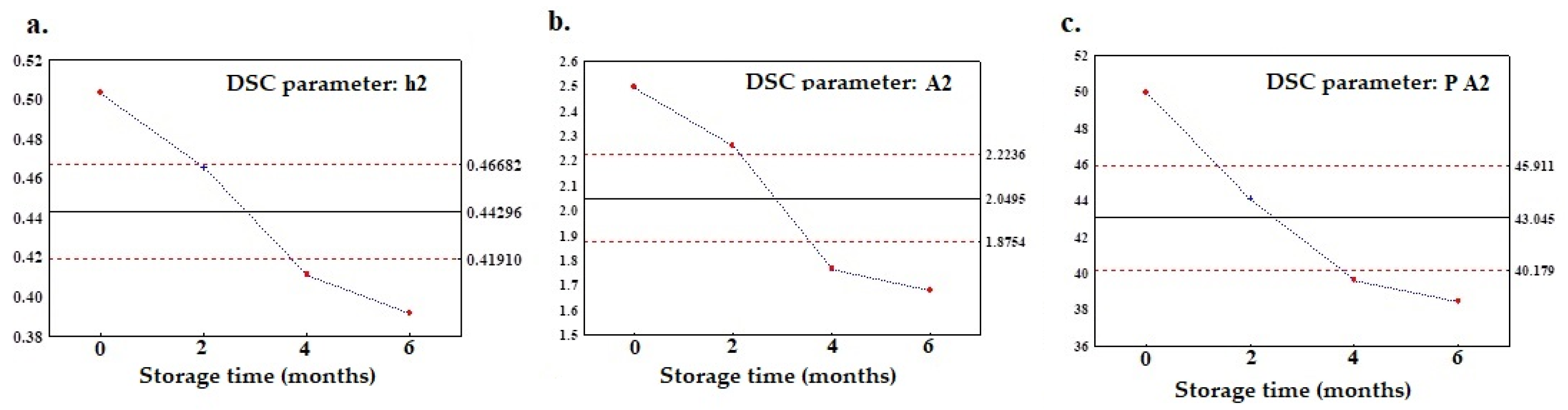

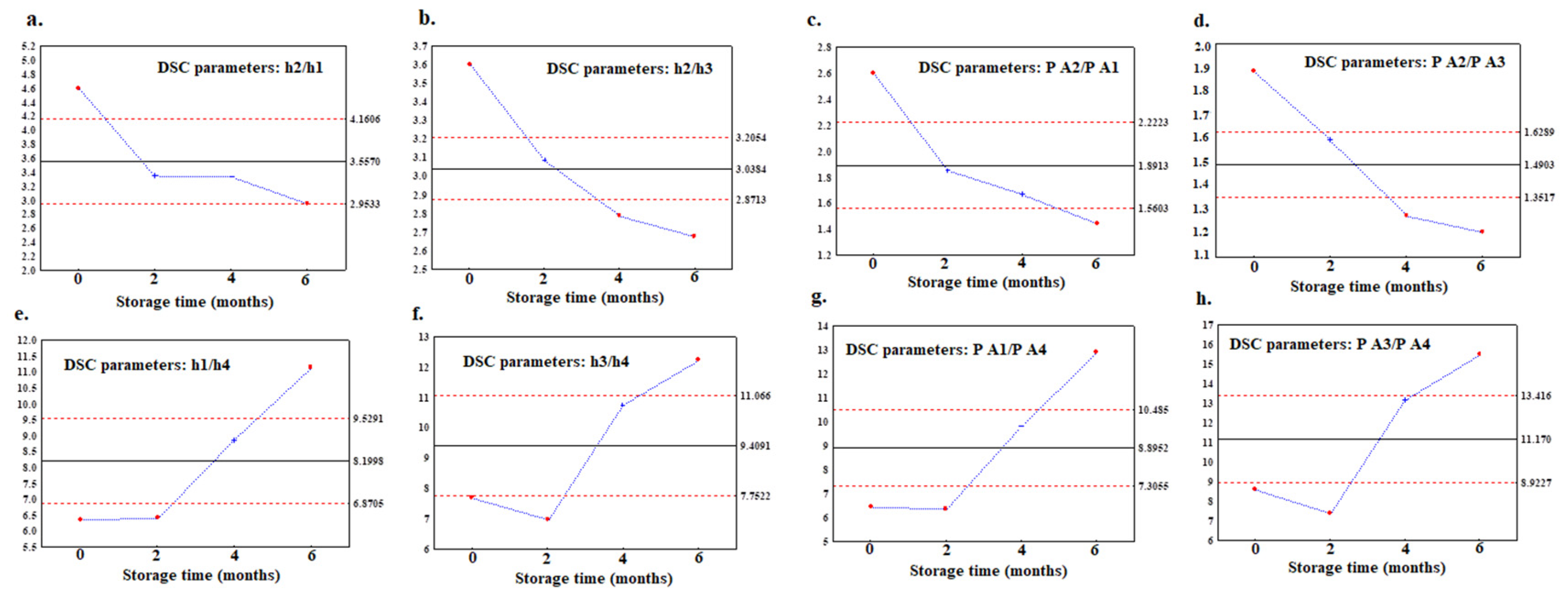

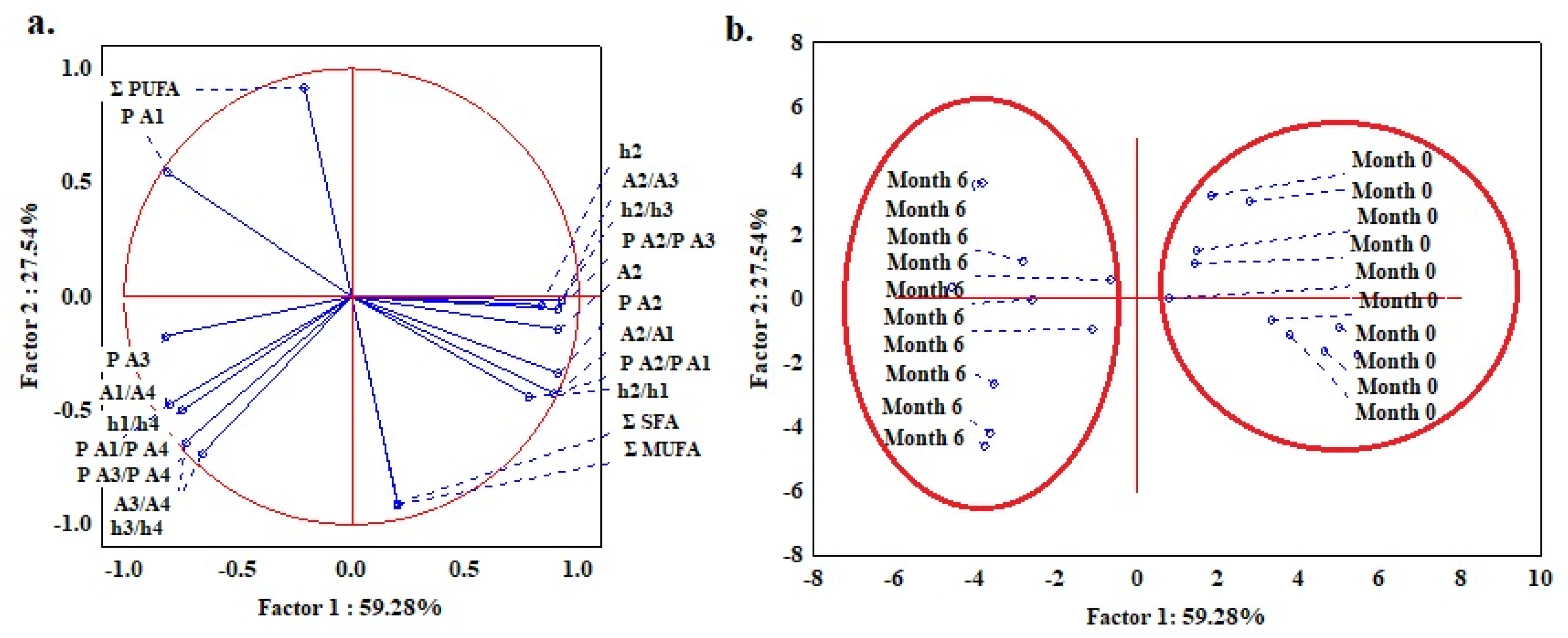

4.1. Determination of DSC Parameters as Markers of Authenticity and Deterioration of Flaxseed Oil

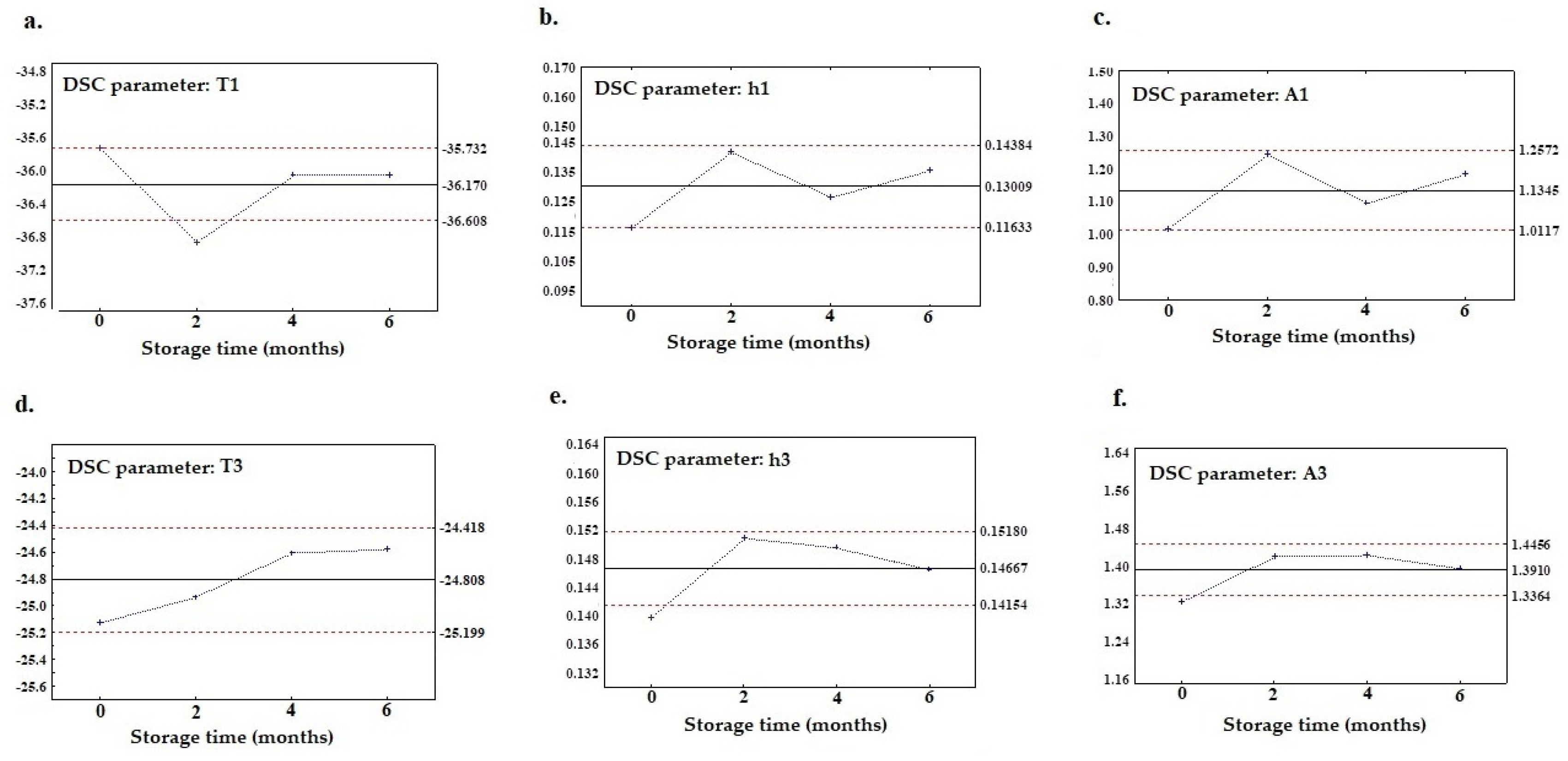

4.1.1. Determination of Stable DSC Parameters as Markers of Oils’ Authenticity during Storage

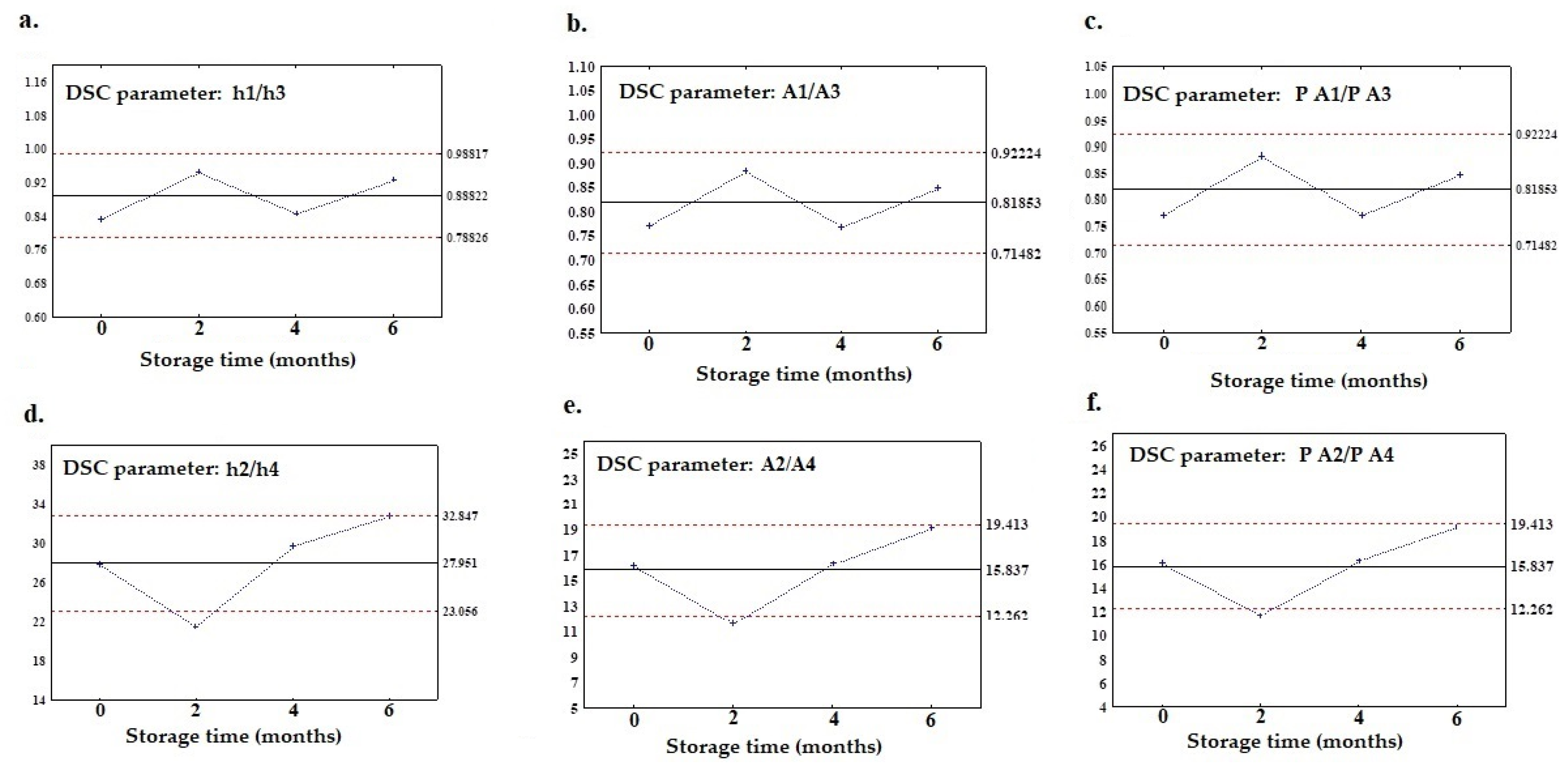

4.1.2. Detection of Flaxseed Oil Deterioration by Unstable DSC Parameters during Storage

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- FAO. Production/Yield quantities of Oil of linseed in World + (Total) [Internet]. 2020. Available from: https://www.fao.org/faostat/en/#data/QCL/visualize.

- Tomaszewska-Gras J, Islam M, Grzeca L, Kaczmarek A, Fornal E. Comprehensive thermal characteristics of different cultivars of flaxseed oil (Linum usittatissimum L.). Molecules. 2021;26. https://doi.org/10.3390/molecules26071958.

- Obranović M, Škevin D, Kraljić K, Pospišil M, Neđeral S, Blekić M; et al. Influence of Climate, Variety and Production Process on Tocopherols, Plastochromanol-8 and Pigments in Flaxseed Oil. 2015;53:496–504. [CrossRef]

- Herchi W, Bouali I, Bahashwan S, Rochut S, Boukhchina S, Kallel H; et al. Changes in phospholipid composition, protein content and chemical properties of fl axseed oil during development. Plant Physiol Biochem [Internet]. Elsevier Masson SAS; 2012;54:1–5. [CrossRef]

- Khattab RY, Zeitoun MA. Quality evaluation of flaxseed oil obtained by different extraction techniques. LWT - Food Sci Technol [Internet]. Elsevier Ltd; 2013;53:338–45. [CrossRef]

- Teh SS, Birch J. Physicochemical and quality characteristics of cold-pressed hemp, flax and canola seed oils. J Food Compos Anal [Internet]. Elsevier Inc.; 2013;30:26–31. [CrossRef]

- El-Beltagi HS, Salama Z, El-Hariri DM. Evaluation of Fatty Acids Profile and the Content of Some Secondary Metabolites in Seeds of Different Flax Cultivars ( Linum Usitatissimum L.). Gen Appl Plant Physiol [Internet]. 2007;33:187–202. Available from: http://www.bio21.bas.bg/ipp/gapbfiles/v-33/07_3-4_187-202.pdf.

- Tavarini S, Castagna A, Conte G, Foschi L, Sanmartin C, Incrocci L; et al. Evaluation of chemical composition of two linseed varieties as sources of health-beneficial substances. Molecules. 2019;24. [CrossRef]

- Gallardo MA, Milisich HJ, Drago SR, González RJ. Effect of cultivars and planting date on yield, oil content, and fatty acid profile of flax varieties (Linum usitatissimum L.). Int J Agron. 2014;2014. [CrossRef]

- Choe E, Min DB. Mechanisms and factors for edible oil oxidation. Compr Rev Food Sci Food Saf. 2006;5:169–86. [CrossRef]

- Choo WS, Birch J, Dufour JP. Physicochemical and quality characteristics of cold-pressed flaxseed oils. J Food Compos Anal. 2007;20:202–11. [CrossRef]

- Hasiewicz-Derkacz K, Kulma A, Czuj T, Prescha A, Zuk M, Grajzer M; et al. Natural phenolics greatly increase flax (Linum usitatissimum) oil stability. BMC Biotechnol. 2015;15:1–14. [CrossRef]

- Islam M, Muzolf-Panek M, Fornal E, Tomaszewska-Gras J. DSC isothermal and non-isothermal assessment of thermo-oxidative stability of different cultivars of Camelina sativa L. seed oils. J Therm Anal Calorim. Springer International Publishing; 2022;147:10013–26. [CrossRef]

- Tańska M, Roszkowska B, Skrajda M, Grzegorz D. Commercial Cold Pressed Flaxseed Oils Quality and Oxidative Stability at the Beginning and the End of Their Shelf Life. J Oleo Sci. 2016. [CrossRef]

- Islam M, Bełkowska L, Konieczny P, Fornal E, Tomaszewska-Gras J. Differential scanning calorimetry for authentication of edible fats and oils - What can we learn from the past to face the current challenges? J Food Drug Anal. 2022;30. [CrossRef]

- Zhang ZS, Li D, Zhang LX, Liu YL, Wang X De. Heating effect on the DSC melting curve of flaxseed oil. J Therm Anal Calorim. 2014;115:2129–35. [CrossRef]

- AOCS. AOCS Official Method Preparations of Methyl Esters of Fatty Acids. 1997. p. 2–66.

- AOCS. AOCS Official Method Acid Value. Cd 3d-63. Urbana, IL, USA; 2009.

- ISO 3960. Animal and Vegetable Fats and Oils—Determination—Iodometric (Visual) Endpoint; International Organization for Standardization: Geneva, Switzerland, 2017. 2010.

- ISO 6885. Animal and Vegetable Fats and Oils: Determination of Anisidine Value. ISO: Geneva, Switzerland 2016. 2016.

- Tomaszewska-Gras J. Rapid quantitative determination of butter adulteration with palm oil using the DSC technique. Food Control. Elsevier Ltd; 2016;60:629–35. [CrossRef]

- Cantele C, Bertolino M, Bakro F, Giordano M, Jędryczka M, Cardenia V. Antioxidant effects of hemp (Cannabis sativa L.) inflorescence extract in stripped linseed oil. Antioxidants. 2020;9:1–18. [CrossRef]

- Malcolmson LJ, Przybylski R, Daun JK. Storage stability of milled flaxseed. JAOCS, J Am Oil Chem Soc. 2000;77:235–8. [CrossRef]

- Prescha A, Grajzer M, Dedyk M, Grajeta H. The antioxidant activity and oxidative stability of cold-pressed oils. JAOCS, J Am Oil Chem Soc. 2014;91:1291–301. [CrossRef]

- Codex Alimentarius. Standard for Named Vegetable Oils Codex Stan 210-1999. Codex Aliment. 1999;1–13.

- Gordon MH. The development of oxidative rancidity in foods [Internet]. Antioxidants Food. Woodhead Publishing Ltd; 2001. [CrossRef]

- Kozub A, Nikolaichuk H, Przykaza K, Tomaszewska-Gras J, Fornal E. Lipidomic Characteristics of Three Edible Cold-pressed Oils by LC / Q-TOF for Simple Quality and Authenticity Assurance. Food Chem. Elsevier Ltd; 2023;135761. [CrossRef]

- Mcelhaney RN. The use of differential scanning calorimetry and differential thermal analysis in studies of model and biological membranes. Chem Phys Lipids,. 1982;30:229–59. [CrossRef]

- Tan CP, Che Man YB. Comparative differential scanning calorimetric analysis of vegetable oils: I. Effects of heating rate variation. Phytochem Anal. 2002;13:129–41.

- Minato A, Ueno S, Yano J, Smith K, Seto H, Amemiya Y; et al. Thermal and structural properties of sn-1,3-dipalmitoyl-2-oleoylglycerol and sn-1,3-dioleoyl-2-palmitoylglycerol binary mixtures examined with synchrotron radiation X-ray diffraction. JAOCS, J Am Oil Chem Soc. 1997;74:1213–20. [CrossRef]

- Pratama Y, Burholt S, Baker DL, Sadeghpour A, Simone E, Rappolt M. Polymorphism of a Highly Asymmetrical Triacylglycerol in Milk Fat: 1-Butyryl 2-Stearoyl 3-Palmitoyl-glycerol. Cryst Growth Des. 2022;22:6120–30. [CrossRef]

- Tan CP, Che Man YB. Differential scanning calorimetric analysis of edible oils: Comparison of thermal properties and chemical composition. JAOCS, J Am Oil Chem Soc. 2000;77:143–55. [CrossRef]

- Konieczny P, Tomaszewska-Gras J, Andrzejewski W, Mikołajczak B, Urbańska M, Mazurkiewicz J; et al. DSC and electrophoretic studies on protein denaturation of Anodonta woodiana (Lea, 1834). J Therm Anal Calorim. 2016;126:69–75. [CrossRef]

- Vega S, Garcia-Gonzalez MA, Lanas A, Velazquez-Campoy A, Abian O. Deconvolution analysis for classifying gastric adenocarcinoma patients based on differential scanning calorimetry serum thermograms. Sci Rep. 2015;5:1–8. [CrossRef]

- Murphy CB. Thermal methods of analysis (Wendlandt, Wesley W.). J Chem Educ. American Chemical Society (ACS); 1965. p. 549–50. [CrossRef]

- Saito Y, Saito K, Ataké T. Theoretical analysis of peak height in classical DTA, power-compensated DSC and heat-flux DSC. Thermochim Acta. 1986;107:277–82. [CrossRef]

- Lim SAH, Antony J, Albliwi S. Statistical Process Control (SPC) in the food industry - A systematic review and future research agenda. Trends Food Sci Technol [Internet]. Elsevier Ltd; 2014;37:137–51. [CrossRef]

- Pudjihardjo I, Mulyana IJ, Asrini LJ. Autocorrelated multivariate control chart in cooking oil industry. Proc Int Conf Ind Eng Oper Manag. 2019;2019:1440–8.

| Seeds varieties | Time | Chemical analysis | |||

|---|---|---|---|---|---|

| AV (mg KOH/g) |

PV (meq O2/kg) |

p-AV | TOTOX | ||

| FL_BU | 0 month | 0.8 ± 0.04b | 3.95 ± 0.63c | 0.87 ± 0.35a | 8.78 ± 1.02c |

| After 6 months | 2.54 ± 0.02g | 14.44 ± 0.08h | 2.02 ± 0.02c | 30.90 ± 0.15h | |

| FL_DL | 0 month | 0.41 ± 0.01a | 2.49± 0.15b | 0.65± 0.01a | 5.63 ± 0.31b |

| After 6 months | 1.59 ± 0.02d | 10.64 ± 0.11f | 1.70 ± 0.07bc | 22.76 ± 0.21f | |

| FL_SZA | 0 month | 1.27 ± 0.03c | 1.41 ± 0.06a | 0.73 ± 0.13a | 3.54± 0.2a |

| After 6 months | 2.40± 0.02f | 9.73 ± 0.13e | 1.49 ± 0.01b | 21.09 ± 0.28e | |

| FL_SZB | 0 month | 0.81± 0.03b | 6.90 ± 0.23d | 0.94 ± 0.12a | 14.74 ± 0.41d |

| After 6 months | 1.79 ± 0.02e | 15.57 ± 0.16i | 1.63± 0.02bc | 33.61 ± 0.30i | |

| FL_NN | 0 month | 1.60 ± 0.02d | 1.21 ± 0.06a | 0.76 ± 0.25a | 3.17 ± 0.24a |

| After 6 months | 3.25 ± 0.10h | 11.69 ± 0.22g | 2.47 ± 0.034d | 25.08 ± 0.5g | |

| Peak temperature (°C) | Time | FL_BU | FL_DL | FL_SZA | FL_SZB | FL_NN |

|---|---|---|---|---|---|---|

| T1 | 0 | -36.85 ± 0.11aA | -36.37 ± 0.12aAB | -36.65 ± 0.22aAB | -36.36 ± 0.07aA | -36.55 ± 0.93aA |

| 2 | -37.19 ± 0.37abA | -36.93 ± 0.27abcA | -37.57 ± 0.36aA | -36.2 ± 0.18cA | -36.44 ± 0.32bcA | |

| 4 | -36.72 ± 0.62aA | -36.58 ± 0.06aAB | -36.44 ± 0.18aB | -35.69 ± 0.46abA | -34.80 ± 0.17bB | |

| 6 | -36.55 ± 0.18aA | -36.12 ± 0.29abB | -36.38 ± 0.20aB | -35.59 ± 0.11bA | -35.59 ± 0.06bAB | |

| T2 | 0 | -31.67 ± 0.09aA | -30.10± 0.11abAB | -30.37 ± 0.25abB | -29.72 ± 0.05bA | -30.01 ± 0.97abA |

| 2 | -31.54 ± 0.2aA | -30.50 ± 0.29bcA | -31.06 ± 0.21abA | -29.64 ± 0.23dA | -30.0 ± 0.25cdA | |

| 4 | -30.88 ± 0.27aB | -29.31 ± 0.28bcB | -29.53 ± 0.12bC | -28.35 ± 0.20dB | -28.66 ± 0.03cdA | |

| 6 | -30.22 ± 0.11aB | -29.39 ± 0.24bB | -29.67 ± 0.08abC | -28.6 ± 0.13cB | -28.55 ± 0.08cA | |

| T3 | 0 | -25.12 ± 0.00aA | -24.94 ± 0.18abA | -24.96 ± 0.2abA | -24.19 ± 0.12bA | -24.58 ± 0.54abA |

| 2 | -25.01 ± 0.00aA | -25.05 ± 0.09aA | -25.14 ± 0.00aA | -24.85 ± 0.08abA | -24.55 ± 0.22bA | |

| 4 | -24.98 ± 0.16aA | -25.10 ± 0.00aA | -25.11 ± 0.00aA | -24.63 ± 0.66aA | -23.31 ± 0.16bB | |

| 6 | -25.12 ± 0.00aA | -24.55 ± 0.77aA | -25.13 ± 0.00aA | -24.47 ± 0.04aA | -22.99 ± 0.07bB | |

| T4 | 0 | -13.63± 0.24aA | -12.50 ± 0.49abA | -12.64 ± 0.34abA | -12.20 ± 0.06bA | -13.87± 0.18aA |

| 2 | -13.57 ± 0.16aA | -12.84 ± 0.18abA | -13.27 ± 0.20aA | -11.76 ± 0.42cA | -12.21 ± 0.61bcB | |

| 4 | -14.02 ± 0.00aA | -10.62 ± 0.23bcB | -11.13 ± 0.24bB | -10.40 ± 0.29bcB | -9.94 ± 0.15cC | |

| 6 | -12.05± 0.24bB | -11.24 ± 0.16aB | -11.13 ± 0.04abB | -10.54 ± 0.28cB | -10.49 ± 0.08cC |

| Peak Height (W/g) |

Time | FL_BU | FL_DL | FL_SZA | FL_SZB | FL_NN |

|---|---|---|---|---|---|---|

| h1 | 0 | 0.15 ± 0.008bB | 0.13 ± 0.008abA | 0.14 ± 0.005abA | 0.12 ± 0.008aA | 0.10 ± 0.014aA |

| 2 | 0.17 ± 0.007cB | 0.15 ± 0.006bA | 0.15 ± 0.008bcA | 0.13 ± 0.004aA | 0.12 ± 0.003aA | |

| 4 | 0.12 ± 0.004abcA | 0.14 ± 0.008bcA | 0.15± 0.002cA | 0.11 ± 0.006abA | 0.11 ± 0.013aA | |

| 6 | 0.15 ± 0.006aB | 0.13 ± 0.024bA | 0.15 ± 0.011abA | 0.12 ± 0.000cA | 0.12 ± 0.001cA | |

| h2 | 0 | 0.47 ± 0.033aB | 0.52 ± 0.099aA | 0.46 ± 0.003aB | 0.52 ± 0.002aC | 0.43 ±0.062aAB |

| 2 | 0.43 ± 0.016aB | 0.46 ± 0.008abA | 0.46 ± 0.012abB | 0.48 ± 0.013bB | 0.50± 0.031bB | |

| 4 | 0.45 ± 0.005cB | 0.37 ± 0.005abA | 0.37± 0.000aA | 0.40 ± 0.005bA | 0.46 ±0.016cAB | |

| 6 | 0.36 ± 0.007aA | 0.42 ± 0.040aA | 0.39 ± 0.013aA | 0.41 ± 0.010aA | 0.38 ± 0.000aA | |

| h3 | 0 | 0.14 ± 0.006aA | 0.14 ± 0.006aA | 0.14 ± 0.000aA | 0.15 ± 0.005aA | 0.13 ± 0.000aA |

| 2 | 0.14 ± 0.002aA | 0.15 ± 0.006bAB | 0.15 ± 0.001bB | 0.16 ± 0.006bA | 0.16 ± 0.002bB | |

| 4 | 0.14 ± 0.003aA | 0.17 ± 0.003bB | 0.16 ± 0.008abB | 0.15 ± 0.010abA | 0.14 ± 0.008aA | |

| 6 | 0.14 ± 0.001aA | 0.14 ± 0.002aA | 0.15 ± 0.001aB | 0.15 ± 0.008aA | 0.14 ± 0.001aA | |

| h4 | 0 | 0.02 ± 0.001cAB | 0.01 ± 0.001aA | 0.02 ±0.001bAB | 0.02± 0.001bcB | 0.02 ±0.002bcB |

| 2 | 0.03 ± 0.002cB | 0.02 ± 0.001abA | 0.02± 0.001bcB | 0.02 ± 0.001aB | 0.02 ±0.003abB | |

| 4 | 0.02 ± 0.002bA | 0.02 ± 0.001abA | 0.02 ± 0.000abA | 0.01 ± 0.002bA | 0.01 ± 0.002bA | |

| 6 | 0.02± 0.000bA | 0.01 ± 0.004abA | 0.01 ± 0.003abA | 0.01 ± 0.003abA | 0.01 ± 0.000aA |

| Peak area | Time | FL_BU | FL_DL | FL_SZA | FL_SZB | FL_NN |

|---|---|---|---|---|---|---|

| A1 | 0 | 1.39 ± 0.07bB | 1.18 ± 0.07abA | 1.19 ± 0.04abA | 1.03± 0.07aA | 0.86 ± 0.12aA |

| 2 | 1.45 ± 0.06cB | 1.27 ± 0.05bA | 1.33 ± 0.07bcA | 1.12 ± 0.04aA | 1.04 ± 0.02aA | |

| 4 | 1.09 ± 0.03abA | 1.14 ± 0.1abA | 1.30 ± 0.02bA | 0.10 ± 0.07aA | 0.93 ± 0.11aA | |

| 6 | 1.36 ± 0.05aB | 1.12 ± 0.21aA | 1.30 ± 0.04aA | 1.07 ± 0.00aA | 1.08 ± 0.01aA | |

| A2 | 0 | 2.50 ± 0.20aB | 2.68 ± 0.73aB | 2.22 ± 0.01aB | 2.7 ± 0.05aC | 2.42± 0.04aA |

| 2 | 2.20 ± 0.08aB | 2.19 ± 0.04aAB | 2.28 ± 0.03aB | 2.21 ± 0.14aB | 2.42 ± 0.26aA | |

| 4 | 2.29 ± 0.04bB | 1.23 ± 0.11aA | 1.40 ± 0.09aA | 1.61± 0.05aA | 2.31 ± 0.20bA | |

| 6 | 1.41 ± 0.06aA | 1.74 ± 0.16abAB | 1.62 ± 0.18abA | 1.72 ± 0.05abA | 1.89 ± 0.02bA | |

| A3 | 0 | 1.20± 0.00aA | 1.35 ± 0.06abA | 1.32 ± 0.00abA | 1.44 ± 0.05bA | 1.25 ± 0.00aA |

| 2 | 1.29 ± 0.03aB | 1.44 ± 0.06bAB | 1.41 ± 0.06abA | 1.5± 0.06bA | 1.48 ± 0.02bB | |

| 4 | 1.29 ± 0.02aB | 1.58 ± 0.02bB | 1.49 ± 0.08abA | 1.44 ± 0.09abA | 1.32 ± 0.08bA | |

| 6 | 1.38 ± 0.01aC | 1.38 ± 0.02aA | 1.47 ± 0.01aA | 1.41 ± 0.08aA | 1.34 ± 0.01aA | |

| A4 | 0 | 0.21 ± 0.01bB | 0.14 ± 0.02aAB | 0.18 ± 0.02abB | 0.18 ± 0.02abB | 0.22 ± 0.02bB |

| 2 | 0.22 ± 0.01bB | 0.19 ± 0.01abB | 0.23± 0.01bC | 0.15± 0.02aB | 0.20 ± 0.04abB | |

| 4 | 0.18 ± 0.02bAB | 0.12 ± 0.01aA | 0.13 ± 0.00abA | 0.08 ± 0.02aA | 0.08 ± 0.02aA | |

| 6 | 0.14 ± 0.00bA | 0.11 ± 0.02abA | 0.11 ± 0.02abA | 0.09 ± 0.02abA | 0.06 ± 0.00aA | |

| % peak area | ||||||

| P A1 | 0 | 26.21 ± 0.07bB | 22.18 ± 2.33abA | 24.25± 0.57abA | 19.23 ± 0.99aA | 18.16 ± 2.17aA |

| 2 | 28.16 ± 1.30cB | 25.02 ± 0.20bA | 25.33 ± 1.09bcA | 22.54± 0.74abB | 20.33 ± 1.62aA | |

| 4 | 22.49± 0.13aA | 28.01 ± 1.06bcA | 30.20 ± 0.25cB | 24.11 ± 1.49abB | 20.13 ± 2.37aA | |

| 6 | 31.65 ± 0.36bC | 25.58 ± 2.89aA | 28.97 ± 0.47abB | 24.93 ± 0.04aB | 24.67 ± 0.15aA | |

| P A2 | 0 | 47.16 ± 1.32aC | 49.72 ± 5.48aC | 45.23 ± 0.42aB | 50.47 ± 1.66aC | 50.93 ± 1.92aA |

| 2 | 42.67 ± 1.12aB | 43.03 ± 0.59aBC | 43.40 ± 0.70aB | 44.35 ± 0.95abB | 47.08 ± 2.32bA | |

| 4 | 47.15 ± 0.22bcC | 30.07 ± 1.38aA | 32.45 ± 1.88aA | 38.94 ± 0.73abA | 49.70 ± 4.3cA | |

| 6 | 32.99 ± 0.62aA | 40.01 ± 0.65bcB | 35.88 ± 2.1abA | 40.12± 1.26bcA | 43.37 ± 0.45cA | |

| P A3 | 0 | 22.68 ± 1.15aA | 25.49 ± 3.05aA | 26.85 ± 0.41aA | 26.85 ± 0.45aA | 26.36 ± 0.49aA |

| 2 | 24.87 ± 0.47aAB | 28.21 ± 0.24bcA | 26.87 ± 1.32abA | 30.03 ± 0.41cAB | 28.80 ± 1.28abAB | |

| 4 | 26.63 ± 0.26aB | 38.92 ± 2.47cB | 34.43 ± 2.14abcB | 34.95 ± 2.58bcB | 28.35 ± 1.59abAB | |

| 6 | 32.18 ± 0.98aC | 31.80 ± 2.79aAB | 32.77 ± 1.96aB | 32.86 ± 1.88aB | 30.68 ± 0.24aB | |

| P A4 | 0 | 3.94 ± 0.10bcAB | 2.61 ± 0.11aA | 3.67 ± 0.26bcB | 3.45 ± 0.22abB | 4.55 ± 0.25cB |

| 2 | 4.30 ± 0.24bB | 3.74 ± 0.16abA | 4.40 ± 0.14bC | 3.07 ± 0.20aAB | 3.78 ± 0.61abB | |

| 4 | 3.73 ± 0.36cAB | 2.99 ± 0.03bcA | 2.92 ± 0.01abcAB | 1.99 ± 0.39abA | 1.81 ± 0.34aA | |

| 6 | 3.17 ± 0.01bA | 2.61 ± 0.76abA | 2.37 ± 0.33abA | 2.09 ± 0.58abA | 1.27 ± 0.06aA | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).